Page 1

Use & Care Guide

Manual de Uso y Cuidado

English / Español

Models/Modelos: 148.16154210

Item / Artículo: 640-03838917-7

Kenmore®

Liquid Propane Gas Grill

Parilla a gas de propane liquido

P/N 2818-2T-Manual

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

www.kmart.com

TM

Page 2

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or your fire department.

1. Do not store or use gasoline or other

flammable liquids or vapors in the vicinity

of this or any other appliance.

2. An LP cylinder not connected for use shall

not be stored in the vicinity of this or any

other appliance.

CALIFORNIA PROPOSITION 65

This product contains chemicals, including lead and

lead compounds in brass fittings. It also produces

combustion by-products when used. These substances

are known to the State of California to cause cancer,

birth defects or other reproductive harm.

Wash your hands after using this product.

Call Grill Service Center For Help And Parts

If you have questions or need assistance during assembly,

please call 1-800-482-0131. You will be speaking to a

representative of the grill manufacturer and not a Sears

employee. To order new parts call Sears at

1-800-4-MY-HOME.

Product Record

IMPORTANT: Fill out the product record information

below.

For residential use only. Do not use for

commercial cooking.

Installation Safety Precautions

• Use grill, as purchased, only with LP (propane) gas and the

regulator/valve assembly supplied. A conversion kit must

be purchased for use with natural gas.

• Grill installation must conform with local codes, or in their

absence of local codes, with either the National Fuel Gas

Code, ANSI Z223.1/ NFPA 54, Natural Gas and Propane

Installation Code, CSA B149.1, or Propane Storage and

Handling Code, B149.2, or the Standard for Recreational

Vehicles, ANSI A 119.2/NFPA 1192, and CSA Z240 RV

Series, Recreational Vehicle Code, as applicable.

• All electrical accessories (such as rotisserie) must be

electrically grounded in accordance with local codes, or

National Electrical Code, ANSI / NFPA 70 or Canadian

Electrical Code, CSA C22.1. Keep any electrical cords

and/or fuel supply hoses away from any hot surfaces.

• This grill is safety certified for use in the United States

and/or Canada only. Do not modify for use in any other

location. Modification will result in a safety hazard.

Safety Symbols

The symbols and boxes shown below explain what each

heading means. Read and follow all of the messages found

throughout the manual.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARNING: Indicates an potentially hazardous

situation which, if not avoided, could resu lt in death

or serious injury.

Model Number: 148.16154210

Serial Number:

See rating label on grill for serial number.

Date Purchased:

© 2012 KCD IP, LLC

CAUTION: Indicates a potentially hazardous

situation or unsafe practice which, if not avoided,

may result in minor or moderate injury.

2

Page 3

TABLE OF CONTENTS

For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . 2

For Sears professional installation of home applia nc es, gar age

door openers, water heaters, and other major home items, in

the U.S.A. call 1-800-4-MY-HOME

®

Grill Service Center. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Record Information . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation Safety Precautions . . .. . . . . . . . . . . . .. . . . . . . 2

Kenmore Grill Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Use and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Natural Gas Conversion Box . . . . . . . . . . . . . . . . . . . . . . 11

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .. .11

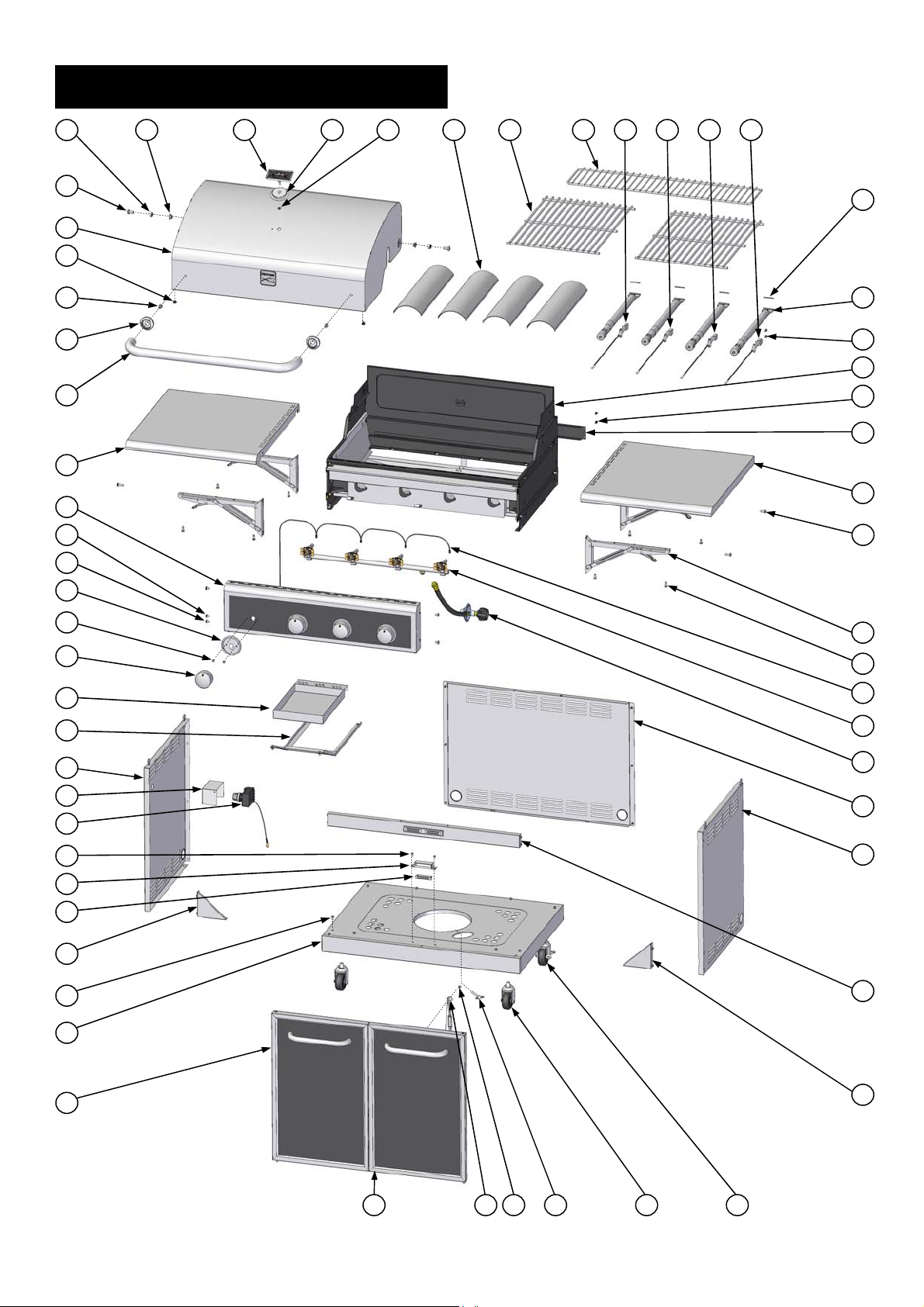

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . 13

Parts Diagram. . . . . . . . . . . . . . . . . . . . . . . .. . . .. . . . . . . 14

Assembly . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .. .. . . . 15-22

Conversion Instructions for 16154. . . . . . . . . . .. . . . . .23-25

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . ... . . . . . . 26-27

Repair Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore

dependable operation. But like all products, it may requ ire

repair from time to time. That’s when having a Repair

Protection Agreement can save you money and a ggravation.

Purchase a Repair Protection Agreement no w and protect

yourself from unexpected hassle and expens e.

Here’s what the Repair Protection Agreement includes:

□ Expert service by our 10,000 professional repair

□ Unlimited service and no charge for parts and labor on

□ Product replacement up to $1500 if your covered

□ Discount of 25% from regular price of service and

□ Fast help by phone – we call it Rapid Resolution –

Once you purchase the Repair Protection Agreeme nt, a simple

phone call is all that it takes for you to schedule service. Yo u

can call anytime day or night, or schedule a servic e

appointment online.

The Repair Protection Agreement is a risk-free purchase. If you

cancel for any reason during the product warranty period, we

will provide a full refund. Or, a prorated refund anytime after

the product warranty period expires. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information call 1-800-827-6655.

Sears Installation Service

®

product is designed and manufactured for year s of

specialists

all covered repairs

product can’t be fixed

related installed parts not covered by the agreement; als o,

25% off regular price of preventive maintena nce check

phone support from a Sears representativ e. Think of us

as a “talking owner’s manual.”

WARRANTY

Kenmore Full Warranty

If this grill fails due to a defect in material or workmanship

within one year from the date of purchas e, call 1-800-4-MY-

®

HOME

proves impossible).

to arrange for free repair (or replacement if repair

Limited Warranty on Burners

For ten years from the date of purchase, any stainless steel

burner that rusts through will be replaced free of charge. After

the first year from the date of purchase, you pay for labor if

you wish to have it installed.

All warranty coverage excludes ignitor batteries and grill part

paint loss, discoloration or rusting, which are either

expendable parts that can wear out from normal use wit hin

the warranty period, or are conditions that can be the result

of normal use, accident or improper maintenance.

All warranty coverage is void if this grill is ever used for

commercial or rental purposes.

All warranty coverage applies only if this grill is used in the

United States.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Sears Brands Management Corporation,

Hoffman Estates, IL 60179

3

Page 4

USE AND CARE

`

• NEVER store a spare LP cylinder under or near

the grill appliance or in an enclosed area.

• Never fill a cylinder beyond 80% full.

• If the information in the two points above is not

followed exactly, a fire causing death or serious

injury may occur.

• An over filled or improperly stored cylinder is a

hazard due to possible gas release from the

safety relief valve. This could cause an intense

fire with risk of property damage, serious injury

or death.

• If you see, smell or hear gas escaping,

immediately get away from the LP cylinder and

grill appliance and call your fire department.

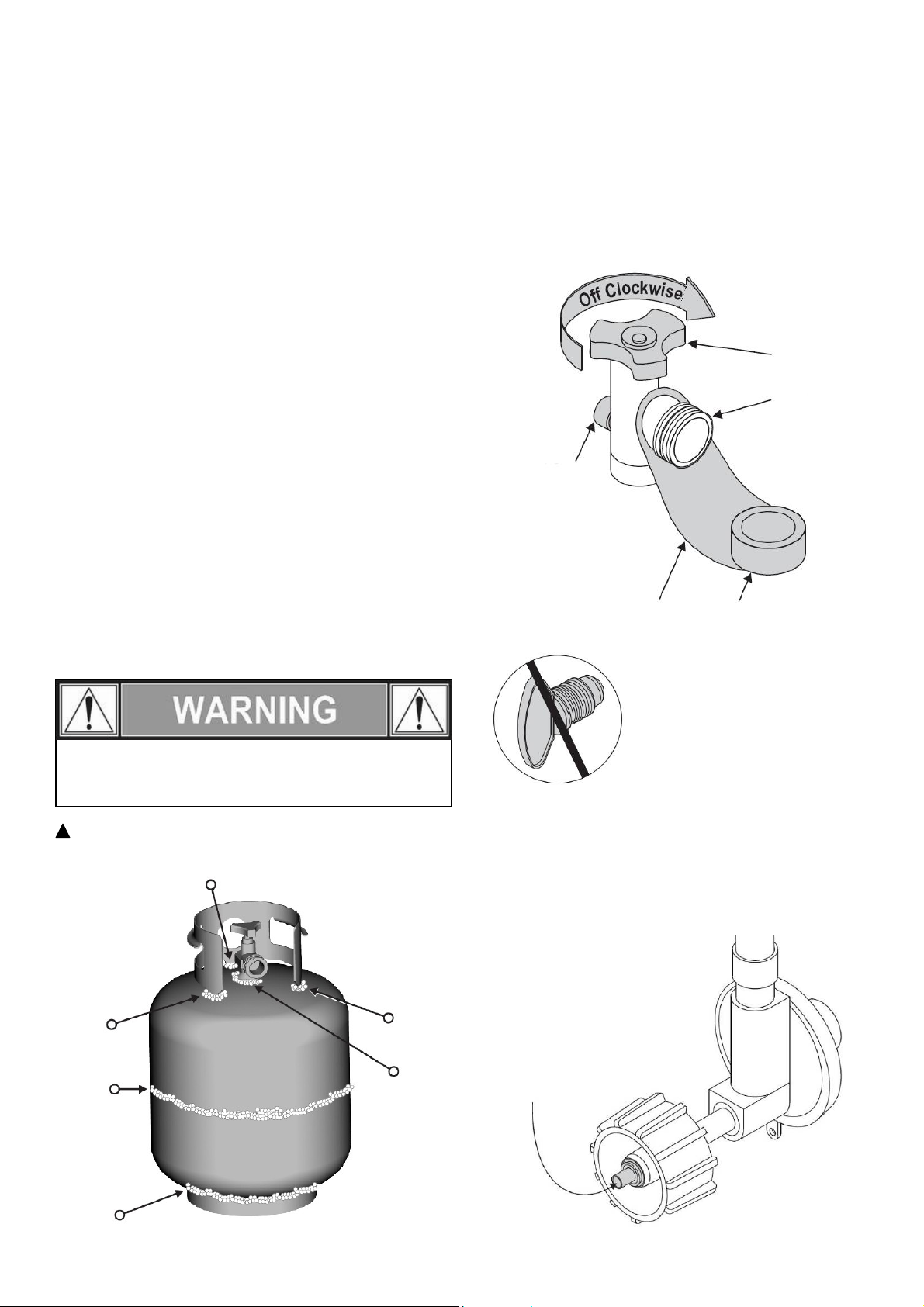

LP Tank Removal, Transport and Storage

• Turn OFF all control knobs and LP tank valve. Turn coupling

nut counterclockwise by hand only - do not use tools to

disconnect. Lift LP tank wire upward off of LP tank collar, then

lift LP tank up and off of support bracket. Install safety cap

onto LP tank valve. Always use cap and strap s upplied with

valve.

Failure to use safety cap as directed may result in

serious personal injury and/or property damage.

LP Tank Valve

• A disconnected LP tank in storage or being transported must

have a safety cap installed (as shown). Do not store a n LP

tank in enclosed spaces such as a carport, garage, por ch,

covered patio or other building. Never leave an LP tank inside

a vehicle which may become overheated by the sun.

• Do not store an LP tank in an area where children play.

Safety Cap

Retainer Strap

LP Cylinder

• The LP cylinder used with your grill must meet the

following requirements:

• Use LP cylinders only with these required meas urements: 12"

(30.5cm) (diameter) x 18" (45.7 cm) (tall) with 20 lb. (9 kg.)

capacity maximum.

• LP cylinders must be constructed and marked in accorda nce

with specifications for LP cylinders of the U.S. Departm ent of

Transportation (DOT) or for Canada, CAN/CSA-B339,

cylinders, spheres and tubes for transportation of dangerous

goods. Transport Canada (TC). See LP cylinder collar for

marking.

• LP cylinder valve must have:

• Type 1 outlet compatible with

regulator or grill.

• Safety relief valve.

• UL listed Overfill Protection

Device (OPD). This OPD safety

feature is identified by a unique triangular hand wheel. Use

only LP cylinders equipped with this type of valve.

• LP cylinder must be arranged for vapor withdrawal and

include collar to protect LP cylinder valve. Al ways keep LP

cylinders in upright position during use, transit or storage.

OPD Hand Wheel

LP cylinder in upright position for vapor withdrawal

LP (Liquefied Petroleum Gas)

• LP gas is nontoxic, odorless and colorless when produced.

For Your Safety, LP gas has been given an odor (similar to

rotten cabbage) so that it can be smelled.

• LP gas is highly flammable and may ignite unex pectedly

when mixed with air.

LP Cylinder Filling

• Use only licensed and experienced dealers.

• LP dealer must purge new cylinder before filling.

• Dealer should NEVER fill LP cylinder more than 80% of LP

cylinder volume. Volume of propane in cylinder will v ary b y

temperature.

• A frosty regulator indicates gas overfill. Immediately close LP

cylinder valve and call local LP gas dealer for assistance.

• Do not release liquid propane (LP) gas into the atm osphere.

This is a hazardous practice.

• To remove gas from LP cylinder, contact an LP dealer or call

a local fire department for assistance. Check the teleph one

directory under “Gas Companies” for nearest certified LP

dealers.

4

Page 5

LP Tank Exchange

•Many retailers that sell grills offer you the option of replac ing

your empty LP tank through an exchange service. Use only

those reputable exchange companies th at inspect, precision

fill, test and certify their cylinders. Exchange your tank only

for an OPD safety feature-equipped tank as described in

the "LP Tank" section of this manual.

•Always keep new and exchanged LP tanks in upright position

during use, transit or storage.

•Leak test new and exchanged LP tanks BEFORE

connecting to grill.

LP Tank Leak Test

For your safety

•Leak test must be repeated each time LP tank is excha nged

or refilled.

•Do not smoke during leak test.

•Do not use an open flame to check for gas leaks.

•Grill must be leak tested outdoors in a well-ventilated area,

away from ignition sources such as gas fired or electri cal

appliances. During leak test, keep grill away from open flames

or sparks.

•Use a clean paintbrush and a 50/50 mild soap and water

solution. Brush soapy solution onto areas ind icated by arrows

in figure below. Leaks are indicated by growing bubbles.

If “growing” bubbles appear do not use or move t he LP

tank. Contact an LP gas supplier or your fire department!

Do not use household cleaning agents. Damage to gas

train components (valve/hose/regulator) can result.

Connecting Regulator To The LP Tank

1. LP tank must be properly secured onto grill. (Refer to

assembly section.)

2. Turn all control knobs to the OFF position.

3. Turn LP tank OFF by turning OPD hand wheel clockwis e to

a full stop.

4. Remove the protective cap from LP tank valve. Always use

cap and strap supplied with valve.

OPD Hand Wheel

Type 1 outlet with

Safety Relief Valve

thread on outside

Strap and Cap

Do not insert a POL transport plug

(plastic part with external threads)

into the Type 1 tank valve outlet . It

will defeat the Safety Relief Valve

feature.

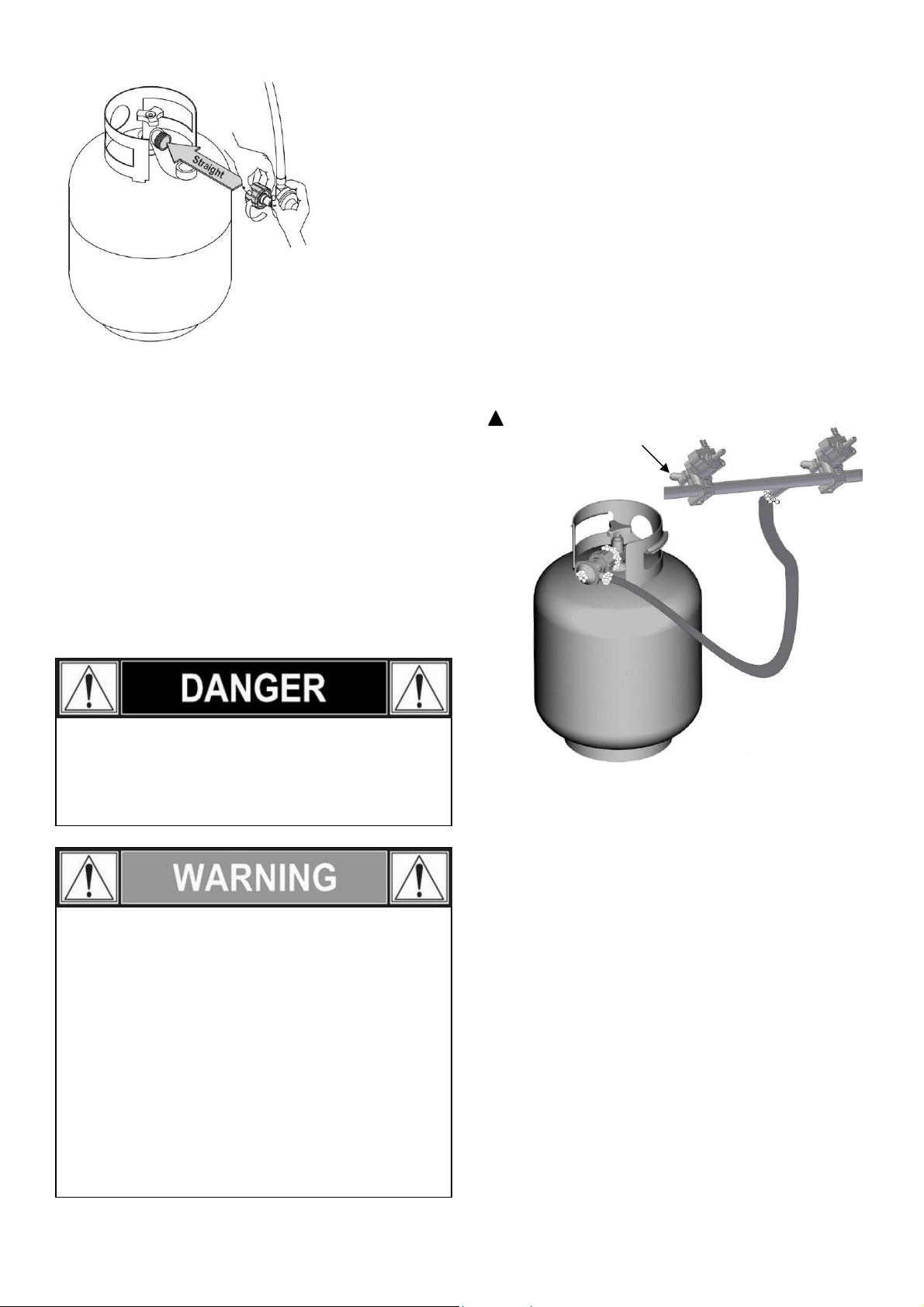

5. Hold regulator and insert nipple into LP tank valve.

Hand-tighten the coupling nut, holding regulator in a straight

line with LP tank valve so as not to crossthread the

connection.

Nipple has to be centered

into the LP tank valve.

5

Page 6

Hold coupling nut and regulator

as shown for proper connection

to LP tank valve.

6. Turn the coupling nut clockwise and tighten to a full stop.

The regulator will seal on the back-check featur e in the LP

tank valve, resulting in some resistance. An additional

one-half to three-quarters turn is required to complete

the connection. Tighten by hand only – do not use tools.

NOTE:

If you cannot complete the connection, disconnect regu lator

and repeat steps 5 and 6. If you are still unable to complete the

connection, do not use this regulator! Call 1-800-482-0131

for assistance.

Leak Testing Valves, Hose and Regulator

1. Turn all grill control knobs to OFF.

2. Be sure regulator is tightly connected to LP tank.

3. Completely open LP tank valve by turnin g OPD hand wheel

counterclockwise. If you hear a rushing sound, turn gas off

immediately. There is a major leak at the connection.

Correct before proceeding by calling Sears for

replacement parts at 1-800-4-MY-HOME

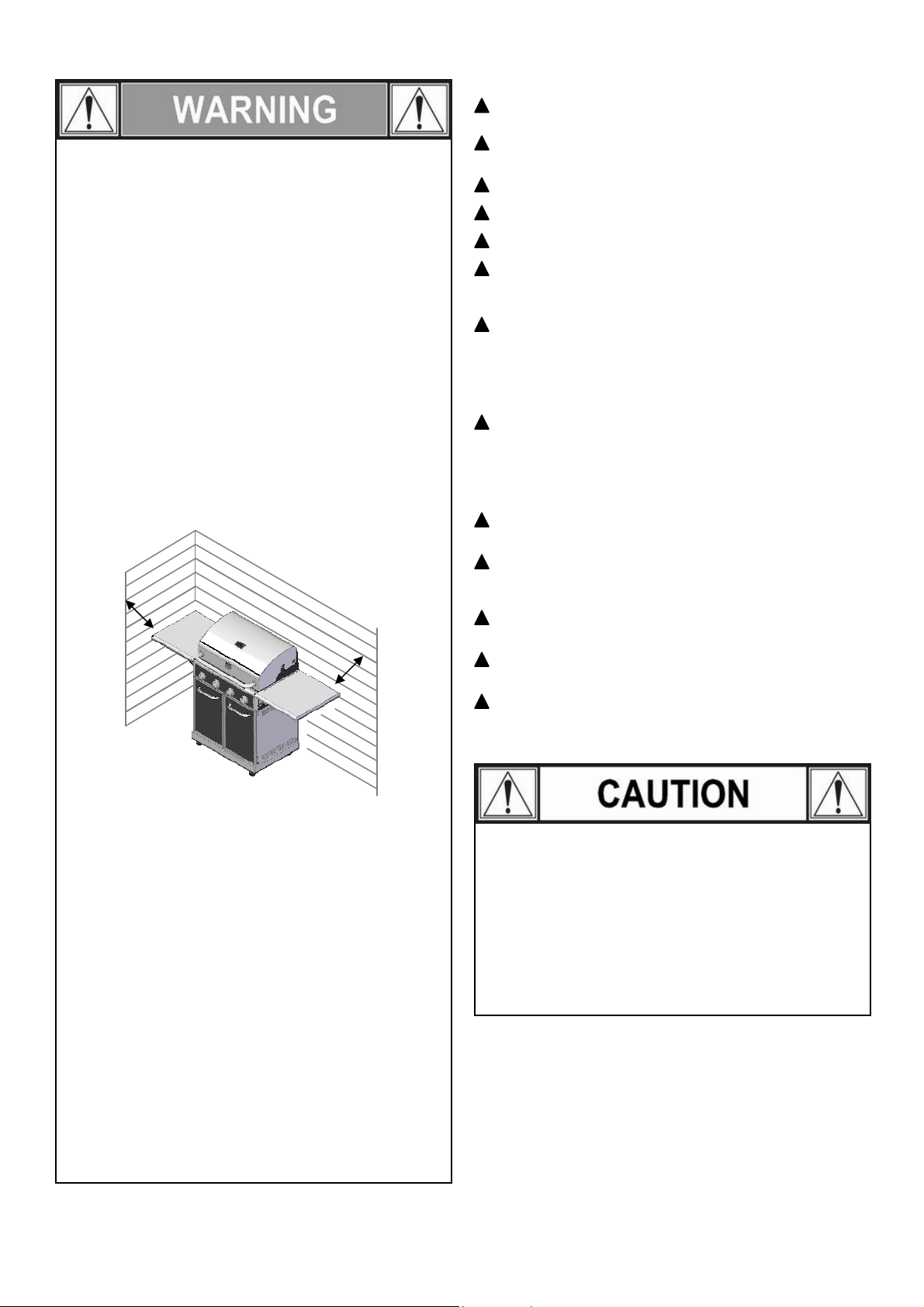

4. Brush soapy solution onto areas where bubbles are shown

in picture below:

Never remove threaded

orifice at end of valve.

®

.

• Do not insert any tool or foreign object into the valve

outlet or safety relief valve. You may damage the valve

and cause a leak. Leaking propane may result in

explosion, fire, severe personal injury, or death.

• Outdoor gas appliance is not intended to be installed

in or on a boat.

• Outdoor gas appliance is not intended to be installed

in or on an RV.

• Never attempt to attach this grill to the self-contained

LP gas system of a camper trailer or motor home.

• Do not use grill until leak-tested.

• If a leak is detected at any time, STOP and call the

fire department.

• If you cannot stop a gas leak, immediately close

LPcylinder valve and call LP gas supplier or your fire

department!

5. If “growing” bubbles appear, there is a leak. Close LP t ank

valve immediately and retighten connections. If leaks

cannot be stopped do not try to repair. Call Sears for

replacement parts at 1-800-4-MY-HOME

6. Always close LP tank valve after performing leak test by

turning hand wheel clockwise.

®

.

6

Page 7

g

p

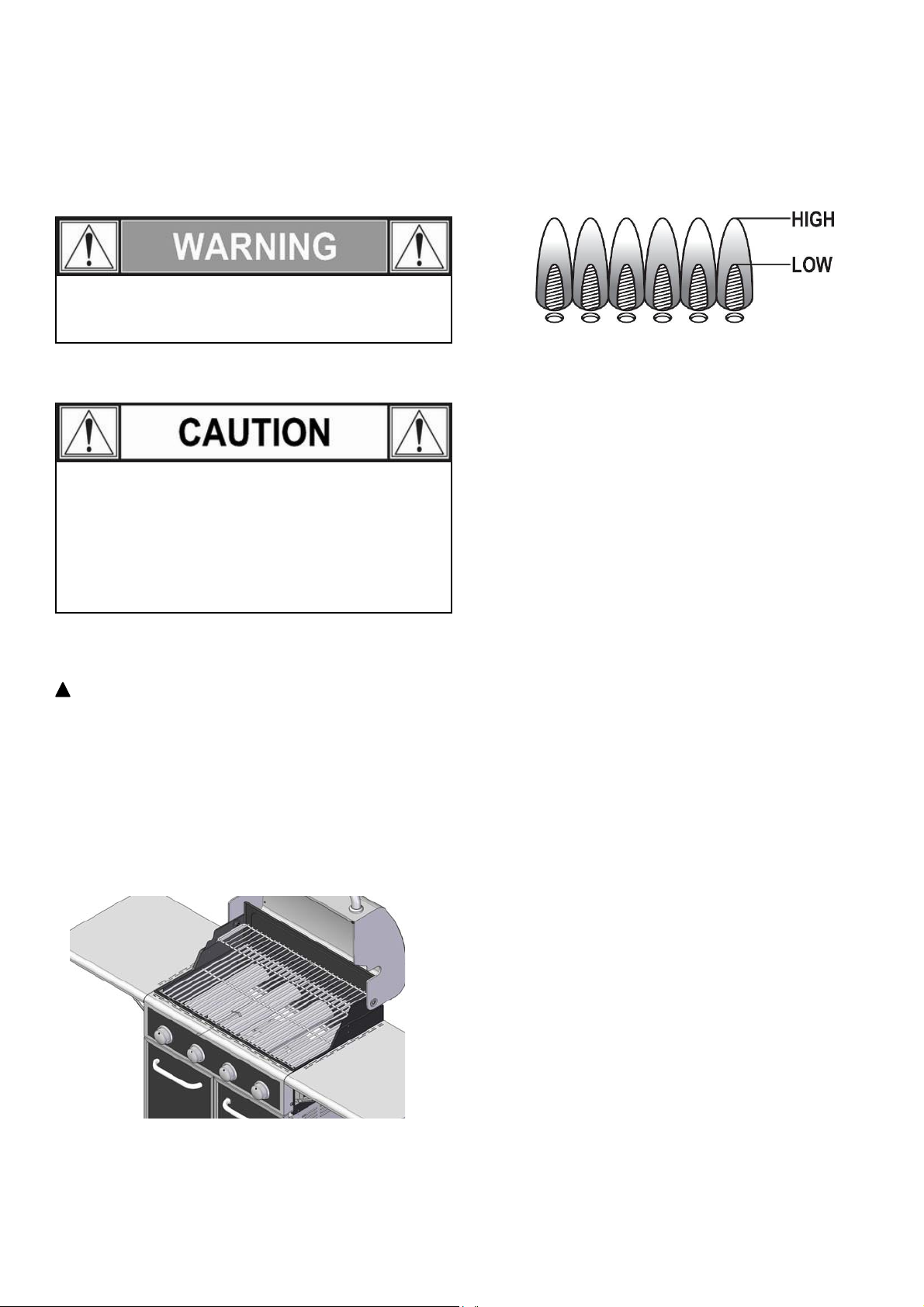

For Safe Use of Your Grill and to Avoid Serious

Injury:

• Do not let children operate or play near grill.

• Keep grill area clear and free from materials that

burn.

• Do not block holes in sides or back of grill.

• Check burner flames regularly.

• Use grill only in well-ventilated space. NEVER use in

enclosed space such as carport, garage, porch,

covered patio, or under an overhead structure of any

kind.

• Do not use charcoal or ceramic briquets in a gas grill.

(Unless briquets are supplied with your grill.)

• Use grill at least 3 ft. from any wall or surface.

Maintain 10 ft. clearance to objects that can catch

fire, or to sources of ignition such as pilot lights on

water heaters, live electrical appliances, etc.

• Apartment Dwellers:

Check with management to learn the requirements

and fire codes for using an LP gas grill in your

apartment complex. If allowed, use outside on the

ground floor with a three (3) foot clearance from walls

or rails. Do not use on or under balconies.

• NEVER attempt to light burner with lid closed. A

buildup of non-ignited gas inside a closed grill is

hazardous.

• Never operate grill with LP cylinder out of correct

position specified in assembly instructions.

• Always close LP cylinder valve and remove

coupling nut before moving LP cylinder from

specified operation position.

Safety Tips

Before opening LP cylinder valve, check the coupling nut

for tightness.

When grill is not i n use, turn off all control knobs and LP

cylinder valve.

Never move grill while in operation or still hot.

Use long-han dled barbecue utensils and oven mitts to

avoid burns and splatters.

Maximum load for sideb urner and side shelf is 10 lbs.

The grease tray must be inserted into grill and emptied

after each use. Do not remove grease tray until grill has

completely cooled.

Clean grill often, preferably after each cookout. If a bristle

brush is used to clean any of the grill cooking surfaces,

ensure no loose bristles remain on cooking surfaces prior

to grilling. It is not recommended to clean cooking surfaces

while grill is hot.

If you notice grease or other hot material dripping from grill

onto valve, hose or regulator, turn off gas supply at once.

Determine the cause, correct it, then clean and i nspect

valve, hose and regulator before continuing. Perform a

leak test.

Keep ventilatio n o penings in cylinder enclosure (grill cart)

free and clear of debris.

Do not store objects or materials inside the grill cart

enclosure that would block the flow of combustion air to the

underside of either the control panel or the firebox bowl.

The regulator may make a humming or whistling noise

during operation. This will not affect safety or use of grill.

If you have a gri ll problem see the "Troubleshooting

Section".

If the regulator frosts, turn off grill and LP cylinder valve

immediately. This indicates a problem with the cylinder and

it should not be used on any product. Return to supplier!

• Putting out grease fires by closing the lid is not

possible. Grills are well ventilated for safety reasons.

• Do not use water on a grease fire. Personal injury may

result. If a grease fire develops, turn knobs and LP

cylinder off.

• Do not leave grill unattended while preheating or

burning off food residue on HI. If grill has not been

regularly cleaned, a grease fire can occur that may

dama

e the

roduct.

Ignitor Lighting the Grill

1. Read instructions before lighting your grill.

2. Open lid during lighting.

3. Open LP cylinder or natural gas valve.

4. Push any burner control knob in and turn the knob to the left

to “HI” position. Keep pressing the knob until the burner is

lit.

7

Page 8

5. If ignition does not occur in 5 seconds, turn the burner

control off, wait 5 minutes for gas to clear away, and repeat

the lighting procedure.

6. To light other burners, repeat step 4.

NOTE: If ignitor does not work, follow Match Lighting

instructions.

Turn controls and gas source or tank OFF when

not in use.

If ignition does not occur in 5 seconds, turn the burner

control off, wait 5 minutes, and repeat the lighting

procedure.

If the burner does not ignite with

the valve open, gas will continue to flow out of the

burner and could accidently ignite with risk of

injury.

Match-Lighting

Do not lean over grill while lighting.

1. Open lid during lighting.

2. Place match into match holder (hanging from si de of cart).

Light match, place into the firebox.

3. Push in and turn right knob to HIGH position. Be sure burner

lights and stays lit.

4. Light other burners by pushing knob in and turning to HI

position.

Burner Flame Check

•Remove cooking grates and heat diffusers. Light burners,

rotate knobs from HIGH to LOW. You should see a smaller

flame in LOW position than seen on HIGH. Perform burner

flame check on sideburner, also. Always check flam e prior to

each use.

Turning Grill Off

•Turn all knobs to position. Turn LP cylinder off by turning

hand-wheel clockwise to a full stop.

Ignitor Check

•Turn gas off at LP cylinder. Push the control knob in and

turn the knob to the left to “HI” position."Click" should be

heard and spark seen each time between collector box or

burner and electrode. See "Troubleshooting" if no click or

spark.

Valve Check

•Important: Make sure gas is off at LP cylinder before

checking valves. Knobs lock in OFF position. To check

valves, first push in knobs and release, knobs should spring

back. If knobs do not spring back, replace valve assembly

before using grill. Turn knobs to LOW position then turn back

to OFF position. Valves should turn smoothly.

Hose Check

•Before each use, check to see if hoses are cut or worn.

Replace damaged hoses before using grill. Use only identical

replacement part valve/hose/regulator as specified in the

Parts List of this Use and Care Guide.

General Grill Cleaning

•Do not mistake brown or black accumulatio n of grease and

smoke for paint. Interiors of gas grills are not painted at the

factory (and should never be painted). Apply a strong

solution of detergent and water or use a grill cleaner with

scrub brush on insides of grill lid and bottom. Rinse and allow

to completely air dry. Do not apply a caustic grill/oven

cleaner to painted surfaces.

• Plastic parts: Wash with warm soapy water and wipe dry.

Do not use citrisol, abrasive cleaners, degreasers or a

concentrated grill cleaner on plastic parts. Damage to and

failure of parts can result.

•Porcelain surfaces: Because of glass-like composition, most

residue can be wiped away with baking s oda/water solution or

specially formulated cleaner. Use nonabrasive scouring

powder for stubborn stains.

•Painted surfaces: Wash with mild detergent or nonabrasive

cleaner and warm soapy water. Wipe dry with a soft

nonabrasive cloth.

8

Page 9

•Stainless steel surfaces: To maintain your grill’s high quality

appearance, wash with mild detergent and w arm so apy water

and wipe dry with a soft cloth after each use. Baked-on

grease deposits may require the use of an abrasive plasti c

cleaning pad. Use only in direction of brushed finish to avoid

damage. Do not use abrasive pad on areas with graphics.

• Cooking surfaces: If a bristle brush is used to clean any of

the grill cooking surfaces, ensure no lo ose bristles remain on

cooking surfaces prior to grilling. It is not recommended to

clean cooking surfaces while grill is hot.

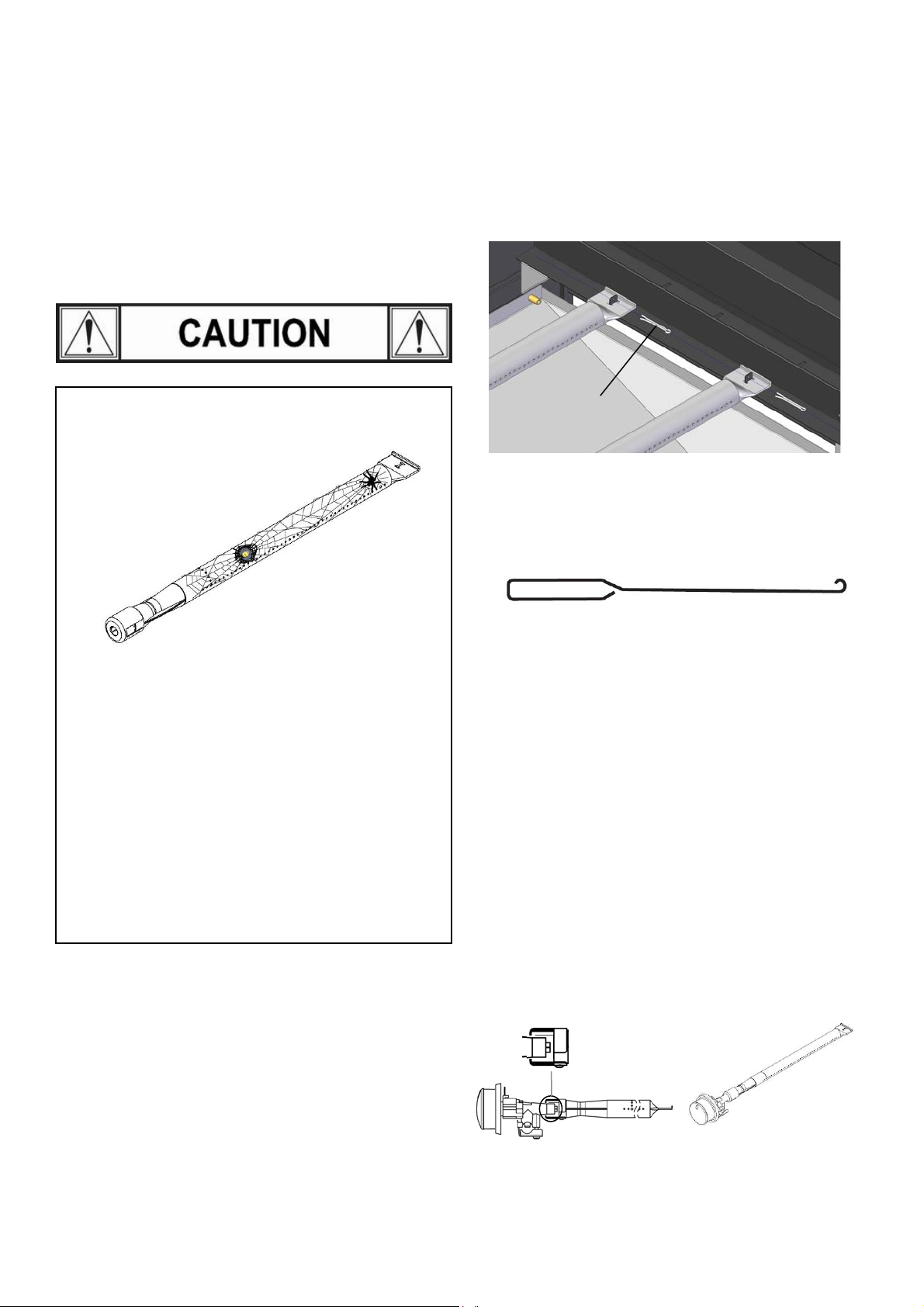

SPIDER ALERT!

SPIDER AND WEBS

INSIDE BURNER TUBE

If you notice that your grill is getting hard to light or that the

flame isn’t as strong as it should be, take the time to check

and clean the burner tubes.

Spiders or small insects have been known to create “flashback”

problems. The spiders spin webs, build nests and lay eggs in the

grill’s burner tubes obstructing the flow of gas to the burner. The

backed-up gas can ignite in the burner tube behind the control

panel. This is known as a flashback and it can damage your grill

and even cause injury.

To prevent flashbacks and ensure good performance the burner

and burner tube assembly should be removed from the grill and

cleaned before use whenever the grill has been idle for an

extended period.

Storing Your Grill

•Fold the two shelves.

•Clean cooking grates.

•Store in dry location.

•When LP cylinder is connected to grill, st ore outdoors in a

wellventilated space and out of reach of ch ildren.

•Cover grill if stored outdoors. Choose from a variety of grill

covers offered by manufacturer.

•Store grill indoors ONLY if LP cylinder is turned off and

disconnected, removed from grill and stored outdoors.

•When removing grill from storage, follow “Cleani ng the Burner

Assembly” instructions before starting grill.

Cleaning the Burner Assembly

Follow these instructions to clean and/ or replace parts of

burner assembly or if you have trouble igniting grill.

1. Turn gas off at control knobs and LP cylinder.

2. Remove cooking grates and heat diffusers.

3. Remove R pins from rear of burners.

4. Carefully lift each burner up and away from valve openings.

R pin

We suggest three ways to clean the burner tubes. Use the one

easiest for you.

(A) Bend a stiff wire (a light weight coat hanger works well)

into a small hook. Run the hook through eac h burner tube

several times.

(B) Use a narrow bottle brush with a flexible handle (do not

use a brass wire brush), run the brush through each burner

tube several times.

(C) Wear eye protection: Use an air hose to force air into

the burner tube and out the burner ports. Check each

port to make sure air comes out each hole.

5. Wire brush entire outer surface of burner to remove food

residue and dirt.

6. Clean any blocked ports with a stiff wire such as an open

paper clip.

7. Check burner for damage, due to normal wear and corrosion

some holes may become enlarged. If any large cracks or

holes are found replace burner.

VERY IMPORTANT: Burner tubes must reengage valve

openings.

Correct burner-to-valve engagement

9

Page 10

Indirect Cooking

Poultry and large cuts of meat cook slowly to perfection on the

grill by indirect heat. Place food over unlit bur ner(s); the heat

from lit burners circulates gently throughout the grill, cooking

meat or poultry without the touch of a direct flame.

This method greatly reduces flare-ups when cooking extra fatty

cuts because there is no direct flame to ig nite the fats and

juices that drip during cooking.

ON

OFF

OFF

1 Burner Cooking

Cook with direct or indirect heat.

Best for smaller meals or foods.

Consumes less fuel.

Indirect Cooking Instructions

• Always cook with the lid closed.

• Due to weather conditions, cooking times may vary.

During cold and windy conditions the temperature setting

may need to be increased to insure sufficient cooking

temperatures.

• Place food over unlit burner(s)

ON

OFF

ON

2 Burner Cooking

Great indirect cooking on low.

Produces slow, even heating.

Ideal for slow roasting and baking.

Food Safety

Food safety is a very important part of enjoying the outdoor

cooking experience. To keep food safe from harmful bacteria,

follow these four basic steps:

Clean: Wash hands, utensils, and surfaces with hot soap y

water before and after handling raw meat a nd poultry.

Separate: Separate raw meats and poultry from ready-to-eat

foods to avoid cross contamination. Use a clean platter and

utensils when removing cooked foods.

Cook: Cook meat and poultry thoroughly to kill bacteria. Use a

thermometer to ensure proper internal food temperatures.

Chill: Refrigerate prepared foods and leftovers promptly.

For more information call: USDA Meat and Poultry Hotline

at 1-800-535-4555 (In Washington, DC (202) 720-3333, 10:00

am-4:00 pm EST).

How To Tell If Meat Is Grilled Thoroughly

• Meat and poultry cooked on a grill often browns very fast on

the outside. Use a meat thermometer to be sure food has

reached a safe internal temperature, a nd cut into food to

check for visual signs of doneness.

• Whole poultry should reach 180° F; breasts, 170° F. Juices

should run clear and flesh should not be pink.

• Hamburgers made of any ground meat or poultry should

reach 160° F, and be brown in the middle with no pink juices.

Beef, veal and lamb steaks, roasts and chops can be cooked

to 145°F. All cuts of pork should reach 160° F.

• NEVER partially grill meat or poultry and finish cooking later.

Cook food completely to destroy harmful bacteria.

• When reheating takeout foods or fully cooked m eats like hot

dogs, grill to 165° F, or until steaming hot.

WARNING: To ensure that it is safe to eat, food must be

cooked to the minimum internal temperatures li sted in the table

below.

USDA* Recommended Safe Minimum Internal

Temperatures

Beef, Veal, Lamb and Pork – Whole Cuts** 145° F

Fish 145° F

Beef, Veal, Lamb and Pork – Ground 160° F

Egg Dishes 160° F

Turkey, Chicken & Duck – Whole, Pieces &

Ground

* United States Department of Agriculture

**Allow meat to rest three minutes before carving or

consuming.

165° F

10

Page 11

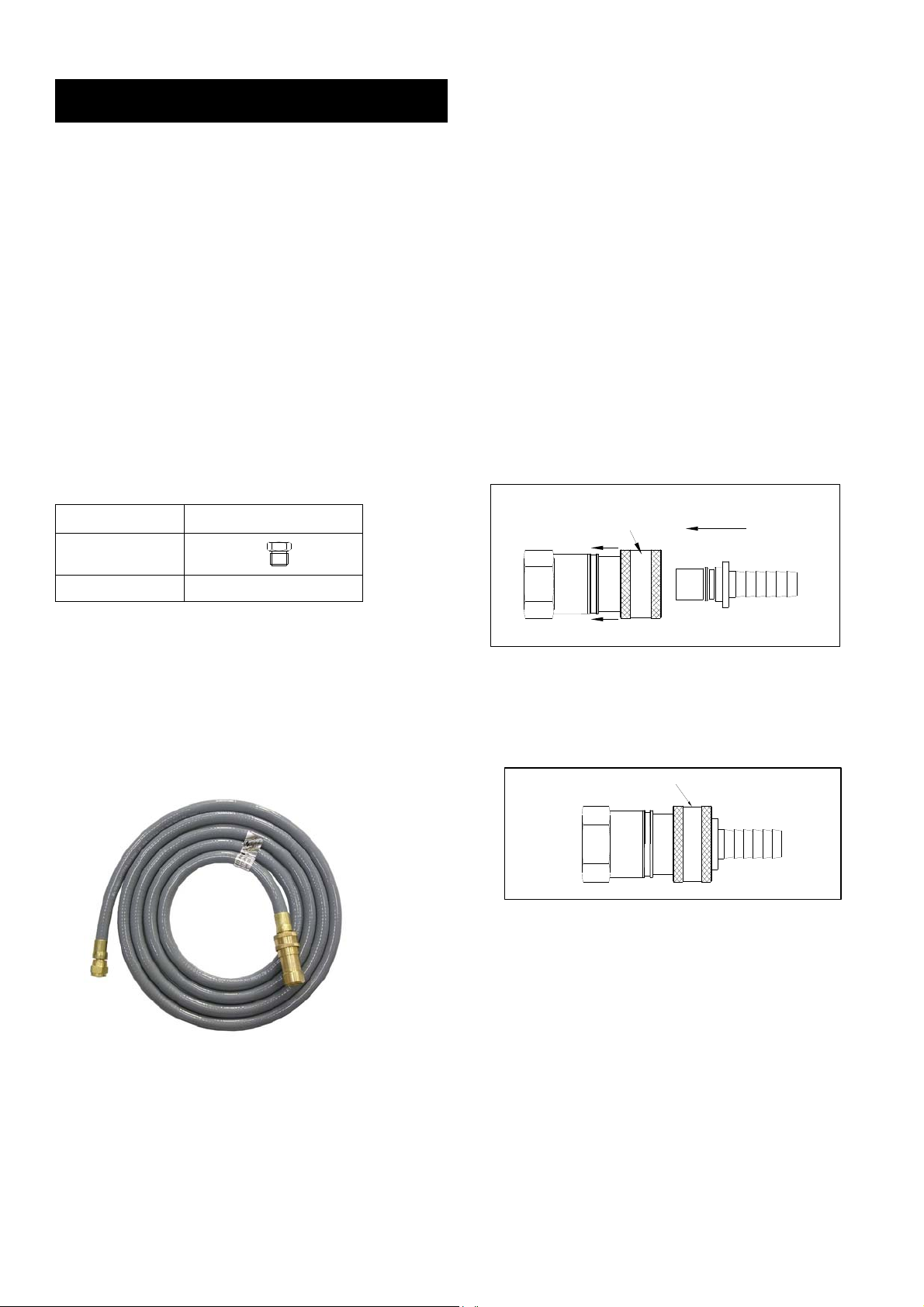

Natural Gas Conversion Kit

To purchase a Natural Gas Conversion Kit call Sears at

R

1-800-4-MY-HOME

○

Natural gas conversion kit

Kenmore Model # 10478

(Manufacturer Part No.: 2818-2T-KIT)

Your grill can be converted to natural gas with this

conversion kit by a qualified gas technician only. In order

to convert this grill the technician will need this

conversion kit.

The kit contains orifices for various grill models. Please

select the orifices as listed below and discard the rest.

Follow the conversion instruction provided with the kit.

Model Main Burner 1.37 mm

Natural Gas Connection Preparation:

1. Turn off gas supply, and then remove cap on gas

supply side.

2. Recommended: Install a shut-off valve on

gas supply side before installing the socket.

3. Socket should be installed by an authorized

technician in accordance with the national fuel gas

code (NFPA 54/ANSI223.1).

4. Before inserting plug, turn on gas supply and leak

test all connections including the stem of the shut-off

valve and the opening of the socket. For best results,

use an ammonia-free soap & water solution.

Operating Instructions:

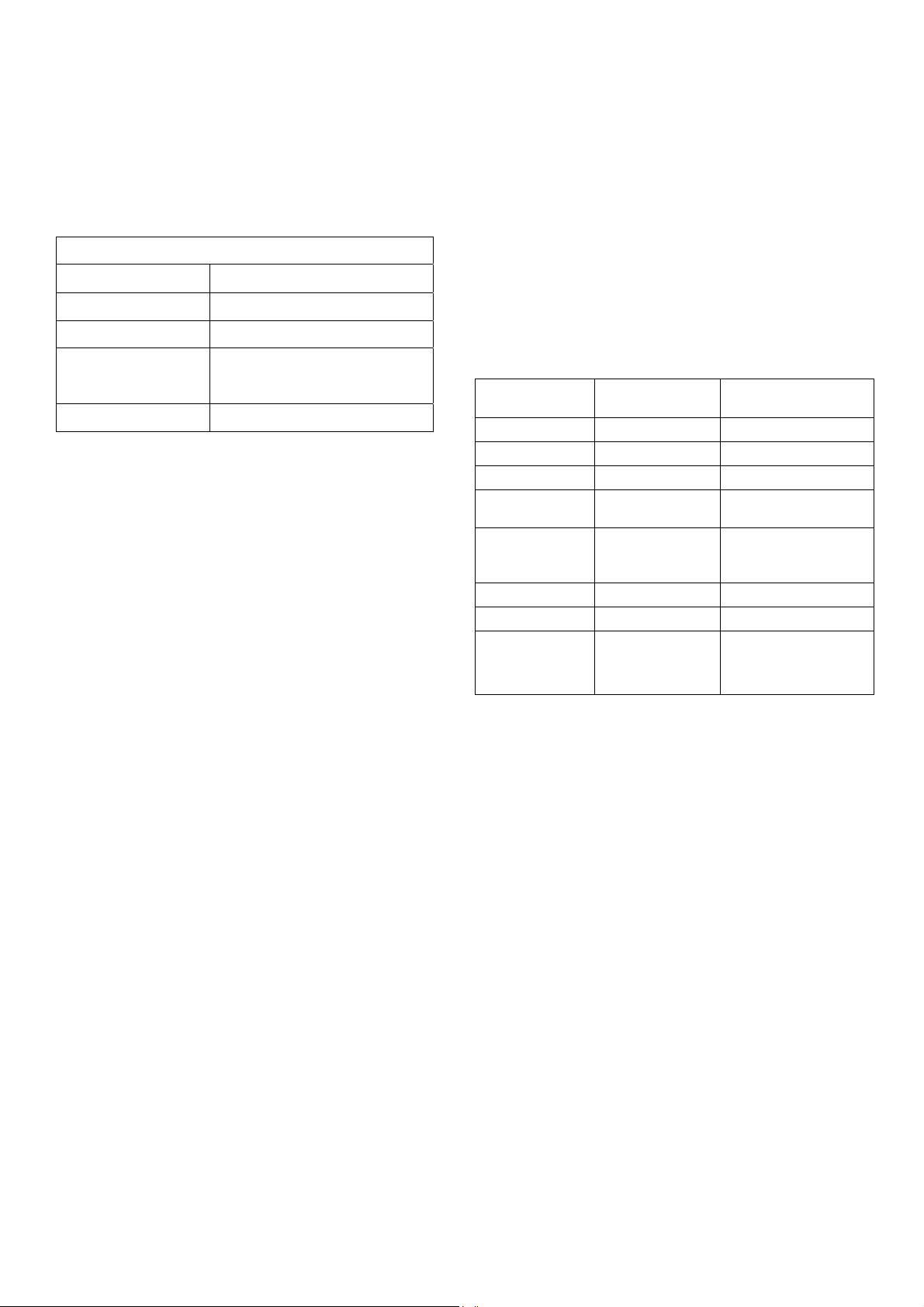

1. To connect, push back socket sleeve.

Socket

Sleeve

Plug

148.16154210 4

12 ft. extension hose with 3/8 in. ID (inner diameter)

If converting the grill to natural gas, the technician in

most cases will need this 12 ft. extension hose with 3/8"

ID (inner diameter), which is included in the natural gas

conversion kit.

2. Insert plug and release sleeve.

3. Push plug until sleeve snaps forward. (Gas will flow

automatically. Failure to connect plug properly to

socket will inhibit gas flow to the appliance.)

Socket

Sleeve

To disconnect

1. Pull Sleeve back. Pull plug out of socket. (Gas is

automatically shut off.)

2. Close shut-off valve or turn off gas supply, and

replace dust caps on socket and plug.

Gas Requirements

LP Gas

Now that your grill is converted to Natural Gas use, it is

set for 7-inch water column (WC) pressure, and cannot

be used with Propane Gas. The factory-supplied

regulator and hose must be used with a 20-lb. LP gas

tank.

11

Page 12

Natural Gas

If your grill is for Natural Gas, it is set for a 7-in. water

column (WC) and is for use with Natural Gas only. Gas

pressure is affected by gas line size and the length of

gas line run from house gas line. Follow the

recommendations in the chart below.

From House to Grill

Distance Tubing Size

Up to 25 ft. 3/8 in. diameter

26-50 ft. 1/2 in. diameter

2/3 of the run: 3/4 in. diameter

51-100 ft.

1/3 of the run :1/2 in. diameter

Over 101 ft. 3/4 in. diameter

CAUTION:

If low flames or burner problems are witnessed after

converting from LPG to NG, the natural gas lines may not

be large enough. Refer to the "From House to Grill" chart

on page 12 for natural gas supply line specifications.

Please contact a plumber to assure proper pressure at 7

in. water column.

Do not return your grill to the store.

Excess Flow Control and Low Heat

The propane regulator assembly incorporates an excess

flow device designed to supply the grill with sufficient gas

flow under normal conditions yet control excess gas flow.

Rapid changes in pressure can trigger the excess flow

device providing a low flame and low temperature. If the

tank valve is turned open to allow gas flow while a burner

valve is open, the surge of pressure will cause the device

to activate. The device will remain closed until the

pressure is equalized. This should occur within 5

seconds.

To ensure this does not cause difficulty in lighting the grill,

follow these instructions:

1. Make sure all burner valves are “OFF”.

2. Open the tank valve and wait 5 seconds.

3. Light the burners one at a time following the lighting

instructions.

Helpful Care and Maintenance Hints

Before grilling, pre-heat grill for 15 minutes on "HI" with

hood down. To avoid uncontrolled flare-ups or grease

fires, grill meats with hood open. Close hood if meats are

thick or weather is cold, or if you are using a rotisserie or

indirect cooking.

Always protect your hand with a pot holder or cooking

glove when coming into contact with a hot surface.

Hood up when grilling meats, especially chicken. Hood

down when indirect or rotisserie cooking.

NEVER leave your grill unattended while cooking.

After use, close hood, turn burners to HI for 15 min. for

self-cleaning, grease burn off.

Care and Maintenance Time Table Chart

Grill Item

Painted surface Twice yearly Car wax

Stainless surface Twice yearly Stainless cleaner

All grates After each use Burn off and wipe

Stainless grates 15 days

Porcelain grates 15 days

Burner heat tents 30 days Wire brush

Burners 90 days Wire brush

Burner box

interior

Frequency Based

on Normal Use

120 days

Cleaning Method

Wire brush/

Dishwasher safe

Scrub pad soapy water

/Dishwasher safe

Interior grill cleaning

products (available at

Sears)

12

Page 13

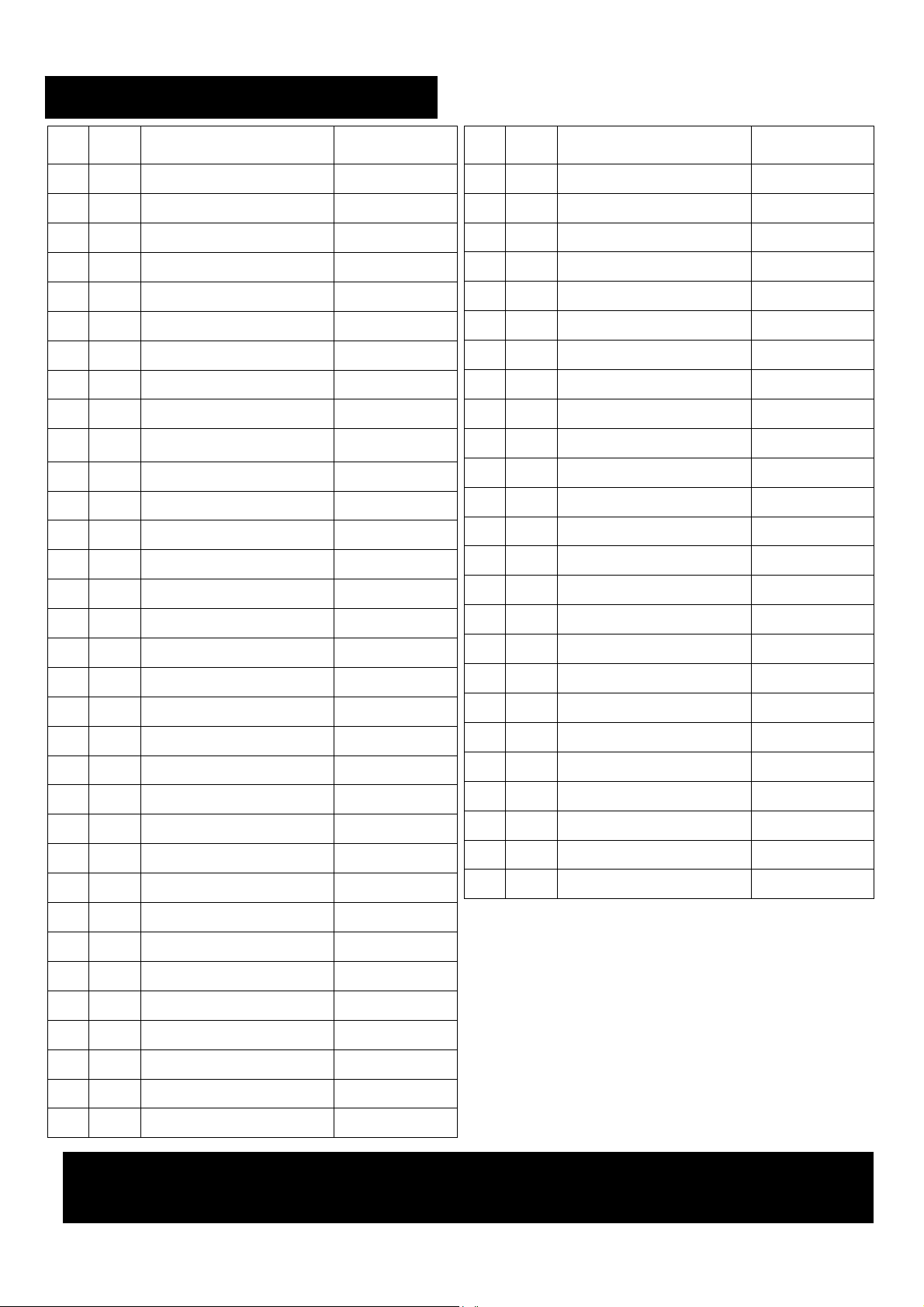

PARTS LIST

Key Qty Description

1 1 HOOD HANDLE 2818-2T-6200

2 2 HANDLE BASE RB2818C-00-4001

3 2 SCREW 1/4-20×5/8 in.

4 4 RUBBER GASKET 3219-8082

5 1 HOOD 2818-2T-6000

6 2 SCREW 5/16-18×3/4 in.

7 2 BUSHING 2818-2T-0001

8 2 FLANGE NUT 5/16-18

9 1 TEMPERATURE GAUGE 2818-2T-A301

10 1

11 1 NUT 5/16-18

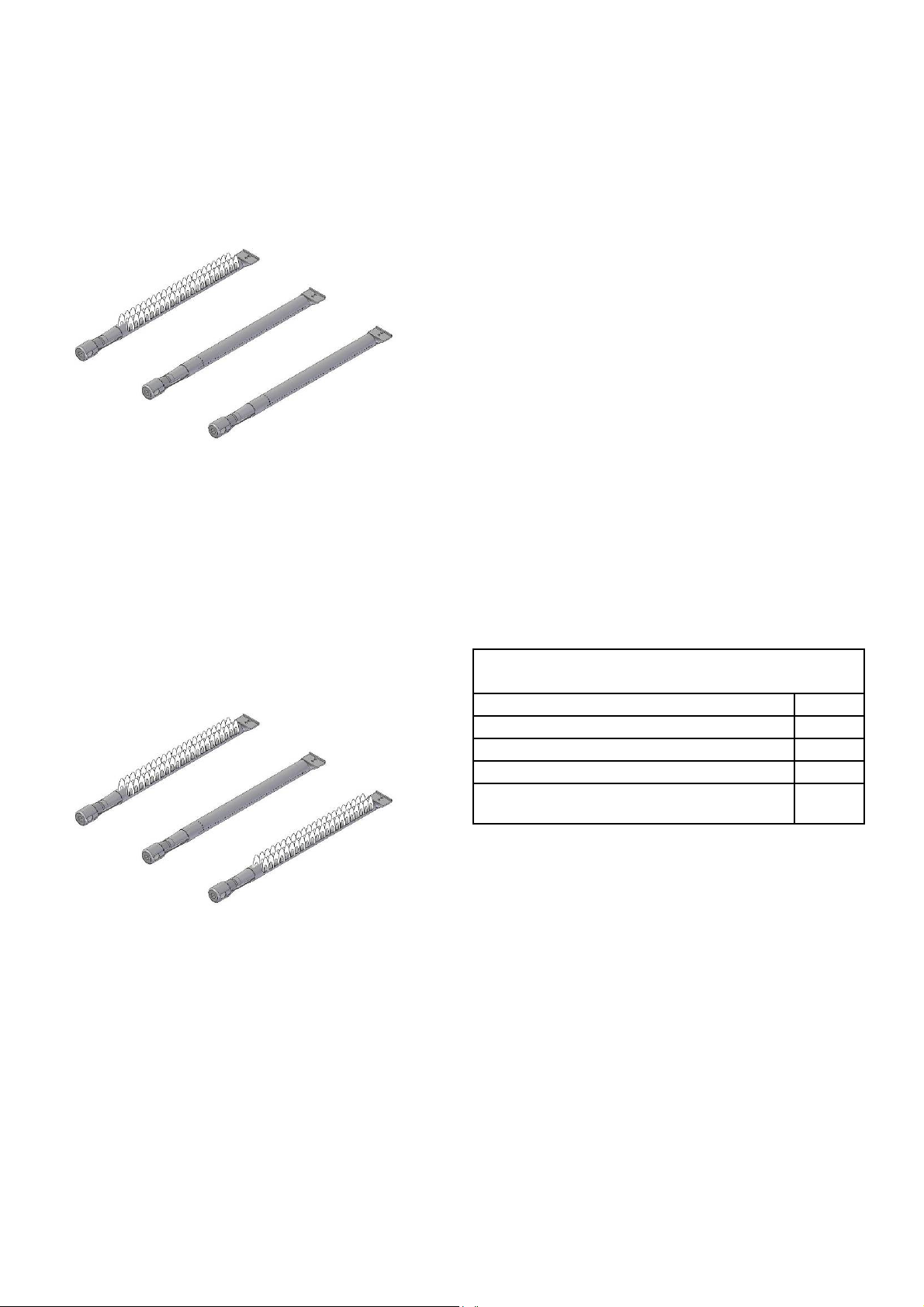

12 4 HEAT DIFFUSER 2818-2T-2007

13 2 COOKING GRIDS 2818-2T-2001

14 1 WARMING RACK 2818-2T-2002

15-1 1 IGNITION PIN ( MAIN BURNER ) 2818-2T-A500-4/1

15-2 1 IGNITION PIN ( MAIN BURNER ) 2818-2T-A500-4/2

15-3 1 IGNITION PIN ( MAIN BURNER ) 2818-2T-A500-4/3

15-4 1 IGNITION PIN ( MAIN BURNER ) 2818-2T-A500-4/4

16 4 PIN 1.6×30

17 4 MAIN BURNER SH3118B-2004

18 16 SCREW 5/32-32×3/8 in.

19 1 BURNER BOX 2818-2T-2000

20 1 WIND SHIELD 2818-2T-2004

21 1 RIGHT WING TABLE 2818-2T-5100

22 8 SCREW 1/4-20×3/4 in.

WASHER,TEMPERATURE

GAUGE

Manufacturer

Part #

2518SL-6002

Key Qty Description

31 1 RIGHT ANGLE BRACKET 2818-2T-1700

32 2 CASTER,LOCKING 2518-3-8007

33 2 CASTER 2518-3-8008

34 1 WING-HEAD SCREW 1/4-20UNC×2 in.

35 1 SCREW W/SHOULDER 5/32-32×3/8 in.

36 1 MATCH HOLDER 3019L-1710

37 1 DOOR(R) 2818-2T-8000

38 1 DOOR(L) 2818-2T-7000

39 1 BOTTOM PANEL ASSEMBLY 2818-2T-1100

40 31 SCREW 3/16-24×3/8 in.

41 1 LEFT ANGLE BRACKET 2818-2T-1600

42 3 MAGNET SH3118-1803

43 1 MAGNET HOUSING 2818-2T-1102

44 2 SCREW 5/32-32×3/8 in.

45 1 ELECTRICAL IGNITER 2818-2T-A600

46 1 IGNITER HOUSING 2818-2T-1302

47 1 LEFT PANEL ASSEMBLY 2818-2T-1300

48 1 DRIP TRAY SUPPORT 2818-2T-1500

49 1 DRIP TRAY 2818-2T-1001

50 4 KNOB E3518-00-3001

51 8 SCREW M4×8

52 4 BEZEL SH3118B-3004

53 4 SCREW 1/4-20×3/8 in.

54 1 CONTROL BOX 2818-2T-3000

55 1 LEFT WING TABLE 2818-2T-4100

Manufacturer

Part #

23 4 WING MECHANISM 2818-2T-A200

24 8 SCREW 3/16-24×5/8 in.

25 1 IGNITION SWITCH WIRE 2818-2T-A400

If you are missing hardware or have

damaged parts after unpacking grill, call

1-800-482-0131 for replacement.

26 1 MANIFOLD,MAIN BURNER 2818-2T-3200

27 1 LP GAS REGULATOR SH3118B-3003

28 1 REAR PANEL 2818-2T-1002

29 1 RIGHT PANEL ASSEMBLY 2818-2T-1400

30 1 BEAM 2818-2T-1200

NOTE: Some grill parts shown in the assembly steps may differ slightly in appearance from

those on your particular grill model. However, the method of assembly remains the same.

To order replacement parts after using grill,

call 1-800-4-MY-HOME

®

13

Page 14

PARTS DIAGRAM

7 8 10 11 12 13 14

9

6

5

4

3

2

1

55

54

53

40

15-1 15-2 15-3 15-4

16

17

18

19

18

20

21

22

52

51

50

49

48

47

46

45

44

43

42

41

40

39

23

24

25

26

27

28

29

30

38

31

32 33 34 35 36 37

14

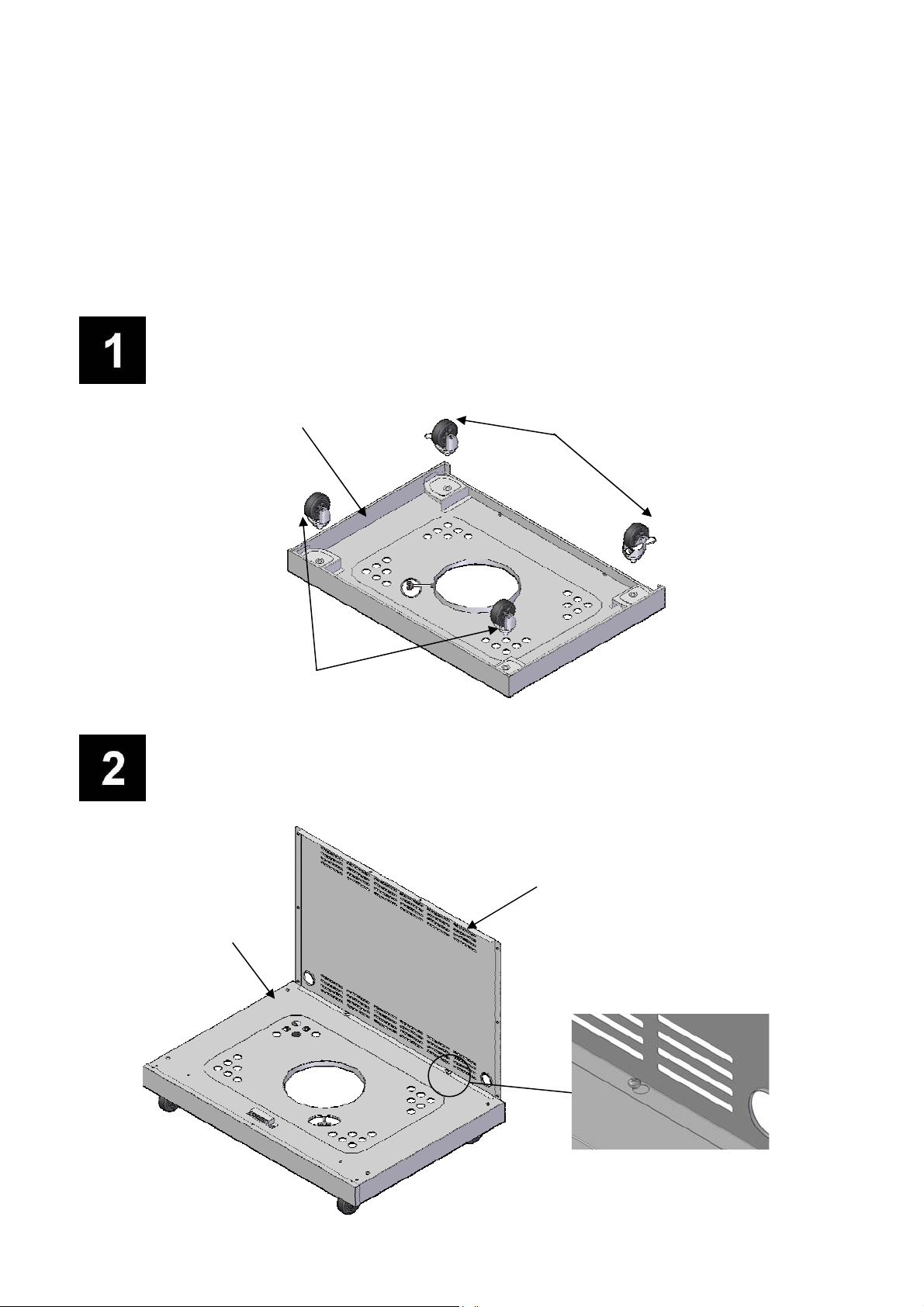

Page 15

UNPACKING

After removing all parts and hardware pack from the top of the shipping box, and when the only part showing is

the grill head, use a box cutting knife to slice down the sides of the box. Be careful of staples along shipping box

edges.

Remove the corner supports from the box and the styrofoam side pieces from the grill head. Allow grill head to

rest on cardboard until placing grill head on cart in Step 7.

Open grill lid and remove all packaged parts and packing material.

WARNING: Assemble the grill on a flat level surface. Compare the parts and hardware with the list and

diagrams. Do not attempt assembly if any part is missing or damaged.

Insert the casters into the holes of the bottom panel, and then tighten with wrench from the hardware

pack. When this process is completed, turn the bottom panel right side up. The two locking casters

should be at the back of the grill.

Bottom Panel

Locking Caster

Caster

Loosen the two screws at the back of the bottom panel 3 to 4 turns.

Place the holes in the base of the rear panel over the two loosened screws and slide the panel to the

left until it stops. Retighten the screws.

Rear panel

Bottom Panel

15

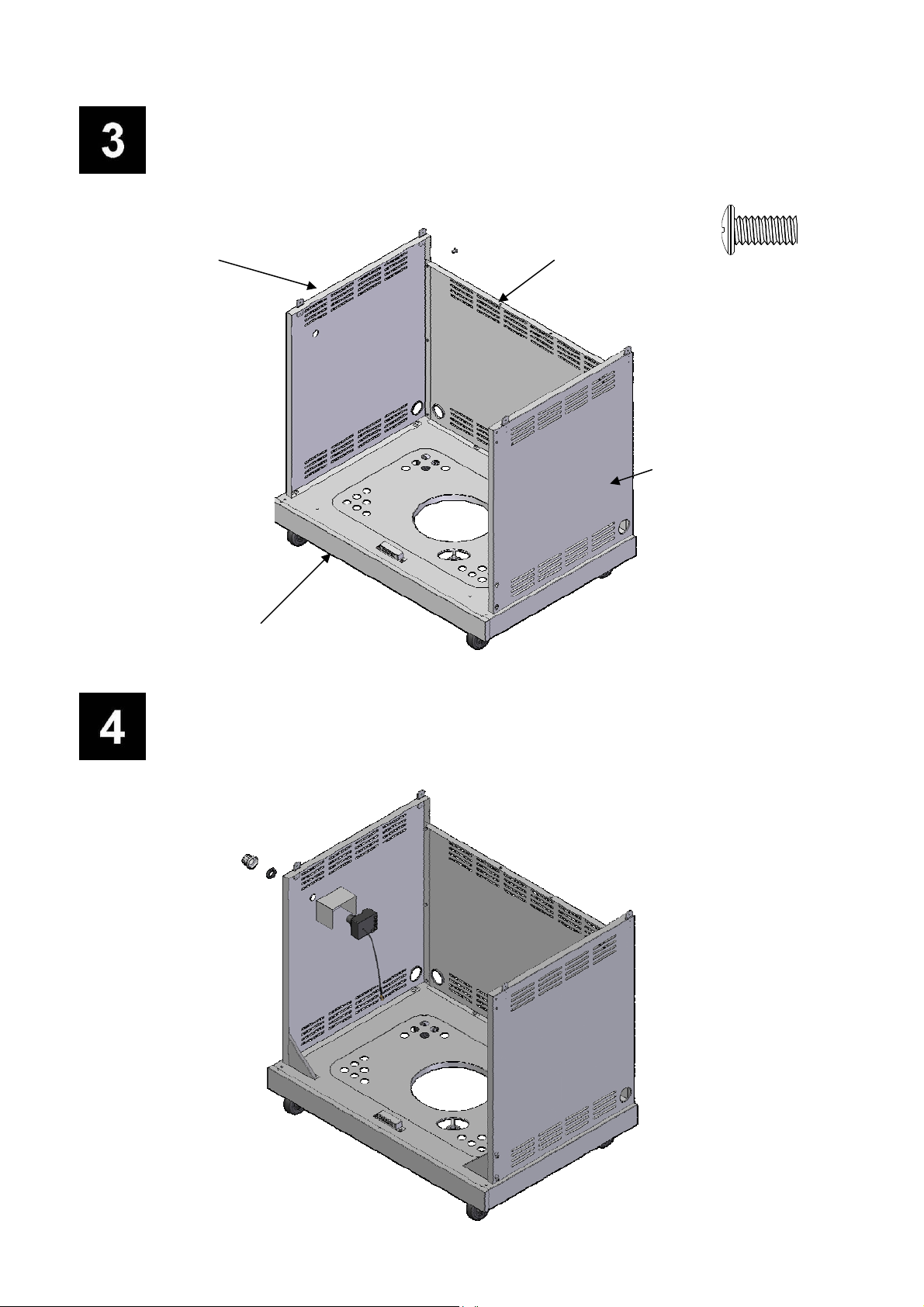

Page 16

Loosen the 4 screws at the corners of the bottom panel 3 to 4 turns.

Place the holes in the base of each side panel over the loosened screws and slide the panel to the

front until it stops. Retighten the screws.

Use six 3/16-24 x3/8 in. screws to fasten the rear panel to side panels.

Left Panel Rear Panel

3/16-24 x 3/8 in. Screw

Qty. 6

Right Panel

Bottom Panel

Remove the cap and nut from the electrical igniter. Use the nut to assemble the igniter and igniter

housing to the left panel as shown. Screw cap onto igniter.

16

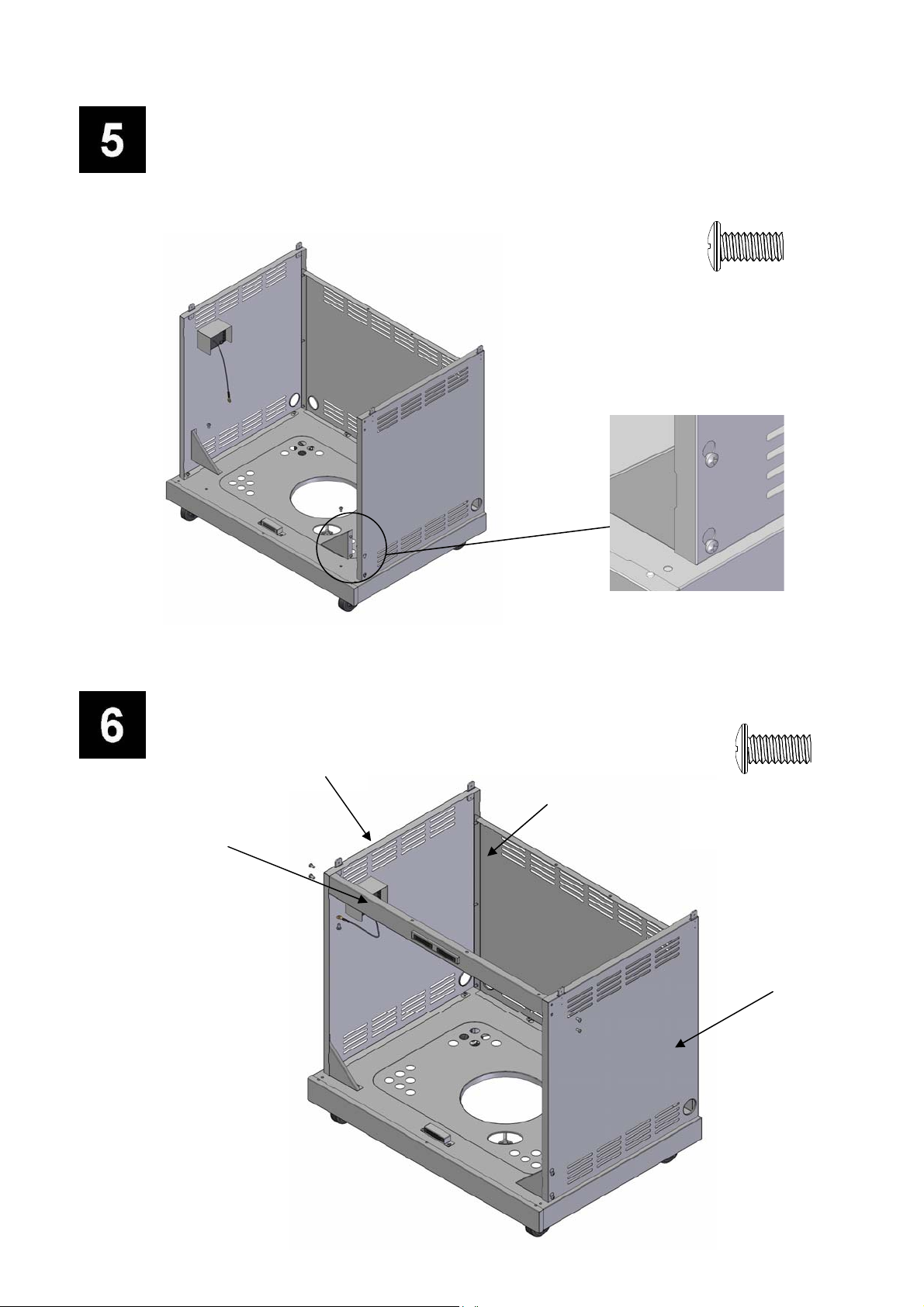

Page 17

Loosen the two screws in the right and left angle brackets 3 to 4 turns.

Insert the screws through the 2 holes at the base of each side panel and slide the bracket down until

it stops. Attach each bracket to the bottom panel with one 3/16-24 x 3/8 in. screw. Retighten the 4

loosened screws.

3/16-24 x 3/8 in. Screw

Qty. 2

Attach the beam to side panels with four 3/16-24 x 3/8 in. screws as shown.

Beam

Left Panel

Rear Panel

3/16-24 x 3/8 in. Screw

Qty. 4

Right Panel

17

Page 18

Attach the drip tray support to the beam and rear panel with four 3/16-24 x 3/8 in. screws as shown.

Note: Tabs at front attach beneath beam upper ledge.

Drip tray support

Left Panel

Rear Panel

3/16-24 x 3/8 in. Screw

Qty. 4

Right Panel

Beam

Grill Head Assembly

First, lock the two rear casters of the grill cart.

Locate the gas pressure regulator and igniter wires under the grill head control panel. Carefully cut

the tie wrap(s) from the regulator hose. With the aid of an assistant, lift and place the grill head onto

the cart, making sure that the regulator hose and igniter wires hang down into the cart. Align the

corner holes at the base of the grill head with the holes in the corner tabs of the cart. Attach the grill

head to the cart with four 3/16-24 x 3/8 in. screws.

WARNING: Do not lift grill head from sides. Grasp the grill head by the front control panel and

rear panel to avoid pinching fingers when lowering grill head onto cart.

3/16-24 x 3/8 in. Screw

Qty. 4

18

Page 19

Connect the four burner ignition wires to the four sockets on the right side of the igniter. Connect the

remaining wire to the remaining open socket.

Place the ground wire through the slots on the side panel as shown below. Loosen one control panel

screw, install the ground wire onto the screw, and retighten it to make a good connection.

Ground Wire

Ground Wire

Install the doors

For each door, insert the bottom hinge pin into the hole in the bottom panel. Push up the top hinge

pin located under the bottom of control panel to get it into the hinge hole in the door. If necessary,

loosen screws on bottom panel magnet housing and adjust and retighten so that doors close

securely.

19

Page 20

Install two wing mechanisms to each wing table with four screws as shown.

3/16-24 x 5/8 in. Screw

Qty. 8

Install Wing Tables

Loosen the 2 screws (as shown) on each side of grill head 4 to 6 turns.

Slide the slot in each wing mechanism bracket over a loosened screw. Insert one 1/4-20 x 3/4 in.

screw through hole in each wing mechanism bracket and tighten to grill head. Note: Attach each wing

table so that rounded edge faces front. Raise each table until it locks into position as shown. Tighten

all four previously loosened screws.

Note: Check wing tables to see if level. If not, add washers from hardware pack beneath screws as

needed.

Slide slots over screws

1/4-20 x 3/4 in. Screw

Qty. 4

Loosen the two screws

20

Page 21

Wing Table Operation.

To lower wing table, press up on the front and back wing mechanism release levers.

To raise wing table, lift table up until wing mechanisms lock into place.

Release Lever Here

Release Lever Here

Slide the drip tray between the drip tray supports.

To lower wing table, press up on the front and back wing mechanism release levers.

To raise wing table, lift table up until wing mechanisms lock into place.

21

Page 22

Position the four heat diffusers, two cooking grids and the warming rack into place.

Note: The diffuser edges fit into slots at front and back of burner box.

Remove battery cap and insert AA battery with positive pole facing out. Replace cap.

LP Tank Installation

Put the tank into the tank support hole with tank collar opening facing to the right as shown. Connect

the regulator to the tank (see page 5 of Use and Care section).

Lock the tank with the wing-head screw as shown.

Wing-head screw

22

Page 23

Conversion Instructions for 16154

Main Burner Conversion

1. Remove the R pins at the back of main

burners to detach burners from bracket.

Lift back of main burners while sliding

burners out of firebox, disengaging main

burners from valves. (Fig. 1)

2. Insert the provided orifice removal tool (B)

into burner openings and unscrew orifices

from ends of valves. (Fig. 2)

R pin

Back of Firebox

Orifice

B

Fig. 1

Fig. 2

23

Page 24

3. Put the new orifice into the orifice

removal tool (B), and then insert the tool

into the burner opening and tighten the new

orifice into the valve.

Repeat this step for all four burners.

Make sure you are using the correct

orifice, which is marked “1.37”. (Fig. 3)

1.37

B

4. Rotate the air shutter opening from the

LP setting to the NG setting.

Air shutter opening to adjust

LP: 1/4" open

NG: 1/6" to 1/8" open

(Fig. 4)

Natural Gas Hose Connection

Remove the LP gas hose and regulator using a wrench, and attach the natural gas

hose in it's place. (Fig. 5)

Fig. 3

Fig. 4

LP gas hose and regulator

NG Hose

Fig. 5

24

Page 25

Adjust valve control screw

1. Pull all the knobs off of valve stems. Adjust

the screw in the valve hole using the flathead

screwdriver (C). Turn screws 6 complete turns

counterclockwise.

(Fig. 6)

Valve hole Fig. 6

2. Press all the knobs back onto valve stems.

After all the conversions are complete, return heat diffusers to firebox, followed by the grates

and warming rack.

25

Page 26

Troubleshooting

Problem Possible Cause Corrective Action

Grill will not light

1. The ignition wire came off

the electrical igniter.

2. The distance between the

ignition pin and the burneris

greater than 0.1-0.2 inch.

3. The ignition wire is broken.

4. The battery has died.

5. The battery is in the wrong

polarity.

6. The electrode tip does not

produce sparks at the

burner port.

7. No gas supplied.

8. Air shutter opening is too

big.

1. Reconnect the ignition wire to the

electrical igniter.

2. Loosen the ignition pin and adjust the

distance, then fasten it again.

3. Call customer service for are

placement ignition wire.

4. Install a new AA battery.

5. Change the battery polarity.

6. Reinstall the electrode.

7. Turn on the regulator valve.

8. Loosen the air shutter and adjust the

opening to a smaller size.

Burner flame is

yellow and gas

odor can be

smelled

Excessive flare-up

Burner blows out

1. The air shutter opening is

not properly set.

2. Spiders or insects block the

air shutter.

3. Gas leaks

1. Grilling fatty meats while

knobs on “HIGH”.

2. Spray water on gas flames.

3. Hood closed when grilling.

1. LP tank is empty.

2. Burner is not aligned with

the control valve.

3. Gas supply is not sufficient.

1. Loosen the air shutter and adjust

theopening to have blue flames.

1/4 in. opening for LPG.

1/8 in. or less opening for NG.

2. Clean blockages.

3. Check for the source of gas leaks.

1. Grill fatty meats when the grids are

cold while the knobs are on the

“LOW” setting. Move the meats to the

warming rack if flare up continues

until flame settles down.

2. Never spray water on gas flames.

3. Hood up when grilling.

1. Refill the LP Tank.

2. Install the burner correctly.

3. Check the gas supply hose and make

sure there are no leaks and no knots.

26

Page 27

Problem Possible Cause Corrective Action

Low heat with the

knob in “HI”

position

Low heat, natural

gas

1. Low heat is found in natural

gas models.

2. Ports are blocked.

3. LP tank has run out.

Gas pressure is significantly

affected by gas line and

length of gas line from house

gas line.

1. This model is set for 7 in. natural gas

usage. Please check your natural gas

supply system to have correct gas

pressure.

Regulator is not needed for NG

model.

Check the orifice if you installed NG

nozzles.

2. Clear ports of any obstructions.

3. Refill the LP tank.

Check your gas line and make

corrections by following the chart below.

From House to Grill

Distance Tubing Size

Up to 25 ft. 3/8 in. diameter

26 -50 ft. 1/2 in. diameter

51 -100 ft.

2/3 in. of run 3/4 in.

1/3 in. of run 1/2 in.

Low heat,

LP gas

Sudden drop in

gas flow or low

flame

The propane regulator

assembly incorporates an

excess flow device designed

to supply the grill with

sufficient gas flow. Rapid

changes in pressure can

trigger the excess flow device,

providing a low flame and low

temperature.

1. Out of gas.

2. Excess flow valve tripped.

3. Vapor lock at coupling

nut/LP cylinder

connection.

Please follow these instructions:

1. Make sure all burners are “OFF”.

2. Open the tank valve and wait 5

minutes.

3. Light the burner one at a time

following the lighting instructions

listed on the door liner

1. Check for gas in LP cylinder.

2. Turn off knobs, wait 30 seconds and

light grill. If flames are still low, turn

off knobs and LP cylinder valve.

Disconnect regulator. Reconnect

regulator and leak test. Turn on LP

cylinder valve, wait 30 seconds and

then light grill.

3. Turn off knobs and LP cylinder valve.

Disconnect coupling nut from

cylinder. Reconnect and retry.

27

Page 28

Si detecta olor a gas:

1. Cierre el gas que va a la unidad.

2. Extinga cualquier llama expuesta.

3. Abra la tapa.

4. Si el olor continúa, manténgase alejado de

la unidad y llame de inmediato a la

compañía que le suministra el gas o al

departamento de bomberos local.

1. No almacene ni utilice gasolina ni otros

líquidos o vapores inflamables cerca de

esta ni de ninguna otra unidad.

2. No deberá almacenar cerca de la parrilla ni

de ninguna otra unidad un cilindro de LP

que no esté conectado para ser utilizado.

PROPOSICION 65 DEL ESTADO DE CALIFORNIA

En el estado de California se sabe que los subproductos

de la combustión, que se producen al usar este

producto, También produce productos de combustión

cuando se utiliza. Contienen substancias químicas que

causan cáncer, defectos congénitos u otras lesiones al

aparato reproductor.

Lávese las manos después de manipular este.

Llame al Centro de Servicio de Parrillas para obtener

ayuda o repuestos

Si tiene dudas o necesita asistencia durante el

ensamblaje, llame al 1-800-482-0131. Hablará con un

representante del fabricante de la parrilla, no con un

empleado de Sears. Para pedir piezas nuevas llame a

Sears al 1-800-4-MY-HOME.

Registro del producto

IMPORTANTE: Llene la información sobre el registro

del producto que aparece a continuación.

№ del modelo: 148.16154210

№ de serie:

Refiérase a la etiqueta de clasificación de la

parrilla para el número de serie.

Fecha de compra:

Para uso residencial únicamente. No utilice

para cocción comercial.

Precauciones de seguridad para la instalación

• Utilice la parrilla, como la compró , sólo con gas LP (propano) y

el ensamble de regulador/válvula que se sumin istra. Deberá

comprar un kit de conversión para uso con ga s n atural.

• La instalación de la parrilla deberá conformarse con la

normativa local, o en ausencia de esta , con la Normativa

Nacional para Combustible de Gas, ANSI Z223.1/ NFPA 54,

Normativa para instalación de gas natural y propano , CSA

B149.1, o la Normativa para almacenaje y manejo de

propano, B149.2, o la Norma para veh í culos recreacionales,

ANSI A 119.2/NFPA 1192, y CSA Z240 Serie RV, Normativa

para vehículos recreacionales, según sea aplicable.

• Todos los accesorios eléctricos (tales como el asador) deberán

estar conectados a tierra de conformidad con las normativas

locales o con la Normativa Nacional sobre Electricidad, ANSI /

NFPA 70 o la Normativa Canadiense de Electricidad, CSA

C22.1. Conserve los cables eléctricos y/o las mangueras de

suministro de combustible alejadas de las superficies calientes.

• Esta parrilla tiene certificación de seguridad para uso en

Estados Unidos y/o Canadá únicamente. No modifique

para utilizar en cualquier otra ubicaci ón. La modificación

constituirá un riesgo a la seguridad.

Símbolos de seguridad

Los símbolos y recuadros que aparecen a c ontinuación

explicar lo que cada enunciado signific a. Lea y observe

todos los mensajes que se encuentran a trav és del manual.

PELIGRO: Indica una situación de peligro

inminente que, de no evitarse, resultará en

muerte o lesiones graves.

ADVERTENCIA: Indica una situación de peligro

potencial que, de no evitarse, podría resultar en

muerte o lesiones graves.

ADVERTENCIA: Indica una situación de peligro

potencial que, de no evitarse, podría resultar en

muerte o lesiones graves.

© 2012 KCD IP, LLC

28

Page 29

ÍNDICE

Para su seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . 28

Centro de Servicio para la parrilla . . . . . . . . .. . . . . . . . . . . 28

Información de registro del producto. . . . . . . . . . . . . . . . . . 28

Símbolos de seguridad. . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Se aplican algunas limitaciones y exclusiones.

Para obtener los precios y más información llame al

1-800-827-6655.

Servicio de instalación Sears

Para la instalación profesional de electrodomésticos Sears,

abridores de puertas de garaje, calenta dores de agua y

cualquier otro artículo grande en EE.UU., lla me al

1-800-4-MY-HOME

®

Precauciones de seguridad para la instalación. . . . . .. . .. . 28

Garantía de la parrilla Kenmore . . . . . . . . . . . . .. . ..... . . . .29

Uso y cuidado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-36

Caja de conversión a gas natural. . . . . . . . . . . . . . . . . . . ...37

Notas . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .. ....37

Lista de piezas . . . . . . . . . . . . . . . . .. . . . . . . .. . . . . . . ... . 39

Diagrama de piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . 40

Ensamblaje . . . . . . . . . . . . . . . . .. . . . . . . . . . .. .. . . .... 41-48

Instrucciones de conversión para 16154 . . . . . .. .. . . .... 49-51

Solución de problemas. . . . . . . . . . . . . . . . . .. . . . ... . . 52-53

Acuerdos de protección para reparación

Felicitaciones por su compra inteligente. S u nu ev o prod uct o

Kenmore

funcionamiento confiable. Pero, como cualquier otro producto,

puede que requiera reparaciones de c uando en cuando. Es allí

cuando tener un Acuerdo de protección para reparación puede

ahorrarle dinero y molestias.

Adquiera un Acuerdo de protección de reparación ahora y

protéjase de molestias y gastos imprevistos.

He aquí lo que el acuerdo de protección para reparación incluye:

□ Servicio experto por parte de nuestros 10.000

□ Servicio ilimitado sin cargo para las piezas y mano de

□ Reemplazo del producto hasta $1500 si el producto

□ Descuento del 25% del precio regular del servici o y l as

□ Ayuda telefónica rápida – la llamamos Resolución

Rápida – apoyo telefónico de un repr esentante Sears. Piense

en nosotros como un manual de servicio parlante.

Una vez que haya adquirido el Acuerdo de Protección para

repara- ción, una simple llamada telefónica es todo lo que

necesita para programar el servicio. Puede llamar en cualquier

momento, de día o de noche, o programar una cita de servicio a

través de Internet.

El Acuerdo de Protección para reparación es una compra sin

riesgos. Si cancela por cualquier razón dur ante el período de

garantía del producto, le proporcionaremos un reembolso

completo. O un reembolso prorrateado en c ualquier momento

después de que venza el período de garantía del producto.

¡Adquiera su Acuerdo de Protección para Re paración hoy

mismo!

®

está diseñado y fabricado para brindarle años de

especialistas profesionales de reparaciones.

obra de todas las reparaciones amparadas

amparado no puede arreglarse

piezas relacionadas instaladas no amparadas por el

acuerdo; también, 25% de descuento sobre el precio

regular de las revisiones preventivas de mantenimiento

GARANTÍA

Garantía total Kenmore

Si esta parrilla presenta una falla originada por un defecto de

material o mano de obra, dentro de un año a partir de la

fecha de compra, llame al 1-800-4-MY- HOME® para

obtener reparación gratis (o reemplazo si no fuese posible

efectuar la reparación).

Garantía limitada en los quemadores

Durante diez años a partir de la fecha de co mpra, cualquier

quemador de acero inoxidable qu e se oxide completamente

será reemplazado sin costo. Después de l primer año a partir

de la fecha de compra, usted paga por la mano de obra si

desea que se lo instalen.

Toda la cobertura de garantía excluye las baterías del

encendedor y la pérdida de pintura de las partes de la

parrilla, la decoloración o el óxido, los cu ales son partes

fungibles que pueden gastarse con el uso n ormal dentro del

período de garantía, o son situaciones que podrían

producirse por el uso normal, accidente o mantenimiento

inadecuado.

Toda la cobertura de garantía queda anulad a si la parrilla se

utiliza para fines comerciales o en alquil er.

Toda la cobertura de garantía aplica únicamente si la parrilla

se utiliza en Estados Unidos.

Esta garantía le otorga derechos legales específi cos y es

posible que usted goce de otros derechos que varían según

el estado.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

29

Page 30

USO Y CUIDADO

`

• NUNCA guarde un cilindro de repuesto de LP debajo

ni cerca de la parrilla ni en un área encerrada

• Nunca llene un cilindro a más del 80% de su capacidad.

• Si la información de los dos puntos anteriores no

se sigue exactamente, puede ocurrir un incendio

que ocasione la muerte o lesiones graves.

• Un cilindro que se haya llenado excesivamente o

inadecuadamente almacenado es un peligro debido

a la posibilidad de que la válvula de seguridad para

alivio de la presión libere gas. Esto podría ocasionar

un incendio intenso con riesgo de daños a la

propiedad, lesiones graves o la muerte.

• Si ve, huele o escucha gas escapando, aléjese

inmediatamente del cilindro de LP y de la parrilla y

llame al departamento de bomberos.

Remoción del tanque de LP, transporte y almacenaje

• Cierre (gire a OFF) todas las perillas de control y la válvula del

tanque de LP. Gire la tuerca de acople en el sentido antihorario

manualmente solamente – no utilice herramientas para

desconectar. Levante el cable del tanque de de LP de la anilla

del tanque LP, luego levante el tanque y sáquelo del soporte.

Instale la tapa de seguridad en la válvula del tanque de LP.

Siempre utilice la tapa y la banda que se suministra con la

válvula.

No utilizar la tapa de seguridad como se indica puede ocasionar lesiones personales graves y/o daño a la propiedad.

Válvula del

tanque de LP

• Un tanque de LP desconectado para almacenar o

transportar deberá tener colocada la tapa de seguridad

Tapa de seguridad

Banda retenedora

(como se ilustra). No almacene un tanque de LP en espacios

cerrados tales como un puesto de estacionamiento, garaje,

porche, patio cubierto u otro edificio. Nunca deje un tanque

de LP dentro de un vehículo que pueda recal entarse con el

sol.

• No guarde un tanque de LP en un área donde jueguen los niños.

Cilindro de LP

• El cilindro de LP utilizado con su parrilla deberá cumplir

con los siguientes requisitos:

• Utilice los cilindros de LP con estas medidas requeridas: 12"

(30,5 cm) (diámetro) x 18" (45,7 cm) (alto) con 20 lb. (9, 1 kg)

de capacidad máxima.

• Los cilindros de LP deberán estar fabricados y marcados de

acuerdo con las especificaciones para cilindros LP del

Departamento de Transporte de EE.UU. (DOT) o para

Canadá, CAN/CSA-B339, cilindros, esferas y tub os p ara

transporte de mercancías peligrosas. Transport C anada (TC).

Refiérase al anillo del cilindro LP para las marcas.

• La válvula del cilindro LP deberá tener:

• Salida tipo 1 compatible con el regulador o la parrill a.

• Válvula de alivio de la presión.

• Dispositivo de protección contra el sobrellenado con

clasificación UL (OPD). Esta característica OPD de segurida d

se identifica por una rueda manual triangular única. Utilice

sólo los cilindros LP equipados con este tipo de válvula.

• El cilindro LP deberá estar acondicionado para salida de vapor e

incluir un anillo para proteger la válvula LP del cilindro. Siempre

conserve los cilindros LP en posición vertical durante el uso,

tránsito o almacenaje.

Cilindro de LP en posición vertical para la eliminación del vapor

GLP (Gas licuado de petróleo)

• El GLP no es tóxico, es inodoro e incoloro cuando se produce.

Para su seguridad, se le ha dado un olor al GLP (similar al de la

col podrida) para que pueda olerlo.

• El GLP es altamente inflamable y puede encenderse

inesperadamente al mezclarse con el aire.

Llenado del cilindro LP

• Utilice sólo distribuidores autorizados y experimentados.

• El distribuidor LP deberá purgar el cilindro nuevo antes de llenarlo.

• El distribuidor NUNCA deberá llenar el cilindro LP más del 80%

del volumen del cilindro LP. El volumen de propano en el cilindro

variará con la temperatura.

• Un regulador con escarcha indicará que está sobrellenado. Cierre

inmediatamente la válvula del cilindro LP y llame al distribuidor de

gas LP local para asistencia.

• No libere gas de propano líquido (LP) en la atmósfera. Esta es una

práctica peligrosa.

• Para retirar el gas del cilindro LP, contacte a un distribuidor LP o

llame a los bomberos locales para obtener asistencia. Revise el

directorio telefónico bajo “Compañías de Gas” para el distribuidor de

LP certificado más cercano.

Rueda manual OPD

30

Page 31

q

Intercambio del tanque LP

• Muchos distribuidores que venden parrillas ofre cen la opción de

reemplazar su tanque vacío de LP a través de un servicio de

intercambio. Utilice sólo las empresas de intercambio con reputación que inspeccionan, llenan con precisión, prueban y

certifican sus cilindros. Intercambie su tanque sólo por un

tanque equipado con la característica de seguridad OPD

según se describe en la sección "Tanque LP" de este

manual.

• Siempre conserve los tanques LP nuevos e intercambiados

en posición vertical durante el uso, trans porte o almacenaje.

• Haga la prueba de fugas en los tanques LP

intercambiados ANTES de conectarlo a la parrilla.

Prueba de fuga del tanque LP

Para su seguridad

• La prueba de fuga deberá repetirse cada vez que se

intercambia o se rellena un tanque de LP.

• No fume durante la prueba de fugas.

• No utilice una llama expuesta para revisar las fugas de gas.

• La parrilla deberá probarse en bus ca de fugas en exteriores,

en un área bien ventilada, alejada de las fuentes de ignición

tales como los aparatos de encendido a gas o eléctrico.

Durante la prueba de fugas, mantenga la parrilla alejada de

las llamas expuestas o chispas.

• Utilice una brocha limpia y una solución de 50/50 detergente

suave y agua. Aplique la solución jabonosa en las áreas que

indican las flechas de la figura. Las fugas s e identifican

mediante burbujas crecientes.

Si aparecen burbujas “creciendo” no utilice ni mueva

el tanque de LP. ¡Contacte un distribuidor de gas LP o

a los bomberos!

No utilice agentes limpiadores domésticos. Podrían causar

daños a los componentes y tuberías de gas

(válvula/manguera/regulador).

Cómo conectar el regulador al tanque de LP

1. El tanque de LP deberá estar adecuadamente fijado a la

parrilla. (Refiérase a la sección de ensamblaj e).

2. Gire todas las perillas de control a la posición OFF.

3. Coloque el tanque de LP en la posición OFF girando la rueda

manual OPD en sentido horario hasta que se detenga totalmente.

4. Retire la tapa protectora de la válvula del tanque LP.

Siempre utilice la tapa y la banda que se s uministran con la

válvula.

Manivela OPD

Salida tipo 1 con hilo

Válvula de descarga

de seguridad

exterior

Correa y capuchón

No inserte un tapón de transporte

POL (pieza plástica con roscas

externas) en la salida tipo 1 de la

válvula del tanque. Anulará la

función de la válvula de seguridad.

5. Sostenga el regulador e inserte el empalme en la válvula del

tanque de LP. Apriete a mano la tuerca de acople,

sosteniendo el regulador en línea recta con la válvula del

tanque de LP a objeto de no dañar la rosca.

El empalme tiene que estar

centrado en la válvula del

ue de LP

tan

31

Page 32

Sostenga la tuerca de empalme y

el regulador como se ilustra para

la conexión adecuada a la

válvula del tanque de LP.

6. Gire la tuerca de acople en el sentido horario y apriete hasta

que se detenga completamente. El regulador sellará en la

función disminución de e revisión de l a válvula

amortiguadora del tanque de LP, lo cual ocasiona cierta

resistencia. Se necesita un giro adicional de mitad o tres

cuartos para completar la conexión. Apriete a mano

únicamente – no utilice herramientas.

NOTA:

Si no puede completar la conexión, desconecte el r eg ulador y

repita los pasos 5 y 6. Si aún no puede concluir la conexión,

¡no utilice este regulador! Llame al 1-800-482-0131 para

obtener asistencia.

• No inserte ninguna herramienta ni objeto extraño en

la salida de la válvula ni en la válvula de seguridad.

Puede dañar la válvula y ocasionar una fuga. Las

fugas de propano podrían ocasionar una explosión,

incendio, lesiones personales graves o la muerte.

• Las unidades de gas para exteriores no están diseñadas

para ser instaladas en un barco.

• Las unidades de gas para exteriores no están diseña das

para ser instaladas en vehículos recreacio nales.

• Nunca intente fijar esta parrilla al sistema de gas LP

autónomo de una caravana, remolque o c asa rodante.

• No utilice la parrilla hasta que haya efectuado la prueba

de las fugas.

• Si detecta una fuga en cualquier momento, PARE y llame

a los bomberos.

• Si no puede detener una fuga de gas inmediatamente

cierre la válvula del cilindro LP y ¡llame al distribuidor de

gas o a los bomberos!

Válvulas para prueba de fugas, manguera y regulador

1. Gire todas las perillas de control de la parrilla a la posición

OFF (cerrado).

2. Cerciórese de que el regulador esté con ectado de forma

bien ajustada al tanque de LP.

3. Abra completamente la válvula del tanque de LP girando la

rueda manual OPD en el sentido antihorari o. Si escucha un

sonido semejante a una ráfaga, cierre el gas

inmediatamente. Hay una fuga importante en la conexión.

Corrija antes de proceder llamando a Sears para obtener

piezas de repuesto al 1-800-4-MY-HOME

4. Aplique la solución jabonosa con una brocha en las áreas

donde aparecen burbujas en la ilustración:

Nunca retire el anillo roscado

del extremo de la válvula

®

.

5. Si aparecen burbujas que “crecen”, hay una fuga. Cierre la

válvula del tanque de LP inmediatamente y vuelva a apretar

las conexiones. Si no puede detener las fugas no trate de

repararlas.

al 1-800-4-MY-HOME

6. Siempre cierre la válvula del tanque d e LP después de

realizar la prueba de fugas, girando la rue da manual en el

sentido horario.

Llame a Sears para pedir piezas de repuesto

®

.

32

Page 33

Para el uso seguro de su parrilla y para evitar

lesiones graves:

• No permita que los niños hagan funcionar la parrilla

ni deje que jueguen cerca de ella.

• Conserve el área de la parrilla despejada y sin

materiales que pudiesen arder.

• No obstruya los agujeros de los costados o la parte

posterior de la parrilla.

• Revise las llamas del quemador regularmente.

• Utilice la parrilla sólo en un espacio bien ventilado.

NUNCA la utilice en un espacio cerrado tal como un

puesto de estacionamiento, garaje, porche, patio

cubierto o bajo una estructura de cualquier tipo.

• No use carbón ni briquetas de cerámica en una

parrilla de gas. (A menos que las briquetas se

suministren con su parrilla.)

• Use la parrilla a una distancia de al menos 3’ (91

cm) de cualquier pared o superficie. Mantenga

una separación de 10’ (3 m) de los objetos que

puedan incendiarse o de las fuentes de ignición

como luces de encendido de calentadores de agua,

electrodomésticos con conexión activa, etc.

Consejos prácticos sobre seguridad

Antes de abrir la válvula del cilindro de LP, verifique que la tuerc a

de acople esté bien apretada.

Cuando la parrilla no esté en uso, cierre todas las perillas de

control y la válvula del cilindro LP.

Nunca mueva la parrilla mientras esté en funcionamiento o aún

caliente.

Utilice utensilios de mango largo para parrilla y guantes para ho rno

para evitar quemaduras o salpicaduras.

La carga máxima para el quemador lateral y el anaquel lateral es

10 lb (4,6 kg).

La bandeja recolectora de grasa deberá estar insertada en la

parrilla y vaciarse después de cada uso. No retire la bandeja de

grasa hasta que la parrilla se haya enfriado completamente.

Limpie la parrilla a menudo, preferiblemente después de termin ar

cada parrillada al aire libre. Si utiliza una brocha de cerdas para

limpiar cualquiera de las superficies de cocción de la parrilla,

cerciórese de no dejar cerdas sueltas en las superficies de cocci ón

antes de asar. No se recomienda limpiar las superficies de cocción

mientras estén calientes.

Si observa grasa u otro material caliente goteando de la parrilla en

la válvula, manguera o regulador, apague el suministro de gas

inmediatamente. Determine la causa, corríjala y limpie e

inspeccione la válvula, manguera y regulador antes de continuar .

Realice una prueba de fugas.

Las aberturas de ventilación en el compartimiento del cilindro (e n

el carrito de la parrilla) deben mantenerse sin obstrucciones ni

desechos.

No almacene objetos ni materiales dentro del compartimiento del

carrito de la parrilla que pudiesen bloquear el flujo del aire de

combustión a la parte inferior del panel de control o del tazón de la

cámara de combustión.

El regulador puede hacer un sonido de silbido o zumbido duran te

el funcionamiento. Esto no afecta la seguridad ni el uso de la

parrilla.

Si tiene un problema con la parrilla, refiérase a la “Sección de

solución de problemas”.

Si el regulador se congela, apague la parrilla y la válvula del cilindro de LP de inmediato. Esto indica un problema con el cilindro y

no debe ser utilizado con ningún producto. ¡Regrese al distribuid or!

• Ocupantes de apartamentos:

Revisen con la administración para conocer los

requisitos y las normativas sobre incendio relativas al

uso de una parrilla de gas LP en su complejo de apartamentos. Si se permiten, utilice fuera sobre piso de planta

baja con una separación de 3 pies (91 cm) de paredes o

barandas. No utilice en balcones o debajo de ellos.

• NUNCA intente encender un quemador con la tapa

cerrada. Una acumulación de gas sin encender

dentro de una parrilla cerrada es peligrosa.

• Nunca haga funcionar la parrilla si el cilindro de

LP no está en la posición correcta especificada

en las instrucciones de ensamblaje.

• Siempre cierre la válvula del cilindro de LP y retire

la tuerca de acople antes de mover el cilindro de la

posición especificada para el funcionamiento.

• Apagar los incendios que produce la grasa cerrando

la tapa no es posible. Las parrillas están bien

ventiladas por razones de seguridad.

• No utilice agua en un incendio ocasionado por la

grasa. Podrían ocurrir lesiones personales. Si se

desarrolla un incendio originado por la grasa, gire las

perillas y el cilindro de LP a la posición de apagado.

• No deje la parrilla desatendida mientras precalienta o

limpia mediante el calor los residuos de comidas en

“HI”. Si la parrilla no se ha limpiado regularmente,

puede ocurrir un incendio causado por la grasa que

pudiera dañar el producto.

Cómo encender la parrilla con el encendedor

1. Lea las instrucciones antes de encender la p arrilla.

2. Abra la tapa durante el encendido.

3. Abra la válvula del cilindro de LP o gas natural.

4. Presione hacia adentro cualquier perilla de control del quemador y gire la perilla hacia la izquierda a la posición “HI”.

Continúe presionando la perilla hasta que el quemador se

encienda.

33

Page 34

5. Si no enciende en 5 segundos, apague el control del

quemador, espere 5 minutos para que se disipe el gas y

repita el procedimiento de encendid o.

6. Para encender otros quemadores, repita el pas o 4.

NOTA: Si el encendedor no funciona, siga las instrucciones

de encendido con fósforos.

Apague (coloque en OFF) los controles y la alimentación de gas del tanque cuando no esté en uso.

Si no enciende en 5 segundos, apague el control del

quemador, espere 5 minutos y repita el procedimiento

de encendido. Si el quemador no enciende con la

válvula abierta, el gas continuará fluyendo por el

quemador y podría encenderse accidentalmente con el

riesgo de lesiones.

Encendido con fósforos

No se incline sobre la parrilla para encenderla.

1. Abra la tapa durante el encendido.

2. Coloque el fósforo en el portafósforos (que cuelga del

costado del carrito). Encienda el fósforo, colóquelo en la

cámara de combustión.

3. Presione hacia adentro y gire la perilla derecha a la posición

HIGH. Cerciórese de que el quemador prende y permanece

encendido.