Kenmore 23352719000, 23352717000, 23352714000, 23352713000, 23352712000 Owner’s Manual

...

®

Use & Care / installation Manual

cocina

Manual de uso y cuidado /instalaci6n

Models

Modelos

233.52612000 (30" wide - White)

233.52613000 (30" wide - Stainless)

233.52614000 (30" wide - Biscuit)

233.52617000 (30" wide - Almond)

233.52619000 (30" wide - Black)

233.52712000 (36" wide - White)

233.52713000 (36" wide - Stainless)

233.52714000 (36" wide - Biscuit)

233.52717000 (36" wide - Almond)

233.52719000 (36" wide - Black)

0

u

0

Patent No,:

US D450,829 S

626987A Sears, Roebuck and Co,, Hoffman Estates, UL60179 U,S,A, www,sears,com

If within 1 year from the date of installation, any part of this

range hood fails to function properly due to a defect in mate-

rial or workmanship, Sears will repair the part or furnish and

install a new part, free of charge=

FULL 30-DAY WARRANTY ON FIN_SB ON PAINTED OR

BRIGHT METAL PARTS

Ifwithin 30 days from the date of installation, the finish on any

painted or bright metal parts of this range hood is defective in

material or workmanship, Sears will furnish and install a new

part, free of charge=

WARRANTY SERVICE iS AVAILABLE BY CONTACTING

THE NEAREST SEARS SEVICE CENTER/DEPARTMENT

iN THE UNITED STATES.

This warranty applies only while this product is in use in the

United States. This warranty gives you specific legal rights

and you may have other rights which vary from state to state.

Sears, Roebuck and Co., Oept 817WA, Hoffman Estates,

IL 6017

A iNTENDED FOR DOMESTIC COOKING ONLY A

WARNING _ A

TO REDUCE THE RiSK OF FIRE, ELECTRIC SHOCK, OR

iNJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufac-

turer. If you have questions, contact the manufacturer at

the address listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally= When the

service disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to the

service panel=

3. Installation work and electrical wiring must be done by a

qualified person(s)in accordance with all applicable codes

and standards, including fire-rated codes and standards=

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. When cutting or drilling into wail or ceiling, do not damage

electrical wiring and other hidden utilities.

6. To reduce the risk of fire or electric shock, do not use this

range hood with an additional speed control device.

7. Ducted fans must always be vented to the outdoors=

8. To reduce the risk of fire, use only metal ductwork.

9. Use with approved cord-connection kit only.

10.This unit must be grounded=

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy sp[llovers that may

ignite. Heat oils slowly on low or medium settings=

2. Always turn hood ON when cooking at high heat or when

cooking flaming foods=

3. Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter=

4. Use proper pan size. Always use cookware appropriate

for the size of the surface element= 2

WARNING _,

TO REDUCE THE RiSK OF INJURY TO PERSONS tN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet,

or metal tray, then turn off the burner= BE CAREFUL TO

PREVENT BURNS= Ifthe flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT=

2. NEVER PICK UPA FLAMING PAN - You may be burned=

3. DO NOT USE WATER, including wet dishcloths or towels

- a v[otent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you

already know how to operate it.

B. The fire is small and contained in the area where it

started=

C. The fire department is being called.

D. You can fight the fire with your back to an exit=

* Based on "Kitchen Firesafety Tips" published by NFPA.

CAUTION A

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors=

2. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall spray, construction

dust, etc. off power unit.

3. For best capture of cooking impurities, your range hood

should be mounted so that the top of the hood is 24-30"

above the cooking surface=

4. Use only with range hood cord-connection kits that have

been investigated and found acceptable for use with this

model range hood=

5. Please read specification label on product for further

information and requirements.

tf hood is to be installed Non-Ducted:

,_ Purchase a set of (2) non-ducted filters from your

moca_distributor or retailer and attach them to the

aluminum mesh filters.

©

LOW HIGH LOW HIGH

iNDiCATOR

LIGHT

Fan

The 3-position rocker switch (on the left) controls the fan. The

left position is Iow speed, center position is off, and right posi-

tion is high speed. An indicator light shows that the fan is on.

Light

The 3-position rocker switch (on the right) controls the lights.

The left position is low light intensity, center position is off, and

right position is high light intensity.

FAN LIGHT

WARNING: To reduce the risk of electric shock,

disconnect from power supply before cJean-

rag.

ABuminum mesh filters

Clean frequently using hot water and a mild detergent or in

your dishwasher. The aluminum mesh filters should be washed

approximately every month depending on the amount of us-

age. Wash more often if your cooking style generates greater

grease - like frying foods or wok cooking.

Nonoducted filters (Cmean Cooking hoods onmy)

(available separately - see page 4)

Clean filter surfaces frequently with a damp cloth and a mild

detergent. DO NOT immerse filters in water or put in dish-

washer. The special "Clean Sense" feature indicates when the

filter is to be repIaced. The blue and yel!ow strips will blend to

green when it is time to change the filter. The "Clean Sense"

feature works best when facing toward the cooking surface.

Painted hood surfaces

Wiping regularly with mild soap/detergent and warm water

should protect painted hood surfaces. Be cautious about us-

ing "New and improved" cleaning agents. Your hood is installed

over hot cooking equipment. Most chemicaIs found in clean-

ing agents react with heat to loosen paint.

Stainless steem hood surfaces

Stainless steel hoods should be washed regularIy with a clean

cloth, warm water and mild soap or dish detergent. Clean in

the direction of the polish Iines. Rinse well with clear water

and wipe dry immediately. You may wish to apply light oil used

for furniture polishing to emphasize it's bright finish.

Fan assembmy

Fan blade can be cleaned with a damp cloth and mild deter-

gent. Use care when cleaning fan blade - it must not become

bent or misaIigned. DO NOT ALLOW WATER TO ENTER

MOTOR. Make sure alI surfaces are completely dry before re-

installing filters and restoring power.

Motor is permanently lubricated. Do not oil or disassemble

motor.

q_

{b

q_

2

3

7-inch Round

Duct Adapter

Light Bumb

(2 per hood)

Sears Part No. 57853

31A" × 10-

Damper/Duct Connector

Aluminum Grease Filter

(2 per hood)

(4 hood mounting screws inside)

Parts Bag

OPTmONAL PARTS (purchase separately)

Clean Cooking Filters

(Non-ducted hoods only)

(2 per hood)

Sears Part Nos. 50191 (30")

(For use with 7-inch Round Duct)

7-inch Round Damper

Sears Part No, 59183

Splashplate

Sears Part Nos,

58120 30" Black/Biscuit

58128 30" White/Almond

58130 36" Black/Biscuit

58138 36" White/Almond

Cord Kit

(Allows hood to be plugged into a

standard 120 VAC wall outlet)

Sears Part No, 233,22HCK44D

50192 (36")

Ducting Accessories

(See "Equivalent Duct Length Chart" on page 5 for Ducting

Accessory Model Nos.

"Parts Not Included With Hood" avaimabte by calming |

Sears at 1-800_4-MY-HOME _

/ / Q /

Screwdriver Tape !/4"

(Fmat& Phillips) Pencil Measure Nutdriver

Sabre Keyhole Wire

Drill Saw -or= Saw Duct Tape Stripper

1

!

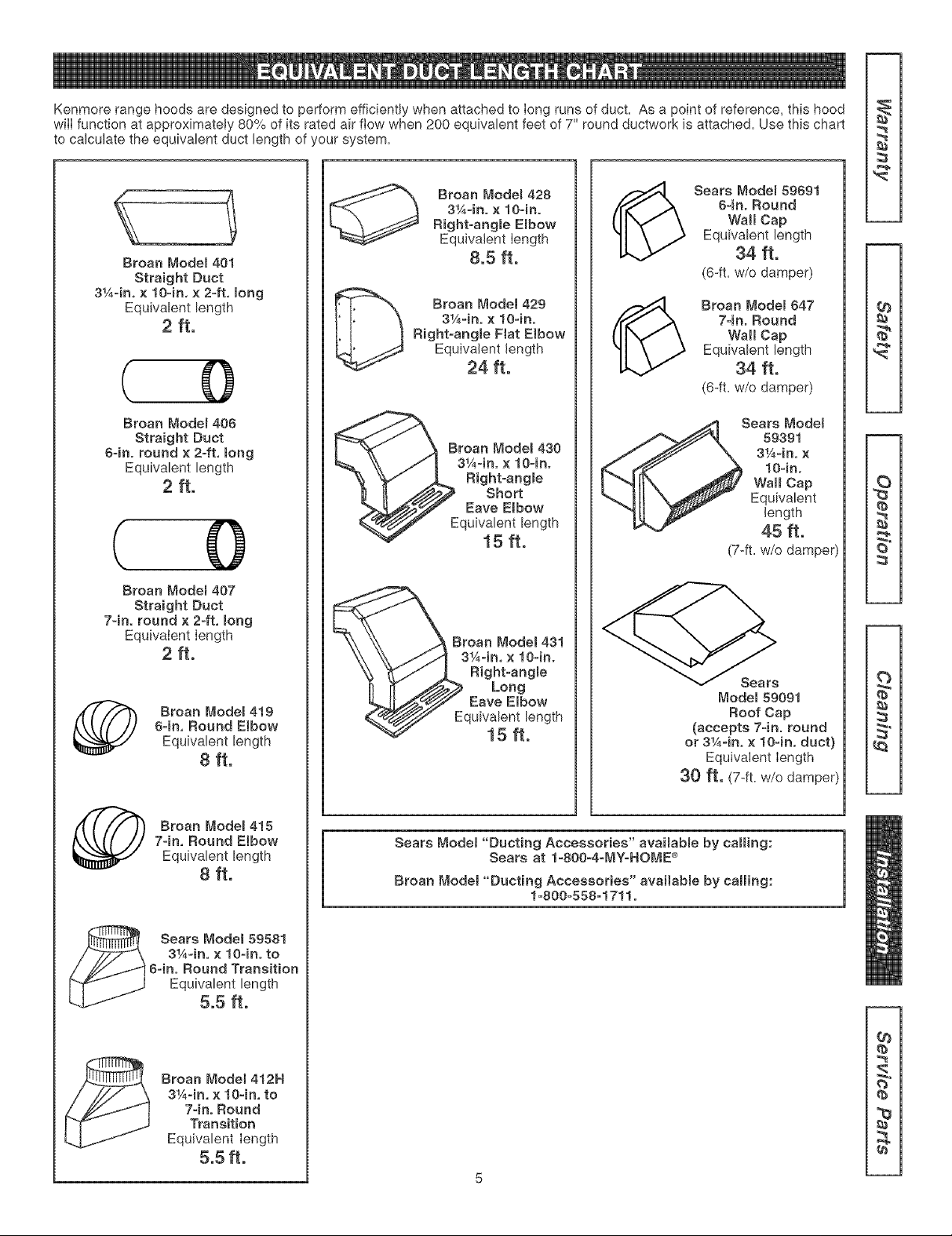

KenmorerangehoodsaredesignedtoperformefficientlywhenattachedtoIongrunsofduct.Asapointofreference,thishood

wiIIfunctionatapproximately80%ofitsratedairftowwhen200equivalentfeetof7"roundductworkisattached.Usethischart

tocalculatetheequivalent duct length of your system.

Broan Modem 401

Straight Duct

3¼=in, x lO-in, × 2=ft, mong

Equivalent length

2ft.

( 0

Broan Modem406

Straight Duct

64n. round × 2-ft, long

Equivalent length

2 ft.

( 0

Broan Modem 407

Straight Duct

7-in. round × 2-ft. long

EquivaIent Iength

2 ft.

64n, Round Elbow

Broan Modem419

Equivalent length

8 ft.

Broan Model 428

3¼-in° x lO=in.

Right=angBe Embow

Equivalent Iength

8.5 ft.

3¼-in. x lO-ino

D Broan _'1odel 429

Right-angle Fiat Elbow

Equivalent length

24 ft.

Broan Model 430

3¼-in. x lO-ino

Right-angme

Short

Eave E{bow

quivalent length

15 ft.

Broan Model 431

3¼-in, x lO-in.

Right-angle

Long

Eave Elbow

quivalent length

15 ft.

8=in° Round

Wall Cap

_ Sears Modem59691

Equivalent length

34 ft.

(6-ft=w/o damper)

74n. Round

Wall Cap

(_ Broan Modem647

Equivalent length

34 ft.

(6-ft=w/o damper)

Sears Model

59391

3¼=in. x

lO-in,

Wall Cap

Equivalent

length

45 ft.

(7-ft= w/o damper)

Model 59091

Roof Cap

(accepts 74n. round

or 3¼-in. × lO-in, duct}

Equivalent Iength

30 ft. (7-fL W/Odamper)

{b

re

7-in, Round Elbow

Broan Modem415

Equivalent length

8 ft.

3¼-in, x lO-in, to

6=in. Round Transition

Sears Model 59581

Equivalent length

5.5 ft.

3¼=in, x lO-in, to

7=inoRound

Broan Model 412H

Transition

Equivalent Iength

5.5 ft.

Sears Modet "Ducting Accessories" avaHabmeby calling:

Sears at 1-800-4-MY_HOME _

Broan Modet "Ducting Accessories" availabme by calling:

1_800=558=1711°

t_

2

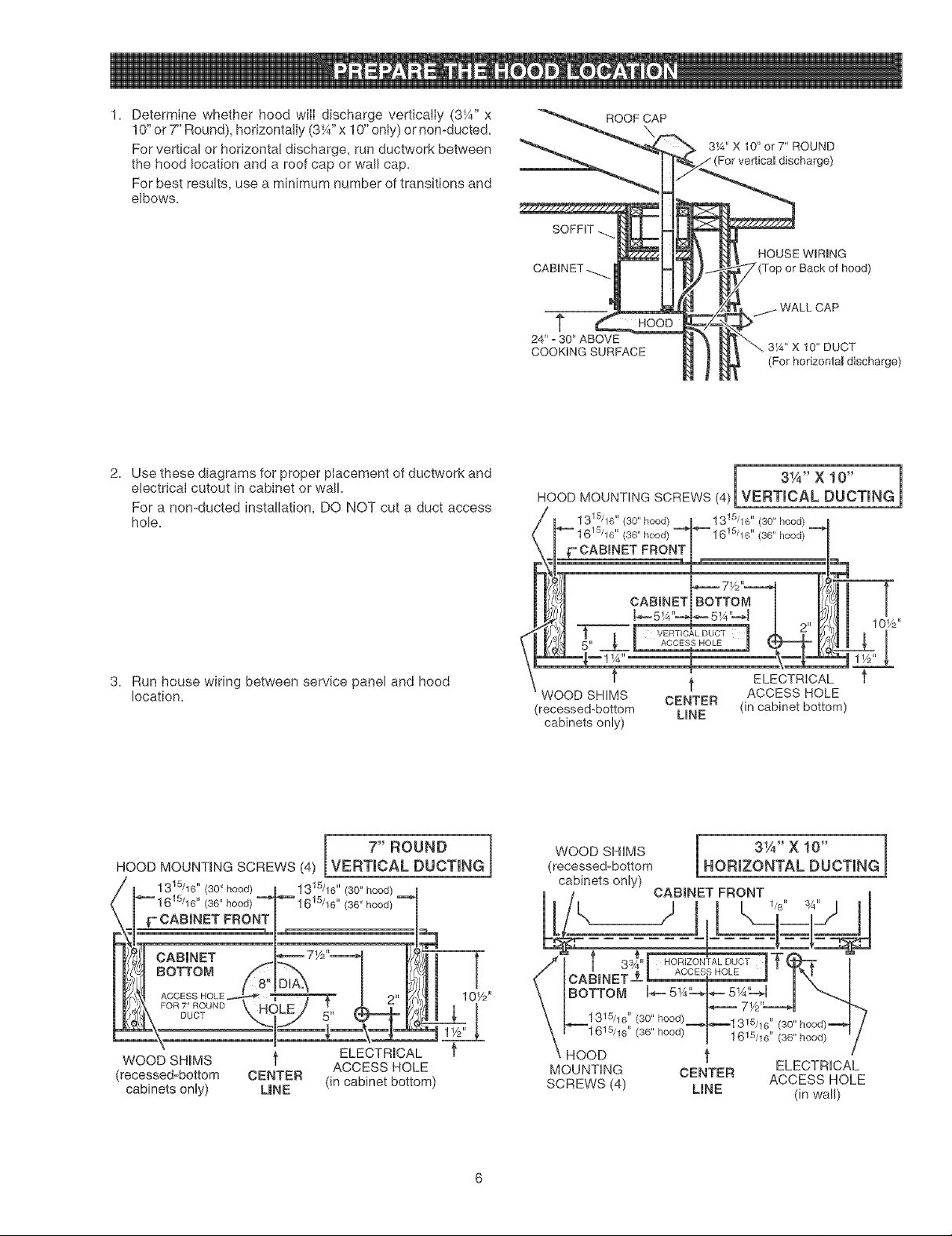

1. Determine whether hood wilI discharge vertically (3¼" x

10" or7" Round), horizontally (3V4"x 10" only) or nomducted.

For vertical or horizontal discharge, run ductwork between

the hood location and a roof cap or wall cap.

For best results, use a minimum number of transitions and

elbows.

2. Use these diagrams for proper placement of ductwork and

electrical cutout in cabinet or wall.

For a nomducted installation, DO NOT cut a duct access

hole.

ROOF CAP

31A'X 10" or 7" ROUND

For vertical discharge)

HOUSE WIRING

or Back of hood)

t

24" =30" ABOVE

COOKINGSURFACE

HOOD MOUNTING SCREWS (4)reVERT CAL DUCT NG

1 315/16 `' (30" hood) 1315/16 `' 30" hood

(36" hood) _ 15/ .... --"_ 16 16 (36 hood)

,F"CABINET FRONT

3W' X 10" DUCT

(For horizontal discharge)

3¼"X 10" 1

3. Run house wiring between service panel and hood

location.

I 7" ROUND

HOOD MOUNTmNGSCREWS (4) [VERTICAL DUCTING

- i

1315/16"(30" hood)

_""- 1615/16 '' (36" hood)

I

,_ 2"

71/2"===._

CABINET BOTTOM

J_-...-5W'-_ ,..=5W_4

T _t VERTICAL DUCT 2'_m

_E 11S_" ACCESSHOLE

ELECTRICAL

WOOD SHIMS CENTER

ACCESS HOLE

(recessed-bottom LINE (in cabinet bottom)

cabinets only)

WOOD SHIMS l 31A" X 10" ]

(recessed-bottom HORIZONTAL DUCTING

cabinets only)

CABBNET FRONT

\

WOOD SHMS t ELECTRm_;AL

(recessed=bottom CENTER (in cabinet bottom)

cabinets only) L|NE

ACCESS HOLE

HOOD _'

MOUNTING CENTER ACCESS HOLE

SCREWS (4) UNE (in wall)

ELECTRICAL

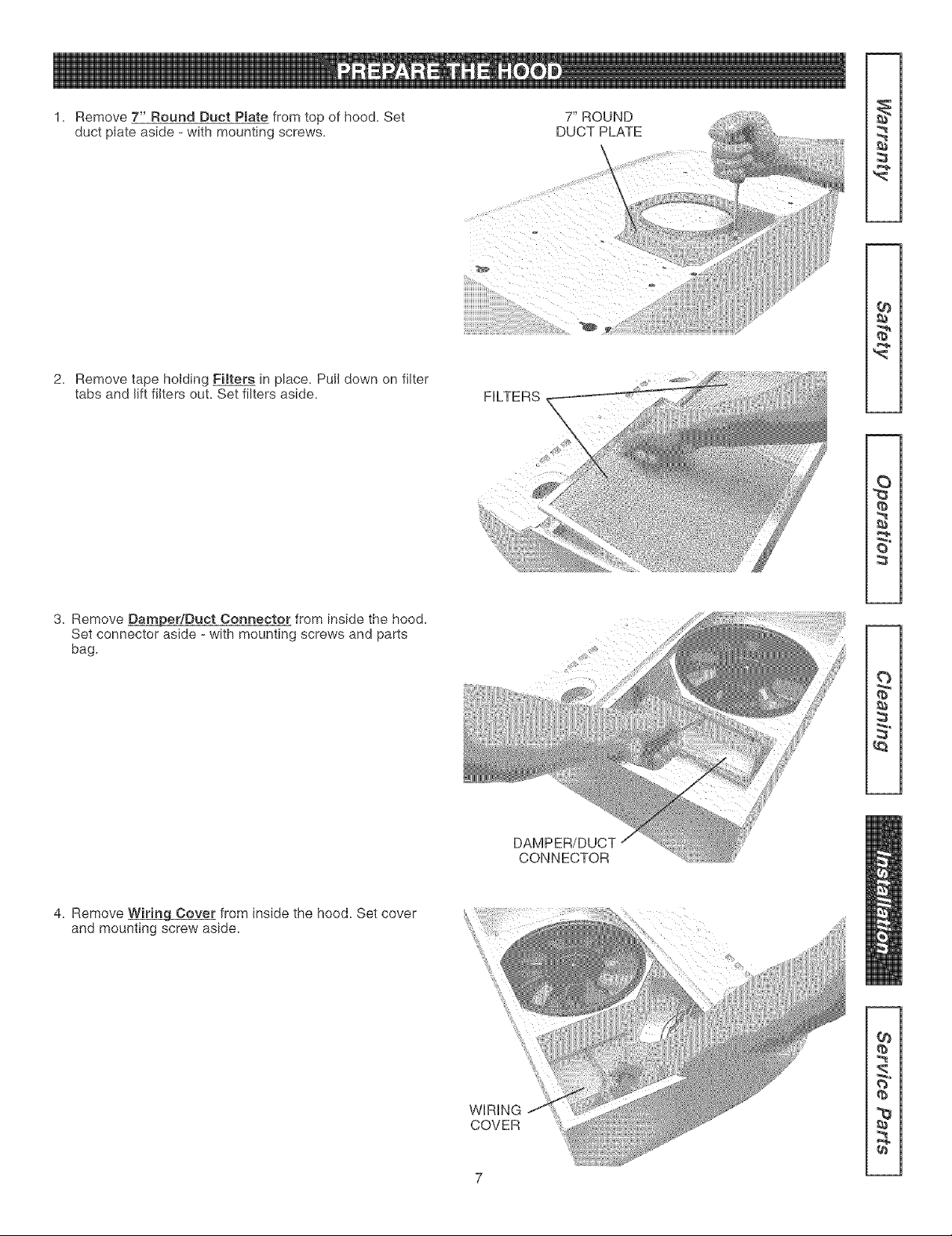

Remove 7" Round Duct Pmatefrom top of hood. Set

duct plate aside - with mounting screws=

2.

Remove tape holding Filters in place. Pull down on filter

tabs and lift filters out. Set filters aside.

7" ROUND

DUCT PLATE

\

FILTERS

3. Remove Damper/Duct Connector from inside the hood.

Set connector aside - with mounting screws and parts

bag.

4. Remove WiringCover from inside the hood. Set cover

and mounting screw aside.

CONNECTOR

¢e

S"

O_

q_

WiRiNG

COVER

7

q_

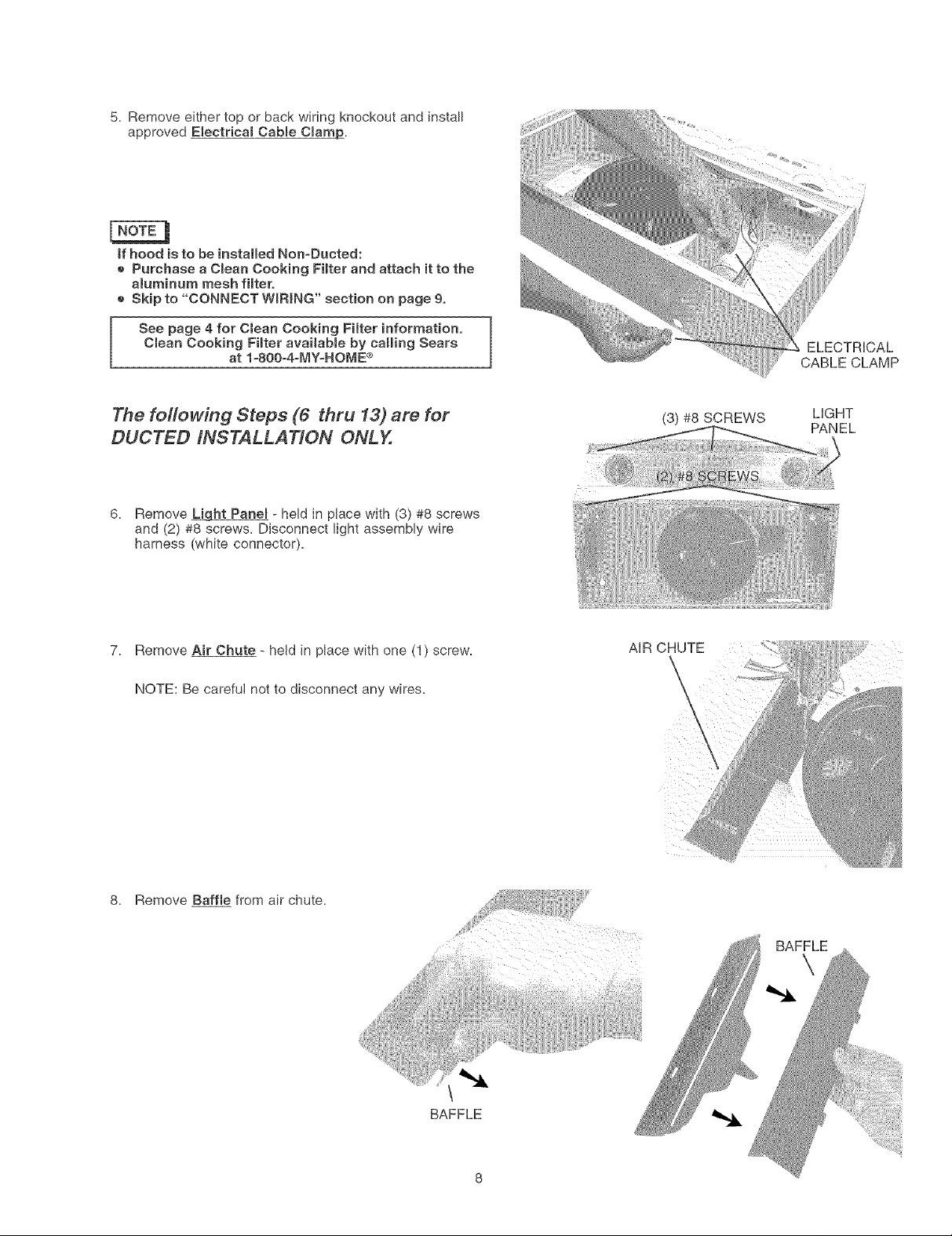

5. Remove either top or back wiring knockout and install

approved Electricam Cabme CmamJo,

if hood is to be installed Non-Ducted:

e Purchase a CmeanCooking Fimter and attach it to the

aluminum mesh filtero

e Skip to "CONNECT WiRiNG" section on page 9,

See page 4 for Cmean Cooking Filter information.

Clean Cooking Fimter available by calling Sears

at 1-800o4-MY-HOME ®

/

ELECTRICAL

CABLE CLAMP

The following Steps (6 thru 13) are for

DUCTED INSTALLATION ONLY.

6.

Remove _ht Panel - held in place with (3) #8 screws

and (2) #8 screws. Disconnect light assembly wire

harness (white connector).

7. Remove Air Chute - held in place with one (1) scre_

NOTE: Be careful not to disconnect any wires.

(3) #8 SCREWS LIGHT

AiR CHUTE

\

\

\

PANEL

8. Remove Baffle from air chute.

BAFFLE

\

BAFFLE

Loading...

Loading...