1'58. 1316O

Hi i i,

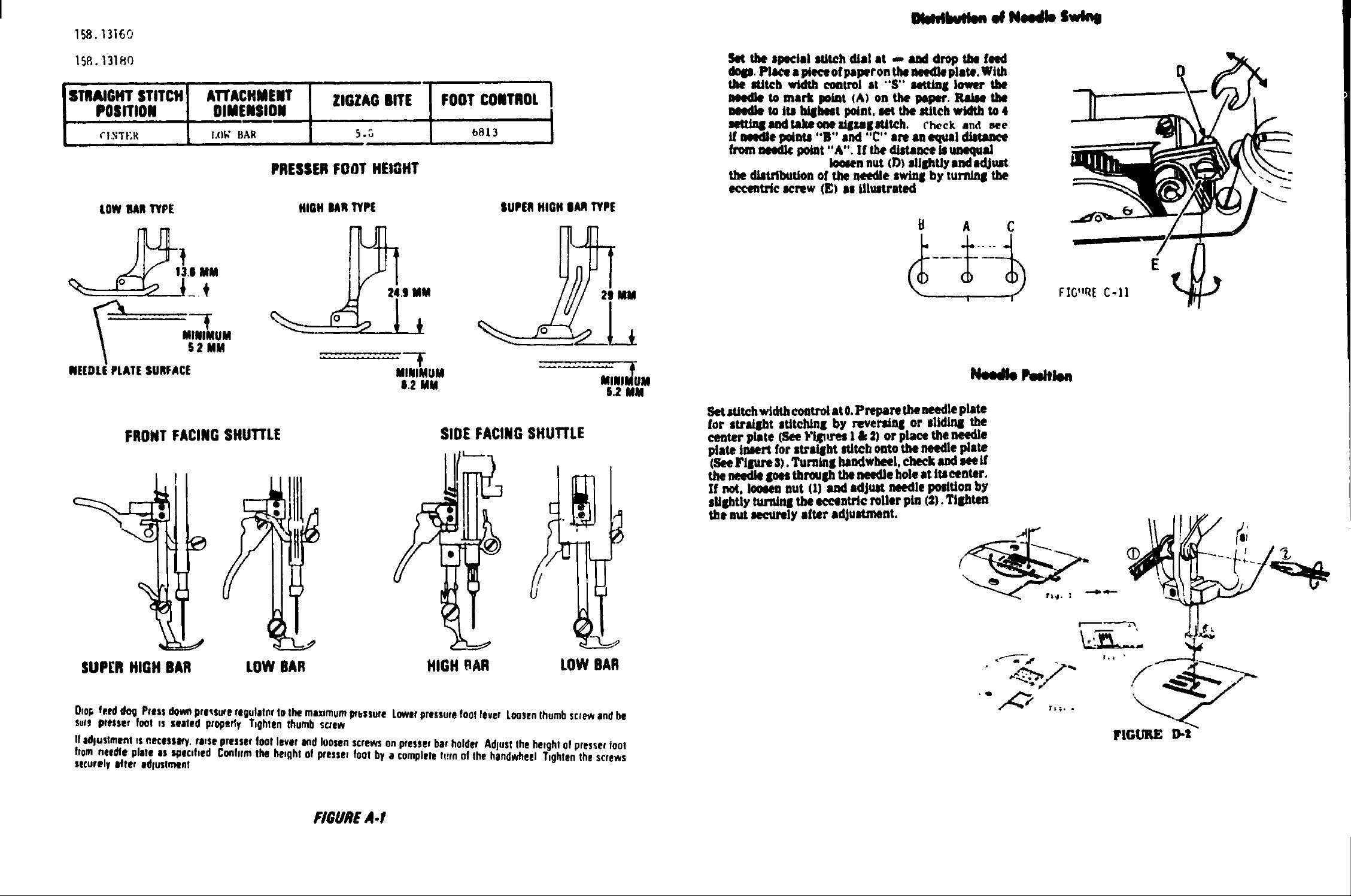

STRAIGHTSTITCH ATTACHMENT ZIGZAG BITE FOOT CONTROL

POSITION DIMENSION

r_t.'¢Tf;R I,()Y; BAR 5._ b813

i • ,

PRESSERFOOTHEIGHT

LOWBARTYPE

HIGHBARTYPE

SUPERHIGHOARTYPE

mmlbv,kn a N,edb Sv,

Set the special stitch dial at ,,- and drop the feqM

dogs. Pla_e • piece of paper on the Mndle plate. With

the Iddtch wklth control at "'S" setting lower il_

laecMieto m•rk paint (A) on the paper. _ tim

needle to its idghest point, set the stitch width to 4

IJett_Jfldt,ldmoileglsgatlglUtch. ('beck and see

If needle pelnte "B" end "C" am an equal distance

from needle point "A". If the distance Is unequal

Io_;en nut (D) sllolttly andndJuat

the dJat_bution of the needle swing by turnin8 the

occentr/e screw (E) as illustrated

8 A C

l_.i MM

MINIMUM

62 MM

NEEDLEPLATESURFACE

FRONTFACINGSHUTTLE

MINIMUM

8.2 MM

i .......

SIDE FACING SHUffLE

2_MM

5.2 MM

I

Set stitch width control •t O.Prepam the needle plate

for straight atttc_n| by reveradn| or slidinll the

center plate (See I_blpU'es1 & 31 or place the needle

plate insert for straight stitch onto the ne4Mle pla_

(See FiiPu'e 3). Tur'ninll handwheei, check and see

the needle goesthrough the needle boleat Its center.

If not, loosen nut (1) and adjust needle poMilon by

sflghtly turnin8 the eccentric miler pin (S). Tighten

the nut securely after •€lJustment.

E

if

SUPERHIGH BAR

Oropfeeddog Pressdo_ pressureregulatertothe max,mumpressure Lowerpressurefootlaver Loosenthumbscrewand be

sure presser foot ,s seated properly Tzghtenthumb screw

Ifedlustment,s necessary,re,as presser foot lever andloosenscrewson presserbar holder Adjustthe betghtof presserfoot

from needle plate as spac,f,ed CtNlflrmthe Ileight of presse, foot by a completett[rnof the handwheei T,ghtenthe screws

securelyafter odlustn_ot

LOW BAR HIGH OAR LOW BAR

FIGUREA.I

FIGLIKE D..t

1_,8 13180

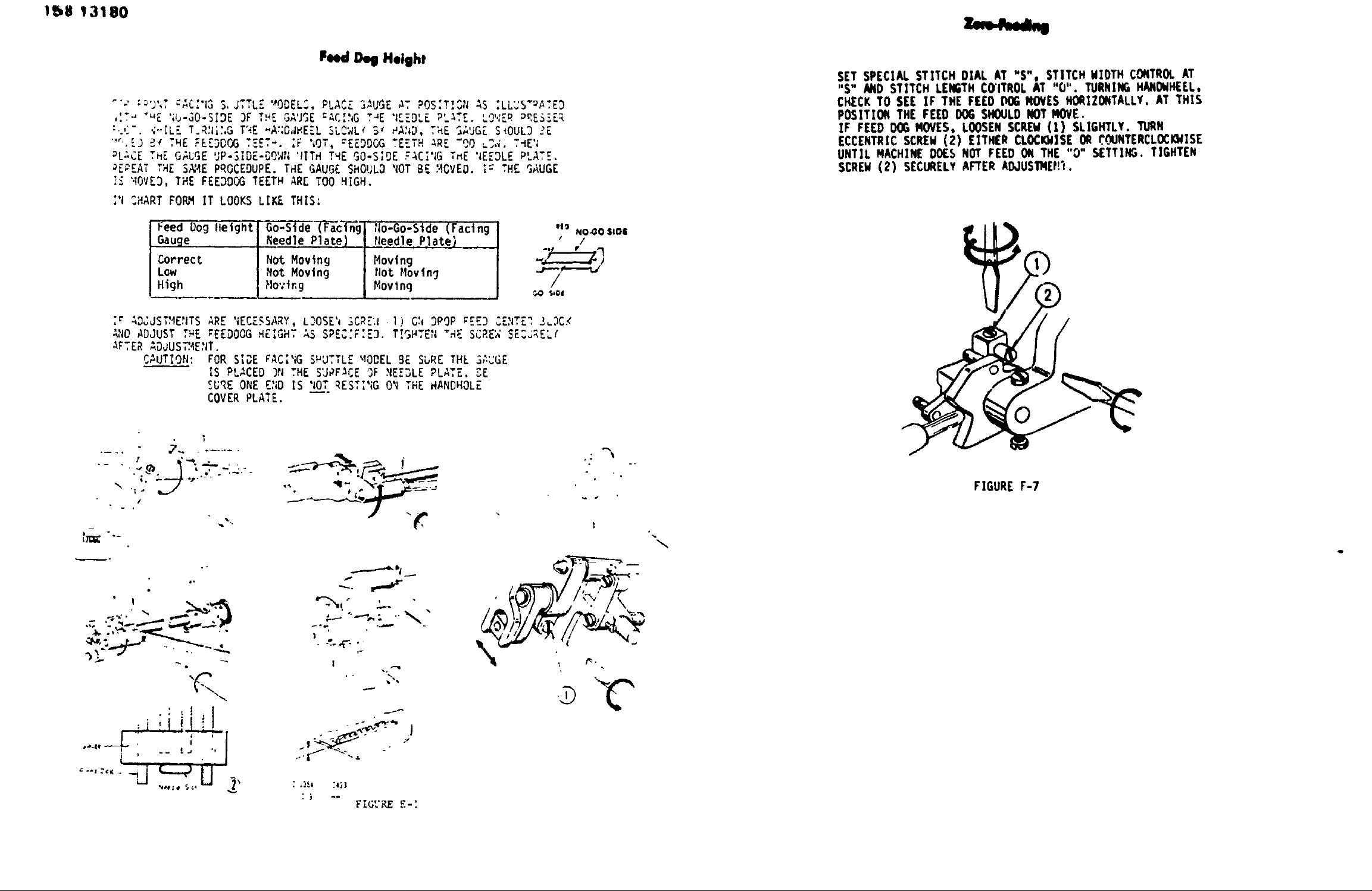

Feed Deg Height

"P ._J',T -C,I.3S,JTTLZ '_0DEL_,PLACE ]HUGE HT ?OS.T.v,;AS .LL.S _,_3

,IT- "uE '_(J-GO-SIDE3F THE ,_-J_E:HC:'_GT_E "IEEDLEPL_TEo '_""_PP_,E_:.ER

:'.'i".','ILET.R'|_:,GT'_E"A::D,JI_E'ZL_LC'_Lf5_ PA'4D,T}IESAUGE S_OUL3 ._Z

'"_'.E]_ THE ,:EEDOCGTE.CT_. ;F '_OT,"EEDDGG TEETH HRE "00 _],V.T_E'_

PL-'CETHE GAI;GE ....... " _....._P-_Dc-uO._,,'IITHTHE S0-SIDE ."_CI';GT_E '_EEOLEP'_'_

_ZPEAT THE S_4E PROCEDUPE. THE GAUGE SHOULD 'lOTBE '4CVED. is THE gAUGE

IS "OVE3, THE FEEDDOG TEETH ARE TOO HIGH.

:'ICHART FORM IT LOOKS LIKE THIS:

SET SPECIAL STITCH DIAL AT "S", STITCH WIOTH CONTRO!.AT

"S" AND STITCH LENGTHCGITROL AT "O". TURNING MANOMHEEL,

CHECKTO SEE IF THE FEED DO6MOVES HORIZONTALLY. AT THIS

POSITION THE FEED DO6 SHOULDNOT MOVE.

IF FEED O_ MOVES, LOOSENSCREW(1) SLIGHTLY. TURN

ECCENTRICSCREW(2) EITHER CLOCI_ISE OR rOUNTERCLOCIO_ISE

UNTIL MACHINE DOESNOT FEED ON THE "0" SETTING. TIGHTEN

SCREW(2) SECURELYAFTER ADJUS1)IEt!_.

Feed Dog lleight Go-Slde (FacT@g, No-Go-Side (Facing

Gauge Needle Plate) Needle Plate)

Correct Not Moving Moving

Low Not Moving Not Movln_

High Moving Movlng

;_ AD_JST'4E:ITSARE 'IECZSSARY,LOOSE'_3CRE',_•I) CN 3POP _EE3 CE,_ITE_,J_OC._

AND ADJUST T_E ;EED00G HEIGHT AS SPEC'F:E3. T._H,E,I HE SCRE"_SE=J_ELf

AFTER -DJUS,AE,JT.

CAUTION: FOR SI_,EF'AC,,G _ U,,L. _ODEL BE SvRE THE _,,_G_

IS PLACED ]N THE SURFACE OF REE3LE PLATE. 3E

SI_REONE E';DIS 'IO__T.RESTI'IGON THE HANDHOLE

COVER PLATE.

/

• /

.7--..

NO-_O liD|

FIGURE F-7

.: *! I

_._._ _ w"_#N "_ " _ _"

}

I

: ) .-

FIG".RE_-'

\

NEEDLETIMINGTOSHUTTLE

NEEDLE TIMING TO SHUTTLE

NEEDLE BAR HEIGHT

THE RADIAL TIMING GAUGESAND TEST PINS, /1_

ILLUSTRATED BELOW, ARE AVAILABLE FROHDIVISION

92, SOURCE192. THE KIT IS IDENTIFIED AS

#69659. EACHGAUGEAND TEST PIN CANALSO BE

ORDEREDINDIVIDUALLY.

THIS KIT IS USED FOR _OURCE 148 AND 158

VERTICAL BOBBIN SEWING MACHINES.

RADIAL

TJ_ING GAUGE

#69894

TEST PIN

#69873

/

_g

RADIAL

TIMING GAUGE ..._'.._.,

#69892 1%._...%,,7;¢. " _

Do net attempt idlvStmlnts other men tflose specifiedin

this manual, if. by fo_lomngthe prescr,bedprocedmos,it LS

determined that o machine is out Ofrod,el time. handleper

Bulletin S-920

Radial Timing Gauge

Instructions

1. Removeneedle end replace ,t w_thtest pmv_ich hase

blunt bp.

2 Remove bobbin case end shuttle hook Insert correct

radial t,mm9 gauge into shuttle dr,ve¢

For this mad€lie) use gauge marked

Source 158 FRONT58 FRONT 40

Use FflONT 5 8 matkmg

3 Set stitch controlat "0" or "S" (depondmgon model

involved)

4 Set needle poslhoncontrol at centerfor modelswhich

have this control

._ Rotatehsndwhanl slowlyby hand (See F@u,'e_;.3aJThe

test pm shouldcome between the correct two vertical

Ira,as,** the end of the counterclockwiserotohon of the

gouge For this model(s)usevemcal hoes,dentifiedv,,th DIMENSION A

one dot

Tochick needle bar hl,ghL continuetorolntehandwhlel

slowlyby hand fSee hgum G.3#I Atthe lowestposst,on

of the needle bar. the end of the test pm shouldcome

between two hor,zontalhnes On the gouge

If necessaet,adjust needle bar ha,ght Loosenscrewon

needle bar holder and adjust height on the list pen

RADIAL

TIMING GAUG_

#69_93

RADIAL

_IHING GAUGE

FIGURE G-t #69895

OIMENSIONN

FIgURIE 0.3

F_g,JreO 3 gives e general _dee of the use of the rad,td

tzmmggauge Follow the tnstlUCtlOnSat the left wh,ch

pertem in this modeKs)

Needle €Icero.ca te Shuttle 158.13180

CIIMI_Ol "a0" "'b." "€," 8nd U_ _e '°d" ire very

cttttc4t points tn _|M_on to _he needle tlmlr_ to shuttle.

H0wlver. these po4ntS ue v,sulllv _torm,ned by _S,ng t/_

Ro4,ad "l_M_ngO_s.

_lOTl:

No acllultment as allow_l fcw "_mem_on C'* for the

•_nt.faang muttle n_€lelo. For adjustmentfor mle-0hutlle

n_kds, pleeN refer to Fiqum Q.3.

SET STITCH WIDTH CONTROL AT THE RED "S".

CHECK TO SEE IF NEEDLE SWINGS BY MOVING

THE ZIGZAG GUIDE BASE IN EITHER

DIRECTION AS SHOWN. NEEDLE SHOULD NOT

SWING. IF ADJUSTMENT IS NECESSARY,

LOOSEN SCREW (I), PRESS THE ZIGZAG

GUIDE BAR DOWNWARD SLIGHTLY AND THEN

TIGHTEN SCREW (1). NOTE THAT THE

ZIGZAG WIDTH A_4 HUST BE KEPT IN

POSITION STEADILY.

Stm| Stitch

Position

/

£et tile special stitcli _ :t _- _Lndthe stitch

_tdU_ co_trn_ ;Lt 4. T_rN, nS the _nd'_heel.

cnecx .;Jld see _f the neecUe side motion on t_e

st_d_rd plane t0,040 tncll _,bove the upper sur-

face o( _he needJ.e plate) _t both needle ponitior

come within the enlItheer_l{ tzmit o( 0.014 inch

(_e Flip, re 3H-l). If not, loosen two screws

(A_ on _be worm i_ear _md rotate the  Loading...

Loading...