Page 1

FitWeld

Evo 300

Operating manual

Bruksanvisning

Gebrauchsanweisung

Manual de instrucciones

Käyttöohje

Manuel d’utilisation

Manuale d’uso

Gebruiksaanwijzing

Brugsanvisning

Instrukcja obsługi

Manual de utilização

EN

DA

DE

ES

FI

FR

IT

NL

NO

PL

PT

Инструкции по эксплуатации

Bruksanvisning

操作手册

RU

SV

ZH

Page 2

Page 3

OPERATING MANUAL

English

Page 4

CONTENTS

EN

1. Introduction

1.1 General

1.2 About welding

....................................................................................................................................... 3

................................................................................... 3

......................................................................................................................... 3

2. Using the machine ......................................................................... 4

2.1 Before use .................................................................................................................................. 4

2.2 Machine introduction ........................................................................................................... 4

2.3 Distribution network ............................................................................................................. 4

2.4 Connecting cables ................................................................................................................. 4

2.4.1 Connecting to mains ....................................................................................................... 5

2.4.2 Earth return cable ............................................................................................................ 5

2.4.3 Shielding gas .................................................................................................................... 5

2.4.4 Welding gun ..................................................................................................................... 6

2.5 Installing ller wire ................................................................................................................. 6

2.5.1 Mounting the wire spool ................................................................................................. 6

2.5.2 Feeding in the welding wire ........................................................................................... 7

2.5.3 Setting the pressure of the feed rolls ............................................................................. 8

2.5.4 Setting the spool brake force .......................................................................................... 8

2.5.5 Wire guide tubes and wire feed rolls .............................................................................. 9

2.5.6 Changing the feed rolls .................................................................................................10

2.6 Controlling welding functions ........................................................................................11

2.6.1 Control panel functions.................................................................................................11

2.6.2 Controls inside the machine .........................................................................................12

2.6.3 Selecting the gun operating mode ..............................................................................12

2.6.4 Adjusting the shielding gas ow ..................................................................................13

2.6.5 Reversing polarity ..........................................................................................................13

2.7 Troubleshooting ...................................................................................................................14

3. Maintenance ................................................................................ 15

3.1 Daily maintenance

3.2 Maintenance of the wire feed mechanism .................................................................15

3.2.1 Cleaning the gun wire liner ..........................................................................................15

3.2.2 Replacing the wire liner.................................................................................................15

3.3 Disposal

....................................................................................................................................15

...............................................................................................................15

4. Ordering codes ............................................................................ 16

5. Technical data .............................................................................. 17

2

FitWeld Evo 300

Page 5

1. INTRODUCTION

1.1 General

Congratulations on choosing the FitWeld welding machine. Used correctly Kemppi welding

machines can increase your productivity and provide years of economical service.

This user manual contains important information on the use, maintenance and safety of your

Kemppi product. The technical specications of the device can be found at the end of the

manual. Please read the operating manual and the safety instructions booklet carefully before

using the equipment for the rst time. For your safety and that of your working environment,

pay particular attention to the safety instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi Web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

NOTE! Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with this symbol. Read these sections carefully and follow their

instructions.

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

1.2 About welding

FitWeld Evo 300 is suitable for many MIG/MAG welding applications, but its quick ignition and

high eciency make it especially fast, safe and economic for tack welding of steel materials. It

can be used for welding with ferrous, stainless steel and aluminium ller materials.

FitWeld Evo 300 is designed for use in demanding environments. It has wire feed cabinet

illumination to facilitate wire adjustment in dark conditions, and its case is made of reinforced

bre plastic.

Tack welding with the MIG/MAG process

Tack welding is used during the fabrication and tting process, using spot-like welds to

establish the joints before primary welding.

Using MIG/MAG process for tack welding makes this phase fast and ecient. It is also a safer

compared to traditional MMA tack welding.

EN

© Kemppi Oy / 1515

3

Page 6

EN

2. USING THE MACHINE

2.1 Before use

The product is packed in cartons designed specically for them. However, always make sure

before use that the products have not been damaged during transportation.

Check also that you have received the components you ordered and the instruction manuals

needed, as described in the Quick start guide. Product packaging material is recyclable.

Please also read the Safety Instructions included with the package before use.

NOTE! When moving the welding machine, always lift it from the handle, never pull it from the

welding gun or other cables.

Operating environment

This machine is suitable for both indoor and outdoor use. Always make sure that the air ow in

the machine is unrestricted. The recommended operating temperature range is -20 ... +40 °C.

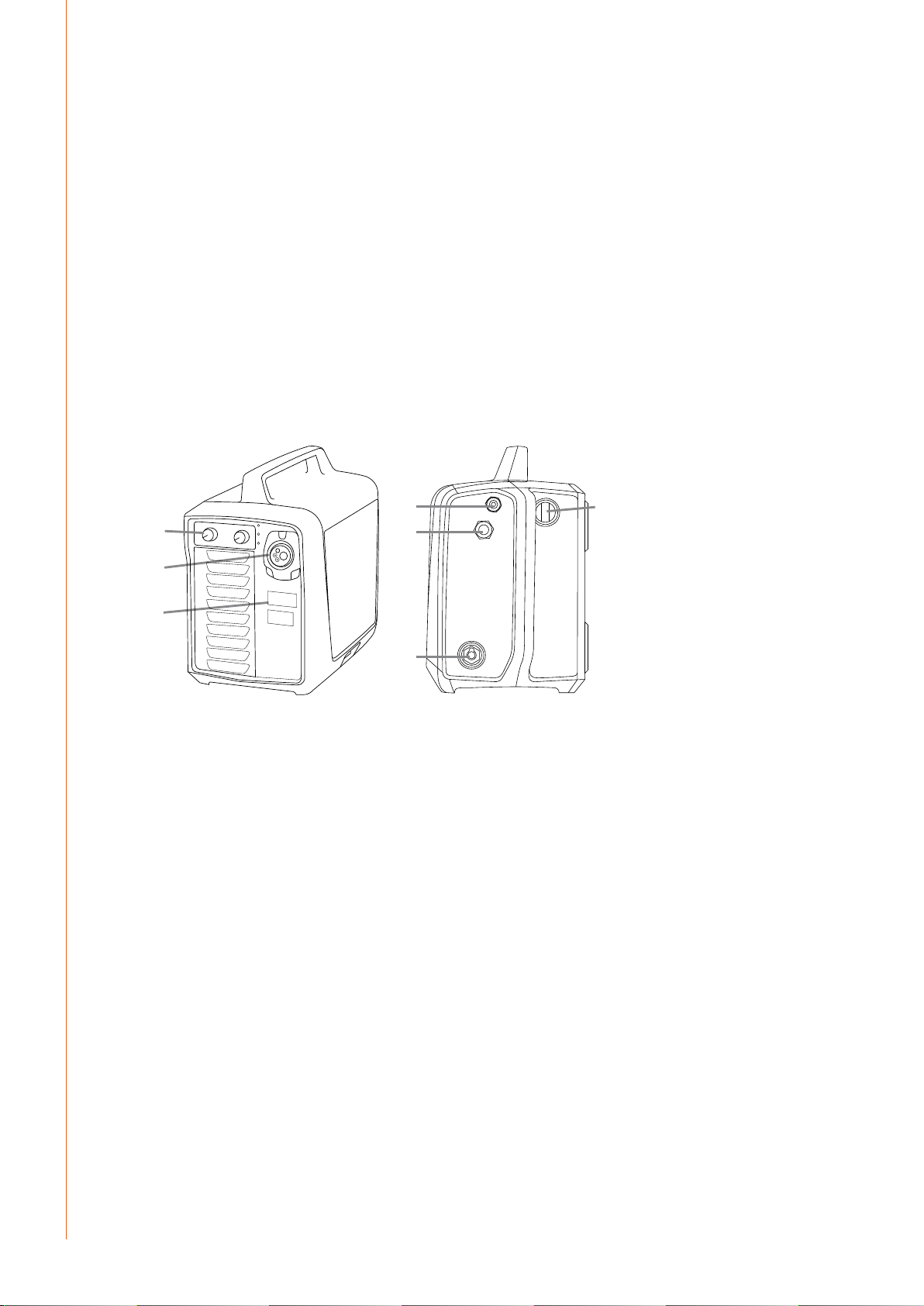

2.2 Machine introduction

7.

5

.

6.

1. ON/OFF

2. Mains supply cable

3. Earth return cable

4. Shielding gas connector

5. EURO gun connector

6. Meter displays

7. Control knobs

2.3 Distribution network

All regular electrical devices without special circuits generate harmonic currents into

distribution network. High rates of harmonic current may cause losses and disturbance to

some equipment.

This equipment complies with IEC 61000-3-12 provided that the short-circuit power Ssc

is greater than or equal to 1.9 MVA at the interface point between the user’s supply and

the public supply network. It is the responsibility of the installer or user of the equipment

to ensure, by consultation with the distribution network operator if necessary, that the

equipment is connected only to a supply with a short-circuit power Ssc greater than or equal

to 1.9 MVA.

4.

2.

3.

1.

4

2.4 Connecting cables

Before you can start welding with FitWeld Evo 300, you must connect the machine to the

mains power supply, attach the welding gun and the earth return cable and the shielding

gas supply. You must also equip the machine with a ller wire spool suitable for your welding

application.

FitWeld Evo 300

Page 7

For quick help about starting with FitWeld, please refer to the Quick Guide delivered with the

product information package.

2.4.1 Connecting to mains

FitWeld Evo 300 is connected to a 3-phase network using the mains cable supplied with the

machine. The cable is not equipped with a wall plug, so you must install a suitable plug before

you use the machine for the rst time.

Check also that the mains cable complies with the local electrical regulations, and replace the

cable if necessary. See ’Technical specications’.

NOTE! The mains cable or wall plug may be installed or replaced only by an electrical contractor or

installer authorised to perform such operations.

2.4.2 Earth return cable

For creating a closed electric circuit needed in welding, you must connect the earth return

cable to the connector located on the back of the FitWeld. The other end of this cable will be

connected to the workpiece before welding.

NOTE! When attaching the earth return clamp to the work piece, remember to clean the work piece

surface so as to achieve safe and undisturbed operation.

2.4.3 Shielding gas

Secure the snap connector of the shielding gas hose to the gas connector on the back of the

FitWeld machine. Connect the other end of the gas hose to a gas cylinder’s control valve or to

the shielding gas distribution network at your worksite.

Make sure that you are using the correct type of shielding gas for the welding application.

The shielding gas used for steel wires is carbon dioxide or a mixture of argon and carbon

dioxide. The shielding gas used for stainless steel ller wires is a mixture of argon and carbon

dioxide (2%). For aluminium ller wires use pure argon shielding gas.

The thickness of the parent material, joint type and welding power dene the required

shielding gas ow rate.

EN

To connect the shielding gas hose to a suitable regulator for MIG/MAG welding

1. Connect the shielding gas hose to the gas cylinder’s control valve and tighten the

connector (connector is not supplied in the package).

2. Adjust the shielding gas ow rate with the control valve screw.

3. Always close the cylinder valve after use.

NOTE! The shielding gas ow rate set from the gas cylinder regulator must exceed the ow rate

measured at the welding gun, if GasGuard function is active. If the ow rate and pressure are the

same, the gas indicator light will shine on the control panel and welding is prevented.

See also instructions and warnings about adjusting the FitWeld's gas ow rate later in this

manual.

© Kemppi Oy / 1515

5

Page 8

EN

2.4.4 Welding gun

Connect the welding gun cable to the Euro adapter socket located on the front panel and

hand tighten only. Do not over tighten the collar.

The welding gun leads the ller wire, shielding gas and electric current to the weld piece.

When you press the welding gun trigger, shielding gas will ow and ller wire will begin to

feed.

The arc will ignite when the ller wire touches the weld piece. If no ignition, check that the

earth return cable is connected and the clamp has good contact to the work piece.

2.5 Installing ller wire

With FitWeld Evo 300 you can use up to 200 mm diameter wire spools and the following ller

wire types:

• solid wires

• ux-cored wires

• self-shielded ux-cored wires

• stainless steel wires

• aluminium wires.

When choosing the ller wire, remember that the wire must have approximately the same

melting point as the base material to be welded.

NOTE! When changing the ller wire, always check that the feed rolls, their groove shape and size

and the wire liner inside the welding cable are suitable for the wire you are using. Also check that

you are using right polarity for the ller wire.

2.5.1 Mounting the wire spool

NOTE! The liner and the feed rolls are colour-coded. See that you are using feed rolls that match the

colour of the wire liner inside the welding gun cable. See the table of feed rolls and wire liners later

in this chapter.

With FitWeld Evo 300 you can use wire spools with a diameter of 200 mm maximum.

1. 2.

To mount the wire spool:

1. Turn the locking knob of the spool holder so that the locking clips are opened (1).

2. Check the rotating direction of the wire spool and push the spool into its place so that it

rotates in the right direction.

3. Turn the locking knob of the spool holder to close the locking clips (2).

6

FitWeld Evo 300

Page 9

2.5.2 Feeding in the welding wire

NOTE! Remember to remove the sharp cut tip of the ller wire before loading the wire to the

welding gun, so preventing damage to the liner inside the welding gun cable. This is particularly

important for soft ller wires such as aluminium. It will also improve feed quality and increase the

service life of your gun liner.

For reliable performance only use Kemppi gun liner materials specially developed for use with

Kemppi machines.

For information on recommended liners and wire feed rolls selection, please see the relevant

sections later in this chapter. Be careful not to let the wire unwind from the spool.

NOTE! When feeding the welding wire into the gun, be sure that you are not pointing the gun at

anyone and that there isn’t anything in front of the gun.

To feed the wire from the spool to the welding gun:

1. Open the pressure arm of the GT02 mechanism and lift the top roll clear on its pivot.

2. Draw some loose wire from the spool and carefully push it through the bronze wire

guide at the back of the mechanism. Push the wire over the feed roll groove and through

the front wire guide until it comes out from the Euro connector by about 150mm.

3. Replace the top feed roll over the wire and close the pressure arm.

4. Cut away any deformed wire section and dress the sharp wire tip as described above.

5. Connect the welding gun and tighten the collar.

6. Press the welding gun trigger and allow the ller wire to feed through the gun cable to

the contact tip.

Check once again that the wire is still properly in the grooves of both feed roll pairs. Now the

FitWeld Evo is ready to weld.

EN

© Kemppi Oy / 1515

7

Page 10

EN

2.5.3 Setting the pressure of the feed rolls

To make ller wire run smoothly into the wire liner and to the welding gun you can adjust the

pressure of the feed rolls of the GT02 WireDrive mechanism.

Turn the orange coloured pressure adjustment knob in a clockwise direction to increase the

pressure applied to the welding ller wire, and anti-clockwise to decrease it.

There is a graduation scale marked on the aluminium arm above the orange adjustment knob.

The more pressure applied, the greater the number of graduation marks visible.

For hard steel and stainless steel ller wires, make sure there is sucient pressure applied,

so avoiding ller wire slippage in the feed rolls.

NOTE! Too much pressure may atten the ller wire, damage its coating, cause friction and

excessive wear to drive roll bearings and therefore reduced life.

For aluminium ller wires select the correct feed roll type from the chart supplied and adjust

for the minimum pressure necessary for reliable ller wire drive.

NOTE! Slight slippage is recommended in the case of aluminium ller wires. This ensures that the

soft wire is not deformed and attened and that the feed rolls skid over the soft wire if gets stuck on

the gun contact tip.

For Aluminium and Stainless Steel ller wires, always use Kemppi DL Chili gun liners. These

liners are especially developed by Kemppi and signicantly reduce friction loses, so improving

welding performance.

2.5.4 Setting the spool brake force

To prevent the ller wire from uncoiling on overrun following use at high feed speeds, you can

change the brake force of the welding spool.

Adjust the spool brake force through the hole in the spool locking mechanism with the Allen

key supplied and mounted below the wire drive mechanism.

Increase the force by turning the Allen key clockwise and decrease it by turning it

anticlockwise.

NOTE! Do not over tighten, and reduce the pressure for light ller wire types.

8

FitWeld Evo 300

Page 11

2.5.5 Wire guide tubes and wire feed rolls

Make sure that you select appropriate wire feed rolls/groove type, welding gun contact tip

and wire liner for the ller wire used.

Kemppi feed rolls and gun liners are colour-coded in order to make identication easy.

Wire guide tubes

ø mm outlet tube inlet tube

Ss, Al, (Fe, Mc, Fc)

plastic

Fe, Mc, Fc

metal

Wire feed rolls, plastic

ø mm lower upper

Fe, Ss, (Al, Mc, Fc)

V-groove

0.8 – 0.9 W001047 W001048

1.0 W000675 W000676

1.2 W000960 W000961

W003963 W003962

W003881 W003536

EN

Fc, Mc, (Fe)

V-groove, knurled

Al, (Fc, Mc, Ss, Fe)

U-groove

Wire feed rolls, metal

Fe, Ss, (Al, Mc, Fc)

V-groove

Fc, Mc, (Fe)

V-groove, knurled

Al, (Fc, Mc, Ss, Fe)

U-groove

1.0 W001057 W001058

1.2 W001059 W001060

1.0 W001068 W001067

1.2 W001070 W001069

ø mm lower upper

0.8 – 0.9 W006074 W006075

1.0 W006076 W006077

1.2 W004754 W004753

1.0 W006080 W006081

1.2 W006082 W006083

1.0 W006088 W006089

1.2 W006090 W006091

© Kemppi Oy / 1515

9

Page 12

EN

2.5.6 Changing the feed rolls

To change the feed rolls:

1. Pull and release the pressure tension arm via the aluminium head above the orange

plastic adjuster.

2. Lift the upper feed roll on its pivot to the maximum open position.

3. Pull out mounting pin of the upper feed pressure roll and replace the roll with a new one.

4. Open the locking screw of the lower feed roll and replace the roll with a new one.

5. Return the upper pressure feed roll to its down position and replace the locking arm

latch.

6. Adjust the pressure tension as instructed in the earlier section.

1.

2.

3.

4.

5.

When using hard, ux-cored ller wires you should select a knurled feed roll to achieve better

grip.

10

FitWeld Evo 300

Page 13

2.6 Controlling welding functions

With FitWeld Evo 300 you can easily control welding parameters, change the welding polarity

and gun operating mode.

The control panel provides two adjustment knobs. You can set the desired welding voltage

and wire feed speed before or during welding, so easily tuning the desired arc performance to

the weld.

2.6.1 Control panel functions

FitWeld

ON

10

9

8

7

6

With the left-hand control knob, set the value for ller wire feed speed. The maximum value is

18 meters per minute.

With the right-hand control knob, set the welding voltage. Adjustment range is from 11V to

32V.

The leds on the front panel indicate the following (from top to bottom):

• Machine is turned on

• Machine is overheated

• Error in shielding gas ow

1

2

3

4

5

I

U

The leds on the right hand side of the upper meter display indicate the showed variable, either

A or m/min. When not welding, the meter displays will show the selected wire feed speed

and voltage. When welding, the meter displays will show the actual current and voltage.

The parameters can be adjusted during welding and the meter displays will show the new

selected value. After welding the meter displays will briey show an average value of the

actual current and voltage.

10

9

8

7

U

6

A

m

min

V

1

2

3

4

5

EN

© Kemppi Oy / 1515

11

Page 14

EN

2.6.2 Controls inside the machine

1. 2.

3.

1. Welding gun operation mode switch.

2. Shielding gas adjustment screw.

3. Cable connections for reversing polarity.

2.6.3 Selecting the gun operating mode

With the three position switch (1) you can set the MIG welding gun to two-sequence (2T) or

four-sequence (4T) mode with GasGuard feature on.

If you are using self-shielded ux-cored ller wire (gasless wire), you must select the upmost

switch position. This position provides 2T operation with GasGuard feature disabled, allowing

welding without shielding gas.

To use the welding gun in 2T operating mode:

1. Press the gun trigger down to start welding.

2. Release the gun trigger to stop welding.

To use the welding gun in 4T operating mode:

1. Press the gun trigger down to start the ow of the shielding gas.

2. Release the trigger to start welding.

3. Press the trigger down again to stop the arc. The shielding gas continues to ow.

4. Release the switch again to stop the ow of the shielding gas.

12

FitWeld Evo 300

Page 15

2.6.4 Adjusting the shielding gas ow

MMT32

Using a rotameter as shown in the picture, you can adjust the gas ow rate to the gun by

turning the shielding gas adjustment regulation valve screw inside the FitWeld Evo 300 wire

cabinet.

By turning the screw anticlockwise you increase the gas ow to the gun nozzle. Clockwise

adjustment will reduce the gas ow rate.

20

15

10

5

l/min

NOTE! The shielding gas ow rate set from the gas cylinder regulator must exceed the ow rate

measured at the welding gun. If these rates are the same, the gas indication light will shine on the

control panel and welding is prevented.

EN

2.6.5 Reversing polarity

Some ller wires are recommended to be welded with the gun in the negative pole, so the

polarity should be reversed. Check the recommended polarity from the ller wire package.

To reverse polarity:

1. Disconnect the machine from the mains.

2. Pull away the rubber covers to expose the terminal pole connections and allow access to

the Allen screws.

3. Using the Allen key attached to the wire cabinet wall, unscrew the pole connection bolts.

Note the correct order of washers.

4. Interchange the cables.

5. Install the washers in the correct order and tighten the bolts rmly.

6. Replace the rubber covers correctly.

NOTE! The rubber cover must always protect the poles.

© Kemppi Oy / 1515

13

Page 16

EN

2.7 Troubleshooting

Problem Cause

The machine stops working and the

shielding gas indicator is lit.

Poor welding result Several factors aect the welding quality.

Overheating indicator lit The device has overheated.

The wire does not move or wire feed

entangles

Main switch indicator does not switch onThe machine has no mains voltage

The maximum ow rate at the gas cylinder is set to a lower value than the ow rate

you are trying to set with the FitWeld Evo 300 ow adjustment screw.

• At the gas cylinder’s ow regulator, set the ow rate much higher than what you

are using in welding. The nal adjustment of the gas ow rate is accomplished

with the adjustment screw located inside the FitWeld’s wire cabin.

• Check that the earth return clamp is properly attached, the point of contact is clean

and that the cable and its connectors are intact.

• Check the voltage and wire speed settings on the control panel are correct for the

given wire size and type.

• Check that the shielding gas ow rate at the gun nozzle is correct.

• Check that the shielding gas is suitable for the ller wire used.

• Check that the wire feed is constant, and adjust if necessary.

• Check that the mains voltage is not irregular, too low or too high.

• Ensure that cooling air has unrestricted ow.

• The machine’s duty cycle has been exceeded. Wait for indicator to turn o.

• Too low or high supply voltage.

Feed rolls, wire liner or contact tips may be defective

• Check that feed rolls are not too tight or too loose.

• Check that the feed roll groove is not too worn or incorrect size for the ller wire

used.

• Check that the wire liner is the correct size and is not blocked or worn out. Replace

if necessary.

• Check that the contact tip is suitable for the wire used and and is not worn out or

blocked.

• Check the mains fuses

• Check the mains cable and the wall plug

If the machine’s malfunction can not be corrected with these measures, contact KEMPPI

maintenance service.

14

FitWeld Evo 300

Page 17

3. MAINTENANCE

When considering and planning routine maintenance, please consider the frequency of

machine use and the working environment.

Correct operation of the machine and regular maintenance will help you avoid unnecessary

downtime and equipment failure.

NOTE! Disconnect the machine from the mains before handling the electrical cables.

3.1 Daily maintenance

• Check the overall condition of the welding gun. Remove welding spatter from the

contact tip and clean the gas nozzle. Replace worn or damaged parts. Only use original

Kemppi spare parts.

• Check the condition and connection of the welding circuit components: welding gun,

earth return cable and clamp, sockets and connectors.

• Check the condition of the feed rolls, needle bearings and shafts. Clean and lubricate

bearings and shafts with a small quantity of light machine oil if necessary. Assemble,

adjust and test function.

3.2 Maintenance of the wire feed mechanism

It is recommended to service the wire feed mechanism every time the you change the wire

spool.

• Check the wear of the feed roll groove and change the feed roll if necessary.

• Clean the welding gun wire guide with compressed air if necessary.

3.2.1 Cleaning the gun wire liner

Pressure of the feed rolls remove metal dust from the ller wire’s surface which then travels

in the wire liner inside the gun cable. If the wire liner is not cleaned, it gradually clogs up,

increasing drag, impairing wire feed performance and weld quality. Ultimately this will will

causes wire feed malfunctions.

To clean the wire liner:

1. Remove the welding gun from the machine.

2. Remove the welding gun’s gas nozzle, contact tip and contact tip adapter.

3. With a pneumatic pistol, blow dry and ltered compressed air through the wire liner.

4. Clean the wire feed mechanism and spool housing with compressed air.

5. Reassemble the welding gun. Firmly tighten the contact tip and contact tip’s adapter.

3.2.2 Replacing the wire liner

If the wire liner is too worn or totally clogged, you must replace it according to the instructions

in welding gun operating manual.

3.3 Disposal

EN

Do not dispose of electrical equipment with normal waste!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment, and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and taken to an appropriate

environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, per the instructions of local authorities or a Kemppi representative. By

applying this European Directive you will improve the environment and human health.

© Kemppi Oy / 1515

15

Page 18

EN

4. ORDERING CODES

FitWeld Evo 300

FitWeld Evo 300 + FE32 3,5M P2103

FitWeld Evo 300 + FE32 5M P2104

FE32 3,5M 6603203

FE32 5M 6603204

FE35 3,5M 6603503

FE35 5M 6603504

MMT 32, 3 m 6253213MMT

MMT 32, 4.5 m 6253214MMT

Earth return cable, 35 mm², 5 m 6184311

Shield gas hose, 6 m W000566

16

FitWeld Evo 300

Page 19

5. TECHNICAL DATA

Connection voltage

Rated power at max. current

Supply current

Output 40 °C

Connection cable

Fuse (delayed)

Open circuit voltage

Power factor at max. current

Efficiency at max. current

Welding voltage range

Wire spool (max. ø)

Wire feed mechanism

Wire feed speed

Filler wires

3 ~, 50/60 Hz 220 V -10% ... 440 V +10 %

10.8 kVA

30 % ED I

1max

30 % ED I

1max

30 % ED I

1e

30 % ED I

1e

30 % ED 300 A / 29.0 V

40 % ED 250 A / 26.5 V

60 % ED 210 A / 24.5 V

100 % ED 170 A / 22.5 V

H07RN-F 4G1.5 (5 m)

220 – 230 V 16 A

380 – 440 V 10 A

220 V AC 42 V DC

440 V AC 86 V DC

220 – 230 V 0.93

380 – 440 V 0.94

220 – 230 V 83 %

380 – 440 V 84 %

Fe solid, Fe cored, Ss0.8 – 1.2 mm

220 – 230 V: 29 A

380 – 440 V: 17 A

220 – 230 V: 16 A

380 – 440 V: 9 A

11 – 32 V

200 mm

2-roll feed

0 – 18 m/min

EN

Al 1.0 – 1.2 mm

External dimensions

L x W x H 457 x 226 x 339 mm

Weight

EMC class

Minimum short circuit power Ssc of supply network*

Degree of protection

Operating temperature range

Storage temperature range

Standards: IEC/EN 60974-1, IEC/EN 60974-5, IEC/EN 60974-10

* See paragraph 2.3.

15.4 kg

A

1.9 MVA

IP23S

-20 °C ... +40 °C

-40 °C ... +60 °C

© Kemppi Oy / 1515

17

Page 20

KEMPPI OY

Kempinkatu 1

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) LTD

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

UNITED KINGDOM

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GMBH

Perchstetten 10

D-35428 LANGGÖNS

DEUTSCHLAND

Tel +49 6 403 7792 0

Telefax +49 6 403 779 79 74

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 240 84 03

Telefax +7 495 240 84 07

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 240 84 03

Telefax +7 495 240 84 07

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY LTD

Unit 105, 1/F, Building #1,

No. 26 Xihuan South Rd.,

Beijing Economic-Technological Development

Area (BDA),

100176 BEIJING

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区

西环南路26号

1号楼1层105室(100176)

电话: +86-10-6787 6064/1282

传真: +86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

Kazura Garden,

Neelankarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

KEMPPI WELDING SOLUTIONS SDN BHD

No 12A, Jalan TP5A,

Taman Perindustrian UEP,

47600 Subang Jaya,

SELANGOR, MALAYSIA

Tel +60 3 80207035

Telefax +60 3 80207835

sales.malaysia@kemppi.com

1903530

1515

www.kemppi.com

Loading...

Loading...