Kenmore 10689599100, 10689592100, 10689553100, 10689593100 Owner’s Manual

Use & Care Guide

Manual de uso y cuidado

Guide d'utilisation et d'entretien

English / Espafiol / Fran_ais

Models/Modelos/Mod_les: 106.8955% 106.8959 _

I<enmore

@

@

,,:,::,:color number, n@nero de colo_, le num@o de la couleur

P/N W10568967A

Sears Brands Management Corporation

Hoffman Estates, IL, U.S.A. 60179

www.kenmore.com

www.sears.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

TABLEOF CONTENTS

PROTECTION AGREEMENTS ................................................... 2

WARRANTY ............................................................................. 3

ICE MAKER SAFETY ................................................................. 3

INSTALLATION INSTRUCTIONS ............................................. 4

Unpack the Ice Maker ..................................................................... 4

Location Requirements ......................................................................5

Electrical Requirements ....................................................................5

Water Supply Requirements ...........................................................5

Connect Water Supply .....................................................................6

Drain Pump Installation ................................................................... 7

Drain Connection .............................................................................10

Door Reversal--Side Swing Only .................................................11

Leveling ..............................................................................................13

Water Filtration System ................................................................. 13

PROTECTION AGREEMENTS

ICE MAKER USE ..................................................................... 14

How Your Ice Maker Works ......................................................... 14

Using the Controls ............................................................................ 15

Normal Sounds ................................................................................. 15

ICE MAKER CARE ................................................................... 16

Cleaning ............................................................................................ 16

Vacation and Moving Care .......................................................... 18

TROUBLESHOOTING .............................................................. 19

Ice Maker Operation ...................................................................... 19

Ice Production ................................................................................. 20

Ice Quality ....................................................................................... 20

Plumbing Problems ........................................................................... 21

Accessories ........................................................................................ 21

PERFORMANCE DATA SHEET ................................................ 21

SERVICE NUMBERS ............................................. BACK COVER

JNDICE ................................................................................... 22

TABLE DESMATII:RES ............................................................ 45

Master Protection Agreements

Congratu/ations on making a smart purchase. Your new

Kenmore _;product is designed and manufactured for years of

dependable operation. But like all products, it may require

preventive maintenance or repair from time to time. That's when

having a Master Protection Agreement can save you money and

aggravation.

The Master Protection Agreement also helps extend the life of

your new product. Here's what the Agreement _ includes:

I/Parts and labor needed to help keep products operating

properly under normal use, not just defects. Our coverage

goes well beyond the product warranty. No deductibles, no

functional failure excluded from coverage--real protection.

I/Expert service by a force of more than 10,000 authorized

Sears service technicians, which means someone you can

trust will be working on your product.

I/Unlimited service calls and nationwide service, as often as

you want us, whenever you want us.

I/"No-lemon" guarantee - replacement of your covered

product if four or more product failures occur within twelve

months.

Product replacement if your covered product can't be fixed.

I/Annual Preventive Maintenance Check at your request - no

extra charge.

I/Fast help by phone- we call it Rapid Resolution - phone

support from a Sears representative on all products. Think of

us as a "talking owner's manual."

Power surge protection against electrical damage due to

power fluctuations.

$250 Food Loss Protection annually for any food spoilage

that is the result of mechanical failure of any covered

refrigerator or freezer.

I/Rental reimbursement if repair of your covered product takes

longer than promised.

I/'25% discount off the regular price of any non-covered

repair service and related installed parts.

Once you purchase the Agreement, a simple phone call is all

that it takes for you to schedule service. You can call anytime

day or night, or schedule a service appointment online.

The Master Protection Agreement is a risk free purchase. If you

cancel for any reason during the product warranty period, we

will provide a full refund. Or, a prorated refund anytime after

the product warranty period expires. Purchase your Master

Protection Agreement today!

Some limitations and exclusions apply. For prices and

additional information in the U.S.A. call 1-800-827-6655.

_Coverage in Canada varies on some items. For full details call

Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in the

U.S.A. or Canada call 1-800-4-MY-HOME ®.

2

I(ENMORE ELITE®LIMITED WARRANTY

When this appliance is installed, operated and maintained

according to all supplied instructions, the following warranty

coverage applies. To arrange for warranty service, call

1-800-4-MY-HOME _ (1-800-469-4663).

One Year Limited Warranty on Appliance

For one year from the date of purchase, free repair will be

provided if any non-consumable part of this appliance fails due

to defects in material or workmanship. If the appliance is ever

used for other than private family purposes, this coverage

applies for only 90 days from the purchase date.

Five Year Limited Warranty on Sealed System

For five years from the date of purchase, the sealed refrigerant

system of this appliance is warranted against any defects in

material or workmanship. New system components will be

supplied for defective ones free of charge. You are responsible

for the labor cost of component installation after the first year

from the date of purchase. If the appliance is ever used for

other than private family purposes, this coverage applies for

only one year from the purchase date.

This warranty covers only defects in material and

workmanship. Sears will NOT pay for:

1. Consumable parts that can wear out from normal use,

including but not limited to filters, belts, incandescent light

bulbs, and bags.

2. A service technician to instruct the user in correct product

installation, operation or maintenance.

3. A service technician to clean or maintain this product.

4. Damage to or failure of this product if it is not installed,

operated or maintained according to the all instructions

supplied with the product.

5. Damage to or failure of this product resulting from accident,

abuse, misuse or use for other than its intended purpose.

6. Damage to or failure of this product caused by the use of

detergents, cleaners, chemicals or utensils other than those

recommended in all instructions supplied with the product.

7. Damage to or failure of parts or systems resulting from

unauthorized modifications made to this product.

Disclaimer of implied warranties; limitation of remedies

Customer's sole and exclusive remedy under this limited

warranty shall be product repair as provided herein. Implied

warranties, including warranties of merchantability or fitness for

a particular purpose, are limited to one year or the shortest

period allowed by law. Sears shall not be liable for incidental or

consequential damages. Some states and provinces do not

allow the exclusion or limitation of incidental or consequential

damages, or limitation on the duration of implied warranties of

merchantability or fitness, so these exclusions or limitations may

not apply to you.

This warranty applies only while this appliance is used in the

United States or Canada _.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

In Canada, in-home repair service is not available in all

areas, nor will this warranty cover user or servicer travel and

transportation expenses if this product is located in a remote

area (as defined by Sears Canada Inc.) where an authorized

servicer is not available.

Sears Brands Management Corporation

Hoffman Estates, IL 60179

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

Product Record

In the space below, record your complete model number, serial

number, and purchase date. You can find this information on the

model and serial number label.

Have this information available to help you obtain assistance or

service more quickly whenever you contact Sears concerning

your ice maker.

Model number

Serial number

Purchase date

Save these instructions and your sales receipt for future

reference.

ICE MAKER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury when using your ice maker, follow these basic

precautions:

Plug into a grounded 3 prong outlet. • Disconnect power before manually cleaning the inside components.

Do not remove ground prong. • Disconnect power before servicing.

Do not use an adapter. • Replace all parts and panels before operating.

Do not use an extension cord. • Use two or more people to move and install ice maker.

SAVE THESE INSTRUCTIONS

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

INSTALLATION

Excessive Weight Hazard

Use two or more people to move and install ice maker.

Failure to do so can result in back or other injury.

Removing Packaging Materials

Remove tape and glue from your ice maker before using.

INSTRUCTIONS

• To remove any remaining tape or glue from the exterior of

the ice maker, rub the area briskly with your thumb. Tape or

glue residue can also be easily removed by rubbing a small

amount of liquid dish soap over the adhesive with your

fingers. Wipe with warm water and dry.

• Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. Do not

use chlorine bleach on the stainless steel surfaces of the ice

maker. These products can damage the surface of your

ice maker.

4

Cleaning Before Use

After you remove all of the packaging materials, clean the

inside of your ice maker before using it. See the cleaning

instructions in the "Ice Maker Care" section.

• To ensure proper ventilation for your ice maker, the front side

must be completely unobstructed. The ice maker may be

closed-in on the top and three sides, but the installation

should allow the ice maker to be pulled forward for

servicing if necessary.

• Installation of the ice maker requires a cold water supply

inlet of 1/4" (6.35 mm) OD soft copper tubing with a shutoff

valve or a supply line Part Number 8212547RB, and on ice

makers that require the installation of a drain pump, an

approved drain pump, Part Number 1901A only, to carry the

water to an existing drain.

• Choose a well ventilated area with temperatures above

55°F (13°C) and below 110°F (43°C). Best results are

obtained between 70°F and 90°F (21°C and 32°C).

• The ice maker must be installed in an area sheltered from

the elements, such as wind, rain, water spray, or drip.

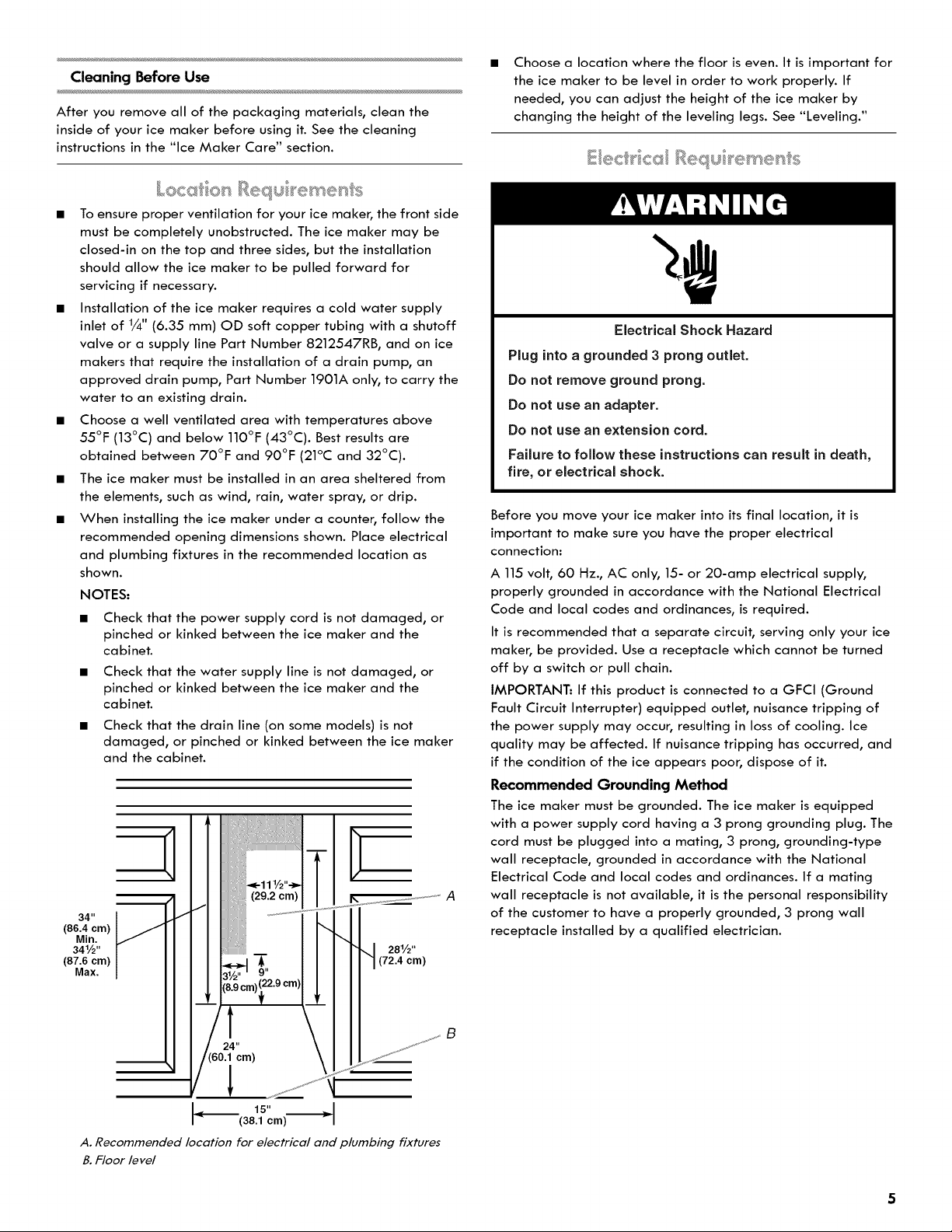

• When installing the ice maker under a counter, follow the

recommended opening dimensions shown. Place electrical

and plumbing fixtures in the recommended location as

shown.

NOTES:

• Check that the power supply cord is not damaged, or

pinched or kinked between the ice maker and the

cabinet.

• Check that the water supply line is not damaged, or

pinched or kinked between the ice maker and the

cabinet.

• Check that the drain line (on some models) is not

damaged, or pinched or kinked between the ice maker

and the cabinet.

34 II

(86.4 cm)

Min.

341/2"

(87.6 cm)

Max.

281/2"

(72.4 cm)

Choose a location where the floor is even. It is important for

the ice maker to be level in order to work properly. If

needed, you can adjust the height of the ice maker by

changing the height of the leveling legs. See "Leveling."

_: e _, _

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Before you move your ice maker into its final location, it is

important to make sure you have the proper electrical

connection:

A 115 volt, 60 Hz., AC only, 15- or 20-amp electrical supply,

properly grounded in accordance with the National Electrical

Code and local codes and ordinances, is required.

It is recommended that a separate circuit, serving only your ice

maker, be provided. Use a receptacle which cannot be turned

off by a switch or pull chain.

IMPORTANT: If this product is connected to a GFCI (Ground

Fault Circuit Interrupter) equipped outlet, nuisance tripping of

the power supply may occur, resulting in loss of cooling. Ice

quality may be affected. If nuisance tripping has occurred, and

if the condition of the ice appears poor, dispose of it.

Recommended Grounding Method

The ice maker must be grounded. The ice maker is equipped

with a power supply cord having a 3 prong grounding plug. The

cord must be plugged into a mating, 3 prong, grounding-type

wall receptacle, grounded in accordance with the National

Electrical Code and local codes and ordinances. If a mating

A

wall receptacle is not available, it is the personal responsibility

of the customer to have a properly grounded, 3 prong wall

receptacle installed by a qualified electrician.

cm)

15"

(38.1 cm)

A. Recommended location for electrical and plumbing fixtures

B. Floor level

B

Check that the water supply lines are insulated against freezing

conditions. Ice formations in the supply lines can increase water

pressure and damage your ice maker or home. Damage from

frozen supply lines is not covered by the warranty.

A cold water supply with water pressure of between 30 and

120 psi (207 and 827 kPa) is required to operate the ice maker.

If you have questions about your water pressure, call a licensed,

qualified plumber.

Reverse Osmosis Water Supply

IMPORTANT:

• A reverse osmosis water filtration system is not

recommended for ice makers that have a drain pump

installed.

• For gravity drain systems only.

• The pressure of the water supply coming out of a reverse

osmosis system going to the water inlet valve of the ice

maker needs to be between 30 and 120 psi (207 and

827 kPa).

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the reverse osmosis

system needs to be a minimum of 40 to 60 psi (276 to 414 kPa).

NOTE: The reverse osmosis system must provide 1 gal. (3.8 L) of

water per hour to the ice maker for proper ice maker operation.

If a reverse osmosis system is desired, only a whole-house

capacity reverse osmosis system, capable of maintaining the

steady water supply required by the ice maker, is

recommended. Faucet capacity reverse osmosis systems are not

able to maintain the steady water supply required by the ice

maker.

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 to 414 kPa):

• Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

• Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

If you have questions about your water pressure, call a licensed,

qualified plumber.

• 7/16" and I/2" open-end wrenches or two adjustable wrenches

• 1/4" nut driver

NOTE: Do not use a piercing-type or 3/16" (4.76 mm) saddle

valve which reduces water flow and clogs more easily.

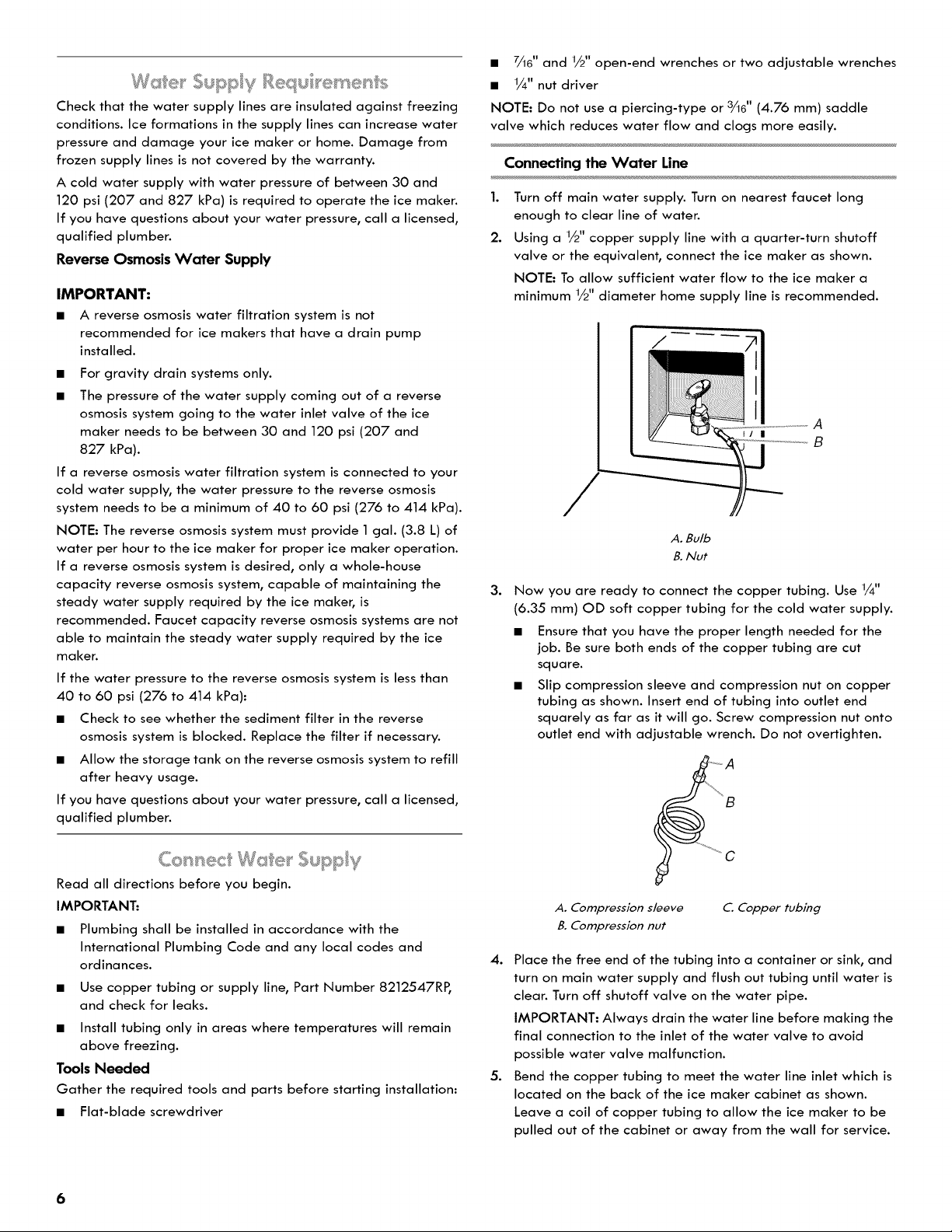

Connecting the Water Line

1.

Turn off main water supply. Turn on nearest faucet long

enough to clear line of water.

2.

Using a 1/2" copper supply line with a quarter-turn shutoff

valve or the equivalent, connect the ice maker as shown.

NOTE: To allow sufficient water flow to the ice maker a

minimum 1/2" diameter home supply line is recommended.

_I I

A. Bulb

B. Nut

3.

Now you are ready to connect the copper tubing. Use 1/4"

(6.35 mm) OD soft copper tubing for the cold water supply.

• Ensure that you have the proper length needed for the

job. Be sure both ends of the copper tubing are cut

square.

• Slip compression sleeve and compression nut on copper

tubing as shown. Insert end of tubing into outlet end

squarely as far as it will go. Screw compression nut onto

outlet end with adjustable wrench. Do not overtighten.

A

B

Read all directions before you begin.

IMPORTANT:

• Plumbing shall be installed in accordance with the

International Plumbing Code and any local codes and

ordinances.

• Use copper tubing or supply line, Part Number 8212547RP,

and check for leaks.

• Install tubing only in areas where temperatures will remain

above freezing.

Tools Needed

Gather the required tools and parts before starting installation:

• Flat-blade screwdriver

6

A. Compression sleeve

B. Compression nut

C Copper tubing

4. Place the free end of the tubing into a container or sink, and

turn on main water supply and flush out tubing until water is

clear. Turn off shutoff valve on the water pipe.

IMPORTANT: Always drain the water line before making the

final connection to the inlet of the water valve to avoid

possible water valve malfunction.

5. Bend the copper tubing to meet the water line inlet which is

located on the back of the ice maker cabinet as shown.

Leave a coil of copper tubing to allow the ice maker to be

pulled out of the cabinet or away from the wall for service.

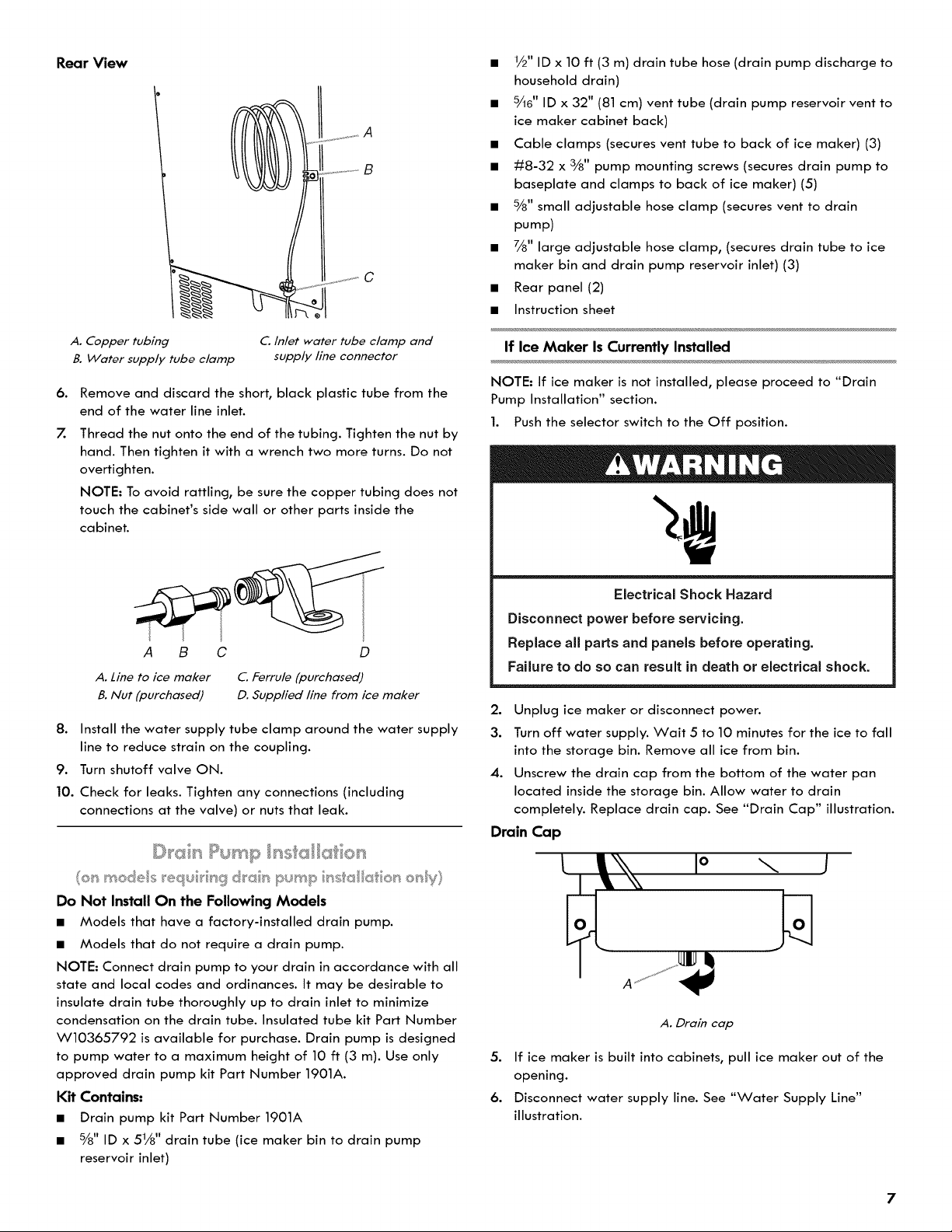

Rear View

• V2" ID x 10 ft (3 m) drain tube hose (drain pump discharge to

household drain)

• 5A6"ID x 32" (81 cm) vent tube (drain pump reservoir vent to

A

ice maker cabinet back)

• Cable clamps (secures vent tube to back of ice maker) (3)

B

• #8-32 x 3/8" pump mounting screws (secures drain pump to

baseplate and clamps to back of ice maker) (5)

• 5/8"small adjustable hose clamp (secures vent to drain

pump)

• 7/8"large adjustable hose clamp, (secures drain tube to ice

C

maker bin and drain pump reservoir inlet) (3)

• Rear panel (2)

• Instruction sheet

A. Copper tubing

B. Water supply tube clamp

6.

Remove and discard the short, black plastic tube from the

C. Inlet water tube clamp and

supply line connector

end of the water line inlet.

7.

Thread the nut onto the end of the tubing. Tighten the nut by

hand. Then tighten it with a wrench two more turns. Do not

overtighten.

NOTE: To avoid rattling, be sure the copper tubing does not

touch the cabinet's side wall or other parts inside the

cabinet.

C D

A. Line to ice maker

B. Nut (purchased)

C. Ferrule (purchased)

D. Supplied line from ice maker

8. Install the water supply tube clamp around the water supply

line to reduce strain on the coupling.

9. Turn shutoff valve ON.

10. Check for leaks. Tighten any connections (including

connections at the valve) or nuts that leak.

If Ice Maker Is Currently Installed

NOTE: If ice maker is not installed, please proceed to "Drain

Pump Installation" section.

1. Push the selector switch to the Off position.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

2. Unplug ice maker or disconnect power.

3. Turn off water supply. Wait 5 to 10 minutes for the ice to fall

into the storage bin. Remove all ice from bin.

4. Unscrew the drain cap from the bottom of the water pan

located inside the storage bin. Allow water to drain

completely. Replace drain cap. See "Drain Cap" illustration.

Drain Cap

Do Not Install On the Following Models

• Models that have a factory-installed drain pump.

• Models that do not require a drain pump.

NOTE: Connect drain pump to your drain in accordance with all

state and local codes and ordinances. It may be desirable to

insulate drain tube thoroughly up to drain inlet to minimize

condensation on the drain tube. Insulated tube kit Part Number

W10365792 is available for purchase. Drain pump is designed

to pump water to a maximum height of 10 ft (3 m). Use only

approved drain pump kit Part Number 1901A.

Kit Contains:

• Drain pump kit Part Number 1901A

• 5/8"ID x 5V8" drain tube (ice maker bin to drain pump

reservoir inlet)

o !

A. Drain cap

5. If ice maker is built into cabinets, pull ice maker out of the

opening.

6. Disconnect water supply line. See "Water Supply Line"

illustration.

Water Supply Line Drain Tube

A

.........._ C

A. _" adjustable hose clamp C. _" adjustable hose clamp

E

B.Drain tube (ice bin to drain pump) D. Drain pump reservoir inlet

A. _ "copper tubing

B. Cable clamp

C. _ "compression nut

D. Ferrule (sleeve)

E. Ice maker connection

Drain Pump Installation

NOTE: Do not kink, smash or damage tubes or wires during

installation.

1.

Unplug ice maker or disconnect power.

2.

Remove rear panel. See "Rear Panel" illustration for 5 screw

locations. Pull rear panel away from the drain tube and

discard.

Rear Panel

A

A

A. Screw locations

3°

Remove the old drain tube and clamp attached to the ice

maker bin.

NOTE: Discard old drain tube and clamp.

4°

Install new drain tube (5/8"ID x 51/8") from ice maker bin to

drain pump reservoir inlet using new adjustable clamps. See

"Drain Tube" illustration.

NOTES:

• Do not kink.

• Trim tube length, if required.

5°

Install vent tube (5/16" ID x 32" [81 cm]) to drain pump

reservoir vent. Use one 5/8"small adjustable clamp, supplied.

See "Parts Locations" illustration.

NOTE: Do not install household drain tube at this time.

Parts Locations

G F

A. Vent tube

B. 5_ ,, hose clamp

C. Drain pump discharge tube

D. Drain pump

6°

Remove power cord clamp and ground screw attached to

E. ice maker unit power cord

F. _8-32 x 3_ "pump mounting screws

G. Drain pump power cord t clamp

and screw

ice maker power cord, which is mounted to the unit base.

See "Parts Locations" illustration.

NOTE: Clamp and screw will be reused.

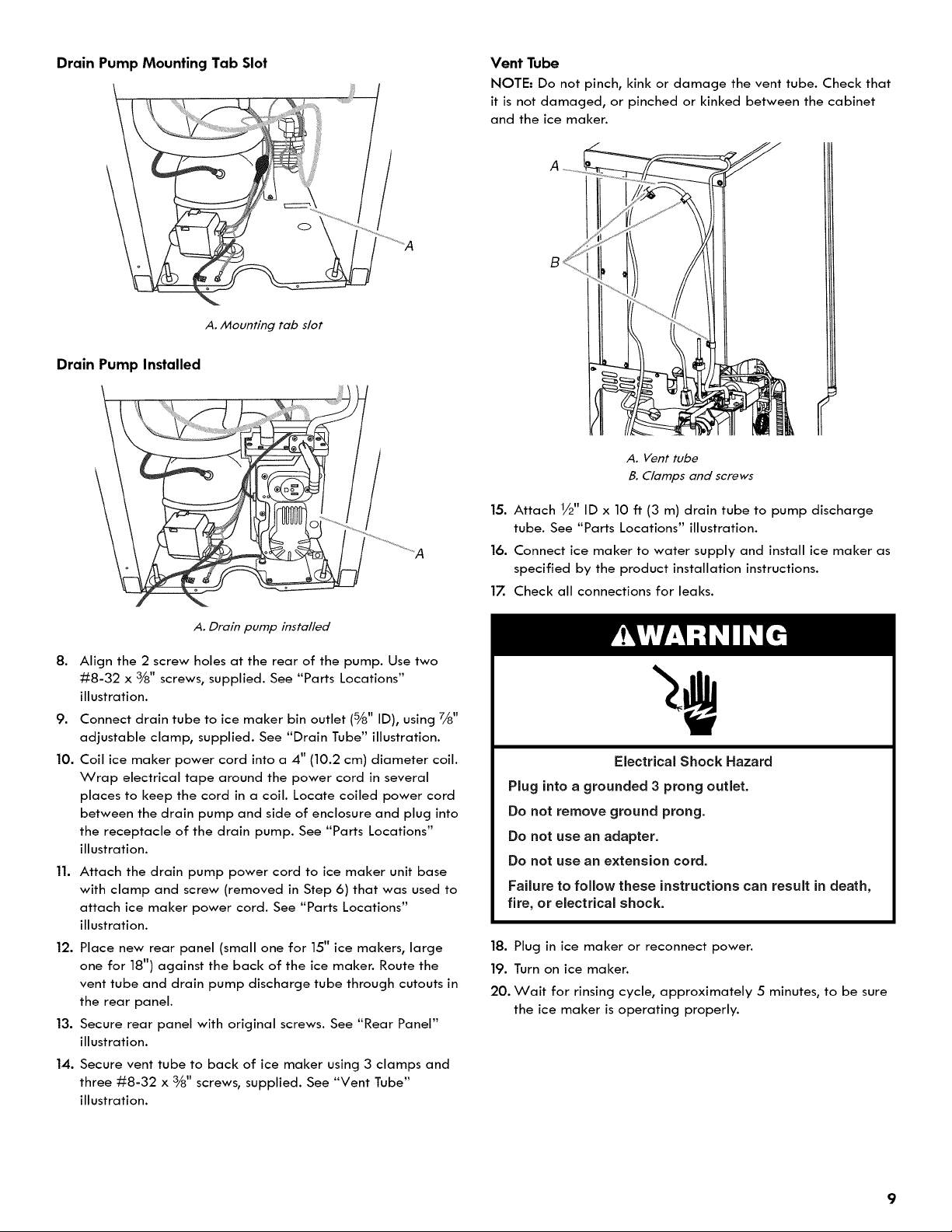

7.

Slide drain pump into the ice maker base on the right side.

The pump mounting tab should slip into the rectangular slot

in the ice maker base. It will be necessary to tip the pump

slightly to slip into the slot. See "Drain Pump Mounting Tab

Slot" illustration.

Drain Pump Mounting Tab Slot

A. Mounting tab slot

Drain Pump Installed

Vent Tube

NOTE" Do not pinch, kink or damage the vent tube. Check that

it is not damaged, or pinched or kinked between the cabinet

and the ice maker.

A. Vent tube

B. Clamps and screws

15. Attach 1/2" ID x 10 ft (3 m) drain tube to pump discharge

tube. See "Parts Locations" illustration.

16. Connect ice maker to water supply and install ice maker as

specified by the product installation instructions.

°

17. Check all connections for leaks.

A. Drain pump installed

8. Align the 2 screw holes at the rear of the pump. Use two

#8-32 x 3/8" screws, supplied. See "Parts Locations"

illustration.

9. Connect drain tube to ice maker bin outlet (5/8" ID), using 7/8"

adjustable clamp, supplied. See "Drain Tube" illustration.

10. Coil ice maker power cord into a 4" (10.2 cm) diameter coil.

Wrap electrical tape around the power cord in several

places to keep the cord in a coil. Locate coiled power cord

between the drain pump and side of enclosure and plug into

the receptacle of the drain pump. See "Parts Locations"

illustration.

11. Attach the drain pump power cord to ice maker unit base

with clamp and screw (removed in Step 6) that was used to

attach ice maker power cord. See "Parts Locations"

illustration.

12. Place new rear panel (small one for 15" ice makers, large

one for 18") against the back of the ice maker. Route the

vent tube and drain pump discharge tube through cutouts in

the rear panel.

13. Secure rear panel with original screws. See "Rear Panel"

illustration.

14. Secure vent tube to back of ice maker using 3 clamps and

three #8-32 x 3/8" screws, supplied. See "Vent Tube"

illustration.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

18. Plug in ice maker or reconnect power.

19. Turn on ice maker.

20. Wait for rinsing cycle, approximately 5 minutes, to be sure

the ice maker is operating properly.

Drain Pump System (on some models)

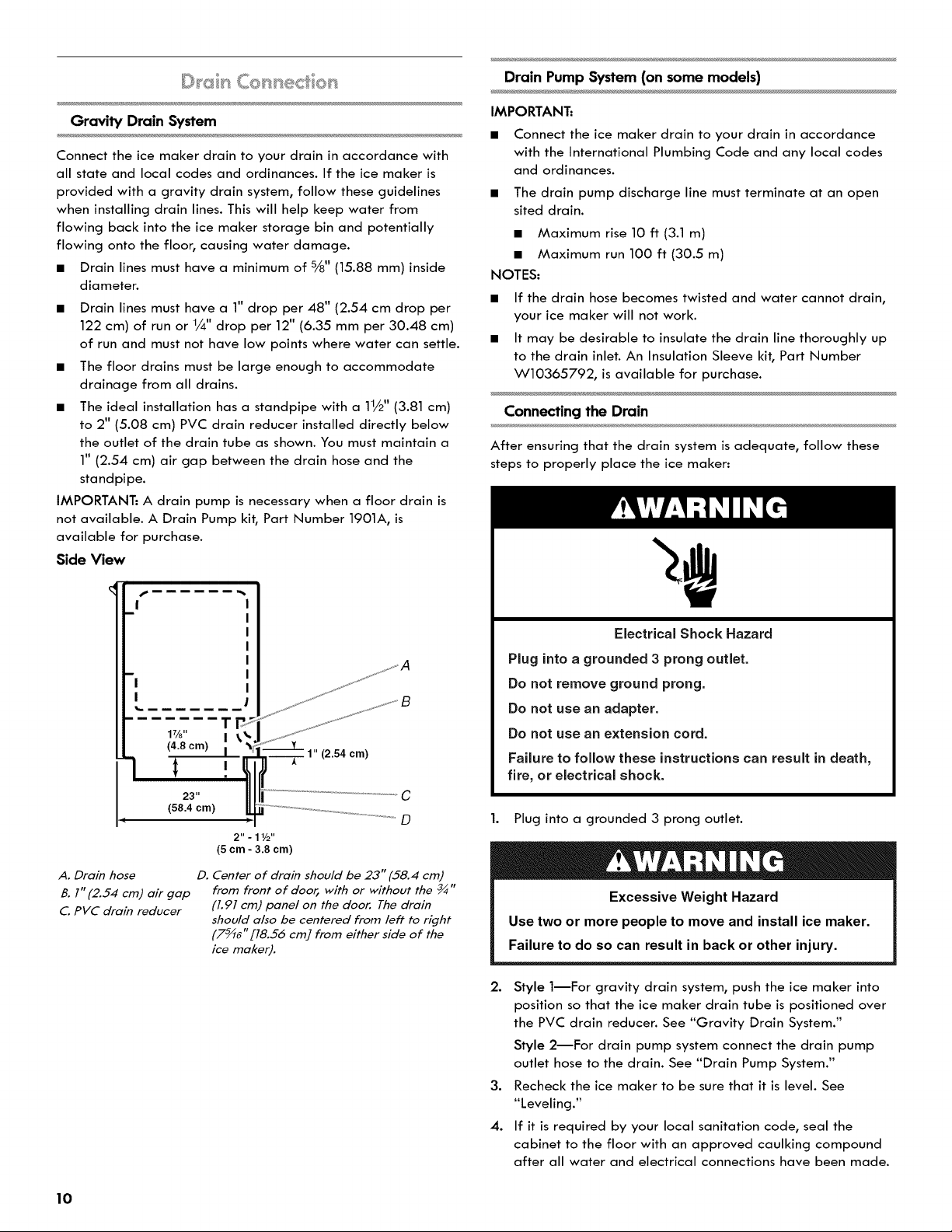

Gravity Drain System

Connect the ice maker drain to your drain in accordance with

all state and local codes and ordinances. If the ice maker is

provided with a gravity drain system, follow these guidelines

when installing drain lines. This will help keep water from

flowing back into the ice maker storage bin and potentially

flowing onto the floor, causing water damage.

• Drain lines must have a minimum of 5/8" (15.88 mm) inside

diameter.

• Drain lines must have a 1" drop per 48" (2.54 cm drop per

122 cm) of run or 1/4" drop per 12" (6.35 mm per 30.48 cm)

of run and must not have low points where water can settle.

• The floor drains must be large enough to accommodate

drainage from all drains.

• The ideal installation has a standpipe with a 11/2" (3.81 cm)

to 2" (5.08 cm) PVC drain reducer installed directly below

the outlet of the drain tube as shown. You must maintain a

1" (2.54 cm) air gap between the drain hose and the

standpipe.

IMPORTANT: A drain pump is necessary when a floor drain is

not available. A Drain Pump kit, Part Number 1901A, is

available for purchase.

Side View

IMPORTANT..

• Connect the ice maker drain to your drain in accordance

with the International Plumbing Code and any local codes

and ordinances.

• The drain pump discharge line must terminate at an open

sited drain.

• Maximum rise 10 ft (3.1 m)

• Maximum run 100 ft (30.5 m)

NOTES:

• If the drain hose becomes twisted and water cannot drain,

your ice maker will not work.

• It may be desirable to insulate the drain line thoroughly up

to the drain inlet. An Insulation Sleeve kit, Part Number

W10365792, is available for purchase.

Connecting the Drain

After ensuring that the drain system is adequate, follow these

steps to properly place the ice maker:

I

I

I

I i23

A. Drain hose

B. 1"(2.54 cm) air gap

C. PVC drain reducer

17/8 II

(4.8 cm)

(58.4 cm)

2"-11/2 ''

(5 cm - 3.8 cm)

D. Center of drain should be 23" (58.4 cm)

from front of door t with or without the 3_,,

(7.91 cm) panel on the door. The drain

should also be centered from left to right

(7_6" [78.56 cm] from either side of the

ice maker).

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Plug into a grounded 3 prong outlet.

Excessive Weight Hazard

Use two or more people to move and install ice maker.

Failure to do so can result in back or other injury.

2. Style 1--For gravity drain system, push the ice maker into

position so that the ice maker drain tube is positioned over

the PVC drain reducer. See "Gravity Drain System."

Style 2--For drain pump system connect the drain pump

outlet hose to the drain. See "Drain Pump System."

3. Recheck the ice maker to be sure that it is level. See

"Leveling."

4. If it is required by your local sanitation code, seal the

cabinet to the floor with an approved caulking compound

after all water and electrical connections have been made.

10

Tools Needed

Gather the required tools and parts before starting installation.

• 5/16"wrench • Flat putty knife

• 1/4"wrench • Phillips screwdriver

Hinge pin

Honc/le screw End cop screw

Remove Exterior Door Wrap and Handle

(on some models)

5_6" hex-heoc/ hinge screw

Door Stop and End-Cap Reversal

!

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Unplug the ice maker or disconnect power.

2. Remove the hinge pin from the top hinge.

Top Hinge

A

A. Hex-heoc/ screws

1. Remove the handle screws and handle (on some models).

2. Remove the 2 hex-head screws located under the stainless

steel door wrap panel flange on the bottom of the door.

3. Pull up and outward on the door wrap panel from the

bottom.

4. Rotate the door wrap panel until it separates from the door

and pull up.

NOTE: Be sure the edge guards do not separate from the

door wrap panel.

A. Hinge pin

B. Phillips-heac/ countersink screw

C. Door stop

Bottom Hinge

0

E

A. Hex-heoc/ hinge screw D. Hinge pin

B. Door stop E. Hinge

C. Phi//ips-heoc/ countersink screw

D. Hinge

E. Hex-heoc/ hinge screw

A

@ IIIit1111.................7

I I .!............

B

c

D

11

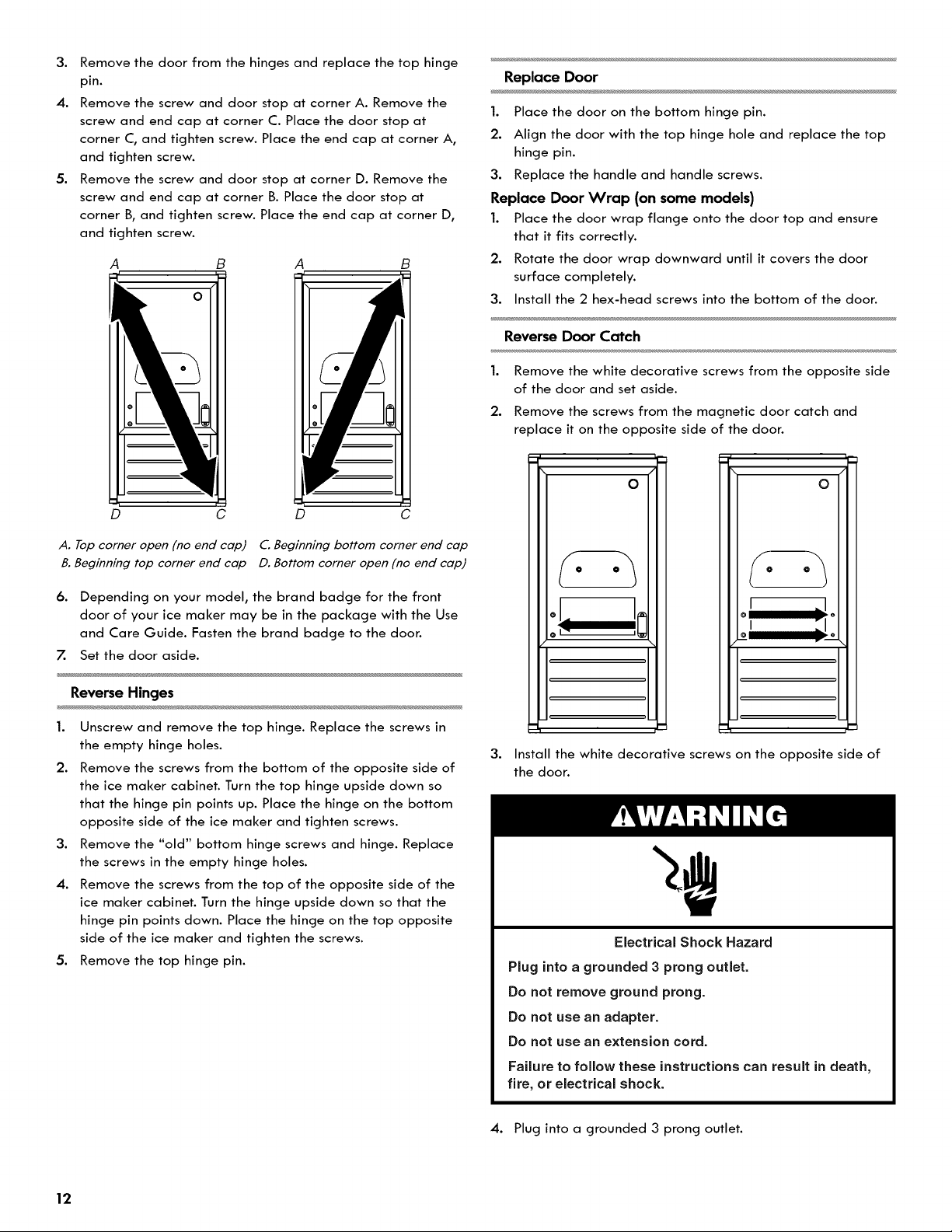

3. Remove the door from the hinges and replace the top hinge

pin.

4. Remove the screw and door stop at corner A. Remove the

screw and end cap at corner C. Place the door stop at

corner C, and tighten screw. Place the end cap at corner A,

and tighten screw.

5. Remove the screw and door stop at corner D. Remove the

screw and end cap at corner B. Place the door stop at

corner B, and tighten screw. Place the end cap at corner D,

and tighten screw.

A B A B

0

D C D C

Replace Door

1. Place the door on the bottom hinge pin.

2. Align the door with the top hinge hole and replace the top

hinge pin.

3. Replace the handle and handle screws.

Replace Door Wrap (on some models)

1. Place the door wrap flange onto the door top and ensure

that it fits correctly.

2. Rotate the door wrap downward until it covers the door

surface completely.

3. Install the 2 hex-head screws into the bottom of the door.

Reverse Door Catch

1.

Remove the white decorative screws from the opposite side

of the door and set aside.

2.

Remove the screws from the magnetic door catch and

replace it on the opposite side of the door.

0

A. Top corner open [no end cap) C. Beginning bottom corner end cap

B. Beginning top corner end cap D. Bottom corner open [no end cap]

6. Depending on your model, the brand badge for the front

door of your ice maker may be in the package with the Use

and Care Guide. Fasten the brand badge to the door.

7. Set the door aside.

Reverse Hinges

1. Unscrew and remove the top hinge. Replace the screws in

the empty hinge holes.

2. Remove the screws from the bottom of the opposite side of

the ice maker cabinet. Turn the top hinge upside down so

that the hinge pin points up. Place the hinge on the bottom

opposite side of the ice maker and tighten screws.

3. Remove the "old" bottom hinge screws and hinge. Replace

the screws in the empty hinge holes.

4. Remove the screws from the top of the opposite side of the

ice maker cabinet. Turn the hinge upside down so that the

hinge pin points down. Place the hinge on the top opposite

side of the ice maker and tighten the screws.

5. Remove the top hinge pin.

3.

Install the white decorative screws on the opposite side of

the door.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

i

12

Failure to follow these instructions can result in death,

fire, or electrical shock.

4. Plug into a grounded 3 prong outlet.

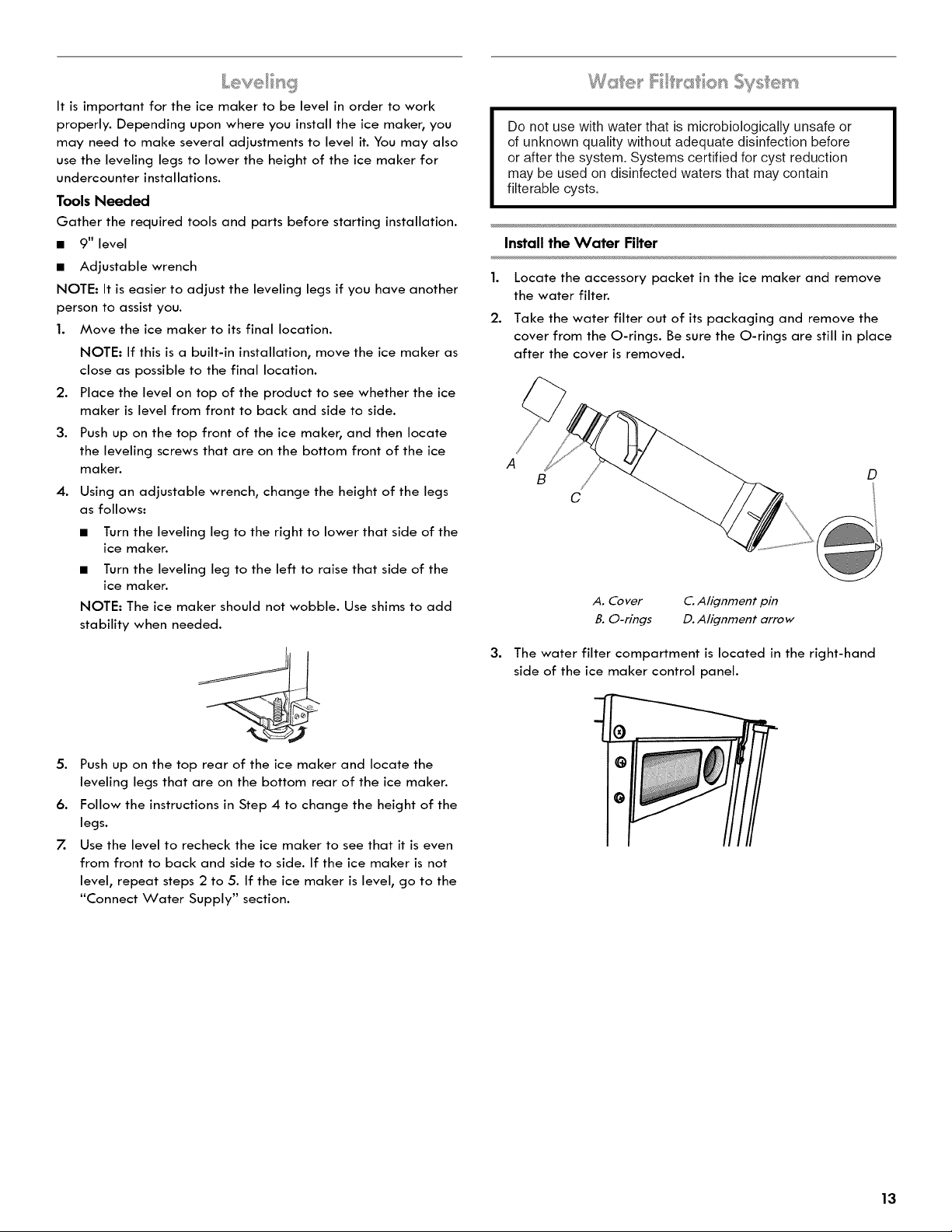

It is important for the ice maker to be level in order to work

properly. Depending upon where you install the ice maker, you

may need to make several adjustments to level it. You may also

use the leveling legs to lower the height of the ice maker for

undercounter installations.

Tools Needed

Gather the required tools and parts before starting installation.

• 9" level

• Adjustable wrench

NOTE: It is easier to adjust the leveling legs if you have another

person to assist you.

1. Move the ice maker to its final location.

NOTE: If this is a built-in installation, move the ice maker as

close as possible to the final location.

2.

Place the level on top of the product to see whether the ice

maker is level from front to back and side to side.

3.

Push up on the top front of the ice maker, and then locate

the leveling screws that are on the bottom front of the ice

maker.

4.

Using an adjustable wrench, change the height of the legs

as follows:

• Turn the leveling leg to the right to lower that side of the

ice maker.

• Turn the leveling leg to the left to raise that side of the

ice maker.

NOTE: The ice maker should not wobble. Use shims to add

stability when needed.

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain

filterable cysts.

Install the Water Filter

.

Locate the accessory packet in the ice maker and remove

the water filter.

2.

Take the water filter out of its packaging and remove the

cover from the O-rings. Be sure the O-rings are still in place

after the cover is removed.

A

B D

C

A. Cover C. A/ignment />in

B. O-rings D. A/ignment arrow

5. Push up on the top rear of the ice maker and locate the

leveling legs that are on the bottom rear of the ice maker.

6. Follow the instructions in Step 4 to change the height of the

legs.

7. Use the level to recheck the ice maker to see that it is even

from front to back and side to side. If the ice maker is not

level, repeat steps 2 to 5. If the ice maker is level, go to the

"Connect Water Supply" section.

3.

The water filter compartment is located in the right-hand

side of the ice maker control panel.

13

4.

Using the arrow pointing to the alignment pin on the side of

the filter and the arrow inside the control housing, align the

alignment pin with the cutout notch and insert the filter into

the housing.

A B

C

F

A. Alignment pin

B. Unlocked symbol

C Locked symbol

5.

Turn the filter clockwise until it locks into the housing. Ensure

that the alignment arrow on the filter head aligns with the

locked symbol on the control box housing.

NOTE: If the filter is not correctly locked into the housing,

the ice maker will not produce ice.

D. Cutout notch inside control housing

E.Arrow pointing to cutout notch

F. Arrow pointing to alignment pin

A

A. Alignment arrow aligned with locked symbol

The Water Filter Status Light

The water filter status lights will help you know when to change

your water filter.

• The "Order Filter" status light will be illuminated when it is

time to order a replacement filter.

• The "Replace Filter" status light will be illuminated when it is

D

E

time to replace the filter.

• Replacing the disposable water filter with a new filter will

automatically reset the filter status tracking feature. See

"Using the Controls."

NOTES:

• "Replace Filter" will remain illuminated if a filter is not

installed.

• The "Filter" status light will flash if the filter is not

correctly installed or there is an obstruction in the water

line.

Replace the Water Filter

To purchase a replacement water filter, see "Accessories."

Replace the disposable water filter when indicated on the water

filter status display or at least every 9 months. If the ice making

rate decreases before the Replace Filter light illuminates, then

replace the filter.

1. Locate the water filter compartment in the right-hand side

of the control housing. See Step 3 in the "Install Water

Filter" section.

2. Turn the water filter counterclockwise (to the left), and pull it

straight out of the compartment.

NOTE: There may be some water in the filter. Some spilling

may occur.

3. Install the replacement water filter by following steps

2 through 5 in the "Install the Water Filter" section.

ICE MAKER USE

When you first start your ice maker, the water pan will fill and

the system will rinse itself before starting to make ice. The

rinsing process takes about 5 minutes.

Under normal operating conditions, the ice maker will cycle at

preset temperatures. The ice level sensor located in the ice

storage bin will monitor the ice levels.

IMPORTANT: If the water supply to the ice maker is turned off,

be sure to set the ice maker control to OFF.

14

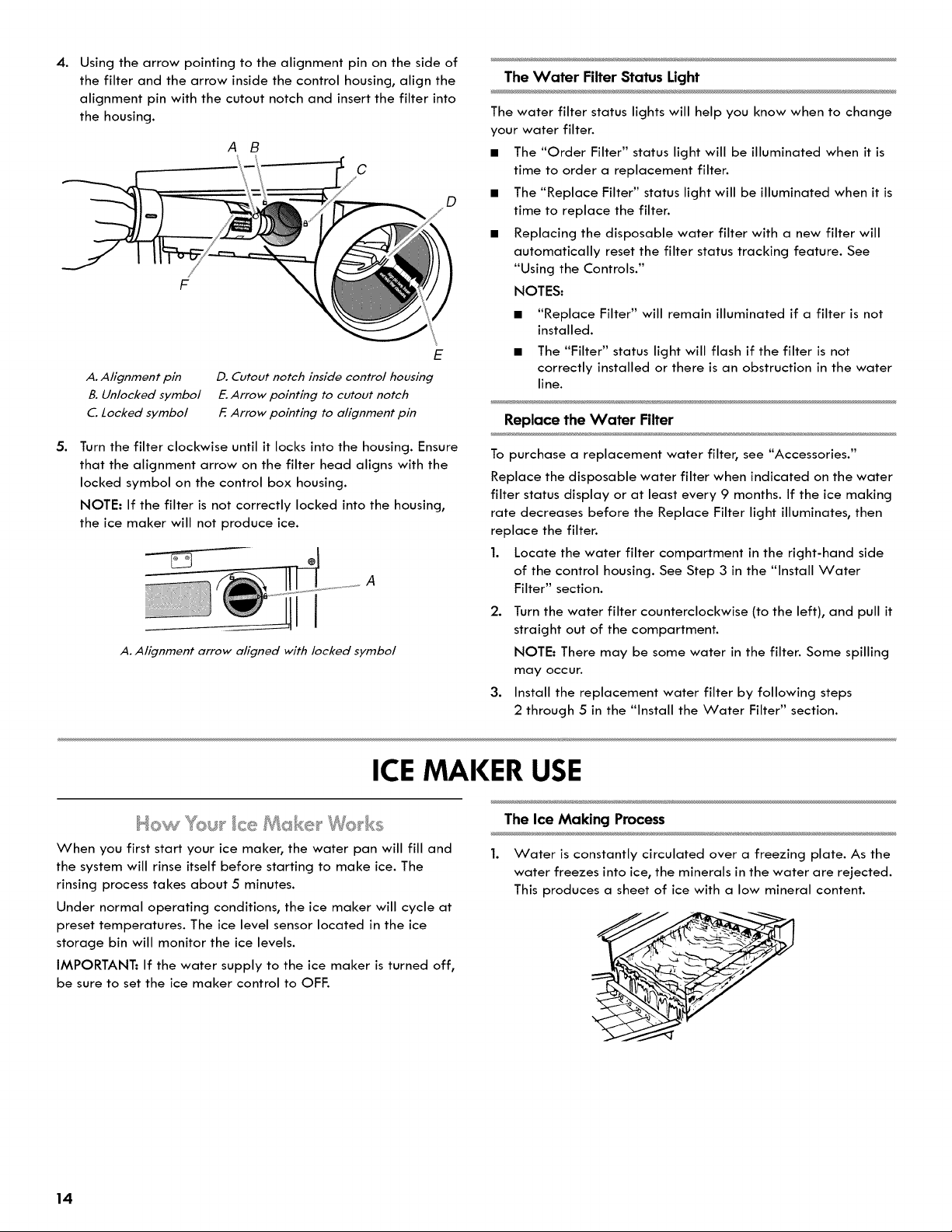

The Ice Making Process

1. Water is constantly circulated over a freezing plate. As the

water freezes into ice, the minerals in the water are rejected.

This produces a sheet of ice with a low mineral content.

2,

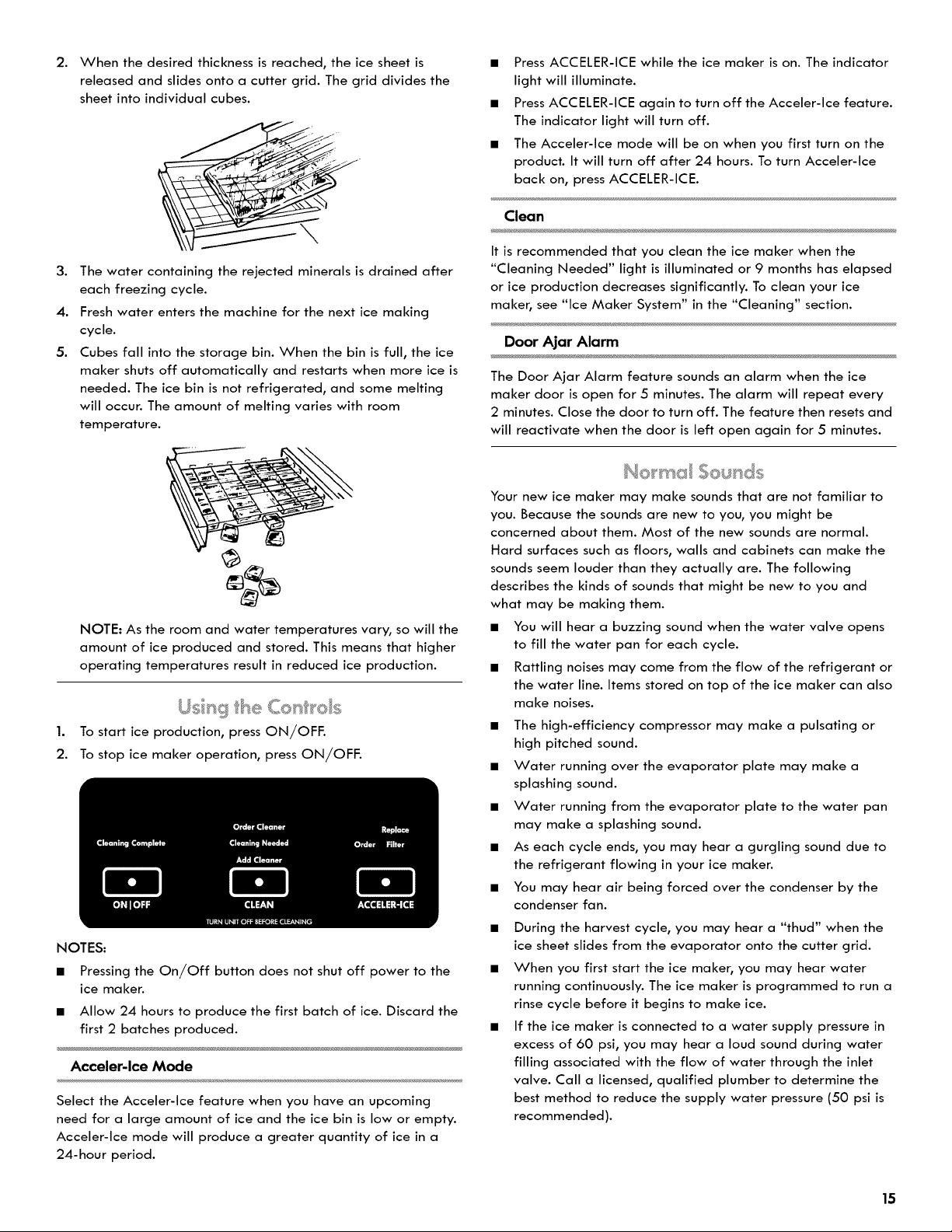

When the desired thickness is reached, the ice sheet is

released and slides onto a cutter grid. The grid divides the

sheet into individual cubes.

3. The water containing the rejected minerals is drained after

each freezing cycle.

4. Fresh water enters the machine for the next ice making

cycle.

5. Cubes fall into the storage bin. When the bin is full, the ice

maker shuts off automatically and restarts when more ice is

needed. The ice bin is not refrigerated, and some melting

will occur. The amount of melting varies with room

temperature.

NOTE: As the room and water temperatures vary, so will the

amount of ice produced and stored. This means that higher

operating temperatures result in reduced ice production.

Usng the

1. To start ice production, press ON/OFF.

2. To stop ice maker operation, press ON/OFF.

{}@sf_o s

NOTES:

• Pressing the On/Off button does not shut off power to the

ice maker.

• Allow 24 hours to produce the first batch of ice. Discard the

first 2 batches produced.

Acceler-lce Mode

Select the Acceler-lce feature when you have an upcoming

need for a large amount of ice and the ice bin is low or empty.

Acceler-lce mode will produce a greater quantity of ice in a

24-hour period.

• Press ACCELER-ICE while the ice maker is on. The indicator

light will illuminate.

• PressACCELER-ICE again to turn off the Acceler-lce feature.

The indicator light will turn off.

• The Acceler-lce mode will be on when you first turn on the

product. It will turn off after 24 hours. To turn Acceler-lce

back on, press ACCELER-ICE.

Clean

It is recommended that you clean the ice maker when the

"Cleaning Needed" light is illuminated or 9 months has elapsed

or ice production decreases significantly. To clean your ice

maker, see "Ice Maker System" in the "Cleaning" section.

Door Ajar Alarm

The Door Ajar Alarm feature sounds an alarm when the ice

maker door is open for 5 minutes. The alarm will repeat every

2 minutes. Close the door to turn off. The feature then resets and

will reactivate when the door is left open again for 5 minutes.

Your new ice maker may make sounds that are not familiar to

you. Because the sounds are new to you, you might be

concerned about them. Most of the new sounds are normal.

Hard surfaces such as floors, walls and cabinets can make the

sounds seem louder than they actually are. The following

describes the kinds of sounds that might be new to you and

what may be making them.

• You will hear a buzzing sound when the water valve opens

to fill the water pan for each cycle.

• Rattling noises may come from the flow of the refrigerant or

the water line. Items stored on top of the ice maker can also

make noises.

• The high-efficiency compressor may make a pulsating or

high pitched sound.

• Water running over the evaporator plate may make a

splashing sound.

• Water running from the evaporator plate to the water pan

may make a splashing sound.

• As each cycle ends, you may hear a gurgling sound due to

the refrigerant flowing in your ice maker.

• You may hear air being forced over the condenser by the

condenser fan.

• During the harvest cycle, you may hear a "thud" when the

ice sheet slides from the evaporator onto the cutter grid.

• When you first start the ice maker, you may hear water

running continuously. The ice maker is programmed to run a

rinse cycle before it begins to make ice.

• If the ice maker is connected to a water supply pressure in

excess of 60 psi, you may hear a loud sound during water

filling associated with the flow of water through the inlet

valve. Call a licensed, qualified plumber to determine the

best method to reduce the supply water pressure (50 psi is

recommended).

15

ICEMAKER CARE

The ice making system and the air cooled condenser need to be

cleaned regularly for the ice maker to operate at peak

efficiency and to avoid premature failure of system

components. See the "Ice Maker System" and the "Condenser"

sections.

Exterior Surfaces

Wash the exterior enamel surfaces and gaskets with warm

water and mild soap or detergent. Wipe and dry. Regular use of

a good household appliance cleaner and wax will help maintain

the finish. Do not use abrasive cleaners on enamel surfaces as

they may scratch the finish.

For products with a stainless steel exterior, use a clean sponge or

soft cloth and a mild detergent in warm water. Do not use

abrasive or harsh cleaners. Do not use chlorine bleach on the

stainless steel surfaces.

Ice Maker System

Minerals that are removed from water during the freezing cycle

will eventually form a hard scaly deposit in the water system.

Cleaning the system regularly helps remove the mineral scale

buildup. How often you need to clean the system depends upon

how hard your water is. With hard water of 15 to 20 grains/gal.

(4 to 5 gralns/llter), you may need to clean the system as often

as every 9 months.

NOTE: Use one 16 oz (473 mL) bottle of approved ice maker

cleaner, Part Number 4396808. To order, please call

1-800-4-MY-HOME ®.

1. Press the ON/OFF button.

2. Wait 5 to 10 minutes for the ice to fall into the storage bin.

Remove all ice from the storage bin.

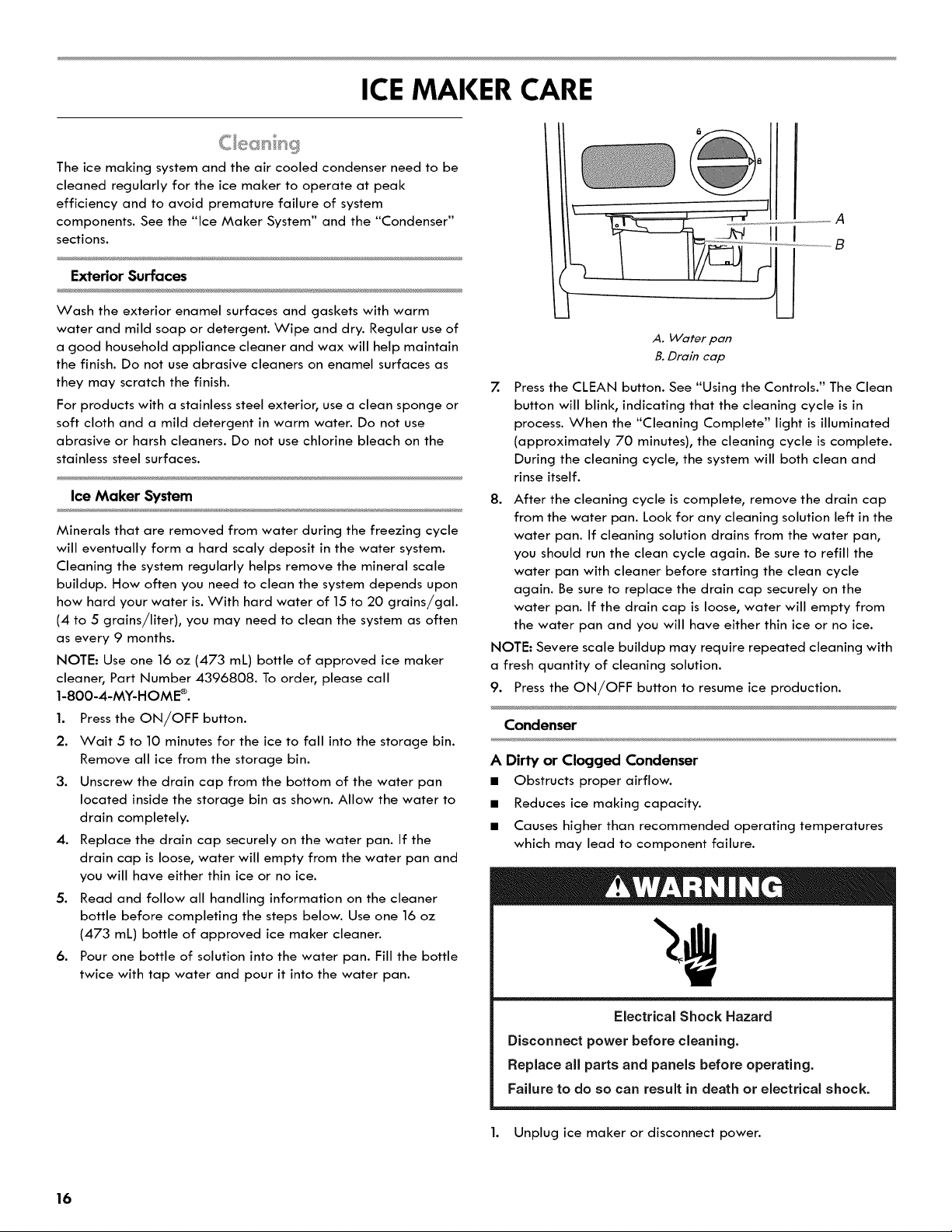

3. Unscrew the drain cap from the bottom of the water pan

located inside the storage bin as shown. Allow the water to

drain completely.

4. Replace the drain cap securely on the water pan. If the

drain cap is loose, water will empty from the water pan and

you will have either thin ice or no ice.

5. Read and follow all handling information on the cleaner

bottle before completing the steps below. Use one 16 oz

(473 mL) bottle of approved ice maker cleaner.

6. Pour one bottle of solution into the water pan. Fill the bottle

twice with tap water and pour it into the water pan.

7.

Press the CLEAN button. See "Using the Controls." The Clean

button will blink, indicating that the cleaning cycle is in

process. When the "Cleaning Complete" light is illuminated

(approximately 70 minutes), the cleaning cycle is complete.

During the cleaning cycle, the system will both clean and

rinse itself.

8. After the cleaning cycle is complete, remove the drain cap

from the water pan. Look for any cleaning solution left in the

water pan. If cleaning solution drains from the water pan,

you should run the clean cycle again. Be sure to refill the

water pan with cleaner before starting the clean cycle

again. Be sure to replace the drain cap securely on the

water pan. If the drain cap is loose, water will empty from

the water pan and you will have either thin ice or no ice.

NOTE: Severe scale buildup may require repeated cleaning with

a fresh quantity of cleaning solution.

9. Press the ON/OFF button to resume ice production.

Condenser

A Dirty or Clogged Condenser

• Obstructs proper airflow.

• Reduces ice making capacity.

• Causes higher than recommended operating temperatures

which may lead to component failure.

16

Electrical Shock Hazard

Disconnect power before cleaning.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Unplug ice maker or disconnect power.

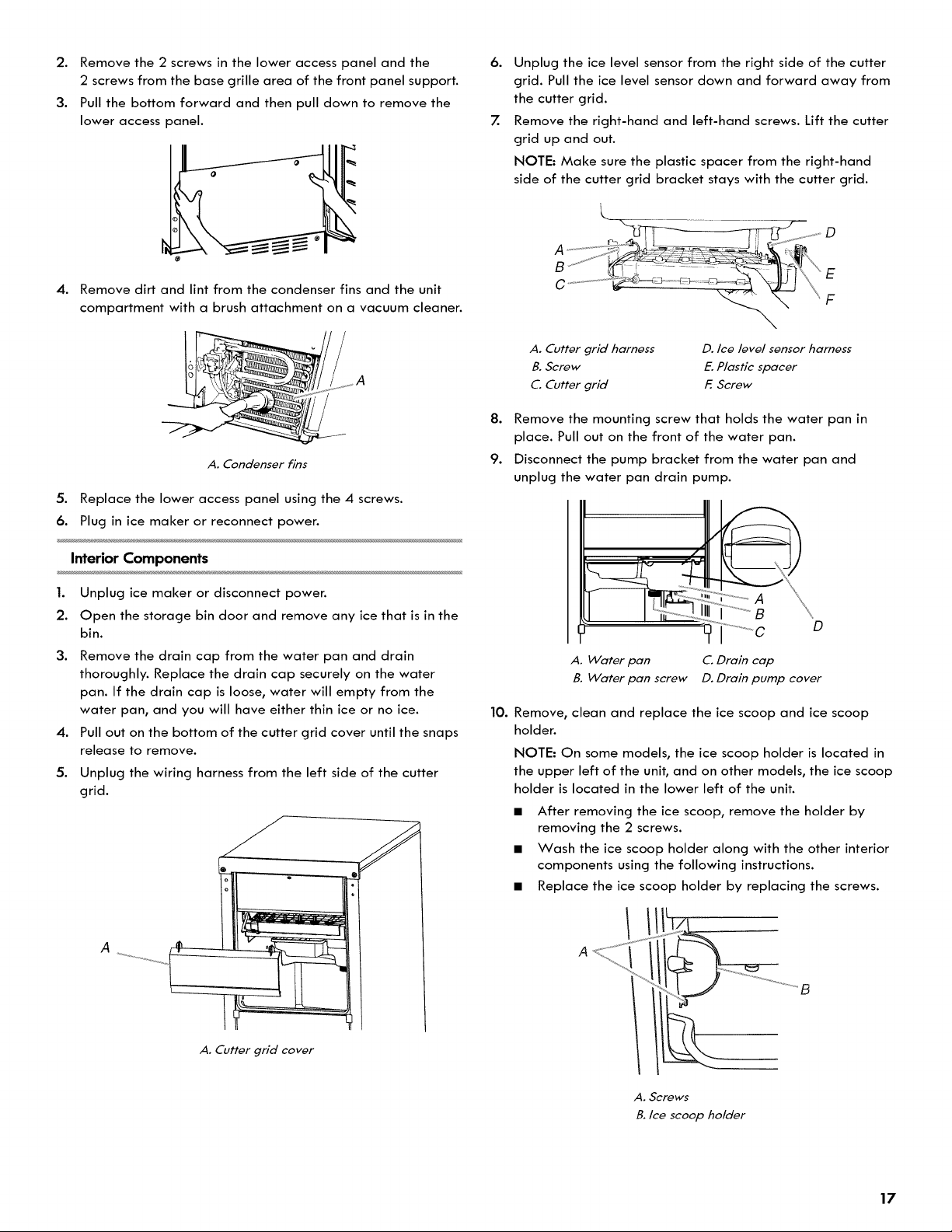

2. Remove the 2 screws in the lower access panel and the

2 screws from the base grille area of the front panel support.

3. Pull the bottom forward and then pull down to remove the

lower access panel.

4. Remove dirt and lint from the condenser fins and the unit

compartment with a brush attachment on a vacuum cleaner.

6. Unplug the ice level sensor from the right side of the cutter

grid. Pull the ice level sensor down and forward away from

the cutter grid.

7. Remove the right-hand and left-hand screws. Lift the cutter

grid up and out.

NOTE: Make sure the plastic spacer from the right-hand

side of the cutter grid bracket stays with the cutter grid.

ABii_:,:,............_:............ _..............................DE

A. Condenser fins

5. Replace the lower access panel using the 4 screws.

6. Plug in ice maker or reconnect power.

Interior Components

1. Unplug ice maker or disconnect power.

2. Open the storage bin door and remove any ice that is in the

bin.

3.

Remove the drain cap from the water pan and drain

thoroughly. Replace the drain cap securely on the water

pan. If the drain cap is loose, water will empty from the

water pan, and you will have either thin ice or no ice.

4.

Pull out on the bottom of the cutter grid cover until the snaps

release to remove.

5.

Unplug the wiring harness from the left side of the cutter

grid.

A. Cutter grid harness

B. Screw

C. Cutter grid

D. lee level sensor harness

E.Plastic spacer

F &crew

8. Remove the mounting screw that holds the water pan in

place. Pull out on the front of the water pan.

9. Disconnect the pump bracket from the water pan and

unplug the water pan drain pump.

A. Water pan C. Drain cap

B. Water pan screw D. Drain pump cover

10. Remove, clean and replace the ice scoop and ice scoop

holder.

NOTE: On some models, the ice scoop holder is located in

the upper left of the unit, and on other models, the ice scoop

holder is located in the lower left of the unit.

• After removing the ice scoop, remove the holder by

removing the 2 screws.

• Wash the ice scoop holder along with the other interior

components using the following instructions.

• Replace the ice scoop holder by replacing the screws.

A

A '_':j_iiilliiiiiiiiiii_i'

A. Cutter grid cover

A. Screws

B. Ice scoop holder

17

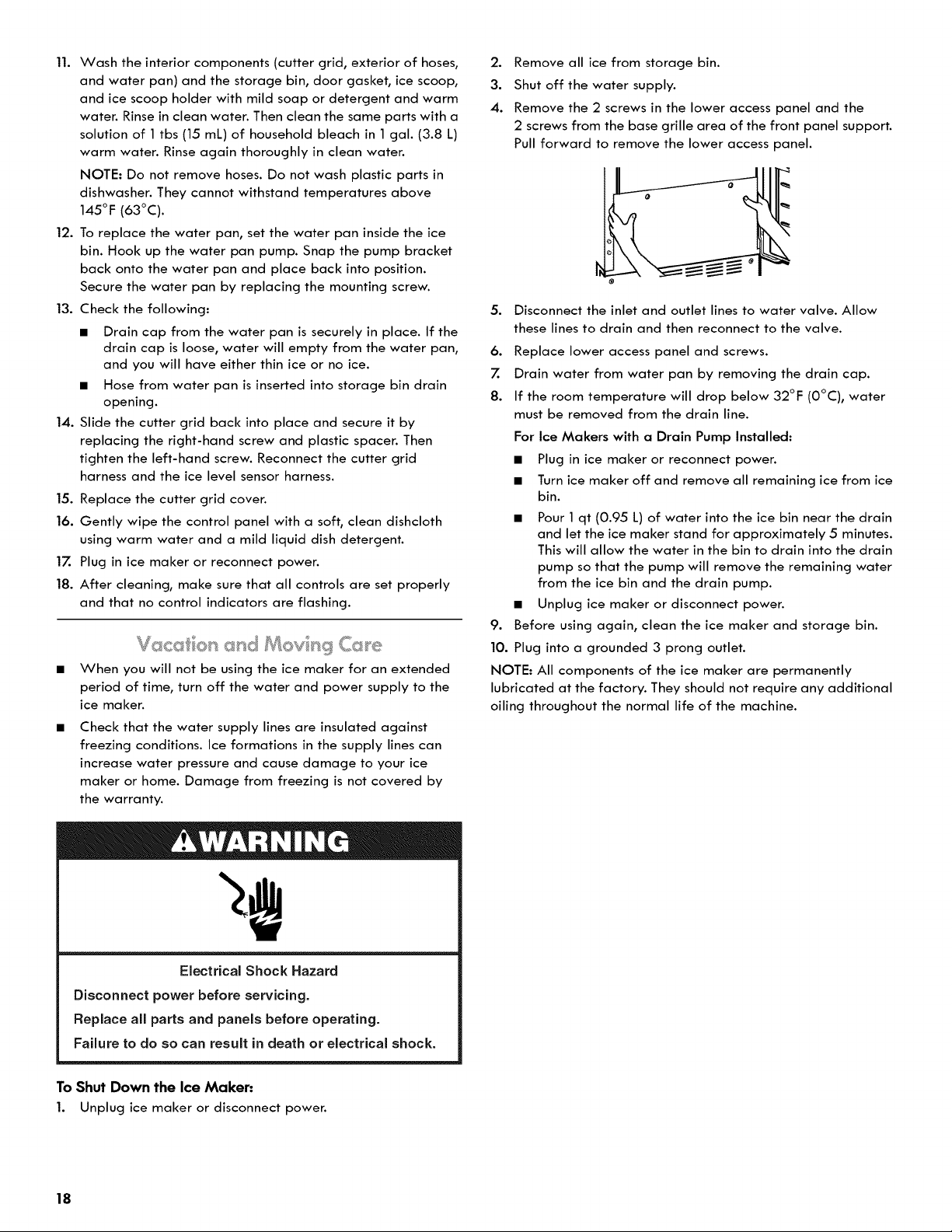

11. Wash the interior components (cutter grid, exterior of hoses,

and water pan) and the storage bin, door gasket, ice scoop,

and ice scoop holder with mild soap or detergent and warm

water. Rinse in clean water. Then clean the same parts with a

solution of 1 tbs (15 mL) of household bleach in 1 gal. (3.8 L)

warm water. Rinse again thoroughly in clean water.

NOTE: Do not remove hoses. Do not wash plastic parts in

dishwasher. They cannot withstand temperatures above

145°F (63°C).

12. To replace the water pan, set the water pan inside the ice

bin. Hook up the water pan pump. Snap the pump bracket

back onto the water pan and place back into position.

Secure the water pan by replacing the mounting screw.

13. Check the following:

• Drain cap from the water pan is securely in place. If the

drain cap is loose, water will empty from the water pan,

and you will have either thin ice or no ice.

• Hose from water pan is inserted into storage bin drain

opening.

14. Slide the cutter grid back into place and secure it by

replacing the right-hand screw and plastic spacer. Then

tighten the left-hand screw. Reconnect the cutter grid

harness and the ice level sensor harness.

15. Replace the cutter grid cover.

16. Gently wipe the control panel with a soft, clean dishcloth

using warm water and a mild liquid dish detergent.

17. Plug in ice maker or reconnect power.

18. After cleaning, make sure that all controls are set properly

and that no control indicators are flashing.

Vaca ' Mov Cas'e

When you will not be using the ice maker for an extended

period of time, turn off the water and power supply to the

ice maker.

Check that the water supply lines are insulated against

freezing conditions. Ice formations in the supply lines can

increase water pressure and cause damage to your ice

maker or home. Damage from freezing is not covered by

the warranty.

2.

Remove all ice from storage bin.

3.

Shut off the water supply.

4.

Remove the 2 screws in the lower access panel and the

2 screws from the base grille area of the front panel support.

Pull forward to remove the lower access panel.

5. Disconnect the inlet and outlet lines to water valve. Allow

these lines to drain and then reconnect to the valve.

6. Replace lower access panel and screws.

7. Drain water from water pan by removing the drain cap.

8. If the room temperature will drop below 32°F (O°C), water

must be removed from the drain line.

For Ice Makers with a Drain Pump Installed:

• Plug in ice maker or reconnect power.

• Turn ice maker off and remove all remaining ice from ice

bin.

• Pour 1qt (0.95 L) of water into the ice bin near the drain

and let the ice maker stand for approximately 5 minutes.

This will allow the water in the bin to drain into the drain

pump so that the pump will remove the remaining water

from the ice bin and the drain pump.

• Unplug ice maker or disconnect power.

9. Before using again, clean the ice maker and storage bin.

10. Plug into a grounded 3 prong outlet.

NOTE: All components of the ice maker are permanently

lubricated at the factory. They should not require any additional

oiling throughout the normal life of the machine.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

To Shut Down the Ice Maker;

1. Unplug ice maker or disconnect power.

18

TROUBLESHOOTING

Try the solutions suggested here first in order to avoid the cost of an unnecessary service call.

ce

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death_

fire_ or electrical shock.

PROBLEM RECOMMENDED SOLUTIONS

Ice Maker Will Not Operate Check that it isplugged into a grounded 3 prong outlet.

Check that the control is turned on. See "Using the Controls."

Replace the fuse or reset the circuit breaker.

NOTE: If problems continue, contact an electrician.

Room temperature must be above 55°F (13°C). Otherwise, bin thermostat may sense cold room

temperature and shut off even though the bin is not full of ice. The ice maker may not restart once it

does shut off.

If there was a large amount of water added to the ice maker, wait a few minutes for the drain pump

to clear. If there is still water in the bin, check to see whether the drain hose is kinked.

For models with drain pumps, check that the drain hose is not damaged, or kinked or pinched

between cabinet and ice maker. Use only approved drain pump kit, Part Number 1901A.

Ice Maker Seems Noisy Is the water in the reservoir overflowing? This is normal. This overflow helps to purge minerals that

were removed from the water during the ice making process.

Is there a "whooshing" sound? Check the following things:

• Make sure that the water supply is hooked up and turned on.

• Make sure that the drain cap is tight and the water drain pan pump is securely attached to the

water pan.

Is there ice between the evaporator plate and the cutting grid? Check that the ice maker is level.

See "Leveling." If the ice maker is level, and the problem persists, run a cleaning cycle. See

"Cleaning."

If the ice maker is connected to a water supply pressure in excess of 60 psi, you may hear a loud

sound during water filling associated with the flow of water through the inlet valve. Call a licensed,

qualified plumber to determine the best method to reduce the supply water pressure (50 psi is

recommended).

19

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

PROBLEM RECOMMENDED SOLUTIONS

ice Maker Runs But Check that the control is turned on.

Produces No ice Check that the water supply is properly connected and turned on.

If the drain cap is loose, water will empty from the water pan, and you will have either thin ice or no

ice. Tighten the drain cap.

Clean the drain tube.

Check that there are no kinks in the drain line.

Ice Maker Runs But

Produces Very Little Ice

Is the accelerated ice production feature turned on? This feature increases the ice production rate to

provide you with more ice in the same amount of time. See "Using the Controls."

Room temperatures of more than 90°F (32°C) will normally reduce ice production.

Dirt or lint may be blocking the airflow through the condenser. See "Condenser" in the "Cleaning"

section.

If there is white scale buildup in the ice maker's water or freezing system, you should clean the ice

maker. See "Interior Components" in the "Cleaning" section.

If the drain cap is loose, water will empty from the water pan, and you will have either thin ice or no

ice. Tighten the drain cap.

Ensure that the cutter grid is securely in place and that its harness plug is connected. See "Interior

Components" section of "Cleaning" for instructions on cutter grid removal.

Check that water filter is properly installed.

PROBLEM RECOMMENDED SOLUTIONS

Off Taste, Odor or Gray

Color in the Ice

Is there unusually high mineral content in the water supply? The water may need to be treated.

Is there mineral scale buildup? Clean your ice maker. See "Ice Maker System" in the "Cleaning"

section.

Do not store any foods in the ice bin.

Make sure that all packaging materials were removed at the time of installation.

Thin, Soft or Clumps of Ice

2O

Is there unusually high mineral content in the water supply? The water may need to be treated.

Is there mineral scale buildup? Clean your ice maker. See "Ice Maker System" in the "Cleaning"

section.

Are there clumps of ice in the bin? If ice is not used regularly, it will melt and form clumps. Break the

clumps with the ice scoop provided.

D ¸_ _ _ _ _ D_ _

Excessive Weight Hazard

Use two or more people to move and install ice maker.

Failure to do so can result in back or other injury.

PROBLEM RECOMMENDED SOLUTIONS

Water Not Entering Drain

Properly

Isthe drain hose aligned over the drain? Move the ice maker to align the drain. See "Connect

Water Supply."

NOTE: Service technicians cannot repair plumbing problems outside of the ice maker. Call a

licensed, qualified plumber.

To order accessories, call 1-800-4-MY-HOME ®and ask for the

appropriate part number listed below or contact your

authorized Kenmore dealer.

Water Filter

Cleaner

Order Part Number 4396808

Stainless Steel Cleaner

Order Part Number D22 M40083 R

Order Part Number 9934

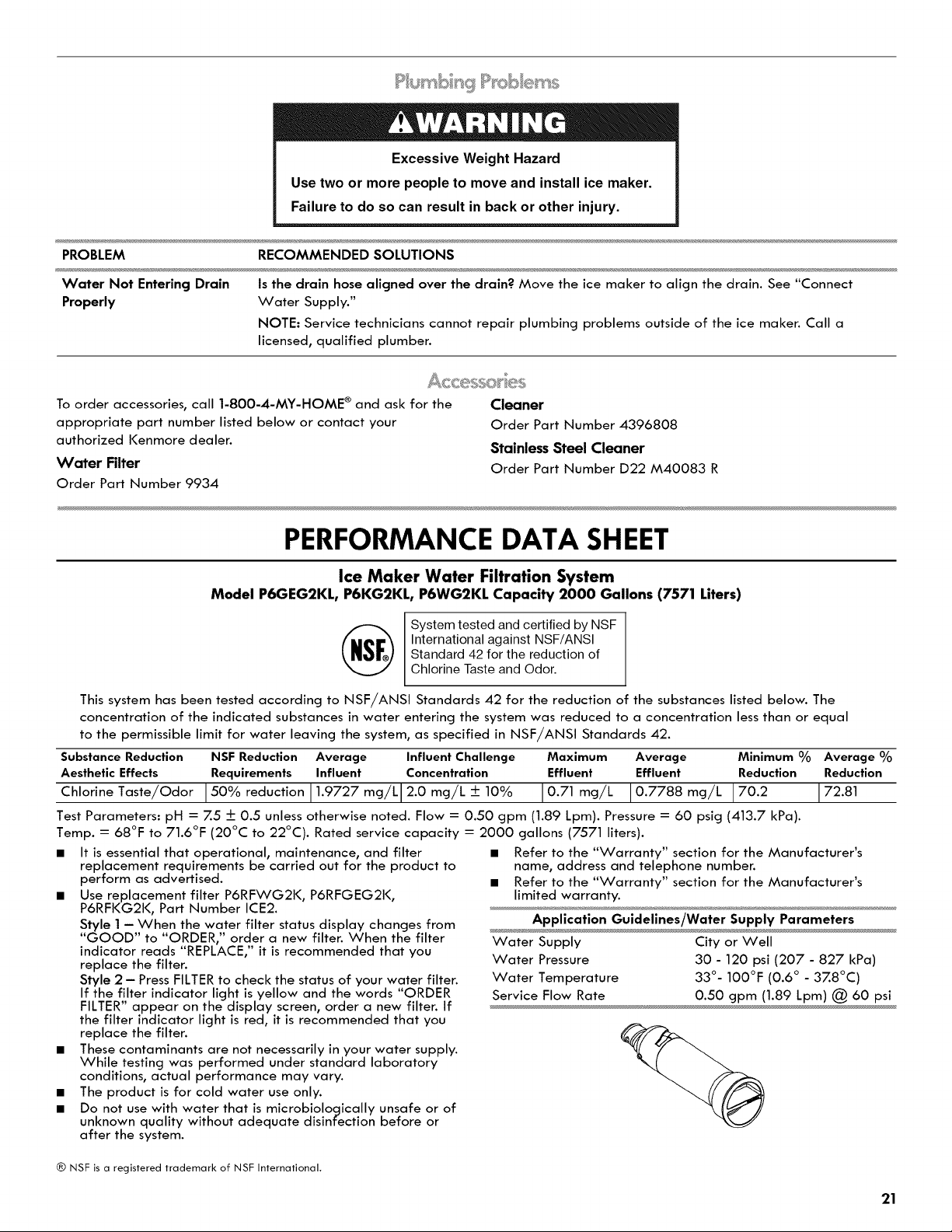

PERFORMANCE DATA SHEET

Ice Maker Water Filtration System

Model P6GEG2KL, P6KG2KL, P6WG2KL Capacity 2000 Gallons (7571 Liters)

System tested and certified by NSF

International against NSF/ANSI

Standard 42 for the reduction of

Chlorine Taste and Odor.

This system has been tested according to NSF/ANSI Standards 42 for the reduction of the substances listed below. The

concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal

to the permissible limit for water leaving the system, as specified in NSF/ANSI Standards 42.

Substance Reduction NSF Reduction Average Influent Challenge Maximum Average Minimum °/o Average °/o

Aesthetic Effects Requirements Influent Concentration Effluent Effluent Reduction Reduction

Chlorine Taste/Odor 150%reduction 11.9727mg/L12.0mg/L -t- 10O/o 10.71mg/L 10.7788mg/L 170.2 172.81

Test Parameters: pH = 7.5 -t- 0.5 unless otherwise noted. Flow = 0.50 gpm (1.89 Lpm). Pressure = 60 psig (413.7 kPa).

Temp. = 68°F to 71.6°F (20°C to 22°C). Rated service capacity = 2000 gallons (7571 liters).

• It is essential that operational, maintenance, and filter

replacement requirements be carried out for the product to

perform as advertised.

• Use replacement filter P6RFWG2K, P6RFGEG2K,

P6RFKG2K, Part Number ICE2.

Style 1- When the water filter status display changes from

"GOOD" to "ORDER," order a new filter. When the filter

indicator reads "REPLACE," it is recommended that you

replace the filter.

Style 2 - Press FILTER to check the status of your water filter.

If the filter indicator light is yellow and the words "ORDER

FILTER appear on the display screen, order a new filter. If

the filter indicator light is red, it is recommended that you

replace the filter.

• These contaminants are not necessarily in your water supply.

While testing was performed under standard laboratory

conditions, actual performance may vary.

• The product is for cold water use only.

• Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or

after the system.

• Refer to the "Warranty" section for the Manufacturer's

name, address and telephone number.

• Refer to the "Warranty" section for the Manufacturer's

limited warranty.

Application Guidelines/Water Supply Parameters

Water Supply City or Well

Water Pressure 30 - 120 psi (207 - 827 kPa)

Water Temperature 33 °- IO0°F (0.6 ° - 37.8°C)

Service Flow Rate 0.50 gpm (1.89 Lpm) @ 60 psi

® NSF is a registered trademark of NSF International.

21

Loading...

Loading...