Page 1

FastMig

MXP 37 Pipe Steel

MXP 37 Pipe Stainless

MXP 38

Operating manual

Brugsanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Bruksanvisning

Instrukcja obsługi

Manual de utilização

Инструкции по эксплуатации

Bruksanvisning

操作手册

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

RU

SV

ZH

Page 2

Page 3

OPERATING MANUAL

English

Page 4

EN

CONTENTS

1. Introduction ................................................................................................. 3

1.1 General ....................................................................................................................................... 3

1.2 About FastMig MXP 37 Pipe and MXP 38 ...................................................................... 3

2. Installation .................................................................................................... 4

2.1 Machine introduction: MXP 37 Pipe and MXP 38 ...................................................... 4

2.2 Connecting cables ................................................................................................................. 5

2.3 Assembly of MIG/MAG system .......................................................................................... 6

2.4 Accessories corresponding to wire diameter ..............................................................7

2.5 Welding gun selection .......................................................................................................... 7

2.6 Mounting and locking of wire spool ............................................................................... 7

2.7 Loading the ller wire and automatic feed ..................................................................8

2.8 GT04 wire feed mechanism in MXP 37 Pipe ................................................................. 8

2.9 DuraTorque™ 400, 4-wheel wire feed mechanism in MXP 38 .............................10

2.10 Adjustment of pressure arms ...........................................................................................12

2.11 Adjustment of spool brake ...............................................................................................12

2.12 Burn back time ......................................................................................................................12

2.13 Earth return cable .................................................................................................................12

2.14 Shielding gas ..........................................................................................................................13

2.15 Main switch I/O .....................................................................................................................14

2.16 Operation of cooling unit, FastCool 10 ........................................................................14

2.17 Hanging kit .............................................................................................................................14

3. XF 37 and xf 38 control panels .............................................................. 14

3.1 Connecting and mounting ...............................................................................................14

3.2 Layout .......................................................................................................................................15

3.3 Button functions ...................................................................................................................16

3.4 Welding software .................................................................................................................18

3.5 Arc voltage display ...............................................................................................................20

4. Basic troubleshooting ............................................................................. 21

5. Maintenance .............................................................................................. 23

5.1 Daily maintenance ...............................................................................................................23

5.2 Periodic maintenance .........................................................................................................23

5.3 Service Workshop maintenance .....................................................................................23

6. Disposal of the machine ......................................................................... 24

7. Ordering codes..........................................................................................24

8. Technical data ............................................................................................ 27

FastMig MXP 37 Pipe, MXP 38

2

Page 5

EN

1. INTRODUCTION

1.1 General

Congratulations on choosing the FastMig MXP welding equipment. Used correctly, Kemppi

products can signicantly increase the productivity of your welding, and provide years of

economical service.

This operating manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the equipment can be found at the end

of the manual.

Please read the operating manual and the safety instructions booklet carefully before using

the equipment for the rst time. For your own safety and that of your working environment,

pay particular attention to the safety instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

Important notes

Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with the ’NOTE!’ notation. Read these sections carefully and follow

their instructions.

1.2 About FastMig MXP 37 Pipe and MXP 38

Kemppi FastMig MXP 37 Pipe is a wire feeder designed for demanding professional use. It

is equipped with the WiseRoot+™ welding process, developed especially for ecient root

welding on pipes and plates.

Kemppi FastMig MXP 38 is a wire feeder designed for demanding professional use. It is

equipped with the WiseThin+™ welding process, developed especially for ecient welding for

thin sheets and position welding, also with CO2 shielding gas.

FastMig MXP 37 Pipe and MXP 38 wire feeders can be used with FastMig X 450 and FastMig

Pulse power sources. However, WiseRoot+™ and WiseThin+™ special welding processes are

only available when used with FastMig X 450 power source.

Operation of the wire feeder is controlled and adjusted by microprocessor. By adding

an optional synchronization unit (MXF Sync 65), SuperSnake sub-feeder device may be

connected to MXP 37 Pipe or MXP 38 wire feeders.

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

3

© Kemppi Oy / 1515

Page 6

EN

2. INSTALLATION

2.1 Machine introduction: MXP 37 Pipe and MXP 38

MXP 37 Pipe MXP 38

4.

2.

1.

3.

5.

2.

1.

3.

5.

4.

6.

1. Control panel XF 37 1. Control panel XF 38

2. ON/OFF button 2. ON/OFF button

3. Euro gun connection 3. Euro gun connection

4. Voltage sensing cable connection 4. Voltage sensing cable connection

5. Remote control connection 5. Remote control connection

6. Sub-feeder sync connector (kit

optional)

6. Sub-feeder sync connector (kit

optional)

8.

11.

10.

9.

7.

8.

10.

9.

7.

7. Shielding gas connection 7. Shielding gas connection

8. Control cable connection 8. Measurement cable connection

9. Measurement cable connection 9. Control cable connection

10. Welding current cable connection 10. Welding current cable connection

11. Lead-in and clamping of cooling

liquid hoses

6.

FastMig MXP 37 Pipe, MXP 38

4

Page 7

EN

2.2 Connecting cables

2.2.1 Liquid-cooled system: FastMig X 450 + MXP + FastCool 10

1.

4.

8.

10.

2.

3.

9.

5.

6.

11.

7.

V

V

1. Wire feed unit

2. FastMig X 450 power source

3. FastCool cooling unit and power connection

4. Gas supply

5. MMA electrode holder

6. Remote control device

7. Liquid-cooled welding gun

8. Power cable

9. Earth return cable and clamp

10. Measurement cable (from power source to wire feeder)

11. Voltage sensing cable (from wire feeder to work piece)

NOTE! MXP wire feeders can also be used with FastMig Pulse power source, but in that case

measurement cable and voltage sensing cable will not be used.

5

© Kemppi Oy / 1515

Page 8

EN

2.2.2 Air-cooled system: FastMig X 450 + MXP

1.

4.

5.

10.

6.

8.

2.

3.

7.

9.

V

V

1. Wire feed unit

2. FastMig X 450 power source

3. Gas supply

4. MMA electrode holder

5. Remote control device

6. Air-cooled welding gun

7. Power cable

8. Earth return cable and clamp

9. Measurement cable (from power source to wire feeder)

10. Voltage sensing cable (from wire feeder to work piece)

NOTE! MXP wire feeders can also be used with FastMig Pulse power source, but in that case

measurement cable and voltage sensing cable will not be used.

2.3 Assembly of MIG/MAG system

Assemble the units in the order mentioned below. Follow the additional mounting and

operation instructions delivered with each package.

1. Installation of power source

Read and follow the installation instructions given in the FastMig power source operating

manual.

2. Mounting of power sources to transport cart

Read and follow the instructions given in the transport cart assembly instructions.

3. Mounting the FastMig MXP wire feed unit to the power source

Remove the cover sticker on top of the power source. Screw the fastening pivot into the

power source – hand tighten only. Place the supplied plastic spacers over the pivot. Lift the

MXP wire feeder into place, locating over the pivot.

4. Connecting cables

Connect the cables in accordance with the equipment notes provided in this manual.

The polarity of the welding wire (+ or –) can be selected by connecting the wire feed unit to

either the positive or negative power source terminals.

Most MIG/MAG applications run the wire feed unit connected to the positive terminal of the

power source.

FastMig MXP 37 Pipe, MXP 38

6

Page 9

EN

5. Mounting FastMig wire feed units to boom and swing arms

When mounting wire feed units to boom and swing arms, the unit must be electrically

isolated from both.

Suspension angle of wire feed unit can be changed by moving the xing point in handle.

2.4 Accessories corresponding to wire diameter

Colour coded wire feed rolls and guide tubes are available to suit a variety of ller wire types

and sizes. Feed roll groove geometry and design vary depending on the application. Further

details are available in the spare parts tables.

Please ensure you select the correct drive rolls and guide tubes from the table to suit your

particular welding application.

2.5 Welding gun selection

Please ensure that the welding gun selected is suitable for the target application. Kemppi

welding gun products are designed to meet many dierent applications. Special wire liners

and contact tips are available for dierent wire types and sizes.

For FastMig X 450 and MXP 37 Pipe setup Kemppi oers the PMT MN welding gun model,

which is specially designed for welding root and ll passes on pipe. The neck is replaceable, so

you can select just the right bending angle for dierent work stages.

Distance wire feeding is accommodated with WeldSnake and SuperSnake products in either

air or liquid cooled models.

2.6 Mounting and locking of wire spool

NOTE! Check that in ller wire spool is correctly mounted and locked into position. Ensure the spool

is not damaged or deformed in such a way that it can rub or cha against the internal surface of

the wire feed unit chassis or door. This may result in increased drag, impacting on weld quality. This

may also result in long term wire feed unit damage, rendering the unit unserviceable or unsafe to

use.

7

© Kemppi Oy / 1515

Page 10

EN

2.7 Loading the ller wire and automatic feed

Automatic wire feed makes wire spool changes faster. When changing the wire spool, the

pressure of feed rolls need not be released.

Simply ensure that the groove of the feed roll matches the diameter of ller wire used. Release

the wire end from the spool and cut o any deformed section. Be careful that the wire does

not spill from the spool sides.

Straighten about 20 cm of ller wire and ensure the tip has no sharp edges. File if necessary, as

a sharp wire edge may damage the wire gun liner - particularly softer plastic liners.

Present the ller wire tip to the back of the wire feed rolls and press the wire inch switch on

the wire feeder panel. Feed the wire to the gun contact tip and prepare to weld.

NOTE! Smaller diameter ller wires may need to be loaded manually and with the feed roll pressure

arms released. This is because it is easy to over estimate the pressure required to feed these smaller

ller wires. Too high feed roll pressures can easily deform ller wires and contribute to later feeding

problems.

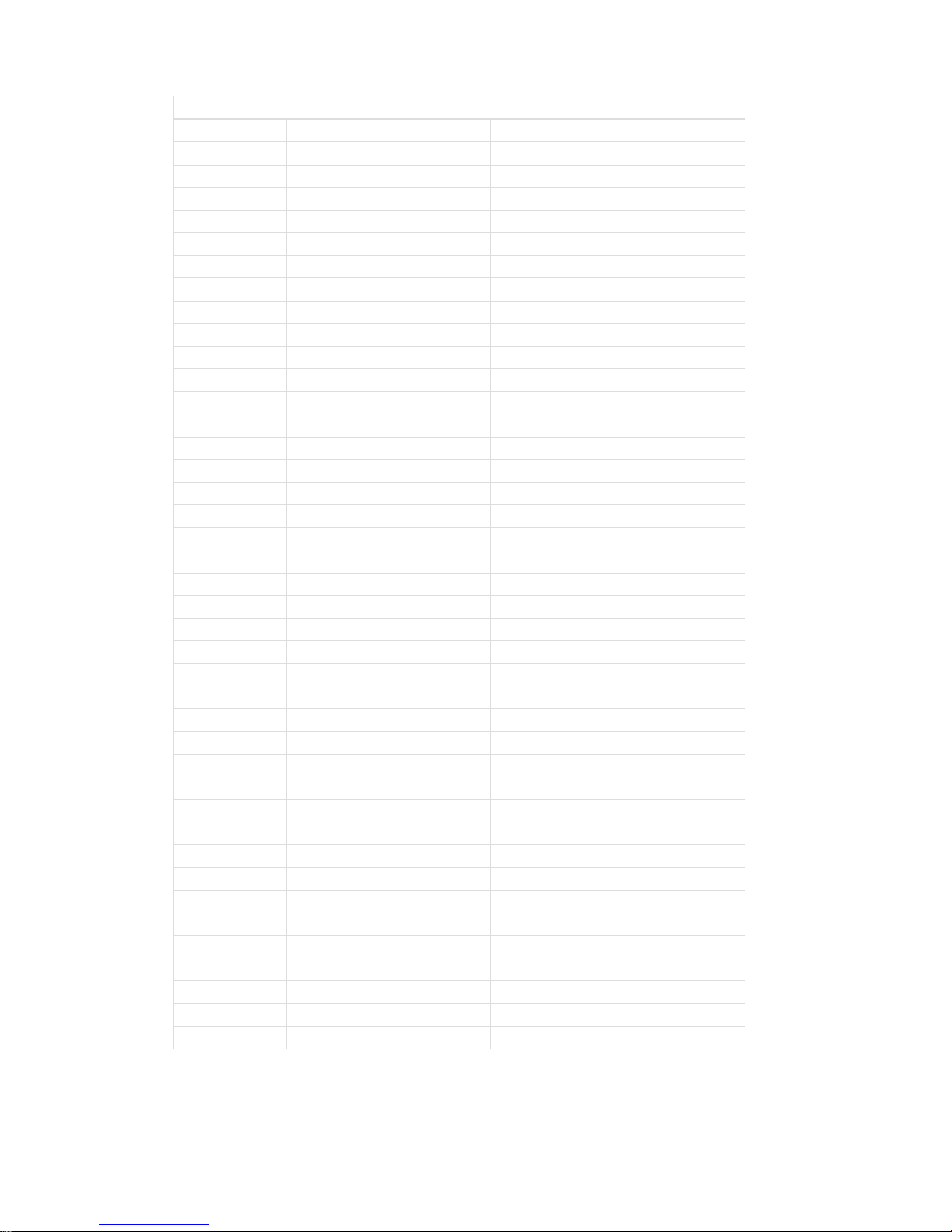

2.8 GT04 wire feed mechanism in MXP 37 Pipe

Wire guide tubes

ø mm outlet tube middle tube inlet tube

Al, Ss (Fe, Mc, Fc)

plastic

0.6 W007285 W007273 W007293

0.8 – 0.9 W007286 W007274 W007294

1.0 W007287 W007275 W007295

1.2 W007288 W007276 W007296

1.4 W007289 W007277 W007297

1.6 W007290 W007278 W007298

2.0 W007291 W007279 W007299

2.4 W007292 W007280 W007300

Fe, Mc, Fc

metal

0.8 – 0.9 W007454 W007536

1.0 W007455 W007537

1.2 W007456 W007538

1.4 – 1.6 W007458 W007539

2.0 W007459 W007540

2.4 W007460 W007541

FastMig MXP 37 Pipe, MXP 38

8

Page 11

EN

Wire feed rolls, plastic

ø mm lower upper

Fe, Ss, (Al, Mc, Fc)

V-groove

0.6 W001045 W001046

0.8 – 0.9 W001047 W001048

1.0 W000675 W000676

1.2 W000960 W000961

1.4 W001049 W001050

1.6 W001051 W001052

2.0 W001053 W001054

2.4 W001055 W001056

Fc, Mc, (Fe)

V-groove, knurled

1.0 W001057 W001058

1.2 W001059 W001060

1.4 – 1.6 W001061 W001062

2.0 W001063 W001064

2.4 W001065 W001066

Al, (Fc, Mc, Ss, Fe)

U-groove

1.0 W001067 W001068

1.2 W001069 W001070

1.6 W001071 W001072

Wire feed rolls, metal

ø mm lower upper

Fe, Ss, (Al, Mc, Fc)

V-groove

0.8 – 0.9 W006074 W006075

1.0 W006076 W006077

1.2 W004754 W004753

1.4 W006078 W006079

Fc, Mc, (Fe)

V-groove, knurled

1.0 W006080 W006081

1.2 W006082 W006083

1.4 – 1.6 W006084 W006085

2.0 W006086 W006087

Fc, Mc, Ss, Fe

U-groove

1.0 W006088 W006089

1.2 W006090 W006091

1.6 W006092 W006093

NOTE! Mount the lower feed roll, ensuring that the pin on the shaft ts in the cut on the feed roll.

9

© Kemppi Oy / 1515

Page 12

EN

2.9 DuraTorque™ 400, 4-wheel wire feed mechanism in MXP 38

Wire guide tubes

ø mm outlet tube middle tube inlet tube

Ss, Al,

(Fe, Mc, Fc)

plastic

0.6 W007437 W007429 W007293

0.8 – 0.9 W007438 W007430 W007294

1.0 W007439 W007431 W007295

1.2 W007440 W007432 W007296

1.4 W007441 W007433 W007297

1.6 W007442 W007434 W007298

2.0 W007443 W007435 W007299

2.4 W007444 W007436 W007300

Fe, Mc, Fc

metal

0.8 – 0.9 W007454 W007465 W007536

1.0 W007455 W007466 W007537

1.2 W007456 W007467 W007538

1.4 – 1.6 W007458 W007469 W007539

2.0 W007459 W007470 W007540

2.4 W007460 W007471 W007541

Wire feed rolls, plastic

ø mm lower upper

Fe, Ss,

(Al, Mc, Fc)

V-groove

0.6 W001045 W001046

0.8 – 0.9 W001047 W001048

1.0 W000675 W000676

1.2 W000960 W000961

1.4 W001049 W001050

1.6 W001051 W001052

2.0 W001053 W001054

2.4 W001055 W001056

Fc, Mc, (Fe)

V-groove, knurled

1.0 W001057 W001058

1.2 W001059 W001060

1.4 – 1.6 W001061 W001062

2.0 W001063 W001064

2.4 W001065 W001066

FastMig MXP 37 Pipe, MXP 38

10

Page 13

EN

Al, (Fc, Mc, Ss, Fe)

U-groove

1.0 W001067 W001068

1.2 W001069 W001070

1.6 W001071 W001072

Wire feed rolls, metal

ø mm lower upper

Fe, Ss,

(Al, Mc, Fc)

V-groove

0.8 – 0.9 W006074 W006075

1.0 W006076 W006077

1.2 W004754 W004753

1.4 W006078 W006079

Fc, Mc, (Fe)

V-groove, knurled

1.0 W006080 W006081

1.2 W006082 W006083

1.4 – 1.6 W006084 W006085

2.0 W006086 W006087

Al, (Fc, Mc, Ss, Fe)

U-groove

1.0 W006088 W006089

1.2 W006090 W006091

1.6 W006092 W006093

NOTE! Mount the lower feed roll, ensuring that the pin on the shaft ts in the cut on the feed roll.

11

© Kemppi Oy / 1515

Page 14

EN

2.10 Adjustment of pressure arms

Adjust the drive pressure to the ller wire with the thumb screws mounted over the pressure

arms. Notice the graduated scales indicating load. The load applied should be sucient to

overcome a light braking force applied by hand to the ller wire, as it exits the welding gun

contact tip.

For smaller diameter and soft ller wires, less feed pressure is required. It should be possible to

apply a light breaking force to the ller wire by hand, as it exits the gun contact tip. But slightly

more wire ow restriction should render the drives rolls to slip slightly over the ller wire

without deforming the wire.

NOTE! Excessive pressure causes attening of the ller wire and damage to coated or cored ller

wires. It also causes undue wear of the feed rolls and increases gearbox load, so reducing service

life.

2.11 Adjustment of spool brake

Brake force is adjusted through the hole behind the locking clip. Remove the locking clip by

hand, and adjust the tension and pressure to the friction pads mounted inside with a screw

driver. See diagram and location A.

A

The load applied varies depending on the size and weight of the ller wire and spool, but also

the ller wire feed speed set. The heavier the wire spool and the faster the feed speed, the

greater the need to increase the braking load. Adjust the pressure, secure the locking clip, set

the wire feed speed and check that the braking force is enough to ensure the ller wire does

not spill from the spool on overrun.

NOTE! Too much or unnecessary loads can impact welding quality, load and wear to the wire feed

system.

2.12 Burn back time

FastMig electronics controls the burn back time. When welding stops an automatic sequence

ensures that the ller wire does not stick to the work piece and that no ball is formed at the

wire tip, ensuring reliable re-ignition. This system works regardless of the wire feed speed.

2.13 Earth return cable

Preferably the earth return cable and clamp should be connected directly to the welding

material.

Always use a good quality, 70 mm² heavy copper cable, and if possible a screw type 600 A

clamp. Ensure that the surface contact to the work piece is clean of metal oxide and or paint.

Make sure the clamp is rmly secured.

FastMig MXP 37 Pipe, MXP 38

12

Page 15

EN

2.14 Shielding gas

NOTE! Handle shielding gas bottle with care. Assess the risks associated with handling and using

compressed gas. Always use a cylinder transport carriage and secure the cylinder safely.

There are many dierent suppliers of quality shielding gases for welding. Please ensure that

you are selecting the correct gas for your application. FastMig products use welding programs

for synergic and pulsed welding. These programs are created and recommend against a

particular shielding gas.

Shielding gas eects welding performance and is a fundamental component to overall weld

quality.

MMT 32

l/min

5

10

15

20

NOTE! Shielding gas ow rate from the welding gun is set according to the application, weld joint,

gas type and gas nozzle shape and size. The ow rate should be measured at the welding gun

nozzle before welding via a rotameter, and normally measure's between 10 – 20 litres per minute

for many welding applications.

2.14.1 Installing gas bottle

Always fasten the gas bottle properly in the vertical position, in a special holder against the

wall or on a cylinder carriage. Remember to close gas bottle valve after welding.

Parts of gas ow regulator

5

2

4

7

1

6

3

1. Gas bottle valve

2. Flow regulation screw

3. Connecting nut

4. Hose tail

5. Hose tail nut

6. Gas bottle pressure gauge

7. Shielding gas ow meter

13

© Kemppi Oy / 1515

Page 16

EN

2.15 Main switch I/O

When you turn the main switch of the FastMig power source into I-position, the pilot lamp

closest to this switch will illuminate, indicating the power source is ready for welding. The

equipment will return to the same operation state where it was before the last shutdown.

Always start and switch o the machine with the main switch, never use the mains plug as a

switch.

2.16 Operation of cooling unit, FastCool 10

When liquid-cooling unit FastCool 10 is connected to the FastMig power source for the

rst time, the cooler function is normally active. To deselect the cooler function, follow the

instructions stated in the FastCool 10 operating manual.

2.17 Hanging kit

The MXP wire feeders can be mounted on a welding boom using the KFH 1000 hanging

device available as an accessory. This allows the wire feed unit to be suspended above the

work area.

3. XF 37 AND XF 38 CONTROL PANELS

3.1 Connecting and mounting

Fasten the ribbon cable connector from the MXP wire feed unit to the control panel. Attach

the yellow-green earth lead into the fork connector on the XF control panel.

XF 37 XF 38

+

FastMig MXP 37 Pipe, MXP 38

14

Page 17

EN

3.2 Layout

XF 37

W007241

CH REMOTE

CHANNEL

PANEL

4T

2T

1. 3.

2.

4.

5. 6.

7. 8. 9.

10.

11.

1. ON/OFF button

2. Activates MIG welding dynamics (short press)

Selects the active wire feeder, if several wire feeders exist (long press)

3. Gas test

4. Wire inch

5. Selects the previous memory channel

6. Selects the next memory channel (short press)

Locks selected memory channel (long press)

7. Selects welding gun trigger mode (short press) or turns MatchLog function ON/OFF

8. Selects crater ll, hot start (short press) or MMA/CC/CV (long press)

9. Selects panel control, gun control unit or hand-held control unit (short press).

Turns memory channel remote selection ON/OFF (long press).

10. Power control knob

11. Arc length and voltage control knob.

Automatic weld data display

Last recorded welding values are displayed post welding.

Voltage display

Voltage display will show arc voltage if selected from the setup panel. Voltage display's last

dot indicates that arc voltage display is selected (for example 23.5. V). If arc voltage feature is

not used, pole voltage of the power source is shown.

15

© Kemppi Oy / 1515

Page 18

EN

3.3 Button functions

3.3.1 ON/OFF button (1)

Short press: XF 37 / X 38 panel returns to initial display.

Long press: XF 37 / X 38 panel is turned ON or OFF.

NOTE! When wire feeder XF 37 / XF 38 control panel is turned ON, also the power source control

panel X 37 turns on and links automatically to this wire feeder.

3.3.2 Dynamics button (2)

Short press: Dynamics setting for 1-MIG, synergic MIG and CC/CV. ArcForce setting for MMA.

Long press: Wire feeder number selection. If there is more than one wire feeder connected to

the system, you can select which of them is active. Each wire feeder has its own number (1–3).

NOTE! Wire feeder number is not available in MMA, CC and CV processes.

3.3.3 Gas test button (3)

This button displays the gas test time. You can change it with the control knob.

Gas test starts when the time adjustment is made, after a short delay.

You can stop gas test by pressing any button.

3.3.4 Wire inch button (3)

This button starts feeding the wire with the default speed of 5.0 m/min. The wire feed stops

when you release the button.

You can change the wire feed speed with the control knob. The changed speed is used if you

press the button again.

3.3.5 Channel down button (5)

W007241

CH REMOTE

CHANNEL

PANEL

4T

2T

WISEROOT

+

/

This button selects the previous memory channel that can be found.

3.3.6 Channel up button (6)

W007241

PANEL

4T

2T

WISEROOT

+

/

Short press: Selects the next memory channel that can be found.

Long press: Locks or unlocs the selected memory channel. No parameter changes are allowed

to a locked memory channel.

FastMig MXP 37 Pipe, MXP 38

16

Page 19

EN

3.3.7 2T/4T button (7)

W007241

PANEL

4T

2T

Short press: Toggles between 2T or 4T gun trigger mode.

Long press: Turns MatchLog ON/OFF. This can be either MatchChannel or Minilog

functionality, depending on which one is dened in the selected memory channel. If neither

one is dened, this selection is unavailable.

3.3.8 Extra functions button (8)

W007241

PANEL

Short press: Selects Crater ll or Hot start function.

Long press: Turns MMA/CC/CV mode ON/OFF.

3.3.9 Remote Selection Button (9)

W007241

PANEL

Short press: Toggles the control between the control panel, gun remote control unit and

hand-held remote control unit.

NOTE! If RemoteAutoRecog setting is ON in X 37 control panel, you can select only those remote

controls, which can be found in the system.

Long press: Turns the memory channel remote selection ON/OFF. This is available only if you

have selected either gun remote control unit or hand-held remote control unit. Not available

in MMA/CC/CV mode.

3.3.10 Power control knob (10)

This control knob adjusts

• wire feed speed or power in MIG/MAG processes (before or during welding)

• MMA/CC current level (before or during welding)

• selected parameter values.

3.3.11 Arc length and voltage control knob (11)

This control knob adjusts the arc length, voltage or selected parameter values before or

during welding.

17

© Kemppi Oy / 1515

Page 20

EN

3.4 Welding software

The FastMig MXP wire feeders are compatible with the following modied welding processes

and functions

• Wis e Root+™ is a modied welding process for open gap root welding without backing.

• WiseThin+™ is a modied welding process developed especially for ecient welding for

thin sheets and position welding, also with the CO2 shielding gas.

• WisePulseMig™ is a licence that allows pulsed MIG welding.

• WiseFusion™ is a welding function for ensuring consistent weld quality in all positions.

• WisePenetration™ is a welding function for delivering constant welding power

regardless of changes in the stick out length.

• MatchLog™ contains MiniLog™ function and the MatchChannel™ function for quickly

changing welding parameters on the run.

Wire feeder Factory-installed

MXP 37 Pipe Steel

WiseRoot+, WiseFusion, Pipe Steel Pack

MXP 37 Pipe Stainless

WiseRoot+, WiseFusion, WisePulseMig, Pipe Stainless Pack

MXP 38

WiseThin+, WisePulseMig, Steel Pack for WiseThin+, Work Pack

If your welding needs change and you wish to update your system in the future, you can order

additional welding programs or other welding software and load them to your system with

Kemppi DataGun eld programming device. Optional features can be purchased through

Kemppi DataStore.

For further information about the available welding programs, modied processes

and special enhanced arc performance solutions, visit Kemppi web site at

www.kemppi.com or contact the local Kemppi dealer.

PIPE STAINLESS PACK

Group Material Wire ø (mm) Shielding gas Process Number

Ss CrNiMo 19 12 0.8 Ar+2%CO₂ WiseRoot+ S01

Ss CrNiMo 19 12 0.9 Ar+2%CO₂ WiseRoot+ S02

Ss CrNiMo 19 12 1.0 Ar+2%CO₂ WiseRoot+ S03

Ss CrNiMo 19 12 1.2 Ar+2%CO₂ WiseRoot+ S04

Ss CrNiMo 19 12 0.8 Ar+2%CO₂ 1-MIG S01

Ss CrNiMo 19 12 0.9 Ar+2%CO₂ 1-MIG S02

Ss CrNiMo 19 12 1.0 Ar+2%CO₂ 1-MIG S03

Ss CrNiMo 19 12 1.2 Ar+2%CO₂ 1-MIG S04

Ss FC-CrNiMo 19 12 1.2 Ar+15–25%CO₂ 1-MIG S84

Ss FC-CrNiMo 19 12 1.2 CO₂ 1-MIG S85

Ss MC-CrNiMo 19 12 1.2 Ar+2%CO₂ 1-MIG S87

Ss CrNiMo 19 12 0.8 Ar+2%CO₂ Pulse/Double Pulse S01

Ss CrNiMo 19 12 0.9 Ar+2%CO₂ Pulse/Double Pulse S02

Ss CrNiMo 19 12 1.0 Ar+2%CO₂ Pulse/Double Pulse S06

Ss CrNiMo 19 12 1.2 Ar+2%CO₂ Pulse/Double Pulse S04

Ss CrNiMo 19 12 1.0 Ar+He+CO₂ Pulse/Double Pulse S26

Ss CrNiMo 19 12 1.2 Ar+He+CO₂ Pulse/Double Pulse S24

FastMig MXP 37 Pipe, MXP 38

18

Page 21

EN

PIPE STEEL PACK

Group Material Wire ø (mm) Shielding gas Process Number

Fe Fe 0.8 Ar+15–25%CO₂ WiseRoot+ F01

Fe Fe 0.9 Ar+15–25%CO₂ WiseRoot+ F02

Fe Fe 1.0 Ar+15–25%CO₂ WiseRoot+ F03

Fe Fe 1.2 Ar+15–25%CO₂ WiseRoot+ F04

Fe Fe 0.8 CO₂ WiseRoot+ F21

Fe Fe 0.9 CO₂ WiseRoot+ F22

Fe Fe 1.0 CO₂ WiseRoot+ F23

Fe Fe 1.2 CO₂ WiseRoot+ F24

Fe Fe Metal 1.2 Ar+15–25%CO₂ WiseRoot+ M04

Fe Fe Metal 1.2 CO₂ WiseRoot+ M24

Fe Fe 0.8 Ar+15–25%CO₂ 1-MIG F01

Fe Fe 0.9 Ar+15–25%CO₂ 1-MIG F02

Fe Fe 1.0 Ar+15–25%CO₂ 1-MIG F03

Fe Fe 1.2 Ar+15–25%CO₂ 1-MIG F04

Fe Fe 0.8 CO₂ 1-MIG F21

Fe Fe 0.9 CO₂ 1-MIG F22

Fe Fe 1.0 CO₂ 1-MIG F23

Fe Fe 1.2 CO₂ 1-MIG F24

Fe Fe Metal 1.2 Ar+15–25%CO₂ 1-MIG M04

Fe Fe Metal 1.2 CO₂ 1-MIG M24

Fe Fe Rutil 1.2 Ar+15–25%CO₂ 1-MIG R04

Fe Fe Rutil 1.2 CO₂ 1-MIG R14

Fe Fe 1.6 InnerShield 1-MIG R56

Fe Fe 2.0 InnerShield 1-MIG R57

Fe Fe 2.4 InnerShield 1-MIG R58

More welding programs are available by purchasing MatchCurve and MatchCustom products.

STEEL PACK FOR WISETHIN+

Group Material Wire ø (mm) Shielding gas Process Number

Fe Fe 0.8 Ar+15–25%CO₂ WiseThin+ F01

Fe Fe 0.9 Ar+15–25%CO₂ WiseThin+ F02

Fe Fe 1.0 Ar+15–25%CO₂ WiseThin+ F03

Fe Fe 1.2 Ar+15–25%CO₂ WiseThin+ F04

Fe Fe 0.8 CO₂ WiseThin+ F21

Fe Fe 0.9 CO₂ WiseThin+ F22

Fe Fe 1.0 CO₂ WiseThin+ F23

Fe Fe 1.2 CO₂ WiseThin+ F24

19

© Kemppi Oy / 1515

Page 22

EN

WORK PACK

Group Material Wire ø (mm) Shielding gas Process Number

Al AlMg5 1.2 Ar Pulse/Double Pulse A02

Al AlSi5 1.2 Ar Pulse/Double Pulse A12

Fe Fe 1.0 Ar+15–25%CO₂ Pulse/Double Pulse F03

Fe Fe 1.2 Ar+15–25%CO₂ Pulse/Double Pulse F04

Ss CrNiMo 19 12 1.0 Ar+2%CO₂ Pulse/Double Pulse S06

Ss CrNiMo 19 12 1.2 Ar+2%CO₂ Pulse/Double Pulse S04

Al AlMg5 1.2 Ar 1-MIG A02

Al AlSi5 1.2 Ar 1-MIG A12

Fe Fe 0.9 Ar+15–25%CO₂ 1-MIG F02

Fe Fe 1.0 Ar+15–25%CO₂ 1-MIG F03

Fe Fe 1.2 Ar+15–25%CO₂ 1-MIG F04

Fe Fe 0.9 CO₂ 1-MIG F22

Fe Fe 1.0 CO₂ 1-MIG F23

Fe Fe 1.2 CO₂ 1-MIG F24

Fe Fe Metal 1.2 Ar+15–25%CO₂ 1-MIG M04

Fe Fe Metal 1.2 CO₂ 1-MIG M24

Fe Fe Rutil 1.2 Ar+15–25%CO₂ 1-MIG R04

Fe Fe Rutil 1.2 CO₂ 1-MIG R14

Ss CrNiMo 19 12 1.0 Ar+2%CO₂ 1-MIG S03

Ss CrNiMo 19 12 1.2 Ar+2%CO₂ 1-MIG S04

Ss FC-CrNiMo 19 12 1.2 Ar+15–25%CO₂ 1-MIG S84

More welding programs are available by purchasing MatchCurve and MatchCustom products.

3.5 Arc voltage display

FastMig X is capable of measuring and showing the voltage close to the welding arc. By taking

this feature into use you don't need to be concerned about the voltage losses in welding

cables anymore. With this feature you are only required to set the voltage for the arc before

welding and after welding you can see the voltage close to the arc.

In order to use the arc voltage feature, follow these steps:

1. After setting up the welding equipment for the rst time, connect the voltage sensing

cable to the welding piece and the measurement cable between the wire feeder and the

power source.

2. If you are using a sub-feeder, enter the length of the sub-feeder to the SubFeederLength

parameter.

3. Set the welding parameters according to your application. Note that the set voltage

when using 1-MIG, MIG and WiseThin+ welding processes means always the voltage in

the arc despite of ArcVoltage setting.

4. Weld with 1-MIG, MIG or with Pulse MIG for at least 5 seconds. During that time the

welding machine calibrates itself for the welding cable length in question. Calibration

values are stored into the welding machine, therefore this calibration is required only

once after installing the welding machine package.

5. If you want to see arc voltage in panels during and after welding, turn the ArcVoltage

setting to ON in X 37 setup panel. Dot after voltage value in XF 37 or XF 38 panel means

that showed value is arc voltage. In the weld data after welding in X 37 panel 'AVol'

means also the arc voltage.

6. Voltage sensing cable can be removed after the calibration procedure, but it is

recommended to use it always.

NOTE! Steps 1-3 should be repeated every time, when the length of the welding or grounding cable

is changed.

FastMig MXP 37 Pipe, MXP 38

20

Page 23

EN

4. BASIC TROUBLESHOOTING

NOTE! The problems listed and the possible causes are not denitive, but serve to suggest some

standard and typical situations that may present during normal environmental use when using

the MIG/MAG process with FastMig X 450 and MXP 37 Pipe or MXP 38.

Problem Check the following

Machine won’t work

• Check mains plug is connected correctly

• Check mains power distribution is switched on

• Check the mains fuse and or circuit breaker

• Check power source 0/I switch is ON

• Check interconnection cable set and connectors between the power source and wire feed unit

are correctly fastened. See the manual schematic

• Check earth return lead is connected

• Check control panels are switched on.

Dirty, poor quality

weld

• Check shielding gas supply

• Check and set gas ow rate

• Check gas type for application

• Check gun/electrode polarity

• Check correct welding program selected

• Check correct channel number selected on wire feeder control panel

• Check power supply – Phase down?

Variable welding

performance

• Check wire feed mechanism is correctly adjusted

• Check correct drive rolls are tted

• Check wire spool overrun tension is correctly adjusted

• Check gun liner is not blocked, replace if necessary

• Check correct gun liner is tted for the ller wire size and type

• Check contact tip for size, type and wear

• Check gun is not over heating in application

• Check cable connections and earth return clamp

• Check welding parameter settings.

Filler wire won’t feed

• Check that pressure arms are closed and adjusted in wire feed mechanism

• Check welding gun switch function

• Check Euro gun collar is correctly fastened

• Check gun liner is not blocked

• Check contact tip, size, type, wear

• Check and tr y alternative gun

High spatter volume

• Check welding parameter values

• Check inductance/Dynamics values

• Check cable compensation value if long cables are tted

• Check gas type and ow

• Check welding polarity – cable connections

• Check ller material selection

• Check correct welding program selected

• Check correct channel number selection

• Check ller wire delivery system

• Check power supply – 3-phase present?

Err1

Power source is not calibrated or calibration data cannot be read

• Restar t power source

• if the problem continues after multiple startups contact Kemppi service representative

Err 3

Overvoltage in the mains supply

• Check the mains voltage

21

© Kemppi Oy / 1515

Page 24

EN

Err 4

Power source is overheated

• Do not shut down, let the fans cool the machine.

• Check ventilation.

• If cooling fans are not running, contact Kemppi service representative.

Err 5

Mains power supply voltage is too low or one of the phases is missing or auxiliary supply is

faulty

• Check the mains supply and auxiliar y supply and contact Kemppi service representative if

necessary.

Err 8

FPGA is not congured

• Restar t the power source.

• If the error persists, contact Kemppi service representative

Err 9

Loose cable connections

• Check the voltage sensing cable, measurement cable and earth return cable.

Err 10

Illegal process

• The welding process is not available in this machine.

Err 12

Plus and minus DIX cable connectors are in contact

• Check welding cables

Err 27

Error in the liquid-cooling unit

• Check the connections in the cooling unit.

Err 42 or Err 43

Over current in wire feeder motor

• Check that the welding gun and consumable parts are properly mounted

Err 45

Gas guard alert

• Check the shielding gas, gas guard and all connections.

Err 50

The function is not activated in this machine

• if you need this function, order a licence for it from a Kemppi representative.

Err 51

Rear feed roll may be loose

• Check that the feed rolls are properly tightened.

Err 52

Front feed roll may be loose

• Check that the feed rolls are properly tightened

Err 62

Power source is not connected or not identied by the wire feeder

• Check the intermediate cable and its connections.

Err 81

Welding program is not found

• If you need the welding program, order a licence for it from Kemppi representative.

MEM ERR & NO DAT

Machine cannot complete read or write functions on the wire feeder memory card

• Check the cables and connections.

• Contact Kemppi service representative.

NO BUS

Control panel cannot establish a connection to the CAN bus

• Check the at cables and the control panels.

• Contact Kemppi service representative.

SUB ERR

WF-number change error

• Connect only one wire feeder to system and try again.

NOTE! Many of these checks may be carried out by the operator. However certain checks relating to

mains power must be completed by an authorised trained electrician.

NOTE! In the case of an error code other than the listed above, contact Kemppi service

representative.

FastMig MXP 37 Pipe, MXP 38

22

Page 25

EN

5. MAINTENANCE

When considering and planning routine maintenance, please consider the frequency of

machine use and the working environment.

Correct operation of the machine and regular maintenance will help you avoid unnecessary

downtime and equipment failure.

NOTE! Disconnect the machine from the mains before handling the electrical cables.

5.1 Daily maintenance

• Check the overall condition of the welding gun. Remove welding spatter from the

contact tip and clean the gas nozzle. Replace worn or damaged parts. Only use original

Kemppi spare parts.

• Check the condition and connection of the welding circuit components: welding gun,

earth return cable and clamp, sockets and connectors.

• Check the condition of the feed rolls, needle bearings and shafts. Clean and lubricate

bearings and shafts with a small quantity of light machine oil if necessary. Assemble,

adjust and test function.

• Check that the feed rolls are suitable for the ller wire you are using, and that their

pressure adjustment is correct.

5.2 Periodic maintenance

NOTE! Periodic maintenance should only be carried out by a suitably qualied person. Disconnect

the plug of the machine from the mains socket and wait about 2 minutes (capacitor charge) before

removing the cover plate.

Check at least every half year:

• Electric connectors of the machine – clean any oxidized parts and tighten loose

connections.

NOTE! You must know the correct tension torques values before starting the reparation of the loose

joints.

Clean the inner parts of the machine from dust and dirt e.g. with a soft brush and vacuum

cleaner. Also clean the ventilation net behind the front grill.

Do not use compressed air, there is a risk that the dirt will compact even more tightly into

gaps of cooling proles.

Do not use pressure washing devices.

Only an authorized trained electrician should carry out repairs to Kemppi machines.

5.3 Service Workshop maintenance

Kemppi Service Workshops complete maintenance according to their Kemppi service

agreement.

The major points in the maintenance procedure are listed as follows:

• Cleaning of the machine

• Checking and maintenance of the welding tools

• Checking of connectors, switches and potentiometers

• Checking of electric connections

• Checking of mains cable and plug

• Damaged parts or parts in bad condition are replaced by new ones

• Maintenance testing.

• Operation and performance values of the machine are checked, and when necessary

adjusted by means of software and test equipment.

Software loading

Kemppi Service Workshops can also test and load rmware and welding software.

23

© Kemppi Oy / 1515

Page 26

EN

6. DISPOSAL OF THE MACHINE

Do not dispose of electrical equipment with normal waste!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment, and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and taken to an appropriate

environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, as per the instructions of local authorities or a Kemppi representative. By

applying this European Directive you will improve the environment and human health.

7. ORDERING CODES

FastMig MXP 37 Pipe Steel wire feeder, 300 mm 6103700

FastMig MXP 37 Pipe Stainless wire feeder, 300 mm 6103710

FastMig MXP 38 wire feeder, 300 mm 6103720

Cables

Earth return cable 5 m, 50 mm² 6184511

Earth return cable 5 m, 70 mm² 6184711

MMA welding cable 5 m, 50 mm² 6184501

MMA welding cable 5 m, 70 mm² 6184701

Magnetic clamp (voltage sensing cable) 200 A 9871580

Magnetic clamp (earth return cable) 600 A 9871570

Interconnection cables, air cooled

FASTMIG X 70-1.8-GH 1.8 m 6260468

FASTMIG X 70-5-GH 5 m 6260469

FASTMIG X 70-10-GH 10 m 6260470

FASTMIG X 70-20-GH 20 m 6260471

FASTMIG X 70-30-GH 30 m 6260472

– For other lengths, please contact Kemppi.

Interconnection cables, liquid-cooled

FASTMIG X 70-1.8-WH 1.8 m 6260473

FASTMIG X 70-5-WH 5 m 6260474

FASTMIG X 70-10-WH 10 m 6260475

FASTMIG X 70-20-WH 20 m 6260476

FASTMIG X 70-30-WH 30 m 6260477

– For other lengths, please contact Kemppi.

Software products

MatchLog™ 9991017

MatchChannel™ Included with MatchLog™ licence

FastMig MXP 37 Pipe, MXP 38

24

Page 27

EN

WisePulseMig™ licence for pulse welding Included with MXP 37 Pipe Stainless and MXP 38

wire feeders

9990417

WiseRoot+™ Included with MXP 37 wire feeder 9990418

WiseThin+™ Included with MXP 38 wire feeder 9990419

WiseFusion™ Included with MXP 37 wire feeder 9991014

WisePenetration™ function 9991000

Pipe Steel welding program package Inlcuded with FastMig MXP 37 Pipe Steel wire

feeder

99904274

Pipe Stainless welding program package Inlcuded with FastMig MXP 37 Pipe Stainless wire

feeder

99904275

Steel Pack for WiseThin+ welding program package Included with MXP 38 wire feeder 99904301

Work Pack Included with MXP 38 wire feeder 99904230

– Other welding software available.

Accessories

Cooling unit FastCool 10 6068100

SuperSnake GT02S sub feeder 10 m 6153100

SuperSnake GT02S sub feeder 15 m 6153150

SuperSnake GT02S sub feeder 20 m 6153200

SuperSnake GT02S sub feeder 25 m 6153250

SuperSnake GT02S W sub feeder 10 m 6154100

SuperSnake GT02S W sub feeder 15 m 6154150

SuperSnake GT02S W sub feeder 20 m 6154200

SuperSnake GT02S W sub feeder 25 m 6154250

SuperSnake GT02S sub feeder synchronization unit

for MXF and MXP wire feeders

W004030

KV 200 mounting plate for two wire feeders and

TIG unit

6185249

Gun holder GH 30 6256030

Transport unit PM 500 6185291

Remote control unit R10 5 m 6185409

Remote control unit R10 10 m 618540901

Remote control unit R20 5 m 6185419

Remote control unit R30 DataRemote 5 m 6185420

Remote control unit R30 DataRemote 10 m 618542001

Remote control extension cable 10 m 6185481

DataGun software installation tool 6265023

25

© Kemppi Oy / 1515

Page 28

EN

MIG guns

PMT MN 1.2 mm / 60° / L198 / ROOT 3.5 m 62503230N04

PMT MN 1.2 mm / 60° / L168 / ROOT 3.5 m 62503230N06

PMT MN 1.2 mm / 60° / L198 / ROOT 5 m 62503250N04

PMT MN 1.2 mm / 60° / L198 3.5 m 62503230N08

PMT MN 1.2 mm / 60° / L198 5 m 62503250N08

PMT MN 1.2 mm / 45° / L222 3.5 m 62503230N02

PMT MN 1.2 mm / 45° / L222 5 m 62503250N02

PMT MN 1.0 mm / Ss / 60° / L198 / ROOT 5 m 62503250N03SS

PMT MN 1.0 mm / Ss / 60° / L198 5 m 62503250N07SS

PMT MN 1.0 mm / Ss / 45° / L222 5 m 62503250N01SS

Neck 45° / L222 SP007229

Neck 60° / L198 / ROOT SP007811

Neck 60° / L168 / ROOT SP007810

Neck 60° / L198 SP008006

Neck 60° / L168 SP008007

PMT 35 3 m 6253513

PMT 35 4.5 m 6253514

PMT 42 3 m 6254213

PMT 42 4.5 m 6254214

PMT 50 3 m 6255013

PMT 50 4.5 m 6255014

PMT 30W 3 m 6253043

PMT 30W 4.5 m 6253044

PMT 42W 3 m 6254203

PMT 42W 4.5 m 6254204

PMT 52W 3 m 6255203

PMT 52W 4.5 m 6255204

WS 35 AL 1.2 mm 6 m 6253516A12

WS 30 W AL 1.2 – 1.6 mm 6 m 6253046A12

WS 30 W AL 1.2 – 1.6 mm 8 m 6253048A12

WS 42 W AL 1.2 – 1.6 mm 6 m 6254206A12

WS 42 W AL 1.2 – 1.6 mm 8 m 6254208A12

WS 35 Ss 1.0 mm 6 m 6253516S10

WS 30 W Ss 1.0 mm 6 m 6253046S10

WS 30 W Ss 1.2 mm 6 m 6253046S12

WS 30 W Ss 1.0 mm 8 m 6253048S10

WS 30 W Ss 1.2 mm 8 m 6253048S12

WS 42 W Ss 1.0 mm 6 m 6254206S10

WS 42 W Ss 1.2 mm 6 m 6254206S12

WS 42 W Ss 1.0 mm 8 m 6254208S10

WS 42 W Ss 1.2 mm 8 m 6254208S12

For a complete list of welding guns, please visit Kemppi web site at www.kemppi.com.

FastMig MXP 37 Pipe, MXP 38

26

Page 29

EN

8. TECHNICAL DATA

FastMig MXP 37 Pipe FastMig MXP 38

Operating voltage (safety voltage)

50 V DC 50 V DC

Rated power

250 W 100 W

Output 40 °C

60 % ED 520 A 520 A

100 % ED 440 A 440 A

Wire feed speed

0.5 – 25 m/min 1 – 25 m/min

Wire feed mechanism

4-roll, two motors 4-roll

Diameter of feed rolls

32 mm 32 mm

Filler wires

ø Fe, Ss 0.6 – 2.0 mm 0.6 – 1.6 mm

ø Cored wire 0.8 – 2.4 mm 0.8 – 2.0 mm

ø Al 0.8 – 2.4 mm 1.0 – 2.4 mm

Wire spool

max. weight 20 kg 20 kg

max. ø 300 mm 300 mm

Maximum gas pressure

0.5 MPa 0.5 MPa

Gun connection

Euro Euro

Operation temperature range

-20…+40 °C -20 ... +40 °C

Storage temperature range

-40…+60 °C -40 ... +60 °C

EMC class

A A

Degree of protection

IP23S IP23S

External dimensions

L x W x H 590 x 240 x 445 mm 625 x 243 x 476 mm

Weight

13.1 kg 12.5 kg

27

© Kemppi Oy / 1515

Page 30

www.kemppi.com

1903700

1515

KEMPPI OY

Kempinkatu 1

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) LTD

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

UNITED KINGDOM

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GMBH

Perchstetten 10

D-35428 LANGGÖNS

DEUTSCHLAND

Tel +49 6 403 7792 0

Telefax +49 6 403 779 79 74

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 240 84 03

Telefax +7 495 240 84 07

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 240 84 03

Telefax +7 495 240 84 07

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY LTD

Unit 105, 1/F, Building #1,

No. 26 Xihuan South Rd.,

Beijing Economic-Technological Development

Area (BDA),

100176 BEIJING

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区

西环南路26号

1号楼1层105室(100176)

电话:+86-10-6787 6064/1282

传真:+86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

Kazura Garden,

Neelankarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

KEMPPI WELDING SOLUTIONS SDN BHD

No 12A, Jalan TP5A,

Taman Perindustrian UEP,

47600 Subang Jaya,

SELANGOR, MALAYSIA

Tel +60 3 80207035

Telefax +60 3 80207835

sales.malaysia@kemppi.com

Loading...

Loading...