Page 1

Service manual

v. 1.0

FastMig

KM 300

KM 400

KM 500

KMS 300

KMS 400

KMS 500

MF 29

MF 33

MSF 53

MSF 55

MSF 57

1

Page 2

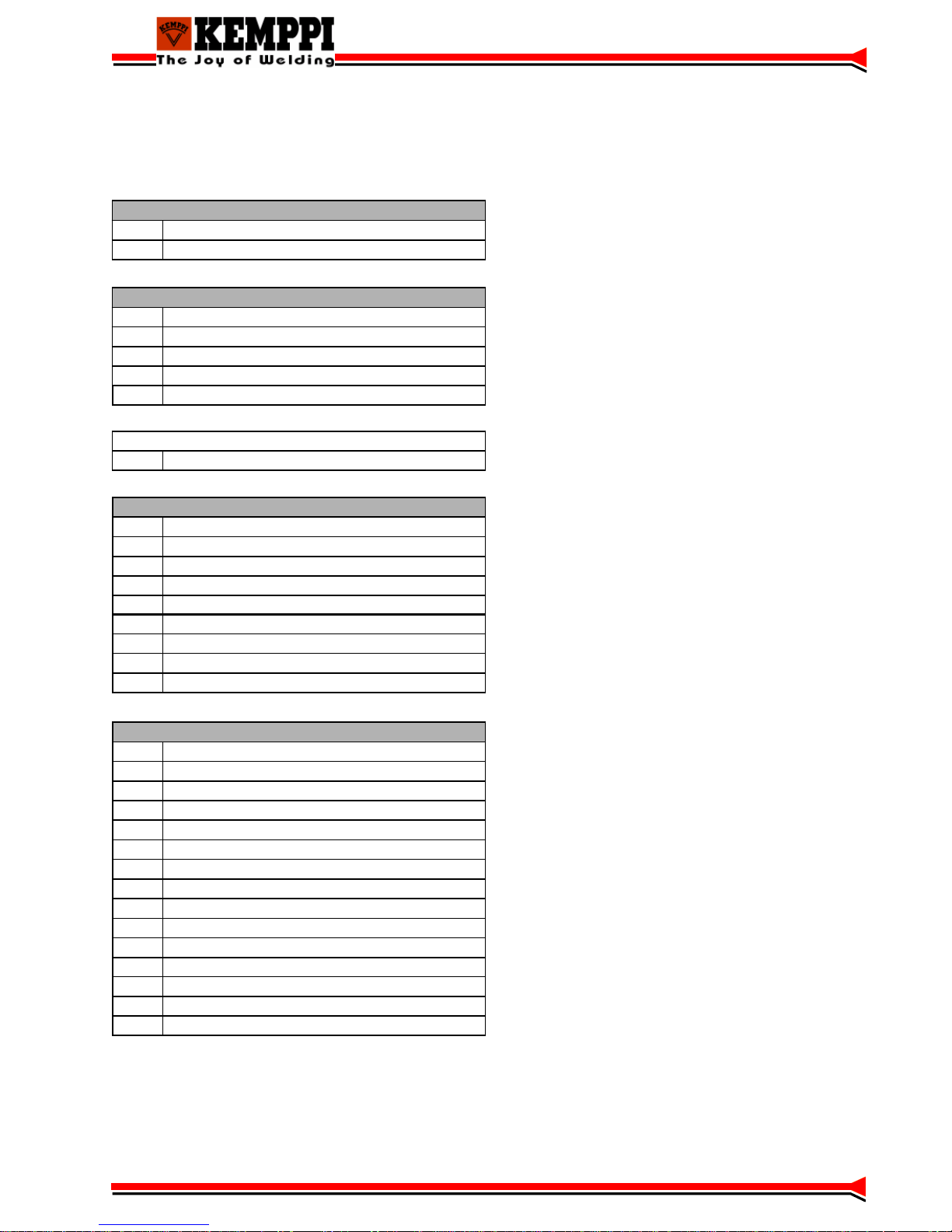

Table of contents

Technical data

Fastmig KM / MF............................................................................. 3

FastMig KMS / MFS........................................................................ 4

Fastmig KMS / MVU........................................................................ 5

Main circuit diagram

KM.................................................................................................... 6-7

MF.................................................................................................... 8

KMS................................................................................................. 9

MSF.................................................................................................10

KM / MVU........................................................................................11

KMS / MVU..................................................................................... 12

Block diagram.................................................................................................... 13

Main circuit card Z001 KM / KMS

Operatingdiagram...........................................................................14

Operationprinciple.......................................................................... 15

Connectors...................................................................................... 16

Operationalmeasurings.................................................................. 17

Capacitor card Z002

Operatingdiagram.......................................................................... 18

Connectors..................................................................................... 18

Secondary rectifier card Z003

Operatingdiagram.......................................................................... 19

Connectors..................................................................................... 19

Operationalmeasurings................................................................. 19

Control card A001

Operatingdiagram.......................................................................... 20

Connectors..................................................................................... 21-22

Operation of the LEDson control card........................................... 22

Motor control card A002

Operatingdiagram.......................................................................... 23

Connectors..................................................................................... 24

ID-chipcardA002 (MSF)

Connectors..................................................................................... 25

Panel card P001

Operatingdiagram.......................................................................... 26

Connectors..................................................................................... 26

Error codes............................... ......................................................................... 27

Setup menu....................................................................................................... 28

Wire feed speed calibration / KM.................................................................... 29-30

Structure

KM / KMS....................................................................................... 31-32

MF.................................................................................................. 33

MFS................................................................................................ 34

IGBT testing....................................................................................................... 35

IGBT replacing...... ............................................................................................. 36

2

Page 3

Technical data

FastMig KM / MF

3

Page 4

Technical data

FastMig KMS / MSF

4

Page 5

Technical data

FastMig KMS / MVU

5

Page 6

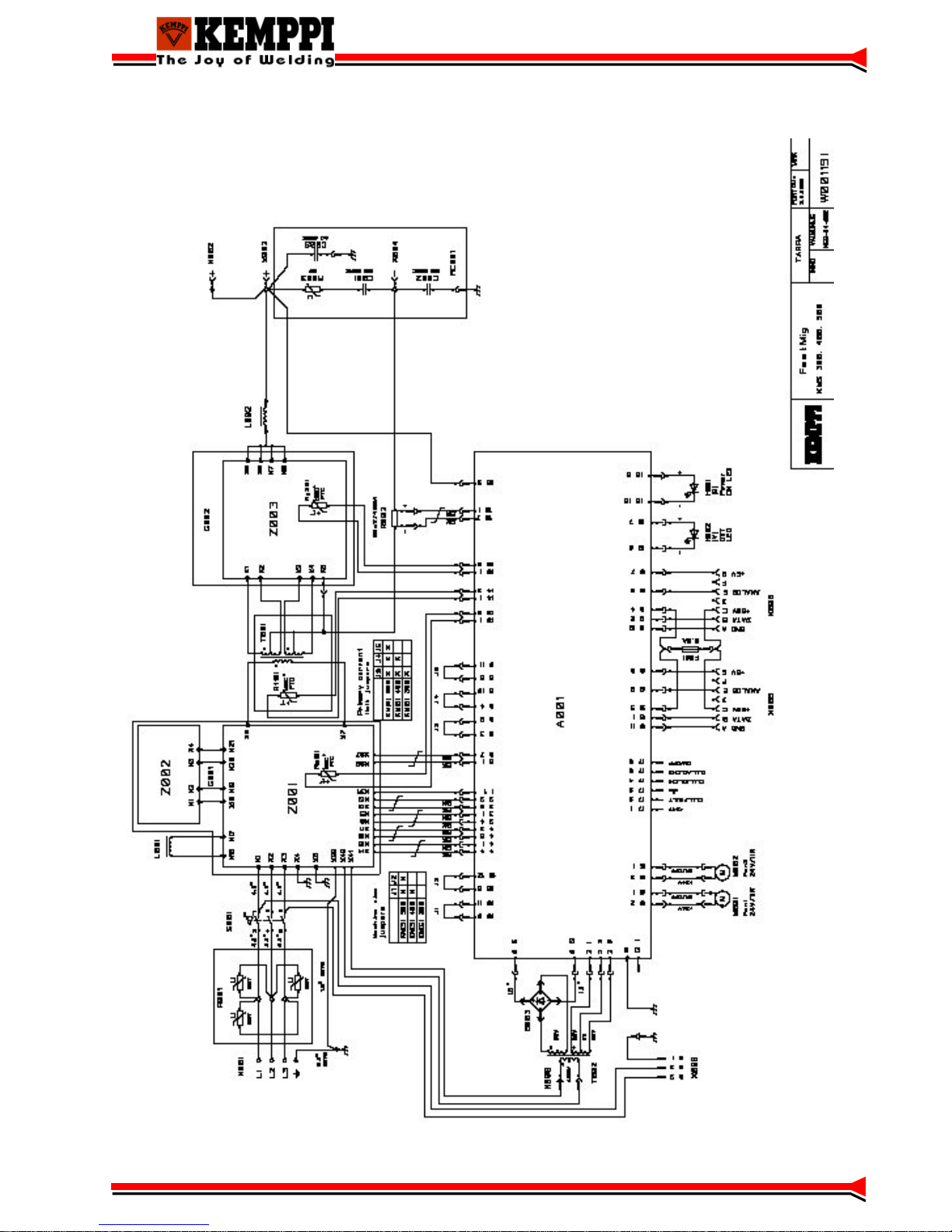

Main circuit diagram

R001

Varistors

L001

Choke

S001

Main switch

Z002

Capasitor card

Z001

Main circuit

card

PTC

T001

Main transformer

PTC

PTC

Z003

Secondary card

L001

Secondary choke

RC001

RC-protection

G003

Diode bridge

T002

Aux. transformer

KM-power sources (A002) also contain circuitry that is needed for wire feeding motor driving and reading of the

potentiometer of the simple wire feeder (MF or other).

M001

Cooling fan

A001

Control card

F001

Fuse 6,3 A

H001 / 002

Leds

A002

Control card

P001

Panel card

6

Page 7

Main circuit diagram KM

7

Page 8

Main circuit diagram MF

8

Page 9

Main circuit diagram KMS

9

Page 10

Main circuit diagram MSF

10

Page 11

Main circuit diagram KM / MVU

11

Page 12

Main circuit diagram KMS / MVU

12

Page 13

Block diagram

Control card A001

•Microcontroller

•PWM circuit

•Secondary voltage measurement

•Secondary current measurement

•IGBT driver

•Auxiliary device connection

•Auxiliary power supply

•Machine size jumpers

•Primary current limit jumpers(J3, J4, J5)

•Operational jumpers

•LED’s

•Water cooler connection

(J1, J2)

Control card A002

•WF-motor control

•Connection to the panel card P001

•Remote controller connection

•MIG gun connection

•Solenoid valve connection

•Fuse

Main circuit card Z001

•EMI filtering

•Three phase rectifier (V6)

•Switching-ON transient suppression

•Power Stage

•Current transformer (T1)

Capasitor card Z002

•Energy storage

•Discharging

Panel card P001

•Main micro controller

•User interface (buttons,

potentiometers, displays, LED’s)

•Connection to the A002

Secondary card Z003

•Rectifying

•Snubber

•Protection against HF

13

Page 14

Main circuit card Z001 KM / KMS

DC-link (+)

From main

switch

IGBT gates

Main transformer

primary coil

Operating diagram

DC-link (-)

- EMI filtering

- Three phase rectifier (V6)

- Switching-ON transient suppression

- Power Stage

- Current transformer (T1)

14

Page 15

Main circuit card Z001

Operation principle

Approx.. + 570 V

G1

U

G3

U

U

U

U

G1

G3

G1

G2

G3

G2

U

G4

U

G2

G4

G5

L1

U

T1

U

G5

U

L1

t

t

t

U

G4

t

U

T1

t

U

G5

t

U

L1

t

When IGBT-transistors G1 and G4 conduct, there is a positive voltage U

and when IGBT-transistors G2 and G3 conduct there is a negative voltage

Power is adjusted by changing the IGBT timings (PWM)

T1

in main transformer T1 primary

U

in main transformer primary.

T1

15

Page 16

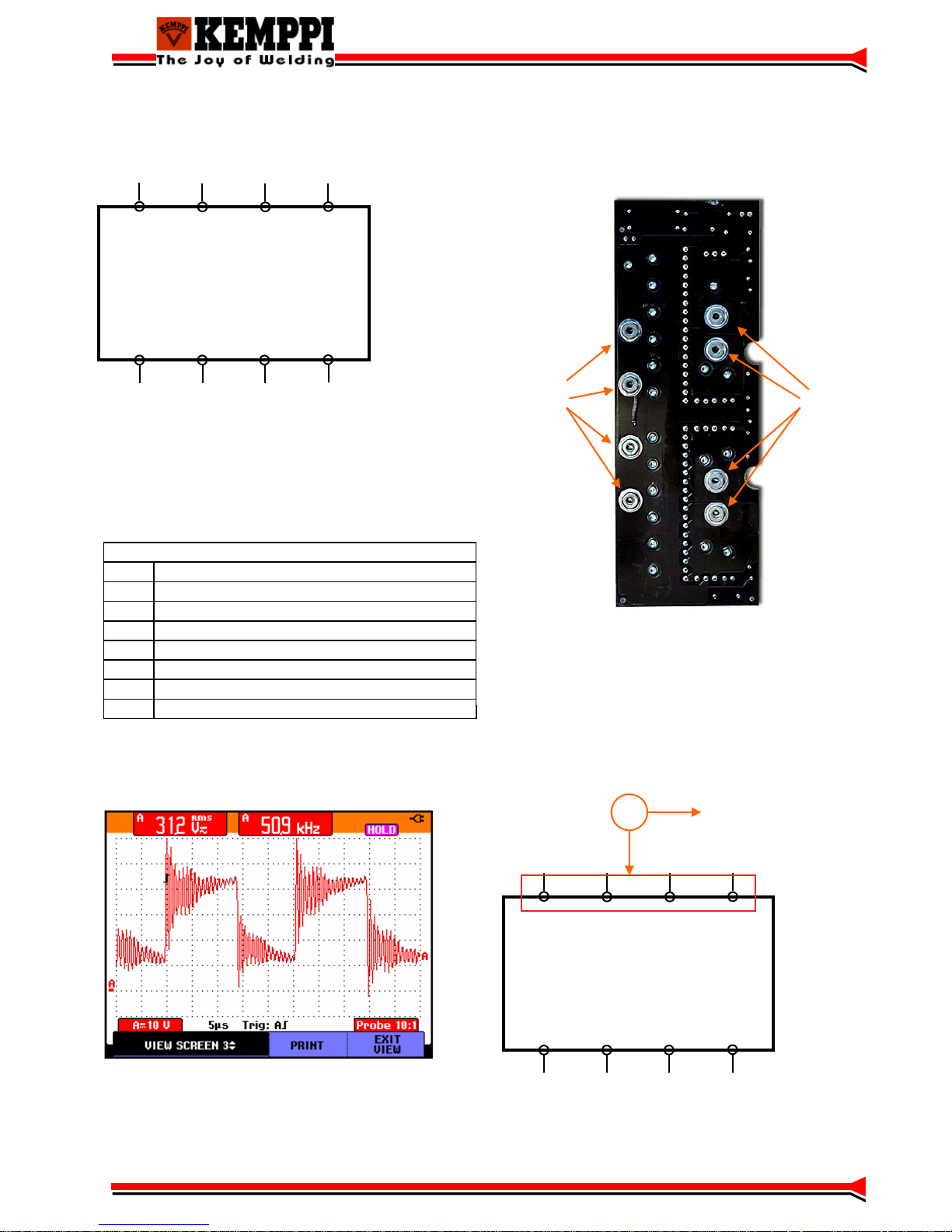

Main circuit card Z001

Connectors

X6

X37

X36

X7

X17

X16

X3

X19 X21

X15

X14

X11

X10

X13

X12

X9

X8

X20

X18

X40

X41

X29

Z001 connectors / signals

X1 Main switch

X2 Main switch

X3 Main switch

X4 Chassis ground

X5 Chassis ground

X6 Main transformer

X7 Main transformer

X8 IGBT gates and emitters

X9 IGBT gates and emitters

X10 IGBT gates and emitters

X11 IGBT gates and emitters

X12 IGBT gates and emitters

X13 IGBT gates and emitters

X14 IGBT gates and emitters

X15 IGBT gates and emitters

X2

X1

Z001 connectors / signals

X16 Primary choke

X17 Primary choke

X18 DC-link voltage (+)

X19 DC-link voltage (+)

X20 DC-link voltage (-)

X21 DC-link voltage (-)

X29 Chassis ground

X36 Current transformer secondary

X37 Current transformer secondary

X40 Auxiliary transformer

X41 Auxiliary transformer

X5X4

16

Page 17

Main circuit card Z001

Operational measurings

A

B

A.

Main transformer T001 primary voltage,

B.

IGBT-gate pulses, set values 50 A/16,5 V

set values 50 A/16,5 V

17

Page 18

Capacitor card Z002

Operating diagram

- Energy storage

- Discharging

X3 X1

Connectors

Z002 connectors / signals

X1 DC +

X2 DC +

X3 DC -

X4 DC -

X4 X2

18

Page 19

Secondary rectifier card Z003

Operating diagram

X5

X6

Z003

X1

-Rectifying

- Snubber

- Protection against HF

Connectors

X1 Main transformer

X2 Main transformer

X3 Main transformer

X4 Main transformer

X5 Secondary choke

X6 Secondary choke

X7 Secondary choke

X8 Secondary choke

X2

Z003 connectors / signals

X7

X3

X8

X4

X5-X8

X1-X4

Operational mesurings

C.

Voltage after secondary rectifier card Z003,

set values 50 A/16,5 V

X5

X1

C

X6

Z003

X2

X003, machine (-) pole

X7

X3

X8

X4

19

Page 20

Control card A001

X2

H7X9X7X6X5

F1

F2

H4

X4

H2

X1

H1

X3

Operating diagram

X8

X17

H8

X15

X14

X13

X16

H10

H9

X11

X10

- Microcontroller

-PWM circuit

- Secondary voltage measurement

- Secondary current measurement

-IGBT driver

- Auxiliary device connection

- Auxiliary power supply

- Machine size jumpers (J1, J2)

- Primary current limit jumpers (J3, J4, J5)

- Operational jumpers

-LED’s

- Water cooler connection

20

Page 21

Control card A001

Connectors

A001 / X1

X1 DC-link voltage (+)

A001 / X2

X2/1 20V auxiliaryvoltage~

X2/2 20V auxiliaryvoltage ground

X2/3 20V auxiliaryvoltage~

A001 / X3

X3/1 IGBT emitter

X3/3 IGBT emitter

X3/4 IGBT gate

X3/6 IGBT gate

A001 / X4

X4/1 IGBT emitter

X4/3 IGBT emitter

X4/4 IGBT gate

X4/6 IGBT gate

A001 / X5

X5/1 Fan (-) (M002)

X5/2 Fan (+) (M002)

A001 / X6

X6/1 Fan (-) (M001)

X6/2 Fan (+) (M001)

A001 / X7

X7 Productionprogramming bus

A001 / X8

X8/1 Current transformer ~

X8/3 Primary current limit jumper (J3)

X8/4 Primary current limit jumper (J4)

X8/5 Primary current limit jumper (J5)

X8/6 GND

X8/7 Current transformer ~

X8/9 GND (Primary current limit jumper J3)

X8/10 GND (Primary current limit jumper J4)

X8/11 GND (Primary current limit jumper J5)

X8/12 GND

A001 / X9 / KM

X9/1 System bus DATA

X9/2 System bus DATA B

X9/3 GND

X9/4 + 50 V

X9/6 X9/7 X9/8 -

X9/9 X9/10 Connection A002 X1/4

X9/11 -

A001 / X9 / KMS

X9/1 System bus DATA B (X005)

X9/2 System bus DATA B (X006)

X9/3 +50V (X005)

X9/4 +50V (X006)

X9/6 +5V (X005)

X9/7 +5V (X006)

X9/8 Analog DATA (X005)

X9/9 Analog DATA (X006)

X9/10 GND (X006)

X9/11 GND (X005)

A001 / X10

X10/1 Shunt (+)

X10/2 X10/3 Secondary voltage (+)

X10/4 X10/5 Machine size jumper J1

X10/6 Machine size jumper J2

X10/7 Shunt (-)

X10/8 TxD0 (possible future use)

X10/9 RxD0 (possible future use)

X10/10 GND

X10/11 GND(MachinesizejumperJ1)

X10/12 GND(MachinesizejumperJ2)

A001 / X11

- Not connected

J6 Forced programming mode

J7 For future purposes

J8 For future purposes

J9 For future purposes

21

Page 22

Control card A001

Connectors

A001 / X13

X13/1 PTC, Rg 101 (Z001)

X13/2 PTC, Rg 101 (Z001)

A001 / X14

X14/1 PTC, Rt 101 (T001)

X14/2 PTC, Rt 101 (T001)

A001 / X15

X15/1 PTC, Rg 201 (Z003)

X15/2 PTC, Rg 201 (Z003)

Operation of the LEDs on control card

A001 / LEDS

H1 IGBT gate pulses

H2 IGBT gate pulses

H3 IGBT gate pulses

H4 IGBT gate pulses

H5 +15V

H6 +5V

H7 Remote control unit connected

H8 Data communication

H9 Micro controller operation

H10 Micro controller operation

A001 / X16

X16/7 H002 + (yellow led)

X16/8 H002 -

X16/9 H001 + (green led)

X16/10 H001 -

A001 / X17

X17/1 +24V

X17/2 CLU_fault

X17/3 GND

X17/4 CLU_AD_CH1

X17/5 CLU_AD_CH2

X17/6 ON/OFF

H1-H4: Indicate the existence of the gate pulses.

H5, H6: Indicate that auxiliary voltages exist (+5V and +15V). If these Leds are not lit when the power source is

switched on, first thing to do is check if control card fuses are OK.

H7, H8: Indicate operation of the auxliary device connection. LED H8 indicates that there is data

communication taking place through the system bus when it is lit. LED H7 indicates that remote control unit is

connected when it is lit.

H9, H10: Indicate state of the microcontroller. In normal situation both leds should be lit.

22

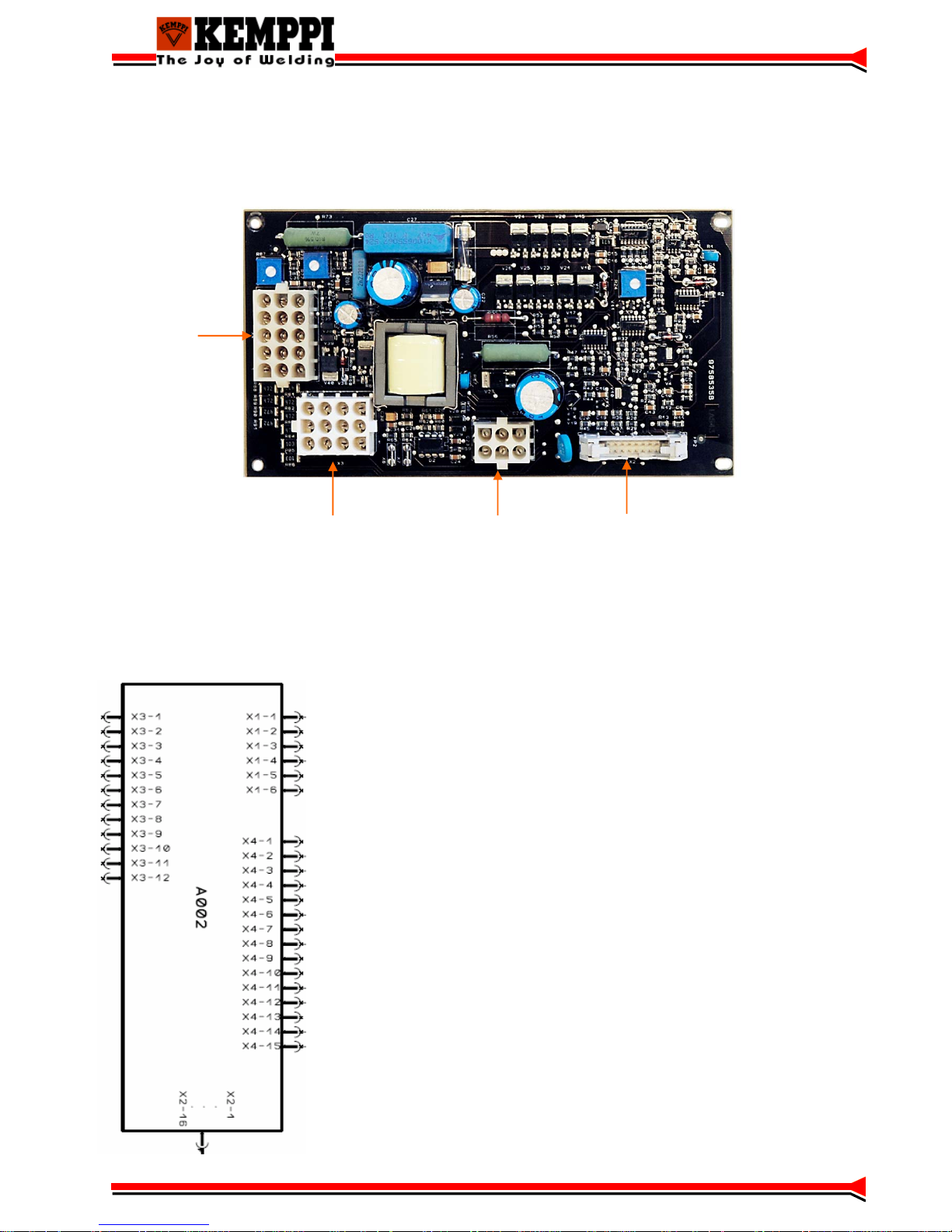

Page 23

Motor control card A002

X4

X3 X1 X2

Operating diagram

- WF-motor control

- Connection to the panel card P001

- Remote controller connection

- MIG gun connection

- Solenoid valve connection

-Fuse

- ID-Chip connection (MSF)

23

Page 24

Motor control card A002 (A001 = MSF)

Connectors

A002 / X1 / KM

X1/1 Connection to A001, X9/4

X1/4 Connection to A001, X9/10

A001 / X1 / MSF

X1/1 Bus +50V

X1/3 Tacho +5V

X1/4 Bus GND

X1/5 Tacho GND

X1/6 Tacho Signal

A002/A001 / X2

X2 Connection to panel card

A002 / X4 / MF

X4/2 Start

X4/3 Motor+

X4/4 U-measurement

X4/6 Pot +5V

X4/8 Connection A001 X9/2

X4/11 WF-pot

X4/12 Valve

X4/14 GND

X4/15 Motor -

X4/1 Pot GND

X4/2 Start 2

X4/3 Motor +

X4/4 Pot 2

X4/5 Start 1

X4/6 Pot +5V

X4/7 ID Bus 2

X4/8 Bus Data

X4/9 General I/O

X4/10 Valve -

X4/11 Pot 1

X4/12 Valve +

X4/13 ID Bus 1

X4/14 GND

X4/15 Motor -

A001 / X4 / MSF

24

Page 25

ID chip card A002 (MSF)

A002

ID-chip card

Connectors

A002

TP1 ID Bus 1 (connection to A001)

TP2 ID Bus 2 (connection to A001)

25

Page 26

Panel card P001 / KM

Operating diagram

- Main micro controller

- User interface (buttons, potentiometers,

displays, LED’s)

- Connection to the A002

Connectors

P001 / X2

X2 Connection to A002

26

Page 27

Error codes

Power source 1 ..... 50

MIG Logic 51 ….. 100

Curve Access 101 ….. 130

Robot Interface 131 ….. 150

MIG / TIG Unit 151 ….. 200

User interface 201 ….. 250

Others 0 ….. 999

Err 2: Power source undervoltage ( new start up )

Err 3: Power source overvoltage ( new start up )

Err 4: Power source is overheated

Err 5: Water unit alarm

Err 11: Two units have the same address in the system bus

Err 12: Data error on communication (2)

Err 13: Member of a wrong FastMIG family connected

Err 14: Data communication problem between power source and auxiliary unit

Err 15: Power source program / updating method problem

Err 21: Power source´s control card +5 V aux. Voltage too low

Err 22: Power source´s control card +15 V aux. Voltage too low

Err 23: Temporarily power source overvoltage

Err 31: Power source calibration error. Welding only possible with default values.

Err 54: No data communication from power source. Perhaps faulty cable/connector.

Err 55: Welding forbidden (congiguration / system bus reserved)

Err 61: The water unit is not found. Cooling unit may be OFF.

Err 153: Overheating of liquid-cooled gun

Err 154: Wire feed motor overcurrent. Perhaps the wire liner is blocked or gun cable too curvy.

Err 155: Wire feed motor overload. Motor´s current is too close to the limit.

Err 161: Warning of the wire feed unit overheating

Err 162: Overloading of the wire feed motor

Err 171: Configuration of the equipment can not be found. Gun start wires cross-connected.

Err 172: Wrong configuration code has been supplied

Err 173: Operation is not activated with right configuration code

Err 184: Control cable not connected or faulty.

Err 185: Machine program update error. Wrong program or updating method.

Err 201: Usage of PMT-gun prevented

Err 221: Data error of the panel (1)

Err 222: Data error of the panel (2)

Err 223: Data error of the panel (3)

Err 224: Data error of the panel (4)

Err 225: Program updating problem.

Err 241: EEPROM is faulty

Err 251: DLI data communication error(another unit in the bus is using same code=conflict)

Err 252: DLI data error (2)

Err 254: DLI data communication error(connection to other units has been interrupted(maybe bad connectors or cable

damages)

Err 255: DLI data communication error(program update problem, maybe a wrong program version etc)

Err 999: Unidentified error (systembus has sent an error message not identified by the panel)

27

Page 28

Setup menu

MF 29 / 33

FastMig Basic (MF) SETUP menu

SF 51, 52, 53, 54

Normal MIG

1-MIG

FR-MIG

All MIG

processes

MMA

FastMig Synergi c (MSF) setup menu

28

Page 29

Wire feed speed calibration / KM

• In factory set Wfs is adjusted in the range of 4... 100 without any unit

• LED light and feed roll symbol tells that the parameter to be set is Wfs

• After Wfs Calibration m/min unit is displayed

• Drive filler wire through the MIG gun and contact tip

• Enter to User Setup Me nu by pressing SETUP button ( appr 5 s )

• Select the Calibration me nu ( CAL ) with left side potentiometer

• Select "Enter" ( Ent ) with right side potentiometer

• Approve your selection by pressing briefly REMOTE / LOCAL key

• Select 'm/min' as calibration value of the quantity with right side potentiometer

• Approve selection by pressing briefly REMOTE / LOCAL key

• Set first Calibration point (e.g. 2.0 m/min ) with left side potentiomet e r

1. Press MIG gun trigger and let the wire run until it stops automatically

2. Measure the length of feeded wire with the accuracy of 1 cm

3. Enter wire length to the panel display ( cm ) with right side potentiometer

4. Approve your selection by pressing briefly REMOTE / LOCAL button

• Set second Calibration point (e.g. 18.0 m/min )

• Repeat steps 1 - 4 with left side potentiometer

• Message "Suc cES" in the display inform that calibration has ended successfully

• After Calibration panel returns to the operation mode

29

Page 30

Wire feed speed calibration

If wire feeding speed is not correct (too slow or too fast), motor

control card A002 must be calibrated by following instruction:

• Set ‘MIN’ and ‘MAX’ -trimmers to middle position.

• Set ‘IR-comp’ -trimmer to clock vice maximum.

• Set wire feeding speed to maximum from the panel (Basic: 100, Synergic: 25,0

m/min). Adjust ‘MAX’ –trimmer until wire feeding speed is same than value adjusted

from the panel.

• Set wire feeding speed to minimum from the panel (Basic: 4, Synergic: 1,0

m/min). Adjust ‘MIN’ –trimmer until wire feeding speed is same than value adjusted

from the panel.

• Check/adjust minimum and maximum again until both are OK.

• If adjustment range is too small, decrease IR -compensation and adjust minimum

and maximum again.

R87

max.

IR

comp

R24

min

30

Page 31

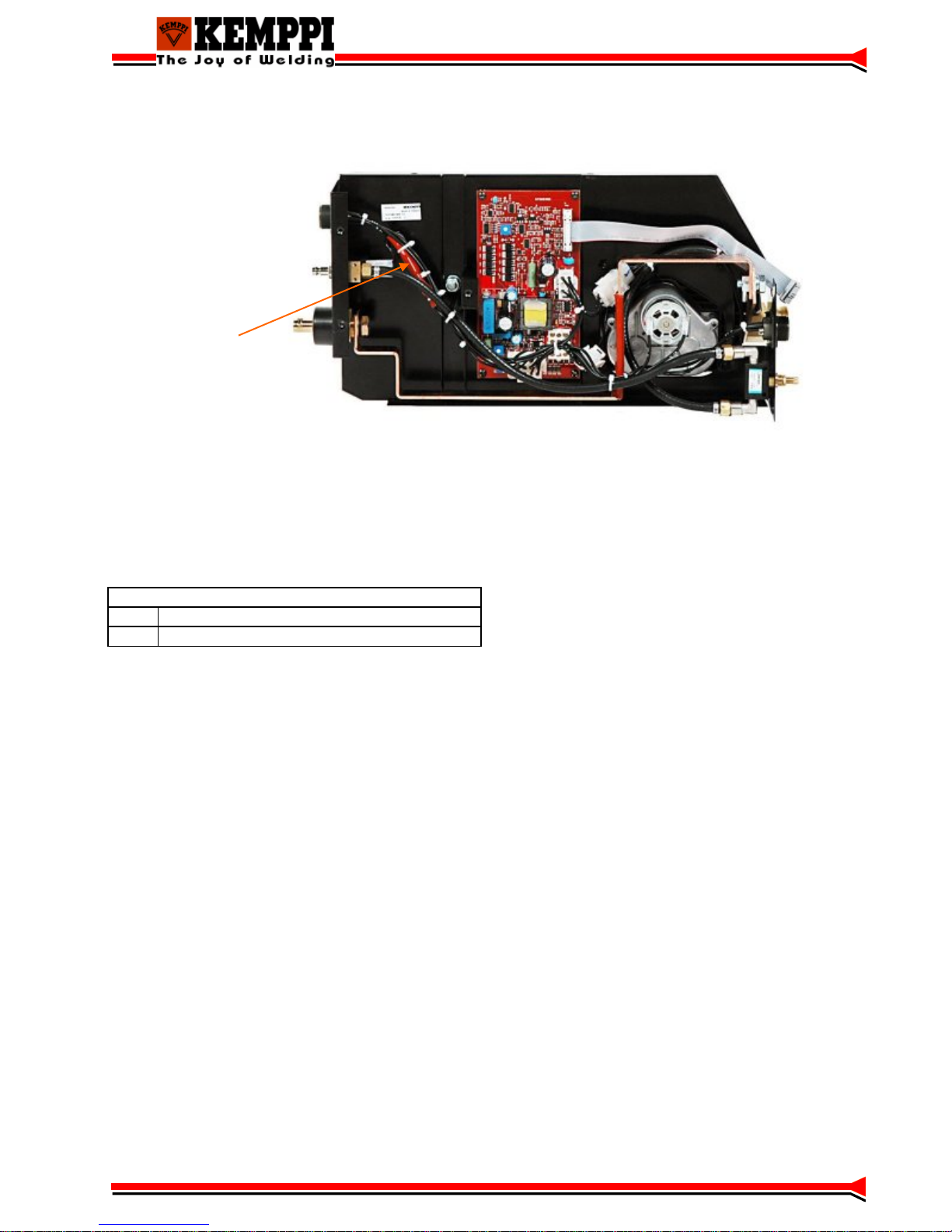

Structure

KM / KMS

Mains connector

and

varistors

Z001

Main circuit board

Z002

DC-link

Capasitor board

S001

Main

switch

R001

Shunt

resistor

A001

Control card

P001

Panel card

A002 (KM)

Wire feed

control card

Water cooler

Power

connector

31

Page 32

Structure

KM / KMS

T002

Auxiliary

transformer

L002

Secondary

choke

Capacitors and

varistors

L001

Choke

Z003

Secondary

rectifier diodes

32

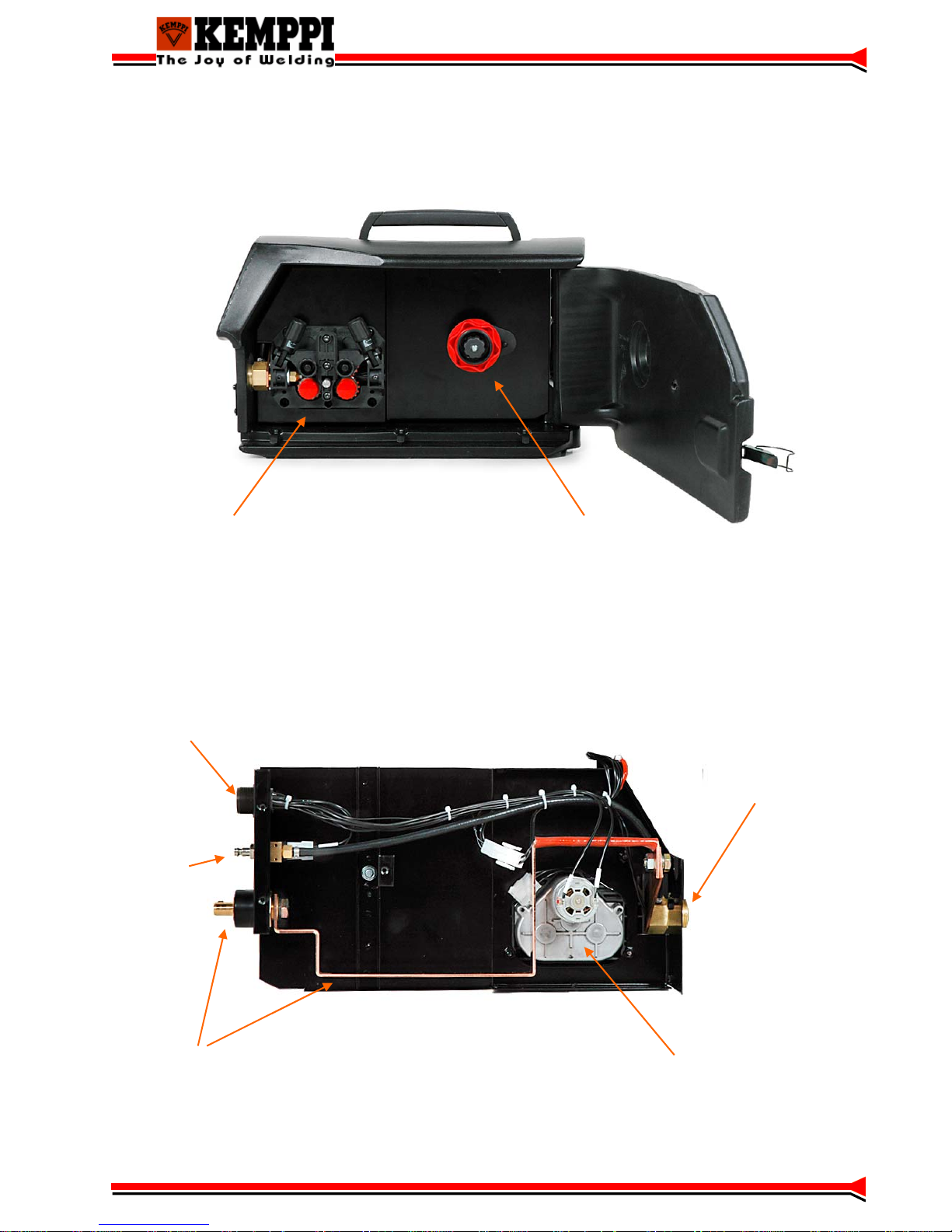

Page 33

Structure

MF 29 / 33

Dura Torque wire feeding mechanism

Control cable connector

& wiring

Solenoid valve

Axle for wire reel coop

Welding gun

connection

Welding current connector

& copper bar

Dura Torque wire feeding mechanism

33

Page 34

Structure

MSF 53 / 55 / 57

A001

Motor control

card

A002

ID-chip

card

34

Page 35

IGBT testing

B1/4

B2/6

X14

G3

X12

G1

X10

G4

X8

G2

C1/3

E2/2

X15

E3

X13

E1

X6

X7

X11

E4

X9

E2

C2E1/1

X6

X7

C1

E2

X15

X14/G3

X11/

X10/G4

X13

X12/G1

X9

X8/G2

B1/4

B2/6

X14

G3

X12

G1

X10

G4

X8

G2

C1/3

E2/2

X15

E3

X13

E1

X6

X7

X11

E4

X9

E2

C2E1/1

GCE

2

/

3

/

1

2

C

B2/6

I

T

G

O

F

F

O

N

R

C

O

N

T

R

O

L

B

1

T

-

T

E

S

T

T

R

E

2

R

E

C2E1/1

B1/4

35

Page 36

IGBT replacing

Mounting the IGBT to the heat sink

The tools and premises used in this work must be clean and free of dirt and dust. Even very

small particles (0,050mm) between the surfaces may increase the gap between heatsink and

module, causing overheating ans possible damage.

Heat transfer compound is to be spread in even layer of approximately 0,1 mm onto the module

base. Then the module should be immediately mounted on the heatsink, in order to minimize

the possibility of dirt getting between the components.

Firts, all the M5 type screws are tightened 0,5...2 NM. After a few minutes the module can be

tightened into the torque of 3 NM.

36

Loading...

Loading...