Kenmore 14816656010 Owner’s Manual

Use& CareGuide

®

LiquidPropaneGasGrill

SearsModelNo. 148.16656010

ThisGrillisfor OutdoorUseOnly

• Safety

• Parts

• Readand followall Safety,Assembly,

and Use& Care Instructionsin this Guide

beforeassembling and cooking

with this grill.

• Failureto followall instructions in this

Use& Care Guide may leadto fire or

explosion,which could result in property

damage, personal injuryor death.

• Useand Care

• Assembly

GrillInformationCenter

Missing Parts?Assembly Questions?

Operation Problems?Before returning

grill to store,call 1-800-482-0131

Tools needed for assembly:

Screwdriver(notprovided)

SAVETHESEINSTRUCTIONS!

See ourextensiveassortmentof outdoorlivingproductson-lineat

www.sears.comandwww.kmart.com

SearsBrandsManagementCorporation,HoffmanEstates,IL60179,U.S.A.

© 2010SearsBrands,LLC PrintedinChina L3018S-ManuaE

Ifyou smell gas:

1.Shut off gas to theappliance.

2. Extinguishany open flame.

3.Open lid.

4. If odor continues, keep awayfrom the

applianceand immediatelycall your gas

supplier or your fire department.

1. Do not store or usegasoline or other

flammable liquids or vapors in the vicinity

of this or any other appliance.

2. An LP cylinder not connectedfor useshall

notbe stored inthe vicinity of this or any

other appliance.

Call Grill Service Center ForHelp And Parts

If you have questions or need assistance during assembly,

please call 1-800-482-0131.Youwill be speaking to a

representativeof the grill manufacturerand nota Sears

employee.To order new parts callSears at

1-800-4-MY-HOME.

Product Record

IMPORTANT: Fillout the productrecord information

below.

CALIFORNIA PROPOSITION 65

1. Combustion by-products producedwhen using

this product contain chemicals known to the State

of California to cause cancer, birth defects, and

other reproductive harm.

2. This product contains chemicals, including lead

and lead compounds, known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Washyour hands after handling thisproduct.

Installation Safety Precautions

• Usegrill, as purchased, onlywith LP (propane) gas and the

regulator/valve assembly supplied.A conversion kit must

be purchased for use withnatural gas.

• Grill installation must conform with localcodes, or in their

absence of local codes, with either the National Fuel Gas

Code, ANSI Z223.1/NFPA 54,Natural Gasand Propane

Installation Code, CSA B149.1, or Propane Storage and

Handling Code, B149.2, or the Standard for Recreational

Vehicles,ANSI A 119.2/NFPA 1192,and CSA Z240 RV

Series, Recreational Vehicle Code,as applicable.

• All electrical accessories (such as rotisserie) must be

electrically grounded inaccordance with local codes, or

National Electrical Code, ANSI/NFPA 70 or Canadian

Electrical Code, CSA C22.1. Keep any electrical cords

and/or fuel supply hosesaway from any hotsurfaces.

•This grillis safety certified for use in the UnitedStates

and/or Canada only. Do not modify for use inany other

location. Modification will result in a safety hazard.

Safety Symbols

The symbols and boxes shown below explain what each

heading means. Readand followall of the messages found

throughout the manual.

Model Number

Serial Number

See rating labelon grill for serial number.

Date Purchased

Forresidential use only. Do not use for

commercialcooking.

DANGER: Indicatesan imminentlyhazardous

situation which, if not avoided,will resultin death or

serious injury.

WARNING: Indicatesan potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

CAUTION:Indicatesapotentiallyhazardous

situationorunsafepracticewhich,ifnotavoided,

mayresultinminorormoderateinjury.

For Your Safety .................................. 2

Grill Service Center............................... 2

Product Record Information........................ 2

cancelforanyreasonduringtheproductwarrantyperiod,we

willprovideafullrefund.Or,aproratedrefundanytimeafter

theproductwarrantyperiodexpires.PurchaseyourRepair

ProtectionAgreementtoday!

Somelimitationsandexclusionsapply.

Forpricesandadditionalinformationcall1-600-627-6655.

SearsInstallationService

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in

the U.S.A. call 1-600-4-MY-HOME®

Safety Symbols.................................. 2

Installation Safety Precautions ....................... 2

Kenmore Grill Warranty ........................... 3

Use and Care ................................ 4-10

Natural Gas Conversion Box ...................... 11

Notes.......................................... 12

Parts List ...................................... 13

Parts Diagram................................... 14

Assembly .................................... 15-25

Troubleshooting............................... 26-27

Repair ProtectionAgreements

Congratulations onmaking asmart purchase. Your new

Kenmore®productis designed and manufacturedfor years of

dependable operation. But like all products, it may require

repair from timeto time. That's when having a Repair

ProtectionAgreement cansave you money and aggravation.

Purchase aRepair Protection Agreement now and protect

yourself from unexpected hassle and expense.

Here's what the Repair Protection Agreement includes:

[] Expert service by our 10,000 professional repair

specialists

[] Unlimited service and no charge for parts and labor on

all covered repairs

[] Product replacement up to $1500 if your covered

product can't be fixed

[] Discount of 10%from regular price of service and

related installed parts not covered by the agreement; also,

10% off regular price of preventive maintenance check

[] Fast help by phone - we call it Rapid Resolution-

phone support froma Sears representative. Think of us

as a "talking owner's manual."

Once you purchase the Repair Protection Agreement, a simple

phone callis all that it takes for you toschedule service. You

can call anytime day or night, or schedule a service

appointment online.

The Repair Protection Agreement isa risk-free purchase. If you

Kenmore FullWarranty

If this grill failsdue to a defect in material or workmanship

within oneyear from the date of purchase, call 1-800-4-MY-

HOME®toarrange for free repair (or replacement if repair

proves impossible).

Limited Warranty on Burners

For ten years from thedate of purchase, any stainlesssteel

burner that rusts throughwill be replaced free of charge. After

the first year from the date of purchase, you payfor labor if

you wish to have it installed.

All warranty coverage excludes ignitor batteries and grill part

paint loss, discoloration or rusting, which are either

expendable parts that canwear outfrom normal use within

the warranty period, or are conditions that can be the result

of normal use,accident or improper maintenance.

All warranty coverage is void if this grill is ever used for

commercial or rental purposes.

All warranty coverage applies only if this grill is used in the

United States.

This warranty gives you specificlegal rights, andyou may

also haveother rights which vary from state to state.

Sears, Roebuck andCo., Hoffman Estates, IL 60179

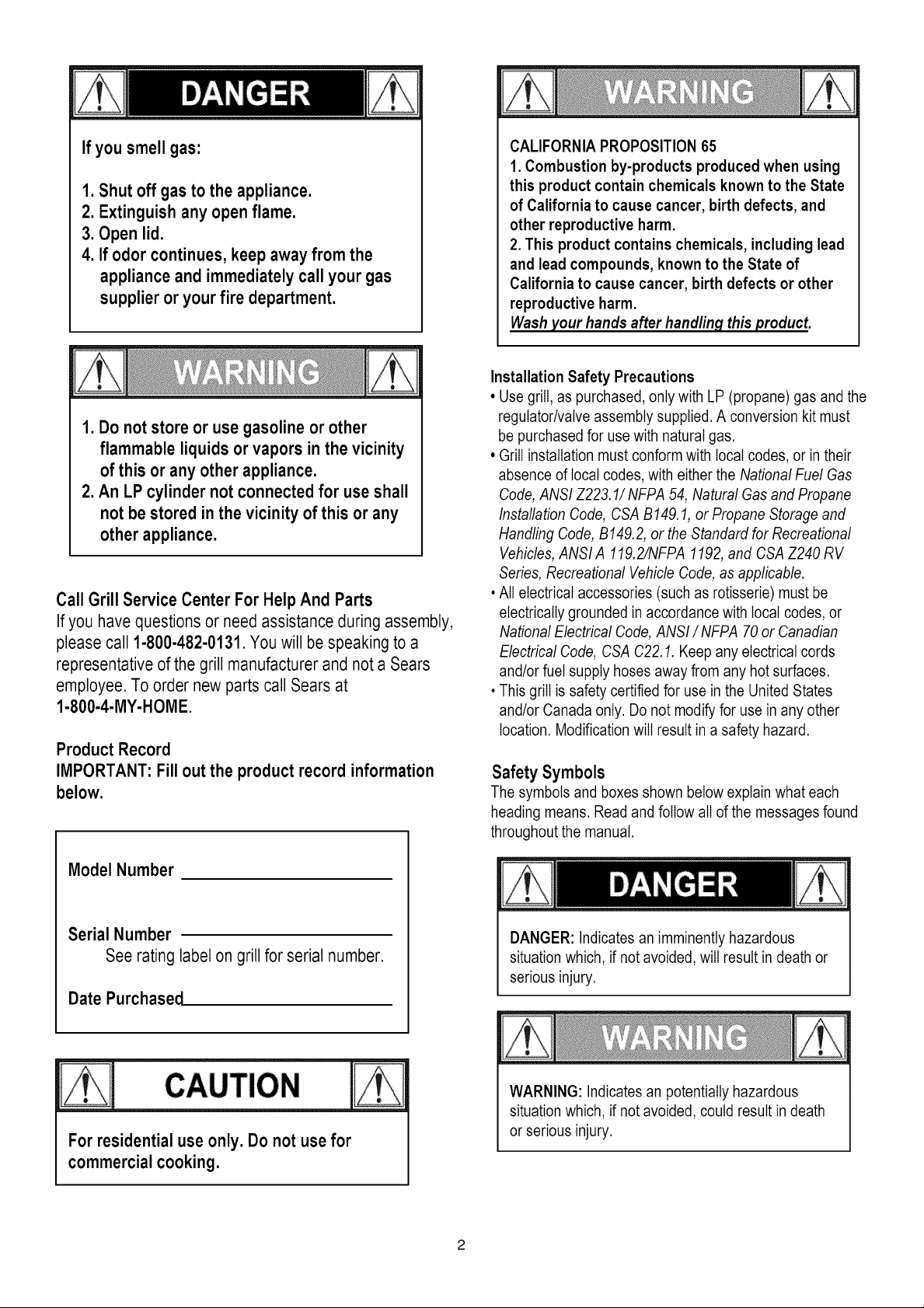

• NEVERstore a spare LP cylinderunder or near

the grill appliance or in an enclosed area.

• Never fill a cylinder beyond80% full.

• If the information in the two pointsaboveis not

followed exactly, a fire causing deathorserious

injurymay occur.

°An over filled or improperlystored cylinder is a

hazarddue to possiblegas release from the

safety relief valve. This couldcause an intense

fire with risk of property damage,serious injury

or death.

° Ifyousee, smell or heargas escaping,

immediatelyget awayfrom the LP cylinderand

grillapplianceand callyour fire department.

LP Cylinder

• The LP cylinder usedwith your grill must meet the

following requirements:

• UseLPcylinders only with these required measurements: 12"

(30.5cm) (diameter) x 18"(45.7 cm)(tall) with 20 lb. (9 kg.)

capacity maximum.

• LPcylinders must beconstructed and marked inaccordance

with specifications for LP cylinders of the U.S. Department of

Transportation (DOT)orfor Canada, CAN/CSA-B339,

cylinders, spheresand tubesfor transportation of dangerous

goods. Transport Canada (TC). See LP cylinder collarfor

marking.

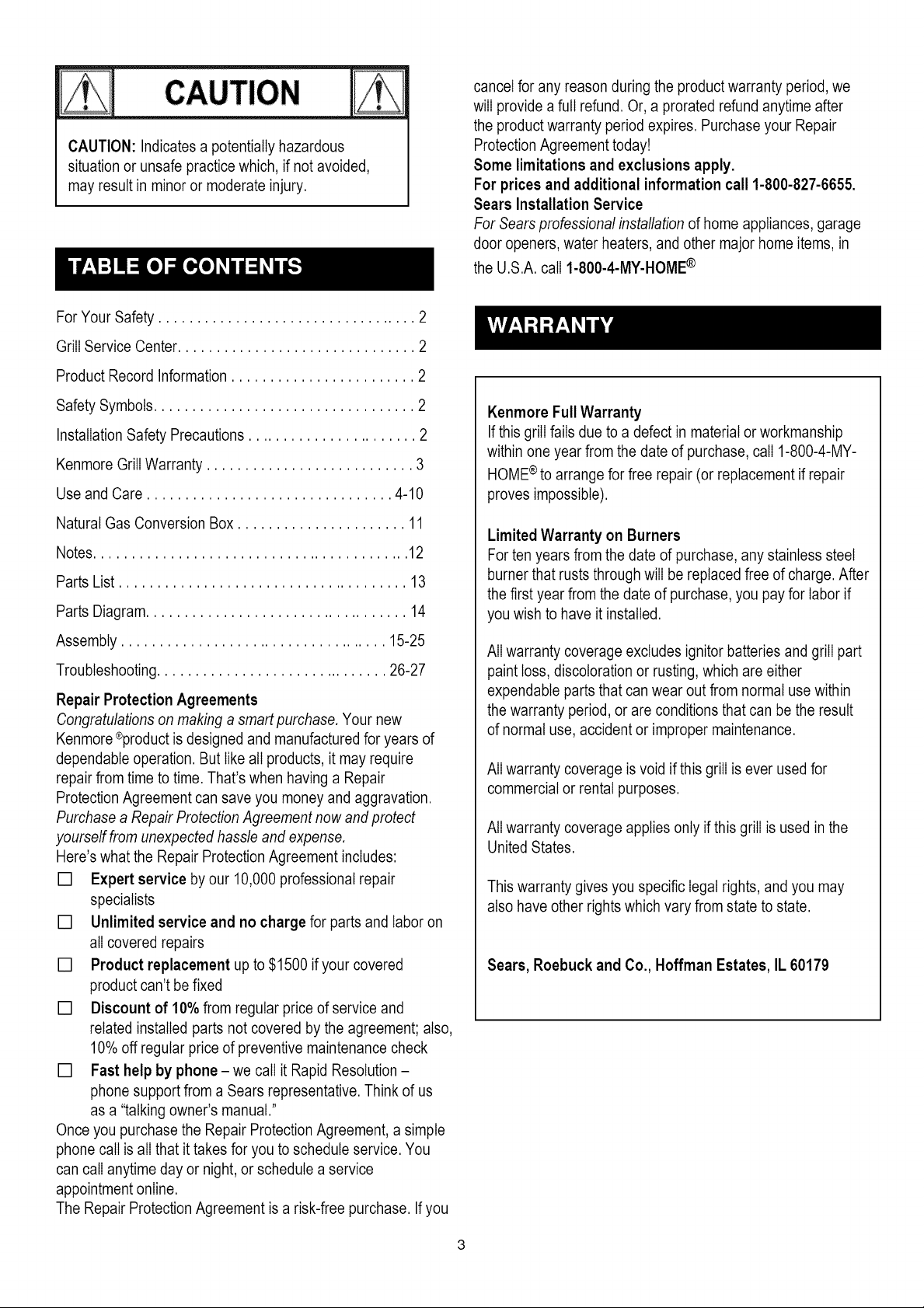

• LPcylindervalve must have:

•Type 1outlet compatible with

regulator or grill.

•Safety relief valve.

• ULlisted Overfill Protection OPDHandWheel

Device(OPD). This OPD safety

feature is identified by a unique triangular handwheel. Use

only LP cylinders equipped with this type of valve.

• LPcylindermust be arranged for vaporwithdrawal and

include collar to protect LP cylinder valve. Always keep LP

cylinders in upright positionduring use, transit or storage.

LP Tank Removal, Transport And Storage

•Turn OFF all control knobs and LP tankvalve. Turn coupling

nutcounterclockwise by hand only -do not use tools to

disconnect. Lift LP tank wire upward off of LP tank collar, then

lift LP tank upand offof support bracket. Install safety cap

onto LP tank valve. Always use cap andstrap suppliedwith

valve.

Failure to use safety cap as directed may result in

serious personal injury and/or property damage.

LPTankValve

@_ Safety Cap

RetainerStrap

•A disconnected LP tank in storage or being transported must

havea safety cap installed (as shown). Do not store an LP

tank inenclosed spaces such as a carport, garage, porch,

covered patio or other building. Never leave an LP tank inside

a vehiclewhich may becomeoverheated by the sun.

• Donot store an LP tank in an area where children play.

LP cylinderin upright position for vapor withdrawal

LP (Liquefied Petroleum Gas)

• LPgas is nontoxic,odorless and colorlesswhen produced.

For Your Safety, LP gas has beengiven an odor (similar to

rotten cabbage) so that it can be smelled.

• LPgas is highly flammable and may ignite unexpectedly

when mixed with air.

LP Cylinder Filling

• Useonly licensed and experienced dealers.

• LPdealermust purge new cylinder before filling.

• Dealershould NEVER fill LPcylinder more than 80% of LP

cylinder volume.Volume of propane incylinderwill vary by

temperature.

•Afrosty regulator indicatesgas overfill. Immediately close LP

cylinder valveand call local LP gas dealer for assistance.

• Donot release liquidpropane (LP)gas intothe atmosphere.

This isa hazardous practice.

•To remove gasfrom LP cylinder, contactan LPdealer or call

a localfire department for assistance. Check the telephone

directory under "Gas Companies" for nearest certified LP

dealers.

LP Tank Exchange

•Many retailersthatsell grillsoffer you the option of replacing

your empty LPtankthrough an exchange service. Useonly

those reputable exchange companies that inspect, precision

fill, test and certify their cylinders. Exchange your tank only

for an OPD safety feature-equipped tank as described in

the "LP Tank" section of this manual.

•Always keep new and exchanged LP tanks in upright position

during use,transit or storage.

,Leak test new and exchanged LP tanks BEFORE

connecting to grill.

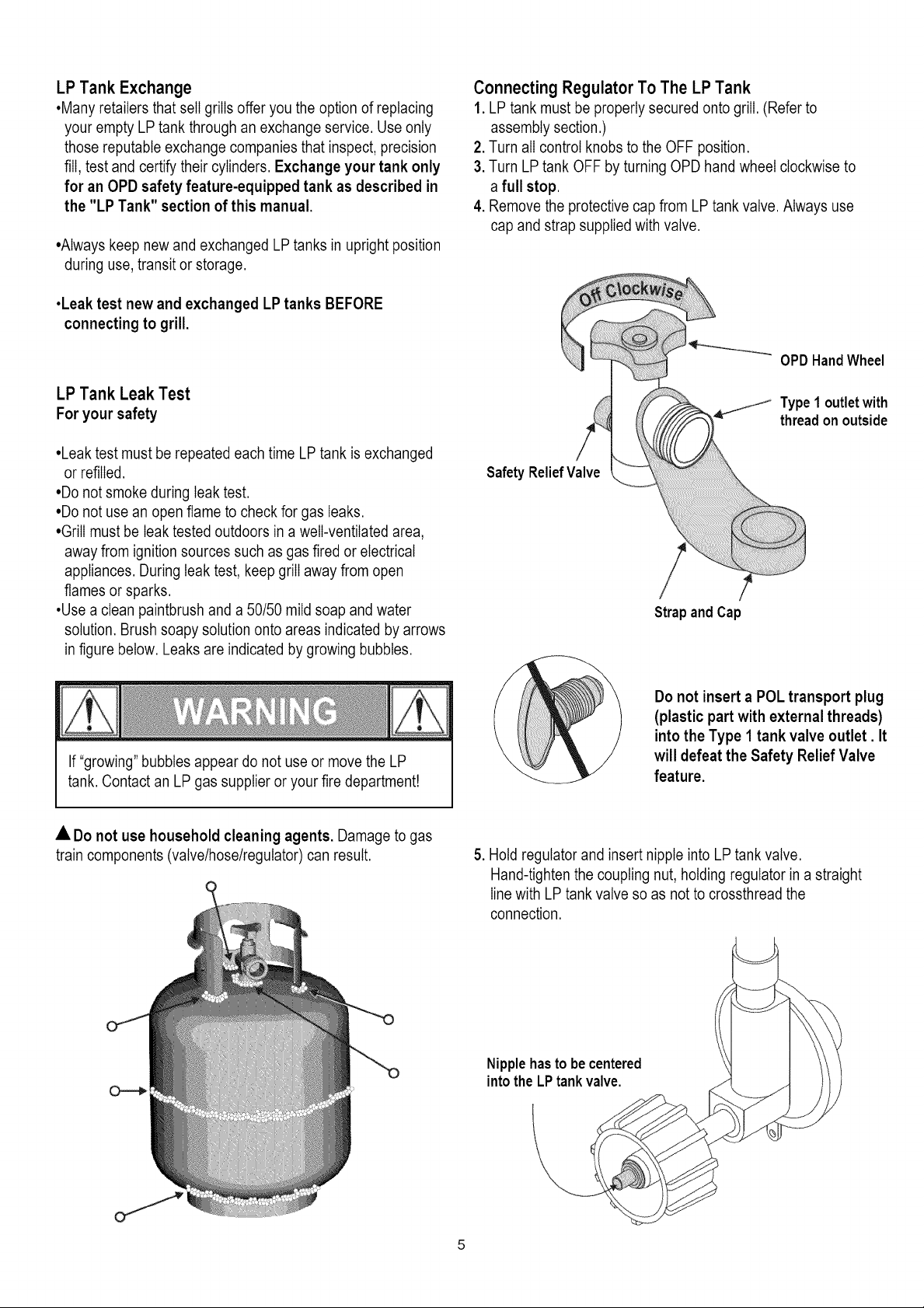

Connecting Regulator To The LP Tank

1. LP tank must beproperly secured onto grill. (Referto

assembly section.)

2.Turn allcontrol knobsto the OFF position.

3.Turn LPtank OFFby turning OPDhand wheel clockwise to

a full stop.

4. Remove the protective cap from LP tank valve. Always use

cap and strap suppliedwith valve.

OPDHandWheel

LP Tank LeakTest

Foryoursafety

•Leak test must be repeatedeach timeLP tank is exchanged

or refilled.

•Do not smoke during leak test.

•Do not use an open flame to checkfor gas leaks.

•Grill mustbe leak tested outdoors inawell-ventilated area,

away fromignition sources such as gas fired or electrical

appliances. During leak test, keep grill away from open

flames or sparks.

•Usea clean paintbrush and a 50/50 mild soap and water

solution. Brushsoapy solutiononto areas indicated by arrows

infigure below. Leaks are indicated by growing bubbles.

If "growing" bubbles appear do not use or move the LP

tank. Contact an LP gas supplier or your fire department!

• Do not use household cleaning agents. Damage to gas

train components (valve/hose/regulator) can result. 5. Hold regulator and insert nipple into LP tank valve.

SafetyReliefValve

/

Strapand Cap

Do not insert a POLtransport plug

(plastic part with external threads)

into the Type 1tank valve outlet. It

will defeat the Safety Relief Valve

feature.

Hand-tightenthe coupling nut, holding regulator in a straight

linewith LPtankvalve so as not to crossthread the

connection.

._ Type1 outletwith

threadonoutside

Nipplehasto be centered

into the LPtank valve.

Holdcouplingnutandregulator

as shownfor properconnection

to LPtankvalve.

6. Turn the coupling nut clockwise and tighten to a full stop.

The regulator will seat on the back-check feature in the LP

tank valve, resulting in some resistance. An additional

one-half to three-quarters turn is required to complete

the connection. Tighten by hand only - do not use tools.

NOTE:

If you cannot complete the connection, disconnect regulator

and repeatsteps 5and 6. Ifyou are still unable to complete the

connection, do not use this regulatort Call 1-800-482-0131

for assistance.

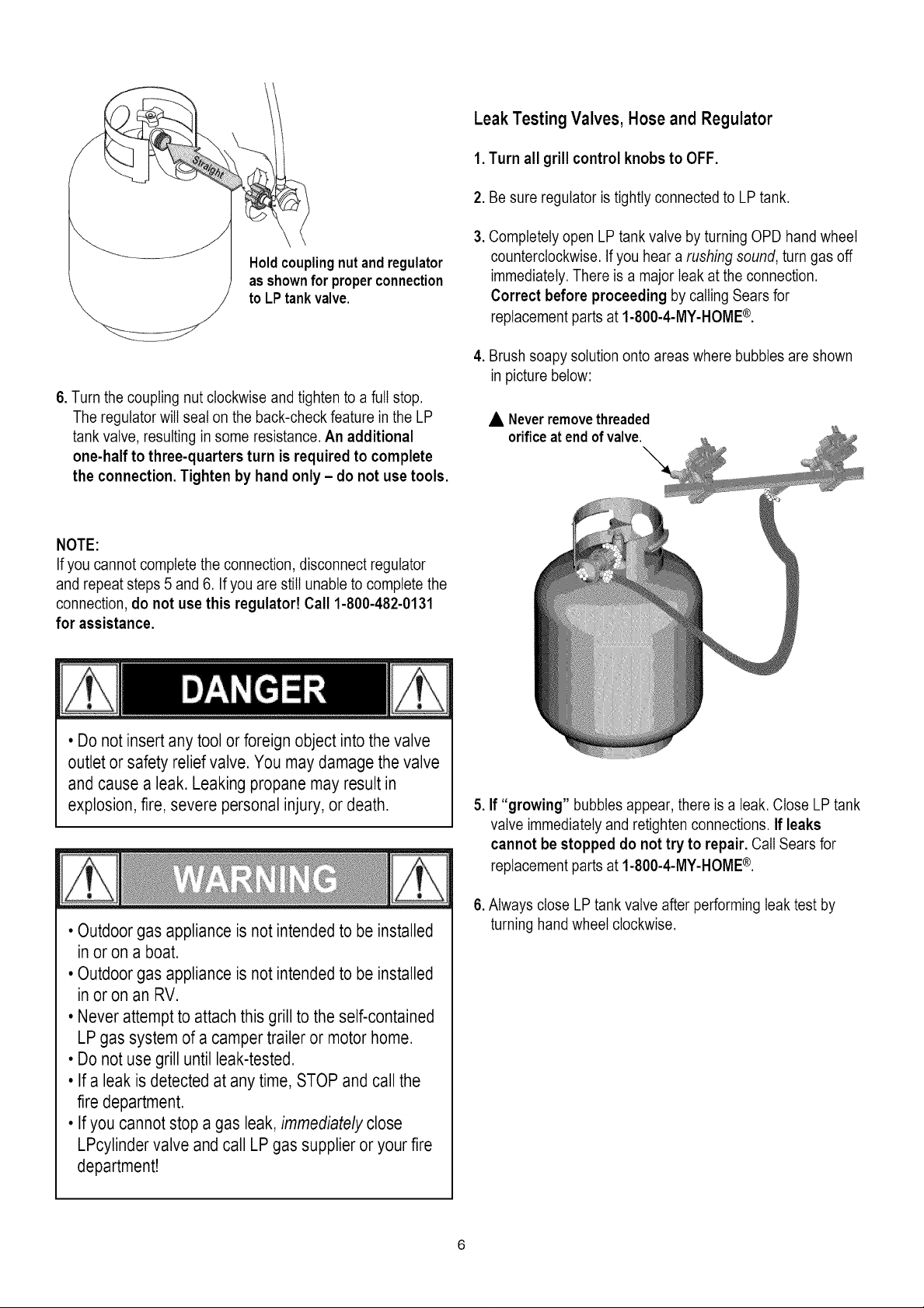

Leak Testing Valves, Hose and Regulator

1.Turnall grillcontrolknobstoOFF.

2. Be sure regulator is tightly connected to LPtank.

.

Completely open LPtank valveby turning OPD handwheel

counterclockwise. Ifyou hear a rushing sound, turn gas off

immediately.There is a major leak at the connection.

Correct before proceeding by calling Searsfor

replacement parts at 1-800-4-MY-HOME®.

4. Brush soapysolution onto areas where bubbles are shown

in picture below:

• Neverremovethreaded

orificeat endofvalve.

• Do not insert any toolorforeign object into the valve

outlet or safety reliefvalve.You maydamagethevalve

and cause a leak. Leakingpropane mayresult in

explosion,fire, severe personal injury,or death.

• Outdoor gas appliance is notintendedto be installed

in or on a boat.

• Outdoor gas appliance is notintendedto be installed

in or on an RV.

• Never attemptto attach this grill to theself-contained

LPgas system of a camper trailer or motor home.

• Do not use grill until leak-tested.

• If a leak isdetected at any time, STOPand call the

fire department.

• If you cannot stop agas leak,immediately close

LPcylindervalve and call LPgas supplier or your fire

department!

5. If "growing" bubbles appear, there is a leak. CloseLP tank

valve immediately andretighten connections. If leaks

cannot be stopped donottry to repair. Call Searsfor

replacement parts at 1-800-4-MY-HOME®.

6.Always closeLP tankvalve after performing leak test by

turning hand wheel clockwise.

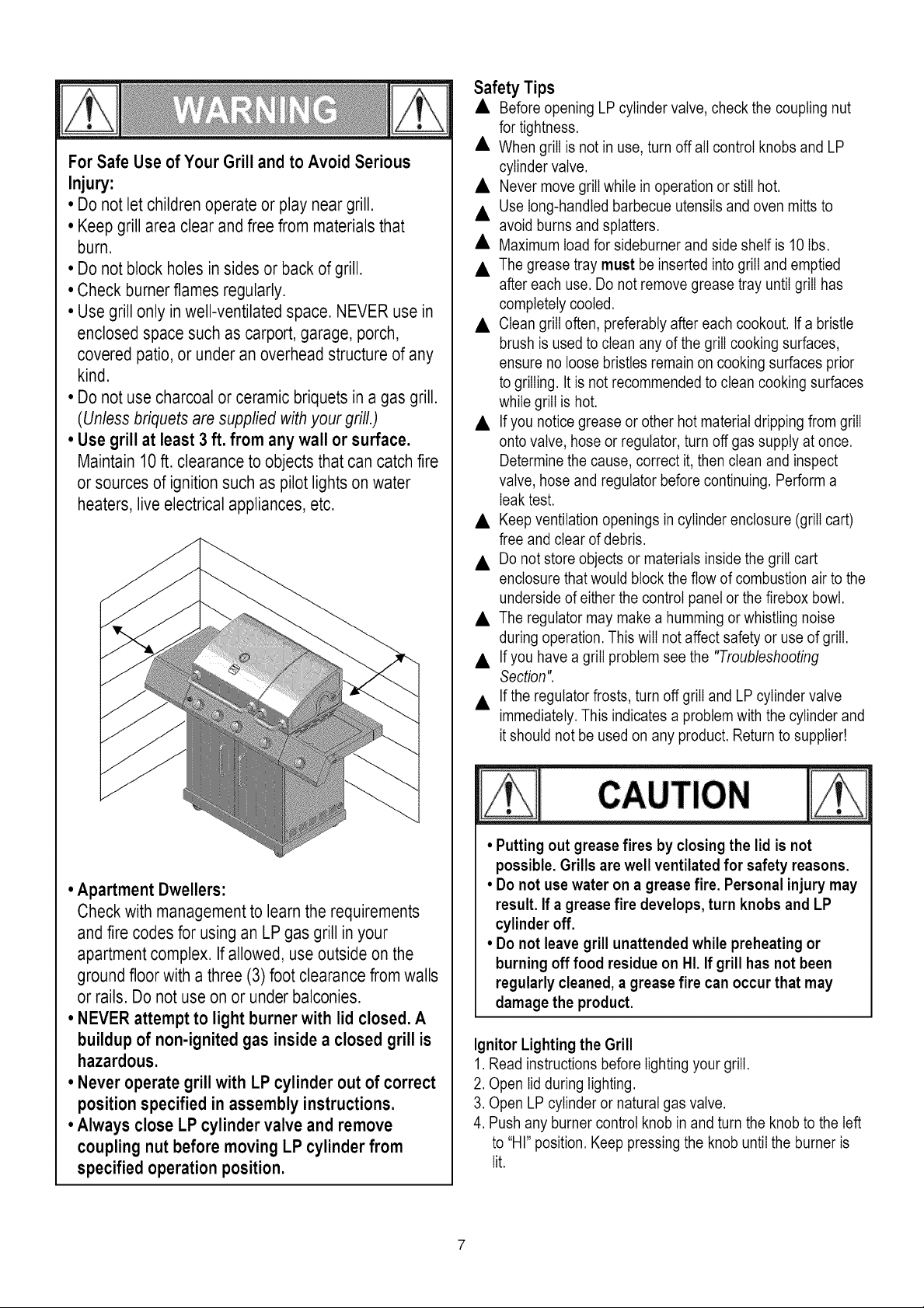

ForSafe Use ofYour Grilland to AvoidSerious

Injury:

• Do not let childrenoperateor play near grill.

• Keepgrill area clear and free from materials that

burn.

• Do not block holes in sidesor backof grill.

• Check burnerflames regularly.

• Use grill only in well-ventilatedspace. NEVER usein

enclosedspace such as carport,garage, porch,

covered patio,or under an overhead structure of any

kind.

• Do not use charcoal or ceramic briquets ina gas grill.

(Unlessbriquets are suppliedwithyour grill.)

• Use grill at least 3 ft. from any wall orsurface.

Maintain 10ft. clearance toobjects that can catch fire

or sourcesof ignition such as pilot lights on water

heaters,live electricalappliances, etc.

Safety Tips

• Beforeopening LP cylinder valve, check the coupling nut

for tightness.

• When grill is not in use, turn off all control knobs and LP

cylinder valve.

• Never move grill while in operation or stillhot.

• Use long-handledbarbecue utensilsand oven mitts to

avoid burns and splatters.

• Maximum loadfor sideburner and side shelf is 10 Ibs.

• The grease tray must be insertedinto grill and emptied

after each use. Donot remove grease tray untilgrill has

completely cooled.

• Clean grill often, preferablyafter each cookout. Ifa bristle

brush isused to clean any of the grill cooking surfaces,

ensure no loose bristles remain on cooking surfaces prior

to grilling. Itis not recommended to clean cooking surfaces

while grill is hot.

• Ifyou notice grease or other hot material dripping from grill

onto valve, hose or regulator, turn off gas supplyat once.

Determinethe cause, correct it,then clean and inspect

valve, hose and regulator before continuing. Perform a

leak test.

• Keep ventilation openings incylinder enclosure (grill cart)

free and clear of debris.

• Do not storeobjects or materials inside the grill cart

enclosure thatwould block theflow of combustionairto the

underside of either the control panel or the firebox bowl.

• The regulator may makea hummingor whistling noise

during operation.Thiswill not affect safety or useof grill.

• Ifyou havea grill problem see the "Troubleshooting

Section".

• If the regulator frosts, turn offgrill and LP cylinder valve

immediately. This indicates aproblem with the cylinder and

it should not be used on any product. Return to supplier!

• Apartment Dwellers:

Checkwith managementto learnthe requirements

andfire codes for usingan LP gas grill in your

apartmentcomplex.If allowed, useoutside onthe

ground floor with a three (3)foot clearance from walls

or rails. Donot useon or underbalconies.

° NEVERattempt to light burner with lid closed. A

buildup of non-ignited gas inside a closed grill is

hazardous.

• Never operate grill with LPcylinder out of correct

position specified in assembly instructions.

• Always close LP cylinder valve and remove

coupling nut before moving LP cylinder from

specified operation position.

CAUTION

• Putting outgrease fires by closingthe lid is not

possible. Grills are well ventilated for safety reasons.

• Do notuse water on a grease fire. Personal injury may

result. Ifa grease fire develops, turn knobs and LP

cylinder off.

• Do notleave grill unattendedwhile preheating or

burning off food residue on HI. If grill has not been

regularly cleaned, a grease fire can occur that may

damage the product.

Ignitor Lightingthe Grill

1. Read instructions before lighting your grill.

2. Open lid during lighting.

3. Open LP cylinder or natural gas valve.

4. Pushany burner control knob in and turn the knob to the left

to "HI" position. Keep pressing the knob untilthe burneris

lit.

5.Ifignitiondoesnotoccurin5seconds,turntheburner

controloff,wait5minutesforgastoclearaway,andrepeat

thelightingprocedure.

6.Tolightotherburners,repeatstep4.

NOTE:Ifignitordoesnotwork,followMatchLighting

instructions.

Turn controls andgassource or tank OFFwhen

not in use.

If ignitiondoesnotoccurin5 seconds,turntheburner

controloff,wait5 minutes,andrepeatthelighting

procedure.If the burner does not ignitewith

the valve open,gas will continueto flow out ofthe

burner and couldaccidently ignitewith risk of

injury.

Match-Lighting

• Do not lean over grillwhile lighting.

1. Open lid during lighting.

2. Place match into match holder (hanging from sideof cart).

Light match, place intothe firebox.

3. Push inand turn right knob to HIGH position. Besure burner

lights and stays Iit.

4. Light other burners by pushing knob in andturning to HI

position.

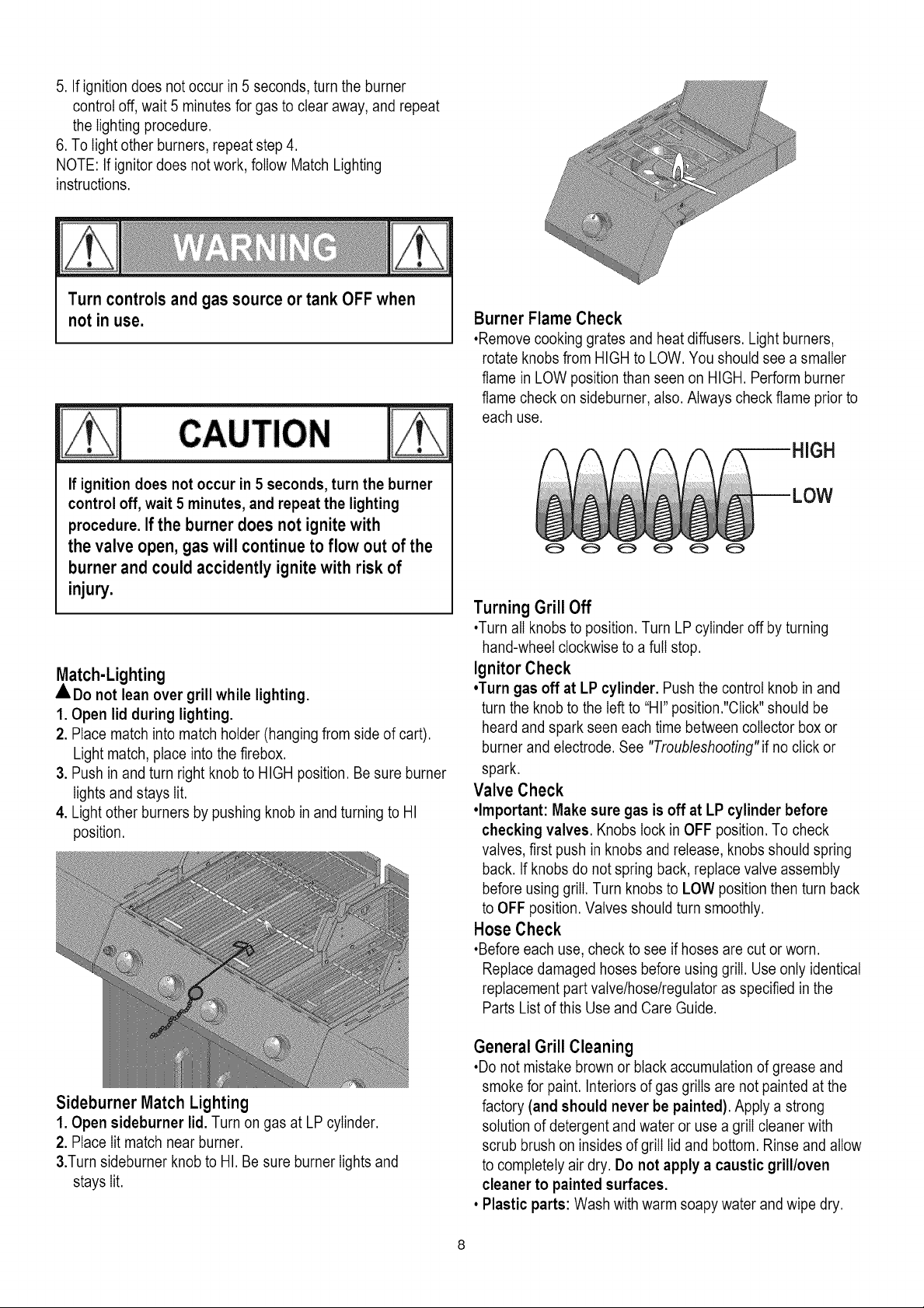

Burner Flame Check

,Remove cookinggrates and heat diffusers. Light burners,

rotate knobsfrom HIGH to LOW. You should see a smaller

flame inLOW position than seen on HIGH.Perform burner

flame checkon sideburner, also. Always checkflame prior to

each use.

TurningGrillOff

•Turn all knobs to position. Turn LP cylinder off by turning

hand-wheel clockwiseto a full stop.

Ignitor Check

•Turn gas off at LP cylinder. Push the controlknob in and

turn the knob to the left to "HI" position."Click" should be

heard andspark seen each time between collector box or

burner andelectrode. See "Troubleshooting"if no click or

spark.

Valve Check

•Important: Make sure gas is off at LP cylinder before

checking valves. Knobs lock in OFF position. To check

valves, first push inknobs and release, knobs should spring

back. If knobs do not spring back, replace valveassembly

before using grill. Turn knobs to LOW position then turn back

to OFF position.Valves should turn smoothly.

Hose Check

•Before each use,check to see ifhoses are cut or worn.

Replace damaged hoses before usinggrill. Use only identical

replacement part valve/hose/regulator as specified in the

Parts List of this Use and Care Guide.

Sideburner Match Lighting

1. Open sideburner lid. Turn on gas at LP cylinder.

2. Place Iitmatch near burner.

&Turn sideburner knob to HI. Besure burner lights and

stays Iit.

General Grill Cleaning

•Do not mistakebrown or black accumulation of grease and

smoke for paint. Interiors of gas grills are not paintedat the

factory (and should never be painted). Apply a strong

solution of detergent and water or use a grill cleaner with

scrub brush on insides of grill lid and bottom. Rinse and allow

to completely air dry. Do not apply a caustic grill/oven

cleaner to painted surfaces.

• Plastic parts: Wash with warm soapywater andwipe dry.

Donotusecitrisot,abrasivecleaners,degreasersora

concentratedgrillcleaneronplasticparts.Damagetoand

failureofpartscanresult.

•Porcelainsurfaces:Becauseofglass-likecomposition,most

residuecanbewipedawaywithbakingsoda/watersolutionor

speciallyformulatedcleaner.Usenonabrasivescouring

powderforstubbornstains.

*Painted surfaces: Wash with mild detergent or nonabrasive

cleanerand warm soapy water. Wipe dry with a soft

nonabrasive cloth.

•Stainless steel surfaces: To maintainyour grill's highquality

appearance, washwith mild detergent and warm soapywater

and wipe dry witha soft cloth after each use. Baked-on

grease deposits mayrequire the use of an abrasive plastic

cleaning pad. Useonly in direction of brushed finish to avoid

damage. Do not use abrasive pad on areaswith graphics.

• Cooking surfaces: Ifa bristlebrush is used to clean any of

the grill cooking surfaces, ensure no loose bristles remain on

cooking surfaces priorto grilling. It is not recommended to

cleancooking surfaces while grill is hot.

Storing Your Grill

•Clean cooking grates.

•Store in dry location.

•When LP cylinder is connected to grill, store outdoorsin a

welIventiIatedspace and out of reach of children.

•Covergrill if stored outdoors. Choose from a variety of grill

covers offered by manufacturer.

•Store grill indoors ONLY if LP cylinder isturned off and

disconnected, removed from grill and stored outdoors.

•When removing grill from storage, follow "Cleaning the Burner

Assembly' instructions before starting grill.

Cleaning the Burner Assembly

Follow these instructions to clean and/or replace parts of

burner assembly orif you have trouble igniting grill.

1.Turn gas off at control knobs and LPcylinder.

2. Remove cookinggrates andheat diffusers.

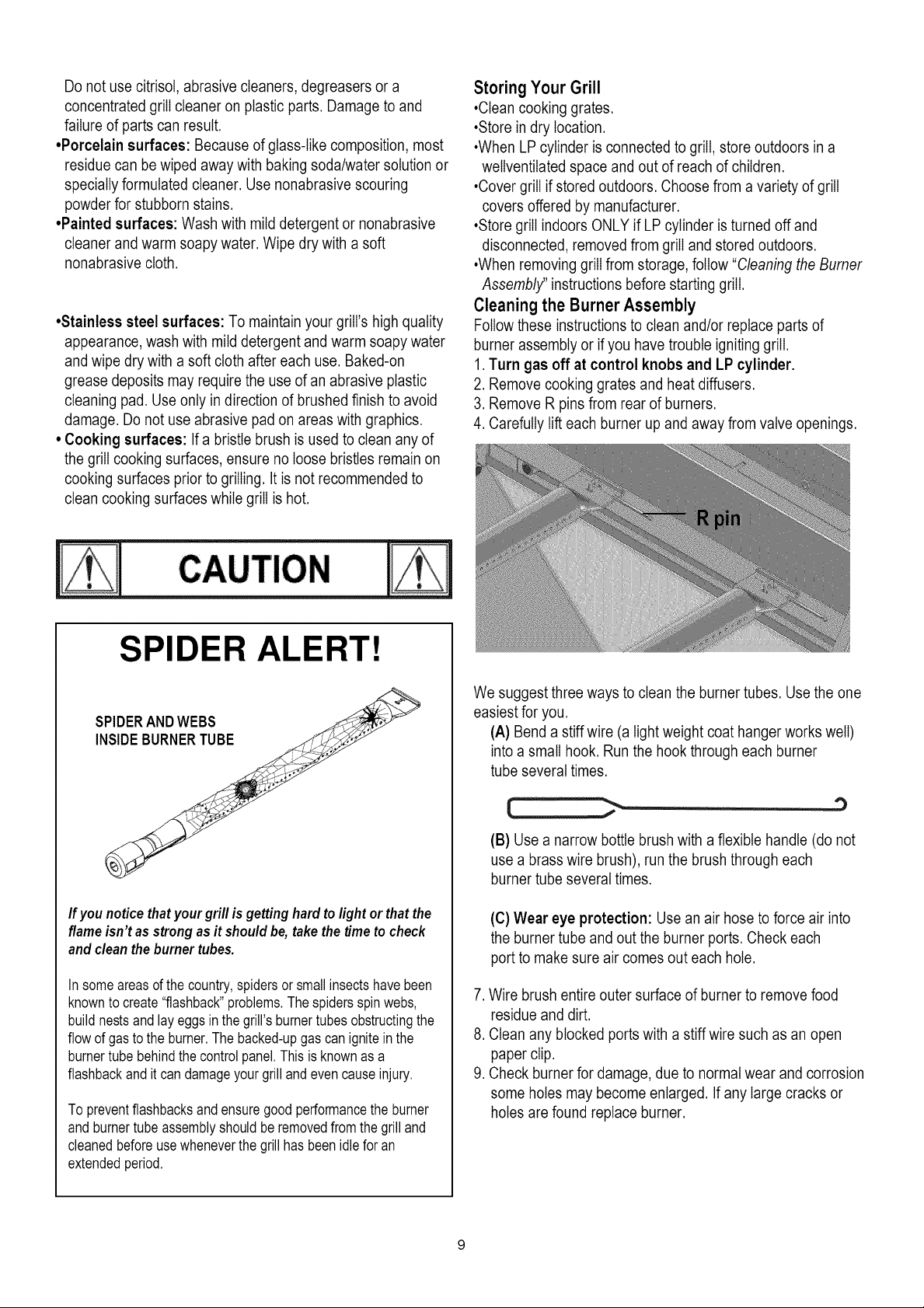

3. Remove R pinsfrom rear of burners.

4. Carefully lifteach burner up and awayfrom valveopenings.

SPIDER ALERT!

SPIDERANDWEBS

NSDE BURNERTUBE , -

If you notice that your grill is getting hard to light or that the

flame isn't as strong as it should be, take the time to check

and clean the burner tubes.

Insomeareasofthe country,spidersorsmallinsectshavebeen

knowntocreate"flashback"problems.Thespidersspinwebs,

buildnestsandlay eggsin thegrill'sburnertubesobstructingthe

flowof gastothe burner.Thebacked-upgascanignitein the

burnertubebehindthecontrolpanel.Thisisknownas a

flashbackanditcan damageyourgrill andevencauseinjury.

To preventflashbacksandensuregoodperformancetheburner

and burnertubeassemblyshouldberemovedfromthegrilland

cleanedbeforeusewheneverthe grillhasbeenidlefor an

extendedperiod.

We suggest three ways to clean the burner tubes. Use the one

easiestfor you.

(A) Bendastiff wire (a lightweight coat hanger works well)

intoa small hook. Runthe hook through each burner

tube several times.

J

(B) Usea narrow bottle brush with a flexible handle (do not

use a brass wire brush), runthe brush through each

burner tube several times.

(C)Wear eye protection: Use an air hose to forceair into

the burner tube and out the burner ports. Check each

port to makesure air comes out each hole.

7.Wire brush entire outer surface of burner to remove food

residue and dirt.

8. Clean any blocked ports with a stiffwire such as an open

paper clip.

9. Check burnerfor damage, due to normal wear and corrosion

some holes may become enlarged. If any large cracksor

holes are found replace burner.

'3

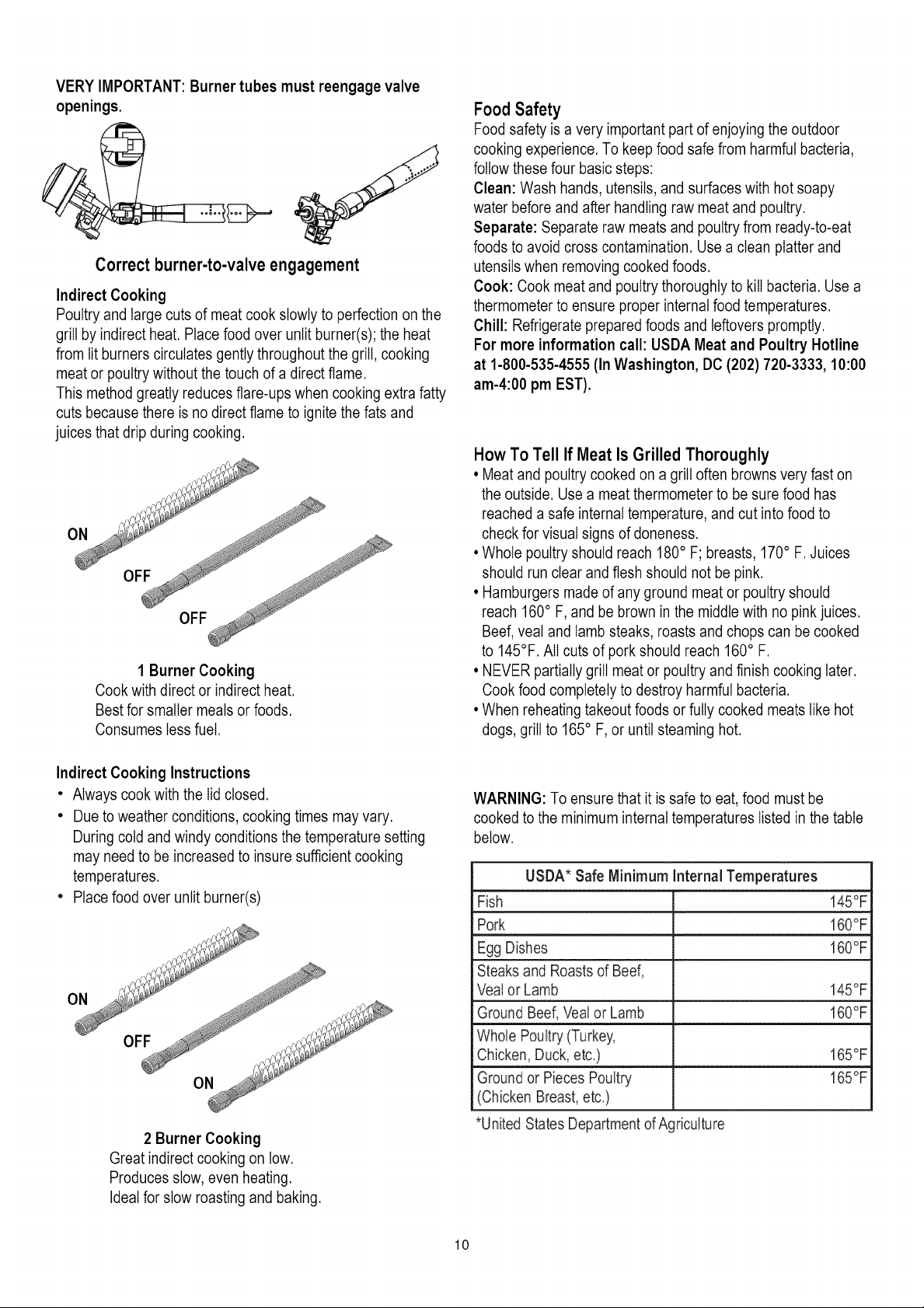

VERY IMPORTANT: Burner tubes must reengagevalve

openings.

Correct burner-to-valveengagement

Indirect Cooking

Poultry and large cutsof meat cook slowly to perfection onthe

grill by indirect heat. Placefood over unlit burner(s);the heat

from lit burners circulatesgentlythroughout the grill, cooking

meat or poultrywithout the touch of a direct flame.

This method greatlyreduces flare-upswhen cookingextra fatty

cuts because there is no direct flame to ignite the fats and

juices that dripduring cooking.

1 Burner Cooking

Cook with director indirect heat.

Best for smaller meals or foods.

Consumes lessfuel.

Food Safety

Food safety is a veryimportant part of enjoying the outdoor

cooking experience. To keepfood safe from harmful bacteria,

follow thesefour basic steps:

Clean: Washhands, utensils,and surfaces with hot soapy

water before and after handling raw meat and poultry.

Separate: Separate raw meats and poultryfrom ready-to-eat

foods to avoid cross contamination. Use a clean platterand

utensilswhen removingcookedfoods.

Cook: Cook meat and poultry thoroughlyto kill bacteria. Use a

thermometer to ensure proper internal food temperatures.

Chill: Refrigerate prepared foods and leftovers promptly.

For more information call: USDA Meat and Poultry Hotline

at 1-800-535-4555 (In Washington, DC (202) 720-3333, 10:00

am-4:00 pm EST).

How To Tell If Meat Is Grilled Thoroughly

• Meatandpoultry cookedon a grill often browns very fast on

the outside. Usea meat thermometer to be sure food has

reached a safe internal temperature,and cut into food to

check for visualsigns of aloneness.

•Whole poultry should reach 180° F; breasts, 170° F.Juices

should run clear andflesh should not be pink.

• Hamburgers madeof any ground meat or poultry should

reach 160° F,and be brown inthe middle with no pink juices.

Beef, veal and lamb steaks, roasts and chops can be cooked

to 145°F. All cuts of pork should reach 160° F.

• NEVERpartiallygrill meator poultry and finish cooking later.

Cook food completely to destroy harmful bacteria.

•When reheating takeout foods or fully cooked meats like hot

dogs, grillto 165° F,or until steaming hot.

Indirect Cooking Instructions

• Always cookwith the lid closed.

• Due toweather conditions, cooking times mayvary.

During cold andwindy conditions the temperature setting

may need to be increased to insure sufficient cooking

temperatures.

• Place food over unlit burner(s)

2 Burner Cooking

Great indirect cooking on low.

Produces slow, even heating.

Idealfor slow roastingand baking.

WARNING: To ensure that it is safe to eat, food must be

cooked to the minimum internal temperatures listed in the table

below.

USDA* Safe MinimumInternal Temperatures

Fish 145°F

Pork 160°F

Egg Dishes 160°F

Steaksand Roasts of Beef,

Vealor Lamb 145°F

Ground Beef, Veal or Lamb 160°F

Whole Poultry (Turkey,

Chicken, Duck, etc.) 165°F

Ground or PiecesPoultry 165°F

(Chicken Breast, etc.)

*United States Departmentof Agriculture

10

To purchase NaturalGas Conversion Partscall Sears at

1-800-4-MY-HOME®

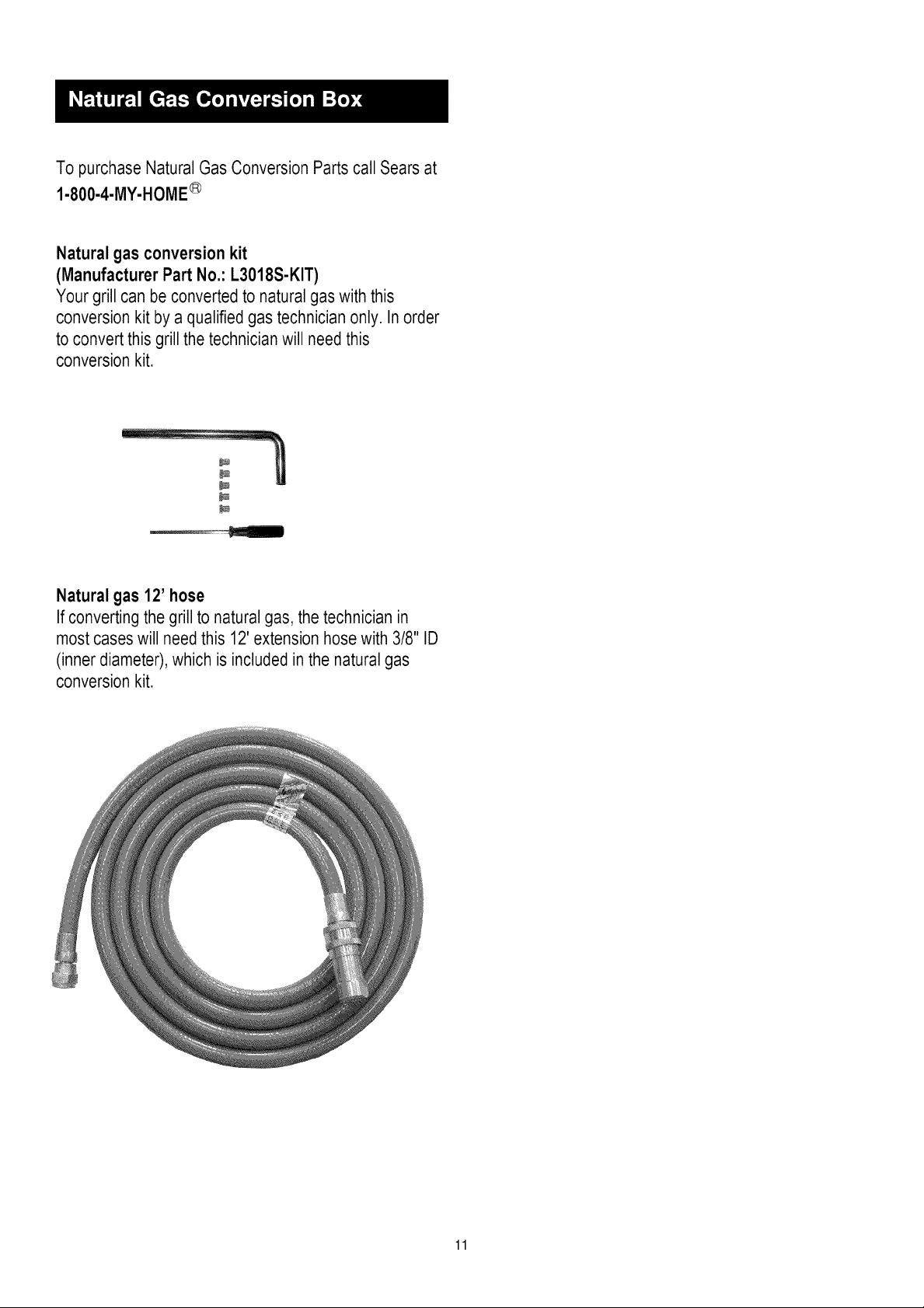

Natural gas conversion kit

(Manufacturer PartNo.: L3018S-KIT)

Yourgrill canbe convertedto naturalgas withthis

conversion kit by a qualified gas technicianonly. Inorder

to convert this grill the technicianwill need this

conversion kit.

Natural gas 12' hose

If converting the grill to naturalgas, the technician in

most cases will needthis 12' extension hose with3/8" ID

(inner diameter),which is included in the naturalgas

conversion kit.

11

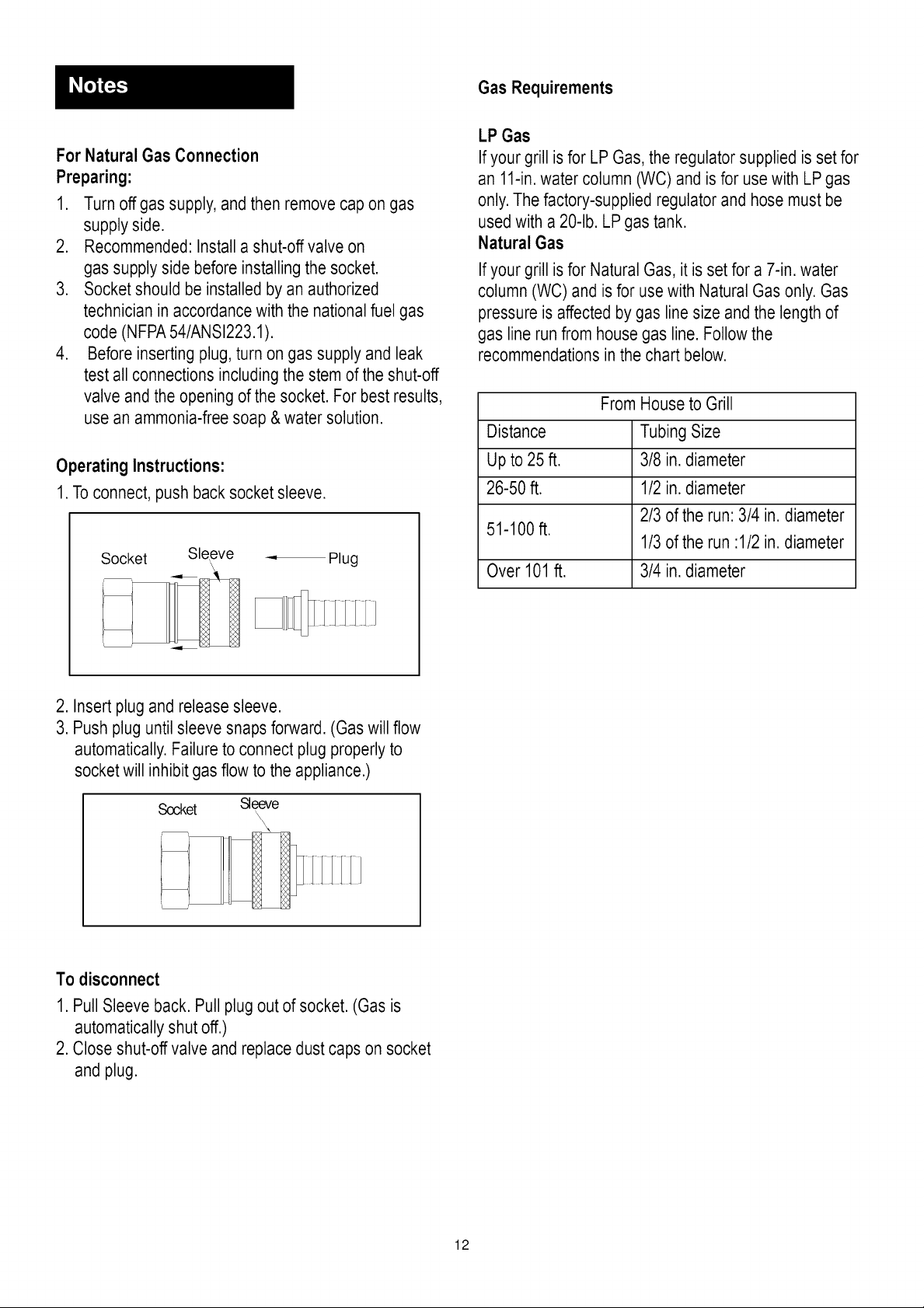

For NaturalGas Connection

Preparing:

1. Turn off gassupply, and then remove capon gas

supplyside.

2. Recommended: Installashut-off valve on

gassupply side before installing the socket.

3. Socket should beinstalled by an authorized

technicianin accordancewith the nationalfuel gas

code (NFPA54/ANSI223.1).

4. Before inserting plug,turnon gas supply and leak

testall connections includingthestem of theshut-off

valve and theopening of thesocket. Forbest results,

use anammonia-free soap& water solution.

Gas Requirements

LP Gas

Ifyour grill isfor LPGas, theregulator supplied isset for

an 11-in.water column (WC)and isfor usewith LP gas

only.Thefactory-supplied regulatorand hosemust be

usedwith a 20-lb. LPgas tank.

Natural Gas

Ifyour grill isfor NaturalGas, itis set fora 7-in. water

column(WC) and isfor use with Natural Gas only.Gas

pressureis affectedby gas line sizeand the lengthof

gas linerun from house gas line. Follow the

recommendationsin thechart below.

FromHouseto Grill

Distance Tubing Size

OperatingInstructions:

1.Toconnect, push back socket sleeve.

Socket Sleeve = Plug

\

2. Insert plug and releasesleeve.

3. Push plug untilsleeve snaps forward. (Gaswill flow

automatically.Failure to connect plugproperlyto

socketwill inhibitgasflowto the appliance.)

Socket Sleeve

\\\

Up to 25 ft. 3/8 in.diameter

26-50 ft. 1/2in.diameter

2/3of the run:3/4 in. diameter

51-100ft.

1/3of the run :1/2 in. diameter

Over 101ft. 3/4 in.diameter

To disconnect

1. Pull Sleeve back. Pullplug out of socket. (Gas is

automaticallyshutoff.)

2. Close shut-offvalve and replacedust caps on socket

and plug.

12

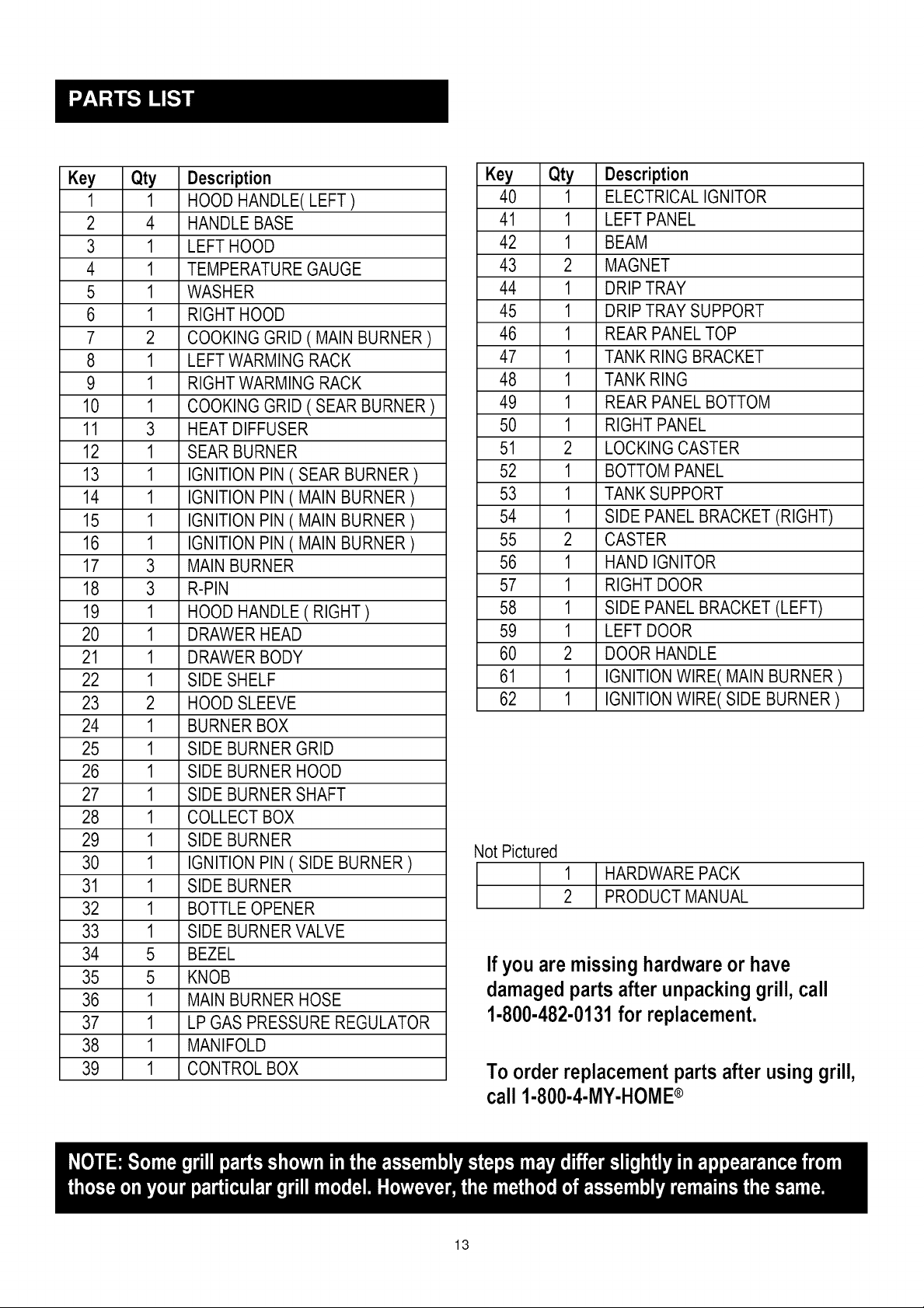

Key Qty Description

1 1 HOODHANDLE(LEFT)

2 4 HANDLEBASE

3 1 LEFTHOOD

4 1 TEMPERATUREGAUGE

5 1 WASHER

6 1 RIGHTHOOD

7 2 COOKING GRID( MAIN BURNER )

8 1 LEFTWARMING RACK

9 1 RIGHTWARMINGRACK

10 1 COOKING GRID( SEAR BURNER)

11 3 HEATDIFFUSER

12 1 SEAR BURNER

13 1 IGNITIONPIN ( SEAR BURNER )

14 1 IGNITIONPIN ( MAIN BURNER)

15 1 IGNITIONPIN ( MAIN BURNER)

16 1 IGNITIONPIN ( MAIN BURNER)

17 3 MAINBURNER

18 3 R-PIN

19 1 HOOD HANDLE ( RIGHT )

20 1 DRAWERHEAD

21 1 DRAWERBODY

22 1 SIDE SHELF

23 2 HOODSLEEVE

24 1 BURNERBOX

25 1 SIDE BURNER GRID

26 1 SIDE BURNER HOOD

27 1 SIDE BURNER SHAFT

28 1 COLLECT BOX

29 1 SIDE BURNER

30 1 IGNITIONPIN ( SIDE BURNER )

31 1 SIDE BURNER

32 1 BOTTLEOPENER

33 1 SIDE BURNER VALVE

34 5 BEZEL

35 5 KNOB

36 1 MAIN BURNERHOSE

37 1 LPGAS PRESSUREREGULATOR

38 1 MANIFOLD

39 1 CONTROL BOX

Key Qty Description

40 1 ELECTRICALIGNITOR

41 1 LEFTPANEL

42 1 BEAM

43 2 MAGNET

44 1 DRIPTRAY

45 1 DRIPTRAY SUPPORT

46 1 REARPANELTOP

47 1 TANK RING BRACKET

48 1 TANK RING

49 1 REARPANELBOTTOM

50 1 RIGHTPANEL

51 2 LOCKINGCASTER

52 1 BOTTOMPANEL

53 1 TANK SUPPORT

54 1 SIDE PANELBRACKET(RIGHT)

55 2 CASTER

56 1 HANDIGNITOR

57 1 RIGHTDOOR

58 1 SIDE PANELBRACKET(LEFT)

59 1 LEFTDOOR

60 2 DOORHANDLE

61 1 IGNITIONWIRE( MAINBURNER )

62 1 IGNITIONWIRE( SIDE BURNER )

Not Pictured

1

HARDWAREPACK

2

PRODUCTMANUAL

If you aremissinghardwareor have

damagedparts afterunpackinggrill, call

1-800-482-0131for replacement.

Toorder replacement parts after using grill,

call 1-800-4-MY-HOME®

13

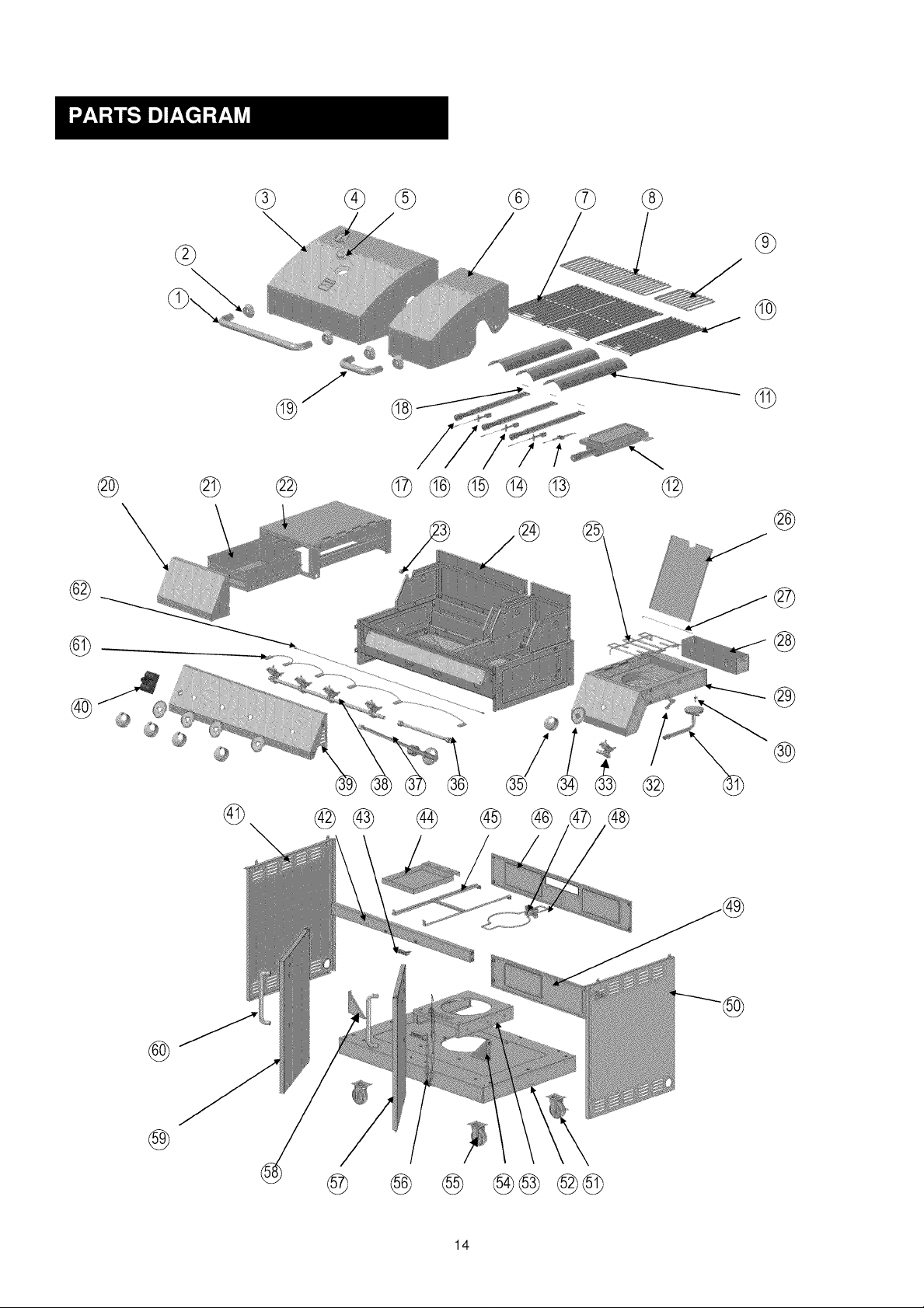

@

@ © ® @®®®_ ®

®

®

@

®

@

@

®

®

®

© @©

@

@ _ @

14

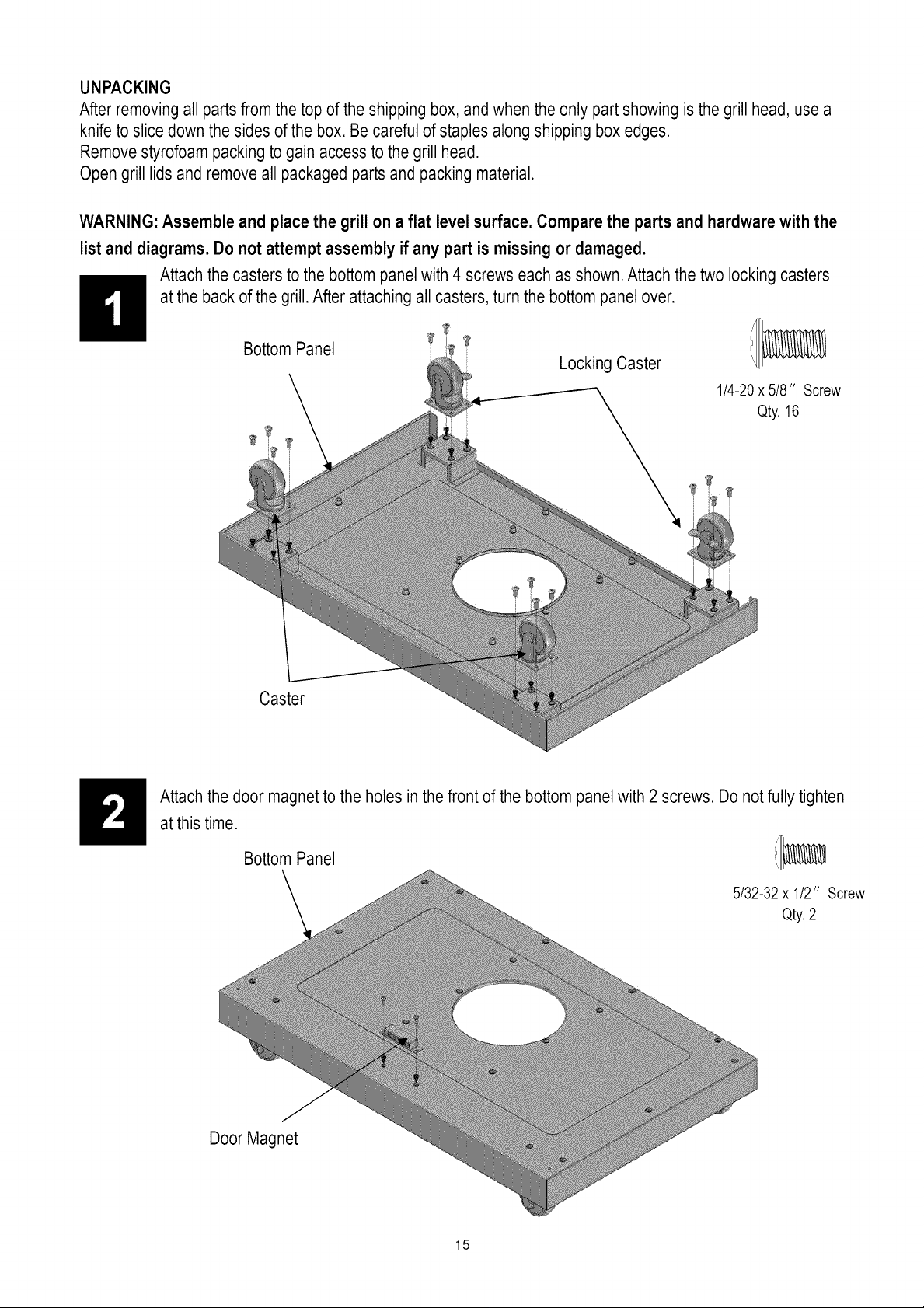

UNPACKING

Afterremoving all parts from the top of theshipping box,andwhen theonly part showing isthe grill head,use a

knifeto slice down the sides of the box.Be careful of staplesalong shipping box edges.

Removestyrofoam packingto gainaccess tothe grill head.

Open grill lids andremoveall packaged partsand packing material.

WARNING:Assemble and place the grill ona flat level surface. Compare the parts and hardwarewith the

list and diagrams. Do not attempt assemblyif any part is missingordamaged.

Attach the casters to the bottompanel with4 screwseach as shown.Attach the two lockingcasters

at the back of the grill.After attaching allcasters,turn the bottompanel over.

Bottom Panel

Locking Caster

1/4-20x 5/8" Screw

Qty.16

Caster

Attach the door magnetto theholes inthefrontof the bottom panelwith 2 screws. Donotfully tighten

at this time.

Bottom Panel i/_

5/32-32x 1/2" Screw

Qty.2

Door Magnet

15

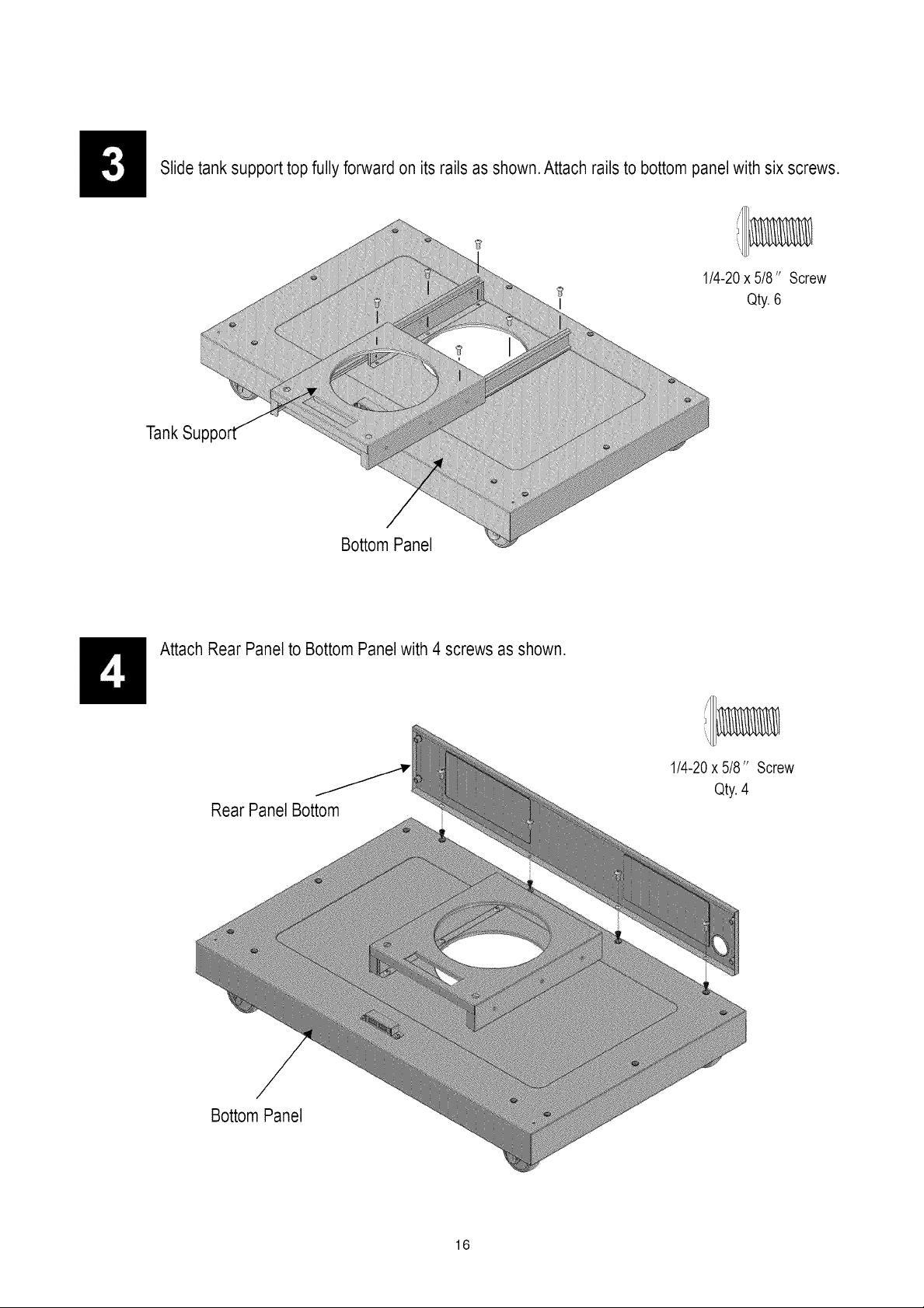

Slidetank supporttop fully forward on itsrails as shown.Attach railsto bottompanel with six screws.

1/4-20x 5/8" Screw

Qty.6

TankSu

BottomPanel

Attach Rear Panelto BottomPanel with 4 screws asshown.

y 1/4-20x 5/8" Screw

Rear Panel Bottom

Qty.4

Bottom Panel

16

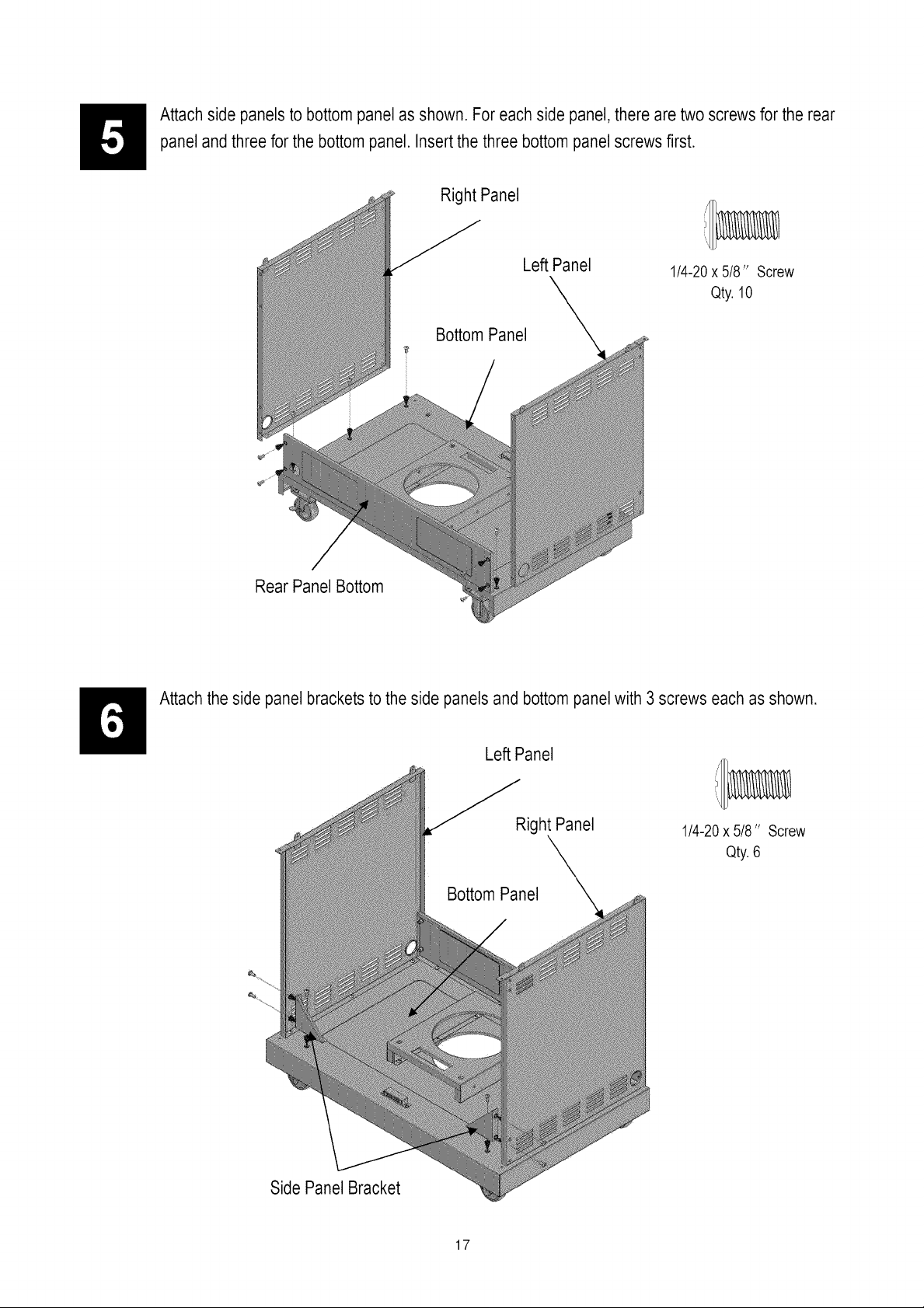

Attach side panels to bottom panel as shown. Foreach side panel, there are two screwsfor the rear

panel and threefor the bottompanel. Insert the three bottom panelscrews first.

RightPanel

Left Panel

1/4-20x 5/8" Screw

Qty.10

Rear Panel Bottom

Attach the side panel bracketsto the side panels and bottompanelwith 3 screws each as shown.

SidePanel Bracket

Left Panel

Right Panel

1/4-20x 5/8" Screw

Qty.6

17

Loading...

Loading...