Ilm#mkmd mmdbk*,e

TIT I AT R

Straight Stitch Attachment Zigzag Bite I_t Control

Position Dimension

i i II III

Left Super High Bar 7.0 6817

' *Left Needle Pos ttonts _t]so referl:ed to as "S" pos ;ton.

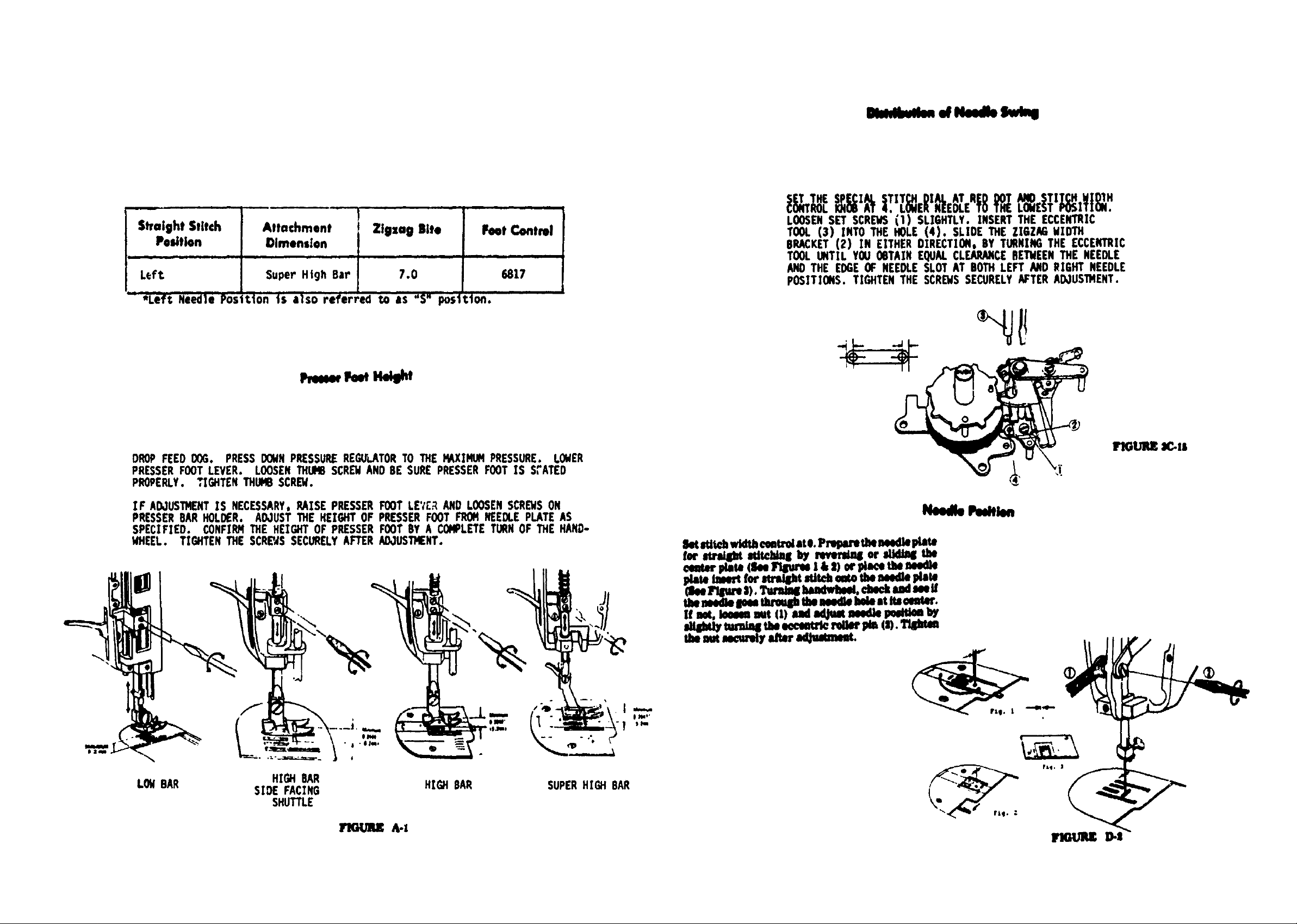

pmoeh,t.,

DROP FEED ODG. PRESS DOMNPRESSUREREGtft.ATORTO THE _XINUtl PRESSURE. LOWER

PRESSERFOOTLEVER. LOOSENTHLIHBSCRENAND BE SURE PRESSERFOOT IS S:'ATED

PROPERLY. TIGHTEN THUMBSCREW.

IF ADJUSTMENTIS NECESSARY,RAISE PRESSERFOOT LETr_ AND LOOSENSCREWSON

PRESSERBARHOL_R. ADJUST THE HEIGHT OF PRESSERFOOT FROMNEEOLEPLATEAS

SPECIFIED. CONFIRMTHE HEIGHT OF PRESSERFOOT BY A COMPLETETURNOF THE HAND-

WHEEL. TIGHTEN THE SCRE'_SSECURELYAFTER N_IUSIMENT.

LOOSENSET SCRENS(i) SLIGHTLY. INSERT THE ECCENTRIC

TOOL (3) INTO THE HOLE (4). SLIDE THE ZlGZkG WIDTH

BRACKET(2) IN EITHER DIRECTION, BY TURNING THE ECCENTRIC

TOOL UNTIL YOU OBTAIN EQUAL CLEARANCEBETMEENTHE NEEDLE

AND THE EDGEOF NEEDLESLOT AT BOTH LEFT AND RIGHT NEEDLE

POSITIONS. TIGHTEN THE SCREMSSECURELYAFTERADJUS1MENT.

IqGUI_ X:.ls

NeedleP_thm

LON BAR

HIGH BAR

SIDE FACING

SHUTTLE

HIGH BAR SUPERHIGH BAR

o.o

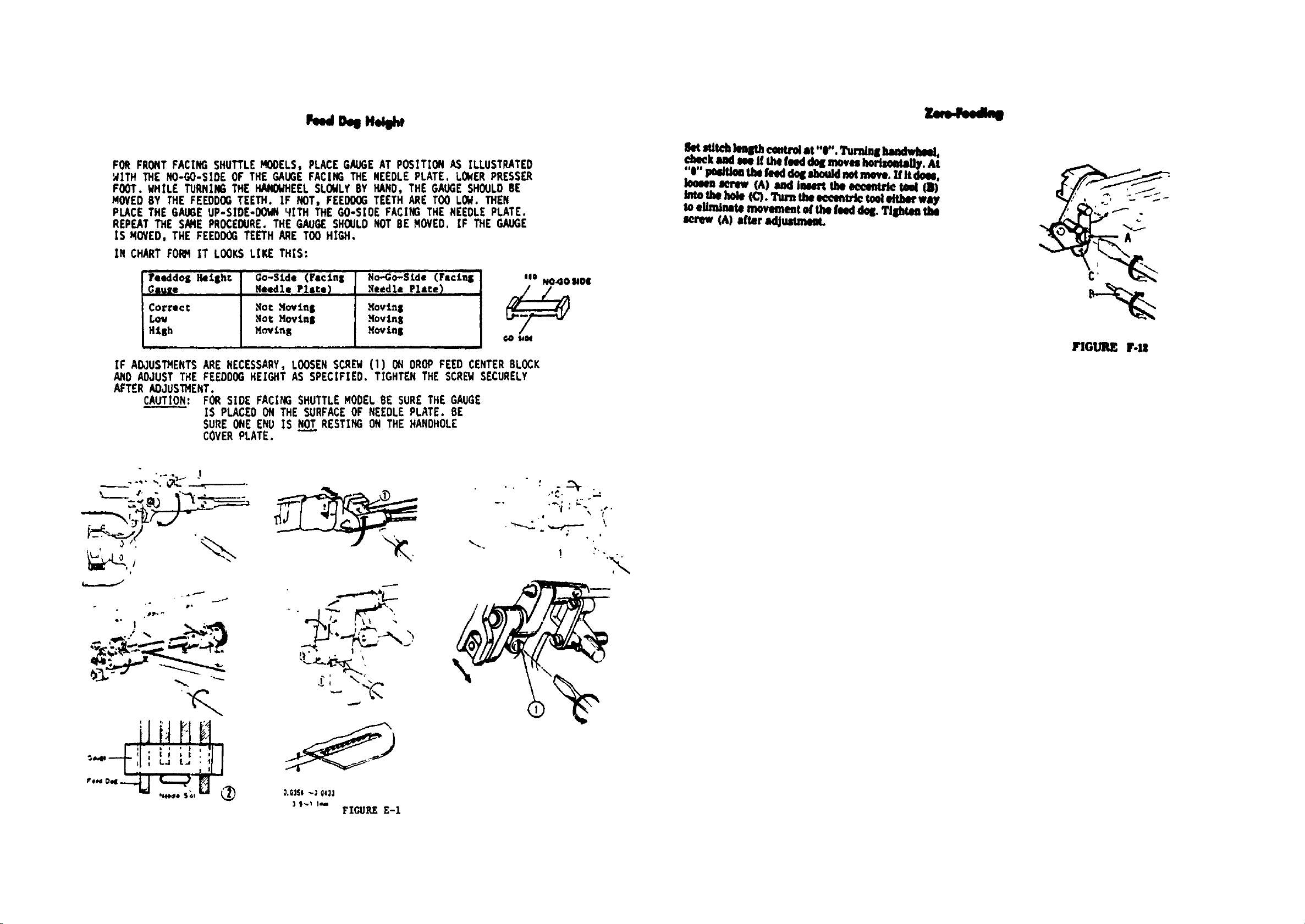

FOR FRONTFACING SHUTTLEMODELS, PLACE GAUGEAT POSITION AS ILLUSTRATED

'AITH THE NO-GO-SIDE OF THE GAUGEFACING THE NEEDLE PLATE. LOWERPRESSER

FOOT. HHILE TURNING THE HANOWHEELSLOWLYBY HAND, THE GAUGESHOULDBE

MOVEDBY THE FEEl)DOGTEETH. IF NOT, FEEDOOGTEETH ARE TOOLOH. THEN

PLACE THE GAUGEUP-SIDE-OOHN '_ITH THE GO-S[DE FACING THE NEEDLEPLATE.

REPEATTHE SAMEPROCEDURE.THE GAUGESHOULDNOTBE HOVEO. IF THE GAUGE

IS qOVED, THE FEEDOOGTEETH ARE TOO HIGH.

IN CHART FOI_4 IT LOOKSLIKE THIS:

[Feeddo$ Ikelsht Go-Side (Fecins No-Go-Side (Faclnl_

Gsu2e NHdle Plste_ _eedle,,Place)

Lov

RtEh

IF AOJUSTHENTSARE NECESSARY,LOOSENSCREH (1) ON DROPFEEO CENTERBLOCK

AN0 ADJUST THE FEEDDGOHEIGHT AS SPECIFIE0. TIGHTEN THE SCREHSECURELY

AFTER AOJUSTHENT.

CAUTIO_____N:FOR SIDE FACING SHUTTLEMODELBE SURETHE GAUGE

[S PLACE0 ON THE SURFACEOF NEEDLEPLATE. BE

SURE ONEENU IS HO_T.TRESTING ON THE HAHOHOLE

COVERPLATE.

Hot Novtn$

Mot Hovtn$

Movtn8

._ovtnS

HoVLnll Go_H

lk_ _t_ lenlPh_"a_-d at "0". l_rni_ hancheheeL

'-'hockMd He ff thefNd dol_movu IsorisoetaHy.At

"O"Poiltk_ tla fe_l dot shouldad laove, if it d_a,

Iomm aerme (k) add imert the eeeoaSrletool _)

Imo II_ hol_ (C) •Turn U_ o¢._nlrle I_I Mtbo_way

toelJminaUimovementof the feeddoll Tlshtm the

screw (A) after _lJussmem.

FIGURE F.IS

.o

• ':_L-'__ _/,,--_'.

_ __-r-

B-

-r..

' "" 'II

,...o.,

_ | .

0.01SO-} 04_l

e

.. . .£_ .

! ,".

._)

\

FIGURE E-I

Needle Timlql te Shuttle

.dq Shv

/hr H,k

(INSTRUCTION FOR RAOIAL TIMING GAUGE)

USE IOURCEIU .FRONT?JISFRONTTJO HDURCE|iIO ,FRONTli.I |FRONT4.11 IOURCE1H

GAUGE $10E4,1

USE • FRONT 7.0 $ FRONT 7JO • FRONT SJ | FRONT4,0

MARK

I|1 10eeO 341 Fm Stmllle

lU 11041 103O0 343 Mod*ll

lee 17010 103Ol 33O

120 17011 10302 121

m 17012 103O4 U2

Nil 1103O 10400 See

922 17031 17741 12010 10401 640

_14 17002 13OEO 1O4O2 041

17000 17033 131110 10430 143

I_001 17011 13180 10140 113O

17490 18011 13180 101144 182

1_$10 11020 13100 liH_I0 3O0

13oI0 11021 901

m

10130 17900 _0

10101 17S70

11143, 17S71 =

m4_ 170TZ am

11143_ 17740 12110

11140 1111119 10941 841

lW

13o22

13o_

13o_4

18o3o

13o_11

13o_

10033

16O34

1M3o

10131

1_00

131101

1321O

lee3o

1M70

13471

leelO

1_1

14W0

14001

14402

14O03

14100

14101

143OO

143O1

14310

14311

11144

1B1EO

13100

13O01

10010

13011

13o1|

14_10

11021

1E210

1L1M

18410

1143o

leO0

14310

10000

10040

1720O

1T3O4

17110

171H;0

17001

11113O

1_3O

11_10

1Mll

• 19400

1N10

19411

1Mll

1_40

19441

11470

19471

3O2

3O3

144

3ON

18000

'_lOdell v_n,¢n _ ntst olive I center needle ;)oSitlOl for

$tri_t stltctting must _e f41 to the canter position _4fore

Jslng thl rid,ld tlmln 9 gauge If the '.ow air Al,nment

Gauge ,s av4,11Oie, the following method rely _1 use,*.

F,rst. insert ",Hi pin with blunt t'O ar_ tigtltefl needle

¢14m0 I¢tt, w securelv Place p4ttesn d_ numUer 1081

18. or r_mber 26842 (acc_tdm 9 to the model) onto the

cam dr_ver mlft and turn ,t i_v hind until the cam follower

12) to_llel the Cam s_rface at the mixiff%lm dUlm•ter of

thll dilx_. On models thet hey• th4 Sse41d_d ,TIHtt l:_ilt in.

set the s_el StitCh di_l to the '_°' _boa.

Rem_:rve .the prester foot and Ittech the tow g4r Align.

merit Gauge oato the _resser b4r. LeVite center needle

Position 0Y rot4tmg stitch width c_ttrol until the test

Om €omes to t1_e C hole on the gluge I_ 1hewn. Confirm

tett ;)in _s,n C hole, raise the needle bit t)v rotating h_ld.

wheel, remove me geuge.

Check ttle rldii! timing and needle _lr height follo_nQ

th• instructions dnder G,3.

FIOURE 64

zi q

Set stitch wld_ eoatrol at maxLmum. 'rumin8 the

Imadwl_el. cl_lek Ind m if the needle lid• moUon

oa the stMdlrd pllme (0._414inch above the upper

lit/ace el Ull needle phlte) at botliillll_tl polliUolli

eon_, within the enllineerLol limit el 0.0131Lacb. I!

aot, _ set screw (2) on _e worm sear elUaer

dlre,..Uon. Tl|lht_ the screw (2) lecurely slier

lldJulltnlent.

The redi81 timing ghulPs and telt plflS,el |iluStrot4(I below, Me ev|ilible through Oep4rtment 20a, _RJI9o only. The kit

isidentified N _.

/

. ,,, .t .. \

i,"" <.l.J \

,.

l: O,OI ll" (O._O_i F'tGI H_

StraightStitch

Pedtkm

REJ40VEAI_4 COVER. SET STITCH WIDTH CONTROLAT RED S OR

DOT. CHECKTO SEE IF THE NEEDLE SWINGSBY MOVING ZIGZAG

GUIDE BASE (C) IN EITHER DIRECTION AS SHOgN. NEEDLE

SHOULDNOT SWING. IF AO,JUS'ff4ENTIS NECESSARY.LOOSEN

SCREW(A). HOLD ZIGZAG GUIDE BAR (O) DOHI_AROSLIGHTLY.

SET STITCH wIDTH CONTROL(B) AT RED S OR DOT ANDTIGHTEN

SCREW(A).

C

D

B

A

?IGUREI-9

0

Avlwm_ Mechee4m

CamendCemfeJlewerMechenlem

kme.mkrevue,Semkkq

hlmdude

If the le_Msbof mverne 84ttebm JsJhortor or ioqer

_ or cumer.dedtwiN, _ you €_n oeunn

Iiw arts_t lmbwce.

Set zJIBI width _ at 4, special stitch dhd at

], Jtlt_ le_l_ m_ it I 8_1Jpe_ll stitch WJl

at middle p_tton between S t_l L. Place m

pathn'n _m into the nuJch_e_i U a i_ttUn'ndi_

_orr_ pattern (u JUum'at_). J_Uwt

themacb_ in the toilowin8 waT. Lowensets_'ew

(1). lwer_ e_%*enurictool (2) LMotheho_e($) andt_m

the tad to either _ (dodmlN or €ouator-

(dockwiM) to move the phKe (4) as WuJtI"shKL

?tShUm t_e s_rew (1) Ncur_ alter adjustment.

FIGURE J-tlA

M limit o1101_111 lU=_m _,.._l--. ,mill v0U

(RI €_IocI_eto41or €_Jlnm"cmmLwmm, ---" -+..

am---_In +dSeax'rect MIsnCe.Tllhten Wenut t^+

jdwrj4jwunent.

FIGUIUE J-IIB

Cam Selector Guide Plate Setting

_It Stlt_9_ llnqtll dill It + Ind 51_41€1115t, t¢_ dill •€ "S" or

rld dot. Thl cam follOW4_f _1ould align _ith • C•m ii shOWn

If not, loosen nut !A). and turn lC¢lntr_€ screw (l_l sl+_jdltly

tO 411thlt dirlction (countlrclockw_s4 or <:lockw_Se) SO that

thl fOIlOWt_' aligns w_th ,1 jm. Ti_lhten n_1 tA_ SIl_'+Jfe_

aft•r adjustment.

X _oo<1 X

Pattern

A

F_GUK_,_-S

Loading...

Loading...