Page 1

®

SENSOR SMART TMGas Dryer

KING SIZE TMCapacity Plus

Secadora a Gas SENSOR SMART TM

de capacidad extra grande

(KING SIZE TM"Plus")

ii'V'!,:,:i:ili!!!_i_i_j_iLjiii_i!:!i,_iiiii,C!i_!!i!i_¸LjiiiS,C_,_,¸_ii!!j¸C:,ii_iiiiCii_i!ii:i!i_ii_C!ii_:iiiiil;_¸

Models/Modelos 110.7408_, 7206_, 7208_

= color number/nemero de color

iiiiii!Jiiiiiiiiiii!il

8533586 Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.sears.com

Page 2

TABLE OF CONTENTS

PROTECTION AGREEMENTS ....................................................... 2

WARRANTY ..................................................................................... 2

DRYER SAFETY .............................................................................. 3

INSTALLATION INSTRUCTIONS .................................................. 5

Tools and Parts ............................................................................ 5

Location Requirements ............................................................... 5

Electrical Requirements ................................................................ 6

Gas Supply Requirements ........................................................... 7

Venting Requirements .................................................................. 8

Plan Vent System ......................................................................... 8

Install Vent System .................................................................... 10

Install Leveling Legs .................................................................. 10

Level Dryer ................................................................................. 11

Make Gas Connection ............................................................... 11

Connect Vent ............................................................................. 11

Complete Installation ................................................................. 11

DRYER USE ................................................................................. 12

Starting Your Dryer .................................................................... 12

Stopping Your Dryer .................................................................. 12

Pausing or Restarting ................................................................ 13

Loading ...................................................................................... 13

Drying and Cycle Tips ............................................................... 13

Dryer Status ............................................................................... 14

Cycles ........................................................................................ 14

Options ...................................................................................... 15

Modifiers .................................................................................... 15

Changing Cycles, Options

and Modifiers ............................................................................. 16

TUMBLE FREF MHeated Dryer Rack ....................................... 16

DRYER CARE ............................................................................... 16

Cleaning the Dryer Location ...................................................... 16

Cleaning the Lint Screen ........................................................... 17

Cleaning the Dryer Interior ........................................................ 17

Removing Accumulated Lint ..................................................... 17

Vacation and Moving Care ........................................................ 17

Changing the Drum Light .......................................................... 17

TROUBLESHOOTING .................................................................. 18

SERVICE NUMBERS ............................................... BACK COVER

PROTECTION AGREEMENTS

Master Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore ®product is designed and manufactured for years of

dependable operation. But like all products, it may require

preventive maintenance or repair from time to time. That's when

having a Master Protection Agreement can save you money and

aggravation.

Purchase a Master Protection Agreement now and protect

yourself from unexpected hassle and expense.

The Master Protection Agreement also helps extend the life of

your new product. Here's what's included in the Agreement:

v' Expert service by our 12,000 professional repair specialists

v' Unlimited service and no charge for parts and labor on all

covered repairs

v' "No-lemon" guarantee - replacement of your covered

product if four or more product failures occur within twelve

months

v' Product replacement if your covered product can't be fixed

v' Annual Preventive Maintenance Check at your request - no

extra charge

v' Fast help by phone - phone support from a Sears technician

on products requiring in-home repair, plus convenient repair

scheduling

v' Power surge protection against electrical damage due to

power fluctuations

v' Rental reimbursement if repair of your covered product takes

longer than promised

Once you purchase the Agreement, a simple phone call is all that

it takes for you to schedule service. You can call anytime day or

night, or schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories. That's

the kind of professionalism you can count on to help prolong the

life of your new purchase for years to come. Purchase your

Master Protection Agreement today!

Some limitations and exclusions apply. For prices and

additional information, call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in the

U.S.A. call 1-800-4-MY-HOME ®.

WARRANTY

Full One-Year Warranty on Mechanical and Electrical Parts

For one year from the date of purchase, when this dryer is

installed and operated according to the instructions provided in

this Use and Care Guide, Sears will repair this dryer, free of

charge, if defective in materials or workmanship.

NOTE: Exhausting this dryer with a plastic vent can void this

warranty. See "Installation Instructions" for the complete exhaust

requirements for this dryer.

Limited Two-Year Warranty on SENSOR SMART TM

Electronic Control Board

For the second year from the date of purchase, Sears will replace

the electronic control board if defective in material or

workmanship. You will be charged for labor after the first year.

Warranty Restriction

If the dryer is subject to other than private family use, the above

warranty coverage is effective for only 90 days.

Page 3

Warranty Service

Warranty service is available by contacting the nearest Sears

Service Center. This warranty applies only while the product is in

use in the United States.

This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

For Sears Warranty information or to contact a Sears Service

Center, please refer to the service numbers located on the back

page of this manual.

Sears, Roebuck and Co.

D/817WA, Hoffman Estates, IL 60179

Product Record

In the space following, record your complete model number,

serial number, and purchase date. You can find this information

on the model and serial number label, located at the top inside

dryer door well.

Have this information available to help you quickly obtain

assistance or service when you contact Sears concerning your

appliance.

Model number 110.

Serial number

Purchase date

Save these instructions and your sales receipt for future

reference.

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

I WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

Page 4

In the State of Massachusetts, the following installation instructions apply:

_, Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

_, If using a ball valve, it shall be a T-handle type.

_, A flexible gas connector, when used, must not exceed 3 feet.

iMPORTANT SAFETY iNSTRUCTiONS

WARNUNG: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

m Read all instructions before using the dryer.

m Do not place items exposed to cooking oils in your dryer.

Htems contaminated with cooking oils may contribute to

a chemical reaction that could cause a Ioad to catch fire.

m Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

m Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

m Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

m Do not reach into the dryer if the drum is moving.

m Do not install or store the dryer where it will be exposed

to the weather.

m Do not tamper with controls.

m Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

m Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

m Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

m Clean Iint screen before or after each load.

m Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

_, The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

_, See insta!lation instructions for grounding requirements.

SAVE THESE iNSTRUCTiONS

IMPORTANT: The gas instailation must conform with local codes, or in the absence of local codes, with the Nationai Fuel Gas

Code, ANSH Z223,1/NFPA 54_

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the Nationai

Electrical Code, ANSH/NFPA 70_

Page 5

INSTALLATION INSTRUCTIONS

Check that you have everything necessary for correct installation.

Proper installation is your responsibility.

8" or 10" pipe wrench

8" or 10" adjustable

wrench (for gas

connections)

Flat-blade screwdriver

Adjustable wrench that

opens to 1" (2.5 cm) or

hex-head socket wrench

(for adjusting dryer feet)

Level

• 1A" nut driver or socket

wrench

• Knife

• Vent clamps

• Pipe-joint compound

resistant to L.R gas

• Caulking gun and

compound (for installing

new exhaust vent)

• Pliers

Parts supplied:

Remove parts package from dryer drum. Check that all parts

were included.

4 leveling legs

Parts needed:

Check local codes and with gas supplier, check existing gas

supply, electrical supply and venting, and read "Electrical

Requirements," "Gas Supply Requirements" and "Venting

Requirements" before purchasing parts.

Mobile home installations require special parts (listed following)

available for purchase from your local Sears store or Sears

Service Center. For further information, please call

1-800-4-MY-HOME ®(1-800-469-4663}.

• Mobile Home Installation Kit. Ask for Part Number 346764.

• Metal exhaust system hardware.

Expmosion Hazard

Keep flammable materials and vapors, such as

gasomine, away from dryer.

Pmacedryer at Beast 18 inches (48 cm) above the floor

for a garage installation.

Failure to do so can resumt in death, expmosion, or fire.

You will need

• A location that allows for proper exhaust installation. A gas

dryer must be exhausted to the outdoors. See "Venting

Requirements."

• A grounded electrical outlet located within 2 ft (61 cm) of

either side of the dryer. See "Electrical Requirements."

• A sturdy floor to support the dryer with a total weight (dryer

and load) of 200 Ibs (90.7 kg).

A level floor with a maximum slope of 1" (2.5 cm) under entire

dryer. (If slope is greater than 1" [2.5 cm], install Extended

Dryer Feet Kit, Part Number 279810.) Clothes may not tumble

properly and dryers with automatic sensor cycles may not

operate correctly if dryer is not level.

Do not operate your dryer at temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

Page 6

Installation Clearances

The location must be large enough to allow the dryer door to

open fully.

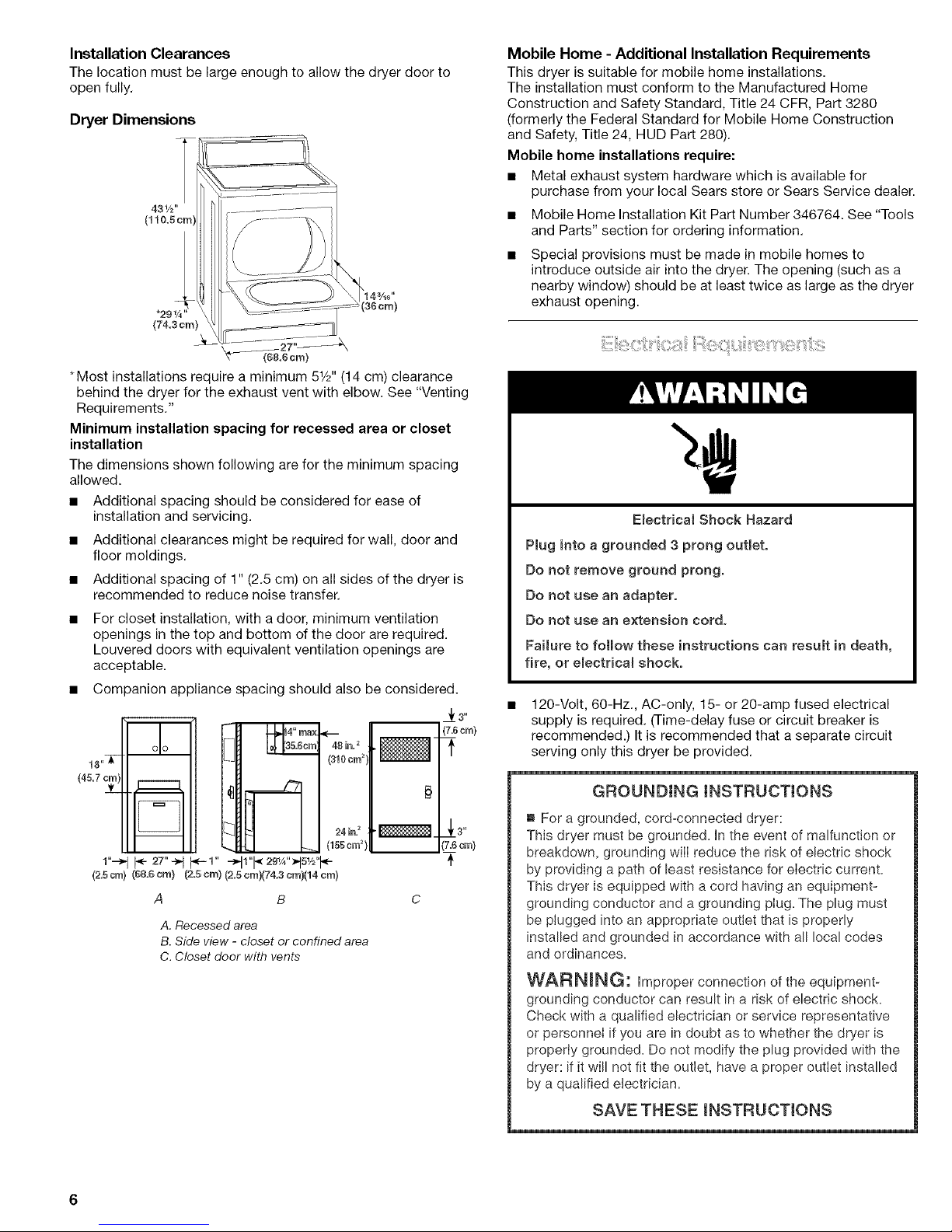

Dryer Dimensions

(6&6cm}

*Most installations require a minimum 51/2'' (14 cm) clearance

behind the dryer for the exhaust vent with elbow. See "Venting

Requirements."

Minimum installation spacing for recessed area or closet

installation

The dimensions shown following are for the minimum spacing

allowed.

• Additional spacing should be considered for ease of

installation and servicing.

• Additional clearances might be required for wall, door and

floor moldings.

• Additional spacing of 1" (2.5 cm) on all sides of the dryer is

recommended to reduce noise transfer.

For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

• Companion appliance spacing should also be considered.

n

olo

A B

Jr s"

17.5crn)

3"

'7=5crn}

A, Recessed area

B. Side view - closet or confined area

C. Closet door with vents

Mobile Home - Additional Installation Requirements

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

Mobile home installations require:

• Metal exhaust system hardware which is available for

purchase from your local Sears store or Sears Service dealer.

• Mobile Home Installation Kit Part Number 346764. See "Tools

and Parts" section for ordering information.

Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

Emectricai Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Faimureto follow these instructions can result in death,

fire, or emectrical shock.

120-Volt, 60-Hz., AC-only, 15- or 20-amp fused electrical

supply is required. (Time-delay fuse or circuit breaker is

recommended.) It is recommended that a separate circuit

serving only this dryer be provided.

GROUNDING mNSTRUCTIONS

" For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding wilI reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances=

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel ifyou are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician=

SAVE THESE INSTRUOTmONS

Page 7

Explosion Hazard

Use a new AGA or CSA approved gas supply mine.

tnstaim a shut-off vaive.

Securely tighten ail gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (33 cm) water

comumn.

Exampmes of a quamified person include:

licensed heating personnel,

authorized gas company personnem, and

authorized service personnel

Failure to do so can result in death, expmosion, or fire.

Gas Type

Natural Gas:

This dryer is equipped for use with natural gas. It is design-

certified by CSA International for L.R (propane or butane) gases

with appropriate conversion.

• Your dryer must have the correct burner for the type of gas in

your home. Burner information is located on the rating plate

in the door well of your dryer. Ifthis information does not

agree with the type of gas available, contact your local Sears

store or Sears Service Center.

L.P. gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier.

Gas Supply Line:

• 1/2"IPSpipe isrecommended.

• %" approved tubing is acceptable for lengths under 20 ft

(6.1 m) if local codes and gas supplier permit.

• Must include Vs"NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer (see illustration).

• Must include a shutoff valve:

An individual shutoff valve must be installed within six (6) feet

(1.8 m) of the dryer in accordance with the National Fuel Gas

Code, ANSI Z223.1. The location should be easy to reach for

opening and closing.

A C E

B D

A. _" flexible gas connector

B. _" pipe to flare adapterfitting

C. _" NPT plugged tapping

D. Y2"NPT gas supply line

E.Gas shutoff valve

Gas supply connection requirements

There are many methods by which your gas dryer can be

connected to the gas supply. Listed here are some guidelines for

two different methods of connection.

Option 1 (Recommended Method):

Flexible stainless steel gas connector:

• If local codes permit, use a new flexible stainless steel gas

connector (Design Certified by the American Gas Association

or CSA International) to connect your dryer to the rigid gas

supply line. Use an elbow and a 3/8"flare x 3/8"NPT adapter

fitting between the stainless steel gas connector and the

dryer gas pipe, as needed to prevent kinking.

Option 2 (Alternate Method):

Approved aluminum or copper tubing:

• Lengths under 20 ft (6.1 m) can use 3/8"approved tubing (if

codes and gas supplier permit).

• If you are using natural gas, do not use copper tubing.

• %" flare x %" NPT adapter fitting between dryer pipe and %"

approved tubing

• Lengths over 20 ft (6.1 m) should use larger tubing and a

different size adapter fitting.

• If your dryer has been converted to use L.R gas, %" L.R

compatible copper tubing can be used. If the total length of

the supply line is more than 20 ft (6.1 m), use larger pipe.

NOTE: Pipe joint compounds that resist the action of L.R gas

must be used. Do not use TEFLON _ttape.

Dryer Gas Pipe

• The gas pipe that comes out through the rear of your dryer

has a %" male pipe thread.

A ¸¸¸

A. _/*" NPT gas supply line

B. _" NPT dryer pipe

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Page 8

Burner Input Requirements:

Elevations up to 10,000 ft (3,048 meters):

• The design of this dryer is certified by CSA International for

use at altitudes up to 10,000 ft (3,048 m) above sea level at

the B.T.U. rating indicated on the model/serial number plate.

Burner input adjustments are not required when the dryer is

operated up to this elevation.

Elevations above 10,000 ft (3,048 meters):

• When installed above 10,000 ft (3,048 m) a 4% reduction of

the burner B.T.U. rating shown on the model/serial number

plate is required for each 1,000 ft (305 m) increase in

elevation.

Gas Supply Pressure Testing

• The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than

1/2psi.

Fire Hazard

Use a heavy metal vent.

Do not use a pmastic vent.

Do not use a metal foil vent.

Faimureto follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

4" (10.2 cm) heavy metal exhaust vent and clamps must be used.

DURASAFE TM venting products are recommended and are

available from your local Sears store or Sears Service Center.

DURASAFE TM vent products can be purchased from your dealer.

For further information, please call 1-800-4-MY-HOME ®

(1-800-469-4663) or visit our Internet site at: www.sears.com

The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, or a concealed space of a building.

Do not use an exhaust hood with a magnetic latch.

Do not install flexible metal vent in enclosed walls, ceilings or

floors.

Use clamps to seal all joints. Exhaust vent must not be

connected or secured with screws or other fastening devices

which extend into the interior of the duct. Do not use duct

tape.

IMPORTANT: Observe all governing codes and ordinances.

improper venting can cause moisture and ()ntto collect

indoors, which may resumt in:

[] Moisture damage to woodwork, furniture, paint,

waiIpaper, carpets, etc=

[] Housecleaning problems and health problems.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home.

Exhaust hood must be at least 12" (30.5 cm) from the ground or

any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, etc.).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

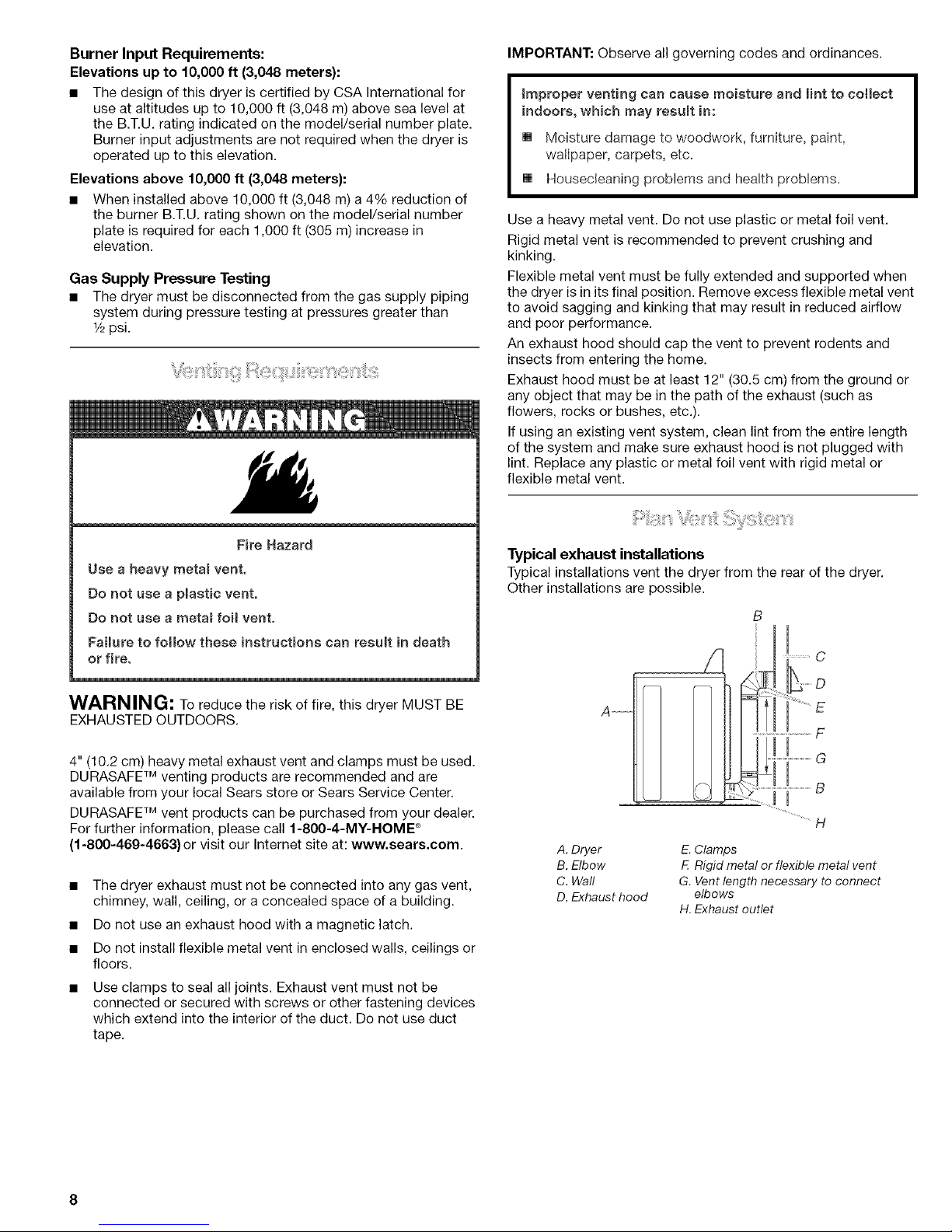

Typical exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

A

/

B

................................H

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

E. Clamps

F. Rigid metal or flexible metal vent

G. Vent length necessary to connect

elbows

H. Exhaust outlet

Page 9

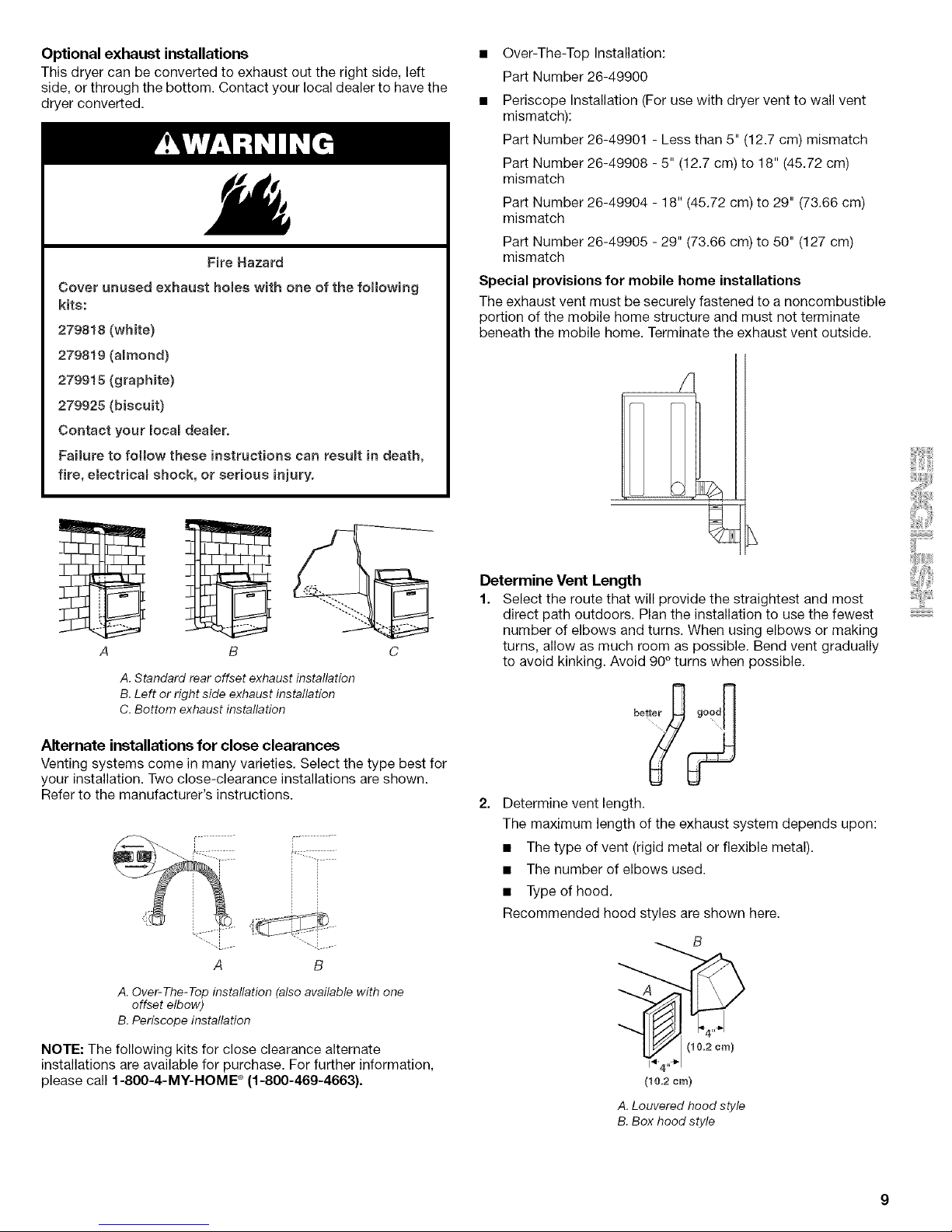

Optional exhaust installations

This dryer can be converted to exhaust out the right side, left

side, or through the bottom. Contact your local dealer to have the

dryer converted.

Fire Hazard

Cover unused exhaust holes with one of the folowing

kits:

279818 (white)

279819 (almond)

279915 (graphite)

279925 (biscuit)

Contact your local dealer°

Failure to fomlow these instructions can result in death,

fire, electrical shock, or serious injury.

A

T!

B C

A. Standard rear offset exhaust installation

B. Left or right side exhaust installation

C. Bottom exhaust installation

Alternate installations for close clearances

Venting systems come in many varieties, Select the type best for

your installation. Two close-clearance installations are shown.

Refer to the manufacturer's instructions.

A B

A. Over-The-Top installation (also available with one

offset elbow)

B. Periscope installation

NOTE: The following kits for close clearance alternate

installations are available for purchase. For further information,

please call 1-800-4-MY-HOME ®(1-800-469-4663).

• Over-The-Top Installation:

Part Number 26-49900

• Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 26-49901 - Less than 5" (12.7 cm) mismatch

Part Number 26-49908 - 5" (12.7 cm) to 18" (45.72 cm)

mismatch

Part Number 26-49904 - 18" (45.72 cm) to 29" (73.66 cm)

mismatch

Part Number 26-49905 - 29" (73.66 cm) to 50" (127 cm)

mismatch

Special provisions for mobile home installations

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

/

Determine Vent Length

1. Select the route that will provide the straightest and most

direct path outdoors. Plan the installation to use the fewest

number of elbows and turns. When using elbows or making

turns, allow as much room as possible. Bend vent gradually

to avoid kinking. Avoid 90° turns when possible.

Determine vent length.

The maximum length of the exhaust system depends upon:

• The type of vent (rigid metal or flexible metal).

• The number of elbows used.

• Type of hood.

Recommended hood styles are shown here.

B

(10.2 cm)

A. Louvered hood style

B. Box hood style

Page 10

The angled hood style (shown following) is acceptable.

(8.4cm)

See the exhaust vent length chart that matches your hood

type for the maximum vent lengths you can use.

Exhaust systems longer than specified will:

3,

• Shorten the life of the dryer.

• Reduce performance, resulting in longer drying times and

increased energy usage.

Determine the number of elbows you will need.

NOTE: Do not use vent runs longer than specified in the Vent

Length Chart.

The chart below helps you determine your maximum vent

length based on the number of 90° turns or elbows you will

need and the type of vent (rigid or flexible metal) and hood

that you will use.

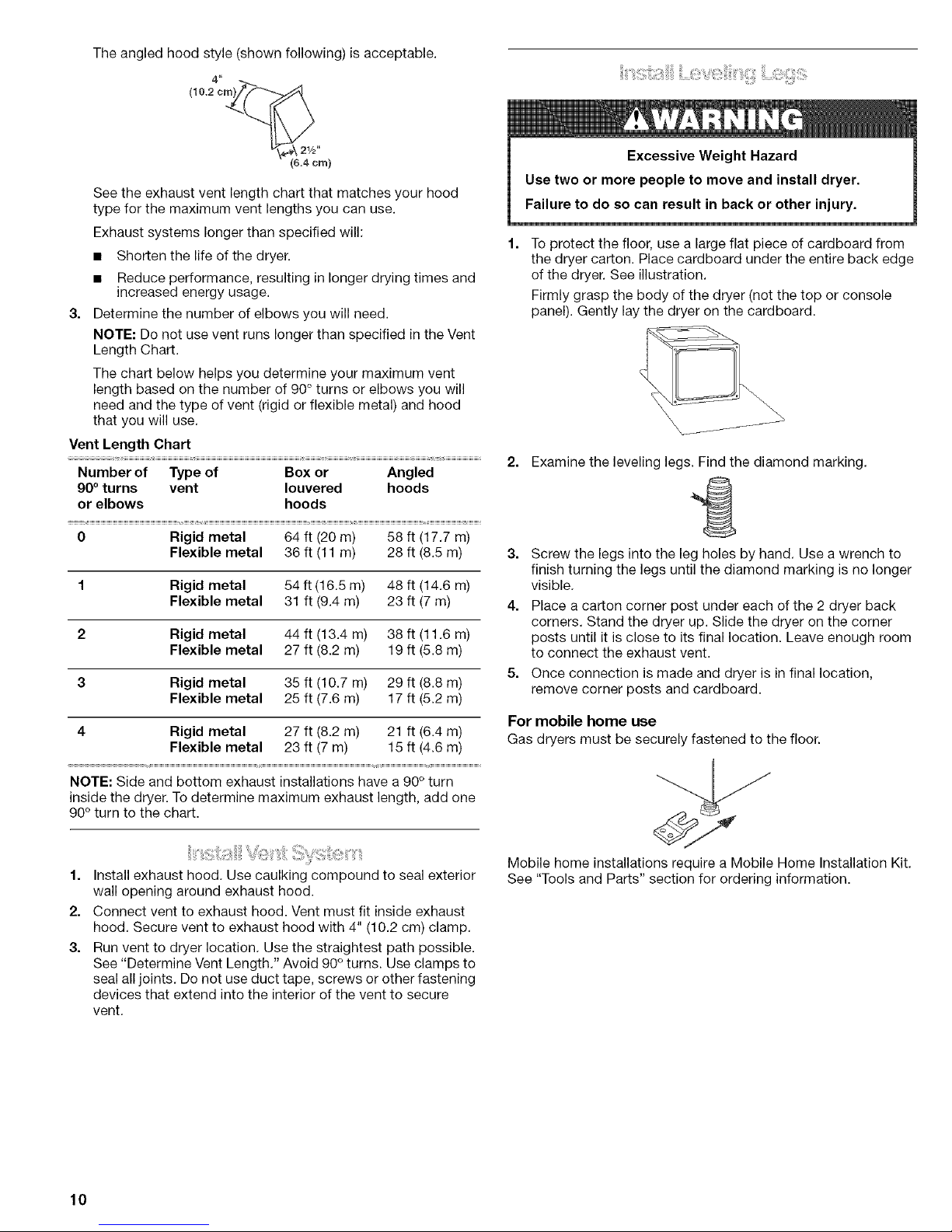

Vent Length Chart

Number of Type of Box or Angled

90° turns vent Iouvered hoods

or elbows hoods

0 Rigid metal 64 ft (20 m) 58 ft (17.7 m)

Flexible metal 36 ft (11 m) 28 ft (8.5 m)

1 Rigid metal 54 ft (16.5 m) 48 ft (14.6 m)

Flexible metal 31 ft (9.4 m) 23 ft (7 m)

2 Rigid metal 44 ft (13.4 m) 38 ft (11.6 m)

Flexible metal 27 ft (8.2 m) 19 ft (5.8 m)

3 Rigid metal 35 ft (10.7 m) 29 ft (8.8 m)

Flexible metal 25 ft (7.6 m) 17 ft (5.2 m)

4 Rigid metal 27 ft (8.2 m) 21 ft (6.4 m)

Flexible metal 23 ft (7 m) 15 ft (4.6 m)

NOTE: Side and bottom exhaust installations have a 90° turn

inside the dryer. To determine maximum exhaust length, add one

90° turn to the chart.

1,

2.

3.

ii ! :::iii:,ii;1::);i!i: i] 1;;ii:1i

Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (10.2 cm) clamp.

Run vent to dryer location. Use the straightest path possible.

See "Determine Vent Length." Avoid 90° turns. Use clamps to

seal all joints. Do not use duct tape, screws or other fastening

devices that extend into the interior of the vent to secure

vent.

il_'_:!i:;;ii!:;;ili;i!_ilii

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

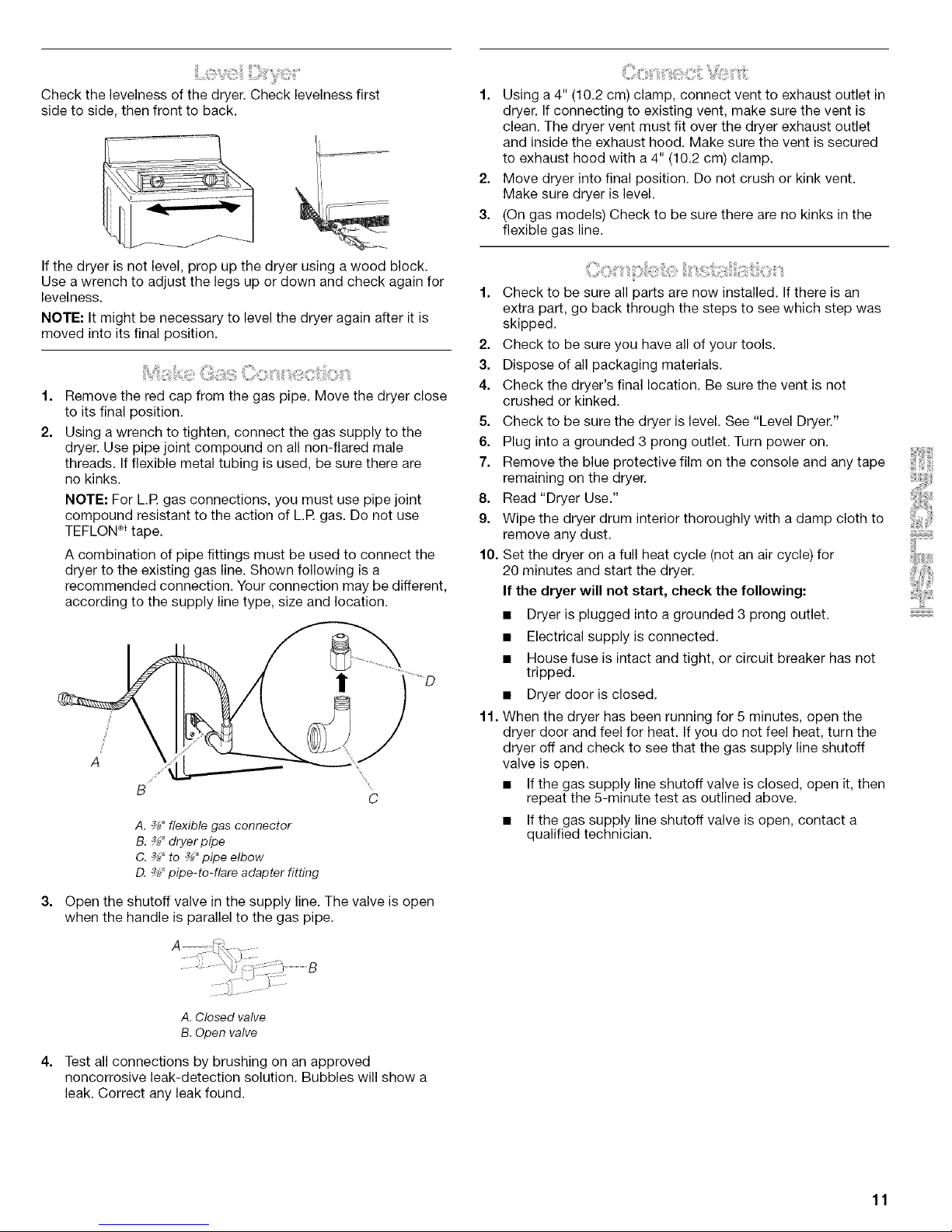

1. To protect the floor, use a large flat piece of cardboard from

the dryer carton. Place cardboard under the entire back edge

of the dryer. See illustration.

Firmly grasp the body of the dryer (not the top or console

panel). Gently lay the dryer on the cardboard.

2,

Examine the leveling legs. Find the diamond marking.

3. Screw the legs into the leg holes by hand. Use a wrench to

finish turning the legs until the diamond marking is no longer

visible.

4. Place a carton corner post under each of the 2 dryer back

corners. Stand the dryer up. Slide the dryer on the corner

posts until it is close to its final location. Leave enough room

to connect the exhaust vent.

5. Once connection is made and dryer is in final location,

remove corner posts and cardboard.

For mobile home use

Gas dryers must be securely fastened to the floor.

Mobile home installations require a Mobile Home Installation Kit

See "Tools and Parts" section for ordering information.

10

Page 11

Check the levelness of the dryer. Check levelness first

side to side, then front to back.

If the dryer is not level, prop up the dryer using a wood block.

Use a wrench to adjust the legs up or down and check again for

levelness.

NOTE: It might be necessary to level the dryer again after it is

moved into its final position.

1,

2.

Remove the red cap from the gas pipe. Move the dryer close

to its final position.

Using a wrench to tighten, connect the gas supply to the

dryer. Use pipe joint compound on all non-flared male

threads. If flexible metal tubing is used, be sure there are

no kinks.

NOTE: For L.R gas connections, you must use pipe joint

compound resistant to the action of L.R gas. Do not use

TEFLON _ttape.

A combination of pipe fittings must be used to connect the

dryer to the existing gas line. Shown following is a

recommended connection. Your connection may be different,

according to the supply line type, size and location.

J

f

A

\

C

A. _" flexible gas connector

B. ¾" dryerpipe

C. _" to _" pipe elbow

D. _" pipe-to-flare adapter fitting

Open the shutoff valve in the supply line. The valve is open

when the handle is parallel to the gas pipe.

1. Using a4" (10.2 cm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 4" (10.2 cm) clamp.

2. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

3. (On gas models) Check to be sure there are no kinks in the

flexible gas line.

1. Check to be sure all parts are now installed. If there is an

extra part, go back through the steps to see which step was

skipped.

2. Check to be sure you have all of your tools.

3. Dispose of all packaging materials.

4. Check the dryer's final location. Be sure the vent is not

crushed or kinked.

5. Check to be sure the dryer is level. See "Level Dryer."

6. Plug into a grounded 3 prong outlet. Turn power on.

7. Remove the blue protective film on the console and any tape

remaining on the dryer.

8. Read "Dryer Use."

9. Wipe the dryer drum interior thoroughly with a damp cloth to

remove any dust.

10. Set the dryer on a full heat cycle (not an air cycle) for

20 minutes and start the dryer.

If the dryer will not start, check the following:

• Dryer is plugged into a grounded 3 prong outlet.

• Electrical supply is connected.

• House fuse is intact and tight, or circuit breaker has not

tripped.

• Dryer door is closed.

11. When the dryer has been running for 5 minutes, open the

dryer door and feel for heat. If you do not feel heat, turn the

dryer off and check to see that the gas supply line shutoff

valve is open.

• If the gas supply line shutoff valve is closed, open it, then

repeat the 5-minute test as outlined above.

• If the gas supply line shutoff valve is open, contact a

qualified technician.

A.Closed valve

B.Open valve

Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show a

leak. Correct any leak found.

11

Page 12

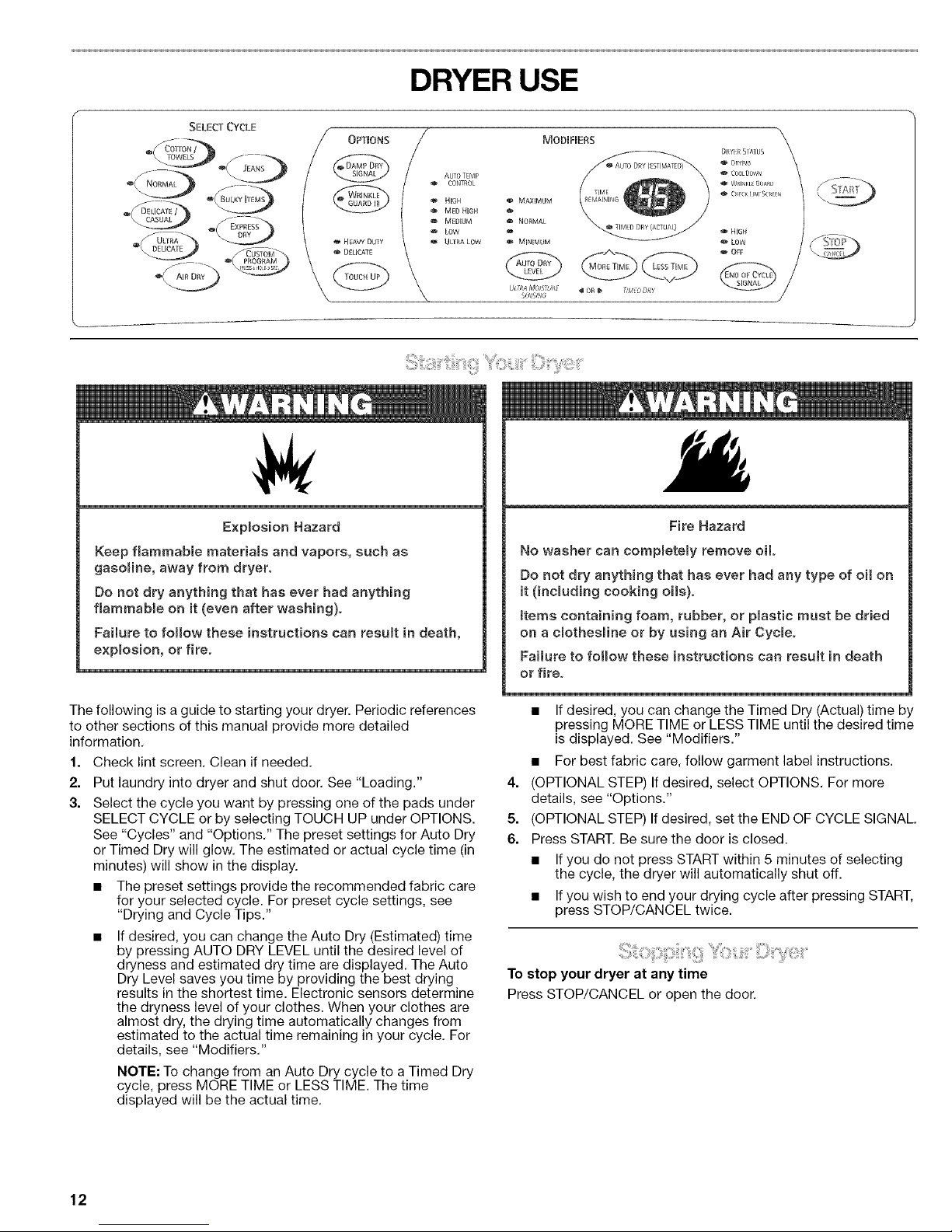

DRYER USE

MODIFIERSSELECT CYCLE / OPTIONS

_FUCAT_ _tJSTO_11_ _ DELICATE

/

/

AUTO ]EMP

CONTROL

HIGH

MED HIGH

MEDIUM

LOW

UE[RA LOW

o MAXIMUM

NORMAL

@

MINIMUM

U_,PAMO/STU_,/?

_UtSH_;

i!i _,T:

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not dry anything that has ever had anything

flammable on it (even after washing).

Failure to folow these instructions can resuR in death,

explosion, or fire.

The following is a guide to starting your dryer. Periodic references

to other sections of this manual provide more detailed

information.

1. Check lint screen. Clean if needed.

2. Put laundry into dryer and shut door. See "Loading."

3. Select the cycle you want by pressing one of the pads under

SELECT CYCLE or by selecting TOUCH UP under OPTIONS.

See "Cycles" and "Options." The preset settings for Auto Dry

or Timed Dry will glow. The estimated or actual cycle time (in

minutes) will show in the display.

• The preset settings provide the recommended fabric care

for your selected cycle. For preset cycle settings, see

"Drying and Cycle Tips."

• Ifdesired, you can change the Auto Dry (Estimated) time

by pressing AUTO DRY LEVEL until the desired level of

dryness and estimated dry time are displayed. The Auto

Dry Level saves you time by providing the best drying

results in the shortest time. Electronic sensors determine

the dryness level of your clothes. When your clothes are

almost dry, the drying time automatically changes from

estimated to the actual time remaining in your cycle. For

details, see "Modifiers."

NOTE: To change from an Auto Dry cycle to a Timed Dry

cycle, press MORE TIME or LESS TIME. The time

displayed will be the actual time.

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had any type of oi on

it (including cooking ois).

Reins containing foam, rubber, or pBastic must be dried

on a cmothesine or by using an Air Cycle.

Failure to folow these instructions can result in death

or fire.

• If desired, you can change the Timed Dry (Actual) time by

pressing MORE TIME or LESS TIME until the desired time

is displayed. See "Modifiers."

• For best fabric care, follow garment label instructions.

4. (OPTIONAL STEP) If desired, select OPTIONS. For more

details, see "Options."

5. (OPTIONAL STEP) If desired, set the END OF CYCLE SIGNAL.

6. Press START. Be sure the door is closed.

• Ifyou do not press START within 5 minutes of selecting

the cycle, the dryer will automatically shut off.

• Ifyou wish to end your drying cycle after pressing START,

press STOP/CANCEL twice.

To stop your dryer at any time

Press STOP/CANCEL or open the door.

12

Page 13

i!:::i_';iz!::i_jik_ji_!!!ii_iiii_i!_!i:iZi!_::iii¢_¸i::::i_;%!!!i!i_:_/:::ii!!;ii_ii!i:ii_ii_i_!!iiii_il;

To pause the dryer at any time

Open the door or press STOP/CANCEL once.

To restart the dryer

Close the door and press START.

NOTE: Drying will continue from where the cycle was interrupted

if you close the door and press START within 5 minutes. If the

cycle is interrupted for more than 5 minutes, the dryer will shut

off, You will need to select new cycle settings before restarting

the dryer.

Properly loading your dryer can lower your utility bill and prolong

the life of your garments.

Loading suggestions

• Load the dryer by the amount of space items take up, not by

their weight.

• Do not overload the dryer. This causes uneven drying and

wrinkling.

KING SIZE TM Capacity Dryers

Heavy Work Clothes

4 jeans 2 sweatpants

4 workpants 2 sweatshirts

4 workshirts

Towels

10 bath towels

10 hand towels

14 washcloths

Mixed Load

3 sheets (1 king, 2 twin) 9 T-shirts

4 pillowcases 9 shorts

3 shirts 10 handkerchiefs

3 blouses

Select the correct cycle and temperature for your load,

The display shows the estimated cycle time when your dryer is

automatically sensing the dryness level of your load. If a cycle is

using Timed Dry, the display shows the exact number of minutes

remaining in the cycle.

Cool Down tumbles the load without heat during the last few

minutes of all cycles, Cool Down makes the loads easier to

handle, The length of the Cool Down depends on the load size

and dryness level.

Drying tips

• Follow care label directions when they are available.

• If you use fabric softener sheets, use only ones labeled as

dryer safe. Follow package instructions.

• Remove the load from the dryer as soon as tumbling stops to

reduce wrinkling. This is especially important for permanent

press, knits, and synthetic fabrics.

Cycle tips

• Dry most loads using the preset cycle settings.

Use this chart as a guide to dry various loads. Drying

temperature and Auto Dry Level (Normal Dry) are preset when

you choose an Auto Dry cycle. You can select a different

dryness level, depending on your load (see "Modifiers").

For a Timed cycle, drying temperature is preset, but the time

can be adjusted.

PRESET CYCLE SETTINGS

Cycle Drying Temp. Time

Load Type Method (minutes)

(Auto Dry

Level)

COTTON/ Auto Dry High 54*

TOWELS (Normal)

Heavyweight

items, towels

JEANS Auto Dry Medium

Denim pants, (Normal) High

jackets

64*

NORMAL Auto Dry

Corduroys, (Normal)

work clothes

Medium 52*

BULKY Auto Dry

ITEMS (Normal)

Bedspreads,

sleeping bags

Medium 60*

DELICATE/ Auto Dry

CASUAL (Normal)

Sheets,

permanent

press, diapers

Low 36*

ULTRA Auto Dry

DELICATE (Normal)

Exercise wear,

sheer curtains,

lace

Ultra Low 22*

EXPRESS

DRY TM

Smafl loads

Timed Dry High 23**

AIR DRY

Rubber,

plastic,

special-care

Timed Dry No heat 30**

TOUCH UP Timed Dry

Heavy Duty High 30**

Heavyweight,

sturdy fabrics

Delicate Low 20**

Lightweight

items,

synthetics

*Estimated preset time

**Actual time

13

Page 14

Follow the progress of your dryer with the Drying Status

indicators.

DRYER STATUS

w DBYING

o COOL DOWN

WRINKLE GUARD

CHECK LINT SCREEN

DRYING glows when Start is pressed.

DRYING flashes when the display shows the actual minutes

remaining in the cycle. DRYING stops flashing at the start of Cool

Down.

COOL DOWN glows during the cool down part of the cycle.

CHECK LINT SCREEN flashes to remind you to clean the lint

screen before starting a cycle. The light turns off when you open

the dryer door or press Start.

Indicator lights

Other indicator lights show what cycle, options and modifiers

have been selected. The display lights also show the estimated

or actual Time Remaining.

Select the drying cycle that matches the type of load you are

drying. A preset range of heat is automatically set for the type of

fabric selected. (See "Drying and Cycle Tips" chart.)

When you select a cycle, your dryer selects a preset temperature,

Auto Dry Level (Normal) and either Auto Dry (Estimated) or Timed

Dry (Actual) Time Remaining. The time displayed for the Auto Dry

cycles are estimated times. Part way through the cycle, the dryer

turns the Auto Dry (Estimated) Time Remaining indicator light off

and displays the actual time remaining on the display. The Timed

Dry (Actual) indicator light will glow only if a Timed Dry cycle was

selected. (See "Modifiers.")

SELECT CYCLE

®(

Cotton/Towels

Use this cycle to get high heat for heavy fabrics.

Jeans

Use this cycle to get medium high heat for drying denims.

Normal

Use this cycle to get medium heat for drying sturdy fabrics.

Bulky Items

Use this cycle for drying large, bulky items that dry quickly on the

outside, but stay wet on the inside. This cycle uses medium heat.

Delicate/Casual

Use this cycle to get low heat for drying synthetic fabrics,

washable knit fabrics and no-iron finishes.

Ultra Delicate

Use this cycle to get ultra low heat to gently dry items such as

exercise wear or sheer curtains.

EXPRESS DRY TM

Use this 23 minute High Heat cycle for drying small loads or

loads that need a short drying time.

Air Dry

Air Dry gives you all the benefits of hang drying with a shorter

drying time. Adjust the Air Dry cycle from 1 to 99 minutes at any

time during the cycle, or use the preset setting of 30 minutes.

Use the Air Dry cycle for items that require drying without heat

such as rubber, plastic and heat-sensitive fabrics. This chart

shows examples of items that can be dried using the Air Dry

cycle.

Type of Load Minutes

Foam rubber - pillows, padded bras, stuffed toys 20 - 30

Plastic - Shower curtains, tablecloths 20 - 30

Rubber-backed rugs 40 - 50

Olefin, polypropylene, sheer nylon 10 - 20

When using Air Dry

• Check to see that coverings are securely stitched.

• Shake and fluff pillows by hand periodically during the cycle.

• Dry item completely. Foam rubber pillows are slow to dry.

NOTE: An Auto Dry Level selection is not available when using

the Air Dry cycle.

Custom Program

Use the Custom Program to select the Cycle, Options and

Modifiers you use most frequently and store them for future use.

To store a cycle for future use

1. Select a Cycle.

2. Select the desired Options.

3. Select the desired Modifiers.

4. Press and hold CUSTOM PROGRAM for 3 seconds until you

hear a beep.

5. Press START.

To reuse this cycle

1. Press CUSTOM PROGRAM.

2. Press START.

14

Page 15

You can customize your cycles by selecting options.

OPTIONS

@

o HEAVYDUTY

DELICATE

@

Damp Dry Signal

Select the Damp Dry Signal to alert you that your clothes are

approximately 80% dry. This is useful when you want to remove

lightweight items in a mixed load (to prevent overdrying), or

remove partially dry items that may need ironing.

NOTE: The Damp Dry Signal is an option that is only available

with Automatic cycle.

WRINKLE GUARD _ III

WRINKLE GUARD ®III prevents wrinkles that form when you

cannot unload the dryer promptly at the end of a cycle.

• Press WRINKLE GUARD _ III to get up to 21/2hours of heat-

free, periodic tumbling at the end of a cycle.

• Stop WRINKLE GUARD ®III at any time by pressing the

WRINKLE GUARD _ III pad or opening the dryer door.

For the Delicate/Casual Auto Dry cycle, WRINKLE GUARD _III

is preset to "ON." The other Auto Dry cycles will retain the

WRINKLE GUARD _ III setting. (For example, if you select

WRINKLE GUARD ®III in the Normal cycle, WRINKLE

GUARD _ III will be on the next time you select the Normal

cycle.)

NOTE: If you do not select WRINKLE GUARD ®III, the dryer stops

after Cool Down.

Touch Up

Select this option to remove wrinkles from clean items such as

clothes packed in a suitcase or items wrinkled from being left in

the dryer too long.

• Press TOUCH UP once to get HEAVY DUTY (30 minutes of

high heat). Use Heavy Duty for medium to heavyweight items

such as bedspreads and jeans.

• Press TOUCH UP twice to get DELICATE (20 minutes of low

heat). Use Delicate for light to medium weight items such as

blouses and skirts.

• Press MORE TIME or LESS TIME to adjust the cycle time.

• The WRINKLE GUARD ®III option is also available in Touch

Up. Remove clothes immediately when tumbling stops.

When you select a cycle, the preset Auto Dry Level (Auto Dry) or

Timed Dry settings for that cycle will glow. Modifiers allow you to

change the preset settings and further customize your cycles.

Auto Dry Level with Ultra Moisture Sensing

Auto Dry Level with Ultra Moisture Sensing provides the most

accurate drying results in the shortest time. This can help you

save money on utility bills and reduce the risk of fabric damage.

Dryness level is determined by dual sensor strips that measure

the moisture in your clothes. Once the desired dryness level is

reached, the electronic sensors signal the dryer to stop to

prevent overdrying your clothes.

MAXIMUM

NORMAL

MiNiMUM

ULfRAMO/STORE

SLNS/NO

NiGH

LOW

_0R_ TIMEODRY

For all Auto Dry cycles, the Auto Dry Level is automatically set at

Normal. This setting provides the recommended fabric care for

your cycle. The display will show the estimated time (in minutes)

required to reach an approximate 80% dry level. After the 80% .....

dryness level is reached, the remaining drying time required will

be displayed as actual time remaining.

Use the Normal setting to dry most loads. At the end of the cycle,

feel the dried clothes.

• If they are damper than you like, select a setting above

Normal the next time you dry a similar load.

• If they are drier than you like, select a setting below Normal

the next time you dry a similar load.

To change the dryness level

Press AUTO DRY LEVEL until the desired dryness level glows.

NOTE: Auto Dry Level is not a selectable option with the

EXPRESS DRY TM cycle, the Air Dry cycle or Touch Up.

To change from estimated to actual drying time

Press MORE TIME or LESS TIME until the desired time is

displayed. The light for Timed Dry (Actual) will glow.

Timed Dry

Use Timed Dry to select a specific amount of drying time. The

preset settings for EXPRESS DRYTM, Air Dry and Touch Up are

automatically set to Timed Dry.

To change the time

Press MORE TIME or LESS TIME until the desired time shows in

the display.

End of Cycle Signal

The End of Cycle Signal produces an audible sound when the

drying cycle is finished. Promptly removing clothes at the end of

the cycle reduces wrinkling.

Press the END of CYCLE SIGNAL pad to adjust the sound level

or turn off the signal.

NOTE: When WRINKLE GUARD ®III is selected and the End of

Cycle Signal is on, an audible sound will emit every five minutes

until the clothes are removed, or WRINKLE GUARD ®III is

finished.

15

Page 16

You can change Cycles, Options and Modifiers anytime before

Start is pressed.

• A short tone sounds when a change is selected.

• Two short tones sound if an unavailable combination is

selected. The last selection will not be accepted.

Changing Cycles after pressing Start

1. Press STOP/CANCELtwice.

2. Select the desired cycle.

3. Press START. The dryer starts at the beginning of the new

cycle.

NOTE: If you do not press Start within 5 minutes of selecting the

cycle, the dryer automatically shuts off.

Changing Options and Modifiers after pressing Start

You can change an Option or Modifier anytime before the

selected Option or Modifier begins.

1. Press STOP/CANCEL.

2. Select the new Option and/or Modifiers.

3. Press START to continue the cycle.

The dryer rack was shipped on top of your dryer. Remove and

discard shipping blocks before use.

Use the TUMBLE FREETM Heated Dryer Rack for items that you

do not want to tumble dry, such as sweaters. When you use the

heated dryer rack, the heated air inside the dryer flows in a

concentrated pattern to allow efficient and uniform drying.

Use Timed Dry to select the desired time.

NOTE: Do not use Automatic cycles with the dryer rack.

To use the heated dryer rack:

Do not remove the lint screen.

1. Open dryer door.

2. Slide dryer rack over the bottom of the dryer door opening.

Push down to secure on the frame.

3. Place wet items on top of the rack. Allow space around items

for air to circulate. The rack does not move, but the drum will

rotate. Make sure items do not hang over the edges or

between rack grille.

4. Close the door.

5. Select the desired cycle to match the fabrics in your load.

Items containing foam, rubber, or plastic must be dried on a

clothesline or by using an air cycle. Refer to the following

table.

6. You must select a time by pressing the MORE TIME or LESS

TIME pads. Refer to the following table.

7. Start the dryer.

NOTE: You must remove rack for normal tumbling. To remove the

dryer rack, lift it straight up and out of the dryer.

NOTE: Check the lint screen and remove any lint accumulated

from items dried on the rack.

Suggested Items for Rack Cycle Suggested

Drying Setting Time*

(minutes)

Washable wool items Touch Up 20

(block to shape and lay flat (Delicate)

on rack)

Stuffed toys or pillows Touch Up 30

(cotton or polyester (Delicate)

fiber filling)

Stuffed toys Air Dry 50

(foam rubber filled)

Tennis shoes Air Dry 20

* Reset time as needed to complete drying.

DRYER CARE

Keep dryer area clear and free from items that would obstruct the

flow of combustion and ventilation air.

E×plosion Hazard

Keep flammabBe materiams and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can resuJt in death, e×plosion, or fire.

16

Page 17

Every load cleaning

The lint screen is located in the door of the dryer. Clean it before

each load. A screen blocked by lint can increase drying time.

To clean

1. Pull the lint screen straight up. Roll lint off the screen with

your fingers. Do not rinse or wash screen to remove lint. Wet

lint is hard to remove.

J

2. Push the lint screen firmly back into place.

IMPORTANT:

• Do not run the dryer with the lint screen loose, damaged,

blocked, or missing. Doing so can cause overheating and

damage to both the dryer and fabrics.

Some towels made of synthetic fibers and natural fibers

(polyester and cotton blends) may shed more lint than other

towels, causing your dryer's lint screen to fill up faster. Be

sure to remove lint from the lint screen before and after drying

new towels.

• If lint falls off the screen into the dryer during removal, check

the exhaust hood and remove the lint. (See "Venting

Requirements.")

As needed cleaning

Laundry detergent and fabric softener residue can build up on the

lint screen. This buildup can cause longer drying times for your

clothes, or cause the dryer to stop before your load is completely

dry. The screen is probably clogged if lint falls off the screen.

Clean the lint screen with a nylon brush every 6 months or more

frequently if it becomes clogged due to a residue buildup.

To wash

1. Roll lint off screen with your fingers.

2. Wet both sides of lint screen with hot water.

3. Wet a nylon brush with hot water and liquid detergent. Scrub

lint screen with the brush to remove residue buildup.

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with a clean towel. Replace screen

in dryer.

To clean the dryer drum

1. Make a paste with powdered laundry detergent and very

warm water.

2. Apply paste to a soft cloth.

OR

Apply a liquid, nonflammable household cleaner to the

stained area and rub with a soft cloth until all excess dye is

removed.

3. Wipe drum thoroughly with damp cloth.

4. Tumble a load of clean cloths or towels to dry the drum.

NOTE: Garments which contain unstable dyes, such as denim

blue jeans or brightly colored cotton items, may discolor the

interior. These stains are not harmful to your dryer and will not

stain future loads of clothes. Dry unstable dye items inside out to

prevent dye transfer.

From Inside the Dryer Cabinet:

Lint should be removed every 2 years or more often, depending

on dryer usage. Cleaning should be done by a qualified person.

From the Exhaust Vent:

Lint should be removed every 2 years, or more often, depending

on dryer usage.

Vacation care

Operate your dryer only when you are at home. If you will be on

vacation or not using your dryer for an extended period of time,

you should:

1. Unplug dryer or disconnect power.

2. Close shutoff valve in gas supply line.

3. Clean lint screen. See "Cleaning the Lint Screen."

Moving care

1. Unplug dryer or disconnect power.

2. Close shutoff valve in gas supply line.

3. Disconnect gas supply line pipe and remove fittings attached

to dryer pipe.

4. Cap the open fuel supply line.

5. Make sure leveling legs are secure in dryer base.

6. Use masking tape to secure dryer door.

The dryer light automatically turns on inside the dryer drum when

you open the door.

To change the drum light

1. Unplug dryer or disconnect power.

2. Open the dryer door. Locate the light bulb cover on the back

wall of the dryer. Remove the screw located in the lower right

corner of the cover. Remove the cover.

3. Turn bulb counterclockwise. Replace the bulb only with a

10-watt appliance bulb. Replace the cover and secure with

the screw.

4. Plug in dryer or reconnect power.

17

Page 18

TROUBLESHOOTING

First try the solutions suggested here and possibly avoid the cost of a service call.

Dryer displaying code message Dryer will not run

• "PF" (power failure), check the following:

Is the dryer connected to the power supply?

• Check the following:

Is the power cord plugged in?

Was the dryer connected to a power supply during

installation or a power failure?

Press STOP/CANCEL to clear display.

Was the drying cycle interrupted by a power failure?

Press START to restart the dryer.

Has a fuse blown, or has a circuit breaker tripped?

Was a regular fuse used? Use a time-delay fuse.

Is the dryer door firmly closed?

Was the START button firmly pressed?

• "E" Variable (El, E2, E3) service codes: Is a cycle selected?

Call for service.

Clothes are not drying satisfactorily

• Checkthe following:

Is the lint screen clogged with lint?

Unusual sounds

• Has the dryer had a period of non-use?

If the dryer hasn't been used for a while, there may be a

thumping sound during the first few minutes of operation.

Is the exhaust vent or outside exhaust hood clogged with lint,

restricting air movement? Run the dryer for 5-10 minutes.

Hold your hand under the outside exhaust hood to check air

movement. If you do not feel air movement, clean exhaust

system of lint or replace exhaust vent with heavy metal or

flexible metal vent. See "Installation Instructions."

Is the exhaust vent crushed or kinked? Replace with a heavy

metal or flexible metal vent. See "Installation Instructions."

Has a fuse blown, or has a circuit breaker tripped?

Has an Air Dry cycle been selected? Select the right cycle for

the types of garments being dried. See "Cycles."

The gas valve clicking is a normal operating sound.

Lint on load

• Is the lint screen clogged?

Clean lint screen. Check for air movement.

• Is load properly sorted?

Sort lint givers (towels, chenille) from lint takers (corduroy,

synthetics). Also sort by color.

• Is the load too big or too heavy?

Dry smaller loads so lint can be carried to the lint screen.

Is the automatic cycle ending early? The load may not be

contacting the electronic sensor strips, level the dryer.

Is the valve open on the gas supply line?

Are fabric softener sheets blocking the grille? Use only one

fabric softener sheet and only use it once.

Is the dryer located in a room with temperature below

45°F (7°C)?

Proper operation of dryer cycles requires temperatures above

45°F (7°C).

Was a cold rinse water used? Was the load very wet?

Expect longer drying times with items rinsed in cold water

and with items that hold moisture (cottons).

Is the load too large and heavy to dry quickly?

Separate the load to tumble freely.

Was the load overdried?

Use correct dryer settings for load type. See "Changing

Cycles, Options and Modifiers." Overdrying can cause

lint-attracting static electricity.

Was paper or tissue left in pockets?

Is pilling being mistaken for lint?

Pilling (surface fuzz) is caused by normal wear and

laundering.

Stains on load or color change

Was dryer fabric softener properly used?

Add dryer fabric softener sheets at the beginning of the cycle

when the load is cold. Do not add fabric softener sheets to a

warm load.

• Were items soiled when placed in the dryer?

Items should be clean before being dried.

• Were items properly sorted?

Sort light colors from dark colors. Sort colorfast items from

noncolorfast items.

18

Page 19

Items shrinking

• Was the dryer overloaded?

Dry smaller loads that can tumble freely.

• Did the load overdry?

Check the manufacturer's care label. Match dryer setting to

load type. See "Cycles."

Loads are wrinkled

• Was load removed from dryer at the end of the cycle?

• Was dryer overloaded?

Dry smaller loads that can tumble freely.

• Did load overdry?

Check the manufacturer's care label. Match dryer setting to

load type. See "Cycles."

Odors

• Have you recently been painting, staining or varnishing in

the area where your dryer is located?

If so, ventilate the area. When the odors or fumes are gone

from the area, rewash and dry the clothing.

Garment damage

• Check the following:

Were zippers, snaps, and hooks left open?

Were strings and sashes tied to prevent tangling?

Were care label instructions followed?

Were items damaged before drying?

19

Page 20

iNDICE

CONTRATOS DE PROTECCION ................................................ 20

GARANTIA .................................................................................... 21

SEGURIDAD DE LA SECADORA ............................................... 22

INSTRUCCIONES DE INSTALACION ........................................ 23

Herramientas y piezas ............................................................... 23

Requisites de ubicaci6n ............................................................ 24

Requisites electricos ................................................................. 25

Requisitos del suministro de gas .............................................. 25

Requisites de ventilaci6n .......................................................... 27

Planificaci6n del sistema de ventilaci6n ................................... 27

Instalaci6n del sistema de ventilaci6n ...................................... 29

Instalaci6n de las patas niveladoras ......................................... 29

Nivelaci6n de la secadora ......................................................... 30

Conexi6n del suministro de gas................................................ 30

Conexi6n del ducto de escape ................................................. 30

Complete la instalaci6n ............................................................. 30

USO DE LA SECADORA ............................................................. 31

Puesta en marcha de su secadora ........................................... 31

C6mo detener su secadora ....................................................... 32

C6mo hacer una pausa o reanudar la marcha ......................... 32

C6mo cargar .............................................................................. 32

Sugerencias de ciclos y de secado .......................................... 32

Estado de la secadora (Dryer Status) ....................................... 33

Ciclos ......................................................................................... 33

Opciones ................................................................................... 34

Modificadores ............................................................................ 35

Cambio de ciclos, opciones y modificadores ........................... 35

Estante termico de la secadora TUMBLE FREETM ................... 36

CUIDADO DE LA SECADORA .................................................... 36

Limpieza del lugar donde esta

la secadora ................................................................................ 36

Limpieza del filtro de pelusa ...................................................... 36

Limpieza del interior de la secadora ......................................... 37

Eliminaci6n de pelusa acumulada ............................................ 37

Cuidado para las vacaciones y

la mudanza ................................................................................ 37

Cambio de la luz del tambor ..................................................... 37

SOLUCION DE PROBLEMAS ..................................................... 38

NUMEROS DE SERVICIO .............................. CONTRAPORTADA

CONTRATOS DE

PROTECCION

Contratos Maestros de Proteccibn

iFelicitaciones per su inteligente adquisici6n! Su nuevo producto

Kenmore ®ha sido diser_ado y fabricado para brindarle argos de

funcionamiento confiable. Pero al igual que todos los productos,

puede necesitar mantenimiento preventivo o reparaci6n de vez

en cuando. Es allf donde el Contrato Maestro de Protecci6n

puede ahorrarle dinero e inconvenientes.

Adquiera un Contrato Maestro de Protecci4n hey y prot_jase

contra molestias y gastos inesperados.

El Contrato Maestro de Proteccidn tambien ayuda a prolongar la

vida de su nuevo producto. He aquf Io que se incluye en el

Contrato:

v' Servicio experto por nuestros 12.000 especialistas en

reparaci6n competentes

v' Servicio ilimitado y gratuito para repuestos y mane de obra

en todas las reparaciones protegidas por el contrato

v' Garantia "sin disgustos" - reemplazo de su producto

protegido si ocurren cuatro o mas fallas del producto en el

transcurso de doce meses

v' Reemplazo del producto si su producto protegido no puede

ser reparado

v' Revisibn Anual de Mantenimiento Preventivo a solicitud

suya - sin costo adicional

v"

Ayuda r_pida por tel_fono - asistencia per telefono a cargo

de un tecnico de Sears para productos que deban ser

reparados en su hogar, ademas de un horario de reparaci6n

conveniente

v' Proteccibn de sobrevoltaje contra dados electricos debido a

fiuctuaciones de electricidad

v' Reembolso de la renta si la reparaci6n de su producto

protegido tarda mas de Io prometido

Una vez adquirido el Contrato, tan s61otiene que Ilamar para fijar

la visita de servicio tecnico, Usted puede Ilamar a cualquier hora,

de dia o de noche, o fijar una visita tecnica en internet.

Sears cuenta con un equipo de mas de 12.000 especialistas en

reparaci6n competentes, quienes tienen a disposici6n mas de

4,5 millones de repuestos y accesorios de calidad. Cse es el tipo

de profesionalismo con el que usted puede contar para ayudarle

a prolongar la vida de su nuevo artefacto per muchos a_os mas.

iAdquiera hey su Contrato Maestro de Protecci6n!

Se aplican algunas limitaciones y exclusiones. Para obtener

precios e informaci6n adicional, Ilame al 1-800-827-6655.

Servicio de Instalacibn de Sears

Para la instalaci6n profesional de Sears de artefactos

electredomestices, abridores de puertas de garaje, calentadores

de agua y otros articulos importantes de la casa, en los EE.UU.

Ilame al 1-800-4-MY-HOME ®.

20

Page 21

GARANTIA

Garantia completa de un aho para las piezas mec&nicas y

componentes el_ctricos

Durante un a_o a partir de la fecha de compra, si se instala y

pone en funcionamiento la secadora de conformidad con las

instrucciones proporcionadas en este Manual de Uso y Cuidado,

Sears reparara esta secadora, gratuitamente, si tuviese defectos

en el material o la mano de obra.

NOTA: El empleo de un ducto de escape de plastico para esta

secadora puede anular esta garantia. Consulte la secci6n de

"lnstrucciones de instalaci6n" para obtener informaci6n

completa sobre los requisitos de ventilaci6n para esta secadora.

Garantia limitada de dos ahos para el tablero de control

electrbnico SENSOR SMART TM

Durante el segundo a_o a partir de la fecha de compra, Sears

reemplazara el tablero de control electr6nico si tuviese defectos

de materiales o de mano de obra. El cliente se hara cargo de los

gastos de mano de obra despues del primer aSo.

Restriccibn de la garantia

Si se somete a esta secadora a un uso ajeno al domestico

privado, la cobertura de las garantfas arriba citadas quedan

restringidas a s61o 90 dias.

Servicio de reparacibn de la garantia

El servicio de reparaci6n de la garantia esta a su disposici6n al

contactarse con el Centro de Servicio Sears mas cercano. Esta

garantia corresponde s61o mientras se use el producto en los

Estados Unidos.

Esta garantia le otorga derechos legales especificos yes posible

que usted tenga tambien otros derechos que pueden variar de un

estado a otro.

Para obtener informaci6n respecto a la garantfa de Sears o para

ponerse en contacto con un Centro de Servicio de Sears, sfrvase

tomar como referencia los nQmeros de servicio tecnico ubicados

en la contraportada del manual.

Sears, Roebuck and Co.

D/817WA, Hoffman Estates, IL 60179

Registro del producto

Use el espacio a continuaci6n para anotar el nQmero completo

del modelo y de la serie, asi como la fecha de compra. Usted

podra encontrar esta informaci6n en la etiqueta con el nQmero de

modelo y de serie, en la cavidad interna superior de la puerta de

la secadora.

Siempre que se ponga en contacto con Sears respecto a su

electrodomestico, tenga esta informaci6n a mano para facilitar la

obtenci6n de ayuda o servicio tecnico.

Ni3mero de modelo 110.

Ni3mero de serie

Fecha de compra

Guarde estas instrucciones y su comprobante de ventas para

referencia futura.

21

Page 22

SEGURIDAD DE LASECADORA

Su seguridad y la seguridad de los demas es muy importante.

Heroes incluido muchos mensajes importantes de seguridad en este manual y en su electrodomestico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el simbolo de advertencia de seguridad.

Este simbolo le llama la atencidn sobre peligros potenciales que pueden ocasionar la muerte o una lesidn a

usted y a los demas.

Todos los mensajes de seguridad iran a continuacion del sfmbolo de advertencia de seguridad y de la palabra

"PELIGRO" o "ADVERTENClA". Estas palabras significan:

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesion grave.

Si no eigue las instrucciones, usted puede morir o sufrir

una lesion grave.

Todos los mensajes de seguridad le dir_.n el peligro potencial, le dir_.n cdmo reducir las posibilidades de sufrir una lesion y Io que

puede suceder si no se siguen las instrucciones.

ADVERTENCIA: Para su seguridad, la informacibn en este manual debe ser observada

para minimizar el riesgo de incendio o explosibn, o para prevenir dahos a propiedades,

heridas o la muerte.

- No almacene o use gasolina u otros liquidos y vapores inflamables cerca de dste u otro

aparato electrodomdstico.

- PASOS QUE USTED DEBE SEGUIR SI HUELE A GAS:

• No trate de encender ningdn aparato electrodomdstico.

• No toque ningdn interruptor eldctrico; no use ningdn teldfono en su edificio.

• Desaloje a todos los ocupantes del cuarto, edificio o area.

• Llame inmediatamente a su proveedor de gas desde el teldfono de un vecino.

Siga las instrucciones de su proveedor de gas.

• Si usted no puede comunicarse con su proveedor de gas, Ilame al departamento

de bomberos.

- La instalacibn y el servicio deben ser efectuados por un instalador calificado, una

agencia de servicio o por el proveedor de gas.

En el estado de Massachusetts se aplican las siguientes instrucciones de instalacidn:

Las instalaciones y reparaciones se deben efectuar per un contratista, plomero o gasista calificado o licenciado per el estado

de Massachusetts.

Si se usa una vatvula de bota, debe set un tipo de manigueta T.

Si se usa un conector de gas flexible no debe exceder de 3 pies.

22

Page 23

iNSTRUCCiONES iMPORTANTES DE SEGURIDAD

ADVERTENCUA: A fin de reducir el riesgo de incendio, descarga electrica o de dane a Ias personas que usen

la secadora, deben seguirse las precauciones basicas, incluidas las siguientes:

• Lea todas las instrucciones antes de usar la secadora.

• No coloque Ios objetos expuestos a aceite para cocinar

en su secadora. Los obietos expuestos a aceites para

cocinar pueden contribuir a una reacci6n quimica que

podria causar que una carga se inflame.

• No seque articulos que ya se hayan limpiado, lavado,

remojado o manchado con gasolina, disolventes de

Iimpieza en seco, u otras sustancias infiamables o

explosivas ya que despiden vapores que pueden

encenderse o causar una explosi6n.

• No permita que jueguen Ios ni¢ios sobre o dentro de la

secadora. Es necesaria la cuidadosa vigilancia de los

nifios toda vez que se use la secadora cerca de elIos.

• Quite la puerta de la secadora al compartimiento de secado

antes de ponerla fuera de funcionamiento o de descartaria.

• No introduzca Ias manos en Ia secadora cuando el tambor

esta en movimiento.

• No instale o almacene esta secadora donde estara

expuesta a agua o a Ia intemperie.

• No trate de forzar los controles.

• No repare o reemptace ninguna pieza de Ia secadora ni

trate de repararia a menos que esto se recomiende

especificamente en ei Manual de! propietario o en

instrucciones de reparaci6n publicadas para eI usuario

que usted comprenda y s61osi cuenta con la experiencia

necesaria para Ilevar a cabo dicha reparaci6n.

• No utilice suavizadores de teiidos o productos para eliminar

el estatico de prendas a menos que Io recomiende e!

fabricante del suavizador de teiidoso las instrucciones del

producto en uso.

• No utilice calor para secar prendas que contengan espuma

de caucho o matedales de caucho con textura similar.

• Limpie eI filtro de pelusa antes o depues de cada carga

de ropa.

• Mantenga el area alrededor de Ia apertura de ventilaci6n

y Ias areas adyacentes a esta apertura sin pelusa, polvo

o tierra.

• La parte interior de la secadora yet ducto de escape se

deben limpiar peri6dicamente. Esta Iimpieza Ia debe lievar

a cabo un reparador calificado.

• Vea la instrucciones de instalaci6n para los requisitos de

conexi6n a tierra.

GUARDE ESTAS iNSTRUCCiONES

IMPORTANTE: La instalaci6n de gas debe hacerse de acuerdo con los c6digos locales, o si no los hay, con el C6digo Nacional

de Gas Combustible (National Fuel Gas Code), ANSI Z223.1/NFPA 54.

La secadora debe estar conectada a tierra de acuerdo con los c6digos locales, o si no los hay, con el C6digo Nacional de

Electricidad (National Electrical Code), ANSI/NFPA 70.

INSTRUCCIONES DE INSTALACION

Verifique si tiene todo Io necesario para una instalaci6n correcta.

La instalaci6n adecuada es responsabilidad suya.

Llave para tubos de 8" 6

10"

Llave de tuercas

ajustable de 8" 6 10"

(para conexiones de gas)

Destornillador de hoja

plana

Llave de tuercas

ajustable que se abra a

1" (2,5 cm) o una Ilave de

cube de cabeza

hexagonal (para regular

las patas de la secadora)

• Nivel

• Llave para tuercas de V4"

o Ilave de cubo

• Cuchillo

• Abrazaderas para ducto

• Pegamento paratuberfas

resistente a gas L.R

• Pistola y masilla para

calafateo (para instalar el

nuevo ducto de escape)

• Alicates

Piezas suministradas:

Retire el paquete de piezas del tambor de la secadora. Verifique

que esten todas las piezas.

4patas niveladoras

Piezas para adquirir:

Verifique los c6digos locales y con la compafiia abastecedora de