Kenmore 2679132K, 2669133K, 2669132K Installation Instructions

Dryer Installation Instructions

Instrucciones de instalación de la secadora

Instructions d’Installation de la sécheuse

English / Español / Français

Table of Contents...2 / Índice...26 / Table des Matières...51

Kenmore®

Gas & Electric Dryer

Secadora a gas y eléctrica

Sécheuse à gaz et électrique

P/N W11101364A

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

TABLE OF CONTENTS

DRYER SAFETY ..................................................................2

INSTALLATION REQUIREMENTS .......................................4

Tools and Parts ............................................................4

LOCATION REQUIREMENTS ..............................................5

ELCTRICAL REQUIREMENTS - U.S.A. ONLY .......................6

ELECTRIC DRYER POWER HOOKUP - CANADA ONLY ......7

GAS DRYER POWER HOOKUP - U.S.A AND CANADA ......7

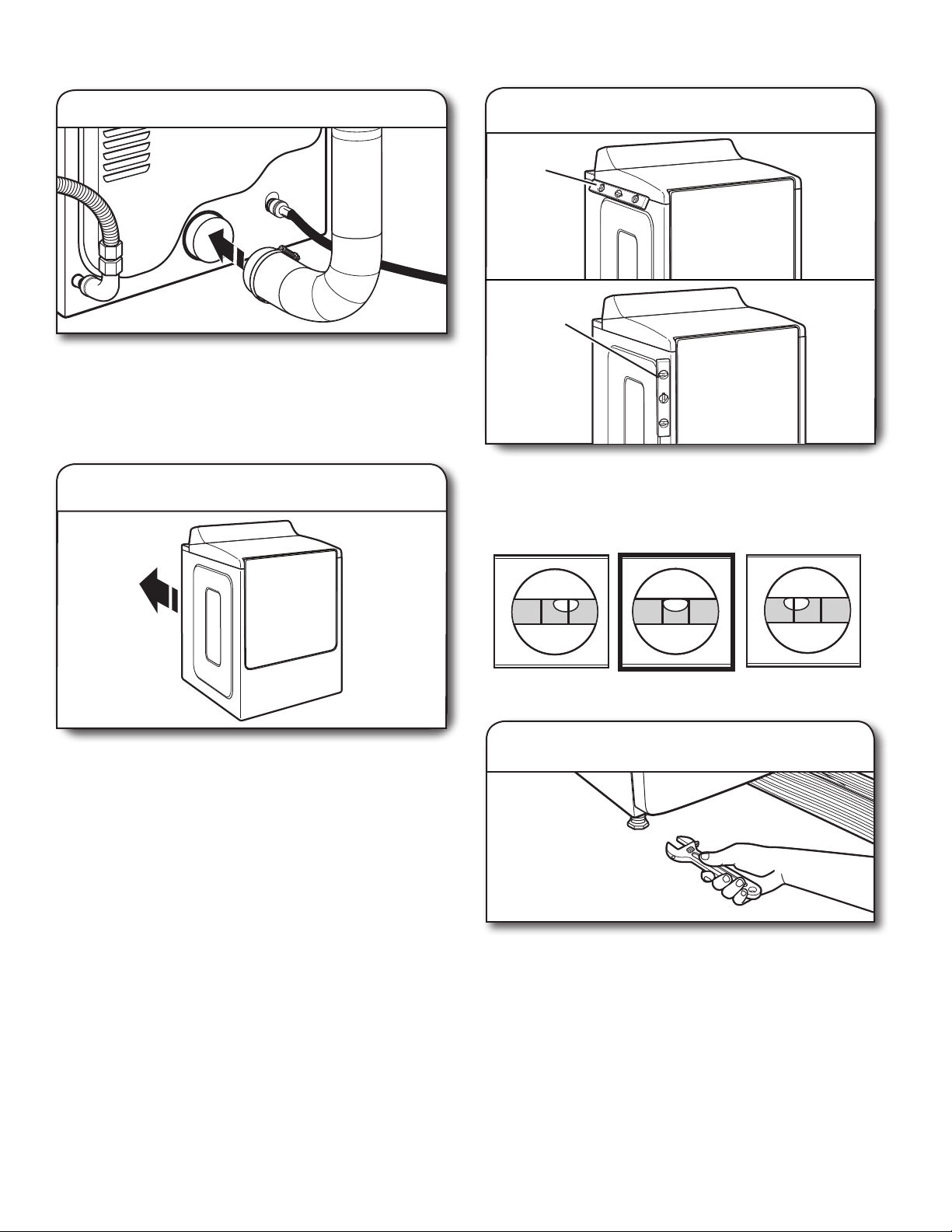

INSTALL LEVELING LEGS...................................................9

MAKE ELECTRICAL CONNECTION - U.S.A. ONLY ........... 10

MAKE GAS CONNECTION - U.S.A AND CANADA .......... 16

INSTALLATION NOTES

Date of purchase: _________________________________

Date of installation: _______________________________

Installer: ________________________________________

Model number: ___________________________________

Serial number: ___________________________________

DRYER SAFETY

VENTING ........................................................................ 16

Venting Requirements ............................................... 16

Plan Vent System ...................................................... 17

Install Vent System .....................................................18

CONNECT INLET HOSES ..................................................18

CONNECT VENT .............................................................20

LEVEL DRYER ..................................................................20

COMPLETE INSTALLATION CHECKLIST ............................21

REVERSE DOOR SWING .................................................. 22

TROUBLESHOOTING .......................................................25

ASSISTANCE OR SERVICE ................................. Back Cover

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gas fitter qualified or licensed by

the State of Massachusetts.

■ Acceptable Shut-off Devices: Gas Cocks and Ball Valves installed for use shall be listed.

■ A flexible gas connector, when used, must not exceed 4 feet (121.9 cm).

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, Part 1, CSA C22.1.

2

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, or property

damage.

–

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this

or any other appliance.

–

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

•

instructions.

If you cannot reach your gas supplier, call the re department.

•

–

Installation and service must be performed by a qualied installer, service agency, or

the gas supplier.

3

INSTALLATION REQUIREMENTS

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed for all installations:

Flat-head screwdriver

Level

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Vent clamps

Tools needed for gas installations:

8" (203 mm) or 10" (254 mm)

pipe wrench

Pipe-joint compound

resistant to propane gas

8" (203 mm) or 10" (254 mm)

adjustable wrench (for gas

connections)

Parts supplied (all models):

Plastic putty knife

Tin snips (new vent

installations)

#2 Phillips screwdriver

Caulking gun and compound

(for installing new exhaust vent)

1/4" (6 mm) nut driver

(recommended)

Wire stripper (direct wire

installations)

Leveling legs (4)

Parts package is located in dryer drum. Check that all parts

are included.

Parts needed (steam models):

“Y” connector

Inlet hose

Short inlet hose

Rubber washer (4)

If using a power supply cord:

Use a UL Listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

Tape measure

4

Pliers

■ A UL Listed 30-amp power supply cord, rated 120/240 volt

minimum, and have a temperature rating of 140ºF (60ºC)

minimum. The cord should be type SRD or SRDT and be

at least 4 ft. (1.22 m) long. The wires that connect to

the dryer must end in ring terminals or spade terminals

with upturned ends.

■ A UL Listed strain relief.

Parts needed: (Not supplied with dryer)

Check local codes. Check existing electrical supply and venting.

See “Electrical Requirements” and “Venting Requirements” before

purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. For further information, please refer to the “Assistance

or Service” section in your Use and Care Guide.

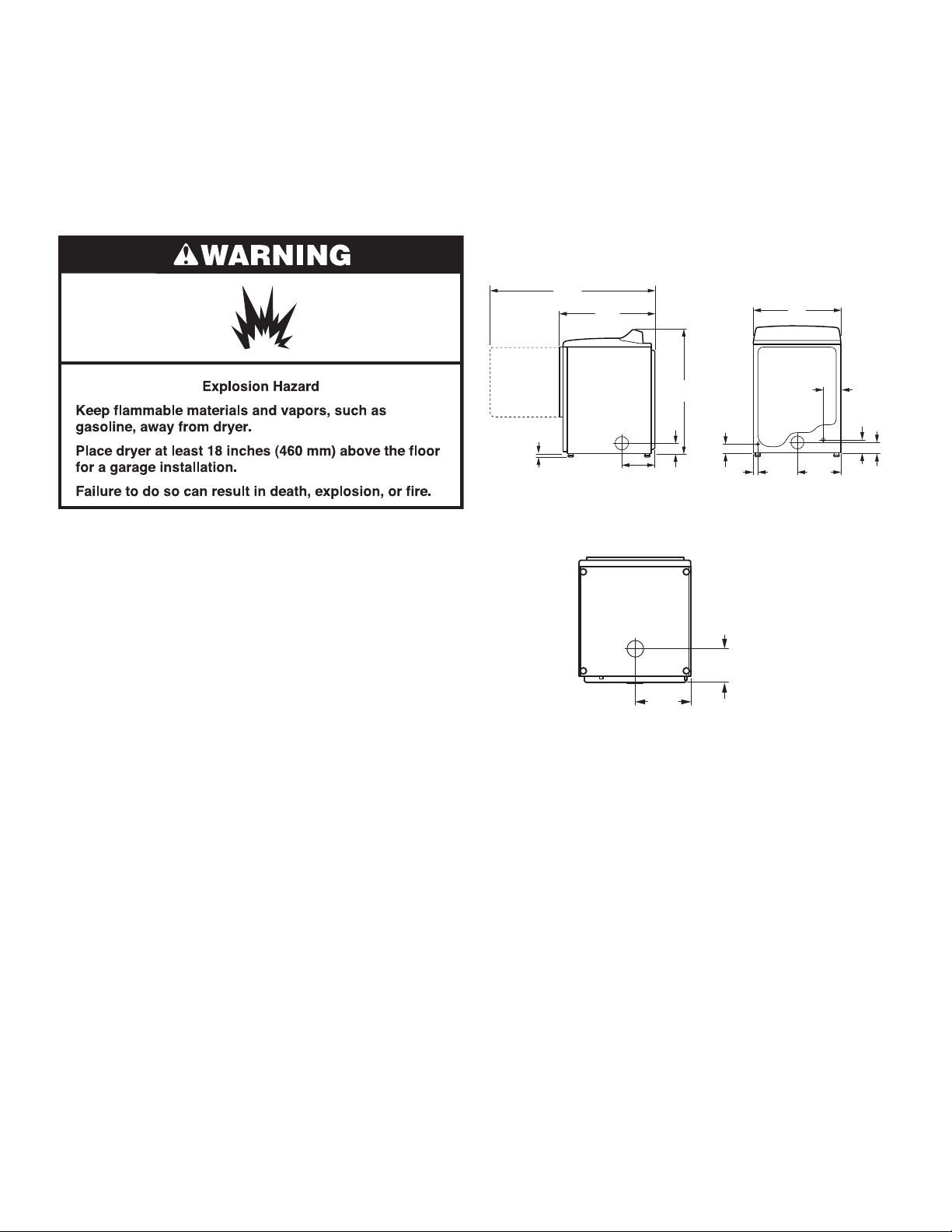

LOCATION REQUIREMENTS

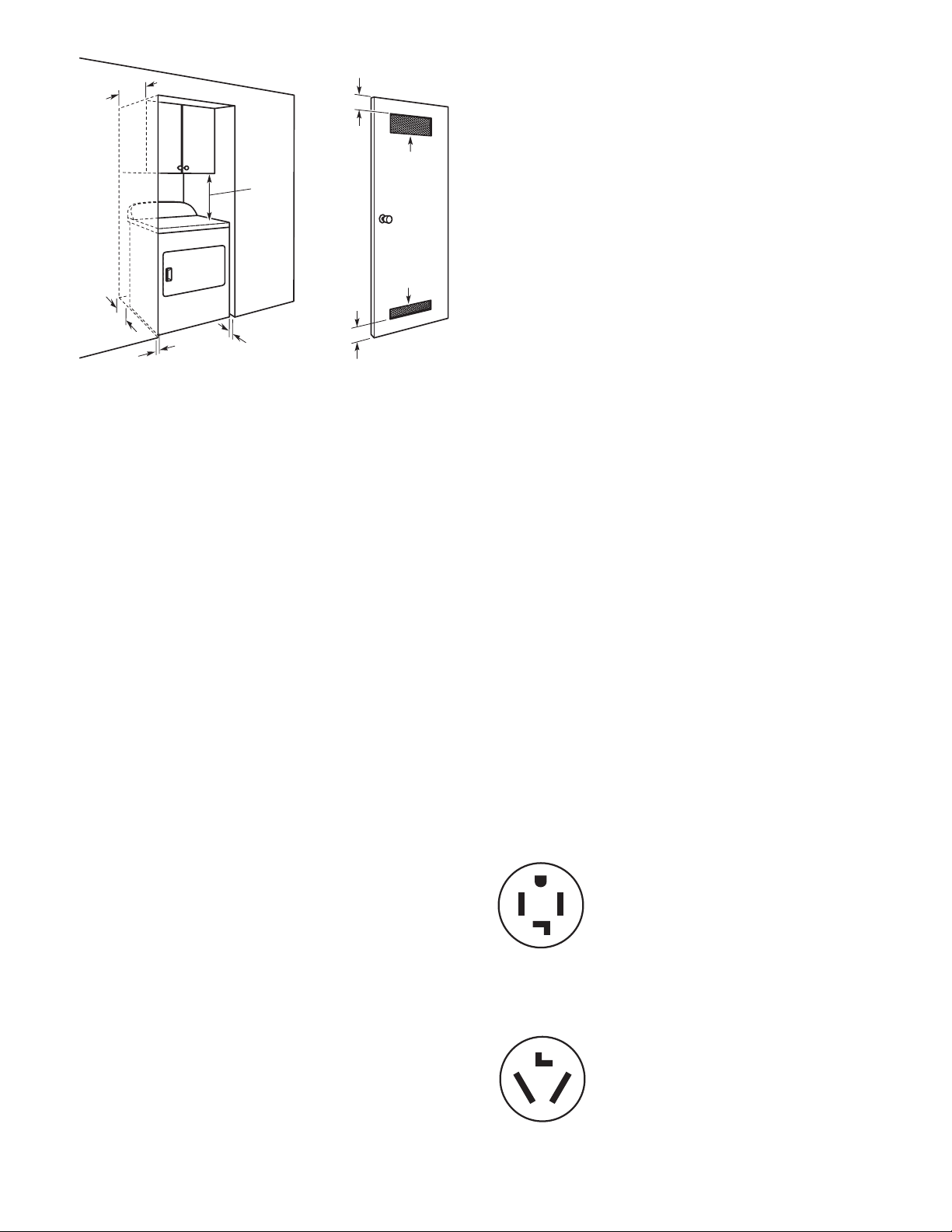

INSTALLATION CLEARANCES

For each arrangement, consider allowing more space for ease of

installation and servicing; spacing for companion appliances and

clearances for walls, doors, and floor moldings. Space must be

large enough to allow door to fully open. Add spacing on all sides

of dryer to reduce noise transfer. If a closet door or louvered door

is installed, top and bottom air openings in door are required.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

DRYER DIMENSIONS

1

56

/4"

(1428 mm)

321/8"

(814 mm)

Door Opened

Door Closed

427/8"

411/8"

(1089 mm)

(1069 mm)

29"

(737 mm)

57/8"

(150 mm)

1

4

/2"

(115 mm)

You will need:

■ A location allowing for proper exhaust installation.

See “Venting Requirements.”

■ A separate 15- or 20-amp circuit needed for gas dryers

and 30-amp circuit needed for electric dryers.

■ If using power supply cord, a grounded electrical outlet

located within 2 ft. (610 mm) of either side of dryer.

See “Electrical Requirements.”

■ Floor must support dryer weight of 200 lbs. (90.7 kg).

Also consider weight of companion appliance.

■ Level oor with maximum slope of 1" (25 mm) under entire

dryer. If slope is greater than 1" (25 mm), clothes may not

tumble properly and automatic sensor cycles may not

operate correctly.

■ For garage installation, place dryer at least 18" (460 mm)

above oor.

■ Steam models only: Cold water faucets located within

4 ft. (1.2 m) of the water ll valves, and water pressure

of 20-100 psi (137.9-689.6 kPa). You may use your washer’s

water supply by purchasing the necessary parts noted in

“Parts needed.”

IMPORTANT: Do not operate, install, or store dryer where it

will be exposed to water, weather, or at temperatures below

45°F (7°C). Lower temperatures may cause dryer not to shut

o at end of automatic sensor cycles, resulting in longer

drying times.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

1"

(25 mm)

Bottom view:

Side view

3

/8"

11

(289 mm)

(365 mm)

14

5

3

/8"

(93 mm)

3

/8"

3"

(77 mm)

81/2"

(218 mm)

13/8"

(35 mm)

Back view

1

/2"

14

(370 mm)

(93 mm)

NOTE: Most installations require a minimum of 6" (152 mm)

clearance behind dryer for exhaust vent with elbow. See

“Venting Requirements.”

Spacing for recessed area or closet installation

The dimensions shown are for the minimum spacing allowed.

■ Additional spacing should be considered for ease of installation

and servicing.

■ Additional clearances might be required for wall, door, and

oor moldings.

■ Additional spacing of 1" (25 mm) on all sides of the dryer is

recommended to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilitation openings are

acceptable.

■ Companion appliance spacing should also be considered.

1

3

/2"

5

14" max

(356 mm)

18"/18"

(457 mm/

457 mm)

3"/3"

(76 mm/

76mm)

2

/48"

48"

(310 cm

310 cm2)

■ To supply the required 3 or 4 wire, single phase, 120/240

volt, 60 Hz, AC only electrical supply (or 3 or 4 wire, 120/208

volt electrical supply, if specied on the serial/rating plate)

on a separate 30-amp circuit, fused on both sides of the line.

Connect to an individual branch circuit. Do not have a fuse in

the neutral or grounding circuit.

2

2/

■ Do not use an extension cord.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

the ground path is adequate.

2/

2

24"

24"

2/

(155 cm

6"/0"

(152 mm/

0 mm)

(25 mm/0 mm)

1"/0"

1"/1"

(25 mm/25 mm)

3"/3"

(76 mm/

76mm)

155 cm2)

Recommended/Minimum spacing

Mobile home - Additional installation requirements:

This dryer is suitable for mobile home installations. The installation

must conform to the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280 (formerly the Federal Standard

for Mobile home construction and Safety, Title 24, HUD Part 280)

or Standard CAN/CSA-Z240 MH.

Mobile home installations require:

All dryers:

■ Metal exhaust system hardware, available for purchase

from your dealer. For further information, see “Assistance

or Service” section in your Use and Care Guide.

■ Special provisions must be made in mobile homes to introduce

outside air into dryer. Openings (such as a nearby window)

should be at least twice as large as dryer exhaust opening.

For gas dryers mobile home installations:

■ Mobile Home Installation Hold-down Kit Part Number

W10432680 is available to order. For further information,

see “Assistance or Service” section in your Use and

Care Guide.

ELECTRICAL REQUIREMENTS -

U.S.A. ONLY (SPÉCIFICATIONS

ÉLECTRIQUES – ÉTATS-UNIS

SEULEMENT)

It is your responsibility:

■ To contact a qualied electrical installer.

■ To be sure that the electrical connection is adequate

and in conformance with the National Electrical Code,

ANSI/NFPA 70 - latest edition and all local codes

and ordinances.

The National Electrical Code requires a 4-wire power supply

connection for homes built after 1996, dryer circuits involved

in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor

is permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground conductor must be

removed from the external ground connector (green screw),

and secured under the neutral terminal (center or white wire)

of the terminal block. When the neutral ground conductor is

secured under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor.

■ If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see “Optional 3-wire

connection” section.

■ A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations,

(2) mobile homes, (3) recreational vehicles, and (4) areas

where local codes prohibit grounding through the neutral

conductors.

If using a power supply cord:

Use a UL Listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

■ A UL Listed 30-amp power supply cord, rated 120/240 volt

minimum, and have a temperature rating of 140ºF (60ºC)

minimum. The cord should be type SRD or SRDT and be at least

4 ft. (1.22 m) long. The wires that connect to the dryer must end

in ring terminals or spade terminals with upturned ends.

■ A UL Listed strain relief.

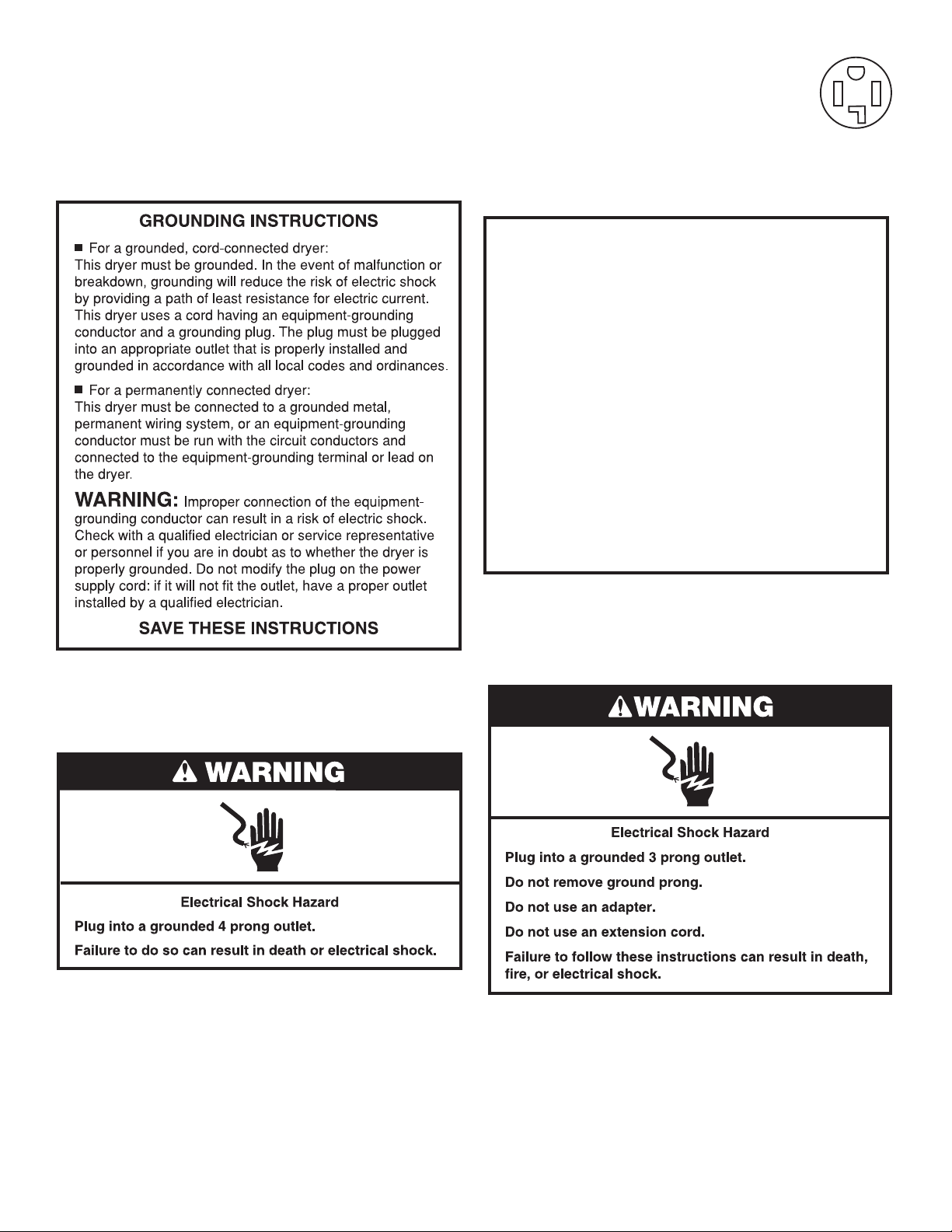

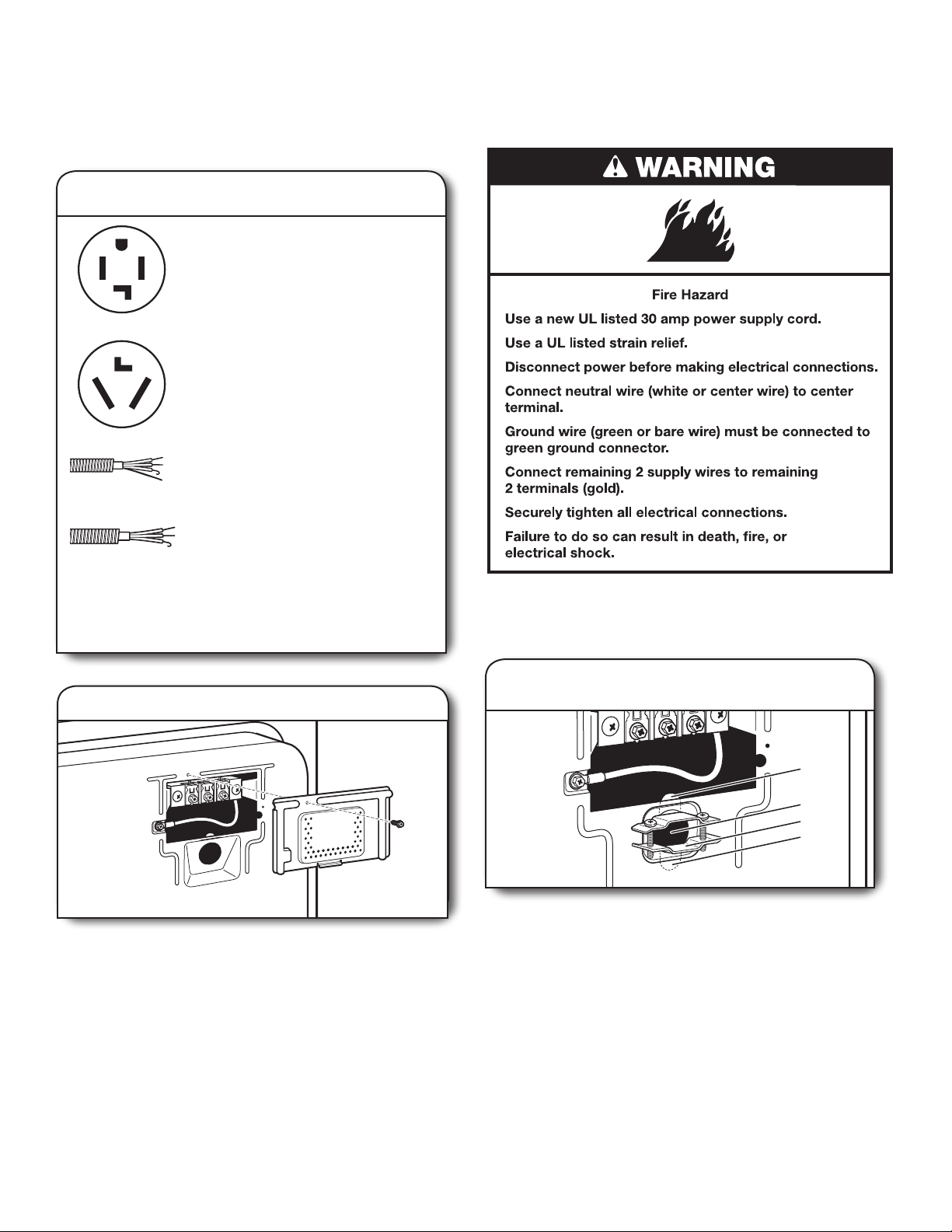

If your outlet looks like this:

Then choose a 4-wire power supply cord with

ring or spade terminals and UL Listed strain

relief. The 4-wire power supply cord, at least

4 ft. (1.22 m) long, must have four 10-gauge

solid copper wires and match a 4-wire

receptacle of NEMA Type 14-30 R. The ground

4-wire

receptacle

(14-30R)

wire (ground conductor) may be either green or

bare. The neutral conductor must be identied

by a white cover.

If your outlet looks like this:

Then choose a 3-wire power supply cord with

ring or spade terminals and UL Listed strain

relief. The 3-wire power supply cord, at least

4 ft. (1.22 m) long, must have three 10-gauge

solid copper wires and match a 3-wire

3-wire

receptacle

(10-30R)

receptacle of NEMA Type 10-30R.

6

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

■ Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), covered with exible metallic conduit. All

current-carrying wires must be insulated.

■ 10-gauge solid copper wire (do not use aluminum) at least

5 ft. (1.52 m) long.

■ This dryer is equipped with a UL listed and/or

CSA International Certied Power Cord intended

to be plugged into a standard 14-30R wall

receptacle. The cord is 5 ft. (1.52 m) long. Be

sure wall receptacle is within reach of dryer’s

nal location.

For further information, please reference service numbers located

in “Assistance or Service” section of your Use and Care Guide.

4-wire receptacle

(14-30R)

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

ELECTRIC DRYER POWER

HOOKUP - CANADA ONLY

ELECTRICAL REQUIREMENTS

It is your responsibility:

■ To contact a qualied electrical installer.

■ To be sure that the electrical connection is adequate and in

conformance with Canadian Electrical Code, C22.1-latest

edition and all local codes. A copy of above codes standard

may be obtained from: Canadian Standards Association,

178 Rexdale Blvd., Toronto, ON M9W 1R3 CANADA.

■ To supply the required 4 wire, single phase, 120/240 volt,

60 Hz, AC only electrical supply on a separate 30-amp circuit,

fused on both sides of the line. A time-delay fuse or circuit

breaker is recommended. Connect to an individual branch

circuit.

SAVE THESE INSTRUCTIONS

GAS DRYER POWER HOOKUP -

U.S.A. AND CANADA

ELECTRICAL REQUIREMENTS

■ 120-Volt, 60 Hz, AC-only, 15- or 20-amp fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate circuit

serving only this dryer be provided.

7

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING:

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

Improper connection of the equipment-

SAVE THESE INSTRUCTIONS

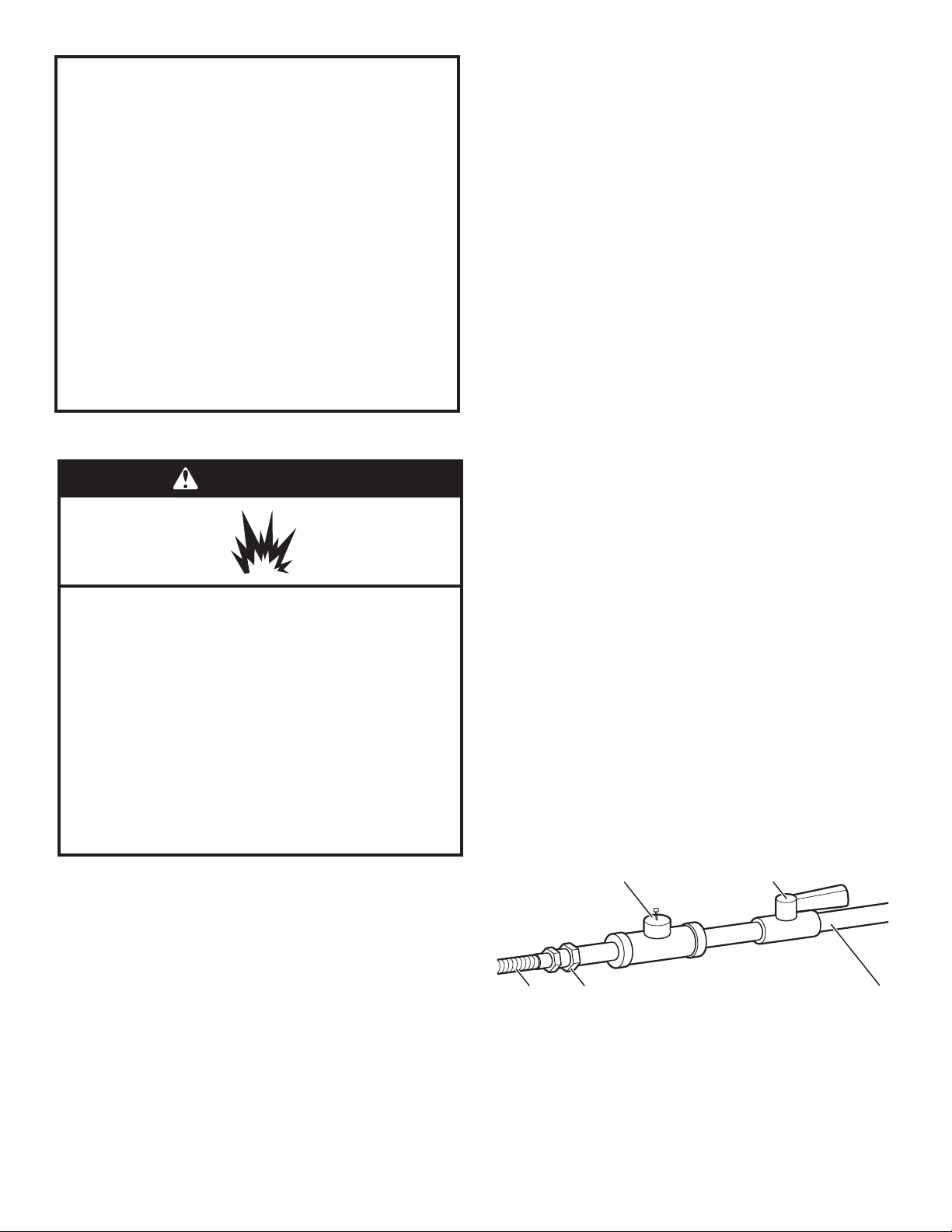

GAS SUPPLY REQUIREMENTS

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 13" (330 mm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Propane Gas Conversion:

IMPORTANT: Conversion must be made by a qualied technician.

No attempt shall be made to convert the dryer from the gas

specied on the model/serial rating plate for use with a dierent

gas without consulting your gas company.

GAS SUPPLY LINE

Option 1 (Recommended Method)

Flexible stainless steel gas connector:

■ If local codes permit, use a new exible stainless steel gas

connector (Design Certied by the American Gas Association

or CSA International) to connect your dryer to the rigid gas

supply line. Use an elbow and a 3/8" are x 3/8" NPT adapter

tting between the stainless steel gas connector and the dryer

gas pipe, as needed to prevent kinking.

Option 2 (Alternate Method)

Approved aluminum or copper tubing

■ Must include 1/8" NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer.

■ 1/2" IPS pipe is recommended.

■ 3/8" approved aluminum or copper tubing is acceptable

for lengths under 20 ft. (6.1 m) if local codes and gas

supplier permit.

■ If you are using Natural gas, do not use copper tubing.

■ Lengths over 20 ft. (6.1 m) should use larger tubing and

a dierent size adapter tting.

■ If your dryer has been converted to use propane gas,

3/8" propane compatible copper tubing can be used.

If the total length of the supply line is more than 20 ft.

(6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of

propane gas must be used. Do not use TEFLON

■ Must include shut-o valve.

In the U.S.A.:

An individual manual shut-o valve must be installed within

six (6) ft. (1.8 m) of the dryer in accordance with the National

Fuel Gas Code, ANSI Z223.1. The location should be easy to

reach for opening and closing.

In Canada:

An individual manual shut-o valve must be installed in

accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual manual

shuto valve be installed within six (6) ft. (1.8 m) of the dryer.

The location should be easy to reach for opening and closing.

®†

tape.

GAS TYPE

Natural Gas:

This dryer is equipped for use with Natural gas. It is certied

by UL for use with propane gas with appropriate conversion.

■ Your dryer must have the correct burner for the type of gas in

your home. Burner information is located on the rating plate in

the door well of your dryer. If this information does not agree

with the type of gas available, contact your dealer or call the

phone numbers referenced in the “Assistance or Service” section

of your Use and Care Guide.

8

C

BA

A. 3/8" exible gas connector

B. 3/8" pipe to are adapter tting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shuto valve

†®TEFLON is a registered trademark of Chemours.

E

D

GAS SUPPLY CONNECTION REQUIREMENTS

■ Use an elbow and a 3/8" are x 3/8" NPT adapter tting

between the exible gas connector and the dryer gas pipe,

as needed to avoid kinking.

■ Use only pipe-joint compound. Do not use TEFLON

■ This dryer must be connected to the gas supply line with a

listed exible gas connector that complies with the standard

for connectors for gas appliances, ANSI Z21.24 or CSA 6.10.

®

tape.

BURNER INPUT REQUIREMENTS

Elevations above 2,000 ft. (610 m):

■ When installed above 2,000 ft. (610 m), a 4% reduction of

the burner Btu rating shown on the model/serial number plate

is required for each 1,000 ft. (305 m) increase in elevation.

Gas supply pressure testing

■ The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than 1/2 psi.

DRYER GAS PIPE

■ The gas pipe that comes out through the rear of your dryer has

a 3/8" male pipe thread.

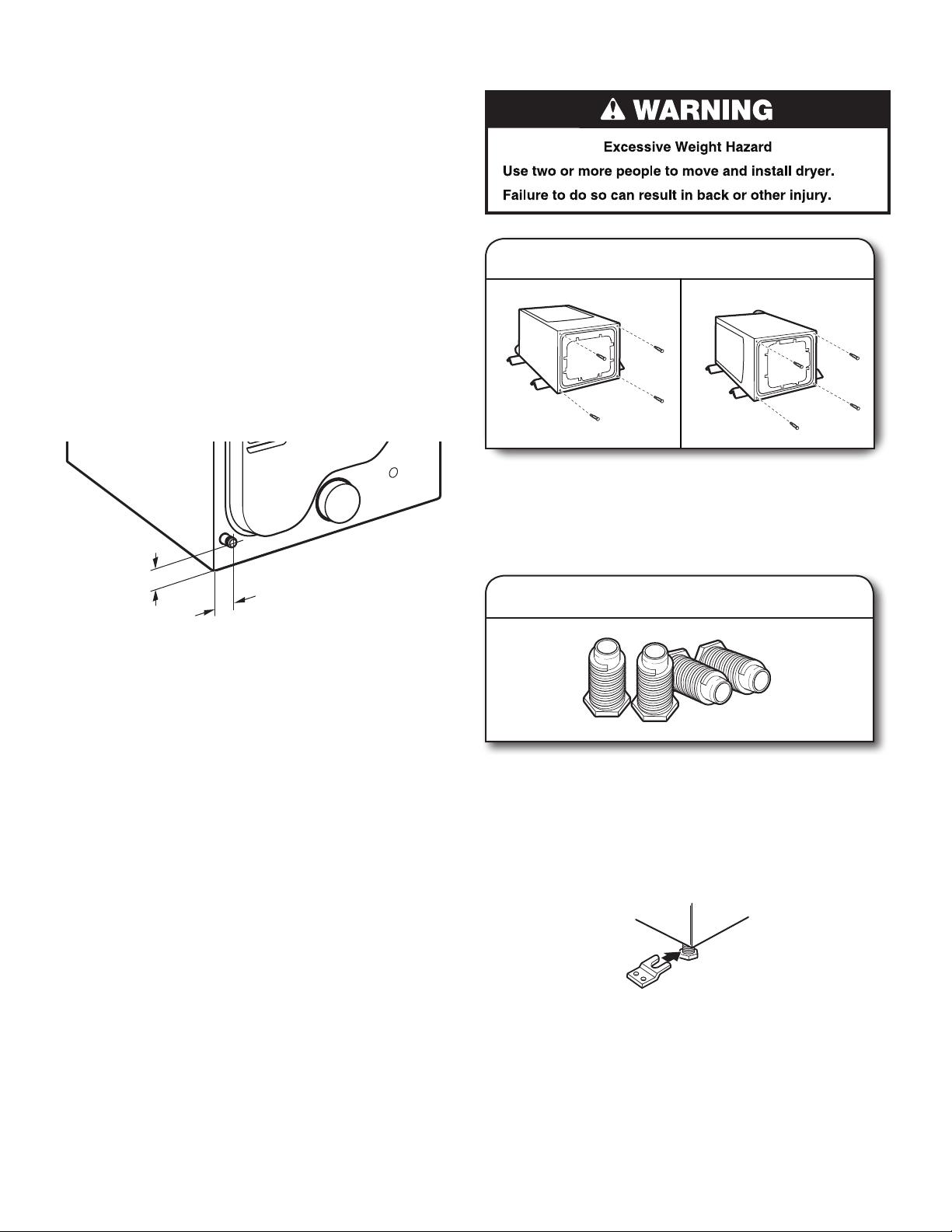

INSTALL LEVELING LEGS

1.

Prepare dryer for leveling legs

Firmly grasp dryer body (not console panel) and gently lay

dryer down on back cardboard corner posts.

IMPORTANT: If laying dryer on its back, use the cardboard

corner posts the dryer was packed with to avoid damaging

the back of the dryer.

3

/8"

1

3"

(77 mm)

3/8" NPT dryer pipe

NOTE: For a garage installation, the gas pipe height must be an

additional 18" (460 mm) from the oor.

(35 mm)

2.

Screw in leveling legs

Using a wrench and tape measure, screw leveling legs into leg

holes until bottom of foot is approximately 1" (25 mm) from

bottom of dryer.

Now stand the dryer on its feet. Slide the dryer until it is close to

its nal location. Leave enough room to connect the exhaust vent.

For mobile home use

Gas dryers must be securely fastened to the oor.

Mobile home installations require a Mobile Home Installation

Hold-down Kit. For ordering information please reference

the Use and Care Guide.

9

MAKE ELECTRICAL CONNECTION - U.S.A. ONLY (EFFECTUER LE

RACCORDEMENT ÉLECTRIQUE – ÉTATS-UNIS SEULEMENT)

Electrical Connection Options

Before you start: disconnect power.

1. Choose electrical connection type

Power supply cord 4-wire receptacle

(NEMA Type 14-30R):

Go to Power Supply Cord Connection.

Power supply cord 3-wire receptacle

(NEMA Type 10-30R):

Go to Power Supply Cord Connection.

4-wire direct connection:

Go to Direct Wire Connection.

3-wire direct connection:

Go to Direct Wire Connection.

POWER SUPPLY CORD CONNECTION

NOTE: If local codes do not permit connection of a

cabinet-ground conductor to neutral wire, go to “Optional

3-wire connection.” This connection may be used with

either a power supply cord or a direct wire connection.

2. Remove terminal block cover

Remove hold-down screw and terminal block cover.

Power Supply Cord Strain Relief

Attach power supply cord

1.

strain relief

A

B

C

D

Remove the screws from a 3/4" (19 mm) UL Listed strain relief.

Put the tabs of the two clamp sections (C) into the hole below

the terminal block opening (B) so that one tab is pointing up

(A) and the other is pointing down (D), and hold in place.

Tighten strain relief screws just enough to hold the two clamp

sections (C) together.

10

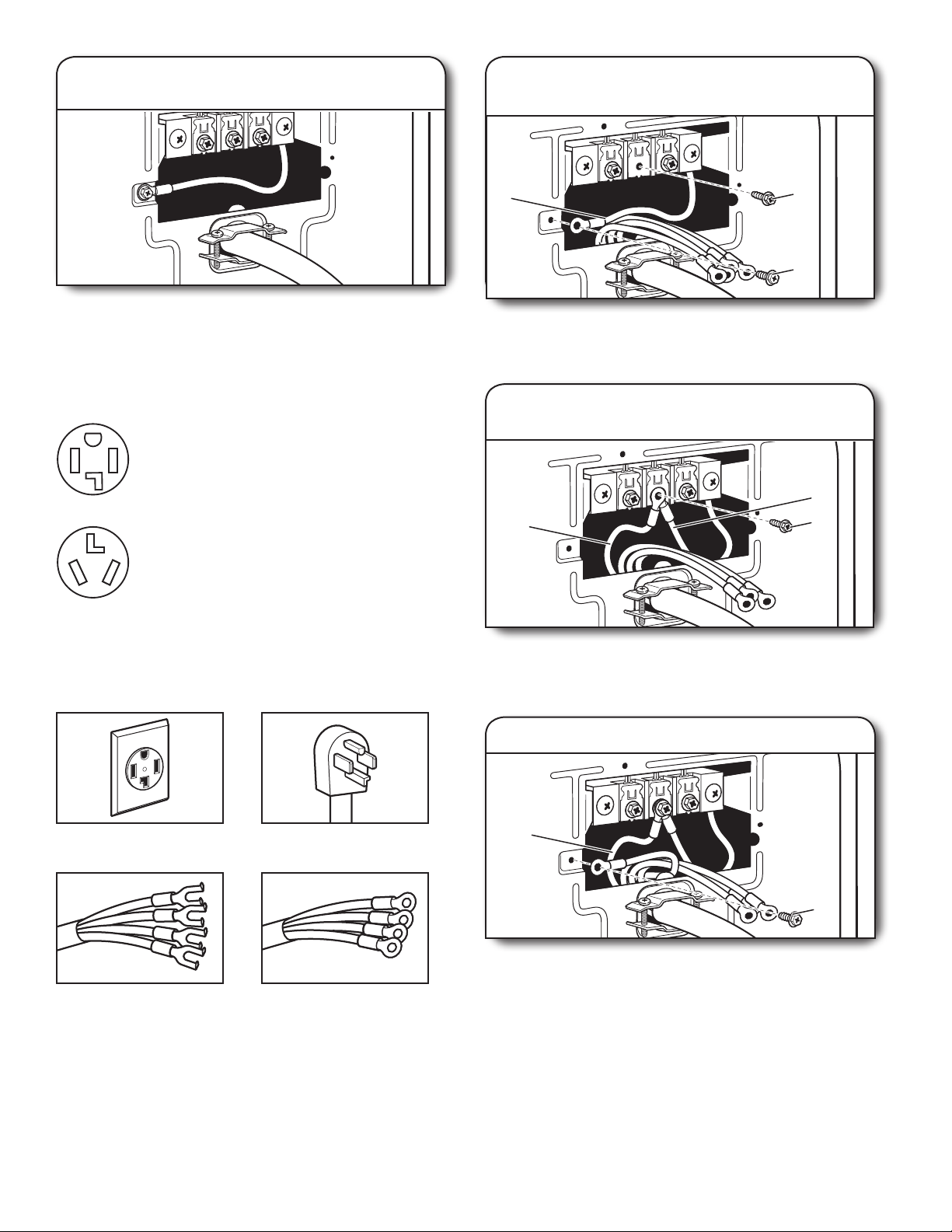

2.

Attach power supply cord

to strain relief

Prepare to connect neutral

1.

ground wire and neutral wire

Put power supply cord through the strain relief. Be sure that

the wire insulation on the power supply cord is inside the strain

relief. The strain relief should have a tight t with the dryer

cabinet and be in a horizontal position. Do not further tighten

strain relief screws at this point.

If your outlet looks like this:

Power supply cord 4-wire receptacle

(NEMA Type 14-30R):

Go to “4-Wire Power Supply Cord

Connection.”

Power supply cord 3-wire receptacle

(NEMA Type 10-30R):

Go to “3-Wire Power Supply Cord

Connection.”

E

Remove center terminal block screw (B). Remove neutral ground

wire (E) from external ground conductor screw (A).

2.

Connect neutral ground wire

B

A

and neutral wire

E

C

B

4-wire Power Supply Cord Connection

IMPORTANT: A 4-wire connection is required for mobile homes and where

local codes do not permit the use of 3-wire connections.

4-wire receptacle

(NEMA type 14-30R)

Spade terminals with

upturned ends

4-prong plug

Ring terminals

Connect neutral ground wire (E) and neutral wire (white) (C)

of power supply cord under center terminal block screw (B).

Tighten screw.

3. Connect ground wire

F

A

Connect ground wire (F) (green or bare) of power supply cord

to external ground conductor screw (A). Tighten screw.

11

4.

Connect remaining wires

2. Connect neutral wire

C

B

Connect remaining wires to outer terminal block screws.

Tighten screws. Finally, reinsert tab of terminal block cover into

slot of dryer rear panel. Secure cover with hold-down screw.

Now, go to “Venting Requirements.”

3-wire Power Supply Cord Connection

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

3-wire receptacle

(NEMA type 10-30R)

Spade terminals with

upturned ends

3-prong plug

Ring terminals

Connect neutral wire (white or center) (C) of power supply cord

to center terminal block screw (B). Tighten screw.

3. Connect remaining wires

Connect remaining wires to outer terminal block screws. Tighten

screws. Finally, reinsert tab of terminal block cover into slot of

dryer rear panel. Secure cover with hold-down screw. Now, go

to “Venting Requirements.”

1. Remove center screw

Remove center terminal block screw (B).

12

B

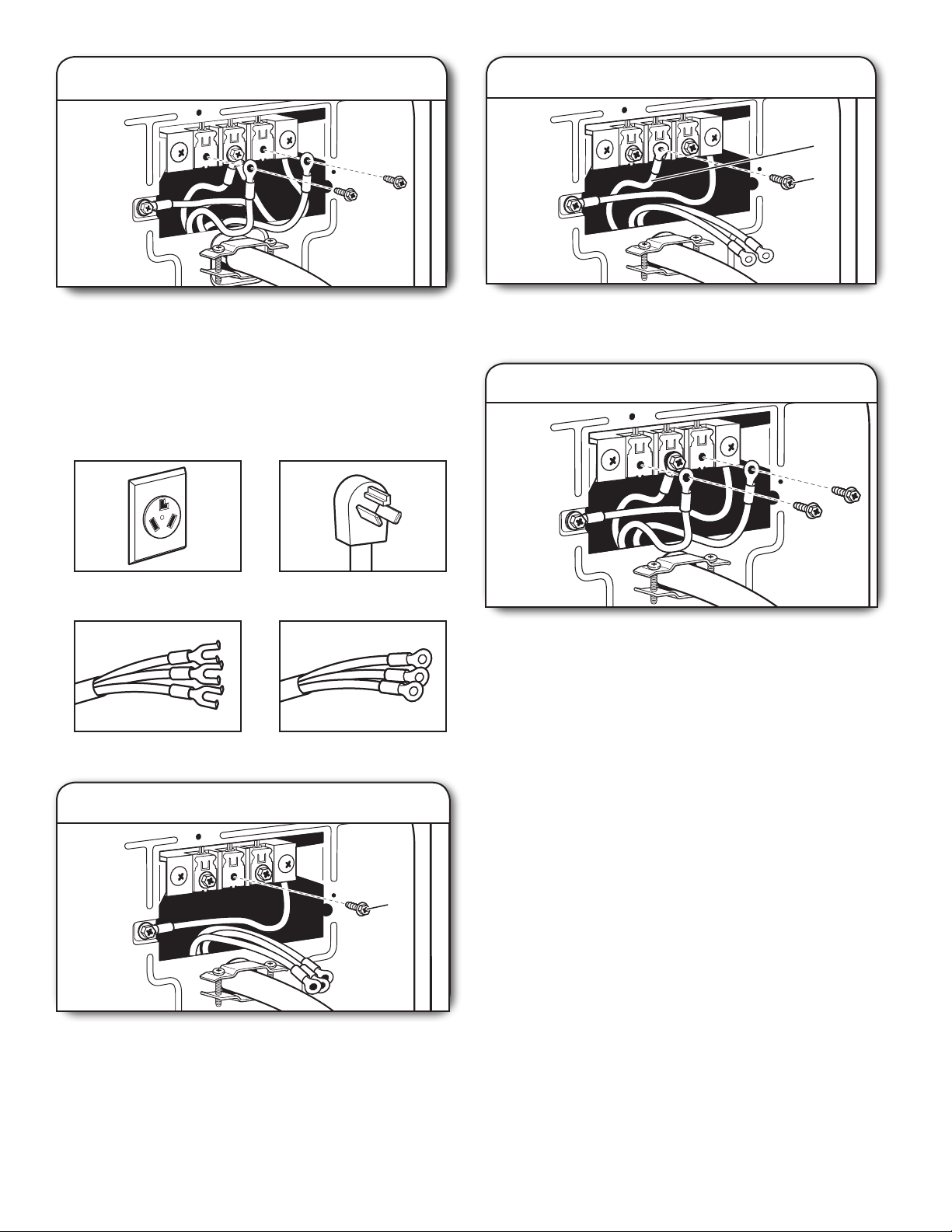

DIRECT WIRE CONNECTION

2. Attach direct wire cable

to strain relief

Put direct wire cable through the strain relief. The strain relief

should have a tight t with the dryer cabinet and be in a

horizontal position. Tighten strain relief screw against the direct

wire cable.

If your wiring looks like this:

4-wire direct connection:

Go to “4-Wire Direct Connection”

on this page.

Direct Wire Strain Relief

1. Attach direct wire strain relief

A

B

C

Unscrew the removable conduit connector (A) and any screws

from a 3/4" (19 mm) UL Listed strain relief. Put the threaded

section of the strain relief (C) through the hole below the

terminal block opening (B). Reaching inside the terminal block

opening, screw the removable conduit connector (A) onto the

strain relief threads.

3-wire direct connection:

Go to “3-Wire Direct Connection.”

4-wire Direct Wire Connection

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit 3-wire connections.

1. Prepare your 4-wire cable for

direct connection

1"

(25 mm)

5"

(127 mm)

Direct wire cable must have 5 ft. (1.52 m) of extra length so

dryer may be moved if needed.

Strip 5" (127 mm) of outer covering from end of cable,

leaving bare ground wire at 5" (127 mm). Cut 11/2" (38 mm)

from remaining 3 wires. Strip insulation back 1" (25 mm).

Shape ends of wires into hooks.

13

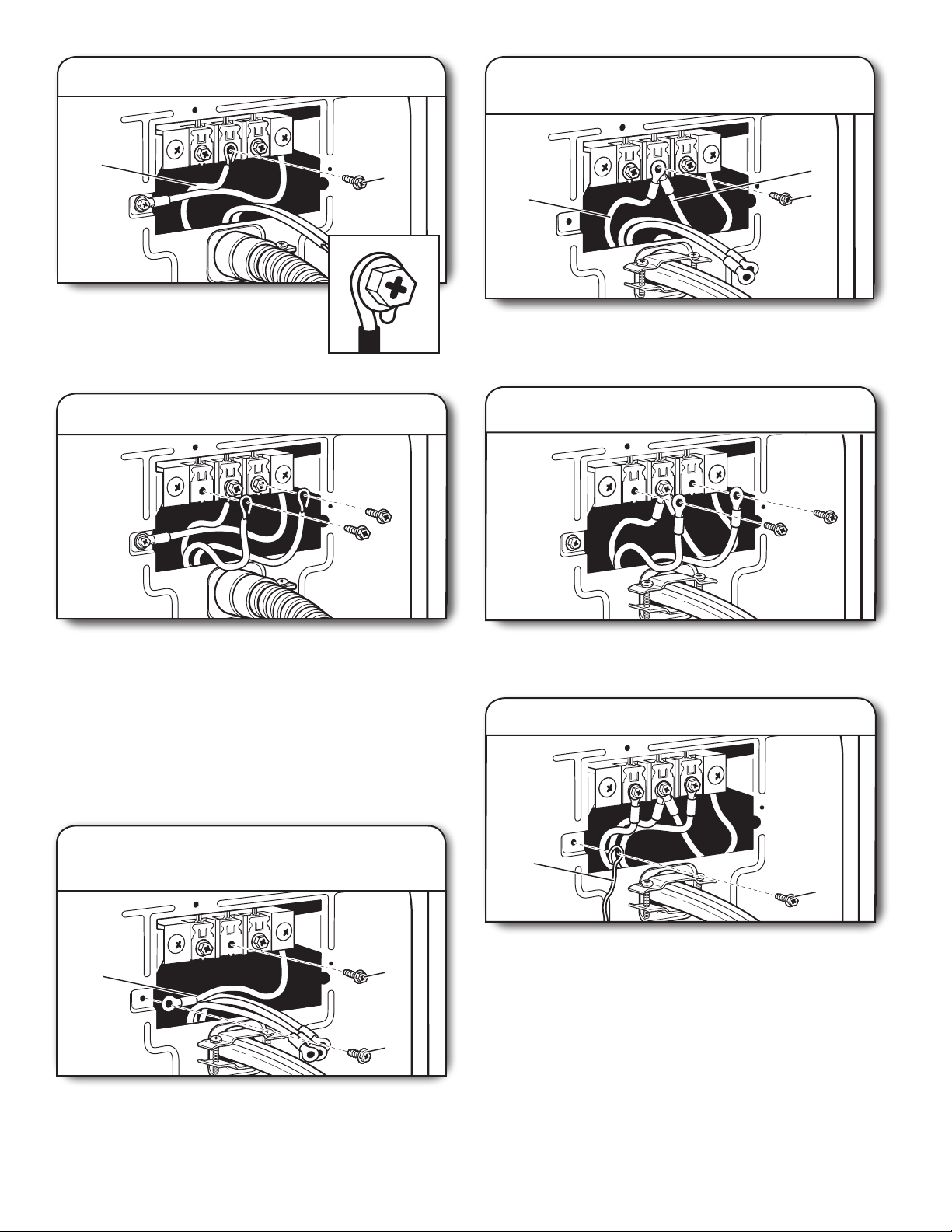

2. Prepare to connect neutral

ground wire and neutral wire

5. Connect remaining wires

E

Remove center terminal block screw (B). Remove neutral

ground wire (E) from external ground conductor screw (A).

B

A

3. Connect neutral ground wire

and neutral wire

E

C

B

Place hooked ends of remaining direct wire cable wires

under outer terminal block screws (hooks facing right).

Squeeze hooked ends together and tighten screws. Finally,

reinsert tab of terminal block cover into slot of dryer rear

panel. Secure cover with hold-down screw. Now, go to

“Venting Requirements.”

3-wire Direct Wire Connection

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

1.

Prepare your 3-wire cable for

direct connection

1"

(25 mm)

Connect neutral ground wire (E) and place

hooked end (hook facing right) of neutral

wire (white or center wire) (C) of direct wire

cable under center screw of terminal block

(B). Squeeze hooked ends together and

tighten screw.

4. Connect ground wire

F

A

Connect ground wire (green or bare) (F) of direct wire cable

to external ground conductor screw (A). Tighten screw.

3½"

(89 mm)

Direct wire cable must have 5 ft. (1.52 m) of extra length so

dryer may be moved if needed.

Strip 31/2" (89 mm) of outer covering from end of cable. Strip

insulation back 1" (25 mm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape wire ends

into hooks.

2. Remove center screw

B

14

Remove center terminal block screw (B).

3. Connect neutral wire

A

G

2.

Connect neutral ground wire

and neutral wire

C

Place hooked end of neutral wire (white

or center) (C) of direct wire cable under

center terminal block screw (B). Squeeze

hooked end together. Tighten screw.

4.

Connect remaining wires

B

C

Connect neutral ground wire (E) and neutral wire (white or

center wire) (C) of power supply cord or cable under center

terminal block screw (B). Tighten screw.

3.

Connect remaining wires

E

B

Place hooked ends of remaining direct wire cable wires under

outer terminal block screws (hooks facing right). Squeeze

hooked ends together and tighten screws. Finally, reinsert

tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw. Now, go to “Venting

Requirements.”

Optional 3-wire Connection

You must verify with a qualified electrician that this

grounding method is acceptable before connecting.

1. Prepare to connect neutral

ground wire and neutral wire

E

B

A

Place hooked ends of remaining wires under outer terminal

block screws (hooks facing right). Tighten screws.

4.

Connect external ground wire

Connect a separate copper ground wire (G) from the external

ground conductor screw (A) to an adequate ground. Finally,

reinsert tab of terminal block cover into slot of dryer rear

panel. Secure cover with hold-down screw. Now, go to

“Venting Requirements.”

Remove center terminal block screw (B). Remove neutral ground

wire (E) from external ground conductor screw (A).

15

A

B

A

B

B

A

D

C

MAKE GAS CONNECTION -

VENTING

U.S.A. AND CANADA

1.

Connect gas supply to dryer

Flared

male tting

Remove red cap from gas pipe. Using a wrench to tighten,

connect gas supply to dryer. Use pipe-joint compound

on threads of all non-ared male ttings. If exible metal

tubing is used, be sure there are no kinks.

NOTE: For propane gas connections, you must use pipe-joint

compound resistant to action of propane gas. Do not use

TEFLON® tape.

2.

Plan pipe tting connection

Non-ared

male tting

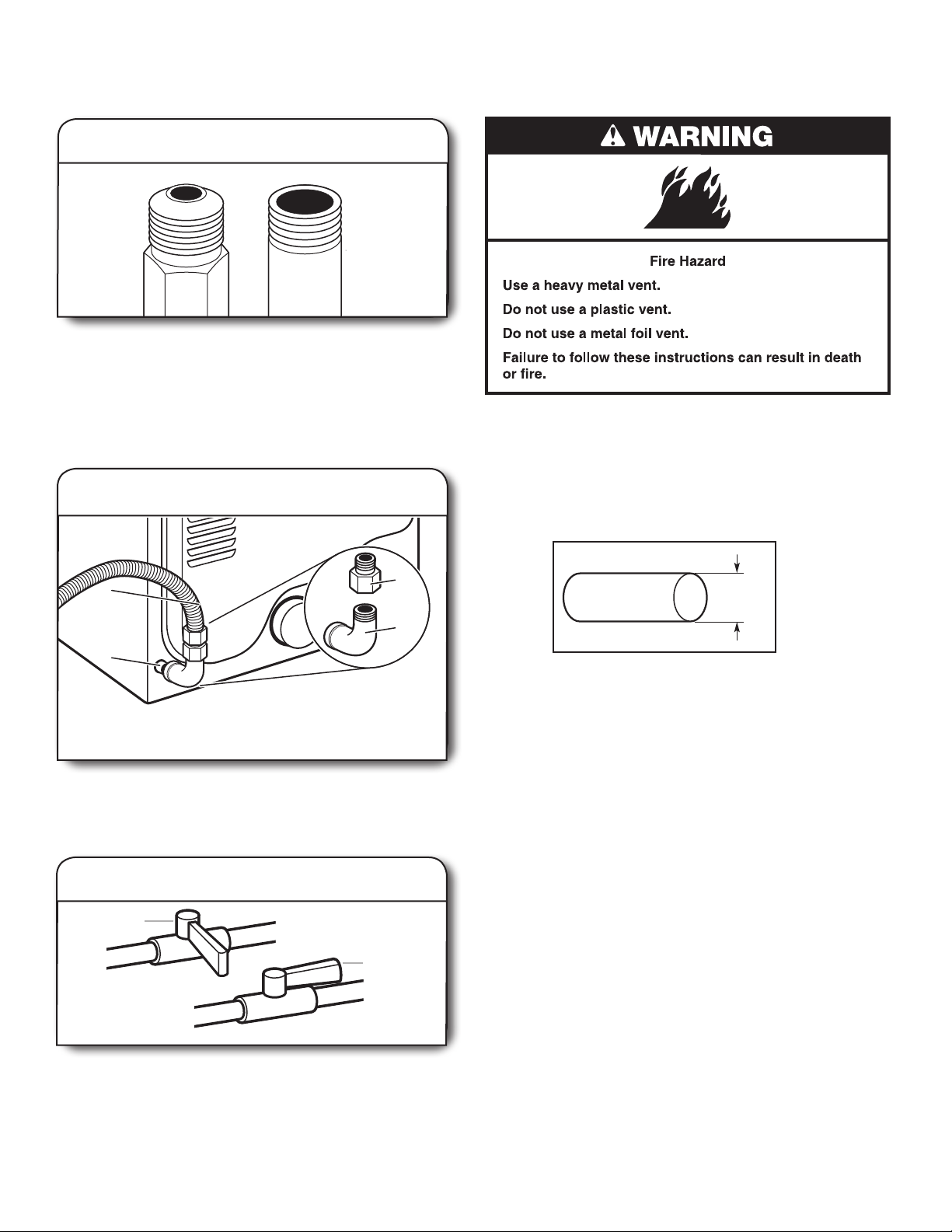

Venting Requirements

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent, chimney,

wall, ceiling, attic, crawlspace, or a concealed space of a

building. Only rigid or exible metal vent shall be used for

exhausting.

A. 3/8" exible gas connector

B. 3/8" dryer pipe

A combination of pipe ttings must be used to connect dryer

to existing gas line. A recommended connection is shown. Your

connection may be dierent, according to supply line type,

size, and location.

3.

Closed valve

Open shut-o valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution. Bubbles

will show a leak. Correct any leaks found.

16

Open shut-o valve

C. 3/8" to 3/8" pipe elbow

D. 3/8" pipe-to-are adapter tting

Open valve

4"

(102 mm)

4" (102 mm) heavy metal exhaust vent

■ Only a 4" (102 mm) heavy metal exhaust vent and clamps

may be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

■ Must be fully extended and supported in nal dryer location.

■ Remove excess to avoid sagging and kinking that may

result in reduced airow and poor performance.

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 7

■ The length of exible metal vent used must be included in the

overall vent system design as shown in the “Vent System Chart.”

NOTE: If using an existing vent system, clean lint from entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace plastic or metal foil vents with rigid metal or exible

metal vents. Review Vent System Chart and if necessary, modify

existing vent system to achieve best drying performance.

3

/4 ft. (2.4 m).

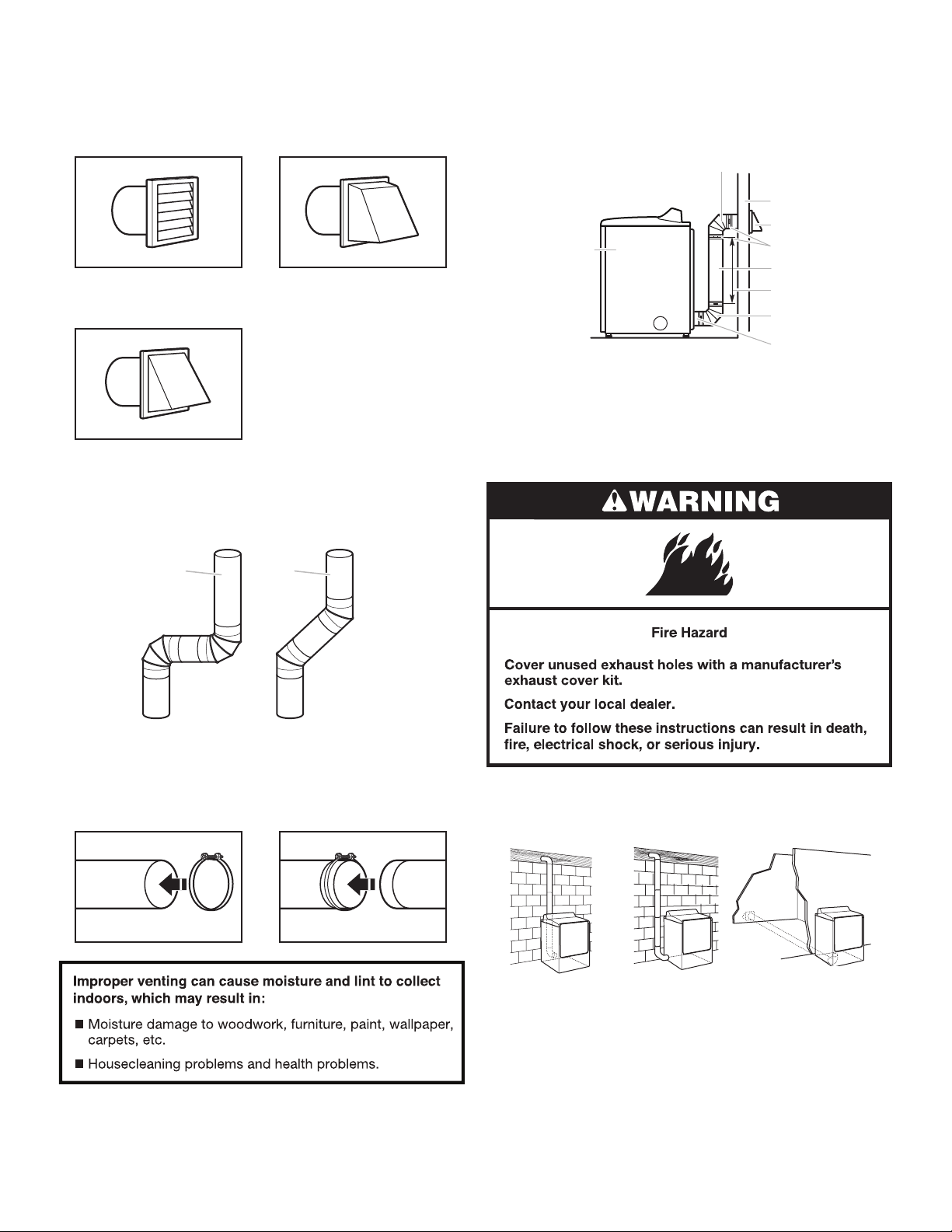

Exhaust hoods:

B

G

H

A

■ Must be at least 12" (305 mm) from ground or any object

that may obstruct exhaust (such as owers, rocks, bushes,

or snow).

Recommended Styles:

Louvered Hood

Box Hood

Plan Vent System

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

C

D

E

F

Acceptable Style:

Angled Hood

Elbows:

■ 45° elbows provide better airow than 90° elbows.

Recommended Styles:

Good

Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

B

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

E. Clamps

F. Rigid metal or exible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Optional exhaust installations:

If you prefer, dryer may be converted to exhaust through the

bottom and sides. You must contact your local dealer to have

dryer converted.

A

A. Standard rear oset exhaust installation

B. Left- or right-side exhaust installation

C. Bottom exhaust installation

B

C

Vent products can be purchased from your dealer. For more

information, see “Assistance or Service” section in your Use and

Care Guide.

17

Special provisions for mobile homes:

12" min.

(305 mm)

12" min.

(305 mm)

Exhaust vent must be securely fastened to a noncombustible

portion of mobile home and must not terminate beneath the

mobile home. Terminate exhaust vent outside.

Install Vent System

1.

Install exhaust hood

Moblie Home Exhaust installation

Determine vent path:

■ Select route that will provide straightest and most direct

path outdoors.

■ Plan installation to use fewest number of elbows and turns.

■ When using elbows or making turns, allow as much room

as possible.

■ Bend vent gradually to avoid kinking.

■ Use as few 90° turns as possible.

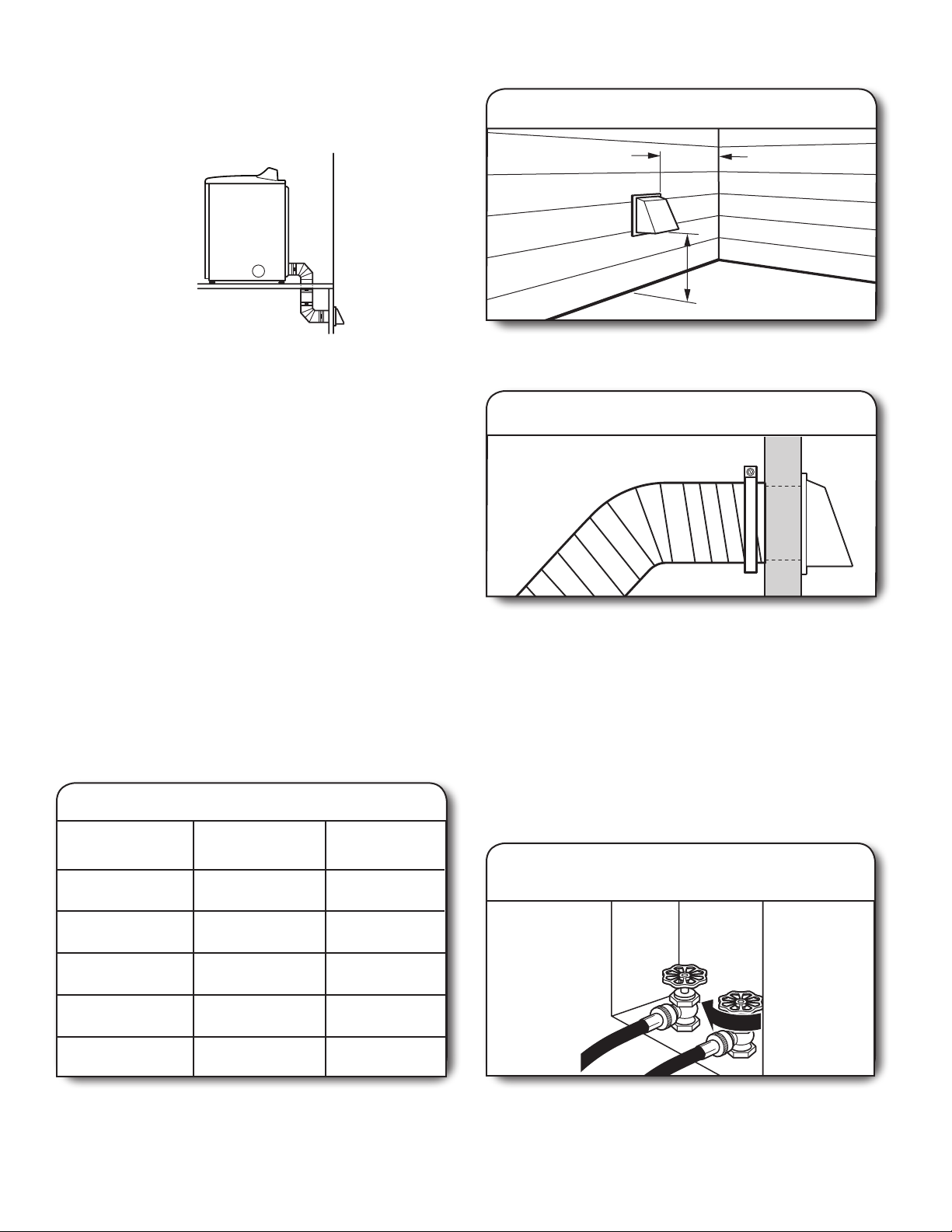

Determine vent length and elbows needed for best drying

performance:

■ Use following Vent System Chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specied

in Vent System Chart. Exhaust systems longer than those

specied will:

■ Shorten life of dryer.

■ Reduce performance, resulting in longer drying times

and increased energy usage.

The Vent System Charts provide venting requirements that will

help achieve best drying performance.

Vent System Chart

Number of

90° elbows

0

Type of vent Angled

hoods

Rigid metal

64 ft. (20 m)

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

2.

Connect vent to exhaust hood

Vent must t over the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location using

straightest path possible. Avoid 90° turns. Use clamps to seal

all joints. Do not use duct tape, screws, or other fastening

devices that extend into interior of vent to secure vent,

because they can catch lint.

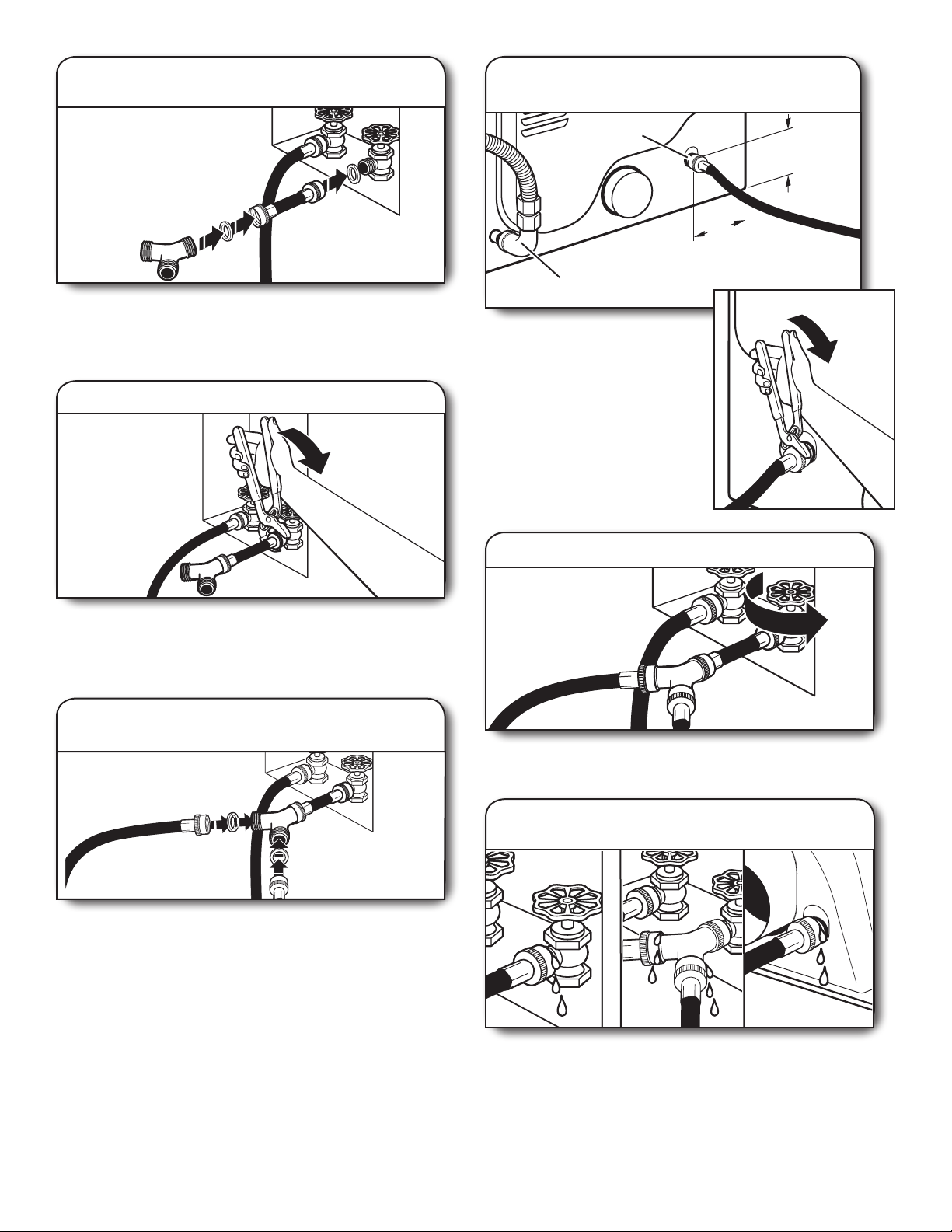

CONNECT INLET HOSES

For non-steam models, skip to “Connect Vent.”

The dryer must be connected to the cold water faucet using

the new inlet hoses. Do not use old hoses.

Turn cold water o, remove and

1.

replace rubber washer

1

2

3

4

NOTE: Bottom exhaust installations have a 90° turn inside the

dryer. To determine maximum exhaust length, add one 90°

turn to the charts.

18

Rigid metal

Rigid metal

Rigid metal

Rigid metal

54 ft. (16.5 m)

44 ft. (13.4 m)

35 ft. (10.7 m)

27 ft. (8.2 m)

Turn cold water faucet o and remove washer inlet hose.

Remove old rubber washer from inlet hose and replace

with new rubber washer.

Attach short hose and

2.

“Y” connector

Attach 2 ft (0.6 m) inlet hose to cold water faucet. Screw on

coupling by hand until it is seated on faucet. Then attach “Y”

connector to male end of the 2 ft (0.6 m) inlet hose. Screw on

coupling by hand until it is seated on connector.

Tighten couplings

3.

Attach long hose to dryer ll valve

5.

and tighten coupling

Fill Valve

Gas Valve

Attach other end of long hose

to ll valve at bottom of dryer

back panel. Screw on coupling

by hand until it is seated on ll

valve connector. Using pliers,

tighten the couplings an additional

two-thirds turn.

NOTE: Do not overtighten.

Damage to the coupling can result.

57/8"

(150 mm)

1

4

/2"

(115 mm)

Using pliers, tighten the couplings with additional two-thirds

turn.

NOTE: Do not overtighten. Damage to the coupling can result.

Attach long hose to “Y” connector

4.

and tighten couplings

Attach dryer 5 ft (1.5 m) inlet hose ends to the “Y” connector.

Attach washer cold inlet hose to other side of “Y” connector.

Screw on coupling by hand until it is seated on connector. Using

pliers, tighten the couplings an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the coupling can result.

Turn on cold water faucet

6.

Check that the water faucet is turned on.

Check for leaks

7.

Check for leaks around “Y” connector, faucets, and hoses.

19

CONNECT VENT

1. Connect vent to exhaust outlet

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must t over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood with

a 4" (102 mm) clamp.

Level Dryer

1.

Place

level here

Place

level here

LEVEL DRYER

2.

Move dryer to nal location. Avoid crushing or kinking vent.

Move dryer to nal location

Check levelness of dryer from side to side. Repeat from

front to back.

NOTE: The dryer must be level for the moisture sensing

system to operate correctly.

Not Level LEVEL Not Level

Adjust leveling legs

2.

20

If dryer is not level, prop up using a wood block. Use wrench

to adjust legs up or down, and check again for levelness.

COMPLETE INSTALLATION

CHECKLIST

■ Check that all parts are now installed. If there is an extra

part, go back through steps to see what was skipped.

■ Check that you have all of your tools.

■ Dispose of/recycle all packaging materials.

■ Check dryer’s nal location. Be sure vent is not crushed

or kinked.

■ Check that dryer is level. See “Level Dryer.”

■ Remove lm on console and any tape remaining on dryer.

■ Wipe dryer drum interior thoroughly with a damp cloth

to remove any dust.

■ Read “Dryer Use” in your Use and Care Guide.

Electric Models:

■ For power supply cord installation, plug into a grounded

outlet. For direct wire installation, turn on power.

Gas Models:

■ Check that gas supply is on.

■ Check for leaks.

Steam models only:

■ Be sure the water faucets are on.

■ Check for leaks around “Y” connector, faucet, and hoses.

■ If you live in a hard water area, use of a water softener is

recommended to control the buildup of scale through the

water system in the dryer. Over time, the buildup of lime

scale may clog dierent parts of the water system, which

will reduce product performance. Excessive scale buildup

may lead to the need for certain part replacement or repair.

All Models:

■ Select a Timed Dry heated cycle, and start dryer.

Do not select Air Only temperature setting.

If dryer will not start, check the following:

• Controls are set in a running or “On” position.

• Start button has been pushed rmly.

• Dryer is plugged into an outlet and/or electrical supply

is connected.

• Household fuse is intact and tight, or circuit breaker has

not tripped.

• Dryer door is closed.

This dryer automatically runs an installation diagnostic routine

at the start of its rst cycle.

If you receive an L2 code, there may be a problem with your

home power supply keeping the dryer’s heater from turning on.

See “Troubleshooting.”

If your airow screen reads “Check Vent”, your dryer vent may

be crushed or blocked. See “Troubleshooting.”

NOTE: You may notice an odor when dryer is rst heated. This

odor is common when heating element is rst used. The odor will

go away.

21

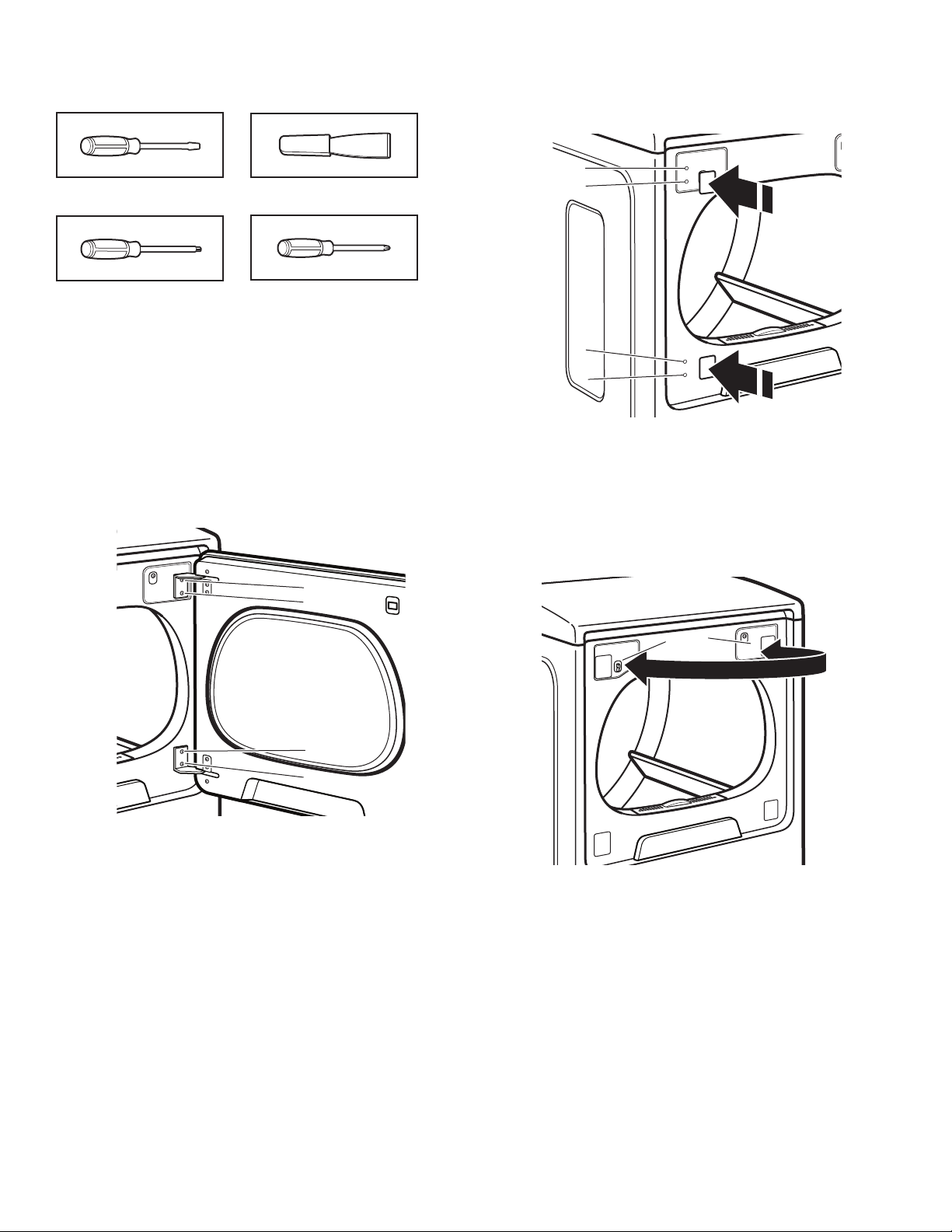

REVERSE DOOR SWING

Tools needed:

Flat-head screwdriver Plastic putty knife

4. Remove the 2 plastic plugs (A) located outside the dryer

door opening.

A

A

Min. 8" (203 mm) long

TORX T25

® †

screwdriver

#2 Phillips screwdriver

You can change your door swing from a right-side opening

to a left-side opening, if desired.

1. Place a towel or soft cloth on top of dryer or work space

to avoid damaging the surface.

Remove door from dryer cabinet

1. Open the dryer door.

2. Using a T25® screwdriver, remove screws (A) and then

(B) screws from each of the two hinges that attach dryer

door to front panel of dryer. Set the hinge screws o to

the side for reinstalling the door.

A

B

A

A

5. Install 2 plastic plugs (A) into screw holes where the hinges were

removed in Step 4.

Reverse the strike

1. Remove the door strike (A) from the dryer door opening.

2. Remove the cosmetic screw (B) opposite the door strike (A).

B

A

A

B

3. Remove the dryer door by lifting upward and out to lift the

door o the cabinet. Lay the door on a at, covered surface,

with the inside of the door facing up.

†®TORX and T25 are registered trademarks of Acument Intellectual Properties, LLC.

22

A. Door strike

B. Cosmetic screw

3. Reinstall the door strike and cosmetic screw on the opposite side

of dryer door opening from where they were removed.

NOTE: Door strike and plugs must be on the same side

of the dryer door opening.

Loading...

Loading...