Page 1

KEMPOMAT

1701, 2100

Operation instructions • english

Gebrauchsanweisung • deutsch

Gebruiksaanwijzing • nederlands

Manuel d’utilisation • français

1921440E

0531

Page 2

© KEMPPI OY2 – KEMPOMAT 1701, KEMPOMAT 2100 / 0531

CONTENTS

1. PREFACE ...... 3

1.1. Introduction ......................................................................................................................... 3

1.2. Product introduction ............................................................................................................ 3

1.3. Main components ................................................................................................................ 3

1.4. Switches and controls .......................................................................................................... 4

1.5. Mains connection ................................................................................................................ 4

1.6. Locating the machine .......................................................................................................... 4

1.7. Operation safety .................................................................................................................. 4

2. INSTALLATION OF WELDING GUN AND WIRE .........................................................................5

2.1. Welding gun main components ........................................................................................... 5

2.2. Wire feeding mechanism components ................................................................................. 5

2.3. Installation of welding gun .................................................................................................. 6

2.4. To fit the wire reel ............................................................................................................... 6

2.5. To install the welding wire .................................................................................................. 6

3. OPERATING WELDING EQUIPMENT .........................................................................................6

3.1. Places of use ........................................................................................................................ 6

3.2. Main switch ......................................................................................................................... 7

3.3. Polarity for welding ............................................................................................................. 7

3.4. Adjustment of arc roughness/Kempomat 2100 ................................................................... 7

3.5. Earthing .............................................................................................................................. 7

3.6. To select welding mode ....................................................................................................... 7

3.7. To select welding parameters .............................................................................................. 8

3.8. Thermostat ........................................................................................................................... 8

3.9. Shield gas ............................................................................................................................ 8

3.10. Welding ............................................................................................................................... 9

3.11. Storage .� 9

4. MAINTENANCE OF WELDING UNIT ...........................................................................................9

4.1. Daily maintenance ............................................................................................................... 9

4.2. Regular maintenance ........................................................................................................... 9

5. DISPOSAL OF THE MACHINE ..................................................................................................10

6. ORDERING NUMBERS ..............................................................................................................10

7. TECHNICAL INFORMATION ..................................................................................................... 11

8. TERMS OF GUARANTEE ..........................................................................................................13

Page 3

© KEMPPI OY KEMPOMAT 1701, KEMPOMAT 2100 / 0531 – 3

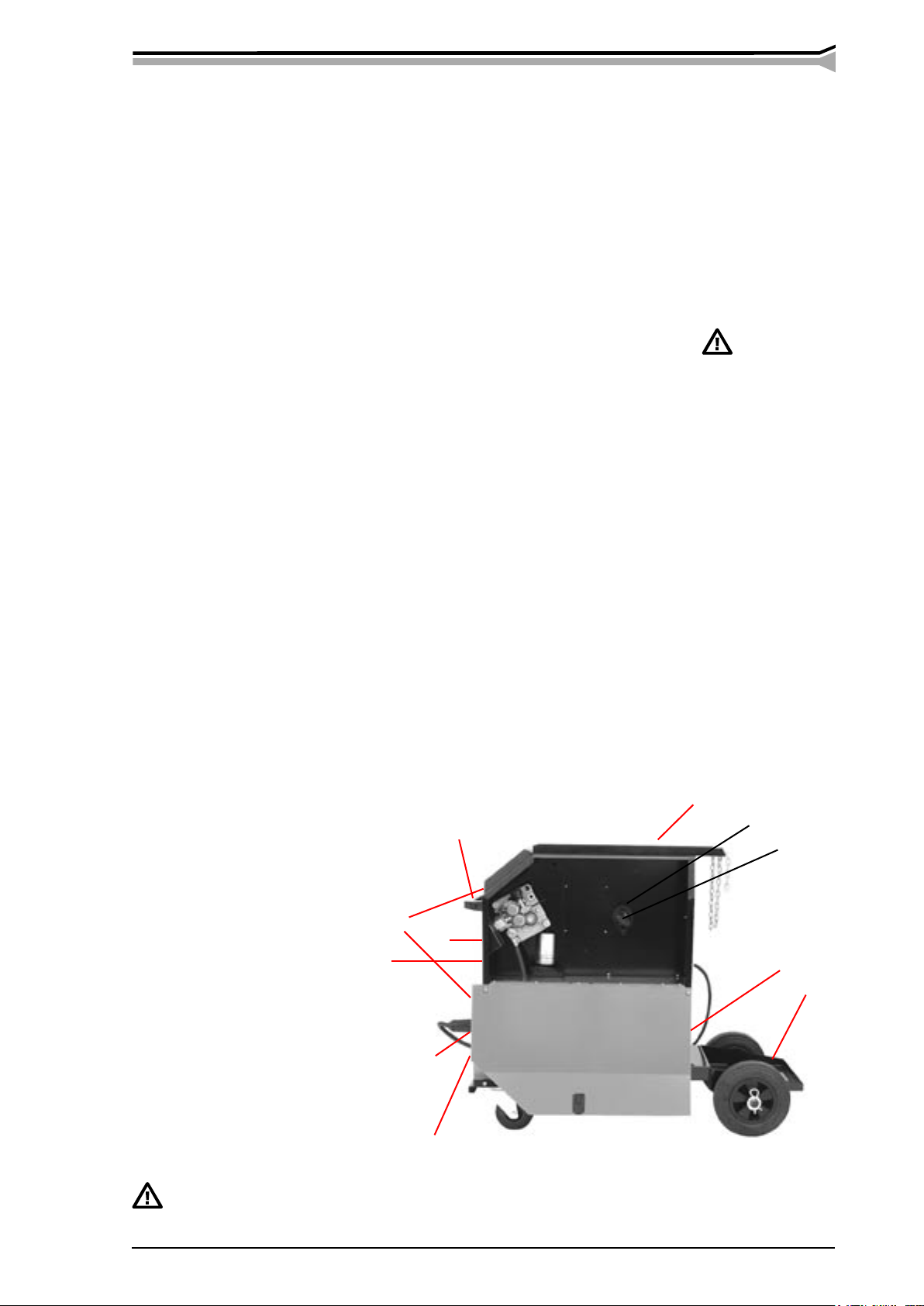

A

J

I

E

D

C

B

H

F

G

K

A

1. PREFACE

1.1. Introduction

Congratulations on having purchased this product. Properly installed Kemppi products should

prove to be productive machines requiring maintenance at only regular intervals. This manual is

arranged to give you a good understanding of the equipment and its safe operation. It also contains maintenance information and technical specifications. Read this manual from front to back

before installing, operating or maintaining the equipment for the first time. For further information on Kemppi products please contact us or your nearest Kemppi distributor.

The specifications and designs presented in this manual are subject to change without prior

notice.

In this document, for danger to life or injury the following symbol is used:

Read the warning texts carefully and follow the instructions. Please also study the Operation

safety instructions and respect them when installing, operating and servicing the machine.

1.2. Product introduction

Kempomat is a welding machine with integrated welding current supply and wire feeder. The

power supply converts the mains voltage suitable for welding. The wire feeding mechanism

feeds wire from a roll through the welding gun nozzle into the arc. A weld is made by moving

the welding gun.

1.3. Main components

A Housing

B Door plate

C Handle

D Earth cable socket

E Gun connector

F Polarity selector

G Switches and controls

H Wire feed mechanism

I Feed roll latch

J Roll brake control

K Gas bottle holder

This equipment’s electromagnetic compatibility (EMC) is designed for use in an industrial

environment. Class A equipment is not intended for use in residential location where the

electrical power is provided by the public low-voltage supply system.

Page 4

© KEMPPI OY4 – KEMPOMAT 1701, KEMPOMAT 2100 / 0531

4

8

3

2

1

7

9

5

6

1.4. Switches and controls

1 Main switch and pilot light

2 Overheat control lamp

3 Voltage selector

4 Polarity selector

5 I Return current dix connector

(coarser arc), only Kempomat 2100

6 II Return current dix connector

(softer arc)

7 Welding method selector (2-way/

spot or 4-sequence)

8 Wire feed rate adjustment

potentiometer

9 Timer potentiometer

1.5. Mains connection

The machine is supplied with the mains cable installed. The cable may be disconnected and the plug

installed only by an authorised electrician! See under “Maintenance”. The fuse rating and the cable

diameter are given in the chapter Technical data in the end of this document.

1.6. Locating the machine

Use the front panel handles to move the machine. Use ropes for lifting. Do not use a hook or a chain!

Place the machine on a horizontal, stable and clean base. Protect from hard rain and intensive sunshine. Ensure unhindered circulation of cooling air.

1.7. Operation safety

Please study these Operation safety instructions and respect them when installing, operating and

servicing the machine.

Welding arc and spatters

Welding arc hurts unprotected eyes. Be careful also with reflecting arc flash. Welding arc and spatter

burn unprotected skin. Use safety gloves and protective clothing.

Danger for fire or explosion

Pay attention to fire safety regulations. Remove flammable or explosive materials from welding place.

Always reserve sufficient fire-fighting equipment on welding place. Be prepared for hazards in special

welding jobs, eg. for the danger of fire or explosion when welding container type work pieces. Note!

Fire can break out from sparks even several hours after the welding work has been finished!

Mains voltage

Never take welding machine inside a work piece (eg. container or truck). Do not place welding

machine on a wet surface. Always check cables before operating the machine. Change defect cables

without delay. Defect cables may cause an injury or set out a fire. Connection cable must not be

compressed, it must not touch sharp edges or hot work pieces.

Welding power circuit

Isolate yourself by using proper protective clothing, do not wear wet clothing. Never work on a wet

surface or use defect cables. Do not put MIG-gun or welding cables on welding machine or on other

electric equipment. Do not press MIG-gun switch, if the gun is not directed towards a work piece.

Welding fumes

Take care that there is sufficient ventilation during welding. Take special safety precautions when

welding metals which contain lead, cadmium, zinc, mercury or beryllium.

Page 5

© KEMPPI OY KEMPOMAT 1701, KEMPOMAT 2100 / 0531 – 5

3

1

4

2

5

6

2.2. Wire feeding mechanism components

2. INSTALLATION OF WELDING GUN AND WIRE

Select the flow nozzle, the wire conduit and the feed roll to match the wire. The machine is

supplied with 0.6 and 0.8 mm dia. wires.

2.1. Welding gun main components

1 Handle

2 Trigger

3 Neck

4 Gas nozzle

5 Gun connector

6 Wire conduit

Page 6

© KEMPPI OY6 – KEMPOMAT 1701, KEMPOMAT 2100 / 0531

2.3. Installation of welding gun

To ensure trouble-free welding use only original Kemppi welding guns. Do not use a damaged

gun.

Make sure the gun wire conduit and the flow nozzle match the manufacturer’s recommendations

for the type and diameter of the wire you use. Too small a conduit may overload the wire feed

device and disturb wire feeding.

Tighten the gun quick connector to eliminate voltage losses. A loose joint will make the gun

and the wire feeder warm. After this check that the conduit inside the wire liner does not touch

the feed rolls.

2.4. To fit the wire reel

2.5. To install the welding wire

Before installing the welding wire check that the feed roll, the wire conduit and the flow nozzle

match the wire.

1. Fit in the feed roll and check once more that the correct groove is in line with the wire.

2. Round the end of the wire and push it through wire guide into burner’s wire tube

3. Check, that the wire is in the groove and set clamping lever on its place. Tighten only a

little.

4. Feed the wire into the gun by pressing the gun switch. Wire clamping force to the feed

roll is correct, when wire coming out of flow nozzle can be lightly slowed down with

fingers.

5. Regulate braking power of wire roll by turning the adjustment screw in the centre of

latch with a screw driver. Do not tighten too much, as the brake puts an additional load

on motor.

1. Release the reel latch claws by turning

them 1/4 of a turn.

2. Insert the reel so that the hole in the reel

will be at the pin of the device. Use reel

supports, when required.

3. Insert the reel. N.B.!The wire travels from

the top of the roll to the wire feed unit.

4. Secure the reel by turning the latch.

Note! Not wire nor wire reel must touch the

unit body, as it creates a danger of short circuit!

When using aluminium wire it might be advisable

to totally remove the spiral part of the back guide. If

you use cored wire, check the wire manufacturer’s

instructions on use and safety first.

3. OPERATING WELDING EQUIPMENT

Also see section 1. Before you start using the welding machine.

Welding in fire or explosion hazard sites is absolutely forbidden!

Note! When welding in other than industrial surroundings, the unit might cause disturbance

in radio equipment. Taking necessary precautions is the responsibility of the user.

3.1. Places of use

Kempomat is a basic welding machine for MIG/MAG welding in maintenance, servicing and

repair works. It is suitable for both normal MIG/MAG welding as well as for welding without

shield gas.

Page 7

© KEMPPI OY KEMPOMAT 1701, KEMPOMAT 2100 / 0531 – 7

3.2. Main switch

In position I control circuit of the unit is live and indicator light of main switch is on. Power

source and welding circuit become active, when gun trigger is pressed.

Note. If mains power is shut off or triggered, you must wait 10 to 15 sec, before switching

power back on.

Always switch the unit on and off from the main switch. Do not use the mains plug as a

switch!

Beware that neither you yourself, gas bottles nor electric equipment become a

part of the welding electric circuit!

3.3. To select polarity for welding

Solid wire is usually welded in + pole and cored wire in - pole gun. Check for the recommended polarity on package or product seller. When welding very thin plates (0.5 to 0.7 mm)

- polarity might also work best for solid wire.

3.4. Adjustment for arc roughness I II

Arc roughness is set by connecting the return current cable or polarity selector cable to the one

of the two dix connectors on the front plate.

The connector marked with symbol I gives a rougher arc, which is used for welding of thin

sheets and ferrous metals by lower currents. Consider especially with CO2 shielding gas.

The connector marked with symbol II is suitable for greater currents and especially for aluminium and stainless materials. The most suitable roughness is, however, most dependent on the

welding case. You will find the best position by testing.

3.5. Earthing

If possible, always fix the earth clamp of return current cable directly on the welding target.

Clean earth clamp touch surface of paint and rust. Secure clamp so, that the surface it is touching is as large as possible. Finally check that clamp sits tightly.

3.6. To select welding mode

Also see section 1.4. Switches and controls.

Use the welding mode selecting switch to select how to regulate shield gas flow and wire feed

in welding gun switch. You have three welding modes to select from:

2T –sequence procedure

Gas flow and wire inch start when gun switch is pressed and end when the switch is released.

Wire feed is in cycles, if timer potentiometer is set on time scale range.

4 T -sequence procedure

Gas flow starts when gun switch is pressed all the way.

When the switch is released, wire inch starts and welding

begins. When the gun switch is pressed again, wire inch is

interrupted and when the switch is released, shield gas flow

ends. Wire inch will be in cycles, if timer potentiometer is set on time scale range.

Spot welding procedure

Shield gas flow and wire inch start, when gun switch is pressed all the way and end when time

set by the timer potentiometer ends or when the gun switch is released. If the timer potentiometer

is in 0 range this procedure will not start.

TIMER potentiometer

Welding can be spaced by selecting a time for welding period on timer potentiometer. Wire feed

and gas flow will be automatically interrupted after set time and automatically restarted.

/Kempomat 2100

Page 8

© KEMPPI OY8 – KEMPOMAT 1701, KEMPOMAT 2100 / 0531

3.7. To select welding parameters

1. Select adjustment step of voltage switch.

2. Set adjustment potentiometer of wire inch speed on the same number.

3. Test the weld and make necessary adjustments in wire inch.

4. If fusion power is not suitable for the target, set the voltage anew. Also adjust wire feed,

if necessary. Repeat until the values suit the target.

3.8. Thermostat

Thermal protection of the unit prevents the power source from overheating. Thus the unit will not be damaged, even if load during welding exceeds load factor. When overheating pilot lamp lights, welding is

not possible. There is an appr. 3 min delay before the light goes out, and

welding can be normally continued by starting from the trigger. The light

can also signify low supply voltage or an overtly long welding period.

3.9. Shield gas

Handle gas bottle with care, it might explode if it falls down!

Because the danger of falling, the gas bottle must not be higher than 1600 mm.

Shield gas shields the arc and in MAG welding it is also used for reinforcing the weld seam.

Shield gas for steel wire is carbon dioxide (CO2) or mixed gas, where main component is argon

(Ar) and the rest is carbon dioxide. When welding aluminium wire, pure argon is used as shield

gas.

Flow meter must be suitable for gas type. Usually suitable flow is 8 to 10 l/min. If flow is too

slow or too big, the weld seam becomes porous.

Your dealer will give you advice on choosing gas and equipment.

Note! Always mount the gas bottle in upright position in a specially made rack

on the wall or in a bottle trolley. Always close the bottle valve after finishing

welding.

Kempomat 1700

Voltage step Open circuit voltage

1 16,1 V

2 17,5 V

3 19,2 V

4 21,1 V

5 23,6 V

6 26,4 V

7 30,1 V

8 34,7 V

Kempomat 2100

Voltage step Open circuit voltage

1 16,9 V

2 18,2 V

3 19,6 V

4 21,1 V

5 22,8 V

6 24,6 V

7 26,4 V

8 28,5 V

9 30,8 V

10 33,1 V

Page 9

© KEMPPI OY KEMPOMAT 1701, KEMPOMAT 2100 / 0531 – 9

4. MAINTENANCE OF WELDING UNIT

4.1. Daily maintenance

Be careful of mains voltage when handling electric cables!

Clean wire passage in gun and check contact tip regularly.

Always check condition of mains and welding cables before use, change damaged ones.

Note! Mains cable can be changed only by a qualified electrician!

Mains cable is changed as follows:

Kempomat 1701

1. Detach back plate of wire reel.

2. Connect mains cable to main switch pins with flat clamps.

3. Connect green and yellow earth to the body plug marked as earth.

4.2. Regular maintenance

KEMPPI service workshops make service contracts with customers about regular maintenance. All parts are cleaned, checked, and if necessary, repaired. Also the operation of welding

machine is tested.

Kempomat 2100

By delivery from the factory the Kempomat machine has

been connected for mains voltage3~400V.

In order to change the mains voltage loosen the right side

plate of the machine, change the connections according to the

enclosed diagram.

3.10. Welding

Never look at the flame arc without a face shield for arc welding! Protect yourself

and your surroundings from the flame arc and hot spatter!

You can start welding, when selections and adjustments demanded by the work have been done.

Welding begins when wire is pressed to the work piece by pressing the gun switch. Arc forms,

shield gas starts to flow and wire feed inches welding wire out of the gun nozzle.

Note! It is advisable to test welding first on something else than the work piece.

Welding fumes are a possible health hazard, make certain there is sufficient

ventilation during welding!

3.11. Storage

Store the unit in a clean and dry place. Shield it from rain and at temperatures exceeding 25 °C

from direct exposure to sun. There must be sufficient free space in front and back of the unit for

air circulation.

Page 10

© KEMPPI OY10 – KEMPOMAT 1701, KEMPOMAT 2100 / 0531

5. DISPOSAL OF THE MACHINE

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment

and its implementation in accordance with national law, electrical equipment that has reached

the end of its life must be collected separately and returned to an environmentally compatible

recycling facility. As the owner of the equipment, you should get information on approved

collection systems from our local representative.

By applying this European Directive you will improve the environment and human health!

6. ORDERING NUMBERS

Part Ordering number

Kempomat 1701 1~ 230 V welding machine 6214171

Kempomat 2100 3~ 230/400 V welding machine 621421001

Earth cable 16mm2, 3 m 4260000

MIG welding gun, 3 m KMG 20 6251113

MIG welding gun, 3 m MT 18 6251013

Hub for wire reel 4289880

Page 11

© KEMPPI OY KEMPOMAT 1701, KEMPOMAT 2100 / 0531 – 11

7. TECHNICAL INFORMATION

Kempomat 1701 1~ 230 V Welding machine

Rated voltage 1~ 230 V 50/60 Hz

Mains cable/fuse 3x1,5 mm2/16 A delayed

Mains connection 220 V -10 %...240 V+ 6%

Connected load 15 % ED 6.5 kVA

60 % ED 3.0 kVA

100 % ED 2.3 kVA

Load capacity

15 % ED 170 A/21 V

60 % ED 85 A / 18.5 V

100 % ED 76 A / 17.5 V

Adjustment range 30 A / 14 V ... 170 A / 22.5 V

Voltage adjustment 8 steps

open circuit voltage, max. 40 V

Efficiency 70 % / 170 A / 21 V

Power ratio 0,85 / 170 A / 21 V

Wire feed speed 0 – 16 m/min, stepless

Wires with filler

Ø Fe, SS 0.6 - 1.0 mm

Ø Cored wire 0.9 - 1.2 mm

Ø Al 1.0 mm

Wire reel:

maximum weight 20 kg

maximum diameter 300 mm

Gun connection Euro

Thermal class H (180 ºC)

Range of temperature for use -20 … +40 ºC

Storage temperature range -40 … +60 ºC

Degree of protection IP 23 C

Measurements: length 850 mm

width 392 mm

height 750 mm

Weight 47 kg

The unit fulfils the CE marking demands.

Page 12

© KEMPPI OY12 – KEMPOMAT 1701, KEMPOMAT 2100 / 0531

Kempomat 2100 3~ 230/400 Welding machine

Rated voltage 3~ 230 V 50/60 Hz / 3~ 400 V 50/60 Hz

Mains cable/fuse 3x1,5 mm2/10 A delayed

Mains connection 220 V -10 %...240 V+6% / 380 V -10 %...415 V +6 %

Connected load 25 % ED 7.5 kVA

60 % ED 4.0 kVA

100 % ED 2.8 kVA

Load capacity

25 % ED 200 A / 23 V

60 % ED 130 A / 20.5 V

100 % ED 100 A / 19 V

Adjustment range 30 A / 14 V ... 200 A / 24 V

Voltage adjustment 10 steps

Idle voltage, max. 40 V

Efficiency 85 % / 200 A / 24 V

Power ratio 0,90 / 200 A / 24 V

Wire feed speed 0 – 18 m/min, stepless

Wires with filler

Ø Fe, SS 0.6 - 1.0 mm

Ø Cored wire 0.9 - 1.2 mm

Ø Al 1.0 mm

Wire reel:

maximum weight 20 kg

maximum diameter 300 mm

Gun connection Euro

Thermal class H (180 ºC)

Range of temperature for use -20 … +40 ºC

Storage temperature range -40 … +60 ºC

Degree of protection IP 23 C

Measurements: length 910 mm

width 410 mm

height 820 mm

Weight 54 kg

The unit fulfils the CE marking demands.

Page 13

© KEMPPI OY KEMPOMAT 1701, KEMPOMAT 2100 / 0531 – 13

8. TERMS OF GUARANTEE

Kemppi Oy provides a guarantee for products manufactured and sold by them if defects in manufacture

and materials occur. Guarantee repairs must be carried out only by an Authorised Kemppi Service Agent.

Packing, freight and insurance costs to be paid by orderer. The guarantee is effected on the date of purchase.

Verbal promises which do not comply with the terms of guarantee are not binding on guarantor.

Limitations on guarantee

The following conditions are not covered under the terms of guarantee: defects due to natural wear and

tear, non-compliance with operating and maintenance instructions, connection to incorrect or faulty supply

voltage (including voltage surges outside equipment spec.), incorrect gas pressure, overloading, transport

or storage damage, fire of damage due to natural causes i.e. lightning or flooding.

This guarantee does not cover direct or indirect travelling costs, daily allowances or accommodation.

Note: Under the terms of guarantee, welding torches and their consumables, feeder drive rolls and feeder

guide tubes are not covered. Direct or indirect damage due to a defective product is not covered under the

guarantee. The guarantee is void if changes are made to the product without approval of the manufacturer,

or if repairs are carried out using non-approved spare parts.

The guarantee is also void if repairs are carried out by non-authorised agents.

Undertaking guarantee repairs

Guarantee defects must be informed to Kemppi or authorised Kemppi Service Agents within the guarantee

period. Before any guarantee work is undertaken, the customer must provide proof of guarantee or proof

of purchase, and serial number of the equipment in order to validate the guarantee. The parts replaced

under the terns of guarantee remain the property of Kemppi.

Following the guarantee repair, the guarantee of the machine or equipment, repaired or replaced, will be

continued to the end of the original guarantee period.

Page 14

KEMPPI OY

PL 13

FIN – 15801 LAHTI

FINLAND

Tel (03) 899 11

Telefax (03) 899 428

www.kemppi.com

KEMPPIKONEET OY

PL 13

FIN – 15801 LAHTI

FINLAND

Tel (03) 899 11

Telefax (03) 7348 398

e-mail: myynti.fi @kemppi.com

KEMPPI SVERIGE AB

Box 717

S – 194 27 UPPLANDS VÄSBY

SVERIGE

Tel (08) 59 078 300

Telefax (08) 59 082 394

e-mail: sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N – 3103 TØNSBERG

NORGE

Tel 33 34 60 00

Telefax 33 34 60 10

e-mail: sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK – 2740 SKOVLUNDE

DANMARK

Tel 44 941 677

Telefax 44 941 536

e-mail:sales.dk@kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL – 4801 EA BREDA

NEDERLAND

Tel (076) 5717 750

Telefax (076) 5716 345

e-mail: sales.nl@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK443WH

ENGLAND

Tel 0845 6444201

Fax 0845 6444202

e-mail: sales.uk@kemppi.com

KEMPPI FRANCE S.A.

S.A. au capital de 5 000 000 F.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel (01) 30 90 04 40

Telefax (01) 30 90 04 45

e-mail: sales.fr@kemppi.com

KEMPPI GmbH

Otto – Hahn – Straße 14

D – 35510 BUTZBACH

DEUTSCHLAND

Tel (06033) 88 020

Telefax (06033) 72 528

e-mail:sales.de@kemppi.com

KEMPPI SP. z o.o.

Ul. Piłsudskiego 2

05-091 ZA¸BKI

Poland

Tel +48 22 781 6162

Telefax +48 22 781 6505

e-mail: info.pl@kemppi.com

KEMPPI WELDING

MACHINES AUSTRALIA PTY LTD

P.O. Box 404 (2/58 Lancaster Street)

Ingleburn NSW 2565, Australia

Tel. +61-2-9605 9500

Telefax +61-2-9605 5999

e-mail: info@kemppi.com.au

Ver. 8

www.kemppi.com

Loading...

Loading...