Owners

Manual

FOR POTABLEWATER

HEATING ONLY

NOT SUITABLEFOR

SPACEHEATING

NOT FOR USE IN

MOBILE HOMES

Model No.

153.337113

153.337162

153.337213

153.337262

153.337362

153.337413

153.337462

153.337513

153.337562

153.337613

153.337662

153.337762

153.337862

153.337960

50 Gal. Short HighAltitude

50 Gal. Short

40 Gal. Short High Altitude

40 Gal. Short

30 Gal.

40 Gal. HighAltitude

40 Gal.

50 GaL High Altitude

50 Gal.

65 Gal. High Altitude

65 Gal.

50 Gal. High Recovery

65 Gal. High Recovery

40 Gal. (LP.)

i

POWER MISERTM9

GAS WATER HEATER

• Safety Instructions

• Installation

• Operation

For Your Safety

AM ODORANT IS ADDED TO THE GAS USED BY THIS

WATER HEATER

WARNING: If the information .in these instructions are not fol-

lowed exactly, a .fire or explosion may result, causing property

damage, personal injury or death.

• Care and Maintenance

• Troubleshooting

• Parts List

Caution:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

Save this Manual for Future Reference.

-Do not store or use gasoline or other flammable vapors and liq-

uids in the vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

: Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your

building. . . ,

Immediately call your _as supp.lier from a neighbor s phone.

i Follow the gas suppher'sinstructions.

If you can not reach your gassuppher, call the fire department.

-Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

&WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause DEATH, SERIOUS BODILY INJURY, OR PROPERTY DAM-

AGE. Refer to this manual for assistance or consult the local Sear

Service Center or gas utility for further information.

&WARNING

Flammable vapors may be drawn by air currents from other areas

of the structure to this appliance.

&WARNING

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE

COVER AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING

OR OPERATING THIS WATER HEATER.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Safety Precautions

Improper installation, adjustment, alteration, service or I

. h'WARNING . I

maintenance can cause DEATH, SERIOUS BODILY I

INJURY,OR PROPERTY DAMAGE. Refer to this man.u-

al for assistance or Consult your local Sears Service I

Center for further information. I

i

i ," i AWARNING

WATER HEATERS EQUIPPED FOR ONE TYPE GAS

'ONLY: This water heater is equipped for one type gas

only. Check the model rating plate near the gas control

valve for the correct gas. DO NOT USE THIS WATER

!HEATER WITH ANY GAS OTHER THAN THE ONE

SHOWN ON THE MODELRATING PLATE. Failure to

!usethe correct gascancauseproblems which can result in

IDEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE. If you have any questions or doubts consult

yourgassupplieror localutility.

A,WARNING

INSTALLATIONS IN AREAS WHERE FLAMMABLE LIQ-

UIDS (VAPORS) ARE LIKELY TO BE PRESENT OR

STORED (GARAGES, STORAGE, AND UTILITY AREAS,

ETC): Flammable liquids (such as gasoline, solvents,

propane(LP) or butane, etc.), allof whichemit flammable

vapors, may be impropedy stored or used in such areas.

The gaswater heater pilot light or main burner canignite

such vapors. The resulting flashback and fire can cause

death or serious burnsto anyone in the area, as well as

property damage.

If installation in such areas is your only option, then the

installation must be accomplishedin a way that the pilot

flame and main burner flame are elevated from the floor

at least 18 inches.While this may reduce the chancesof

flammable vaporsfrom a floor spill being ignited,gasoline

and other flammable substancesshouldnever be storedor

used in the same room or area containing a gas water

heater or other openflame or spark producingappliance.

NOTE: Flammable vapors may be drawn by air currents

from other areas of the structure to the appliance.

AWARNING

If this water heater will be used in beauty shops,barber

shops, cleaning establishments, or self-service laundries

with dry cleaning equipment, it is imperative that the

water heater or water heaters be installed so that com-

bustion and ventilation air be taken from outside these

areas. Refer to the "Facts to Consider About the

Location" section of this manual and also the latest edi-

tion of the National Fuel Gas Code, ANSI Z223.1, also

!referred to as NFPA 54 for specificsprovided concerning

Iair required.

I A,W..A.RNING I

A fire can start if combustiblematerials suchas cloth!ng,

cleaningmaterials, or flammable IKluidsare placed ag;unstI

or nextto the water hea_, J

AWARNING

At the time of manufacture this water heater _ provid-

ed with a combination temperature-pressures relief valve

certified by a nationally recognized testing laboratory

that maintains periodic inspectionof production of listed

equipment or materials, as meeting the requirements

for Relief Valvesand Automatic Gas Shutoff Devices for

Hot Water Supply Systems, and the latest edition of

ANSI Z21.22 and the code requirements of ASME. If

replaced, the valve must meet the requirements of local

codes,but not lessthan a combination temperature and

pressure relief.valve certified as meeting the require-

ments for Rehef Valves and Automatic Gas Shutoff

Devicesfur Hot Water Supply Systems,ANSI Z21.22 by

a nationally recognized testing laboratory that maintains

periodic inspection of production of listed equipment or

materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostaticworking pressure

of the water heater (150 Ibs./sq. in.) and a discharge

capacity not less than the water heater input rate as

shown on the model rating plate. (Electric heaters -

watts dividedby 1000 x 3415 equal BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the

use of a temperature-pressure relief valve complying

with ANSI Z21.22 and ASME, may require avalve model

different from the one furnishedwith the water heater.

Compliance with suchlocal requirements must be satis-

fied by the installer or end user of the water heater with

a locally prescribed temperature-pressure relief valve

installedin the designatedopeningin the water heater in

place of the factory furnishedvalve.

For safe operation of the water heater, the relief valve

must not be removed from it's designated opening or

plugged.

The temperature-prossure relief valve must be installed

directly into the fitting of the water heater designated

for the relief valve. Position the valvedownwardand pro-

vide tubing so that any dischargewill ex'_ only within 6

inches above, or at any distance below the structural

floor. Be certain that no contact is made with any live

electrical part. The discharge opening must not be

I • . I

blocked or reduced n smzeunder any cmrcumstances.

Excessivelength ever 30 feet or useof more than four

elbows can cause restriction and reduce the d_scharge

capacityof the valve.

No valve or other obstruction is to be placed between

the relief valve and the tank. Do not connect tubing

directly to dischargedrain unlessa 6" air gap is provided.

To prevent bodily injury, hazard to life, or property dam-

age, the relief valve must be allowed to dischargewater

in quantities should circumstances demand. If the dis-

chargepipe isnot connected to a drain or other suitable

means,the water flow may causeproperty damage.

The Discha_e Pipe:

Must not be smaller in sizethan the outlet pipe size of

the valve, or have any reducing couplings or other

restrictions.

Must not be pluggedor blocked.

Must beof material listed for hot water distribution.

Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the

dischargepipe.

Must terminate at an adequate drain.

Must not have any valve between the relief valve and

tank,

Safety Precautions

&WARNING

A gaswater heater cannot operate properly without the

correct amount of air for combustion.Do not installin a

confined area such a closet, unless you provide air as

showninthe "Facts to ConsiderAbout the Location" sec-

tion. Never obstructthe flowof ventilationair. If you have

any doubts or questions at all, call your gas company.

Failure to provide the proper amount of combustion air

can resultin a fire or explosionand can CAUSE DEATH,

SERIOUS BODILY INJURY,OR PROPERTYDAMAGE.

AWARNING

HOTTER WATER CAN SCALD: Water heaters are

intended to produce hot water. Water heated to a tam-

)erature which will satisfyclothes washing,dish washing,

and other sanitizing needs can scald and permanently

injure you upon contact. Some people are more likelyto

be permanently injured by hot water than others. These

includethe elderly,children,the infirm,or physically/men-

tally handicapped.If anyone usinghot water in your home

fits into oneof these groupsor if there is a local code or

statelaw requiring a certain temperature water at the hot

water tap, then you musttake specialprecautions.In addi.

tion to usingthe lowestpossibletemperature setting that

satisfiesyour hot water needs, a means suchas a mixing

valve,should be usedat the hot water taps usedby these

people or at the water heater. Mixingvalvesare available

at plumbing supplyor hardware stores. Follow manufac-

turers instructions for installation of the valves. Before

changingthe factory setting on the thermostat, read the

"Temperature Regulation"section in this manual.

AWARNING

Soot build-up indicates a problem that requires correc-

tion before further use. Turn "OFF" gasto water heater

and leave "OFF" until repairs are made, becausefailure

to correct the cause of the sootingcan result in a fire or

explosion causing DEATH, SERIOUS BODILY INJURY,

OR PROPERTY DAMAGE.

AWARNING

This water heater must not be installed directly on car-

petlng.Carpeting must be protected .bya metal orwood

panel beneath the appliance extending beyond the full

width and depth of the appliance by at least 3 inches

(76.2mm) in any direction, or if the applianceisinstalled

in an alcove or closet,the entire floor must be coveredby

the panel. Failure to heed this warning may result in a

fire hazard.

AWARNING

VENT DAMPERS- Anyvent damper,whether it is.operat-

ed thermally or otherwise must be removed if its use

inhibitsproperdraftingofthe water heater.

Thermally Operated Vent Dampers: Gas-fired water

heaters having thermal efficiencyin excessof 80% may

producea relatively lowflue gastemperature. Suchtem-

peratures may not be highenoughto properlyopenther-

mally operated vent dampers.This wouldcausespillageof

fluegasesand maycausecarbonmonoxidepoisoning.

Vent dampers must bear evidenceof certificationas com-

plying with the latest edition of American National

Standard ANSI Z21.68 (ANSI Z21.66 & 67, respectively,

cover electrically and mechanically actuated vent

dampers). Beforeinstallationof any vent damper, consult

your localSears Service Center or the gasutility for fur-

ther information.

_,WARNING

• The applianceandits individualshutoff valvemustbe dis-

connectedfrom the gassupply piling systemduringany

pressure testing of the gassystem at test pressuresin

excessof ½poundper squareinch(3.SkPa).

• The appliance must be isolatedfrom the gassupplypip-

ing system by dosing its individualmanualshutoffvalve

during any pressuretesting of the gassupplypipingsys-

tem at test pressuresequal or lessthan % pound per

squareinch(3.SkPa).

AWARNING

BEFORE LIGHTING [PROPANE (L.P.) GAS WATER

HEATERS]: Propane (I-R) gas is heavierthan air. Should

there be a leak inthe system,the gaswill settle near the

ground. Basements, crawl spaces,skirted areas under

mobile homes (even when ventilated), closetsand areas

below groundlevelwill serve as pocketsfor the accumula-

tion of this gas.Before attempting to light or relight the

water heater's pilot or turning on a nearby electricallight

switch,be absolutelysure there is no accumulatedgas in

the are_ Searchfor odor of gasbysniffingat ground level

in the vicinity of the appliance. If odor is detected, follow

steps indicatedat "For Your Safety" on the cover pageof

this manualthen leavethe premises.

AWARNING

Chemical vapor corrosion of the flue and vent system

may occurif air for combustioncontainscertain chemical

vapors.Spray can propellants,cleaningsolvents,refrigera-

tor and air conditioner refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes,bleach,

and processchemicalsare typical compoundswhich are

potentiallycorrosive.

AWARNING

Obstructed or deteriorated vent systemsmay present a

serioushealthriskor asphyxiation.

Safety Precautions continued on page 4.

3

Safety Precautions

AWARNING I

The water heater _ draft hood installed must be prep- I

erly vented to a chimney which terminates outdoors, i

[ Never operate the water heater unless it is vented to the [

outdoors and h.as adequate air supply to avoid risks ofl

I improper operation, explosion or asphyxiation. }

&WARNING

Minimum clearances between the water heater and com-

bustible construction are I" at the sides and rear, 4" at the

front, and 6" from the vent pipe. Clearance from the top

of the jacket is 18" on most models. Note that a lesser

dimension may be allowed on some models. Refer to the

label on the water heater adjacent to the gas control valve

for all clearances.

I .AWARNING I

Do not use this apphance if any part of.it has been under

water, Immediately call a Sears Service Technician to [

Inspect the appliance and to replace the gas control or any I

part of the bumar system which has been under water.

_,CAUTION

WATER HEATERS EVENTUALLY LEAK_ Installation of

the water heater must be accomplished in such a manner

that if the tank or any connections should leak, the flow

of water will not cause damage to the structure. For this

reason, it is not advisable to install the water heater in an

attic or upper floor. When such locations cannot be i

avoided, a suitable drain pan should be installed under

the water heater. Drain pans are available at your local

Sears store. Such a drain pan must be not greater than

1I/2 inches deep, have a minimum length and width of at

east 2 inches greater than the water heater dimensions

and must be piped to an adequate drain. The pan must

not restrict combustion air flow. Under no circumstances

is the manufacturer or Sears to be held liable for any

water damage in connection with this water heater.

&WARNING

HYDROGEN GAS: Hydrogen gas can be produced in a hot

water system that has not been used for a long period of

time (generally two weeks or more). Hydrogen gas is

extremely flammable and explosive. To prevent the possi-

bility of injury under these conditions, we recommend the

hot water faucet be opened for several minutes at the

_itehen sink before any electrical appliances which are

connected to the hot water system are used (such as a

dishwasher or washing machine), If hydrogen gas is pre-

sent, there will probably be an unusual sound similar to air

escaping through the pipe as the hot water faucet is

opened. There must be no smoking or open flame near

the faucet at the time it is open.

AWARNING

INSULATING JACKETS: When installing an external

rater heater insulation jacket on a gas water heater:

DO NOT cover the temperature-pressure relief valve.

DO NOT put insulation over any part of the top of the

gaswater heater.

DO NOT put insulation over the gas control valve or gas

control valve/burnar cover, or any access areas to the

burner.

DO NOT let insulation around the gas water heater to

get within 8 inches of the floor (air must get to the

burner).

DO NOT cover or remove operating instructions, and

safety related warning labels and materials affixed to the

water heater.

Failure to heed this will result in the possibility of a Ere or

Iexplosion.

4

Table of Contents

Safety Precautions ............................................................................................................................................2.

Table of Contents ................................................................................................................................................5

Customer Re.s_onsibilities .......................................................................................................................6

Product Specincations ..................................................................................................................................6

Materials and Basic Tools Needed ............................................................................................... 7

Materials Needed ...................................................................................................................................................................... 7

Basic Tools ................................................................................................................................................................................ 7

- --""Installation Instructions ........................................................................................................................8-16

Removing the Old Water Heater ............................................................................................................................................... 8

Facts to Consider About the Location ....................................................................................................................................... 9

Combustion Air and Ventilation for Appliances in Unconfined Spaces ................................................................................... 10

Combustion Air and Ventilation for Appliances in Confined Spaces ....................................................................................... 10

Water Piping ........................................................................................................................................................................... 11

Tempe,_tu_-Pressure l_lief Valve ........................................................................................................................................... 12

Filling the Water Heater .......................................................................................................................................................... 13

Venting .............................................................................................................................................................................. 13-14,

Gas Piping ......................................................................................................................................................................... 14-15

Installation Checklist .............................................................................................................................................................. 16

---Operating Instructions .........................................................................................................................17-19

Fighting ......... 7............................................................................................................................................................... [-.17-18

Temperature Regulation .......................................................................................................................................................... 19

Service and Adjustment ...................................................................................................................... 20-22

Tank (Sediment) Cleaning ...................................................................................................................................................... 20

Venting System Inspection ...................................................................................................................................................... 20

Burner Inspection ................................................................................................................................................................... 20

Burner Cleaning ..................................................................................................................................................................... 20

L.E Gas Control Valve & Burner Assembly Replacement Information .................................................................................... 21

Draining ................................................................................................................................................................................. 21

Temperature-Pressure Relief Valve Operation .......................................................................................................................... 21

Drain Valve Washer Replacement ........................................................................................................................................... 22

Housekeeping ......................................................................................................................................................................... 22

Service .................................................................................................................................................................................... 22

Troubleshooting Guide ........................................................................................................................23-25

Start Up Conditions ............................................................................................................................................................... 23

Condensation ........................................................................................................................................................................ 23

Smoke/Odor ......................................................................................................................................................................... 23

Thermal Expansion ............................................................................................................................................................... 23

Strange _un& ...................................................................................................................................................................... 23

Operational Conditions .......................................................................................................................................................... 24

Smelly Water ......................................................................................................................................................................... 24

Air in Hot Water Faucets ...................................................................................................................................................... 24

High Temperature Shut Off System ...................................................................................................................................... 24

Not Enough or No Hot Water .............................................................................................................................................. 24

Water is too Hot ................................................................................................................................................................... 24

Leakage Checkpoints .............................................................................................................................................................. 25

Parts ---OrderList...............................................................................................................................................28-35

Customer Responsibilities

Thank You for purchasinga Sears water heater.

Properly installed and maintained, it should give you years of

trouble free service. If you should decide that you want the new

water heater professionally installed by Sears call the local Sears

Service Center or any Sears store. They will arrange for prompt,

quality installation by Searsauthorized contractors.

Abbreviations Pound In This Instruction Manual

I.A.S. - International Approval Services, A Division of CSA

A.N.S.I. - American National Standards Institute

N.EEA. - National Fire Prevention Association

AWARNING

This gas.fired water heater is design certified by the

International Approval Services,A Divisionof CSA under

American National Standard/CSA Standardfor Gas Water

Heaters ANS Z21.10.1 • CSA 4.1 (latest edition). The

installation must conformwith this manual, Local Codes

and with the latest editionof the National Fuel Gas Code,

ANSI Z223. I.

Thispubhcationisavailable from your local.g_.ernment or

public library, gas company, or by writing NFPA,

Batterymarch Park, Quincy,MA 02269.

• Read the "Safety Precautions" section, pages 2 through 4 of

this manual first and then the entire manual carefully. If you

don't follow the safety rules, the water heater will not operate

PNjroperly.It could cause DEATH, SERIOUS BODILY

URYAND/OR PROPERTY DAMAGE.

This manual contains instructions for the installation, opera-

tion, and maintenance of the gas-fired water heater. It also

contains warnings through out the manual that you must read

and be aware of, All warningsand all instructions are essential

to the proper operation of the water heater and your safety.

Since we cannot put everything on the first few pages, READ

THE ENTIRE MANUAL BEFORE ATTEMPTING TO

INSTALL OR OPERATE THE WATER HEATER.

The installation must conform with the instructions in this

manual; gas company rules; and Local Codes, or in the

absence of LocalCodes, with the latestedition of the National

Fuel Gas code, ANSI Z223.1, also referredto as NFPA 54.

This publication is available from your local government or

public library or gas company or by writing NFPA,

Battetymarch Park, Quincy, MA 02269.

If after reading this manual you have any questions or do not

understand any portion of the instructions, call the Sears

Service Center.

Carefully plan the place where you are going to put the water

heater. Corsect combustion, vent action, and vent pipe instal-

lation are very important in preventing death from possible

carbon monoxide poisoning and fires.

Examine the location to ensure the water heater complies with

the "Facts to Consider About the Location" section in this

manna].

For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during an

earthquake. See instructions for correct installation proce-

dures. Instructions may be obtained from your local dealer,

wholesaler, public utilities or California Office of the State

Architect, 400 P Street, Sacramento, CA 95814.

Product Specifications

MODEL NUMBER

153.337113

153.337162

153.337213

153.337262

153.337362

153.337413

153.337462

153.337513

153.337562

153.337613

153.337662

153.337762

153.337862

153.337960

TANK

CAPACITY

IN GALLON_

50

50

40

40

30

40

40

50

50

65

65

50

65

40

TYPE

OF

GAS

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

NATURAL

PROPANE

B.T.U.

RATE

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

40,000

52,500

50,000

40,000

RECOVERY

RATE GAI.S.

, PER HOUR

@90OFRISE

4O.9

40.9

40.9

40.9

40.9

40.9

40.9

40,9

40,9

40,9

40.9

53,7

51.2

40.9

MINIMUM

VENT

PIPE

3" or 4"

3" or 4"

3" or 4"

3" or 4"

3" or 4"

Y' or 4"

3" or 4"

3" or 4"

3" or 4"

3" or 4"

Y' or 4"

4"

4"

3" or 4"

DIMENSIONS IN INCHES

HEIGHT TO

DIAMETER

22"

22"

20"

20"

16"

18"

18"

20"

20"

22"

22"

20"

22"

18"

ACKET TOP

49"

49"

47½"

47½"

57½"

58¼"

58W'

58"

58"

59½"

59½"

58¾"

59'A"

58¼"

6

Materials and Basic Tools Needed

Materials Needed

To simplify the installation Sears has available the installation

parts shown below. You may or may not need all of'these materi-

als, depending-on your type of installation.

WATER HEATER STAND 24"x24"xl 8"

FOR USE WITH WATER HEATERS

_i_ a//a//on

THERMAL SYPHONING

INSTALLED IN RESIDENTIAL

GARAGES HAVING A DIAMETER 24"

OR LESS AND A RATED CAPACITY 75

GALLONS OR LESS

EXPANSION TANKS

FOR THERMAL

EXPANSION CONDI-

TIONS AVAILABLE IN

@

VENT ELBOW

WATER HEATER INSTAL-

LATIOH KIT WITH FLEXI-

BLE CONNECTORS FOR

3/4" OR I/2" THREADED

OR COPPER PLUMBING

2 GALLON AND 5

GALLON CAPACITY

THROUGH LOCAL

SEARS STORE OR

SERVICE CENTERS

C

VENT PIPE

Basic Tools

You may or may not need all of these tools, depending on your

type of installation. These tools can be purchased at your local

Sears store.

• Pipe Wrenches (2) 14"

• Screwdriver

• Tin Snips

• 6 Foot Tape of Folding Rule

• Garden Hose

• Drill

• Pipe dope or Teflon Tape

FLEXIBLE WATER

HEATER GAS CON-

NECTOR WITH

FITTINGS

O

DRAIN PANS AVAILABLE IN 20"

DIAMETER FOR WATER HEATERS

HAVING A DIAMETER 18" OR LESS

AND AVAILABLE IN 28" DIAMETER

FOR WATER HEATERS HAVING A

DIAMETER 26" OR LESS

ADDITIONAL TOOLS NEEDED

WHEN SWEAT SOLDERING

• Tubing Cutters or Hacksaw

• Propane Torch

Sof_ Solder

• Solder Flux

• Emery Cloth

• Wire Brushes

GARDEN HOSE 6 FOOT TAPE

SLOT-HEAD SCREWDRIVER

PHILLIPS SCREWDRIVER

ROLL OF TEFLON TAPE

(USE ONLY ON WATER

CONNECTIONS)

PIPE DOPE (SQUEEZE TUBE)

USE FOR WATER AND

_AS CONNECTIONS)

PIPE

WRENCH

TIN SNIPS

HACKSAW

314" WIRE BRUSH

I/2" WIRE BRUSH

ROLL OF LEAD FREE

SOFT SOLDER

ROLL OF EMERY

CLOTH

8

SOLDER FLUX

PROPANE

TORCH

TUBING

CUTTER

Installation Instructions

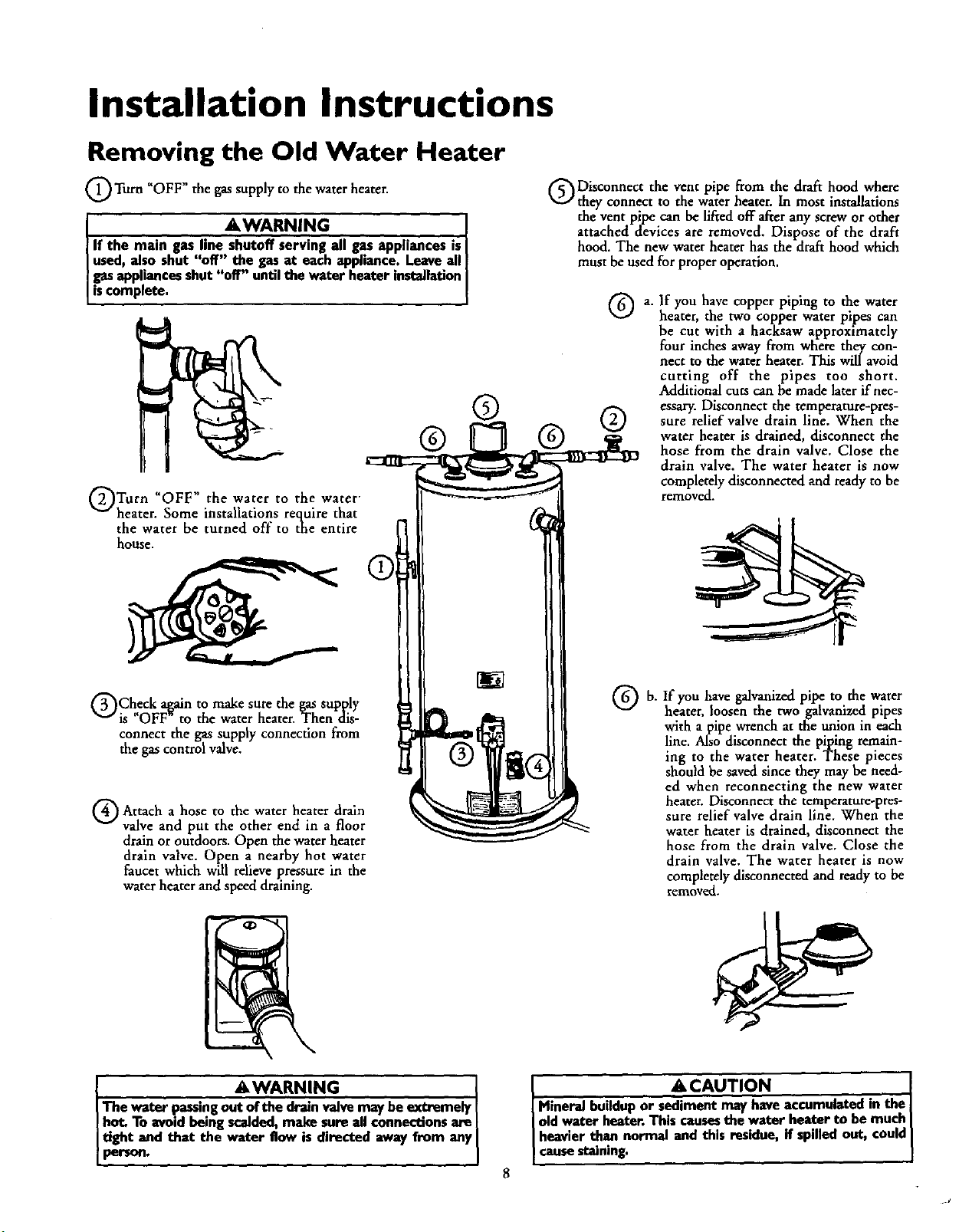

Removing the Old Water Heater

_OWW"the the heater.

Turn gassupply to water

AWARNING . ]

I If the main gas line shutoff serving all gasappliances isI

[ used, also shut "off" the gas at each appliance.Leaveall]

gasappliancesshut "off" until the water heater installation|

[is complete. I

Turn "OFF" the water to the water

heater. Some installations require that

the water be turned off to the entire

house.

Disconnect the vent pipe from the draft hood where

they connect to the waterheater. In most installations

the vent pipe can be lifted off after any screw or other

attached devices are removed. Dispose of the draft

hood. The new water heater has the drafthood which

must be used for proper operation.

a.

®

If you have copper piping to the water

heater, the two copper water pipes can

be cut with a hacksaw approximately

four inches away from where they con-

nect to the water heater. This will avoid

cutting off the pipes too short.

Additional cuts can be made laterif nec-

essary. Disconnect the temperature-pres-

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and ready to be

removed.

Check a[,ain to make sure the gas supply

is "OFF to the water heater. Then dis-

connect the gas supply connection from

the gas control valve.

G Attach hose the heater drain

The water passingout ofthe drain valvemay be extremely

hot. To avoidbeing scalded,make sure all connectionsare

tight and that the water flow is directed awayfrom any

person.

a to

valve and put the other end in a floor

drainor outdoors. Open the water heater

drain valve. Open a nearby hot water

faucet which will relieve pressure in the

water heater and speed draining.

water

AWARNING

If you have galvanizedpipe to the water

heater, loosen the two galvanized pipes

with a pipe wrench at the union in each

line. Also disconnect the piping remain-

ing to the water heater. These pieces

should be saved since they may be need-

ed when reconnecting the new water

heater. Disconnect the temperature-pres-

sure relief valve drain line. When the

water heater is drained, disconnect the

hose from the drain valve. Close the

drain valve. The water heater is now

completely disconnected and readyto be

remove.

IL" A CAUTION

meral buildupor sediment mayhave accumulatedin the i

d water heater.Thiscausesthe water heater to be much

eavier than normal and this residue,if spilled out, could

sestaining.

8

Installation Instructions (cont'd)

Facts to Consider About the

Location

You should carefully choose an indoor location for the new

water heater, because the placement is a very important consid-

eration for the safety of the occupants in the building and for

the most economical use of the appliance. This water heater is

not for use in mobile homes or outdoor installation.

Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed. '

• The location selected should be indoors as close as practical

to the gas vent or chimney to which the water heater vent is

going to be connected, and as centralized with the water pip-

ing system as possible. The water heater, as all water heaters,

will eventually leak. Do not install without adequate

drainage provisions where water flow will cause damage.

A CAUTION

WATER HEATERSEVENTUALLY LEAK: Installationof the

water heater mustbe accomplishedin sucha mannerthat if

the tankor anyconnectionsshouldleak,tee flowofwater will

not causedamageto the structure.For this reason,it is not

to installthewater heater inan atticor upperfloor.

When suchlocationscannotbe avoided,a suitabledrain pan

shouldbe installedunder the water heater.Drain pansare

availableat yourload Searsstore.Sucha drain panmust be

not grenterthen I Y2inchnsdee_ havea mlnlmum kmgthand

of at least2inchesgreaterthan the water heaterdimen-

sions_ mustbe pipedto anadequatedrain.The pan must

notrestrictcombestionairflow.Undernodrcumstaneasisthe

manufactureror Searsto be heldliableforanywater damage

in €onnectinnwiththis water beater.

• The location selection must provide adequate clearances for ser-

vicing and proper operation of the water heater.

AWARNING

Thiswater heater mustnot be installeddirectlyonearpeting.

Carpeting must be protected by a metal or wood panel

beneaththe app lanceextendingbeyondthe ful _dth and

depthof the appliance by at least 3 inches(76.2mm) in any

direction,or if the applianceisinstalledin an akove or duset,

the entire floormustbe coveredbythe paneLFailureto heed

this warningmayresultinafire hazard.

AWARNING

Minimum clearancesbetween the water heater end com-

bustibleconstructionare I" at the r_dusand rear, 4" at the

frout,and 6"from the ventpipe.Cleanmcefromthe tep ofthe

_cket is 18"onmost models.Note that a lesserdimensionmay

be allowedon somemodek. Referto the labelon the water

heateradjacentto thegascontrolvalvefor alldearance_

VENT_TION

OPENINGS

AWARNING

INSTALLATIONSIN AREASWHERE FLAMMABLEUQUIDS

(VAPORS) ARE lIKELY TO BE PRESENT OR STORED

(GARAGES, STORAGE, AND UTILITY AREAS, ETC):

Flammableliquids(suchasgasoline,solvents,propane(LP) or

butane, etc.), all of which emit flammable vapors, may be

improperlystoredor usedin suchareas.The gaswater heater

pilot lightor mainburneram ignitesuchvapors.The resulting

Rashbeckandfirecancausedeathor seriousburnsto anyonein

thearea,aswellesproperty_.

If inst_latieninsuchareasisyouronlyoption,thenthe ias_din-

tion must be aCcomplishedin a waythat the pilot flame and

mainburner eameam elevatndfromtheflenr at least18inche_

While this n_/reduce the chancesof flammablevaporsfrom a

floorsp,Ibeingignited,gasolineandotherflammablesubmmces

shouldneverbe storedor usedinthe sameroom or areacon-

talninga gaswaterheateror otheropenflameor sparkproduc-

ingappliance.

NOTE: Flammablevaporsmaybe drawnbyair currentsfrom

otherereusofthestructuretotimappliance.

AWARNING

Propellants of anrosolspraysandvolatilecompounds,(clean-

ers,chlorinebasedchemicals,refrigerants,etc.)in additionto

beinghighlyflmnmable.in manycases,will alsochangeto .cor-

rosive hydroch|orlcacidwhen exposedto the combustion

productsof the water heater.The resultscanbe hazardous,

and also cause productfailure.

I Figure ! I

AWARNING

A gaswater heater cannotoperateproperlywithoutthe cor-

rectamount of air for combustion.Do not installin a confined

areasucha duset,unlessyou provideair as shownin Figures

I-5. Never obstructthe flowof ventilationair. Ifyou haveany

doubtsorquestionsat all,callyourgascompany.Failureto pro-

videcheproper_mt ofcombes6onair am resultina life or

explosionand can causeDEATH, SERIOUSBODILY INJUI_,

OR PROPERTYDAMAGE.

AWARNING

If thiswater heaterwifibe usedin beautyshops,barbershops,

cleaningestablishments,or self-servicelaundrieswith dry

cleaningequipment,it is imperativethat the water heateror

wa_erheatersbe installed sothat combustion andven_

Bir betakenfrom outsidethese areas.Referto the "Facts to

ConsiderAboutthe Location"sectionof this manualandalso

thelatestedition of the NationalFuelGasCode,ANSI Z223.1,

alsoreferredto as NFPA 54 for specificsproddedconcerning

air required.

Installation Instructions (cont'd)

Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

Unconfined Space is a space whose volume is not less than 50

cubic feet per 1,000 Btu pet hour of the aggregate input rating

of all appliances installed in that space. Rooms communicating

directly with the space in which the appliances are installed,

through openings not furnished with doors, ate considered a

part of the unconfined space

In unconfined spaces in buildings, infiltration may be adequate

to provide air for combustion, ventilation and dilution of flue

gases. HoWever, in buildings of tight construction (for exampl€,

weather stripping, heavily insulated, caulked, vapor barri€r, etc.),

additional air may need to be provided using the methods

described in Combustion Ait and Ventilation t'orAppliances

Located in Confined Spaces, b.

Combustion Air and Ventilation

for Appliances Located in

Confined Spaces

Confined Space is a space whose volume is less than 50 cubic

feet per 1,000 Bm per hour of the aggregate input ratingof all

appliances installed in that space.

a. ALL AIR FROM INSIDE BUILDINGS.

(See Page9 Figure 1,and Figure2 below)

The €onfined space shall be provided with two permanent

openings communicating directlywith an additional room(s)

of suiTlcient volume so that the combined volume of all

spaces meets the criteria for an unconfined space. The total

input of all gas utilization equipment installed in the com-

bined space Mall be consideredin making this determination.

Each opening shall have a minimum free areaof one square

inch per 1,000 BTU per hour of the total input rating of all

gas utilization equipment in the confined space, but not less

than 100 square inches. One opening shall commence within

12 inches of the top and one commencing within 12 inches

of the bottom of the enclosure.

1. When directly communicating with the outdoors, each open-

ing shallhave a minimum free areaof 1square inch per 4,000

BTU per hour of total input rating of all equipment in the

€ndosure. (SeeFigure 3.)

2. When communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of 1

square inch per 4,000 BTU per hour of total input rating of

all equipment in the endosure. (See Figure 4.)

Figure 4 ]

3. When communicating with the outdoors through horizontal

ducts, each opening shall have a minimum free area of l

alsctuareinch per 2,000 BTU per hour of total input rating of

equipment in the enclosure. (SeeFigure 5.)

_L_IEy Off Otd VEIcr

V_Tga_'flO_ LO_EF*O

b. ALL AIR FROM OUTDOORS: (seeFigures3-5)

The confined space shall be provided with two permanent

openings, one commencing within 12 inches of the top and

one commencing within 12 inches from the bottom of the

enclosure. The openings shall communicate directly, or by

ducts, with the outdoors orspaces (crawl or attic) that freely

communicate with the outdoors.

IFI re']

Figure 5 ]

4. When ducts are used, they shall be of the same cross-sectional

area as the free area of the openings to which they connect.

The minimum short side dimension of rectangularair ducts

shall not be less than 3 inches. (SeeFigure 5.)

5. Louvers and Grilles: In calculating free area, consideration

shall be given to the blocking €ffect of louvers, grilles or

screens protecting openings. Screens used shall not be smaller

than ¼ inch mesh. If the Free area through a design of louver

or grille is known, it should be used in calculating the size

opening required to provide the free area specified. If the

design and free area is not known, it may be assumed that

wood louvers will be 20-25 percent free areaand metal louvers

and grilles will have 60-75 percent free area. Louvers and

grilles shall be fixed in the open position or interlocked with

the equipment so that they are opened automaticallyduring

equipment operation.

6. Special Conditions Created by Mechanical Exhausting or

Fireplaces: Operation of €xhaust fans, ventilation systems,

clothes dryers or fireplacesmay create conditions requiring

special attention to avoid unsatisfactory operation of installed

gasutilization equipment.

10

Installation Instructions (cont'd)

Water Piping

AWARNING

HOTTERWATERCAN SCALI_.Water heatersam intendedto

producehotwater.Waterheatodto a W.._yhi_ *dll

satisfydod_ washln&dishwashin&andothersanitizingneeds

(an scaldandpermanentlyInjureyouuponcontact.Somepeo-

_eare morelikelyto be penmanentlyinjuredbyhotwater b_an

otherL Theseincludethe eklerl_chlldmrkthe infirm,or physical-

ly/mentallyhandicapped.Ifanyoneusinghotwater inyourhome

fitsintooneulthese greupsorIf thereisalocal€odeor statelaw

requiringacertaintemperaturewaterat_ hotwaterta_ then

mumusttakespecialpmceutienLIn addidouto usingtbelowest

x_ibin temperaturesettingthat sallsfiesyourhot waterneeds,

Lmeanssuchasa mixingvalve,shouldbeusedat the hotwater

tapsusedbythese peophor at thewaterheatenMixingvalves

areavailableat plumbingsupplyor hardwarestore_Followman-

ufacturersinstructions for installationof the valves.Before

changingthe factory setting on the thermostat, read the

_l'emperatore Regulation"sectioninthismanual.

This water heater shall not be connected to any heating systems

or component(s) used with a non-potable water heating

appliance.

If a water heater is instal|ed in a dosed water supply system;

such as one having a back-flow preventer, check valve, water

meter with a check valve, etc.., in the cold water supply; means

shall be provided to control thermal expansion. Contact the

local utility or local Sears Service Center on how to control this

situation.

NOTE: To protect against untimely corrosion of hot and

cold water fittings, it is strongly recommended that all-elec-

tric unions or couplings be installed on this water heater

when connected to copper pipe.

• Look at the top cover of the water heater. The cold water

inlet is marked-cold. Put two or three turns of teflon tape

around the threaded end of the threaded-to-sweat coupling

and around both ends of the ¾"threaded nipple. Using flexi-

ble connectors, connect the cold water pipe to the coldwater

inlet of the water heater.

NOTE: This water heater is super insulated m

heat loss from the tank. Further reduction in heat loss

can be accomplished by insulating the hot water lines

from the water heater.

INSTALLATION COMPLETED USING

SEARS INSTALLATION KIT

FLEXIBLE

HOT OUTLET

TO HOUSE /

THREADED TO

SWEAT COUPLING

314" THREADED

COUPLING

WATER

CONNECTORS

SHUTOFF

VALVE

THREADED TO

SWEAT COUPLING

314" THREADED

COUPLING

WATER LINE

COLD INLET

The illustration shows the attachment of the water pipin_ to the

water heater. The water heater is equipped with ¼ inch water

connections.

NOTE: If using copper tubing, solder tubing to an adapter

before attaching _e adapter to the cold water inlet enunec-

tion. Do not solder the cold water supply line directly to the

cold water inlet. It will harm the dip tube and damage the

tank.

• Look at the top cover of the water heater. The water oudet is

marked hot. Put two or three turns of teflon tape around the

threaded end of the threaded-to-sweat coupling and around

both ends of the ¾ threaded nipple. Using flexible connec-

tors, connect the hot water pipe to the hot water oudet on

the water heater.

11

[]

PRESSURE

RELIEF VALVE

PiPE (Do not cap

or plug)

6" AIR GAP

FLOOR DRAIN

Installation Instructions (cont'd)

Temperature-Pressure Relief Valve

_WARNING

At the time of manufacturethis water heaterwas provided

witha combinationtemperature.pressuresraliofvalvecertified

by a nationallyrecognizedtestinglaboratorythat maintains

.p_'odic inspectionof productionof listedequipmentor mete-

rmals,as meeting the requirements for Relief Valves and

AutomaticGasShutoffDevicesforHot Water SupplySystems,

andthe latestedition ofANSI Z21.22 and the coderequire-

!mentsof ASME.If replaced,the valvemustmeetthe require-

menu ofIoealcodes,but notlessthana combinationtempera-

ture and pressurerelief valvecertifiedasmeetingthe require-

mentsforReliefValvesandAutomaticGasShutoffDevicesfor

Hot Water SupplySystems,ANSI Z21.22bya nationallyrecog-

nizadtesting laboratorythat mmntainsperiodicinspectionof

productionof listedequipment ormaterials.

The valvemust he markedwith a maximumsat pressureloot

to exceedthe marked hydrostaticworkingpressureof the

waterheater(IS0 II_J_, in.)anda dischargecapacitynot less

thanthe waterheaterinputrate asshownonthemodelrating

plate.(Electricheaters• watts dividedby 1000x 3415 equal

BTU/Hr.rate.)

Yourlocaljurisdictionalanthori_, whilemandatingthe useofa

temperature-pressurereliefvalvecomplyingwithANSI Z21.22

andASME, mayrequire a valvemodeldifferentfromthe one

fomishedwiththewakerheater.

Compliancewithsuchlocalrequirementsmustbe satisfiedby

the installerorenduserof the water heaterwith a locallypre-

scribedtemperature-pressurereliefvalveinstalledinthe desig.

natedopeningin thewater heaterin placeofthefactoryfur-

nisbedvalve,

Forsafeoperationofthewater heater,the reliefvalvemustnot

beremovedfromit_ designatedopeningorplugged,

IThetemperature-pressurereliefvalvemustbe installeddirectly

intothefittingofthewaterheaterdesignatedfor thereliefvalve.

Positiontilevalvedownwardend providetubingsothat anydis-

chargewill exitonlywithin6 inchesabove,or at anydistance

belowthe structuralfloor.Be certainthat no contact ismade

withanyliveelectricalpart.Thedischargeopeningmustnotbe

blockedor reducedinsize underanycircumstances.Excessive

length,over30 feet,or useofmorethan fourelbowscancause

restflcdonandreducethedischargecapacityofthevalve.

No valveor otherobstructionisto he placedbetweenthe relief

valveandthetank.Do not connecttubingdirectlyto discharge

drainunlessa6" airgapisprovided.Topreventbodilyinjury,hez.

ardto life,or propertydamagethe reliefvalvemustbeallowed

to dischargewater inquantitiesshouldc_rcumstancesdemand.If I

the dischargepipeisnotconnectedto a drainor othersuitable

means,thewaterRowmaycausepropertydamage,

TheDischargePipe:

• Mustnot be smallerin sizethanthe outlet pipesizeof the

valve,orhaveanyreducingcouplingsor otherrestrictions.

• Mustnetbepluggedorblocked.

• Mustbeofmateriallistedfor hotwater distribution.

I. Mustbe installedsoasto allowcompletedrainageofboth

the temperature.pressurerelief valve,and the discharge

pipe.

• Mustterminateat anadequatedrain.

• Mustnothaveanyvalvebetweenthe reliefvalveandtank.

AWARNING

The temperature-pressure relief valve must be manually

operatedat leastoncea yea_ Cautionshouldbe takento

ensurethat (I) no one is infrontof or aroundthe outletof

the temperature-pressurerelief valvedischargeline,and (2)

the water manually dischargedwill not causeany bodily

injury or property damage because the water may be

extremelyhot.

If after manuallyoperatingthe valve,it failsto completely

resetand continuesto releasewater,immediatelydosethe

coldwater inlet to the water heater, follow the draining

instructions,and replace the temperature-pressurerelief

valvewith a newone.

HOT

SHUTOFF COLD

VALVE

"EHPERATURE-

PRESSURE

RELIEF VALVE

(Do not cap or plus)

[]

6" AIR GAP

RELIEFVALVEOPENING

At the time of _ocu_, thiswater heaterwas providedwith a combinationtem-

perature-pressurerelief valvelisted ascomNyfeg with the standa_lfor rdiet"valvesand

automatic gasshut-offdevices for hot war_r supplysystems,ANSi Z21.22. For safe

operationof the water heater,the _lef valvemust not be removed from its designated

ypOouintof instaibtion cr plugged.

r load urisdictiona{authori_, while mandatingthe use of a tem_rature-pre_sure

re{ief valvecomplyingwithANSI 7-.21,22andASPIE,mayrequire a _alvemodel dfferent

fromthe one furnishedwith the water heater

Compliancewith suchlocal requirements must be satisfied by the ins_ler or end user

of the water heater with a locallyprescril_ temperature-pressure relief valveinstalled

in the designatedopeninginthe water heater

See manual heading-'q'ernperature-FYessureRelief Valves"for instalbtion and mainte-

nance of relief valve,dischargeline,and other safer7 precautions.

12

Installation Instructions (cont'd)

Filling the Water Heater

A CAUTION

Neverusethisvrat_rheater unlessit iscompletelyElledwith I

water. To preve_ damnge to the tenk, the tenk must be filled I

with water. Water must flow from the hot water faucet

before turn ng ' ON ' gas to the water beater.

To fill the water heater with water:

• Close the water heater drain valve by turning the handle to

the right (clockwise). The drain valve is on the lower front of

the water heater.

Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open

when the water heater is in use.

To insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to tun

until a constant flow is obtained. This will let air out of the

water heater and the piping.

• Check all new water piping for leaks. Repair as needed.

Venting

Ai.WARNING

VENT DAMPERS - Any vent damper, whether it is operated

thermally or otherwise must be removed ifitsuseinhibit3 prop-

er drafting of the water heate_.

Thermally Operated Vent Dampers: Gas-fired water heaters

havingthermal efficiency in eacessof 80% may produce a rela-

tively lowfluegastemperature. Such temperatures maynotbe

high enough to properly open thermally operated vent

dampers. This wonld ceuse spillageof flue gasasand rnay canse

ced_on monoKidepoisoning.

Vent dampen must bear evidenceof certification ascomplying

with the latest edition of American National Standard ANSI

Z21.68 (ANSI Z21.66 & 67, respecd_, cover electrically and

mechanically actuated vent dampers). Before installationof any

vent dampe_ comuit your local SearsServiceCenter or the gas

utility for further information.

&WARNING

To insureproper ventingof this gas-firedwater heater,the

correctvent pipediameter mustbe utilized.Any additionsor

deletionsof othergasapplianceson acommonvent withthis

water heatermayadversely_q_ct the operationof thevm_r

heater,Consultthe localSearsServiceCenter or gasutilityif

anysuchchangesareplanned.

For proper venting in certain installations, a larger diameter vent

pipe may be necessary. Due to great variances in installations,

unforeseeable by the manufacturer of the water heater, you must

consult your gas company to aid you in determining the proper

venting for your water heater from the vent tables in the latest edi-

tion of the National Fuel Gas Code ANSI Z223.1, also referred to

as NFPA 54.

Check the venting system for signs of obstruction or deterioration

and replace if needed.

The combustion and ventilation air flow must not be obstructed.

AWARNING

Obstructedor deter_ratedventsystems_ presentaserious

healthriskor asphyxiation.

• Place the draft hood legs in the receiving holes on the top of

the water heater. The legs will snap in the holes to give a tight

fit.

• Place the vent pipe over the draft hood. With the vent pipe in

position, drill a small hole through both the vent pipe and

draft hood. Secure them together with a sheet metal screw.

DRAFT HOOD _ _VENT'_I I _'

.... _ ISCRE__._I _DRAFT HOOD

--a L_VENT TO OUTDOORS OR

DRAFTHC_Off'-J_-cH''NtY

A,WARNING

I The water heater with draft hood inmdled must be properly I

vented to a chimney which terminates outdoor_ Never oper-

I atethe waterheateranlessit isventedtotbeontdonrsandhasI

I edequateair.su.pPlyte aveidrisksof improperoperation,explo-I

I I

AWARNING I

The vent pipe from the water heater must be no lessthan the I

diameter of the draft hood outlet on the water heater, and

13

Installation Instructions (cont'd)

Venting (cont'd)

All vent gases must be completely vented to the outdoors of the

structuze (dwelling). Installonly the draft hood provided with

the new water heater and no other draft hood.

Vent pipes must be secured at each joint with sheet metal screws.

TO

CHIMNEY

l

VENT PIPE INSTALLATION

There must be a minimum of 6" cleaeance between single wall

vent pipe and any combustible material. Fill and seal any dear-

ancebetween single wall vent pipe and combustible material

with mortar mix, cement, or other noncombustible substance.

For other than single wall, follow vent pipe manufacturer's clear-

ance specifications. To insure a tight fit of the vent pipe in a

brick chimney, seal around the vent pipe with mortar mix

cement.

AWARNING

Failureto haverequired clearancesbetweenventpipingand

€ombusttl_ematerialwillresultina firehazard.

Besurevent Ixpeis prnperlyconnectedto prexentescapeof

I . AWARNING I

dangerousfluegaseswhichcouldcausedeadly_spl_dation.

Gas Piping

AWAJRNING

Hake sure the gassuppliedis the same type listed on the

modelrating plate. The inlet gaspressuremustnot exceed

10.5in.water column(2.6kPa)for naturalgasor 13in. water

column(3.2kPa) for propane(/E) gas.The minimum inlet

gaspressureI"..L_ on the modelrating plate isfor the pur-

poseofinputadlUStmant.

I AWARNm(; I

If the gascontrolvalveis subjectedto pressuresexceeding½

poundper squareinch(3.5kPa),the _ to the gascon-[

trnl valvecouldresultin afireor explosionfrom leoldnggas. I

AWAR_I. ING I

[ If the maingasline shutoffsorwng all gasappliancesisused,I

alsoturn "of/" the gasat eachappi.uu_e..Leaveallgasappii-

I antesshutoffuntilthe waterheater matailationiscomplete. I

A gas line of su_cient size must be run to the water heater.

Consult the latest edition of National Fue! Gas Code ANSI

Z223.1, also referred to as NFPA 54 and the gas company con-

cerning pipe size.

There must be:

• A readily accessiblemanual shut off valve in the gas supply line

servingthe water heater, and

• A drip leg (sediment trap) aheadof the gas control valve to hdp

prevent dirt and foreign materials from entering the gas control

Valve.

• A flexible gas connector or a ground joint union between the

shutoff valveend control valveto permit servicingof the unit.

AWARNING

Chemical vapor corrosionof the flue and vent systemmm/

Occurif air for combustioncontainscertain chemicalvapor_

Spraycan propellants,cleaningsolvents,refrigerator and air

conditionerrefrigerants,swimmingpool chemicals, caJcium

andsodiumchloride,waxes,bleach,andprocesschemicalsare

typicalcompoundswhich arepetandallycorrosive.

Be sure to check all the gas piping for leaks before lighting the

water heater. Use a soapy water solution, not a match or open

flame. Rinse offsoapy solution and wipe dry.

Standard Models are for installation up m 3,300 feet above sea

level.

Altitude Mode_ are for installation from 3,300 to 5,500

feet abovesea level.

Ifa standard model is installed above3,300 feet or a high aldmde

model is installed above 5,500 feet, the input rating must be

reduced at the rate of 4 percent for each 1,000 feet above sea levd,

Contact your local Sears Service Center or gas utility for further

information.

_,WARNING

The applianceand its gas connectionmust be leak tested

beforeplacingthe appliancemoperation.

14

Installation Instructions (cont'd)

AWARNING

. Tbe appEanceaed its individueJsbetoffvalve must be discon-

nected from the gassupplypipingsym_n during any pressure

testing of the gas system at test pressures in excess of 'A

poundper squareinch (3.5k1%).

. The appliancemustbeisobtedfromffmgassupplypipingsys-

tem bydosing i_ individual manual shutoffvalve during any

pr--_ure tosting of the gas supply pipingsystem at test pres-

suresequal or lessthan _ pound per square inch (3.SkPa_

I AWARNING I

Use pipe joint compound or teflon tape marked as being

resistantto tbeactionof peU'oleum[Propane(LR)] gases. I

SEDIMENT TRAP

A sediment trap shall be installed as close to the inlet of the

water heater as practical at the time of water heater installation.

The sediment trap shall be either a tee fitting with a capped nip

pie in the bottom outlet or other device recognized as an effec-

tive sediment trap. If a tee fitting is used, it shall be installed in

conformance with one of the methods of installation shown

below.

Connecting the gas piping to the gas control valve of the water

heater can be accomplished by either of the two methods shown,

GAS PIPING WITH

FLEXIBLE CONNECTOR

GROUND

UNION(Optional)

DRIP LEG

(Sedimenttrap)

CAP

LOOP

GAS

CONTROL

VALVE

GAS PIPING WITH ALL BLACK IRON

PIPE TO GAS CONTROL

GROUND IO!NT -_ BLACK PIPE

UNION(Op_on_)__ /

CO NTVALvP_EOL

AWARNING

Contaminonts in the gas lines may cause improper operatinn

of the gas €ontrol valve that may rasult in Ere or explosion.

Bofore attaching tbe gasline be sure that afl Ips pipe is dean

on the imide. To trap any dirt or foreign n_ter_l in the gas

supply line, a drip leg (sometimes called a sediment trap)

must be incorporated in the piping. The drip leg must be

readily accessible.Install in accordance with the '_,as Piping"

section. Refer to the latest edition of the National Fuel Gas

Code, ANSI 7.223.1, also referred to asNFPA 54.

3"

_-J CAP

15

Installation Instructions (cont'd)

Installation Checklist

BEFORE LIGHTING THE PILOT:

* Check the gas lines for leaks.

a. Use a soapy water solution• DO NOT test for gas leaks

usinga match or open flame.

b. Brush the soapy water solution on all gas pipes, joints and

fittings.

c. Check for bubbling soap• This means you have a leak.

Turn OFF gas andmake the necessary repairs.

d. Recheck for leaks.

e. Rinse offsoapy solution and wipe dry.

• Is the new temperature-pressure relief valve properly installed

and piped to an adequate drain? See Temperature-Pressure

ReliefValve section.

• Are the cold and hot water lines connected to the water

heater correctly. See Water Plpmg mstrucnons in the

"Installation Instructions" section.

• Is the water heater completely fdled with water? See "Filling"

instructions in the _Installation Instructions" section.

• Will a water leak damage, anything? See the "Facts to

Consider About the Location section.

• Is there proper clearance between the water heater and any-

thing that might catch fire? See the Facts to Consider About

the Location" section.

HOT

GAS SUPPLY

VENT PIPE TO UNION

OUTDOORS \

OR CHIMNEY _1 SHUTOFF VALVE

DRAFT HOOD

SHUTOFF VALVE

_ TEMPERATURE-

PRESSURE

RELIEF VALVE

DISCHARGE PIPE

(Do not cap or plug)

• Do you have adequate ventilation so that the water heater

will operate properly. See Combustion Air and Ventilation

in the "Factsto Consider About the Location" section.

• is the draft hood vent piping properly secured? See "Venting"

mstrUCtlOnS in the Installation Instructions seenon.

• Is there proper clearance between the vent pipe and anything

that might catch on fire_ See Venting instructions in the

"Installation Instructions section.

• Is the vent pipeproperly sloped and does the vent terminate

outdoors. _ee "Venting instructions in the Installation

Instructions"section.

Do you need to call your gas company to check the gas pipe

and its hookup?

TEE

(Sediment

trap) PIPE CAp

DRAIN VALVE

6" AIR GAP

FLOOR DRAIN

16

MODEL RATING PLATE

Operating Instructions

Lighting

AWARNING

BEFORE LIGHTING [PROPANE (L.R) GAS WATER

HEATERS]: Propane (I.R) gasb henvierthan air. Should there

be a leak in the system, the gas will settle near the ground.

Basements, crawl spaces, skirted areas under mobile homes

(even when vendlatod_ closetsand areasbelow ground level will

serve as pockets for the accumulation of this gas. Before

attempting to light or relight the water heater's pilot or turning

on a nearby electrical light switch,be absolutelysure there b no

accumulated gasin the area. Searchfor odor of gasby sniffingat

ground levelin the Vicinity of the appliance.If odor isdetected,

follow stepsindicatedat "For Your Safety" on the cover page of

this manual then leavethe promises.

Lighting and operating instructions are located on front of the

water heater, above or to one side of the gas control valve.

_WARNING

AN ODORANT IS ADDED TO THE GAS USED

BY THIS WATER HEATER.

FOR YOUR SAFETY

IF YOU SMELL GAS:

• Do not try to light anyappliance.

• Do not touch anyelectrical switch;do not useany phone in

your building.

• Immediately callyour gas suppiierfrom a neighbor's phone.

Follow the gassuppliers inm'uctions.

• If you cannot reach your gas supplier, call the fire depart-

ment.

Figure 7 1

AWARNING

DO NOT forcethe gascontrolknob,Use onlyyour handto

pushit downto lightthe pilot, or to tom it to "ON" "OFF"

or "PILOT". Never usea toolsuchasa lever,wrenchor pli-

ers.Do not hit or damagethe knob.A damagedknobmay

result in an explosionand seriousinjury.If youhaveproblem

turning the Imob,callthegassupplierimmediately.

CHECK FOR LEAKS

Be sure to check all your gas pipes for leaks before lighting your

water heater. Use a soapy water solution, not a match or open

flame. Check the factory gas fittings after pilot is lit and gas con-

trol knob is still in _PILOT" position. Then, check the fittings

when the main burner is turned tON". Use a soapy water solu-

tion for this, too.

17

Figure 8 I

Figure 9 1

__NNER DOOR

OUTER

DOOR

Operating Instructions (cont'd)

Lighting label on the water heater as it appears above the thermostat

FOR YOUR SAFETY READ BEFORE LIGHTING

If you do not follow these instructions exactly, a fire or explosion

may result caus ng property damage, persona njury or loss of life.

A. Thisappliancehasa pilot which must be lightedby

hand.Whenlightingthepilot,followtheseInstructions

exactly.

B,BEFORELIGHTINGsmellall aroundtheappliancearea

for gas. Be sure to smell next to the floor because

somegasis heavierthenairandwill settleonthefloor.

WHATTODO IFYOUSMELLGAS

• Donot fryto lightanyappliance.

• Do not touch any electric switch; do not useany

phonein yourbuilding.

• Immediatelycallyourgas supplierfroma neighbor's

phone.Followthegas suppUer'sinstructions,

WARNING I

LIGHTING INSTRUCTIONS

1.STOP!ReadthesafetyInformationaboveonthislabel.

2,Removeouterdoor.

3. Set the thermostatto lowestsettinLby turning the

watertemperaturedial clockwise,(( "_)to itslowest

temperaturesetting(witharrowondial)as shown.DO

NOT FORCE,

4.Turngas controlknobclockwise_ to "OFF" posi-

tion. Knob cannotbe turnedfrom "PILOT" to "OFF"

unlessknob Is depressedslightly.DO NOT FORCE.

(Figure6, page17)

5. Waitfive (5) minutestoclearout anygas. If youthen

smellgas, STOPIFollow"B" inthe safetyinformation

aboveon this label.If youdon't smellgas, go to the

nextstep.

6. Remove(or open) inner door locatedbelow the gas

control unit.

7. Findpllot-loitowmetaltubefromgascontrol.Thepilot

IslocatedInfrontoftheburner

PILOT BURNER ._ THERMOCOUPLE

8. Ifyoudon'tsmellgas,turnknobongascontrolcounter

dockwise_@ to"PILOT"position.(Figure7, page17)

• If you cannotreach your gassupplier,callthefire

department.

C. Useonly yourhandtopushin or turnthe gascontrol

knob.Neverusetools.If theknobwillnot pushInor

turnby hand,don'ttryto repairIt, calla qualifiedser-

vicetechnician.Forceor attemptedrepairmayresult

ina fireorexplosion.

D. Do not usethisapplianceif anyparthas been under

water.Immediatelycall a qualifiedservicetechnician

toinspecttheapplianceandto replaceanypart of the

controlsystemand anygas controlwhichhasbeen

underwater.

9. Push in control knob all the wayand hold down.

Immediatelylightthe pilotwitha match.Continueto

holdcontrol knob in for aboutone (1) minute after

the pilot islit. Releaseknobend it will pop back up.

Pilotshould remainlit. If it goesout, repeatsteps3

through8.

• Ifknob doesnotpop upwhenreleased,stopand

immediatelycall yourservicetechnicianor gas

supplier,

• If the pilotwill not stay lit after severaltries,

depress__ andturnthe gas controlknobclockwisetechnician=;

V to"OFF"and sell yourservice

or gassupplier.(Figure6,page17)

10. Replace(orclose)innerdoor.Replaceouterdoor if

door doesnotcovergas controlon/offknobortem-

peratureadustmentknob.(Figure9,page17)

11. At arms engthaway,turngascontrolknobcounter-

clockwise(_ to the full "ON" position. Warning

do not use gas control knob to regulate gas

flow. (Figure8,page17)

12.At arms lengthaway,set the thermostatto desired

setting. The mark ( • ) indicativeof approximate

120°F is preferred starting point. Some local laws

may requirea lowerstartingpoint. If hotterwater is

desired,seeinstructionmanualand"warning"below.

13,Replacetheouterdoorifnotreplacedinstep 10.

WARNING

HotterwaterIncreasesthe riskof scaldinjury.Before changingtemperaturesettingseeinstructionmanual.

TO TURN OFF GAS TO APPLIANCE

1. Set thethermostatto lowestsetting byturningthe

watertemperaturedialclockwise(F"_) to its lowest

temperaturesetting(witharrowon dial)as shown.DO

NOT FORCE,

2. Turn gas controlknob clockwise !_,; to "OFF"

position. Knob cannot be turned from "PILOT" to

"OFF" unlessknob is depressedslightly.OO NOT

FORCE,

3.Replaceouterdoor(ifremoved),

]8

Operating Instructions (cont'd)

Temperature Regulation

Due to the nature of the typical gas water heater, the water tem-

_oeratute [rt certain situations may vary up to 30°F higher or

wer at the point of usesuch as, bathtubs, showers, sink, etc.

This means that when the temperature ad)ustment dial is set at

the mark approximating 120 ° F, the actual water temperature at

any hot water tap could be as high as 150°F or as low as 90°E

Any water heater's intended purpose is to heat water. Hot water

is needed for cleaning (bodies, dishes, clothing). Hot water will

present ascald hazard. Depending on the time element, and the

people involved (normaladults, children, toddlers, elderly,

infirm, etc.) scalding may occur at different temperatures.

AWARNING

HOTTERWATERCAN SCAI._.Wa_" hoatersareintendedto

i_d...ucehot water..Water heatedto a temperature whichwill

satisfyclotheswashm&dishwashing,andothersanitizingneeds

canscaldandpermanentlyinjureyouuponcontact.Somepe_

piearemore likelyto bepermanentlyinjuredbyhot waterthan

othe_ Theseincludetheelder_,children,the infirm,or physical-

lylrn_€ handicapped. Ifanyoneusinghot water inyourhome

fitsintoone ofthesegroupsor ifthereisalocalcodeorstatelaw

requiringa certaintemperaturewaterat thehotwatertap,then

roumusttakespecialprecautions.Inadditionto usingthe lowest

3os_le temperaturesettingthatsatisfiesyourhotwater needs,

i meanssuchasamixingvalve,shouldbe usedat the hot water

tap_usedbythese peopleor at the water heater.Mixingvalves

areavailableat plumbingsupplyorhardwarestores.Followman-

ufacturersinstructionsfor installationof the valves.Before

changingthe factory setting onthe thermostat, read the

'rl'emperatureRegulation"sectioninthis manual.

Turn the water temperature dial dockwise (_'_) to decrease

the temperature, or counterclockwise (_-"_) to increase the

temperature.

PILOT LIGHTING-Set here before attempting to light pilot.

A-Is a thermostat setting of approximately

120°F, which will supply hot water at the

most economical temperatures. The

temperature adjustment knob Can be

turned lower than 120°F if desired.

A-Is a thermostat setting of approximately

130°E

B-Is a thermostat setting of approximately

140°E

AWARNING

NeveraUowsmallchildren_ousea hot water top, or to drasv_

their ownbathwater.Never leaveachildor handicappedper-

sonunattendedina bathtubor shower. I

The thermostat of this water heater has been factory set at its

lowest position, to reduce the risk of scald injury. It is adjustable

and must be reset to the desired temperature setting. The mark

(A) indicative of approximately 120°F is the preferred starting

point. Some states have a requirement for a lower setting. If you

need hotter water, follow directions for temperature adjustment,

but beware of the warnings in this section.

C-Is a thermostat setting of approXimately

150°E

VERY HOT-Is a thermostat setting of 160°E It is

recommended that the dial be set lower

whenever possible.

NOTE: Water temperature range of 120°--140°F recom-

mended by most dishwasher manufacturers.

AWARNING

Shouldoverheatingoccur or the gassupplyfail to shut off,

torn OFF' the manualgas€ontro valveto the applance.

19J

Service and Adjustment

Tank (Sediment) Cleaning

Sediment build-up on the tank bottom may create varying

amounts of noise, and if left in the tank will cause premature

tank failure. In some water areas, you may not be able to drain

all sediment deposits by simply draining the tank. In these cases

Mag Erad (part no. 23600) can be used to help remove the sedi-

ment deposits. This may be ordered from the Sears Service

Center. For ordering, refer to the _Repair Parts" section.

Venting System Inspection

At least once a year a visual inspection should be made of the

venting system. You should look for:

Obstructions which could cause improper venting. The com-

bustion and ventilation air flow must not be obstructed.

Damage or deterioration which could cause improper vent-

ing or |eakage of combustion products.

• Rusted flakes around top of water heater.

&WARNING

Chemical vapor corrosion of the flue and vent system may

occur if air fur combustion contains certain chemical vapors.

Spray can propellants, cleaning solvents, refrigerator and air

conditioner refriger-_ts, swimming poo! chemicals, calcium

and sodium ch oride, waxes, bleach, and processchemicals an

typical compounds which are potentially corrosive.

I _WARNING

Obstructed or deteriorated vent systemsmay present a serious

heaJthriskor asphyxiation.

Burner Inspection

J AWARNING 7

Do not usethisappr_nceifanypartofit hasbeenunderwater.]

Immediately call a Sears ServiceTechnicianto respecttheJ

applianceand to.replace the gascontrol or any part of the I

burnersystemwhichhasbeenunderwater. |

At least once a _,ear a visual inspection should be made of the

main burner annpilot burner. The drawing is for your reference.