Page 1

Kempomat

2500, 3200, 4200

Operating manual • English

Käyttöohje • Suomi

Bruksanvisning • Svenska

Bruksanvisning • Norsk

Brugsanvisning • Dansk

Gebrauchsanweisung • Deutsch

Gebruiksaanwijzing • Nederlands

Manuel d’utilisation • Français

Manual de instrucciones • Español

Instrukcja obsługi • Polski

Инструкции по эксплуатации • По-русски

EN

FI

SV

NO

DA

DE

NL

FR

ES

PL

RU

Page 2

Page 3

OPERATING MANUAL

English

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

Page 4

CONTENTS

EN

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

1. PREFACE

1.1 General

1.2 Product introduction

........................................................................................................................................................ 3

................................................................................................................................................................. 3

................................................................................................................................. 3

2. INSTALLATION OF THE POWER SOURCE ...........................................................4

2.1 Positioning of the machine ...................................................................................................................4

2.2 Connection to the mains supply ....................................................................................................... 4

2.3 Mounting of the mains cable ..............................................................................................................4

2.4 Welding and return current cables ..................................................................................................5

3. USE OF WIREFEEDER ....................................................................................................................6

3.1 Parts of wire feed mechanism

3.2 Installation of the wire feed system

3.3 Installation of wire feed ........................................................................................................................... 8

3.4 Mounting of MIG welding gun

3.5 Mounting and locking of wire reel

3.6 Automatic wire feed to gun

3.7 Adjustment of tightness of wire reel brake

3.8 Shielding gas ................................................................................................................................................ 11

............................................................................................................. 6

................................................................................................ 8

........................................................................................................... 9

.................................................................................................. 9

............................................................................................................... 10

............................................................................ 10

4. OPERATION AND USE OF POWER SOURCE .................................................12

4.1 Kempomat panels .....................................................................................................................................12

4.2 Wire feed panel ...........................................................................................................................................13

4.3 Wire feeder unit ..........................................................................................................................................13

4.4 Main switches and pilot lamps ........................................................................................................ 14

4.5 Adjustment for arc roughness .........................................................................................................15

4.6 Operation of cooling fan ...................................................................................................................... 15

5. CONTROL PANELS AND ADJUSTMENTS .........................................................15

5.1 Wire feed speed potentiometer .....................................................................................................15

5.2 Burn back time

5.3 KMW timer functions .............................................................................................................................. 16

............................................................................................................................................ 15

6. ACCESSORIES ...................................................................................................................................... 17

6.1 KMW sync ........................................................................................................................................................ 17

6.2 Installation and mounting of KMW sync .................................................................................. 17

7. OPERATION DISTURBANCES .......................................................................................... 18

8. REGULAR MAINTENANCE OF THE EQUIPMENT .................................... 18

8.1 Cables ................................................................................................................................................................. 19

8.2 Power source ................................................................................................................................................19

8.3 Disposal of the machine .......................................................................................................................19

9. ORDERING NUMBERS ...............................................................................................................20

10. TECHNICAL DATA ...........................................................................................................................21

2

Page 5

1. PREFACE

1.1 GENERAL

Congratulations on choosing the Kempomat™ equipment. Used correctly, Kemppi products

can signicantly increase the productivity of your welding, and provide years of economical

service.

This operating manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the equipment can be found at the end

of the manual.

Please read the manual carefully before using the equipment for the rst time. For your

own safety and that of your working environment, pay particular attention to the safety

instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

Important notes

Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with the ’NOTE!’ notation. Read these sections carefully and follow

their instructions.

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

EN

1.2 PRODUCT INTRODUCTION

The power sources Kempomat 3200 and 4200 are compact MIG welding machines, designed

for heavy industrial use. Kempomat 2500 is compact MIG welding machine, designed for

repair shops and light and heavy industrial use.

Power source

Supply voltage of the Kempomat 2500 power source is 3~ 230 V/400 V. Supply voltage of the

Kempomat 3200 power source is 3~ 230 V/400 V. Welding voltage adjustment is in 10-steps.

Adjustment for voltage of power source is in 40-steps.

In Kempomat 4200 product range there are dierent units for mains voltages 3~ 230 and 400

V. The welding voltage adjustment for 230 V power source is made in 32 steps, 400V power

source in 56-steps. The Volt/Ampere metering unit MSD 1 (available as accessory) displays

voltage or welding current.

Wire feeder unit

The wire feeder unit is a xed unit in the equipment for air-cooled guns. Kempomat 2500 is

equipped with 2 wheel wire drive mechanism, Kempomat 3200 and 4200 are equipped with

4 wheel wire drive mechanism. Accessory unit KMW sync is needed for connection and use of

push-pull guns.

3

Page 6

2. INSTALLATION OF THE POWER SOURCE

L1

L2

L3

2.1 POSITIONING OF THE MACHINE

Place the machine on a rm, dry and level surface. Where possible, do not allow dust or other

impurities to enter the machines cooling air ow. Preferably site the machine above oor level;

for example on a suitable carriage unit.

Notes for positioning the machine

• The surface inclination should not exceed 15 degrees.

• Ensure the free circulation of the cooling air. There must be at least 20 cm of free space in

front of and behind the machine for cooling air to circulate.

• Protect the machine against heavy rain and direct sunshine.

NOTE! The machine should not be operated in the rain as the protection class of the machine,

IP23S, allows for outside preserving and storage only.

NOTE! Never aim metallic grinding spray/sparks towards the equipment.

2.2 CONNECTION TO THE MAINS SUPPLY

Connection and change of the mains cable and the plug must be carried out only by a

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

competent electrician. Remove for the mounting of the mains cable the left side plate, seen

from the front of the power source.

The Kempomat power source is equipped with 5 m supply cable without plug. The mains

cable is according to the marking H07RN-F of the norm CENELEC HD22. The mains cable must

be changed if it doesn´t meet local regulations.

EN

2.3 MOUNTING OF THE MAINS CABLE

The cable is entered into the machine through the inlet ring on the rear wall of the machine

and locked with a cable clamp (05).

The phase conductors of the cable are coupled to connectors L1, L2 and L3. The earth

protection coloured green-yellow is coupled to connector marked with earth protection

symbol

the cable´s protective shield.

In cables of S type there is protective grounding conductor coloured green-yellow.

Kempomat 2500 3200 4200

Connection voltage

Connection cable

Fuse, delayed

. If you are using 5-conductor cable, you must cut the zero conductor to the level of

230 V 400 V 230 V 400 V 230 V 400 V

4G2.5 (5 m) 4G2.5 (5 m) 4G2.5 (5 m) 4G2.5 (5 m) 4G6.0 (5 m) 4G2.5 (5 m)

16 A 10 A 20 A 16 A 25 A 16 A

4

Page 7

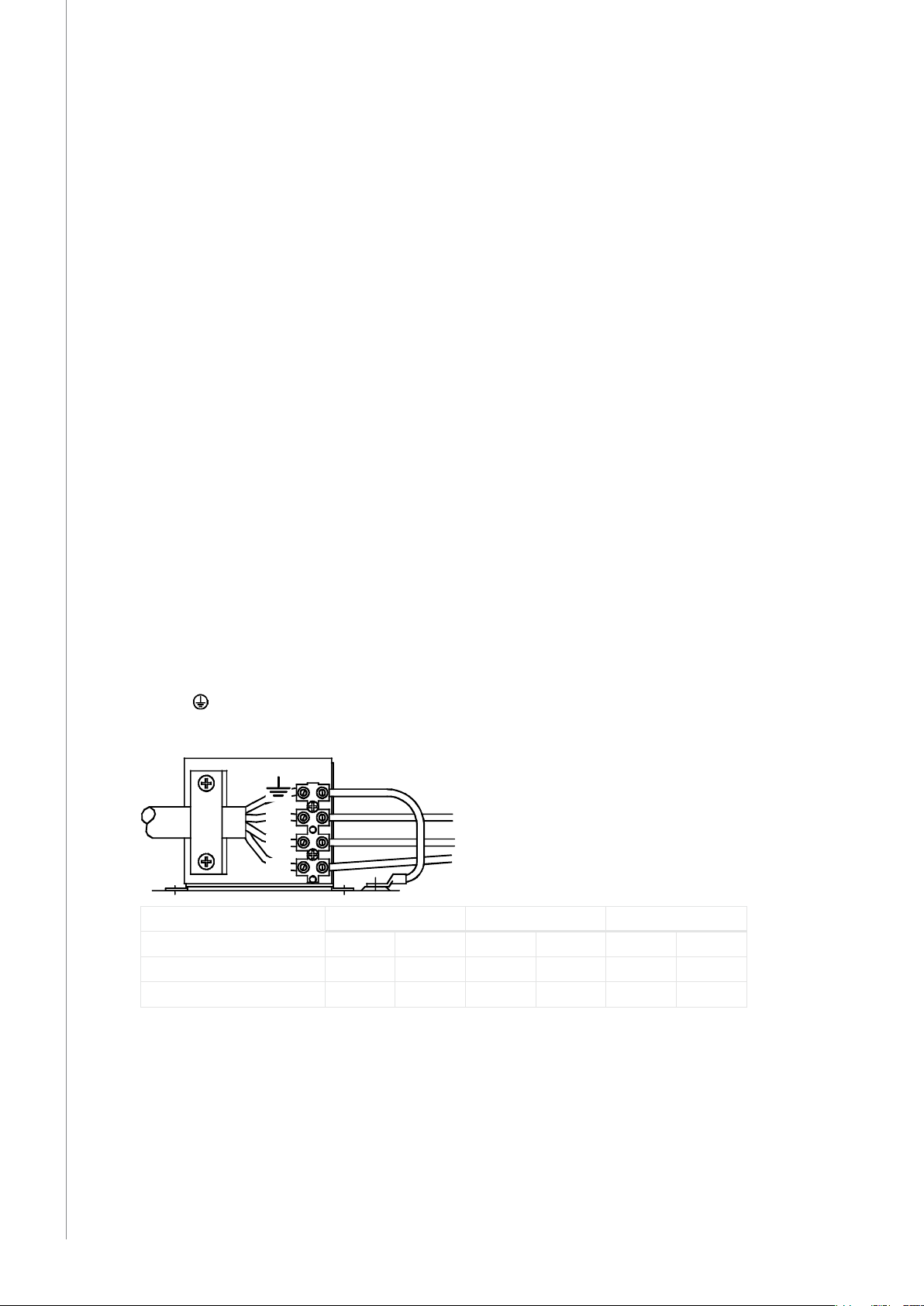

Change of mains voltage / Kempomat 2500, 3200

Connection and change of the mains cable and the plug must be carried out only by a

competent electrician.

230 V

201

204

203

206

205

202

T002

230 V

0

230 V

400 V

201

400 V

204

203

206

205

202

T002

400 V

0

230 V

400 V

Connection 3~ 230 or 3~ 400 V of mains voltage

By delivery from the factory the Kempomat 3200 and 2500 machine has been connected for

mains voltage 3~ 400 V. In order to change the mains voltage in the Kempomat 2500/3200

machine, remove the side plate of the machine. Change the connections according to the

enclosed diagram. You nd the corresponding wiring diagram on the instruction label, which

is under terminal block.

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

EN

NOTE! The Kempomat 4200 machine has the connection for only one mains voltage!

2.4 WELDING AND RETURN CURRENT CABLES

In enclosed table are shown typical loading capacities of rubber insulated copper cables,

when ambient temperature is 25 °C and conductor temperature is 85 °C.

Kempomat 2500

Cable cross-section Duty cycle ED Voltage loss / 10 m

Cu 100 % 60 % 30 % for 100 A

25 mm² 180 A 230 A 330 A 0.7 V

35 mm² 225 A 290 A 410 A 0.5 V

Kempomat 3200, 4200

Cable cross-section Duty cycle ED Voltage loss / 10 m

Cu 100 % 60 % 40 % for 100 A

50 mm² 285 A 370 A 450 A 0.35 V

70 mm² 355 A 460 A 560 A 0.25 V

NOTE! Don´t overload welding cables over permissible values due to voltage losses and heating.

Fasten the earthing press of the return current cable carefully, preferably direct onto the piece to

be welded. The contact surface area of the press should always be as large and steady as possible.

Clean the contact surface from paint and rust.

5

Page 8

3. USE OF WIREFEEDER

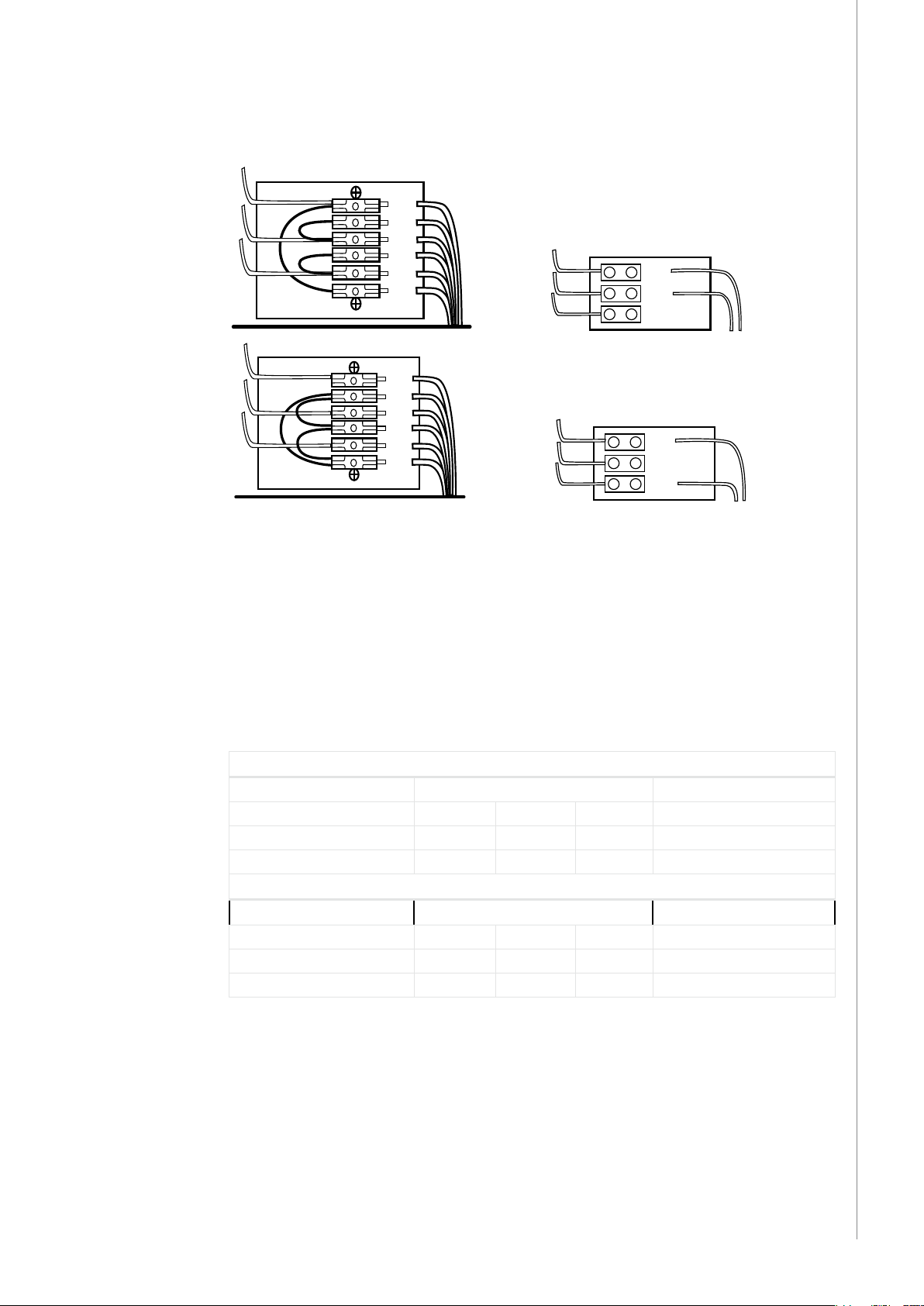

3.1 PARTS OF WIRE FEED MECHANISM

Kempomat 2500

Wire guide tubes for 2-roll wire feed mechanism

Wire ø mm Wire guide tube ø mm

Fe, Mc,

Fc

Ss, Al

0,6 ... 0,8 White 1,0 3134140 brass 4285900 1,8 plastic 4102283

0,9 ... 1,6 Orange 2,0 3133700

0,8 ... 1,6 Silver 2,5 3134290

EN

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

A.

B.

Pressure adjustment

A. B.

C.

Gear wheel, 2-roll wire feed mechanism

ø 28 mm (0–18 m/min) 4265240 muovi

ø 28 mm (0–18 m/min) 4287860 teräs

Feed rolls 2-roll (2500) 2500, 3200, 4200

Feed roll groove selection

Fe, Ss, Al

Plain V-groove

Colour ø mm

White 0.6/0.8 3133810

White 0.8/0.8 (L) 3143180

Red 3133210

Red 1.0/1.0 (L) 3138650

Orange 1.2/1.2 (L) 3137390

Yellow 1.4-1.6 3133820

Yellow 1.6/1.6 (L) 3141120

C.

Fe, Fc, Mc

Knurled

V-groove

Fe, Fc, Mc,

Ss, Al

Trapezoid

Red 1.0/1.2 3133940 Transfer of gear wheel selector plate

Orange 1.2/1.2 (L) 3137380

Yellow 1.4-1.6 3133990

Yellow 1.6/1.6 (L) 3141130

Orange 1.2/1.2 (L) 3142210

Brown 1.4/1.4 (L) 3142220

Yellow 1.6/1.6 (L) 3142200

groove

(L) = Fitted with ball bearings

6

Page 9

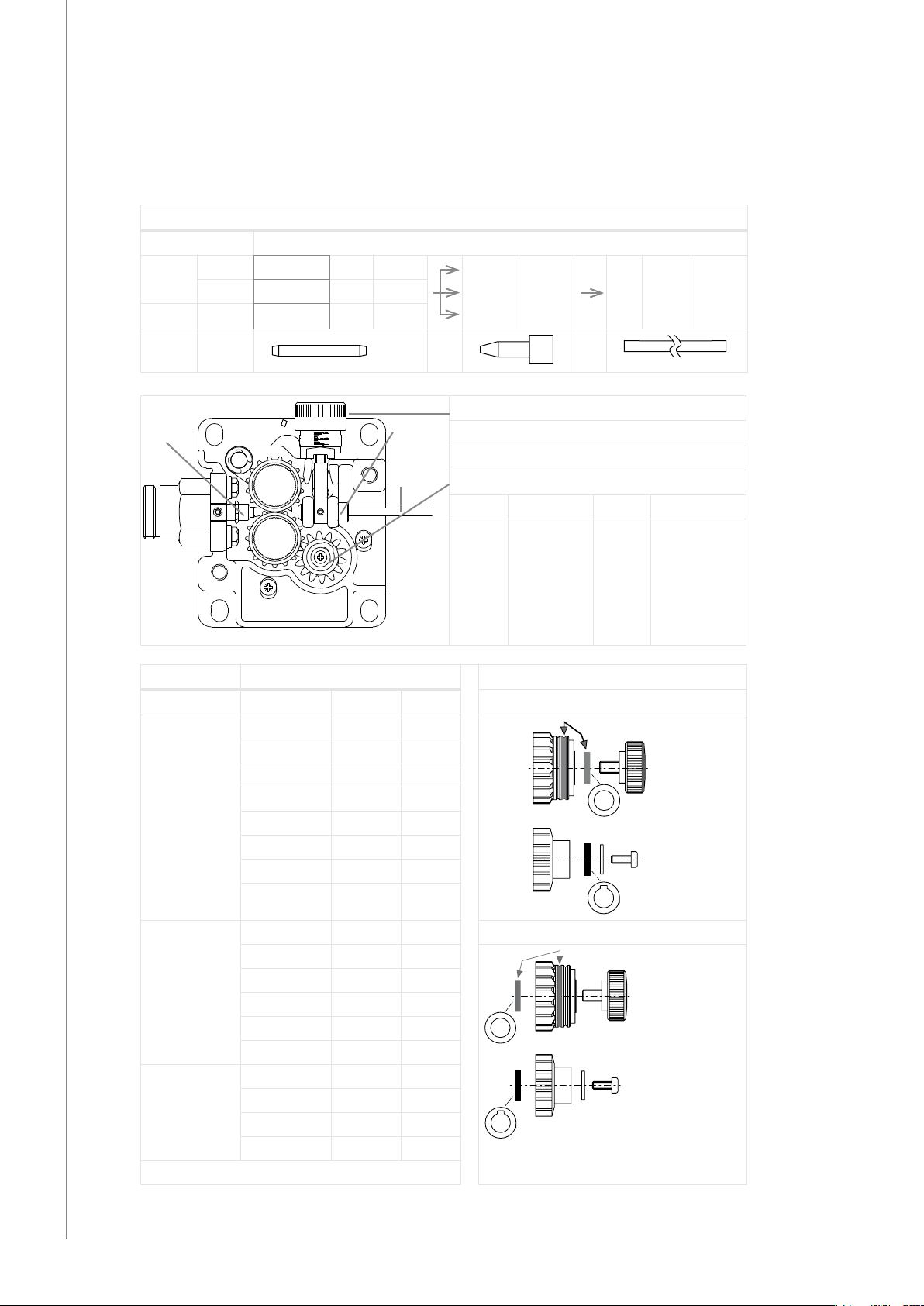

Kempomat 3200, 4200

plastic 2.0 4266970

D.

C.

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

A. B.

1.6 ... 2.4 Blue 4.0 3134130 Blue 4.0 3134110 brass 4.0 4267030

0.6 ... 0.8 1.0 3134140 Orange 2.0 3134120 plastic 2.0 4267220 yellow 2.4 4268210

Wire guide tubes for 4-roll wire feed mechanism

Wire ø mm Wire guide tube ø mm

FeMcFc

0.9 ... 1.6 Orange 2.0 3133700 plastic 4.0 4270180 ProMig 511

1.6 ... 2.4 Yellow 3.0 3134710 Yellow 3.0 3134720 plastic 4.0 4270180

0.8 ... 1.6 Grey 2.5 3134290 Grey 2.5 3134300 plastic 2.0 4267220 yellow 3.0 4268560

Ss

Al

Pressure adjustment

C.

A.

D.

Gear wheel, 4-roll wire feed mechanism

ø 28 mm (0–18 m/min) 4265240 plastic

ø 28 mm (0–18 m/min) 4287860 steel

ø 40 mm (0–25 m/min) 4265250 plastic

B.

Feed rolls 4-roll (3200, 4200) Colour ø mm

Colour ø mm Fe, Fc, Mc

Fe, Ss, Al

Plain V-groove

White 0.6/0.8 3133810 Orange 1.2/1.2 (L) 3137380

White 0.8/0.8 (L) 3143180 Yellow 1.4-1.6/2.0 3133990

Red 1.0/1.2 3133210 Yellow 1.6/1.6 (L) 3141130

Red 1.0/1.0 (L) 3138650 Black 2.4 3134030

Orange 1.2/1.2 (L) 3137390 Blue 3.2 3134060

Yellow 1.4-1.6/2.0 3133820

Yellow 1.6/1.6 (L) 3141120 Brown 1.4/1.4 (L) 3142220

Black 2.4 3133880 Yellow 1.6/1.6 (L) 3142200

Blue 3.2 3133910 Grey 2.0/2.0 (L) 3142230

(L) = Fitted with ball bearings

Knurled V-groove

Fe, Fc, Mc,

Ss, Al

Trapezoid groove

Red 1.0/1.2 3133940

Orange 1.2/1.2 (L) 3142210

Black 2.4 (L) 3142240

ø 40 mm (0–25 m/min) 4297270 steel

EN

7

Page 10

3.2 INSTALLATION OF THE WIRE FEED SYSTEM

Wire feeder unit:

1. Mount the return current cable to connector on the Kempomat´s front panel.

2. The MIG gun is mounted to the EURO connector of the wire feeder unit. Use guide tubes

and contact tips according to manufacturer´s operation instructions. Accessories which

are too tight or otherwise unsuitable for the wire type used by you, will cause wire feed

disturbances.

3. Max. wire feed speed

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

When the unit is delivered the max. wire feed speed is 18 m/min, which is enough for the most

welding works. If you need a higher speed, you can increase the max. wire feed speed to 25 m/

min by replacing the gear wheel on motor shaft to a bigger one. The big gear wheel (D40) is

delivered on order.

EN

When necessary speed is changed according to following:

• Open tightening lever (20). Remove lower feed rolls (21). Release screw (23) and its

washer. Remove gear wheel D28 (24) from motor shaft.

• Loosen screws (25) (3 pc) 1 twist. Mount the D40 gear wheel onto motor shaft. Screw the

screw (23) with its washer back.

• Put feed rolls (21) back to their axles, however don´t fasten yet fastening screws of the

feed rolls (22).

• Lift the motor so that the tooth gap between gear wheel and both lower feed rolls is

approx. 0,2 mm.

• Tighten screws (25). Check gear teeth gaps, when necessary put the motor into a better

position. Screw on the mounting rolls of feed rolls (22).

• Too small gap between gear wheel and feed rolls will overload motor.

• Too big gap for its part might cause too rapid wearing for teeth of feed rolls and gear

wheel.

4. The shielding gas hose is mounted to the snap connector on the rear wall of the

unit. Mounting to the gas bottle and shielding gas ow regulation, see paragraph for

SHIELDING GAS.

3.3 INSTALLATION OF WIRE FEED

Accessories according to wire feed

Wire feed rolls are available with plain groove, knurled groove and with trapezoidal groove for

dierent purposes.

Kempomat 2500

Colour Filler wire ø, mm inch

Feed rolls

white 0.6 and 0.8 0.030

red 0.9/1.0 and 1.2 0.035, 0.045 and 0.052

Guide tubes

orange 0.6-1.6 0.024-1/16

8

Page 11

Kempomat 3200, 4200

Colour Filler wire ø, mm inch

Feed rolls

white 0.6 and 0.8 0.030

red 0.9/1.0 and 1.2 0.035, 0.045 and 0.052

yellow 1.4, 1.6 and 2.0 1/16 and 5/64

Guide tubes

orange 0.6-1.6 0.024-1/16

Feed roll with plain groove:

Universal feed roll for welding of all kinds of wires

Feed rolls with knurled groove:

Special feed roll for cored wires and steel wires

Feed rolls with trapezoidal groove:

Special feed roll for aluminium wires

Wire feed rolls have two grooves for dierent ller wire diameters. Correct wire groove is

selected by moving selecting washer from one side to another in feed roll.

Feed rolls and wire guide tubes have colour codes in order to make identication easier.

By delivery Kempomat is equipped with red feed rolls with plain groove and with orange wire

guide tubes for welding ller wires 0.9 - 1.2 mm (0.035”, 0.045” and 0.052”).

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

3.4 MOUNTING OF MIG WELDING GUN

In order to ensure trouble-free welding check in operation instructions of gun used by you

that wire guide tube and contact tip of gun are according to manufacturer´s recommendation

suitable to be used for wire feed diameter and type in question. Too tight a wire guide tube

might cause for wire feeder unit a bigger stress than normally as well as disturbances in wire

feed.

Screw snap connector of gun tight that there won´t come any voltage losses on connecting

surface.

A loose connection will heat gun and wire feeder unit.

NOTE! Make sure that the welding gun in your use is designed for max. welding current needed by

you! Never use a damaged welding gun!

3.5 MOUNTING AND LOCKING OF WIRE REEL

• Release locking nails of wire reel hub by turning locking knob to the position OPEN.

• Mount the reel at its place. Note rotating direction of reel!

• Turn the locking knob to the position LOCKED.

NOTE! Check in ller wire reel that there are no parts sticking out, which could e.g. chafe against

chassis or door of wire feeder unit. Dragging parts might expose chassis of wire feeder unit under

voltage.

EN

LOCKED OPEN

9

Page 12

EN

3.6 AUTOMATIC WIRE FEED TO GUN

Automatic wire feed makes change of wire reel more rapid. In reel change the pressure of feed

rolls need not to be released and ller wire goes automatically to correct wire line.

• Make sure that groove of feed roll matches the diameter of welding wire used. Feed roll

groove is selected by moving the groove selecting washer. Also the selector plate for

changing the feed roll groove has to be moved similarly. (see tables on pages 6 and 7).

Groove selecting washer

• Release the wire end from reel and cut o the bent length. Be careful that the wire does

not spill from the reel to sides!

• Straighten about 20 cm of the wire and see that the end of it has no sharp edges (le

o if necessary). A sharp edge may damage the wire guide tube and contact tip of the

welding gun.

• Draw a bit of loose wire from wire reel. Feed wire through back liner to feed rolls. Don´t

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

release pressure of feed rolls!

• Press the gun switch and feed a bit wire until wire goes through feed rolls to gun. See

that wire is in grooves of both feed roll pairs!

• Press still the gun switch until wire has come through contact tip.

Automatic feed may sometimes fail with thin wires (Fe, Ss: 0.6 ... 0.8 mm, Al, Fc: 0.8 ... 1.0 mm).

Then it might be possible that you must open feed rolls and feed wire manually through feed

rolls.

Adjustment of pressure

Adjust the pressure of feed rolls with the control screw (20) so that the wire is fed into the wire

guide tube evenly and allows a little braking when coming out from the contact tip without

slipping at the feed rolls.

NOTE! Excessive pressure causes attening of the ller wire and damage to the coating. It also

causes undue wear of the feed rolls as well as friction.

3.7 ADJUSTMENT OF TIGHTNESS OF WIRE REEL BRAKE

Brake force is adjusted through hole in locking device of reel hub by screwing the control

screw with screwdriver.

Adjust brake force as so big that the wire cannot spill from the reel when the rotation of the

reel stops. Need for brake force is increased with increase of the wire feed speed.

Since the brake loads for its part the motor, you shouldn´t keep it unnecessarily tight.

Adjustment screw

10

Page 13

3.8 SHIELDING GAS

As MIG shielding gas is used carbon dioxide, mixed gases and argon. Shielding gas ow rate is

dened by welding current size. Typical rate of gas in welding of steel is 8-15 l / min.

Gas ow regulator

Gas ow regulator should be suitable for shielding gas used by you. The regulator being in

your use might be dierent from the one in picture, however, following general instructions

are valid for all pressure regulators.

Before mounting of ow regulator

1. Step aside and open the bottle valve (A) for a while to blow out possible impurities from

the bottle valve.

2. Turn the press regulation screw (B) of the regulator until no spring pressure can be felt.

3. Close needle valve, if there is one in the regulator.

4. Install the regulator on bottle valve and tighten connecting nut (C) with a wrench.

5. Install hose spindle (D) and jacket nut (E) into gas hose and tighten with hose clamp.

6. Connect the hose with the regulator and the other end with the power source. Tighten

the jacket nut.

7. Open bottle valve slowly. Gas bottle pressure meter (F) shows the bottle pressure. Note!

Do not use the whole contents of the bottle. The bottle should be lled when the bottle

pressure is 2 bar.

8. Open needle valve if there is one in the regulator.

9. Turn regulation screw (B) until hose pressure meter (G) shows the required ow (or

pressure). When regulating ow amount, the power source should be switched on and

gas test button on the panel pressed simultaniously.

Close bottle valve after having nished welding. If the machine will be out of use for a long

time, unscrew the pressure regulation screw.

A

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

C

F

EN

G

B

E

D

A. Gas bottle valve

B. Pressure regulation screw

C. Connecting nut

D. Hose spindle

E. Jacket nut

F. Gas bottle pressure meter

G. Gas hose pressure meter

NOTE! The gas bottle may explode if it falls!

Always fasten gas bottle tightly in vertical position, to wall stand or bottle cart, specially designed

for it! For safety reasons always remove gas bottle from transport stand of the machine before

lifting or car transport of machine!

11

Page 14

4. OPERATION AND USE OF POWER SOURCE

4.1 KEMPOMAT PANELS

1. 13.

EN

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

2.

3.

4.

5.

6.

8.

7.

9.

10.

11.

12.

1. Wire feed panel

2. Push-pull gun connector and switch (accessory)

3. Welding gun connector (EURO)

4. Mounting place for MSD 1 V/A metering unit (accessory)

5. Signal lamp for Kempomat 4200 main switch

6. Signal lamp for overheating (power source)

7. Kempomat 3200 main switch

8. Kempomat 4200 main switch and voltage selecting range

9. Voltage selecting switch (ne grading)

10. Voltage selecting switch (coarse grading)

11. I Return current dix-connector (coarser arc)

12. II Return current dix-connector (softer arc)

13. Control fuse (8 A delayed)

14. Shielding gas connector

15. Gennemføring til netkabel

16. Inlet of mains cable

14.

15.

16.

12

Page 15

4.2 WIRE FEED PANEL

Kempomat 2500

1. Adjustment potentiometer for wire feed

2. KMW timer, continuous/hold, continuous/spot/cycle arc, welding spot or cycle time

Kempomat 3200, 4200

1.

2.

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

1. Adjustment potentiometer for wire feed

2. KMW timer, continuous/hold, continuous/spot/cycle arc welding, spot or cycle time

4.3 WIRE FEEDER UNIT

SS

BURNBACK

WIRE INCH

1. Burn back time (according to f iller material and wire feed)

2. Wire inch switch (wire feed into gun)

Al

5

4

3

2

1

ø

1.

2.

Fe

6

7

8

1.

9

1 0

2.

EN

13

Page 16

4.4 MAIN SWITCHES AND PILOT LAMPS

Main switch (Kempomat 2500 and 3200)

In zero position all control and welding current circuits of the equipment are dead (without

voltage). In position I the control circuits of the machine become live (get voltage). The

primary and welding circuits are dead, if the welding mode has not been started with the gun

trigger.

Main switch (Kempomat 4200)

In zero position all control and welding current circuits of the equipment are dead (without

voltage). In positions 15 - 28 V and 28 - 48 V the control circuits and cooling fan of the

equipment get voltage. The primary and welding circuits are dead, if the welding mode has

not been started with the gun trigger.

Always switch on and switch o the machine from the main switch. Never use the mains plug

for switching on or switching o the units and equipment!

Adjustment of welding voltage

Table of adjustments, switch positions:

In Kempomat 2500 the welding voltage is adjusted with one 10-step turn switch. In

Kempomat 3200 and 4200 the welding voltage is adjusted with two turn switches. In

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

Kempomat 4200 rst select the other welding voltage area from the main switch

is 4-step switch for coarse control, where voltage value of each step can be ne-adjusted

with the switch . The switch for ne-adjustment in Kempomat 3200 is with 10-steps, in

Kempomat 4200 230V with 4-steps, and in Kempomat 4200 400V with 7-steps.

. There

EN

Kempomat 2500 Kempomat 3200

Voltage step Open circuit

voltage

1 13.7 V 1 / 4 1 / 10 – 10 / 10 15.5 – 18.2 V

2 15.2 V 2 / 4 1 / 10 – 10 / 10 18.6 – 22.5 V

3 16.9 V 3 / 4 1 / 10 – 10 / 10 23.1 – 29.3 V

4 18.8 V 4 / 4 1 / 10 – 10 / 10 30.4 – 41.6 V

5 20.8 V

6 23.0 V

7 25.5 V

8 28.3 V

9 31.4 V

10 34.9 V

Coarse control Fine control Open circuit

voltage

Kempomat 4200

Main switch. Coarse control Fine control

(400V)

15 – 28 V 1 / 4 1 / 7 – 7 / 7 1 / 4 – 4 / 4 14.6 –16.3 V

15 – 28 V 2 / 4 1 / 7 – 7 / 7 1 / 4 – 4 / 4 16.6 – 18.8 V

15 – 28 V 3 / 4 1 / 7 – 7 / 7 1 / 4 – 4 / 4 19.2 – 22.0 V

15 – 28 V 4 / 4 1 / 7 – 7 / 7 1 / 4 – 4 / 4 22.5 – 26.1 V

Fine control (230V) Open circuit

voltage

14

28 – 48 V 1 / 4 1 / 7 – 7 / 7 1 / 4 – 4 / 4 27.1 – 30.0 V

28 – 48 V 2 / 4 1 / 7 – 7 / 7 1 / 4 – 4 / 4 30.5 – 34.2 V

28 – 48 V 3 / 4 1 / 7 – 7 / 7 1 / 4 – 4 / 4 34.9 – 39.7 V

28 – 48 V 4 / 4 1 / 7 – 7 / 7 1 / 4 – 4 / 4 40.5 – 47.1 V

Page 17

Pilot lamps of the machine report about electric function:

The green pilot lamp indicating that the machine is ready for operation is always illuminated,

when the machine is connected to mains voltage and you have selected welding voltage

range from the main switch.

The yellow pilot lamp for thermal protection is illuminated, when thermal protection of the

welding circuit has released due to overheating. The protection releases if the power source is

continuously loaded over rated values or the cooling air circulation has been obstructed.

The cooling fan is cooling down the machine and after the pilot lamp has switched o, the

machine is again ready for welding from the gun trigger.

Control fuse

On the rear plate of the power source the fuse 8 A delayed is the short-circuit protection. Use

the fuse size and type according to markings. Damage caused by a wrong type fuse is not

covered by the guarantee. If the fuse is blowing again, send the unit to service.

4.5 ADJUSTMENT FOR ARC ROUGHNESS

Arc roughness is adjusted by connecting the return current cable to the applicable one of the

two dix-connectors on the front plate.

The connector marked with symbol I gives a rougher arc, which is used for welding of thin

sheets and ferrous metals by 0.6 - 1.0 mm wires and especially with CO² shielding gas. The

connector marked with symbol II is suitable for thicker wires and especially for aluminium and

stainless materials. The most suitable roughness is, however, most dependent on the welding

case. You will nd the best position by testing the dierent positions.

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

4.6 OPERATION OF COOLING FAN

The cooling fan on the rear plate of the Kempomat machine is started and stopped according

to use. The cooling fan is started after ca. 15 s after weld start and stopped after ca. 10 min

after weld end or release of the overheat protection.

NOTE! The fan is intaking air from rear plate side! Don´t switch o the unit with the main switch

before the cooling fan has automatically stopped. By open circuit the cooling fan does not get

started.

5. CONTROL PANELS AND ADJUSTMENTS

5.1 WIRE FEED SPEED POTENTIOMETER

The wire feed speed is adjusted steplessly with the potentiometer on the front panel, see the

paragraph Panels. The potentiometer has the memory scale for max. speeds of 18 m/min and

25 m/min. See the section Installation of wire feed equipment, paragraph 3. Max. wire feed

speed.

5.2 BURN BACK TIME

Dierent ller materials and shielding gases behave in dierent ways in the welding end, so

that you should switch o the welding current with a delay, which is suitable for wire feed

stopping according to the welding case.

If you try to end welding with an unsuitable burn back time, the wire will burn in the contact

tip, there will be too big “balloon” at the wire end, or the wire will stick at the ending point.

EN

15

Page 18

Factors inuencing on the delay:

The wire feed speed has a signicant inuence on required burn back time. By low wire feed

speeds always select the short burn back time.

• Melting of aluminium is much quicker than by steel-base materials, so that the burn back

time is clearly shorter.

• Steel and especially ller wires require longer time than the stainless materials.

• Thicker ller wires require longer time. Also by increase of wire feed speed the required

time should be longer. In the instruction label are given starting points for adjustment.

The ne-adjustment should be carried out according to each case in question.

• Memory scale for adjustment potentiometer

• The wire inch switch starts the wire feed motor and mechanism, but not the power

source.

The ller wire can be driven to the wire feeder unit, gun and interconnection cable also

with the welding gun´s switch, but then also the power source will get started and the wire

becomes live (gets voltage), and this can cause a danger situation by accidental contact to

surrounding objects.

EN

Al

SS

ø

4

3

2

1

BURNBACK

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

WIRE INCH

5.3 KMW TIMER FUNCTIONS

The control includes the welding with the closed-open operation of the gun trigger, this is

called the 2-sequence procedure. The KMW timer also has the 4-sequence procedure, with

which you can release the trigger for the time of welding, as well as the wire feed timer, which

helps you to control the spot or cycle arc welding.

2 / 4-sequence procedure

2T: The welding with the 2-sequence trigger procedure of the gun.

1. Switch pressed: welding starts

2. Switch open: welding stops

4T: The welding with the 4-sequence trigger procedure of the gun.

1. Switch pressed: shielding gas is owing

2. Switch open: welding starts

3. Switch pressed: welding stops

4. Switch open: gas ow stops after the post gas time

5

Fe

6

7

8

9

1 0

16

Spot, cycle arc and continuous welding

(is operating only in the 2-sequence procedure position)

Spot welding

1. Set the spot time with the potentiometer.

2. The gun switch pressed: welding starts

3. Welding ends automatically after the set time

Cycle arc welding

1. Set the welding cycle time with the potentiometer. The pause time is adjusted automatically.

2. The gun switch pressed: welding is started and continued for so long as the switch is

pressed.

Page 19

6. ACCESSORIES

Volt / Ampere metering unit MSD 1

For the mounting of the MSD 1 remove the cover plate on the front panel of the unit.

The connector of at cable fastened to the cover plate is connected to the corresponding

connector of the MSD 1. From the metering unit you can with lever switch select momentary

display for either voltage or current. By open circuit only voltage value is displayed, because

there is no welding current present.

The voltage value is the voltage between the unit´s welding connectors or terminal voltage.

The value of the open circuit voltage has not very much importance for the welding, so that

the display of the metering unit is adjusted according to the welding situation. The display

of the open circuit voltage diers 1 - 2 V from the true voltage. During welding the terminal

voltage is varying and the arc voltage diers from the terminal voltage due to cable etc. losses.

Accuracy of voltage true value in respect to real value is ±4.0 % ±0.2 V by welding values

according to the norm. Accuracy of current true value in respect to real value is ±2.5 % ±2 A.

The metering unit doesn´t show wire feed values. The MSD 1 doesn´t need any calibration in

the Kempomat units. The switch positions: V = voltage display, A = current display.

6.1 KMW SYNC

The push-pull gun is most often used for feed of thin aluminium wires, when over 5 m reach

is required. You can connect the gun equipped with the EURO adaptor to the KMW sync unit.

The push-pull gun´s potentiometer is connected to amphenol connector, mounted onto front

wall of the Kempomat. You can connect to this connector also some other potentiometer,

which has suitable values for it. With the unit´s switch you can select the Kempomat operation

or the push-pull gun operation. Concerning the right connections in the gun, contact your

KEMPPI dealer.

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

EN

6.2 INSTALLATION AND MOUNTING OF KMW SYNC

In the accessories of the KMW timer are included electronics card, potentiometer knob, switch

protections, at cable and fastening screws.

1. Remove the side plate as well as frame and panel cover plate of the wire feed panel.

2. Remove protective knobs of the holes on the panel plate.

3. Mount the KMW timer electronics card in such a way that the switch levers and

potentiometer axle penetrate through the holes.

4. Mount the protective caps of the switches above the levers.

5. Fasten the card to back edge of the base with two screws. Don´t tighten unnecessarily

much. Mount the panel cover plate with its frame back at its place.

6. Turn the potentiometer axle into clockwise direction to extreme position. Mount the

potentiometer knob onto axle in such a way that the dial line shows the reading more

than 1.5 s. Check that the knob can be turned freely and that in the other extreme

position the dial line shows the value less than 0.1 s. Correct if necessary. Mount the

knob cap.

7. Connect one connector of the at cable to the KMW timer card connector.

8. Connect the other connector of the at cable to connector for KMW timer on the control

card A001.

9. Fasten the side plate back at its place.

17

Page 20

EN

1. KMW sync control card

2. KMW sync, mode selecting switch, control connector for push-pull gun

3. MSD 1 V/A metering unit

7. OPERATION DISTURBANCES

The amount of use and the working environment should be taken into consideration when

planning the frequency of maintenance of the Kempomat. Careful use and preventive

maintenance will help to ensure trouble-free operation.

The following maintenance operations should be carried out at least every six months.

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

Wire feed:

• The wear of the grooves of the feed rolls. Excessive wear of grooves causes problems in

wire feed.

• The wear of the wire guide tubes of the wire feeder unit. Badly worn feed rolls and wire

guide tubes should be dis carded.

• The wire guide tube should be set as near the feed rolls as possible, but not touching

them and the wire must follow a straight line from the end of the tube to the groove of

the feed roll.

• Reel brake adjustment.

• Electric connections

*Oxidized couplings must be cleaned.

*Loose couplings must be tightened.

Clean dust and dirt from the equipment.

When using compressed air, always protect your eyes with proper eye protection.

1.

2.

3.

8. REGULAR MAINTENANCE OF THE EQUIPMENT

Kemppi service repair shops make regular maintenance according to the agreement.

The major points in the maintenance procedure are listed as follows:

• Cleaning of the machine

• Checking and maintenance of the welding tools

• Checking of connectors, switches and potentiometers

• Checking of electric connections

• Metering units checking

• Checking of mains cable and plug

• Damaged parts or parts in bad connection are replaced by new ones

• Maintenance testing. Operation and performance values of the equipment are checked,

and adjusted when necessary by means of test equipment.

The amount of use and the working environment should be taken into consideration

when planning the frequency of maintenance of the machine. Careful use and preventive

maintenance will help to ensure trouble-free operation.

18

Page 21

8.1 CABLES

Check the condition of welding and connection cables daily. Do not use faulty cables!

Make sure that the mains connection cables in use are safe and according to regulations!

The repair and mounting of mains connection cables should be carried out only by an

authorized electrician.

8.2 POWER SOURCE

NOTE! Disconnect the plug of the power source from the mains socket before removing the cover

plate.

Check at least every 6 months (twice a year):

• Electric connections of the unit - clean the oxidized parts and tighten the loosened ones.

• NOTE! You must know correct tension torques before starting the repair of the joints.

• Clean the inner parts of the machine from dust and dirt e.g. with soft brush and vacuum

cleaner.

• Do not use compressed air. Do not use pressure washing device!

• There is a risk that dirt is packed even more tightly into gaps of components!

• Only authorized electrician shall carry out repairs to the machines.

8.3 DISPOSAL OF THE MACHINE

Do not dispose of electrical equipment with normal waste!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment, and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and taken to an appropriate

environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, per the instructions of local authorities or a Kemppi representative. By

applying this European Directive you will improve the environment and human health.

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

EN

19

Page 22

9. ORDERING NUMBERS

EN

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

Kempomat 2500 230/400 V

Kempomat 3200 230/400 V

Kempomat 4200 230 V

Kempomat 4200 400 V

KMW sync 2 (Synchronization unit)

MSD 1 (Volt / Ampere metering unit)

GH 20 (Gun holder)

Hub for wire reel

MT 25

MT 25

KMG 25

KMG 25

KMG 32

KMG 32

MMT 25

MMT 25

MMT 27

MMT 27

MMT 32

MMT 32

MMT 35

MMT 35

WS 35 (Al 1.2)

WS 35 (SS 1.0)

MMT 42

MMT 42

KMP 300

KMP 300

Branch cable KMP/Kempomat

Earth cable 25 mm²

Earth cable 35 mm²

Earth cable 50 mm²

Earth cable 70 mm²

621425002

621432002

6214422

6214424

6219150

6185666

6256020

4289880

3 m 6252023

4,5 m 6252024

3 m 6252123

4,5 m 6252124

3 m 6253033

4,5 m 6253034

3 m 6252513MMT

4,5 m 6252514MMT

3 m 6252713MMT

4,5 m 6252714MMT

3 m 6253213MMT

4,5 m 6253214MMT

3 m 6253513MMT

4,5 m 6253514MMT

6 m 6253516A12

6 m 6253516S10

3 m 6254213MMT

4,5 m 6254214MMT

6 m 6257306

8 m 6257310

3151360

5 m 6184211

5 m 6184311

5 m 6184511

5 m 6184711

20

Page 23

10. TECHNICAL DATA

Kempomat 2500

Rated voltage

Connection voltage

Rated power at max. current 230 V / 400 V

Load capacity 40 °C (nominal values)

Control range

Voltage steps

Open circuit voltage max.

Efficiency at max. current

Power factor at max. current

Fuse, delayed

Wire feed mechanism

Diameter of feed roll

Wire feed speed

Filler wires

Wire spool

Gun connector

Temperature class

Operating temperature range

Storage temperature range

Degree of protection

EMC class

External dimensions

Weight

230 V / 400 V

3~ 400 V 380 V -10% ... 415 V +6%

3~ 230 V 220 V -10% ... 240 V +6%

30 % ED 9,2 kVA

60 % ED 5,9 kVA

100 % ED 4,0 kVA

30 % ED 250 A/26 V

60 % ED 180 A/23 V

100 % ED 140 A/21 V

40 – 250 A/14 – 26 V

10 steps

35 V

250 A/26 V 75 %

250 A/26 V 0,95

8 A

2 wire feed

32 mm

I 0 – 18 m / min

II 0 – 25 m / min

ø Fe, Ss 0,6 – 1,2 mm

ø Cored wire 0,8 – 1,2 mm

ø Al 1,0 – 1,2 mm

max. weight 20 kg

max. size ø 300 mm

Euro

H (180 °C)

-20 ... +40 °C

-40 ... +60 °C

IP23S

A

LxWxH 930 x 440 x 860 mm

80 kg

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

EN

21

Page 24

Kempomat 3200 4200

Rated voltage

Connection voltage

Rated power at max. current

3 ~ 400 V 380 V -10% ... 415 V +6% 380 V -10% ... 415 V +6%

3 ~ 230 V 220 V -10% ... 240 V +6% 220 V -10% ... 240 V +6%

40% ED 13,6 kVA 18,5 kVA

230 V / 400 V

230 V / 400 V

60 % ED 10,0 kVA 13,5 kVA

100 % ED 6,6 kVA 9,0 kVA

Load capacity 40 °C (nominal values)

40 % ED 320 A / 32 V 420 A / 37,5 V

60 % ED 265 A / 27 V 325 A / 31 V

100 % ED 205 A / 24 V 265 A / 27 V

EN

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

Control range

Voltage steps

Open circuit voltage max.

Efficiency at max. current

Power factor at max. current

Fuse, dealayed

Wire feed mechanism

Diameter of feed roll

Wire feed speed

Filler wires

Wire spool

Gun connector

Temperature class

Operating temperature range

Storage temperature range

Degree of protection

EMC class

External dimensions

Weight

40 - 320 A / 15 - 32 V 40 - 420 A / 15 - 37,5 V

40 steps 32 steps / 230 V

56 steps / 400 V

42 V 48 V

(320 A / 32 V ) 75 % (420 A / 37,5 V ) 80 %

(320 A / 32 V ) 0,95 (420 A / 37,5 V) 0,95

8 A 8 A

4 wire feed 4 wire feed

32 mm 32 mm

I 0 – 18 m / min 0 – 18 m / min

II 0 – 25 m / min 0 – 25 m / min

ø Fe, Ss 0,6 – 1,2 mm 0,6 – 1,2 mm

ø Cored wire 0,8 – 1,6 mm 0,8 – 1,6 mm

ø Al 1,0 – 1,6 mm 1,0 – 1,6 mm

max. weight 20 kg 20 kg

max. size ø 300 mm ø 300 mm

Euro Euro

H (180 °C) H (180 °C)

-20 ... +40 ° -20 ... +40 °

-40 ... +60 °C -40 ... +60 °C

IP23S IP23S

A A

LxWxH 970 x 480 x 970 970 x 480 x 970

118 kg

22

Page 25

Kempomat 2500, 3200, 4200 / © Kemppi Oy / 1117

EN

23

Page 26

KEMPPI OY

Hennalankatu 39

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

UNITED KINGDOM

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GmbH

Otto-Hahn-Straße 14

D-35510 BUTZBACH

DEUTSCHLAND

Tel +49 6033 88 020

Telefax +49 6033 72 528

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD.

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY,

LIMITED

Room 420, 3 Zone, Building B,

No.12 Hongda North Street,

Beijing Economic Development Zone,

100176 Beijing

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区宏达北路12号

创新大厦B座三区420室 (100176)

电话: +86-10-6787 6064

+86-10-6787 1282

传真: +86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

KAZURA Gardens,

Neelangarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

www.kemppi.com

1922000

1117

Loading...

Loading...