Owner's Manual

305 and 505 Models

Direct Vent Tankless Water Heaters

FOR OUTDOOR APPLICATIONS ONLY

MODEL NO.

154.330040 Natural Gas 305 Series

154.330050 Propane Gas 305 Series

154.330080 Natural Gas 505 Series

154.330090 Propane Gas 505 Series

• Safety Instructions

• Installation

• Operation

• Care and Maintenance

• Troubleshooting

Read and understand instruction

manual and safety messages

before installing, operating or

servicing this water heater.

Failure to follow instructions and

safety messages could result in

death or serious injury.

Instruction manual must remain

with water heater.

INSTALLER:

• AFFIX THESE INSTRUCTIONS TO OR

ADJACENT TO THE WATER HEATER.

OWNER:

• RETAIN THESE INSTRUCTIONS AND

WARRANTY FOR FUTURE REFERENCE.

RETAIN THE ORIGINAL RECEIPT AS PROOF

OF PURCHASE.

For Your Safety

AN ODORANT ISADDED TO THE GAS USED BY THIS WATER HEATER.

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

m Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

m lnstallation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A

PRINTED IN THE U.S.A 0409 www.sears.com

PART NO. 316052-001

Your safety and the safety of others is extremely important in the installation, use and servicing of this water heater.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others of

a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important that the meaning

of each safety message is understood by you and others who install, use or service this water heater.

n

,_ I This is the safety alert symbol, it is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

I

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result

in death or injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, could result

in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, could result inproperty damage.

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message and

how to avoid the risk of injury.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of substances known to

the State of California to cause cancer, birth defects, or other reproductive harm, and requires businesses to warn of potential exposure

to such substances. WARNING: This product contains a chemical known to the State of California to cause cancer, birth defects, or other

reproductive harm. This appliance can cause low-level exposure to some of the substances included in the Act.

IMPORTANT DEFINITIONS

• Qualified Technician: A qualified technician must have ability equivalent to a licensed tradesman in the fields of plumbing, air supply,

venting, and gas supply, including a thorough understanding of the requirements of the National Fuel Gas Code as it relates to the

installation of gas fired water heaters. The qualified technician must also have a thorough understanding of this instruction manual.

• Service Agency: A service agency also must have ability equivalent to a licensed tradesman in the fields of plumbing, air supply, venting

and gas supply, including a thorough understanding of the requirements of the National Fuel Gas Code as it relates to the installation of

gas fired water heaters. The service agency must also have a thorough understanding of this instruction manual, and be able to perform

repairs strictly in accordance with the service guidelines provided by the manufacturer.

• Gas Supplier: The natural gas or propane utility or service who supplies gas for utilization by the gas burning appliances within this

application. The gas supplier typically has responsibility for the inspection and code approval of gas piping up to and including the natural

gas meter or propane storage tank of a building. Many gas suppliers also offer service and inspection of appliances within the building.

FIRE AND EXPLOSION HAZARD

flammable vapors and liquids in the vicinity of this

or any other appliance. Storage of or use of

gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance can result in

serious injury or death.

Read and follow water heater warnings and instructions.

© Sears, Roebuck and Co.

2 305 & 505 Outdoor Manual

Can result in serious injury or death

Do not store or use gasoline or other

Safety Behavior and Practices

Keep the area around the appliance clear and free

from combustible materials, gasoline, and other

flammable vapors and liquids.

Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

Safety Features

• Overheat: The appliance will automatically shut

down when the appliance exceeds a predetermined

temperature.

• Flame Failure: The appliance will automatically

shut down if the burner flame is extinguished.

• Power Failure: The appliance will cut off the gas if

it loses electrical power.

• Any alteration to the appliance or its controls can

be dangerous and will void the warranty.

• Always check the water temperature before

entering a shower or bath.

• Power Surge Fuse: A glass fuse protects against

overcurrent. If the fuse blows then all indicator

lamps will be off.

• Fusible Link: In case the overheat feature does not

prevent the temperature from rising then the fusible

link will break shutting off the appliance.

305 & 505 Outdoor Manual 3

Safe Installation, Use and Service ........................... 2

Safety Precautions .................................................... 2

Safety Behaviors and Practices ............................ 3

Safety Features ..................................................... 3

Table of Contents ...................................................... 4

Product Warranty ...................................................... 5

Consumer Responsibilities ...................................... 6

Product Specifications ............................................. 7

Dimensions ................................................................ 8

Technical Data ........................................................... 9

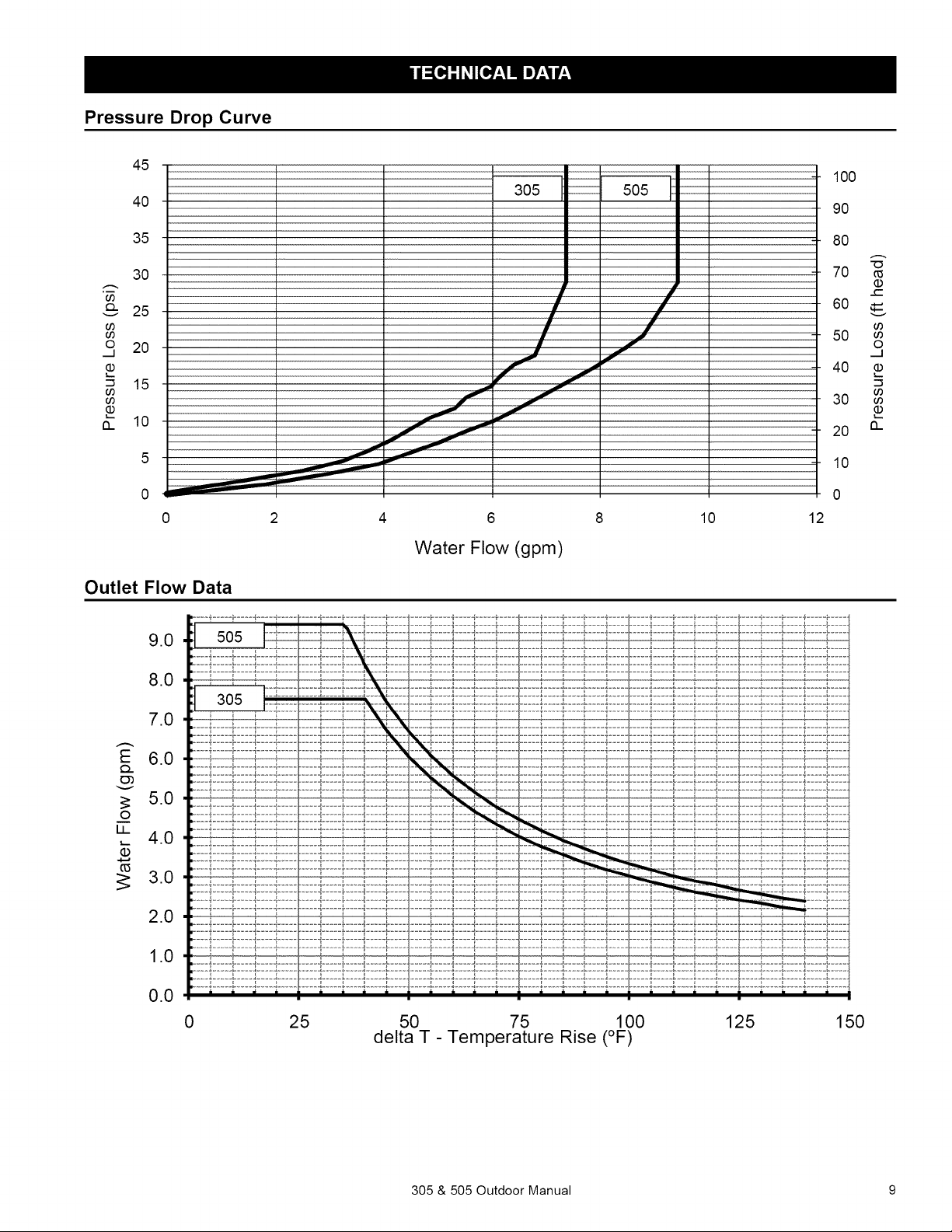

Pressure Drop Curve ............................................ 9

Outlet Flow Data ................................................... 9

Installation Instructions .......................................... 10

General Instructions ............................................ 10

Clearances from Appliance ................................. 10

Attachment of the Water Heater ......................... 11

Electrical Connection .......................................... 11

Gas Supply ............................................................... 11

General Instructions ........................................... 11

Pipe Sizing Procedure- Example ...................... 12

Water Piping ............................................................. 13

General Instructions............................................ 13

Pressure Relief Valve.......................................... 13

Freeze Protection........................................... 13-14

Recommended Piping For Basic Installation ...... 15

Recommended Piping For

Circulation Systems ............................................ 16

Optional Piping For Circulation Systems ............ 17

Venting Instructions ................................................ 18

Additional Clearances - Vent Terminal ................ 19

High Altitude Installations ...................................... 20

Connecting Multiple Water Heaters ....................... 20

Temperature Controller Installation ....................... 21

Location .............................................................. 21

Configurations ..................................................... 21

Cable Lengths And Size ..................................... 21

Mounting The Controller ..................................... 21

Description of Operation ........................................ 22

Operating Instructions ............................................ 22

Sequence of Operation ....................................... 22

Features Available on Temperature Controllers.. 22

Temperature Adjustment ........................................ 23

Temperature Options without a Temperature

Controller ............................................................. 24

Temperature Ranges ........................................... 24

Setting the Controller to Mute ............................. 24

Operating Your Water Heater ................................. 25

Maintenance ............................................................. 26

Cleaning .............................................................. 26

Vent System ........................................................ 26

Motors ................................................................. 26

Temperature Controller ........................................ 26

Lime/Scale Build-up ............................................ 26

Snow Accumulation ............................................. 26

Visual Inspection of Flame .................................. 26

Troubleshooting ................................................. 27-30

Error Code Table ............................................ 27-28

Troubleshooting for Common Issues .................. 29

Accessing Operating Information ........................ 29

Water Quality ....................................................... 29

Flushing the Heat Exchanger

(Error Code: LC or 00) ........................................ 30

Wiring Diagram ........................................................ 31

Service and Adjustment ......................................... 32

Repair Parts List .................................................. 32

Kenmore Tankless Water Heater Accessories .... 32

Notes .................................................................... 33-35

4 305 & 505 Outdoor Manual

12 Year Limited Warranty on Heat Exchanger

For 12 years from the date of purchase, if this water heater is installed and operated in a single family home in

accordance with the owner's manual instructions and all local codes, Sears will supply a free heat exchanger f\_r one

that develops a leak.

For the second through twelfth year from purchase date, you must pay the labor cost l\_r installation of the heat

exchanger

5 Year Limited Warranty on Parts

For 5 years from the date of purchase, if this water heater is installed and operated in a single f:amily home in

accordance with the owner's manual instructions and all local codes, if a part f:ails due to material or workmanship,

Sears will supply a free replacement part.

1 Year Exclusive Kenmore Labor Warranty

For the first year from the date of purchase, Sears will, free of charge, supply and install new water heater parts l\_r

detective ones or a new heat exchanger l\_r one that develops a leak.

Warranty Service

To obtain warranty sela:ice, call 1-800-4-MY-HOME¢_) (1-800-469-4663). This warranty applies only while this

product is in the United States.

For Commercial, institutional, industrial, or residential use by two or more families, the above limited warranty for

heat exchanger leaks is effective f\_r five years from date of purchase and the above parts warranty is effective f\_r

three years from the date of purchase.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., Dept.817WA, Hoffman Estates, IL 60179

The price of your water heater does not include a free checkup service call. On water heater installations arranged by Sears, Sears

warrants the installation.

A charge will be made on service calls due to poor or incomplete installation. These include:

a. Adjusting thermostat b. Condensation c. Leaks in pipes or fittings

Master Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore ® product is designed and manufactured for years

of dependable operation. But like all products, it may require

preventive maintenance or repair from time to time. That's when

having a Master Protection Agreement can save you money and

aggravation.

The Master Protection Agreement also helps extend the life of your

new product. Here's what the Agreement* includes:

• Parts and labor needed to help keep products operating

properly under normal use, not just defects. Our coverage

goes well beyond the product warranty. No deductibles, no

functional failure excluded from coverage-- real protection.

• Expert service by a force of more than 10,000 authorized

Sears service technicians, which means someone you can

trust will be working on your product.

• Unlimited service calls and nationwide service, as often as

you want us, whenever you want us.

• "No-lemon" guarantee - replacement of your covered product

if four or more product failures occur within twelve months.

• Product replacement if your covered product can't be fixed.

• Annual Preventive Maintenance Check at your request - no

extra charge.

• Fast help by phone - we call it Rapid Resolution - phone

support from a Sears representative on all products. Think of

us as a "talking owner's manual."

Power surge protection against electrical damage due to

power fluctuations.

305 & 505 Outdoor Manual 5

• $250 Food Loss Protection annually for any food spoilage

that is the result of mechanical failure of any covered

refrigerator or freezer.

• Rental reimbursement if repair of your covered product takes

longer than promised.

• 10% discount off the regular price of any non-covered repair

service and related installed parts.

Once you purchase the Agreement, a simple phone call is all that it

takes for you to schedule service. You can call anytime day or night,

or schedule a service appointment online.

The Master Protection Agreement is a risk free purchase. If you

cancel for any reason during the product warranty period, we

will provide a full refund. Or, a prorated refund anytime after the

product warranty period expires. Purchase your Master Protection

Agreement today!

Some limitations and exclusions apply. For prices and additional

information in the U.S.A. call 1-800-827-6655.

* Coverage in Canada varies on some items. For full details,

call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door

openers, water heaters, and other major home items, in the U.S.A.

or Canada call 1-800-4-MY-HOME ®.

Thank You for purchasing a Kenmore water heater.

Properly installed and maintained, it should give you years

of trouble free service. Ifyou should decide that you want

the new water heater professionally installed by Sears call

1-800-4-MY-HOME ®. They will arrange for prompt, quality

installation by Sears authorized contractors.

Abbreviations Found In This Instruction Manual:

For California installation, this water heater must

be braced, anchored, or strapped to avoid falling or

moving during an earthquake. See instructions for

correct installation procedures. Instructions may be

obtained from California's Office of the State Architect,

1102 Q Street, Suite 5100, Sacramento, CA 95811.

Instructions can also be downloaded to your computer

at www.dsa.dgs.ca.gov/Pubs.

• CSA- Canadian Standards Association

• ANSI- American National Standards Institute

• NFPA- National Fire Protection Association

• ASME - American Society of Mechanical Engineers

• GAMA- Gas Appliance Manufacturers Association

ImportantInformationAboutThisWaterHeater:

This manual has been prepared to acquaint you

(trained service technician) with the installation,

operation, and maintenance of the on-demand water

heater and provide important safety information in

these areas.

Service to the on-demand system should only be

performed by a trained service technician.

READ THE ENTIRE MANUAL BEFOREATTEMPTING TO

INSTALL OR OPERATE THE WATER HEATER.

The installation must conform with these instructions

and the local code authority having jurisdiction. In the

absence of local codes, installations shall comply with

the following:

In the United States: The National Fuel Gas Code

ANSI Z223.1/NFPA 54. This publication is available

from the Canadian Standards Association, 8501 East

Pleasant Valley Rd, Cleveland Ohio 44131, or The

National Fire Protection Association, 1 Batterymarch

Park, Quincy, MA 02269.

Massachusetts Code requires this water heater to be

installed in accordance with Massachusetts 248-CMR

2.00: State Plumbing Code and 248-CMR 5.00.

Excessive Weight Hazard

Usetwoormorepeopletomoveandinstallthewaterheater.

Failuretodosocanresultininjury(includingbackinjury).

IMPORTANT: Do not remove any permanent instructions,

labels, or the data label from either the outside of the water

heater or on the inside of water heater panels.

Remove exterior packaging and place installation

components aside.

Inspect all parts for damage prior to installation and

start-up.

Completely read all instructions before attempting to

assemble and install this product.

After installation, dispose of/recycle all packaging

materials.

If after reading this manual you have any questions or

do not understand any portion of the instructions, call

the Sears Service Center.

Carefully plan the place where you are going to put the

water heater. Correct combustion, vent action, and vent

pipe installation are very important in preventing death

from possible carbon monoxide poisoning and fires.

Examine the location to ensure the water heater

complies with the Installation Instructions section in this

manual.

6 305 & 505 Outdoor Manual

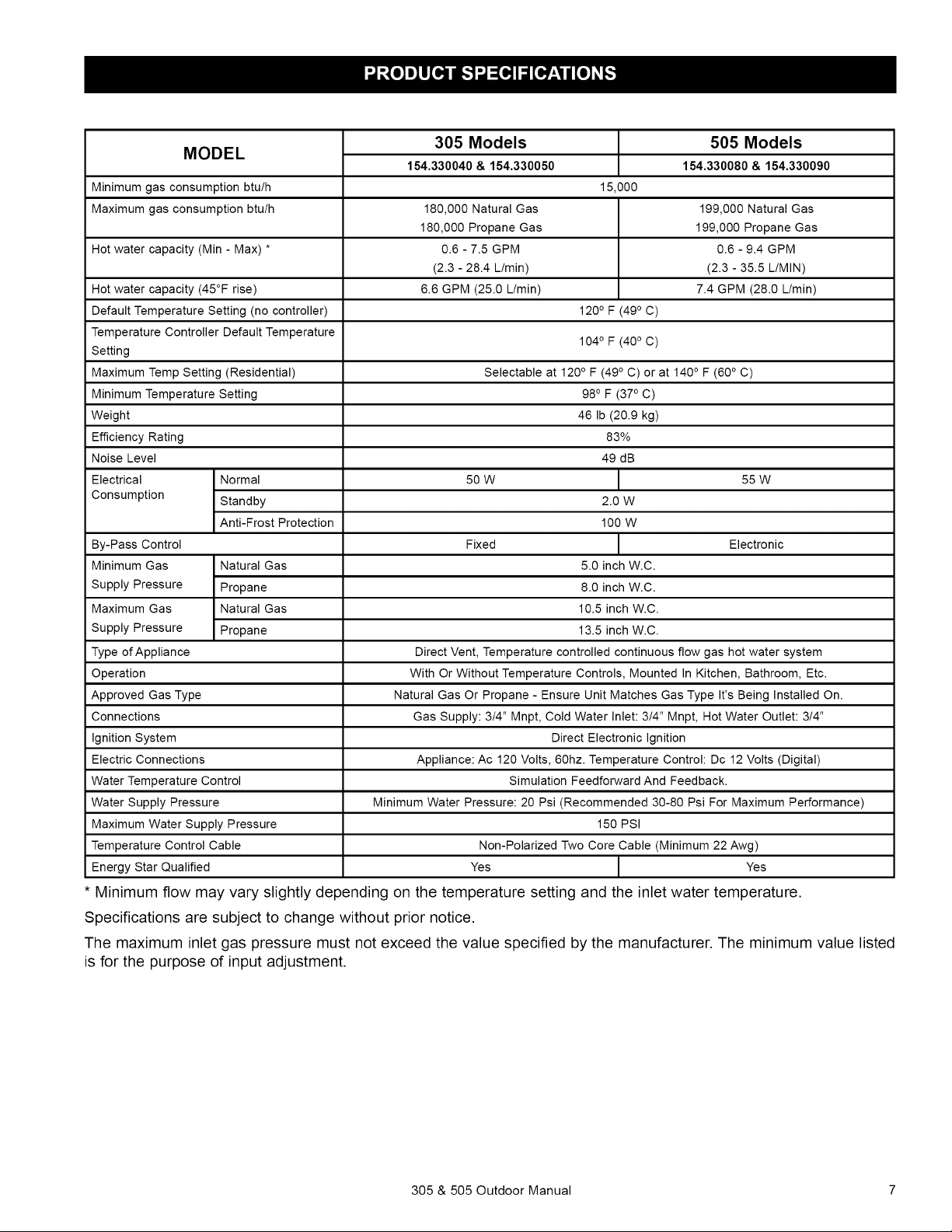

MODEL

Minimum gas consumption btu/h

Maximum gas consumption btu/h

Hot water capacity (Min - Max) * 0.6 - 7.5 GPM 0.6 - 9.4 GPM

Hot water capacity (45°F rise) 6.6 GPM (25.0 L/min) 7.4 GPM (28.0 L/min)

Default Temperature Setting (no controller) 1200 F (490 C)

Temperature Controller Default Temperature 1040 F (400 C)

Setting

Maximum Temp Setting (Residential) Selectable at 1200 F (490 C) or at 1400 F (600 C)

Minimum Temperature Setting 980 F (370 C)

Weight 46 Ib (20.9 kg)

Efficiency Rating 83%

Noise Level 49 dB

Electrical Normal 50 W 55 W

Consumption Standby 2.0 W

Anti-Frost Protection 100 W

By-Pass Control Fixed Electronic

Minimum Gas Natural Gas 5.0 inch W.C.

Supply Pressure Propane 8.0 inch W.C.

Maximum Gas Natural Gas 10.5 inch W.C.

Supply Pressure Propane 13.5 inch W.C.

Type of Appliance Direct Vent, Temperature controlled continuous flow gas hot water system

Operation With Or Without Temperature Controls, Mounted In Kitchen, Bathroom, Etc.

Approved Gas Type Natural Gas Or Propane - Ensure Unit Matches Gas Type It's Being Installed On.

Connections Gas Supply: 3/4" Mnpt, Cold Water Inlet: 3/4" Mnpt, Hot Water Outlet: 3/4"

Ignition System Direct Electronic Ignition

Electric Connections Appliance: Ac 120 Volts, 60hz. Temperature Control: Dc 12 Volts (Digital)

Water Temperature Control Simulation Feedforward And Feedback.

Water Supply Pressure Minimum Water Pressure: 20 Psi (Recommended 30-80 Psi For Maximum Performance)

Maximum Water Supply Pressure 150 PSI

Temperature Control Cable Non-Polarized Two Core Cable (Minimum 22 Awg)

Star Qualified Yes I Yes

Energy

305 Models

154.330040 & 154.330050

15,000

180,000 Natural Gas 199,000 Natural Gas

180,000 Propane Gas 199,000 Propane Gas

(2.3 - 28.4 L/min) (2.3 - 35.5 L/MIN)

I

505 Models

154.330080 & 154.330090

Minimum flow may vary slightly depending on the temperature setting and the inlet water temperature.

Specifications are subject to change without prior notice.

The maximum inlet gas pressure must not exceed the value specified by the manufacturer. The minimum value listed

is for the purpose of input adjustment.

305 & 505 Outdoor Manual 7

+,,el

++D

K

DIM DESCRIPTION 305 Series 505 Series

A Width 14 (355.6) 14 (355.6)

B Depth * 9.8 (249.5) 9.8 (249.5)

C Height- Unit 22.9 (582) 22.9 (582)

D Height- with brackets 25.4 (646.4) 25.4 (646.4)

E Hot Water Outlet - from wall * 3.8 (96) 3.8 (96)

F Hot Water Outlet - from center 4.3 (110) 4.3 (110)

G Cold Water Inlet - from wall * 3.0 (76) 3.0 (76)

H Cold Water Inlet - from center 1.1 (27) 1.1 (27)

I Gas Connection - from wall * 4.1 (104) 4.1 (104)

J Gas Connection - from center 3.5 (89) 3.5 (89)

From base to gas connection 1.6 (40) 1.6 (40)

K From base to cold connection 2.0 (50) 2.0 (50)

From base to hot connection 1.6 (41) 1.6 (41)

* This is the minimum dimension from the wall. The wall bracket is adjustable to allow an additional 1.57 inches (40 mm).

in. (mm) in. (mm)

8 305 & 505 Outdoor Manual

Pressure Drop Curve

45

40

35

3O

o_ 25

v

09

09

o 20

d

-' 15

09

09

n 10

Outlet Flow Data

305 505 i--

/

4 6 8 10 12

Water Flow (gpm)

100

9O

8O

70 m

6O

50

_J

4O

30

2O a_

10

d)

1..

o

E 6.0

c_

o')

v

0

ii

9.0

8.0

7.0

5.0

4.0

a.o

2.0

1.0

0.0

0 25 50 75 100

delta T - Temperature Rise (°F)

125 150

305 & 505 Outdoor Manual 9

Only properly trained and qualified installers should

install this appliance. The warranty may be voided due

to improper installation or installation by a non-qualified

installer.

It is highly recommended that all installers attend a

product knowledge class.

General Instructions

Donot use substitute materials.

Use only parts certified with the appliance.

• This appliance must be installed by a state qualified or

licensed contractor. It is the responsibility of the person

having the water heater installed to ensure the installing

contractor has proper licenses and permits for installing

water heaters in your location. It is highly recommended

that installers attend a product knowledge class to ensure

customer satisfaction and warranty coverage. Failure to

comply with state and local codes pertaining to water

heater installations may void the warranty.

• This appliance is not to be installed indoors.

• Aqualified installer or service technician should install the

appliance, inspect it, and leak test it before use.

• The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1.

• The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the absence

of local codes, with the National Electrical Code, ANSI/

NFPA 70, or the Canadian Electrical Code, CSA C22.1.

• The appliance and its appliance main gas valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa) (13.84 in W.C.).

• The appliance must be isolated from the gas supply piping

system by closing itsindividual manual shutoffvalve during

any pressure testing of the gas supply piping system at

test pressures equal to or greater than 1/2 psi (3.5 kPa)

(13.84 in W.C.).

• The appliance should be located inan area where

water leakage of the unit or connections will not result in

damage to the area adjacent to the appliance or to lower

floors of the structure. When such locations cannot be

avoided, it is recommended that a suitable metal drain pan,

adequately drained, be installed under the appliance. The

pan must not restrict combustion airflow.

• The flow of combustion and ventilation air shall not be

obstructed.

• This appliance isnot suitable for use in an application such

as a pool or spa heater that uses chemically treated water.

(This appliance is suitable for filling large or whirlpool bath

tubs with potable water.)

• As water is heated, it expands (thermal expansion). In a

dosed system, the volume of water will grow.As the volume

of water grows, there will be a corresponding increase

in water pressure due to thermal expansion.Thermal

expansion can cause premature tank failure (leakage). This

type of failure is not covered under the limited warranty.

Thermal expansion can also cause intermittent pressure

relief valve operation: water discharged from the valve due

to excessive pressure build up. The pressure relief valve is

not intended for the constant relief of thermal expansion.

This condition is not covered under the limited warranty.

A properly-sized thermal expansion tank should be

installed on all closed systems to control the harmful

effects of thermal expansion. Contact a plumbing service

agency or your retail supplier regarding the installation of

a thermal expansion tank. NOTE: Reference Figures 4-7

to see ifyour installation recommends the use of a thermal

expansion tank.

• Should overheating occur or the gas supply fail to shut off,

turn off the manual gas control valve to the appliance.

• Keep the air intake location free of chemicals such as

chlorine or bleach that produce fumes. These fumes

can damage components and reduce the life of your

appliance.

Clearances from Appliance

to top

tos_

to floor/ground

Figure 1

Table 1: to Combustibles to Non-Combustibles

305/505 305/505

Top of 12 inches 2 inches

Heater (305 mm) (51 mm)

10 305 & 505 Outdoor Manual

Table 1: to Combustibles to Non-Combustibles

Back of

Heater

0 (zero) 0 (zero)

Front of 24 inches 24 inches

Heater (610 mm) (610 mm)

Sides of 6 inches 1/8inches

Heater (152 mm) (3.2 mm)

Floor/ 12 inches 2 inches

Ground (305 mm) (51 mm)

The clearance for servicing is 24 inches in front of the

water heater.

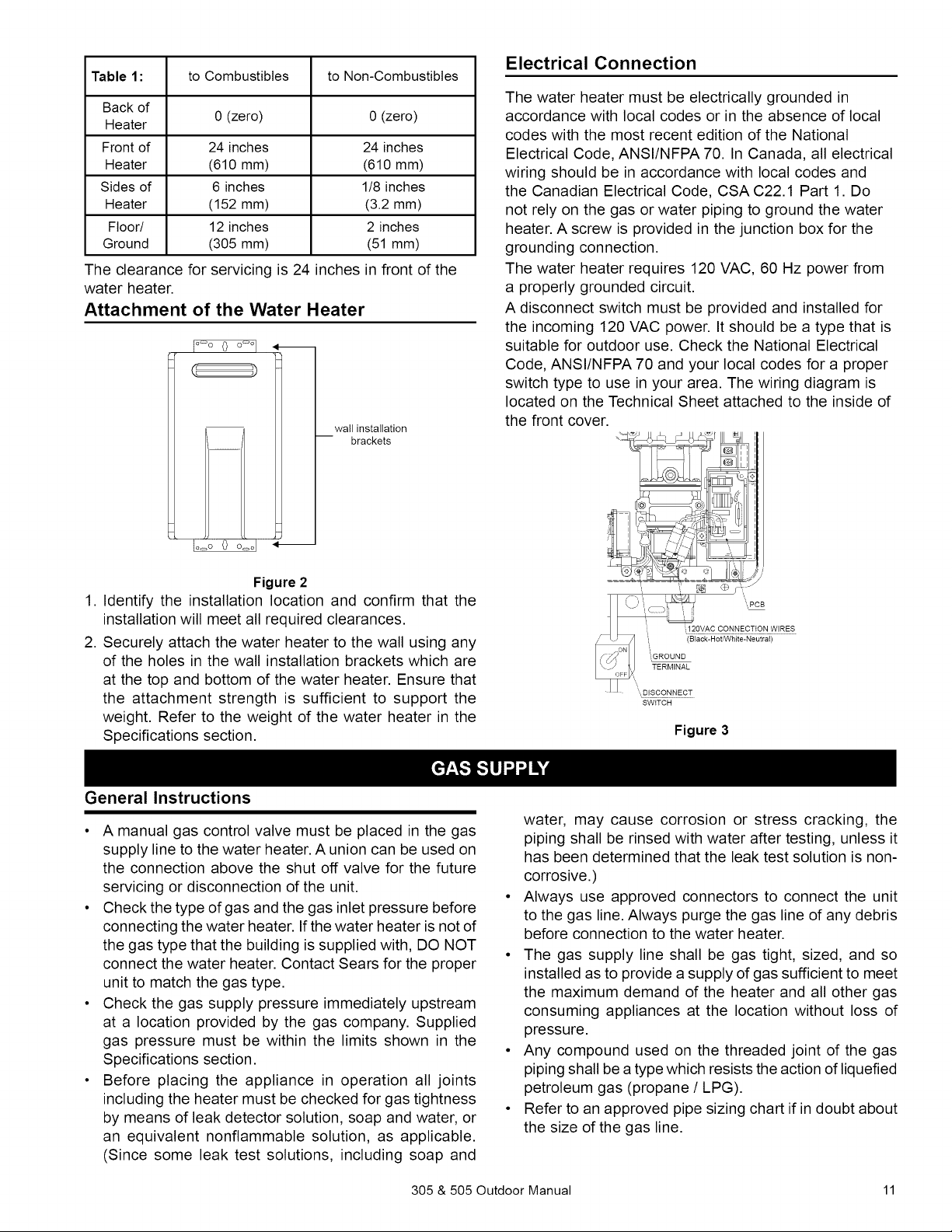

Attachment of the Water Heater

I°_° 0 o°° --

wall installation

brackets

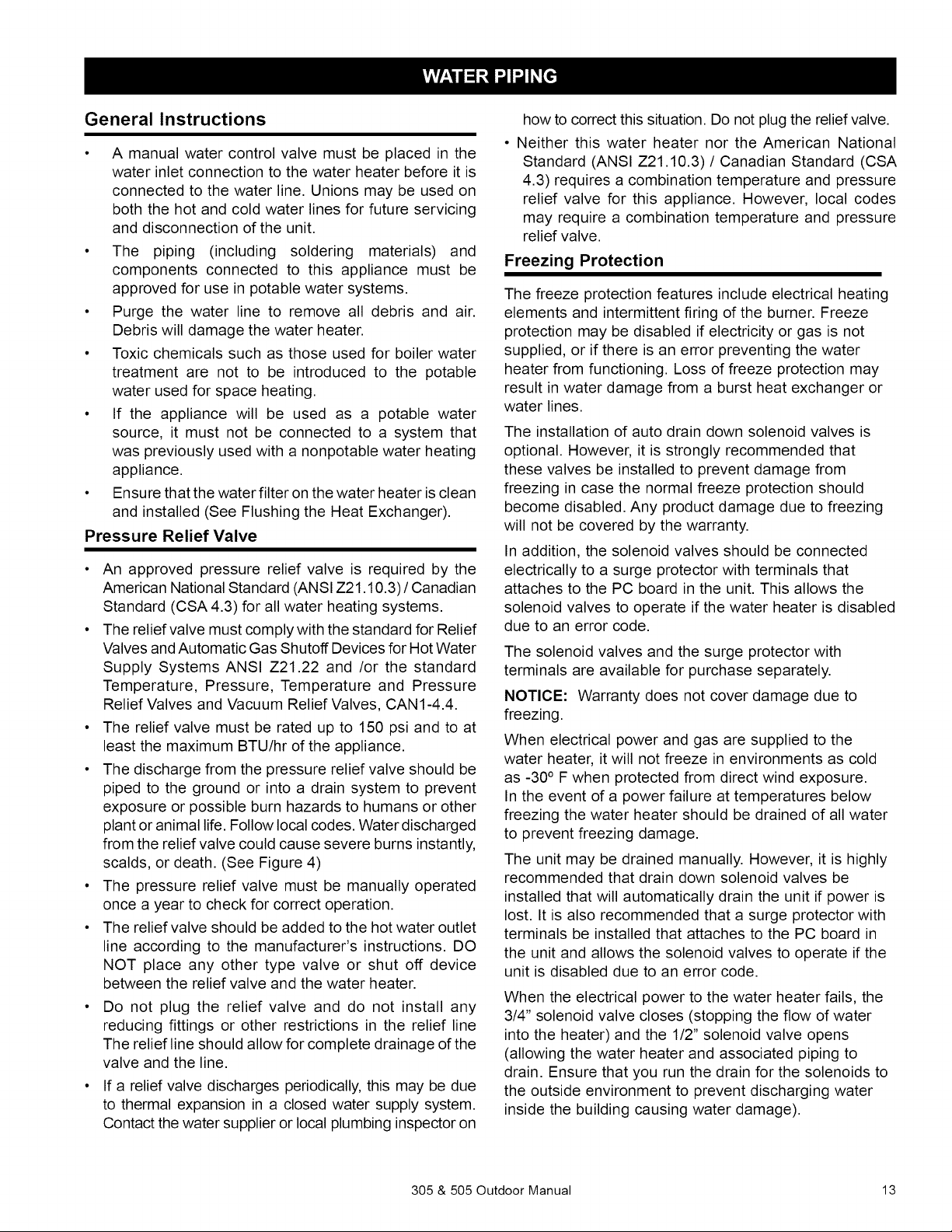

Electrical Connection

The water heater must be electrically grounded in

accordance with local codes or in the absence of local

codes with the most recent edition of the National

Electrical Code, ANSI/NFPA 70. In Canada, all electrical

wiring should be in accordance with local codes and

the Canadian Electrical Code, CSA C22.1 Part 1. Do

not rely on the gas or water piping to ground the water

heater. A screw is provided in the junction box for the

grounding connection.

The water heater requires 120 VAC, 60 Hz power from

a properly grounded circuit.

A disconnect switch must be provided and installed for

the incoming 120 VAC power. Itshould be a type that is

suitable for outdoor use. Check the National Electrical

Code, ANSI/NFPA 70 and your local codes for a proper

switch type to use in your area. The wiring diagram is

located on the Technical Sheet attached to the inside of

the front cover.

Figure 2

1. Identify the installation location and confirm that the

installation will meet all required clearances.

2. Securely attach the water heater to the wall using any

of the holes in the wall installation brackets which are

at the top and bottom of the water heater. Ensure that

the attachment strength is sufficient to support the

weight. Refer to the weight of the water heater in the

Specifications section.

General Instructions

• A manual gas control valve must be placed in the gas

supply line to the water heater. A union can be used on

the connection above the shut off valve for the future

servicing or disconnection of the unit.

• Check the type of gas and the gas inlet pressure before

connecting the water heater. If the water heater is not of

the gas type that the building is supplied with, DO NOT

connect the water heater. Contact Sears for the proper

unit to match the gas type.

• Check the gas supply pressure immediately upstream

at a location provided by the gas company. Supplied

gas pressure must be within the limits shown in the

Specifications section.

• Before placing the appliance in operation all joints

including the heater must be checked for gas tightness

by means of leak detector solution, soap and water, or

an equivalent nonflammable solution, as applicable.

(Since some leak test solutions, including soap and

PCB

i 120vAcco..EcTe,o22,RES

_ liGROUN_

SW{TCH

Figure 3

water, may cause corrosion or stress cracking, the

piping shall be rinsed with water after testing, unless it

has been determined that the leak test solution is non-

corrosive.)

• Always use approved connectors to connect the unit

to the gas line. Always purge the gas line of any debris

before connection to the water heater.

• The gas supply line shall be gas tight, sized, and so

installed as to provide a supply of gas sufficient to meet

the maximum demand of the heater and all other gas

consuming appliances at the location without loss of

pressure.

• Any compound used on the threaded joint of the gas

piping shall be a type which resists the action of liquefied

petroleum gas (propane / LPG).

• Refer to an approved pipe sizing chart if in doubt about

the size of the gas line.

305 & 505 Outdoor Manual 11

Pipe Sizing Procedure - Example

The gas supply must be capable of handling the entire gas load at the location. Gas line sizing is based on gas type,

the pressure drop in the system, the gas pressure supplied, and gas line type. Refer to the National Fuel Gas Code,

NFPA 54, for proper gas line sizing. The below information is provided as an example.

1. Determine the cubic feet per hour of gas required by dividing the gas input (on the rating plate) by the heating value

of the gas (available from the local gas company). The gas input needs to include all gas products at the location

and the maximum BTU usage at full load when all gas products are in use.

Gas Input of the water heater (BTU / HR)

Cubic Feet per Hour (CFH) -

Heating Value of Gas (BTU / FT3)

2. Use the table for your gas type to find the pipe size required for your cubic feet per hour of gas and your pipe

length.

Example: The heating value of natural gas for your location is 1020 BTU/FT 3

The gas input is 199,000 BTU/HR. Additional appliances at the location require 75,000 BTU/HR.

Therefore the cubic feet per hour = (199,000 + 75,000) / 1020 = 268.6 FTS/HR.

If the pipe length is 100 ft then the 1 1¼inch pipe size capable of supplying 304 FT3/HR of natural gas will

be adequate.

TABLE 2: Pipe Sizing Table - Natural Gas

cubic feet per hour Schedule 40 Metallic Pipe

Inlet Pressure: less than 2 psi (55 inches W.C.)

Pressure Drop: 0.3 inches W.C.

Specific Gravity: 0.60

Pipe Size (inches)

Length

3/4 1 1 1/4 1 1/2

10 273 514 1060 1580

20 188 353 726 1090

30 151 284 583 873

40 129 243 499 747

50 114 215 442 662

60 104 195 400 600

70 95 179 368 552

80 89 167 343 514

90 83 157 322 482

100 79 148 304 455

125 70 131 269 403

150 63 119 244 366

175 58 109 224 336

200 54 102 209 313

TABLE 3: Pipe Sizing Table - Propane Gas

cubic feet per hour Schedule 40 Metallic Pipe

Inlet Pressure: 11 inches W.C.

Pressure Drop: 0.5 inches W.C.

Specific Gravity: 1.50

Pipe Size (inches)

Length

1/2 3/4 1 1 1

10 291 608 1150 2350

20 200 418 787 1620

30 160 336 632 1300

40 137 287 541 1110

50 122 255 480 985

60 110 231 434 892

80 101 212 400 821

100 94 197 372 763

125 89 185 349 716

150 84 175 330 677

175 74 155 292 600

200 67 140 265 543

12 305 & 505 Outdoor Manual

General Instructions

A manual water control valve must be placed in the

water inlet connection to the water heater before it is

connected to the water line. Unions may be used on

both the hot and cold water lines for future servicing

and disconnection of the unit.

• The piping (including soldering materials) and

components connected to this appliance must be

approved for use in potable water systems.

• Purge the water line to remove all debris and air.

Debris will damage the water heater.

• Toxic chemicals such as those used for boiler water

treatment are not to be introduced to the potable

water used for space heating.

• If the appliance will be used as a potable water

source, it must not be connected to a system that

was previously used with a nonpotable water heating

appliance.

• Ensure that the water filter on the water heater is clean

and installed (See Flushing the Heat Exchanger).

Pressure Relief Valve

• An approved pressure relief valve is required by the

American National Standard (ANSI Z21.10.3) / Canadian

Standard (CSA 4.3) for all water heating systems.

• The relief valve must comply with the standard for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water

Supply Systems ANSI Z21.22 and /or the standard

Temperature, Pressure, Temperature and Pressure

Relief Valves and Vacuum Relief Valves, CAN1-4.4.

• The relief valve must be rated up to 150 psi and to at

least the maximum BTU/hr of the appliance.

• The discharge from the pressure relief valve should be

piped to the ground or into a drain system to prevent

exposure or possible burn hazards to humans or other

plant or animal life. Follow local codes. Water discharged

from the relief valve could cause severe burns instantly,

scalds, or death. (See Figure 4)

• The pressure relief valve must be manually operated

once a year to check for correct operation.

• The relief valve should be added to the hot water outlet

line according to the manufacturer's instructions. DO

NOT place any other type valve or shut off device

between the relief valve and the water heater.

Do not plug the relief valve and do not install any

reducing fittings or other restrictions in the relief line

The relief line should allow for complete drainage of the

valve and the line.

If a relief valve discharges periodically, this may be due

to thermal expansion in a closed water supply system.

Contact the water supplier or local plumbing inspector on

how to correct this situation. Do not plug the relief valve.

• Neither this water heater nor the American National

Standard (ANSI Z21.10.3) / Canadian Standard (CSA

4.3) requires a combination temperature and pressure

relief valve for this appliance. However, local codes

may require a combination temperature and pressure

relief valve.

Freezing Protection

The freeze protection features include electrical heating

elements and intermittent firing of the burner. Freeze

protection may be disabled if electricity or gas is not

supplied, or if there is an error preventing the water

heater from functioning. Loss of freeze protection may

result in water damage from a burst heat exchanger or

water lines.

The installation of auto drain down solenoid valves is

optional. However, it is strongly recommended that

these valves be installed to prevent damage from

freezing in case the normal freeze protection should

become disabled. Any product damage due to freezing

will not be covered by the warranty.

In addition, the solenoid valves should be connected

electrically to a surge protector with terminals that

attaches to the PC board in the unit. This allows the

solenoid valves to operate if the water heater is disabled

due to an error code.

The solenoid valves and the surge protector with

terminals are available for purchase separately.

NOTICE: Warranty does not cover damage due to

freezing.

When electrical power and gas are supplied to the

water heater, it will not freeze in environments as cold

as -30 ° F when protected from direct wind exposure.

In the event of a power failure at temperatures below

freezing the water heater should be drained of all water

to prevent freezing damage.

The unit may be drained manually. However, it is highly

recommended that drain down solenoid valves be

installed that will automatically drain the unit if power is

lost. It is also recommended that a surge protector with

terminals be installed that attaches to the PC board in

the unit and allows the solenoid valves to operate if the

unit is disabled due to an error code.

When the electrical power to the water heater fails, the

3/4" solenoid valve closes (stopping the flow of water

into the heater) and the 1/2" solenoid valve opens

(allowing the water heater and associated piping to

drain. Ensure that you run the drain for the solenoids to

the outside environment to prevent discharging water

inside the building causing water damage).

305 & 505 Outdoor Manual 13

Figure 4: Freeze Protection Piping - Drawing

o o

Water Heater

Vacuum

Breaker

NOTE:

Heat trace (heat tape) ALL water pipe and fittings

located outside home (attic, crawl space) or

building structure. (ALL water pipe and fittings

shown above the dashed line in the drawing.)

NOTE:

ALL pipe and fittings shown below dashed line

should be located inside home or building

structure.

The vacuum breaker line should be located

inside the building structure.

Minimum 3/4" Hot Water

Supply Line

1/2" Minimum

Normally Open

Solenoid Valve

0 0

_] _--___ -- 3/4" Gas Connection

J

3/4" Minimum Minimum 3/4"

Normally Closed Cold Water

Solenoid Valve Supply Line

D

Route to Floor Drain

KEY

i&

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

14

_ Pressure Regulator

Circulating Pump

I-_ Boiler Drain Valve

[_ Solenoid Valve

305 & 505 Outdoor Manual

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

Figure 5: Recommended Piping for Basic Installation

I_o n o_1

o o

314" HotWater Supply Lin,

For Building Fixtures

Water Heater

O O

i

Equipment List QTY

Water Heaters 1

Plumbing Installation 1

Kit (Optional)

(3/4" Fittings Include:

2 Unions, 2 Ball Valves,

2 Drain Valves and

1 Pressure Relief Valve.)

314" Gas Connection

Gas Supply

314" Cold Water S_ly Line

I_ 3/4" Ball Valve

-- 3/4" Union

Check Valve

z_ Pressure Relief Valve

KEY

_ Pressure Regulator

I_ Circulating Pump

I-_ Boiler Drain Valve

[_ Solenoid Valve

This is not an engineered drawing, It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed, This drawing does

not imply compliance with local building code requirements, It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

305 & 505 Outdoor Manual 15

Figure 6: Recommended Piping for Circulation Systems

NOTE:

Applications, using this piping

arrangement maintains full

warranty.

For this application:

Pump should be controlled by an Aqua-

stat, Timer or Combination Aquastat and

Timer.

Pump to be sized to maintain circulation

I_=o n o91

o o

Water Heater

O

Equipment List QTY

Water Heaters 1

Plumbing installation I

Kit (Optional)

(314" Fittings Include:

2 Unions, 2 Ball Valves,

2 Drain Valves and

I Pressure Relief Valve.)

O

3/4" Gas Connection

The pump should be sized to overcome

the pressure loss through the tank water

heater, and supply and return plumbing.

loop temperature.

Pump to be of bronze or stainless

construction.

IMPORTANT: Connect the building

return line to the hot water supply line._

as close as possible to the water

heater.

L6

_..}_s Supply

Minimum 3/4" Cold Water sUpprLVLine

Tank Water Heater to be Sized for

Heat Loss of Circulation Loop.

Building Supply

___ Electreia_WaterI

Ux' u"n

Expansion Tank

-1

KEY

I_ 3/4" Ball Valve S Pressure Regulator

Z 3/4" Union _ Circulating Pump

CheckValve _ Boiler Drain Valve

[] Pressure Relief Valve D_ Solenoid Valve

16

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation,

305 & 505 Outdoor Manual

Figure 7: Optional Piping for Circulation Systems

NOTE:

Applications, using this piping

arrangement reduces the

warranty to the following:

3 years on heat exchanger

3 year on parts

Full warranty will be maintained if an

on-demand recirculation system in

incorporated. Refer to the Limited

Warranty.

For this application:

Pump should be controlled by an Aquastat,

Timer or Combination Aquastat and Timer.

Pump to be sized to maintain circulation

loop temperature.

A minimum of 3 GPM flow is recommended

for the circulation system.

The pump should be sized to overcome the T

pressure loss through the water heater,

supply and return plumbing.

Pump to be of bronze or stainless construc-

tion.

o o

Water Heater

o o

Equipment List QTY

Water Heaters 1

Plumbing Installation 1

Kit (Optional)

(314" Fittings Include:

2 Unions, 2 Ball Valves,

2 Drain Valves and

I Pressure Relief Valve.)

3/4" Gas Connection

Gas Supply

Note: Water heater outlet temperature

cannot be adjusted when

circulation pump is running.

Minimum 3/4" Hot Water

Supply Line

0

Building Fixture Outlets _ ;

KEY

I & 3/4" Ball Valve

-- 3/4" Union

Check Valve

Z_ Pressure Relief Valve

_ Pressure Regulator

[_ Solenoid Valve

(Optional)

2-6 Gallon

Storage Tank

(To eliminate cold water

sandwich effect caused by

frequent On/Off operation)

Circulating Pump

Boiler Drain Valve

305 & 505 Outdoor Manual 17

Minimum 3/4" ColdWaterSupply Une

Expansion Tank

This is not an engineered drawing, It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

CLOSED

(_ AIR SUPPLY INLET

E_] VENT TERMINAL

AREA WHERE

TERMINAL IS NOT

PERMITTTED

Ref

A

Clearance above grade, veranda, porch, deck, or balcony

B

Clearance to window or door that may be opened

C

Clearance to permanently closed window

D

Vertical clearance to ventilated soffit, located above the terminal within a

horizontal distance of 2 feet (61 cm) from the center line of the terminal

E *

Clearance to unventilated soffit

F Clearance *

G Clearance *

H Clearance *

assembly

I Clearance

J

Clearance to nonmechanical air supply inlet to building or the combustion air

inlet to any other appliance

K

Clearance to a mechanical air supply inlet

L Clearance above paved sidewalk or paved driveway located on public property O

M Clearance under veranda, porch, deck, or balcony Q

d)

A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves

both dwellings.

©

Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

For clearances not specified in ANSI Z223.1/NFPA 54 or CSA B149.1, clearances are in accordance with local installation codes and the

requirements of the gas supplier.

to outside corner

to inside corner

to each side of center line extended above meter/regulator

to service regulator vent outlet

Description

US Installations

12 inches (30 cm)

12 inches (30 cm)

12 inches (30 cm)

3 feet (91 cm) above if within

10 feet (3 m) horizontally

18 305 & 505 Outdoor Manual

Additional Clearance - Vent Terminal

Local codes supersede these clearances,

• Avoid termination locations near a dryer vent,

• Avoid termination locations near commercial cooking exhaust.

ventilated or unventilated soffit or eve vent; or

to a deck or porch

(50 mm) between water heater terminals at same level

CORNER

Figure 8

305 & 505 Outdoor Manual 19

Set dip switches 2 and 3 to the values shown in table

below for your altitude. The default setting for the

appliance is 0-2000 ft (0-610 m) with switches No. 2 and

No. 3 in the OFF position.

0-2000 ft 2001-5200 ft 5201-7700 ft 7701-10200 ft

Table 4: (0-610 m) (610-1585 m) (1585-2377 m) (2378-3109 m)

Switch No. 2 OFF OFF ON ON

Switch No. 3 OFF ON OFF ON

DO NOT adjust the other dip switches unless specifically

instructed to do so.

Switch No.

ON

O 1

2

3

4

5

6

7

8

The 2-Unit connection cable is an optional accessory

that connects 2 water heaters and allows them to

function as one hot water source.

The Multi-Unit connection kit and Multi-Unit connection

cables are optional accessories that connect 2 to 5

water heaters and allow them to function as one hot

water source.

The Multi-Unit connection kit includes a PC board and

one Multi-Unit connection cable.

Refer to the instructions that come with the accessory

for complete installation information.

Switch No.

ON

O 1

Fm

m 3

4

5

6

7

8

Switch No.

ON

O 1

m 2

• 3

Switch No.

O 1

F

F •2

4

5

6

7

8

Guidelines

• Do not install both the 2-Unit connection cable and the

Multi-Unit connection kit because they are not designed

to operate together.

• Water heaters should be installed less than 18 inches

apart so that the cables will reach between units and to

prevent temperature fluctuations (cold water sandwich

effect) when the water is shut off and turned back on.

• Temperature settings can only be changed on the

controller for the primary unit.

ON

•3

4

5

6

7

8

Table 5:

Number of Connected Water Heaters: Accessories Necessary:

2 (1) 2-Unit connection cable or (1) Multi-Unit connection kit

3 (1) Multi-Unit connection kit and (1) Multi-Unit connection cable

4 (1) Multi-Unit connection kit and (2) Multi-Unit connection cables

5 (1) Multi-Unit connection kit and (3) Multi-Unit connection cables

20 305 & 505 Outdoor Manual

Location Mounting the Controller

Outdoor models are supplied with one remote control

unit. Additional controllers can also be installed.

• The controller should be out of reach of small

children.

• Avoid locations where the controller may become hot

(near the oven or radiant heater).

• Avoid locations in direct sunlight. The digital display may

be difficult to read in direct sunlight.

• Avoid locations where the temperature controller could

Do not attempt to connect the temperature controllers with

the power on. There is 120 volt potential, next to the

temperature controller connections inside the unit.

Do not connect the temperature controller to the 120VAC

terminals provided for the optional solenoid drain valves.

All service and wiring should be performed by a registered

installer.

be splashed with liquids.

• Do not install in locations where it can be adjusted by

the public.

Configurations

A maximum of 4 temperature controllers can be installed

for a water heater or bank of water heaters.

Controllers can only be wired in parallel. Controllers

cannot be wired in series.

Follow the procedure below to install additional

controllers.

1. Determine a suitable location for the controller.

2. Make three holes in the wall as shown.

3. Run the cable between the controller and the water

heater or the controller and the other controller.

4. Remove the face plate from the temperature controller

using a screwdriver.

5. Connect the cable to the temperature controller.

6. Mount the controller to the wall using the holes drilled

If 4 temperature controllers are installed, simultaneously

press the Priority and On/Off buttons on the fourth

controller until a beep sounds.

in step 2.

7. Disconnect the power from the water heater.

8. Remove the cover of the water heater.

9. Remove the plastic cover from the PCB and electrical

connections.

10. Thread the cable through the access hole at the base

Controllers

Water

Heater

of the unit and connect the wires to the controller

terminals on the right hand side bottom of the PCB.

11. Secure the controller cable using the clamp

provided.

12. Replace plastic cover over PCB and then replace the

cover of the water heater.

Outline of Controller

securing screw _),

.......................................[

Wire controllers in parallel

Figure 9

wiring hole i-..... c_ j! _ _ _,._

securing .............C) i .............................................................{.......

i ..... ii 5-bl'le

Cable Length and Size

CONNECTION TERMINALS

The cable for the temperature controller should be a

non-polarized two-core cable with a minimum gauge

of 22 AWG. The maximum cable length from each

controller to the water heater depends on the total

number of wired controllers connected to the water

heater.

"-- f

i 1-21/3z'i

Table 6:

Number of Wired Maximum Cable Length for each

Controllers Controller to Water Heater

1 328 ft (100 m)

2 164 ft (50 m)

3 or 4 65 ft (20 m)

305 & 505 Outdoor Manual 21

Figure 10

This appliance is one of the most advanced water

heaters available. It provides a continuous supply of

hot water at a preset temperature. This appliance is

direct vent where air is brought in from the outside and

combustion gases are exhausted to the outside.

While electricity, water, and gas supplies are connected,

this appliance produces hot water whenever a hot water

tap is open.

Ignition is electronic. There is no pilot light consuming

gas while the water heater is not being used. The gas

burner lights automatically when the hot water tap is

opened and goes out when the tap is closed. Installation

of the temperature controller is highly recommended.

The temperature controller can set the temperature

within a specific range and can provide error codes to

diagnose any problems.

The temperature of the outgoing hot water is constantly

monitored. This appliance may adjust the water flow

in order to maintain the temperature setting. The

water flow may vary from summer to winter due to the

difference in ground water temperature.

Sequence of Operation

1. Water Flow Begins

• Water Flow Sensor sends a pulse to the electronic

Features Available on Temperature Controllers

The temperature controller is supplied with the

appliance. Dimensions (inches): 3.5 W x 4.75 H x 0.75 D.

control board

• Electronic control board senses flow greater than

0.6 GPM

• Firing Sequence begins

2. Firing Sequence

Indicator

k,

ITemperature

Display F

• Electronic control board monitors inlet/outlet water

temperature, temperature set point, and water

flow rate.

'-Thermostat

• Combustion fan energized. Purges combustion

chamber.

• Spark igniter begins sparking.

• Gas control valve opens to minimum fire rate.

• Flame rod proves ignition

• Spark igniter stops sparking

Features Description

Error Codes When a fault is detected an error code

3. Normal Operation

• Electronic control board monitors flame rod,

fan motor frequency, outlet water temperature,

controller temperature set point and water flow

rate.

• Gas control valve modulates gas input to required

In Use Indicator Indicates that hot water is being supplied

ON/OFF Button Used to turn the water heater ON or OFF.

Priority Button / Indicates that this controller is setting the

Indicator temperature. Priority can be switched to

firing rate.

• Combustion fan speed is adjusted for the required

firing rate.

• Water flow control valve is adjusted as needed.

Temperature Display Shows the temperature setting.

Thermostat Increases or decreases the temperature

4. Shutdown Sequence

• Electronic control board senses water flow rate

less than 0.5 GPM.

• Gas control valve closes.

• Water flow control valve resets to standby

position.

• Combustion fan runs for a short period of time at

low speed.

5. Standby Mode

• Electronic control board monitors water temperature

and remote controls

• Freeze protection is activated as needed.

22 305 & 505 Outdoor Manual

In Use 1

I

"F/'C

i

Approx Water Temp

flashes at the temperature

(i.e. a hot water tap is open).

another controller by pressing its Priority

Button when no hot water is running.

setting.

In Use

J Priority /

Figure 11

IF!IImT± d -'tl

For systems with storage tanks, the water temperature

in certain situation may vary up to 30°F (16.7°C) higher

or lower at the point of use such as, bathtubs, showers,

sink, etc.

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a

temperature which will satisfy space heating, clothes

washing, dish washing, and other sanitizing needs can

scald and permanently injure you upon contact. Some

people are more likely to be permanently injured by hot

water than others. These include the elderly, children,

the infirm, or physically/mentally handicapped. If anyone

using hot water in your home fits into one of these groups

or if there is a local code or state law requiring a certain

temperature water at the hot water tap, then you must

take special precautions. In addition to using the lowest

possible temperature setting that satisfies your hot water

needs, a means such as a mixing valve should be used

at the hot water taps used by these people or at the water

heater. Mixing valves are available at plumbing supply

or hardware stores. Follow manufacturer's instructions

for installation of the valves. Before changing the factory

setting on the thermostat, Using the lowest hot water

temperature that meets your needs will also provide the

most energy efficient operation of the water heater.

Never allow small children to use a hot water tap, or

to draw their own bath water. Never leave a child or

handicapped person unattended in a bathtub or shower.

The thermostat on the water heater has been factory set

at 120°F, to reduce the risk of scald injury. It is adjustable

and can be reset to the desired temperature setting.

Some states have a requirement for a lower setting. If

you need hotter water, follow direction for temperature

adjustment, but beware of the warnings in this section.

NOTICE: While any hot water is being provided, the

temperature setting can only be adjusted between 98° F

and 110° R

Water temperature over 125°F (52°C)

can cause servere burns instantly

resulting in severe injury or death.

Children, the elderly, and the

physically or mentally disabled are at

highest risk for scald injury.

Feel water before bathing or

showering.

Temperature limiting valves are

available.

Read instruction manual for safe

temperature setting.

NOTICE: Check local codes for the maximum water

temperature setting allowed when used in nursing

homes, schools, day care centers, and all other public

applications.

NOTICE: If a newly installed unit with a temperature

controller has not been powered for at least 6 hours then

the temperature will return to the default setting of 104° F

(40° C) if power is interrupted.

NOTICE: There may be a variation between the

temperature displayed on the temperature controller and

the temperature at the tap due to weather conditions or

the length of pipe to the water heater.

160°F (71°C)

150°F (66°C)

140°F (60°C)

130°F (54°C)

120°F (49°C)

80°F (27°C)

Hot water temp.

5[

1. Press the "Priority button"

on the temperature controller.

The green Priority light will glow

indicating that this controller is

controlling the temperature and

that the water heater is ready to

supply hot water.

The priority can only be changed

while no hot water is running.

Press the • or • buttons to

obtain the desired temperature

setting.

All hot water sources are able to

provide water at this temperature

setting until it is changed again

at this or another temperature

controller.

About 1/2 second

About 1-1/2 second

Less than 5 seconds

About 30 seconds

More than 5 minutes

305 & 505 Outdoor Manual 23

Temperature Options without a Temperature Controller

Donot adjust the other dip switches unless specifically

instructedto do so.

The default temperature setting for this appliance

installed without a remote controller is 120° F (49° C). If

desired the temperature setting can be changed to 140°

F (60° C) by adjustment of a dip switch. Set dip switch

5 to ON to obtain 140° F water temperature setting.

120° F (49° C)

Switch No.

ON

O----1

F ----

F 2

3

---- 4

--i ....i 5

mm

7

8

140° F (60° C)

Switch No.

ON

O----1

F -- --

F 2

-- -- 3

-- -- 4

.... m;

:'_c-. ,or _.

-- -- 7

-- -- 8

I

Set dip switch 5 to OFF (default) to obtain 120° F water

temperature setting.

Figure 12

Temperature Ranges

This water heater will attempt to provide hot water at the temperature setting even when the water flow is varied or

when more than 1 tap is in use. The water heater can deliver water at only one temperature setting at a time. The

available temperatures for a given model are provided below.

Table 8:

Model Temperature Settings Available (°F)

305 Series 98 100 102 104 106 108 110 115 120 125" 130" 135" 140"

505 Series 98 100 102 104 106 108 110 115 120 125" 130" 135" 140"

Temp. in Celsius 37 38 39 40 41 42 43 46 49 52 54 57 60

* Re-setting the Maximum Temperature

Temperature settings from 125-140 °F (52-60 °C) are available by setting dip switch 6 to ON in the SW1 bank of 8

dip switches.

Table 9:

Suggested temperatures are: These temperatures are suggestions only.

Kitchen 120°F (49°C) A temperature lower than 98°F (37°C) can be obtained

Shower 98°- 110°F (37 ° - 43°C) at the tap by mixing with cold water.

To change the temperature scale from Celsius to Fahrenheit or visa versa, press and hold the "On/Off" button for 5

seconds while the water heater is OFF.

Setting Controller to Mute

To eliminate the beeps when keys are pressed or to turn the beeps back on, press and hold both the Aand •

buttons until a beep is heard (approximately 5 seconds).

24 305 & 505 Outdoor Manual

FOR YOUR SAFETY READ BEFORE OPERATING

If you do not follow these instructions exactly, a fire or explosion I

may result causing property damage, personal injury or loss of life.

A.

This appliance does not have a pilot. It is

equipped with an ignition device which

automatically lights the burner. Do not try to light

the burner by hand.

a.

BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air and

will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance using

the ON/OFF button.

.

This appliance is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

.

Locate the manual gas valve on the side of the

heater. Turn the manual valve

clockwise to the full OFF position. /-_

Manual Valve

CLOSE OPEN

I

I

• If you cannot reach your gas supplier, call the

fire department.

C.

Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, do not try to repair it, call a

qualified service technician. Force or attempted

repair may result in a fire or explosion.

U.

Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

.

Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you smell

gas, STOP! Follow "B" in the safety information

above. If you don't smell gas, go to the next step.

7. Turn the manual gas valve counterclockwise to the

full ON position.

8. Turn on all electric power to the appliance using

the ON/OFF button.

g.

Set the thermostat to desired setting.

10.

Open a hot water tap. If the appliance will not

operate, follow the instructions "To Turn Off Gas

To Appliance" and call your service technician or

gas supplier. See manual for additional

information.

TO TURN OFF GAS TO APPLIANCE

.

Turn off all electric power to the appliance using 3. Locate the manual gas valve on the side of the

the ON/OFF button.

.

Set the thermostat to lowest setting. OFF position.

305 & 505 Outdoor Manual 25

heater. Turn the manual valve clockwise to the full

Turnoffthe electrical power supply, the manual gas valve

and the manual water control valve whenever servicing the

unit.

Repairs and maintenance should be performed by a

qualified service technician. The appliance should be

inspected annually by a qualified service technician.

Verify proper operation after servicing.

Cleaning

It is imperative that control compartments, burners, and

circulating air passageways of the appliance be kept

clean.

Clean as follows:

1. Turn off and disconnect electrical power. Allow to

cool.

,

Remove and clean the water inlet filter.

3.

Remove the front panel by removing 4 screws.

4.

Use pressurized air to remove dust from the main

burner, heat exchanger, and fan blades. Do not

use a wet cloth or spray cleaners on the burner. Do

not use volatile substances such as benzene and

thinners. They may ignite or fade the paint.

,

Use soft dry cloth to wipe cabinet.

Vent System

Lime / Scale Build-up

If you receive Error Code "LC", refer to the procedure,

Flushing the Heat Exchanger. Refer to the section on

Water Quality to see if your water needs to be treated or

conditioned. (When checking maintenance code history,

"00" is substituted for "LC".)

Snow Accumulation

Keep the area around flue terminal free of snow and ice.

The appliance will not function properly if the intake air

or exhaust is impeded (blocked or partially blocked) by

obstructions.

Visual Inspection of Flame

The burner must flame evenly over the entire surface

when operating correctly. The flame must burn with a

clear, blue, stable flame. See the parts breakdown of the

burner for the location of the view ports.

The flame pattern should be as shown in the figures

below.

FRONT VIEW

SATISFACTORY

BLUEFLAME

ME ROD

I I

The vent system should be inspected at least annually

for blockages or damage.

Motors

Motors are permanently lubricated and do not need

periodic lubrication. Keep fan and motor free of dust and

dirt by cleaning annually.

Temperature Controller

Use a soft damp cloth to clean the temperature

controller. Do not use solvents.

UNSATISFACTORY

FRONT VIEW

YELLOW FLAME

FLAME ROD

Figure 13

26 305 & 505 Outdoor Manual

This appliance has the ability to check its own operation

continuously. If a fault occurs, an error code will flash

on the Display of the temperature controller. This

assists with diagnosing the fault and may enable you

to overcome a problem without a service call. Please

identify the code displayed when inquiring about service.

Table 10: Error Codes

Some of the checks below may need to be done by a

qualified service technician. Call a service technician for any

remedy that involves gas or electricity. Call a service

technician if you have any doubt or reservation about

perform ng the remedy yourse f.

Code Remedy

02 ServiceCall- Checkfor possiblefreezedamage to heatexchanger.

10

11

12

Fault

No burner operation during freeze

protection mode

Air Supply or Exhaust Blockage

No Ignition

Flame Failure

Ensure approved venting materials are being used.

Check that nothing is blocking the flue inlet or exhaust.

Check all vent components for proper connections.

Ensure vent length is within limits.

Ensure condensation collar was installed correctly.

Verify dip switches are set properly.

Check fan for blockage.

Check that the gas is turned on at the water heater, gas meter, or cylinder.

Ensure gas type and pressure is correct.

Ensure gas line, meter, and/or regulator is sized properly.

Bleed all air from gas lines.

Verify dip switches are set properly.

Ensure appliance is properly grounded.

Disconnect all 2-Unit or Multi-Unit connections to isolate the problem.

Ensure igniter is operational.

Check igniter wiring harness for damage.

Check gas solenoid valves for open or short circuits.

Remove burner cover and ensure all burners are properly seated.

Remove burner plate and inspect burner surface for condensation or debris.

Check that the gas is turned on at the water heater and gas meter. Check

for obstructions in the flue outlet.

Ensure gas line, meter, and/or regulator is sized properly.

Ensure gas type and pressure is correct.

Bleed all air from gas lines.

Ensure proper venting material was installed.

Ensure condensation collar was installed properly.

Ensure vent length is within limits.

Verify dip switches are set properly.

Ensure appliance is properly grounded.

Disconnect keypad.

Disconnect all 2-Unit or Multi-Unit connections to isolate the problem.

Check power supply for loose connections.

Check power supply for proper voltage and voltage drops.

Ensure flame rod wire is connected.

Check flame rod for carbon build-up.

Disconnect and reconnect all wiring harnesses on unit and PC board.

Check all components for electrical short.

Check gas solenoid valves for open or short circuits.

Remove burner plate and inspect burner surface for condensation or debris.

305 & 505 Outdoor Manual 27

Code Fault

14 Thermal Fuse

16

32

33

34

52 Modulating Solenoid Valve Signal

61 Combustion Fan Failure Ensure fan will turn freely.

65 Water Flow Control Fault If blank screen is present on remote control then the flow control has

71 SV0, SVl, SV2, and SV3 Solenoid Valve Check wiring harness to all solenoids for damage and/or loose connections.

72 Flame Sensing Device Fault

LC or

O0

No

Code

28 305 & 505 Outdoor Manual

Over Temperature Warning

Outgoing Water Temperature Sensor

Fault

Heat Exchanger Outgoing Temperature

Sensor Fault

Combustion Air Temperature Sensor

Fault

Abnormal

Circuit Fault Measure resistance of each solenoid valve coil.

Scale Build-up in Heat Exchanger (when

checking maintenance code history, "00"

is substituted for "LC")

Nothing happens when water flow is

activated.

Remedy

Check gas type of unit and ensure it matches gas type being used.

Check for restrictions in air flow around unit and vent terminal.

Check for low water flow in a circulating system causing short-cycling.

Ensure dip switches are set to the proper position.

Check for foreign materials in combustion chamber and/or exhaust piping.

Check heat exchanger for cracks and/or separations.

Check heat exchanger surface for hot spots which indicate blockage due to

scale buildup.

Refer to instructions in manual for flushing heat exchanger.

Measure resistance of safety circuit.

Ensure high fire and low fire manifold pressure is correct.

Check for improper conversion of product.

Check for restrictions in air flow around unit and vent terminal.

Check for low water flow in a circulating system causing short-cycling.

Check for foreign materials in combustion chamber and/or exhaust piping.

Check for clogged heat exchanger.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

Check for restrictions in air flow around unit and vent terminal.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Ensure fan blade is tight on motor shaft and is in good condition.

Replace sensor.

Check modulating gas solenoid valve wiring harness for loose or damaged

terminals.

Measure resistance of valve coil.

Check wiring harness to motor for damaged and/or loose connections.

Measure resistance of motor winding.

shorted. Unplug flow control. If remote lights up and unit starts operating

then replace flow control assembly.

Ensure flame rod is touching flame when unit fires.

Check all wiring to flame rod for damage.

Remove flame rod and check for carbon build-up; clean with sand paper.

Check inside burner chamber for any foreign material blocking flame at

flame rod.

Measure micro amp output of sensor circuit with flame present.

Replace flame rod.

Flush heat exchanger. See Flushing the Heat Exchanger section.

Clean inlet water supply filter.

On new installations ensure hot and cold water lines are not reversed.

Check for bleed over.

Isolate unit from building by turning off hot water line to building.