4300B

k

/"

.y,

,r

iNSTRUCTIONS

Z1GoZAG SEWING MACHINE

# 4300B

TABLE OF

CONTENTS

Adjusting for Good Stitches .................. 24

Adjusting Pressure of Presser Foot ......... 10

Adjusting Tensions .......................... 12- 13

Blind Stitching ....................................... 19

Buttonholes .......................................... 17

Buttons ................................................... 17

Needle & Thread Table .......................... 5

Needle Size ........................................ 5

Oiling Machine ..................................... 21

Overcasting ....................................... 19

Picking up Bobbin Thread ..................... 10

Placement of Needle ............................. 5

Changing the Presser Feet ..................... 15

Connecting Machine ............................. 4

Darning ................................................ 16

Fastening a Seam ................................. 11

Feed Dog Control ................................. 15

Identification- Head Parts .................. 2- 3

Inserting Bobbin into Bobbin Case ......... 8

Inserting & Removing Material ............... 14

Installing Machine Head ........................ 4

Locking Stitch Width .............................. 18

Removing Bobbin Case

from Shuttle ..................... 6

Removing Lint .................................... 20

Replscement of Belt ............................ 20

Reverse Stitching ............................. 11

Setting Stitch Length ............................ 11

Setting Stitch Width .............................. 18

Sewing Light ......................................... 4

Threading Upper Machine ..................... 9

Turning a Corner ................................. 15

What to Do ...................................... 22- 23

Winding the Bobbin .............................. 7

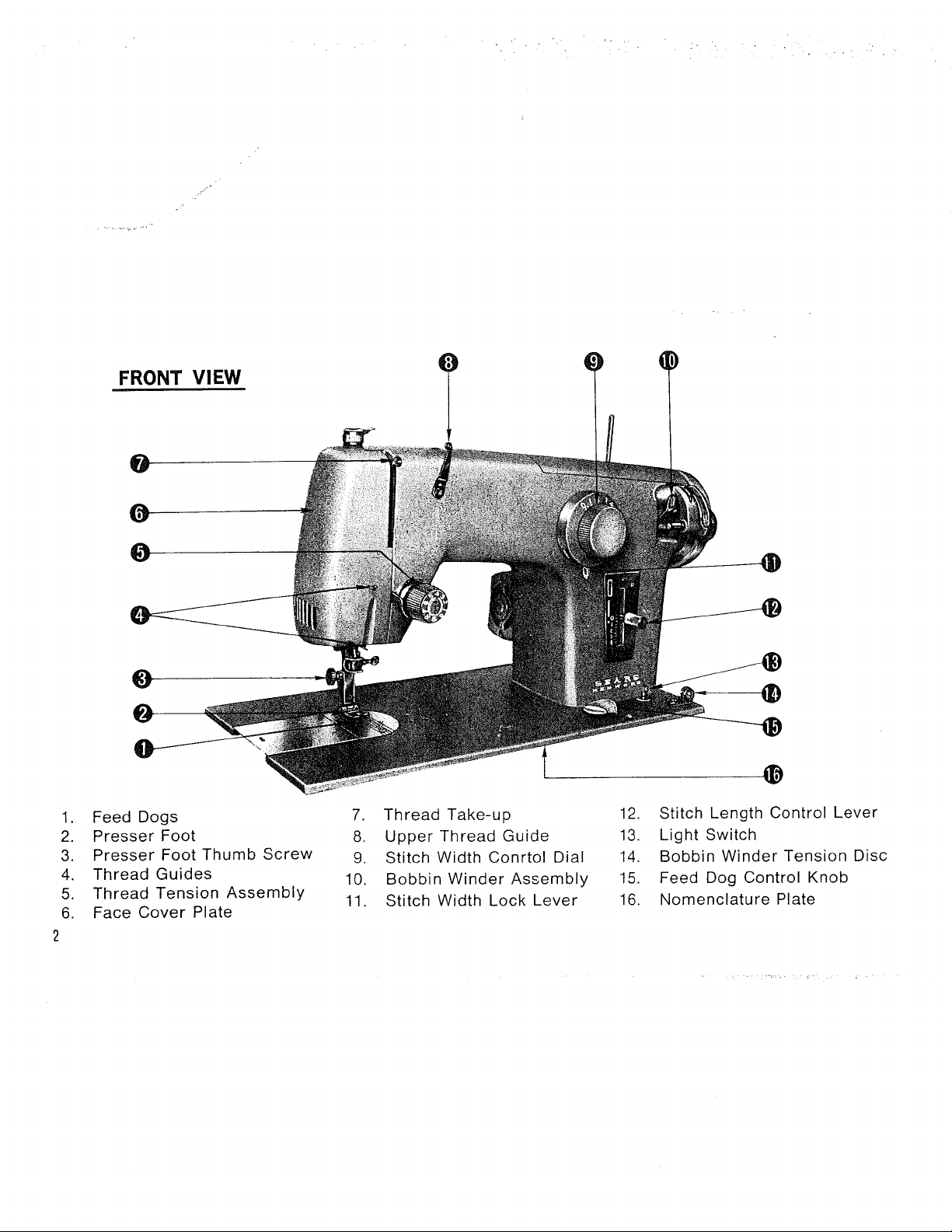

FRONT VIEW

L

1. Feed Dogs

2. Presser Foot

3. Presser Foot Thumb Screw

4. Thread Guides

5. Thread Tension Assembly

6. Face Cover Plate

2

7. Thread Take-up

8. Upper Thread Guide

9. Stitch Width Conrtol Dial

10. Bobbin Winder Assembly

11. Stitch Width Lock Lever

12. Stitch Length Control Lever

13. Light Switch

14. Bobbin Winder Tension Disc

15. Feed Dog Control Knob

16. Nomenclature Plate

f"

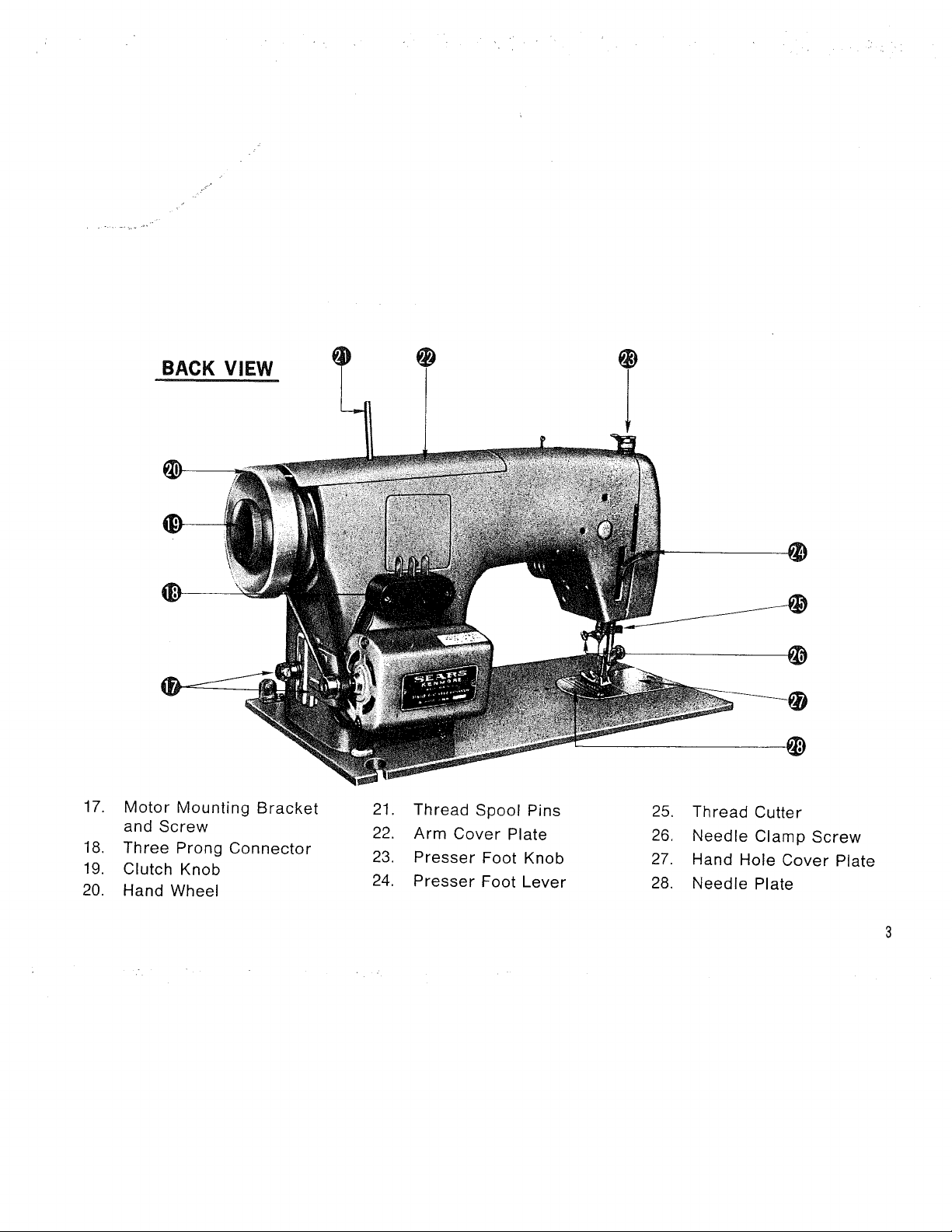

BACK VIEW

" r i: • ,

17. Motor Mounting Bracket

and Screw

18. Three Prong Connector

19. Clutch Knob

20. Hand Wheel

21. Thread Spool Pins

22. Arm Cover Plate

23. Presser Foot Knob

24. Presser Foot Lever

25. Thread Cutter

26. Needle Clamp Screw

27. Hand Hole Cover Plate

28, Needle Plate

@

@

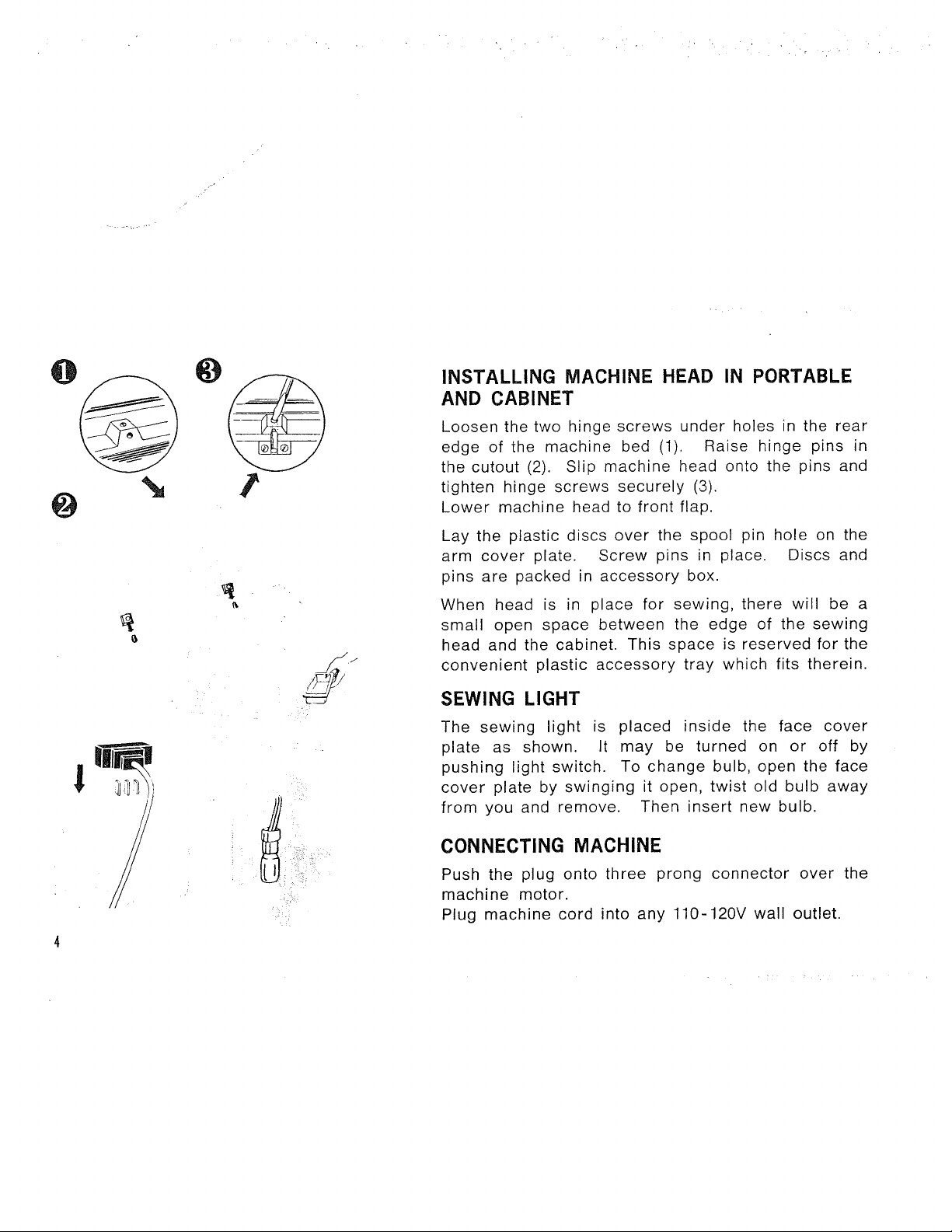

INSTALLING MACHINE HEAD IN PORTABLE

AND CABINET

Loosen the two hinge screws under holes in the rear

edge of the machine bed (1). Raise hinge pins in

the cutout (2). Slip machine head onto the pins and

tighten hinge screws securely (3).

Lower machine head to front flap.

Lay the plastic discs over the spool pin hole on the

arm cover plate. Screw pins in place. Discs and

pins are packed in accessory box.

When head is in place for sewing, there will be a

small open space between the edge of the sewing

head and the cabinet. This space is reserved for the

convenient plastic accessory tray which fits therein.

SEWING LIGHT

The sewing light is placed inside the face cover

plate as shown. It may be turned on or off by

pushing light switch. To change bulb, open the face

cover plate by swinging it open, twist old bulb away

from you and remove. Then insert new bulb.

CONNECTING MACHINE

Push the plug onto three prong connector over the

machine motor.

Plug machine cord into any 110-120V wall outlet.

/,

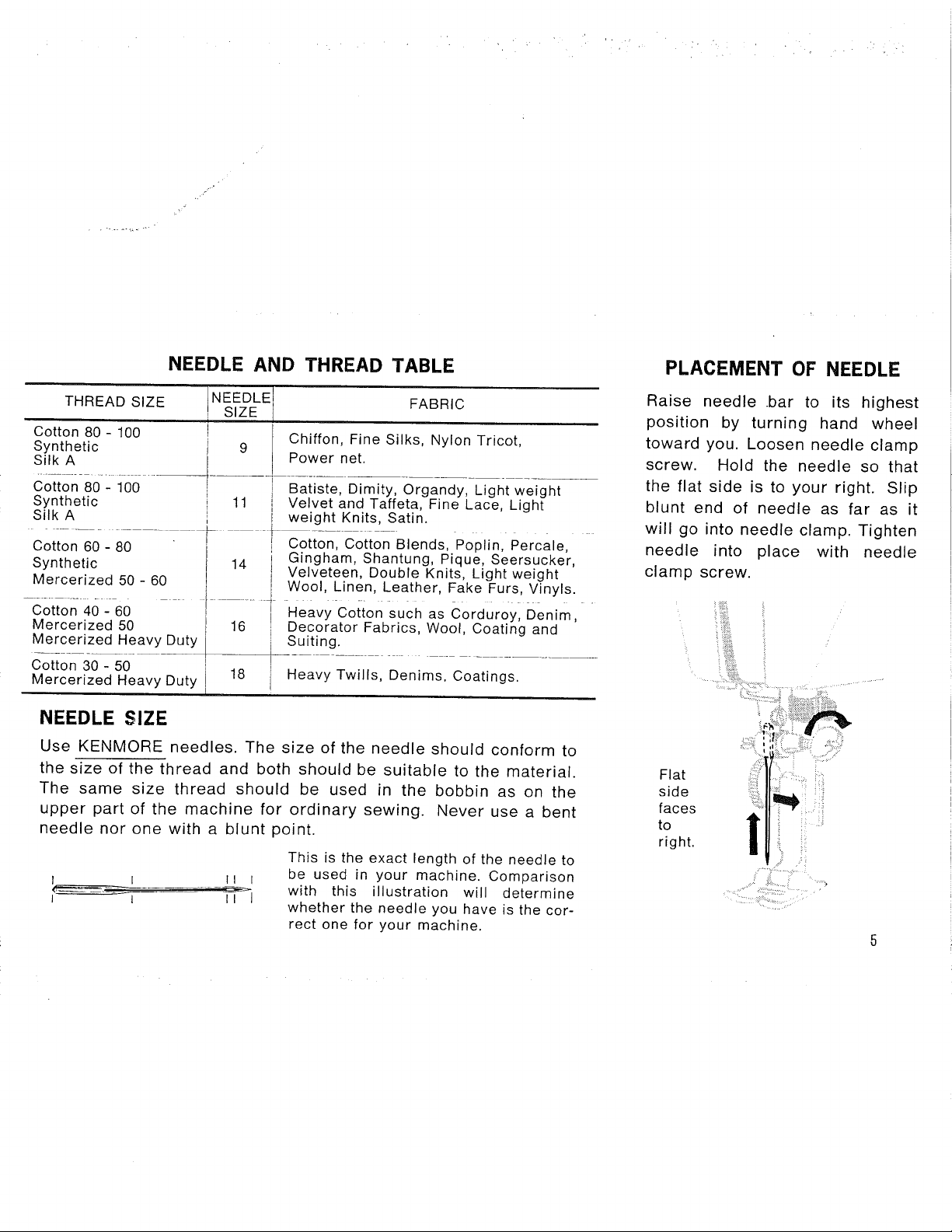

NEEDLE AND THREAD TABLE

THREAD SIZE I SIZE / FABRIC

Cotton 80 - 100

Synthetic

Silk A

Cotton 80 - 100

Synthetic

Silk A

Cotton 60 - 80 P Cotton, Cotton Blends, Poplin, Percale,

Synthetic 14 Gingham, Shantung, Pique, Seersucker,

Mercerized 50 - 60 / Wool, Linen, Leather, Fake Furs, Vinyls.

Mercerized 50 16 I Heavy Cotton such as Corduroy, Denim,

Mercerized Heavy Duty Suiting.

Cot on30- 0----- 18 '

Mercerized Heavy Duty Heavy Twills, Denims, Coatings.

NEEDLE SIZE

Use KENMQRE needles. The size of the needle should conform to

the size of the thread and both should be suitable to the material.

The same size thread should be used in the bobbin as on the

upper part of the machine for ordinary sewing. Never use a bent

needle nor one with a blunt point.

I II I

NEEDLE

9

11

I

Chiffon, Fine Silks, Nylon Tricot,

Power net.

Batiste, Dimity, Organdy, Light weight

Velvet and Taffeta, Fine Lace, Light

weight Knits, Satin.

Velveteen, Double Knits, Light weight

Decorator Fabrics, Wool, Coating and

This is the exact length of the needle to

be used in your machine. Comparison

with this illustration will determine

whether the needle you have is the cor-

rect one for your machine.

PLACEMENT OF NEEDLE

Raise needle .bar to its highest

position by turning hand wheel

toward you. Loosen needle clamp

screw. Hold the needle so that

the flat side is to your right. Slip

blunt end of needle as far as it

will go into needle clamp. Tighten

needle into place with needle

clamp screw.

:; ::.::

............

Flat

side

faces

to

right.

ill

::::::

°

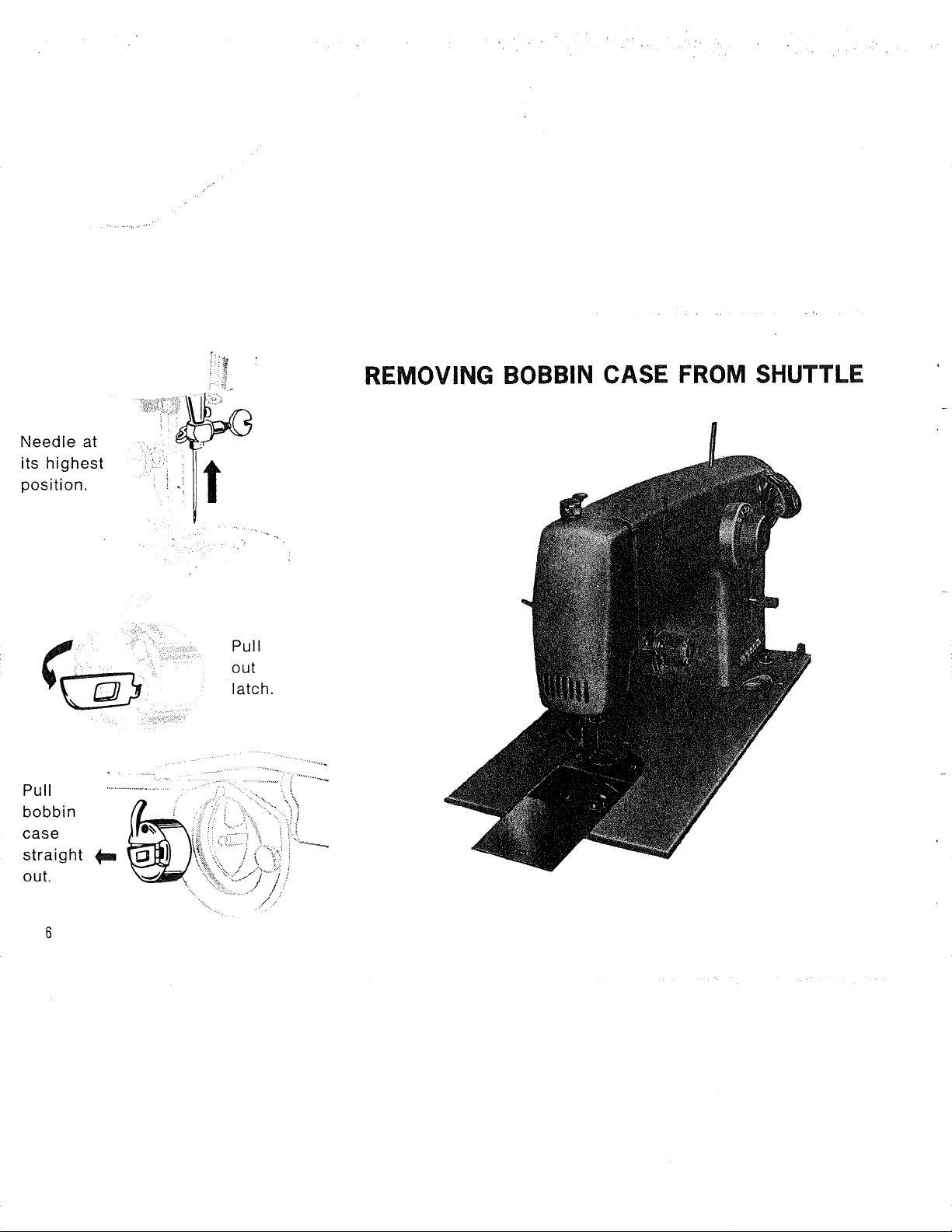

REMOVING BOBBIN CASE FROM SHUTTLE

Needle at

its highest

position.

Pull

bobbin

case

straight

out,

td

_ )i.... "

Pull

out

latch.

............ :....... .............. ; _..........

¢

1

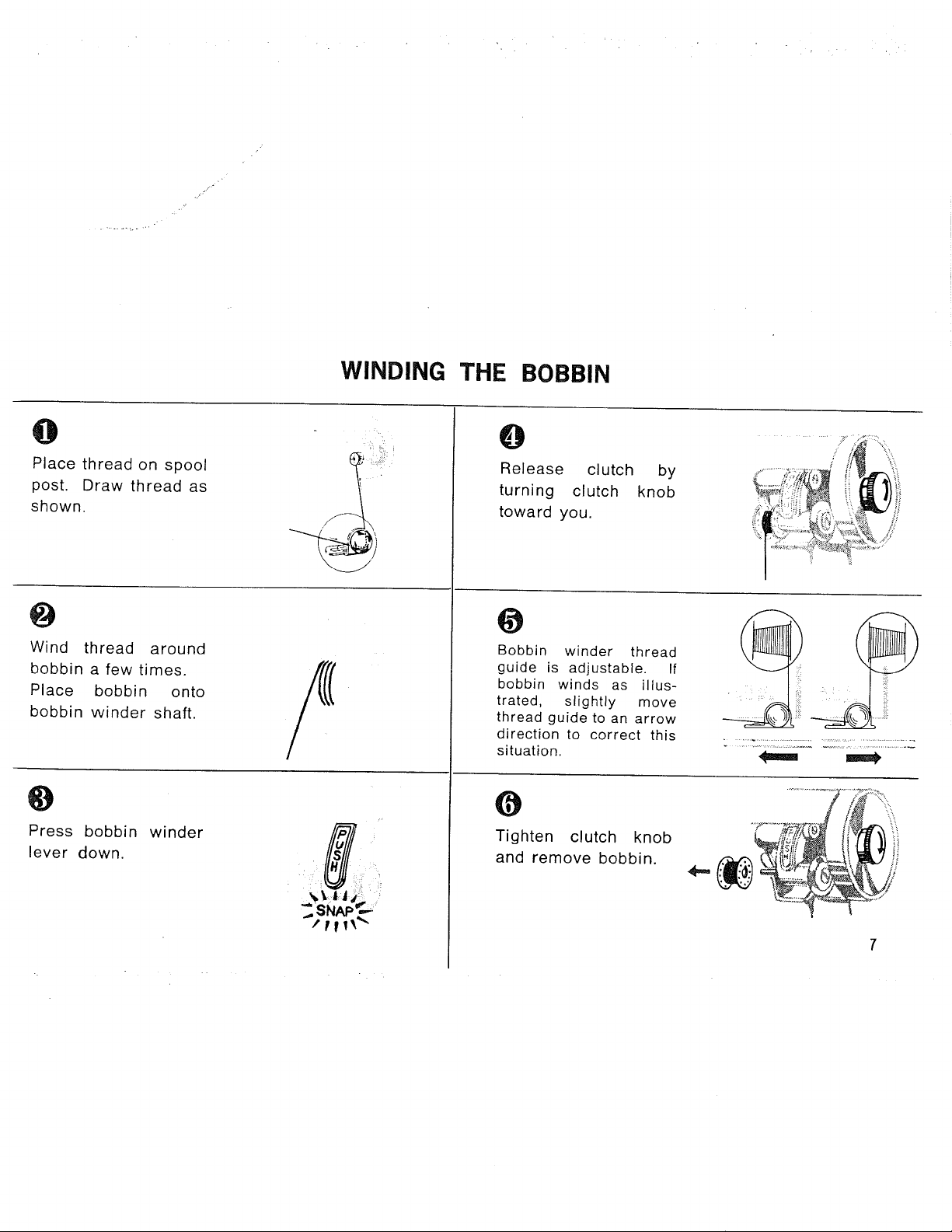

WINDING THE BOBBIN

0

Place thread on spool

post. Draw thread as

shown.

Wind thread around

bobbin a few times.

Place bobbin onto

bobbin winder shaft•

0

Press bobbin winder

lever down.

i_ _iiI

0

Release clutch by

turning clutch knob

toward you.

@

Bobbin winder thread

guide is adjustable• If

bobbin winds as illus-

trated, slightly move

thread guide to an arrow

direction to correct this

situation.

Tighten clutch knob

and remove bobbin.

m

' 1:::, ,_%,,:,i_i_

•i

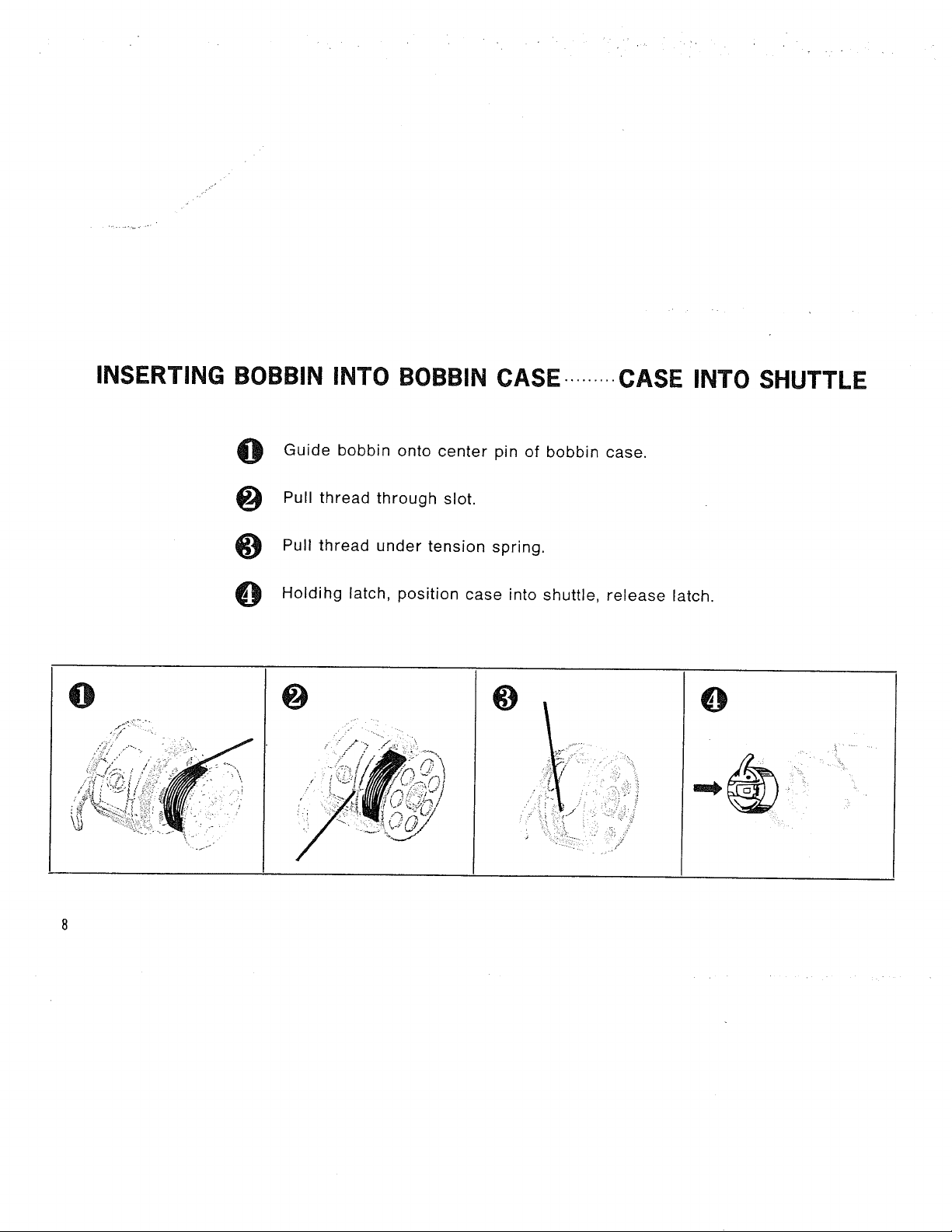

INSERTING BOBBIN INTO BOBBIN CASE .........CASE INTO SHUTTLE

0

Guide bobbin onto center pin of bobbin case.

Pull thread through slot.

0

0

0

Pull thread under tension spring.

Holdihg latch, 3osition case into shuttle, release latch.

_)

0

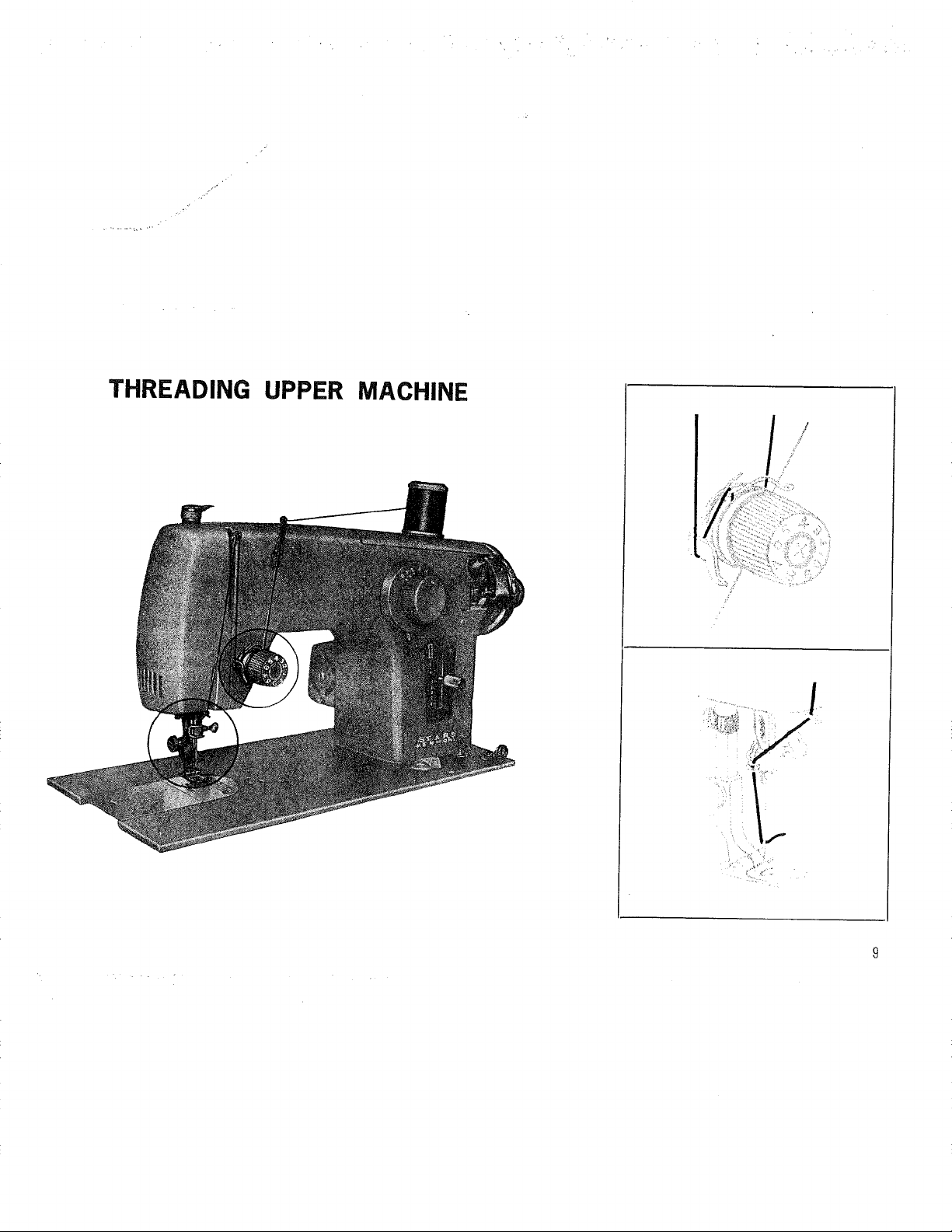

THREADING UPPER

MACHINE

//

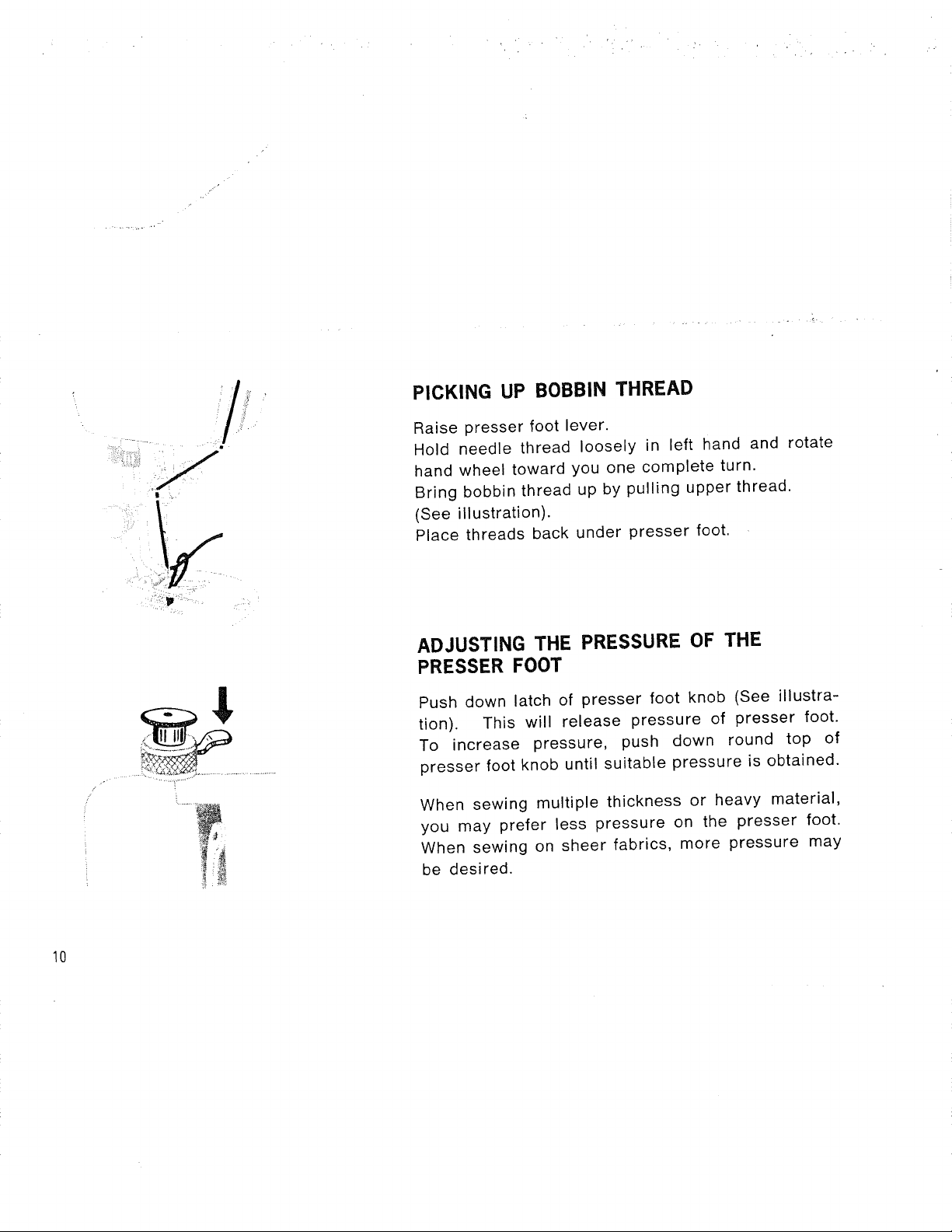

PICKING UP BOBBIN THREAD

Raise presser foot lever.

Hold needle thread loosely in left hand and rotate

hand wheel toward you one complete turn.

|

Bring bobbin thread up by pulling upper thread.

(See illustration).

Place threads back under presser foot.

10

ADJUSTING THE PRESSURE OF THE

PRESSER FOOT

Push down latch of presser foot knob (See illustra-

tion). This will release pressure of presser foot.

To increase pressure, push down round top of

presser foot knob until suitable pressure is obtained.

When sewing multiple thickness or heavy material,

you may prefer less pressure on the presser foot.

When sewing on sheer fabrics, more pressure may

be desired.

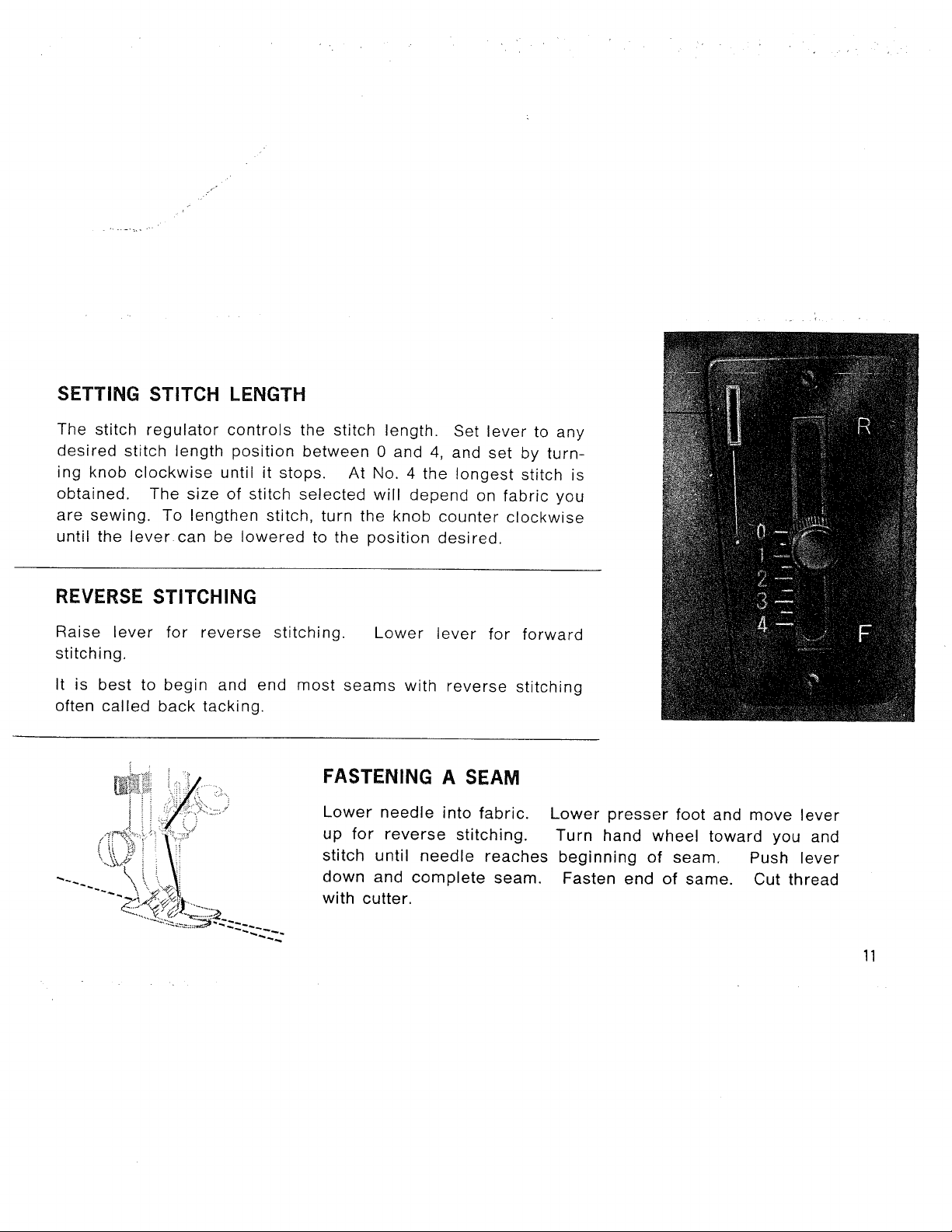

SETTING STITCH LENGTH

The stitch regulator controls the stitch length. Set lever to any

desired stitch length position between 0 and 4, and set by turn-

ing knob clockwise until it stops. At No. 4 the longest stitch is

obtained. The size of stitch selected will depend on fabric you

are sewing. To lengthen stitch, turn the knob counter clockwise

until the lever can be lowered to the position desired.

REVERSE STITCHING

Raise lever for reverse stitching. Lower lever for forward

stitching.

It is best to begin and end most seams with reverse stitching

often called back tacking.

FASTENING A SEAM

Lower needle into fabric. Lower presser foot and move lever

up for reverse stitching. Turn hand wheel toward you and

stitch until needle reaches beginning of seam. Push lever

down and complete seam. Fasten end of same. Cut thread

with cutter.

11

O

, , , , •

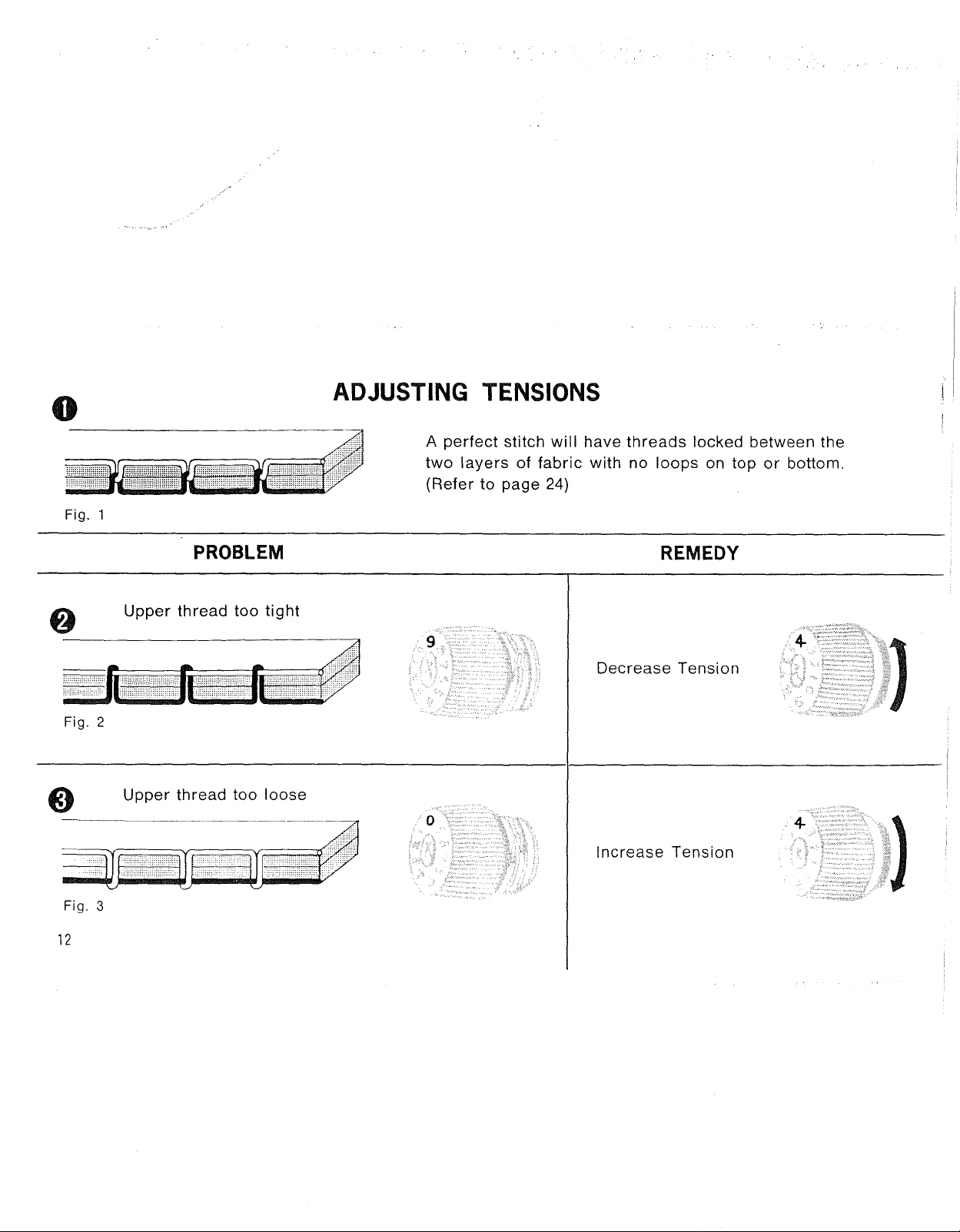

ADJUSTING TENSIONS

A perfect stitch will have threads locked between the

two layers of fabric with no loops on top or bottom.

(Refer to page 24)

Fig. 1

Fig. 2

Fig. 3

12

PROBLEM REMEDY

Upper thread too tight

Decrease Tension

:.[: :-

Upper thread too loose

o ......

Increase Tension

• =

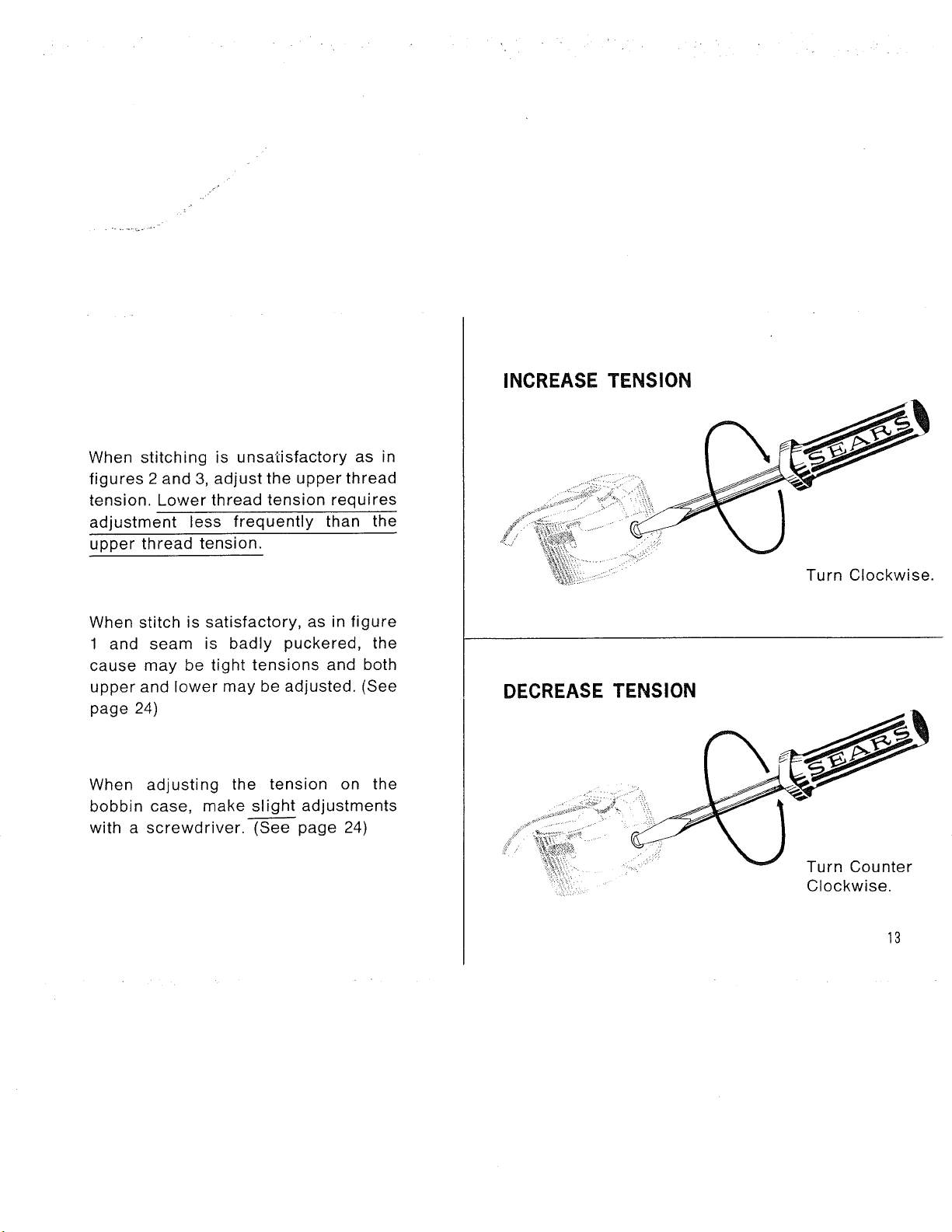

When stitching Is unsatisfactory as in

figures 2 and 3, adjust the upper thread

tension. Lower thread tension requires

adjustment less frequently than the

upper thread tension.

When stitch is satisfactory, as in figure

1 and seam is badly puckered, the

cause may be tight tensions and both

upper and lower may be adjusted. (See

page 24)

INCREASE TENSION

Turn Clockwise.

DECREASE TENSION

When adjusting the tension on the

bobbin case, make slight adjustments

with a screwdriver. (See page 24)

Clockwise.

13

INSERTING AND REMOVING THE MATERIAL

For all kinds of sewing, consult chart on

page 5.

Before placing the material on the machine,

see that:

• The presser foot and needle clamp

screws are both tight.

• The sizes of needle and thread suit the

kind of work to be done.

• The needle and take-up lever are at

their highest position.

The ends of the threads have been drawn

about 4 inches to the rear of the machine.

• The feed dogs are up.

• Stitch length and width controls are set

at desired settings.

Experiment by sewing on the fabric to be

used to determine tension adjustment and

correct stitch settings.

Place material under the presser foot, nsert

the needle into the material by turning the

hand wheel toward you, lower presser foot

and start sewing.

To remove the work, first turn hand wheel

toward you until needle is at its highest

position, then raise the presser foot, draw

material to the rear and cut off excess

thread with the thread cutter located on the

presser bar.

IMPORTANT: Always turn the hand wheel

toward you! When machine is not being

used, place a piece of material over the feed

dog and lower the presser foot. Always have

fabric under the presser foot when operat-

ing the machine. Operating threaded ma-

chine without fabric will cause it to jam by

forcing thread into the shuttle." See page 20.

14

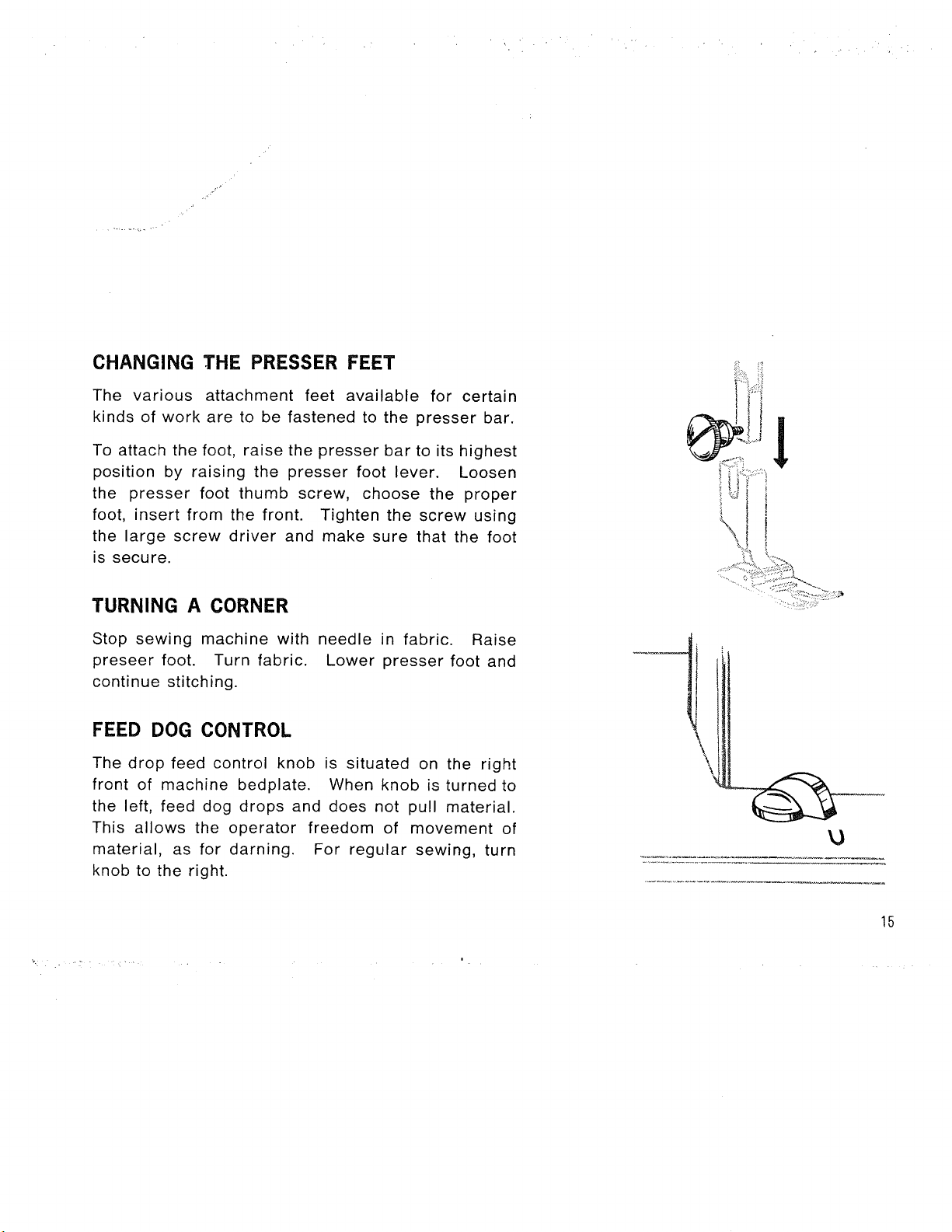

CHANGING THE PRESSER FEET

The various attachment feet available for certain

kinds of work are to be fastened to the presser bar.

To attach the foot, raise the presser bar to its highest

position by raising the presser foot lever. Loosen

the presser foot thumb screw, choose the proper

foot, insert from the front. Tighten the screw using

the large screw driver and make sure that the foot

is secure.

TURNING A CORNER

Stop sewing machine with needle in fabric. Raise

preseer foot. Turn fabric. Lower presser foot and

continue stitching.

FEED DOG CONTROL

The drop feed control knob is situated on the right

front of machine bedplate. When knob is turned to

the left, feed dog drops and does not pull material.

This allows the operator freedom of movement of

material, as for darning. For regular sewing, turn

knob to the right.

!

_J

15

i

Loading...

Loading...