Page 1

1908

1918820

FA Flow Control

Operating

manual

Operating manual – Brugsanvisning – Gebrauchsanweisung – Manual

de instrucciones – Käyttöohje – Manuel d’utilisation – Manuale d’uso –

Gebruiksaanwijzing – Bruksanvisning – Instrukcja obsługi – Manual de

utilização – Инструкции по эксплуатации – Bruksanvisning – 操作手册

Page 2

1

2

3

6

7

!

4

8

2.

> 1 s

5

1.

9

3.

> 1 s

10

© Kemppi Oy 2019

Page 3

ENGLISH

1. Introduction

1.1 General

Congratulations on choosing the FA Flow Control respiratory system.

This operating manual contains important information on

the use, maintenance and safety of your FA Flow Control

respiratory system. The technical specications of the

equipment can be found at the end of the manual.

Please read the operating manual and other instructions

carefully before using the equipment for the rst time.

Important notes

Items in the manual that require particular attention in

order to minimise damage and personal harm are indicated

with the ’NOTE!’ notation. Read these sections carefully

and follow their instructions.

Disclaimer

While every eort has been made to ensure that the

information contained in this guide is accurate and

complete, no liability can be accepted for any errors

or omissions. Kemppi reserves the right to change the

specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit

the contents of this guide without prior written permission

from Kemppi.

1.2 About FA Flow Control system

FA Flow Control is a battery powered air purifying respirator

unit for Kemppi's respiratory protective system, which is

based on the principle of circulated pressurized air in the

hood. The belt-mounted blower unit delivers air through

a lter and via an air hose into a headpiece. The supply of

ltered air creates positive pressure inside the headpiece,

which prevents the external contaminated air from

entering the user’s breathing zone.

FA Flow Control unit meets the European standard EN

12941, when used with Delta 90/Delta+ 90 SFA and XFA

helmets.

FA Flow Control respiratory system can be used for

protection against solid and liquid particles in breathing

air in welding and similar processes. It is not to be used for

protection against toxic gases and vapours.

2. Preconditions for use

Before you can use the system correctly and safely, you

must fully understand all of the following precautions.

• Oxygen concentration in the surrounding area must

not drop under 17%.

• Type and concentration of the contaminants in the

working place must be known to the user.

• The FA respiratory system must not be used in

unventilated areas such as tanks, pipes, channels etc.

• The FA respiratory system must not be used in areas

with danger of explosion.

• The respiratory system must only be used with the

blower unit switched on.

• The air ow must be checked before use.

• If the blower unit stops working for any reason, the

user must leave the contaminated area immediately.

• If the blower unit is switched o, the respiratory

system gives little or no respiratory protection. There

is also a risk of high concentration of carbon dioxide

(CO₂) and of oxygen reduction inside the headpiece.

During a period of really hard work when user’s

breathing becomes very intense, pressure may

decrease inside the hood and thus the protective

eect can decrease.

• The headpiece must t the user´s face perfectly, only

then the eciency of the system is sucient. The

protective eect of the complete system is reduced,

if the seal of the headpiece is not tted properly, for

example, due to beards or long hair breaking the

seal.

• It must be ensured that the air hose does not make

a loop and does not get caught or trapped in the

surroundings.

• Respiratory system FA Flow Control is restricted for

protection against solid and liquid particles only. Do

not use it against toxic gases and vapours.

• The unit does not protect the user against gases.

• It is essential to choose the correct type of lter

according to the type of contamination.

• Immediately replace the lter(s) as soon as the

contaminant can be smelt.

• When using lters protecting against contaminants,

which are dicult to identify by smell or other senses,

special rules depending on the current conditions

must be followed.

• Use only original lters certied for the particular

respiratory system.

FA Flow Control

3

Note! If the recommendations stated in this

manual are ignored, the warranty is automatically

invalidated and the level of personal protection may

not meet the designated standards.

Page 4

ENGLISH

3. Unpacking and assembly

3.1 Unpacking

Check that the package is complete and that no part has

been damaged in transit or for other reasons.

A package with the complete system including

accessories contains:

1. Blower unit including battery 1 pc

2. Belt 1 pc

3. Flexi hose 1 pc

4. Air ow indicator 1 pc

5. Battery charger 1 pc

6. Operating manual 1 pc

The FA Flow Control is supplied with P R SL lter.

3.2 Assembly

1. Connect the battery to the blower unit.

2. Attach the unit onto the belt. Make sure that the

lter or lters are tted properly.

3. Connect the air hose to the blower unit.

4. Connect the air hose to the headpiece and hand

tighten.

4. Usage

4.1 Inspection before every use

Do the following checks always before you start using the

equipment:

• Check that all components are in good condition

with no visible damage. Replace any damaged or

worn parts. Carefully examine the air hose, seals and

the facepiece.

• Check that there is a good connection between the

air hose and the headpiece as well as the blower unit

• Ensure that there is sucient air ow as explained in

section "Air ow test".

• Check that the air is supplied through the whole

respiratory system from the blower to the hood.

Fully charge the battery before rst use.

4.2 Air ow test

Before every use, you should conduct an air ow test on the

equipment as follows:

1. Disconnect the air hose from the blower unit.

2. Connect the air ow indicator to the unit.

3. Turn the unit on and check the air ow using the

bottom air ow level.

If the pointer on the air ow indicator goes into the red

zone, the air ow is insucient and the lter(s) must be

replaced.

4.3 Using the FA Flow Control

1 Switch on the unit by pressing the ON/OFF button on

the control panel.

2 The airow can be adjusted with the plus and minus

buttons (+ and –) from 170 l/min up to 240 l/min. The

number of lit green LED diodes indicates the airow level.

The unit ensures a constant supply of air. The microprocessor

inside the unit automatically regulates the motor speed to

compensate the lter clogging and the battery state.

If the microprocessor cannot maintain the adjusted airow,

an acoustic alarm signal can be heard and the LED diodes

display RED in colour. If possible, the microprocessor

automatically reduces the airow to the next lower level.

3 When the airow falls below the minimum level, the

alarm intensies. Then the user must stop working at once

and change the lter or recharge/change the battery.

To check the alarm function, perform the air ow test as

follows:

1. Disconnect the air hose from the headpiece.

2. Cover the disconnected end of the air hose with

your hand. The blower starts to run faster after

about 20 seconds, the audible alarm activates and

the LED diodes on the control panel start blinking.

3. Remove your hand . The blower speed should

decrease.

If the blower speed does not change, it is necessary to

check the unit.

4.4 Checking the battery state

4 Press and hold the left button (–) for more than 1

second. The more red coloured LED diodes come on, the

higher the remaining battery capacity is.

4.5 Checking the lter

5 Press and hold the right button (+) for more than 1

second. The more yellow LED diodes come on, the more

clogged the lter is.

After releasing the buttons, the LED diodes return to the

green light state indicating the current airow.

© Kemppi Oy 2019

4

Page 5

ENGLISH

5. Maintenance

It is recommended to clean the respiratory system after

each use. Also inspect all parts and replace any which are

damaged or worn.

• Always clean the respiratory unit in a ventilated room

or outside. Be aware of harmful dust settled on any

parts of the unit.

• Never use ammable cleaning liquids or abrasive

cleaners!

• The outer surface of the blower unit can be cleaned

with a soft cloth and mild detergent solution. The

unit must be completely dry before assembling the

ller and cover.

• Ensure that no water or detergents enter the blower

unit!

• The air hose itself, detached from the blower unit and

the headpiece, can be rinsed in clean water.

6. Filters

The respiratory power unit is equipped with a high

eciency particle lter of class P R SL.

The lter must be checked regularly and replaced when

necessary. See section 4.2: "Air ow test".

Make sure that the new lter is within its expiry date,

unused and not noticeably damaged.

From the hygienic point of view the maximum working

time of a lter is 180 hours and should not be exceeded.

6.1 Changing lter

Remove the lter cover:

1. Pull the locking clips outwards and move the lter

cover o the unit.

Note! Never use any tools to uncover the lter.

Remove the lter:

2. Turn the lter and pull it away from the main body.

3. Remove any dust with a soft cloth.

Insert a new lter:

4. If you are using a prelter or an odor lter, place

and x it around the new lter as tightly as possible,

sticking the ends together using the sticky tape

located on the ends of the prelter or odor lter.

5. Put the lter back into position using the same

rotating motion and gently push until it ts well

onto the body of the unit.

6. Put the lter cover back. Ensure you snap the cover

into place on both sides.

6

7

8

7. Battery

Note! The battery must be charged before the rst

use.

The charger must not be used for any other purpose

than that for which it was manufactured. Please read the

following precautions:

• Do not charge the battery where there is a risk of

explosion.

• The battery charger is intended for indoor use only.

• The charger must be protected against damp.

7.1 Removing and inserting the battery

9

7.2 Charging the battery

1. Check that the voltage of the electrical power

supply is correct.

2. Plug the charger into the socket.

3. Remove the battery from the unit and connect it to

the charger.

4. Once the battery is fully charged, a green LED is lit.

5. Disconnect the charger from the power supply.

The charger controls the charging automatically. After

the battery has been charged, the charger switches to

maintenance mode and keeps the battery fully charged.

Charging time is 4 – 5 hours.

Note! Do not leave the charger in the power supply

if not in use !

8. Storage

All parts of a FA Flow Control system must be stored in an

environment with temperature between -10 – 55 °C and

humidity between 20 – 80 % Rh. The storage life is 2 years

for the product if stored in its original unopened package.

Note! Batteries get discharged even if not in

use. Therefore for long-term storage it is highly

recommended to charge the batteries for an hour

every 3 months.

9. Warranty

There is a 12 month warranty covering production defects

and a 6 month warranty for batteries.

The warranty begins from the date of purchase. The claim

must be lodged with the dealer. The paid invoice or receipt

must be produced if claiming on the warranty.

The claiming procedure will be successful only if there were

no changes made on the blower unit including the battery

and charger.

FA Flow Control

5

If the damage is caused by not changing a clogged lter

in time or using a lter which has been cleaned by the

customer, the claim will not be processed.

Page 6

ENGLISH

10. Troubleshooting

Fault Probable reason Recommendation

The blower unit does

not work at all.

Low airow. Blocked air hose or airduct. Check and remove blockage.

Short operating time. Clogged Filter. Change the lter.

Battery cannot be

charged.

Battery cannot be

charged suciently.

11. Technical data

FA Flow Control

Airow 140 – 210 l/min at 8 adjustable ow rates

Weight of the blower unit incl. the lter and battery 980 g

Noise level < 70 dB

Battery lifetime Max. 500 charging cycles

Charging time 4 – 5 hours

Belt size Max. 150 cm

Recommended temperature range 10 – 40 °C

Recommended humidity range 20 – 80 % Rh

Certication EN 12941/A2 TH2 P R SL

Manufacturer (manufactured for Kemppi by) CleanAir Ltd.

Entirely discharged battery.

Verify if the blower unit works with

another charged battery.

Faulty motor, circuit board or

connector.

Leakage. Check all seals, connectors and the air

Battery is not suciently charged. Charge the battery.

Blocked Filter. Change the lter.

Battery is not charged properly. Charge the battery.

Battery contact is damaged. Replace the battery.

Charger is faulty. Contact your supplier.

Battery is worn out. Replace the battery.

Charge the battery.

If problem persists, replace the battery.

Contact your supplier.

hose. Make sure that air cannot leak

through holes or tears.

If problem persists, replace the battery.

If problem persists, replace the battery.

Notied body for CE testing:

Výzkumný ústav bezpečnosti práce, v.v.i. – ZL

Testing Laboratory No. 1024

Jeruzalémská 9, 116 52 Praha 1

Authorized Body 235

Notied Body 1024

© Kemppi Oy 2019

6

Page 7

ENGLISH

Expected operating time of the blower unit after

being fully charged (hours)

Airow Filter

min. middle max. P R SL

X 10 h

X 6 – 7 h

X 4 – 5 h

Note! Operating time can be decreased if the lters

are clogged.

12. Ordering codes

Delta 90 SFA welding helmet + FA Flow Control 9873310

Delta+ 90 XFA welding helmet + FA Flow Control 9873320

FA Flow Control unit with Li-ion battery Complete package W013560

Spare parts and consumables

FA Battery charger, Li-ion W013564

FA Li-ion battery, 4.4 Ah W007507

FA Flow Control Flexi hose W007487

FA Flow Control Flow indicator W007488

FA Comfort belt W007489

FA Basic lter 2 pcs, standard W007490

FA Flow Control sealing ring for lter W007491

FA Flow Control pre-lter 10 pcs W007492

FA FLow Control odour lter 10 pcs W007494

FA Flow Control Filter cover W013565

Optional

FA Flexi hose cover W007788

FA Heavy duty comfort belt W007789

FA Head cover W007827

FA Protective neck cover W007828

FA Flow Control

7

Page 8

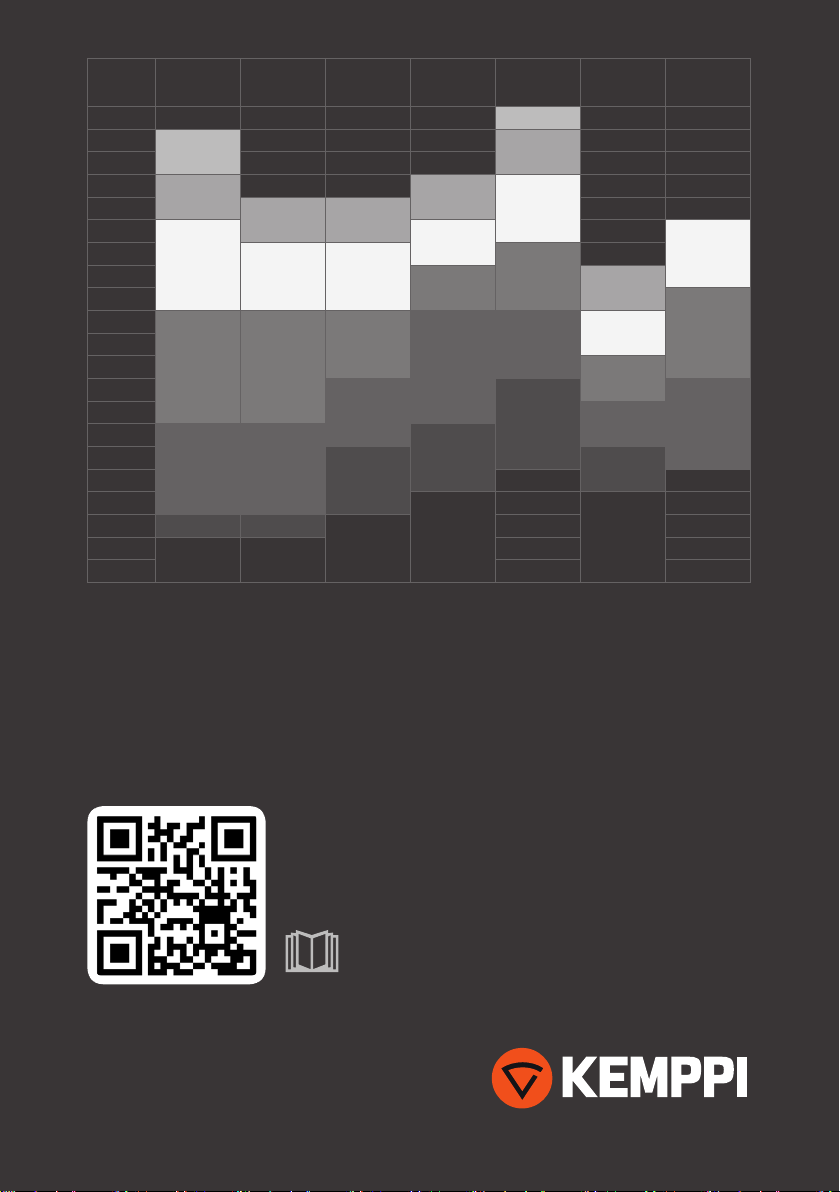

15 A

20 A

30 A

40 A

60 A

80 A

100 A

125 A

150 A

175 A

200 A

225 A

250 A

275 A

300 A

350 A

400 A

450 A

500 A

550 A

600 A

MMA

(E-Hand)

MIG, Ss MIG, AI MAG, CO TIG Gouging Plasma

9 10

10 10

10 10

11

11

11 11 12

12 10

12

12 12

13

13

13 13

14 14

15 15

14

15

14

15 15

cutting

9

11

11

13

11

12

12

14 13

13

14

Declarations of Conformity – Overensstemmelseserklæringer –Konformitäts-erklärungen –

Declaraciones de conformidad – Vaatimustenmukaisuusvakuutuksia – Déclarations de conformité –

Dichiarazioni di conformità – Verklaringen van overeenstemming – Samsvarserklæringer –

Deklaracje zgodności – Declarações de conformidade – Заявления о соответствии – Försäkran om

överensstämmelse – 符合性声明

userdoc.kemppi.com

Loading...

Loading...