Page 1

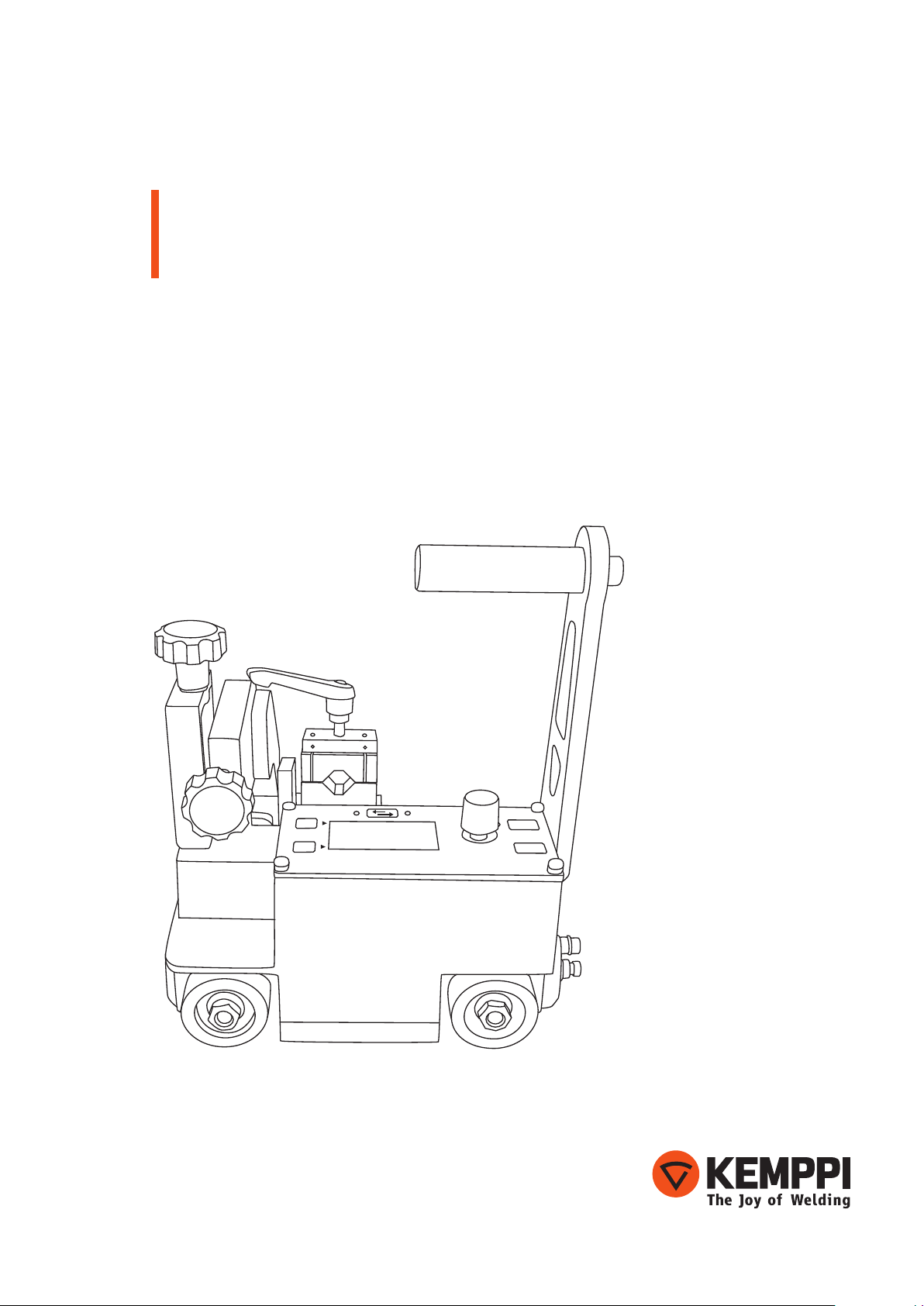

MagTrac

F 61

Operating manual

Käyttöohje

Bruksanvisning

Bruksanvisning

Brugsanvisning

Gebrauchsanweisung

Gebruiksaanwijzing

Manuel d’utilisation

Manual de instrucciones

Instrukcja obsługi

Инструкции по эксплуатации

EN

FI

SV

NO

DA

DE

NL

FR

ES

PL

RU

Manual de utilização

Manuale d’uso

PT

IT

Page 2

Page 3

OPERATING MANUAL

English

EN

Page 4

EN

CONTENTS

1. Introduction ....................................................................................................... 3

1.1 General ....................................................................................................................................... 3

1.2 About the product ................................................................................................................. 3

1.3 Operation safety ..................................................................................................................... 3

1.4 Compatibility ........................................................................................................................... 3

1.5 Product parts ............................................................................................................................ 4

2. Preparing the carriage for use .....................................................................4

2.1 Welding machine connections ......................................................................................... 4

2.2 MagTrac F 61 connections .................................................................................................. 5

2.3 Working environment ......................................................................................................... 7

3. Using the control panel ................................................................................. 9

3.1 Control panel buttons .......................................................................................................... 9

3.2 Starting up the control panel ........................................................................................... 9

3.3 Control panel menus...........................................................................................................10

3.3.1 MagTrac F 61 main menu ..............................................................................................10

3.3.2 Memory channel selections (MEMORY CH) .................................................................11

3.3.3 Travel speed selections ( ) ......................................................................................11

3.3.4 Wire feed speed selections ( ) ................................................................................11

3.3.5 Welding current selections (CURRENT) .......................................................................11

3.3.6 Welding voltage selections (VOLTAGE) .......................................................................12

3.3.7 Welding arc selections (ARC ON) .................................................................................12

3.3.8 Cycle weld selections ( CYCLE WELD) ....................................................................12

3.3.9 Gas test selections ( GAS TEST) ...............................................................................12

3.3.10 Wire inch selections (WIRE INCH) .................................................................................12

3.3.11 Weld data selections (WELD DATA) ..............................................................................13

3.3.12 Setup selections (SETTINGS) .........................................................................................13

4. Disposal of the machine ..............................................................................14

5. Ordering codes ............................................................................................... 14

6. Technical data ................................................................................................. 16

2

MagTrac F 61

Page 5

1. INTRODUCTION

1.1 General

Congratulations on choosing the MagTrac F 61 equipment. Used correctly, Kemppi products

can signicantly increase the productivity of your welding, and provide years of economical

service.

This operating manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the equipment can be found at the end

of the manual.

Please read the operating manual and the safety instructions booklet carefully before using

the equipment for the rst time. For your own safety and that of your working environment,

pay particular attention to the safety instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi web site at www.kemppi.com.

For Kemppi’s standard safety instructions and warranty terms and conditions, please visit our

web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

Important notes

Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with the ’NOTE!’ notation. Read these sections carefully and follow

their instructions.

EN

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

1.2 About the product

MagTrac F 61 is a welding carriage for mechanisation of longitudinal MIG/MAG welding

applications. Used in combination with the high quality process control system of Kemppi

FastMig welding equipment, the MagTrac F 61 is an easy and ecient way of improving the

welding productivity and quality.

The MagTrac F 61 is equipped with Kemppi's unique welding gun quick-xing mechanism

(patent pending), which makes it quick and easy to set up and adjust the carriage.

1.3 Operation safety

When using the carriage in applications where weakened magnetic force may pose a threat of

the carriage falling down, make sure that such possible accident can not cause any hazard to

people or equipment.

Read also the safety guide delivered in the MagTrac F 61 product package.

NOTE! Welding heat can little by little weaken the carriage's magnetic force.

1.4 Compatibility

MagTrac F 61 is compatible with the following welding equipment

• FastMig KMS 300 and 400 power sources

• FastMig Pulse 350 and 450 power sources

• MXF 65 wire feed unit

• Control panels SF 52W and SF 53W.

© Kemppi Oy / 1131

3

Page 6

1.5 Product parts

Front view Side view

5.

1. 2.

7.

4.

3.

EN

8.9.

1. Control panel

2. Control knob for scrolling and selecting values

3. Welding gun xing mechanism

4. Approximate adjustment handles

5. Fine adjustment screws

6. Hex screws for adjusting the guide roller arms

7. Handle for lifting the device and disabling the magnet.

8. Limit switch detects the end of the weld and stops the carriage automatically

9. Wheels

2. PREPARING THE CARRIAGE FOR USE

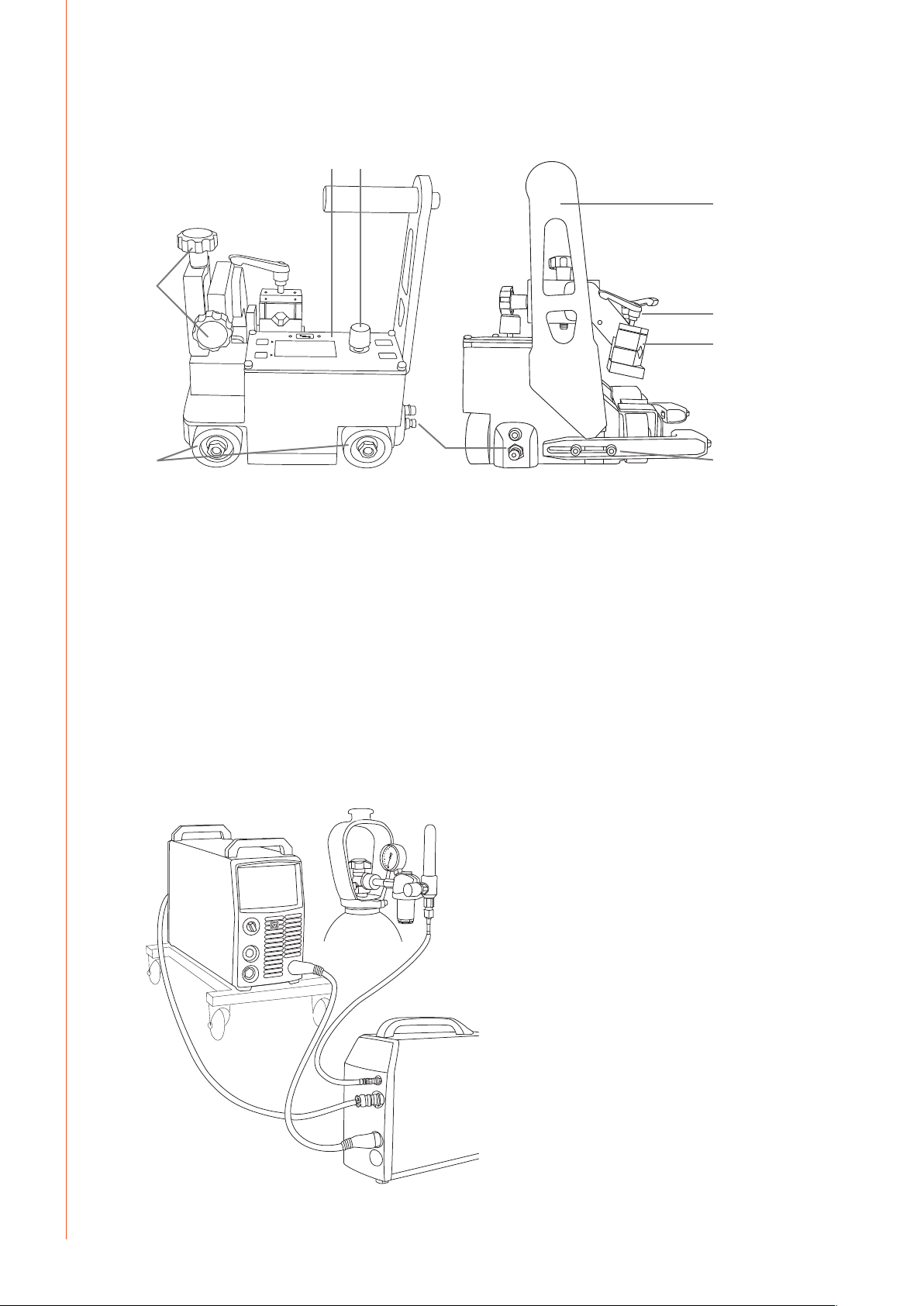

2.1 Welding machine connections

To use the MagTrac F 61, you need a FastMig power source, wire feeder, and a shielding gas

cylinder or other source of shielding gas appropriate for your welding task.

6.

4

MagTrac F 61

Page 7

Connect the wire feeder to power source as follows:

1. Connect the welding cable between the plus pole of the power source and the cable

connector on the backside of the wire feeder.

2. Connect the control cable between the power source and the wire feeder (the

connectors are on the backside of the machines).

3. Connect the shielding gas hose between the gas cylinder and the wire feeder (the

connector is on the backside of the wire feeder).

2.2 MagTrac F 61 connections

Attach the welding power cable to the Euro connector and the control cable to the data

connector either in the wire feeder unit or in Kemppi SuperSnake subfeeder. See the pictures

below.

EN

To connect the welding gun to MagTrac device:

The MagTrac F 61 is equipped with Kemppi's unique welding gun quick-xing mechanism.

1. Loosen the slide block xing screw (1) and open it a few rounds so that the slide block (2)

comes out.

2. Put the welding gun into the slot and replace the slide block.

3. Tighten the gun into its place using the xing screw.

4. Attach the control cable to the bus connector on the carriage.

1.

2.

© Kemppi Oy / 1131

5

Page 8

EN

Adjust the position of the carriage against the wall:

1. If necessary, change the position of the welding gun mechanism on the carriage by

opening the two hex screws (see the picture).

2. Adjust the position of the carriage so that it slightly pushes against the wall when

moving. To accomplish this, set the guide roller arms so that the front arm is a little

shorter than the back arm.

2.

Adjust the welding gun position:

1. Loosen the orange handles (1 and 2) and make approximate adjustment of the welding

gun position.

NOTE! You can use the adjustment handle like a ratchet wrench by lifting the handle and

turning it to a better position.

2. To ne adjust the gun position, change the distance and height of the welding gun with

the adjustment knobs (see the picture).

NOTE! You can use the ne adjustment knobs also when the carriage is moving.

1.

6

MagTrac F 61

Page 9

2.3 Working environment

Kemppi MagTrac F 61 welding carriage is equipped with a strong magnet that keeps it steadily

in it's track also if you drive the device uphill or downhill.

EN

max. 60°

You can also use the MagTrac F 61 on curved surfaces.

ø > 3000 mmø > 2000 mm

© Kemppi Oy / 1131

7

Page 10

EN

Wide range of adjustments

MagTrac F 61 oers a wide range of adjustments. For example, you can turn the guide roller

arms 180° to point outwards if you need to improve visibility to the welding arc, or you can

swing the welding gun over the side (see the picture).

NOTE! The limit switch might not work if you change the position of the roller arms or welding gun

mechanism. This may prevent the carriage from stopping automatically in the end of the weld.

Activating and releasing magnet

When you lift the handle to its up position in order to move the device, the magnet is

automatically inactivated.

When you place the device to its welding position, you just push the handle down, and the

magnet is automatically activated.

Magnet activated Magnet inactivated

8

MagTrac F 61

Page 11

3. USING THE CONTROL PANEL

MagTrac F 61 control panel allows you to view and adjust the welding parameter values.

You can use the values stored in the memory channels of the wire feeder, or you can set the

desired values on the welding carriage without using the memory channels.

If the memory channel function is active, you can see the channel number on the top row of

the carriage control panel display. The MagTrac F 61 communicates with the wire feeder via a

control cable integrated in the welding gun cable.

3.1 Control panel buttons

1.4.

3.

2.

BACK

HEAT: 0.00 kJ/mm

RESET WELD DATA

RESET

WELD DATA

ARC

ON

START

STOP

6.

5.

MagTrac F 61

1. Multi-function knob for browsing and selecting values

• Turn to scroll menus, press to select values

2. Lower soft key for entering menus and executing commands

• Press to select the active menu item

3. Upper soft key for exiting menus and approving selections

• Press to approve the selected value and to return to the previous menu level

4. Direction button

• Press briey to change the carriage travel direction

• Push for at least 3 seconds to reverse the direction of the display

(this helps the menu usage when MagTrac runs along vertical surface)

5. Start and stop button

• Press this button to start or stop the welding operation

6. Welding arc on/o button

• Press this button to turn the welding arc on and o. With the welding arc o, you can

test the carriage operation

NOTE! When making selections in the MagTrac F 61 menu, you can use a quick shortcut: Turn and

press the multi-function knob 1 instead of pressing soft keys 2 and 3.

EN

3.2 Starting up the control panel

When you start the welding system from the power source's main switch, the system turns on

and the MagTrac F 61 welding carriage is ready for use.

You can inactivate the system with a long press of the wire feeder's ON/OFF button. When the

system is inactive, the carriage cannot be used for welding.

PANEL OFF

Press wire feeder

on/off button

© Kemppi Oy / 1131

MEMORY CH

300 mm/min

5.0 m/min

SET

CH OFF

9

Page 12

EN

ARC

ON

START

STOP

MagTrac F 61

3.3 Control panel menus

CH OFF

MEMORY CH

300 mm/min

5.0 m/min

SET

To browse menu items, turn the multi-function knob 1.

To select the highlighted menu item, press the multi-function knob 1.

• The selected active menu items are marked with a solid box.

• The Selected inactive menu items are marked with a dotted box. You cannot changed

the values of these menu items.

3.3.1 MagTrac F 61 main menu

Menu item Description

MEMORY CH Load and save memory channels.

300 mm/min

5.0 m/min

CURRENT: Change the welding current.

VOLTAGE: Change the welding voltage.

FINETUNING: Fine tune the welding values.

BASECURRENT: Set the base current value.

ARC ON: Enable or disable the welding arc. When this function is OFF, you can test the carriage operation

CYCLE WELD

GAS TEST

WIRE INCH Drive the ller wire into the gun.

WELD DATA Check the weld data recorded from the last welding session.

SETTINGS Open MagTrac F 61 settings menu.

Change the carriage travel speed.

The selected speed is shown in the menu name.

Change the wire feed speed.

The selected speed is shown in the menu name.

The selected current is shown in the menu name.

The selected voltage is shown in the menu name.

(Available only when using pulsed or double-pulsed welding process.)

(Available only when using WiseRoot or WiseThin welding process.)

without igniting the welding arc. (Note that this function is the same as pressing the ARC ON

button.)

Open the cycle weld submenu, where you can enable or disable the cycle weld function and set

its parameters.

Run the gas test.

10

MagTrac F 61

Page 13

3.3.2 Memory channel selections (MEMORY CH)

Menu item Values Description

CH MODE * ON, OFF, SET Select the memory channel usage mode.

ON = Memory channels are enabled, and you can select the

channel to be used. Parameters can be edited on the carriage

panel

OFF = Memory channels are disabled. You can set the welding

parameters on the carriage panel, but they are not stored in the

memory.

SET = Memory channel contents can be edited and saved. You

can change the welding parameters and save your changes into

the active memory channel.

LOAD CH 0…9 Select memory channel to load. Enabled only when CH MODE

selection is ON.

SAVE CH * 0…9 Select memory channel to save. Enabled only when CH MODE

selection is SET.

*) These menu items are not available with FastMig Pulse. CH MODE setting is always ON, and

the channel parameter values are saved automatically.

To change the memory channel in use, do the following

1. In MEMORY CH menu, select CH MODE: ON.

2. In MEMORY CH menu, select LOAD CH and press the multi-function knob.

3. Turn the multi-function knob to select the memory channel number you want to use.

(You can scroll numbers also with the lower soft key 'CH'.)

4. When the desired channel number is displayed, press the upper soft key 'BACK'.

NOTE! If the welding parameter values come from a memory channel, you cannot change any of

the values at the MagTrac menu while operating the carriage.

EN

3.3.3 Travel speed selections ( )

Select this menu item to change the carriage travel speed in the range of 150 - 1500 mm/min.

In cycle welding, the carriage travels non-welded sections at the maximum speed of 1800

mm/min.

NOTE! When the speed reaches 1000 mm/min, the unit of measure changes automatically to

m/min.

To change carriage travel speed, do the following

1. Press the multi-function knob on the travel speed menu item.

2. Turn the multi-function knob to change the speed.

3. Press the multi-function knob to accept the new speed.

3.3.4 Wire feed speed selections ( )

Select this menu item to change the wire feed speed. Note that the welding current value

changes automatically to reect the new wire feed speed.

To change wire feed speed, do the following

1. Press the multi-function knob on the wire feed speed menu item.

2. Turn the multi-function knob to change the speed.

3. Press the multi-function knob to accept the new speed.

3.3.5 Welding current selections (CURRENT)

Select this menu item to change the welding current. Note that the wire feed speed value

changes automatically to reect the new welding current.

To change welding current, do the following

1. Press the multi-function knob on the CURRENT menu item.

2. Turn the multi-function knob to change the current value.

3. Press the multi-function knob to accept the new current.

© Kemppi Oy / 1131

11

Page 14

EN

3.3.6 Welding voltage selections (VOLTAGE)

Select this menu item to change the welding voltage.

To change welding voltage, do the following

1. Press the multi-function knob on the VOLTAGE menu item.

2. Turn the multi-function knob to change the voltage value.

3. Press the multi-function knob to accept the new voltage.

NOTE! Voltage selection may be replaced by either FINETUNING (in pulsed or double-pulsed

processes) or BASECURRENT (in WiseRoot or WiseThin processes) setting.

3.3.7 Welding arc selections (ARC ON)

You can use this menu item to test MagTrac F 61 operation before starting the actual welding.

When the welding arc is OFF, the carriage performs the operations without igniting the

welding arc.

To turn the welding arc on or o, do the following

1. Press the multi-function knob on the ARC ON menu item.

2. Turn the multi-function knob to select ON or OFF.

3. Press the multi-function knob to accept the value.

NOTE! You can also use the ARC ON button turn the welding arc on and o.

3.3.8 Cycle weld selections ( CYCLE WELD)

With MagTrac F 61 you can use the cycle welding function, which means that the carriage

repeatedly welds a predened length and then skips another predened length.

In CYCLE WELD menu you can dene the settings used in cycle welding.

Menu item Values Description

ON, OFF Turn cycle welding on or o.

10mm…10.00m Set the length of each weld.

CYCLE COUNT CONT, 1…255 Set the number of cycles to be welded

When cycle welding is on, there is a cycle weld symbol ( ) in the top right corner of the

MagTrac F 61 control panel display.

NOTE! Crater ll feature is available in wire feeder control panel.

10mm…2.00m Set the length of the non-weld section between the welds.

3.3.9 Gas test selections ( GAS TEST)

Select this menu item to test the gas ow. First select the menu item, and then start the gas

ow by pressing the multi-function knob or the soft key START. The shielding gas ows for 10

seconds.

NOTE! You can interrupt the gas ow at any time by clicking the multi-function knob or the soft key

STOP.

3.3.10 Wire inch selections (WIRE INCH)

Select this menu item to run the ller wire into the welding gun. In MagTrac F 61, the wire inch

speed is always the same as the selected wire feed speed.

NOTE! If the wire inch function is activated on the wire feeder's panel, the wire inch function on

MagTrac is not available.

– CONT means that the carriage continues cycle welding

continuously, until it is stopped.

12

MagTrac F 61

Page 15

3.3.11 Weld data selections (WELD DATA)

MagTrac F 61 records useful information about the latest welding session. Select Weld data

menu to check the data.

Menu item Description

Length of the latest weld.

TOT ARC (m) Total welded length of the latest welding session.

Does not include the non-weld length in cycle welding.

TOT ARC (min, s) Total time of the latest welding session.

Does not include the non-weld time in cycle welding.

CURRENT Average welding current during the latest welding session.

VOLTAGE Average welding voltage during the latest welding session.

HEAT Heat input in the latest welding session in kJ/mm.

RESET WELD DATA This resets all weld data settings.

3.3.12 Setup selections (SETTINGS)

Select this menu to check or change the MagTrac F 61 settings. The settings are stored in the

carriage memory.

Menu item Values Description

CONTRAST

RESTORE SETTINGS YES, NO Restore the parameter values to their initial settings.

PANEL INFO PANEL SW

SYSTEM SW

PRG DATE

EN

Change the contrast of the carriage display.

Open information about the carriage software: Control panel

version, system version and the date of the carriage software.

Initial parameter settings

When you use the RESTORE SETTINGS function, the parameter settings are restored to the

following values:

Parameter Factory value

ARC ON OFF (welding arc is o)

DIRECTION RIGHT (carriage travels to the right)

CONTRAST 20 (contrast of the control panel display)

CYCLE WELD OFF (cycle welding is not in use)

WELD LENGTH 50 mm (length of the welded section in cycle welding).

IDLE LENGTH 50 mm (length of the non-welded section in cycle welding).

CYCLE COUNT CONT (cycle welding continues until it is stopped )

LAST WELD LENGTH 0 mm

TOT ARC 0 mm (total arc length in the latest welding session)

TOT ARC 0 min 0 s (total arc time in the latest welding session)

CURRENT 0 A (average current in the latest welding session)

VOLTAGE 0 V (average voltage in the latest welding session)

HEAT 0.0 kJ/mm (heat input in the latest welding session)

© Kemppi Oy / 1131

13

Page 16

EN

4. DISPOSAL OF THE MACHINE

Do not dispose of electrical equipment with normal waste!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment, and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and taken to an appropriate

environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, per the instructions of local authorities or a Kemppi representative. By

applying this European Directive you will improve the environment and human health.

5. ORDERING CODES

MagTrac F61, FastMig KMS, air-cooled P08818

FastMig KMS 400 power source 6054000

FastMig MXF 65 wire feeder 6152100

FastMig SF 53W control panel 6085300W

PM 500 undercarriage 6185291

MMT 42 C welding gun 3 m 6254205

KWF 70-5-GH interconnection cable 6260405

Earth return cable 50 mm², 5 m 6184511

MagTrac F61 welding carriage 6190610

MagTrac F61, FastMig KMS, SuperSnake, air-cooled P08819

FastMig KMS 400 power source 6054000

FastMig MXF 65 wire feeder 6152100

FastMig SF 53W control panel 6085300W

PM 500 undercarriage 6185291

MMT 42 C welding gun 3 m 6254205

MXF SYNC mounting kit W004030

SuperSnake GT 02SC 15 m 61531501

KWF 70-1.8-GH interconnection cable 6260401

Earth return cable 50 mm², 5 m 6184511

MagTrac F61 welding carriage 6190610

MagTrac F61, FastMig Pulse, air-cooled P08822

FastMig Pulse 450 power source 6150500

FastMig MXF 65 wire feeder 6152100

FastMig Pulse PF 65 control panel 6155100

PM 500 undercarriage 6185291

MMT 42 C welding gun 3 m 6254205

KWF 70-5-GH interconnection cable 6260405

Earth return cable 50 mm², 5 m 6184511

MagTrac F61 welding carriage 6190610

14

MagTrac F 61

Page 17

MagTrac F61, FastMig Pulse, SuperSnake, air-cooled P08828

FastMig Pulse 450 power source 6150500

FastMig MXF 65 wire feeder 6152100

FastMig Pulse PF 65 control panel 6155100

PM 500 undercarriage 6185291

MMT 42 C welding gun 3 m 6254205

MXF SYNC mounting kit W004030

SuperSnake GT 02SC 15 m 61531501

KWF 70-1.8-GH interconnection cable 6260401

Earth return cable 50 mm², 5 m 6184511

MagTrac F61 welding carriage 6190610

MagTrac F61, FastMig KMS, liquid-cooled P08826

FastMig KMS 400 power source 6054000

FastMig MXF 65 6152100

FastMig SF 53W 6085300W

FastCool 10 6068100

PM 500 undercarriage 6185291

MT51MWC welding gun 4,5 m 6255162

KWF 70-5-WH interconnection cable 6260410

Earth return cable 50 mm², 5 m 6184511

MagTrac F61 welding carriage 6190610

EN

MagTrac F61, FastMig Pulse, liquid-cooled P08827

FastMig Pulse 450 power source 6150500

FastMig MXF 65 wire feeder 6152100

FastMig Pulse PF 65 control panel 6155100

FastCool 10 cooling unit 6068100

PM 500 undercarriage 6185291

MT51MWC welding gun 4.5 m 6255162

KWF 70-5-WH interconnection cable 6260410

Earth return cable 50 mm², 5 m 6184511

MagTrac F61 welding carriage 6190610

Optional:

SuperSnake GT 02SC 15 m 61531501

FastMig KMS 300 power source 6053000

FastMig MXF 63 wire feeder 6152300

MMT 42 C welding gun 4.5 m 6254207

Control extension cable 6 m W005871

MT51MWC welding gun 4,5 m 6255162

© Kemppi Oy / 1131

15

Page 18

EN

6. TECHNICAL DATA

MagTrac F 61

Input power

Data bus type

Travel speed

Towing power

Driving method

Wheels

Tracing method

Guide roller height range

Non-welding distance

Auto-stop function

Welding gun

Gun angle adjustment range

Gun distance adjustment range

External dimensions

Weight

Max surface temperature

EMC class

Degree of protection

Operating temperature range

Storage temperature range

Standards IEC 60204-1 and partially IEC 60974-1

50 VDC / 1 A

KempBus

150–1800 mm/min

30 kg

Rail-less drive with permanent

magnetic suction

4 rubber wheels

Guide rollers

10–38 mm, 3 positions

Start 127 mm

End 127 mm

Limit switch on both sides

Kemppi MMT 42C

+/–30°

vertical, horizontal 45 mm

L x W x H 259 x 259 x 285 mm

6.9 kg

150 °C

A

IP2X

–20…+40 °C

–40…+60 °C

16

MagTrac F 61

Page 19

Page 20

KEMPPI OY

Kempinkatu 1

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

UNITED KINGDOM

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GmbH

Otto-Hahn-Straße 14

D-35510 BUTZBACH

DEUTSCHLAND

Tel +49 6033 88 020

Telefax +49 6033 72 528

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD.

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY,

LIMITED

Room 420, 3 Zone, Building B,

No.12 Hongda North Street,

Beijing Economic Development Zone,

100176 Beijing

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区宏达北路12号

创新大厦B座三区420室 (100176)

电话: +86-10-6787 6064

+86-10-6787 1282

传真: +86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

Kazura Garden,

Neelankarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

1920200

1131

www.kemppi.com

Loading...

Loading...