Kenmore 10689489993, 10689483995, 10689483994, 10689483993, 10689482995 Owner’s Manual

...

Ice Maker

F_brica de hielo

_' '_ _....... _i_::_ " '__:_'_"_ " F_'_'_ _'_"<;;_''_''_"_

Machine _ glagons

®

Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.sears.com

2217243 Sears Canada, Inc., Toronto, Ontario, Canada M5B 2B8 www.sears.ca

TABLEOF CONTENTS

WARRANTY

WARRANTY ..................................................................................... 2

ICE MAKER SAFETY ...................................................................... 3

ICE MAKER INSTALLATION ......................................................... 4

Unpacking .................................................................................... 4

Location Requirements ................................................................ 4

Electrical Requirements ................................................................ 4

Leveling ......................................................................................... 5

Water Supply Connection ............................................................ 5

Reversing the Door Swing ............................................................ 7

Normal Sounds ............................................................................. 8

ICE MAKER USE ............................................................................. 8

How Your Ice Maker Works ......................................................... 8

Using the Controls ........................................................................ 9

ICE MAKER CARE .......................................................................... 9

Cleaning ........................................................................................ 9

Vacation and Moving Care ........................................................ 11

TROUBLESHOOTING .................................................................. 12

FULL ONE-YEAR WARRANTY ON ICE MAKER

For one year from the date of purchase, when this ice maker is

operated and maintained according to instructions attached to or

furnished with the product, Sears will repair this ice maker, free of

charge, if defective in material or workmanship.

LIMITED ONE-YEAR WARRANTY ON ICE MAKER

For one year from the date of purchase, when this ice maker is

used for commercial use and is operated and maintained

according to instructions attached to or furnished with the ice

maker, Sears will provide, free of charge, replacement parts for

any parts defective in materials or workmanship. You pay for

labor.

FULL FIVE-YEAR WARRANTY ON SEALED REFRIGERATION

SYSTEM

For five years from the date of purchase, when this ice maker is

operated and maintained according to instructions attached to or

furnished with the ice maker, Sears will repair the sealed system

(consisting of: refrigerant, connecting tubing, and compressor

motor), free of charge, if defective in materials or workmanship.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE

NEAREST SEARS SERVICE CENTER IN THE UNITED STATES

OR CANADA.

This warranty applies only while this product is in use in the

United States or Canada. This warranty gives you specific legal

rights, and you may also have other rights which vary from state

to state or province to province.

Warranty terms may vary in Canada. Contact your local Sears

Service Center for complete details.

Sears, Roebuck and Co.

D/817WA, Hoffman Estates, IL 60179

Sears Canada, Inc., Toronto, Ontario, Canada M5B 2B8

In the space below, record your complete model number, serial

number, and purchase date. You can find this information on the

model and serial number label.

Have this information available to help you obtain assistance or

service more quickly whenever you contact Sears concerning

your ice maker.

Model number

Serial number

Purchase date

Save these instructions and your sales receipt for future

reference.

ICE MAKER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or

This is the safety alert symbol.

"WARNING." These words mean:

You can be killed or seriously injured if you don't

immediately follow instructions.

You can be killed or seriously injured if you don't

follow instructions.

All safety messages willtell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury when using your ice maker, follow these basic

precautions:

• Plug into a grounded 3 prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Do not use an extension cord.

• Disconnect power before cleaning.

• Disconnect power before servicing.

• Replace all panels before operating.

• Use two or more people to move and install ice maker.

SAVE THESE INSTRUCTIONS

ICE MAKER

INSTALLATION

Excessive Weight Hazard

Use two or more people to move and install

ice maker.

Failure to do so can result in back or other injury.

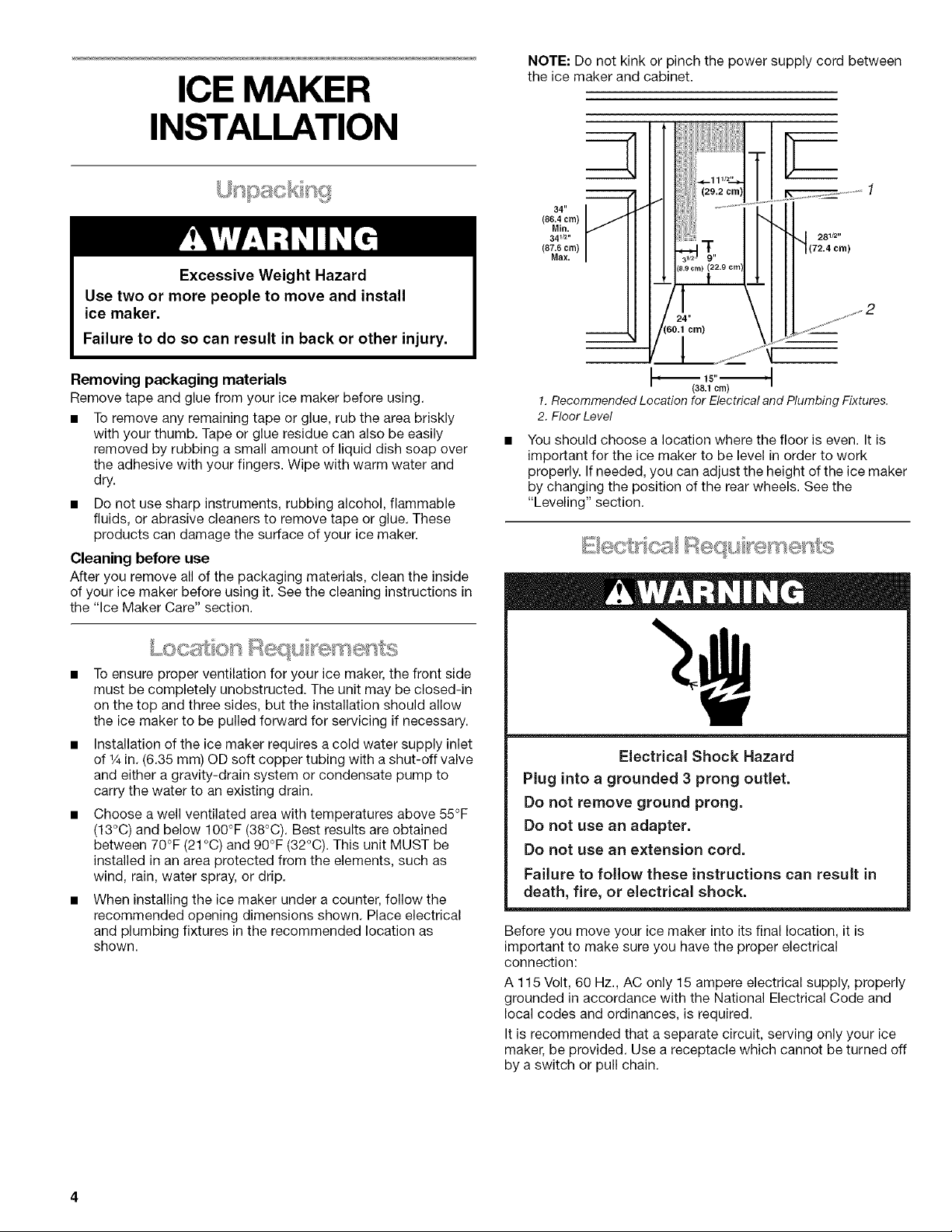

NOTE: Do not kink or pinch the power supply cord between

the ice maker and cabinet.

34"

(86.4 cm)

Min.

341/2"

(87.6 cm)

Max.

281/2 ,,

(72.4 cm)

Removing packaging materials

Remove tape and glue from your ice maker before using.

• To remove any remaining tape or glue, rub the area briskly

with your thumb. Tape or glue residue can also be easily

removed by rubbing a small amount of liquid dish soap over

the adhesive with your fingers. Wipe with warm water and

dry.

• Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your ice maker.

Cleaning before use

After you remove all of the packaging materials, clean the inside

of your ice maker before using it. See the cleaning instructions in

the "Ice Maker Care" section.

To ensure proper ventilation for your ice maker, the front side

must be completely unobstructed. The unit may be closed-in

on the top and three sides, but the installation should allow

the ice maker to be pulled forward for servicing if necessary.

Installation of the ice maker requires a cold water supply inlet

of % in. (6.35 mm) OD soft copper tubing with a shut-off valve

and either a gravity-drain system or condensate pump to

carry the water to an existing drain.

Choose a well ventilated area with temperatures above 55°F

(13°C) and below 100°F (38°C). Best results are obtained

between 70°F (21 °C) and 90°F (32°C). This unit MUST be

installed in an area protected from the elements, such as

wind, rain, water spray, or drip.

When installing the ice maker under a counter, follow the

recommended opening dimensions shown. Place electrical

and plumbing fixtures in the recommended location as

shown.

1. Recommended Location for Electrical and Plumbing Fixtures.

(38.1 crn)

2. Floor Level

You should choose a location where the floor is even. It is

important for the ice maker to be level in order to work

properly. If needed, you can adjust the height of the ice maker

by changing the position of the rear wheels. See the

"Leveling" section.

_,_._, ..............._@ ...........

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

Before you move your ice maker into its final location, it is

important to make sure you have the proper electrical

connection:

A 115 Volt, 60 Hz., AC only 15 ampere electrical supply, properly

grounded in accordance with the National Electrical Code and

local codes and ordinances, is required.

It is recommended that a separate circuit, serving only your ice

maker, be provided. Use a receptacle which cannot be turned off

by a switch or pull chain.

Recommended grounding method

For your personal safety, this appliance must be grounded. This

appliance is equipped with a power supply cord having a 3 prong

grounding plug. To minimize possible shock hazard, the cord

must be plugged into a mating, 3 prong, grounding-type wall

receptacle, grounded in accordance with the National Electrical

Code and local codes and ordinances. If a mating wall receptacle

is not available, itis the personal responsibility of the customer to

have a properly grounded, 3 prong wall receptacle installed by a

qualified electrician.

It is important for the ice maker to be level in order to work

properly. Depending upon where you install the ice maker, you

may need to make several adjustments to level it.

Tools required

• Carpenter's level

• Adjustable wrench

• 1/4in. socket wrench

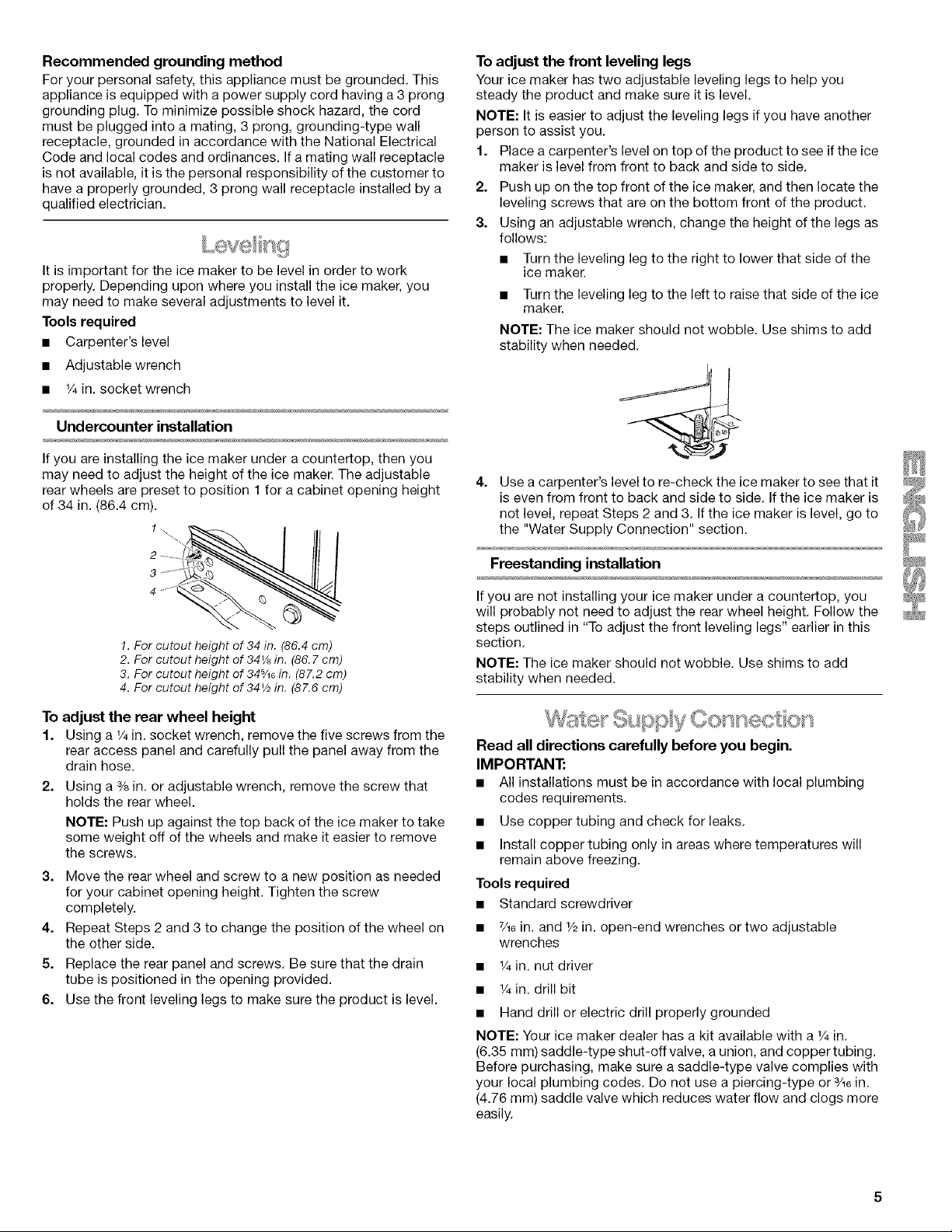

Undercounter installation

If you are installing the ice maker under a countertop, then you

may need to adjust the height of the ice maker. The adjustable

rear wheels are preset to position 1 for a cabinet opening height

of 34 in. (86.4 cm).

To adjust the front leveling legs

Your ice maker has two adjustable leveling legs to help you

steady the product and make sure it is level.

NOTE: It is easier to adjust the leveling legs if you have another

person to assist you.

1. Place a carpenter's level on top of the product to see if the ice

maker is level from front to back and side to side.

2. Push up on the top front of the ice maker, and then locate the

leveling screws that are on the bottom front of the product.

3. Using an adjustable wrench, change the height of the legs as

follows:

• Turn the leveling leg to the right to lower that side of the

ice maker.

• Turn the leveling leg to the left to raise that side of the ice

maker.

NOTE: The ice maker should not wobble. Use shims to add

stability when needed.

4.

Use a carpenter's level to re-check the ice maker to see that it

is even from front to back and side to side. If the ice maker is

not level, repeat Steps 2 and 3. If the ice maker is level, go to

the "Water Supply Connection" section.

!. For cutout height of 34 in. (86.4 cm)

2. For cutout height of 34_A in. (86. 7 cm)

3. For cutout height of 345/_6in. (87.2 cm)

4. For cutout height of 34V2 in. (87.6 cm)

To adjust the rear wheel height

1. Using a 1/4in. socket wrench, remove the five screws from the

rear access panel and carefully pull the panel away from the

drain hose.

2. Using a % in. or adjustable wrench, remove the screw that

holds the rear wheel.

NOTE: Push up against the top back of the ice maker to take

some weight off of the wheels and make it easier to remove

the screws.

3. Move the rear wheel and screw to a new position as needed

for your cabinet opening height. Tighten the screw

completely.

4. Repeat Steps 2 and 3 to change the position of the wheel on

the other side.

5. Replace the rear panel and screws. Be sure that the drain

tube is positioned in the opening provided.

6. Use the front leveling legs to make sure the product is level.

If you are not installing your ice maker under a countertop, you

Freestanding installation

will probably not need to adjust the rear wheel height. Follow the

steps outlined in "To adjust the front leveling legs" earlier in this

section.

NOTE: The ice maker should not wobble. Use shims to add

stability when needed.

Read all directions carefully before you begin.

IMPORTANT:

• All installations must be in accordance with local plumbing

codes requirements.

• Use copper tubing and check for leaks.

• Install copper tubing only in areas where temperatures will

remain above freezing.

Tools required

• Standard screwdriver

• 7/16in. and 1/2in. open-end wrenches or two adjustable

wrenches

• 1/4in. nut driver

• 1/4in. drill bit

• Hand drill or electric drill properly grounded

NOTE: Your ice maker dealer has a kit available with a 1/4in.

(6.35 mm) saddle-type shut-off valve, a union, and copper tubing.

Before purchasing, make sure a saddle-type valve complies with

your local plumbing codes. Do not use a piercing-type or 3/16in.

(4.76 mm) saddle valve which reduces water flow and clogs more

easily.

Connecting the water line

1=

Turn off main water supply• Turn on nearest faucet long

enough to clear line of water•

2=

Find a 1/2in. (12.70 mm) to 11/4in. (3.18 cm) vertical cold water

pipe near the ice maker•

NOTE: Horizontal pipe will work, but the following procedure

must be followed: Drill on the top side of the pipe, not the

bottom• This will help keep water away from the drill• This

also keeps normal sediment from collecting in the valve.

3. Using a grounded drill, drill a 1/4in. (6.35 mm) hole in the cold

water pipe you have selected.

4. Fasten shut-off valve to cold water pipe with pipe clamp• Be

sure outlet end is solidly in the 1/4in. (6.35 mm) drilled hole in

the water pipe and that washer is under the pipe clamp.

Tighten packing nut. Tighten the pipe clamp screws carefully

and evenly so washer makes a watertight seal. Do not

overtighten the pipe clamp or you may crush cold water pipe

if it is soft copper tubing. Do not use a piercing-type or 3A6in.

(4.76 mm) saddle-type valve which reduces water flow and

clogs more easily•

5. Now you are ready to connect the copper tubing. Use 1/4in.

(6.35 mm) OD soft copper tubing for the cold water supply.

• Measure from the connection at the front of the ice maker

to the cold water pipe. Add 3 ft (91.4 cm) to ensure that

you have the proper length. This is the length of 1/4in.

(6.35 mm) OD soft copper tubing you need for the job. Be

sure both ends of the copper tubing are cut square.

• Slip compression sleeve and compression nut on copper

tubing as shown. Insert end of tubing into outlet end

squarely as far as it will go. Screw compression nut onto

outlet end with adjustable wrench. Do not overtighten.

................. 1

8 _ "J"" •.............. 2

*% ............. 3

REARVIEW

1

2

/

!. Drain Hose (Drain Pump models only)

2• Vent Hose (Drain Pump models only)

3. Water Supply Line

8=

Thread the nut onto the coupling on the end of the copper

tubing. Tighten the nut by hand. Then tighten it with a wrench

two more turns. Do not overtighten.

1 2 3 4

1.Line to ice maker

2. Nut (purchased)

9=

Remove the two screws in the lower access panel and the

two screws in the base grille area of the front panel support.

Pull forward to remove the lower access panel.

NOTE: To prevent rattling, be sure the copper tubing does not

touch the cabinet's side wall or other parts inside the cabinet.

FRONT VIEW

3 2

3. Ferrule (purchased)

4. Coupling (purchased)

3

1.Cold Water Pipe 5. Compression Nut

2. Pipe Clamp 6. Compression Sleeve

3. Copper Tubing 7.Shut-Off Valve

4• Coupling (purchased) 8. Packing Nut

6=

Place the free end of the tubing into a container or sink, and

turn on main water supply and flush out tubing until water is

clear. Turn off shut-off valve on the water pipe.

NOTE: Always drain the water line before making the final

connection to the inlet of the water valve to prevent possible

water valve malfunction.

7.

Bend the copper tubing to meet the water line inlet which is

located on the back of the ice maker cabinet as shown.

(30.9 cm)

F 123/6" ID,

i

(14,5 cm)

(18.6 cm)

5%"

(14.3 cm)

1. WaterPan Drain

2. Water Valve

10. Turn shut-off valve ON.

11. Check for leaks. Tighten any connections (including

connections at the valve) or nuts that leak.

12. Replace the lower access panel and screws.

Connecting the drain

Gravity drain system

Connect the ice maker drain to your drain in accordance with all

state and local codes and ordinances. If the ice maker is

provided with a gravity drain system, follow these guidelines

when installing drain lines. This will prevent water from flowing

back into the ice maker storage bin and potentially flowing onto

the floor causing water damage.

• Drain lines must have a minimum of % in. (15.88 mm) inside

diameter.

Drain lines must have a I in. drop per 48 in. (2.54 cm drop per

122 cm) of run or 1/4in. drop per 12 in. (6.35 mm per

30.48 cm) and must not have low points where water can

settle.

• The floor drains must be large enough to accommodate

drainage from all drains.

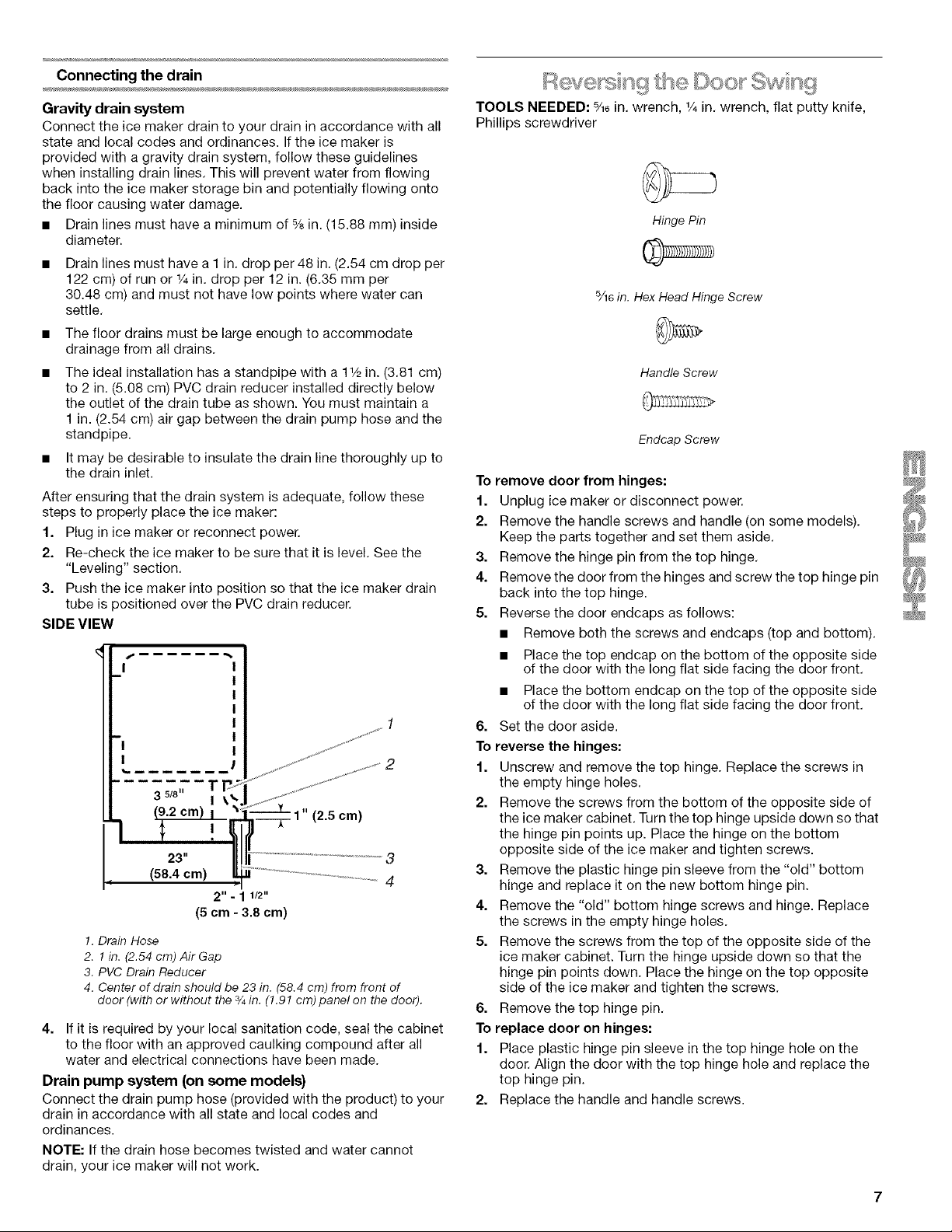

The ideal installation has a standpipe with a 11/2in. (3.81 cm)

to 2 in. (5.08 cm) PVC drain reducer installed directly below

the outlet of the drain tube as shown. You must maintain a

1 in. (2.54 cm) air gap between the drain pump hose and the

standpipe.

• It may be desirable to insulate the drain line thoroughly up to

the drain inlet.

After ensuring that the drain system is adequate, follow these

steps to properly place the ice maker:

f. Plug in ice maker or reconnect power.

2. Re-check the ice maker to be sure that it is level. See the

"Leveling" section.

3. Push the ice maker into position so that the ice maker drain

tube is positioned over the PVC drain reducer.

SIDE VIEW

I

23"

(58.4 cm)

3

4

2" - 1 1/2"

(5 cm - 3.8 cm)

!. Drain Hose

2. 1 in. (2.54 cm) Air Gap

3. PVC Drain Reducer

4. Center of drain should be 23 in. (58.4 cm) from front of

door (with or without the 3/4in. (1.91 cm) panel on the door).

4. If it is required by your local sanitation code, seal the cabinet

to the floor with an approved caulking compound after all

water and electrical connections have been made.

Drain pump system (on some models)

Connect the drain pump hose (provided with the product) to your

drain in accordance with all state and local codes and

ordinances.

NOTE: If the drain hose becomes twisted and water cannot

drain, your ice maker will not work.

t DOO ' t

TOOLS NEEDED: %e in. wrench, _/4in. wrench, flat putty knife,

Phillips screwdriver

Hinge Pin

5/16in. Hex Head Hinge Screw

Handle Screw

Endcap Screw

To remove door from hinges:

1. Unplug ice maker or disconnect power.

2. Remove the handle screws and handle (on some models).

Keep the parts together and set them aside.

3. Remove the hinge pin from the top hinge.

4. Remove the door from the hinges and screw the top hinge pin

back into the top hinge.

5. Reverse the door endcaps as follows:

• Remove both the screws and endcaps (top and bottom).

• Place the top endcap on the bottom of the opposite side

of the door with the long flat side facing the door front.

• Place the bottom endcap on the top of the opposite side

of the door with the long flat side facing the door front.

6. Set the door aside.

To reverse the hinges:

1. Unscrew and remove the top hinge. Replace the screws in

the empty hinge holes.

2. Remove the screws from the bottom of the opposite side of

the ice maker cabinet. Turn the top hinge upside down so that

the hinge pin points up. Place the hinge on the bottom

opposite side of the ice maker and tighten screws.

3. Remove the plastic hinge pin sleeve from the "old" bottom

hinge and replace it on the new bottom hinge pin.

4. Remove the "old" bottom hinge screws and hinge. Replace

the screws in the empty hinge holes.

5. Remove the screws from the top of the opposite side of the

ice maker cabinet. Turn the hinge upside down so that the

hinge pin points down. Place the hinge on the top opposite

side of the ice maker and tighten the screws.

6. Remove the top hinge pin.

To replace door on hinges:

1. Place plastic hinge pin sleeve in the top hinge hole on the

door. Align the door with the top hinge hole and replace the

top hinge pin.

2. Replace the handle and handle screws.

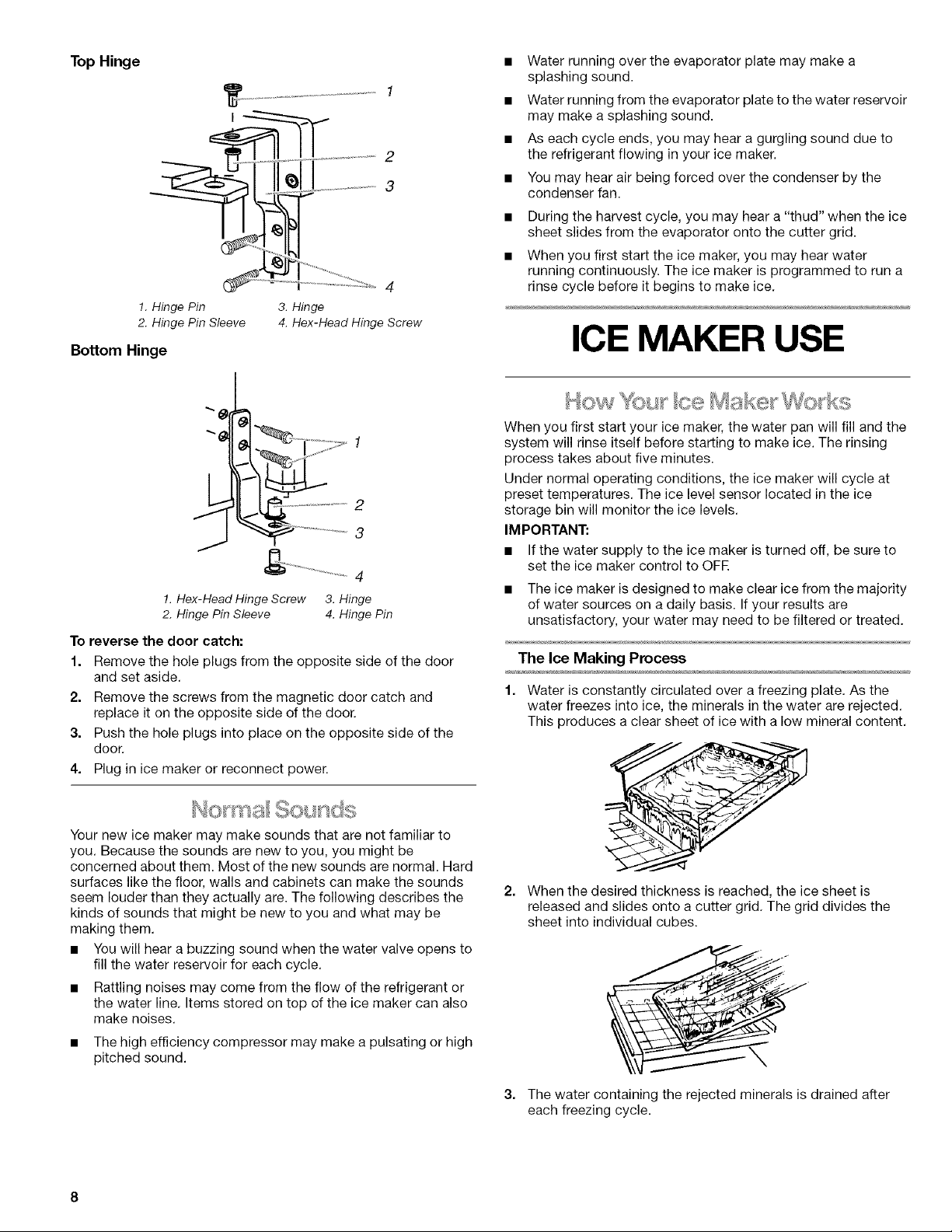

TopHinge

..........

2

3

4

!. Hinge Pin

2. Hinge Pin Sleeve

3. Hinge

4. Hex-Head Hinge Screw

Bottom Hinge

_ .........2

3

J

_ ...................................... 4

!. Hex-Head Hinge Screw

2. Hinge Pin Sleeve

To reverse the door catch:

1. Remove the hole plugs from the opposite side of the door

and set aside.

2. Remove the screws from the magnetic door catch and

replace it on the opposite side of the door.

3. Push the hole plugs into place on the opposite side of the

door.

4. Plug in ice maker or reconnect power.

3. Hinge

4. Hinge Pin

Water running over the evaporator plate may make a

splashing sound.

Water running from the evaporator plate to the water reservoir

may make a splashing sound.

As each cycle ends, you may hear a gurgling sound due to

the refrigerant flowing in your ice maker.

You may hear air being forced over the condenser by the

condenser fan.

During the harvest cycle, you may hear a "thud" when the ice

sheet slides from the evaporator onto the cutter grid.

When you first start the ice maker, you may hear water

running continuously. The ice maker is programmed to run a

rinse cycle before it begins to make ice.

ICE MAKER USE

When you first start your ice maker, the water pan will fill and the

system will rinse itself before starting to make ice. The rinsing

process takes about five minutes.

Under normal operating conditions, the ice maker will cycle at

preset temperatures. The ice level sensor located in the ice

storage bin will monitor the ice levels.

IMPORTANT:

• If the water supply to the ice maker is turned off, be sure to

set the ice maker control to OFR

• The ice maker is designed to make clear ice from the majority

of water sources on a daily basis. If your results are

unsatisfactory, your water may need to be filtered or treated.

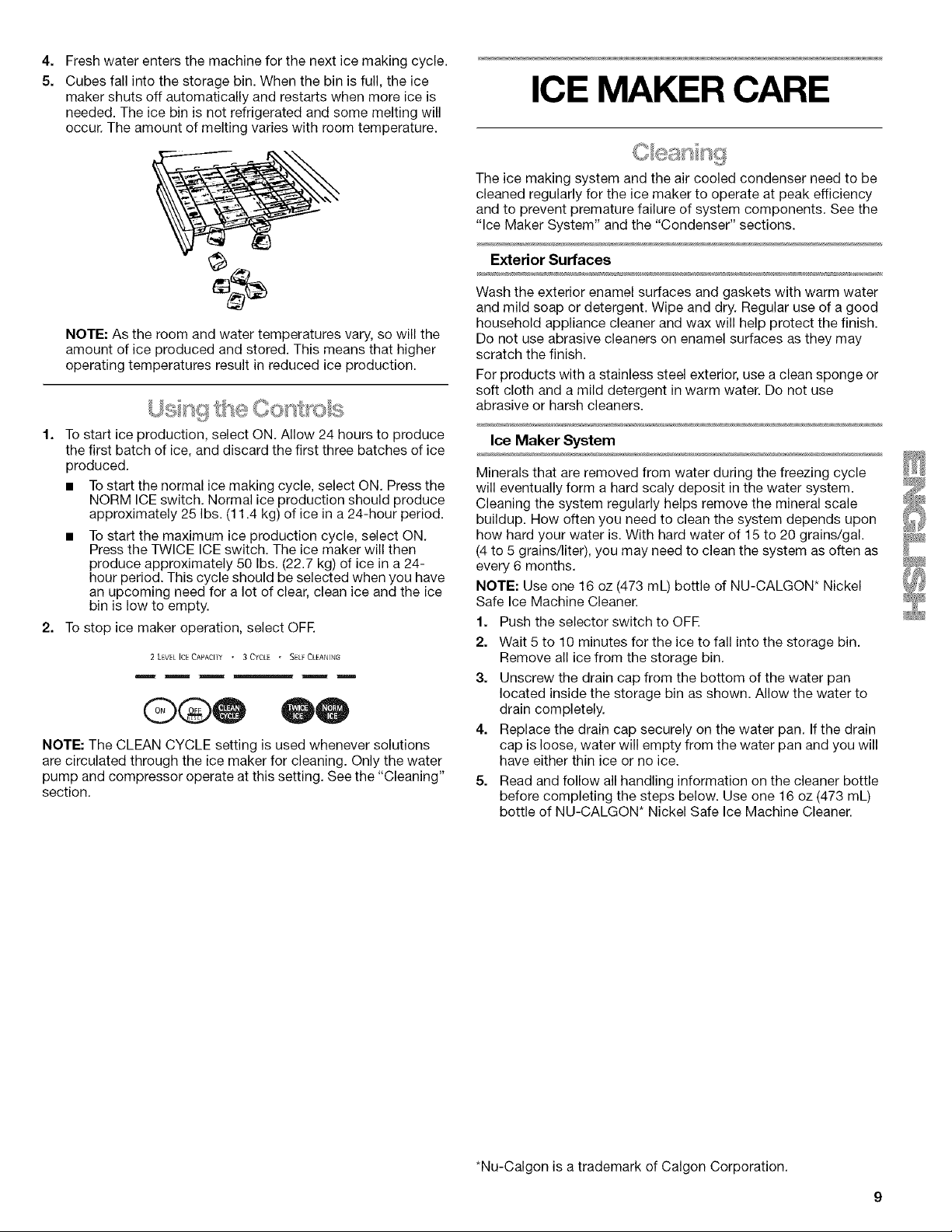

The Ice Making Process

1. Water is constantly circulated over a freezing plate. As the

water freezes into ice, the minerals in the water are rejected.

This produces a clear sheet of ice with a low mineral content.

Your new ice maker may make sounds that are not familiar to

you. Because the sounds are new to you, you might be

concerned about them. Most of the new sounds are normal. Hard

surfaces like the floor, walls and cabinets can make the sounds

seem louder than they actually are. The following describes the

kinds of sounds that might be new to you and what may be

making them.

• You will hear a buzzing sound when the water valve opens to

fill the water reservoir for each cycle.

• Rattling noises may come from the flow of the refrigerant or

the water line. Items stored on top of the ice maker can also

make noises.

• The high efficiency compressor may make a pulsating or high

pitched sound.

2. When the desired thickness is reached, the ice sheet is

released and slides onto a cutter grid. The grid divides the

sheet into individual cubes.

3. The water containing the rejected minerals is drained after

each freezing cycle.

4,

Fresh water enters the machine for the next ice making cycle.

5.

Cubes fall into the storage bin. When the bin is full, the ice

maker shuts off automatically and restarts when more ice is

needed. The ice bin is not refrigerated and some melting will

occur. The amount of melting varies with room temperature.

NOTE: As the room and water temperatures vary, so will the

amount of ice produced and stored. This means that higher

operating temperatures result in reduced ice production.

ICE MAKER CARE

The ice making system and the air cooled condenser need to be

cleaned regularly for the ice maker to operate at peak efficiency

and to prevent premature failure of system components. See the

"Ice Maker System" and the "Condenser" sections.

Exterior Surfaces

Wash the exterior enamel surfaces and gaskets with warm water

and mild soap or detergent. Wipe and dry. Regular use of a good

household appliance cleaner and wax will help protect the finish.

Do not use abrasive cleaners on enamel surfaces as they may

scratch the finish.

For products with a stainless steel exterior, use a clean sponge or

soft cloth and a mild detergent in warm water. Do not use

abrasive or harsh cleaners.

1. Tostart ice production, select ON. Allow 24 hours to produce

the first batch of ice, and discard the first three batches of ice

produced.

• To start the normal ice making cycle, select ON. Press the

NORM ICE switch. Normal ice production should produce

approximately 25 Ibs. (11.4 kg) of ice in a 24-hour period.

• To start the maximum ice production cycle, select ON.

Press the TWICE ICE switch. The ice maker will then

produce approximately 50 Ibs. (22.7 kg) of ice in a 24-

hour period. This cycle should be selected when you have

an upcoming need for a lot of clear, clean ice and the ice

bin is low to empty.

2. To stop ice maker operation, select OFF.

2 LEVEE ICECAPACITY " 3 CYCLE " SELF CLEANING

@®@

NOTE: The CLEAN CYCLE setting is used whenever solutions

are circulated through the ice maker for cleaning. Only the water

pump and compressor operate at this setting. See the "Cleaning"

section.

Ice Maker System

Minerals that are removed from water during the freezing cycle

will eventually form a hard scaly deposit in the water system.

Cleaning the system regularly helps remove the mineral scale

buildup. How often you need to clean the system depends upon

how hard your water is. With hard water of 15 to 20 grains/gal.

(4 to 5 grains/liter), you may need to clean the system as often as

every 6 months.

NOTE: Use one 16 oz (473 mL) bottle of NU-CALGON* Nickel

Safe Ice Machine Cleaner.

1. Push the selector switch to OFF.

2. Wait 5 to 10 minutes for the ice to fall into the storage bin.

Remove all ice from the storage bin.

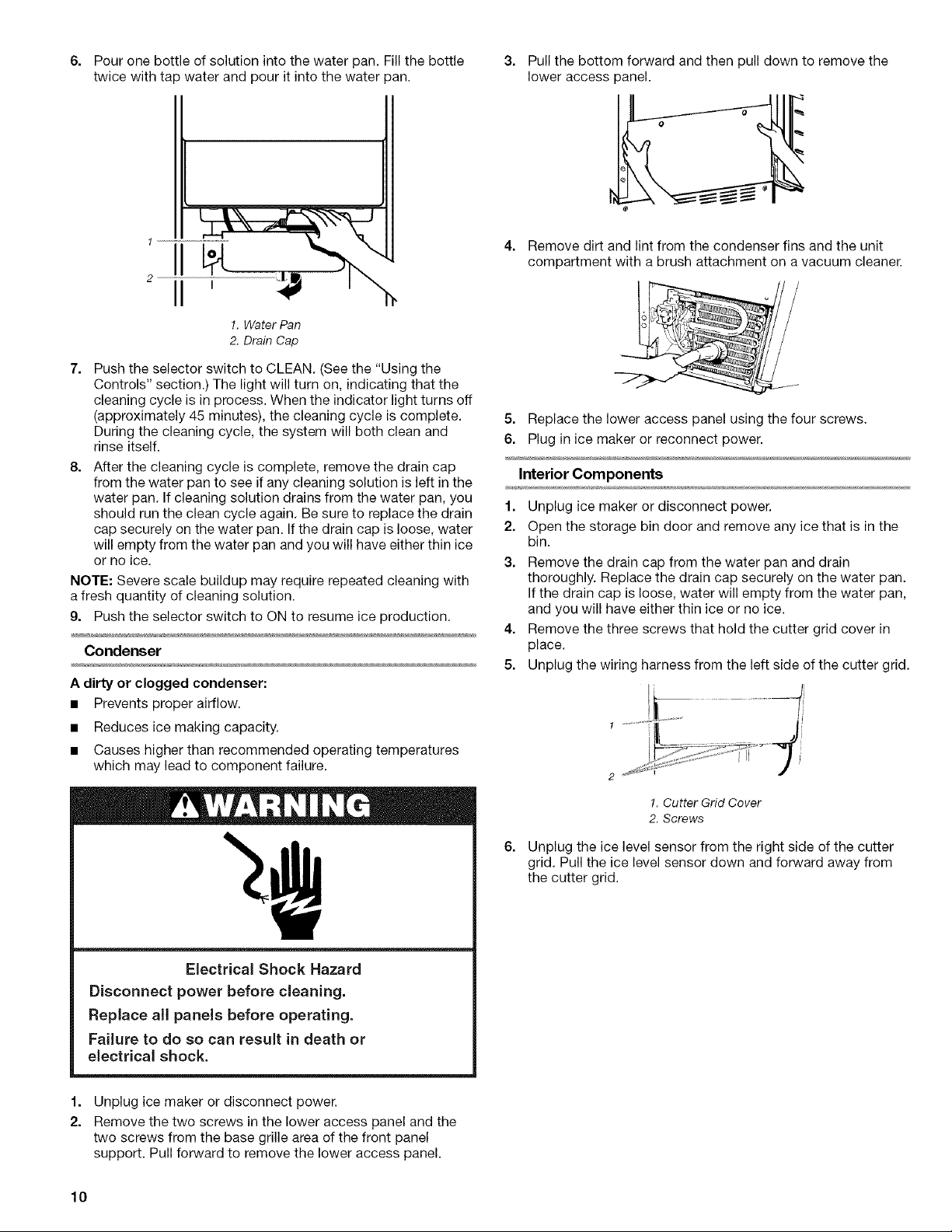

3. Unscrew the drain cap from the bottom of the water pan

located inside the storage bin as shown. Allow the water to

drain completely.

4. Replace the drain cap securely on the water pan. If the drain

cap is loose, water will empty from the water pan and you will

have either thin ice or no ice.

5. Read and follow all handling information on the cleaner bottle

before completing the steps below. Use one 16 oz (473 mL)

bottle of NU-CALGON* Nickel Safe Ice Machine Cleaner.

N

*Nu-Calgon is a trademark of Calgon Corporation.

6. Pouronebottleofsolutionintothewaterpan.Fillthebottle 3. Pullthebottomforwardandthenpulldowntoremovethe

twicewithtapwaterandpouritintothewaterpan. loweraccesspanel.

4. Remove dirt and lint from the condenser fins and the unit

compartment with a brush attachment on a vacuum cleaner.

!. Water Pan

2. Drain Cap

7. Push the selector switch to CLEAN. (See the "Using the

Controls" section.) The light will turn on, indicating that the

cleaning cycle is in process. When the indicator light turns off

(approximately 45 minutes), the cleaning cycle is complete.

During the cleaning cycle, the system will both clean and

rinse itself.

8. After the cleaning cycle is complete, remove the drain cap

from the water pan to see if any cleaning solution is left in the

water pan. If cleaning solution drains from the water pan, you

should run the clean cycle again. Be sure to replace the drain

cap securely on the water pan. If the drain cap is loose, water

will empty from the water pan and you will have either thin ice

or no ice.

NOTE: Severe scale buildup may require repeated cleaning with

a fresh quantity of cleaning solution.

9. Push the selector switch to ON to resume ice production.

Condenser

A dirty or clogged condenser:

• Prevents proper airflow.

• Reduces ice making capacity.

• Causes higher than recommended operating temperatures

which may lead to component failure.

5. Replace the lower access panel using the four screws.

6. Plug in ice maker or reconnect power.

Interior Components

1. Unplug ice maker or disconnect power.

2. Open the storage bin door and remove any ice that is in the

bin.

3. Remove the drain cap from the water pan and drain

thoroughly. Replace the drain cap securely on the water pan.

If the drain cap is loose, water will empty from the water pan,

and you will have either thin ice or no ice.

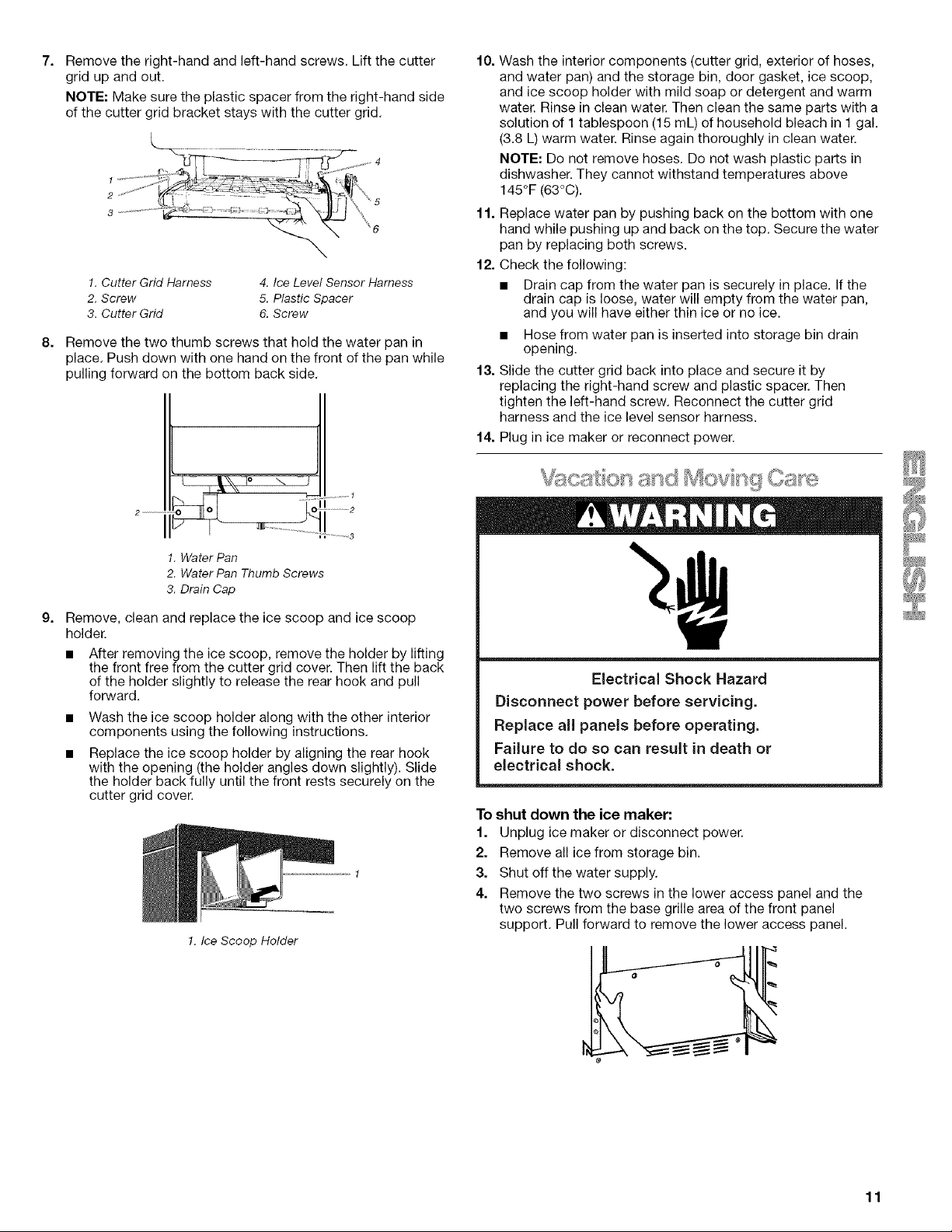

4. Remove the three screws that hold the cutter grid cover in

place.

5. Unplug the wiring harness from the left side of the cutter grid.

Electrical Shock Hazard

Disconnect power before cleaning.

Replace all panels before operating.

Failure to do so can result in death or

electrical shock.

1.

Unplug ice maker or disconnect power.

2.

Remove the two screws in the lower access panel and the

two screws from the base grille area of the front panel

support. Pull forward to remove the lower access panel.

10

1. Cutter Grid Cover

2. Screws

6. Unplug the ice level sensor from the right side of the cutter

grid. Pull the ice level sensor down and forward away from

the cutter grid.

7.

Remove the right-hand and left-hand screws. Lift the cutter

grid up and out.

NOTE: Make sure the plastic spacer from the right-hand side

of the cutter grid bracket stays with the cutter grid.

1. Cutter Grid Harness

2. Screw

3. Cutter Grid

8.

Remove the two thumb screws that hold the water pan in

place. Push down with one hand on the front of the pan while

pulling forward on the bottom back side.

4. Ice Level Sensor Harness

5. Plastic Spacer

6. Screw

d

,kX o \ .......,

2 ¸--

1. Water Pan

2. Water Pan Thumb Screws

3. Drain Cap

9.

Remove, clean and replace the ice scoop and ice scoop

holder.

• After removing the ice scoop, remove the holder by lifting

the front free from the cutter grid cover. Then lift the back

of the holder slightly to release the rear hook and pull

forward.

Wash the ice scoop holder along with the other interior

components using the following instructions.

Replace the ice scoop holder by aligning the rear hook

with the opening (the holder angles down slightly). Slide

the holder back fully until the front rests securely on the

cutter grid cover.

!. Ice Scoop Holder

,..............id[

10.

Wash the interior components (cutter grid, exterior of hoses,

and water pan) and the storage bin, door gasket, ice scoop,

and ice scoop holder with mild soap or detergent and warm

water. Rinse in clean water. Then clean the same parts with a

solution of I tablespoon (15 mL) of household bleach in 1 gal.

(3.8 L) warm water. Rinse again thoroughly in clean water.

NOTE: Do not remove hoses. Do not wash plastic parts in

dishwasher. They cannot withstand temperatures above

145°F (63°C).

11. Replace water pan by pushing back on the bottom with one

hand while pushing up and back on the top. Secure the water

pan by replacing both screws.

12. Check the following:

• Drain cap from the water pan is securely in place. If the

drain cap is loose, water will empty from the water pan,

and you will have either thin ice or no ice.

• Hose from water pan is inserted into storage bin drain

opening.

13. Slide the cutter grid back into place and secure it by

replacing the right-hand screw and plastic spacer. Then

tighten the left-hand screw. Reconnect the cutter grid

harness and the ice level sensor harness.

14. Plug in ice maker or reconnect power.

Electrical Shock Hazard

Disconnect power before servicing.

Replace ail panels before operating.

Fai(ure to do so can result in death or

electrical shock.

To shut down the ice maker:

1. Unplug ice maker or disconnect power.

2. Remove all ice from storage bin.

3. Shut off the water supply.

4. Remove the two screws in the lower access panel and the

two screws from the base grille area of the front panel

support. Pull forward to remove the lower access panel.

F

11

Loading...

Loading...