Page 1

Three-Speed Automatic Washers with TRIPLE SMART^*^ Dispenser

Lavadoras automáticas con tres velocidades

y Depósito TRIPLE SMART™

ÎY/f.€Â.i

'í-4 i

Jw Vi

0^'..........

distributeurs TRIPLE SMART ™

Models/Modelos/Modèles 110.2497H:, 2498^, 2499H:

^ = color number, número de color, numéro de couleur

8537204

SeaiB Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Sears Canada Inc*, Toronto, Ontario, Canada M58 2B8

www.sears.com

www.sears.ca

Page 2

TABLE OF CONTENTS

PROTECTION AGREEMENTS..................................................2

In the U.S.A..

In Canada

WARRANTY...

WASHER SAFETY........................................................... ....4

INSTALLATION REQUIREMENTS

Tools and Parts.......................................................................5

Location Requirements...........................................................5

Drain System

Electrical Requirements..............

INSTALLATION INSTRUCTIONS............................................ 7

Before You Start

Remove Shipping Strap...................................................

Connect Drain Hose.......................................................... 8

Connect the Inlet Hoses..........................................................8

Secure the Drain Hose............................................................9

Level the Washer................................................................ 9

Complete Installation......................................................... 10

FEATURES AND BENEFITS................................................. 10

WASHER USE................................................................... 11

Starting Your Washer

Selecting Wash/Spin Speeds.............................................. 12

Selecting a Cycle and Time.....

Rinse and Spin......................................................................13

Drain and Spin

Understanding Washer Cycles........

Normal Sounds...

LAUNDRY TIPS............

Loading.................................................................................14

WASHER CARE.......................................................................15

Cleaning Your Washer

Water Inlet Hoses...

Vacation, Storage, and Moving Care

TROUBLESHOOTING

.......

............................................................... 2

..........................................................................

.................................................................. .....3

...........................................

......

...............................................................

........................................

.....................................................................

.....7

...........................................................

......

........................................13

......................................................................

......................................13

..............................................................

.......................................................

..........................................................15

.......................................................... 15

....................................

........................................................

3

6

6

11

13

14

14

15

..15

PROTECTION

iril

Master Protection Agreements

5

Congratulations on making a smart purchase. Your new

Kenmore® appliance is designed and manufactured for years of

dependable operation. But like all products, it may require

preventive maintenance or repair from time to time. That’s when

having a Master Protection Agreement can save you money and

aggravation.

7

Purchase a Master Protection Agreement now and protect

yourself from unexpected hassle and expense.

The Master Protection Agreement also helps extend the life of

your new appliance. Here’s what’s included in the Agreement:

✓ Expert service by our 12,000 professional repair specialists

✓ Unlimited service and no charge for parts and labor on all

covered repairs

✓ “No-lemon” guarantee - replacement of your covered

product if four or more product failures occur within twelve

months

✓ Product replacement if your covered product can’t be fixed

✓ Annual Preventive Maintenance Check at your request - no

extra charge

✓ Fast help by phone - phone support from a Sears technician

on products requiring in-home repair, plus convenient repair

scheduling

✓ Power surge protection against electrical damage due to

power fluctuations

✓ Rental reimbursement if repair of your covered product takes

longer than promised

Once you purchase the Agreement, a simple phone call is all that

it takes for you to schedule service. You can call anytime day or

night, or schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories. That’s

the kind of professionalism you can count on to help prolong the

life of your new purchase for years to come. Purchase your

Master Protection Agreement todayl

Some limitations and exclusions apply. For prices and

information, call 1-800-827-6655.

Sears Installation Senrice

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in the

U.S.A. call 1-800-4-MY-HOME®.

Page 3

Maintenance Agreements

Your purchase has added value because you can depend on

Sears HomeCentral® for service. With over 2,400 Service

Technicians and access to over 900,000 parts and accessories,

we have the tools, parts, knowledge and skills to back our

pledge; We Service What We Sell.

Your Kenmore® appliance is designed, manufactured and tested

to provide years of dependable operation. Yet any major

appliance may require service from time to time. The Sears

Maintenance Agreement offers you an outstanding service

program, affordably priced.

The Sears Maintenance Agreement

■ Guarantees tomorrow’s service at today’s price.

■ Eliminates repair bills resulting from normal wear and tear.

■ Covers non-technical and instructional service calls.

■ Provides an annual Preventive Maintenance Check, at your

request, to ensure that your appliance is in proper running

condition.

Some limitations apply. For information concerning Sears

Home Central® Maintenance Agreements, call

1-800-361-6665.

KENMORE ELITP

WASHER WARRANTY

Limited Lifetime Warranty on White Porcelain Basket

For the lifetime of the washer from the date of purchase. Sears

will replace the white porcelain wash basket if it chips or rusts

due to defective material or workmanship. After the first year, you

will be charged for labor.

Limited 10-Year Warranty on Plastic Tub*

For the second through tenth year from the date of purchase,

Sears will replace the plastic tub if it is defective in material or

workmanship. After the first year, you will be charged for labor.

Limited 5-Year Warranty on Gearcase Parts*

For the second through fifth year from the date of purchase.

Sears will replace any gearcase parts that are defective in

material or workmanship. After the first year, you will be charged

for labor.

Limited 2-Year Warranty on SENSOR SMART“

Control Board

For two years from the date of purchase, Sears will replace the

SENSOR SMART“ control board if it is defective in material or

workmanship. You will be charged for labor after the first year.

Full 1-Year Warranty on Mechanical and Electrical Parts

For one year from the date of purchase, when this washer is

installed and operated according to the instructions that come

with it. Sears will repair or replace any of its mechanical or

electrical parts if they are defective in material or workmanship.

Service must be provided by a Sears Service Department in the

United States or Canada or an authorized agent.

Warranty Restriction

If this washer is operated for any purpose other than private

family use, all warranty coverage is restricted to 90 days from the

date of purchase.

Travel or transportation expenses for customers who reside in

remote areas are not covered by this warranty.

Warranty Service

Warranty service is available by contacting the nearest Sears

Service Center in the United States or Canada. This warranty

applies only while the product is in use in the United States or

Canada.

This warranty gives you specific legal rights and you may also

have other rights which vary from state to state or province to

province.

For Sears warranty information or to contact a Sears Service

Center, please reference the service numbers located on the

back page of this manual.

Sears, Roebuck and Co.

D/817WA, Hoffman Estates, IL 60179

Sears Canada Inc.

Toronto, Ontario, Canada MSB 2B8

* In Canada a different warranty may apply.

Product Record

In the space below, record your complete model number, serial

number, and purchase date. You can find this information on the

model and serial number label, as shown.

Have this information available to help you quickly obtain

assistance or service when you contact Sears concerning your

appliance.

Model number 110__________________________________________

Serial number______________________________________________

Purchase date

Save these instructions and your sales receipt for future

reference.

Page 4

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER" or

“WARNING.” These words mean;

You can be killed or seriously injured if you don't

ADANGER

AWARNING

Ail safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

immediately follow instructions.

You can be killed or seriously injured if you don't follow instructions.

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer, follow basic

precautions, including the following:

I Read all instructions before using the washer.

I Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, other flammable,

or explosive substances as they give off vapors

that could ignite or explode.

I Do not add gasoline, dry-cleaning solvents, or

other flammable, or explosive substances to the

wash water. These substances give off vapors

that could ignite or explode.

I Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not

been used for such a period, before using the

washing machine, turn on all hot water faucets

and let the water flow from each for several

minutes. This will release any accumulated

hydrogen gas. As the gas is flammable, do not

smoke or use an open flame during this time.

■ Do not allow children to play on or in the washer. Close

supervision of children is necessary when the washer is

used near children.

■ Before the washer is removed from service or discarded,

remove the door or lid.

■ Do not reach into the washer if the drum, tub or agitator

is moving.

■ Do not install or store the washer where it will be

exposed to the weather.

■ Do not tamper with controls.

■ Do not repair or replace any part of the washer or

attempt any servicing unless specifically recommended

in this manual or in published user-repair instructions

that you understand and have the skills to carry out.

■ See “Electrical Requirements” for grounding instructions.

3AVE THESE INSTRUCTIONS

Page 5

INSTALLATION

Alternate Parts

Parts listed are available from your local Sears store or Sears

Service Center. For further information, please call 1-800-4-MY-

HOME® (1-800-469-4663).

If You Have: You Will Need to Buy:

too

Assemble the necessary tools and supplies before beginning the

washer installation. The parts supplied are in the washer basket.

Tools needed for connecting the drain hose and water inlet hoses:

■ Piiers that open to 1 ®/i6 in. (3.95 cm)

■ Fiashlight (optional)

Parts supplied:

2. Silver, double-wire hose damp

(for the bottom of the drain hose)

3. Yellow, single-wire hose clamp

(for the top of the drain hose)

4. Water inlet hoses (2)

6. Flat water inlet hose washers (4)

Laundry tub or

standpipe taller

than 96 in. (2.4 m)

1 in. (2.5 cm)

diameter

standpipe

Overhead sewer Standard 20 gal. (76 L) 39 in. (99 cm) tall

Floor drain Siphon break, Part Number 285320;

Water faucets

beyond reach of

fill hoses

Drain hose too

short

Drain hose that is

too long

Lint clogged drain Drain protector, Part No. 367031

Sump pump system (if not already

available)

2 in. (5 cm) diameter to 1 in. (2.5 cm)

diameter standpipe adapter, Part No.

3363920

drain tub or utility sink, sump pump and

connectors (available from local

plumbing suppliers)

additional drain hose. Part Number

3357090 and connector kit,

Part Number 285442

2 longer water fill hoses:

6 ft (1.8 m) Part Number 76314,

10 ft (3.0 m) Part Number 350008

Drain hose, Part No. 388423 and hose

kit, Part No. 285442

Hose kit. Part No. 285442

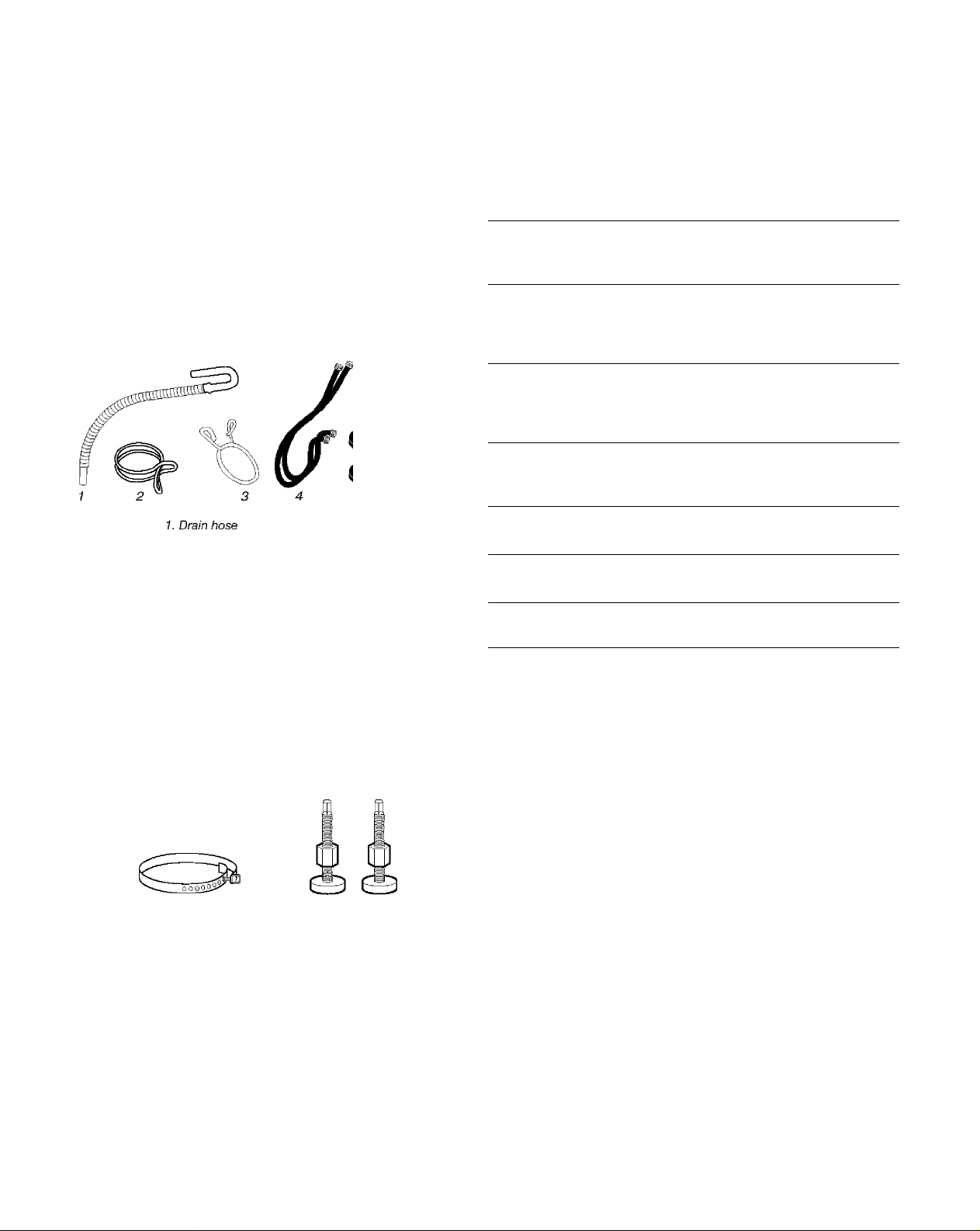

Tools needed for securing the drain hose and

leveling the washer:

■ Adjustable or open end wrench ®/i6 in. (14 mm)

■ Levei

■ Wood block

■ Ruler or measuring tape

Parts supplied:

1

1. Shipping strap with fastener

2. Front leveling feet with nuts (2)

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer “walk.”

Your washer can be installed in a basement, laundry room,

closet, or recessed area. (See “Drain System.”)

IMPORTANT: Do not install or store the washer where it will be

exposed to the weather.

Proper installation is your responsibility.

You will need:

■ A water heater set to deliver 120°F (49'’C) water to the

washer.

■ A grounded electrical outlet located within 4 ft (1.2 m) of

where the power cord is attached to the back of the washer.

(See “Electrical Requirements.”)

■ Hot and cold water faucets located within 4 ft (1.2 m) of the

hot and cold water fill valves, and water pressure of 5-100 psi

(34.5-690 kPa). Washers with triple dispensers require

20-100 psi (138-690 kPa) for best performance.

■ A level floor with a maximum slope of 1 in. (2.5 cm) under

entire washer. Installing the washer on carpeting is not

recommended.

■ A sturdy floor to support the washer weight (washer, water

and load) of 315 lbs (143 kgs).

Do not store or operate your washer in temperatures at or below

32"F (0°C). Some water can remain in the washer and can cause

damage in low temperatures. See “Washer Care" for winterizing

information.

Page 6

Recessed area or closet installation

The dimensions shown are for the recommended spacing

aliowed, except the cioset door ventilation openings. The

dimensions shown for the closet door ventiiation openings are

the minimum required.

7. Front view

2. Side view

3. Closet door with vents

Additional spacing should be considered for ease of

instailation and servicing.

Additionai ciearances may be required for wali, door and floor

moldings.

Additional spacing of 1 in. (2.5 cm) on all sides of the washer

is recommended to reduce noise transfer.

If a cioset door is installed, the minimum air openings in the

top and bottom of the door are required. Louvered doors with

air openings in the top and bottom are acceptable.

Companion appliance spacing should also be considered.

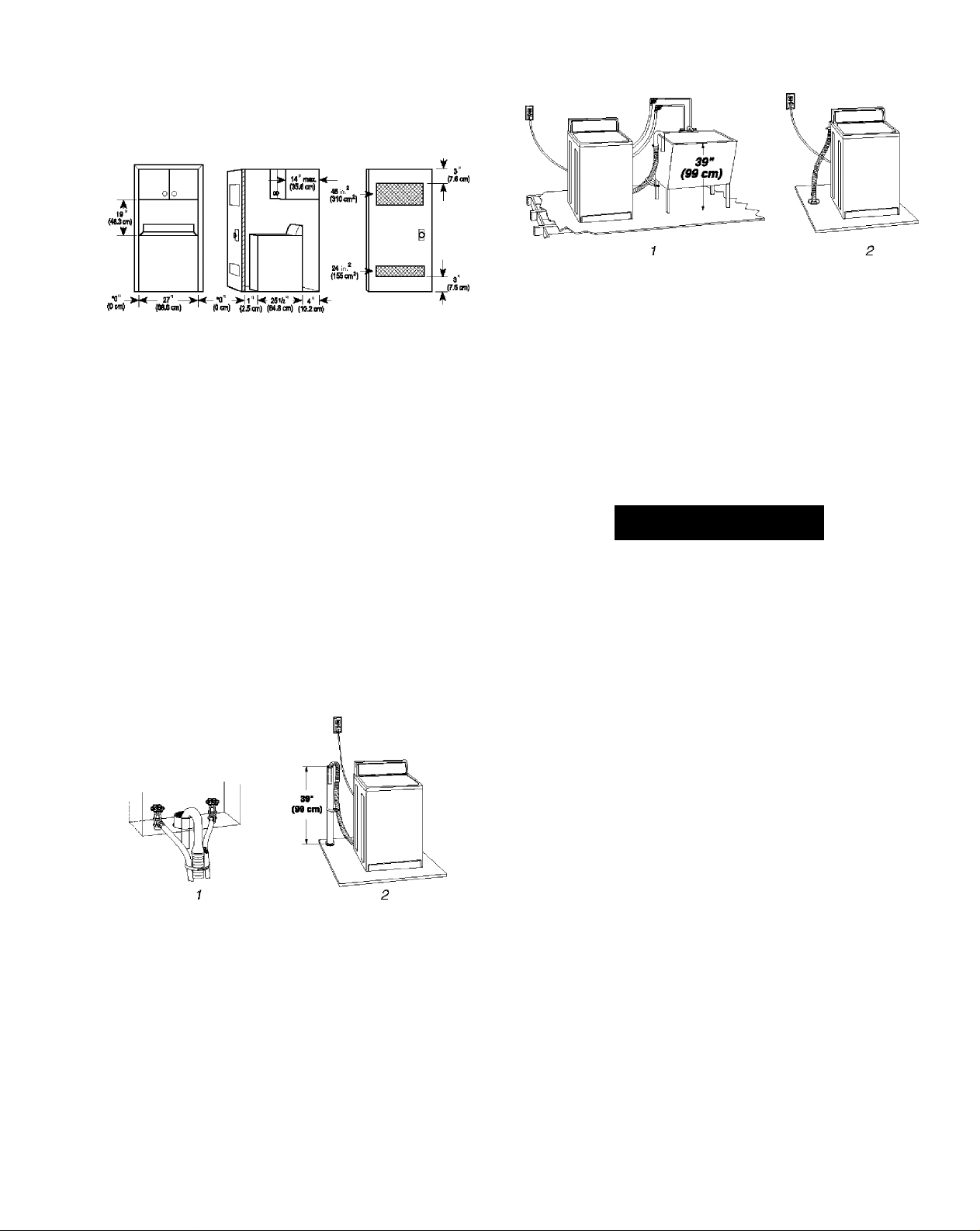

The top of the standpipe must be at least 39 in. (99 cm) high and

no higher than 96 in. (244 cm) from the bottom of the washer.

Laundry tub drain system (view 1)

The laundry tub needs a minimum 20 gal. (76 L) capacity. The top

of the laundry tub must be at least 39 In. (99 cm) above the floor

and no higher than 96 in. (244 cm) from the bottom of the washer.

Floor drain system (triew 2)

The floor drain system requires a siphon break that may be

purchased separately. See “Alternate Parts."

The siphon break must be a minimum of 28 in. (71 cm) from the

bottom of the washer. Additional hoses might be needed.

Ш i m

AWARNING

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system. Select the drain hose installation method you need. See

“Alternate Parts."

Standpipe drain system - wall or floor (view 1 & 2)

The standpipe drain requires a minimum diameter standpipe of

2 in. (5 cm). The minimum carry-away capacity can be no less

than 17 gal. (64 L) per minute. A 2 in. (5 cm) diameter to 1 in.

(2.5 cm) diameter standpipe adapter kit is available. See

“Alternate Parts.”

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

A 120-volt, 60-Hz., AC-oniy, 15- or 20-ampere, fused

electrical supply is required. Time-delay fuse or circuit

breaker is recommended. It is recommended that a separate

circuit serving only this appliance be provided.

This washer is equipped with a power supply cord having a 3

prong grounded plug.

To minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, ground-type outlet, grounded

in accordance with local codes and ordinances. If a mating

outlet is not available, it is the personal responsibility and

obligation of the customer to have the properly grounded

outlet installed by a qualified electrician.

Page 7

If codes permit and a separate ground wire is used, it is

recommended that a quaiified electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a quaiified eiectrician if you are not sure the

washer is properly grounded.

Do not have a fuse in the neutral or ground circuit.

INSTALLATION

INSTRUCTIONS

Bef Btcirt

AWARNING

Excessive Weight Hazard

Use two or more people to move and install

washer.

Failure to do so can result in back or other injury.

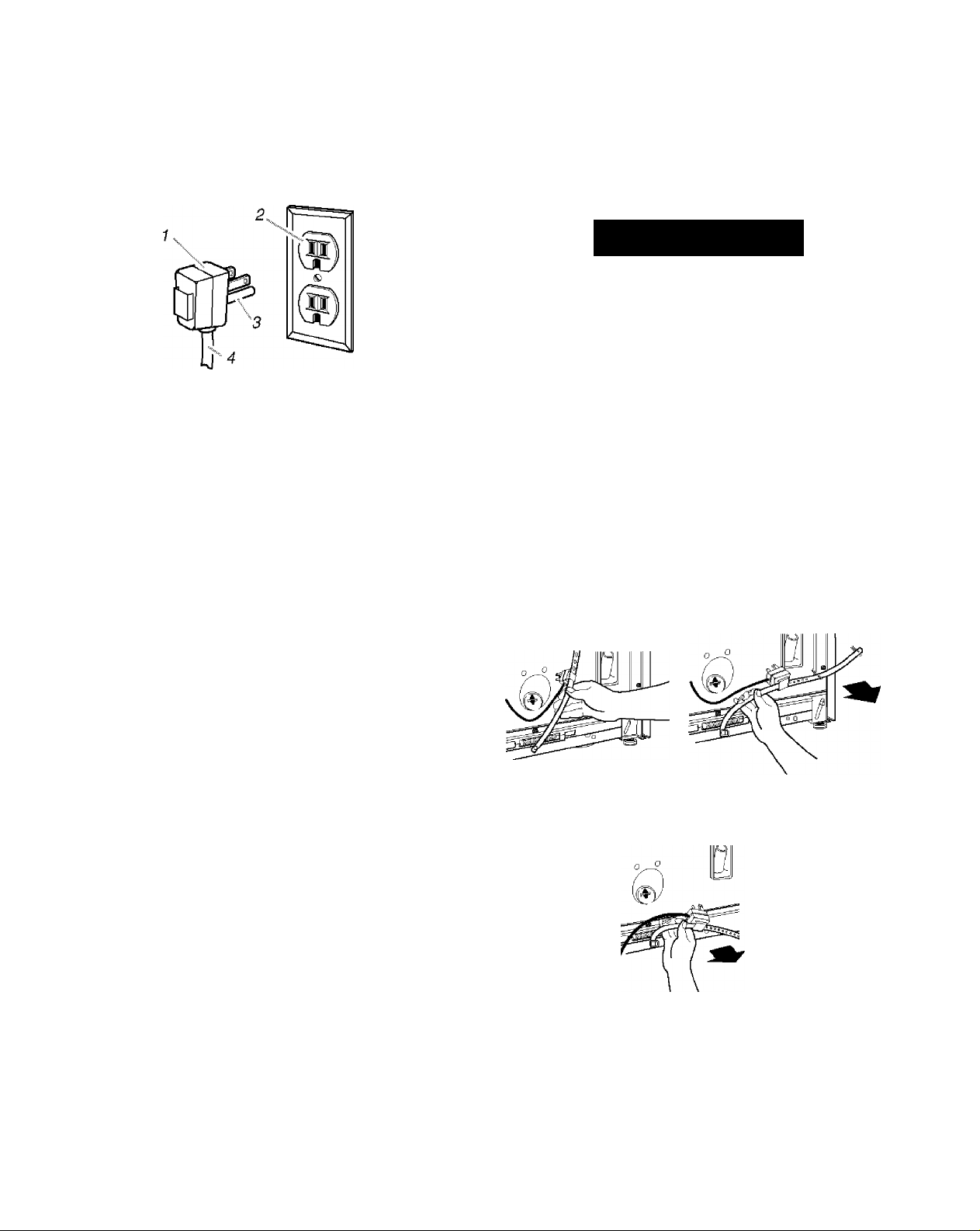

1. 3 prong grounding plug

2. 3 prong grounding-type outlet

3. Ground prong

4. Power supply cord

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the event of a mal

function or breakdown, grounding will reduce the risk

of electrical shock by providing a path of least resist

ance for electric current. This washer is equipped with

a cord having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and ground

ed in accordance with all local codes and ordinances.

WARNING: improper connection of the equipment

grounding conductor can result in a risk of electric

shock. Check with a qualified eiectrician or serviceman

if you are in doubt as to whether the appliance is prop

erly grounded.

Do not modify the plug provided with the appliance if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

To prevent floor damage, set the washer onto cardboard

before moving across floor.

Move the washer to within approximately 3 ft (90 cm) of the

final location.

Removing the shipping strap is necessary for smooth operation.

If the shipping strap is not removed, the washer will make

excessive noise.

1. Do not cut yellow strap. Pull yellow strap firmly, until

completely removed from washer. Depending on your model,

there will be either two or three cotter pins on the end of the

shipping strap when It is pulled out of the washer. The

electrical plug is attached to this shipping strap.

2. Puli firmly to remove the end of the shipping strap that

remains pinned to the back of the washer. This will release the

rear self-leveling feet.

For a permanently connected washer:

This washer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead

on the appliance.

Page 8

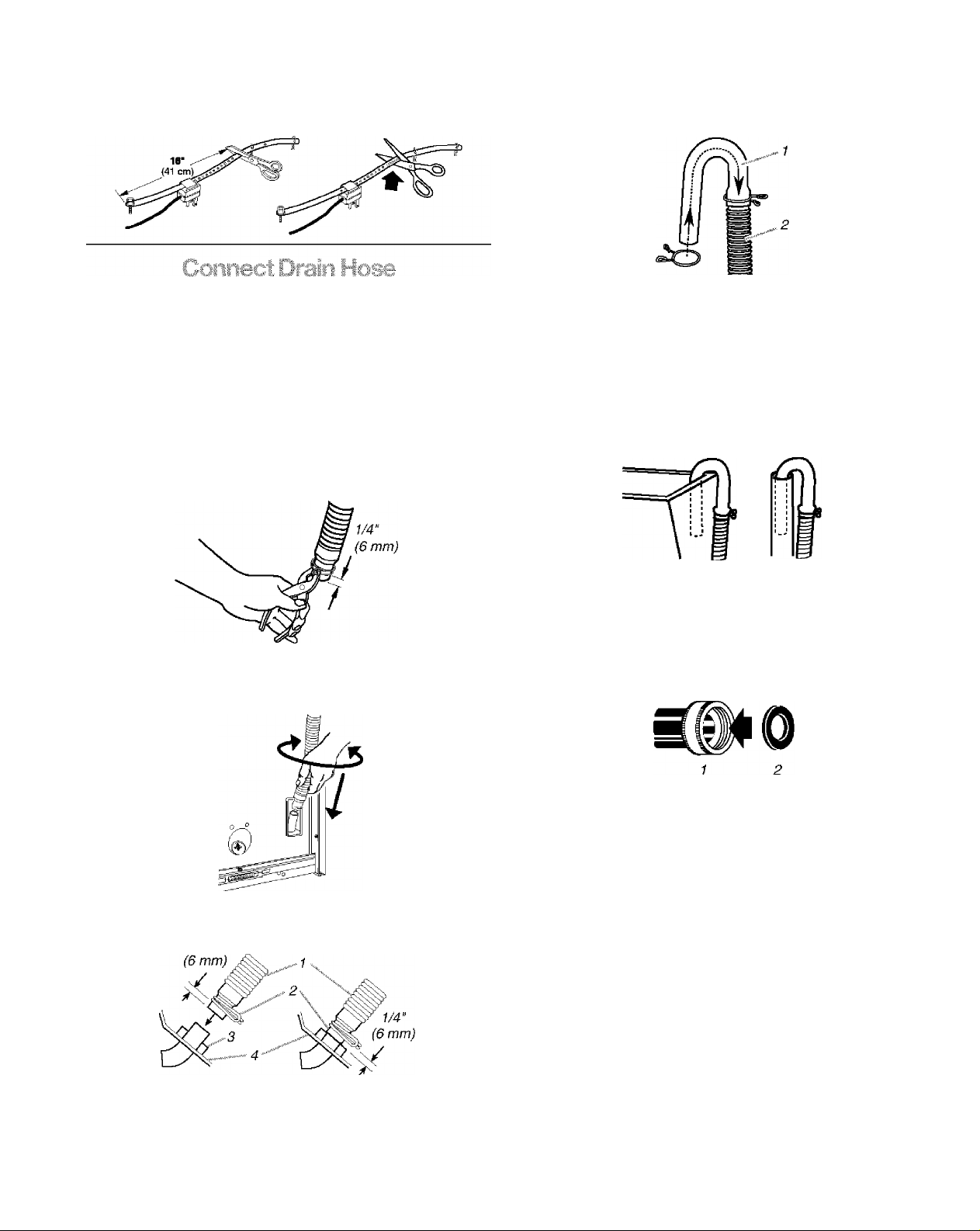

3. Cut the shipping strap about 16 in. (41 cm) from piug end.

Look for the words “CUT HERE." Discard end with the cotter

pins. Slide remainder of shipping strap from the power cord.

You wili use the remainder of the shipping strap iater to

secure the drain hose.

For standpipe or laundry tub drain systems;

1. Open yellow, single-wire clamp with pliers and slide over

hooked end of drain hose to secure the rubber and

corrugated sections together.

Proper connection of the drain hose wili protect your fioors from

damage due to water ieakage. To prevent the drain hose from

coming off or leaking, it must be instaiied per the foliowing

instructions.

IMPORTANT: To ensure proper instailation, this procedure must

be foilowed exactiy.

1. Check the drain hose to see if it is the proper length.

2. Wet the inside of the straight end of the drain hose with tap

water. DO NOT USE ANY OTHER LUBRiCANT.

3. Squeeze ears of siiver, doubie-wire ciamp with pliers to open.

Piace ciamp over the straight end of the drain hose 14 In.

(6 mm) from the end.

4. Open clamp. Twist hose back and forth while pushing down

onto drain connector at the bottom of the washer. Continue

until hose contacts the ribbed stop on the cabinet.

1. Hooked end

2. Drain hose

2.

Put hooked end of drain hose into laundry tub or standpipe.

Rotate hook to eliminate kinks.

To prevent drain water from going back into the washer:

■ Do not straighten hooked end of drain hose. Do not force

excess drain hose into standpipe. Hose should be secure,

but loose enough to provide a gap of air.

■ Do not lay excess drain hose in bottom of laundry tub.

For floor drain installation, see kit number required under

“Alternate Parts.”

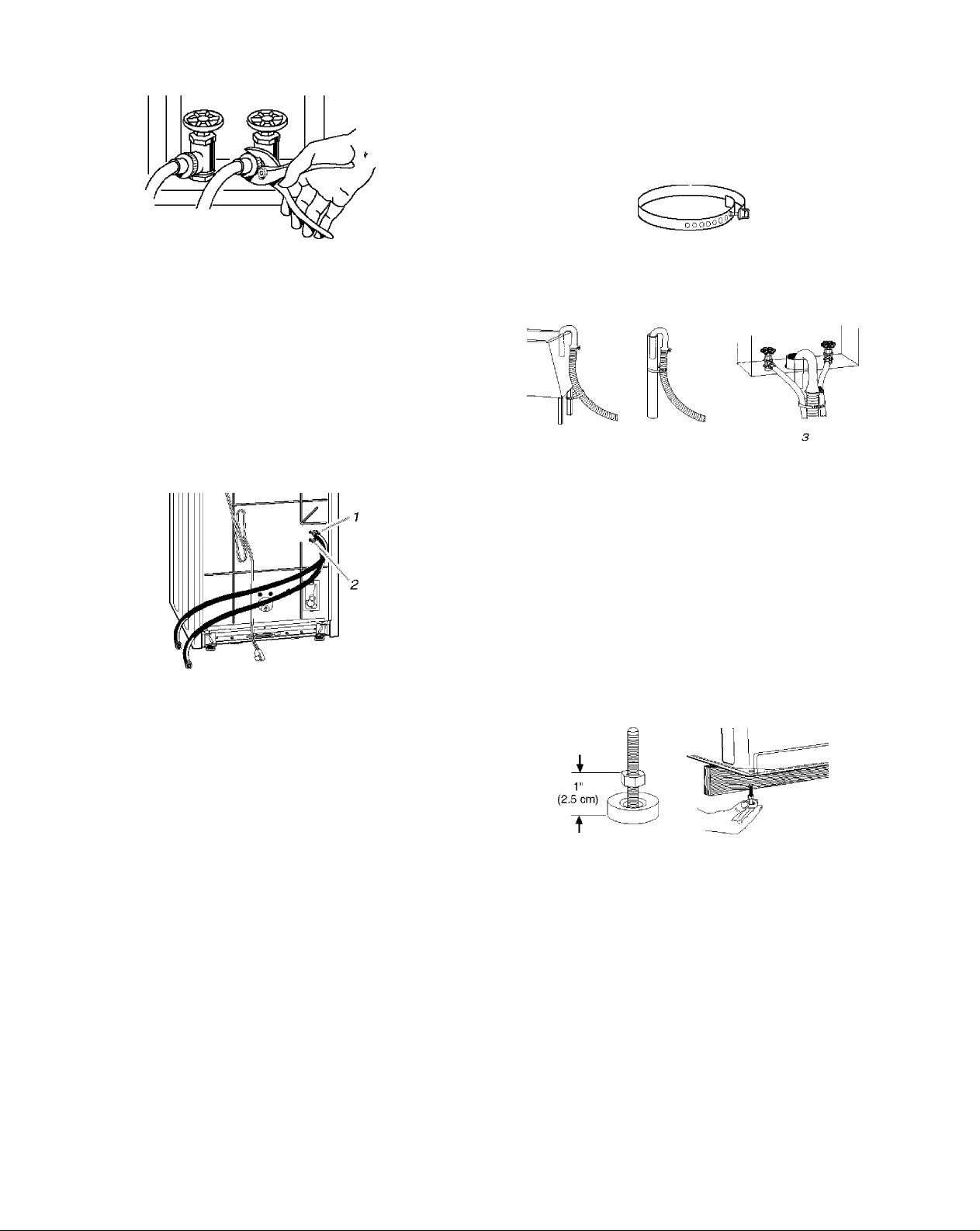

Connect lie inlet Hoses

1. Insert new flat washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

5. Place clamp over area marked “CLAMP” Release clamp.

1/4"

1. Drain Hose

2. Clamp

3. Ribbed Stop

4. Cabinet

1. Coupling

2. Washer

Connect the inlet hoses to the water faucets

Make sure the washer basket is empty.

2. Attach the hose with the red coupling to the hot water faucet.

Screw on coupling by hand until seated on the washer.

3. Attach the hose with the blue coupling to the cold water

faucet. Screw on coupling by hand until seated on the

washer.

Page 9

4. Using pliers, tighten the couplings with an additional twothirds turn.

Drape the power cord over the console.

1.

Remove any cardboard used to move washer.

2.

Locate the remaining portion of shipping strap (not the end

3.

with the cotter pins) from step 3 of “Remove Shipping Strap.”

NOTE: Do not overtighten. Damage to the valves can result.

Clear the water lines

5. Run water through both faucets and inlet hoses, into a bucket

or laundry tub, to get rid of particles in the water lines that

might clog the inlet valve screens.

Connect the inlet hoses to the washer

6. Attach the hose with the red coupling to the HOT (bottom)

Inlet valve. Attaching the red coupling first makes it easier to

tighten connection with pliers. Screw on coupling by hand

until seated on the washer. Using pliers, tighten the couplings

with an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the valves can result.

7. Cold water inlet valve (blue)

2. Hot water inlet valve (red)

NOTE: The inlet valve may be on the right or the left side of

the washer, depending on your model.

7. Attach the hose with the blue coupling to the COLD water

(top) inlet valve. Screw on coupling by hand until seated on

the washer. Using pliers, tighten the couplings with an

additional two-thirds turn.

NOTE: Do not overtighten. Damage to the valves can result.

Check for leaks

8. Turn on the water faucets and check for leaks. A small

amount of water might enter the washer. You will drain this

later.

NOTE: Replace inlet hoses after 5 years of use to reduce the

risk of hose failure. Record hose installation or replacement

dates for future reference.

■ If you connect only one water hose, you must cap off the

remaining water inlet port.

■ Periodically inspect and replace hoses if bulges, kinks,

cuts, wear, or leaks are found.

Remaining portion of Shipping Strap

4.

Wrap the drain hose to the laundry tub leg or standpipe with

the tie strap. Push fastener into the nearest hole in the

shipping strap. (See illustration 1 or 2.)

If the washer faucets and the drain standpipe are recessed,

put the hooked end of the drain hose in the standpipe. Tightly

wrap the tie strap around the water inlet hoses and the drain

hose. (See illustration 3.)

i...-.''■ 'ff I

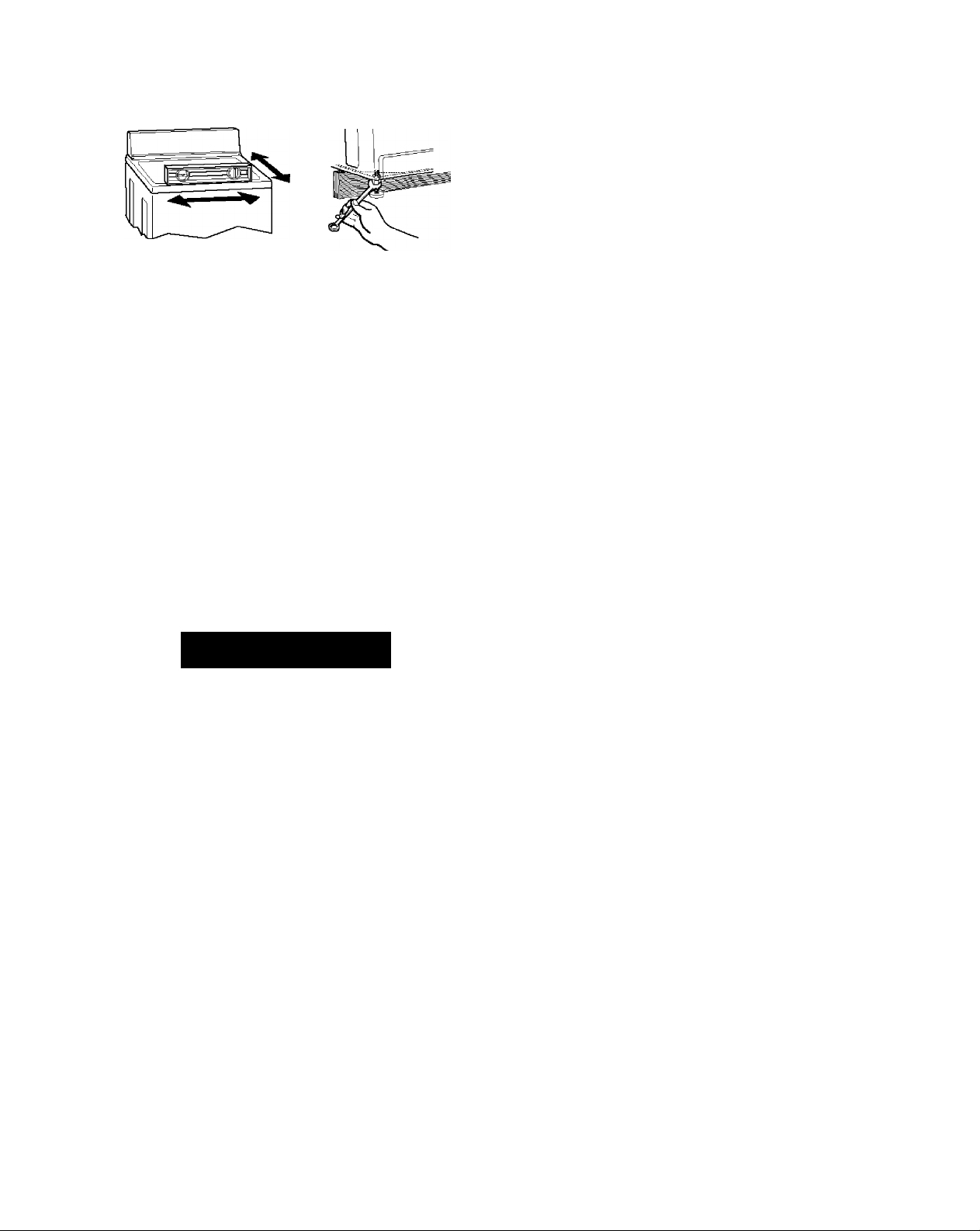

Properly leveling your washer prevents excessive noise and

vibration.

Install the front leveling feet

1.2.Prop up the front of the washer about 4 in. (10.2 cm) with a

wood block or similar object. The block needs to support the

weight of the washer.

Screw the lock nut onto each foot to within 1 In. (2.5 cm) of

the base.

3. Screw the feet into the correct holes at the front corner of the

washer until the nuts touch the washer.

NOTE; Do not tighten the nuts until the washer is level.

4. Tilt the washer back and remove the wood block. Gently

lower the washer to the floor.

5. Slide to final location.

6. Tilt the washer forward until the rear of the washer is at least

4 in. (10.2 cm) off the floor. You may hear the self-adjusting

rear feet click into place. Lower the washer to the floor.

7. Check the levelness of the washer by placing a level on the

top edges of the washer, first side to side, then front to back.

Page 10

8. If the washer is not level, move the washer out slightly, tip

back, prop up the front of the washer with the wood block

and adjust the feet up or down as necessary. Repeat steps

5 through 8 until washer is level.

9. After the washer is in the final location and level, use a ®/is in.

(14 mm) open-end wrench to turn the nuts on the feet tightly

against the washer cabinet.

If the nuts are not tight against the washer cabinet, the

washer may vibrate.

1.

Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method. (See “Electrical Requirements.”)

2.

Check to be sure all parts are now installed. If there is an

extra part, go back through the steps to see which step was

skipped.

3.

Check to be sure you have all of your tools.

4.

Check to be sure that the yellow shipping strap was removed

from the back of the washer and used to secure the drain

hose.

5.

Dispose/recycle all packaging materials.

6.

Check to be sure the water faucets are on.

7.

Check for leaks around faucets and inlet hoses.

AWARNING

ti

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

8. Plug into a grounded 3 prong outlet.

9. Remove the protective film on the console and any tape

remaining on the washer.

10. Read “Washer Use” In the Washer User Instructions.

11. To test your washer, measure 1/2 of the normal

recommended amount of powdered or liquid detergent and

pour it into the washer basket or detergent dispenser (on

some models). Close the lid. Select any cycle, and then press

START. Allow it to complete one whole cycle.

FEATURES AND

BENEFITS

Your new washer has many special features that contribute to

proper cleaning and fabric care. Here are descriptions of the

features and their benefits:

TOTAL CARE™ Agitator

The TOTAL CARE™ Agitator moves in three directions to ensure

proper cleaning. At the bottom of your washer the agitator vanes

move back and forth to flex the fabric, loosening the soil. The

upper portion of the agitator has vanes that push the clothes

down in a spiraling pattern to the area of best cleaning action. A

“rollover” motion displaces the clothes already at the bottom. For

your largest loads, the TOTAL CARE’’’'^ Agitator responds with a

vertical motion that senses the “large load” and guides items to

the bottom.

KING SIZE™ Capacity

Your washer can handle full-sized loads of heavy work clothes,

towels, or mixed items (see “Loading”). Loads with oniy a few

items can have a lower water level setting and they need less

wash time.

Ultra Rinse System

You can adjust your wash cycle with a five-position rinse Options

control. First, set the Cycle Selector Control (Timer) knob where

you want the cycle to start. Then, set the rinse Options control

knob where you want the cycle to stop. In addition, you can add

an automatic second rinse to the Ultra Clean cycle and to the

Permanent Press II cycle.

QUiET PAK™ III System

The QUIET PAK^'^ III System is designed to reduce water sounds

and ringing noises. The cabinet is insulated with sound-damping

materials. A sound-absorbing blanket under the motor and

gearcase also helps to insulate the washer to reduce vibration

noise.

TRIPLE SMART™ Dispensers

The Triple Smartdispenser ensures that detergent, bleach, and

fabric softener are introduced into the washer at the proper time

and are properly diluted. The dispenser makes your washer truly

automatic by making it unnecessary for you to return to the

washer during the cycle to put in detergent, bleach, or fabric

softener.

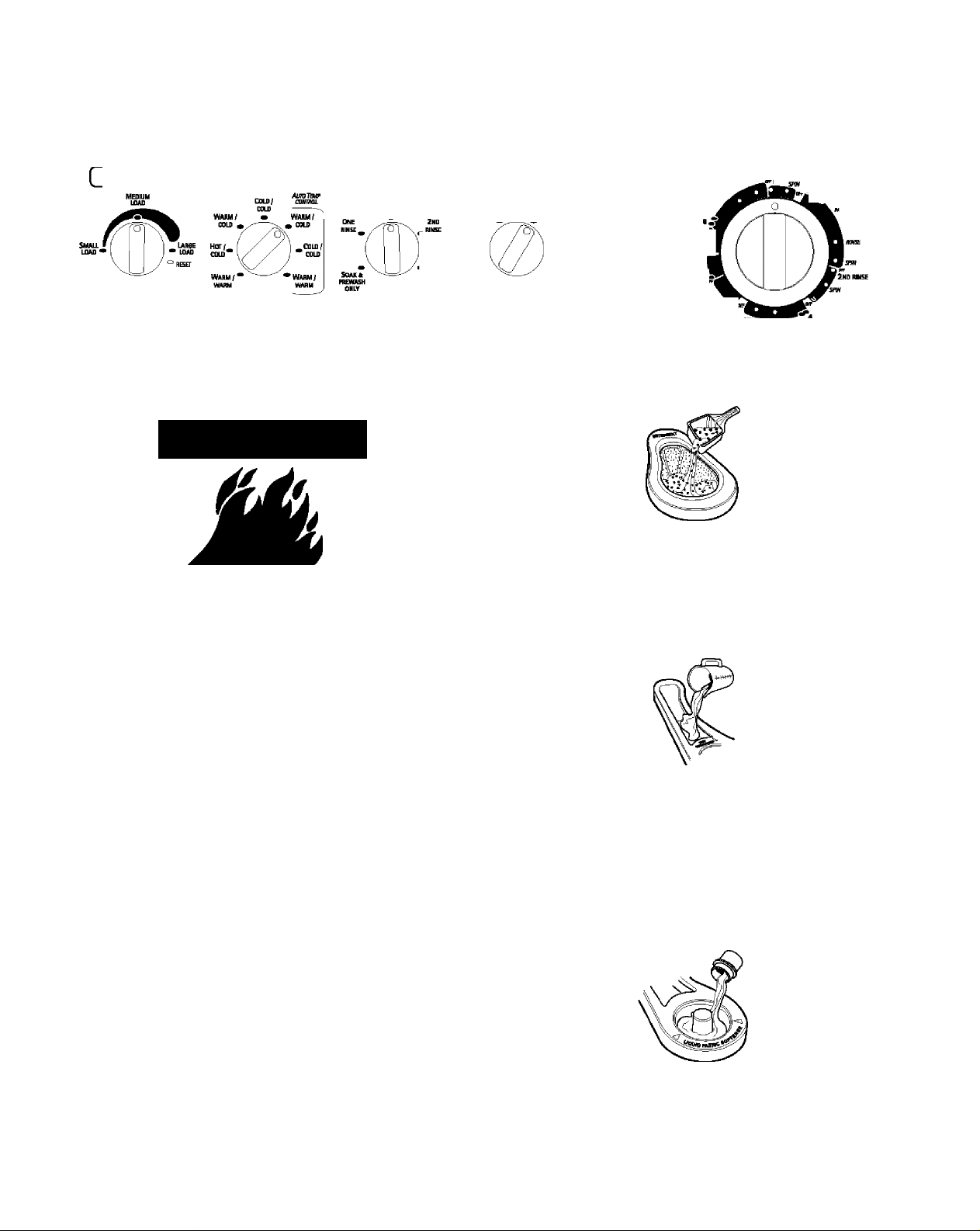

Wash/Spin Speeds

Six combinations of speeds are provided for wash action (of

agitator) and spin motion (of basket). A Speeds selector control

knob lets you select a wash/spin speed for different types of

fabrics and soil levels.

Water Level and Temperature

A Water Level control gives you the flexibility to save water when

washing small loads. Another control knob lets you select a wash

and rinse water temperature setting based on the type of load

you are washing. The settings for Automatic Temperature Control

(АТС) take away the worry of undissolved detergent and ensure

consistent cleaning results from season to season with warm and

cold washes.

10

Page 11

WATER Level Wash/Rinse Temp Options

AWARNING

Fire Hazard

Never place items in the washer that are

dampened with gasoline or other flammable

fluids.

No washer can completely remove oil.

WASHER USE

Speeds АвгтАТЕ/SPIN

Aura Advance

PREWASH

HANDWASH

CASUAL •

eoMSidw/uiN

Soak

ONLY

HANG DRV

RKT/SLOW

2.3.Pour measured powdered or liquid detergent into the

detergent dispenser.

NOTE: You can add color-safe bleach (powered or liquid) to

this dispenser. Be sure to match powdered color-safe bleach

with powdered detergent or match liquid color-safe bleach

with liquid detergent.

Pour measured liquid chlorine bleach into the liquid chlorine

bleach dispenser, if desired. Bleach is diluted and

automatically dispensed during the wash cycle.

Ultra CLEAN

SUPH

----------

PREWASH

AUTO SOAK ^

PERMANENT

_2HD RINSE PRESS II

to-----------------Super

ksÌ4

-------------

MBE Express Wash

Shoitt

osoooLoom

Do not dry anything that has ever had any type of

oil on it (including cooking oils).

Doing so can result in death, explosion, or fire.

WARNING: To reduce the risk of fire, electric shock, or injury to

persons, read the IMPORTANT SAFETY INSTRUCTIONS before

operating this appliance.

The following is a guide to starting your washer. Periodic

references to other sections of this manual provide more detailed

information.

1. Drop a load of sorted clothes loosely into the washer.

■ Load evenly to maintain washer balance. Mix large and

small items.

■ Items should move easily through the wash water.

Overloading can cause poor cleaning.

■ To reduce wrinkling of permanent press clothes and some

synthetic knits, use a large load setting to provide more

space (see step 6).

■ Never use more than 1 cup (250 mL) for a full load. Use

less for a smaller load size.

■ Follow the manufacturer’s directions for safe use.

■ To avoid spilling, use a cup with a pouring spout. Do not

let bleach splash, drip, or run down into the washer

basket.

■ Use only liquid chlorine bleach in this dispenser.

4. Pour measured liquid fabric softener into the fabric softener

dispenser, if desired.

Do not overfill. The dispenser holds 3 oz (94 mL), or a

standard capful of fabric softener.

The fabric softener is dispensed in the final rinse.

Do not spill or drip any fabric softener on the clothes.

Use only liquid fabric softener in this dispenser.

11

Page 12

5. Close the washer lid.

6. Turn the Water Level selector to the correct setting for your

vi/ash load and the type of fabric being washed.

■ Choose a water level that allows the load to move freely

for best fabric care. See “Loading.”

■ You may change to a higher level setting after the washer

has started filling by turning the knob to a different

setting.

7. Set the Water Temperature selector to the correct setting for

the type of fabric and soils being washed. Use the warmest

water safe for fabric. Follow garment label instructions.

Water Temp Use for Hot Whites and pastels

Heavy soils

Warm Bright colors

Moderate to light soils

Cold Colors that bleed or fade

Light soils

9. Set the Speeds Control knob according to the type of fabric

in the load. See “Selecting Wash/Spin Speeds.”

10. Push in the Cycle Selector Control (Timer) knob and turn it

clockwise to the wash cycle you want. Reduce the wash time

when using a small load size setting. See “Selecting a Cycle

and Time.”

Pull out the Cycle Selector Control (Timer) knob to start the

washer.

To stop or restart your washer

■ To stop the washer at any time, push in the Cycie Selector

Control (Timer) knob.

■ To restart the washer, close the lid (if open) and pull out

the Cycle Selector Control (Timer) knob.

Selecting Ifash/Spin SpeecJs

This section describes the wash/spin speeds you can select with

the Speeds control. Each speed setting is designed for different

types of fabric and soil levels.

Delicate

SLOW/SLOW

normal

SLOW/FAST

NOTE: In wash water temperatures colder than 70°F (21 ®C),

detergents do not dissolve well. Soils can be difficult to

remove. Some fabrics can retain wear wrinkles and have

increased pilling (the formation of small lint-like balls on the

surface of garments).

(OPTIONAL) An Automatic Temperature Control (АТС)

electronically senses and maintains a uniform water

temperature by regulating incoming hot and cold water.

■ Even in cold wash, some warm water is let into the

washer to maintain a minimum temperature of

approximately es^F (19“C).

■ Warm wash is maintained at approximately 95“F (35°С).

■ Warm rinse is maintained at approximately 70“F (21“C) for

all warm rinse settings.

8. (RINSE OPTIONS) You can customize your wash by adding

rinse Options to your cycie selections. A cycle will “start"

where you set the Cycle Selector Control (Timer) knob. See

“Selecting a Cycie and Time." The cycle will “stop” where you

set the Options Control knob. This knob has settings for:

■ One Rinse. Use this option for one rinse after a basic

wash cycle, Rinse & Spin, and Drain & Spin.

■ 2nd Rinse. A 2nd Rinse can be added to the Ultra Clean

cycle and to the Permanent Press II cycle.

■ Soak Only. Use this option for set-in stains and soil that

need extra time for removal.

■ Soak & Prewash. Select the prewash option to ensure

thorough cleaning of your heavily soiled and stained

loads.

■ Auto Advance after Prewash. This setting will save your

detergent from Prewash and automatically start the Ultra

Clean cycle. Expect a 2-minute pause between cycles.

NOTE: The Prewash cycle and Soak & Prewash Only option

should be followed by a main wash cycle with additional

detergent added. The Soak Only option should be followed

by a main wash cycle without additional detergent.

Heavy Duty

' FAST/FAST

HANDWASH PLUS

FINE DEUCATES

INTERMITTENT

EXTRA SLOW/SLOW

Speeds Selector knob

HANG Dry

FAST/SLOW

Normal speed

This speed setting is for normally soiled cottons and linens.

Setting combines slow speed agitation and fast spin speeds to

shorten drying time.

Heavy Duly speed

This speed setting is for sturdy or heavily soiled loads. Setting

combines fast speed agitation and fast spin speeds.

Hang Dry speed

This speed setting is for sturdy permanent press fabrics that wili

be line dried. Setting combines fast speed agitation and slow

spin speeds to reduce wrinkling.

Handwash Plus Fine Délicates speed

Use this speed setting for hand washable and special-care items.

The wash action has repeating periods of extra-slow speed

agitation and soaking. Slow spin speeds help reduce wrinkling.

NOTE: Do not use this cycle for large items such as blankets.

Some “Hand Wash" items, particularly wool, naturally shrink

when washed. When still wet, block these items by gently

stretching to original measurements. Allow the items to dry fiat.

12

Page 13

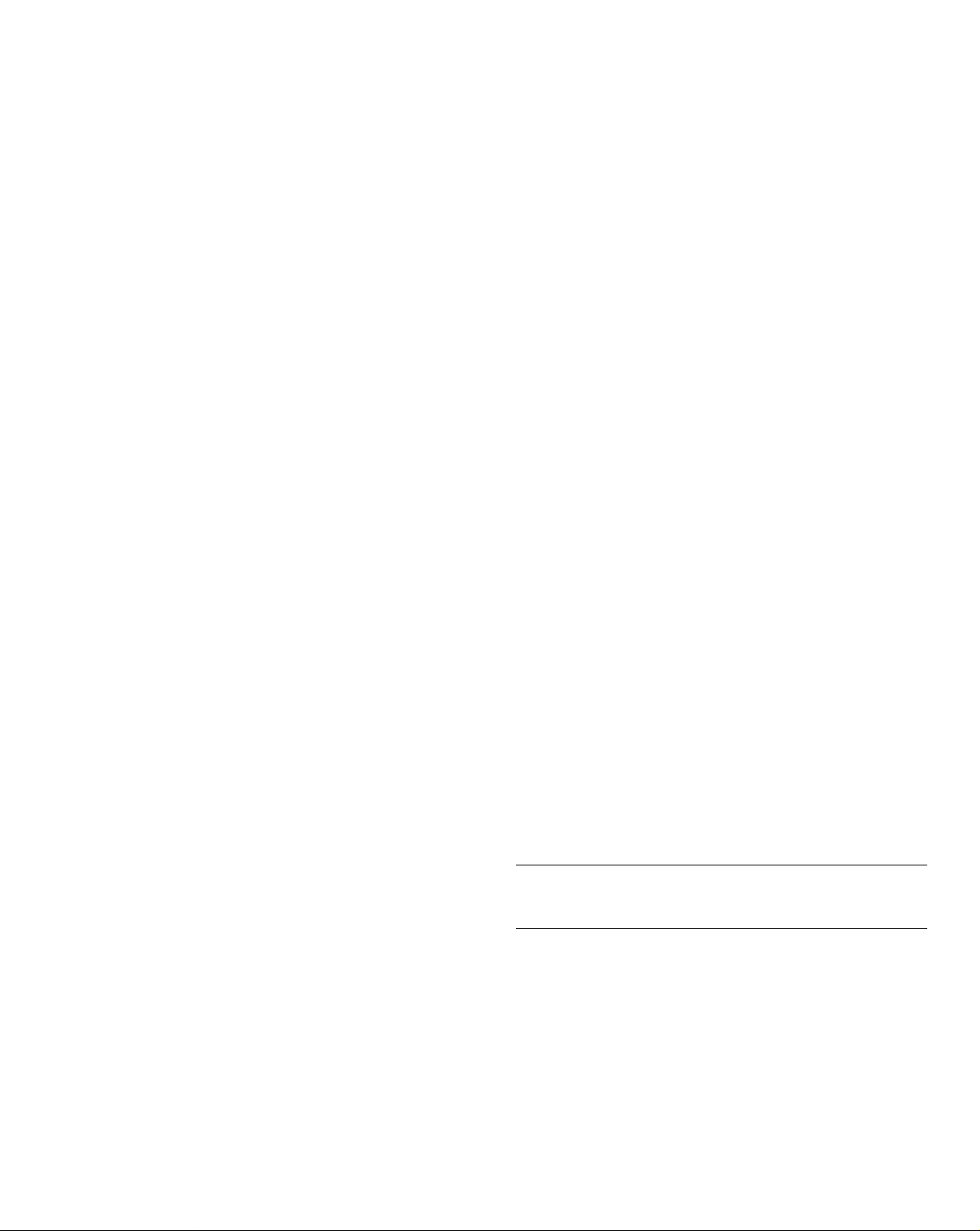

Handwash/Casual speed

This speed setting is for lingerie and loosely knit items. Setting

combines extra-slow speed agitation for gentle soil removal and

slow spin speeds to reduce wrinkling.

Delicate speed

This speed setting is for washable knit fabrics and permanent

press fabrics. Setting combines slow speed agitation for gentle

soil removal and slow spin speeds to reduce wrinkling.

it II I iim

This section describes the available wash cycles and will help

you make the best cycle selections for your wash loads. Each

cycle is designed for different types of fabric and soil levels.

■ The washer pauses briefly throughout each cycle. These

pauses are normal. Refer to “Normal Sounds" to learn more

about the sounds you may hear during a wash cycle.

■ Refer to “Understanding Washer Cycles” to learn what

happens during a wash cycle.

NOTE: Use the control to choose agitation time and to start the

washer. For heavy soil and sturdy fabrics, use the full time. Use

less time for light soil and delicate fabrics.

^ 10

PERMANENT

PRESSI

2nd Rinse

Auto Soak and Prewash Combined

Use this cycle to combine the features of Auto Soak and Auto

Prewash. Add detergent to dispenser after setting Water Level

and Water Temperature. Set the Options control to Soak &

Prewash Only. Set the Cycle Selector Control (Timer) knob to

Auto Soak, then pul! out the knob to start washer. The washer will

complete the Auto Soak cycle and automatically start the Auto

Prewash cycle.

NOTE: Hot water is not recommended for soaking. It may set

some stains.

Express Wash

Use this cycle to wash small loads of lightly soiled garments that

are needed in a hurry. This cycle combines fast speed tumbling, a

shortened wash time, and extra high speed spin to shorten

drying time.

After using extra detergent in a cycle for heavily soiled clothes, or

when washing special-care items, you may find that an extra

rinse and spin is needed.

1. Set the controls for Water Level, Water Temperature, Options

(to One Rinse), and Speeds.

2. Push in the Cycle Selector Control (Timer) knob and turn it

clockwise to any of the rinse settings.

3. Pul! out the Cycle Selector Control (Timer) knob. The washer

fills to the selected water level, agitates, drains, and spins.

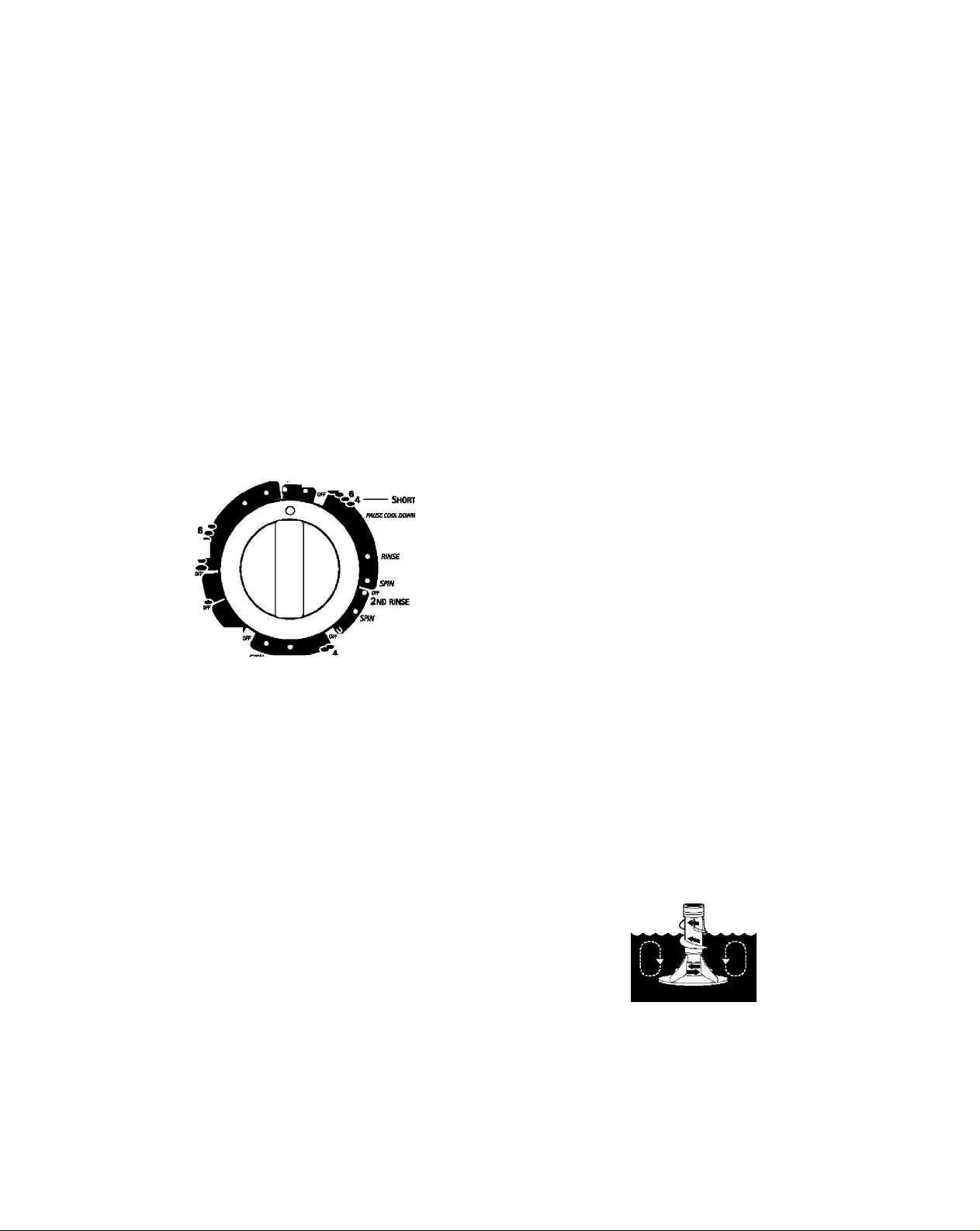

SHORT

--------

ULTRA Cl£AN

SUPER

--------

16

PREWASH

AUTO SOAK ^

R/NSE Express wash

Cycle Selector Control (Timer) knob

Permanent Press II cycle

This cycle includes a load-cooling process that reduces wrinkling

compared to other cycles. Select up to 10 minutes of wash time.

NOTE: When the timer reaches Pause, the washer will drain and

pause for no more than two minutes while some of the wash

water is drained and replaced with rinse water.

Ultra Clean cycle

Use this cycle for most loads to get between 6 and 16 minutes of

wash time.

Prewash cycle

Use this cycle to get several extra minutes of agitation to help

remove heavy soils and stains that need pretreatment. Add

detergent to washer basket for this cycle. When the prewash is

complete, the washer will drain and spin. Add detergent and set a

new wash cycle.

Auto Soak cycle

This cycle is designed to help remove heavy soils and stains that

need pretreatment. This cycle features brief periods of agitation

and soak, ending in unlimited soak time. Reset to a Spin setting

to remove the water. If water is removed, add detergent and set

washer to a desired wash cycle. If water is not removed, select a

new wash cycle (do not add additional detergent).

NOTE: Hot water is not recommended for soaking. It may set

some stains.

A drain and spin may help shorten drying times for some heavy

fabrics or special-care items by removing excess water.

1. Set Options Control (to One Rinse).

2. Set Speeds Control:

■ For fast spin, use the Heavy Duty setting.

■ For slow spin, use the Delicate setting.

3. Push in the Cycle Selector Control (Timer) knob and turn it

clockwise to any of the Spin settings.

4. Pul! out the Cycle Selector Control (Timer) knob. The washer

drains, then spins.

fri

When the Cycle Control knob is set to a number and pulled out,

the washer fills (to the selected load size) before agitation and

timing start. The washer begins agitating Immediately after filling;

agitation occurs with the washer lid down.

During agitation, the agitator creates a continuous rollover action

that provides a thorough cleaning of the wash load.

After agitation starts, the Cycle Control knob turns clockwise until

it points to an OFF area and the cycle ends.

NOTE: The washer pauses briefly throughout each cycle. These

pauses are normal for washer operation.

13

Page 14

WASH RINSE

1. FiH 1. Fill

2. Wash selected

time

2. Rinse

Jr

3. Drain’ No

agitation

4. Spin

I»

' The Permanent Press cyole

partiaiiy drains, fills, agitates

briefly and drains.

Your new washer may make sounds your old one didn’t. Because

the sounds might be unfamiliar, you may be concerned about

them. These sounds are normal.

During washing

When you select a small load size setting, your washer has a

lower water level. This can cause a clicking sound from the upper

part of the agitator.

During drain

If water is drained quickly from your washer (depending on your

installation), you may hear air being pulled through the pump

during the end of draining.

After drain and before spin

When the cycle changes from draining to spinning, you may hear

gears engaging.

3. Drain No

agitation

4. Spin-Spray rinse

S. Spin

6. Off

LAUNDRY TIPS

Preparing clothes for washing

Follow these recommendations to help you prolong the life of

your garments.

■ Close zippers, snaps, and hooks to avoid snagging other

items. Remove pins, buckles, and other hard objects to avoid

scratching the washer interior. Remove non-washable trim

and ornaments.

■ Empty pockets and turn them inside-out.

■ Turn down cuffs; brush away lint and dirt.

■ Turn synthetic knits inside-out to avoid pilling.

■ Tie strings and sashes so they will not tangle.

■ Mend tears, loose hems, and seams.

■ Treat spots and stains.

■ Stained or wet garments should be washed promptly for best

results.

Sorting

■ Separate heavily soiled items from lightly soiled ones, even if

they would normally be washed together. Separate lint-givers

(towels, chenille) from lint-takers (corduroy, synthetics,

permanent press). When possible, turn lint-givers inside-out.

■ Separate dark colors from light colors, colorfast items from

noncolorfast items.

■ Sort by fabric and construction (sturdy cottons, knits, delicate

items).

Unloading

■ Remove clothes from washer after the cycle is completed.

Metal objects such as zippers, snaps, and buckles may rust if

left in the washer basket for a long time.

Loading suggestions (maximum size loads)

KING SIZE^h* Capacity Plus Washer

Heavy Work Clothes

4 jeans

4 workpants

4 workshirts

2 sweatpants

2 sweatshirts

14

Towels

10 bath towels

10 hand towels

Mixed Load

3 sheets (1 king, 2 twin) 9 T-shirts

4 pillowcases 9 shorts

3 shirts

3 blouses

14 washcloths

10 handkerchiefs

Page 15

WASHER CARE

Cleaiiirig Ybyr Washer

Cleaning the exterior

Use a soft, damp cloth or sponge to wipe up any spills such as

detergent or bleach. Occasionally wipe the outside of your

washer to keep it looking new.

Cleaning the interior

To clean your washer interior, add 1 cup (250 mL) of chlorine

bleach and 1 scoop or capful of detergent into your dispenser,

and run the washer through the Normal cycle using hot water.

Repeat this process if necessary.

NOTE: Remove any hard water deposits using only cleaners

labeled as washer safe.

Welter inlet Hoses

Replace inlet hoses after five years of use to reduce the risk of

hose failure. Periodically inspect and replace inlet hoses if

bulges, kinks, cuts, wear or leaks are found.

When replacing your inlet hoses, mark the date of replacement

on the label with a permanent marker.

To transport the washer

1. Shut off both water faucets.

2. Disconnect and drain water inlet hoses.

3. If washer will be moved during freezing weather, put in 1 qt (1

L) of R.V.-type antifreeze in the basket. Run washer on an

Extended Spin cycle.

Disconnect the drain from the drain system.

Unplug the power cord.

Place the inlet hoses into the basket.

Drape the power cord and drain hose over edge into the

basket.

8. Place the expanded foam plug retained from the washer’s

shipping material into basket opening. Close the lid and put a

piece of tape over the lid and down to the front of the washer.

Reinstalling the washer

1. Follow the “Installation Instructions” to locate, level and

connect the washer.

2. Run the washer through any cycle with V2 the normal

recommended amount of detergent to clean out the

antifreeze, if used.

TROUBLESHOOTING

First try Hie solutions suggested here and possibly avoid

the cost of a service call...

Install and store your washer where it will not freeze. Because

some water may stay in the hoses, freezing can damage your

washer. If storing or moving your washer during freezing weather,

winterize it.

Non-use or vacation care:

Operate your washer only when you are at home. If you will be on

vacation or not using your washer for an extended period of time,

you should:

■ Unplug washer or disconnect power.

■ Turn off the water supply to the washer. This helps avoid

accidental flooding (due to a water pressure surge) while you

are away.

To winterize washer

1. Shut off both water faucets.

2. Disconnect and drain water inlet hoses.

3. Put 1 qt (1 L) of R.V.-type antifreeze in the basket.

4. Run washer on a cycle with extra spin time.

5. Unplug washer or disconnect power.

To use washer again:

1. Flush water pipes and hoses.

2. Reconnect water inlet hoses.

3. Turn on both water faucets.

4. Plug in washer or reconnect power.

5. Run the washer through any cycle with Vi the normal

recommended amount of detergent to clean out the

antifreeze.

Washer won’t fill, rinse or wash

Does the water level seem too low, or does the washer appear to not fill completely?

The top of the agitator is much higher than the highest water

level. This creates a perception that the washer is not filling

completely. This is normal.

Check the following:

Is the power cord plugged into a grounded 3 prong outlet?

Is there power at the plug? Check electrical source or call

electrician.

Are the hot and cold water faucets turned on?

Is the water inlet hose kinked?

Are the water Inlet valve screens clogged?

Washer stops

Check the following:

Is the power cord plugged into a grounded 3 prong outlet?

Are the hot and cold water faucets turned on?

Is the water inlet hose kinked?

Are the water inlet valve screens clogged?

Is there power at the plug?

Check electrical source or call electrician.

Has a fuse blown or has the circuit breaker tripped?

If problem continues, call electrician.

Are you using an extension cord?

Do not use an extension cord.

Is the lid closed?

The washer will not agitate or spin with the lid open.

15

Page 16

Is the Cycle Selector Control (Timer) knob lined up and pulled out?

Turn Cycle Selector Control (Timer) knob to cycle and pull out

to start washer. If washer still doesn’t start, push knob back

In, turn slightly to the right and puli out again.

Is the washer overloaded?

Wash smaller loads. See “Starting Your Washer" for

maximum load size.

Washer won’t drain or spin

Is the drain hose clogged, or the end of the drain hose more than 96 in. (244 cm) above the floor?

See “Installation Instructions” for proper installation of drain

hose.

Is the lid open?

The lid must be closed during operation. The washer will not

agitate or spin with the lid open.

Is there excessive sudsing?

Always measure detergent. Follow manufacturer’s directions.

If you have very soft water, you may need to use less

detergent.

Is your voltage low?

Check electrical source or call electrician. Do not use an

extension cord.

Washer continues to fill or drain, or the cycle seems stuck

Does the drain hose fit too tightly in the standpipe, or is it

taped to the standpipe?

The drain hose should be loose yet fit securely. Do not seal

the drain hose with tape. The hose needs an air gap. (See

“Installation Instructions.")

Washer makes noise

Is the load balanced and the washer level?

The wash load should be balanced. See “Starting Your

Washer” for maximum load size.

The washer must be level. The front feet should be properly

Installed and the nuts tightened. Reset the rear leveling legs if

needed. (See “Installation Instructions.”)

Are the self-adjusting rear feet installed?

Can you hear water spraying? This is part of the wash action.

If water is drained quickly from the washer, you may hear air

being pulled through the pump. This happens during the end

of draining. It is normal.

When the cycle changes from washing to draining or

spinning, you may hear a noise as the drive system shifts.

This is normal.

Are you washing items with metal snaps, buckles or zippers?

You may hear metal items touching the basket. This is normal.

Are you washing a small load?

You will hear more splashing sounds when washing small

loads. This is normal.

Is the washer installed on a solid floor?

Refer to the “Installation Instructions" for flooring

requirements.

Washer leaks

Check the following:

Are the fill hoses tight? Are the fill hose washers properly

seated? Is the drain hose clamp properly installed? (See

“Installation Instructions.’’)

Is the sink or drain clogged?

Sink, floor drain and standpipe must be able to handle 17 gal.

(64 L) of water per minute.

Is water bouncing off the tub ring or the load?

The wash load should be balanced and not overloaded. If

not, the fill or spray rinses can bounce off the load.

The washer must be level. The front and rear feet should be

properly installed and the nuts tightened. Reset the self

adjusting rear feet if needed. (See “Installation Instructions.’’)

Did you pull the drain hose from the washer cabinet and

install it in a standpipe or laundry tub?

See “Installation Instructions.”

Check household plumbing for leaks.

Washer basket is crooked

■ Is the load balanced and the washer level?

The wash load should be balanced.

The washer must be level. The front feet should be properly

installed and the nuts tightened. Reset the rear leveling legs,

if needed. (See “Installation Instructions.”)

Dispensers clogged or leaking

■ Are the laundry products in the correct dispenser?

Add the correct amounts of detergent (powder or liquid),

liquid chlorine bleach, or fabric softener to the correct

dispenser. You can add powder or liquid color safe bleach to

the detergent dispenser. Be sure to match powdered colorsafe bleach with powdered detergent or match liquid colorsafe bleach with liquid detergent. Use only liquid chlorine

bleach in the bleach dispenser.

Load too wet

■ Did you use the right cycle for the load being washed?

Select a control setting with a higher spin speed.

■ Did you use a cold rinse?

Cold rinses leave loads wetter than warm rinses. This is normal.

16

Page 17

Residue or lint on load

Did you add detergent to the dispenser?

For best results, use the dispenser to dissolve the detergent.

Did you sort properly?

Sort lint givers (towels, chenille) from lint takers (corduroy,

synthetics). Also sort by color.

Did you overload the washer?

The wash load must be balanced. See “Starting Your Washer”

for maximum load size. Lint can be trapped in the load if

overloaded. Wash smaller loads.

Was paper or tissue left in pockets?

Did you use enough detergent?

Follow manufacturer’s directions. Use enough detergent to

hold the lint in the water.

Is your water colder than 70®F (21 "C)?

Wash water colder than 70°F (21 "C) may not completely

dissolve the detergent.

Are you using a gentle wash cycle?

Consider using liquid detergent for slow speed cycles such

as Handwash, Casual or Delicate.

Stains on load

Did you add detergent to the dispenser?

For best results, use the dispenser to dissolve the detergent.

Did you use enough detergent?

Use enough detergent to remove soil and hold it in suspension.

Add the manufacturer's recommended amounts.

Did you add fabric softener directly to the load?

Use your fabric softener dispenser. Do not drip fabric softener

on clothes.

Is there above average iron (rust) in water?

You may need to install an iron filter.

Did you properly sort the load?

Sort dark clothes from whites and lights.

Did you unload the washer promptly?

To avoid dye transfer, unload the washer as soon as it stops.

Did you use a fabric softener dispensing ball?

Use the fabric softener dispenser provided with the washer.

Dispensing balls will not operate correctly with this washer.

Did you use powder detergent in a low speed cycle?

Consider using liquid detergent.

Did you add detergent, chlorine bleach or fabric softener

too late in the cycle?

Detergent, chlorine bleach, and fabric softener should be

added to the dispensers before starting the washer.

Load is wrinkled

Did you overload the washer?

The wash load must be balanced and not overloaded. Loads

should move freely during washing.

Are the hot and cold water hoses reversed?

Check to be sure the hot and cold water hoses are connected

to the right faucets. (See “Installation Instructions.”)

Load is tangled or twisted

Did you overload the washer?

See “Starting Your Washer” for maximum load size. Loads

should move freely during washing.

Gray whites, dingy colors

Did you properly sort the load?

Dye transfer can occur when mixing whites and colors in a

load. Sort dark fabrics from whites and lights.

Was the wash temperature too low?

Use hot or warm washes if safe for the load. Make sure your

hot water system is adequate to provide a hot water wash.

Did you use enough detergent, or do you have hard

water?

Use more detergent for washing heavy soils in cold or hard

water. Water temperature should be at least 70“F (2T’C) for

soap to dissolve and work properly.

Garment damage

Check the following:

Were sharp items removed from pockets before washing?

Empty pockets, zip zippers, snap or hook fasteners before

washing.

Were strings and sashes tied to prevent tangling?

Were items damaged before washing?

Mend rips and broken threads in seams before washing.

Did you overload the washer?

See “Loading” for maximum load size.

Did you properly add chlorine bleach?

Do not pour chlorine bleach directly on load. Use your liquid

chlorine bleach dispenser. Wipe up bleach spills. Undiluted

bleach will damage fabrics. Do not place load items on top of

the bleach dispenser when loading and unloading the washer.

Did you follow the manufacturer’s care label instructions?

Wash temperature is not what I selected

Are the hot and cold water inlet hoses reversed?

As washing progresses, the wash temperature will decrease

slightly for hot and warm washes. This is normal.

Did you unload the washer promptly?

Unload the washer as soon as it stops.

Did you use the right cycle for the load being washed?

Use the Delicate cycle or another cycle with a low spin speed

to reduce wrinkling.

17

Page 18

18

Page 19

INDICE

CONTRATOS DE

CONTRATOS DE PROTECCION

En los EE.UU

En Canadá.

GARANTÍA ........................................................................ 20

SEGURIDAD DE LA LAVADORA

REQUISITOS DE INSTALACIÓN

Herramientas y piezas..........................................................22

Requisitos de ubicación........................................................22

Sistema de desagüe...............................................................

Requisitos eiéctricos.........................................................

INSTRUCCIONES DE INSTALACIÓN..........

Antes de empezar.................................................................24

Quite el fleje de embalaje..

Conecte la manguera de desagüe .......................................

Conecte las mangueras de entrada......................................26

Asegure la manguera de desagüe

Nivele la lavadora...........

Complete la instalación..................................................... 28

CARACTERÍSTICAS Y BENEFICIOS......

USO DE LA LAVADORA........................................ ...............29

Puesta en marcha de la lavadora

Selección de velocidades de lavado/exprimido ....................

Selección del ciclo y duración

Enjuague y exprimido

Desagüe y exprimido

Para comprender los ciclos de la lavadora..............

Sonidos normales

CONSEJOS DE LAVANDERÍA.

Cómo cargar

CUIDADO DE LA LAVADORA................................................33

Limpieza de su lavadora...

Mangueras de entrada de agua

Cuidado para las vacaciones,

almacenaje o en caso de mudanza

SOLUCIÓN DE PROBLEMAS...............................................

................................ .

.........

.......................... .

...........................................................

............................................................

.............................................................

.........................................................................

............................................19

.......................................

.......................................

........................................

............................................

...........

...............24

....................................................

........................................

..................................................

.............................

.........................................

................................................

.............

............................................

.................................................

......

..................................

......................................

21

22

24

27

27

28

29

31

32

32

32

33

33

33

33

33

34

34

19

PROTECCIÓN

20

Contratos Maestros de Protección

jFelicitaciones por su inteligente adquisiciónl Su nuevo

electrodoméstico Kenmore® ha sido diseñado y fabricado para

23

25

25

31

brindarle años de funcionamiento confiable. Pero al igual que

todos los productos, puede necesitar mantenimiento preventivo

o reparación de vez en cuando. Es allí donde el Contrato Maestro

de Protección puede ahorrarle dinero e inconvenientes.

Adquiera un Contrato Maestro de Protección hoy y protéjase

contra molestias y gastos inesperados.

El Contrato Maestro de Protección también ayuda a prolongar la

vida de su nuevo artefacto. He aquí lo que se incluye en el

Contrato:

✓ Servicio Experto por nuestros 12.000 especialistas en

reparación competentes

✓ Servicio iiimitado y gratuito para repuestos y mano de obra

en todas las reparaciones protegidas por el contrato

✓ Garantía “sin disgustos” - reemplazo de su producto

protegido si ocurren cuatro o más fallas del producto en el

transcurso de doce meses

✓ Reemplazo del producto si su producto protegido no puede

ser reparado

✓ Revisión Anual de Mantenimiento Preventivo a solicitud

suya - sin costo adicional

✓ Ayuda rápida por teléfono - asistencia por teléfono a cargo

de un técnico de Sears para productos que deban se

reparados en su hogar, además de un horario de reparación

conveniente

✓ Protección de sobrevoltaje contra daños eléctricos debido a

fluctuaciones de electricidad

✓ Reembolso de la renta si la reparación de su producto

protegido tarda más de io prometido

Una vez adquirido el Contrato, tan sólo tiene que llamar para fijar

la visita de servicio técnico. Usted puede llamar a cualquier hora,

de día o de noche, o fijar una visita técnica en Internet.

Sears cuenta con un equipo de más de 12.000 especialistas en

reparación competentes, quienes tienen a disposición más de

4,5 millones de repuestos y accesorios de calidad. Ése es el tipo

de profesionalismo con el que usted puede contar para ayudarle

a prolongar la vida de su nuevo artefacto por muchos años más.

¡Adquiera hoy su Contrato Maestro de Protección!

Se aplican algunas limitaciones y exclusiones. Para obtener

preoios e información adicional, llame al 1-888-784-6427.

Servicio de Instalación de Sears

Para la instalación profesional de artefactos electrodomésticos,

arbridores de puertas de garaje, calentadores de agua y otros

artículos importantes de la casa, en los EE.UU. llame al

1-800-4-MY-HOME®.

19

Page 20

Contratos de mantenimiento

Su compra adquiere un nuevo valor ya que usted puede confiar

en Sears HomeCentral® para obtener servicio de reparación. Con

más de 2.400 especialistas capacitados en reparaciones y

acceso a más de 900.000 piezas de repuesto y accesorios,

contamos con ¡as herramientas, piezas, conocimiento y la

destreza para asegurarnos de respaldar nuestra promesa de que:

Reparamos lo que vendemos.

Su electrodoméstico Kenmore® está diseñado, fabricado y

sometido a prueba para proporcionarle años de funcionamiento

confiable. No obstante, cualquier electrodoméstico moderno

puede necesitar servicio técnico de vez en cuando. Ei contrato

de mantenimiento Sears le ofrece un programa de servicio

excepcional, a un precio accesible.

El contrato de mantenimiento Sears

■ Garantiza el servicio técnico del mañana a precios de hoy.

■ Elimina las facturas de reparación producidas por el uso

normal y el desgaste.

■ Cubre las visitas de servicio no técnicas y educativas.

■ Proporciona una revisión anual de mantenimiento preventivo

a solicitud suya, para asegurarse de que su electrodoméstico

está en condiciones apropiadas de funcionamiento.

Se aplican ciertas restricciones. Para obtener información

referente a los Contratos de mantenimiento de Sears Home

Central®, llame al 1-800-361-6665.

r

.

GARANTIA DE

LA LAVADORA

Garantía Limitada de Vida Útil Para la Canasta de

Porcelana Blanca

Durante la vida útil de la lavadora, a partir de la fecha de compra,

Sears reemplazará la canasta de lavado en porcelana blanca si

ésta se desportillara u oxidara como resultado de defectos de

material o de fabricación. Después del primer año, usted será

responsable de los gastos de mano de obra.

Garantía Limitada de 10 Años para el Tambor Plástico*

Desde el segundo año y por un máximo de diez años a partir de

la fecha de compra, Sears reemplazará el tambor plástico si éste

tuviese algún defecto de material o de fabricación. Después del

primer año, usted será responsable de los gastos de mano de

obra.

Garantía Limitada de 5 Años para las Piezas de la Caja de

Engranajes*

Desde el segundo año y por un máximo de cinco años a partir de

la fecha de compra, Sears reemplazará cualquier pieza de la caja

de engranajes que tuviese algún defecto de material o de

fabricación. Después del primer año, usted será responsable de

los gastos de mano de obra.

Garantía Limitada de 2 años para el Panel de Conbol SENSOR SMART™

Durante 2 años a partir de la fecha de compra, Sears

reemplazará el panel de control SENSOR SMART^'^ si tuviese

algún defecto de material o de fabricación. Después del primer

año, usted será responsable de la mano de obra.

Garantía completa de un año para las piezas mecánicas y componentes eléctricos

Durante un año a partir de la fecha de compra, si se instala y

pone en funcionamiento la lavadora en conformidad con las

instrucciones que vienen con la misma, Sears reparará o

reemplazará cualquier pieza mecánica o componente eléctrico

de esta lavadora que tuviese algún defecto de material o de

fabricación.

El servicio debe ser proporcionado por un departamento de

servicio Sears en los Estados Unidos o en Canadá, o por un

agente autorizado.

Restaicción de la Garantía

Si se somete a esta lavadora a un uso ajeno al familiar privado,

todas las coberturas de las garantías arriba citadas quedan

restringidas a 90 días a partir de la fecha de compra.

Los gastos de viaje o de transporte para los clientes que residen

en zonas alejadas no se cubren por esta garantía.

Servicio de Reparación de la Garantía

El servicio de reparación de la garantía está a su disposición al

contactarse con el Centro de Servicio Sears de su localidad en

los Estados Unidos o en Canadá. Esta garantía corresponde sólo

mientras se use esta lavadora en los Estados Unidos o en

Canadá.

Esta garantía le otorga derechos legales específicos y es posible

que usted tenga también otros derechos que pueden variar de un

estado al otro o de una provincia a otra.

Para información respecto a la garantía Sears, o para ponerse en

contacto con el Centro de Servicio Sears, sírvase tomar como

referencia los números de servicio ubicados en la contraportada

de este manual.

Sears, Roebuck and Co.

D/817WA, Hoffman Estafes, IL 60179

Toronto, Ontario, Cañada MSB 2B8

*La garantía que se aplique en Canadá puede ser diferente.

Sears Cañada Inc.

Registro del producto

Use el espacio a continuación para anotar el número completo

del modelo y de la serie así como la fecha de compra. Usted

podrá encontrar esta información en la etiqueta con el modelo y

número de serie, tal como se ilustra.

Siempre que se ponga en contacto con Sears respecto a su

electrodoméstico, tenga esta información a mano para facilitar la

obtención de ayuda o servicio técnico.

Número de modelo 110.

Número de serie _

Fecha de compra

Guarde estas instrucciones y su comprobante de compra para

referencia futura.

____ _______ ________

20

Page 21

SEGURIDAD DE LA LAVADORA

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico.

Lea y obedezca siempre todos los mensajes de seguridad.

Este es el símbolo de advertencia de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una

lesión a usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad

y de la palabra “PELIGRO” o “ADVERTENCIA”. Estas palabras significan:

Si no sigue las instrucciones de inmediato, usted

APELIGRO

AADVERTENCIA

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir

una lesión y lo que puede suceder si no se siguen las instrucciones.

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA: Para reducir el riesgo de incendio, choque eléctrico o lesiones a personas al usar su

lavadora, siga las precauciones básicas, incluyendo las siguientes:

puede morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir una lesión grave.

Lea todas las instrucciones antes de usar la

lavadora.

No lave artículos que hayan sido previamente

limpiados, lavados, remojados o humedecidos

con gasolina, solventes para lavar en seco, u

otras sustancias inflamables o explosivas ya

que éstas emanan vapores que podrían

encenderse o causar una explosión.

No agregue gasolina, solventes para lavar en

seco, u otras sustancias inflamables o explosivas

al agua de lavado. Estas sustancias emanan

vapores que podrían encenderse o causar una

explosión.

En ciertas condiciones, puede generarse gas

hidrógeno en un sistema de agua caliente que no

se haya usado por dos semanas o un período

mayor. EL GAS HIDRÓGENO ES EXPLOSIVO.

Si no se ha usado el agua caliente durante dicho

período, antes de usar la lavadora, abra todos los

grifos de agua caliente y deje que corra el agua

por varios minutos. Esto liberará todo el gas

hidrógeno que se haya acumulado. Debido a la

inflamabilidad de dicho gas, no fume ni use una

llama abierta durante este lapso.

GUARDE ESTAS INSTRUCCIONES

No permita que los niños jueguen encima o dentro de

la lavadora. Es necesario una supervisión cuidadosa

de los niños toda vez que se use la lavadora cerca de

ellos.

I Antes de poner la lavadora fuera de servicio o

desecharla, quítele la puerta o la tapa.

I No introduzca las manos en la lavadora si el tambor,

la tina, o el agitador están funcionando.

I No instale ni almacene esta lavadora donde pudiese estar

sometida a la intemperie.

I No trate de forzar los controles.

I No repare ni cambie pieza alguna de la lavadora ni

intente realizar tarea alguna de servicio técnico, excepto

cuando así se le indique específicamente en este manual

o en instrucciones de reparación para el usuario publi

cadas, que usted entienda y para cuya ejecución cuente

con la habilidad necesaria.

I Para obtener información respecto a los requisitos de co

nexión a tierra, refiérase a los “Requisitos Eléctricos”.

21

Page 22

REQUISITOS DE

INSTALACIÓN

Piezas alternativas

Las piezas enumeradas se pueden adquirir en su tienda Sears o

en el Centro de Servicio Sears más cercano a su localidad. Para

más información, llame por favor al

469-4663).

Si tiene: Tendrá que comprar:

1-800-4-MY-HOME® (1-800

Reúna las herramientas y materiales necesarios antes de

comenzar la instalación de la lavadora. Las piezas que vienen

con la lavadora están en la canasta de la misma.

Herramientas necesarias para conectar la manguera de desagüe y las mangueras de entrada del agua:

■ Alicates que se abran a 1 ®/is pulg (3,95 cm)

■ Linterna (opcional)

Piezas proporcionadas:

1. Manguera de desagüe

2. Abrazadera plateada de dos hilos para mangueta

(para la parte inferior de la manguera de desagüe)

3. Abrazadera amarilla unifilar para manguera

(para la parte superior de la manguera de desagüe)

4. Mangueras de entrada del agua (2)

5. Arandelas planas para mangueras de entrada

dei agua (4)