Kenmore 14812201, 14812200, 14812181, 14812180 Owner’s Manual

I N

ZIG- ZAG SEWING MACHINE

52880

R U C T I 0 N S

@ ©

FRONT VIEW

@

1. Bobbin Winder

2. Special Stitch Control and Width Control

3. Stitch Length Control

4. Light Switch

5. Feed Dog Control

6. Nomenclature Plate

!

7. Needle Plate

8. Feed Dog

9. Needle Clamp Screw

10. Hand Hole Cover Plate

11. Presser Foot

12, Presser Foot Screw

I

®

®

-®

13. Thread Guides

14. Upper Thread Tension Control

15. Thread Take-up Lever

16. Bobbin Winder Thread Guide

17. Upper Thread Guide

2

@

BACK VIEW

@

@

18. Presser Foot Pressure Regulator

19. Face Plate

20. Presser Foot Lever

21, Thread Cutter

22. Hand Wheel

23. Clutch Knob

24, Thread Spool Pins

3

e

o

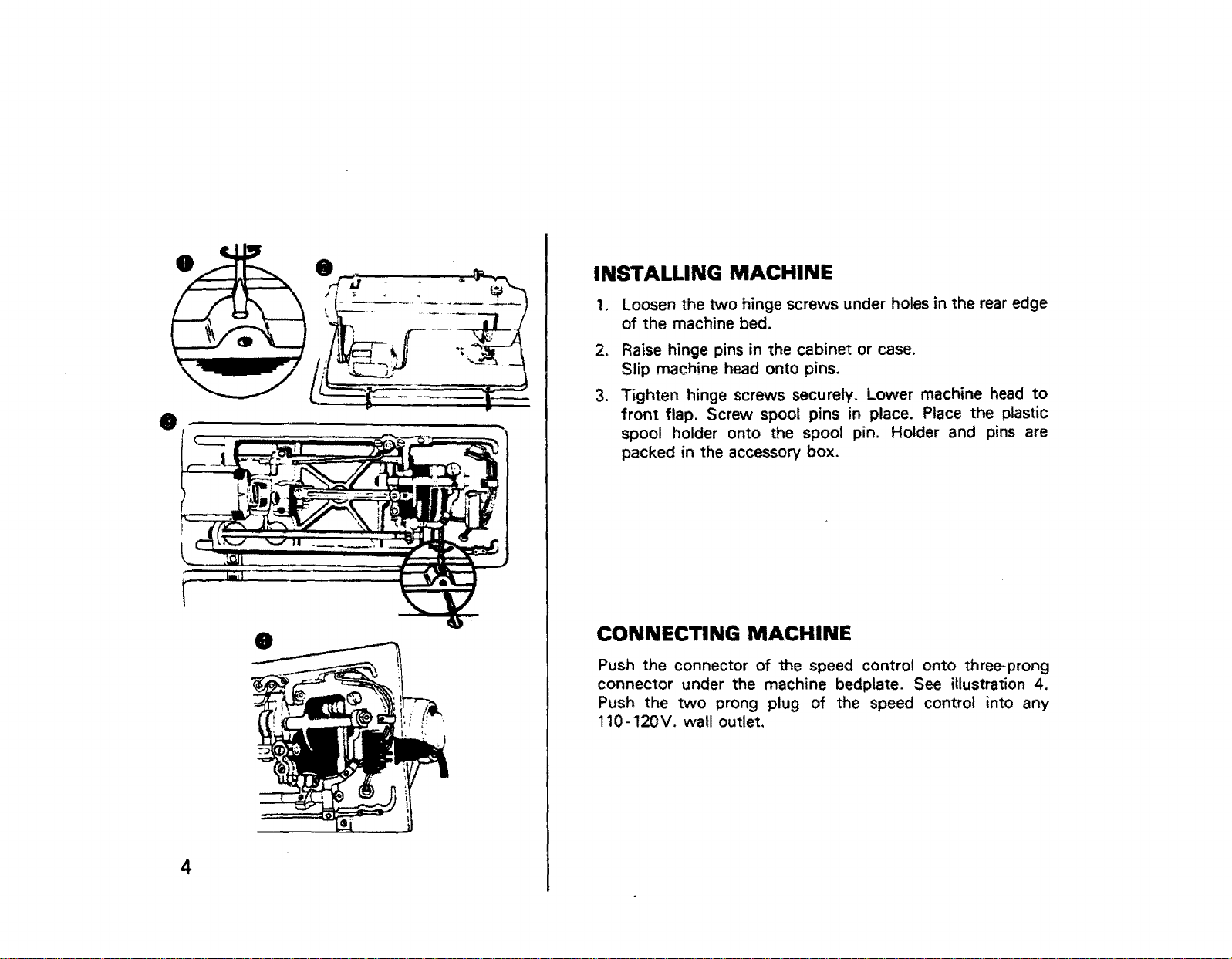

INSTALLING MACHINE

1, Loosen the two hinge screws under holes in the rear edge

of the machine bed.

2, Raise hinge pins in the cabinet or case.

S!ip machine head onto pins.

3. Tighten hinge screws securely. Lower machine head to

front flap. Screw spool pins in place. Place the plastic

spool holder onto the spool pin. Holder and pins are

packed in the accessory box.

CONNECTING MACHINE

Push the connector of the speed control onto three-prong

connector under the machine bedplate. See illustration 4.

Push the two prong plug of the speed control into any

110-120V. wall outlet,

4

Fig.1

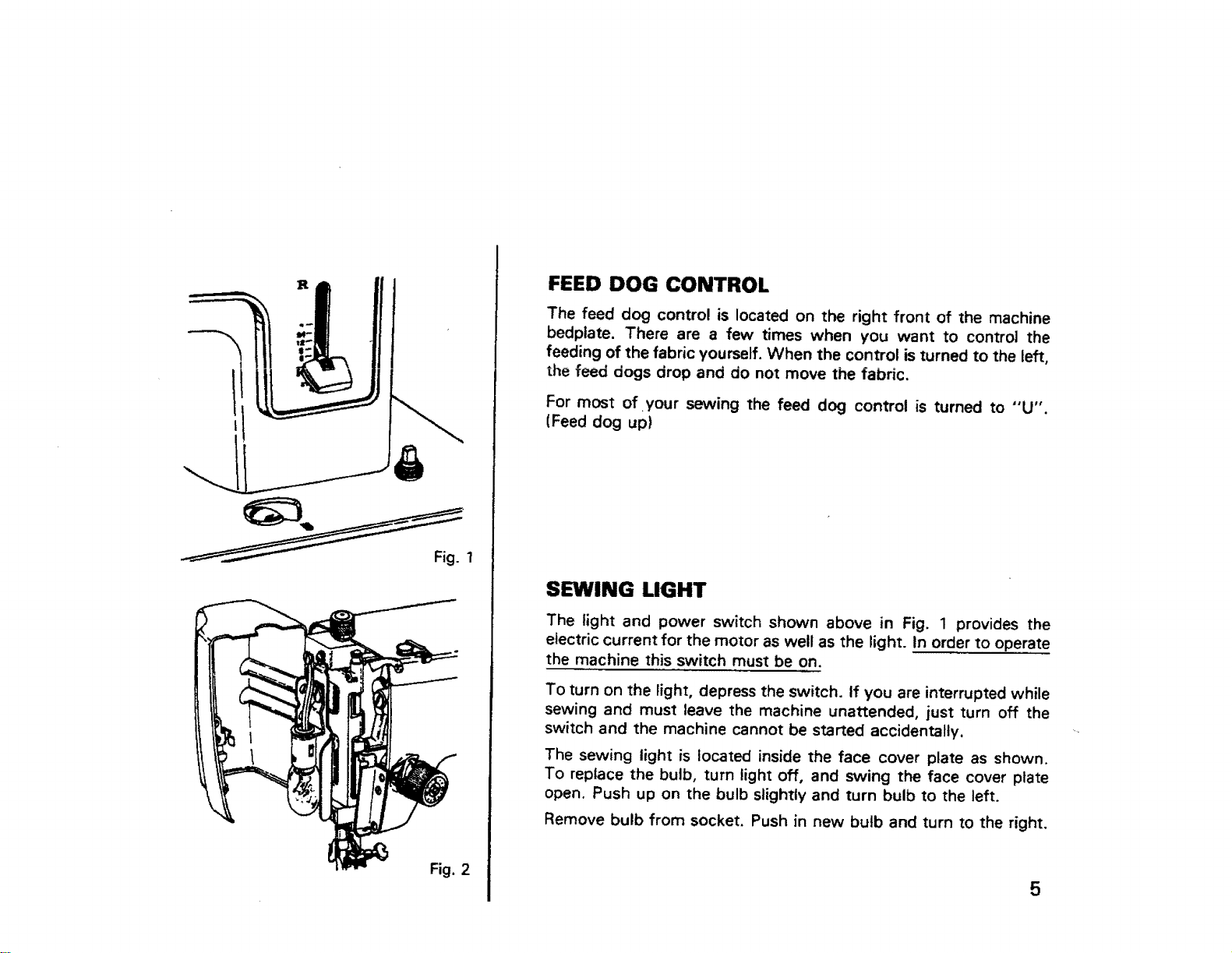

FEED DOG CONTROL

The feed dog control is located on the right front of the machine

bedplate. There are a few times when you want to control the

feeding of the fabric yourself. When the control is turned to the left,

the feed dogs drop and do not move the fabric.

For most of your sewing the feed dog control is turned to "'U".

(Feed dog up)

SEWING LIGHT

The light and power switch shown above in Fig. 1 provides the

electric current for the motor as well as the light. In order to operate

the machine this switch must be on.

To turn on the light, depress the switch. If you are interrupted while

sewing and must leave the machine unattended, just turn off the

switch and the machine cannot be started accidentally.

Fig. 2

The sewing light is located inside the face cover plate as shown.

To replace the bulb, turn light off, and swing the face cover plate

open. Push up on the bulb slightly and turn bulb to the left.

Remove bulb from socket. Push in new bulb and turn to the right.

5

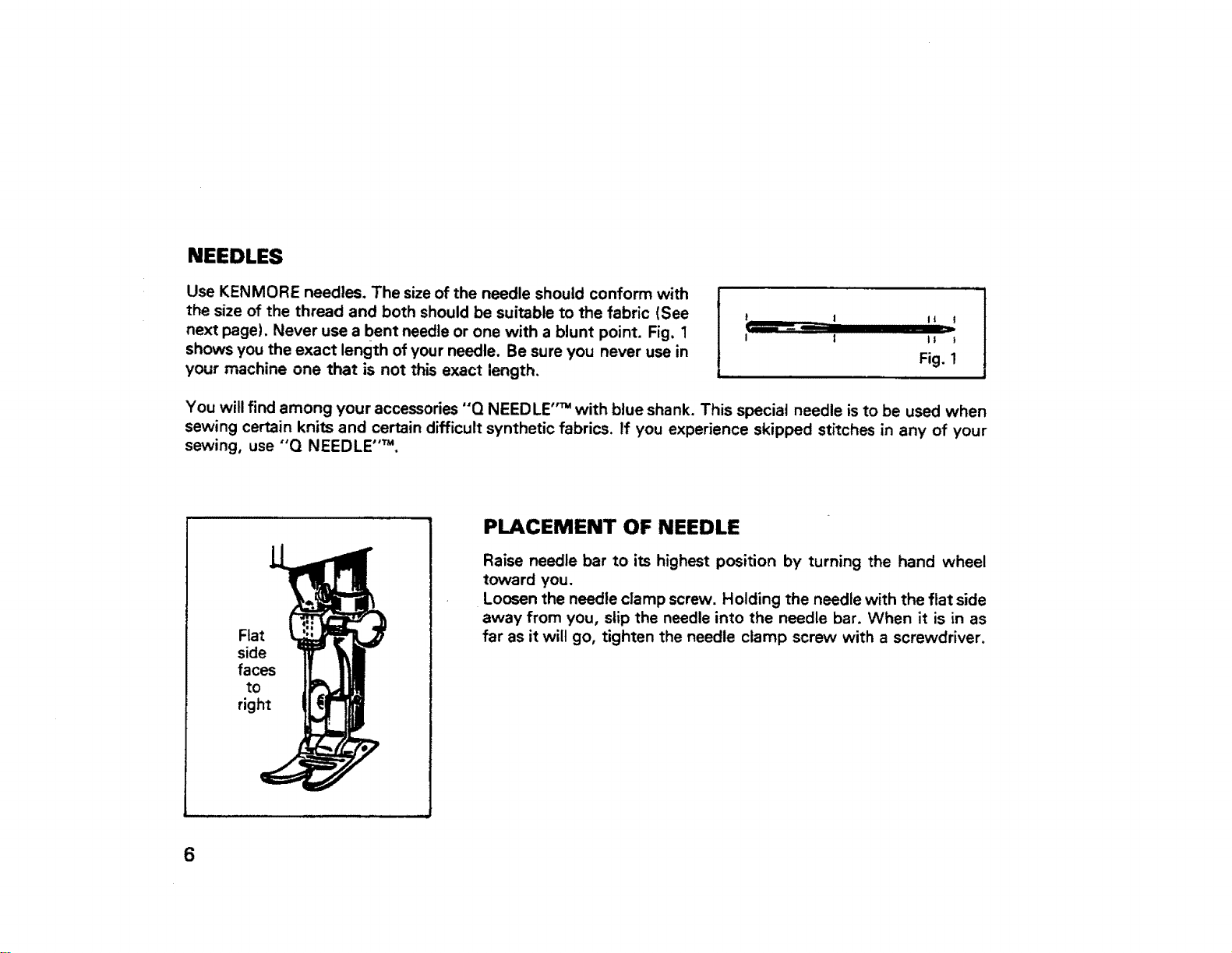

NEEDLES

Use KENMORE needles. The size of the needle should conform with

the size of the thread and both should be suitable to the fabric (See

next page). Never use a bent needle or one with a blunt point. Fig. 1

shows you the exact length of your needle. Be sure you never use in

your machine one that is not this exact length.

You will find among your accessories "'Q NEEDLE ''_ with blue shank. This special needle is to be used when

sewing certain knits and certain difficult synthetic fabrics. If you experience skipped stitches in any of your

sewing, use "'Q NEEDLE ''T".

PLACEMENT OF NEEDLE

Raise needle bar to its highest position by turning the hand wheel

toward you.

Loosen the needle clamp screw. Holding the needle with the flat side

away from you, slip the needle into the needle bar. When it is in as

Flat

side

faces

to

right

far as it will go, tighten the needle clamp screw with a screwdriver.

t | It |

I l It I

Fig. 1

6

NEEDLE, THREAD, FABRIC CHART

THREAD SIZE

POLYESTER CORE/COTTON WRAP

FINE MERCERIZED COTTON

POLYESTER SYNTHETIC

SILK A

NEEDLE SIZE

,, ,,,,, ,,,,,,

9or 1!

FABRIC

Lightweight: Batiste, Dimity,

Chiffon, Silks, Synthetic

Jerseys, Fine Lace, Organza,

Crepe. Taffetta, Voile,

Organdy

Medium Weight: Cotton, Cotton

50 MERCERIZED COTTON

POLYESTER SYNTHETIC

SILK A

t4

Blends, Percale, Gingham,

Shantung, Pique, Seersucker,

Satin, Knits. Vinyl, Suitings,

Linen, Wool Crepe, Leather

50 MERCERIZED COTTON

MERCERIZED HEAVY DUTY

POLYESTER sYhrTHETIC

SILK A

14 or 16

Medium Heavy Weight: Corduroy,

Denim, Wool, Sailcloth, Wool

Flannel, Gabardine, Velvets,

Leather

HF_AVY DUTY MERCERIZED COTTON Heavy Weight: Coatings,

POLYESTER SYNTHETIC 18 Upholstery, Cotton Duck.

SILK A Heavy Twills, Canvas

16, 18 or

SILK BUTTONHOLE TWIST "Q NEEDLE"TM Decorative Top-stitching on all

"Q SET"TM

POLYESTER SYNTHETIC

50 MERCERIZED COTTON

("Q NEEDLE'TM

and

"Q FOOT"TM)

ilUll lUUllllll i

Synthetic Knits and Stretch

Fabrics: Polyester Double

Knits, Nylon Tricot, Jersey,

Stretch Terry, Sl_ndex,

Cire Tricot

7

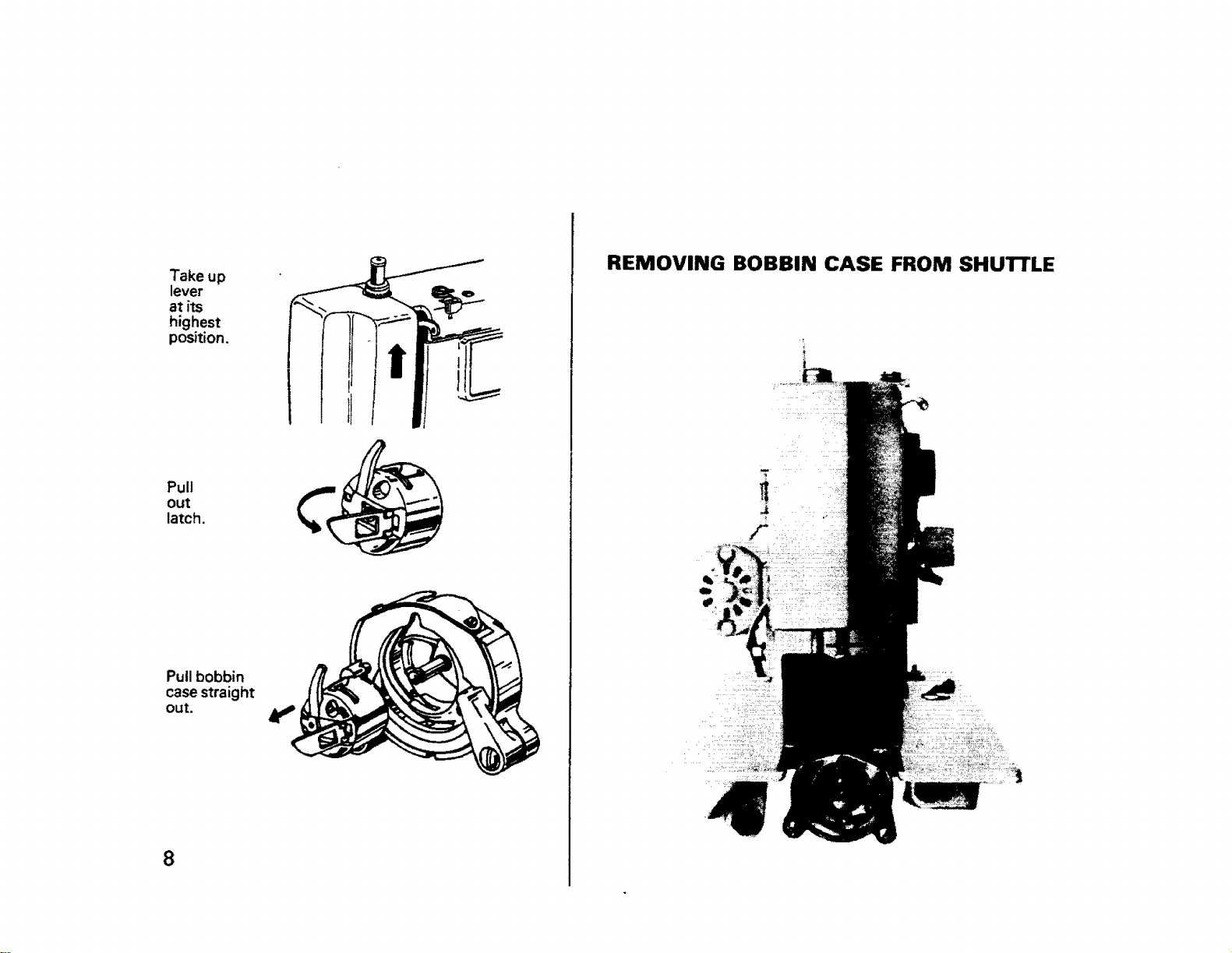

Take up

lever

at its

highest

position.

Pull

out

latch.

Pullbobbin

case straight

out.

REMOVING BOBBIN CASE FROM SHUTTLE

_J

I I l! tt'_r _

I l't

8

O

O

@

@

@

O

WINDING THE BOBBIN

1. Release clutch by turning clutch

knob toward you.

2. Draw thread from spool through

bobbin winder tension discs as

shown.

3. Pull end of thread through hole in

bobbin as shown.

4. Place bobbin onto bobbin winder

shaft with end of thread coming

from-the top of the bobbin.

Push bobbin winder latch against

bobbin until it clicks. Holding onto

end of thread, start machine.

When bobbin is slightly filled, snip

off end of thread.

5. Start machine. Wind thread until

bobbin winder latch releases.

6. Tighten clutch knob and remove

bobbin.

Two spool pins have been included

with this machine to aid in bobbin

winding, By placing a spool of thread

on the second spool pin, you may

wind your bobbin without unthreading

the machine.

9

THREADING THE BOBBIN CASE

INSERTING BOBBIN INTO BOBBIN CASE ........ CASE INTO SHUI"rLE

L

O

@

O @

i

@

t.

Insert bobbin into bobbin case

making sure thread is coming from

bobbin as shown.

.

Pull thread through slot of case as

shown.

.

Pull thread under tension spring.

4.

Turn hand wheel to raise needle to

its highest position. Holding latch

open, position case into shuttle,

and release latch. Case should lock

into place when latch is released.

,

Hold needle thread loosely in ieft

hand and rotate hand wheel toward

you one complete turn. Bring

bobbin thread up by pulling upper

thread.

10

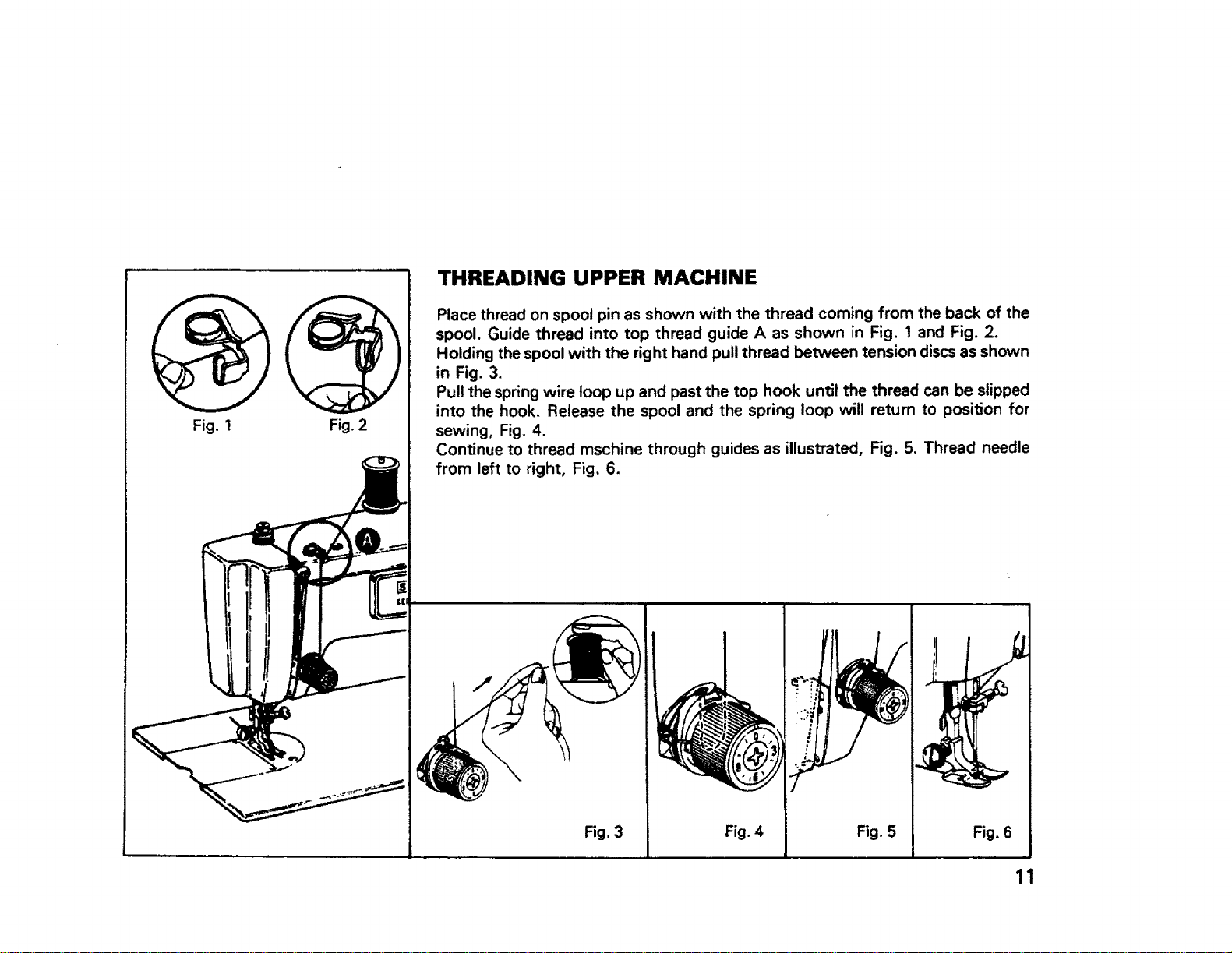

Fig.I Fig. 2

THREADING UPPER MACHINE

Place thread on spool pin as shown with the thread coming from the back of the

spool. Guide thread into top thread guide A as shown in Fig. 1 and Fig. 2.

Holding the spool with the right hand pull thread between tension discs as shc_wn

in Fig. 3.

Pull the spring wire loop up and past the top hook until the thread can be slipped

into the hook. Release the spool and the spring loop will return to position for

sewing, Fig. 4.

Continue to thread mschine through guides as illustrated, Fig. 5. Thread needle

from left to right, Fig. 6.

Fig. 3 Fig. 4 Fig. 5 Fig. 6

11

Loading...

Loading...