Kenmore 15813470 Owner’s Manual

INSTRUCTIONS

MODEL[

3470

ZIG o ZAG

i

i b p!r

•._Q_i:i._,

Sears, Roebuck and Co.

Dear Homem_i_er :

You have just invested in a very fine zigzag sewing machine,.

Before using your new Kenmore machine, please pause for a

moment and carefully read this booklet which contains

instructions on how to operate and care for your machine.

specific instructions are given on threading, tension

a_justments, cleaning, oiling, etco This Will help you

obtain the best sewing results and avoid unnecessa_/

service expense for conditions beyond our control°

AOvice on the operation and care of your machine is always

available at your nearest Sears Retail Store.. Should you

have any further questions on your sewing machine, please

write to me at the address given below._

Please remember, an}' correspondence or reference to your

machine must mention the mode! number and serials,number

of your machine,.

Kenmore Sewin_ Machine

Record in space provided below the model

number and serial number of this appliance°

The model number and serial number are

located on _e nomenclature plate, as

identified on Page 2 of _is booklet°

Mode! No_ Serial NO_

Retain these nun_ers for future reference.

_,,::::i:,__/_i_

<••i!kp::!

] .

Consumer Services Manager

Department 620

Simpsons-Sears Limited

Yoronto, Ontario, Canada

Consumer Services Manager

Department 620

Sears, Roebuck and Co.

Sears Tower

Chicago, Illinois 60684

TABLE OF

CONTENTS

Section

_[ Knowing Your Sewing Machine

identifying Parts ..................... 2, 3

Installing Machine ................... 4

Winding the Bobbin .......................... 5

Threading the Bobbin Case ................... 6

Threading of Top Thread .... 7

Using the Controls

Top Tension Control .................... 8, 9

Bobbin Tension Adjusting ................. 10

Checking Tensions ........................ 11

Stitch Width Control .................. 12, 13

Stitch Length Control ................... 12, 13

Reverse Stitch Control ................. 14

Special Stitch Dial .......................... 15

Pressure Regulator ..................... 16

Feed Dog Control ...................... 17

Sewing Light ................................. 17

Seam Guides .......................... t8

Presser Foot Lever ..................... 18

Accessories

Needles ........................................ 19

Needle, Thread, Fabric Chart ............ 20

Presser Feet .................................. 21

Buttonhole Attachment .................. 22

Section ]_ Starting to Sew ............... 1

Garment Construction Stitches

Straight Stitching ....................... 2

Zigzag Stitching ..................... 3

Stretch Stitching ......................... 4

Special Finishing Stitches

Satin Stitching ..................... 5

Zipper Application .................... 6

Buttonhole Making ........................ 7

Appliqueing ................................. 8

Blind Hemming .................................. 8,9

Mending, Darning .............................. 10

Button Sewing, Bar Tacking ................ 11

Section ]]_ Checking Performance Problems

Section IV" Caring for the Machine

Cleaning Feed Dogs and Shuttle ............. i

Oiling Under Arm Cover Plate ............. 2

Oiling Underside .............................. 3

Oiling in Face Cover Plate ................... 3

Parts List ..................................... 5, 6

• i• : •_ •• •

®

®

®

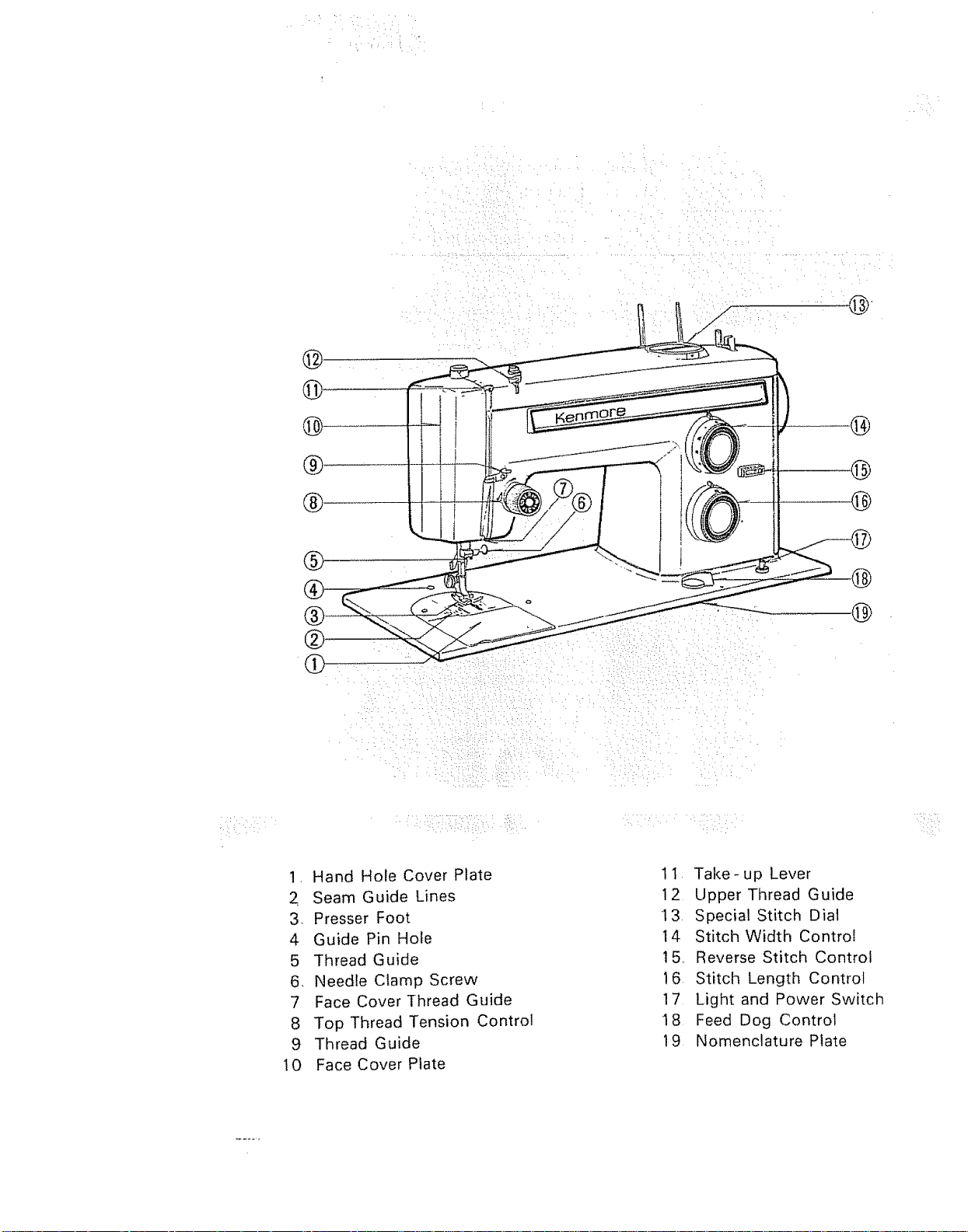

1, Hand Hole Cover Plate

2 Seam Guide Lines

3, Presser Foot

4 Guide Pin Ho_e

5 Thread Guide

6, Needle Clamp Screw

7 Face Cover Thread Guide

8 Top Thread Tension Control

9 Thread Guide

10 Face Cover Plate

@

..... • r•

11 Take- up Lever

12 Upper Thread Guide

13 Special Stitch Dial

14 Stitch Width Control

15,, Reverse Stitch Control

16, Stitch Length Control

17 Light and Power Switch

18 Feed Dog Control

19 Nomenclature Plate

@

@

@

@

@

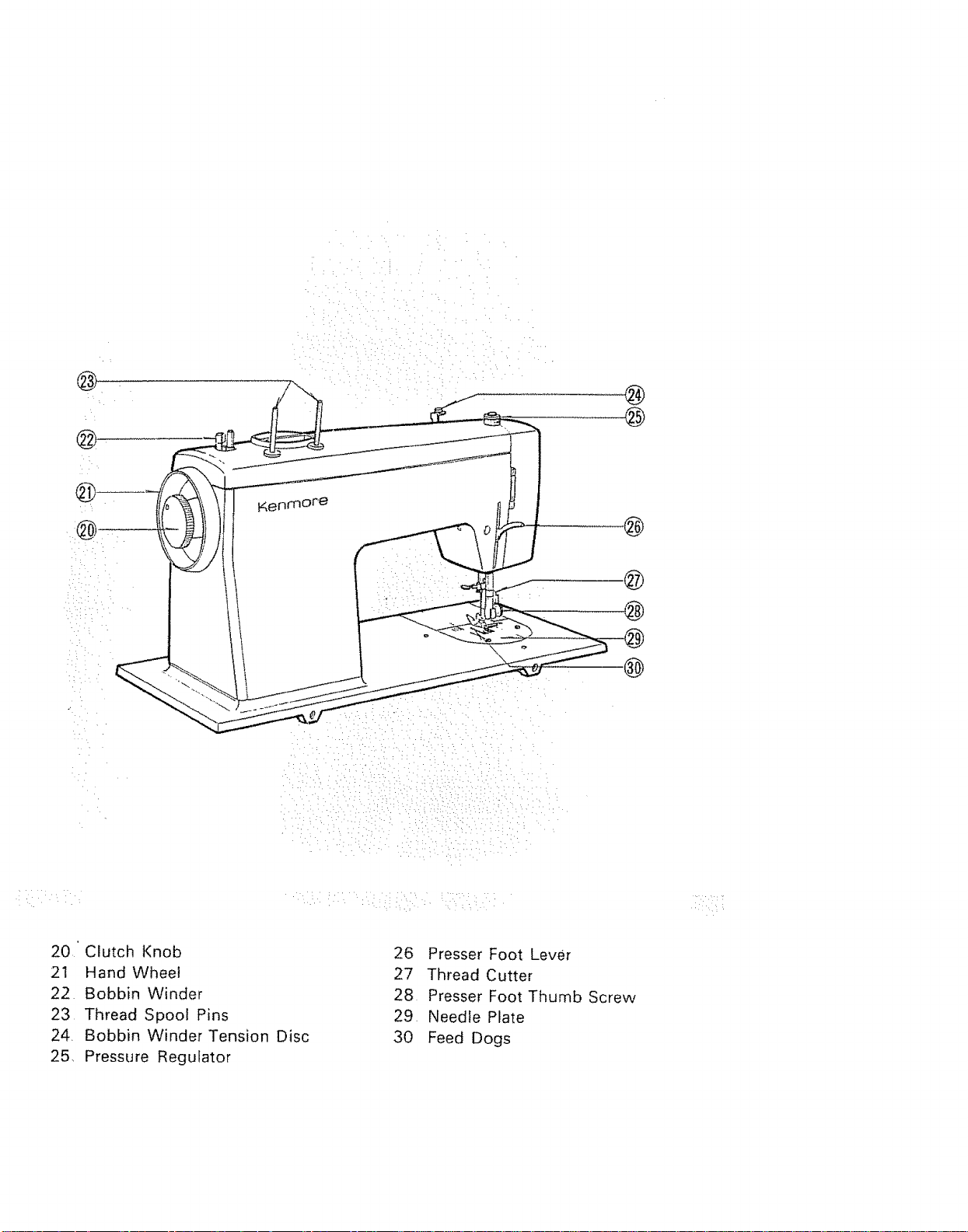

20' Clutch Knob

21 Hand Wheel

22 Bobbin Winder

23 Thread Spool Pins

24. Bobbin Winder Tension Disc

25. Pressure Regulator

• .:• i•:• "::LI::i!::,i':•;•:._:I:Y:•••¸/•

26 Presser Foot Lever

27 Thread Cutter

28 Presser Foot Thumb Screw

29 Needle Plate

30 Feed Dogs

®

®

®

jl

J

; :;ii:_i :;iiii;i:!:i_i_ii:!_i!ii_i_¸; _: ;:i/{;/:_!_:_;!iii_!iiii_i_:i_:;_:_ : i •

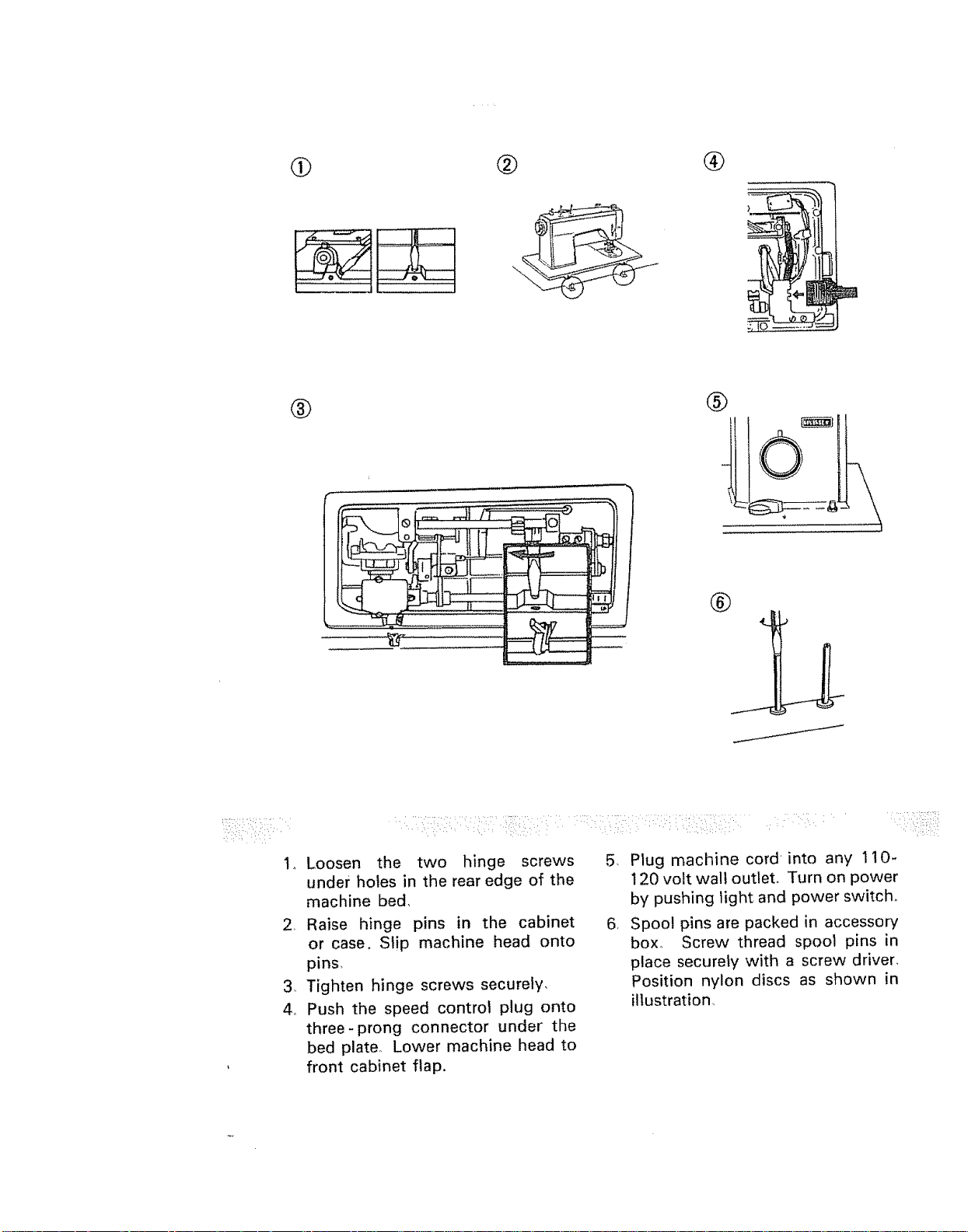

1o Loosen the two hinge screws

under holes in the rear edge of the

machine bed,

2, Raise hinge pins in the cabinet

or case. Sfip machine head onto

pins,

3 Tighten hinge screws securely,

4o Push the speed control plug onto

three-prong connector under the

bed plate_ Lower machine head to

front cabinet flap.

54

Plug machine cord into any 110-

120 volt walt outlet° Turn on power

by pushing light and power switch.

r

Spool pins are packed in accessory

box. Screw thread spool pins in

place securely with a screw driver.

Position nylon discs as shown in

illustration,

®

®

/

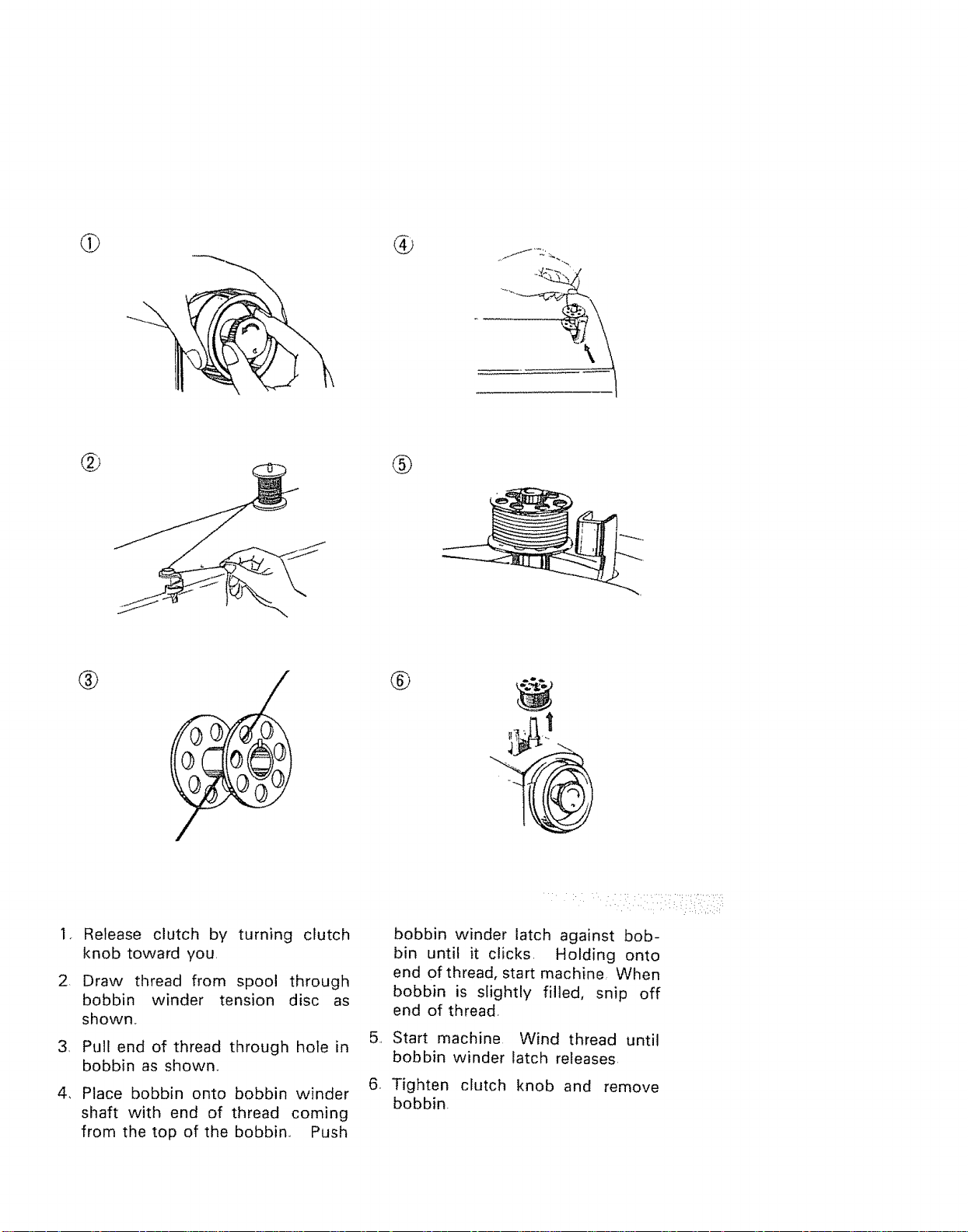

1. Release clutch by turning clutch

knob toward you,

2, Draw thread from spool through

bobbin winder tension disc as

shown,,

3, Pull end of thread through hole in

bobbin as shown.

4, Place bobbin onto bobbin winder

shaft with end of thread coming

from the top of the bobbin_ Push

®

:i:i: =

bobbin winder latch against bob-

bin until it clicks. Holding onto

end of thread, start machine, When

bobbin is slightly filled, snip off

end of thread,

5,, Start machine, Wind thread until

bobbin winder latch releases

6. Tighten clutch knob and remove

bobbin,

®

®

®

®

®

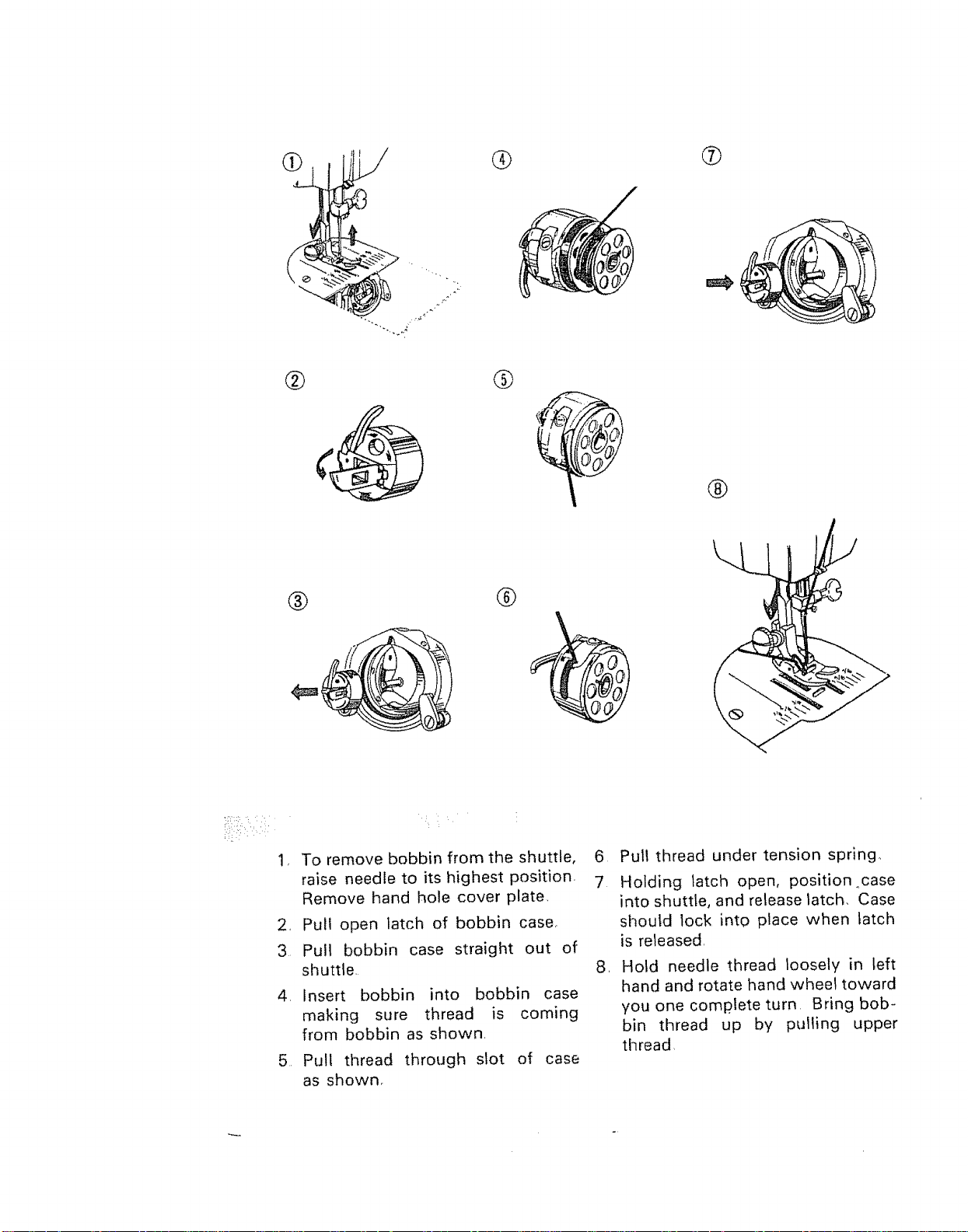

1, To remove bobbin from the shuttle,

raise needle to its highest position.

Remove hand hole cover plate,,

2, Pull open latch of bobbin case.

3 Pull bobbin case straight out of

shuttle.

,

Insert bobbin into bobbin case

making sure thread is coming

from bobbin as shown.

•

Pull thread through slot of case

as shown r

®

Pull thread under tension spring.

7

Holding latch open, positionocase

into shuttle, and release latch, Case

should lock into place when latch

is released,

8, Hold needle thread loosely in left

hand and rotate hand wheel toward

you one complete turn Bring bob-

bin thread up by pulling upper

thread

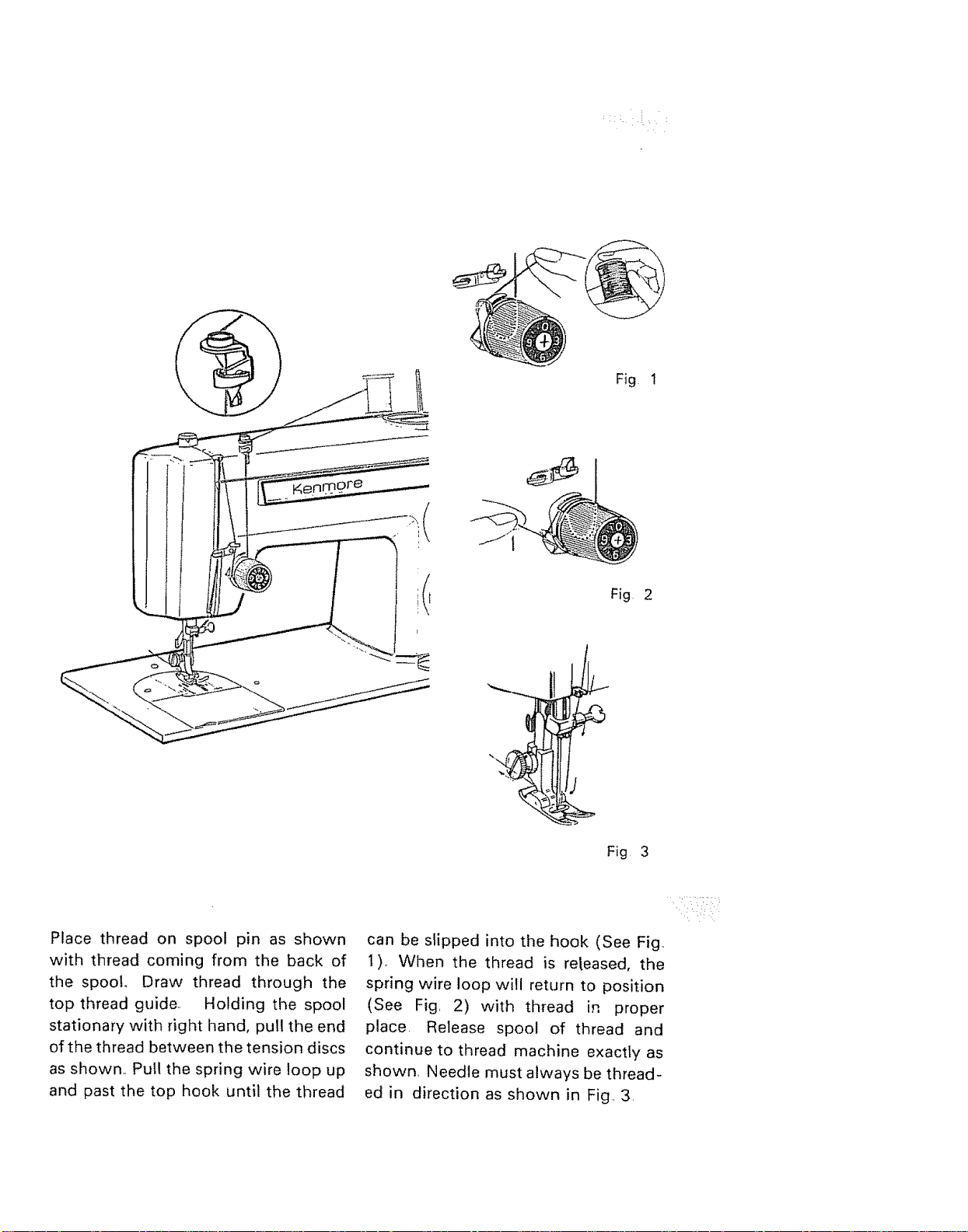

Fig 1

Fig 2

Place thread on spool pin as shown

with thread coming from the back of

the spool_ Draw thread through the

top thread guide.. Holding the spool

stationary with right hand, pull the end

of the thread between the tension discs

as shown.. Pull the spring wire loop up

and past the top hook until the thread

Fig 3

can be slipped into the hook (See Fig,

1)_ When the thread is rejeased, the

spring wire loop will return to position

(See Fig, 2) with thread in proper

place. Release spool of thread and

continue to thread machine exactly as

shown Needle must always be thread-

ed in direction as shown in Fig, 3,

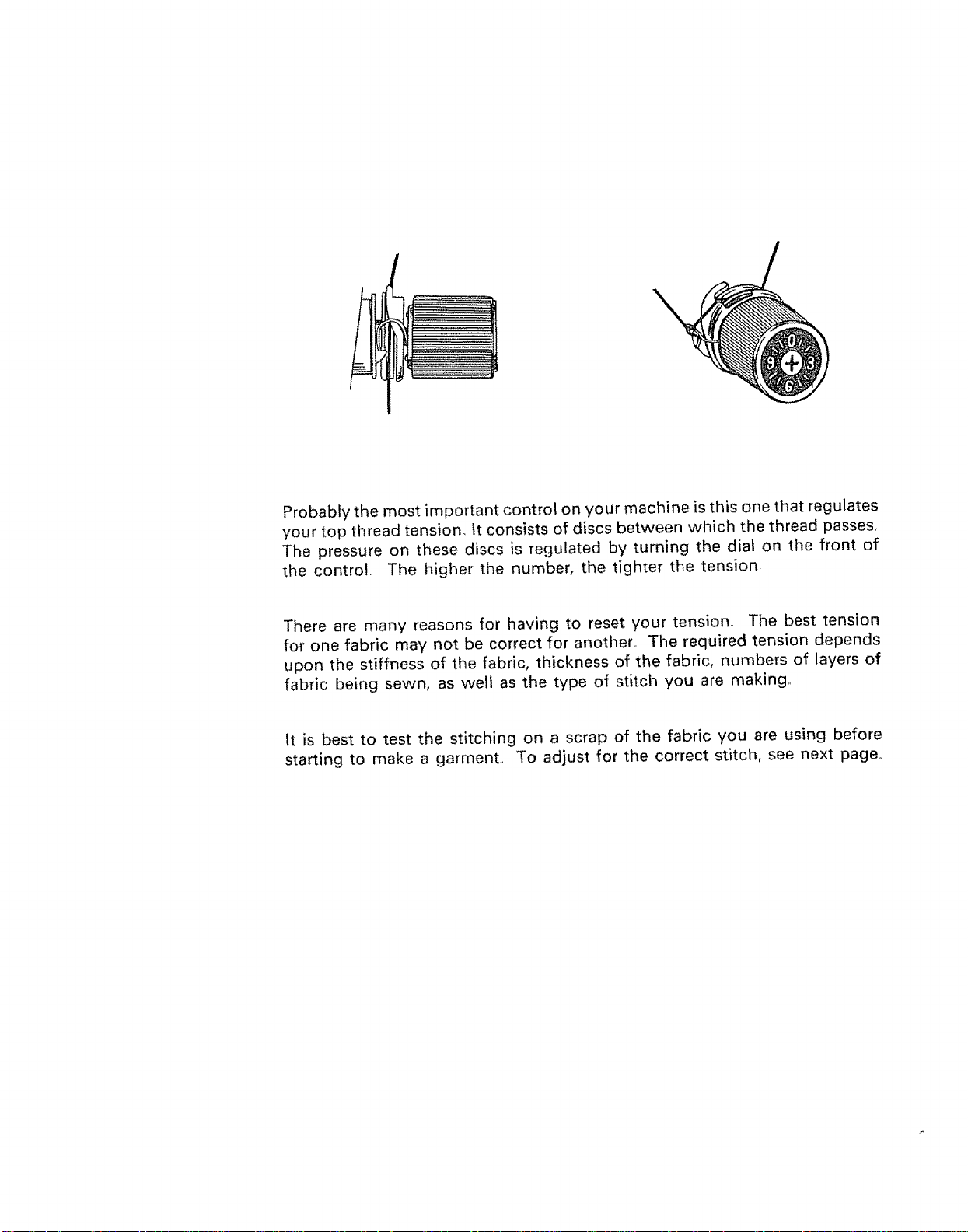

Probablythe mostimportantcontrolonyourmachineisthisonethat regulates

yourtop threadtension,tt consistsof discs between which the thread passes,

The pressure on these discs is regulated by turning the dial on the front of

the control.. The higher the number, the tighter the tension,

There are many reasons for having to reset your tension.. The best tension

for one fabric may not be correct for another. The required tension depends

upon the stiffness of the fabric, thickness of the fabric, numbers of layers of

fabric being sewn, as well as the type of stitch you are making.

it is best to test the stitching on a scrap of the fabric you are using before

starting to make a garment._ To adjust for the correct stitch, see next pager

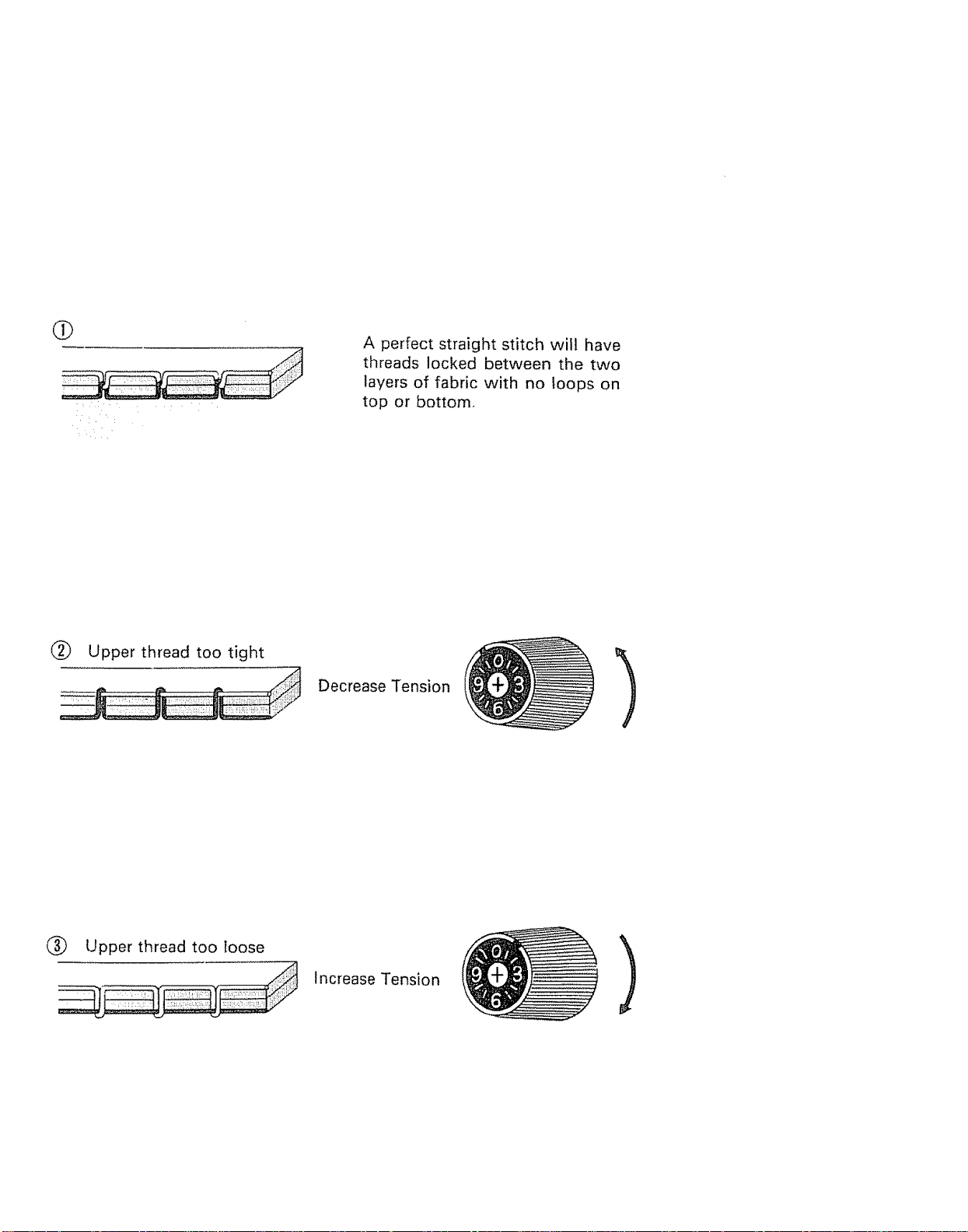

@

(_ Upper thread too tight

A perfect straight stitch wil! have

threads locked between the two

layers of fabric with no loops on

top or bottom.

Decrease Tension

(_ Upper thread too loose

Increase Tension

{: .... •

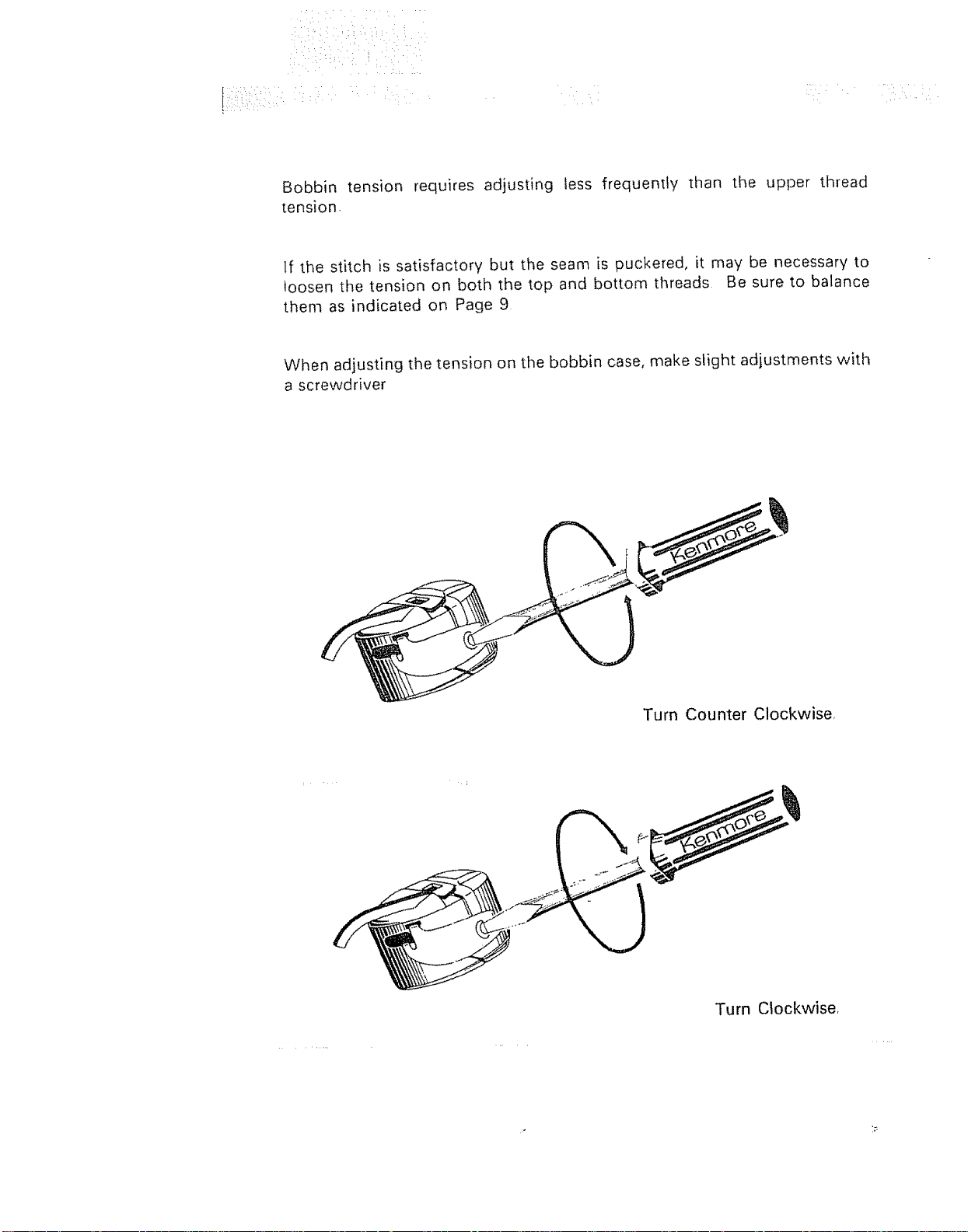

Bobbin tension requires adjusting tess frequently than the upper thread

tension

If the stitch is satisfactory but the seam is puckered, it may be necessary to

loosen the tension on both the top and bottom threads Be sure to balance

them as indicated on Page 9

When adjusting the tension on the bobbin case, make slight adjustments with

a screwdriver

Turn Counter Clockwise,

Turn Clockwise,

• i• : •!:i• •: !• •••

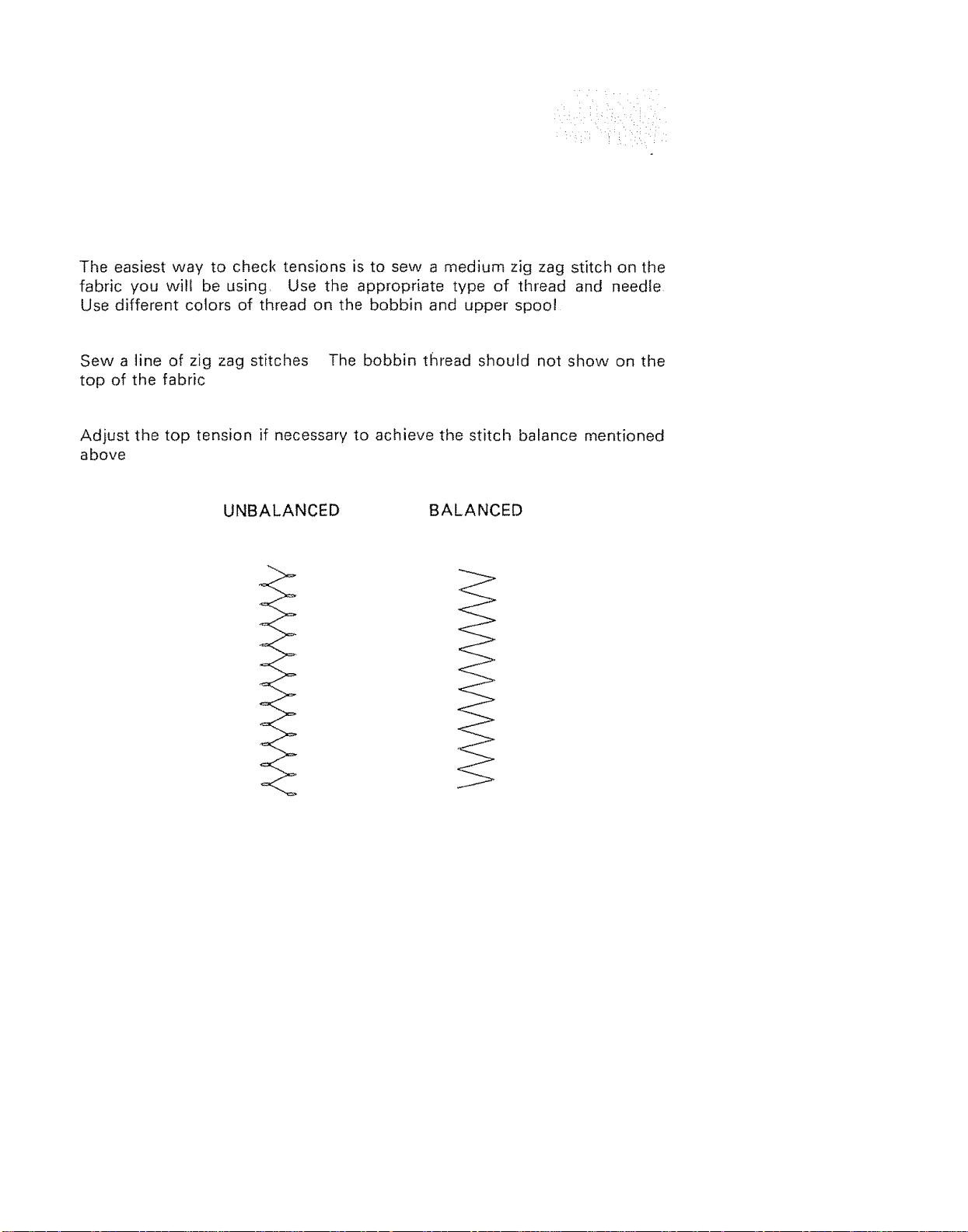

The easiest way to check tensions is to sew a medium zig zag stitch on the

fabric you will be using, Use the appropriate type of thread and needle

Use different colors of thread on the bobbin and upper spool

Sew a line of zig zag stitches The bobbin thread should not show on the

top of the fabric

Adjust the top tension if necessary to achieve the stitch balance mentioned

above

UNBALANCED BALANCED

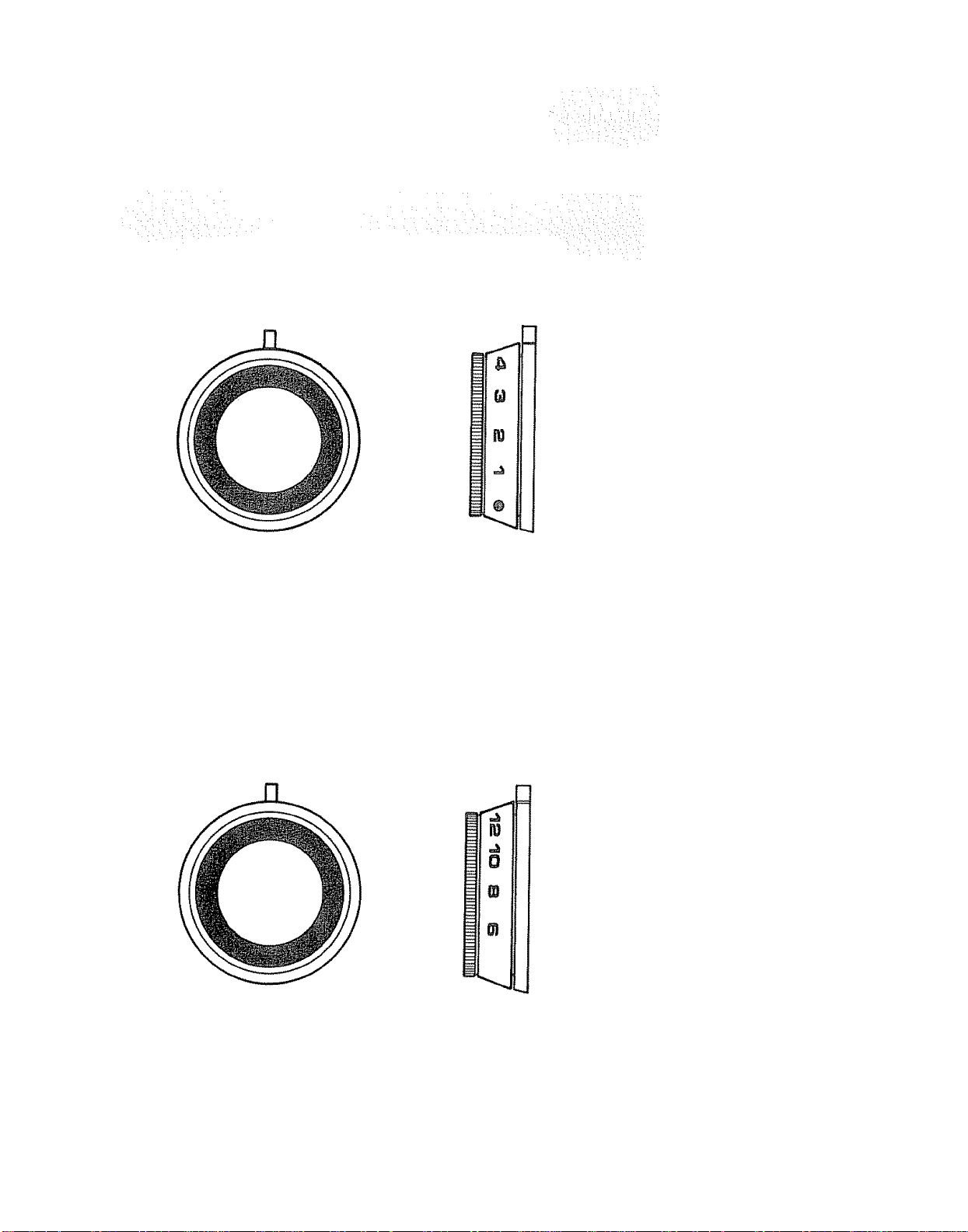

Thiscontrolregulatesthe width of the stitchyouselect THEHIGHERTHE

NUMBER- THEWIDERTHESTITCH,Youmayvaryyourzigzagstitchwidth

by adjustingthis control to tile settingyou desire,

This control must beon RedDot in orderto do straight stitching

Thestitch length controlregulatesthe length of the stitchyou select THE

HIGHERTHENUMBER- THESHORTERTHESTITCH,

The numberon stitch length control indicatesthe approximatenumberof

stitches per inch The stitch setting you use wilt be determinedby the

thicknessof thefabric you aresewing

A longer stitch setting should be usedfor thicker fabric or morelayersof

fabric.

Themiddlerangeof the controlis the 10-12 stitch per inch rangewhich is

the mostcommonlyused.

A basting stitch is made by using the longest possible stitch setting - 6 stitches

per inch°

The red marking _, on the control is the setting used for the shortest

stitches such as in Satin Stitching.

f_

113

0

_i_:_:_:_i,"__i__:_!,_i,__:

J_

O

m

ol

Loading...

Loading...