Page 1

1920130

0808

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Operating manual • English

Gebrauchsanweisung • Deutsch

KEMPARC™

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

SYN 300

SYN 400

SYN 500

DT 400

FI

SV

NO

DA

EN

DE

NL

FR

ES

PL

RU

Page 2

Page 3

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

OPERATING MANUAL

English

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

Page 4

CONTENTS

FI

SV

NO

DA

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

1. PREFACE ......................................................................................

1.1 General .................................................................................................................................................................3

1.2 Safety Instructions .......................................................................................................................................3

1.3 Introduction .....................................................................................................................................................5

2. USE ...............................................................................................6

2.1 Power source

2.1.1 Power source components ...............................................................................................................6

2.1.2 Locating the power source ...............................................................................................................6

2.1.3 Connecting the power source to the electric network ...........................................................7

2.1.4 Connecting the cables ........................................................................................................................8

2.1.5 Installing the eld bus card ..............................................................................................................9

2.1.6 Starting the power source..............................................................................................................10

2.1.7 Power source indicators ..................................................................................................................10

2.2 Control panel

2.2.1 Control panel parts ...........................................................................................................................10

2.2.2 Adjusting MIG dynamics (Arc Force) ..........................................................................................11

2.2.3 Gas test ..................................................................................................................................................11

2.2.4 Wire feed test ...................................................................................................................................... 11

2.2.5 Selection of liquid- or gas-cooled MIG gun .............................................................................12

2.2.6 Retrieving weld data ........................................................................................................................12

2.2.7 Selecting the welding process .....................................................................................................12

2.2.8 Additional MIG features included in the standard delivery ............................................... 12

2.2.9 Optional additional MIG features ................................................................................................14

2.2.10 Memory features (MEMORY button) ..........................................................................................14

2.2.11 Synergetic 1-MIG welding and AAA-MIG welding ................................................................15

2.2.12 SETUP features of the control panel ........................................................................................... 17

2.3 Wire feeder ..................................................................................................................................................... 18

...................................................................................................................................................6

................................................................................................................................................10

3. MAINTENANCE .........................................................................19

3.1 Cables .................................................................................................................................................................19

3.2 Power source ................................................................................................................................................20

3.2.1. DuraTorque™ 400, 4-wheel wire feeder mechanism ............................................................20

3.3 Regular maintenance .............................................................................................................................21

3.4 Disposal of the machine .......................................................................................................................21

3

EN

EN

DE

NL

FR

ES

PL

RU

4. TROUBLESHOOTING ................................................................21

4.1 Overload (yellow indicator lit)

4.2 Control cable connector fuse

4.3 Electric network overvoltage or undervoltage ...................................................................21

4.4 Missing phase in the electric network

4.5 Error codes

......................................................................................................................................................22

..........................................................................................................21

...........................................................................................................21

.......................................................................................22

5. ORDERING NUMBERS .............................................................. 23

6. TECHNICAL DATA ..................................................................... 23

7. WARRANTY POLICY ..................................................................25

2

Page 5

1. PREFACE

1.1 GENERAL

Congratulations on your choice of the Kemparc™ SYN-series welding system. Reliable

and durable, Kemppi products are aordable to maintain, and they increase your work

productivity.

This user manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the device can be found at the end of

the manual. Please read the manual carefully before using the equipment for the rst time.

For your safety and that of your working environment, pay particular attention to the safety

instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi Web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

NOTE! Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with this symbol. Read these sections carefully and follow their

instructions.

1.2 SAFETY INSTRUCTIONS

Kemppi welding devices conform to international safety standards. Safety is an important

issue in equipment design and manufacturing. Therefore, Kemppi welding solutions are

unparalleled in safety. There are, however, always certain hazards involved in using welding

equipment. Therefore, to ensure your personal safety and the safety of your working

environment, carefully read the safety instructions below and respect them.

Use of personal protective equipment

• The arc and its reecting radiation damage unprotected eyes. Shield your eyes and

face appropriately before you start welding or observe welding. Also note the dierent

requirements for the darkness of the screen in the mask as the welding current changes.

• The arc radiation and spatters burn unprotected skin. Always wear protective gloves,

clothing and footwear when welding.

• Always wear hearing protection if the ambient noise level exceeds the allowable limit

(e.g., 85 dB).

General operating safety

• Exercise caution when handling parts heated in welding. For example, the tip of the

welding torch, the end of the welding rod and the work piece will heat during gouging to

a burning temperature.

• Never wear the device on the shoulder during welding and never suspend it by the

carrying strap during welding.

• Do not expose the machine to high temperatures, as this may cause damage to the

machine.

• Keep the torch cable and earthing cable as close to each other as possible throughout

their length. Straighten any loops in the cables. This minimises your exposure to harmful

magnetic elds, which may interfere with a pacemaker, for example.

• Do not wrap the cables around the body.

• In environments classied as dangerous, only use S-marked welding devices with a safe

idle voltage level. These work environments include, for example, humid, hot or small

spaces where the user may be directly exposed to the surrounding conductive pieces.

Spatter and re safety

• Welding is always classied as hot work, so pay attention to re safety regulations during

welding and after it.

• Remember that re can break out from sparks even several hours after the welding work

is completed.

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

RU

3

Page 6

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

• Protect the environment from welding spatter. Remove ammable materials, such as

ammable uids, from the welding vicinity and supply the welding site with adequate re

ghting equipment.

• In special welding jobs, be prepared for hazards such as re or explosion when welding

container-type work pieces.

• Never direct the spark spray or cutting spray of a grinder toward the welding machine or

ammable materials.

• Beware of hot objects or spatter falling on the machine when working above the machine.

• Welding in ammable or explosive sites is absolutely forbidden.

General electric safety

• Only connect the welding machine to an earthed electric network.

• Note the recommended mains fuse size.

• Do not take the welding machine inside a container, vehicle or similar work piece.

• Do not place the welding machine on a wet surface and do not work on a wet surface.

• Do not allow the mains cable to be directly exposed to water.

• Ensure cables or welding torches are not squashed by heavy objects and that they are not

exposed to sharp edges or a hot work piece.

• Make sure that faulty and damaged welding torches are changed immediately as they can

be lethal and may cause electrocution or re.

• Remember that the cable, plugs and other electric devices may be installed or replaced

only by an electrical contractor or engineer authorised to perform such operations.

• Turn o the welding machine when it is not in use.

Welding power circuit

• Insulate yourself from the welding circuit by using dry and undamaged protective

clothing.

• Never touch the work piece and welding rod, welding wire, welding electrode or contact

tip at the same time.

• Do not put the welding torch or ground cable on the welding machine or other electric

equipment.

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

Welding fumes

• Ensure proper ventilation and avoid inhaling the fumes.

• Ensure sucient supply of fresh air, particularly in closed spaces. You can also ensure the

supply of clean and sucient breathing air by using a fresh-air mask.

• Take extra precautions when working on metals or surface-treated materials containing

lead, cadmium, zinc, mercury or beryllium.

Transportation, lifting and suspension

• Never pull or lift the machine by the welding torch or other cables. Always use the lift

points or handles designed for that purpose.

• Only use a transport unit designed for the equipment.

• Try to transport the machine in an upright position, if possible.

• Never lift a gas cylinder and the welding machine at the same time. There are separate

provisions for gas cylinder transportation.

• Never use a welding machine when suspended unless the suspension device has been

designed and approved for that particular purpose.

• Do not exceed the maximum allowed load of suspension beams or the transportation

trolley of welding equipment.

• It is recommended that the wire coil be removed during lifting or transportation.

Environment

• Protect welding machines from heavy rain and direct sunshine even if it were suitable for

outdoor use.

• Always store the machine in a dry and clean space.

• Protect the machine from sand and dust during use and in storage.

• The recommended operating temperature range is -20 to +40 °C. The machine’s operation

eciency decreases and it becomes more prone to damage if used in temperatures in

excess of 40 °C.

• Place the machine so that it is not exposed to hot surfaces, sparks or spatter.

4

Page 7

• Make sure the airow to and from the machine is unrestricted.

• This electromagnetic compatibility (EMC) of professional equipment is usually designed

for industrial use. Such class-A equipment is not intended for use in residential locations

where the electrical power is provided by the public low-voltage supply system. The

machine may interfere with sensitive home electronic devices.

Gas bottles and pneumatic devices

• Adhere to the instructions for handling pneumatic devices and gas bottles.

• Make sure that gas bottles are used and stored in properly ventilated spaces. A leaking gas

bottle may replace the oxygen in the inhaled air, causing suocation.

• Before use, make sure that the gas bottle contains gas suitable for the intended purpose.

• Always x the gas cylinder securely in an upright position, against a cylinder wall rack or

purpose-made cylinder cart.

• Never move a protective gas bottle when the ow adjuster is in place. Put the valve cover

in place during transportation.

• Close the cylinder valve after use.

1.3 INTRODUCTION

KempArc™ SYN is a product family for welding automation that includes all welding devices

needed in robot welding. The KempArc™ SYN welding system includes the following devices:

• KempArc™ SYN 300, SYN 400 and SYN 500 are synergetic welding power sources

designed particularly for welding automation that are suitable for MIG welding with direct

current. There are three power types of power sources: the 300, 400 and 500 ampere

models. For more information on using power sources and their functions, see "Power

source".

• RF 59 is a control panel that contains the programs and welding parameters needed

in controlling the welding hardware. The panel functions allow the user to control the

operation of the welding hardware and adjust its welding settings. The control panel is

located in the front panel of the welding power source. For more information on using the

control panel and its functions, see "Control panel".

• KempArc™ DT 400 is a wire feeding device that feeds welding wire to the welding robot

at the speed it requires at any time. For more information on using the wire feeder and its

functions, see "Wire feeder".

This guide presents the functions, operation and technical properties of the above devices.

The devices also include the KempArc™ Cool 10 cooler, but its functions and features are

presented in a separate guide.

The KempArc™ Synergic hardware is connected to the welding robot control system with the

control unit on top of the power source.

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

5

Page 8

2. USE

2.1 POWER SOURCE

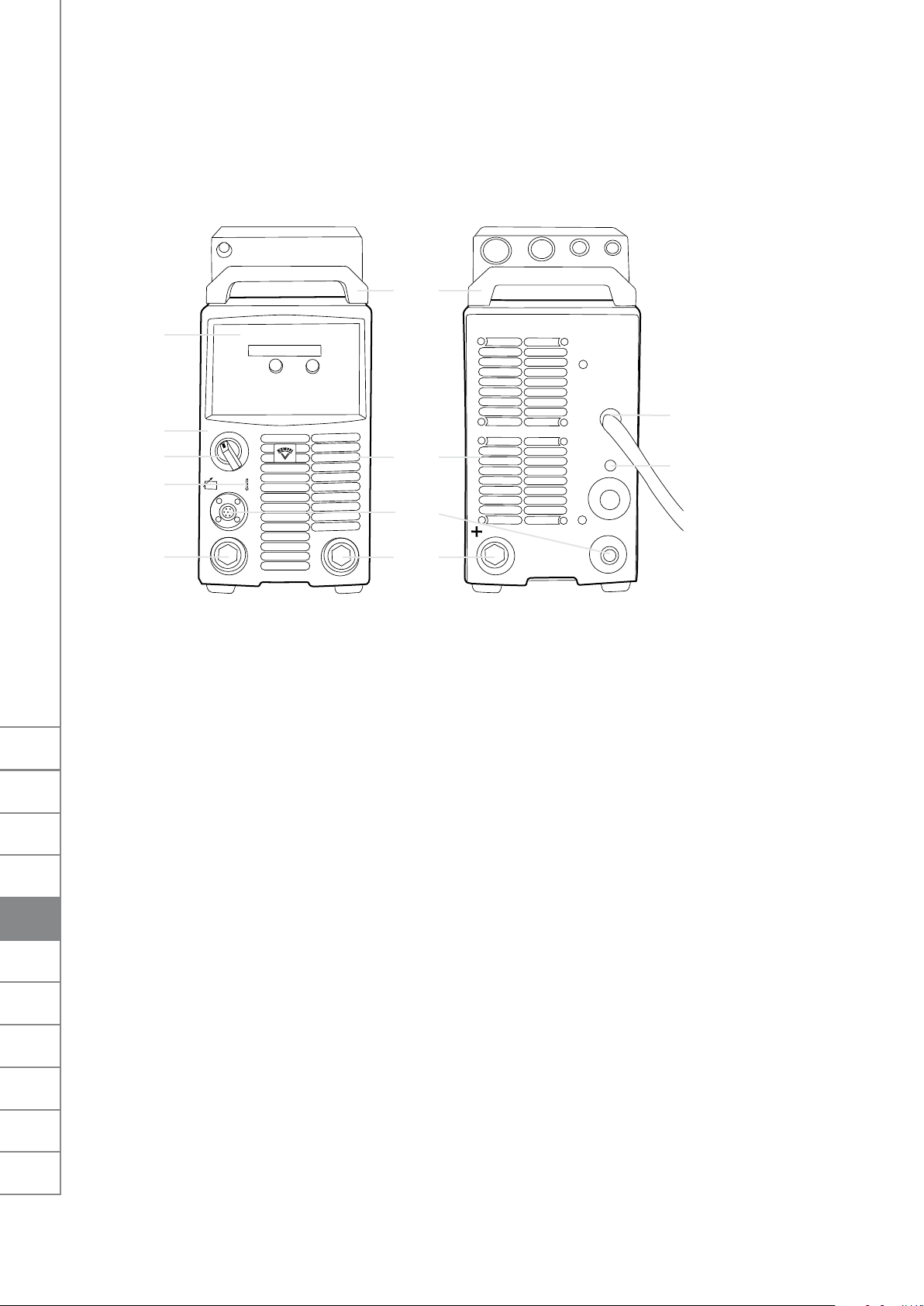

2.1.1 Power source components

A1

A3

A2

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

A4

A11

A10

A7

1 2 3 4

A8

A9

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

A6

A1 Control panel

A2 Main switch

A3 Signal light (I/O)

A4 Thermal warning light

A5 Welding cable connection (parallel)

A6 Earthing cable connection

A7 Control cable connection (parallel)

A8 Mains cable

A9 Fuse for control cable connection (6.3 A slow)

A10 Fan grill

A11 Transportation handles

2.1.2 Locating the power source

Place the machine on a sturdy, level surface that is dry and does not release dust or other

impurities to the suction air through the fan grill.

Notes for positioning of the machine

• Preferably, place the machine somewhat above oor level.

• The surface inclination may not exceed 15 degrees.

• There must be at least 20 cm of free space in front of and behind the machine for cooling

air circulation.

• Protect the machine against heavy rain and direct sunshine.

• Ensure the free circulation of the cooling air.

The protection class of the machine, IP23C, allows water spray to hit the machine’s outer

covering at a maximum angle of 60 degrees.

NOTE! Never aim the spray of sparks from a grinding machine toward the power source.

A5

1 Robot Control

2 Wire Feeder

3 Throughput

4 Analog

RU

6

Page 9

2.1.3 Connecting the power source to the electric network

The KempArc™ SYN power source is connected to a 400-V three-phase network. The machine

is equipped with a ve-metre mains cable that does not have a plug. Before use, check the

mains cable and install a mains plug. If the cable does not comply with the local electrical

regulations, replace it with a compliant cable.

NOTE! The mains cable or plug may be installed or replaced by only an electrical contractor or

installer authorised to perform such operations.

Replacement of the mains cable

1. Unscrew the mounting screws on the top and sides of the machine, and remove the case

by lifting it.

2. Disconnect the phase leads from connectors L1, L2, and L3, and disconnect the protective

earth lead.

3. Pass the cable to the machine through the inlet ring at the rear of the machine, and secure

the cable with a cable clamp.

4. Connect the cable’s phase leads to connectors L1, L2, and L3.

5. Connect the yellow-green protective earth lead to its connector .

NOTE! Do not connect the zero lead if you are using a ve-lead cable.

The table below lists the fuse sizes for 100% load in a 400-V three-phase network with

4 x 6-mm² cable for dierent power source models.

Model Fuse

SYN 300 20 A delayed

SYN 400 25 A delayed

SYN 500 35 A delayed

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

7

Page 10

2.1.4 Connecting the cables

+

+

G

E

F

B

A

B

D

C

Wire feeder

control

Analog

SYN 300/400/500

DT 400

Robot

KempArc

Cool10

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

A air hose

B shield gas hose

C air blow

D intermediate cable

E earthing cable

F cooling liquid hoses

G robot controller

Welding and earthing cables

The welding and earthing cables are rubber-insulated copper cables. The recommended

cross-sections of the cables for dierent power source models are as follows:

Model Welding cable

SYN 300 50 ... 70 mm

SYN 400 70 ... 90 mm

SYN 500 70 ... 90 mm

The table below shows the typical load capacities of the cables when the ambient

temperature is 25 ºC and the lead temperature is 85 ºC.

Welding cable Duty cycle (ED) Voltage loss / 10 m

50 mm 285 A 370 A 520 A 0.35 V / 100 A

70 mm 355 A 460 A 650 A 0.25 V / 100 A

95 mm 430 A 560 A 790 A 0.18 V / 100 A

NOTE! Do not overload the welding cables, as an overload may cause voltage loss and

overheating.

100 % 60 % 30 %

8

Page 11

Connecting welding and earthing cables

The power source has two welding cable and control cable connectors. With them, the

welding robot's welding torch and, if necessary, a manual welding torch for tack welding can

be connected to the power source.

Connect the welding and earthing cables as follows.

1. Connect the power source to the electric network according to the instructions above.

2. Connect the earthing cable to the earthing connector A6.

3. Connect the welding cable to the welding current connector A5.

NOTE! Do not overload the welding cables, as an overload may cause voltage loss and

overheating.

You can conect the control cables of manual welding wire feeders or the control cable of a

remote controller to the control cable connectors.

Before starting the welding, connect the earth clamp directly to the work piece in such a way

as to maximise the contact surface of the clamp. The point of connection must be unpainted

and free of corrosion.

2.1.5 Installing the eld bus card

1. Remove the cover of the control unit on top of the power source by unscrewing the cover

screws.

2. Put the eld bus card on top of the interface card and attach with two M3 nuts (see

image).

3. Put the control unit cover back in place.

4. Connect the welding robot's eld bus cable to the control unit connector.

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

M3 nuts

Field bus card

Interface card

NOTE! Separate the eld bus cable for the welding robot from the mains cables, as they may

interfere with the control logic operation.

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

9

Page 12

2.1.6 Starting the power source

Start the power source by turning the main switch A2 on the front panel to the I position. The

standby indicator A3 turns on.

NOTE! Always turn the device on and o using the main switch, not via the mains socket.

The cooling fan is started for a moment when the main switch is turned to the ‘I’ position. The

fan turns o after a while and then restarts during welding when the machine has warmed up

suciently. The fan continues running even after up to 10 minutes of welding, depending on

the temperature of the machine.

2.1.7 Power source indicators

The following indicators can be found on the front panel of the power source:

• When the green mains indicator A3 is on, the power source is in standby mode. This

indicator is on when the machine is connected to the mains supply with the main switch

in the ‘I’ position.

• When the yellow overheating indicator A4 is on, the machine has overheated. When the

indicator turns o, the machine can be used again.

• When indicator A4 blinks, the machine has encountered a failure. Attempt to remedy the

problem according to the instructions in Section 4, ‘Troubleshooting’. If the failure cannot

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

be eliminated, turn o the machine, and turn it on again. If the failure persists, write down

any fault code that may be shown on the display and contact authorised Kemppi service

agent.

2.2 CONTROL PANEL

FI

SV

NO

DA

EN

EN

DE

NL

2.2.1 Control panel parts

P8

P7

P2

P9 P10

P6P11 P13P5P3 P4

FR

ES

PL

RU

The control panel is used for controlling and monitoring the operation of the power source

and the wire feeder. The buttons are used for adjusting functions. The displays and indicators

reect the operating modes of the machine.

10

Page 13

Esc button

Use the Esc button to move to the previous menu level.

Displays

• The control panel displays show adjustable operation parameters, their values, and the

units of measure.

• During welding, display P2 shows the welding current value that is currently in use, while

display P6 shows the welding voltage.

Control knobs

• The left-hand control knob P11 allows the adjustment of the speed of wire feeding. The

selected speed is shown on the display on the left-hand side.

• The right-hand side control knob P13 allows for controlling the welding voltage in MIG

and 1-MIG processes, in which case the selected voltage is shown on the right-hand side

display, and the base current in AAA-MIG processes, in which case the adjustment range

is +/- 50.

These control knobs are also used for specifying the operating parameters. A parameter for

adjustment is selected with the left-hand knob, while the value of the parameter is selected

with the right-hand knob.

2.2.2 Adjusting MIG dynamics (Arc Force)

When you press button P3, you can adjust the MIG welding dynamics of the machine by

means of the right-hand knob.

When using the MIG or 1-MIG welding process, the welding dynamics setting aects the

features of the welding arc and the amount of welding spatter as shown below:

• The value 0 is the recommended basic setting.

• Use values -1...-9 if you want a softer arc and less spatter.

• Use values 1...9 if you want a rougher and more stable arc. This setting is useful when you

are using 100% CO₂ shielding gas when welding steel.

When using the AAA-MIG process, the welding dynamics setting aects the forming pulse as

shown below:

• Use values -1...-30 if you want a softer arc and smaller penetration.

• Use values 1...30 if you want a rougher and greater penetration.

2.2.3 Gas test

The gas test button P4 opens the gas valve without activating the wire feed or power source.

By default, gas ows for 20 seconds. The gas ow time remaining is shown on the display.

The right-hand knob allows you to set the default gas ow time, between 10 and 60 seconds,

and store the new default value in the machine’s memory. To stop the gas test, press the ESC

button.

2.2.4 Wire feed test

When you press the Wire inch button, P6, the wire feeder engine starts but the gas valve does

not open and the power source is not activated.

The wire feed pace is 2 m/min for the rst two seconds, and then 10 m/min.

When the button is released, the wire feeding stops. The machine automatically goes back

to the normal state after approximately 3 seconds from release of the button or immediately

when you press the ESC button.

FI

SV

NO

DA

EN

EN

DE

NL

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

11

FR

ES

PL

RU

Page 14

2.2.5 Selection of liquid- or gas-cooled MIG gun

You can select a MIG gun cooled with liquid or gas by pressing buttons P3 and P4

simultaneously and holding them down for at least one second.

• When the display reads GAS, you can use a gas-cooled MIG gun with the equipment.

• When the display reads COOLEr, you can use a liquid-cooled MIG gun with the equipment.

You can change the gun selection by pressing buttons P3 and P4 again, as above. With a

liquid-cooled gun selected, the liquid cooling function is started when the power source is

started the next time.

2.2.6 Retrieving weld data

The weld data function allows you to return to the welding current and voltage used during

the previous session, with the weld data feature. To use the feature, press buttons P4 and P5

simultaneously.

2.2.7 Selecting the welding process

The welding process selector button P9 allows you to select the welding process you want to

use. You can select one of the following processes:

• normal MIG welding

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

• 1-MIG welding

• AAA-MIG (optional)

In normal MIG welding, the wire feed speed and welding voltage are adjusted separately.

Unlike the above, the 1-MIG and AAA-MIG processes are synergetic welding processes where

the welding voltage and other welding parameters are interconnected so that the welding

power and arc length are adjusted to attain optimal welding values.

The AAA-MIG process is an optional feature intended for welding automation. It must be

acquired separately and is therefore not available in all congurations.

FI

SV

NO

DA

EN

EN

DE

NL

FR

2.2.8 Additional MIG features included in the standard delivery

The standard welding machine delivery includes three additional MIG features that facilitate

welding and improve weld quality. These additional features are creep start, hot start and

crater ll.

To use an additional MIG feature, press the feature selector button P10. Press the selector

button repeatedly to use one or several features. Only the additional features allowed for the

welding method you have chosen will be available.

Creep start

The purpose of the creep start feature is to make controlled weld start easier and smoothen

the initial stage of welding, for example when welding with high wire feed speeds. At the

beginning, the machine will use a slow wire feed speed until the wire touches the work piece

and the current starts owing.

Creep start is available for normal MIG welding and the synergetic 1-MIG welding.

Hot start

The purpose of hot start is to reduce start faults, for example when welding aluminium or

other materials with particularly good thermal conductivity. In this scenario, there is a xed

pre-gas time at the beginning of the welding, after which the welding power briey rises

above the specied power level. The power and time parameters for hot start can be specied

in the SETUP settings.

Hot start is available for synergetic 1-MIG welding.

ES

PL

RU

12

Page 15

Crater ll

Welding Level

Crater Fill Start Level

Crater Fill Time

Crater Fill End Level

The purpose of crater ll is to facilitate controlled nishing of welding and to reduce the

welding faults caused by the nal crater. When you press the welding gun trigger completely

down at the end of welding, the welding power is reduced to a preset crater ll level. To end

the crater ll stage, release the gun trigger. The crater ll parameters can be specied in the

SETUP settings.

Crater ll is available for synergetic 1-MIG welding.

Specifying the SETUP settings for additional features

To set the values of the functional parameters for additional MIG features, use either the

SETUP feature in the control panel (see 2.2.12 "SETUP functions in the control panel") or the

QUICK SETUP feature, which you can activate by pressing the QUICK SETUP button, P8.

Select the parameter to adjust using the left-hand side control knob P11 or the button P10

and then set the parameter value with the right-hand side control know P13. The value

you specied is instantly stored in the control panel memory. The following table lists the

parameter values that can be specied for additional MIG features.

Name of

parameter

Creep Start Level

Hot Start Level

Hot Start Time

Crater Fill Start

Level

Crater Fill End

Level

Crater Fill Time

NOTE! In crater ll, the initial value of the welding power must be greater than the nal value,

and therefore the adjustment ranges for the initial and nal values are restricted automatically, if

necessary.

Name

displayed

Cre 10 ... 170 % 50 % Percent of wire feed

Hot -50 ... 75 % 30 % Percent of welding power:

H2t 0 ... 9.9 s 1.2 s The duration of the hot start in

CrS 10 ... 90 % 90 % The welding power at the

CrL 10 ... 90 % 30 % The welding power at the end of

Crt 0...9.9 s 2 s The duration of the crater ll stage

Parameter values Factory setting Description

speed default

10% refers to slow start,

170% refers to fast start

-50% refers to cold start

+75% refers to hot start

seconds.

beginning of the crater ll stage as

a percentage of the welding power

preset value.

the crater ll stage as a percentage

of the welding power preset value.

in seconds.

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

FI

SV

NO

DA

13

EN

EN

DE

NL

FR

ES

PL

RU

Page 16

2.2.9 Optional additional MIG features

In addition to the additional MIG features included in the standard delivery, it is also possible

to acquire optional features that further expand the operating features of the machine.

To use the optional features, enter a machine-specic activation code in the machine's control

panel as shown below. To purchase an activation code, contact a Kemppi representative.

Activating optional additional features

1. Press and hold down the SETUP button P8 for at least 5 seconds. The SETUP settings menu

appears on the display.

2. Select the Cod alternative with the left-hand side control knob in the control panel and

then select the value Ent using the right-hand side control knob.

3. Briey press the SAVE button.

4. When the display on the left-hand side reads 1, enter the rst value of the activation code

using the right-hand side control knob. The value you have entered is shown in the righthand side display.

5. Select the entry of the next value using the left-hand side control knob.

6. Enter the value corresponding to the value shown in the left-hand side display using the

right-hand side control knob.

7. Repeat steps 5 and 6 until you have entered all values of the activation code.

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

8. Finally, press the SAVE button briey.

The control panel will read Suc cEs to indicate that the activation code has been entered

correctly and the additional feature is available. You can exit the code entry mode at any time

by briey pressing ESC.

If the code entry failed, the control panel display will show an error code. For more

information on error codes, see "Troubleshooting".

The operating instructions for optional additional features can be found in the documentation

supplied with the additional feature.

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

2.2.10 Memory features (MEMORY button)

Use the control panel memory features to store welding parameters you use into the

machine's memory for easy use later without the need to readjust all parameters. The control

panel has 90 memory positions, numbered 0...89.

You can store the welding parameters you use, i.e., the wire feed speed and the welding

voltage. You can also store additional feature settings, such as creep start or crater ll settings.

Storing welding parameters in memory

1. Press the MEMORY button twice. If a memory channel is free, the SET indicator starts

ashing. In other cases the indicator will be turned on constantly.

(If the memory is empty, one push of the button is enough.)

2. Select the memory channel you want using the CH button.

3. Specify the welding settings you want and store the selections by pressing SAVE.

4. Press the MEMORY button twice. The ON indicator light will turn on and the welding

parameters you selected are activated.

5. Start welding.

If you want to change the welding parameters stored in a welding channel, go to the SET

mode by pressing the MEMORY button. Now select the parameters you want and store them

by pressing SAVE.

You can also store the welding parameters with the SET button when the memory feature is in

the OFF state, i.e., when the MEMORY indicators are not on.

To clear the data in a memory channel, press the MEMORY and CH buttons simultaneously

when the control panel is in the SET mode (the SET indicator is on).

Using stored welding parameters

1. Press the MEMORY button to turn on the ON indicator.

2. Select the memory channel you want from the robot.

3. Start welding.

14

Page 17

2.2.11 Synergetic 1-MIG welding and AAA-MIG welding

In synergetic 1-MIG welding, the machine selects the optimal welding parameters suitable to

the ller wire and shield gas using the programs, or synergetic curves, stored in the control

panel. The welder controls the welding by adjusting the welding power and arc length.

The synergetic AAA-MIG process (advanced auto arc) is a synergetic welding process

developed for the special needs of robotic welding with weldig characteristics optimised

particularly for welding automation.

Selecting a welding program

1. Before you start welding, nd the welding program suitable to your ller wire and shield

gas in the tables below and then activate the program as follows:

2. Press the SYNERGIC PROGRAM button P7 for more than 1 second. This will activate

program selection and the control panel displays start ashing.

3. Select the material group with the left-hand side control knob and the welding program

for the material group with the right-hand side control knob according to the tables

below. The program you selected is immediately recorded in the memory.

4. Press ESC button or the SYNERGIC PROGRAM button P7 to exit the menu.

MIG programs in the KempArc™ SYN machine

1-MIG, Fe group

Program number Wire, mm Material Shield gas

101 0,8 Fe Ar+18%-25%CO

102 0,9 Fe Ar+18%-25%CO

103 1,0 Fe Ar+18%-25%CO

104 1,2 Fe Ar+18%-25%CO

106 1,6 Fe Ar+18%-25%CO

111 0,8 Fe CO

112 0,9 Fe CO

113 1,0 Fe CO

114 1,2 Fe CO

116 1,6 Fe CO

121 0,8 Fe Ar+8%CO

122 0,9 Fe Ar+8%CO

123 1,0 Fe Ar+8%CO

124 1,2 Fe Ar+8%CO

126 1,6 Fe Ar+8%CO

152 0,9 FEMC Ar+18%-25%CO

154 1,2 FEMC Ar+18%-25%CO

164 1,2 FEMC CO

174 1,2 FEFC rutile Ar+18%-25%CO

184 1,2 FEFC rutile CO

194 1,2 FEFC basic Ar+18%-25%CO

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

FI

SV

NO

DA

EN

EN

DE

NL

FR

15

ES

PL

RU

Page 18

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

1-MIG, SS group

Program number Wire, mm Material Shield gas

201 0,8 SS-316 Ar+2%CO

202 0,9 SS-316 Ar+2%CO

203 1,0 SS-316 Ar+2%CO

204 1,2 SS-316 Ar+2%CO

206 1,6 SS-316 Ar+2%CO

211 0,8 SS-316 Ar+30%He+1%O

212 0,9 SS-316 Ar+30%He+1%O

213 1,0 SS-316 Ar+30%He+1%O

214 1,2 SS-316 Ar+30%He+1%O

216 1,6 SS-316 Ar+30%He+1%O

221 0,8 SS-309 Ar+2%CO

222 0,9 SS-309 Ar+2%CO

223 1,0 SS-309 Ar+2%CO

224 1,2 SS-309 Ar+2%CO

231 0,8 SS-309 Ar+30%He+1%O

232 0,9 SS-309 Ar+30%He+1%O

233 1,0 SS-309 Ar+30%He+1%O

234 1,2 SS-309 Ar+30%He+1%O

242 0,9 FC-316 Ar+18%-25%CO

244 1,2 FC-316 Ar+18%-25%CO

252 0,9 FC-316 CO

254 1,2 FC-309L Ar+18%-25%CO

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

1-MIG, AI group

Program number Wire, mm Material Shield gas

303 1,0 Al-5356 Ar

304 1,2 Al-5356 Ar

306 1,6 Al-5356 Ar

313 1,0 AL-4043 Ar

314 1,2 Al-4043 Ar

316 1,6 Al-4043 Ar

1-MIG, SPE group

401 0,8 CuSi 3 Ar

402 0,9 CuSi 3 Ar

403 1,0 CuSi 3 Ar

404 1,2 CuSi 3 Ar

411 0,8 CuSi 3 Ar+2% CO

412 0,9 CuSi 3 Ar+2% CO

413 1,0 CuSi 3 Ar+2% CO

421 0,8 CuAl 8 Ar

423 1,0 CuAl 8 Ar

424 1,2 CuAl 8 Ar

16

Page 19

AAA-MIG, Fe group

903 1,0 Fe Ar+18%-25%CO

904 1,2 Fe Ar+18%-25%CO

913 1,0 Fe CO

914 1,2 Fe CO

AAA-MIG, SS group

923 1,0 SS-316 Ar+2%CO

924 1,2 SS-316 Ar+2%CO

933 1,0 SS-316 Ar+30%He+1%O

934 1,2 SS-316 Ar+30%He+1%O

Using the welding program

1. Select the welding process 1-MIG with the P9 button.

2. Press the SYNERGIC PROGRAM button to display the material group and the welding

program number. Make sure that the welding program corresponds to the ller wire and

shield gas you use.

3. Check the wire type and shield gas for the welding program in the table below.

4. Adjust the welding power with the left-hand side knob and the arc length with the righthand side knob.

2.2.12 SETUP features of the control panel

The machine has a number of additional features, or parameters, whose settings can be

specied with the control panel's SETUP function as follows:

1. Press and hold down the SETUP button P10 for at least 5 seconds.

2. Select the parameter to adjust using the left-hand side control knob. The parameter name

is shown in display 2.

3. Specify the parameter value with the right-hand side control knob. The selected value is

shown in the display P6. The parameter’s value is immediately stored in the memory.

4. You can exit the SETUP mode by pressing and holding down the SETUP button again for

at least 5 seconds or by briey pressing the ESC button.

All welding processes have their own SETUP parameters. For example, adjusting the postcurrent for synergetic MIG welding does not aect the post-current of normal MIG welding.

The tables below show the additional features available in this welding machine and their

possible values.

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

FI

SV

Normal MIG welding parameters and their values

Name of

parameter

Pre Gas Time PrG 0.0 ... 9.9 s 0.0 s Pre-gas time 0 ... 9.9 s.

Post Gas Time PoG Aut, 0.1 ... 32.0 s 1,0 Post gas time,

Creep Start Level Cre 10 ... 170% 50 % Percentage of wire feed speed, 10% refers

Post Current Time PoC -9 ... +9 0 Post-welding current time

Name

displayed

Parameter

values

Factory setting Description

Aut = Automatic, depending on welding

current 0.1 ... 32 s

to slow start, 170% to accelerated start

17

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

Page 20

Synergetic MIG welding parameters and their values

1.

2.

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

Name of

parameter

Creep Start Level Cre 10 ... 170 % 50 % Percentage of wire feed speed, 10% refers

Hot Start Level Hot -50 ... 75 % 30 % Percent of welding power: -50% refers to

Crater Fill Level CrL 10 ... 90 % 30 % The crater ll level, 10% is the lowest

Post Current Time PoC -9 ... +9 0 Post-welding current time

Synergic MIG Unit Unl m/min, mm, A m/min In synergic welding, the parameter shown

Parameters common to all MIG processes and their values

Name of

parameter

Cable

Compensation

Code Entry Cod ---, Ent --- Entry of additional features, see page 14.

Restore Factory

Settings

Scaling SCA 0 ... 5000 0 A coecient with which the values in the

Name

displayed

Name

displayed

CAL -5.0 ... 9.0 V/100 A 1.0 V/100 A Cable compensation (MIG) for voltage

FAC OFF, PAn, All OFF Restores factory settings if you select ON

Parameter values Factory setting Description

to slow start, 170% to accelerated start

cold start and +75% to hot start

power and 90% the greatest one, relative to

welding power (preset value).

in the left-hand side display (wire feed

speed/plate thickness/average current).

Parameter values Factory setting Description

losses.

and exit the menu.

welding machine are scaled to the scale

used by the robot.

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

Checking the parameters in the MEMORY ON state

You can check parameter values in the MEMORY ON state by pressing the button of the

parameter you want. The parameter value will be shown in the display. You cannot modify

parameter values in the MEMORY ON state.

2.3 WIRE FEEDER

Wire guide adapter

The welding wire is taken to the wire feeder through a metallic wire guide adapter. Push the

wire guide to the end of the adapter and screw in with the top xing locks. Attach a spring at

the end of the adapter to serve as the bend support for the wire guide and to prevent the wire

from bending too heavily. Fix the support spring with the bottom xing locks.

Threading the wire and adjusting tightness

RU

18

Page 21

1. 1.

2.2.

FI

SV

NO

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

3. MAINTENANCE

The utilisation level of the power source and its working environment should be taken into

consideration in planning the frequency of maintenance of the machine. Proper use of the

machine and regular maintenance help you avoid unnecessary downtime and failures.

3.1 CABLES

• Check the condition of welding and mains cables daily.

• Make sure to replace damaged cables immediately. Only use original Kemppi spare parts.

• Make sure that all extension cables used in the mains connection are in proper condition

and compliant with regulations.

NOTE! The mains cables may be repaired and installed only by electrical contractors and installers

authorised to perform such operations.

DA

EN

EN

DE

NL

FR

ES

PL

RU

19

Page 22

FI

SV

3.2 POWER SOURCE

Before cleaning the interior of the machine, you need to remove the case by unscrewing the

mounting screws of the machine.

NOTE! To prevent damage, wait approximately two minutes after disconnecting the mains cable

before removing the machine’s case.

Perform the following cleaning and maintenance at least every six months:

1. Clean the interior of the machine and the fan grill’s net of any dust and stains – for

example, with a soft brush and vacuum cleaner.

• Do not use pressurised air. The stain may become compressed into the grooves of the

coolers.

• Do not use a pressure-washing device.

2. Check the electrical connections of the machine. Clean any oxidised connections, and

tighten the loosened ones.

• Check for the right tension before tightening the connections.

NOTE! Remember that the machine may be repaired only by an electrical contractor or installer

authorised to perform such operations.

3.2.1. DuraTorque™ 400, 4-wheel wire feeder mechanism

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

Wire guide tubes

Ss, Al, Fe,

Mc, Fc

Fe, Mc, Fc ø 0.6..0.00.8

ø 0.6...1.6 mm ø 2.5/64 mm,

W000762,

silver, plastic

ø 1.6..0.20.4

mm

mm

ø 0.9...1.6 mm ø 2.0/64 mm,

ø 1.6..0.20.4

mm

ø 3.5/64 mm,

W001430,

silver, plastic

ø 1.0/67 mm,

W001432,

white, steel

W001433,

orange, steel

ø 4.0/63 mm,

W001434,

blue, steel

ø 2.5/33 mm,

W000956,

silver, plastic

ø 3.5/33 mm,

W001431,

silver, plastic

ø 2.0/33 mm,

W001435,

orange, steel

ø 4.0/33 mm,

W001436,

blue, steel

ø 2.0 mm,

W000624,

plastic

ø 3.5 mm,

W001389,

plastic

ø 2.0 mm,

W000624,

plastic

ø 3.5 mm,

W001389,

plastic

ø 3.5 mm,

W001391,

brass

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

2.

1.

20

Page 23

Parts of the DT400 metal feed rolls

W000731 gear ring 1 driving 2 pcs per unit

W000732 gear ring 2 pressing 2 pcs per unit

W000711 drive ring V groove 1,2/1,2 optional 4 pcs per unit

W000718 drive ring V groove 1,0/1,0 optional 4 pcs per unit

W000891 drive ring V groove 1,0/1,2 optional 4 pcs per unit

9420507 washer 10.5x30x2.5 2 pcs per unit

3.3 REGULAR MAINTENANCE

Make sure that the machine receives regular and appropriate maintenance. Authorised

Kemppi service agents perform regular maintenance by agreement. For more information on

regular maintenance, contact a Kemppi representative.

3.4 DISPOSAL OF THE MACHINE

Do not dispose of electrical equipment with normal waste!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment, and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and taken to an appropriate

environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, per the instructions of local authorities or a Kemppi representative. By

applying this European Directive you will improve the environment and human health.

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

4. TROUBLESHOOTING

In the event of a failure of the machine, contact an authorised Kemppi service agent. Before

taking your unit for servicing, check the list below.

4.1 OVERLOAD YELLOW INDICATOR LIT

Two simultaneously operating fans cool the power source. The machine may, however,

overheat if continuously loaded above the rated values or if the circulation of cooling air is

prevented.

Overheating is indicated by a yellow indicator light in the front panel of the power source. You

then need to stop welding and let the machine cool down. The indicator light turns o when

welding can be resumed.

4.2 CONTROL CABLE CONNECTOR FUSE

The back panel of the power source has a fuse that protects the control cable connector. Using

an incorrect type of fuse will damage the power source. Therefore, it is important that you

always use the correct fuse type. The type and size of the fuse are indicated next to the fuse

socket.

4.3 ELECTRIC NETWORK OVERVOLTAGE OR UNDERVOLTAGE

If the power source is used in an electric network with insucient voltage (less than 300 V),

the control features of the device are automatically disabled.

The primary circuits of the power source are protected against power spikes. The product’s

mains voltage range is broad enough to prevent over-voltage problems at up to 440 V. Make

sure that the voltage remains within the allowed range, especially if the operating power is

supplied by a generator set. For information on the allowable voltage range, see "Technical

specications" in this guide.

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

21

RU

Page 24

4.4 MISSING PHASE IN THE ELECTRIC NETWORK

If a phase is missing from the mains current, the welding features will be adversely aected or

the machine may have problems starting. Loss of a phase can be caused by a:

• Blown mains fuse

• Damaged mains cable

• Poor mains cable connection in the machine’s terminal block or mains socket

4.5 ERROR CODES

The machine always checks its operation automatically during start-up and reports any

failures detected. If failures are detected during start-up, they are shown as error codes on the

control panel display.

Err3: Power source overvoltage

The machine has stopped the welding because it has detected momentary voltage spikes or

continuous overvoltage dangerous to the machine in the electric network. Check the quality

of the supply network.

Err4: Power source overheating

The power source has overheated. The cause may be one of the following:

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

• The power source has been used for a long time at maximum power.

• The circulation of cooling air to the power source is blocked.

• The cooling system has experienced a failure.

Remove any obstacle to air circulation, and wait until the power source fan has cooled down

the machine.

FI

SV

NO

DA

EN

EN

DE

NL

Err5 Water unit alarm

The water circulation is blocked. The cause may be one of the following:

• Congestion or disconnection in the cooling pipeline

• Insucient cooling liquid

• Excessive cooling liquid temperature

Check the circulation of the cooling liquid and the air circulation of the water unit.

Err23: Power source overvoltage warning

The power source has detected voltage spikes in the electric network. Short power spikes

can be managed. They do not lead to interruptions in welding but may decrease the welding

quality. Check the quality of the supply network.

Err61: The water unit is not found

The water unit is not connected to the equipment, or the connection has failed. Connector the

water unit.

Other error codes:

If an error code not listed above is shown, contact Kemppi service and tell them the error

code.

FR

ES

PL

RU

22

Page 25

5. ORDERING NUMBERS

Power source/Interface

KempArc™ SYN 300 (digital) 6201300

KempArc™ SYN 300 (analogue) 6201300AN

Wire feeder DT 400 6203400

Interbus S 9774120IBC

Interbus S optical 9774120IBO

Probus 9774120PRF

Devicenet 9774120DEV

Cooler KempArc Cool10 6128100

Cables

Intermediate cable 5 m (power source - wire feeder) 6260421

Intermediate cable 10 m (power source - wire feeder) 6260425

Earthing cable 70 mm, 5 m 6184711

Earthing cable 70 mm, 10 m 6184712

SYN 400 (digital) 6201400

SYN 500 (digital) 6201500

SYN 400 (analogue) 6201400AN

SYN 500 (analogue) 6201500AN

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

6. TECHNICAL DATA

KempArc™ SYN 300 SYN 400 SYN 500

Mains voltage 400 V -15 % ... +20 %

Rated power 60% ED - 26.1 kVA

Primary current 50% ED I

Connector cable HO7RN-F 4G6 (6 mm)

Fuse, slow 25 A 35 A

Idle power 25 W

Eciency 87%

Power factor 0,9

Load capacity 40 ˚C 60% ED - 500 A

Voltage supply for auxiliary devices 50 VDC

Fuse (X14, X15) 6.3 A delayed

Voltage supply for the cooling device 1~, 400 V / 250 VA

Welding voltage range MIG 10 V ... 37 V 10 V ... 39 V 10 V ... 42 V

Max. welding voltage 46 V

Open circuit voltage 50 V

80% ED - 19.5 kVA 100% ED 13.9 kVA 18.5 kVA 20.3 kVA

19.8 28 40

1max

100% ED I

80% ED - 400 A 100% ED 300 A 380 A 430 A

19.8 25.5 31

1

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

23

RU

Page 26

FI

SV

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

KempArc™ SYN 300 SYN 400 SYN 500

Operating temperature range -20 ... +40 ˚C

Storage temperature range -40 ... +60 ˚C

Degree of protection IP23C

Dimensions Length 590 mm

Width 230 mm

Height 500 mm

Weight 35 kg 36 kg 37 kg

The machines comply with the requirements for the CE label.

DT 400

Operating voltage 50 V DC

Rated power 100 W

Load capacity 80% ED 600 A

100% ED 500 A

Operating principle 4-wheel feed

Wire feed speed 0 ... 25 m/min

Filler wires Fe, Ss 0.6 ... 1.6 mm

Flux-cored wire 0.8 ... 1.6 mm

Al 1.0 ... 1.6 mm

Welding gun connector Euro

Operating temperature range -20 ... +40 ˚C

Storage temperature range -40 ... +60 ˚C

Degree of protection IP23

Dimensions Length 269 mm

Width 175 mm

Height 169 mm

Weight 4.5 kg

The machine complies with the requirements for the CE label.

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

24

Page 27

7. WARRANTY POLICY

Kemppi Oy provides a warranty for products manufactured and sold by the company if defects

in materials or workmanship occur. Warranty repairs are to be carried out only by an authorised

Kemppi Service Agent. Packing, shipping, and insurance are at the orderer’s expense.

The warranty starts on the date of purchase. Spoken promises not included in the terms of

warranty are not binding on the warrantor.

Limitations of the warranty

The following conditions are not covered under the terms of warranty: defects arising

from normal wear and tear, non-compliance with operation and maintenance instructions,

overloading, negligence, connection to incorrect or faulty supply voltage (including voltage

surges outside equipment specications), incorrect gas pressure, anomalies or failures in the

electric network, transport or storage damage, and re or damage due to forces of nature. This

warranty does not cover direct or indirect travel costs, daily allowances, or accommodation

related to warranty service.

The warranty does not cover welding torches and their consumables, feeder drive rolls,

and feeder guide tubes. Direct or indirect damage caused by a defective product is not

covered under the warranty.

The warranty becomes void if modications are made to the machine that are not approved

by the manufacturer or if non-original spare parts are used in repairs. The warranty is also

voided if repairs are carried out by a repair agent not authorised by Kemppi.

Undertaking warranty repairs

Warranty defects must be reported to Kemppi or an authorised Kemppi Service Agent without

delay.

Before a warranty repair is undertaken, the customer must present proof of warranty or

otherwise prove the validity of the warranty in writing. The proof must indicate the date of

purchase and the manufacturing number of the unit to be repaired. The parts replaced under

the terms of this warranty remain the property of Kemppi and must be returned to Kemppi if

requested.

After a warranty repair, the warranty of the machine or equipment, repaired or replaced, shall

be continued to the end of the original warranty period.

KempArc SYN 300, 400, 500 / © Kemppi Oy / 0808

FI

SV

NO

DA

EN

EN

DE

NL

FR

ES

PL

RU

25

Page 28

KEMPPI OY

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

www.kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

e-mail: sales.nl@kemppi.com

KEMPPI AUSTRALIA PTY LTD.

25A, Stennett Road

INGLEBURN NSW 2565

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

e-mail: info.au@kemppi.com

KEMPPIKONEET OY

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 734 8398

e-mail: myynti. @kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

e-mail: sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

e-mail: sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

e-mail:sales.dk@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK443WH

ENGLAND

Tel +44 (0)845 6444201

Fax +44 (0)845 6444202

e-mail: sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

e-mail: sales.fr@kemppi.com

KEMPPI GmbH

Otto-Hahn-Straße 14

D-35510 BUTZBACH

DEUTSCHLAND

Tel +49 6033 88 020

Telefax +49 6033 72 528

e-mail:sales.de@kemppi.com

KEMPPI SPOLKA z.o.o.

Ul. Piłsudskiego 2

05-091 ZĄBKI

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

e-mail: info.pl@kemppi.com

Kemppi OY LIMITADA

Av. Pdte. Edo. Frei Montalva 6001-81

Conchalí, SANTIAGO,

CHILE

Tel +56-2-949 1990

Telefax +56-2-949 1991

e-mail: arturo.silva@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 739 4304

Telefax +7 495 739 4305

e-mail: info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 739 4304

Telefax +7 495 739 4305

e-mail: info.ru@kemppi.com

www.kemppi.com

Loading...

Loading...