Page 1

Model DAQ6510

Data Acquisition and Multimeter System

User’s Manual

DAQ6510-900-01 Rev. A / April 2018

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

*PDAQ6510-900-01A*

DAQ6510-900-01A

Page 2

Data Acquisition / Multimeter System

DAQ6510

User's Manual

© 2018, Keithley Instruments, LLC

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, LLC, is strictly prohibited.

These are the original instructions in English.

TSP®, TSP-Link®, and TSP-Net® are trademarks of Keithley Instruments, LLC. All Keithley

Instruments product names are trademarks or registered trademarks of Keithley Instruments, LLC.

Other brand names are trademarks or registered trademarks of their respective holders.

The Lua 5.0 software and associated documentation files are copyright © 1994 - 2015, Lua.org,

PUC-Rio.

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: DAQ6510-900-01Rev. A / April 2018

Page 3

Page 4

Safety precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are measurement, control, and data I/O

connections, with low transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high

transient overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley Instruments measuring instruments may be

connected to mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 5

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

If a

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is marked on the instrument.

The

symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The

symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this

symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the

symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley Instruments. Standard fuses with applicable national

safety approvals may be used if the rating and type are the same. The detachable mains power cord provided with the

instrument may only be replaced with a similarly rated power cord. Other components that are not safety-related may be

purchased from other suppliers as long as they are equivalent to the original component (note that selected parts should be

purchased only through Keithley Instruments to maintain accuracy and functionality of the product). If you are unsure about the

applicability of a replacement component, call a Keithley Instruments office for information.

Unless otherwise noted in product-specific literature, Keithley Instruments instruments are designed to operate indoors only, in

the following environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution

degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2017.

Page 6

Page 7

Page 8

Table of contents

Introduction ............................................................................................................... 1-1

Welcome .............................................................................................................................. 1-1

Introduction to this manual ................................................................................................... 1-1

Extended warranty ............................................................................................................... 1-2

Contact information .............................................................................................................. 1-2

Documentation set ............................................................................................................... 1-2

Organization of manual sections .......................................................................................... 1-2

Application examples ........................................................................................................... 1-3

Front-panel overview ................................................................................................ 2-1

Front-panel overview ............................................................................................................ 2-1

Instrument power ................................................................................................................. 2-3

Connect the power cord ............................................................................................................ 2-4

Turn the DAQ6510 on or off ...................................................................................................... 2-4

Touchscreen display ............................................................................................................ 2-5

Select items on the touchscreen ............................................................................................... 2-5

Scroll bars ................................................................................................................................. 2-5

Enter information ....................................................................................................................... 2-6

Adjust the backlight brightness and dimmer .............................................................................. 2-6

Review event messages ........................................................................................................... 2-7

Interactive swipe screens ..................................................................................................... 2-7

Swipe screen heading bar ......................................................................................................... 2-7

FUNCTIONS swipe screen ....................................................................................................... 2-9

SETTINGS swipe screen .......................................................................................................... 2-9

STATISTICS swipe screen...................................................................................................... 2-10

SECONDARY swipe screen.................................................................................................... 2-11

USER swipe screen ................................................................................................................ 2-12

GRAPH swipe screen ............................................................................................................. 2-12

SCAN swipe screen ................................................................................................................ 2-14

Menu overview ................................................................................................................... 2-16

Channel menu ......................................................................................................................... 2-17

Measure Menu ........................................................................................................................ 2-17

Views menu............................................................................................................................. 2-18

Trigger menu ........................................................................................................................... 2-18

Scripts menu ........................................................................................................................... 2-18

System menu .......................................................................................................................... 2-19

Using a remote interface .......................................................................................... 3-1

Remote communications interfaces ..................................................................................... 3-1

Supported remote interfaces ................................................................................................ 3-2

LAN communications ........................................................................................................... 3-2

Set up LAN communications on the instrument ........................................................................ 3-3

Set up LAN communications on the computer .......................................................................... 3-4

USB communications ........................................................................................................... 3-5

Page 9

Table of contents

User's Manual

DAQ6510 Data Acquisition / Multimeter System

Connect a computer to the DAQ6510 using USB ..................................................................... 3-5

Communicate with the instrument ............................................................................................. 3-6

GPIB communications .......................................................................................................... 3-9

Install the KTTI-GPIB accessory card ....................................................................................... 3-9

Set the GPIB address ............................................................................................................. 3-12

RS-232 ............................................................................................................................... 3-12

Install the KTTI-RS232 accessory card ................................................................................... 3-12

TSP-Link ............................................................................................................................ 3-14

Install the KTTI-TSP accessory card ....................................................................................... 3-14

Using the web interface...................................................................................................... 3-15

Connect to the instrument web interface ................................................................................. 3-15

LAN troubleshooting suggestions ............................................................................................ 3-16

Web interface Home page....................................................................................................... 3-17

Identify the instrument ............................................................................................................. 3-18

Determining the command set you will use ....................................................................... 3-18

Making basic front-panel measurements ................................................................ 4-1

Introduction .......................................................................................................................... 4-1

Equipment required for this example ................................................................................... 4-1

Device connections .............................................................................................................. 4-2

Basic front-panel measurements ......................................................................................... 4-3

Scanning temperature using thermocouples ......................................................... 5-1

Introduction .......................................................................................................................... 5-1

Equipment required .............................................................................................................. 5-1

Device connections .............................................................................................................. 5-2

Thermocouple temperature scanning .................................................................................. 5-3

Using the front panel ................................................................................................................. 5-4

Using SCPI commands ............................................................................................................. 5-5

Using TSP commands .............................................................................................................. 5-6

Test results................................................................................................................................ 5-7

Scanning low-level DCV ........................................................................................... 6-1

Introduction .......................................................................................................................... 6-1

Equipment required .............................................................................................................. 6-1

Device connections .............................................................................................................. 6-2

Scanning low-level DCV....................................................................................................... 6-3

Using the front panel ................................................................................................................. 6-4

Using SCPI commands ............................................................................................................. 6-4

Using TSP commands .............................................................................................................. 6-6

Scanning resistors using 4W measurement ........................................................... 7-1

Introduction .......................................................................................................................... 7-1

Equipment required .............................................................................................................. 7-2

Page 10

DAQ6510

of contents

Data Acquisition / Multimeter System User's Manual Table

Device connections .............................................................................................................. 7-3

Scanning resistors using 4-wire measurements .................................................................. 7-5

Using the front panel ................................................................................................................. 7-5

Using SCPI commands ............................................................................................................. 7-6

Using TSP commands .............................................................................................................. 7-7

Test results................................................................................................................................ 7-8

Mixed function multi-channel scanning .................................................................. 8-1

Introduction .......................................................................................................................... 8-1

Equipment required .............................................................................................................. 8-1

Device connections .............................................................................................................. 8-2

Mixed function multi-channel scanning ................................................................................ 8-3

Using the front panel ................................................................................................................. 8-4

Using SCPI commands ............................................................................................................. 8-5

Using TSP commands .............................................................................................................. 8-6

Test results................................................................................................................................ 8-7

Speed scanning for increased test throughput ...................................................... 9-1

Introduction .......................................................................................................................... 9-1

Equipment required .............................................................................................................. 9-1

Device connections .............................................................................................................. 9-2

Speed scanning for increased production test throughput .................................................. 9-3

Using SCPI commands ............................................................................................................. 9-4

Using TSP commands .............................................................................................................. 9-6

Test results................................................................................................................................ 9-7

Pre-scan monitor .................................................................................................... 10-1

Introduction ........................................................................................................................ 10-1

Equipment required ............................................................................................................ 10-1

Device connections ............................................................................................................ 10-2

Pre-scan monitor ................................................................................................................ 10-3

Using the front panel ............................................................................................................... 10-3

Using SCPI commands ........................................................................................................... 10-4

Using TSP commands ............................................................................................................ 10-5

Troubleshooting/FAQ ............................................................................................. 11-1

About this section ............................................................................................................... 11-1

Where can I find updated drivers? ..................................................................................... 11-1

Is there any software to help me get started ...................................................................... 11-2

How do I upgrade the firmware? ........................................................................................ 11-2

Why can't the DAQ6510 read my USB flash drive?........................................................... 11-3

How do I change the command set? ................................................................................. 11-3

How do I save the present state of the instrument? .......................................................... 11-4

Page 11

Table of contents

User's Manual

DAQ6510 Data Acquisition / Multimeter System

Why did my settings change? ............................................................................................ 11-5

What is the ethernet port number? .................................................................................... 11-5

Next steps ............................................................................................................... 12-1

Additional DAQ6510 information ........................................................................................ 12-1

Index ........................................................................................................................... I-1

Page 12

Application examples ............................................................... 1-3

Welcome

Thank you for choosing a Keithley Instruments product. The DAQ6510 is a 6½ digit graphical

sampling data-acquisition system that provides high-speed digitizing and a large graphical color

touchscreen display. This DAQ offers a broad range of measurement capabilities, including 15

measurement functions. In addition to industry-leading DC accuracies, functions such as capacitance,

3 A current, and 16-bit current and voltage digitizing are included. Tying all these features together is

a large 5-inch color touchscreen display that brings users an unprecedented combination of data

visualization and interaction, enabling users to gain deeper insight into their measurements.

Section 1

Introduction

In this section:

Welcome .................................................................................. 1-1

Introduction to this manual ....................................................... 1-1

Extended warranty ................................................................... 1-2

Contact information .................................................................. 1-2

Documentation set ................................................................... 1-2

Organization of manual sections .............................................. 1-2

The DAQ6510 provides superior measurement accuracy and the speed necessary for a broad range

of applications including system, production testing, and benchtop applications. The DAQ6510 meets

application requirements for production engineers, research and development engineers, test

engineers, and scientists.

Introduction to this manual

This manual provides detailed applications to help you achieve success with your Keithley

Instruments DAQ6510. In addition, this manual provides information about the basics of the front

panel to familiarize you with the instrument.

This manual presents an overview of each application, followed by instructions to complete the

application using the front panel, SCPI code, TSP code, or Keithley KickStart Startup Software.

More information about the commands that are used in these applications is available. Refer to the

SCPI and TSP command reference sections of the Model DAQ6510 Reference Manual. This manual

is on tek.com/keithley

.

Page 13

Section

User's Manual

1: Introduction DAQ6510 Data Acquisition / Multimeter System

Extended warranty

Additional years of warranty coverage are available on many products. These valuable contracts

protect you from unbudgeted service expenses and provide additional years of protection at a fraction

of the price of a repair. Extended warranties are available on new and existing products. Contact your

local Keithley Instruments office, sales partner, or distributor for details.

Contact information

If you have any questions after you review the information in this documentation, please contact your

local Keithley Instruments office, sales partner, or distributor. You can also call the corporate

headquarters of Keithley Instruments (toll-free inside the U.S. and Canada only) at 1-800-935-5595,

or from outside the U.S. at +1-440-248-0400. For worldwide contact numbers, visit tek.com/keithley

Documentation set

The DAQ6510 documentation is supported by the following technical/product information

documentation.

• Quick Start Guide: Provides unpacking instructions, describes basic connections, reviews basic

operation information, and provides a quick test procedure to ensure the instrument is

operational.

• User’s Manual: Provides application examples that you can use as a starting point to create your

own applications.

• Reference Manual: Includes advanced operation topics, maintenance information,

troubleshooting procedures, and in-depth descriptions of programming commands.

• Accessories information: Documentation for accessories that are available for the DAQ6510.

.

Organization of manual sections

This manual is organized into the following sections:

• Using the front-panel interface: (on page 2-1

interface.

• Using a remote interface: (on page 3-1) Describes the basics of remote communications and

using the instrument web interface.

• Application examples (see below): Provides detailed examples of how to use the DAQ6510 in

some typical situations.

For the latest drivers and additional support information, see tek.com/keithley

• Troubleshooting FAQs: (on page 11-1

you troubleshoot common problems encountered with the DAQ6510.

• Next steps: (on page 12-1) Provides information about additional resources that can help you use

the DAQ6510.

The PDF version of this manual contains bookmarks for each section. The manual sections are also

listed in the Table of Contents at the beginning of this manual.

For more information about bookmarks, see Adobe

) Provides answers to frequently asked questions to help

.

) Describes the basics of using the front-panel

®

Acrobat® or Reader® help.

1-2 DAQ6510-900-01Rev. A / April 2018

Page 14

DAQ6510

Introduction

Data Acquisition / Multimeter System User's Manual Section 1:

Application examples

This manual provides application examples that show you how to perform tests from the front panel

and over a remote interface. The applications include:

• Making basic front-panel measurements: (on page 4-1

using a single DAQ6510 and a two-terminal device under test.

• Making basic scans: (on page 4-1) Shows the basic measure scan functionality using a single

DAQ6510.

• Scanning temperature using thermocouples: (on page 5-1) Shows how to use the DAQ6510 to

log thermocouple-based temperature measurement scans.

• Scanning low-level DCV: (on page 6-1) Shows how to use the DAQ6510 to accurately measure

DC voltage in a variety of ranges

• Scanning resistors using 4W measurement: (on page 7-1) Shows how to use the DAQ6510 to

accurately measure resistance devices

• Mixed function multi-channel scanning: (on page 8-1) Shows how to use the DAQ6510 to perform

complex multi-channel, mixed function scanning in a production-test environment.

• Speed scanning for increased production test throughput: (on page 9-1) Shows how selecting the

right multiplexer module can increase your productivity by reducing overall test time.

• Pre-scan monitoring: (on page 10-3) Shows how to configure the DAQ6510 to delay its scanning

function until the testing environment has reached a specific temperature.

) Shows the basic measure functionality

DAQ6510-900-01Rev. A / April 2018 1-3

Page 15

Page 16

In this section:

Menu overview ....................................................................... 2-16

Turns the instrument on or off. To turn the instrument on, press

LED is amber when turned off.

Returns the display to the Home screen.

Front-panel overview................................................................ 2-1

Instrument power...................................................................... 2-3

Touchscreen display................................................................. 2-5

Interactive swipe screens ......................................................... 2-7

Front-panel overview

The front panel of the DAQ6510 is shown below. Descriptions of the controls on the front panel follow

the figure.

Section 2

Front-panel overview

Figure 1: DMM6500 front panel

POWER switch

HOME key

and hold the power switch. To turn it off, press and hold the power

switch again. The LED is green when the instrument is on and the

Page 17

Section

User's Manual

Opens the main menu. Press the icons on the main menu to open

Opens a menu of of preconfigured TSP scripts with a graphical

user interface.

overview information for the screen you are viewing.

Saves reading buffer data and screen snapshots to a USB flash

drive.

The DAQ6510 has a high-resolution, five-inch color touchscreen

Refer to Touchscreen display (on page 2-5) for details.

Selects the highlighted choice or allows you to edit the selected

field.

Returns to the previous screen or closes a dialog box. For

to the main menu screen.

function name on the screen.

Accesses trigger-related settings and operations. The action of

DAQ6510 Reference Manual.

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

MENU key

channel, measure, views, trigger, scripts, and system screens.

For details, refer to Menu overview (on page 2-16).

APPS key

HELP key

Opens help for the area or item that is selected on the display. If

there is no selection when you press the HELP key, it displays

USB port

drive. You can also store and retrieve scripts to and from a USB

flash drive. The flash drive must be formatted as a FAT or FAT32

Touchscreen

display. The touchscreen accesses swipe screens and menu

options. You can access additional interactive screens by

pressing the front-panel MENU, APPS, and FUNCTION keys.

ENTER key

EXIT key

example, press the EXIT key when the main menu is displayed to

return to the Home screen. When you are viewing a subscreen

(for example, the Event Log screen), press the EXIT key to return

FUNCTION key

Displays instrument functions. To select a function, touch the

TRIGGER key

the TRIGGER key depends on the instrument state. For details,

see "Switching between measurement methods" in the Model

2-2 DAQ6510-900-01Rev. A / April 2018

Page 18

DAQ6510

panel overview

Use the SENSE HI and SENSE LO terminals and the INPUT

INPUT terminals

Use the INPUT HI and INPUT LO terminals for all measurements

AMPS

Use the AMPS connection with the INPUT LO terminal to

Activates the terminals on the front or rear panel. Selecting the

LED is visible.

Data Acquisition / Multimeter System User's Manual Section 2: Front-

SENSE terminals

terminals with the 4-wire resistance, 3-wire and 4-wire RTD

temperature, and DC voltage ratio functions.

except current.

measure ≤3A DC or AC

RMS

current.

TERMINALS

switch

Instrument power

Follow the steps below to connect the DAQ6510 to line power and turn on the instrument. The

DAQ6510 operates from a line voltage of 100 V to 240 V at a frequency of 50 Hz or 60 Hz. Make sure

the operating voltage in your area is compatible. The default setting is 240V.

Before plugging in the line cord, check the line setting block on the rear of the instrument. If it doesn’t

match their mains installation setting, remove the block and reinsert to select voltage.

You must turn on the DAQ6510 and allow it to warm up for at least 30 minutes to achieve rated

accuracies.

Operating the instrument on an incorrect line voltage may cause damage to the instrument,

possibly voiding the warranty.

rear panel provides the proper connections to an inserted

moduleWhen the front-panel terminals are active, the green LED

is visible. When the rear-panel terminals are active, the amber

DAQ6510-900-01Rev. A / April 2018 2-3

Page 19

Section

User's Manual

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

The power cord supplied with the DAQ6510 contains a separate protective earth (safety

ground) wire for use with grounded outlets. When proper connections are made, the

instrument chassis is connected to power-line ground through the ground wire in the power

cord. In the event of a failure, not using a properly grounded protective earth and grounded

outlet may result in personal injury or death due to electric shock.

Do not replace detachable mains supply cords with inadequately rated cords. Failure to use

properly rated cords may result in personal injury or death due to electric shock.

Connect the power cord

To connect the power cord:

1. Make sure that the front-panel POWER switch is in the off (O) position.

2. Connect the female end of the supplied power cord to the AC receptacle on the rear panel.

3. Connect the male end of the power cord to a grounded AC outlet.

Turn the DAQ6510 on or off

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, remove power from the instrument or test system and

discharge any energy storage components (for example, capacitors or cables) before

changing any connections that might allow contact with an uninsulated conductor.

On some sensitive or easily damaged devices under test (DUTs), the instrument power-up or powerdown sequence can apply transient signals to the DUT that may affect or damage it.

When testing this type of DUT, do not make final connections to it until the instrument has completed

its power-up sequence and is in a known operating state. Disconnect it from the instrument before

turning the instrument off.

To prevent any human contact with a live conductor, connections to the DUT must be fully insulated

and the final connections to the DUT must only use safety-rated safety jack socket connectors that

do not allow bodily contact.

To turn a DAQ6510 on:

1. Disconnect any devices under test (DUTs) from the DAQ6510.

Press and hold the front-panel POWER switch to place it in the on position.

The instrument displays a status bar as the instrument powers on. The Home screen is displayed

when power on is complete.

To turn a DAQ6510 off:

1. Press and hold the front-panel POWER switch to place it in the off position.

2-4 DAQ6510-900-01Rev. A / April 2018

Page 20

DAQ6510

panel overview

Data Acquisition / Multimeter System User's Manual Section 2: Front-

Touchscreen display

The touchscreen display gives you quick front-panel access to measure settings, system

configuration, instrument and test status, reading buffer information, and other instrument

functionality. The display has multiple swipe screens that you can access by swiping the front panel.

You can access additional interactive screens by pressing the front-panel MENU, APPS, and

FUNCTION keys.

Do not use sharp metal objects, such as tweezers or screwdrivers, or pointed objects, such

as pens or pencils, to touch the touchscreen. It is strongly recommended that you use only

fingers to operate the instrument. Use of clean-room gloves to operate the touchscreen is

supported.

Select items on the touchscreen

To select an item on the displayed screen:

• Press the corresponding icon on the screen.

Scroll bars

Some of the interactive screens have additional options that are only visible when you scroll down the

screen. A scroll indicator on the right side of the touchscreen identifies these screens. Swipe the

screen up or down to view the additional options.

The figure below shows a screen with a scroll bar.

Figure 2: Scroll bar

The following topics describe the DAQ6510 touchscreen in more detail.

DAQ6510-900-01Rev. A / April 2018 2-5

Page 21

Section

User's Manual

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

Enter information

Some of the menu options open a keypad or keyboard that you can use to enter information. For

example, if you are creating a new reading buffer from the front panel, you see the keypad shown in

the following figure.

Figure 3: DAQ6510 front-panel keyboard for information entry

You can enter information by touching the screen to select characters and options from the keypad or

keyboard. You can move the cursor in the entry box by touching the screen. The cursor is moved to

the spot in the entry box where you touched the screen.

Adjust the backlight brightness and dimmer

You can adjust the brightness of the DAQ6510 touchscreen display and buttons from the front panel

or over a remote interface. You can also set the backlight to dim after a specified time has passed

with no front-panel activity (available from the front-panel display only). The backlight settings set

through the front-panel display are saved through a reset or power cycle.

Screen life is affected by how long the screen is on at full brightness. The higher the brightness

setting and the longer the screen is bright, the shorter the screen life.

To adjust the backlight brightness from the front panel:

1. Press the MENU key.

2. Under System, select Settings.

3. Select the Backlight Brightness. The Backlight Brightness dialog box opens.

4. Drag the adjustment to set the backlight.

5. Select OK.

2-6 DAQ6510-900-01Rev. A / April 2018

Page 22

DAQ6510

panel overview

Data Acquisition / Multimeter System User's Manual Section 2: Front-

To set the backlight dimmer from the front panel:

1. Press the MENU key.

2. Under System, select Settings.

3. Select Backlight Dimmer. The Backlight Dimmer dialog box opens.

4. Select a dimmer setting.

Review event messages

During operation and programming, front-panel messages may be briefly displayed. Messages are

either information, warning, or error notifications. For information on event messages, refer to "Using

the event log" in the Model DAQ6510 Reference Manual.

Figure 4: Example front-panel event message

Interactive swipe screens

The DAQ6510 touchscreen display has multiple screens that you can access by swiping left or right

on the lower half of the display. The options available in the swipe screens are described in the

following topics.

Swipe screen heading bar

The heading bar of the swipe screen contains the following options.

Figure 5: DAQ6510 swipe screens, maximized and minimized

DAQ6510-900-01Rev. A / April 2018 2-7

Page 23

Section

User's Manual

2

Swipe screen indicator

Each circle represents one swipe screen. As you swipe right or left, a different

3

Calculations shortcut

Select to open the CALCULATION SETTINGS menu. Only available when

4

Measure Settings

Select to open the MEASURE SETTINGS menu for the selected function. Only

5

Restore indicator

Indicates that you can swipe up to display the swipe screen.

6

Graph shortcut

Select to open the Graph screen.

Scan shortcut

Not shown. Select to open the SCAN screen.

Channel control shortcut

Not shown. Select to open the CHANNEL CONTROL screen.

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

# Screen element Description

1 Minimize indicator You can swipe down to minimize the swipe screens.

circle changes color, indicating where you are in the screen sequence. Select a

circle to move the swipe screen without swiping.

TERMINALS is set to FRONT.

shortcut

Channel Settings

available when TERMINALS is set to FRONT.

Not shown. Select to open the CHANNEL SETTINGS screen.

shortcut

2-8 DAQ6510-900-01Rev. A / April 2018

Page 24

DAQ6510

panel overview

Data Acquisition / Multimeter System User's Manual Section 2: Front-

FUNCTIONS swipe screen

The FUNCTIONS swipe screen highlights the selected measure function and allows you to select a

different function.

Figure 6: FUNCTIONS swipe screen

SETTINGS swipe screen

The SETTINGS swipe screen gives you front-panel access to some instrument settings for the

selected measure function. It shows you the present settings and allows you to change them. The

available settings depend on which measure function is active.

Figure 7: SETTINGS swipe screen

To disable or enable a setting, select the box next to the setting so that it shows an X (disabled) or a

check mark (enabled).

DAQ6510-900-01Rev. A / April 2018 2-9

Page 25

Section

User's Manual

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

STATISTICS swipe screen

The STATISTICS swipe screen contains information about the readings in the active reading buffer.

When the reading buffer is configured to fill continuously and overwrite old data with new data, the

buffer statistics include the data that was overwritten. To get statistics that do not include data that

has been overwritten, define a large buffer size that will accommodate the number of readings you

will make. You can use the Clear Active Buffer button on this screen to clear the data from the

active reading buffer.

Figure 8: STATISTICS swipe screen

2-10 DAQ6510-900-01Rev. A / April 2018

Page 26

DAQ6510

panel overview

Data Acquisition / Multimeter System User's Manual Section 2: Front-

SECONDARY swipe screen

The SECONDARY swipe screen allows you to display the results of two measurements on the

front-panel display.

To start displaying secondary measurements, select the Second Function and select Secondary

Measure. Secondary measurements are only available in Continuous Measurement Mode and

Manual Trigger Mode. This feature is only available from the front panel of the instrument.

Refer to "Display results of two measure functions" in the Model DAQ6510 Reference Manual.

Figure 9: SECONDARY swipe screen

Depending on the selected functions, a relay may click when the instrument switches between the

measurement types. Leaving secondary measurements on for extended periods may shorten the life

of the relays.

DAQ6510-900-01Rev. A / April 2018 2-11

Page 27

Section

User's Manual

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

USER swipe screen

If you program custom text, it is displayed on the USER swipe screen. For example, you can program

the DAQ6510 to show that a test is in process. Refer to "Customizing a message for the USER swipe

screen" in the DAQ6510 Reference Manual. This swipe screen is only displayed if custom text has

been displayed. Refer to "Customizing a message for the USER swipe screen" in the Model

DAQ6510 Reference Manual.

Figure 10: USER swipe screen

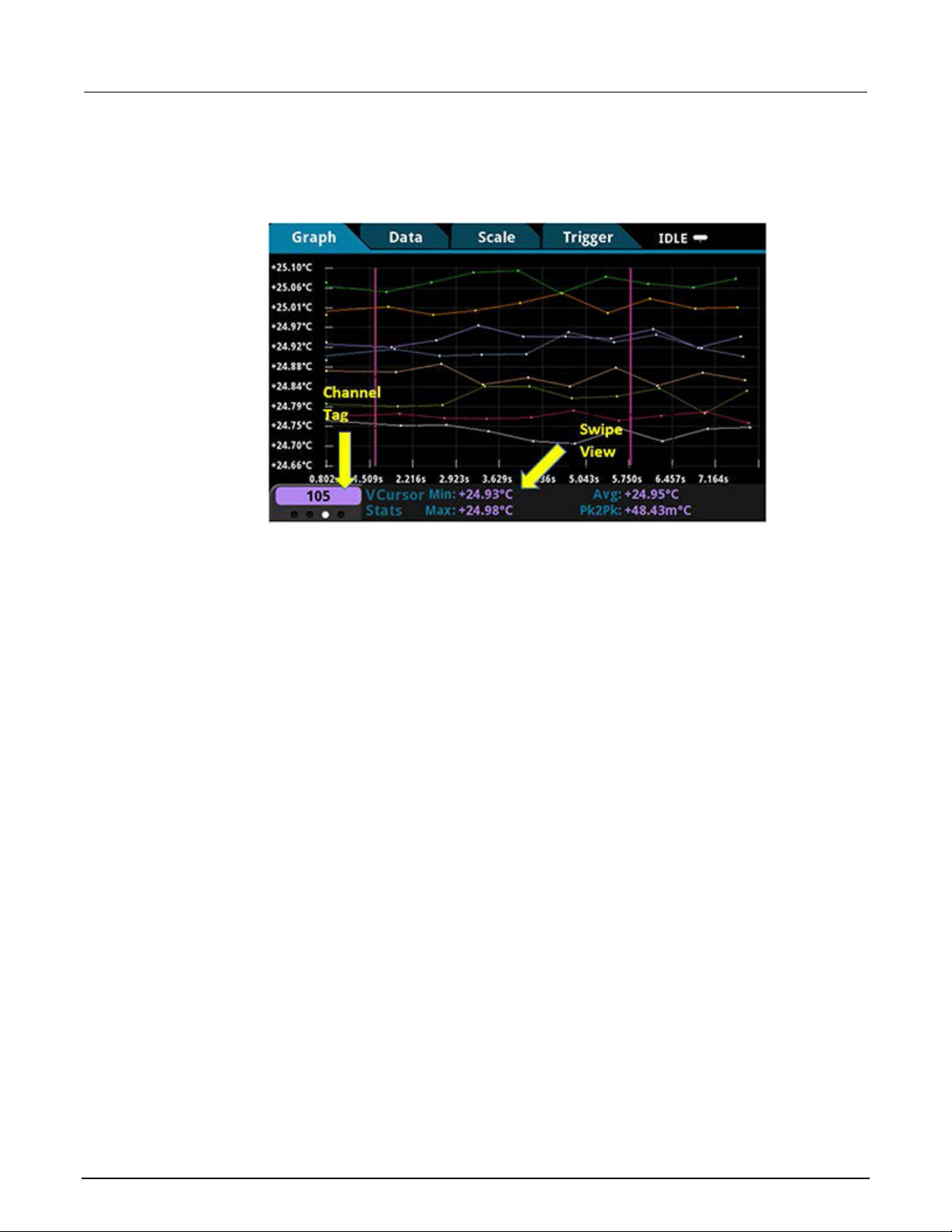

GRAPH swipe screen

The GRAPH swipe screen shows a graphical representation of the readings in the presently selected

reading buffer.

Figure 11: GRAPH swipe screen

2-12 DAQ6510-900-01Rev. A / April 2018

Page 28

DAQ6510

panel overview

Data Acquisition / Multimeter System User's Manual Section 2: Front-

To view the graph in the full screen and to access graph settings, select the graph icon on the right

side of the swipe screen header. You can also open the full-function Graph screen by pressing the

MENU key and selecting Graph under Views.

For more information about graphing measurements, see "Graphing" in the Model DAQ6510

Reference Manual.

DAQ6510-900-01Rev. A / April 2018 2-13

Page 29

Section

User's Manual

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

SCAN swipe screen

The SCAN swipe screen gives you front-panel access to build a scan, edit a scan, start a scan, step

through a scan, and display scan results. You can also save the scan results to a USB flash drive.

The icon on the right side of the swipe screen heading bar is a shortcut to the Channel Scan menu.

You can also use the Channel Scan menu to build or edit a scan.

For more information about viewing a scan preview and editing or running a scan, see "Channel scan

menu" in the Model DAQ6510 Reference Manual.

This screen is only available when the rear terminals are selected.

Figure 12: SCAN swipe screen - initial view

Figure 13: SCAN swipe screen - scan results

2-14 DAQ6510-900-01Rev. A / April 2018

Page 30

DAQ6510

rview

scan.

flash drive.

Runs a scan.

Incrementally steps through a scan, channel by channel.

Data Acquisition / Multimeter System User's Manual Section 2: Front-panel ove

The scan swipe screen has the following control options:

Button Description

Build Scan

Edit

Opens the SCAN screen, where you can set up a new scan.

Opens the SCAN screen, where you can change the setup of a

Save to USB

Saves the data in the scan reading buffer toa CSV file on the USB

Start Scan

Step Scan

DAQ6510-900-01Rev. A / April 2018 2-15

Page 31

Section

User's Manual

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

Menu overview

To access the main menu, press the MENU key on the DAQ6510 front panel. The figure below shows

the organization of the main menu. The options change depending upon which set of terminals are

selected, front or rear.

Figure 14: DAQ6510 main menu, front terminals selected

Figure 15: DAQ6510 main menu, rear terminals selected

The main menu includes submenus that are labeled in green across the top of the display. Selecting

an option in a submenu opens an interactive screen.

2-16 DAQ6510-900-01Rev. A / April 2018

Page 32

DAQ6

panel overview

510 Data Acquisition / Multimeter System User's Manual Section 2: Front-

Channel menu

The Channel menus allow you to set up and control channels and scans from the front panel.

The Channel Settings menu allows you to select and configure channels.

The Channel Control menu contains options to open and close channels.

The Channel Scan menu contains options to set up and run scans. Options include

control of groups, which are channels that are sequential and have the same

functions applied to them.

Measure Menu

The Measure menus allow you to select, configure, and perform measure operations from the front

panel. The menu content depends upon which set of terminals is selected.

With front terminals selected:

The QuickSet menu allows you to change the function and adjust performance.

The Measure Settings menu contains settings for the presently selected measure

function, which is identified by the function indicator in the upper right corner of the

menu. The available settings depend on the front-panel FUNCTION key selection.

The Calculations menu contains settings that specify the way measurement

information is processed and returned.

The Reading Buffers menu allows you to view the list of existing reading buffers

and select one to be the active buffer. You can also create, save, delete, resize,

and clear buffers from this screen.

With rear terminals selected:

The Reading Buffers menu allows you to view the list of existing reading buffers

and select one to be the active buffer. You can also create, save, delete, resize,

and clear buffers from this screen.

DAQ6510-900-01Rev. A / April 2018 2-17

Page 33

Section

User's Manual

2: Front-panel overview DAQ6510 Data Acquisition / Multimeter System

Views menu

The Views menus allow you to select, configure, and view data that was gathered from measure

operations.

The Graph menu opens a screen that displays a graph of the measurements in

selected reading buffers as traces. It also contains tabs that you use to customize

the graph display.

You can also select the trigger mode and initiate the trigger model from this screen.

The Histogram menu allows you to graph the distribution of measurement data in

the selected reading buffer. It also contains tabs that you use to customize the

histogram.

The Reading Table menu allows you to view data in the selected reading buffer.

Trigger menu

The Trigger menus allow you to configure the trigger model from the front panel.

The Templates menu allows you to choose from one of several preprogrammed

trigger models. When you select a template, settings you can specify for that

template are shown in the lower part of the screen.

The Configure menu allows you to view and modify the structure and parameters

of a trigger model. You can also monitor trigger model operation.

Scripts menu

The Scripts menus allow you to configure, run, and manage scripts from the front panel. Scripts are

blocks of commands that the instrument can run as a group.

The Run menu contains a list of scripts that you can select to run immediately. You

can also copy a script to a script that runs each time the instrument power is turned

on. You can access scripts that are in the instrument or on a USB flash drive.

The Manage menu allows you to copy scripts to and from the instrument and the

USB flash drive. You can also delete scripts from the instrument or USB flash drive.

The Save Setup menu allows you to save the present settings and configuration

lists of the instrument into a configuration script. You can use this script to recall the

settings.

The options in the Record menu allow you to record your actions and store them in

a macro script. The script can be run and managed like any other script using the

options in the Scripts menu or remote commands. Note that only settings are

stored; no key presses or front-panel only options are stored.

2-18 DAQ6510-900-01Rev. A / April 2018

Page 34

DAQ6510

panel overview

Data Acquisition / Multimeter System User's Manual Section 2: Front-

System menu

The menus under System in the main menu allow you to configure general instrument settings from

the DAQ6510 front panel. Among these settings are the event log, communications, backlight, time,

and password settings, calibration, and info/manage.

The Event Log menu allows you to view and clear event log entries. You can also

adjust which events are displayed or logged.

The Communication menu opens a set of tabs that contain information about the

communications settings. Most of the tabs contain settings that you can change.

The Settings menu contains general instrument settings. It includes beeper and

key click, backlight brightness and timer, time and date, system access level,

password, and reading format settings.

The Calibration menu allows you to start or manage auto calibration. Auto

calibration removes measurement errors that are caused by the effects of

temperature and time on components. You can also review factory adjustment and

verification dates.

The Info/Manage menu gives you access to version and serial number information

and settings for instrument firmware and reset functions.

DAQ6510-900-01Rev. A / April 2018 2-19

Page 35

Page 36

Determining the command set you will use ............................ 3-18

In this section:

Remote communications interfaces ......................................... 3-1

Supported remote interfaces .................................................... 3-2

LAN communications ............................................................... 3-2

USB communications ............................................................... 3-5

GPIB communications .............................................................. 3-9

RS-232 ................................................................................... 3-12

TSP-Link ................................................................................ 3-14

Using the web interface .......................................................... 3-15

Remote communications interfaces

Section 3

Using a remote interface

You can choose from one of several communication interfaces to send commands to and receive

responses from the DAQ6510.

The instrument automatically detects the type of communications interface (LAN, USB, GPIB,

RS-232, or TSP-Link) when you connect to the respective port on the rear panel of the instrument.

The GPIB, RS-232, and TSP-Link options require an optional accessory card. In most cases, you do

not need to configure anything on the instrument. In addition, you do not need to reboot if you change

the type of interface that is connected.

You can only use one communications interface to control the DAQ6510 at a time. The USB

connection takes precedence over LAN connections. For other communications interfaces, the first

interface on which the instrument receives a message takes control of the instrument. If another

interface sends a message, that interface can take control of the instrument. You may need to enter a

password to change the interface, depending on the access mode.

Page 37

Section

User's Manual

3: Using a remote interface DAQ6510 Data Acquisition / Multimeter System

Supported remote interfaces

The DAQ6510 supports the following remote interfaces:

• Ethernet: Built-in local area network (LAN) ethernet communications.

• USB: Built-in USB communications port (Type B).

• GPIB: IEEE-488 instrumentation general purpose interface bus.

• RS-232: Serial communication data standard.

• TSP-Link: A high-speed trigger synchronization and communications bus that test system

builders can use to connect multiple instruments in a master-and-subordinate configuration.

The GPIB, RS-232, and TSP-Link interfaces require an optional communications accessory.

For details about TSP-Link, see "TSP-Link System Expansion Interface" in the Model DAQ6510

Reference Manual.

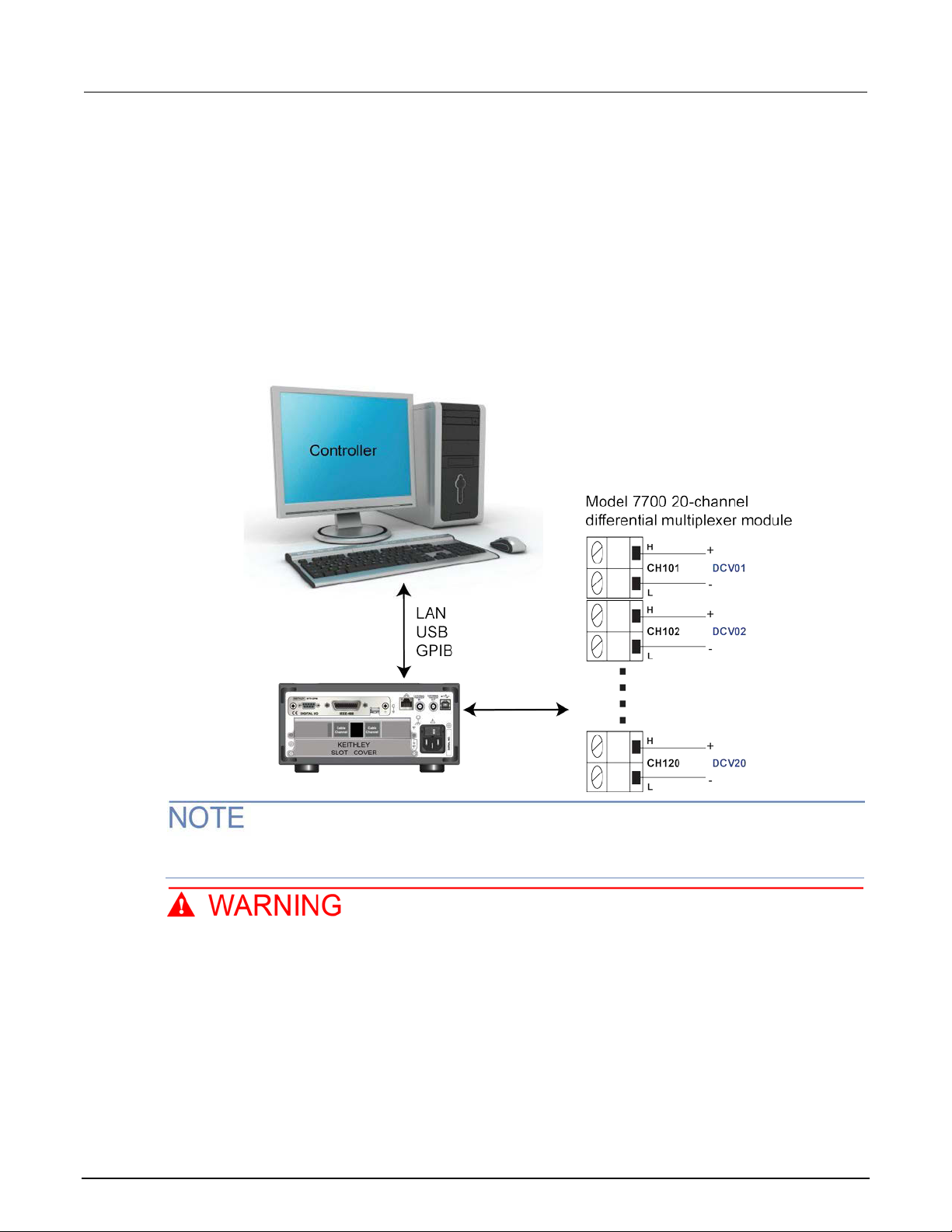

Figure 16: DAQ6510 remote interface connections

LAN communications

You can communicate with the instrument using a local area network (LAN).

When you connect using a LAN, you can use a web browser to access the internal web page of the

instrument and change some of the instrument settings. For more information, see

interface (on page 3-15).

The DAQ6510 is an LXI version 1.5 Core 2016 compliant instrument that supports TCP/IP and

complies with IEEE Std 802.3 (ethernet LAN). There is one LAN port (located on the rear panel of the

instrument) that supports full connectivity on a 10 Mbps or 100 Mbps network. The DAQ6510

automatically detects the speed.

The DAQ6510 also supports Multicast DNS (mDNS) and DNS Service Discovery (DNS-SD), which

are useful on a LAN with no central administration.

3-2 DAQ6510-900-01Rev. A / April 2018

Using the web

Page 38

DAQ6510

Using a remote interface

Data Acquisition / Multimeter System User's Manual Section 3:

Contact your network administrator to confirm your specific network requirements before setting up a

LAN connection.

If you have problems setting up the LAN, refer to LAN troubleshooting suggestions (on page 3-16

).

Set up LAN communications on the instrument

This section describes how to set up manual or automatic LAN communications on the instrument.

Check communication settings

Before setting up the LAN configuration, you can check the communication settings on the instrument

without making any changes.

To check communication settings on the instrument:

1. Press the MENU key.

2. Under System, select Communication. The SYSTEM COMMUNICATIONS window opens.

3. Select LAN to see the settings for that interface.

4. Press the EXIT key to leave the SYSTEM COMMUNICATION window without making any

changes.

Set up automatic LAN configuration

If you are connecting to a LAN that has a DHCP server or if you have a direct connection between the

instrument and a host computer, you can use automatic IP address selection.

If you select Auto, the instrument attempts to get an IP address from a DHCP server. If this fails, it

reverts to an IP address in the range of 169.254.1.0 through 169.254.254.255.

Both the host computer and the instrument should be set to use automatic LAN configuration.

Though it is possible to have one set to manual configuration, it is more complicated to set up.

To set up automatic IP address selection using the front panel:

1. Press the MENU key.

2. Under System, select Communication.

3. Select the LAN tab.

4. For TCP/IP Mode, select Auto.

5. Select Apply Settings to save your settings.

DAQ6510-900-01Rev. A / April 2018 3-3

Page 39

Section

User's Manual

3: Using a remote interface DAQ6510 Data Acquisition / Multimeter System

Set up manual LAN configuration

If necessary, you can set the IP address on the instrument manually.

You can also enable or disable the DNS settings and assign a host name to the DNS server.

Contact your corporate information technology (IT) department to secure a valid IP address for the

instrument when placing the instrument on a corporate network.

The instrument IP address has leading zeros, but the computer IP address cannot.

To set up manual IP address selection on the instrument:

1. Press the MENU key.

2. Under System, select Communication.

3. Select the LAN tab.

4. For TCP/IP Mode, select Manual.

5. Enter the IP Address.

6. Enter the Gateway address.

7. Enter the Subnet mask.

8. Select Apply Settings to save your settings.

Set up LAN communications on the computer

This section describes how to set up the LAN communications on your computer.

Do not change your IP address without consulting your system administrator. If you enter an

incorrect IP address, it can prevent your computer from connecting to your corporate network or it

may cause interference with another networked computer.

Record all network configurations before modifying any existing network configuration information on

the network interface card. Once the network configuration settings are updated, the previous

information is lost. This may cause a problem reconnecting the host computer to a corporate

network, particularly if DHCP is disabled.

Be sure to return all settings to their original configuration before reconnecting the host computer to a

corporate network. Contact your system administrator for more information.

Wait for the LAN status indicator to turn green

Make sure that your DAQ6510 is connected to the network by confirming that your instrument was

assigned an IP address.

To verify the LAN connection:

1. Press the MENU key.

2. Under System, select Communication.

3. Select the LAN tab.

A green LAN status indicator on the lower left of the LAN tab confirms that your instrument was

assigned an IP address.

3-4 DAQ6510-900-01Rev. A / April 2018

Page 40

DAQ6510

Using a remote interface

Data Acquisition / Multimeter System User's Manual Section 3:

Use the LXI Discovery Tool

To find the IP address of the DAQ6510, use the LXI Discovery Tool, a utility that is available from the

Resources tab of the LXI Consortium website

USB communications

To use the rear-panel USB port, you must have the Virtual Instrument Software Architecture (VISA)

layer on the host computer. See "How to install the Keithley I/O Layer" in the Model DAQ6510

Reference Manual for more information.

VISA contains a USB-class driver for the USB Test and Measurement Class (USBTMC) protocol that,

once installed, allows the Microsoft Windows operating system to recognize the instrument.

When you connect a USB device that implements the USBTMC or USBTMC-USB488 protocol to the

computer, the VISA driver automatically detects the device. Note that the VISA driver only

automatically recognizes USBTMC and USBTMC-USB488 devices. It does not recognize other USB

devices, such as printers, scanners, and storage devices.

In this section, "USB instruments" refers to devices that implement the USBTMC or

USBTMC-USB488 protocol.

.

Connect a computer to the DAQ6510 using USB

To connect the DAQ6510 to a computer using a USB connection, use Keithley Instruments

Model USB-B-1.

Each DAQ6510 needs its own USB cable to be connected to the computer.

To connect an instrument to a computer using USB:

1. Connect the Type A end of the cable to the computer.

2. Connect the Type B end of the cable to the instrument.

3. Turn on the instrument power. When the computer detects the new USB connection, the Found

New Hardware Wizard starts.

4. If the "Can Windows connect to Windows Update to search for software?" dialog box opens, click

No, and then click Next.

5. On the "USB Test and Measurement device" dialog box, click Next, and then click Finish.

DAQ6510-900-01Rev. A / April 2018 3-5

Page 41

Section

User's Manual

3: Using a remote interface DAQ6510 Data Acquisition / Multimeter System

Communicate with the instrument

For the instrument to communicate with the USB device, you must use NI-VISATM. VISA requires a

resource string in the following format to connect to the correct USB instrument:

USB0::0x05e6::0x6510::[serial number]::INSTR

Where:

• 0x05e6: The Keithley vendor ID

• 0x6510: The instrument model number

• [serial number]: The serial number of the instrument (the serial number is also on the rear

panel)

• INSTR: Use the USBTMC protocol

To determine these parameters, you can run the Keithley Configuration Panel, which automatically

detects all instruments connected to the computer.

If you installed the Keithley I/O Layer, you can access the Keithley Configuration Panel through the

®

Microsoft

Windows® Start menu.

If you have a USB connection, you cannot switch to a LAN connection while the USB is connected.

USB takes precedence over LAN.

To use the Keithley Configuration Panel to determine the VISA resource string:

1. Click Start > Keithley Instruments > Keithley Configuration Panel. The Select Operation

dialog box is displayed.

Figure 17: Select Operation dialog box

2. Select Add.

3-6 DAQ6510-900-01Rev. A / April 2018

Page 42

DAQ6510

Using a remote interface

Data Acquisition / Multimeter System User's Manual Section 3:

3. Select Next. The Select Communication Bus dialog box is displayed.

Figure 18: Select Communication Bus dialog box

4. Select USB.

5. Click Next. The Select Instrument Driver dialog box is displayed.

Figure 19: Select Instrument Driver dialog box

6. Select Auto-detect Instrument Driver - Model.

7. Click Next. The Configure USB Instrument dialog box is displayed with the detected instrument

VISA resource string visible.

DAQ6510-900-01Rev. A / April 2018 3-7

8. Click Next. The Name Virtual Instrument dialog box is displayed.

Page 43

Section

User's Manual

3: Using a remote interface DAQ6510 Data Acquisition / Multimeter System

Figure 20: Name Virtual Instrument dialog box

9. In the Virtual Instrument Name box, enter a name that you want to use to refer to the instrument.

10. Select Finish.

11. Select Cancel to close the Wizard.

12. Save the configuration. From the Keithley Configuration Panel, select File > Save.

Verify the instrument through the Keithley Communicator:

1. Click Start > Keithley Instruments > Keithley Communicator.

2. Select File > Open Instrument to open the instrument you just named.

Figure 21: Keithley Communicator Open an Instrument

3. Click OK.

4. Send a command to the instrument and see if it responds.

3-8 DAQ6510-900-01Rev. A / April 2018

Page 44

DAQ6510

Using a remote interface

Data Acquisition / Multimeter System User's Manual Section 3:

If you have a full version of NI-VISA on your system, you can run NI-MAX or the VISA Interactive

Control utility. See the National Instruments documentation for information.

GPIB communications

The DAQ6510 GPIB interface is IEEE Std 488.1 compliant and supports IEEE Std 488.2 common

commands and status model topology.

You can have up to 15 devices connected to a GPIB interface, including the controller. The maximum

cable length is the lesser of either:

• The number of devices multiplied by 2 m (6.5 ft)

• 20 m (65.6 ft)

You may see erratic bus operation if you ignore these limits.

To use the GPIB interface your computer will need a GPIB card. Check the documentation for your

GPIB controller for installation information and where to acquire drivers.

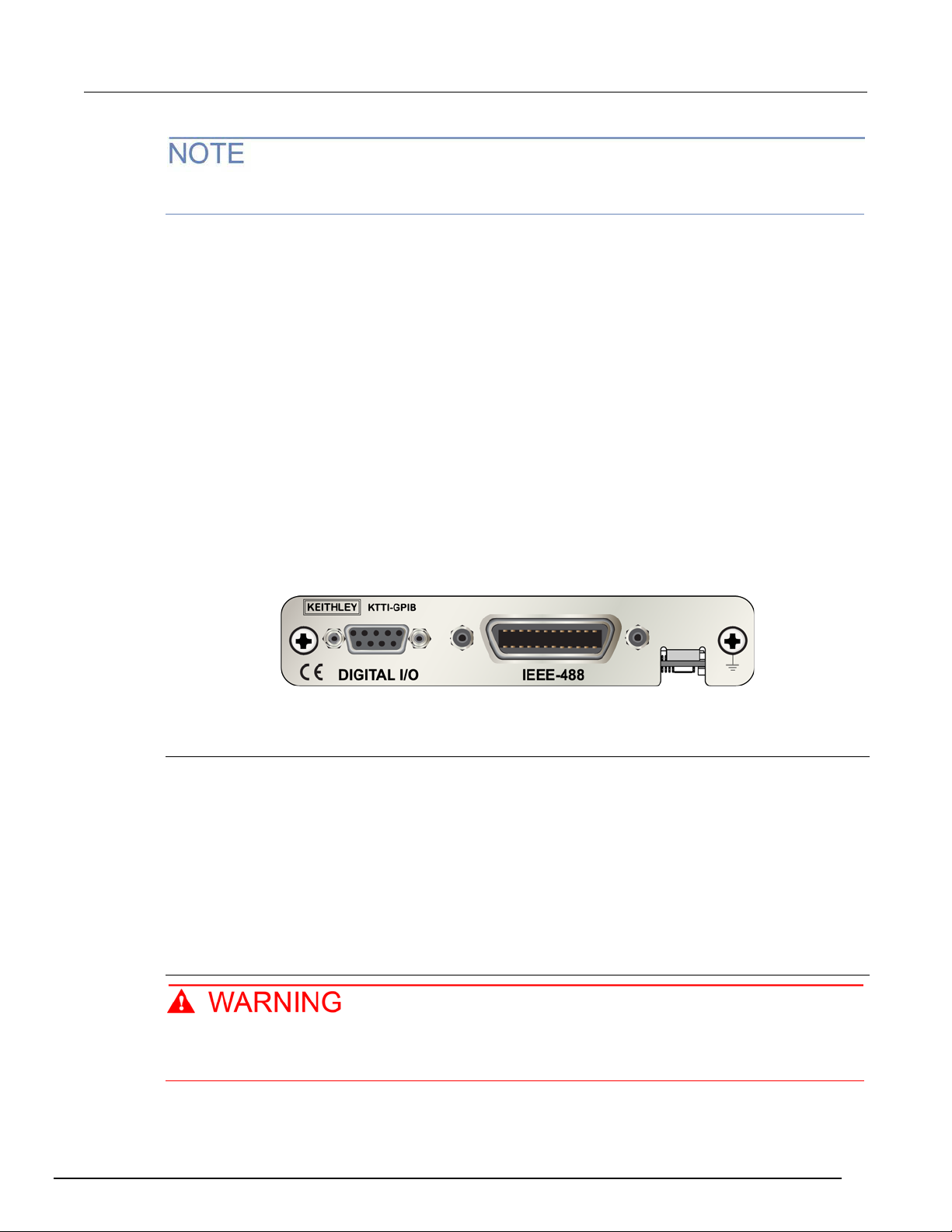

Install the KTTI-GPIB accessory card

Figure 22: KTTI-GPIB connector view

Unpack and inspect

Make sure to handle the KTTI-GPIB carefully. Always grasp the card by the side edges. Do not touch

board surfaces, components, or areas adjacent to electrical contacts. Contamination from foreign

materials such as dirt, dust, and body oils can substantially degrade card performance.

To unpack and inspect your instrument:

1. Inspect the box for damage.

2. Open the box.

3. Remove the card and inspect for any obvious signs of physical damage.

4. Report any damage to the shipping agent immediately.

Installation

Slot covers must be installed on unused slots to prevent personal contact with high-voltage

circuits. Failure to recognize and observe standard safety precautions could result in

personal injury or death due to electric shock.

DAQ6510-900-01Rev. A / April 2018 3-9

Page 45

Section

User's Manual

3: Using a remote interface DAQ6510 Data Acquisition / Multimeter System

To install the communications card:

1. Turn the instrument off and disconnect the power line cord and any other cables connected to the

rear panel.

2. Position the instrument so that you are facing the rear panel.

3. Remove the slot cover plate from the slot on the back of the instrument. Retain the plate and

screws for future use.

4. Align the card with the connector toward the inside edge of the slot and slide the card into the

chassis. For the last ¼ inch or so, press in firmly to mate the card to the connector.

5. On each side of the card, there is a spring-loaded mounting screw. Tighten these two screws,

either by hand or with a Phillips-head screwdriver, to secure the card in the case. Do not

overtighten.

6. Reconnect the power line cable and any other cables to the rear panel.

7. Turn on the instrument.

Connect GPIB cables to your instrument

To connect a DAQ6510 to the GPIB interface, use a cable equipped with standard GPIB connectors,

as shown below.

Figure 23: GPIB connector

To allow many parallel connections to one instrument, stack the connectors. Each connector has two

screws on it to ensure that connections remain secure. The figure below shows a typical connection

diagram for a test system with multiple instruments.

To avoid possible mechanical damage, stack no more than three connectors on any one

instrument. To minimize interference caused by electromagnetic radiation, use only shielded

GPIB cables. Contact Keithley Instruments for shielded cables.

3-10 DAQ6510-900-01Rev. A / April 2018

Page 46

DAQ6510

Using a remote interface

Data Acquisition / Multimeter System User's Manual Section 3:

Figure 24: DAQ6510 Instrument GPIB connections

Additional information

Additional information is available in the KTTI-GPIB Accessory Installation Sheet.

DAQ6510-900-01Rev. A / April 2018 3-11

Page 47

Section

User's Manual

3: Using a remote interface DAQ6510 Data Acquisition / Multimeter System

Set the GPIB address

Set the GPIB address. The default GPIB address is 16. You can set the address from one to 30 if it is

unique in the system. This address cannot conflict with an address that is assigned to another

instrument or to the GPIB controller.

GPIB controllers are usually set 0 to 21. To be safe, do not configure any instrument to have an

address of 21.

The instrument saves the address in nonvolatile memory. It does not change when you send a reset

command or when you turn the power off and on again.

To set the GPIB address from the front panel:

1. Press the MENU key.

2. Select Communication.

3. Select the GPIB tab.

4. Set the GPIB address.

5. Select OK.

RS-232

Install the KTTI-RS232 accessory card

You can also set the GPIB address using remote commands. Set the GPIB address with the SCPI

command :SYSTem:GPIB:ADDRess or the TSP command gpib.address.

Unpack and inspect

Make sure to handle the KTTI-RS232 carefully. Always grasp the card by the side edges. Do not

touch board surfaces, components, or areas adjacent to electrical contacts. Contamination from

foreign materials such as dirt, dust, and body oils can substantially degrade card performance.

To unpack and inspect your instrument:

1. Inspect the box for damage.

2. Open the box.

3. Remove the card and inspect for any obvious signs of physical damage.

4. Report any damage to the shipping agent immediately.