158.19460

158.19461

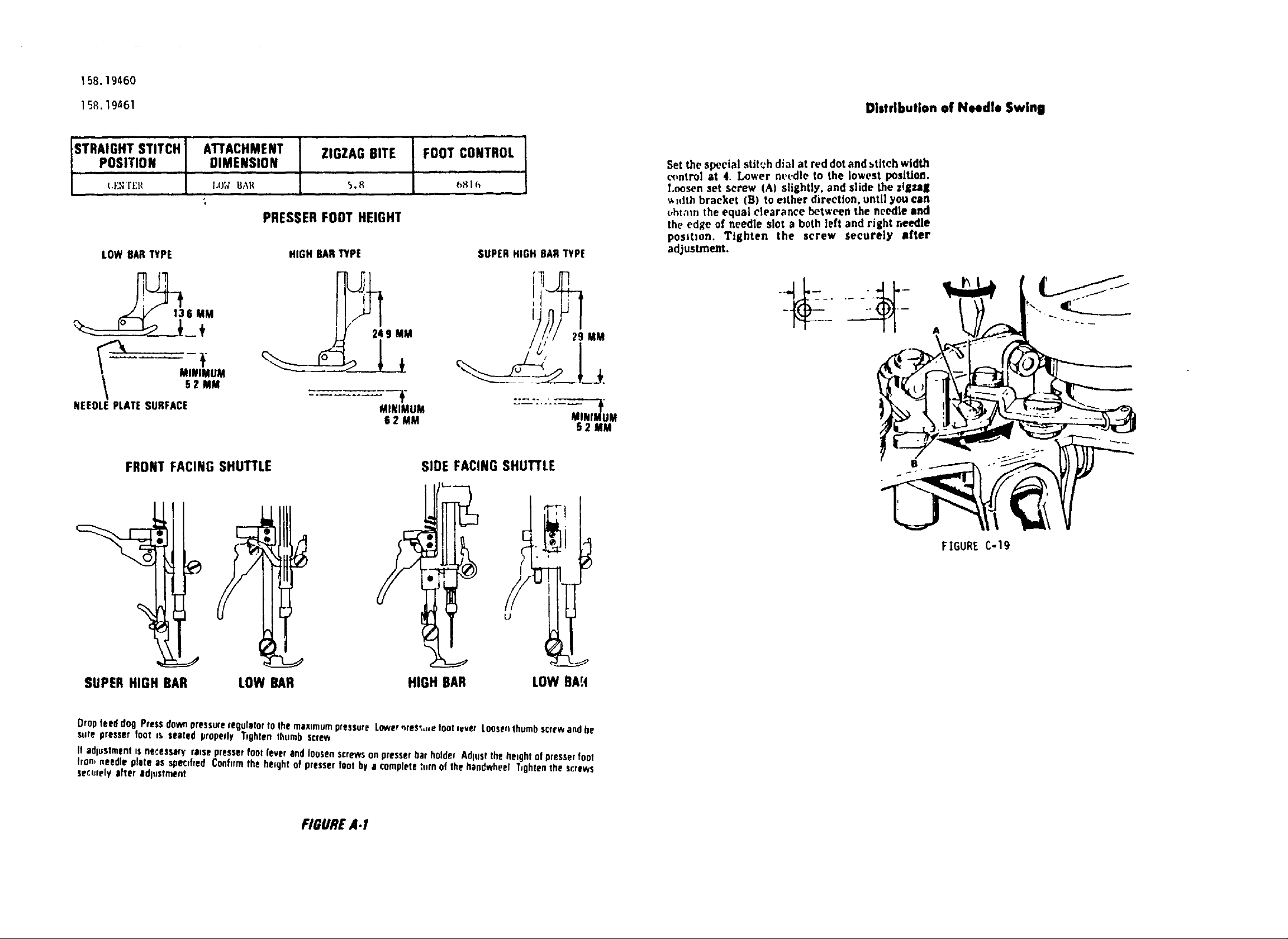

STRAIGHT STITCH ATTACHMENT ZIGZAG BITE FOOT CONTROL

POSITION DIMENSION

(.I':NI't:g 1.t£¢ BAR 5.8 _ I h

PRESSERFOOTHEIGHT

LOW BAR TYPE

6 MM

HIGH BARTYPE

SUPERHIGHBARTYPE

_÷

52 MM

NEEDLE PLATESURFACE

MINIMUM

62 MM

29 MM

52 MM

Distribution of NHdlo Swing

Set the special stlt'_h dial at red dot and stitch width

('_ntrol at 4. Tower needle to the lowest posiUon,

Loosen set screw (A) slightly, and slide the ztgXal

v,lrtth bracket (B) to either direction, until you can

(,htam the equal clearance between the needle and

the edge of needle slot a both left and right needle

positron. Tighten the screw securely after

adjustment.

A

FRONT FACING SHUTTLE

SUPERHIGH BAR LOW BAR

Dropfeed dog Pressdownpressureregulatorto fhe maximumpressure Lower,_res';,J,etootlever Loosenthumbscrew andbe

sure presser foot is seated properly T,ghten thumb screw

ff adlustmentis ne_.essan/raise presser foot lever and loosenscrewson presserbar holder Adlustthe he,ght ofpresserfoot

fromneedle plate as speclfrerJConfirmthe herght of presser foot by e complete,*urnof the handwheel Tightenthe screws

secerely tiler adlostment

SIDE FACINGSHUTTLE

U

HIGH BAR LOW BAt4

FIGURE C-19

FIGUREA.I

158.19460

158.19461

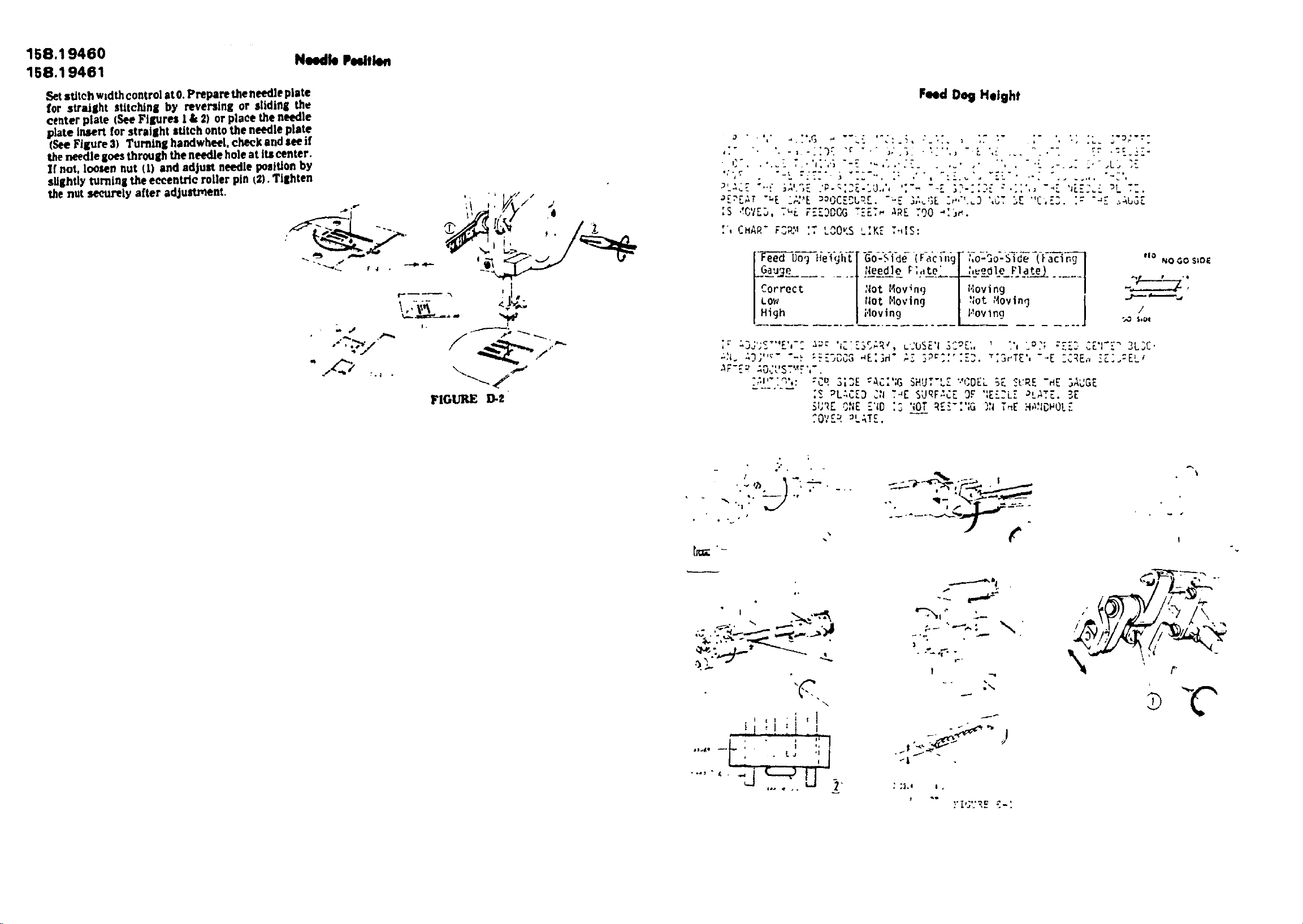

Needle Peelfle.

Set sUteh width control at 0. Prepare the needle plate

for straillht stitchinll by reversing or sliding the

center plate (See Fillure$ I & 2) or place the needle

plate insert for straJllht stitch onto the needle plate

(See Fl&,ure 3) Turnlnll handwheet, cheek and see if

the needle goes through the needle hole at its center.

If not, loosen nut (t) and adjust needle position by

slightly turninl the eeeentrle roller pin (2}. Tillhten

the nut securely after adjustment.

FIGURE D-Z

Feed Dog Height

:} " ' ........,_.. ,G _ " 4.: _'..:_,..'.','.. _ "',, :........ , ., ._. _'_:':'. .

-_[.'[,_T "="E "'' .............

'" . _OKS '' :• , CHAR" _3P_"_'T '^ .,K_ ,,,I.:

F--_ Dog i,eight [-G-o--Si-de-!Facing[ i,o-3o-Side (Facing I .o NOOOS,D{

.Go--_L...... l-_L_t _,,,t__--__,_,__-____rJ.____..... I "I ' "

Correct I :lot14ovlng I Hoving I --_ '

LOW | !lotMoving _ ;lot"4ovlng -_

l High I 'I°ving V '°v Ing J _ ,,o_

_h. _,3;''_""-._:._Z_,OC3_E:;_" ,:_3PC_:''F.]._'3eTZ',"_E ZCRE,-,IZ].:EL_

_F-[_ =,O.'UST'._F',".

-_'":q',: 'Cq 3_3E "AC;';GSHUT'LZ "CDEL 5E ._URE-HE 3AUGE

:_ _LZCZD C'IT_E SURFZCE OF ':E;_._LZaL,_TE.5E

SURE O;;E-"ID:S ';OTRE'.":'iG)N T_E HA:IDHO!-"

COVE_,PLATE.

/

",..:' _]

• ,. :.-_,,-_

._ ,_.4:.._---.._._._,'_!

-L

_'"_" I ""

!

(,

/

=.,

I

1 58.19460

158.19461

Set stitch length control at "0". Turning handwheel,

cheek and see zfthe feed dog moves horizontally. At

"0" position the feed dog should not move. It _tdoes,

loosen screw (A_ and lneert the eeeent_, tool (B_

into the hole (C). Turn the eccentric toole|'.her way

to elinlinate movement of the feed dog. Tighten the

screw (@,_aftPr "_dJu_tment.

Zero-F_ding

NEEDLE TIMING TO SHUTTLE

NEEDLE BAR HEIGHT

THE RADIAL TIMING GAUGES AND TEST PINS, AS

ILLUSTRATED BELOW, ARE AVAILABLE FROM DIVISION

92, SOURCE 192. THE KIT IS IDENTIFIED AS

#69659. EACH GAUGE AND TEST PIN CAN ALSO BE

ORDERED INDIVIDUALLY.

THIS KIT IS USED FOR SOURCE 148 AND 158

VERTICAL BOBBIN S_ING MACHINES.

FIGI.'RE F-I_

IIf.lINGGAUGE _-".,.

RAD'IAL _ i T

_69894 . '- TEST PIr_

_'_ #b9_73

RADIAL _"

TIMING GAUGE

%9892 ',

RADIAL

TIMING GAUGE

#69B93

j

FIGURE G-I e69895

I

RADIAL

TIMING GAUGE

NEEDLETIMINGTOSHUTTLE

On not attempt adJuStmentsother than those spocd,ed m

tills manual Jl. byfollpw,ngthe prescribedprocedures,d is

determinedthat a mach.nPis out of radialtrine, handle per

Bulletin $.820

Radial Timing Gauge

Instructions

I Removeneedle and replaced with test pmwh,ch has e

blunt lip

2 Remove bobbin case and shuttlehook Insert correct \

tad,el timing gauge into shuttle driver

For th,s ntodel(sl use gauge marked

$n _rcJ 158 FROPdT5 8 FRONT4 0

Use FRO?_r 58 mathng

3 Set stitch control at "0""or '5" tdependmg on model

involved)

4 Set needle posJhon controlat center tot n,odels which

have Ibis _ootrol

5 Rol,,te handwheelslo_'dybyhand /SeeFigure G.3a t The

test pm should come between the correct |wo v_r_ical

hoes at the end of the counterclockwiserotation of the

gauge For this modells)useverticallinesidentifiedcnth

one dot

6 Tocheckneedlebarhe_ght. contmuetorotatehsndwheel

slowlybyhand /See FigureG 3b JAt the Iowes;positron

ot the needle bar, the end of the test pin shouldcome

between t_o hoftcontalhnes on the gau,_e

if necessary, adlust needle,bar hllght Loosenscrewon

needle bar holder pod adlusl he,ght on the test pm

DIM[ NSION A

Zig_:ql Synchronization

Set stjiteh width COntrol at maximum. Turning ,,he

handwheeI, check and see if the needle side .-::.orlon

on the standard piano _0o394:nch above the uplP._r

surface ol the needle plate, at both needle p_slt_uPs

.... ., L..-" \\

come wtthin the engineering ]lmR of 0.0138inch. £f

nL," _ooset, set screw s2_ on the wor/n gear eztl_er

direc,;_n. Tighten the screw ,2) securely j,qer

adjustment.

DIMENSIONB

FIGUREG-3

F,gure G.3 gives a general idea of tho use of the radrul

hmmg gauge Follow the snstructronSat the loft wh_h

pinata to th_s modells_

158.1 g460 Straight Stitch

158.19461 Puitlon

Autematicleve, te Stitching

Stmch Stitch

)_. b ', ; ... ," s[ ^'; "_ "'" °"

,.E..L_.*,,,_S TM "_; :_;G"'_''3_ ....

j,R..... _ S _0.,.,. IE:_L_.S_ubL.,';OT ..,.,._.

;S 'IECES_'P'. LOOSe',T..,OSCrEwS _ ,_,1"SE.ET':_ ""_._3

_JlO _'' _ ' ' " '' ''_ne''3,_L OR, ;,EMo'/r ;'IST_" "'.L, 3UT '.j,

3CRE'4_.._F,, "OL_ Z.G::,GGUI3E BAR '.E_........,u.,,,,_P._...... _,",,_'

A_ID"* '

,..R.I3TI'CH .'I.3T#'_.ON"POLA: .......;'" .... 'IA,......I.-.l

..... _ , _-_,,IG.;,F'zRAD_,U...._.,., ._E" S":T_,-

, ÷ .... ..,- ._,. _;l{_.4,D,,_ ,..O,hROL 'G _T RE3 30T, TIGHTE'I _"?c ,r .-'

tSS_4BLE ' r" ?' ; A _ ' ; r LJ O . O : _L .......' ;S_"m ' : t I " '' _. J_', _,._.......

OS..O,i.

". - _.- A ,; . "/_, @ ".: _-

,_t sdteh len_h control at & "lw'clal stJtehdlal at red

:l:o,¢oro ,. ,1.,o

see if Iorwam lt/tehes are equal In lenlth wi_

r_verme stitches by _lzag stitching on IxlPer. If the

length of reverse ltltehel is Ihorter or longer than

that ot forward _tches ' loosen nut (A) and turn

adJu_unent.

. , _ over me feed dolls. Cheek and

. equal m length. Tighten aut (A) after

'I

_I_'RL J'2_

FI ;I.'R:Ti-_,

' "'.'" 1 "V _._-'_ iutematic ltW_ Stitching

If the len_h of reverse sUtehes is shorter or longer

than that of f,_rward stltehes, turn screw IA) either

way until you can obtain the corree b. ce

FIGURE J.l_

fnrwa rd and

Ex_plc ,,f 0

Yever _

stitch._

equal in

length.

159.19460 Avtemotic Mechonism

158.19561 Cam and Cam fellewor Medlonkm

TO tdlust _hl ._eche_._rn, slit the stl_cil _,dttl control it 4

ilnd special _tltch d,al _lt w_n any two _lttln_e. _ _llut'.ret/d

I.o<Hi4n screw (C) e_d _urn trail e¢cent;'_¢ coillr fO) ,n

_lthilf direction a_ _.hown. _ntll you ¢_ln gqt th_P_orrilct

clearance {0 00_ ,nc_) between thil h,gmrst point of c,lm |A)

end cam follower (IlL T,gntiln screw (C| att_t _dlustment

FIGURE K,21

Loading...

Loading...