Page 1

Operation instruction • english

Gebrauchsanweisung • deutsch

Gebruiksaanwijzing • nederlands

Manuel d'utilisation • français

KEMPACT

PULSE 3000

KEMPACTCooL

10

19101811E

0813

Page 2

CONTENTS

1. PREFACE....................................................................................................................... 3

1.1. INTRODUCTION .........................................................................................................

1.2. PRODUCT INTRODUCTION ...................................................................................... 3

1.3. SAFETY INSTRUCTIONS ........................................................................................... 3

2. BEFORE YOU START USING THE UNIT .................................................................... 6

2.1. UNPACKING ...............................................................................................................

2.2. PLACEMENT OF THE UNIT ....................................................................................... 6

2.3. SERIAL NUMBER ....................................................................................................... 6

2.4. CONNECTION TO THE MAINS SUPPLY ................................................................... 6

2.5. GROUND CABLE ........................................................................................................ 6

2.6. INSTALLATION OF WELDING GUN ........................................................................... 8

2.7. MOUNTING AND LOCKING OF WIRE REEL ............................................................. 8

2.8. AUTOMATIC WIRE FEED TO GUN ............................................................................ 8

2.9. ADJUSTMENT OF PRESSURE .................................................................................. 8

2.10. ADJUSTMENT OF TIGHTNESS OF SPOOL BRAKE ............................................... 9

2.11. SHIELDING GAS ....................................................................................................... 9

2.12. COOLING UNIT (KEMPACTCOOL 10) ................................................................... 10

3. OPERATION .................................................................................................................11

3.1. MAIN SWITCH AND SIGNAL LIGHTS .......................................................................

3.2. TO SELECT POLARITY FOR WELDING ...................................................................11

3.2.1. CHANGING THE POLARITY ...................................................................11

3.3. PANEL ....................................................................................................................... 12

3.3.1. CHOOSING START SWITCH FUNCTION ............................................. 12

3.3.2. CHOOSING THE WELDING METHOD .................................................. 12

3.3.3. SELECTING 1-MIG/PULSE MIG SYNERGY CURVES .......................... 13

3.3.4. ADJUSTMENTS, DISPLAY AND WELD DATA ....................................... 15

3.3.5. TIMER ..................................................................................................... 15

3.3.6. ADJUSTMENT OF WELDING DYNAMICS............................................. 15

3.3.7. REMOTE CONTROL .............................................................................. 15

3.3.8. MIG EXTRA FUNCTIONS ....................................................................... 15

3.3.9. USE OF GAS TEST ................................................................................ 16

3.3.10. TESTING WIRE FEED .......................................................................... 16

3.3.11. MEMORY CHANNELS, MEMORY ........................................................ 17

3.3.12. SETUP .................................................................................................. 17

3.3.13. ERROR CODES ................................................................................... 19

3.4. COOLING UNIT OPERATION (KEMPACTCOOL 10) ............................................... 19

11

3

6

4. MAINTENANCE ........................................................................................................... 20

4.1. DAILY MAINTENANCE .............................................................................................

4.2. REGULAR MAINTENANCE ...................................................................................... 20

4.3. DISPOSAL OF THE MACHINE ................................................................................. 20

5. ORDERING INFORMATION ........................................................................................ 20

6. TECHNICAL DATA ...................................................................................................... 22

7. TERMS OF GUARANTEE ........................................................................................... 23

2 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

20

Page 3

1. PREFACE

1.1. INTRODUCTION

Congratulations on having purchased a KEMPPI product. Properly installed and used KEMPPI

products should prove to be productive machines requiring only a small amount of regular

maintenance.This manual is designed to give you a good understanding of the equipment and its safe

use. There is also information on maintenance of the unit and the machine´s technical data. Read

the instructions before bringing the machine into use or servicing it for the rst time. Additional

information on Kemppi products and their use can be obtained from Kemppi or a Kemppi dealer.

The specications and designs presented in this manual are subject to change without prior notice.

In this document, the following symbol is used to indicate a risk of injury or death:

Read the warnings carefully and follow the instructions. Please also study the instructions for safe

operation and follow them when installing, operating and servicing the machine.

1.2. PRODUCT INTRODUCTION

The Kempact Pulse 3000 is a compact MIG inverter suitable for repair and installation use, and

for light and medium industrial use.

1.3. SAFETY INSTRUCTIONS

Kemppi welding devices conform to international safety standards. Safety is an important issue

in equipment design and manufacturing. Therefore, Kemppi welding solutions are unparalleled in

safety. There are, however, always certain hazards involved in using welding equipment. Therefore,

to ensure your personal safety and the safety of your working environment, carefully read the safety

instructions below and respect them.

Use of personal protective equipment

• The arc and its reflecting radiation damage unprotected eyes. Shield your eyes and

face appropriately before you start welding or observe welding. Also note the different

requirements for the darkness of the screen in the mask as the welding current changes.

• The arc radiation and spatters burn unprotected skin. Always wear protective gloves, clothing

and footwear when welding.

• Always wear hearing protection if the ambient noise level exceeds the allowable limit (e.g.,

85 dB(A)).

General operating safety

• Exercise caution when handling parts heated in welding. For example, the tip of the welding

torch, the end of the welding rod and the work piece will heat during gouging to a burning

temperature.

• Never wear the device on the shoulder during welding and never suspend it by the carrying

strap during welding.

• Do not expose the machine to high temperatures, as heat may cause damage to the

machine.

• Keep the torch cable and earthing cable as close to each other as possible throughout their

length. Straighten any loops in the cables. This minimises your exposure to harmful magnetic

elds, which may interfere with a pacemaker, for example.

• Do not wrap the cables around the body.

• In environments classied as dangerous, only use S-marked welding devices with a safe idle

voltage level. These work environments include, for example, humid, hot or small spaces

where the user may be directly exposed to the surrounding conductive pieces.

Kempact pulse 3000, Kempactcool 10 / 0813 – 3© Kemppi oy

Page 4

Spatter and re safety

• Welding is always classied as hot work, so pay attention to re safety regulations during

welding and after it.

• Remember that re can break out from sparks even several hours after the welding work is

completed.

• Protect the environment from welding splatter. Remove ammable materials, such as

ammable uids, from the welding vicinity and supply the welding site with adequate re

ghting equipment.

• In special welding jobs, be prepared for hazards such as re or explosion when welding

container type work pieces.

• Never direct the spark spray or cutting spray of a grinder toward the welding machine or

ammable materials.

• Beware of hot objects or splatter falling on the machine when working above the

machine.

• Welding in ammable or explosive sites is absolutely forbidden.

General electric safety

• Only connect the welding machine to an earthed electric network.

• Note the recommended mains fuse size.

• Do not take the welding machine inside a container, vehicle or similar work piece.

• Do not place the welding machine on a wet surface and do not work on a wet surface.

• Do not allow the mains cable to be directly exposed to water.

• Ensure cables or welding torches are not squashed by heavy objects and that they are not

exposed to sharp edges or a hot work piece.

• Make sure that faulty and damaged welding torches are changed immediately as they can

be lethal and may cause electrocution or re.

• Remember that the cable, plugs and other electric devices may be installed or replaced only

by an electrical contractor or engineer authorised to perform such operations.

• Turn off the welding machine when it is not in use.

Welding power circuit

• Insulate yourself from the welding circuit by using dry and undamaged protective

clothing.

• Never touch the work piece and welding rod, welding wire, welding electrode or contact tip

at the same time.

• Do not put the welding torch or ground cable on the welding machine or other electric

equipment.

Welding fumes

• Ensure proper ventilation and avoid inhaling the fumes.

• Ensure sufcient supply of fresh air, particularly in closed spaces. You can also ensure the

supply of clean and sufcient breathing air by using a fresh-air mask.

• Take extra precautions when working on metals or surface-treated materials containing lead,

cadmium, zinc, mercury or beryllium.

4 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 5

Transportation, lifting and suspension

• Never pull or lift the machine by the welding torch or other cables. Always use the lift points

or handles designed for that purpose.

• Only use a transportation platform designed for the equipment.

• Try to transport the machine in an upright position, if possible.

• Never lift a gas cylinder and the welding machine at the same time. There are separate

provisions for gas cylinder transportation.

• Never use a welding machine when suspended unless the suspension device has been designed

and approved for that particular purpose.

• Do not exceed the maximum allowed load of suspension booms or the transportation trolley

of welding equipment.

• It is recommended that the wire coil be removed during lifting or transportation.

Environment

• Protect welding machines from heavy rain and direct sunshine even if it were suitable for

outdoor use.

• Always store the machine in a dry and clean space.

• Protect the machine from sand and dust during use and in storage.

• The recommended operating temperature range is -20 to +40 °C. The machine’s operation

efciency decreases and it becomes more prone to damage if used in temperatures in excess

of 40 °C.

• Place the machine so that it is not exposed to hot surfaces, sparks or spatter.

• Make sure the airow to and from the machine is unrestricted.

• This electromagnetic compatibility (EMC) of professional equipment is usually designed for

industrial use. Such class-A equipment is not intended for use in residential locations where

the electrical power is provided by the public low-voltage supply system. The machine may

interfere with sensitive home electronic devices.

Gas bottles and pneumatic devices

• Adhere to the instructions for handling pneumatic devices and gas bottles.

• Make sure that gas bottles are used and stored in properly ventilated spaces. A leaking gas

bottle may replace the oxygen in the inhaled air, causing suffocation.

• Before use, make sure that the gas bottle contains gas suitable for the intended purpose.

• Always x the gas cylinder securely in an upright position, against a cylinder wall rack or

purpose-made cylinder cart.

• Never move a protective gas bottle when the ow adjuster is in place. Put the valve cover

in place during transportation.

• Always close the gas cylinder valve after use.

Kempact pulse 3000, Kempactcool 10 / 0813 – 5© Kemppi oy

Page 6

2. BEFORE YOU START USING THE UNIT

2.1. UNPACKING

The equipment is packed in durable packages, designed specially for it. Nevertheless, before using

the equipment, always make sure it was not damaged during transport. Also check that you have

received what you ordered and it is accompanied by the appropriate instructions. NOTE! The

packaging material is suitable for recycling.

2.2. PLACEMENT OF THE UNIT

Place the unit on a horizontal, solid, and clean surface. Shield it from heavy rain and scorching

sun. Make sure that cooling air circulates freely.

2.3. SERIAL NUMBER

The serial number of the unit is marked on its rating plate. The serial number makes it possible to

trace product manufacturing series. You might need the serial number when placing spare parts

orders or when planning maintenance.

2.4. CONNECTION TO THE MAINS SUPPLY

The Kempact Pulse 3000 is delivered with a ve metre mains cable without a plug. Installation of

the plug should be carried out only by a competent electrician. For fuse and cable sizes, see the

technical data in the end of this document.

2.5. GROUND CABLE

Fasten the earth clamp of the return current cable carefully, preferably direct onto the piece to be

welded. The contact surface of the earth clamp should always be as large as possible.

Clean the fastening surface of paint and rust. Use at least two 35 mm² cables. Thinner cross sectional

areas may cause the connectors to overheat.

6 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 7

2. 2.

1.

Kempact pulse 3000, Kempactcool 10 / 0813 – 7© Kemppi oy

Page 8

2.6. INSTALLATION OF WELDING GUN

Make sure the gun wire conduit and the contact tip match the manufacturer’s recommendations

for the type and diameter of wire you use. Too small a conduit may overload the wire feed device

and impede the wire feeding. Tighten the gun’s quick connector to eliminate voltage loss. A loose

joint will heat up the gun and wire heater.

Never use defected gun.

2.7. MOUNTING AND LOCKING OF WIRE REEL

LOCKED OPEN

– Release locking nails of wire reel hub by turning locking knob a quarter round.

– Mount the reel at its place. Note rotating direction of reel!

– Lock the reel with locking knob, locking nails of hub remain to outside position and will

lock the reel.

2.8. AUTOMATIC WIRE FEED TO GUN

Automatic wire feed makes change of wire reel more rapid. In reel change the pressure of feed

rolls need not to be released and ller wire goes automatically to correct wire line.

– Make sure that groove of feed roll matches the diameter of welding wire used.

– Release the wire end from reel and cut off the bent length. Be careful that the wire does not

spill from the reel to sides!

– Straighten about 20 cm of the wire and see that the end of it has no sharp edges (le off if

necessary). A sharp edge may damage the wire guide tube and contact tip of the welding

gun.

– Draw a bit of loose wire from wire reel. Feed wire through back liner to feed rolls. Do not

release pressure of feed rolls!

– Press the gun switch and feed a bit wire until wire goes through feed rolls to gun. See that

wire is in grooves of both feed roll pairs!

– Press still the gun switch until wire has come through contact tip.

Automatic feed may sometimes fail with thin wires (Fe, Fc, Ss: 0,6...0,8 mm, Al: 0,8...1,0 mm). In

that case you might have to open feed rolls and feed wire manually through feed rolls.

Note! Check that the wire or wire reel does not touch the equipment body, there is

a danger of short circuit

2.9. ADJUSTMENT OF PRESSURE

Adjust the pressure of the feed rolls with the control screw so that the wire is fed into the wire

guide tube evenly and allows a little braking when emerging from the contact tip, without slipping

on the feed rolls.

Excessive pressure will cause the ller wire to atten and damage its coating, as well

as undue wear and tear of the feed rolls and friction damage.

8 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 9

2.10. ADJUSTMENT OF TIGHTNESS OF SPOOL BRAKE

Brake force can be adjusted through the hole in the spool hub’s locking device of spool hub by

screwing the control screw with a screwdriver. Adjust the braking force so that it is sufcient to

prevent the wire from becoming too loose on the spool and spilling when the spool stops rotating.

The greater the wire feed speed, the greater the braking force required. Do not keep the brake

unnecessarily tight, since this will impose a strain on the motor.

A

2.11. SHIELDING GAS

The MIG shielding gas consists of carbon dioxide, mixed gases and argon. Shielding gas ow

rate is determined by the amount of welding current. The typical ow rate of gas in the welding

steel is 8-15 l /min.

A Gas bottle valve

B Press regulation screw

C Connecting nut

D Hose spindle

E Jacket nut

F Gas bottle pressure meter

G Gas hose pressure meter

The following installation instructions are valid for

most gas ow regulator types:

1. Step aside and open the bottle valve (A) for a while to blow out possible impurities.

2. Turn the press regulation screw (B) of the regulator until no spring pressure can be felt.

3. Close the needle valve if there is one in the regulator.

4. Install the regulator onto bottle valve and tighten the connecting nut (C) with a wrench.

5. Install the hose spindle (D) and jacket nut (E) into the gas hose and tighten with a hose clamp

6. Connect the hose with the regulator and the other end with the wire feed unit.

Tighten jacket nut.

7. Open the bottle valve slowly. The gas bottle pressure meter (F) shows bottle pressure.

Note! Do not use the whole contents of the bottle. The bottle pressure should be lled when

bottle pressure is 2 bar.

8. Open the needle valve if there is one in the regulator.

9. Turn the regulation screw (B) until the hose pressure meter (G) displays the required ow

(or pressure). When regulating the ow amount, the power source should be switched on

and the "GAS PURGE" -switch pressed simultanously.

Close the bottle valve after welding is nished. If the machine will not be in use for a long time,

unscrew the pressure regulation screw.

CAF

G

B

E

D

Always fasten the gas cylinder securely in an upright position on a wall rack intended

for the purpose or on a cylinder cart. Always close the cylinder valve after you have

nished welding.

Kempact pulse 3000, Kempactcool 10 / 0813 – 9© Kemppi oy

Page 10

2.12. COOLING UNIT (KEMPACTCOOL 10)

Cooling liquid is injurious! Avoid also contact with skin or eyes. In case of injury,

seek for medical advice.

Cooling unit KempactCool 10 together with MIG-gun of Kemppi's PMT-W and MMT-W range

enables MIG welding with water-cooled gun.

The cooling unit is installed beneath the power source with screws and mounting plate. Electrical

connections are on the bottom of power source. Fill the reservoir with a 20 - 40 % mixture of etanol

and water, or with any other suitable antifreeze. The capacity of the reservoir is 3 litres.

Electrical connection

for the cooling unit:

Installation of cooling unit:

The bottom of power source

1. 400 V

2. Control connector

3. Equipment earth

Only an authorised electrician is allowed

to install electrical connection!

Filling the reservoir:

10 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 11

3. OPERATION

3.1. MAIN SWITCH AND SIGNAL LIGHTS

With the switch in the ‘I’ position, the primary and control circuits of the machine become live

and the ‘ON’ signal light on the panel lights up. The welding circuit receives voltage when the gun

switch is operated or when the wire feed test switch is pressed. Always use the main switch to turn

the machine on and off with the main switch; do not use the power plug for this purpose.

3.2. TO SELECT POLARITY FOR WELDING

Solid wire is usually welded in the +pole and gasfree ller wires in the - pole gun. When welding

with other ller wires, check for the recommended polarity on the package or consult the supplier

of the product. The welding of very thin steelplates (0.5 to 0.7 mm) a - polarity might also work

best for solid wire.

3.2.1. Changing the polarity

- pole

+ pole

Only a service shop authorised by Kemppi may change the polarity.

Kempact pulse 3000, Kempactcool 10 / 0813 – 11© Kemppi oy

Page 12

3.3. PANEL

3.3.1. Choosing start switch function

MIG welding by 4-function start switch, MIG 4T

MIG welding by 2 function start switch, MIG 2T

3.3.2. Choosing the welding method

Normal MIG/MAG welding:

with a separate wire feed and voltage regulation can be chosen in the 1-MIG position.

Curve number “00” provides a free wire feed range between 1-18 m/min. The voltage

can be set between special pre-programmed limits depending on the wire feed. Curve

number “01” wire feed speed and voltage are not depended on each other. When curve

“01” is selected, the wire feed speed and voltage will be independent of one another.

Synergic MIG/MAG welding (1-MIG)

Synergic MIG/MAG welding (1-MIG): MIG welding in which the wire feed speed

determines all the other welding parameter values, allowing the adjustment of welding

power with a single knob. Choose the appropriate synergy curve for the ller wire and

shielding gas to determine how the wire feed speed affects the pulse parametres.

Synergic Pulse MIG welding:

through this welding method, based on pulsing the welding current, the ller metal on the

workpiece is kept spatter-free. The power source pulse parameters change automatically

(synergy) enabling welding power regulation using a single knob. Choose the appropriate

synergy curve for the ller wire and shielding gas to determine how the wire feed speed

affects the pulse parametres.

Double pulse:

the wire feed will become higher or lower according to the wire feed range. While the

synergic welding parameters change to correspond to the momentary wire speed. The

purpose is to get a goodlooking weld and a proper penetration while improving the

controllability of the weld pool during position welding.

12 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 13

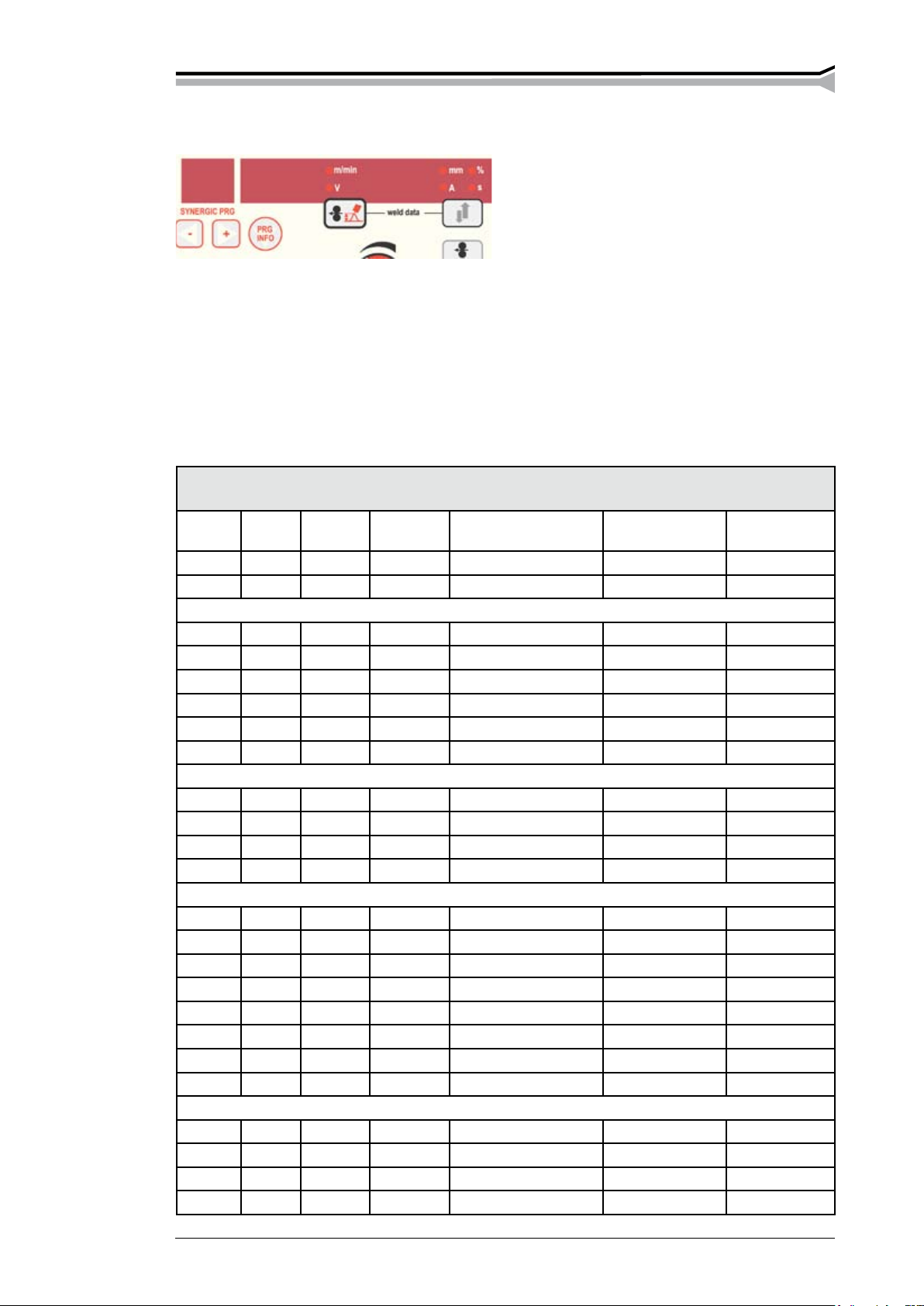

3.3.3. Selecting 1-mig/pulse mig synergy curves

The program number of the synergy curve is selected using the plus-minus buttons and is displayed

on "SYNERGIC PRG".

The middle display is actual material group display (eg. SS, AL, CUS, FE, GEN). Wire diameter

(mm) can be seen on the right side. This information will only be displayed for a while.

The “PRG INFO” button gives more curve information:

One press will revert to the material group and diameter display, a second will display the type

number of the material and a third run through the gas consistency components one by one.

KEMPACT PULSE 3000 Synergic programs

1-MIG Pulse Double

Pulse

00 All All All 1,0 - 18,0

01 All All All 0,5 - 18,0

SS-group

S1 S1 S1

S2 S2 S2

S3 S3 S3

S4 S4 S4

S5

S7

Al-group

A1 A1 A1 1,0 mm AlMg5 / AlMg4,5Mn Ar

A2 A2 A2 1,2 mm AlMg5 / AlMg4,5Mn Ar

A6 A6 A6 1,0 mm AlSi5 / AlSi12 Ar

A7 A7 A7 1,2 mm AlSi5 / AlSi12 Ar

Cu-group

C1 C1 C1 0,8 mm CuSi3 Ar

C2 C2 C2 0,9 mm CuSi3 Ar

C3 C3 C3 1,0 mm CuSi3 Ar

C4 C4 C4 1,2 mm CuSi3 Ar

C5 C5 C5 0,8 mm CuAl8 Ar

C6 C6 C6 0,9 mm CuAl8 Ar

C7 C7 C7 1,0 mm CuAl8 Ar

C8 C8 C8 1,2 mm CuAl8 Ar

Fe-group

F1 F1 F1 0,8 mm Fe Ar + 18 % CO

F2 F2 F2 0,9 mm Fe Ar + 18 % CO

F3 F3 F3 1,0 mm Fe Ar + 18 % CO

F4 F4 F4 1,2 mm Fe Ar + 18 % CO

Wire, ø Material Gas Wire Feed

Range

0,8 mm SS 308 / 316 Ar + 2 % CO

0,9 mm SS 308 / 316 Ar + 2 % CO

1,0 mm SS 308 / 316 Ar + 2 % CO

1,2 mm SS 308 / 316 Ar + 2 % CO

0,9 mm SS 316 FC Ar + 18 % CO

1,2 mm SS 316 FC Ar + 18 % CO

²

²

²

²

²

²

²

²

²

²

Kempact pulse 3000, Kempactcool 10 / 0813 – 13© Kemppi oy

Page 14

1-MIG Pulse Double

Pulse

F5 0,8 mm Fe CO

F6 0,9 mm Fe CO

F7 1,0 mm Fe CO

F8 1,2 mm Fe CO

FA FA FA 1,0 mm FeMC Ar + 18 % CO

FB FB FB

FD 1,2 mm FeFC Ar + 18 % CO

Wire, ø Material Gas Wire Feed

Range

²

²

²

²

²

1,2 mm FeMC Ar + 18 % CO

²

²

Auto

20 20 1,0 mm CuSi3-A Ar 1,1 – 2,0

1 21 21 1,0 mm CuSi3-A Ar 2,0 – 2,6

2 22 22 1,0 mm CuSi3-A Ar 2,4 – 3,1

3 23 23 1,0 mm CuSi3-A Ar 3,0 – 3,6

4 24 24 1,0 mm CuSi3-A Ar 3,5 – 4,1

5 25 25 1,0 mm CuSi3-A Ar 4,0 – 4,6

6 26 26 1,0 mm CuSi3-A Ar 4,5 – 5,1

7 27 27 1,0 mm CuSi3-A Ar 5,0 – 5,5

8 28 28 1,0 mm CuSi3-A Ar 5,5 – 6,0

9 29 29 1,0 mm CuSi3-A Ar 6,0 – 6,5

10 30 30 1,0 mm CuSi3-A Ar 6,4 – 7,0

11 31 31 1,0 mm CuSi3-A Ar 6,9 – 7,6

12 32 32 1,0 mm CuSi3-A Ar 7,4 – 8,1

14 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 15

3.3.4. Adjustments, display and weld data

Display for welding current and welding material

thickness. Changing can be made using the button

behind the display. There is a percentage display

(eg. gas consistency) and seconds display (see

timer). The relative length of arc will be displayed

when adjusted. Otherwise the predicted current

value is displayed (not in 2-MIG).

Process Manager™ for setting all welding

parameters.

The display for wire feed speed, welding voltage or material group. This can be switched using

the button under the display (wire feed speed/length of arc). The voltage can be adjusted in the

normal and 1-MIG position (wire feed range/the length of arc). During pulse welding the voltage

is determined by the wire feed speed while the length of arc affects some other parameters.

When pressed simultaneously, the weld data buttons recall the wire feed speed on the display, the

welding voltage and welding current values which have been used when welding was stopped.

3.3.5. Timer

intermittent welding

spot welding

The spot time is set immediately after pressing the switch button, on the display SPt.

The pause time is set accordingly, on the PSE display. The time is set using the Process

Manager.

3.3.6. Adjustment of welding dynamics

For adjusting of MIG/MAG welding dynamics, the adjustment value dyn -9...0...9 is

displayed. The welding stability and quantity of spatter are affected by the welding

dynamics control, the 0-position is the recommended reference range. Values -9...-1

give a smoother arc and less spatter, while values 1...9 give a rougher arc and increased

stability, when using a 100% CO² shielding gas when welding steel.

3.3.7. Remote control

Gun control, wire feed speed or welding power control is changed using RMT 10.

Control of the welding voltage or the length of the welding arc can be adjusted using

the potentiometer on the panel. Panel control, adjustments using the potentiometer on

the panel.

3.3.8. Mig extra functions

Crater lling, 1-MIG and pulse MIG:

Crater lling reduces welding mistakes caused by end craters. By pressing the 4T-trigger

continuously at the end of weld, a descending welding power is achieved which lls end

craters in a controlled manner. The descending time is kept constant using the 2T function,

and the welding power and end level can be changed using the SETUP-function.

Kempact pulse 3000, Kempactcool 10 / 0813 – 15© Kemppi oy

Page 16

Hot Start

Wire range/power/

Welding current

Start switch 4T

Crater lling

The Hot Start:

The Hot Start function is used with 1-MIG and pulse MIG welding. The Hot Start time by 4T Hot

Start time is determined by trigger function (see picture) and while by 2T function it is determined

by the SETUP parameters. The level of Hot Start can be changed by SETUP function.

The Hot Start level, Hot Start time by 2T, crater ll level and downslope time can be easily adjusted

using the ‘QUICK SETUP’ function:

1. Select the gun trigger function: 4T or 2T.

2. First, press the SETUP button and then , while still pressing the SETUP button, press the

extra function button.

3. Adjust the Hot Start level.

4. Repeat step 2, upon which the display will show the next adjustable parameter, depending

on the switch mode.

Exit by pressing any button (except SETUP)

3.3.9. Use of gas test

If you press the gas test button, gas will begin to ow without any starting power source

or wire feed. Gas ow can be measured by using an external measuring device.

Cut off the gas ow by pressing the same button again, or the gun trigger. If the trigger

is not pressed again, the gas ow will end within 20 seconds.

The display will show “GAS” and the time.

3.3.10. Testing wire feed

The wire feed switch will start the wire feed motor without opening the gas valve. The

power source will start up, but without providing welding power. The wire feed range

will be 5m/min but can be adjusted as desired.

16 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 17

3.3.11. Memory channels, MEMORY

The pulse panel has 100 channels for different welding options. Memory channels can be chosen

on the lower part of the panel using the memory block. Both welding values and functions can be

saved. Do the following:

1. Press twice if needed and and the SET light will start blinking if the channel is not

in use, while the light will stay on if the channel is in use.

2. Select the memory channel you want by pressing CH button

3. Make settings and save by pressing SAVE button.

4. Press twice. ON light turns on.

5. Start welding and set the values.

To change the values, the light must be switched from the ON to SET and then you can choose the

parameters, pressing the SAVE button afterwards. It is also possible to save the used parameters by

pressing SET when memory function is OFF (no lights). The channel can be emptied by pressing

and SET button in SET simultaneously.

Using saved settings

1. Press button.

2. Select the memory channel by pressing the CH button.

3. Start welding.

Memory channels in control device

Select memory channels by pressing the CH REMOTE button simultaneously and the gun control

light will start to blink. Use the saved values through the gun’s remote control.

You can use ve channels.

3.3.12. SETUP

Using the SETUP function, the user can change welding parameters which do not have their own

panel functions. These parameters can be set separately for 1-MIG and Pulse MIG. SETUP settings

are separate for each memory channel.

Kempact pulse 3000, Kempactcool 10 / 0813 – 17© Kemppi oy

Page 18

Setup functions on pulse panel

Parameter Name Nr Display 1-MIG Pulsed

MIG

PostGasTime 1 PoG X X Curve s PostGas time 0.0…9.9 s

PreGasTime 2 PrG X X Curve s PreGas time, functions by

HotStartLevel 11 Hot X X 30 % Hot start ratio to welding

HotStartTime 2T 12 H2t X X 2 s 2T Hot start timer 0.1-9.9 s

CraterFillLevel 14 CFL X X 30 % Welding end level 10-90 %

CraterFillSlope 15 CFS X X 1 s/10m Wire slowing-down

CreepStartLevel 17 CSL X X Syn Wire speed start value

CreepStartSlope 18 CSS X X 0 s/10m Wire speed up time

DoubleFrequency 21 dFr X Curve Hz Double pulse frequency

DoubleAmpiltude 22 dA X Curve m/min Double pulse power

StartPower 31 StP X X 0 Start power control

PulseCurrent 33 PuC X 0 % Pulse top current control

ArcLength

AdjRange

Calibration 42 CAL X X 1 V/100A Setting mid value of arc

WFS

Gun 53 Gun On liquidcooled thermal

GunRemote 54 GrE On Disabling of gun remote

Display reset

time

PRG INFO - feeld

selection

Restore 99 FAC X OFF Restoring factory settings

41 ALr X X 0 % Arc length adjustment

51 FS 18 m/min Wire feed maximum

81 dLY X X 5 s 1...20 s

82 diS X X 1 1,2,3

Factory

value

Unit Explanation

2T 0.0…9.9 s

power 50…+75%

1…20 s/10m

10…90

0.1…5 s/10m

control 0.4…8.0 Hz

variation

control 0.1…3.0 m/min

-9…0…+9

10…+15%

range 50…+75%

length ne adjustment

0.0…10.0 V/100A

18 or 25 m/min

protection on/off

control automatic

identication

(OFF=no reset,

Pan=panel and setup

ALL= also memory

channels)

18 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 19

Changing parameters

By pressing the 2T/4T (SETUP) selection switch a little longer the machine will enter the SETUP

state. The display will show the set parameter’s runnning number (blinking), its abbreviation and

value. Select the parameter number using the “SYNERGIC PRG” + and - buttons or the “SETUP”

button (which will jump by tens). Change the value using the control button (in some cases, the

value can be found from the synergy curve). “Syn” and the curve value will blink by turns on the

right of the display. Set the value by turning the button anticlockwise.

Exit for SETUP using a long press.

Frequency and amplitude of double pulse can be set in the separate ‘SET’ mode, obtained by rst

pressing the 2T/4T (SETUP) and, without releasing it, the method button. “dFr” and the frequency

in Hz will be displayed. “Syn” will appear if the frequency is based on synergy curves. Change this

value by turning the control button anticlockwise. Press it twice to display “dA” i.e. the amplitude

(m/min). Adjust this accordingly and exit SETUP by pressing any button other than SETUP.

3.3.13. Error codes

Error codes are among others the following:

Err 3: Overvoltages in the mains supply. Also the pilot light of overvoltage is lighting.

Err 4: The thermal protection of power suorce has stopped welding. Also the pilot light of

thermal protection is lighting.

Err 5: The cooling device has stopped welding.

Err 6: The terminal voltage has rised. Take the device to service.

Err 153: Liquid cooled PMT- or WS-gun is overheated. Or torch-PTC or RMT10 has beeb installed,

but the jumber inside the torch is in FU-position, look also instruction of torch.

Err 154: Overloading of the wire feed motor

Error code is eliminated when the reason is aborted, except Err 6, which demands to turn down

the machine.

3.4. COOLING UNIT OPERATION (KEMPACTCOOL 10)

The operation of cooling units KempactCool 10 is

controlled by the power source. The cooling unit pump

starts automatically when welding starts. Proceed as

follows:

1. Start power source.

2. Check water level and input ow of the reservoir, add

liquid if needed.

3. If you use a water-cooled gun you can ll it with

cooling liquid by pressing TEST-button (on cooling

unit).

The pump operates for 5 another minutes after welding has

been nished to cool the liquid to the same temperature

as in the machine surrounds. This reduces the need of

service.

Thermal overload

The thermal overload light is lit, the machine stops and display shows Err 5 when temperature

control of the machine has detected cooling water overheating. The cooling unit fan cools down

the water, and when the light goes out welding can be started again.

Water ow signal

Display shows Err 5 when water ow is blocked.

Kempact pulse 3000, Kempactcool 10 / 0813 – 19© Kemppi oy

Page 20

4. MAINTENANCE

4.1. DAILY MAINTENANCE

Be careful of mains voltage when handling electric cables!

Clean the wire channel of the gun and check the contact tip regularly. Always check the condition

of the mains and welding cable before operation and replace defective cables.

Note! Only a qualied electrician should remove or install the mains cable!

4.2. REGULAR MAINTENANCE

KEMPPI -service workshops sign special service contracts with customers for regular maintenance.

All parts are cleaned, checked and if necessary, repaired. The operation of the welding machine

is also tested.

4.3. DISPOSAL OF THE MACHINE

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic

Equipment and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and returned to an

environmentally compatible recycling facility. As the owner of the equipment, you should

get information on approved collection systems from our local representative.

By applying this European Directive you will improve the environment and human

health!

5. ORDERING INFORMATION

Item Ordering number

Kempact Pulse 3000 621830002

KempactCool 10 621860001

GH 30 Gun holder 6256030

PMT 25 3 m 6252513

PMT 25 4,5 m 6252514

PMT 27 3 m 6252713

PMT 27 4,5 m 6252714

PMT 32 3 m 6253213

PMT 32 4,5 m 6253214

PMT 30W 6253043

PMT 30W 6253044

PMT 35 3 m 6253513

PMT 35 4,5 m 6253514

WS 35 6 m Al1,2 6253516A12

WS 35 6 m Ss1,0 6253516S10

WS 30W 6 m Al 1,2 6254206A12

WS 30W 6 m Ss 1,0 6254206S10

20 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 21

MMT 25 3 m 6252513MMT

MMT 25 4,5 m 6252514MMT

MMT 27 3 m 6252713MMT

MMT 27 4,5 m 6252714MMT

MMT 30W 3 m 6253043MMT

MMT 30W 4,5 m 6253044MMT

Remote Control Unit RMT 10 6185475

Earth cable 35 mm² 5 m 6184311

Transport unit ST 7 6185290 (for power source and gas bottle)

Transport unit P20 6185261 (power source, cooling unit and gas bottle)

Transport unit P250 6185268 (power source)

Lift hook 4298180

Gas hose 6 m W000566

Wire spool pole 4289880

5 kg spool adapter 4251270

DuraTorque™ 400 metal feed rolls

Parts of the DT400 metal feed rolls

W000731

W000732

W000711

W000718

W000891

9420507 washer 10.5x30x2.5 2 pcs per unit

gear ring 1 driving 2 pcs per unit

gear ring 2 pressing 2 pcs per unit

drive ring V groove 1,2/1,2 optional 4 pcs per unit

drive ring V groove 1,0/1,0 optional 4 pcs per unit

drive ring V groove 1,0/1,2 4 pcs per unit

Recommended for aluminium welding with Pulse MIG.

Kempact pulse 3000, Kempactcool 10 / 0813 – 21© Kemppi oy

Page 22

6. TECHNICAL DATA

Kempact Pulse 3000

Mains connection 3~400V +/-15%, 50/60Hz

Connected load

40% ED 12 kVA 250A

60% ED 10 kVA 207A

100% ED 7,5 kVA 160A

Mains cable/fuse 4x1,5 mm² - 5 m/16A delayed

Load capacity

40% ED 250A /26,5V

60% ED 207A /24V

100% ED 160A /22V

Adjustment range 8 - 30V

Wire feed speed

Open circuit voltage 56 V

Power ratio 0,69 (250A / 26V)

Efciency 0,84 (250A / 26V)

Filler wires

Fe, Ss

Cored wire 0,9 ... 1,2 mm

Al 0,9 ... 1,2 mm

CuSi

Shielding gas CO², Ar, Ar & CO² mixed gases

Wire spool diameter

Feed roll Ø 32 mm

Thermal class H (180 °C) / B (130 °C)

Dimensions

length 580 mm

width 280 mm

height 440 mm

Weight

Gun connector EURO

Principle of operation 4-wheel feed

1 - 18 m/min

0,6 ... 1,2 mm

0.8 ... 1,2 mm

300 mm (15 kg)

22 kg

Cooling unit KempactCool 10

Connection voltage 400 V - 15 % ... 10 %

Connection capacity 250 W

Cooling power 1 kW

Start pressure, max 4,5 bar

Cooling liquid 20 % - 40 % etanol/water

Reservoir volume n. 3 l

External dimensions length 580 mm

width 280 mm

height 300 mm

Weight

Kempact Pulse 3000 and Cooling unit KempactCool 10

Range of temperature for use - 20 °C ...+ 40 °C

Storage temperature for use - 40 °C ...+ 60 °C

Degree of protection IP23C

13 kg

The products meet conmormity reguirements for CE marking.

22 – Kempact pulse 3000, Kempactcool 10 / 0813 © Kemppi oy

Page 23

7. TERMS OF GUARANTEE

Kemppi Oy provides a guarantee for products manufactured and sold by them if defects in

manufacture and materials occur. Guarantee repairs must be carried out only by an Authorised

Kemppi Service Agent. Packing, freight and insurance costs to be paid by orderer. The guarantee is

effected on the date of purchase. Verbal promises which do not comply with the terms of guarantee

are not binding on guarantor.

Limitations on guarantee

The following conditions are not covered under the terms of guarantee: defects due to natural wear

and tear, non-compliance with operating and maintenance instructions, connection to incorrect or

faulty supply voltage (including voltage surges outside equipment spec.), incorrect gas pressure,

overloading, transport or storage damage, re of damage due to natural causes i.e. lightning or

ooding.

This guarantee does not cover direct or indirect travelling costs, daily allowances or accommodation.

Note: Under the terms of guarantee, welding torches and their consumables, feeder drive rolls and

feeder guide tubes are not covered. Direct or indirect damage due to a defective product is not

covered under the guarantee. The guarantee is void if changes are made to the product without

approval of the manufacturer, or if repairs are carried out using non-approved spare parts.

The guarantee is also void if repairs are carried out by non-authorised agents.

Undertaking guarantee repairs

Guarantee defects must be informed to Kemppi or authorised Kemppi Service Agents within the

guarantee period. Before any guarantee work is undertaken, the customer must provide proof of

guarantee or proof of purchase, and serial number of the equipment in order to validate the guarantee.

The parts replaced under the terns of guarantee remain the property of Kemppi.

Following the guarantee repair, the guarantee of the machine or equipment, repaired or replaced,

will be continued to the end of the original guarantee period.

Kempact pulse 3000, Kempactcool 10 / 0813 – 23© Kemppi oy

Loading...

Loading...