Kenmore 3401991180 Owner’s Manual

',I_,;'d MAt lil'll

%gil, P_', I'J'll ''

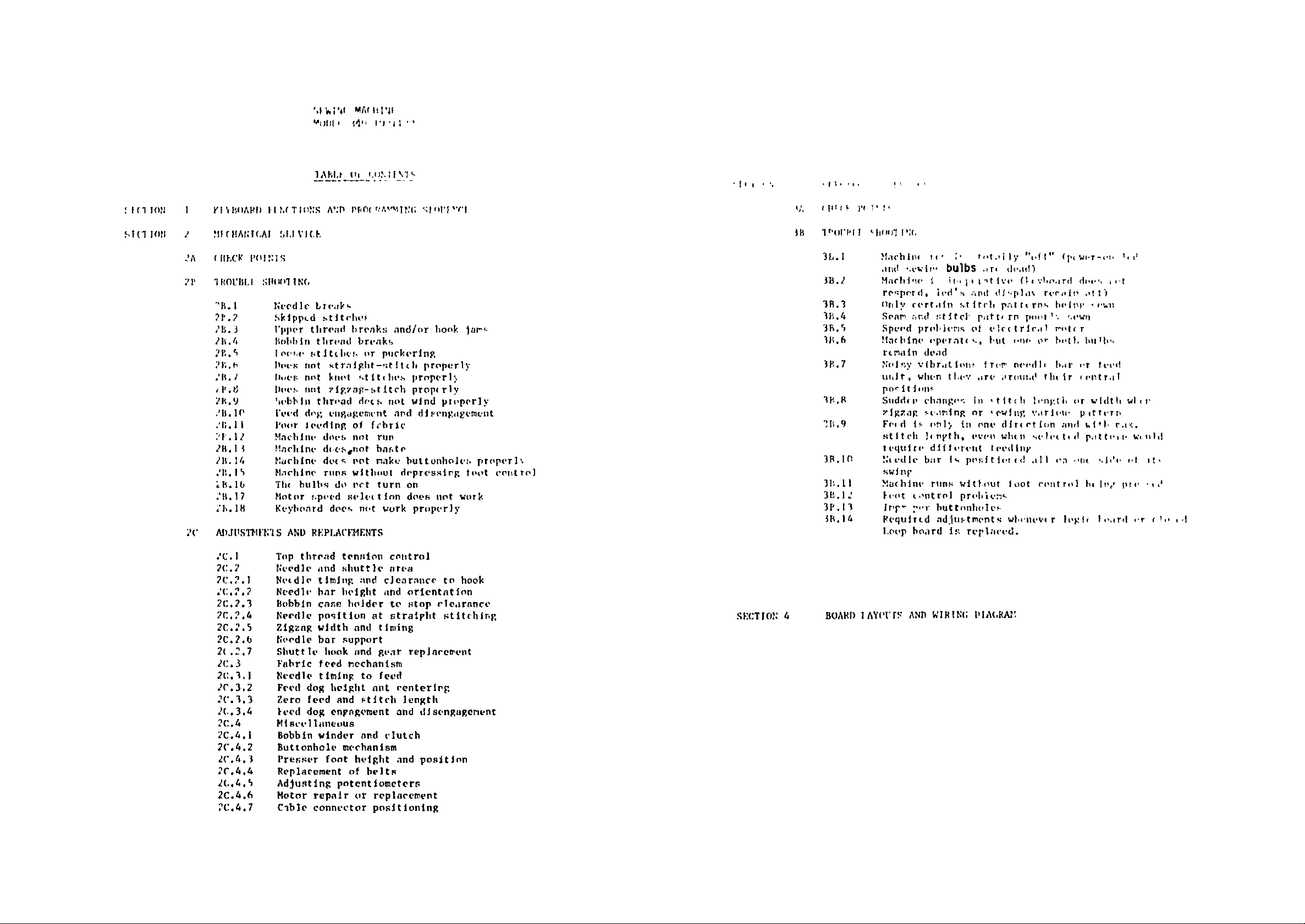

lAhl.t Ih 1,(}._.;1_,1_

I

FI _{}iIAFIillh( T {{i;:SA':P p_l_(T,'&_'N|P'I; ql 'It'{"el

J

;I11"lIAr; l (,AI IA,I V I(11",

"A

( llkCl':l'{ll;:IS

7I'

1 ROUB[+I :;I11_+1 l N(,

"B.I

21'.2

,B. 3

2h.4

2P.. e,

?)..€_

2B. /

+Y.P;

21%9

,'B. 10

.'1;. l I

:'t.I/

2P,,l 4

2IL 14

,'I'.I'_

; B. 16

211.17

.h. 1R

Reed lc b r,,,,{,_

,%kt pp_d ._t I t ('lit';

I'pper thread break,.+ andl(ir hook Jar',.

l{obbin lhri.0d brt.aks

Io(.+.l. stit(I,e_, or puckering

ill,t'_ /lOt st ratght-,it t t i h properly

[i,,el; ni_t knot _+tltibt'+% properl)

ll(.t.s tl(}t zlgvng-slttch propirly

'iPbb|ll thri,ad d,,ts not wind plt,perly

|'el'd dot I l.,llgilgelIll..nt add dJPengugeffl(.,nt

Poor let.ding Of f+'brie

._aCll_lle do(,l, not rtln

P!acl, lne (h+e._#,mthallo

P:.l'blne do(_ not laake buttonhole.', f,roperl_

Hacblne rum_ without d(.pres_trg toot control

Till htllb_ do )_¢t turn on

Hotor :,peed ._elettlon doe_ not work

Reyt, oard doe_ m,t work properly

71' NIJItSltIII'ilS ASD BEPI.ACF$_ENTS

' [ I I ' '. +fl, ,+, !t ,_

( {lill |'! l' l'

tB

1 {'qll'F'l I t }lllifi lit(.

3b.l

•llilch{l_+ I.' ;' h,t.,lly "pill' (|,iwiir-i,i, 1,1.

.,tid '.e_¢h" bulbs .,r, d,.,id)

lB.2

Hlicil]'!l' { il,+iil-llvl. /|lv!.o.lrd dl+l.', i('t

renperd, ted's :,Pit dl-pl,i_ r+..r,,It+ ,,It)

3B.3

_IP,.4

3_.5

3_.6

Illily c('rl.lhl _t it('b pain rn_ bi'il_!' ,+,_.l+

SCRIP" :,l_d ::lftcl' rilt_: I rn plil+l 1, <,l%qll

Speed prol.il.rl_ oi iil¢(irlc.i1 r"t,l{ r

Ha_binv epelatt ..,|'ut .us o_ |.,tl,hulb,.

r_maln dead

IP,.7

Nol_;y vihr.t|on_ fri.P nrvdh bar ,.r teed

tJl,Jt. _ht.n tlil,',' .re .,rl,iil,t I rll_ Jr +¢mtr,il

_lB.8

po _ I t | fin,

Suddlp change,; hi .llt(tl |..lil:lh or _.'ldlh Will.

/|gzag st,,tP_tnp, or ,ewillg %',lril,ll+ plttl'/ll

",'lh 9

3B.IP.

31%11

3B.12

3P.l'l

{B,I4

FPid t_ i,nl) In one (llilrllim ;iii+| I.t_l, r.i<.

stitch }€lni_lfl I (1'_'1'11 I_'|lln %l.]l.(lli! p.!ltl.il. '_'¢llllt

leqtltrl, diitiir_.llt let, dll W

,_Tiudle b;ir 1_ politti_.t(d .ill oa ,.lit ,.|.ll. i.l it,

sWi llp

._lathlnl, rllS_ Wit|eel toot el,nice} hi It,,, pr,' .,,'

}I'OI tontro] proli'l+.,71_

It,p- 7,,r butt,mbt,le_

gequlrtd adJu._tment_ wi,,'nevtr h,gh l,,,ird,.r { !,, +.!

1.(,op board t.q replaced.

•'C. I

2(:. 2

2(?.2.1

Jl:.?.2

2C.2.3

2C.2.4

2C.2.5

2C.7.0

2{ .2.7

2(". 3

21:. 1.1

2C.3,2

2('.3.3

2(.. 3.4

2(:. 4

2C.4. l

2(%4.2

21".4.

2¢.4.&

2(..4.5

2C.4.6

?C.4.7

Top thread tensio, collie(}]

Needle +lad ._lluttlc area

Netdlc tilnlng and clearance to hook

Needh' bar lieight and orientation

Bobbin case bolder to .qtop clearance

Needle poqttion at _trafght stitching.

Zigzag width and timing

Needle bar support

Shuttle hook and gear replacement

Fabric feed mechanists

Needle tiinleg to feed

Feed dog height ant conteripg

Zero feed and pt4tch length

l-eed dog engagement and dlst.ngagenent

l_| Bt'e l llineous

Bobbin winder and clutch

Buttonhole mechantm_

Presser foot height and position

Replacement of belts

Adjusting potent tometers

Hotor repair or replacement

C'lble connector positioning

SE('T I0,'_ 4

BOARDI AYt'I'r._ AND _','IRINI; DIAl,RAIl

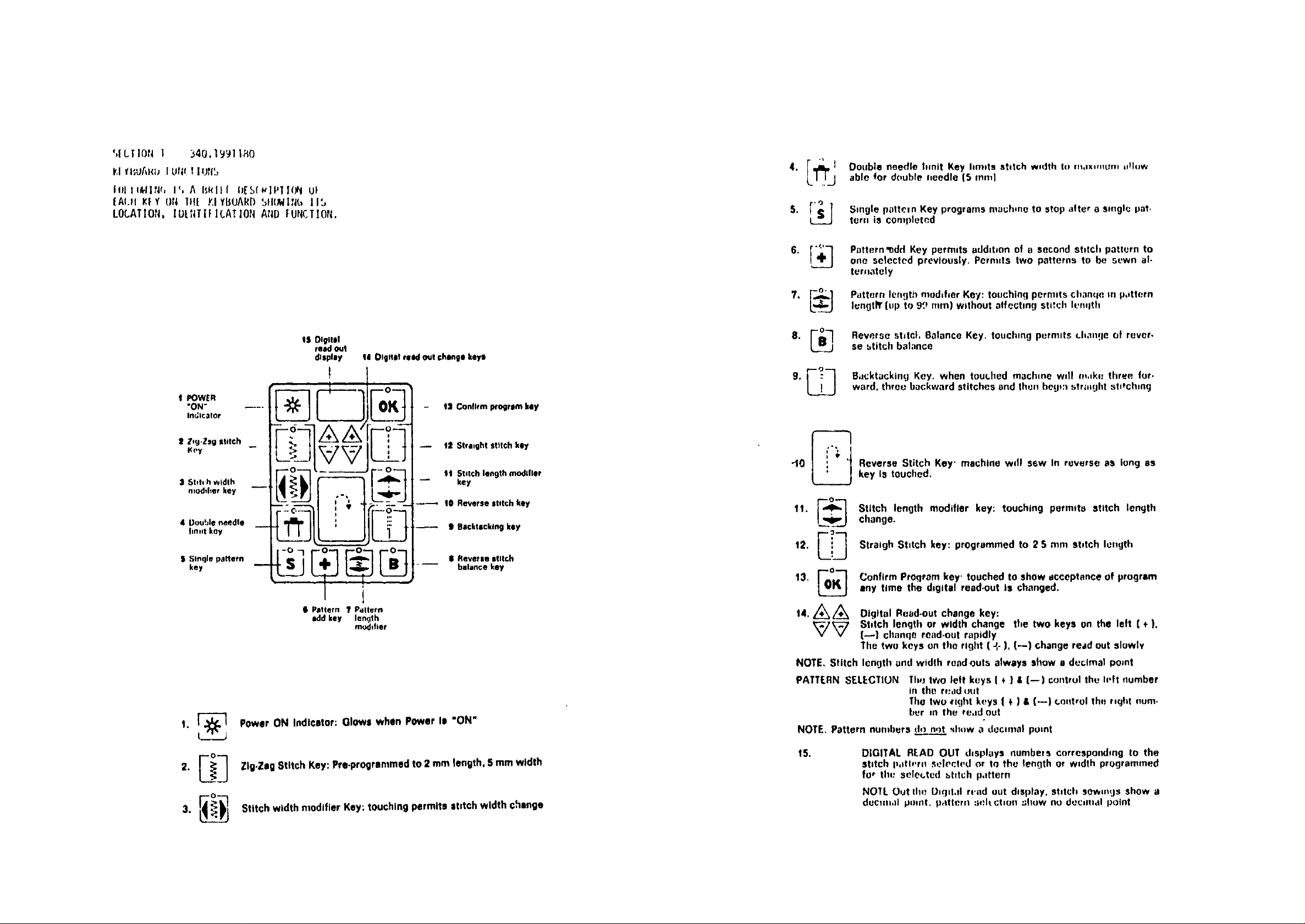

',1Lf101,11 340,19_1 |_0

I,.Ifi,loA}(lJ I Oflt.l lUllS

llllltlN|tU, I', A BRItl i}[SiwlPTlON Ot

[Al.II Klf ()N ll!l KIYBOARD 51t(;41flt, ll_,

LO(.ATION,IOLNflfI(.ATIOI'IAridfONCflOI;.

.

.

Double needle hmit Key hmlts stitch w=dth to mac,mum _llh_w

able for double tleedle (5 ram)

Single patteln Key programs mach,ne to stop after a smgl_ pat.

tar. is completed

Pattern'Ddd Key permits addltmn of a second shtch pattern to

one selected previously. Pern.ts two patterns to he sewn al.

ter.ately

Pattern lenotn modzher Key: touching permits change m pattern

lungtl_"(up to 9/! ram) wmthout atfechng stiIch lemlth

t lOWER

"ON"

In(JlcMor

e ZJg.Zsg stitch

Key

:1 Snh h width

moddser key

4 Uouble needle

Im.t key

II Single pattern

key

,%

Is DIgltsl

toad OUt

display f4 Olgltsl reedOUtchangekeys

t

--i t'''l -''°°°'°-"

u-,:;I- ,.

i IO Revtrse linch key

;• -- -- _1_ -- $1 StitCh len9th modifier

.... balancekey

.i

i i

e P41ttllrrl 7 Pdtt_rlt

Idd key len_lth

Power ON Indicator: Glows when Power It "ON"

moddler

s E_

"40 I ', "1 Reverse Stitch Key' machine will ssw In reverse as long as

L_L_J

12.

t3.

,,.AA

NOTE. Stitch length and width readouts always shaw i decimal point

PATTERN SELECTION

NOTE. Pattern numbers do not Mtuw a decimal point

Reverse sbtcl, Balance Key. touching permits _.h,_.!le of raver.

se _titch balance

Backtacking Key. when tou(.hed machine will m,_k,: three for.

ward. throe backward stitches and then heg_:r straight stitching

key Is touched.

Stitch length modifier key: touching permttu stitch length

change.

Stralgh Stitch key: programmed to 2 5 mm stdch length

Confirm Programkey. touched to show acceptance of program

any time the d=gltalread.out Is changed.

Digital Plead.out change key:

St,tch length or width change the two keys on the left ( ÷ ).

(_) chanqe read-out rapidly

The two keys on the right ( 4- ), (--) change read out slowly

fh,_ two left keys I + ) & (--) control Ihe h,lt number

tn the r,:ad out

The two ,right keys ( 4.) & (--) cant,el th. l,ght num-

ber m the read out

Zig-Zig Stitch Key: Pre.programmed to 2 mmlength, 5 mm width

Stitch width modifier Key: touching permits stitch width change

15. DIGITAL READ OUT displays numbms corresponding to the

stitch p,lth,rn selected or to the length or w*dlh programmed

re, the sele(.tcd btdch pattern

NOTL Out tit(; D_gzl.tl read out display, stdch sewings show a

decllnal p(rmt, pattern 5eli ctloe ,_.howno de,.'illlal point

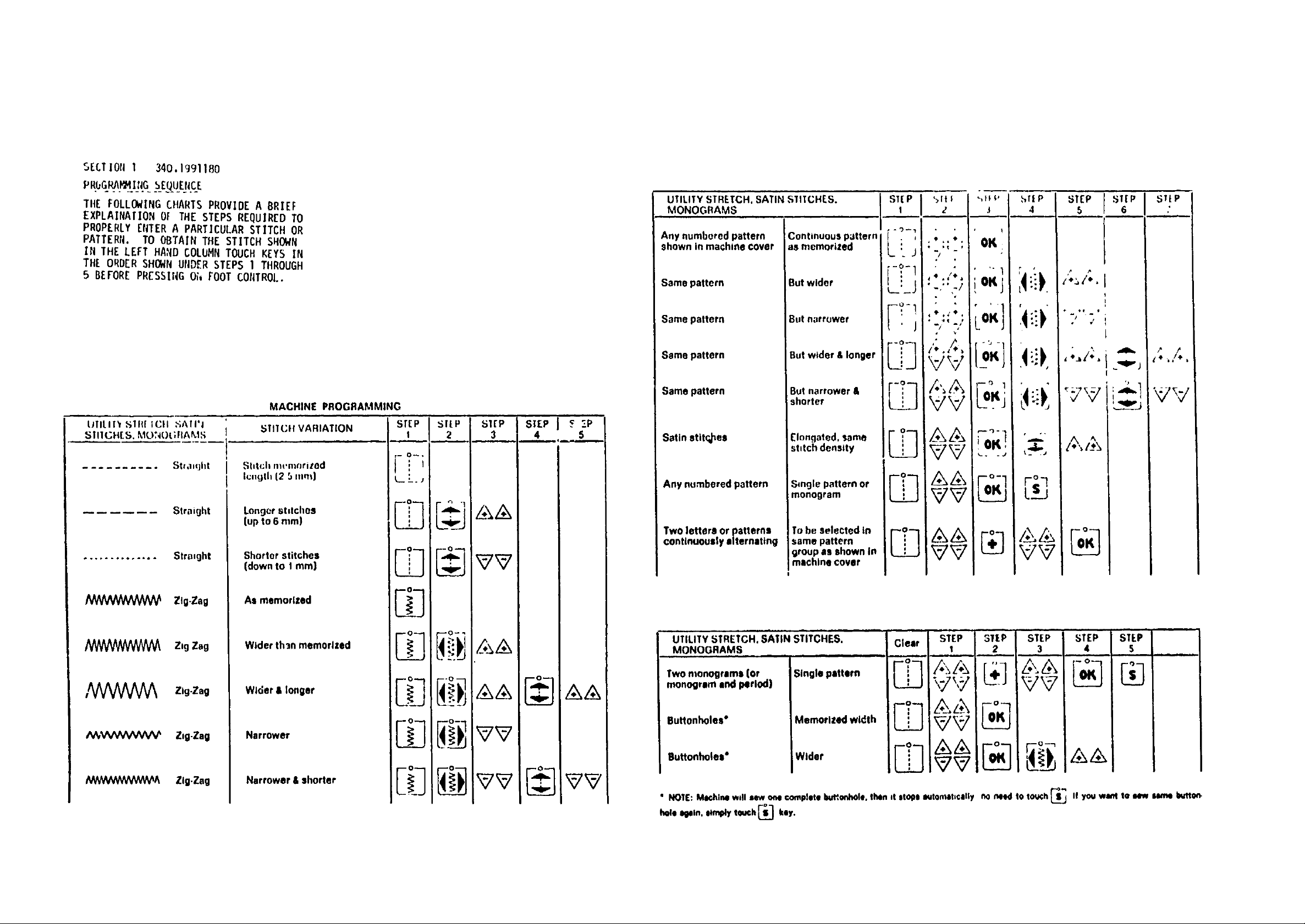

SU.,T1ON I 340.1991180

PRL,GRAF141NG _EQUEr4CE

TIIEFOLLOWING CHARTS PROVIDE A BRIEF

EXPLAINAIION OI THE STEPS REQUIRED TO

PROPERLY ENTER A PARTICULAR STITCH OR

PATTE_I. TO OBTAIN THE STITCH SHOWN

IN THE LEFT HAND COLUMN TOUCH KEYS IN

THE ORDER SHOWN UNDER STEPS I THROUGH

5 BEFORE PRESSING Oh FOOT COrlTROI..

UTILITYSTRETCH, SATIN ,%TtTCHES. SlfP

MONOGRAMS

Any numberedpattern

shown in machinecover

as memorized _, j

+-+"+ -il

Same pattern

Same pattern

But wider

-?-1

But narrower i j

STEP STEP SttP

5 I 6 ,'

UTILII_ ,SIITi ICII ;';AII'I

StilL;HIS MO,,t_,)L flAMS

Stt,llqht

Straight

............. . Straight

Zlg-Za_

Zig Zag

]VV_V_ ZIg-Zag

/_/_VVVVV_NV_ Zig-Zag

MACHINE PROGRAMMING

tSTITGI! VARIATION

Stdt:h memorized

Ic.gth 12 5 ITIql)

Longer stnches

(up to 6 ram)

Shorter stitches

(down to I ram]

As memorized

Wider th_o memorized

Wider &longer

Narrower

-- o

+,,?,l+,+P+..

I

_._i

Aa

Same pattern

Same pattern

Satin stitq_ea Elongated. same

numbered pattern S,ngle pattern or F _

Any

Two lettera or patterns

continuouslyalternating

UTILITY STRETCH, SATIN STITCHES.

MONOGRAMS __

Twomonograml (or

monogrlm and period)

Buttonholes"

But wider 8, longer _,"_]

But narrower & r-T-_

shorter

st,tch dens|ty

monogram

Tobe selected In ,-"

same pattero

groupasshownIn __.

machinecover i

Single pattern

tmemor,z+.,dth

Buttonholes"

IWId,,

L_

Clear STEP

nn _, ,,

t

31EP

2

14"1

\'/'V

-°_ AA --+--

51EP

Vv

AA

I OKI

STEP

3

4

!0KI

S'{EP'

5

I$I

AA

ZIg-Zag

Narrower &shorter

• NOTE: MKhlmi will w lwI r.o_piete liill, wllio|e, thin it Itogl litlmlt_lilly ill flii(I to t_l¢h _._ I| yml wlm_ to llW IImwI

hole Issln, llfl_ly toich_J kly,

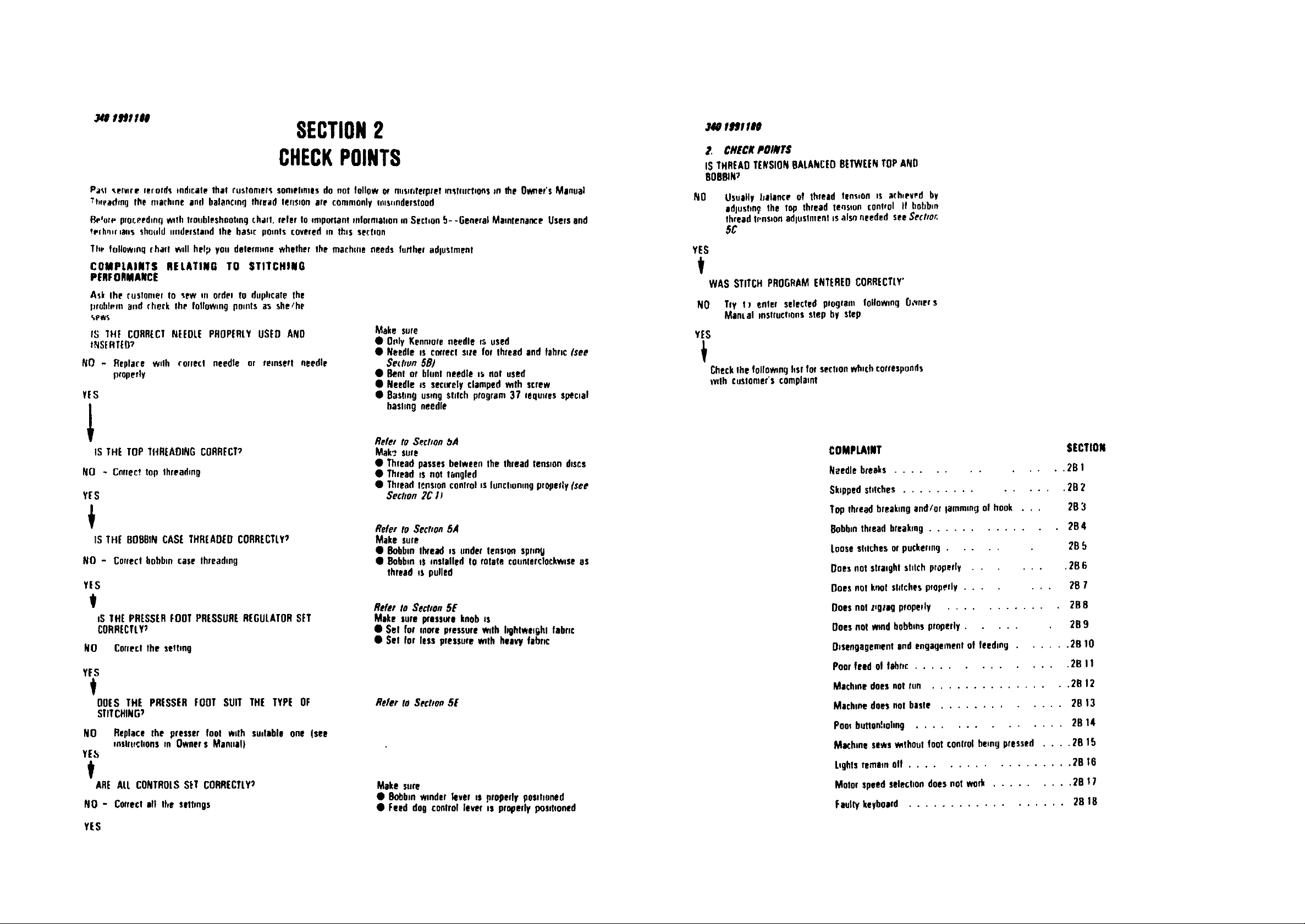

341 InllU

SECTION2

CHECKPOINTS t c.,c,,.o,,,.

IS THREADTEKSIONBALANCEDBETWEENTOPAND

BOBBIN?

Pa_I q,ervire lerords indicate thai rustonlers sometimes do not follow or nusmterpzet instructions fn 1he Ovw1ef's Manual

?t_feadrngthe rnarhlne and balancingthread tension are commonlyrmsunderstood NO Usually |faience of thread tension is arhteved by

{_'orr proce,z,dmq with trotlhieshuotingchaff, refer In importantnrfmmation m Section_- -GeneralMamfenarhceUsersand threadtPnsionodlnstmentis alsoneeded seeSector

'rPfhnirlau$shu.ld mtdelstand the baser pools coveredm this section 5C

Tripfollowingtheir will helpyoudelernnnewhetherthe marhmeneedsfurlhoradlustment

COMPLAINTS RELATING TO STITCHING

PERFORMANCE

A_k Ihe rustamer to sew ns ordnl to duphcate the

t)rohipru end rherk the following pomts as she/he

%ews

IS THF CORRECTNEEDLE PROPERLYUSED ANO

INSERTED?

NO - Reptare with reflect needle or remserl needle

properly

YES

IS THE TOP 71-1REAOINGCORRFCT?

NO - Cnnec! top threadmg

Y[S

Make sure

• Only Konmoreneedle is used

• Needle is correct size for thread nod tah.c/see

Sect,on 58)

• Bent or blunt needle ts fief used

• Needle Js securelyclamped vath screw

• Bastmgusmg shtch program37 requires special

baslmg needle

Re/eL to $octmn bA

Make sure

• Thread passesbetween the thread tension discs

• Thread is not tangled

• Threadtensioncontrolts functtomngproperly(see

Sectron 2C I!

adlushn9 the fop thread tenssoucontrol if bobbin

YES

t

WAS STITCHPROGRAMENT}REOCORRECTLY"

NO Try t r enter selected program followmg _lh._uers

Mental mstrucftons step by step

YES

Checkthe lolfowmglistfor section whichcorresponds

_vzthcustomer'scomplaint

COMPLAINT SECTION

Needle breaks ............. 2B 1

Skippedstdches ............... 2B 2

Top thread breakmgand/or lammmcJof hook . . . 2B 3

IS THEBOBBINCASETHREADEDCORRECTLY?

NO - Correcthohbm case threadmg

YES

t

tS THEPRESSERFOOTPRESSUREREGULATORSET

CORRECTLY?

NO Correct the seftmg

YES

t

DOESTHE PRESSERFOOTSUIT THE TYPE OF

STITCHING?

NO Replace the presser foot with su_table one (see

tnslftrchonsm Owners Manual)

YE_

t

AREALLCONTROLSSETCORRECTLY?

NO - Correctoil the sottmgs

YES

Refer to Sec_on 5A

Make sum

• Bobbmthread ts under tensqortsprmu

• Bebbm }s mstalled to rotate counterclockwiseas

thread is pulled

Refer to Sectmn 5E

Make sure pressureknob ts

• Set for taore pressurewith hghtwetght fabrrc

• Set lot less pressurewith heaw fahrfc

Refer to Sectron5E

Makesure

• Bebbmwinderleveris properlypositioned

• Feeddogcontrolleveris properlypos0honed

8obbm threadbreakmg............. 2B 4

Looseshtchesor puckering ..... 2B 5

Doesnot straight stitch properly ...... 2B6

Doesnot knot shfches properly ....... _}07

Doesnet z.gzagpfopelly ............ 2R 8

Doesnot wordbobhmsproperly ..... 2B9

Disengagementand engagementof feedmg ...... 2B 10

Poorfeed of fabric .............. 2B 11

Machme doesnot run ................ 2B 12

Machmedoes notbaste ............. 20 13

Pool buttonholing .............. 2B 14

MKhme sewswithout foot control bemgpressed .... 28 1,_

Lightsremoraoft .................. 2B 16

Motor speedselectiondoes not work ......... 2B 17

Faulty keyboard .................. 28 18

lffl t8

t# rmouILt$#Oor_

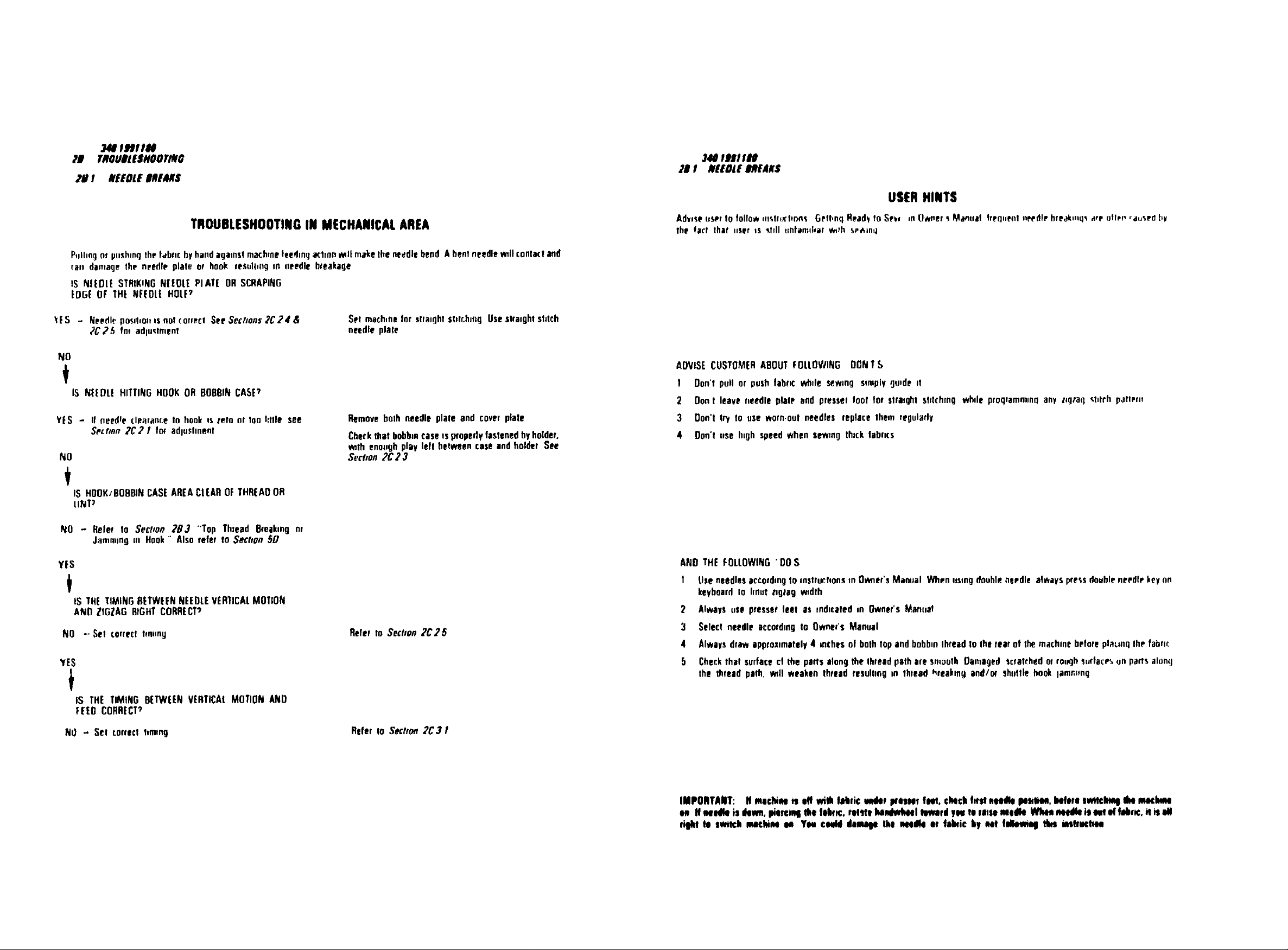

2U t IlttOLF IRt4K$

.1140Ittl l#8

2t I NEtOLEIltt41r$

USERHINTS

TROUBLESHOOTINGIN MECHANICALAREA

Pqlhngor pushingthe fabricbybandagamsl machine leedmgaChnn_ll makethe needlebend A bentneedlewdl contacl and

rmr dammJethe needle plate or hook resultingin oeedle breakage

IS NfEOIE STRIKINGNEEOLEPLATEOR SCRAPING

EDGEOF THE NEEDLEHOLE?

ti S - Needle posihOlris not rorfecf See Settmns 2C24 &

_'C2_, for adlu_lmen!

Sel machznefor straightstdchJng Usestraight shlcb

needle plate

NO

IS NEEOLI:HITTINGHOOK OR DOBBINCASE?

YES - g needle clearance In hook ,s taro or 1oo bllle see

Se_tmn 2C2 ! for adluShnent

NO

Removeboth needle plale and cover plate

Checkthat bobbincase Is properlyfastenedbyholder.

Wllh eno.gh play fell between case and holder See

Sechon 2C23

+

IS HOOK/BOBBINCASEAREACLEAROFTHREADOR

liNTY

NO - Refer to Sectmn 2B3 "Top Thread Breaking or

Jamming tit Hook" Also refer fo Sechon 5D

Adv,seuser to follow m,_tr_rftnns Getl,oq Readyto Sew ,n Owlet s Manna! tre(pleul .ladle break,.q,_a+eotle_.,a_JSe(1l_v

lhe laL'rthal tlser is strll uolanilhar w_!h Se_,mq

ADVISECUSTOMERABOUT FOLLOWING DONT S

1 Oon'l pull or push fabric while s_wlng rumply 9rode *I

2 Dont leave needle plate and presser IDol for sltazghl sf,lchmg while prnqrammmr!any ,ngtac]_t,trh pafleru

3 Oon'l fry to use worn.ool needles replace lhem regularly

4 Don't use high speed when sewing thzckfabrics

YES

IS THETIMINGBETWEENNEEDLEVERTICALMOTION

ANDZIGZAGBIGHTCORRECT?

NO --Set correcl Imlmg

YES

IS THE TIMING BETWEENVERTICALMOTION AND

FEED CORRECT?

NU - Sel correcl liming

Refer to Section 2C25

Refer to Section 2C3 1

ANO THE FOLLOWING' DOS

I Elseneedlesaccordingto inslruchonsm Owner'sManual When using doubleneedle always pre_sdoubleneedlekey on

keyboardIo bou! zzgZa9_dlh

2 Always use presserfeel as mdzceledm Owner's Marmot

3 Select needle accmdmg to Owners Manual

4 Always draw approximately4 inches ol bolhlop and bobbinthreadto lhe rear of the machine beforeplaLmqIlle fabric

5 Checklhal surface cf the paris along the lhtead pathare smoolh Damaged scralchedor roughsurfaceson parisalong

the thread pelh. _nll weaken thread resullmg m thread _reokmg and/m shntlle hook ]amnunq

IMPORTANT: If machiM ts elf wflk lalilic redes pressesfeet. chick feel needlepesdHm,befwa smtclMql die mackae

n Ifmmeeisdw.. werc,q_e eeb,€,mm I,oFdw_ethpwardyevleraiseMedlklWhian_dlklisevfoffakrg,o1tsIN

fil_ll _I ewl_h mg_ee M Tee gqH_ daln4qll lhi 11414141141M |illli¢ by _ feNevnq Ibl 111111111;11141

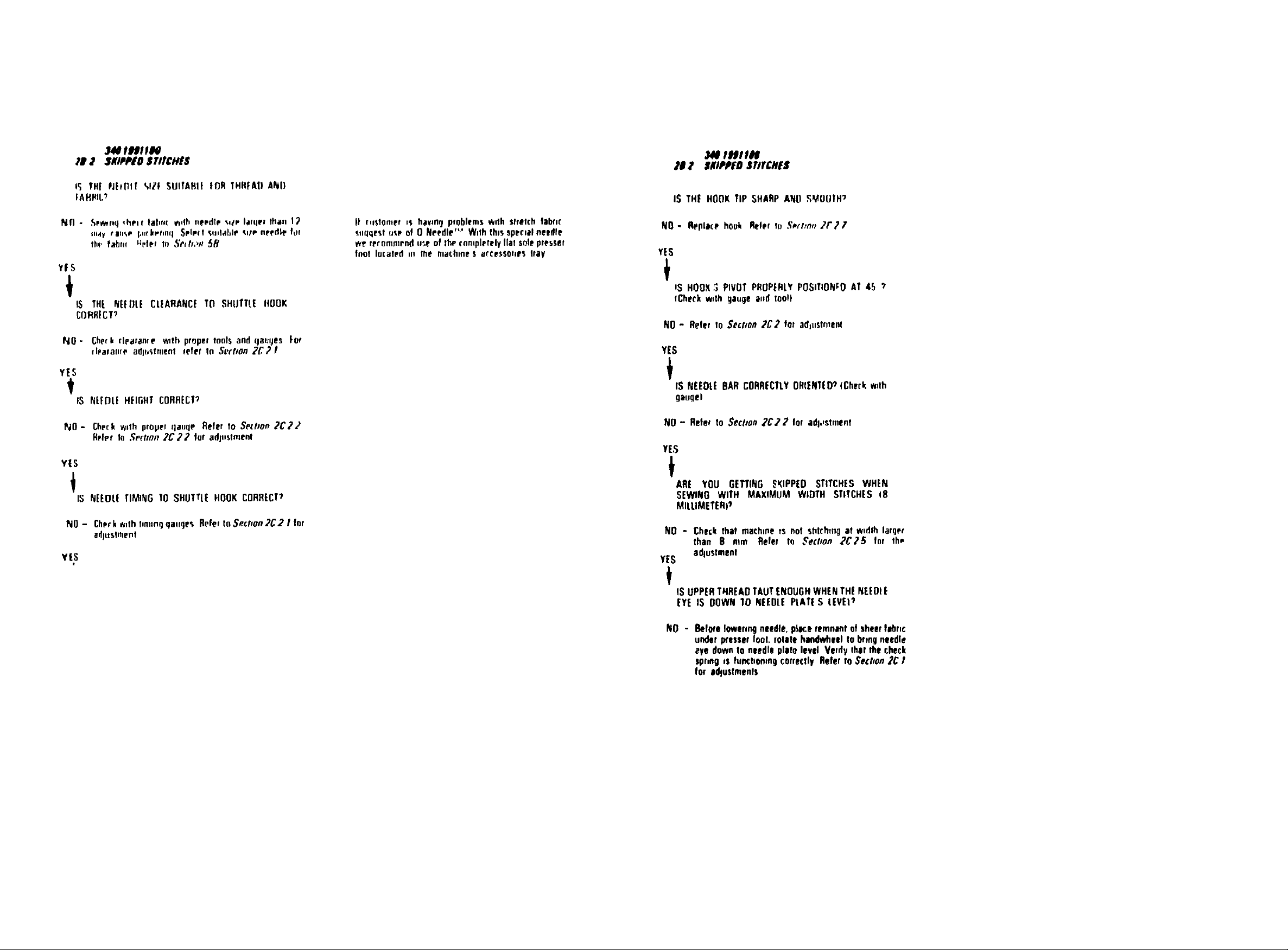

I_ TH| PJittllf %l_'f _,UIfAHIf _Or THrFAt) 4iqf)

IAKrll. _

IS THE HOOKTiP SHARP AND _MO(JTH?

NfI - .%pw.zq _helr tat.. _dh .eedtr ,.It lalqer lha. 1;)

may razz_0, i.urk_,rmq SPIPrf _.udah_e q,lle ftecdle Idr

fit1, fahl, refer In SPIh,,/I _8

YES

iS THL NEEDLECLEAHANC! TEl SHUTP.E IIOOK

CORRECT?

NO- Chrrl, rlearanre wzth proper tools and qau!jes ('of

rleafalifn adle_sfment lefer In St,felon .7_'_ I

YES

t

IS NlfDII HHGHT CORRECT?

NO - Cheek with propel qauqe Refer to Se_fmn 2C22

Relpt to ._;e,rtmn2¢22 for adj.smlenf

YES

IS NEEDLLTIMING TO SHUTTI| HOOK CORRECT?

NO - Chef k ruth fro.no qa.rjes Refer to Sect/on 2C21 for

adl*tstnlent

YIS

I| lil$lOnler iS havmrj pt'oblem$ with $lfefch fabfK

_,liqqest use of 0 Needle TM Wdh this sperlal needle

wr fernmnlrnd .':,e of the rnnlplefely flat sole presser

foot I,Jlated ii1 the mar.bloc 5 arcesso.es tray

NO- Replace hool_ P_,ier to ,T_,(hmt2r27

YES

IS HOOX3 PIVOT ProPERLY POSITIONrO Af 45 ?

fCheck with _jaz_geand too!l

NO - Refer to Sectmn 2£2 for adj.stment

YES

IS NEEOL| BAR CORRECTLYORIENTED? IChetk wdh

Oan_zel

NO - Refer to $ectmn 2C22 for adl,,stment

YES

ARE YOU GETTING SKIPPED STITCHES WH|N

SEWING WITH MAXIMUM WIDTH STITCHES 18

MILLIMETERi?

NO - Check that mKhioe rs not st=tchmgat width larriet

than 8 mm Relet to Sectmn 2C25 for th,,

YES odlustmenl

ISUPPERTHREADTAUTENOUGHWHENTHENfEOIE

EYEIS OOWNTO NEEDLEPLATES lEVEl?

NO - Beforeloweringneedle, pike remnant ofsheerflbrJc

underpresserIDol, tolate h_dwhanl to brrngneedle

eye down to needle plato level Verify theethe theck

=pnng Js fur,chonmgcorrectly Refer In Sechon 2C I

for edlustmenft

I', lll'Pllr TIkl%iUl_l LI]RNFCTIY _I'T _

NIl (,el If.troll floqi,N_l HelF_ |rl _'tl{lllll i_,

I_, 1'HL HOBfll!l |J_f Hi!Ill, IATfFI Ph(]PlHiY

P/)_'.,illOkl|l) ANI) I'% t1" PHiIF'IHIV TIGHILNL!) HY

BOTH SMAll LATLNf_ (IF THE 5PNPoG HOIr_fH"

Yf5

IS GOODQIIAIITYTHREt_OuSED_'

NO " Some poor quahfy threads on The matleel are not

,_,fJlable for machine _ewinrj Use good qoahly Ihfead

_urh as _olfon wrapped polyesler

YeS

t

,S TOP THRFAO TANGLINGON PART,_ALONGTHE

IF,READPAtH_

YF5 .-Che_k needle spool pros thread qo,de$ fensaon

ass-mhly err Relhread ma(h,ne

NO

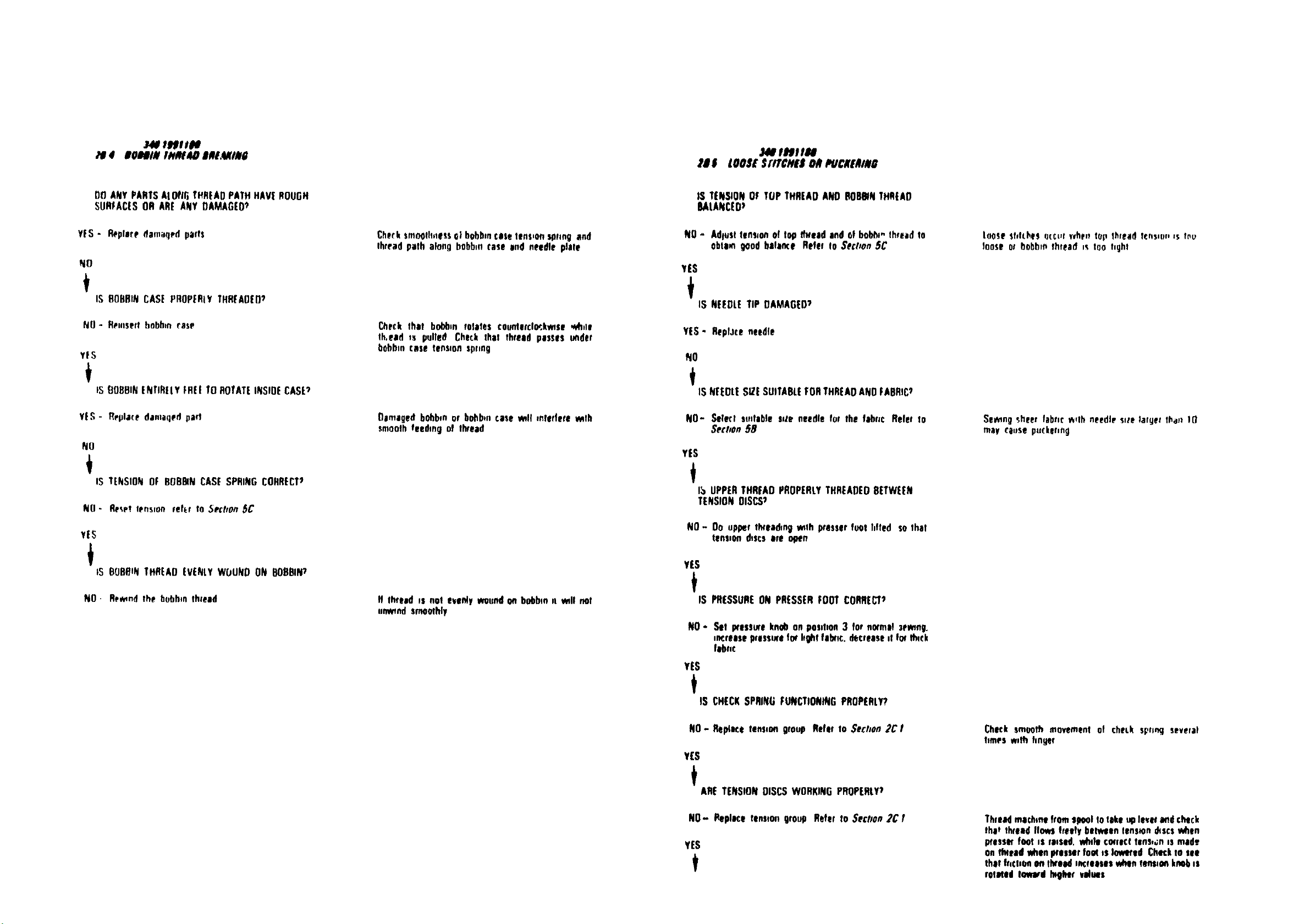

IlO ANY PARTSALONGTHHEAOPATHHAVEROUGH

SURFACE3OR ARE ANY DAMAG[D_

Y|_, - [.he(It thread _zJides fensron ronfrol lhlead lake up

low; t_eedle eve presser loot Doodle hole needle

plate _olary ,_huflle hook eft Replace pMf'_ if

Ilef e_%afy

NI)

NO - Properly,ese! leith

YES

ARE NEEDLEHEIGHT.NEEDLETIMING TO SHUTTLE

HOOK CLEARANCEBETWEENBOBBIN CASE AND

LATCHCORRECT_

NO- Reler to Se_hon_ 2C21 2C22 #nd 2C23 for

adluslme_ts

USER HINTS

threads to the rear ol the mazhme before pla_,nq The1,abe,(

Use proper needle z((mdmzj |o kendof fable( add rfl_ea_l

15 THI TIP OF THE SHU_'IE HOOK SHARP AND

SMOOTH7

NO - Heplare ,,bottle hook R_,fer to Se_tmn 2C27

YES

IS LIPJTOR BROKEN THREAD ACCUMULATED IN

5HLI_IE HOOK OR FEEDOOG AR(A?

YES- Clean sh,rtflehook and feed dogareas Referto

Sectmn5D

NO

Lm1,oqbrokenthread m these areasml! delaylaming

ol fhfe_l escapefrom shottlehook resulhngm thread

breaking

DO ANY PARIS AtOtifi THREADPATHHAVEROUGH

SURFACESOR ARE ANY DAMAGED?

IS TENSIONOtt TOPTHREADAND BOBOINTHREAD

BALANCED?

YES - Replere damuqed parts

NO

IS BOBBINCASE PROPERLYTHflfADEB?

NO- Remserihobhm rose

YES

i,

IS BOBBINENtIRElY ERE| TOROTATEINSIDECASE?

YES - Replete damaqed part

NO

+

IS TENSIONOF BOBBIN CASESPRING CORRECT?

N(I. Re_et tensmn refer to 5cotton _C

YES

i,

IS BOBWNTHREADEVENLYWOUNDON BOBBIN?

CheEksmoOlll+lessoi hohhmcase ions,offspfmg god

thread path along hohbm Easeand needle plate

Check thai bobbin rotates tountlrcl_kw_se whdl

ih,ead rs pulled Check that thread posses under

hohhm (ase tension swing

Damaged bobbin or bohbmcase ell enlerfere _lh

smooth feeder of thread

NO - Adfusliensmn of lop ffwead and of bol_', threadto

obiam good Balance Refer Io ..eectron5C

YES

IS NEEDLETiP DAMAGED?

YES- RepUte needle

NO

t

ISNEEDLESIZESUITABLEFORTHREADANDFABRIC?

NO- Select sudable smzeneedle foe the fabric Refer to

Sechon 58

YES

t

I_ UPPERTHREADPROPERLYTHREADEDBETWEEN

TENSIONDISCS?

NO - Do upper tlweadmg ruth presser fool hired so thai

tone,on d_scsare open

YES

Loose shith#$ otcvr whelr top thread teusiolz Is tPt3

loose Of bobbin thread i+ too tight

Sewer sheer fabt.r '_,th needle site larger fhaJI I0

may _ausn puckering

NO- Rewind the hubhm thread

R thread ,s not evenly wound on bobbmn ell not

oovwnd smoothly

IS PRESSUREONPRESSERFOOTCORRECT?

NO * Sll IXess_e knobon posmon3 for normal sarong.

,i_relse preservefor h_lf fl_l(;, decrease,t for thick

IOB.€

YES

IS CHECKSPRINGEUNCTIONINGPROPERLY!

NO- Replace tansies group Refer io $e+hon 2C !

YES

ARETENSIONDISCSWORKINGPROPERLY?

NO- Replace tonsron group Refer to Section 2C I

YES

t

Check smooth movemeni of check spring several

limes mlh finger

Threadmachine from spoolio take uplever ond check

ther threadflows heely betweeniensmn (kscs when

pfessln font la raised, v_lo €Oqre¢ituns,,Jnis made

on El#earlwhen i_esar foot is lowered Ch_:kto see

11111frt¢iion on llwod loTrtaste w_n fellllOfl kl_ll IS

roilted IO_nud h_mr vl_oos

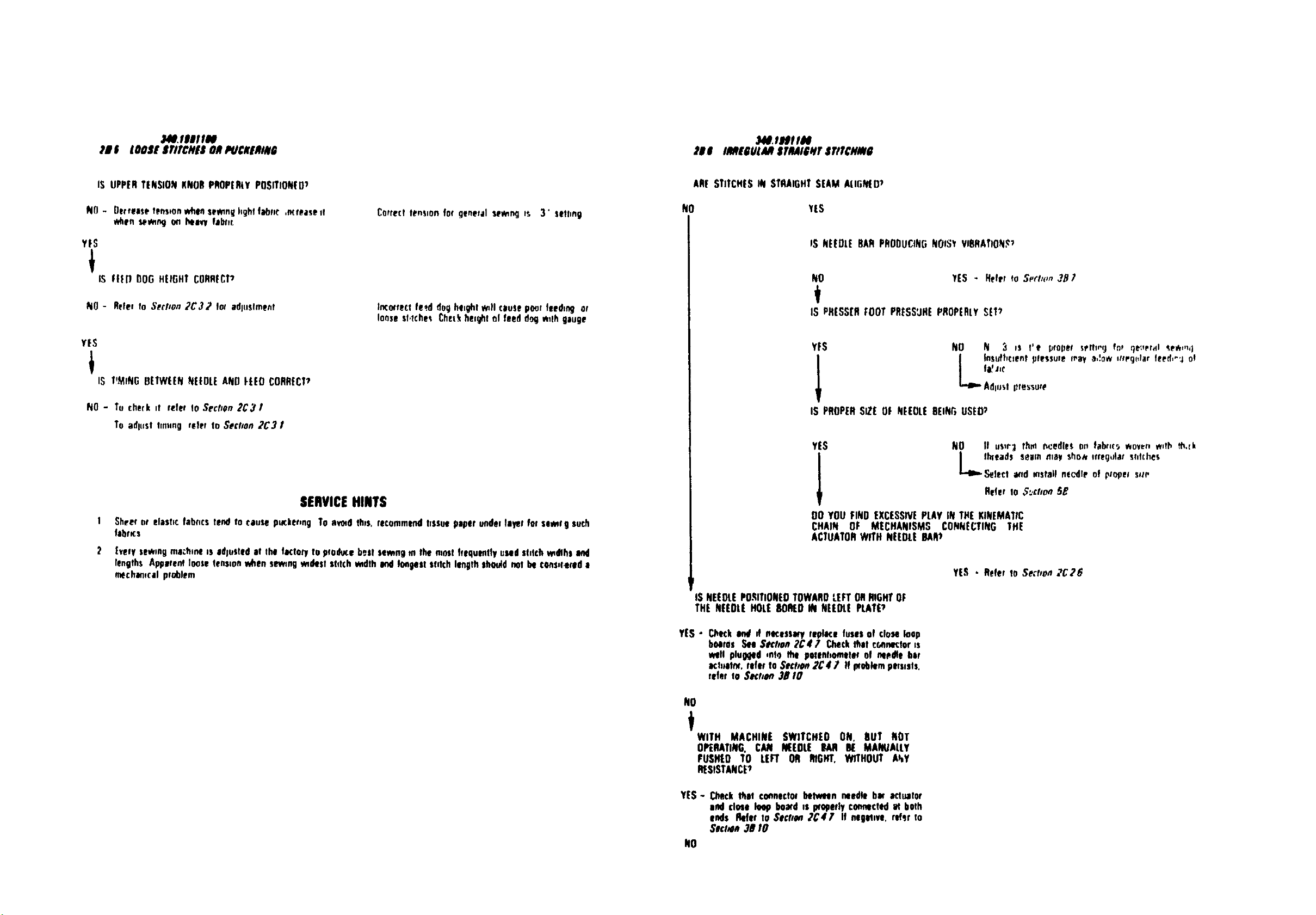

_, FIM IN .11411.llfl IN

tltl lOOSE Srlrcltl# ORI_UCItfAIII_ 218 IIMEBUI4R SrlMIG_Ir #1?PCHIII8

IS UPPERTENSION KNOBPROPERLYPOSITIONED')

NO - OlrrulSe lenstoov_u semn_ hghff,'Ibf_(',n(ruasu II

when se_ on heew lebuc

yfS

i

iS |||[100G H[IGH? CORRECT?

NO - Refer Io Section 2C32 Io# adluslmenf

YES

IS f!MING BEIWEfN NEEDLEAND FEEDCORRECT')

NO - To cherk it refer lo Sect+on2C31

To adlUSl hmmg ruler to Seclmn 2C3 1

SERVICEHINTS

I

Sheer ur elashc fabrics tend to cauSepucker,ng To avoedthts. recommendtissuepiper under liver for sewslgsuch

fibres

2

every sewmgme,:hmeis Idfusled el 1111factory to producebesl sevmngm Ihe mostfrequwllly ugd shlch veo'lhsI_1

lenglhs Apperenf loosefenswn _en sewmg m_sl shtch v+sdthGodlongestsldch lengthshould nol _ cons,lemdI

mechamcalproblem

Correct tension lot general _ewsng it, 3' selling

Ir_co.eClle_.d dogheight wallcause poor fuedm9 or

loosesf,tche_ Checkheight of feed dog wtlh gauge

ARESTITCHESIN STRAIGHTSEAMAIIGNID')

NO YES

IS NEEDLEBARPROOUCINGNOISYVIBRATION,_

NO 'fES o Helot+oSeth+,. 3117

t

IS PRESSER_OOTPRESS3R[PROPERTYSET')

YES NO N _ is l'e proper 5prhr'9 ln_ t_e_ve,r,41 _e_+,,l_)

IS PROPERSIZE OF NEEDLEBEINGUSEO?

YES

DO YOUFINDEXCESSIVEPLAYIN THEKINEMATIC

CHAIN OF MECHANISMS CONNECTING)'HE

ACTUATORWITH NEEDLEBARS

fW,#,c

L..

Adlust pressure

|lnsufhcJent pressure may a,!aw !ttegtdar feed,':l o!

NO II us_r;I thinP_edles un fabric.'+woven w,lb _,rk

ib;tacit seam may sho_ irreg,dar stitches

St!loci +lt'ed.+stall nellie ol ptope, s,/e

Refer 1o S:.£hon 5_

YES • Ruler1oSe:t,on2C26

ISNEEOLEPOSITIONEDTOWAROLEFTORNIGHTOF

THENEEDLEHOLEBOREDiN NEEDLEPLATE')

YES " Cl_tckImtl it e#eseuvy reld_Ce lusts ot close loop

boarOs See S_hon 2C47 CheckthiS cr,,,ant_lorss

will plugged Enid the pelenlJomele¢of mlel_e bar

Khllt_lt', refer to Sectmn2_47 If p+obkempltusls.

refer to Sectmn 311!0

NO

i

WITH MACHINE SWITCHED ON. BUT NOT

OPERATING.CAN NEEDLELIARRE MANUALLY

F'USNEOTO LEFT OR RIGHT,WITHOUT A_Y

RESISTANCE+/

YES - Check that €o_neclor betw_n needle bw dictualor

ifltJ dose loop bo_'d is properly connected lit both

ends Refer to Sectmn 2C47 If negllive, refer to

SectPen30 !0

NO

Wllt! l!lOIt fLAIl IqlgllOltfO loll SIUAIGHI

ShTCItltlGt,_IItAU 10010 lqllllllOW! ,._ NIIOII

POINTCORIqftli'f CIPJIIRIUovtl_PlAit HOLt+

HINTS FORUSER

Au,OO,JfhOa!_'_s_otJl-,ol you' irlilchvlz_youflr,d the !_e_al qlramghtlhllh l_e_l$1trIoo! Ifh_ o_ wdhI sf_lll h_e _dlpd rn_t

above,Ihe prL._,te_'Iool IDyll 1o h! os!_ vdlen Sl_nn_ she!l lfretr:h II_l._

Needle plale shooedhe pos_:_onedwvththe, small round hole Ira"sltazOhts'_lchdlg

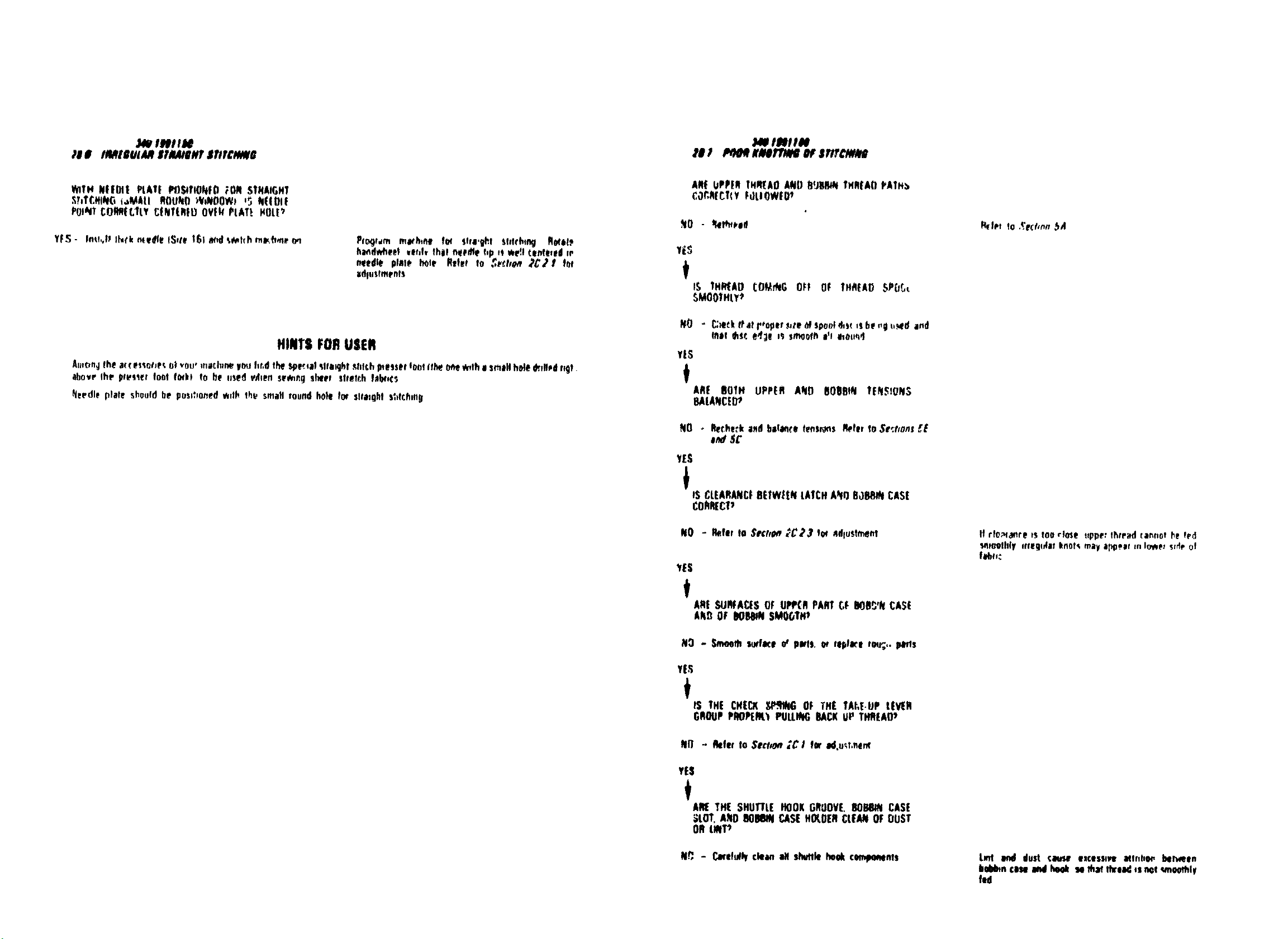

AN| _PR!! THH[AOAlP l_JIl_t_tIHIq|AD PATH)

C_IC_q(_l{Y ldtl OWlOf

_det Io .£e(/,,_o ,_A

vls

SMOOTHLY_

NO - C;_k I1_tIr*oper s,zeof spool_s( zt be ,_ _,_edarid

Inl! IhK e_je i'_smoofh Ill II011_14

vl$

I

ARt IOlX UPPER AND BOBBIN TEN,_IUN3

BALANCID_

NO o Reche,'k and hell,re fensrxms N,pIer fo Se'_.honz _E

e_d_C

YES

IS CLtARANCfBtI'WItN LATCHANDB_lflBl_CASt

COkRECP

NO " Refer to Sech_ _'23 to_ ._dluslment

YES

I

AN| SiJfl_ACtSOf UPPCRPARTCFBOBC'NCA5|

AN9 OFBOBBINSMOGTNt

NO - Smooth lorfli_e 0_ plrlt. O_repll(! ro%_. l_rls

yES

I

IS THE CHECK_ OF THE TAr,t.UP tt_R

GROUPPRO_M.'t PUKINGBACKUP THltEAIP

NO - Refer to Sectton ;C I far _,u_t,,or_

AR_ THE SHUI"]'L[ HOOKGROOVE.BOBI_ CASE

SLOT,ANDBQII_ CASEHOq.OENCLEANOFDUST

ORLINP

If rle_,l_re e$Ioo ridge teppe: Ihce,ad [a_rlot _e lpl_

_gglhll Illlgl_ll tnol_ mi t lppelr _n I_e_ s_rfe,ol

I1_ - _llelu!l I tk_ _ sh_k_ he_ cOmpm_nts

L_ end dust €_e eKessgme_llnh_, bergen

IId_n cese ira41ho_ so lfla_lhreK _se_! _ly

fed

Thissectiondills vlnlhpfo_kemsof machinezigcegstitches producingip(o.ect or deformed patternsof _n,_ulf_Jentz_gtag

vwdlh

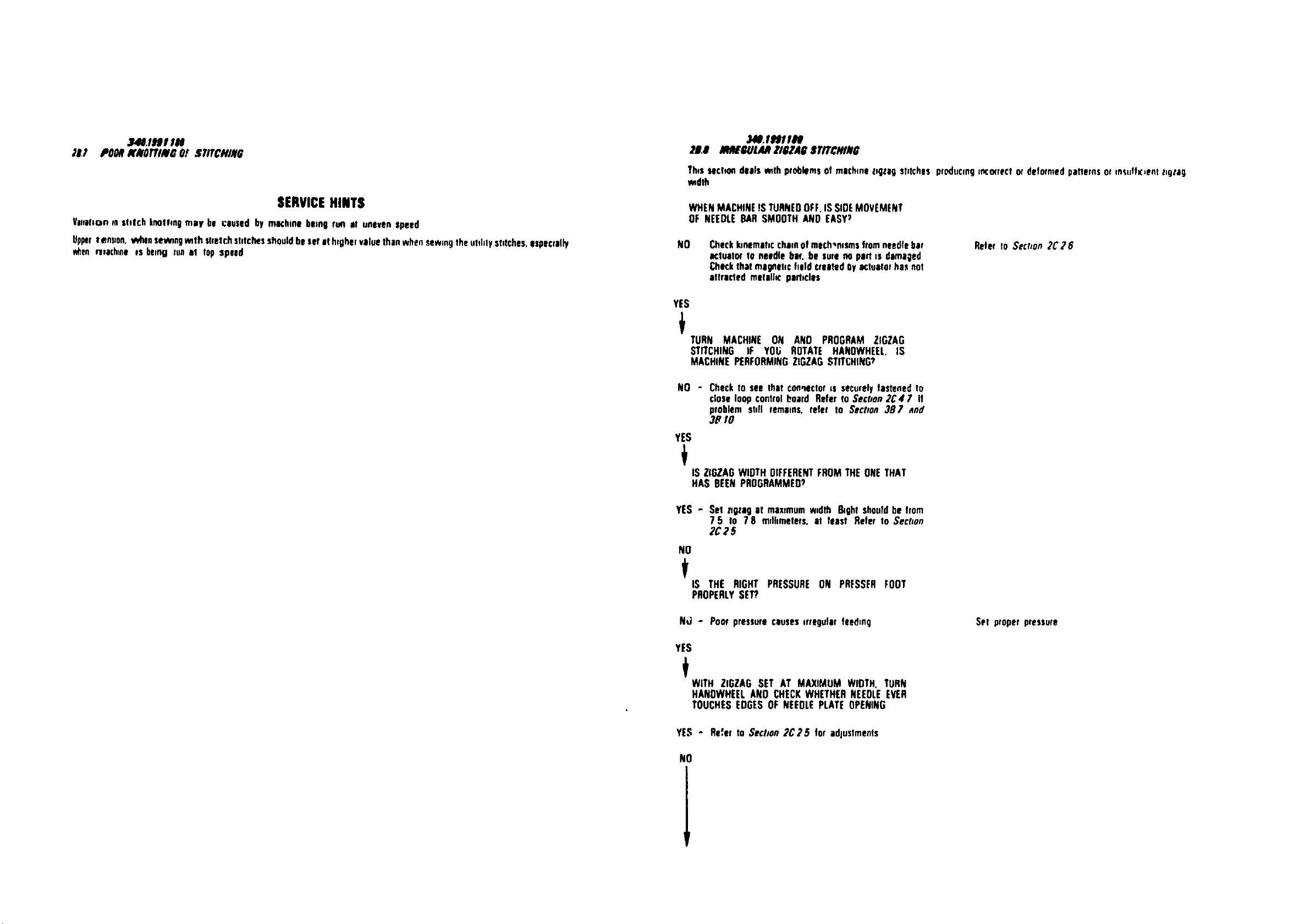

SERVICEHINTS

Vzieelionin st_fch knottingmay be caused by mKhma being run at uneven speed

Uppertension, when oewm9ruth slrelch stitches shouldbe set el h,ghervaluethanwhensewingtheutdlty stitches, especially

whennrechme cs being tun at top speed

WHENMACHINEISTURNEDOFF.ISSIDEMOVEMENT

OFNEEDLEBARSMOOTHAND EASY?

NO Checkk_nemahcchain of roach"rosins ffam needleher

KIuIIOf In needle bar. be sine no part ,s damaged

Checkthat megeetlc field created by actuatorhas not

attracted metall_ perhclas

YES

TURN MACHINE ON AND PROGRAMZIGZAG

STITCHING IF YOU ROTATEHANOWHEEL.IS

MACHINEPERFORMINGZIGZAGSTITCHING?

NO - Checkto see that con_¢tor 8o securelyfattened to

crest loop control I_oard Refer to Section2C47 If

problem shll remains, refer to Section 307 and

3B 10

YES

ISZIGZAGWIDTHDIFFERENTFROMTHEONETHAT

HASBEENPROGRAMMED?

YES - Setzigzagel maximumwidth I_ghtshouldbe from

75 to 78 millimeters,at toast Refer to Sectmn

2C25

NO

Refer to So,hen 2C26

IS THE RIGHT PRESSUREON PRESSERFOOT

PROPERLYSET?

N_ - Pool pressurecauses .regular feeding Set proper pressure

YES

WITH ZIGZAGSET AT MAXIMUMWIDTH.TURN

HANDWHEELANOCHECKWHETHERNEEOLEEVER

TOUCHESEDGESOF NEEOLEPLATEOPENING

YES * Re:or to Section 2C25 for adjustments

NO

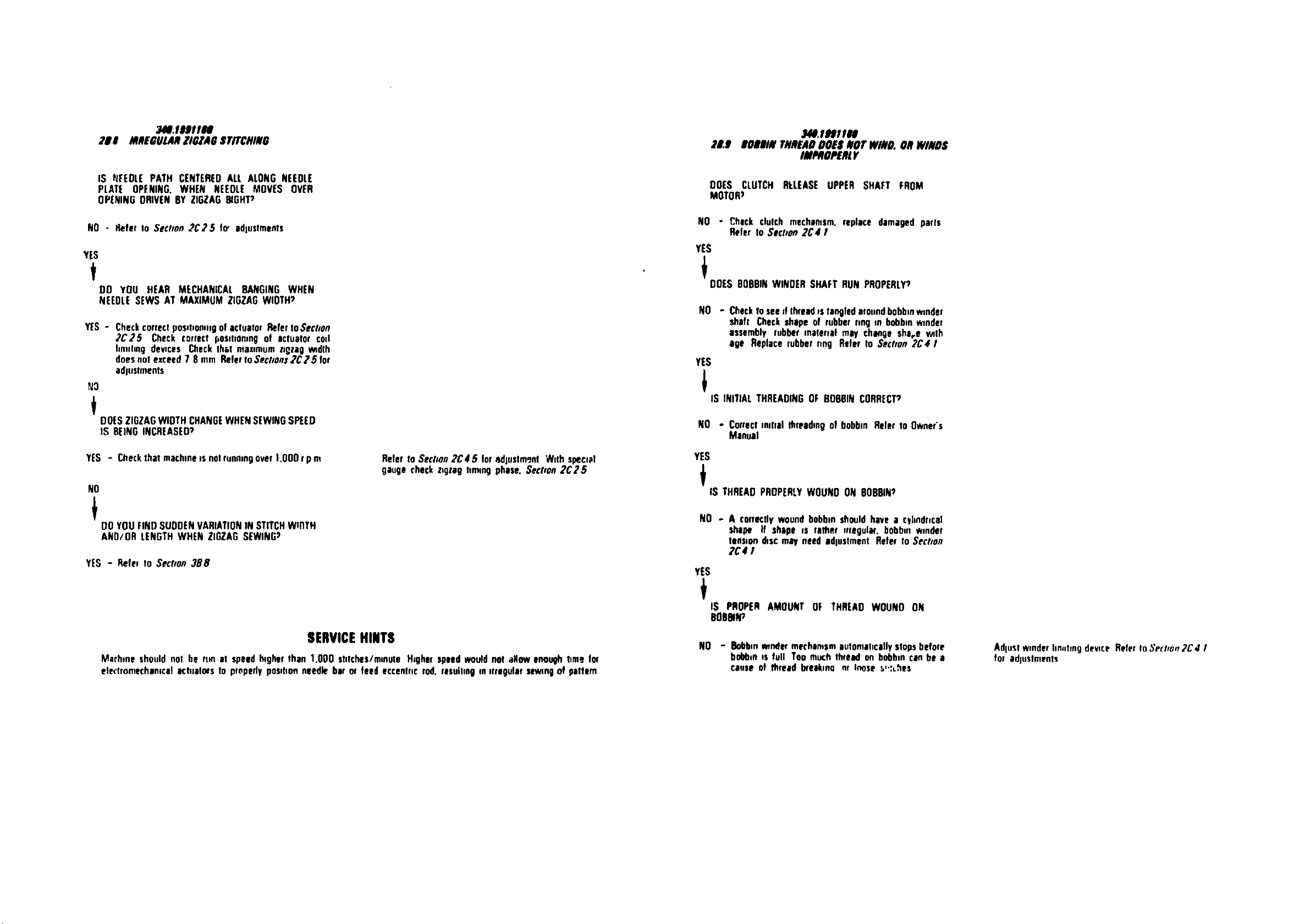

34W.ltlIIN ZalO.IHItN

211 IIIRIDUIAR IliAD STITCHIIID 20.1 IODIIN TIlllEdDODESIIOT WIND. DI/ WINDS

INPRONRIY

IS I_IFEDLEPATH CENTEREDALL ALONG NEEDLE

PLATE OPENING. WHEN NEEDLE MOVES OVER

OPENING DRIVEN BY ZIGZAG BIGHT?

NO - Refer Io Secfron 2C25 to" adtustments

YES

t

DO YOU HEAR MECHANICALRANGINGWHEN

NEEDLESEWSATMAXIMUMZIGZAGWIDTH?

YES - Check correct posmonmg of actuator Refer toSechon

2€25 Check correct posrttoumg of actuator cod

hn,fmo devices Check Ihat maximum _qgzag vlndth

does not exceed 7 Omm Refer to Sectmns 2C 25 for

adluslments

_Jo

DOESZIGZAGWIDTHCHANGEWHENSEWINGSPEED

IS BEINGINCREASED?

YES - Checkthat machineIsnol runningoverI.OOOr p m

NO

Refer to Sectmn2C45 for adjustment With specael

gauge check zmgzaghmmg phase. Sectron 2C25

DOES CLUTCHRELEASEUPPER SHAFT FROM

MOTOR?

NO - Check clutch mechanzam, replace damaged paris

Refer to Sectmn 2C4 1

YES

DOESBOBBINWINDERSHAFTRUNPROPERLY?

NO - Checkto see d thread*stangledaroundbobbinwinder

shaft Checkshape of rubberring m bobbinwinder

assembly rubber material may chamgeshe,,o wulh

age Replace rubber rmg Refer to Section 2C4 1

YES

1

IS INITIAL THREADINGOF BOBBINCORRECT?

NO - Correctmmalthreadingof bobbinReferto Owner's

Manual

YES

IS THREADPROPERLYWOUNDON BOBBIN?

O0 YOUFIND SUDDENVARIATIONINSTITCHW_DTH

AND/OR LENGTHWHEN ZIGZAG SEWING?

YES - Rule, Io Sectmn 388

SERVICEHINTS

Much,he should not be mn at speed higherthan 1.000 shtches/mmote Higher speed would not aXow enough time for

ele_tromechamcalactnat_s to properlypuS,hunneedle bar or feed eccentoc rod. resulting m irregular sewingof pattern

NO - A correctly wound bobbin should have a cyhndracal

shape R shape is rather _rregola_.bobbm w,nder

tensiondisc may need edlustment Refer to Sectmn

2C4!

YES

IS PROPERAMOUNTOF THREADWOUNOON

BOBBIN?

NO - Bobbinwinder mecbentsm automahcaflyslopsbefore

boWamis full Too much thread on hobhmcan be a

cause of thread Meglklna m' Inose _,,.:Lhes

AdluSlwinder hm,tmg device Referto Sertmn2E4 !

for adluslments

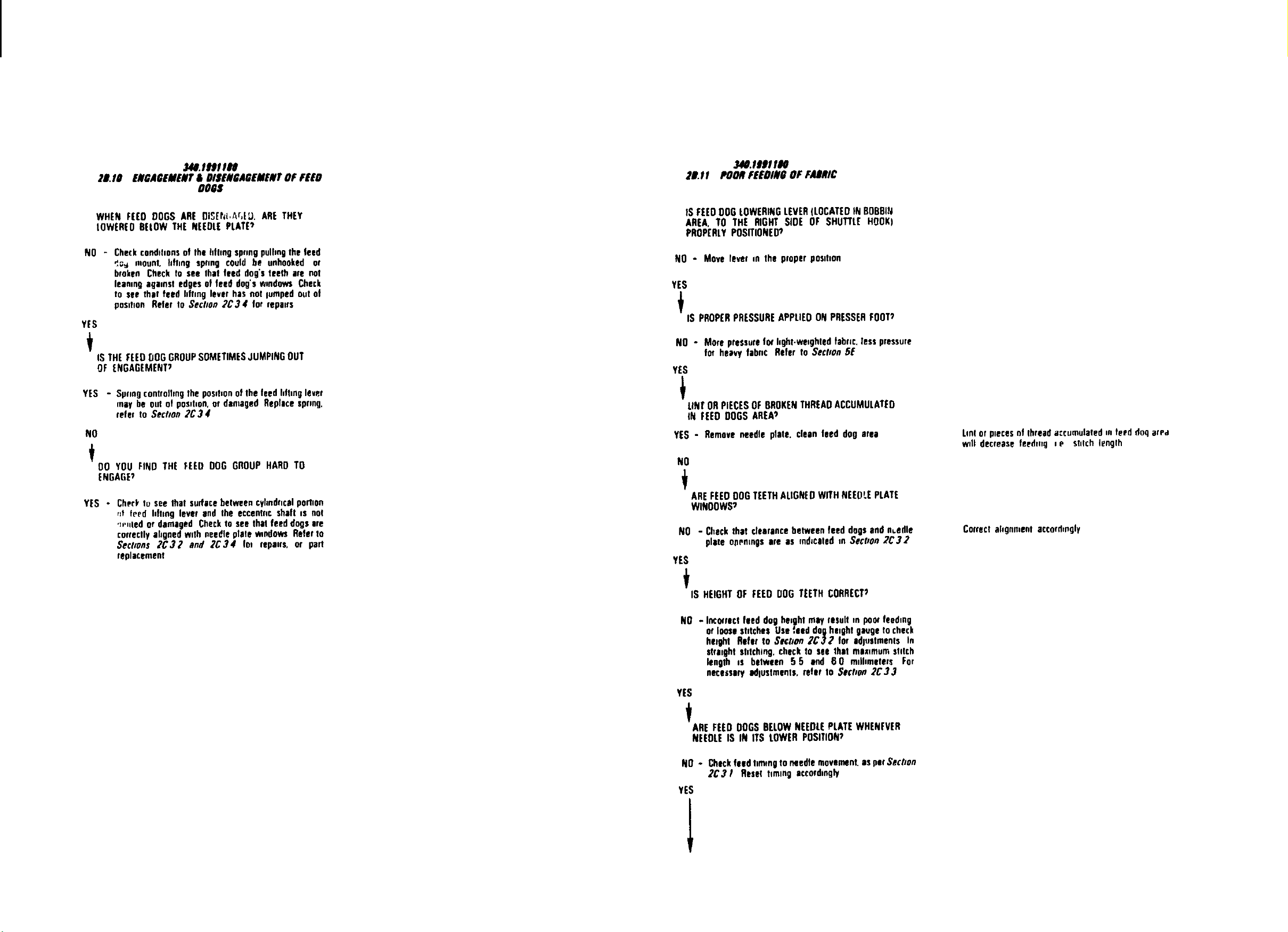

WHENFE(ODOGSARE OiSEf_I.Ar,EL).ARETHEY

LOWEREOBELOWTHENEEDLEPLATE?

ISFEEDDOGLOWERINGLEVER(LOCATEDINBOBRIf,_

AREA.TO THE RIGHTSIDE OF SHUTTL[ HOOK)

PROPERLYPOSITIONED?

NO " Checkcondlhonsof the lifting springpulhngthe feed

_Q_ mount, hfhng spnng could be unhooked or

broken Check to see that feed dog's teeth are not

leaning against edges of feed dog'swindows Check

to see that feed hiring lever has not lumped out of

position Refer to Section 2C34 for repairs

YFS

ISTHEFEEDDOGGROUPSOMETIMESJUMPINGOUT

OFENGAGEMENT?

YES - Spring€ontTollmgthe pos_honof the feed hiringlever

may be out of positron,or damaged Replacespring.

refer to Sectron 2C34

NO

O0 YOU FIND THE FEED DOG GROUP HARD TO

ENGAGE?

YES - Checkto see that surfacebetweencyhndncalportion

,_t t[.e.dhftmg lever end the eccentncshaft is not

•]f,.ied or damaged Checkto see thai feed dogs ere

co,ectly ahgnedwith needleplate windows Refer to

Sections 2C32 and 2C34 fm captors,or part

replacement

NO - Move lever m the proper pasthon

YES

IS PROPERPRESSUREAPPLiEOONPRESSERFOOT';

NO * Mare pressurefor hght.wezghted fabric,less pressure

for heavy fabric Refer to Sectmn bE

YES

LINI"ORPIECESOFBROKENTHREADACCUMULATEO

IN FEEDDOGSAREA_

YES - Removeneedle plate, clean feed dog area

NO

AREFEEDOOGTEETHALIGNEDWITHNEEOLEPLATE

WINDOWS?

NO - Checkthat clearancebetween feed dogsend n_edle

plate opemngsere as rod_caledm Sectmn 2C32

YES

Lintof piecesof thread accumulatedm feeddoqareal

Wig decrease feeding _e shlch lenglh

Correctahgnmeotaccordingly

IS HEIGHTOF FEEDGOGTEETHCORRECT?

NO - Incorrectfeed dog hmghl mayresult in poor feeding

or loosestitches Use ,_eeddogheight gaugeto check

herght Refer to Section 2C32 for adluetmento In

straight stitching,check to sea that maximum sfrtch

length is between 55 and B 0 millimeters For

necessaryadlustments, refer 10 Section 2C33

YES

AREFEEDDOGSBELOWNEEDLEPLATEWHENFVER

NEEDLEIS IN ITS LOWERPOSITION?

NO

- Checkfeedtimingto needlemovement,asperSection

2C3! Resettimingaccordingly

YES

1

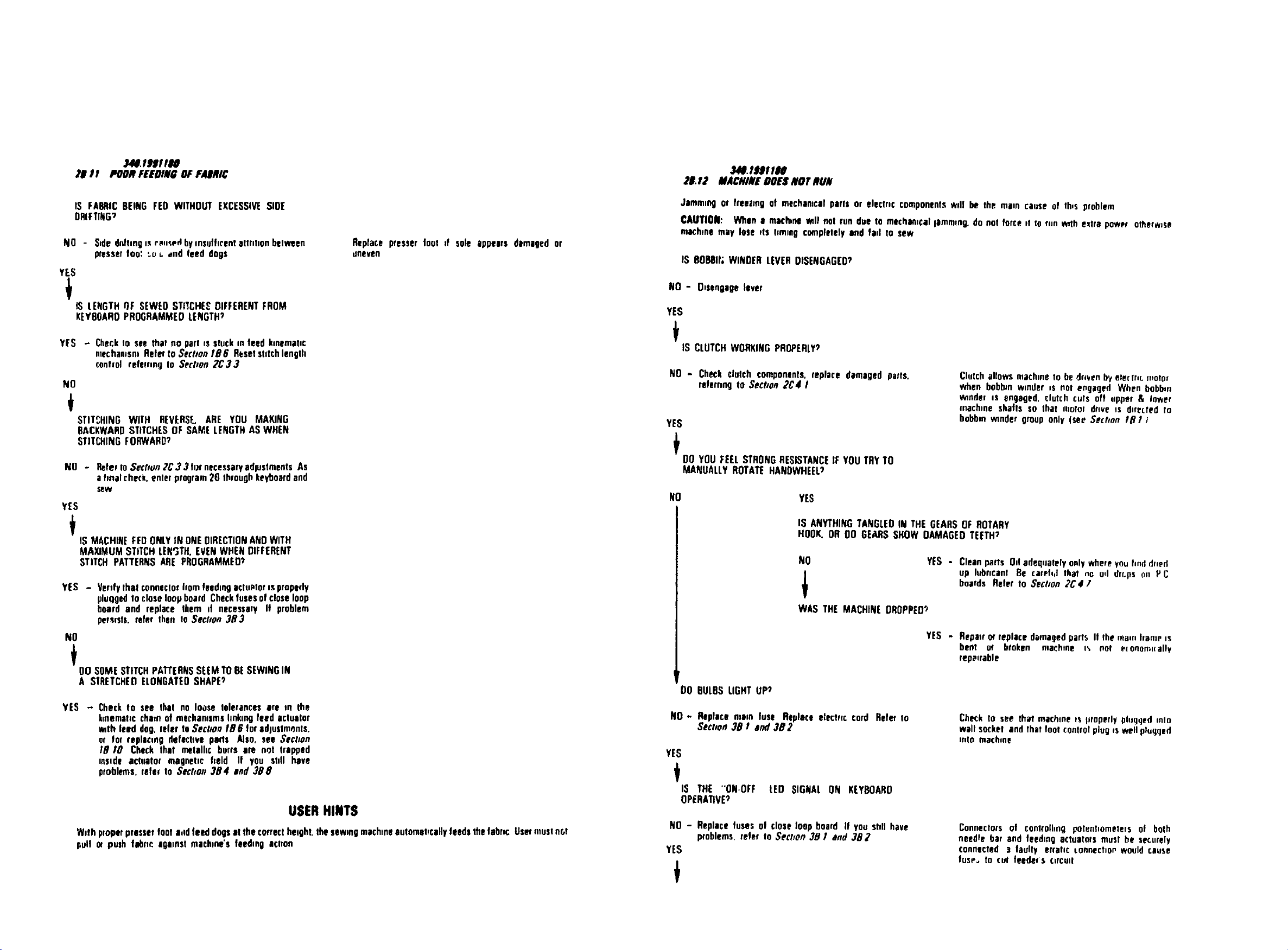

7# It POORF£f#ING OFFABRIC

,I_.tHI litO

340.till lifo

2#.17 MACHINEDOESNOTRUN

IS FABRICBEINGFEDWITHOUTEXCESSIVESIDE

DRIFTING?

NO - Szdednftingis rou_pdbymsufficentaririhonbetween

presserfoe: '.(__.,rod feed dogs

YES

Replace presser fool if so_ appears damaged or

dfleven

IS LENGTHqF SEWEOSTITCHESDIFFERENTFROM

KEYBOARDPROGRAMMEDLENGTH?

YES - Checkto see thal no part Is stuckin feed kinematic

mechamsmReferto Seehon186 Resetstitchlength

control refelrmg to Settmn 2C33

NO

STITCHINGWITH REVERSE,ARE YOU MAKING

BACKWARDSTITCHESOF SAMELENGTHASWHEN

STITCHINGFORWARD?

NO - Referto Sectmn 2C33 for necessaryadlustmeotsAs

ahnal cheer, enter program26 Ihroughkeyboardand

sew

Y£S

ISMACHINEFEDONLYIN ONEDIRECTIONANDWITH

MAXIMUMSTITCHLENSTH.EVENWHENDIFFERENT

STITCHPATTERNSAREPROGRAMMED?

YES - Vertfythat connectorhomfeedingacluptortsproperly

pluqgedto close loopboard Cheekfusesof closeloop

hoard and replace them if necessary I! problem

persists,refer then to Seclron 3B3

NO

O0 SOMESTITCHPATTERNSSEEMTOBESEWINGIN

A STRETCHEDELONGATEOSHAPE?

YES - Cheekto see that no loose tolerances ore to the

imemahe chain of mechanisms hoklng lied lctoitor

vathlead dog. tiler to Section IB$ for Idluslments.

or foe replacmg defacbvo paris Also. see Section

IR tO Check that metallic burrs are not trapped

ms,de acloator magnetic held If you still have

problems,refer to Section 3B4 and 3B8

USERHINTS

Wrih properpressertool addfeed dogsat the correctheight,thesewmgmachineautomaticallyfeedsthe fabric Usermust nGt

pull o_ push fabric against machine's feeding aelron

Jamming or ftoelmg of mechanicalparis or elacffic componentswill be the main cause of Ih,5 problem

CAUTION: W11ene machine y_ll not run due to mechamzcalIommmg.do not force elto runwsth extra power otherw)se

machine may lose ,Is liming cwnplelely end fad to sew

IS BOBRIt;WINDERLEVERDISENGAGEO?

NO - D,sengagelever

YES

IS CLUTCHWORKINGPROPERLY?

NO - Cheek clutch components,replace damaged paris.

refemng to Sectmn 2C4 1

YES

Clutchallows machine to he dr*yenby ele(tru, maim

when bobbin winder Js nol engaged When bobbin

_nde! _s engaged, clutch cuts off upper & lower

machme shafts so that motor dr_ve _s d,re[ted to

bobbinwinder grouponly Isee So(ban IB I

DOYOUFEELSTRONGRESISTANCEIFYOUTRYTO

MAI_UALLYROTATEHANOWHEEL?

NO YES

IS ANYTHINGTANGLEDIN THEGEARSOFROTARY

HOOK.OR00 GEARSSHOWDAMAGEDTEETH?

NO

WAS THE MACHINE DROPPED`>

YES - Cleanparts Oil odequalelyonlywhere youh,d dued

up luhncant Be careh,I that ,o o,I dri.ps Oll PC

boards Refer to Sectmn 2C4/

YES - Repastoqreplace damagedparts If the ma,u IfanlP is

bent or broken machme i,, nol e_onomually

repairable

DOBULBSLIGHTUp?

NO *. Replace mum fuse Replace etectrrecord Refer Io

Sectmn 3B t and 3B 2

Cheek to see that machine r5 properly plngqed mfo

wall sockel and that fool control plug es well phJgqed

Into mochifle

YES

IS THE "ON.OFF

OPERATIVE?

NO - Replace fuses of close loop board If you st,II have

problems,refer to Sechon 30 ! and 362

YES

tED SIGNALON KEYBOARD

Conneclors of eonlrolhng potentmmeter5 of both

needle bar and feeding oetuatms must he securely

connected o foully e,attc Lonnectlonwould cause

fuse. to cut feeders cneuit

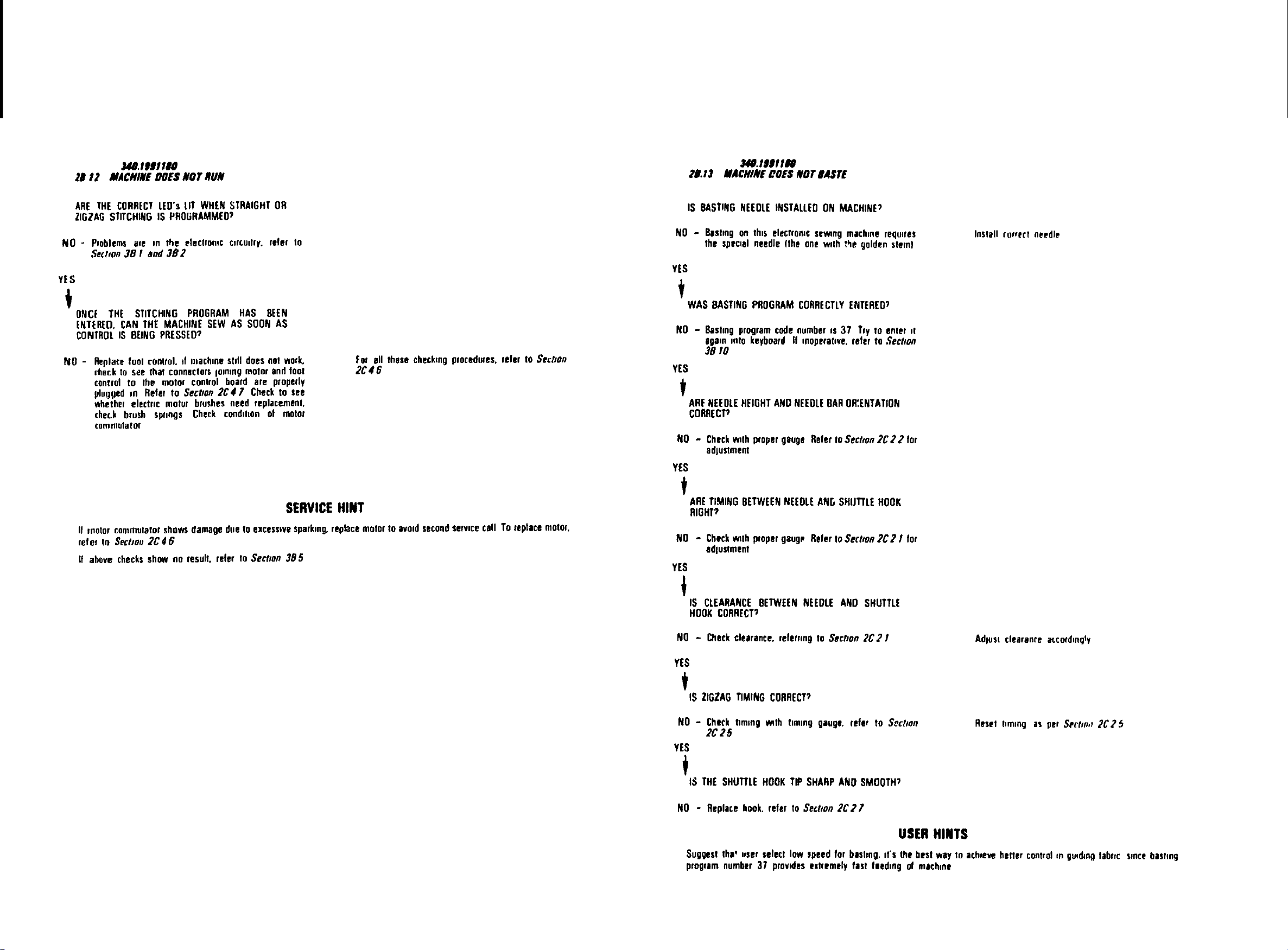

21112 MACHINEDOESNOTRUN 21.13 MACHINEl_Of$ KOTIIASrE

J410.1$111110 _kP.II OIIN

ARE THE CORRECTLED'sliT WHEN STRAIGHTOR

ZIGZAGSTITCHING IS PROGRAMMEO?

NO - Problems ore in the elocfromc cffcoltry, reler to

Secfron3B I and 382

YES

ONCE THE STITCHING PROGRAM HAS BEEN

ENTERED,CAN THE MACHINE SEW AS SOON AS

CONTROLI$ BEING PRESSED?

NO - Replacefool control, if machine still doesnot work,

checkto see that connectorsiommgmotor and foot

control to the motor coolrol board are properly

pluggedin Refer to Section 2C47 Checkto see

whether elecmc motor brushes need replacement.

cbe(.k hrnsh springs Check condmon of motor

commutator

For all thesecheckmgprocedures,refertOSec_on

2C46

SERVICEHINT

if motor commutator showsdamagedue to escesswesparking,replacemotor to avoidsecondservicecall To replacemotor.

refer to Sectlmr 2C46

If above checksshow no result, refer Io Sectron 3B5

IS BASTINGNEEDLEINSTALLEDONMACHINE?

NO - Besting on this electronicsownngmachine reqmres

the special needle (the one w,th tt'te golden stem)

YES

WASBASTINGPROGRAMCORRECTLYENTEREO?

NO - Bastingprogramcodenumberis 37 Tryto enter*t

againinto keyboardIf moperat,ve,referto Sectmn

38 tO

YES

t

ARENEEDLEHEIGHTANDNEEDLEBAROR:ENTATION

CORRECT'_

NO - CheckwithpropergaugeRefertoSectmn2C22 for

adjustment

YES

t

ARETIMINGBETWEENNEEDLEANGSHUTTLEHOOK

RIGHT?

NO - Checkwith propergaugeReferInSection2C 2 ! for

adlostmenl

YES

Install to.err needle

IS CLEARANCEBETWEENNEEDLEAND SHUTTLE

HOOKCORRECT?

NO - Checkclearance, referring to Section 2C2 ! Adlusl clearance accmdznqty

YES

IS ZIGZAGTIMINGCORRECT?

NO - Checkhmmgveth hmlnggauge,refer to $ectmn

2C25

YES

IS THE SHUTTLEHOOKTIP SHARPAND SMOOTH?

NO - Replacehook.refer to Sectmn2C27

Reset hmmg as per Sectm,_ 2C2_

USERHINTS

Suggestthe* user select low speed for basting,it's the best way to nob,evehomercontrolm gusdmofabrfc since basting

programnumber37 prov,desextremely fast feeding of machine

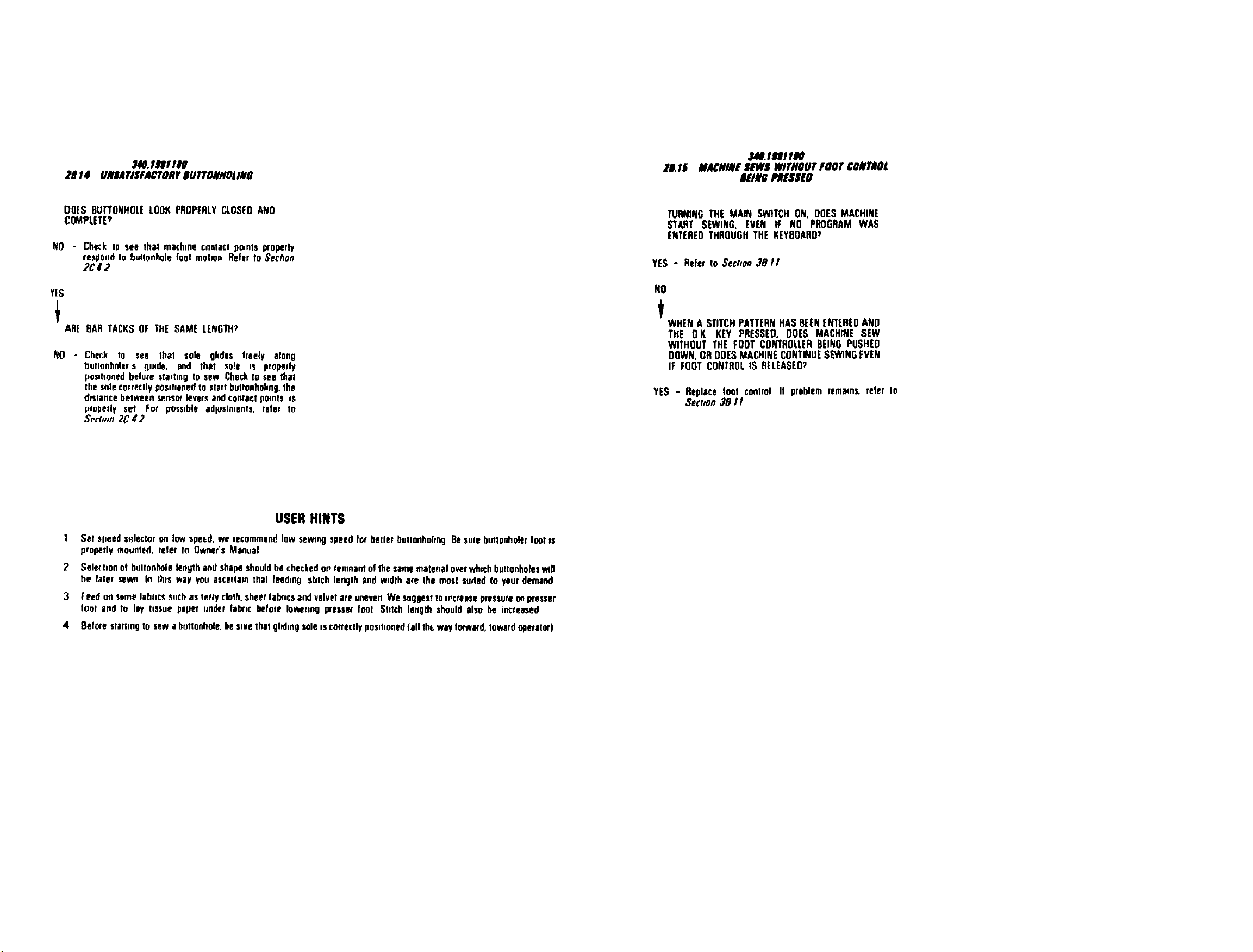

J_.Illl lN 21t.15 MACHINE $1W$ WIIWOUT FOOl' COAti'ROt

2114 UNSATI$FA_-?'ORVIUTTONHOUNO IIEllBleRESSED

._IO.IH! IN

DOES BUTTONHOL[LOOKPROPFBEYCLOSEDAND

COMPLETE?

NO - Check to see that machine cnntacl points PrOperly

respond Io hutlonhole foot mohon Refer In Secfmn

2C42

Yfs

ARE BAR TACKS OF THE SAME LENGTH?

NO -Check to see thai sole ghdes freely along

butlonholers guide, and that sn?e ,s properly

posthonedbelme starting to sew Checkto see thai

the solecorre(lly positionedto start bultonhobn9,the

d,slancebetween sensorleversand contact points tS

properly set For possible adlustments, refer to

•":;eOron2C 42

USERHINTS

1

Sel speedselectoron low spe,:d, we recommend low se_ng speedfor better butlonhohng Besurebuttonholerfoot rs

properly mounted,refer In Owner's Manual

2

Selectionof holtonholelengthand shapeshouldbe checkedonremnant of the samematerialoverwhzchbuttonholesvail

be later sewn I,n th,s way you ascertainthai feeding stitch length and width are the most suded Io your demand

3

l:eed on somelahr_cssuchas ferry€loth.sheerlabncsand velvetare uneven We suggesttoircreosepressureonpresser

font and to lay t,ssue paper under fabric before lowering presserloot Stitch length should also be increased

4

Before startingto sew a buttonhole,be surethat ghdmgsoleiscorrectlyposzf,onedfall the.wayforword,towardoperator)

TURNINGTHE MAIN SWITCHON. DOESMACHINE

START SEWING.EVEN IF NO PROGRAMWAS

ENTEREDTHROUGHTHEKEYBOARO?

YES " Refer to Sectron 3811

NO

WHENA STITCHPATTERNHAS BEENENTEREDAND

THE OK KEY PRESSED. DOES MACHINE SEW

WITHOUT THE FOOT CONTROLLERBEING PUSHEO

DOWN.OR DOESMACHINECONTINUESEWINGEVEN

IF FOOT CONTROLIS RELEASED?

YES - Replace toot control If problem remains, refer to

Sectron3B I I

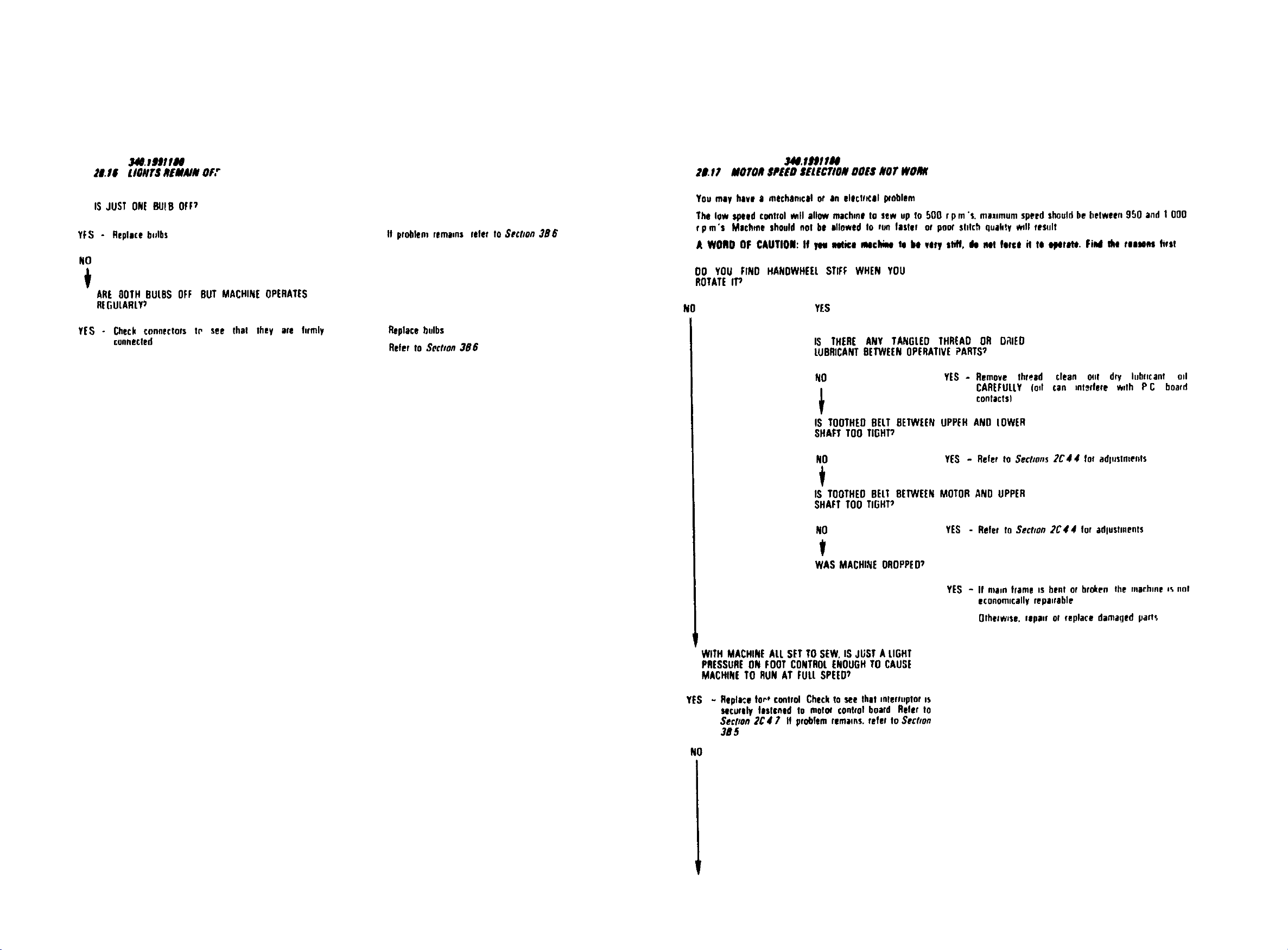

.1NW.lnltM

,t#.l$ lIGHTS REMAINOF:

,le4_.lot/N

2#.17 MOTORSPEEDSELECTIONDOtS NOTWORK

ISJUSTOREBU!BOff?

YES - Replacehidbs

NO

ARE80TH BULBSOFF BUTMACHINEOPERATES

REGULARLY_

YES - Check connectors tr, see thai they are firmly

connected

If problem remoras refer to Secl/on 3B6

Replacebulbs

Refer to Section 3B6

You may have 8 mechgmclll or In electr_al Problem

The low speedc_ffoi _11 allow machme to sew up to ,500 r pm 's. maximum speedshouldbe between 950 and t 000

r p o's Methme shouldnot be allowed to run taster or poor stitch quahty wallresult

A WORD OF CAUTION: If ply _ico mch_ to ke eal'y aiifi, do nit fwce H to operate. Find Ike raesoM tirol

OO YOU FINO HANOWHEELSTIFF WHEN YOU

ROTATEIT)

NO YES

IS THEREANY TANGLEDTHREADOR DRIED

LUBRICANTBETWEENOPERATIVEPARTS?

NO YES - Remove thread clean out dry lubricant oil

CAREFULLY lad can mterfere wdh PC board

contacts)

IS TOOTHEDBELT BETWEENUPPEH AND LOWER

SHAFT TOO TIGHT?

NO YES - Refer to Sections 2C44 for adlustmerds

IS TOOTHEDBELTBETWEENMOTORAND UPPER

SHAFTTOOTIGHT?

NO

WAS MACHINEOROPPEO?

WITHMACHINEALLSETTOSEW.ISJUSTA LIGHT

PRESSUREONFOOTCONTROLENOUGHTOCAUSE

MACHINETO RUNAT FULLSPEED?

YES - Repla:e for* control Checkto see that inlemiplor is

_curaly lesioned to motor control board Refer to

Sect/on 2C4 7 H problem remoras,refer to Sect/on

3B5

NO

YES - Refer to Sectron2C44 for adluSh,ents

YES - If mare frame is henl or broken the rnachme _'; nor

economically repaffahle

OlherwJse. tape, o€ replace damaged paris

21.17 MOTOR,fPIEO SELECTIONOOE$NOTWORK

NI.IRII_

,14_.III I18

211# FAUtlI' KEvlOARD

KEEPINGSAMEPRESSUREONFOOTCONTROL.00

YOU NOTICEA DIFFERENCEIN SPEED.WHEN

FLIPPINGSPEEDCONTRQELEVERFROMtOWERTO

HIGHSPEED.ANDVICEVERSA?

NO - Refer I0 Secfron 3B5

YES

IS THE MAXIMUM SPEEOWITHIN SUGGESTED

RANGE?

NO- Reter to Section 2C45 for adl.Stmenl oF

polentromefer

YES

IS FOOT CONTROlMAINTAININGSAME SPEEO.

WRENBEINGPRESSEDWITH EQUALPRESSURE?

_0 - Replace toot control

YES

i,

ASSOOFJAS A STITCHINGPROGRAMISENTERED,

DOESMACHINERUN WITHOUTFOOTCONTROL

BEINGPRESSED?

Fimlty keyboardperformancers uszmlly related 1o a problem zn the eleclror, c r*tcuJtr_,

Refer to Section 302

YES - Replace foot control It problem remains fetal to

3eoLian3B II

SERVICEHINTS

It is always adv,_lhle to (hack ta.slons of toolhed balls Too much tension is stressing pulley supports, excasswe tension on

maim belt redz_esspeedendit tallg_as motel

J4_.l_flN

#E, AOJUSrMEIIt ANDM/_ACtMtNF

,P_.MPFIm

?C.I tOP TIIMAD rE!I#10# CUmTRI

I

A

L

D

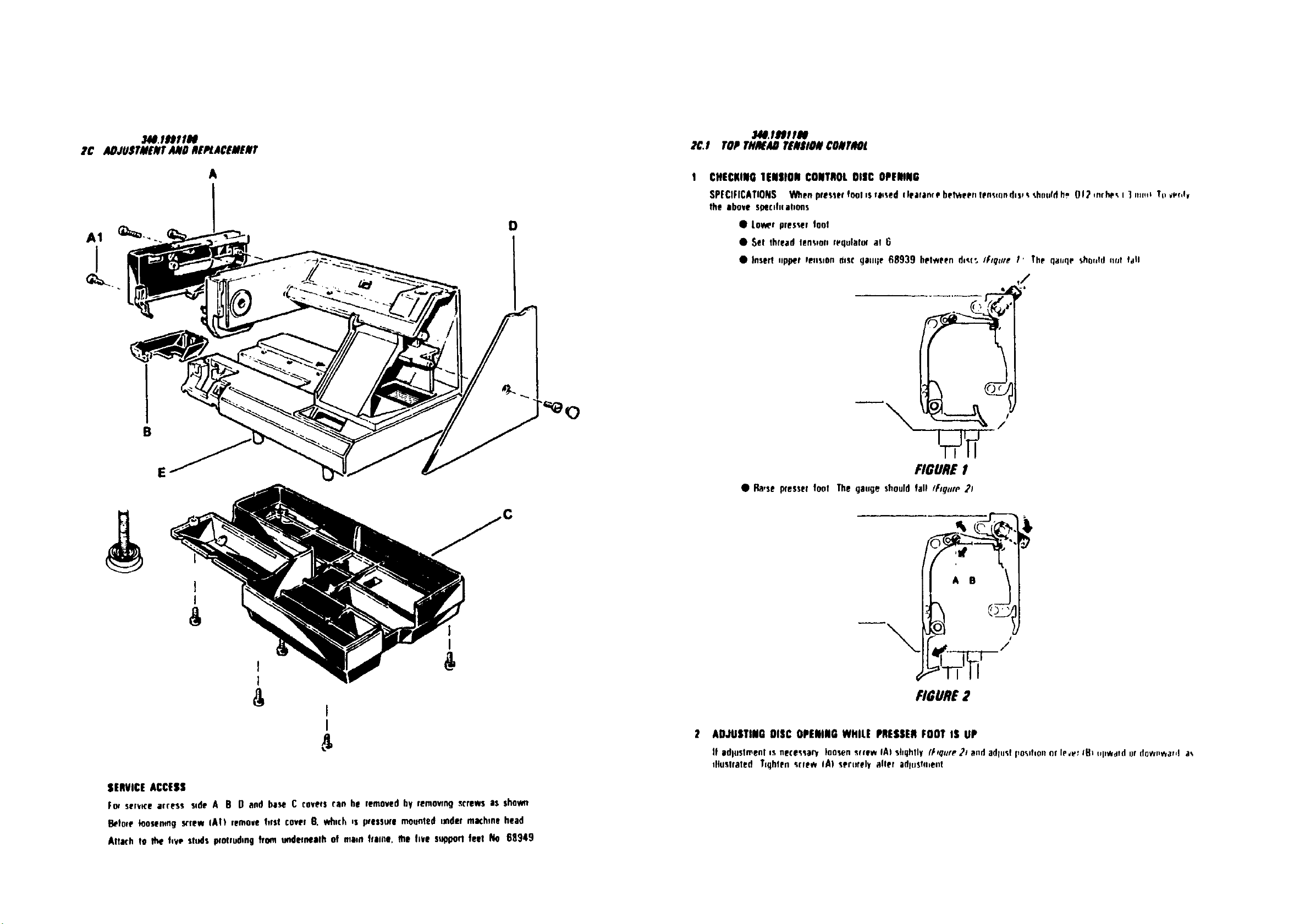

CHECKING1ENSIGN CONTROLDISC OPENING

SPECIFICATIONS When presser fOol is f#;sed rleara_ e bel_eerl leo_mn disf s _hoofd _.? 0 i _)_he_ i ] itlfq_l ?|l _l,r,fv

the above SHt:lhlahoos

• [o_r presser foot

• 5el thread len*,,on requlafm at 5

• Insert iip_r renslofl disc goalie 68939 between dl_r'_ IFequt_, I' The qa.qe sho.id oat tall

,/

_C

B

E

• Ra.se pfesseT fool The (]aoge should fall /Figm'e 2r

FIGURE I

]

I

I

I

SERVICEACCESS

Fo_ serv_e arress s_de A O D and base C covers ran he removed by removmo screws as shown

BelGie _ooseflmg s¢few lAIr remove flfsl covet e. W_l(5 is pressurl mounted trader mKhlfle head

AIIMh fo I_ hvqe slods protruding from undefMalh of mien |faille. _le five su_pof_ feet No 68349

2 ADJUSTING DISC OPENING WHILE PRESSER FOOT IS UP

I| adluSlmeolis flecessa_ loosenstrew IAI shghtly fFtq_lfe21 end ado,st_O_,IIIOII nf le_t,,"rt]_ ,pw_td i)r dowe,_af,I as

_lluslrated T_qhfensrrew IAI serurely alter adlusfment

Loading...

Loading...