Kenmore 10644109300, 10644103300, 10644102300 Owner’s Manual

®

Cabinet Depth

Side by Side Refrigerator

Refrigerador de dos puertas

con profundidad para armario

v< ==,_ f,+] = I '=_ = "*

L_.,>Oy

R_frig_rateur c6te _ c6te

profondeur d'armoire

50t9 637 33061 Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.sears.com

2300222 Sears Canada Inc., Toronto, Ontario, Canada M5B 2B8 www.sears.ca

TABLE OF CONTENTS

WARRANTY

WARRANTY ..................................................................................... 2

REFRIGERATOR SAFETY .............................................................. 3

Proper Disposal of Your Old Refrigerator .................................... 3

INSTALLATION INSTRUCTIONS .................................................. 4

Unpacking .................................................................................... 4

Location Requirements ................................................................ 4

Electrical Requirements ................................................................ 5

Water Supply Requirements ........................................................ 5

Removing the Door Handles ........................................................ 5

Base Gdlle .................................................................................... 6

Leveling Refrigerator .................................................................... 6

Water Supply Connection ............................................................ 6

Water System Preparation ........................................................... 7

Normal Sounds ............................................................................. 7

REFRIGERATOR USE .................................................................... 8

Ensuring Proper Air Circulation .................................................... 8

Using the Controls ........................................................................ 8

Water and Ice Dispensers ............................................................ 9

Water Filtration System ............................................................. 10

Ice Maker and Storage Bin........................................................ 11

REFRIGERATOR FEATURES ..................................................... 11

Refrigerator Shelves .................................................................. 11

Convertible Vegetable/Meat Drawer, Crisper and Covers ....... 12

Convertible Vegetable/Meat Drawer Temperature Control ...... 12

Crisper Humidity Control ........................................................... 12

FREEZER FEATURES ................................................................. 12

Freezer Shelf .............................................................................. 12

Freezer Basket ........................................................................... 13

DOOR FEATURES ....................................................................... 13

Door Bins ................................................................................... 13

REFRIGERATOR CARE ............................................................... 13

Cleaning ..................................................................................... 13

Changing the Light Bulbs .......................................................... 14

Power Interruptions ................................................................... 14

Vacation and Moving Care ........................................................ 14

TROUBLESHOOTING .................................................................. 15

PROTECTION AGREEMENTS .................................................... 17

Inthe U.S.A ................................................................................ 17

In Canada .................................................................................. 18

Accessories ............................................................................... 18

WATER FILTER CERTIFICATIONS ............................................ 18

PRODUCT DATA SHEETS .......................................................... 19

SERVICE NUMBERS ............................................... BACK COVER

ONE-YEAR FULL WARRANTY ON REFRIGERATOR

For one year from the date of purchase, when this refrigerator is

operated and maintained according to instructions attached to or

furnished with the product, Sears will repair this refrigerator, free

of charge, if defective in material or workmanship.

FIVE-YEAR FULL WARRANTY ON SEALED REFRIGERATION

SYSTEM

For five years from the date of purchase, when this refrigerator is

operated and maintained according to owner's instructions

attached to or furnished with the product, Sears will repair the

sealed system (consisting of refrigeration, connecting tubing, and

compressor), free of charge, if defective in materials or

workmanship.

The above warranty coverage applies only to refrigerators which

are used for storage of food for private household purposes and

excludes original and replacement Kenmore Filtered Ice & Water

filter cartridges (if equipped with the filter system). Original and

replacement cartridges are warranted for 30 days, parts only,

against defects in material or workmanship.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE

NEAREST SEARS SERVICE CENTER IN THE UNITED STATES

OR CANADA.

This warranty applies only while this product is in use in the

United States or Canada. This warranty gives you specific

legal rights, and you may also have other rights which vary

from state to state or province to province.

Warranty terms may vary in Canada. Contact your local Sears

Service Center for complete details.

Sears, Roebuck and Co.

Dept. 817WA, Hoffman Estates, IL 60179

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2B8

Product Record

In the space below, record your complete model number, serial

number, and purchase date. You can find this information on the

model and serial number label located on the inside wall of the

refrigerator compartment.

Have this information available to help you obtain assistance or

service more quickly whenever you contact Sears concerning

your refrigerator.

Model number 106.

Serial number

Purchase date

Save these instructions and your sales receipt for future

reference.

2

REFRIGERATOR SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This symbol alerts you to potential hazards that can kilt or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or

This is the safety alert symbol.

"WARNING." These words mean:

You can be killed or seriously injured if you don't

immediatelv follow instructions.

You can be killed or seriously injured if you don't

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury when using your refrigerator, follow these basic

precautions:

• Plug into a grounded 3 prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Do not use an extension cord.

• Disconnect power before servicing.

• Replace all panels before operating.

• Remove doors from your old refrigerator.

Use nonflammable cleaner.

• Keep flammable materials and vapors, such as

gasoline, away from refrigerator.

• Use two or more people to move and install

refrigerator.

• Disconnect power before installing ice maker (on

ice maker kit ready models only).

• Use a sturdy glass when dispensing ice or water

(on some models).

SAVETHESEINSTRUCTIONS

Proper Disposal of

Your Old Refrigerator

IMPORTANT: Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are still dangerous

- even if they will sit for "just a few days." If you are getting rid of

your old refrigerator, please follow these instructions to help

prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take off the doors.

• Leave the shelves in place so that children may not easily

climb inside.

INSTALLATION INSTRUCTIONS

Removing packaging materials

• Remove tape and glue residue from surfaces before turning

on the refrigerator. Rub a small amount of liquid dish soap

over the adhesive with your fingers. Wipe with warm water

and dry.

Do not use sharp instruments, rubbing alcohol, flammable

fluids, or abrasive cleaners to remove tape or glue. These

products can damage the surface of your refrigerator. For

more information, see the "Refrigerator Safety" section.

When Moving Your Refrigerator:

Your refrigerator is heavy. When moving the refrigerator

for cleaning or service, be sure to protect the floor.

Always pull the refrigerator straight out when moving it.

Do not wiggle or "walk" the refrigerator when trying to move

it, as floor damage could occur.

Cleaning before use

After you remove all of the packaging materials, clean the inside

of your refrigerator before using it. See the cleaning instructions

in the "Refrigerator Care" section.

Important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

For your protection, tempered glass is designed to shatter

into many small, pebble-size pieces. This is normal. Glass

shelves and covers are heavy. Use special care when re-

moving them to avoid impact from dropping.

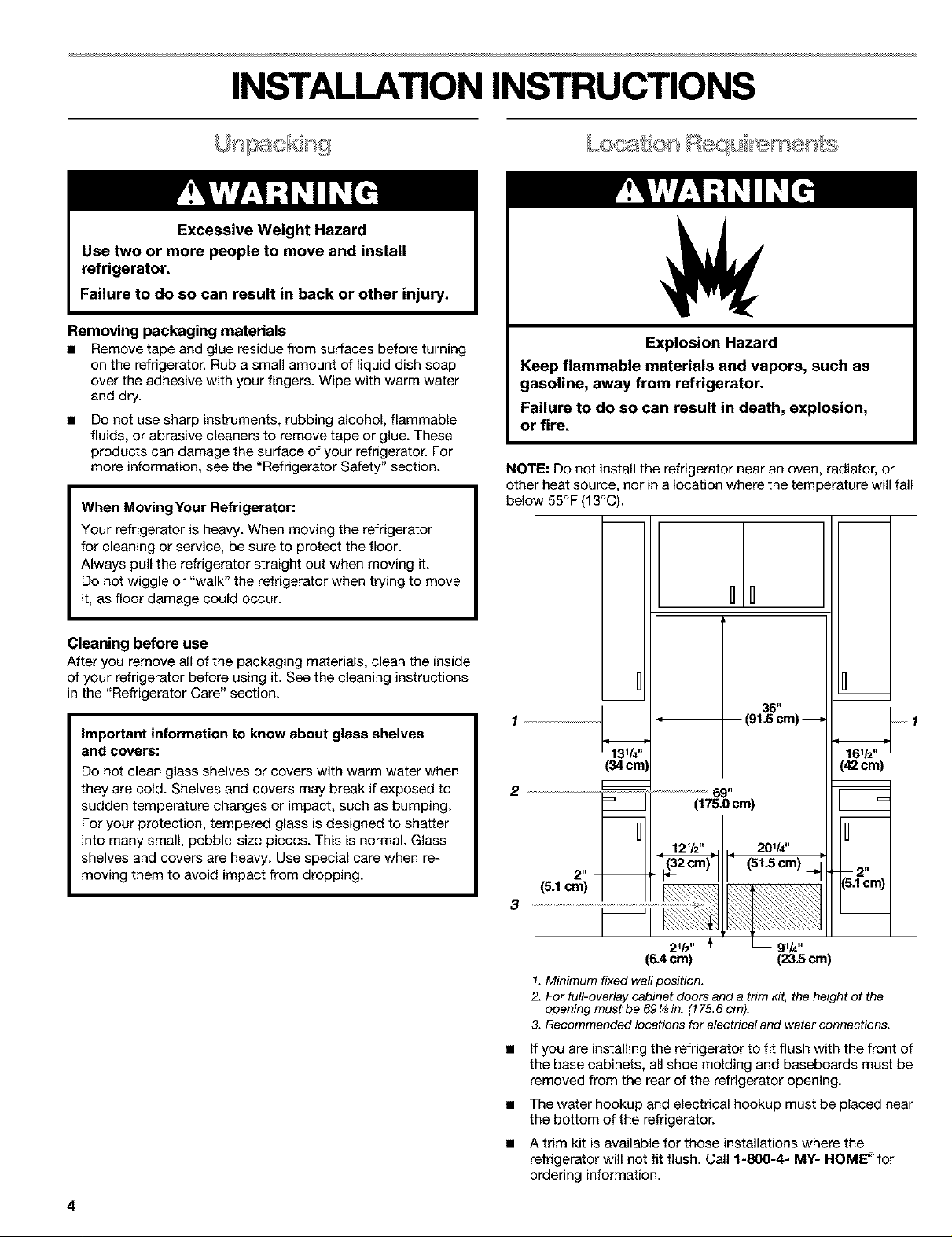

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from refrigerator.

Failure to do so can result in death, explosion,

or fire.

NOTE: DOnot install the refrigerator near an oven, radiator, or

other heat source, nor in a location where the temperature will fall

below 55°F (13°C).

II

l

36"

(42_cm)=

12V2" ,, 20114

=" ==ql (51.5cm)4

[5.tcm)

21/2"_ h 91h,,

(&4 cm) (23.5 cm)

1. Minimum fixed wall position.

2. For full-overlay cabinet doors and a trim kit, the height of the

opening must be 69 _ in. (175.6 cm).

3. Recommended locations for electrical and water connections.

If you are installing the refrigerator to fit flush with the front of

the base cabinets, all shoe molding and baseboards must be

removed from the rear of the refrigerator opening.

The water hookup and electrical hookup must be placed near

the bottom of the refrigerator.

A trim kit is available for those installations where the

refrigerator will not fit flush. Call 1-800-4- MY- HOM_ for

ordering information.

4

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in

death, fire, or electrical shock.

Before you move your refrigerator into its final location, it is

important to make sure you have the proper electrical

connection:

Recommended grounding method

A 115 Volt, 60 Hz., AC only 15 or 20 ampere fused, grounded

electrical supply is required. It is recommended that a separate

circuit serving only your refrigerator be provided. Use an outlet

that cannot be turned off by a switch. Do not use an

extension cord.

IMPORTANT: If this product is connected to a GFCI

(Ground Fault Circuit Interrupter) protected outlet, nuisance

tdpping of the power supply may occur, resulting in loss of

cooling. Food quality and flavor may be affected. If nuisance

tripping has occurred, and if the condition of the food appears

poor, dispose of it.

NOTE: Before performing any type of installation, cleaning, or

removing a light bulb, turn the control (Thermostat, Refrigerator

or Freezer Control depending on the model) to OFF and then

disconnect the refrigerator from the electrical source. When you

are finished, reconnect the refrigerator to the electrical source

and reset the control (Thermostat, Refrigerator or Freezer Control

depending on the model) to the desired setting.

Water Pressure

A cold water supply with water pressure of between 30 and

120 psi (207-827 kPa) is required to operate the water dispenser

and ice maker. If you have questions about your water pressure,

see "Troubleshooting" or call a licensed, qualified plumber.

Reverse Osmosis Water Supply

if a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the system needs to be

a minimum of 40 to 60 psi (276 - 414 kPa).

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 - 414 kPa), a booster pump can be inserted into

the small tubing that goes from the cold water line to the reverse

osmosis system.

If the water dispenser is still not dispensing water properly:

• Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

• Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

• if your refrigerator has a water filter cartridge, it may further

reduce the water pressure when used in conjunction with a

reverse osmosis system. Remove the water filter cartridge.

See "Water Filtration System."

If you have questions about your water pressure, refer to

"Troubleshooting" or call a licensed, qualified plumber.

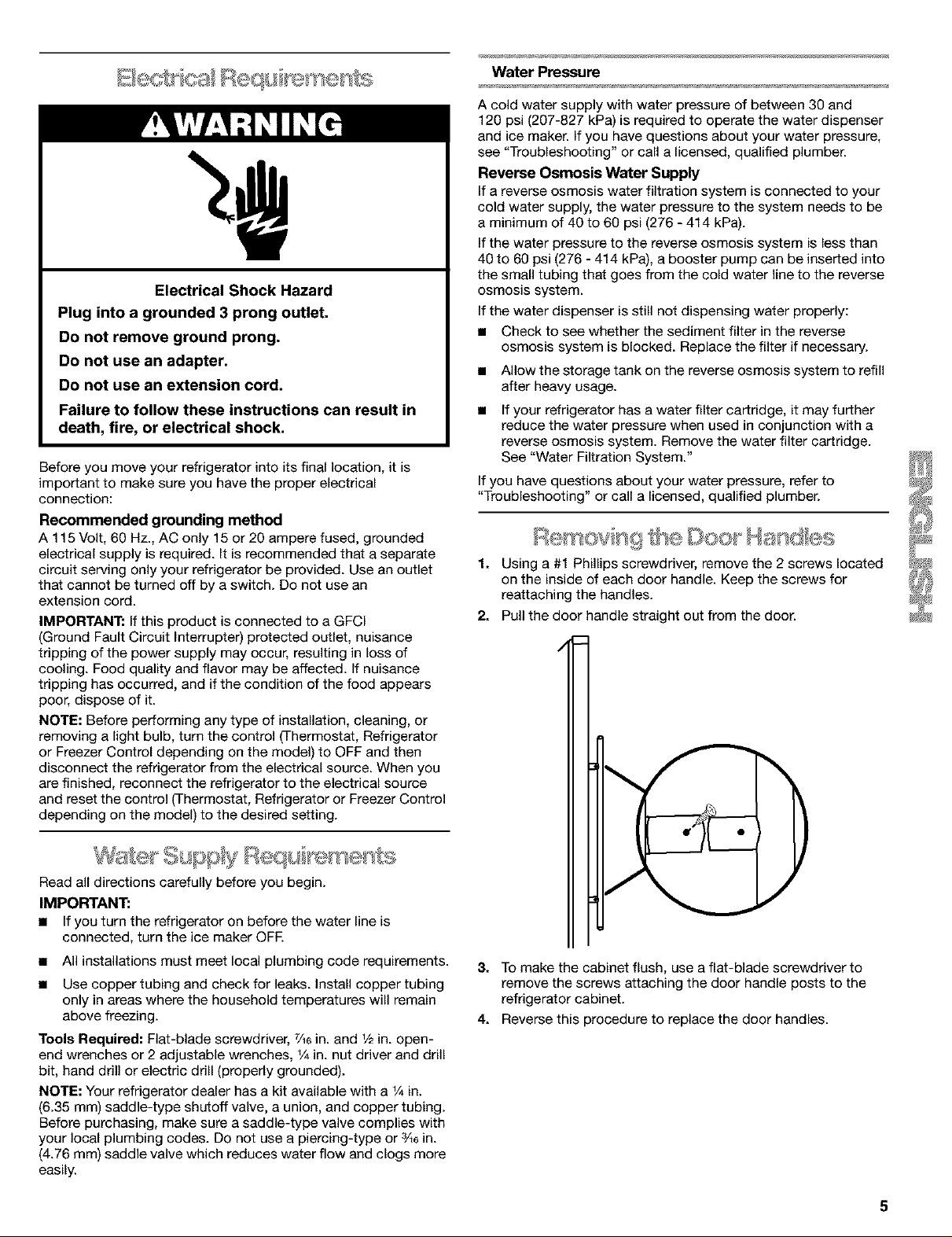

1. Using a #1 Phillips screwdriver, remove the 2 screws located

on the inside of each door handle. Keep the screws for

reattaching the handles.

2. Pull the door handle straight out from the door.

Read all directions carefully before you begin.

IMPOm'ANT:

• if you turn the refrigerator on before the water line is

connected, turn the ice maker OFR

• All installations must meet local plumbing code requirements.

• Use copper tubing and check for leaks. Install copper tubing

only in areas where the household temperatures will remain

above freezing.

Tools Required: Flat-blade screwdriver, z/_6in. and V2in. open-

end wrenches or 2 adjustable wrenches, V4in. nut driver and drill

bit, hand drill or electric drill (properly grounded).

NOTE: Your refrigerator dealer has a kit available with a V4in.

(6.35 ram) saddle-type shutoff valve, a union, and copper tubing.

Before purchasing, make sure a saddle-type valve complies with

your local plumbing codes. Do not use a piercing-type or 3Aein.

(4.76 ram) saddle valve which reduces water flow and clogs more

easily.

3. TOmake the cabinet flush, use a flat-blade screwdriver to

remove the screws attaching the door handle posts to the

refrigerator cabinet.

4. Reverse this procedure to replace the door handles.

To remove the base grille:

1. Open the refrigerator and freezer doors 90°.

2. Using a Phillips screwdriver, remove the screws attaching the

base grille to the refrigerator cabinet.

3. Pull the base grille toward you.

NOTE: Do not remove the Tech Sheet that is fastened behind

the base grille.

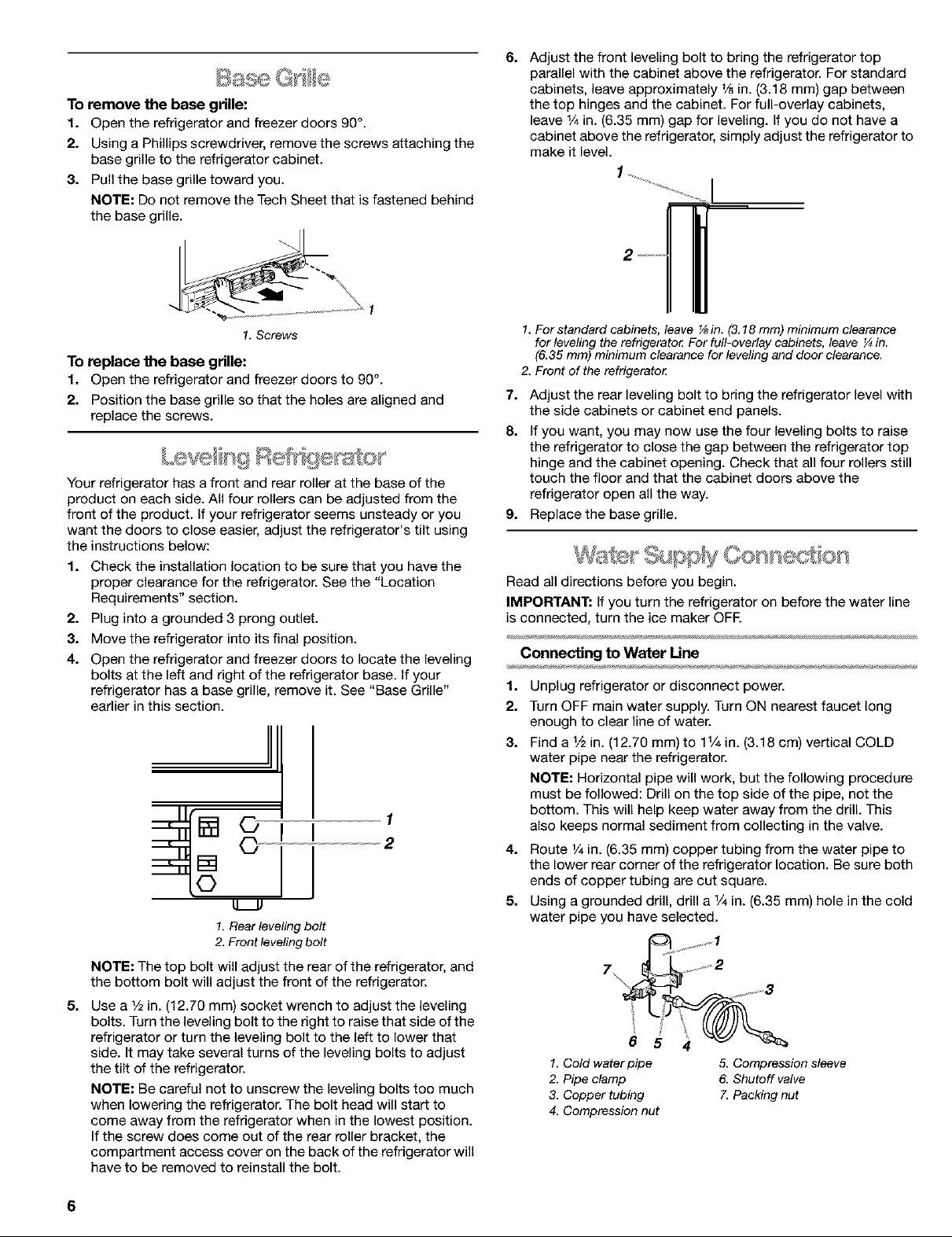

6. Adjust the front leveling bolt to bring the refrigerator top

parallel with the cabinet above the refrigerator. For standard

cabinets, leave approximately 1/8in. (3.18 mm) gap between

the top hinges and the cabinet. For full-overlay cabinets,

leave I/4in. (6.35 mm) gap for leveling. If you do not have a

cabinet above the refrigerator, simply adjust the refrigerator to

make it level.

1.Screws

To replace the base grille:

1. Open the refrigerator and freezer doors to 90°.

2. Position the base grille so that the holes are aligned and

replace the screws.

Your refrigerator has a front and rear roller at the base of the

product on each side. All four rollers can be adjusted from the

front of the product. Ifyour refrigerator seems unsteady or you

want the doors to close easier, adjust the refrigerator's tilt using

the instructions below:

1. Check the installation location to be sure that you have the

proper clearance for the refrigerator. See the "Location

Requirements" section.

2. Plug into a grounded 3 prong outlet.

3. Move the refrigerator into its final position.

4. Open the refrigerator and freezer doors to locate the leveling

bolts at the left and right of the refrigerator base. If your

refrigerator has a base grille, remove it. See "Base Grille"

earlier in this section.

G W ......................... 1

1. Rear leveling bolt

2. Front leveling bolt

NOTE: The top bolt will adjust the rear of the refrigerator, and

the bottom bolt will adjust the front of the refrigerator.

5. Use a 1/2in. (12.70 ram) socket wrench to adjust the leveling

bolts. Turn the leveling bolt to the right to raise that side of the

refrigerator or turn the leveling bolt to the left to lower that

side. It may take several turns of the leveling bolts to adjust

the tilt of the refrigerator.

NOTE: Be careful not to unscrew the leveling bolts too much

when lowering the refrigerator. The bolt head will start to

come away from the refrigerator when in the lowest position.

If the screw does come out of the rear roller bracket, the

compartment access cover on the back of the refrigerator will

have to be removed to reinstall the bolt.

1. For standard cabinets, leave _ in. (3.18 ram) minimum clearance

for leveling the refrigerato_ For full-overlay cabinets, leave ¼in.

(6.35 mm) minimum clearance for leveling and door clearance.

2. Front of the refrigerato_

71

Adjust the rear leveling bolt to bring the refrigerator level with

the side cabinets or cabinet end panels.

8.

If you want, you may now use the four leveling bolts to raise

the refrigerator to close the gap between the refrigerator top

hinge and the cabinet opening. Check that all four rollers still

touch the floor and that the cabinet doors above the

refrigerator open all the way.

9. Replace the base grille.

Read all directions before you begin.

IMPORTANT: If you turn the refrigerator on before the water line

is connected, turn the ice maker OFE

Connecting to Water Une

11

Unplug refrigerator or disconnect power.

2.

Turn OFF main water supply. Turn ON nearest faucet long

enough to clear line of water.

31

Find a _/2in. (12.70 ram) to 1% in. (3.18 cm) vertical COLD

water pipe near the refrigerator.

NOTE: Horizontal pipe will work, but the following procedure

must be followed: Drill on the top side of the pipe, not the

bottom. This will help keep water away from the drill. This

also keeps normal sediment from collecting in the valve.

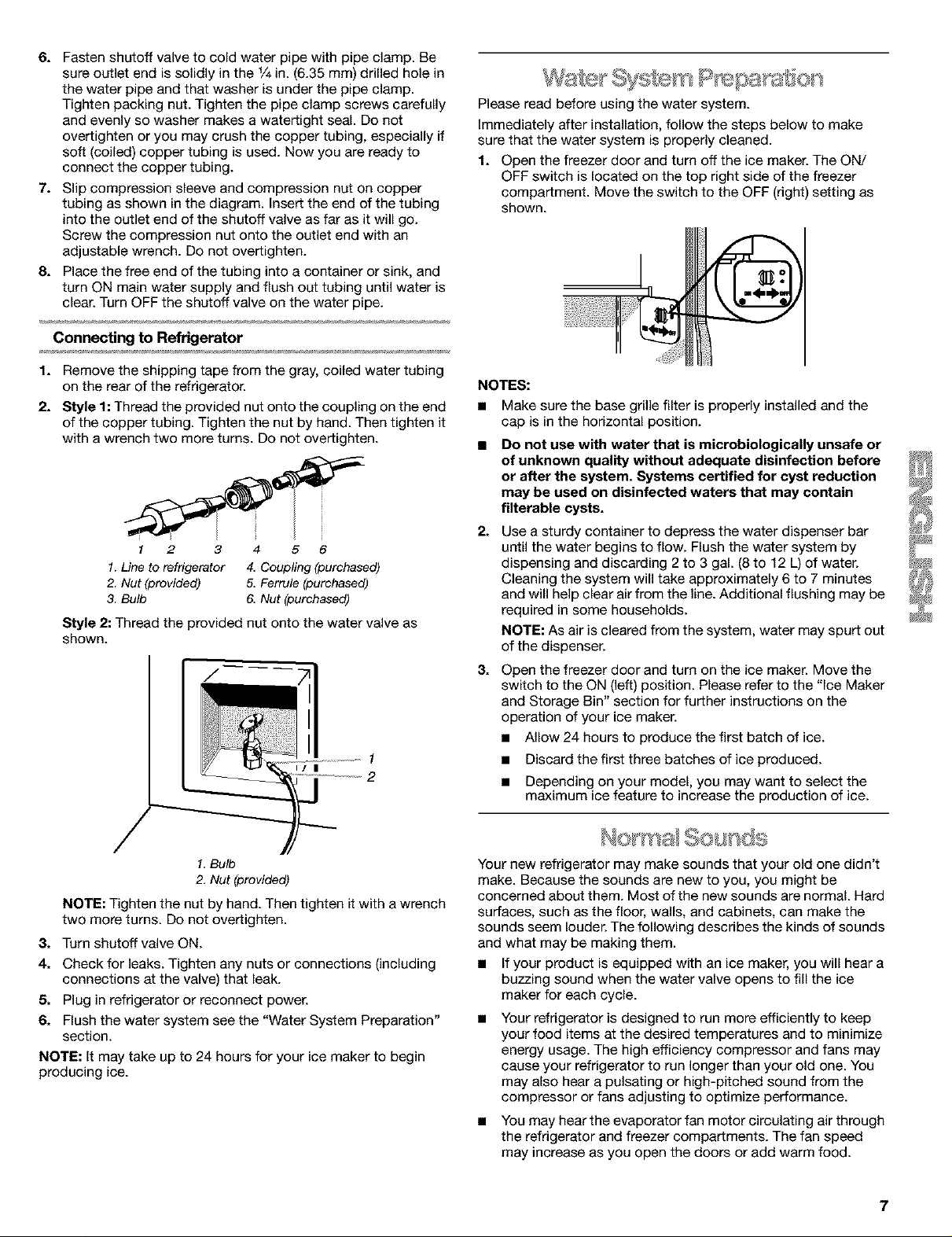

4. Route V4in. (6.35 mm) copper tubing from the water pipe to

the lower rear corner of the refrigerator location. Be sure both

ends of copper tubing are cut square.

5. Using a grounded drill, drill a 1/4in. (6.35 mm) hole in the cold

water pipe you have selected.

1. Cold waterpipe 5. Compression sleeve

2. Pipe clamp & Shutoff valve

3. Copper tubing 7.Packing nut

4. Compression nut

6

6. Fasten shutoff valve to cold water pipe with pipe clamp. Be

sure outlet end is solidly in the 1/4in. (6.35 mm) drilled hole in

the water pipe and that washer is under the pipe clamp.

Tighten packing nut. Tighten the pipe clamp screws carefully

and evenly so washer makes a watertight seal. Do not

overtighten or you may crush the copper tubing, especially if

soft (coiled) copper tubing is used. Now you are ready to

connect the copper tubing.

7. Slip compression sleeve and compression nut on copper

tubing as shown in the diagram. Insert the end of the tubing

into the outlet end of the shutoff valve as far as it will go.

Screw the compression nut onto the outlet end with an

adjustable wrench. Do not overtighten.

8. Place the free end of the tubing into a container or sink, and

turn ON main water supply and flush out tubing until water is

clear. Turn OFF the shutoff valve on the water pipe.

Connecting to Refrigerator

Please read before using the water system.

Immediately after installation, follow the steps below to make

sure that the water system is properly cleaned.

f. Open the freezer door and turn off the ice maker. The ON/

OFF switch is located on the top right side of the freezer

compartment. Move the switch to the OFF (right) setting as

shown.

1. Remove the shipping tape from the gray, coiled water tubing

on the rear of the refrigerator.

2. Style 1: Thread the provided nut onto the coupling on the end

of the copper tubing. Tighten the nut by hand. Then tighten it

with a wrench two more turns. Do not overtighten.

/ 2 3 4 5 6

1. Line to refrigerator 4, Coupling (purchased)

2. Nut (provided) 5. Ferrule (purchased)

3. Bulb 6. Nut (purchased)

Style 2: Thread the provided nut onto the water valve as

shown.

i/ |

1

2

NOTES:

• Make sure the base grille filter is properly installed and the

cap is in the horizontal position.

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain

filterable cysts.

2.

Use a sturdy container to depress the water dispenser bar

until the water begins to flow. Flush the water system by

dispensing and discarding 2 to 3 gal. (8 to 12 L) of water.

Cleaning the system will take approximately 6 to 7 minutes

and will help clear air from the line. Additional flushing may be

required in some households.

NOTE: As air is cleared from the system, water may spurt out

of the dispenser.

3. Open the freezer door and turn on the ice maker. Move the

switch to the ON (left) position. Please refer to the "Ice Maker

and Storage Bin" section for further instructions on the

operation of your ice maker.

• Allow 24 hours to produce the first batch of ice.

• Discard the first three batches of ice produced.

• Depending on your model, you may want to select the

maximum ice feature to increase the production of ice.

1.Bulb

2. Nut (provided)

NOTE: Tighten the nut by hand. Then tighten it with a wrench

two more turns. Do not overtighten.

3. Turn shutoff valve ON.

4. Check for leaks. Tighten any nuts or connections (including

connections at the valve) that leak.

5. Plug in refrigerator or reconnect power.

6. Flush the water system see the "Water System Preparation"

section.

NOTE: It may take up to 24 hours for your ice maker to begin

producing ice.

'#l/J !.1 / ll]iEl

Your new refrigerator may make sounds that your old one didn't

make. Because the sounds are new to you, you might be

concerned about them. Most of the new sounds are normal. Hard

surfaces, such as the floor, walls, and cabinets, can make the

sounds seem louder. The following describes the kinds of sounds

and what may be making them.

• If your product is equipped with an ice maker, you will hear a

buzzing sound when the water valve opens to fill the ice

maker for each cycle.

Your refrigerator is designed to run more efficiently to keep

your food items at the desired temperatures and to minimize

energy usage. The high efficiency compressor and fans may

cause your refrigerator to run longer than your old one. You

may also hear a pulsating or high-pitched sound from the

compressor or fans adjusting to optimize performance.

• You may hear the evaporator fan motor circulating air through

the refrigerator and freezer compartments. The fan speed

may increase as you open the doors or add warm food.

Rattlingnoisesmaycomefromtheflowofrefrigerant,the

waterline,oritemsstoredontopoftherefrigerator.

Waterdrippingonthedefrostheaterduringadefrostcycle

maycauseasizzlingsound.

Aseachcycleends,youmayhearagurglingsounddueto

therefrigerantflowinginyourrefrigerator.

Contractionandexpansionoftheinsidewallsmaycausea

poppingnoise.

Youmayhearairbeingforcedoverthecondenserbythe

condenserfan.

Youmayhearwaterrunningintothedrainpanduringthe

defrostcycle.

REFRIGERATOR USE

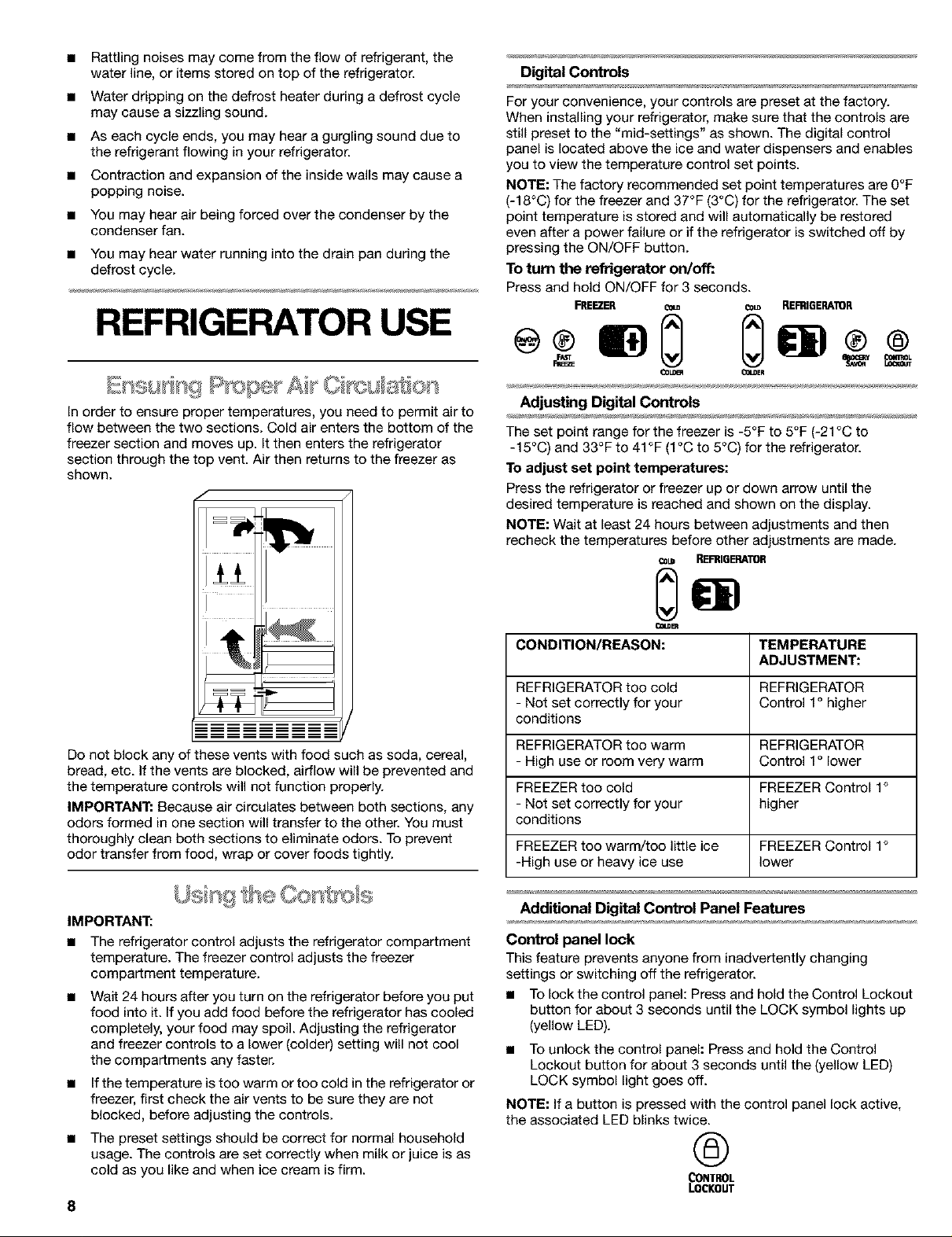

Digital Controls

For your convenience, your controls are preset at the factory.

When installing your refrigerator, make sure that the controls are

still preset to the "mid-settings" as shown. The digital control

panel is located above the ice and water dispensers and enables

you to view the temperature control set points.

NOTE: The factory recommended set point temperatures are 0°F

(-18°C) for the freezer and 37°F (3°C) for the refrigerator. The set

point temperature is stored and will automatically be restored

even after a power failure or if the refrigerator is switched off by

pressing the ON/OFF button.

To turn the refrigerator on/off:

Press and hold ON/OFF for 3 seconds.

FREEZER _ _ REFRIQERATOR

In order to ensure proper temperatures, you need to permit air to

flow between the two sections. Cold air enters the bottom of the

freezer section and moves up. It then enters the refrigerator

section through the top vent. Air then returns to the freezer as

shown.

J

Do not block any of these vents with food such as soda, cereal,

bread, etc. If the vents are blocked, airflow will be prevented and

the temperature controls will not function properly.

IMPORTANT: Because air circulates between both sections, any

odors formed in one section will transfer to the other. You must

thoroughly clean both sections to eliminate odors. To prevent

odor transfer from food, wrap or cover foods tightly.

Adjusting Digital Controls

The set point range for the freezer is -5°F to 5°F (-21°C to

-15°C) and 33°F to 41°F (f °C to 5°C) for the refrigerator.

To adjust set point temperatures:

Press the refrigerator or freezer up or down arrow until the

desired temperature is reached and shown on the display.

NOTE: Wait at least 24 hours between adjustments and then

recheck the temperatures before other adjustments are made.

COLD REFRIGERATOR

ouln_

CONDITION/REASON: TEMPERATURE

ADJUSTMENT:

REFRIGERATOR too cold REFRIGERATOR

- Not set correctly for your Control 1° higher

conditions

REFRIGERATOR too warm REFRIGERATOR

- High use or room very warm Control 1° lower

FREEZER too cold FREEZER Control 1°

- Not set correctly for your higher

conditions

FREEZER too warm/too little ice FREEZER Control 1°

-High use or heavy ice use lower

IMPORTANT:

• The refrigerator control adjusts the refrigerator compartment

temperature. The freezer control adjusts the freezer

compartment temperature.

Wait 24 hours after you turn on the refrigerator before you put

food into it. If you add food before the refrigerator has cooled

completely, your food may spoil. Adjusting the refrigerator

and freezer controls to a lower (colder) setting will not cool

the compartments any faster.

• Ifthe temperature is too warm or too cold in the refrigerator or

freezer, first check the air vents to be sure they are not

blocked, before adjusting the controls.

• The preset settings should be correct for normal household

usage. The controls are set correctly when milk or juice is as

cold as you like and when ice cream is firm.

8

Additional Digital Control Panel Features

Control panel lock

This feature prevents anyone from inadvertently changing

settings or switching off the refrigerator.

• To lock the control panel: Press and hold the Control Lockout

button for about 3 seconds until the LOCK symbol lights up

(yellow LED).

• To unlock the control panel: Press and hold the Control

Lockout button for about 3 seconds until the (yellow LED)

LOCK symbol light goes Off.

NOTE: If a button is pressed with the control panel lock active,

the associated LED blinks twice.

®

CONTROL

LOCKOUT

GrocerySavor TM

The GrocerySavor TM feature assists with periods of high

refrigerator use, full grocery loads, or temporarily warm room

temperatures. Use this function to chill the fresh food stored in

the refrigerator rapidly.

• Press GrocerySavor TM until the symbol lights up (yellow LED).

The GrecerySavor TM function shuts off automatically after 6

hours OR manually by pressing the Grocery Savor button

again.

NOTE: The temperature display will not change. After 6

hours, the refrigerator returns to the previous temperature set

point.

®

GROCERY

SAVOR

Fast Freeze

The Fast Freeze feature assists with periods of high freezer use,

or freezing large quantities of fresh food.

NOTE: This function must be activated before freezing fresh

food.

Press the Fast Freeze button until the symbol lights up (yellow

LED). The Fast Freeze function shuts off automatically after

24 hours OR manually by pressing the Fast Freeze button

again.

®

FAST

FREI_

Power InterrupUon Indicator

A blinking temperature reading in the Freezer display indicates

there has been an interruption of power and shows the warmest

temperature reached in the freezer compartment during the

power interruption. The temperature reading will continue to blink

until the Freezer up or down button is pushed.

NOTE: Check the condition of the food in both compartments

before refreezing it or using it.

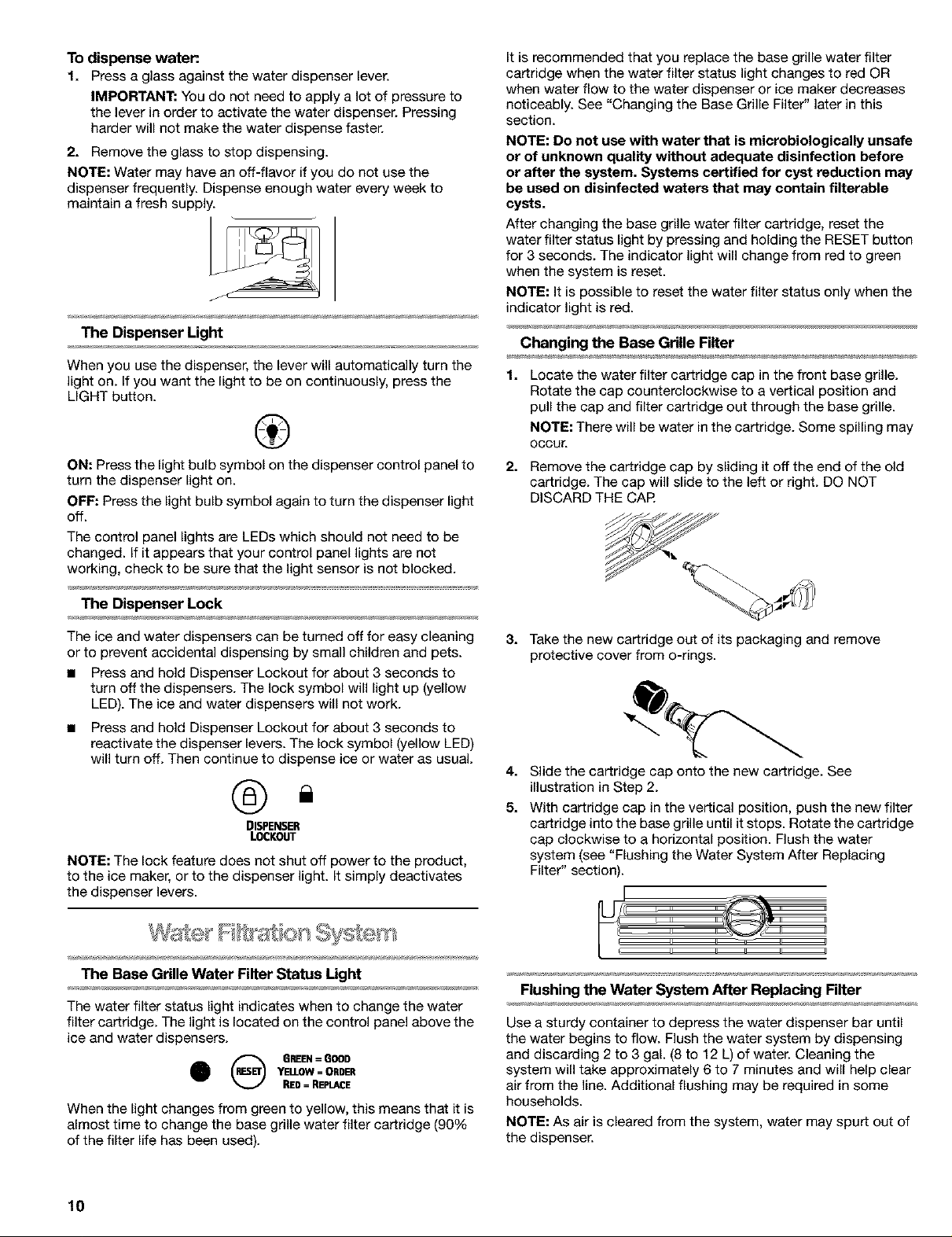

E e ¢@

• When you release the dispenser lever, the trap door closes

and the ice dispensing stops. The dispensing system will not

operate when the freezer door is open.

Before dispensing ice, select which type of ice you prefer.

• For cubed ice, press the arrow button pointing toward the

cubed ice display until the cubed ice symbol lights up (yellow

LED).

• For crushed ice, press the arrow button pointing toward the

crushed ice display until the crushed ice symbol lights up

(yellow LED).

NOTE: For crushed ice, cubes are crushed before they are

dispensed. This may cause a slight delay when dispensing

crushed ice. Noise from the ice crusher is normal, and pieces

of ice may vary in size. When changing from CRUSHED to

CUBED, a few ounces of crushed ice will be dispensed along

with the first cubes.

®@@®

ICE

To dispense ice:

1. Press button pointing toward the desired type of ice.

2. Press a sturdy glass against the ice dispenser lever. Hold the

glass close to the dispenser opening so ice does not fall

outside of the glass.

IMPORTANT: You do not need to apply a lot of pressure to

the lever in order to activate the ice dispenser. Pressing hard

will not make the ice dispense faster or in greater quantities.

3. Remove the glass to stop dispensing.

NOTE: The first few batches of ice may have an off-flavor

from new plumbing and parts. Throw the ice away. Also, take

large amounts of ice from the ice bin, not through the

dispenser.

Cut Hazard

Use a sturdy glass when dispensing ice or water.

Failure to do so can result in cuts.

Your electronic dispenser offers several options: the ability to

select crushed or cubed ice, a light that turns on when you use

the dispenser or press the LIGHT button, and a lock option to

avoid accidental dispensing.

The Ice Dispenser

Ice dispenses from the ice maker storage bin in the freezer.

When the dispenser lever is pressed:

• A trap door opens in a chute between the dispenser and the

ice bin. Ice moves from the bin and falls through the chute.

The Water Dispenser

if you did not flush the water system when the refrigerator was

first installed, press the water dispenser bar with a glass or jar

until you draw and discard 2 to 3 gal. (8 to 12 L) or approximately

6 to 7 minutes of water after water begins dispensing. It will take

3 to 4 minutes for the water to begin dispensing. The water you

draw and discard cleans the system and helps clear air from the

lines. Allow several hours for the refrigerator to cool down and

chill water.

IMPORTANT: The small removable tray at the bottom of the

dispenser is designed to catch small spills and allow for easy

cleaning. There is no drain in the tray. The tray can be removed

from the dispenser and carried to the sink to be emptied or

cleaned.

/

To dispense water.

1. Press a glass against the water dispenser lever.

IMPORTANT: You do not need to apply a lot of pressure to

the lever in order to activate the water dispenser. Pressing

harder will not make the water dispense faster.

2. Remove the glass to stop dispensing.

NOTE: Water may have an off-flavor if you do not use the

dispenser frequently. Dispense enough water every week to

maintain a fresh supply.

The Dispenser Light

When you use the dispenser, the lever will automatically turn the

light on. If you want the light to be on continuously, press the

LIGHT button.

®

ON: Press the light bulb symbol on the dispenser control panel to

turn the dispenser light on.

OFF: Press the light bulb symbol again to turn the dispenser light

off.

The control panel lights are LEDs which should not need to be

changed. If it appears that your control panel lights are not

working, check to be sure that the light sensor is not blocked.

It is recommended that you replace the base grille water filter

cartridge when the water filter status light changes to red OR

when water flow to the water dispenser or ice maker decreases

noticeably. See "Changing the Base Grille Filter" later in this

section.

NOTE: Do not use with water that is microbiologically unsafe

or of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction may

be used on disinfected waters that may contain filterable

cysts.

After changing the base grille water filter cartridge, reset the

water filter status light by pressing and holding the RESET button

for 3 seconds. The indicator light will change from red to green

when the system is reset.

NOTE: It is possible to reset the water filter status only when the

indicator light is red.

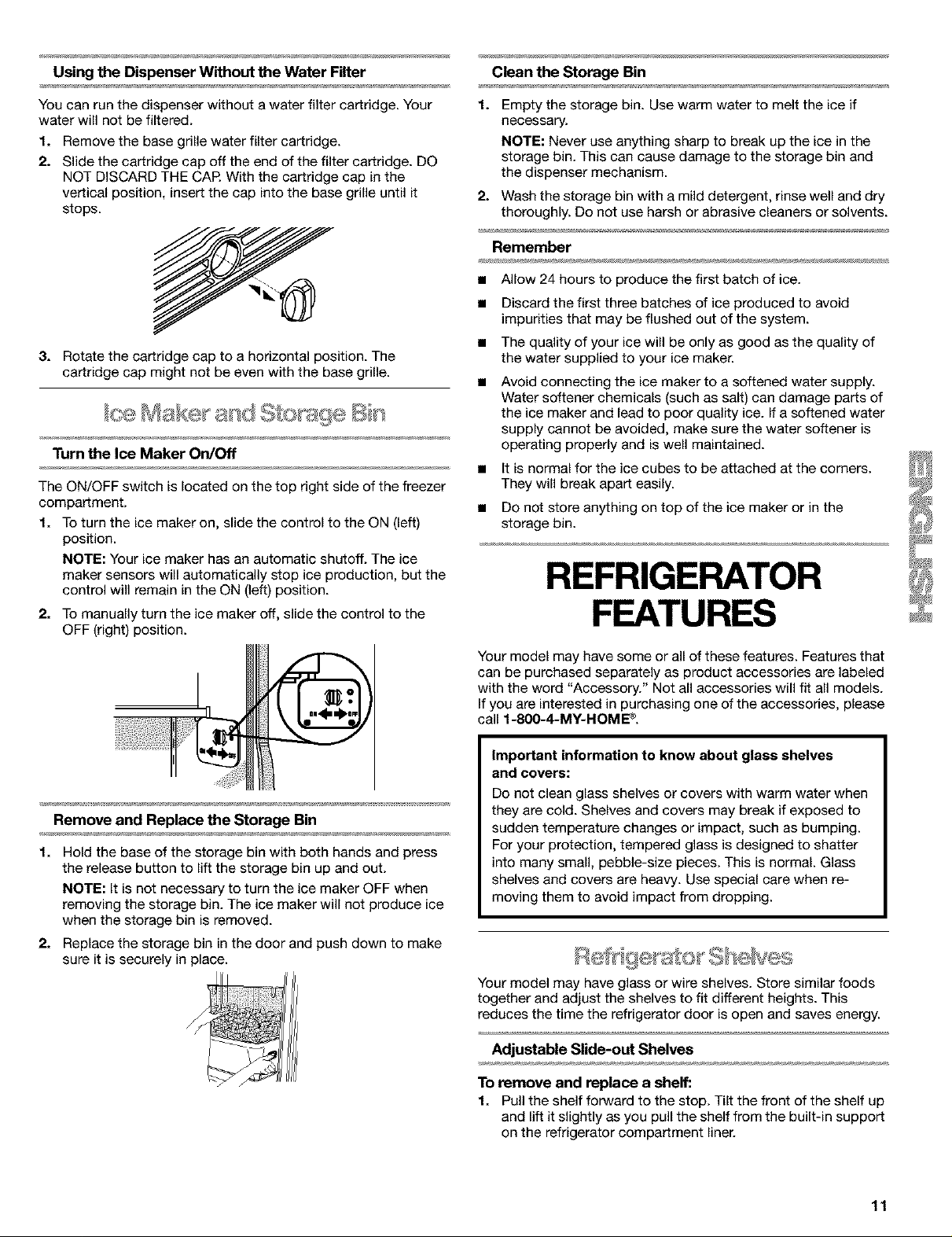

Changing the Base Grille Filter

1. Locate the water filter cartridge cap in the front base grille.

Rotate the cap counterclockwise to a vertical position and

pull the cap and filter cartridge out through the base grille.

NOTE: There will be water in the cartridge. Some spilling may

OCCUR

2. Remove the cartridge cap by sliding it off the end of the old

cartridge. The cap will slide to the left or right. DO NOT

DISCARD THE CAR

The Dispenser Lock

The ice and water dispensers can be turned off for easy cleaning

or to prevent accidental dispensing by small children and pets.

• Press and hold Dispenser Lockout for about 3 seconds to

turn off the dispensers. The lock symbol will light up (yellow

LED). The ice and water dispensers will not work.

• Press and hold Dispenser Lockout for about 3 seconds to

reactivate the dispenser levers. The lock symbol (yellow LED)

will turn off. Then continue to dispense ice or water as usual.

DISPENSER

LOCKOUT

NOTE: The lock feature does not shut off power to the product,

to the ice maker, or to the dispenser light. It simply deactivates

the dispenser levers.

The Base Grille Water Filter Status Light

The water filter status light indicates when to change the water

filter cartridge. The light is located on the control panel above the

ice and water dispensers.

YELLOW ORDER

(_ GREEN= GOOD

When the light changes from green to yellow, this means that it is

almost time to change the base grille water filter cartridge (90%

of the filter life has been used).

RED= REPLACE

3. Take the new cartridge out of its packaging and remove

protective cover from o-rings.

4. Slide the cartridge cap onto the new cartridge. See

illustration in Step 2.

5. With cartridge cap in the vertical position, push the new filter

cartridge into the base grille until it stops. Rotate the cartridge

cap clockwise to a horizontal position. Flush the water

system (see "Flushing the Water System After Replacing

Filter" section).

I

Flushing the Water System After Replacing Filter

Use a sturdy container to depress the water dispenser bar until

the water begins to flow. Flush the water system by dispensing

and discarding 2 to 3 gal. (8 to 12 L) of water. Cleaning the

system will take approximately 6 to 7 minutes and will help clear

air from the line. Additional flushing may be required in some

households.

NOTE: As air is cleared from the system, water may spurt out of

the dispenser.

10

Using the Dispenser Without the Water Filter

Clean the Storage Bin

You can run the dispenser without a water filter cartridge. Your

water will not be filtered.

1. Remove the base grille water filter cartridge.

2. Slide the cartridge cap off the end of the filter cartridge. DO

NOT DISCARD THE CAR With the cartridge cap in the

vertical position, insert the cap into the base grille until it

stops.

3. Rotate the cartridge cap to a horizontal position. The

cartridge cap might not be even with the base grille.

)c®Mak® "ssd Sto 5,g®

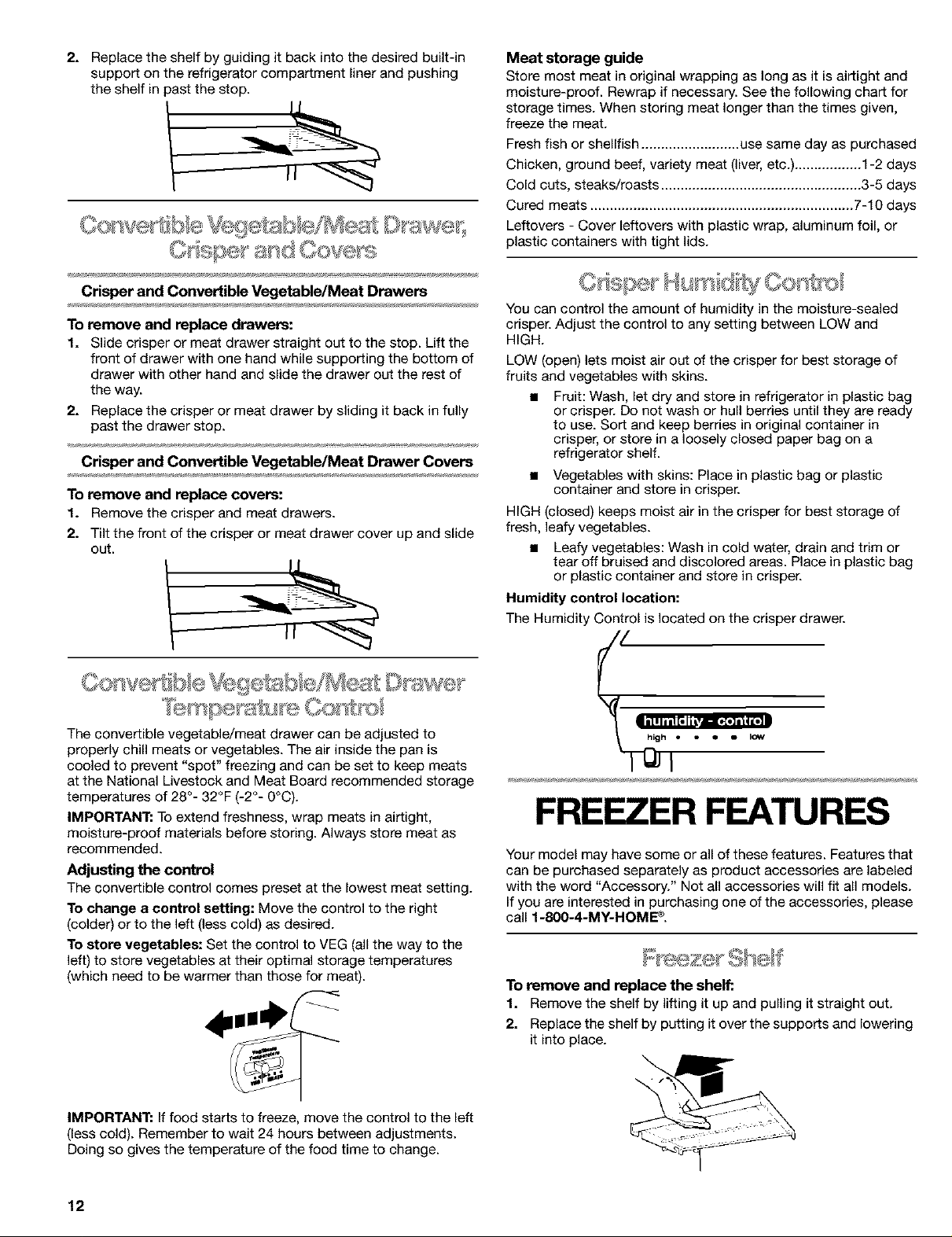

Turn the lee Maker On/Off

The ON/OFF switch is located on the top right side of the freezer

compartment.

1. To turn the ice maker on, slide the control to the ON (left)

position.

NOTE: Your ice maker has an automatic shutoff. The ice

maker sensors will automatically stop ice production, but the

control will remain in the ON (left) position.

2. To manually turn the ice maker off, slide the control to the

OFF (right) position.

1. Empty the storage bin. Use warm water to melt the ice if

necessary.

NOTE: Never use anything sharp to break up the ice in the

storage bin. This can cause damage to the storage bin and

the dispenser mechanism.

2. Wash the storage bin with a mild detergent, rinse well and dry

thoroughly. Do not use harsh or abrasive cleaners or solvents.

Remember

• Allow 24 hours to produce the first batch of ice.

• Discard the first three batches of ice produced to avoid

impurities that may be flushed out of the system.

• The quality of your ice will be only as good as the quality of

the water supplied to your ice maker.

• Avoid connecting the ice maker to a softened water supply.

Water softener chemicals (such as salt) can damage parts of

the ice maker and lead to poor quality ice. If a softened water

supply cannot be avoided, make sure the water softener is

operating properly and is well maintained.

• It is normal for the ice cubes to be attached at the corners.

They will break apart easily.

• Do not store anything on top of the ice maker or in the

storage bin.

REFRIGERATOR

FEATURES

Your model may have some or all of these features. Features that

can be purchased separately as product accessories are labeled

with the word "Accessory." Not all accessories will fit all models.

If you are interested in purchasing one of the accessories, please

call 1-800-4-MY-HOME*.

Remove and Replace the Storage Bin

11

Hold the base of the storage bin with both hands and press

the release button to lift the storage bin up and out.

NOTE: It is not necessary to turn the ice maker OFF when

removing the storage bin. The ice maker will not produce ice

when the storage bin is removed.

2. Replace the storage bin in the door and push down to make

sure it is securely in place.

Important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

For your protection, tempered glass is designed to shatter

into many small, pebble-size pieces. This is normal. Glass

shelves and covers are heavy. Use special care when re-

moving them to avoid impact from dropping.

Your model may have glass or wire shelves. Store similar foods

together and adjust the shelves to fit different heights. This

reduces the time the refrigerator door is open and saves energy.

Adjustable Slide-out Shelves

To remove and replace a shelf."

1. Pull the shelf forward to the stop. Tilt the front of the shelf up

and lift it slightly as you pull the shelf from the built-in support

on the refrigerator compartment liner.

11

2. Replace the shelf by guiding it back into the desired built-in

support on the refrigerator compartment liner and pushing

the shelf in past the stop.

Crisper and Convertible Vegetable/Meat Drawers

To remove and replace drawers:

1. Slide crisper or meat drawer straight out to the stop. Lift the

front of drawer with one hand while supporting the bottom of

drawer with other hand and slide the drawer out the rest of

the way.

2. Replace the crisper or meat drawer by sliding it back in fully

past the drawer stop.

Crisper and Convertible Vegetable/Meat Drawer Covers

To remove and replace covers:

1. Remove the crisper and meat drawers.

2. Tilt the front of the crisper or meat drawer cover up and slide

Out.

Meat storage guide

Store most meat in original wrapping as long as it is airtight and

moisture-proof. Rewrap if necessary. See the following chart for

storage times. When storing meat longer than the times given,

freeze the meat.

Fresh fish or shellfish ......................... use same day as purchased

Chicken, ground beef, variety meat (liver, etc.) ................. 1-2 days

Cold cuts, steaks/roasts ................................................... 3-5 days

Cured meats ................................................................... 7-10 days

Leftovers - Cover leftovers with plastic wrap, aluminum foil, or

plastic containers with tight lids.

You can control the amount of humidity in the moisture-sealed

crisper. Adjust the control to any setting between LOW and

HIGH.

LOW (open) lets moist air out of the crisper for best storage of

fruits and vegetables with skins.

• Fruit: Wash, let dry and store in refrigerator in plastic bag

or crisper. Do not wash or hull berries until they are ready

to use. Sort and keep berries in original container in

crisper, or store in a loosely closed paper bag on a

refrigerator shelf.

• Vegetables with skins: Place in plastic bag or plastic

container and store in crisper.

HIGH (closed) keeps moist air in the crisper for best storage of

fresh, leafy vegetables.

• Leafy vegetables: Wash in cold water, drain and trim or

tear off bruised and discolored areas. Place in plastic bag

or plastic container and store in crisper.

Humidity control location:

The Humidity Control is located on the crisper drawer.

Co,sire/

The convertible vegetable/meat drawer can be adjusted to

properly chill meats or vegetables. The air inside the pan is

cooled to prevent "spot" freezing and can be set to keep meats

at the National Livestock and Meat Board recommended storage

temperatures of 28 °- 32°F (-2°- 0°C).

IMPORTANT: To extend freshness, wrap meats in airtight,

moisture-proof materials before storing. Always store meat as

recommended.

Adjusting the control

The convertible control comes preset at the lowest meat setting.

To change a control setting: Move the control to the right

(colder) or to the left (less cold) as desired.

To store vegetables: Set the control to VEG (all the way to the

left) to store vegetables at their optimal storage temperatures

(which need to be warmer than those for meat).

IMPORTANT: If food starts to freeze, move the control to the left

(less cold). Remember to wait 24 hours between adjustments.

Doing so gives the temperature of the food time to change.

FREEZER FEATURES

Your model may have some or all of these features. Features that

can be purchased separately as product accessories are labeled

with the word "Accessory." Not all accessories will fit all models.

If you are interested in purchasing one of the accessories, please

call 1-800-4-MY-HOME*.

To remove and replace the shelf:.

1. Remove the shelf by lifting it up and pulling it straight out.

2. Replace the shelf by putting it over the supports and lowering

it into place.

12

Frozen food storage guide

Storage times will vary according to the quaUty and type of food,

the type of packaging or wrap used (should be airtight and

moisture-proof), and the storage temperature. Ice crystals inside

a sealed package are normal. This simply means that moisture in

the food and air inside the package have condensed, creating ice

crystals.

Put no more unfrozen food into the freezer than will freeze within

24 hours (no more than 2 to 3 Ibs of food per cubic foot [907-

1,350 g per L] of freezer space). Leave enough space in the

freezer for air to circulate around packages. Be careful to leave

enough room for the door to close tightly.

For more information on preparing food for freezing, check a

freezer guide or reliable cookbook.

REFRIGERATOR CARE

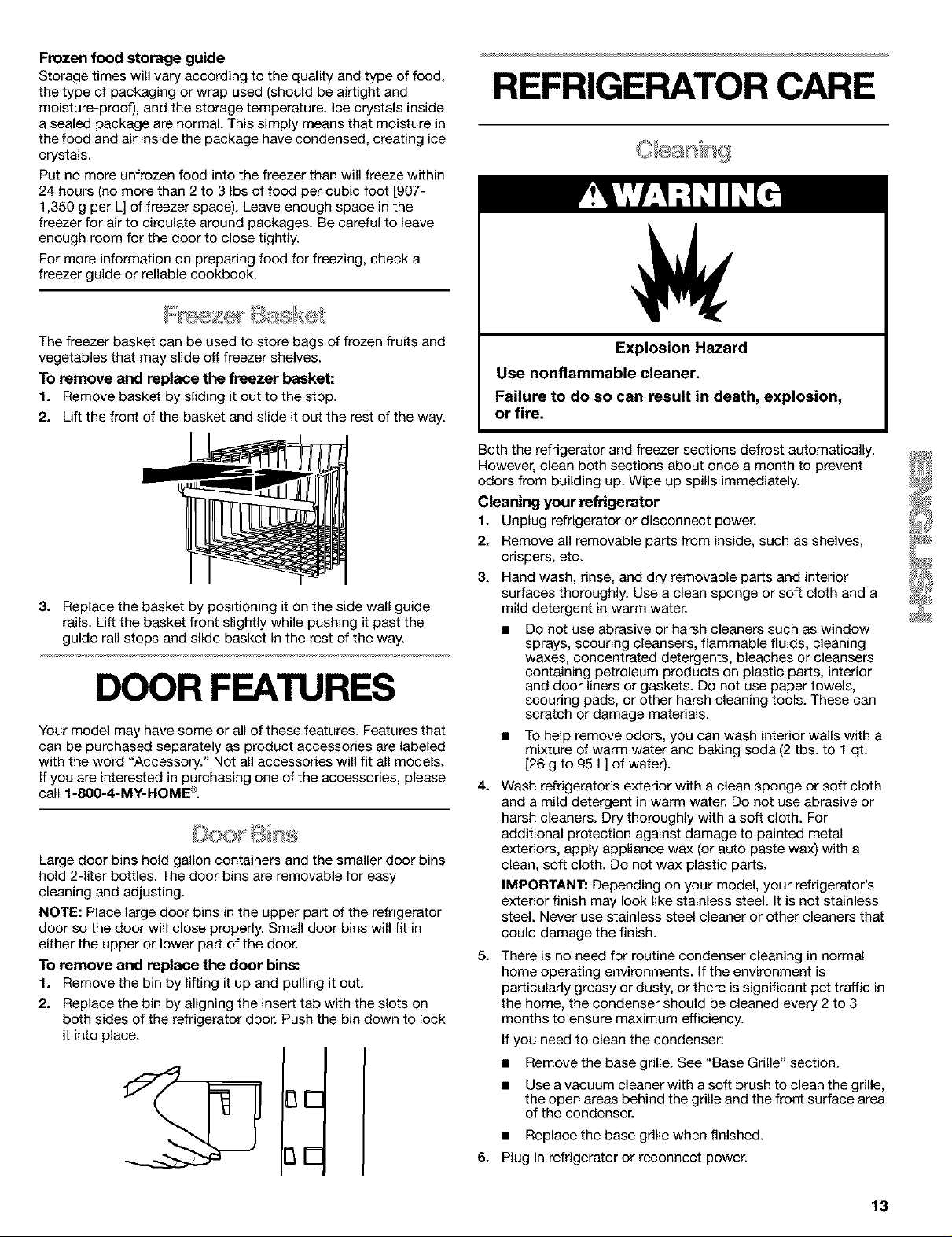

The freezer basket can be used to store bags of frozen fruits and

vegetables that may slide off freezer shelves.

To remove and replace the freezer basket:

1. Remove basket by sUding it out to the stop.

2. Lift the front of the basket and slide it out the rest of the way.

3. Replace the basket by positioning it on the side wall guide

rails. Lift the basket front slightly while pushing it past the

guide rail stops and slide basket in the rest of the way.

DOOR FEATURES

Your model may have some or all of these features. Features that

can be purchased separately as product accessories are labeled

with the word "Accessory." Not all accessories will fit all models.

If you are interested in purchasing one of the accessories, please

call 1-800-4-MY-HOME ®.

Large door bins hold gallon containers and the smaller door bins

hold 2-liter bottles. The door bins are removable for easy

cleaning and adjusting.

NOTE: Place large door bins in the upper part of the refrigerator

door so the door will close properly. Small door bins will fit in

either the upper or lower part of the door.

To remove and replace the door bins:

1. Remove the bin by lifting it up and pulling it out.

2. Replace the bin by aligning the insert tab with the slots on

both sides of the refrigerator door. Push the bin down to lock

it into place.

Dr-

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion,

or fire.

Both the refrigerator and freezer sections defrost automatically.

However, clean both sections about once a month to prevent

odors from building up. Wipe up spills immediately.

Cleaning your refrigerator

1. Unplug refrigerator or disconnect power.

2. Remove all removable parts from inside, such as shelves,

crispers, etc.

3. Hand wash, rinse, and dry removable parts and interior

surfaces thoroughly. Use a clean sponge or soft cloth and a

mild detergent in warm water.

• Do not use abrasive or harsh cleaners such as window

sprays, scouring cleansers, flammable fluids, cleaning

waxes, concentrated detergents, bleaches or cleansers

containing petroleum products on plastic parts, interior

and door liners or gaskets. Do not use paper towels,

scouring pads, or other harsh cleaning tools. These can

scratch or damage materials.

• To help remove odors, you can wash interior walls with a

mixture of warm water and baking soda (2 tbs. to 1 qt.

[26 g to.95 L] of water).

4.

Wash refrigeratoCs exterior with a clean sponge or soft cloth

and a mild detergent in warm water. Do not use abrasive or

harsh cleaners. Dry thoroughly with a soft cloth. For

additional protection against damage to painted metal

exteriors, apply appliance wax (or auto paste wax) with a

clean, soft cloth. Do not wax plastic parts.

IMPORTANT: Depending on your model, your refrigerator's

exterior finish may look like stainless steel. It is not stainless

steel. Never use stainless steel cleaner or other cleaners that

could damage the finish.

5.

There is no need for routine condenser cleaning in normal

home operating environments. If the environment is

particularly greasy or dusty, or there is significant pet traffic in

the home, the condenser should be cleaned every 2 to 3

months to ensure maximum efficiency.

If you need to clean the condenser:

• Remove the base grille. See "Base Grille" section.

• Use a vacuum cleaner with a soft brush to clean the grille,

the open areas behind the grille and the front surface area

of the condenser.

• Replace the base grille when finished.

6. Plug in refrigerator or reconnect power.

13

NOTE: Not all appliance bulbs will fit your refrigerator. Be sure to

replace the bulb with one of the same size and shape. The

dispenser light requires a heavy duty 10-watt bulb. All other lights

require a 40-watt appliance bulb. Replacement bulbs are

available from Sears.

1. Unplug refrigerator or disconnect power.

2. Remove light shield when applicable as shown.

NOTE: To clean a light shield, wash it with warm water and a

liquid detergent. Rinse and dry the shield well.

3. Remove light bulb and replace with one of the same size,

shape and wattage.

4. Replace light shield when applicable as shown.

5. Plug in refrigerator or reconnect power.

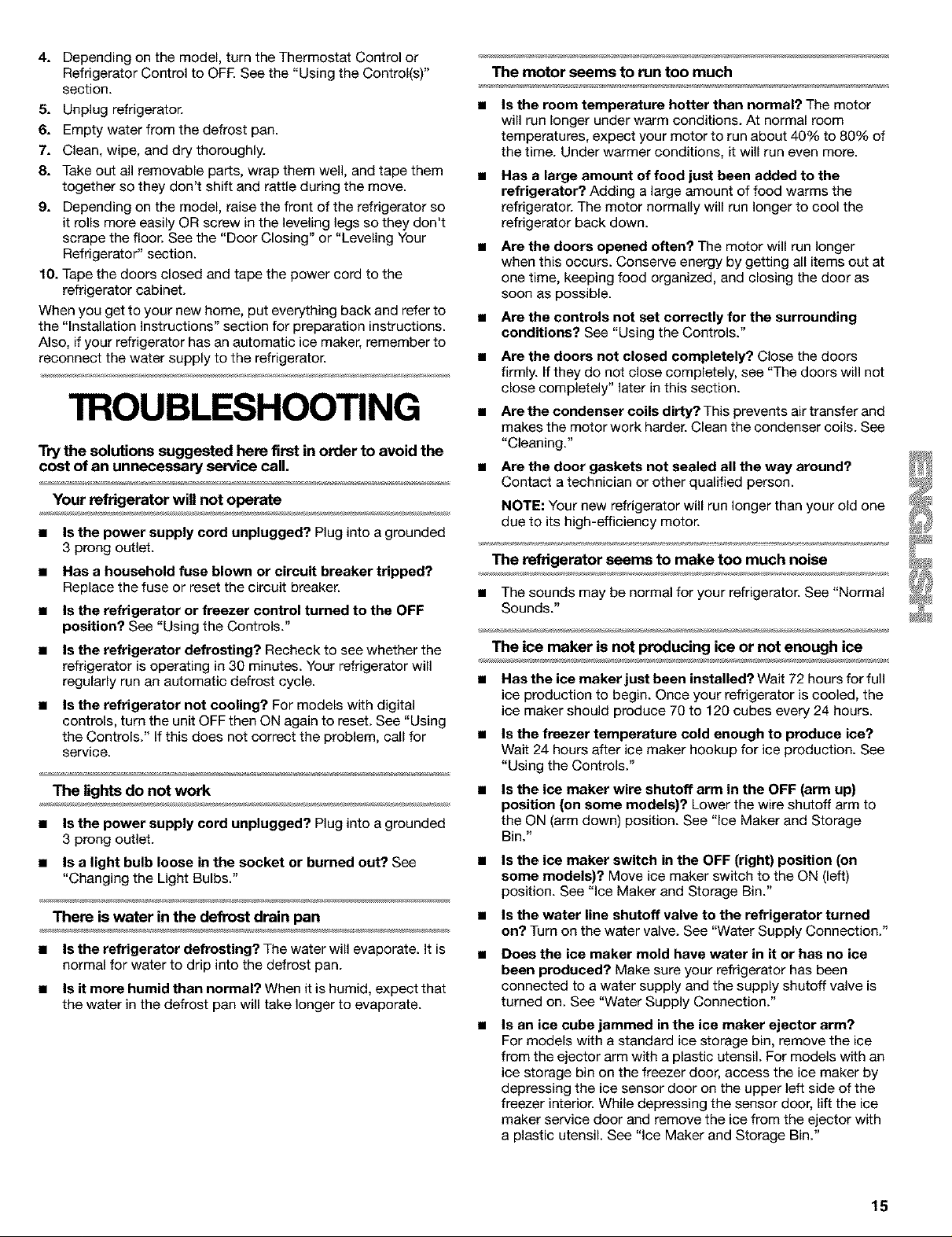

Dispenser Light

Reach through the dispenser area to remove and replace light

bulb.

1. Dispenser Light

If the power will be out for 24 hours or less, keep the door or

doors closed (depending on your model) to help food stay cold

and frozen.

If the power will be out for more than 24 hours, do one of the

following:

• Remove all frozen food and store it in a frozen food locker.

• Place 2 Ibs (907 g) of dry ice in the freezer for every cubic foot

(28 L) of freezer space. This will keep the food frozen for 2 to

4 days.

• If neither a food locker nor dry ice is available, consume or

can perishable food at once.

REMEMBER: A full freezer stays cold longer than a partially filled

one. A freezer full of meat stays cold longer than a freezer full of

baked goods. If you see that food contains ice crystals, it may be

refrozen, although the quality and flavor may be affected. If the

condition of the food is poor, dispose of it.

Vacations

If you choose to leave the refrigerator on while you're

away:

1. Use up any perishables and freeze other items.

2. If your refrigerator has an automatic ice maker:

• Raise wire shutoff arm to OFF (up) position or move the

switch to the OFF (right) setting.

• Shut off water supply to the ice maker.

Refrigerator Light 3. Empty the ice bin.

If yOU choose to turn the refrigerator off before you leave:

• Remove the light shield by using a Phillips screwdriver to 1. Remove all food from the refrigerator.

remove the screw located at the rear of the light shield.

• Replace the light shield by positioning the light shield over the

light and replacing the screw.

2. If your refrigerator has an automatic ice maker:

• Turn off the water supply to the ice maker at least one day

ahead of time.

• When the last load of ice drops, raise the wire shutoff arm

to the OFF (up) position or move the switch to the OFF

(right) setting.

3.

Depending on the model, turn the Thermostat Control or

Refrigerator Control to OFR See the "Using the Control(s)"

section.

4.

Clean refrigerator, wipe it, and dry well.

5.

1. Screw

Tape rubber or wood blocks to the tops of both doors to prop

them open far enough for air to get in. This stops odor and

mold from building up.

Freezer Light

• Remove the light shield by grasping the sides and pulling the

light shield toward you.

• Replace the light shield by inserting the tabs into the holes in

the freezer compartment liner.

Moving

When you are moving your refrigerator to a new home, follow

these steps to prepare it for the move.

1. If your refrigerator has an automatic ice maker:

• Turn off the water supply to the ice maker at least one day

ahead of time.

• Disconnect the water line from the back of the

refrigerator.

• When the last load of ice drops, raise the wire shutoff arm

to the OFF (up) position or move the switch to the OFF

(right) setting.

2. Remove all food from the refrigerator and pack all frozen food

in dry ice.

3. Empty the ice bin.

14

4. Depending on the model, turn the Thermostat Control or

Refrigerator Control to OFE See the "Using the Control(s)"

section.

5. Unplug refrigerator.

6. Empty water from the defrost pan.

7. Clean, wipe, and dry thoroughly.

8. Take out all removable parts, wrap them well, and tape them

together so they don't shift and rattle during the move.

9. Depending on the model, raise the front of the refrigerator so

it rolls more easily OR screw in the leveling legs so they don't

scrape the floor. See the "Door Closing" or "Leveling Your

Refrigerator" section.

10. Tape the doors closed and tape the power cord to the

refrigerator cabinet.

When you get to your new home, put everything back and refer to

the "Installation Instructions" section for preparation instructions.

Also, if your refrigerator has an automatic ice maker, remember to

reconnect the water supply to the refrigerator.

TROUBLESHOOTING

Try the solutions suggested here first in order to avoid the

cost of an unnecessary service call.

Your refrigerator will not operate

• Is the power supply cord unplugged? Plug into a grounded

3 prong outlet.

• Has a household fuse blown or circuit breaker tripped?

Replace the fuse or reset the circuit breaker.

• Is the refrigerator or freezer control turned to the OFF

position? See "Using the Controls."

• Is the refrigerator defrosting? Recheck to see whether the

refrigerator is operating in 30 minutes. Your refrigerator will

regularly run an automatic defrost cycle.

• Is the refrigerator not cooling? For models with digital

controls, turn the unit OFF then ON again to reset. See "Using

the Controls." If this does not correct the problem, call for

service.

The lights do not work •

• Is the power supply cord unplugged? Plug into a grounded

3 prong outlet.

• Is a light bulb loose in the socket or burned out? See •

"Changing the Light Bulbs."

There is water in the defrost drain pen •

• Is the refrigerator defrosting? The water will evaporate. It is •

normal for water to drip into the defrost pan.

• Is it more humid than normal? When it is humid, expect that

the water in the defrost pan will take longer to evaporate.

The motor seems to run too much

• Is the room temperature hotter than normal? The motor

will run longer under warm conditions. At normal room

temperatures, expect your motor to run about 40% to 80% of

the time. Under warmer conditions, it will run even more.

Has a large amount of food just been added to the

refrigerator?. Adding a large amount of food warms the

refrigerator. The motor normally will run longer to cool the

refrigerator back down.

Are the doors opened often? The motor will run longer

when this occurs. Conserve energy by getting all items out at

one time, keeping food organized, and closing the door as

soon as possible.

Are the controls not set correctly for the surrounding

conditions? See "Using the Controls."

Are the doors not closed completely? Close the doors

firmly. Ifthey do not close completely, see "The doors will not

close completely" later in this section.

Are the condenser coils dirty? This prevents air transfer and

makes the motor work harder. Clean the condenser coils. See

"Cleaning."

Are the door gaskets not sealed all the way around?

Contact a technician or other qualified person.

NOTE: Your new refrigerator will run longer than your old one

due to its high-efficiency motor.

The refrigerator seems to make too much noise _!_

• The sounds may be normal for your refrigerator. See "Normal _

Sounds." _

The ice maker is not producing ice or not enough ice

• Has the ice maker just been installed? Wait 72 hours for full

ice production to begin. Once your refrigerator is cooled, the

ice maker should produce 70 to 120 cubes every 24 hours.

• Is the freezer temperature cold enough to produce ice?

Wait 24 hours after ice maker hookup for ice production. See

"Using the Controls."

IS the ice maker wire shutoff arm in the OFF (arm up)

position (on some models)? Lower the wire shutoff arm to

the ON (arm down) position. See "ice Maker and Storage

Bin."

IS the ice maker switch in the OFF (right) position (on

some models)? Move ice maker switch to the ON (left)

position. See "ice Maker and Storage Bin."

Is the water line shutoff valve to the refrigerator turned

on? Turn on the water valve. See "Water Supply Connection."

Does the ice maker mold have water in it or has no ice

been produced? Make sure your refrigerator has been

connected to a water supply and the supply shutoff valve is

turned on. See "Water Supply Connection."

Is an ice cube jammed in the ice maker ejector arm?

For models with a standard ice storage bin, remove the ice

from the ejector arm with a plastic utensil. For models with an

ice storage bin on the freezer door, access the ice maker by

depressing the ice sensor door on the upper left side of the

freezer interior. While depressing the sensor door, lift the ice

maker service door and remove the ice from the ejector with

a plastic utensil. See "Ice Maker and Storage Bin."

J3_

15

• Has a large amount of ice just been removed? Allow

24 hours for ice maker to produce more ice.

• Are the controls set correctly? See "Using the Controls."

Is there a water filter installed on the refrigerator?. The

filter may be clogged or installed incorrectly. Check the filter

installation instructions to ensure that the filter was installed

correctly and is not clogged. If installation or clogging is not a

problem, call a technician or other qualified person.

• Is a reverse osmosis water filtration system connected to

your cold water supply? See "Water Supply Requirements."

NOTE: If not due to any of the above, there may be a problem

with the water line. Call for service.

Is the ice dispenser stalling while dispensing "crushed"

ice? Stop dispensing ice. Change the ice button from

"crushed" to "cubed." Depress the ice dispenser arm using a

sturdy glass. If cubed ice dispenses correctly, depress the

button for "crushed" ice and begin dispensing again. See

"Water and Ice Dispensers."

• Is there ice in the storage bin? See "The ice maker is not

producing ice" earlier in this section.

Has the dispenser arm been held in too long? Release

dispenser arm. Ice will stop dispensing when the arm is held

in too long. Wait 3 minutes for dispenser motor to reset

before using again. It is best to take large amounts of ice

directly from the ice storage bin, not through the dispenser.

Off-taste, odor or gray color in the ice

• Are the plumbing connections new, causing discolored or

off-flavored ice? Discard the first few batches of ice.

• Have the ice cubes been stored too long? Throw old ice

away and make a new supply.

• Does the freezer and ice storage bin need to be cleaned?

See "Cleaning" or "ice Maker and Storage Bin."

• Has food in the freezer or refrigerator been wrapped

properly? Use airtight, moisture-proof packaging to help

prevent odor transfer to stored food.

• Does the water contain minerals (such as sulfur)? A filter

may need to be installed to remove the minerals.

Is there a water filter installed on the refrigerator? Gray or

dark discoloration in ice indicates that the water filtration

system needs additional flushing. Run additional water

through the water dispenser to flush the water filtration

system more thoroughly (at least 2 to 3 gal. [8 to 12 L] or 6 to

7 minutes initiaUy). Discard discolored ice.

The ice dispenser will not operate properly

• Is the freezer door closed completely? Push the door firmly

closed. If it will not close all the way, see "The doors will not

close completely" later in this section.

Is the ice storage bin installed correctly? For models with a

standard ice storage bin, push the ice storage bin in all the

way. For models with an ice storage bin on the freezer door,

the bin should sit level. Remove and replace the bin in the

door making sure it is properly aligned and snapped securely

into place. See "ice Maker and Storage Bin."

Has the wrong ice been added to the bin? Use only cubes

produced by the current ice maker. If other cubes have been

added, remove all cubes and check to see that none have

become stuck in the delivery chute.

• Has the ice frozen in the ice storage bin? Shake the ice

storage bin to separate cubes. If cubes do not separate,

empty bin and wait 24 hours for ice to restock.

Has the ice melted around the auger (metal spiral) in the

ice storage bin? Dump the ice cubes and clean the ice

storage bin completely. Allow 24 hours for the ice maker to

restock. Do not try to remove the melted ice with a sharp

object. You could damage the ice storage bin.

• Is ice stuck inthe delivery chute? Clear the ice from the

delivery chute with a plastic utensil. Do not use anything

sharp to remove the ice. You could cause damage.

Ice storage bin difficult to remove

Is the ice storage bin difficult to remove (on some

models)? For models with an ice storage bin located on the

freezer door, select "cubed" ice. Using a sturdy glass, quickly

depress and release the ice dispenser arm. Open the freezer

door, depress the release button on the ice storage bin and

lift upward. See "ice Maker and Storage Bin."

The water dispenser will not operate properly

Has the water system not filled? The water system needs

to be filled the first time it is used. Use a sturdy container to

depress the water dispenser bar until the water begins to

flow. Flush the water system by dispensing and discarding

2 to 3 gal. (8 to 12 L) of water. Cleaning the system will take

approximately 6 to 7 minutes and will help clear air from the

line. Additional flushing may be required in some households.

See "Water and Ice Dispensers."

Is the water shutoff valve not turned on or the water line

connected at the source? Make sure the water shutoff valve

is turned on and the water source is connected to the

refrigerator. See "Water Supply Connection."

• Is the water shutoff valve clogged or incorrectly installed?

See "Water Supply Connection." If clogging or installation is

not a problem, call for service or contact a plumber.

• Is there a kink in the home water source line? If you find or

suspect a kink in the water line, contact a licensed, qualified

plumber.

Is there a water filter installed on the refrigerator?. The

filter may be clogged or incorrectly installed. First, check the

filter installation instructions to ensure that the filter was

installed correctly and is not clogged. If installation or

clogging is not a problem, call for service.

• Is a reverse osmosis water filtration system connected to

your cold water supply? See "Water Supply Requirements."

Water or ice is leaking from the dispenser

Is the glass not being held under the ice dispenser long

enough, causing the ice to spill? Hold the container under

the ice chute for 2 to 3 seconds after releasing the dispenser

lever. Water or ice may continue to dispense during this time.

• Is an ice cube stuck in the chute and holding the trap

door open? Remove the cube.

Is there a water filter installed on the refrigerator?. The

water filtration system may have air in the lines, causing water

to drip. Additional flushing may help clear air from the lines.

Normal dispenser use should flush air from the lines within 24

to 72 hours.

16

Water flow from the dispenser decreases noticeably The doors will not close completely

• Is there a water filter installed on the refrigerator?. •

The filter may be full or incorrectly installed. Remove the

water filter cartridge. See "Water Filtration System." Operate

the dispenser. If the water flow increases noticeably, replace •

the filter.

The dispenser water is not cool enough

• Has the refrigerator been newly installed? Allow 24 hours

for the refrigerator to cool completely.

• Has a large amount of water been recently dispensed?

Allow 24 hours for the water to cool completely.

• Has water not been recently dispensed? The first glass of

water may not be cool. Discard the first glass of water.

The divider between the two compartments is warm

• The warmth is probably due to normal operation of the

automatic exterior moisture control. If still concerned, call for

service.

Temperature is too warm

• Are the air vents blocked in either compartment? This

prevents the movement of cold air from the freezer to the

refrigerator. Remove any objects from in front of the air vents.

See "Ensuring Proper Air Circulation" for the location of air

vents.

• Are the door(s) opened often? The refrigerator will warm

when this occurs. Keep the refrigerator cool by getting all

items out at one time, keeping food organized, and closing

the door as soon as possible.

• Has a large amount of food just been added to the

refrigerator or freezer? Adding a large amount of food

warms the refrigerator. It can take several hours for the

refrigerator to return to the normal temperature.

• Are the controls set correctly for the surrounding

conditions? See "Using the Controls."

• Is the refrigerator not cooling? For models with digital

controls, turn the unit OFF then ON again to reset. See "Using

the Controls." If this does not correct the problem, call for

service.

There is interior moisture buildup

• Are the air vents blocked in the refrigerator? Remove any

objects from infront of the air vents. See "Ensuring Proper Air

Circulation" for the location of air vents.

• Are the doors opened often? Avoid humidity buildup by

getting all items out at one time, keeping food organized, and

closing the door as soon as possible.

• Is the room humid? It is normal for moisture to build up

inside the refrigerator when the room air is humid.

• Is the food packaged correctly? Check that all food is

securely wrapped. Wipe off damp food containers before

placing in the refrigerator.

• Are the controls set correctly for the surrounding

conditions? See "Using the Controls."

• Was a self-defrost cycle completed? It is normal for

droplets to form after the refrigerator self-defrosts.

Are food packages blocking the door open? Rearrange

containers so that they fit more tightly and take up less

space.

Is the ice storage bin out of position? For models with an

interior ice storage bin, push the ice storage bin in all the way.

If the ice storage bin does not go in all the way, it may not be

put in straight. Pull it out and try again. For models with an ice

storage bin located on the freezer door, the bin should sit

level. To remove the bin, press the release button on the right

side of the bin and Uftstraight up. Replace the bin in the door

making sure it is properly aUgned and snapped securely into

place. See "Ice Maker and Storage Bin."

Are the pans, shelves, bins, or baskets out of position?

Put the crisper cover and all pans, shelves, bins, and baskets

back into their correct positions. See the "Convertible

Vegetable/Meat Drawer, Crisper and Covers" section for

more information.

Are the gaskets sticking? Clean gaskets according to the

directions in the "Cleaning" section.

Does the refrigerator wobble or seem unstable? Level the

refrigerator. See "Door Closing."

Were the doors removed during product installation and

not properly replaced? Remove and replace the doors

according to the instructions in the "Door Removal" section,

or call a qualified service technician.

The doors are difficult to open

• Are the gaskets dirty or sticky? Clean gaskets according to _

the directions in the "Cleaning" section. _

PROTECTION

AGREEMENTS

Master Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore®appliance is designed and manufactured for years of

dependable operation. But like all products, it may require

preventive maintenance or repair from time to time. That's when

having a Master Protection Agreement can save you money and

aggravation.

Purchase a Master Protection Agreement now and protect

yourseff from unexpected hassle and expense.

The Master Protection Agreement also helps extend the life of

your new appliance. Here's what's included in the Agreement:

V Expert service by our 12,000 professional repair specialists

V Unlimited service and no charge for parts and labor on all

covered repairs

V "No-lemon" guarantee - replacement of your covered

product if four or more product failures occur within twelve

months

V Product replacement if your covered product can't be fixed

J3_

17

v" Annual Preventive Maintenance Check at your request - no

extra charge

v" Fast help by phone - phone support from a Sears technician

on products requiring in-home repair, plus convenient repair

scheduling

v" Power surge protection against electrical damage due to

power fluctuations

v" Rental reimbursement if repair of your covered product takes

longer than promised

Once you purchase the Agreement, a simple phone call is all that

it takes for you to schedule service. You can call anytime day or

night, or schedule a service appointment online.

Sears has over 12,000 professional repair specialists, who have

access to over 4.5 million quality parts and accessories. That's

the kind of professionalism you can count on to help prolong the

life of your new purchase for years to come. Purchase your

Master Protection Agreement today!

Some limitations and exclusions apply. For prices and

information, call 1-800-827-6655.

Sears Installation Service

For Sears professional installation of home appliances, garage

door openers, water heaters, and other major home items, in the

U.S.A. call 1-800-4-MY-HOME ®.

Replacement Parts

To order stainless steel cleaner or replacement filters, call

f-8OO-4-MY-HOME ®and ask for the appropriate part number

listed below or contact your authorized Kenmore dealer.

Stainless Steel Cleaner & Polish:

Order Part #D22 M40083 R

Base grille water filter cartridges:

NOTE: Do not use with water that is microbiologically unsafe

or of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction may

be used on disinfected waters that may contain filterable

cysts.

Cyst Cartridge:

Order Part #9908 (WF-NLC240V and WF-LC400V)

Maintenance Agreements

Your purchase has added value because you can depend on

Sears HomeCentral ® for service. With over 2,400 Service

Technicians and access to over 900,000 parts and accessories,

we have the tools, parts, knowledge and skills to back our

pledge: We Service What We Sell.

Your Kenmore ® appliance is designed, manufactured and tested

to provide years of dependable operation. Yet any major

appliance may require service from time to time. The Sears

Maintenance Agreement offers you an outstanding service

program, affordably priced.

The Sears Maintenance Agreement

• Guarantees tomorrow's service at today's price.

• Eliminates repair bills resulting from normal wear and tear.

• Covers non-technical and instructional service calls.

• Provides an annual Preventive Maintenance Check, at your

request, to ensure that your appliance is in proper running

condition.

Some limitations apply. For information concerning Sears

HomeCentral ®Maintenance Agreements, call

1-800-361-6665.

WATER FILTER

CERTIFICATIONS

St_e _ Cslifom_

De_1_em at Healt5 _rvices

Water Treatment Device

_ficate Number

03- 1558

I_t= I_J_ M=_dh3, 20_

2,4-D

18

Do ut use wher_ wal_ it m_rob_tes_r uJsfe or witk watt" of lmlmowa qlutllW, exempt _ | _

gertdfled for cyst re_tcl_u may be used e_adhdn_cted wa/ers 6_t/may gQnt_ht m/_rable gyl;_

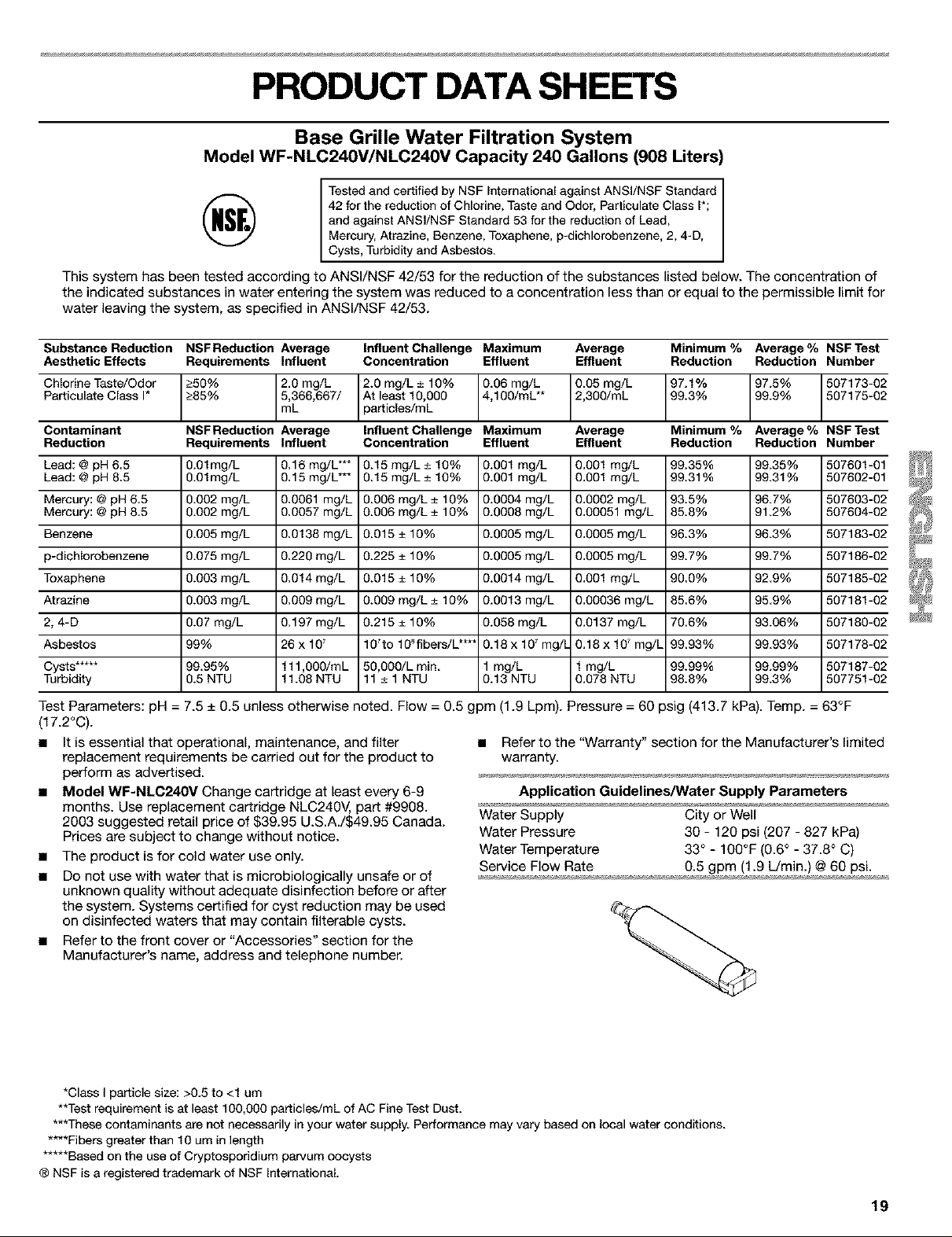

PRODUCT DATA SHEETS

Base Grille Water Filtration System

Model WF-NLC240V/NLC240V Capacity 240 Gallons (908 Liters)

Tested and certified by NSF International against ANSI/NSF Standard

42 for the reduction of Chlorine, Taste and Odor, Particulate Class I*;

and against ANSI/NSF Standard 53 for the reduction of Lead,

Mercury, Atrazine, Benzene, Toxaphene, p-dichlorobenzene, 2, 4-D,

Cysts, Turbidity and Asbestos.

This system has been tested according to ANSI/NSF 42/53 for the reduction of the substances listed below. The concentration of

the indicated substances in water entering the system was reduced to a concentration less than or equal to the permissible limit for

water leaving the system, as specified in ANSI/NSF 42/53.

Substance Reduction NSF Reduction Average Influent Challenge Maximum Average Minimum % Average % NSF Test