Page 1

KGnmar^

Owners

Manual

FOR POTABLE WATER

HEATING ONLY

NOT SUITABLE FOR

SPACE HEATING

Model No.

153.321340 30

153.32134! 30

153.321440 40

153.32144! 40

153.321540 50

153.32154! 50

153.321640

153.32164!

153.321840 80

153.32184! 80 Ga!.

Ga!.

Ga!.

Ga!.

Ga!.

Ga!.

Ga!.

66 Ga!.

66 Ga!.

Ga!.

LISTED

Caution:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

Save this Manual for Future Reference.

POWER MISER^'^ll

WATTER HEAXER

Safety Instructions

Installation

Operation

EFFICIENCY

FiATiNG

CEPTiFiED

G

READ THE GENERAL SAFETY SECTION BEGINNING ON INSIDE COVER

AND THEN THIS ENTIRE MANUAL BEFORE INSTALLING OR OPERAT

ING THIS WATER HEATER.

ama

GAMA certification applies to all residential electric water heaters with

capacities of 20 to 120 Gallons. Input rating of 12 Kw or less at a voltage

no greater than 250 V.

• Care and Maintenance

• Troubleshooting

• Parts List

Awarning

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Printed in the U.S.A. 1203 www.sears.com Part No. 184730-000

Page 2

Safety Precautions

AWÂRNING

Improper installation, adjustirient, alteration, service or mainte

nance can cause DEATH, SERIOUS BODILY INJURf, OR PROP

ERTY DAMAGE, Refer to thiis manual for distance or consult

your local Seam Service Center for further information.

AWARNING

At the time of manufacture this water heater was provided with

a combination temperature-pressures relief valve certified by a

nationally recogni^d testing laboratory that maintains periodic

inspection of production of listed equipment or materials, as

meeting the requirements for Relief Wlros and Automatic Gas

Shutoff Devices for Hot Water Supply System^ and the current

edition of ANSI Z2I.22 • CSA 4,4 and the code requirements of

ASME, If replaced, the valve must meet the requirements of

local codes, but not less than a combination temperature and

pressure relief valve certified as meeting the requirements for

Relief Valves and Automatic Gas Shutoff Devices for Hot VWter

Supply Systems, ANSI Z21,22 • CSA 4,4 by a nationally recog

nized testing laboratory that maintains periodic inspection of

production of listed equipment or materials.

The valve must be marked with a maximum set pressure not

to exceed the marked hydrostatic working pressure of the

water heater (150 lbs, p,s,i,) and a dischar^ capacity not less

than the water heater input rate as shown on the mmlel reting

plate, (Electric heaters - watts divided by 1000 x 3412 equal

BTU/Hr. rate,)

Your local jurrsdictional authority, while mandating the u!% of a

temperature-presure relief valve complying with ANSI Z21.22 •

CSA 4,4 and ASME, m^qr require a val^ model different from

the one furnished with the water heater.

Compliance with such local requirements must be satisfied

the installer or end user of the water heater with a locally pre

scribed temperature-pressure relief valve installed in the desig

nated opening in the water heater in place of the factory for^

nished valve.

For safe operation of the water heater, the relief valve must not

be removed from it% designated opening or plug^d.

The temperature-pressure relief valve must be installed directly

into the fitting of the water heater designated for the relief

valve. Position the valve downwanJ and provide tubing so that

any discharge will exit only within $ inches above, or at any dis

tance below the structural floor. Be certain that no contact is

made with any live electrical part. The dischar^ opening must

not be blocked or reduced in size under any circumstances.

Excessive length, over 30 feet, or use of more than four elbows

can cause restriction and reduce the discharge capacity of the

valve.

No valve or other obstruction is to be placed between the relief

valve and the t§nk. Do not connect tubing directly to discharge

drain unless a 6 air ^ is provided. To prevent bodily injury, haz

ard to life, or property dama^, the relief valve must be allowed

to discharge water in quantities should circumstances demand. If

the discharge pipe is not connected to a drain or other suitable

m^ns, the water flow may cause property damage.

The Dischar^ Pipe:

• Must not be smaller in size than the outlet pipe size of the

valve, or have any reducing couplings or other restrictions.

• Must not be plumed or blocked.

* Must be of mat^al listed for hot water distribution,

* Must be installed so as to allow complete draini^ of both the

temperature-pressure relief valve, and the discharge pipe,

* Must terminate at an adequate drain.

• Must not hare any valve betvreen the relief valve and tank.

AWARNING

HAZARD OF ELECTRICAL SHOCK! Before removing any

access panels or servicing the water heater, make sure the

electrical supply to the water heater is turned “OFF”, Failure

to do this could result in DEATH, SERIOUS BODILY INJURT,

OR PROPERTY DAMAGE.

AWARNING

HOTTER WATER CAN SCALD: Water heaters are intended to

produce hot water. Water heated to a temperature which will ^Is-

space heating, clothes washing, dish washing, and other sanitizing

needs can scald and permanently injure you upon contact Some

people are more litely to be permanently injured by hot water than

others. These include the elderly, children, the infirm, or physical

ly/mentaJly handicapped. If anyone using hot water in your home

fits into one of these groups or if there Is a local code or state law

requiring a certain temperature water at the hot water ta(^ then

you must tals special precautions. In addition to using the lowest

possible temperature setting that satisfies your hot water needs, a

means such as a mixing valre, shall be used at the hot water

u^d by these people or at the water heater. Mixing valres are avaik

able at plumbing supply or hardware stores. Follow manufacturers

instructions for installation of the valves. Before changing the facto

ry setting on the therm^taL tiie "Temperature Regulation”

section in this manual.

AWARNING

WATER HEATERS EQUIPPED FOR ONE VOLTAGE ONLY: This

water heater is equipped for one type voltage only. Check the

rating plate near the bottom access panel for the correct volt>

age. DO NOT use this water heater with any voltage other than

the one shown on the model rating plate. Failure to use the eor^

rect voltage can cause problems which can result in DEATH,

SERIOUS BODILY INJURY, OR PROPERTY DAMAGE. If you

have any questions or doubts consult your electric company.

AWARNING

INSULATING JACKETS; When installing an external water

heater insulation jacleet on an electric water heater;

a. DO NOT cover the temperature-pressure relief valve.

b. DO NOT put insulation over the access covers or any

access areas.

c. DO NOT cover or remove operating instructions, and safe

ty related warring labels and materials affixed to the water

heater,

d. DO obtain new warning and instruction labels from Sears

for placement on the jacket directly over the existing labels.

AWARNING

Do not use this appliance if any part of it has been under

water. An electrical short or malfunction could occur. The

water heater should be replaced.

A CAUTION

WATER HEATERS EVENTUALLY LEAK; Installation of the

water heater must be accomplished in such a manner that if

the tank or any connections should leak, the flow of water

will not cause dama^ to the structure. For this reason, it is

not advisable to install the water heater in an attic or upper

floor. When such locations cannot be avoided, a suitable

drain pan should be installed under the water heater. Drain

pans are available at your local Sears Store. Such a drain pan

must be piped to an adequate drein.

Page 3

Table of Contents

Safety Precautions

Table of Contents

Introduction

.......................................

.............................

..............................

Product Specifications.......................

Preparing for the New Installation

Materials and Basic Tools Needed,.

Materials Needed.,

Basic Tools

.........................................................

Installation Instructions,

Removing the Old. Water Heater.............................................

Facts to Consider About the Location

Facts to Consider About the Convertible Lower FJcmcot,

Water Piping.............................................................................

T&P Valve and. Pipe Insulation

Temperature-Pressure Relief Valve

Filling the Water Heater...........................................................

Converting the T-ower FJement,,,,,

Wiring Diagrams......................................................................

Wiring.......................................................................................

Installation Checklist

...

...............................

.....................................

...........................................

.........................................

.................................

,,,,,,,............,,,,,,,,

,,,,,,,

.....

6-15

...........

...........

...........

...........

...........

...........

.........

...10-12

.........

.........

.........

„2

„3

.,4

.4

,5

„5

„5

6

7

7

8

8

9

10

13

14

15

Service and Adjustment..............

Temperature Regulation...........................................................

Thermostats...............................................................................

Thermostat Settings..................................................................

Upper and. Lower Thermostat Adjustment

Temperature-Pressure Relief Valve Operation

Draining....................................................................................

Element Cleaning and Replacement.........................................

Anode Rod Inspection..............................................................

Drain Valve Washer Replacement...........................................

Service

.............................................................

.............................

........................

Troubleshooting Guide,

Start Up Conditions

Thermal pA-pansion

Strange Sounds...............................................

Operational Conditions.....................................

Smelly Water.,.,,,,,,,,,

Air in Hot Water Faucet’s...............................

Rumbling Noise..............................................

High Temperature Shut Off" System

Not F.nough. or No Hot Water

Water is Too Hot

Leakage Checkpoints........................................

..........................................

.......................................

............

,,,,,,,............,,,,,,

.............

.......................

............................................

...16-20

.........

16

.........

16

.........

16

.........

17

.........

17

.........

17

...18-20

.........

20

.........

20

.........

20

...21-24

.........

21

.........

21

.........

21

,...22,23

.........

22

.........

22

.........

22

,...22,23

.........

23

.........

23

.........

24

Parts Order List.

Warranty

..............

...28-31

...........

32

Page 4

Introduction

Thank You for purchasing a Scars water heater.

Properly installed, and maintained, it should give you years of

trouble free service. If you should, decide that you want the new

water heater professionally installed, contact the local Scars

Service Center or any Scars store. They will arrange for prompt,

quality installation by Scars authorfred contractors.

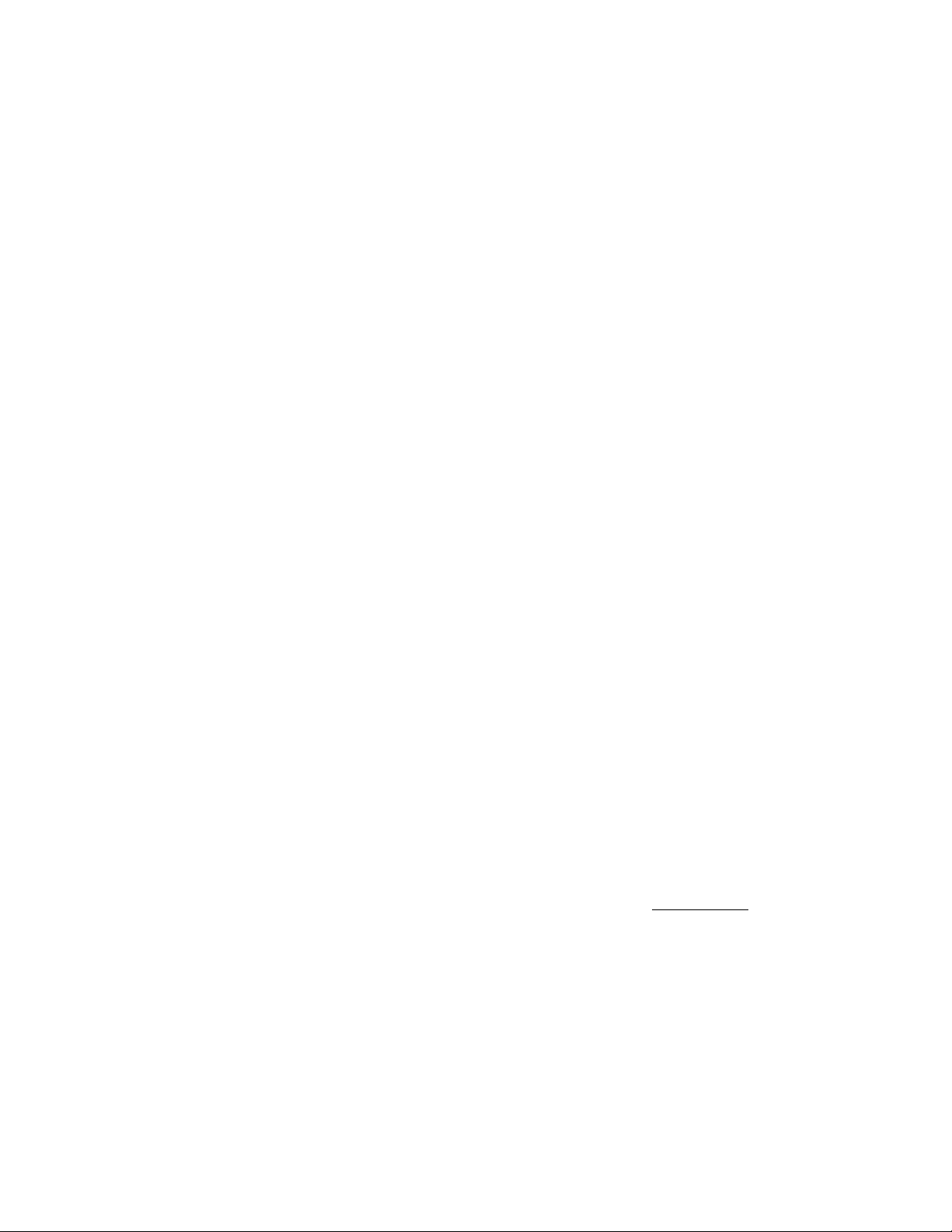

Product Specifications

MODEL

NUMBER

153.321340

153.321341

153.321440

153.321441

153.321540

153.321541

153.321640

153.321641

153.321840

153.321841

TANK

CAPACITY

IK GALLONS

30

40 20 6015,

50

66

80 26

DIMENSIONS IN INCHES

DIAMETER HEIGHT UPPER LOWER

19 47

2215. 62

24 62

62

RECOVERY RATE

GALS. PER HOUR

@ 90“F, RISE

Abbirviatioiis Found In This Instruction ^Manual

U.L. '■ Underwriters laboratories Inc.

NEC - National Electrical Code

ANSI - American National Standards Institute

ELEMENT

WTAGE

AT 240 VOLTS

17.3

25.0 3800 5500 10 30

17.3

25.0 3800 5500 10 30

17.3

25.0 3800 5500 10 30

17.3

25.0 3800 5500 10 30

17.3

25.0 3800 5500 10 30

3800 3800

3800 3800

3800 3800

3800 3800

3800 3800

MINIMUM

WIRE SIZE*

(GAUGE)

12

12

12

12

12

MAXIMUM FUSE

OR CIRCUIT

BREAKER

SIZE (AMPS)

20

20

20

20

20

^Wiring sixe based, on standard bO’C copper wire. If distance from fuse box to water heater is more than 90 feet, refer to your l ocal electri

cal code.

Preparing for the New Installation

Read the “Safety Precautions” section, page 2 of this manual

first and then the entire manual carefully. If you don’t follow

the safety rules, the water heater will not operate properly. It

could cause DEATH, SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE,

This manual contains instructions for the installation, opera

tion, and, maintenance of this electric water heater. It also

contains warnings throughout the manual that you must read

and be aware of All warnings and, all instructions arc essen

tial to the proper operation of the water heater and your safe

ty, Since we cannot put everything on the first few pages,

READ THIS ENTIRE MANUAl. BEFORE ATTEMPT

ING TO INSTALL OR OPERATE THE WATER

HEATER.

The installation must conform with the instructions in this

manual; electric company rules; and, Ixical Codes, or in the

absence of Ix)cal Codes, with, the current edition of the NEC

National Electrical Code, NFPA 70, This publication is

available from your local government or public library or

electric company or by writing Underwriters Laboratories

Inc,, 333 Pfingsten Roid, Northbrook, II. 60062,

If after reading this manual you have any questions or d.o not

understand, any portion of foe instructions, call Scars Service

Center,

Carefully plan foe place where you arc going to put foe water

heater. Correct electrical wiring and connections arc very

important in preventing d.cafo. from possible electrical shock

and fires.

Examine the location to ensure the water heater complies with

foe “Facts to Consider About foe Location" section.

For California installation this water heater must be braced,

anchored, or strapped, to avoid falling or moving d.uring an

earthquake. Sec instructions for correct installation proce

dures. Instructions may be obtained from your local dealer,

wholesaler, public utilities or California office of the State

Architect, 400 P Street, Sacramento, CA 95814,

Massachusetts Code requires this water heater to be installed

in accordance with Massachusetts 248-CMR 2,00: State

Plumbing Code and 248-CMR 5,00,

Page 5

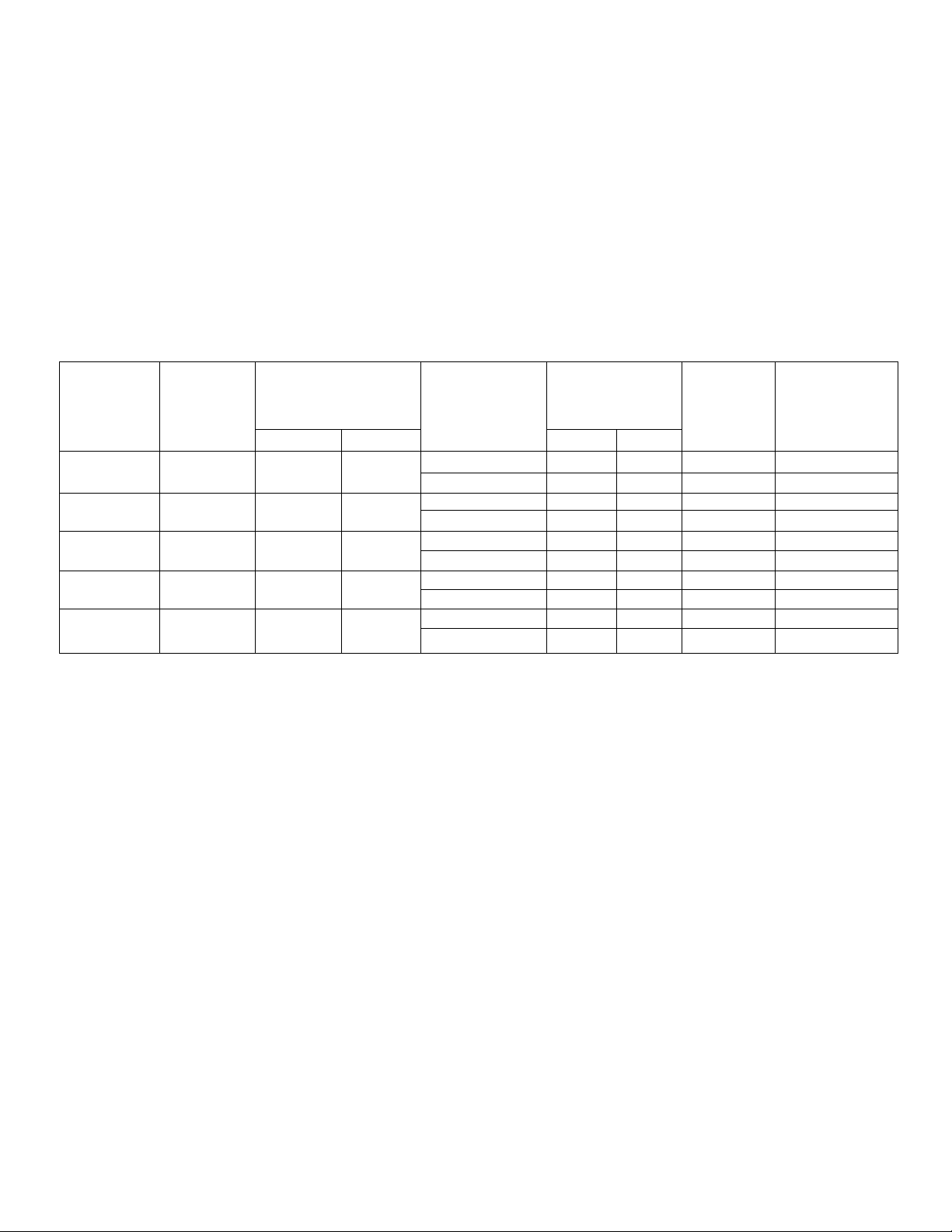

Materials and Basic Tools Needed

Materials Needed

To simplify the installation Scars has available the installation

parts shown below; You may oi may not need all of these materi

als, depending on your type of installation.

EXPANSION TANI» FOR THERMAL

EXPANSION CONDITIONS AVAILABLE

WATER HEATER INSTALLA

TION KIT WITH FLEXIBLE

CONNECTORS FOR 3/4" OR

1/2" THREADED OR COPPER

PLUMBING

IN 2 GALLON AND 5 GALLON CAPACITY

THROUGH LOCAL SEAF^ STORE OR

SERVICE CENTER

Basle Tools

You may or may not need all of these tools, depending on your

type of installation. These tools can be purchased at youi local

Scars store.

Pipe Wrench (2)

Screwdriver

6 Foot Tape or Folding Rule

Garvlen Hose

Drill

Pipe Dope or Teflon Tape

GARDEN HOSE

SLOT-HEAD SCREW DRIVER

PHILLIPS SCREWDRIVER

8 FOOT TAPE

PIPE

WRENCH

DRAIN PANS AVAILABLE IN 20"

DIAMETER FOR WATER HEATERS

HAVING A DIAMETER 18" OR LESS,

24" DIAMETER FOR WATER

HEATERS HAVING A DIAMETER 22"

OR LESS AND AVAILABLE IN 28”

DIAMETER FOR WATER HEATERS

HAVING A DIAMETER U" OR LESS

ADDITIONAL TOOLS NEEDED

WHEN SWEAT SOLDERING

Tubing Cutters or Hacksaw

Propane Torch

Soft Solder

Solder Flux

Ennery Cloth

Wire Brushes:

HACKSAW

3/4" WIRE BRUSH

1/2" WIRE BRUSH

ñ

*C:

PIPE DOPE

(SQUEEZE TUBE)

(Use only on vmter connections)

ROLL OF TEFLON TAPE DRILL

ROLL OF LEAD FREE

SOFT SOLDER

ROLL OF EMERV

CLOTH

SOLDER

FLUX

PROPANE TORCH

FTÒhì

TUBING

CUTTER

Page 6

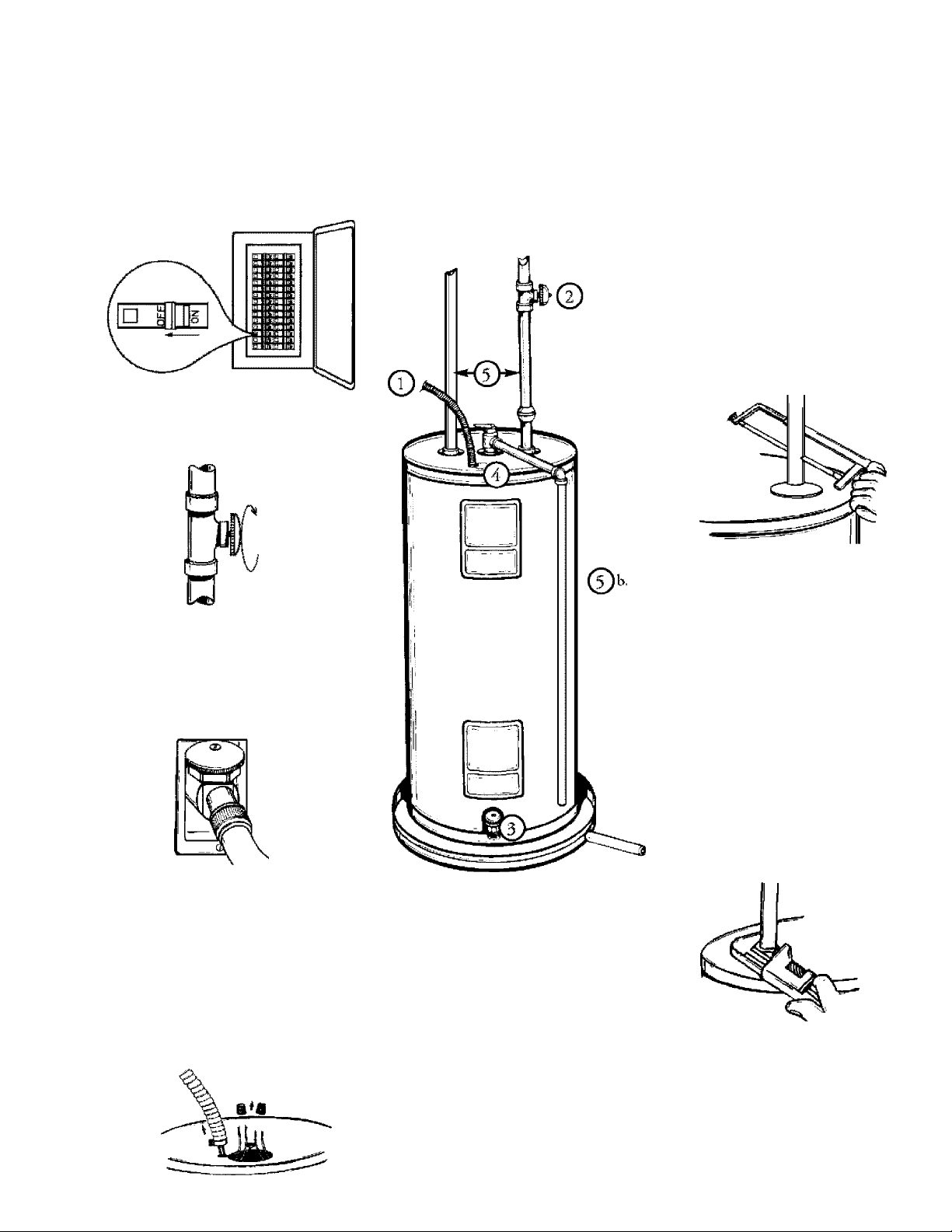

Installation Instructions

Removing the Old Water Heater

^^Turn “OFF” electrical supply to the water heater.

Turn “OFF” the water supply to the

©

water heater at the water shutoff valve or

water meter.

r^a. If you have copper piping to the water

heater, the two copper water pipes can be

cut with a hacksaw approximately 4" away

from where they connect to the water

heater. This will avoid, cutting off the pipes

too short. Additional cuts can be made

later if necessary. Disconnect the tempera

ture-pressure relief valve drain line, ^Ticn

the water heater is drained,, disconnect the

hose from the drain valve. Close the drain

valve. The water heater is now completely

disconnected and ready to be removed.

Attach a hose to the water heater drain

valve and put the other end, in a floor

drain or outdoors. Open the water heater

drain valve. Open a nearby hot water

faucet which will relieve pressure in the

water heater and speed draining.

AWARNING

The water passing out of the drain valve be extreme

ly hot. To avoid being scalded, make sure all connections

are tight and that the water flow is directed away from

any person.

Check again to make sure the electrical supply is

turned, “OFF” to the water heater. Then disconnect

the electrical supply connection from the water

heater junction box.

If you have galvanixcd, pipe to the water

heater, loosen the two galvanixcd, pipes

with a pipe wrench at the union in each

line. Also disconnect the piping remaining

to the water heater. These pieces should be

saved since they may be needed when

reconnecting the new water heater.

Disconnect the temperature-pressure relief

valve drain line. When the water heater is

drained, disconnect the hose from the

drain valve. Close the drain valve. The

water heater is now completely disconnect

ed and ready to be removed.

A CAUTION

Mineral buildup or sediment may have accumulated in the

old water heater. This causes the water heater to be

much heavier than normal and this residue, if spilled out,

could cause staining.

Page 7

Installation Instructions (cont’d)

Facts to Consider About the Location

You should, carefully choose an indoor location for the new

water heater, because the placement is a very important consid

eration for the safety of the occupants in the building and for

the most economical use of the appliance. This water heater is

not intended for outdoor installation,

'Whether replacing an old water heater or putting the water

heater in a new location, the following critical points must be

observed,

• The location selected should be indoors as close to and as

centralized with the water piping system as possible. This

water heater, as well as all water heaters, will eventually leak.

Do not install without adequate drainage provisions where

water flow will cause damage.

A CAUTION

WATER HEATERS EVENTUALLY LEAK; Installation of

the water heater must be accomplished in such a manner

that if the tank or any connections should leak, the flow of

water will not cause damage to the structure. For this

reason, it is not advisable to install the water heater In an

attic or upper floor. When such locations cannot be ®ioided, a suitable drain pan should be installed under the

water heater. Drain pans are available at your local Sears

stores. Such a drain pan must be piped to an adequate

drain.

Facts to Consider About The

Convertible Lower Element

The Upper Element (if a double element model), is a conven

tional 3800 watt clement which only operates at its rated

wattage on 240 volts, (Sec rating plate on water heater).

The Ixjwcr FJement of the water heater can be converted from

operation at 3800 watts to .5.500 watts on a 240 volt system.

Read and follow water heater warnings and instructions. If after

reading these instructions in this manual, if you do not under

stand any portion, call Scars Service Center.

AWÂRNING

Before making the conversion to SSOO watts, check the

(I) power supply...must be 240 volts, (2) wiring... 10 gauge

AWG, Type TW, 60*C or equivalent, and (3) Circuit

brealffirs or fuslng.„capable of 30 amp loading. Also, the

Installation must conform with this manual, local codes

and electric utility rules. Failure to comply can result in

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE,

«4 ooRfiespowEMce re- xTS. .гиатАМРп

ШУ9 ИВШЮН MOOEL & CUI J

ELECTRIC VWTER HEATER eco

THIS №ATCR AL- /11- Л tHSfiALLtU

MODEL NUMBER СаРАСГГУ

A CAUTION

INSTALLATION IN RESIDENTIAL GARAGES; The

water heater must be located and/or protected so It Is

not subject to physical damage by a moving vehicle.

The location selection must provide adequate clearances for

servicing and proper operation of the wutcr heater.

nguniT Е1.ЕЮГГ MMHUtlU WLTR'-’ : yncLKKJ Fient WQHHHaFnea.pwi

VÏATTS WATTS WATTS . :: IF CONVERTED

^iCTORV equipped WTTH .

150

WATT8 WAT13

3PTIONM.WATTAOE

UROt L0M91

NOTE; Whetlier or not the element, coiivewaott is made the

model rating plate must be marked. Using a bard point ink

pen, check the appropria.te block witbiii the model rating

plate, which is located adjacent to the lower access panel.

WATTS A.C. P INSTALLED

MMiMLiM CHËCKi.'mEBE ’

■' ..fACTOPVEQUIPI

è:::-": WARNINQ

CONVERSЮN

INSTRUCTION

?ED

Page 8

Installation Instructions (cont’d)

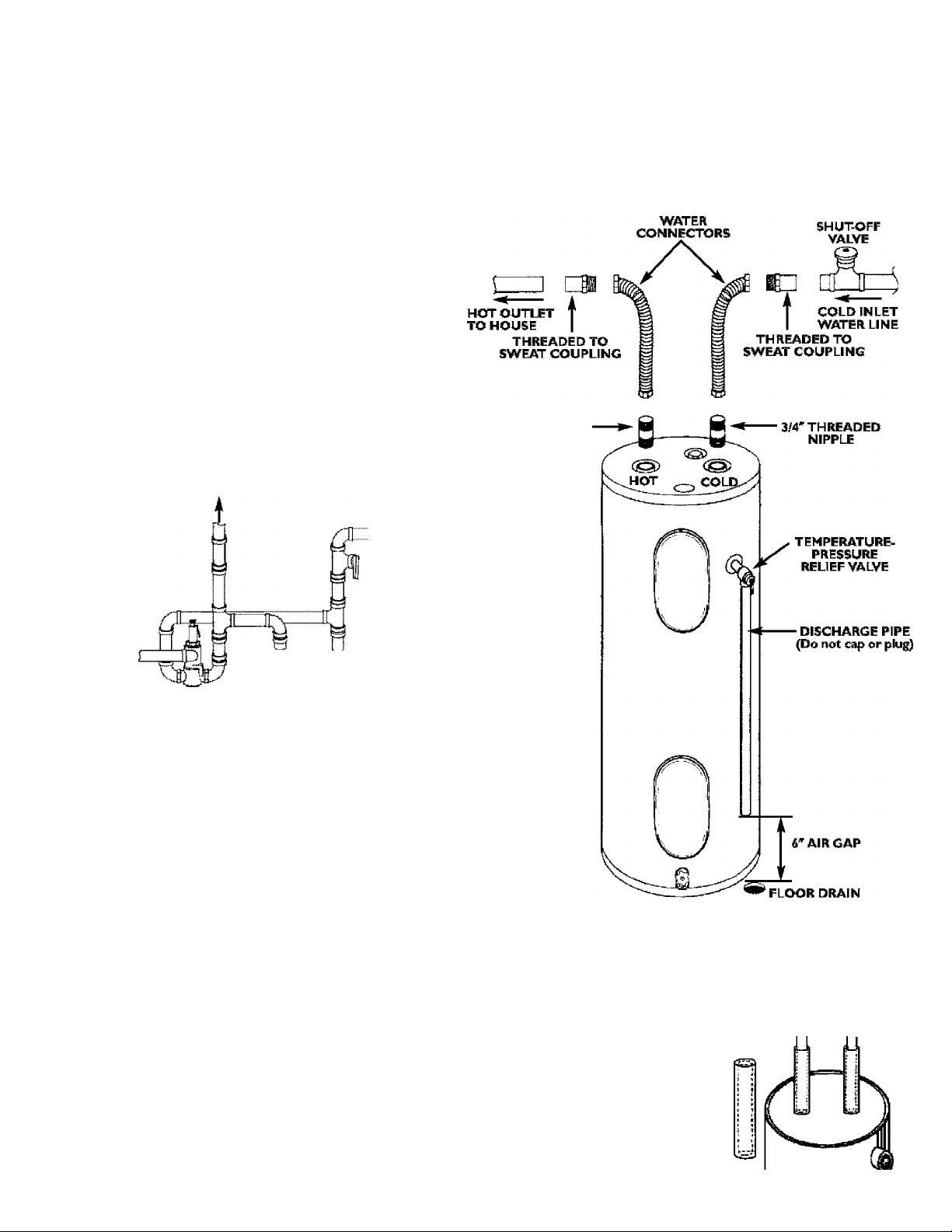

Water Piping

WARNING

HOTTER WATER CAN SCALD; Water heaters are

intended ta produce hot water. Water heated to a temper

ature which will satisfy space heating, clothes washing, dish

washing, and other sanitizing needs can scald and perm№

nentfy injure you upon contact Some people are more like

ly to be permanently injured by hot water than others.

These include the elderly, children, the infirm, or physical-

ly/mentalfy handicapped. If anyone using hot water in your

home fits into one of these groups or if there is a local code

or state law requiring a certain temperature water at the

hot water tap, then you must take special precautions. In

addition to using the lowest possible temperature setting

that satisfies your hot water needs, a means such as a mix

ing valve, shall be used at the hot water taps used by these

people or at the water heater, Mbdng valves are available at

plumbing supply or hardware stores. Follow manufacturers

instructions for installation of the valves. Before changing

the factory setting on the thermostat, read the

“Temperature Regulation” section in this manual.

HOT WATER

OUTLET

COLD WATER

INLET

Installation completed using

Installation Kit

3/4* THREADED

NIPPLE

FLEXIBLE

TEMPERED

WATER OUTLET

I

FROM HOT

«MIXING VALVE

The illustrition shows the attachment of the water piping to the vrater

heater. The water heater is equipped with ¥f water connections.

If a water heater is installed in a closed water supply system; such as one

having a back- flow prevxnter, check valve, water meter with a check valve,

etc, in the cold water supply, means shall be provided to contml thermal

expansion, Qsntact the local, utility or local Seara Service Center on how

to control this situation,

NOTE; If osLug copper hibing. solder tubing to an adapter before

attadiiiig tlie ac^t^ to die cold water inlet cotmecdoti. Do not sol

der foe cold water supply line direedy to die cold waiter inlet. It will

liartn foe dip tube and damage die taiik,

• look at the top cover of the water heater. The water outlet is markd

hot. Put two or thiee turns of teflon tape amund the thieaded end of

the threaded-to-sweat coupling and around both ends of the ¥f

threaded nipple. Using flexible connectors, connect the hot water pipe

to the hot water outla of the water heater,

• Look at the top cover of the water heater. The cold water inlet is

marked cold. Put two or three turns of teflon tape amund the threaded

end of the threaded-to-sweat coupling and around both ends of the ¥f

threaded nipple. Using flexible connectors, connect the cold water pipe

to the cold water inlet of the water heater.

NOTE: Your water heater is super insulated to inmimree heat loss

from die tank. Further reduction in heat loss can be accomplished by

iusulatiug foe hot wetter lines from foe heater,

WATER OUTLET

ON WATER HEATER

I TO COLD WATER

Y INLET ON

WATER HEATER

T&P Valve and Pipe Insulation

Remove insulation for T&P Valve and pipe connections from

Fit pipe insulation over foe incoming cold water line and

water line. Make sure that the insula

tion is against the top cover of the

heater.

Fit T&P Valve insulation, over v-alvc.

Malx sure that the insulation docs

not interfere with the lever of the

T6iP valve.

Secure all insulation using tape.

catton.

the hot

Page 9

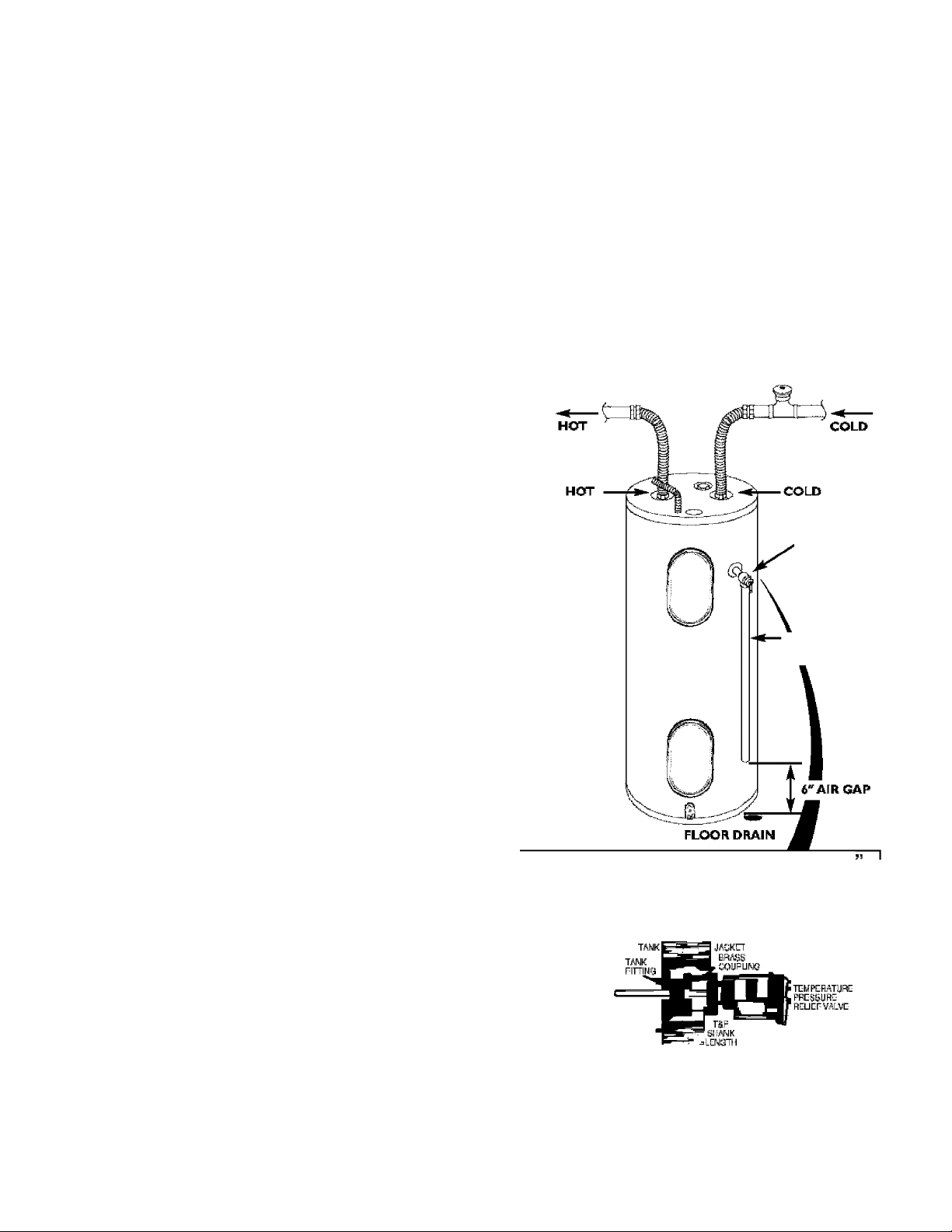

Installation Instructions (cont’d)

Tempe ratu re- P ressu re

Relief Valve

AWARNING

At the tíme of manufacture this water heater was provided

with a combination temperature-pressures relief valve cer

tified by a nationally recognized testing laboratory that

maintains periodic inspection of production of listed equip

ment or materiaJs, as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water

Supply Systems, and the current edition of ANSI Z2I.22 •

CSA 4.4 and the code requirements of ASME. If replaced,

the valve must meet the requirements of local codes, but

not less than a combination temperature and pressure

relief valve certified as meeting the requirements for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water

Supply Systems, ANSI Z21.22 * CSA 4.4 fcy a nationally rec

ognized testing laboratory that maintains periodic inspec

tion of production of listed equipment or materials.

The valve must be marked with a maximum set pressure

not to exceed the marked hydrostatic working pressure of

the water heater (ISO IbsJsq, in,} and a dischai^e capacity

not less than the water heater input rate as shown on the

model rating plate. (Electric heaters - watts divided by

1000 X 3412 equal BTU/Hr. rate.)

Your local jurisdictional authority, while mandating the use

of a temperature-pressure relief valve complying with ANSI

Z21,22 * CSA 4,4 and ASME, may require a valve model dif

ferent from the one furnished with the water heater.

Compliance with such local requirements must be satisfied

by the installer or end user of the water heater with a

locally prescribed temperature-pressure relief valve

installed in the designated opening in the water heater in

place of the factory furnished valve.

For safe operation of the water heater, the relief valve must

not be removed from itis designated opening or plumed.

The temperature-pressure relief valve must be installed

directly into the fitting of the water heater designated for

the relief valve. Position the valve downwat^ and provide

tubing so that an^ discharge will exit only within ¿ inches

above, or at any distance below the structural floor. Be cer

tain that no contact is made with any live electrical part

The discharge opening must not be blocked or reduced in

size under any circumstances. Excessive length, over 30

feet, or use of more than four elbows can cause restriction

and reduce the discharge capacity of the valve.

No valve or other obstruction is to be placed between the

relief valve and the tank, not connect tubing directly to

dischai^e drain unless a « air gap is provided. To prevent

bodily injury, hazard to life, or property dama:^, the relief

valve must be allowed to discharge water in quantities

should circumstances demand. If the discharge pipe is not

connected to a drain or other suitable means, the water

flow m^ cause property damage.

The Discharge Pipe;

* Must not be smaller in size than the outlet pipe size of

the valve, or have any reducing couplings or other

restrictions.

* Must not be plui^ed or blocked,

* Must be of material listed for hot water distribution,

* Must be installed so as to allow complete drainage of

both the temperature-pressure relief valve, and the dis

charge pipe,

* M ust terminate at an adequate d rain,

* Must not have any valve between the relief valve and

tank.

AWARNING

The temperature-pressure relief valve must be manually

operated at least once a year. Caution should be taken to

ensure that (I) no one is in front of or around the outlet

of the temperature-pressure relief valve discharge line,

and (2) the water manually discharged will not cause any

bodily injury or property damage because the water m^

be extremely hot.

If after manually operating the valve, it fails to completely

reset and continues to release water, immediately, close

the cold water inlet to the water heater, follow the drain

ing instructions, and replace the temperature-pressure

relief valve with a new one.

TEMPERATURE-

PRESSURE

RELIEF VALVE

' DISCHARGE PIPE

(Do not cap or plug)

WARNING “RELIEF VALVE OPENING

TMs hsgÈsr is piwitístí wfh e>rnbiftafcn Tsmiiaalui^isssíjfei flsisf Vaivs líaetí íompíyíiTg saih

lor ReJii' Valvg® and Autofnsüç WI loî Siipísíy Sysfenis, MiB SI

end ihç ADtiE.

Vsgi Icç^jiiri^ielicnal küíNíí%, rnairdsíiíig ihç isf ^ Teitií)ííraigi5-Pisí&ür^

e liwally prgsioribsd Tsit^raíiíf^-Prgísyi^ îiçlisf hslsJIsíJ in ih? ifesignaì&d cpening in ihç ss^r

hçetef-

'InstóllaqujifnsfììrsqulRHj ìjy IscalfcttìTisi tes®ilian açornblnBìten Temper^iirs-Pfessiifi^ Relish Valve seüífied as mesílrig tlie fsqiiiramsnis fer RíHisí V^lvís and

hg laixìfaìsfy thaï main^iTis psrfodç IrBjisdsn ot pràfiitlioir st listed ísqjipmení isf másríals. Tita va^

miKt be orèiTìsd, pníiiiJed №g. or iiisfellíHj so ílral di^har^ çaii sdì only ivííIiíti g ìiiof^

aîRsve, or at arw det^ice boiois ih§ stmctifal floor, and cariiría soTiiaoi «iiy If^ eleàrìo^l iiéì.“

Tor s0Js operalìoiT oì the ssaìer teater, the Relief miBí nsi be isnwsJ isf píiig^.

Seí> m^iTUíl heading ■ 'TampíHeliífe-PRsesure Relií^f ìer iiislallalisfi ana maiirionansa oí Rslíei

Valve, díssliarge ppe and sllisf pieeauítoiTs.

^ ift^ r^ir^ @ N10^ tn^rn tho Iuttiìsìi^ vuith tho h^r.

wfifi sudi itgsi 1;^ ^ ihg iiisisli^ srd Uier of iiis ii^r saih

TSF RCLIEF

VALVE PRC^BE

MUST EKTEND

ÌHTOTAHK

ÒRiiSS

NÌPPLT

• If a short shank (less tì^n 2") iempsiHUre-pr^uTs rslist te ì

(as a nìpplD and ©supling must Lo uo^.

• If a Ipng sharili (2" or fori^r) is te be ins^lsd, de noi tiss nipple arid ceupling.

SasShiiìeiT Dsvíí^íorlli3í-WateraipplyS^™MSZ21.22byanaíisf»al¥i^rio^

Page 10

Installation Instructions (cont’d)

Filling the Water Heater

To fill the water heater with water;

• Close the water heater drain vulve by turning the handle to

the right (clockwise). The drain valve is on the lower front of

the water heater,

• Open the cold water supply valve to the water heater,

NOTE; The cold water supply valve must be left open

when the water heater is in use.

• To insure complete filling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run

until a constant flow is obtained. This will let air out of the

water heater and the piping.

A CAUTION

Never use this water heater unless It Is complete^ full of

water. To prevent damage to the tank and heating ele

ment, the tank must be filled with water. Water must

flow from the hot water faucet before turning “ON”

power.

• Check all new water piping for leaks. Repair as needed.

Converting the Lower

Element

These instructions only cover the conversion of the convertible

elements read this entire manual before attempting to install or

operate the water heater. The water heater is factory set to oper

ate at 3800 watts. The lower element can be converted, to oper

ate at 5500 watts. Refer to the “Facts to Consider About the

Convertible liswcr FJement” section.

The Upper Elements (if a double clement model) is a conven

tional 3800 watt element which only operates at its rated

wattage on 240 volts, (See rating plate on water heater).

M COHRESPOd^l^ RE-

QAmtNQ THIS HESTER

mvB heifnOH ik

FACTORY SQUIPPED WITH

«ATT8 WATTS

OPTIONAL WATTAGE

OPPBR tgWR

ELECTRIC Wi

MODELNUMBER

V«Tra WATnS.::-lFCOWVEBTED::-

w*Tra A.C. DHCV IF AS ■ p,s,l

uwiuiw CHECK HERE ;

------------------

.TER HEATER

æHIALNUMEER

VC<.TS :.,VHfcUK If} nbric TiKpwNaweasiiBe

EQUIPPED

-------------^--------

WARNING

SEE CONVERSION

MsmucTiON

ECO

INSTALLED

150

NOTE; Whetlier or not. the element conversion is made the

model rating plate must be marked. Using a hard point ink

pen, check the appropriate block within the model rating

plate, which is located adjacent to tlie lower acc^s panel.

Necessary element conversion parts arc located in a small bag

contained within the electrical junction box on top of the water

heater.

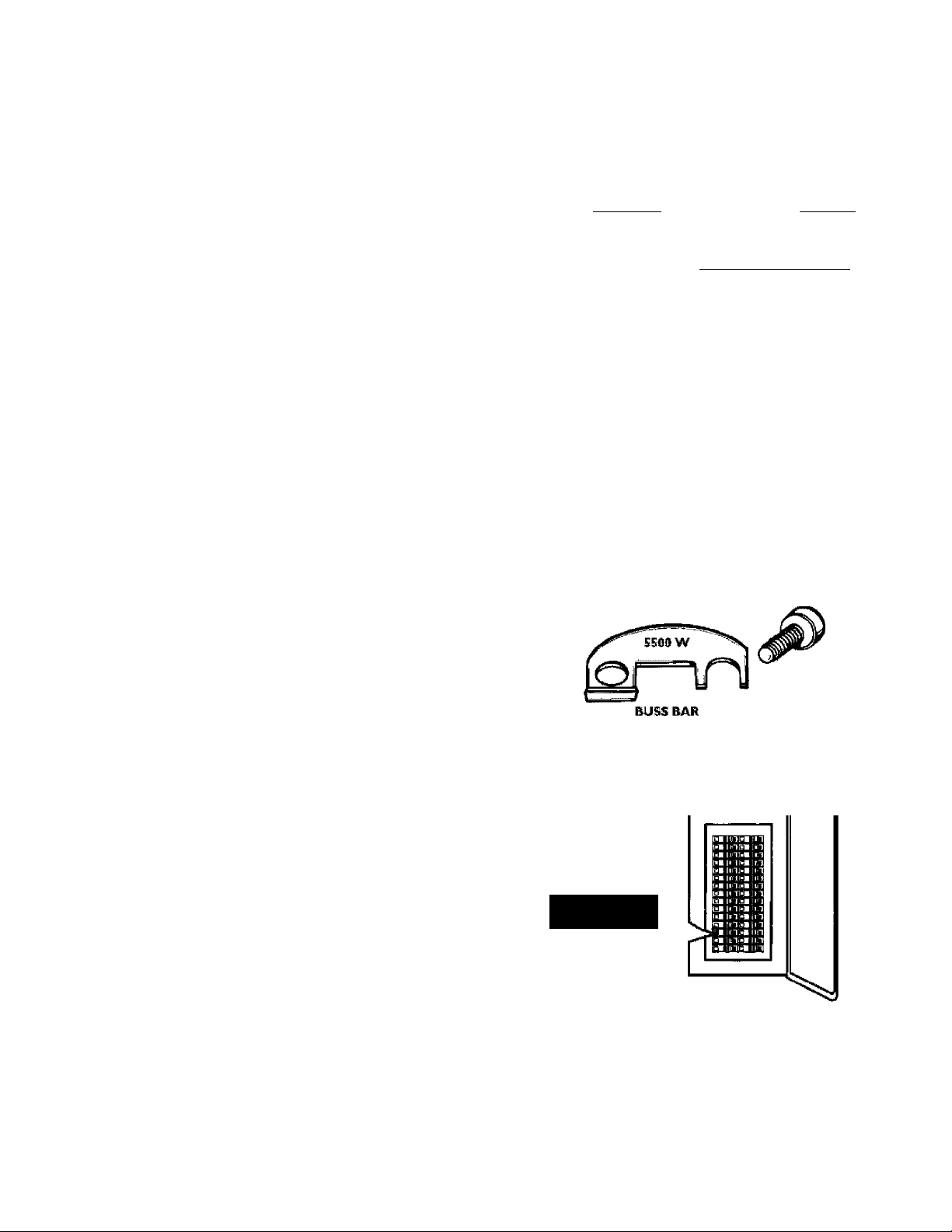

CONVERSION PAFTTS

SCREW

The Lower Element of the water heater can be converted from

operation at 3800 watts to 5500 watts on a 240 volt system.

If after reading these instructions and this manual, if you do not

understand any portion, call Scars Service Center.

AWARNING

Before making the conversion to SSOO watts, check the

(I) power supply,..must be 240 volts, (2) wiring,,,10 gauge

AWG, Type TW, 60*C or equivalent, and (3) Circuit

brealmrs or fusing,„capable of 30 amp loading. Also, the

Installation must conform with this Manual, local codes

and electric utility rules. FAILURE TO COMPLY CAN

RESULT IN DEATH, SERIOUS BODILY INJURY OR

PROPERTY DAMAGE.

I , Before beginning the conversion turn “OFF” electric power

supply to the water heater.

IIKIPII

AWARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater, make

sure the electrical supply to the water heater is turned

“OFF”. FAILURE TO DO THIS COULD RESULT IN

DEATH, SERIOUS BODILY INJURY, OR PROPERTY

DAMAGE,

10

Page 11

Installation Instructions (cont’d)

The convertible element is located, behind, the lower access

panel of the wmer hcatcj', 'Remove the two screws securing

the access panel, and remove panel.

3. Remove the insulation block and pad.

,5. Remove the screws from terminal 2 of the element, and. move

the looped end, of the wire asid e.

6. The buss bar is labeled 5.500 W. Place the buss bar over

terminals 2 and 3 with the 5.500 W visible. Install the extra

screw provided, into terminal 3.

The wire removed from terminal 2 has a looped end. It must

remain looped and now be placed (as shown) on top of the

buss bar, over the opening of terminal 2, and secured using

the remaining screw.

4. Lower Elemeut: Lift out the tab as shown to unclip the ter

minal cover from the thermostat. The terminal cover can be

removed from the thermostat.

8. Tighten terminals 2 and 3 to ensure proper electrical

connection.

AWARNING

Failure to tighten terminal screws can cause a Pre which

can result In DEATH, SERIOUS BODILY INJURY, OR

PROPERTY DAMAGE.

Page 12

Installation Instructions (cont’d)

Converting the Lower

Element (cont’d)

9. Replace tciminal cover on the thermostat, making sure the

notch is in place over the tab.

Tït sj*a?¥a

W 7SP OF

AWÂRNING

Make sure the thermostat Is flush against the tank, the

terminal cover is in place, and the Insulation Is replaced.

Failure to do so can result in DEATH, SERIOUS BODILY

INJURY, OR PROPERTY DAMAGE,

10. Replace the insulation block and pad so that it completely

covers the thermostat and element.

11, Replace the access panel.

12. Complete wiring to the water heater, or if completed, turn

“ON” electric power to the water heater after filling the

tank with water.

Bglllli

A CAUTION

Never use this water heater unless It Is completely full of

water. To prevent damage to the tank and heating ele

ment, the tank must be filled with water. Water must

flow from the hot water faucet before turning “ON”

power.

Page 13

Installation Instructions (cont’d)

Wiring Diagrams

STANDARD WIRING FOR

2 WIRE LEAD WATER HEATERS

NON-SIMULTANEOUS OPERATION

240 VOLT DOUBLE ELEMENT

TO ELECTRIC

POWER SUPPLY

WIRING FOR 3 WIRE LEAD WATER HEATERS

NON-SIMULTANEOUS OPERATION

240 VOLT DOUBLE ELEMENT

FOR 3800 WATTS

^NOTE: Some Lower Hi-Temp Limit

Switches may have 4 terminals. Use

only the 2 terminals on left.

YELLOW

LOWER

HEATING ELEMENT

:i3

1

TIME CLOCK SWITCH

OPERATES BOTTOM ELEMENT ONLY

TO ELECTRIC w

POWER SUPPLY

YELLOW I TBLUe|BLACÍC

«OFF PEAK” METER

OPERATES BOTTOM ELEMENT ONLY

TO ELECTRiC

POWER SUPPLY LI

FOR TWO WIRE CONNECTION

POWER SUPPLY

LI

^ 9

yellow!

THREE TYPES OF FIELD

CONNECTIONS YOU MAY

HAVE

TO TÍME

L2 L2 clcx:íc switch

JUNCTION SOX

I2l-'L2 TO^'OFF

- PEAK” MCTER

JUNCTION BOX

------

1

L2

JUNCTION BOX

TbLU^ BLACK

Page 14

Installation Instructions (cont’d)

Wiring

A CAUTION

Never use this viater heater unless it is completely full of

water. To prevent damage to the tank and heating ele

ment, the tank must be filled with water. Water must

flow from the hot water faucet before turning on power.

You must provide all wiring of the proper sixe outside of the

water heater. You must obey local codes and. electric company

requirements when you install this wiring.

If you arc not familiar with electric codes and practices, or if you

have any doubt, even the slightest doubt, in your ability to con

nect the wiring to this water heater, obtain the service of a com

petent electrician. Contact your Scars salesperson to arrange for

a professional electrician.

AWARNING

WATER HEATERS EQUIPPED FOR ONE VOLTAGE

ONLY: This water heater Is equipped for one type voltage

only. Check the rating plate near the bottom access panel

for the correct voltage. DO NOT use this water heater

with any voltage other than the one shown on the model

rating plate. Failure to use the correct voltage can cause

problems which can result In DEATH, SERIOUS BODILY

INJURf, OR PROPERTY DAMAGE. If you have any ques

tions or doubts consult your electric company.

C, Flexible metal conduit or flexible metallic tubing shall be

permitted for grounding if all the following conditions arc

met:

1, The length in any ground, return path docs not exceed

6 feet,

2, The circuit conductors contained, therein arc protected

by overcurrent devices rated at 20 amperes or less,

3, The conduit or tubing is terminated in Fittings

approved for grounding.

For complete grounding details and all allowable exceptions,

refer to the current edition of the National FJectrical Code,

NFPA70.

4, A standard. V” cond.uit opening has been made in the water

heater junction box for the conduit connection.

3, Wiring Diagrams (See Wiring Diagrams Section) have been

supplied, showing the two most common types of connec

tions between the water heater and. the power supply. You can

easily sec which type connection you have by removing the

junction box cover on top of the water heater,

A, Two WTre Counecticui Diagrams! is the most common

requiring you to simply connect red to red., black to black,

and the ground wire to the green ground screw in the junc

tion box of the water heater,

A CAUTION

If wiring from your fuse box or circuit brealrer box was

aluminum for your old water heater, replace It with cop

per wire. If you wish to reuse the existing aluminum wire,

have the connection at the water heater made by a com

petent electrician. Contact your Sears salesperson to

arrange for a professional electrician.

1. Piovid.c a way to easily shut off the electric power when

working on the water heater. This could, be with a circuit

breaker or fuse block in the entrance box or a separate dis

connect switch,

2. Install and. connect a circuit directly from the main fuse or

circuit breaker box. This circuit must be the right she and

have its own fuse or circuit breaker. Refer to the chart in the

“Product Specifications” section for the correct sixe wire and

fuse or circuit breaker,

3. If metal conduit is used for the grounding conductor:

A, The grounding electrode conductor shall be of copper,

aluminum, or coppcrclad aluminum. The material shall

be of one continuous length without a splice or joint.

B. Rigid metal conduit, intermediate metal conduit, or elec

trical metallic tubing may be used for the grounding

means if conduit or tubing is terminated in fittings

approved, for grounding.

B. Three Wire Counection Diagmau is used when you arc

connecting the water heater to power a supply that has a

“Time Clock” or “Off Peak” Meter, To make these connec

tions refer to block i or 2 in this wiring diagram for the type

of system you h ave,

NOTE: If you have purchased, a three wire comiectiou

water heater but yow are not on a “Time Clock” or “OIF

Peak” meter and have a standard two wire connection

power supply, simply follow the connection diagram in

block 3. of the Three Wj« Connection Diagram.

6. Use wire nuts and. connect the power supply wiring to the

wires inside the water heater’s junction,

7. The water heater must be electrically “grounded” by the

installer. A green ground screw has been provided, on the

water heater's junction box. Connect ground wire to this

location.

8. Replace the wiring junction cover using the screw provided.

14

Page 15

Installation Instructions (cont’d)

Installation Checklist

'Whether 01 not the element conversion is made, the model

rating plate must be marked. Using a hard point ink pen,

check the appropriate block within the model rating plate,

which is located adjacent to the lower access panel.

Is the fuse or circuit breaker sixe correct as shown in the chart

in the “Product Specifications” section?

Arc the wires from the circuit breaker or fuse service to the

water heater's junction box on the correct wire size (gauge) as

shown in the chart in the “Product Specifications” section?

Is the new tcmpcraturc'prcssure relief valve properly

installed, and piped, to an ad.equate drain? See “TemperaturePressure Relief’Valve” section.

Is the water heater completely fdled. with water? See “Filling

the "Water Heater” instructions in the “Installation

Instructions” section.

Will a water leak damage anything? Sec “Facts to Consider

About the location” section.

Arc the cold and hoc water lines connected to the water heater

correctly? Sec “Water Piping” instructioas iu the “Instalktion

rascruccions” section.

COLD

Is there adequate clearance for maintenance around the water

heater?

Do you need to call your electric company to check your

wiring?

ELECTRIC ¥WIER HEATER ego

KRUtW HJKMeir !№№liU HlStllB í(iiSSíi»5ÍWWíC

WATTS wftTTfi ag

OPTIONAL WATTABe . .V, EQUff»P€D

iAAMWÜgy CHECK i ^

1

WMTB liMrrrB IF CONVERTED

DISCHARGE PIPE

(Do not cap or plug)

OAFASn-y SEfilALWUWSBi:

1

yAtsM,. :

ivHT . 150

ífi'’'- IHSTRIJÍCTKSÍ

6* AIR GAP

MODEL RATING PLATE

Page 16

Service and Adjustment

Temperature Regulation

AWARNING

HOTTER WATER CAN SCALD; Water heaters are

intended to produce hot water. Water heated to a tem

perature which will satisfy space heating, clothes washing,

dish washing, and other sanitizing needs can scald and

perrranently injure you upon contact. Sorre people are

more likely to be permanently injured by hot water than

others. These include the elderly, children, the infirm, or

physically/mentally handicapped. If anyone using hot

water in your home fits into one of these groups or if

there is a local code or state law requiring a certain tem

perature water at the hot water tap, then you must take

special precautions. In addition to using the lowest possi

ble temperature setting that satisfies your hot water

needs, a means such as a mixing valve, shall be used at

the hot water taps used by these people or at the water

heater. Mixing valves are available at plumbing supply or

hardware stores. Follow manufacturers instructions for

installation of the valves. Before changing the factory set

ting on the thermostat, read the "Temperature

Regulation" section in this manual.

AWARNING

Never allow small children to use a hot water tap, or to

draw their own bath water. Never leave a child or handi

capped person unattended in a bathtub or shower.

The lower thermostat is factory set at a position which approxi

mates 120*'F (HOT) and is adjustable it a different water tem

perature is desired. Read, all warnings in this manual and on the

water heater before proceeding.

ADJUSTABLE LOWER

THERMOSTAT

(2 wire lead models)

ADJUSTABLE LOWER

THERMOSTAT

WITH HIGH LIMIT

(3 wire lead models)

Thermostats

The thermostat(s) of this water heater have been factory set at a

position which, approximates 1.20“F (HOT) to red.ucc the risk of

scald injury.

The upper thermostat is factory set at a position which approxi

mates 1.20“? (HOT) and, is adjustable if a different water tem

perature is desired. Read, all warnings in this manual and on the

water heater before proceeding.

UPPER THERMOSTAT ADJUSTABLE

BEHIND UPPER ACCESS PANEL

Temperature Settings

HOT-Is a thermostat setting of approximately IRO^F,

which will supply hot wutcr at the most economi

cal temperatures.

A-Is a thermostat setting of approximately ITO^F.

B-Is a thermostat setting of approximately I40“F,

C-Is a thermostat setting of approximately t 30'’F.

VERY HOT-ls a thermostat setting of approximately 1.60“E It

is recommended that the dial be set lower when

ever possible.

NOTE; Water temperature range of 120“—^140"F recom

mended by most dishwasher manufoctarers.

Tiiivy u> Pi'iirdijj;,!“

'¿iid ÿt 3fd

Eiurni C'li Addi.. 5l<iii

[«T

l5(fF

ItOT

I30T

I20“F

AtiDiA 1/2 seconds

Attouir 1-1/2 seconds

Less than 5 seconds

Aboyrt 30 seconds

More tlian 5 minutes

1.6

Page 17

Service and Adjustment (cont’d)

Upper and Lower Thermostat

Adjustment

{Refer to thermostat illustrations under

“Thermostats”)

NOTE: It is not necessary to adjtist tlie upper thermostat.

However, if it is ad.j«isted above tke factory set point of

120“F (НСУГ) is is recommended that it not be set higher

than the lower thennostat setting.

The upper and lower thermostats are adjustable if a different

water temperature is desired,. Read all warnings in the

“Temperature-Regulation” section before proceeding.

L Turn “OFF” the dcctiical power to the water heater at the

junction box.

2. Take off the upper and/or lower access panel, insulation

block and pad,

3. The slotted, adjustment (using a screwdriver) can be turned

clockwise ( to increase the temperature setting or

counter clockwise (

setting,

4. Replace the insulation block, pad, and, access panel.

3. Turn “ON” the power supply.

______

to decrease the temperature

Failure to install and maintain a new properly listed, temperaturc-pressure relief valve will release the manufacturer from any

claim which might result from excessive temperature or pressure.

AWARNING

If the temperature-pressure relief valve on the appliance

weeps or discharges periodically, this be due to ther

mal expansion. Your water heater m^ have a check valve

Installed In the water line or a water meter with a check

valve. Consult your local Sears Service Center for further

Infbnnatlon, Do not plug the temperature-pressure relief

valve.

Draining

The water heater should be drained, if being shut d,own d,uring

ffcc/ing tcmpciaturcs, .Also periodic draining and, cleaning of

sediment from the tank may be necessary,

• Before beginning turn “OFF” the electric power supply to the

water heater.

Temperature-Pressure Relief Valve Operation

The tem perature-pressure relief valve must be manually operated

at least once a year,

TEMPERATURE-PRESSURE

AWARNING

The temperature-pressure relief valve must be manually

operated at least once a year. Caution should be taken to

ensure that (I) no one is in front of or around the outlet of

the temperature-pressure relief valve discharge line, and (2)

the water manually discharged will not cause any proper^

damage or bodily injury. The water may be extremely hot.

If after manually operating the valve, it fails to completely

reset and continues to release water, immediately close the

cold water inlet to the water heater, follow the draining

Instructions, and replace the temperature-pressure relief

valve with a new one.

AWARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater, make

sure the electrical supply to the water heater Is turned

“OFF”, Failure to do this could result In DEATH, SERI

OUS BODILY injury; OR PROPERTY DAMAGE,

• CLOSE the cold water IrLlct valve to the water heater,

• OPEN a nearby hot water faucet and leave open to allow for

draining,

• Connect a hose to the drain valve and terminate to an

adequate drain or outdoors,

• OPF.N the water beater drain valve to allow for tank draining.

NOTEt If the water beater is going to be shut down and

drained for on extended perioi^ tbe drain valve sbotdd be

left open witb hose connected allowing water to terminate

to on adequate drain,

• Close the drain valve.

• Follow “Filling the Water Heater” instructions in the

“Installation Instructions” section,

• Turn “ON” power to the water heater.

A CAUTION

Never use this water heater unless it is completely full

water. To prevent damage to the tank and heating ele

ment, the tank must be filled with water. Water must

flow ftom the hot water faucet before turning “ON”

power.

Page 18

Service and Adjustment (cont’d)

Element Cleaning/

Replacement

NOTEi Tkese iiistractiofis are "writteii for efomeut clmuiiig

aud element replacemeut for the lower element. If it is iieces'

sary to clean or replace the upper element, then repeat tli^e

instructions.

To remove the element from youi tank in order to clean or

replace it:

1. Before beginning turn “OFF” the electric power supply to the

water heater.

(•■lll'MIin

<Bllli*lin

|)-Hr

iiO

|| JI.HRill 1

H 1" Ili1

>■

Hi

\i

1l-

111 I

Hi 11 It.

tin

hr

IJ- r.»■ ti:i

EKlIIJi

r>l 11- Jh.-■ IT J

infr

■ U.1

inh

-■

■ in

Ivl■1lull*

■ in

uni*

■ R:l

AWARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater, make

sure the electrical supply to the water heater Is turned

“OFF”, Failure to do this could result In DEATH, SERI

OUS BODILY injury; or property damage.

Turn off the water supply to the water beater at the water

shutoff valve or water meter.

4, Remove the two screws securing the access panel, and. remove

panel.

5, Remove the insulation block and pad.

6, lift out the tab as shown to unci ip the terminal cover from

the thermostat. The terminal cover can now be removed

from the thermostat.

3. Attach a hose to the water heater drain valve and put the

other end in a floor drain or outdoors. Open the water heater

drain valve. Open a nearby hot water faucet which will relieve

pressure in the water heater and speed draining.

AWARNING

The water passing out of the drain valve may be extremely

hot. To aw>id being scalded, make sure all connections are tight

and that the water flow is directed aw^ from any person.

18

Page 19

Service and Adjustment (cont’d)

10. A new gasket should, be used, in all cases to prevent a possi

J)1 y

TERMINAL

COVER ON

UPPER

THERMOSTAT

Disconnect the two wires on the element and unscrew the

old element from the tank.

ble water leak. (See Element Gasket in the “Parts Order

list” Chart). Place the new clement gasket on the thread

side of the cleaned or new element and screw into tank,

securing tightly using an element wrench.

Close the water heater drain valve by turning the handle to

II.

the right (clockwise). The drain valve is on the lower front

of the water heater.

12.

Open the cold wuter supply valve to the wuter heater,

NOTEs The cold, water supply valve must be left орем

when the water heater is in tise.

To insure complete filling of the tank, allow air to exit by

13.

opening the nearest hot water faucet. Allow water to run

until a constant flow is obtained. This will let air out of the

water heater and the piping.

8. Clean the area around, the clement opening. ^Remove any

sediment from or around the element opening and inside

the tank.

9. If you are cleaning the clement you have removed, do so by

scraping or soaking in vinegar or a d.e'liming solution.

AWARNING

Replacement elements must (I) be the same voltage and

(2) no greater wattage than listed on the model rating

plate affixed to the water heater.

A CAUTION

Never use this vtater heater unless it Is completely full of

water. To prevent damage to the tank and heating ele

ment, the tank must be filled with water. Water must

flow from the hot water faucet before turning “ON”

power.

14,

Check element for wmer leaks. If leakage occurs, tighten

element or repeat steps 2 and 3, remove clement and, reposi

tion gasket. Then repeat steps 10 through 14,

Reconnect the two wires to the dement and. th.cn check to

15.

make sure the thermostat remains firmly against the surface

of the tank.

T)

Page 20

Service and Adjustment (cont’d)

Element Cleaning/

Replacement (cont’d)

16. Replace the terminal cover on thermostat,

X/'

17. Replace the insulation block and pad, so that it com

covers the thermostat and, element.

This does not affect the waters taste or color. The rod, must be

maintained to keep the tank in operating condition,

,4nodc d,ctcrioration d,cpcnds on water conductivity, not neces

sarily water condition, A corroded or pitted anode rod indicates

high water conductivity and should be checked and/or replaced

more often than an anode rod that appears to be intact.

Replacement of a depleted anode rod can extend the life of your

water heater. Inspection should be conducted, by a Scars service

technician, and at a minimum should, be checked annually after

the warranty period,.

Drain Valve Washer

Replacement

NOTEi For replacemeut, use a x x Yf thick washer

available at. yonr nearest hardware store. For ordering a

replacement washerj refer to the “Parts Order List” section,

• Before beginning turn “OFF” the electrical power supply to

the water heater.

AWARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater, make

sure the electrical supply to the water heater Is turned

“OFF”, Failure to do this could result In DEATH, SERI

OUS BODILY injury; or property damage.

18. Replace access panel.

19. Turn “ON” electric power to water heater.

A CAUTION

Never use this water heater unless It is completely full of

water. To prevent damage to the tank and heating element,

the tank must be filled with water. Water must flow from

the hot water faucet before turning “ON” power.

Anode Rod Inspection

The anode rod is used, to protect the tank from corrosion. Most

hot water tanks are equipped with, an anode rod. The sub

merged rod sacrifices itself to protect the tank. Instead, of cor

roding the tank, water ions attack and cat away the anode rod.

Follow “Draining” instructions in the “Service and

Adjustment” section.

Turning counter clockwise, remove the hex cap below the

screw handle.

Remove the washer and put the new one in place.

Screw the handle and cap assembly back into the drain valve

and retighten using a wrench, DO NOT OVERTIGHTEN.

Follow “Filling the Water Heater” instructions in the

“Installation Instructions” section.

Check for leaks.

Turn “ON” electric power to the water heater.

Service

Before calling for repair service, read the Start Up Conditions

and. Operational Conditions found, in the Troubleshooting

Guide of th is manual.

If a condition persists or you are uncertain about the operation

of the water heater, let a qualified, person check it out.

Contact SEARS Repair Services at l-SOO-d-MY-HOME

(1-800-469-4663).

Page 21

Troubleshooting Guide

Start Up Conditions

THERMAL EXPANSION

Water supply systems may, because of such events as high line

pressure, frequent cut-offt, the effects of water hammer among

others, have installed devices such as pressure reducing valves,

check valves, back flew preventers, etc,,,to control these types of

problems. When these devices arc not equipped with an internal

by-pass, and. no other measures arc taken, the devices cause the

water system to be closed. As water is heated, it expands (ther

mal expansion) and, closed, systems do not allow for the expan

sion of heated water.

The water within the water heater tank expands as it is heated and

in creases the pressurc of the water sj’stem. If the rel ieving point of

the water heater's temperature-pressure relief valve is reached, the

valve will relieve the excess pressure. The teinperatune-piessiure

reHef valve is not inteud.ed for the constant relief of thermal

expansion. This is an unacccpable condition and must be cor

rected.

It is rccommend.ed, that any d.evices installed, which could create a

closed, system have a by-pass and/or the system have an expan

sion tank to relieve the pressure built by thermal expansion.

Thermal expansion tanks arc available from Scars stores and

through the Scars Service Centers, Contact the local plumbing

inspector, water supplier and/or the Scars Service Center for

assistance in controlling these situations.

WATER HEATER

COLD WATER

INLET FITTIMG

FLOOR, CEILING

JOIST, ETC.

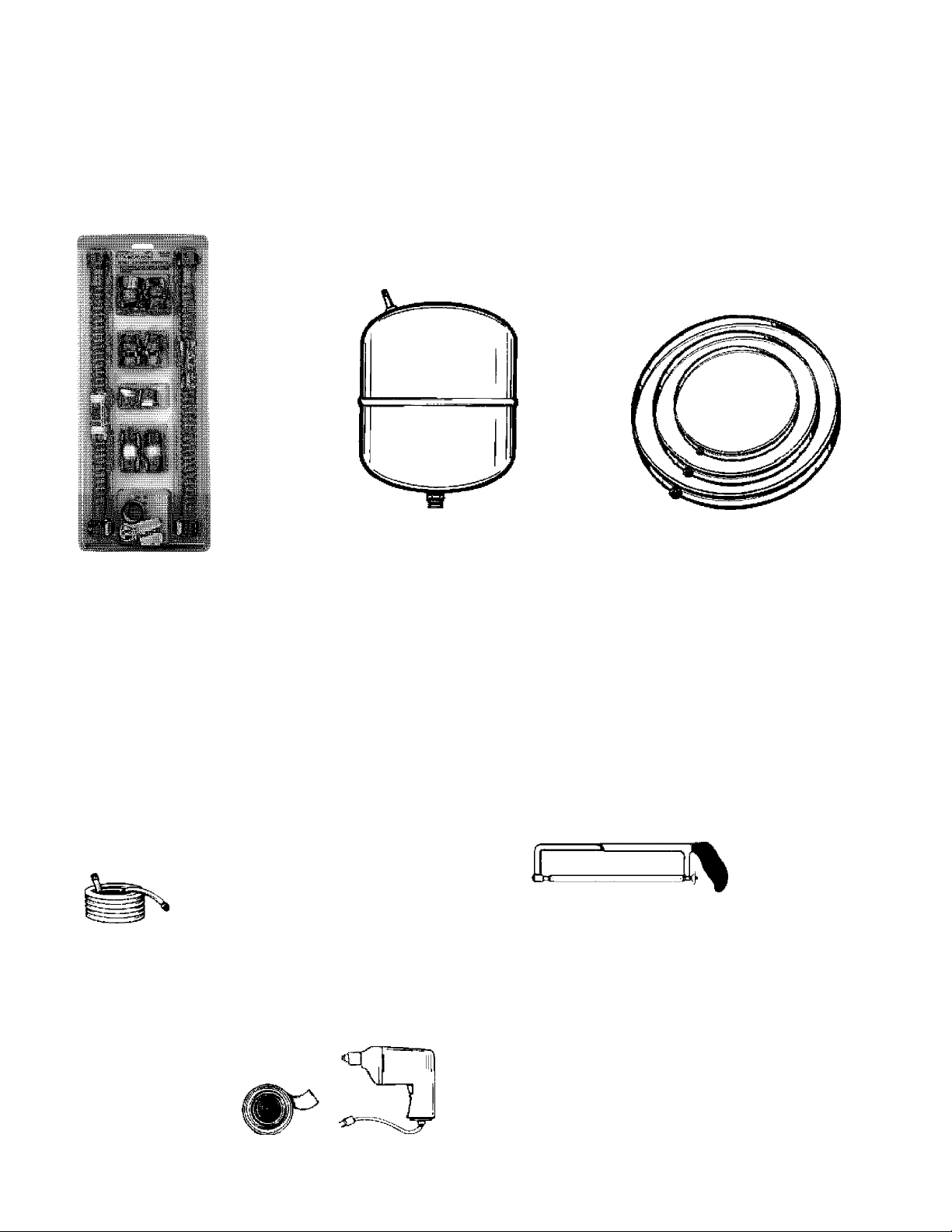

Thermal Expansion Tank Specifications

Model

Number

153.331020

153.331050 5

Tank Capacitv

In Gallons

Dimensions in Inches

Diameter Length.

8 inches

■] ■] inches

12% inches

14% inches

Pipe Fitting

On Tank

Male

y/' Male

Expansion Tank Sizing Chart

Inlet*

Water

Expansion

Tank

Capacity

Needed

*Highcst recorded inlet water pressure in a 24 hour period or

regulated, water pressure,

NOTE; Expansion tanks arc prc-chargcd with a 40 psi air

charge. If the inlet water pressure is higher than 40 psi, the

expansion tank’s air pressure must be adjusted to match that

pressure, but must not be higher than 80 psi.

Pressure

40 psi

50psi

60psi

70psi

80psi

Water Heater Capacity (Gallons)

30 40 50 66 80

5 5

2

2 jC.

2 jC.

2

5 5 5

5 5 5

5 5 5 5

5 5

STRANGE SOUNDS

Possible noises due to expansion and contraction of some metal

parts during periods of heat-up and cool- down do not represent

harmful or dangerous conditions.

Page 22

Troubleshooting Guide (cont’d)

Operational Conditions

SMELLY WATER

Tn each water heater there is installed at least one anode rod (see

parts section) for corrosion protection of th e tank. Certain water

conditions will cause a reaction between this rod, and the water.

The most common complaint associated with the anode rod is

one of a “rotten egg smell”. This odor is derived from hydrogen

sulfide gas dissolve in the water. The smell is the result of fxsur

factors which must all be present for the odor to develop;

a, a concentration of sul fate in the supply water,

b, little or no dissolved oxygen in the water,

c, a sulfate reducing bacteria within the water heater,

(This harmless bacteria is non- toxic to humans.)

d, an excess of active hydrogen in the tank. This is caused

by the corrosion protective action of the anode.

Smelly water may be eliminated or reduced in some water heater

models by replacing the anodc(s) with one of less active material,

and then chlorinating the water heater tank and all hot water

lines. Contact the local Scars Service Center for further informa

tion concerning an .Anode Replacement Kit #9001453 and this

Chlorination Treatment,

If th e smelly water persists after the anode replacement and, chlo

rination treatment, we can only surest that continuous chlori

nation and, filtering conditioning equipment be considered to

eliminate the water problem.

Do uot remove tlie auode leaving the tank unprotected. By

doing so, all warranty on the water heater tank is voided.

RUMBLING NOISE

In some water areas, scale or mineral deposits will build up on

your beating dements. This build,up will cause a rumbling noise.

Follow “Element Cleaning/'Rcplaccment” instructions to clean

and, replace the elements.

HIGH TEMPERATURE SHUT OFF SYSTEM

The water heater has a high, limit shut off system with a reset

button located on the thermostat.

Follow the resetting instructions which refer to the high limit

behind the access panel,

NOTE; If your water heater is connected to an “OFF PEAK”

clock, and uses the “3 wire lead” wiring diagram in the

“‘Wiring Diagram” section, then the vrater heater will have a

hi'liinit on both the upper and lower thermostats. Follow

the instmetions to reset the hhlimit behind the upper and

lower access panels,

• Before beginning, turn “OFF” electrical power supply to the

water heater.

"/IfR" IN HOT WATER FAUCET’S

AWARNING

HYDROGEN GAS: Hydrogen gas can be produced in a

hot water system that has not been used for a long peri

od of time (generally two weeks or more). Hydrogen gas

is extremely flammable and explosive. To prevent the

possibility of injury under these conditions, we recom

mend the hot water faucet be opened for several min

utes at the kitchen sink before any electrical appliances

which are connected to the hot water system are used

(such as a dishwasher or washing machine). If hydre^en

gas Is present, there will probably be an unusual sound

similar to air escaping through the pipe as the hot water

faucet is opened. There must be no smoking or open

flame near the faucet at the time It Is open.

AWARNING

HAZARD OF ELECTRICAL SHOCK! Before removing

any access panels or servicing the water heater, make

sure the electrical supply to the water heater Is turned

“OFF”, Failure to do this could result in DEATH, SERI

OUS BODILY

injury; or PROPERTY DAMAGE.

Page 23

Troubleshooting

(cont*d)

HIGH TEMPERATURE SHUT OFF SYSTEM

(cont’d)

• Remove the two screws securmg the access panel and remove

panel,

• Remove the insulation block and. pad,

• Reset the high limit by pushing in the red button marked

“RESET”. ■

-RESET BUTTON

• Replace the insulation block and, pad so that it com'

covers the thermostat and element.

• Replace the access panel,

• Turn “ON” electric power to the water heater.

NOT ENOUGH OR NO HOT WATER

• In a new installation, the water heater may not be properly

connected. Make sure the cold water supply valve is open.

Review and, check piping installation. Make sure that the

cold water line is connected to the cold water inlet to the

water heater and. the hot water line to the hot water outlet

on the water heater.

• Make sure the electrical supply to your water heater is

“ON”, ■ ■

• Cheek for loose or blown fuses in your water heater circuit.

Circuit breakers weaken with age and may not handle their

rated load, and. should be replaced,.

• Make certain the disconnect switch, if used, is in the “ON”

position,

• Cheek to see the electric service to your house has not been

interrupted. If this is the ease, contact the electric company,

• Arc the thermostats set to the desired temperature? See

“Temperature Regulation” section,

• If you had experienced very hot water and now no hot

water, the problem may be due to the high temperature

shut off system. See “High Temperature Shut Off’ System”

in the “Troubleshooting” section.

• During very cold, weather, the incoming water will also be

colder and, it will require a longer time to become heated.

A CAUTION

If the high limit must be reset again, call Sears Service

Department to find out why the high limit turned “OFF”

the electric power.

• The hot water usage may exceed the capacity of the water

heater. If so, wait for water heater to recover after abnormal

demand,. .Also examine pipes and faucet’s for possible water

leaks,

• rf you can not determine the problem, then call the Scars

Service Department.

WATER IS TOO HOT

Adjust the thermostat to a lower setting. See the “Temperature

Regulation” section.

Page 24

Troubleshooting

Leakage Checkpoints

(cont*d)

Use this guide to check a “Leaking” water heater. Many suspect

ed “Leakers” are not leaking tanks. Often the source of the water

can be found and, corrected.

rf you arc not thoroughly familiar with electric codes, the water

heater, and, safety practices, contact your local Scars Service

Center to check the water heater.

^A) *Cond,cnsation may be seen on pipes in humid weather

or pipe connections may be leaking.

The primary anode rod, may be leaking.

Small amounts of water from temperature-pressure

relief valve may be due to thermal expansion or high

water pressure in your area.

*Thc temperature-pressure relief valve may be leaking at

the tank fitting.

The elements may be leaking at the tank fitting.

A WARNING

HAZARD OF ELECTRICAL SHOCK! Before

removing any access panels or servicing the water

heater, make sure the electrical supply to the

water heater is turned “OFF”, Failure to do this

could result in DEATH, SERIOUS BODILY

INJUFTT, OR PROPEFtTY DAMAGE.

A CAUTION

Read this manual first, then before checking the water

heater make sure the electric supply has been turned

“OFF”, and never turn the electric supply “ON” before

the tank is completely full of water.

Turn electrical power “OFF”, remove access panels and

insulation block and, pad. If leaking around, elements,

follow proper draining instructions and remove

clement. Reposition or replace gasket on dement. Place

clement into opening and tighten securely. Then follow

“Filling the Water Heater” instructions in the

“Installation Instructions” section.

Water from drain valve may be d,uc to the valve being

^ ^ opened, slightly.

*The drain val ve may be leaking at the tank fitting.

*Watcr in the water heater bottom or on the floor may

be from condensation, loose connections or the

temperature-pressure relief valve. DO NOT replace

the water heater until a full inspection of all possible

water sources is made and necessary corrective steps

taken,

I,cakagc from other appliances, wutcr lines, or ground

seepage should, also be checked,

NOTE; *To check where threaded portiou enters

tank, insert cotton swab bctwecii jacket opening and

fitting. If cotton is wet, follow “TImining” instmetions in the “Service and Adjustment” section and

then remoTO fitting. Put pipe dope or teflon tape on

the threads and replace. Then follow “PUliag the

Water Heater” instructions in the “Installation

Instructions!” section.

24

Page 25

Notes

Page 26

Notes

Page 27

Notes

Page 28

Parts Order List

KE?iMORE POWER MISER™ 12 ELECTRIC WATER HEATERS

MODEL NUMBERS;

153.321340 30 CkJ.

153.321341 30 CkJ.

153.321440 40 CkJ.

153.321441 40 CkJ.

153.321540 50 Gal.

NOTE; A

UPPER ELEMENT; These water heaters are equipped witli

3800 watt eleineiiite.

LOWER ELEMENT; These water heateis axe equipped witli

iactoxy imtalled coirvextible elemeniSj which can. be operated

at 3800 watts or 5500 watts. Convertible elements are not

offered as replacemeut parts.

ELEMENT ORDERING INFORMATION

If a replaccinent 3800 watt, 240 volt element is needed, order

item no. 42-31906 replacement element. If at tlie time of instal

lation, tlie water better was converted to operate at 5500 watts.

Older item number 42-31908 replacement element. (See model

rating plate “If Converted” box).

NOIE;B

These water heaters are equipped with a Rofo-Swirl™ dip

tube to retard a build-up of dissolved solids.

Page 29

Parts Order List (contad)

KENMORE POWER MISER™ 12 ELECTRIC WOER HESTERS

MODEL NUMBERS:

153.321340

153.321341

153.321440

153.321441

153.321540

KEY

NO.

PART

DESCRIPTION

1, Tempemture-Pressure Relief Valve*

Heat Trap Nipple (Cold Inlet)

Secondary .Anode w/Heat Trap Nipple (Hot Outlet)

3,

4, Roto- Swirl™ Dip Tube (Sec NCyTR “B” page 28}

Drain Valve

3,

Drain Ysht msher (%"x r thick)**

6,

'7

Fdement Gasket 9000308 9000308 9000308 9000308 9000308

8, luwcr F,lcment* (See NOTE “A”on page 28) 3800 Watt

Buss Bar Kit

9,

10. Tlietmostat Bracket

n. 2 Pole Thermostat (Two Wire Lead Modcls'i'i’*

12.

Terminal Cover & Barrier

luwcr Thermostat w/Hi I.imit

13.

(Three Wire lead Modds)tt*

14.

Terminal Cover

lower Access Panel

15.

16. Upper Access Panel

Terminal Cover

17.

Upper Thermostat w/Hi Limit*

18.

Tlietmostat Bracket

19.

20. Upper Element* (See NOTE “A” page 28) 42 31906 42 31906 42 31906 42 31906 42 31906

21. Fdement Gasket

22.

23.

Model Rating Plate t

Primary Anode

//

Manual 184730-000

30 Gal.

30 Gal.

40 Gal.

40 Gal.

50 Gal.

MODEL NUMBERS

153.321340

153.321341

153.321440

153.321441

153.321540

PART NUMBERS

9002403 9002403 9002403 9002403 9002403

9003931 9003931 9003915 9003915 9003909

9003937 9003937

9003501 9003501

9003911 90039II

9003941 9003941

9003939

9003929 9003929 9003919

9003098 9003098 9003098

9001584 9001584 9001584 9001584 9001584

42 31906

5500 “Watt

42 31908

3800 Watt

42 31906

5500 Watt

42 31908

3800Watt

42 31906

5500 'Watt

42 31908

3800 Watt

42 31906

5500 Watt

42 31908

3800 'Watt

42 31906

5500 'Watt

42 31908

9001591 9001591 9001591 9001591 9001591

9000309 9000309 9000309 9000309 9000309

42 31919

9002276

—

-

—

-

4231918

9002303

42 31919

9002276

—

-

-

-

42 31918

9002303

42 31919

9002276

9002671 9002671 9002671 9002671 9002671

9002671 9002671 9002671 9002671 9002671

9002303 9002303 9002303 9002303 9002303

42 31917 42 31917 42 31917 42 31917 42 31917

9000309 9000309 9000309 9000309 9000309

9000308 9000308 9000308 9000308 9000308

0270182 0270182 0270182 0270182 0270182

9003927 9003927

9003928 9003928 9003728

—

-

*Thcsc parts arc also available at most Scars retail stores.

**Also available at most hardware stores.

tRcplaccd only on return of damaged plate,