Kenmore 3851564180 Owner’s Manual

OWNER'S MANUAL

OVERLOCK 3j4

MODEL 385. 564180

Dear Customer:

You have just invested in a very fine overtock. Before using your new Kenmore machine, please pause for a moment and carefully read this booklet which contains

instructions on how to operate and care for your machine.

Specific instructions are gLven on threading, tension adjustments, cleaning, oiling, etc. This will help you obtain the best sewing results and avoid unnecessary service

expense tor conditions beyond our control.

Advtce on tile operation and care of your machine is always available at your nearest Sears Retail Store. Please remember, if you have questions about your machine

or need parts and service, always mention the model number and serial number when you inquire.

Safety Cautions:

e Be sure that the electrical voltage of the wall outlet (wall receptacle) is the same as the rated voltage of the motor.

e Disconnect the power supply plug from the wall outlet when changing needles, presser foot or needle plate, or when leaving the machine unattended.

This efiminates the possibility of sta_ing the machine by accidentally pressing the foot control.

e All covers must be closed when operating the machine.

e Do not pull the fabric while you are stitching as this may deflect the needle, causing it to break.

e Before cleaning your machine, disconnect the power supply plug from the walt outlet.

e Do not attempt to adjust the motor belt. Contact your nearest Service Center should any adjustment be required.

e Handle the foot control with care and avoid dropping it on the floor. Be sure not to place anything on top of it.

e Closely watch the area being sewn to avoid injuries from needles and knives.

e Use only the handle to lift and move the machine,

Kenmore Overiock

Record in space provided below the model number and serial

number of this appliance. The model number and serial number

are located on the nomenclature plate, as identified on Page 3 of

this booklet.

Model No, 385, Serial No.

Retain these numbers for future reference.

TABLE OFCONTENTS

SECTION

SECT! ON

SECTION

1. KNOW YOUR MACHINE

Locate and Identify the Parts ............... 3_4

Identify the Accessories ..................... 4

2. PREPARE YOUR MACHINE FOR SEWING

Plug in the Machine and Switch on the Power .... 5

Foot Control Use .... ...................... 5

How to Turn Hand Wheel ....................... 6

Opemng and Closing the Side Cover ................ 6

Opening and Closing the Looper Cover ............. 6

The Position of Thread Guide Bar ............... 7

Attaching the Spool Cap and Net ............... 7

Raising or Lowering the Presser Foot ............... 8

Threading the Machine ..................... 9_17

e Threading the Lower Looper ............... t0_11

e Threading the Upper Looper ............. 12"13

e Threading the Needle on the Right ........... 14_15

e Threading the Needle on the Left ............ t6_17

3. LEARN THE STITCHES

Starting Sewing ........................ 18

Finishing Sewing ........................... !8

Sewing Continuously ........................ 18

Securing Ends ........................... 19_20

Thread Tension (4 threads) ................... 21"_23

Threading the Machine (3 threads) ................ 24

Thread Tension (3 threads) ................... 24_25

Adjustment of Stitch Length ................... 26

Adjustment of Foot Pressure ................... 26

Removing the Presser Foot ..................... 27

Attaching the Presser Foot .................... 27

Changing Needle ........................... 28

To Disengage the Upper Knife .................. 29

To Engage the Upper Knife ...................... 29

Types of Needle Plates ....................... 30

Changing the Needle Plate ..................... 30

Thread and Needle Chart ................... 31

Rolled Hemming, Picot Edging and

Narrow Hemming ........................ 32_34

Decorative Overedging .................. 35

Pin Tucking .............................. 36

SECTION 4. CARE FOR YOUR MACHINE

Cleaning Upper Knife Area .................. 37

Cleaning the Feed Dog ..................... 37

Replacing the Light Bulb .................... 38

Oiling the Machine .......................... 39

Replacing the Upper Knife ................... 40

SECTION 5. PERFORMANCE PROBLEMS CHART

What to Do When ........................ 4t

PARTS LIST ........................................ 42

INDEX ............................................ 43

Specification of the Machine .............................. 44

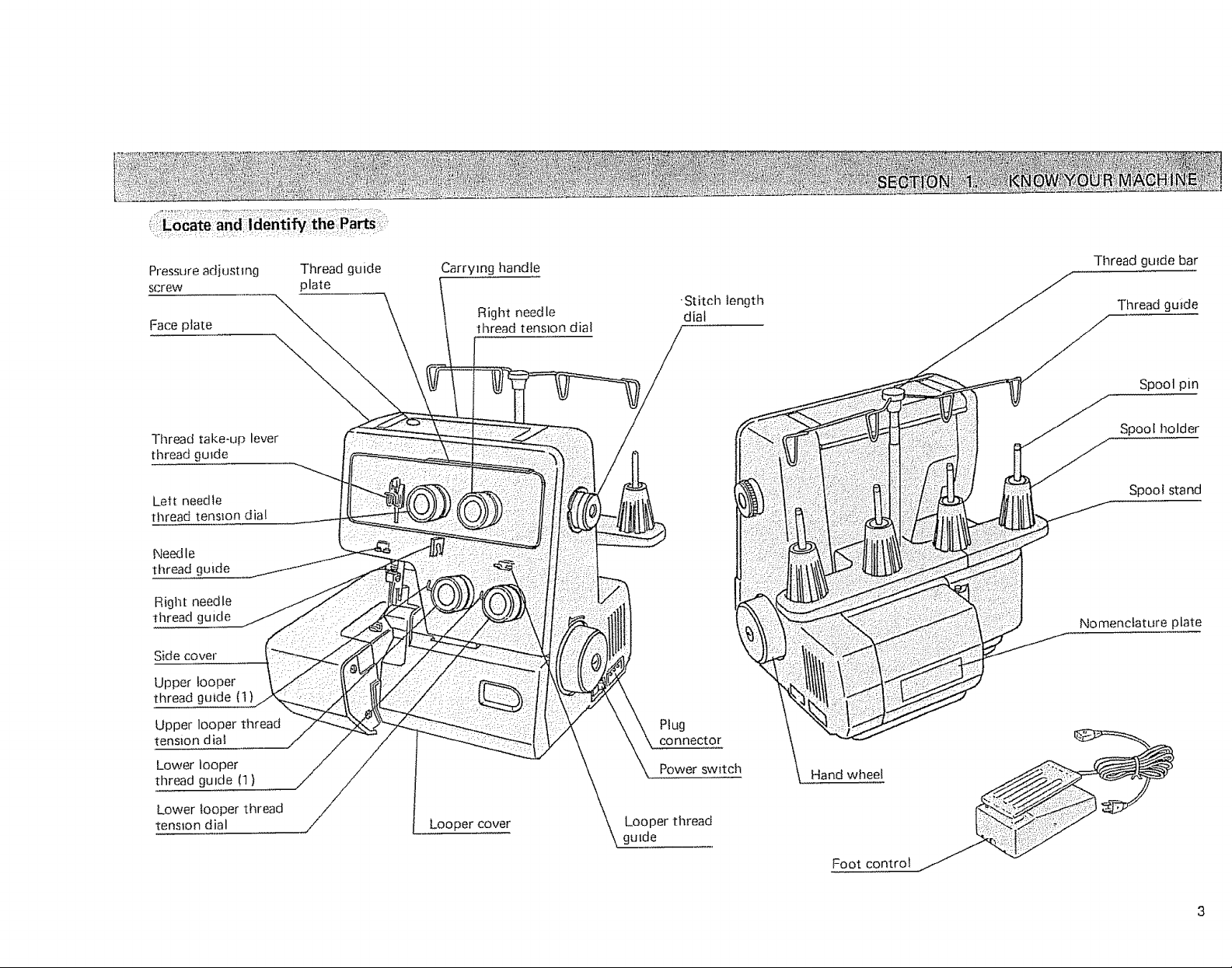

Carrying handle

Thread guide bar

Face plate

Thread take-up lever

thread gude

Let[ needle

thread tension dia!

Need le

thread guide

Rigilt needle

tllread guide

Side cover

Upper looper

thread guide (t)

Upper looper thread

tension dial

Lower looper

thread gude (1)

Right needle

thread tension dial

-Stitch tength

dial

Thread guide

\

Spool pin

Spool holder

Spool stand

NomencLature plate

Plug

connector

Power switch

Hand wheel

Lower looper thread

tension dial

Looper cover

Looper thread

guide

Foot control

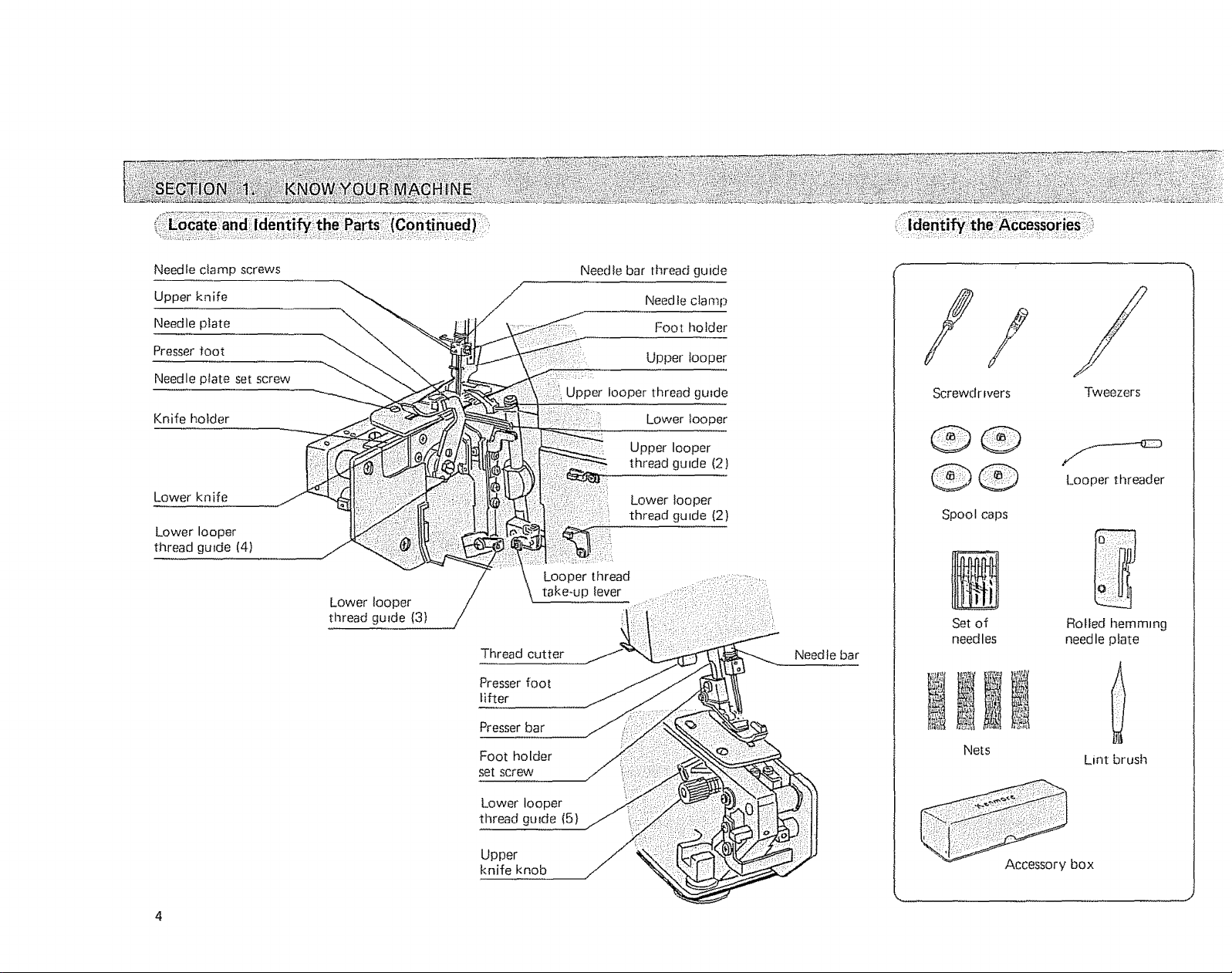

Needle clamp screws

Upper knife

Needle ptate

Presser foot

Needle plate set screw

Knife holder

knife

Lower looper

thread guide 14)

Lower looper

thread guide (3}

Thread cutter

Presser foot

lifter

Presser bar

Foot holder

set screw

Needle bar thread guide

Needle clamp

Foot holder

Upper looper

Upper looper thread guide

Lower looper

Upper looper

thread guide (2)

"!_ Lower looper

thread guide (2)

Needle bar

/

Screwdr _vers

QQ

QQ

Spool caps

Set of

need les

Nets

/

Tweezers

Looper threader

Rolled hemming

needle plate

0

Lint brush

Lower looper

thread gutde (5}

Upper

knife knob

Accessory box

_r _IU_ _ i_ _ _ i_ _M a chrin_ _a _d Swit_ h _ _ _t_ _ J_w_ _ _ _

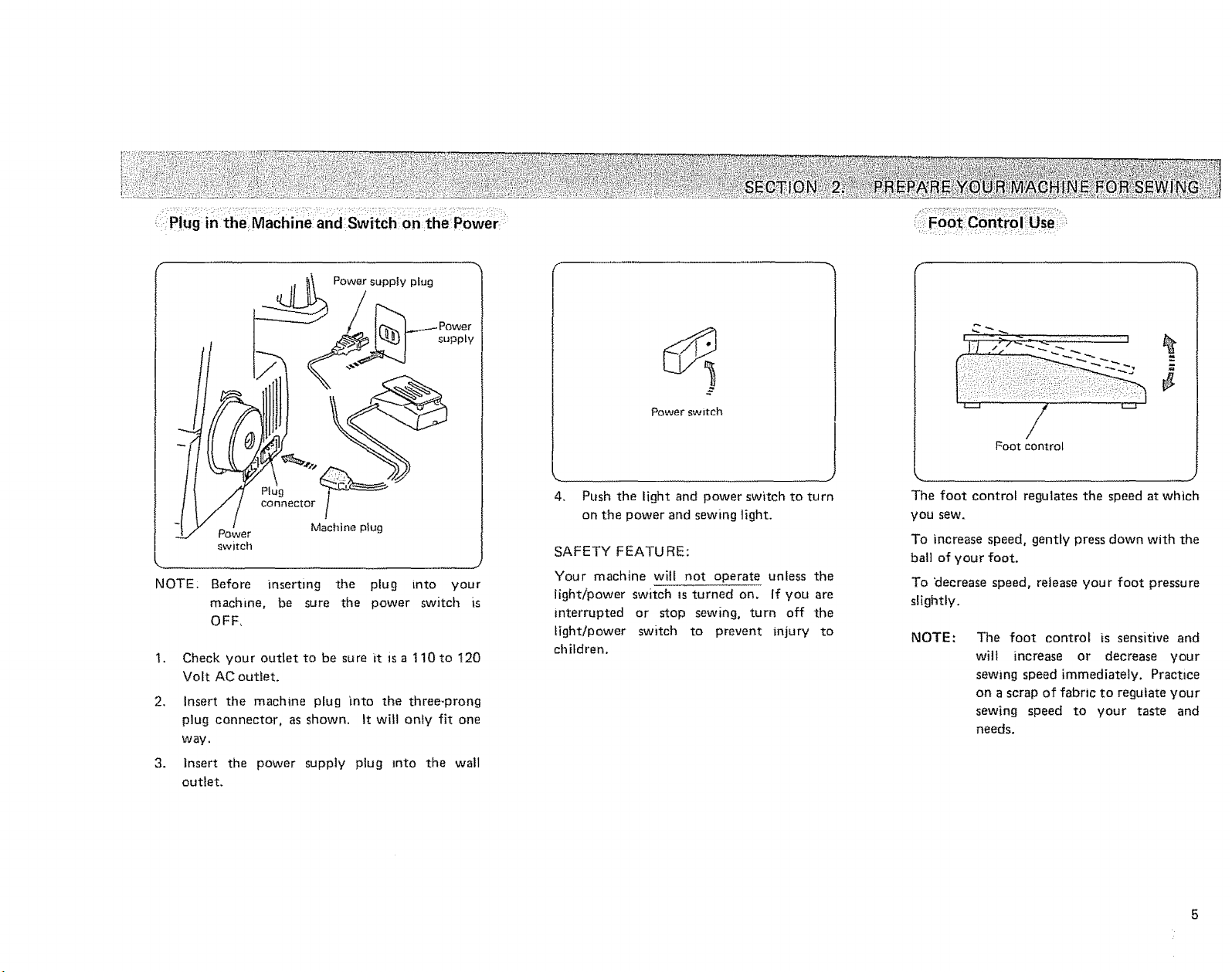

Power supply plug

supply

conneCtOr

Power

switch

NOTE: Before inserting the plug into your

machine, be sure the power switch is

OFF,

1, Check your outlet to be sure it is a 110to 120

Volt AC out_et.

2, insert the machine plug into the three-prong

plug connector, as shown, _t wilt only fit one

way.

3. |nsert the power supply plug _nto the wall

outlet.

Machine plug

Power switch

4. Push the light and power switch to turn

on the power and sewing light.

SAFETY FEATURE:

Your machine will not operate unless the

light/power switch Is turned on, If you are

interrupted or stop sewing, turn off the

light/power switch to prevent injury to

children.

/

Foot control

J

The foot control regulates the speed at which

you sew,

To increase speed, gently press down with the

ball of your foot.

To "decrease speed, release your foot pressure

stightty.

NOTE: The foot control is sensitive and

wilt increase or decrease your

sewing speed immediately. Practice

on a scrap of fabric to reguiate your

sewing speed to your taste and

needs.

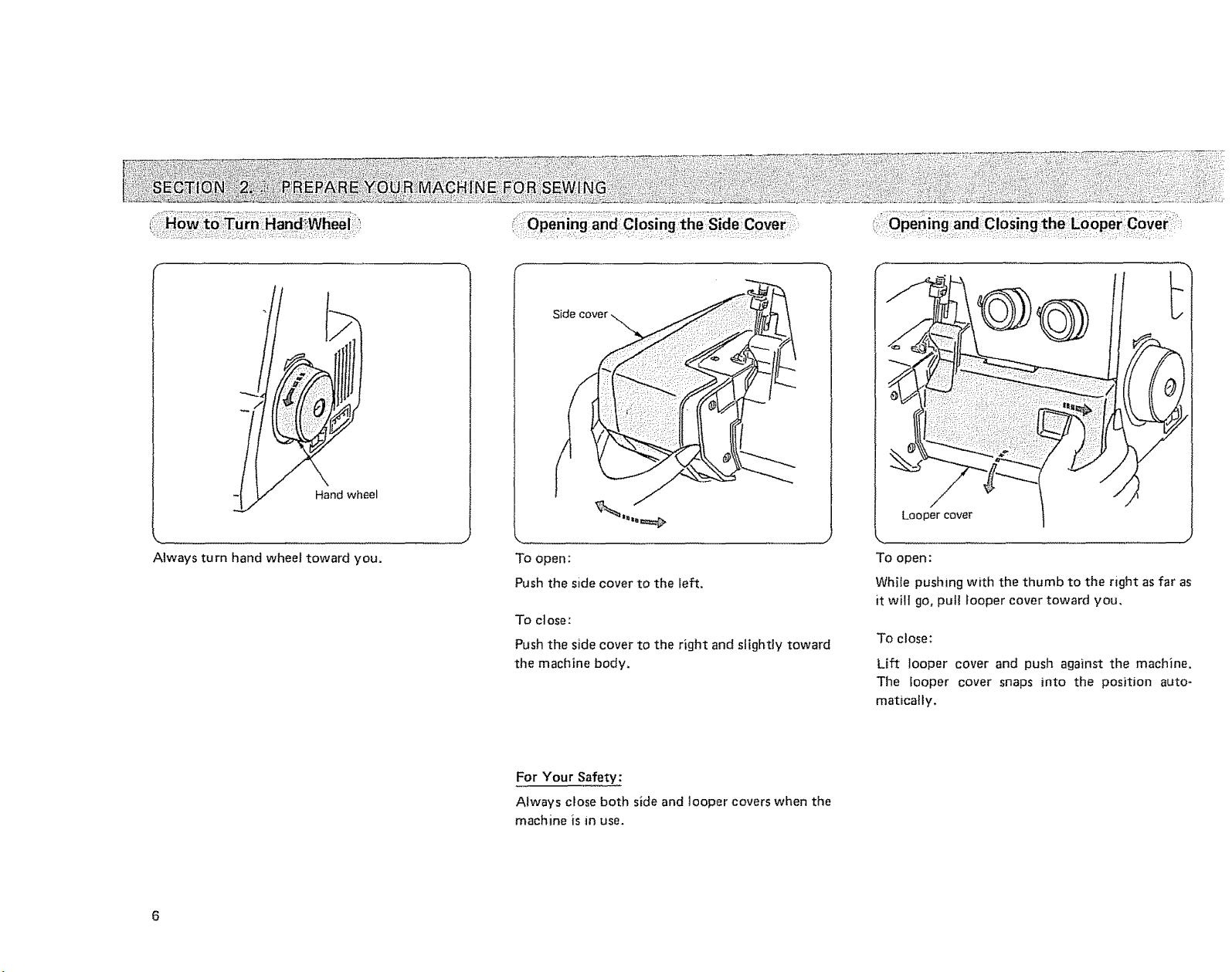

_eel

¸¸,

Side

Looper cover

Alwaysturnhandwheeltowardyou.

To open:

Push the side cover to the left.

To close:

Push the side cover to the right and slightly toward

the mach}ne body,

For Your Safety:

Always close both side and looper covers when the

machine is in use.

To open:

While pushing with the thumb to the right as far as

it will go, pull looper cover toward you.

To close:

Lift looper cover and push against the machine.

The looper cover snaps into the position auto-

matically,

•v ":: :: !=i::_:L•¸": •:i/>;: ?i:¸:! • ••i_•LI/h :¸" _'_•i':'_ ,:i::•j!:j ii:¸ >!:i:: :-:•7_:••:• :•_ _" : •/:=::-•

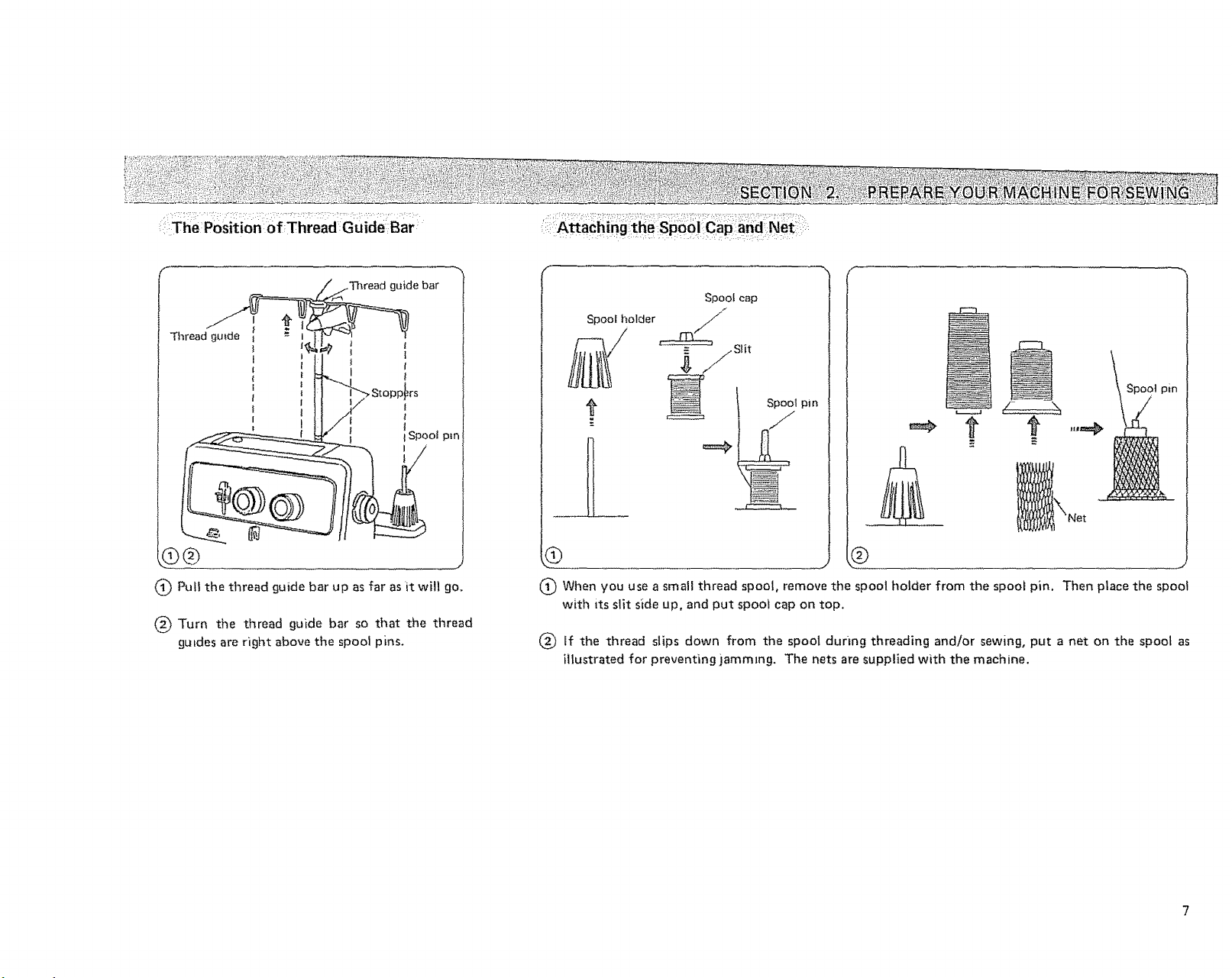

The Position 0fThread GuideBar

e bar

|Thread gutde i = I I1"_ _! 1

| , lJ?l ]

i _ I H----J o

| i , 11_-I_s,o_4,,

| 1 Jl II V

! , _II fi !

LOI® __.

(_ Pull the thread guide bar up as far as it will go.

Turn the thread guide bar so that the thread

gutdes are right above the spool pins.

Spool cap

Spool pin

u

N

,o

(_ When you use a small thread spool, remove the spool holder from the spool pin. Then place the spool

with its slit side up, and put spool cap on top.

2_ If the thread slips down from the spool during threading and/or sewing, put a net on the spool as

illustrated for preventing)ammlng. The nets are supplied with the machine.

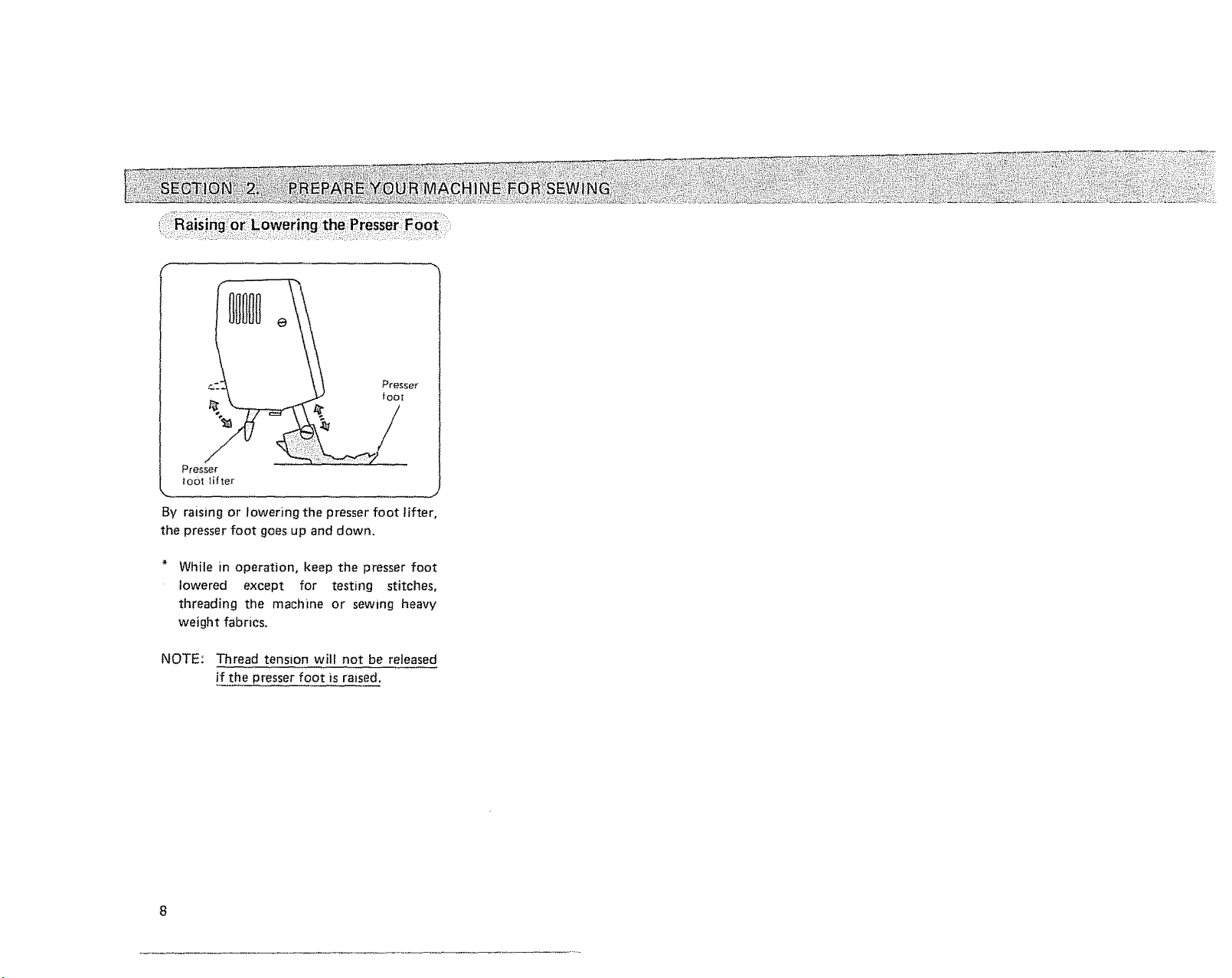

,; Raising.o_ L"_ ;'=_,_:T:_,:_"_;,._o_=_,,:werin=, _,.g _=.,_ =thePresser Foot,_'= :_.._ =,

_feSSer

_oOt Iifter

By raising or lowering the presser foot lifter,

the presser foot goes up and down.

While in operation, keep the presser foot

lowered except for testing stitches,

threading the machine or sewing heavy

weight fabrics.

NOTE: Thread tension will not be released

if the presser foot is raised.

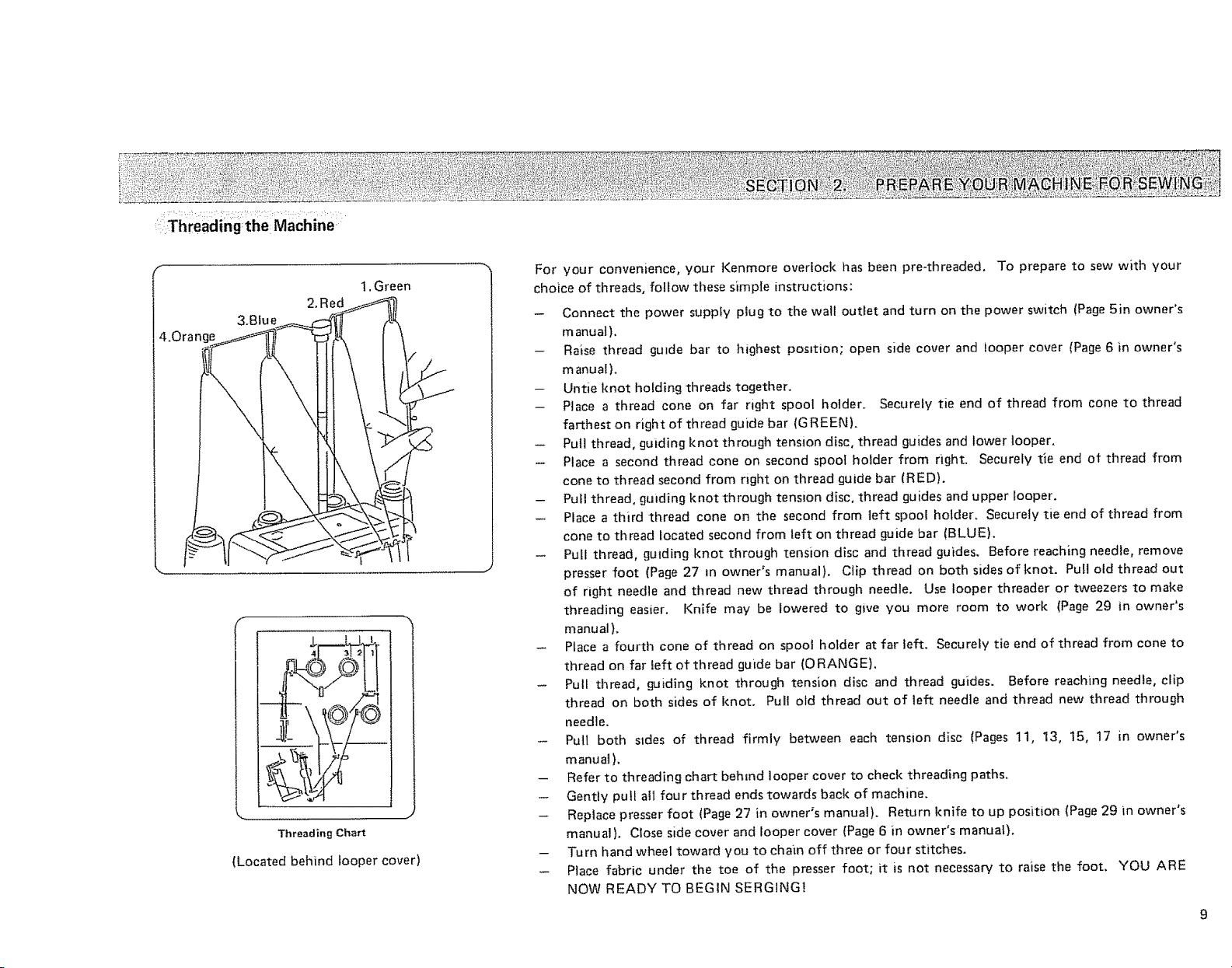

::iI:Th _eadinglthe Mach ine I

I. Green

| 3.Blu e_------___,::2_]IJ ,_'k

p.Orano - I\

f

Threading Chart

(Located behind tooper cover)

For your convenience, your Kenmore ovedock has been pre-threaded. To prepare to sew with your

choice of threads, follow these simple instructions:

- Connect the power supply plug to the wall outlet and turn on the power switch (Page 5in owner's

manual).

-- Raise thread guide bar to highest pos+tion; open side cover and Looper cover (Page 6 in owner's

manual).

-- Untie knot holding threads together.

-- Place a thread cone on far right spool holder+ Securely tie end of thread from cone to thread

farthest on right of thread guide bar (GREEN).

-- Pull thread, guiding knot through tension disc, thread guides and lower looper.

- Place a second thread cone on second spool holder from right. Securely tie end of thread from

cone to thread second from right on thread guide bar (RED).

- Pull thread, guiding knot through tension disc, thread guides and upper looper.

-- Place a third thread cone on the second from left spool holder. Securely tie end of thread from

cone to thread located second from left on thread guide bar (BLUE)+

- Pull thread, guiding knot through tension disc and thread guides, Before reaching needle, remove

presser foot (Page 27 +n owner's manual). Clip thread on both sides of knot. Pull old thread out

of right needle and thread new thread through needle. Use looper threader or tweezers to make

threading easier. Knife may be lowered to give you more room to work (Page 29 in owner's

manual).

- Place a fourth cone of thread on spool holder at far left. Securely tie end of thread from cone to

thread on far left of thread guide bar (O RANGE),

- Pull thread, guiding knot through tension disc and thread guides. Before reaching needle, clip

thread on both sides of knot. Pull old thread out of left needle and thread new thread through

needle.

+ Pull both sides of thread firmly between each tension disc (Pages 11, 13, 15, 17 in owner's

manual),

- Refer to threading chart behind looper cover to check threading paths.

- Gently pull all four thread ends towards back of machine.

- Replace presser foot (Page 27 in owner's manual). Return knife to up position (Page 29 in owner's

manual). Close side cover and looper cover (Page 6 in owner's manual).

- Turn hand wheel toward you to chain off three or four stitches.

- Place fabric under the toe of the presser foot; it is not necessary to raise the foot, YOU ARE

NOW READY TO BEGIN SERGING!

9

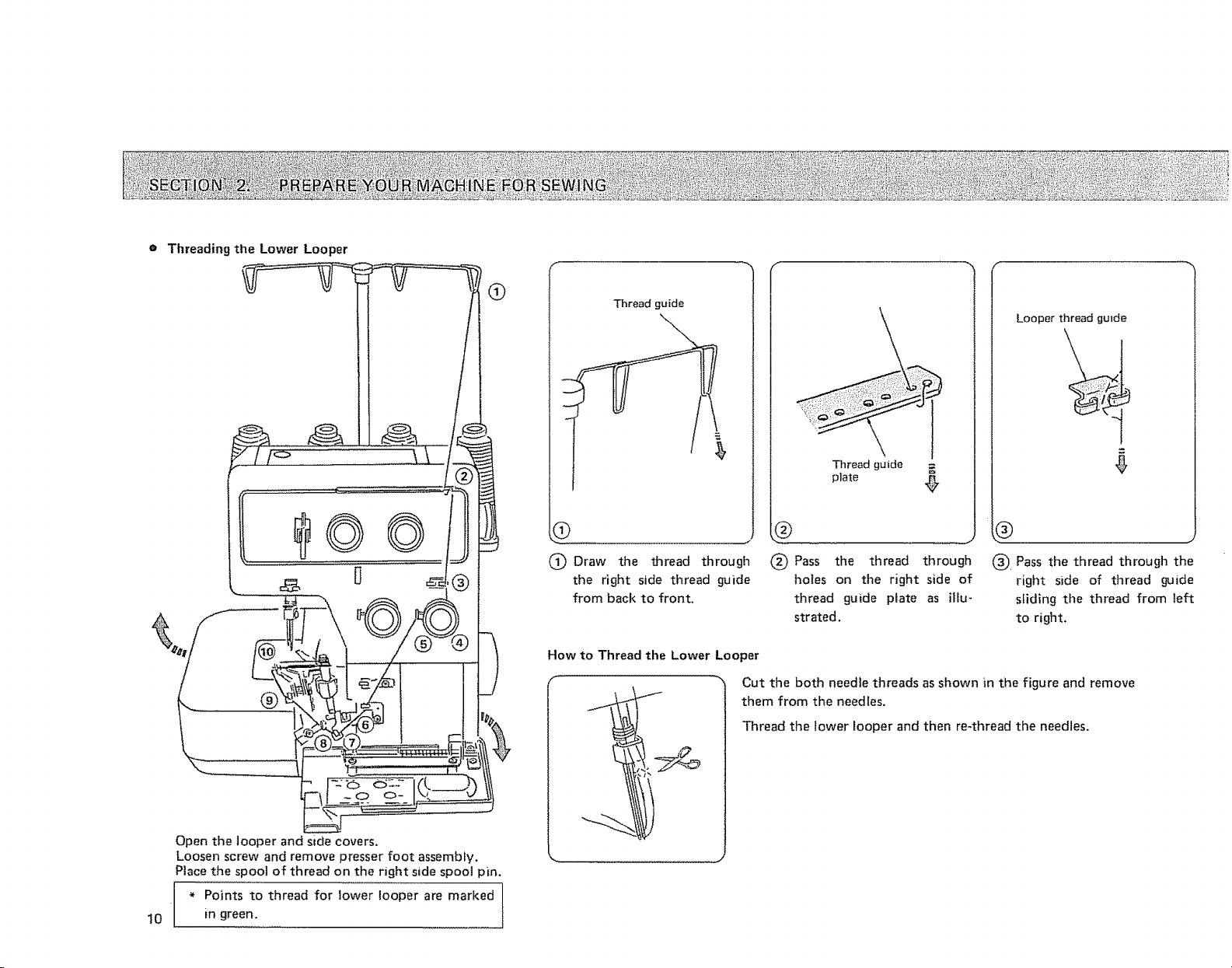

e Threading the Lower Looper

®

Thread guide

\

(9

_ ....................... J

(_) Draw the thread through

the right side thread guide

from back to front.

How to Thread the Lower Looper

Looper thread gutde

1

Thread guide

plate

4

® ®

(_ Pass the thread through (_) Pass the thread through the

holes on the right side of right side of thread guide

thread guide plate as iliu- sliding the thread from left

strated, to right.

Cut the both needle threads as shown in the figure and remove

them from the needles.

Thread the lower looper and then re-thread the needles.

Open the looper and side covers.

Loosen screw and remove presser foot assembly.

Place the spool of thread on the right side spool pin.

i * Points to thread for lower looper are marked

10 [ in green.

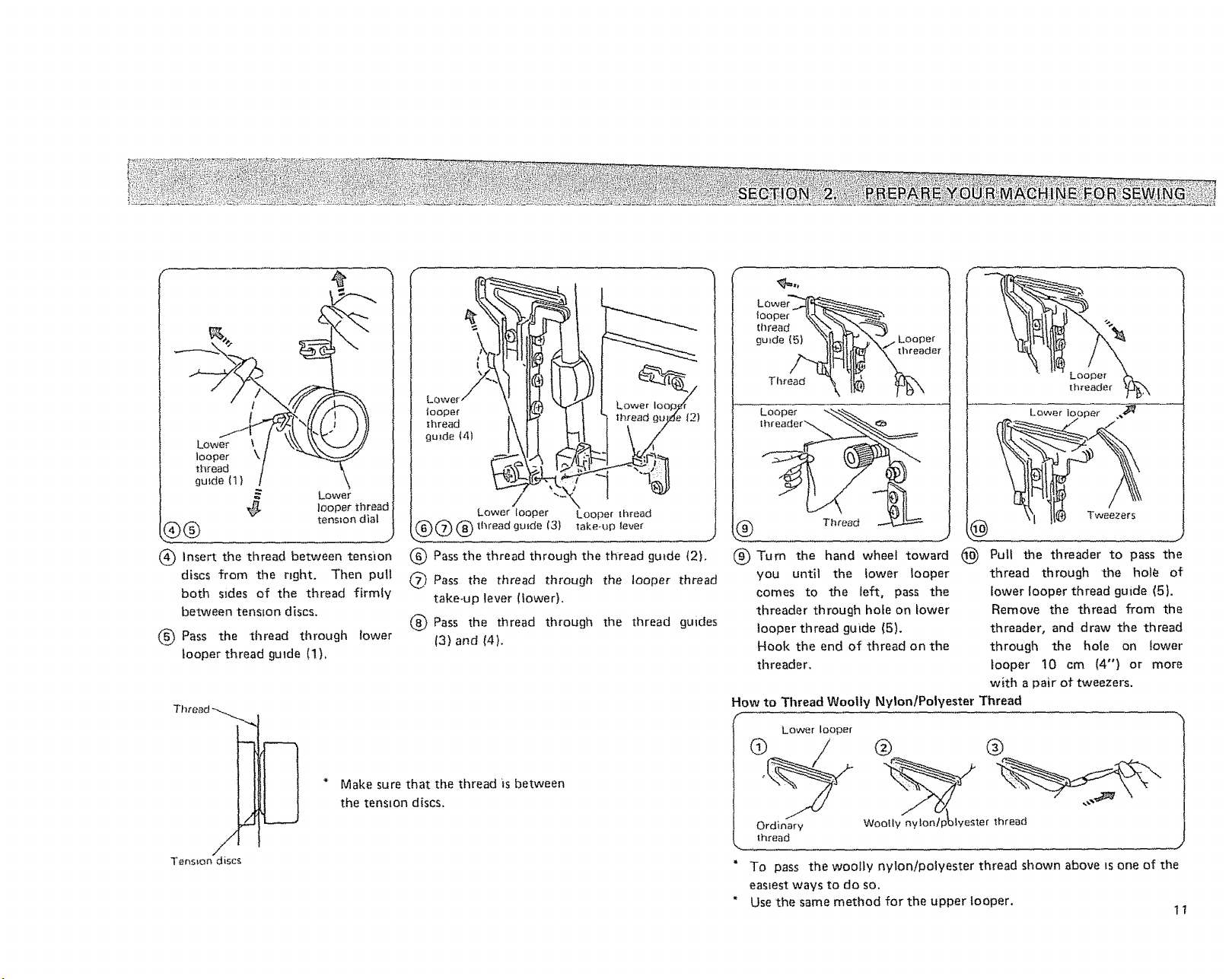

._- looperIk-k%._-___ I

g_,deI_l 31_ EL;xT..-LooperI

" ,..oooo,

/ _ Lower ! //

| _ looper thread I

(_) Insert the thread between tension (_) Pass the thread through the thread gutde (2}. (_ Turn the hand wheel toward (_ Putt the threader to pass the

discs from the right Then pull _) Pass the thread through the looper thread you until the Iower looper thread through the hote of

both sides of the thread firmly take-up lever (lower). comes to the left, pass the lower looper thread guide (5}.

between tension discs, threader through hole on lower Remove the thread from the

(_) Pass the thread through lower f3) and I4). Hook the end of thread on the through the hole on lower

looper thread guide (1), threader, looper 10 cm (4"') or more

Thread _

[

* Make sure that the thread is between

the tenston discs.

0 ,deI41 I\IIhl I\ /, I

(_) Pass the thread through the thread guides tooperthread guide (5). threader, and draw the thread

Lower looper Looper li_read w

/

Tension discs

threader __ __

with a pair of tweezers.

How to Thread Woolly NylonlPolyester Thread

d

* To pass the woolly nylon/polyester thread shown above is one of the

* Use the same method for the upper looper,

Lower looper

Ordinary WoolIy nyion/pio!yester thread

thread

easiest ways to do so.

11

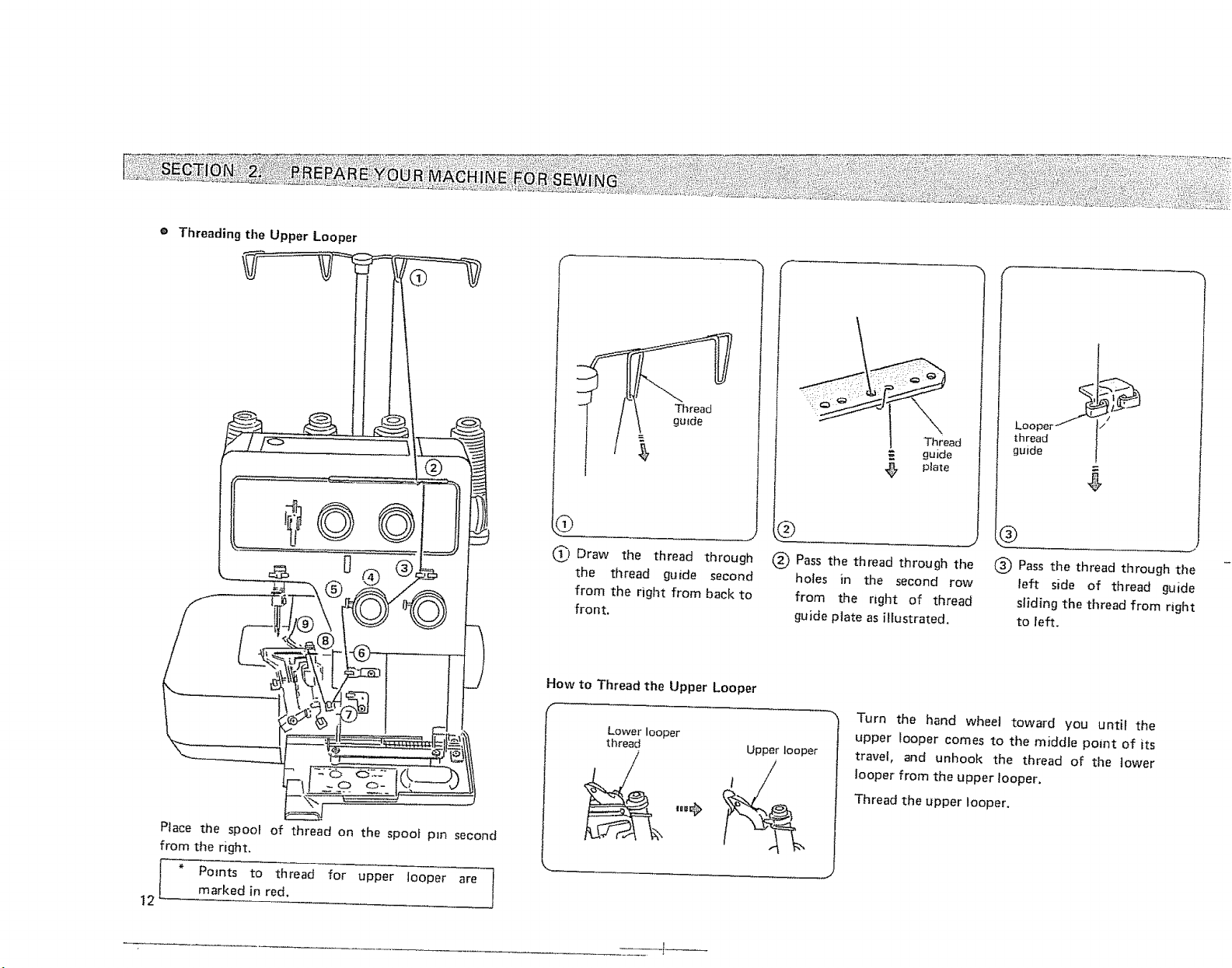

e Threading the Upper Looper

Place the spool of thread on the spool pm second

from the right.

Thread

guide

p_ate

C) Draw the thread through (_) Pass the thread through the (_ Pass the thread through the

the thread guide second holes in the second row left side of thread guide

from the right from back to from the right of thread sliding the thread from right

front, guide plate as illustrated, to left,

How to Thread the Upper Looper

Turn the hand wheel toward you until the

Lower looper

threa#

Upper looper

upper looper comes to the middle point of its

travel, and unhook the thread of the lower

looper from the upper looper.

Thread the upper looper.

thread

guide

i./

&

I * Points to thread for upper Iooper are

12

marked in red,

Loope_

threader_

/Uppe_ fooper

-,_ toope_thread

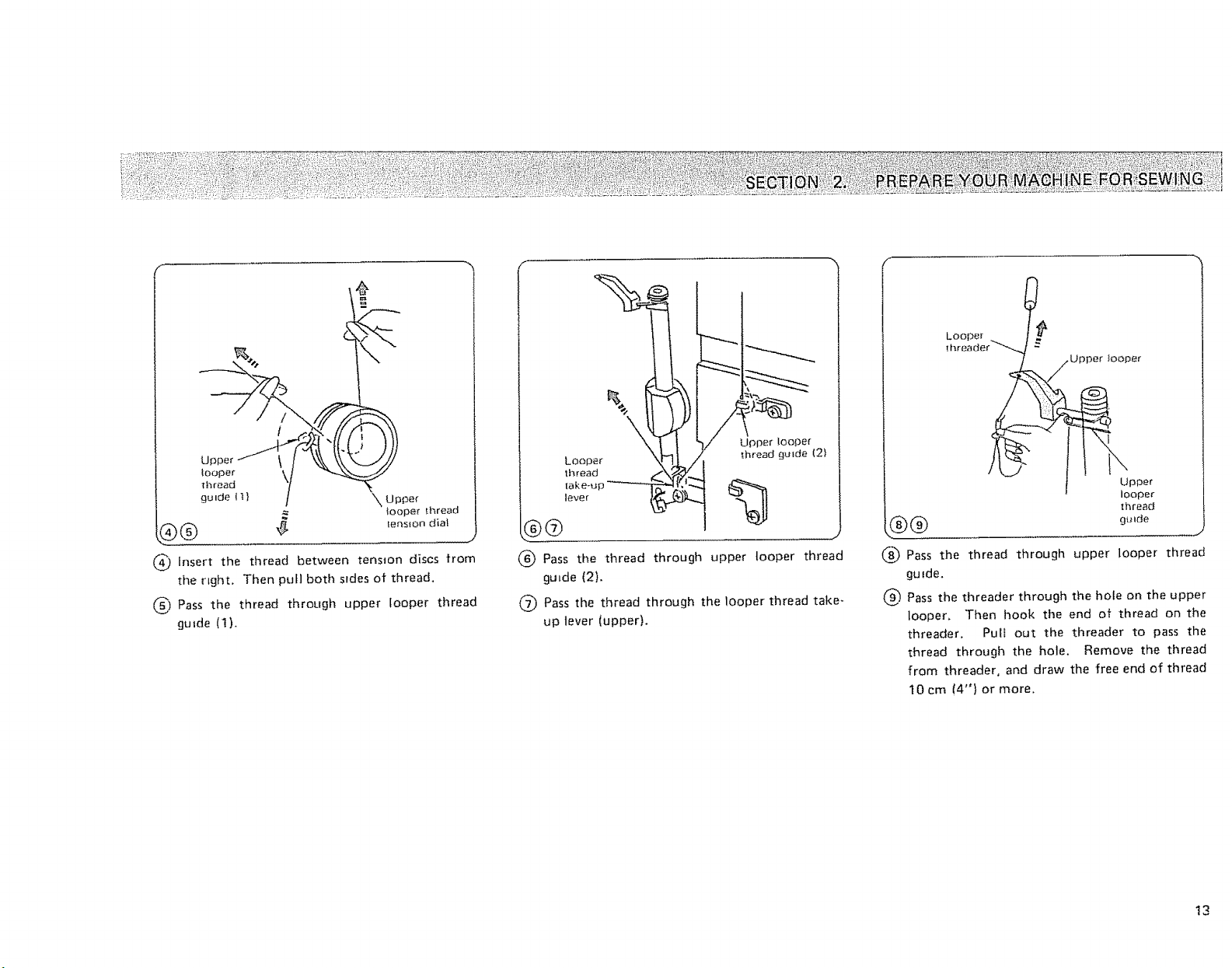

_(_ _ ,ens,on dia,

the thread between

Insert tension discs from

the right, Then pufl both sides of thread.

_) Pass the thread through upper looper thread

guide (1).

lhread

J

(_ Pass the thread through upper looper thread

guJde (2).

(_ Pass the thread through the looper thread take-

up lever (upper).

(_ Pass the thread through upper looper thread

gu _de.

Pass the threader through the hole on the upper

looper, Then hook the end of thread on the

threader. Pull out the threader to pass the

thread through the hole. Remove the thread

from threader, and draw the free end of thread

10 cm (4"} or more.

13

Loading...

Loading...