Kenmore 1581789180 Owner’s Manual

SERVICE MANUAL

II

MODLL INFOR_T_[ON

15aJ.1789180

• Attact_,ent dlmens_on

n,v,H. .c

Super high bar

• Built - in buttonholer

• Euttonholer attach_.ent

t Shuttle system

• Drop feed dog

• Clutch system for bobbzn winding

• "'eedle positlon

• Cam _haft ¢_cle

• ZzgZag blght

• Stztch _elections

• Meter

• Foot control

" Others

One touch buttonholer

Snap-in (F-type)

Xorizontal full rotary

chu_tle

Feed cover plate

Automatic push-pull clutch

I_,C,L

1:3,1,24

5.8

24 stations

(1 station for BH)

YM45B (65001)

Y4.250 (54867)

2 speed motor

Snap-on foot

model

i

1789180

5tztch package (Built-in)

(Ut_lzty-9) (Stretch-9)

btrazgnt

2_gZag

Mcn_zr,g

51_rd

Box (fancy)

Fagoting

Shell her.

2-p_znt shell

Llastlc shell

Ftrazght

R_ck-rack

Smocking

Overcast

[iastic

Overedge

Patching

Overlock

Elastic edge

(Decorative-5)

Diamond

Do. ino

Scallop

Arrow head

Pyramid

NEEDLE BAR HEZGHT

USE GAUGE KIT No. 68173

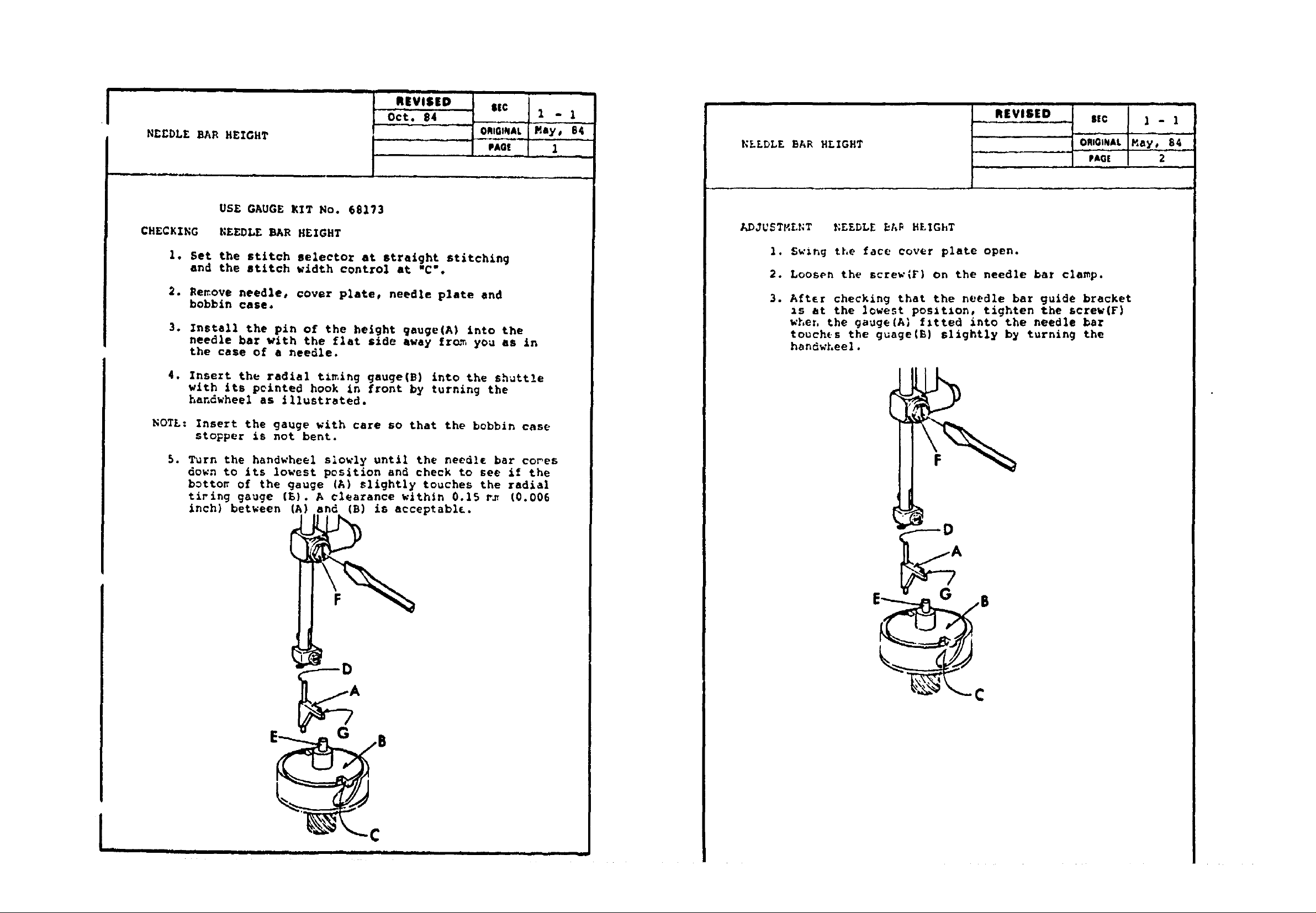

CHECKING NEEDLE BAR HEIGHT

REVILED SIC

Oct. 84 I - 1

+ ommm,L KJy, s4

PAO! l

NELDLE BAR HEIGHT

ADJUdTHLNT _EEDLE _A% HE%GhT

REVISED

$sc 1 - 1

ORIGINAL May, S4

PAG[ 2

le

Set the stitch selector at straight stitching

and the stitch width control at "C'.

2.

Re_ove needle, cover plate, needle plate end

bobbin case.

3. Install the pin of the height gauge(A) into the

needle bar with the flat side away fr_. you as in

the case of a needle.

4. Insert the radial t_ing gauge(B) into the shuttle

with its pclnted hook in front by turning the

handwheel as illustrated.

NOTE: Insert the gauge with care so that the bobbin case

stopper is not bent.

5. Turn the handwheel slowly until the needle bar co_es

down to its lowest position and check to see if the

botto_ of the gauge (A) slightly touches the radial

tiring gauge (_). A clearance within 0.15 r_ (0.006

inch) between (A) and (B) is acceptabl_.

1. Swlng the face cover plate open.

2. Loosen the screw(F} on the needle bar clamp.

3. After checking that the needle bar guide bracket

_s at the lowest pos_t_on, tighten the screw(F)

whet, the gauge(A_ f;tted into the needle bar

touches the guage{E) slightly by turning the

hsndwheel.

LD

I_

F

G

, ,, ................ iII i iii , ,,.,.

G

¢

,iris=p__1 ,,: . ; -

NEEDLE TIMIt;G TO SHUTTLE

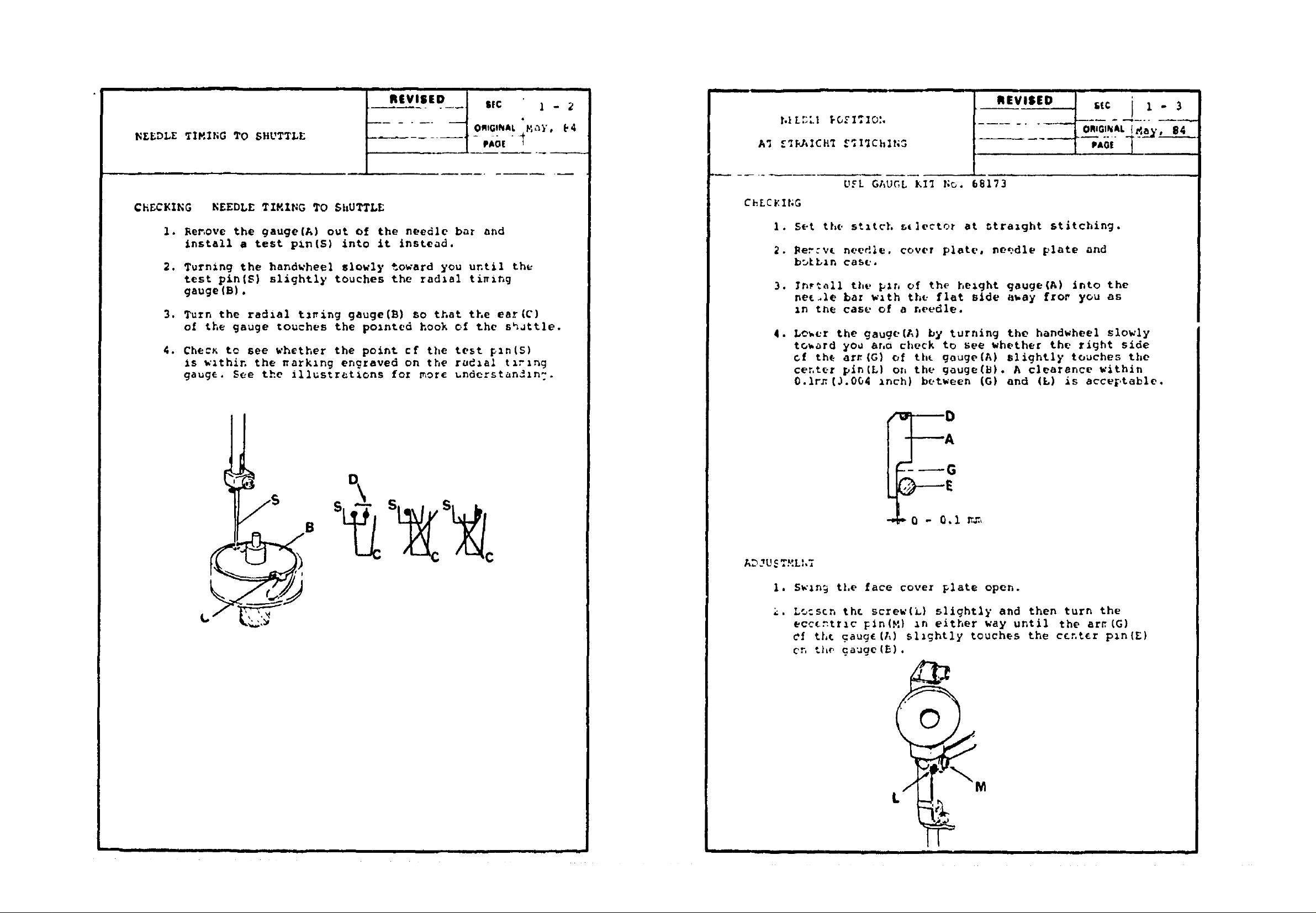

CHECKING NEEDLE TZMZNG TO $itUTTLE

1. Renove the gauge(A) out of the needle bar and

install a test pin(S) into it instead•

Turning the handwheel slowly toward you until th_

teat pin(S) slightly touches the radial ti_ng

gauge(B),

,

Turn the ra_ial t_ing gauge(B) so that the ear(C)

of the gauge touches the polnted hook of the shuttle.

4. Che:_ to see whether the point cf the test p_n(S)

Is within the narklng engraved on the radial txrlng

gauge. See the illustretions fez more understandln?.

I u i

J

Aq .e3KAICB_ _,I_Chlt, o

J .,= j 1.3

UEL GAUGL KIT l;_. 68173

ChLC_I_;G

1. Set the stxtch 5+lector at _tralght stitching.

2. Rer:vt needle, cover plat(,, needle plate and

buLLxn cas_..

3, Inr_all the plr, of the height gauge(A) into the

me_le bar wlth the flat slde a_ay fror yOU as

In t_e case of a needl_.

•

Lo_cr the gauge(A] by turning %he handwheel slowly

to_ard you ano check to see whether the right side

cf th_ am(G) of thL gouge(A) slightly touches the

center pln(L) on the gauge(B)• A clearance within

0.1rz(3.0O4 Inch} between (G) and (L) is accvF,table.

D

--_G

AD. U.... L,,_

1. Swln9 tl,e face cover plate open.

2. L_:stn th_ screw(L) slightly and then turn the

ecc_ntrlc Fin(M) _n either way until the ar_(G)

Cf tL_ gaug£(A) slightly touches the c£nt_r pln{£)

Cn the gauge(5).

[ i[

i

DISTRIBUTION OF NLEDLE SWING

REVISED

s_c I

PAGE '

I ° 4

I I

L-_ _CSI_LOhL_

REVISED

ORIGINAL

t SIC

PAGE

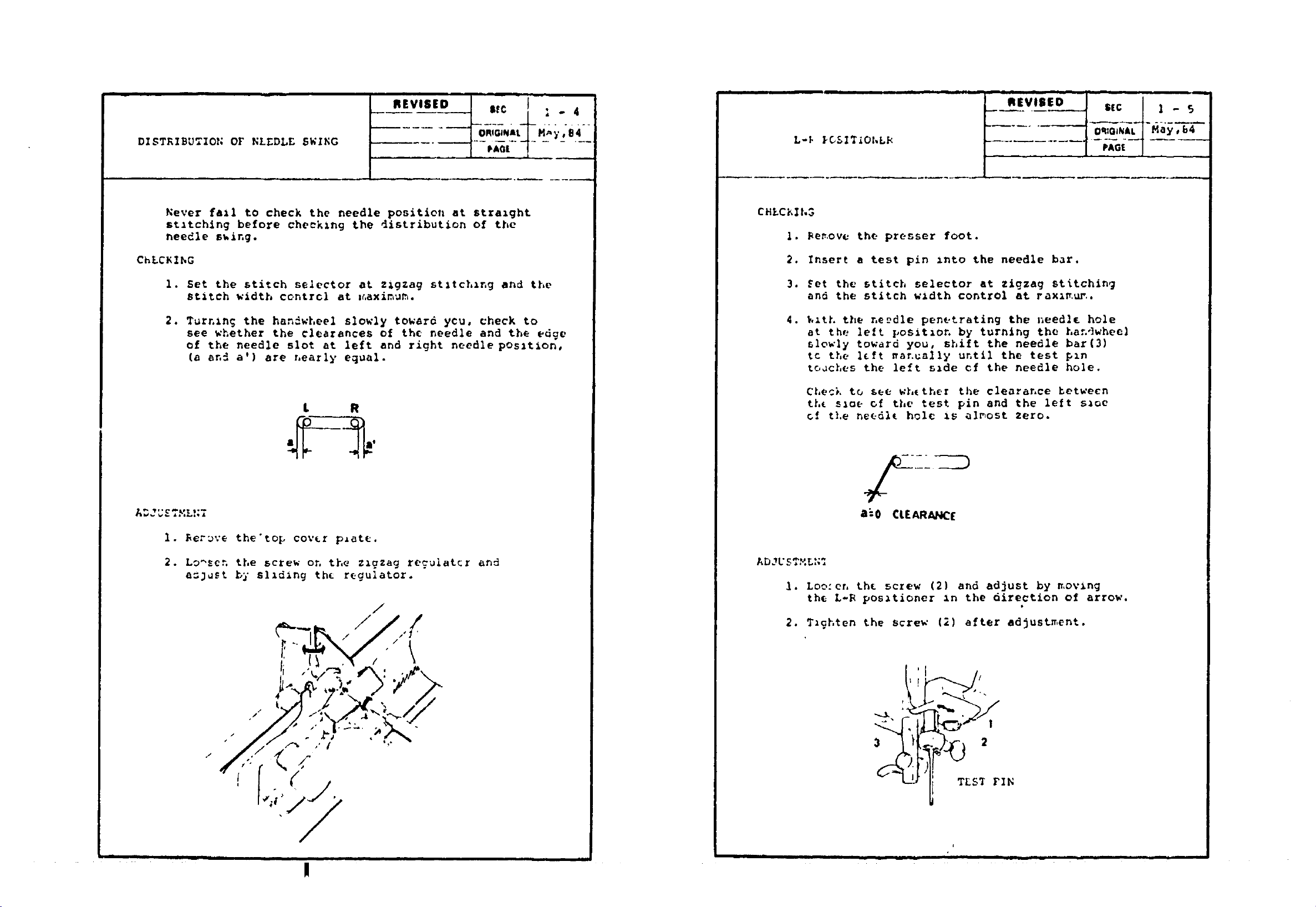

Never fail to check the needle position at straight

stitching before checking the distribution Of the

needle s_ing.

ChLCKZhG

I. Set the stitch selector at zigzag stltchlng and the

stitch width contrcl at :_,aximu_.

2. Turning the han_wheel slowly toward ycu, check to

see whether the clearances of the needle and the edge

of the needle slot at left and right needle posltion,

(a an_ a') are nearly equal.

L R

• _- Ia'

ADJUSTML_;_

CHiCl_lh3

i. _e_ove the presser foot.

2. Insert a test pin into the needle bar.

3. Set the stitch selector at zigzag stitching

and the stitch width control at raxi_.ur..

4.

_ith the needle penetrating the needle hole

at the left posit_on by turning the hanqwheel

slowly toward you, shift the needle bar(3)

tc the left _ar.ually until the test pin

%oJches the left side cf the needle hole.

Check to see wh_ther the clearance between

th_ sloe of the test pin and the left sloe

of t].e ne_dl_ hole is almost zero.

a_o CLEARANC[

I. _erDve the'top cover p_at_.

2. Lo_sen the screw on the zigzag reculatcr and

a_uSt by sliding th_ r_gulator.

/

......................... , ,=,,

ADJUSTMLN:

I. Loe:en th_ screw (2) and adjust by ,.ovlng

the L-B posztioner In the direction of arrow.

2. Tzghten the screw [2) after adjustment.

r

i Jill II

Loading...

Loading...