Page 1

Model 7072-HV

High Voltage Semiconductor Matrix Card

Instruction Manual

A GREATER MEASURE OF CONFIDENCE

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Page 2

W ARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMIT A TION OF W

ARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc.

Sales Offices BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

KOREA: FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-130 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

© Copyright 2001 Keithley Instruments, Inc.

Printed in the U.S.A.

11/01

Page 3

Model 7072-HV High V oltage Semiconductor Matrix Card

Instruction Manual

©1990, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, January 2002

Document Number: 7072-HV-901-01 Rev. B

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately into

the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the new Revision of the manual. Each new Revision includes

a revised copy of this print history page.

Revision A (Document Number 7072-901-01) ............................................. February 1988

Revision B (Document Number 7072-901-01) ................................................... April 1988

Addendum B (Document Number 7072-901-02)................................................ April 1988

Addendum B (Document Number 7072-901-03).......................................... February 1996

Revision C (Document Number 7072-901-01) ................................................... April 2000

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

SAFETY PRECAUTIONS

The following safety precautions should be observed before using the Model 707%HV and the associated instruments.

This matrix card is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read over this manual carefully before using the matrix card.

Exercise extreme caution when a shock hazard is present at the test circuit. User-supplied lethal voltages may be present

on the card connector jacks. The American National Standards Institute (ANSI) states that a shock hazard exists when

voltage levels greater than 30V RMS or 42.4V peak are present. A good safety practice is to expect that hazardous voltage

is present in any unknown circuit before measuring.

Do not exceed 13OOV between signal or guard and earth ground on Rows A and B.

Do not exceed ZOOV between any two pins or between any pin and earth ground on Rows C through H.

Inspect the connecting cables and test leads for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the test cables or any instruments while power is applied to the circuit under test.

Turn off the power and discharge any capacitors before connecting or disconnecting cables from the matrix card.

Do not touch any object which could provide a current path to the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of with-

standing the voltage being measured.

Do not exceed the maximum allowable input of the matrix card, as defined in the specifications and operation section of

this manual.

Instrumentation and accessories should not be connected to humans.

Page 6

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specif cations and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test f xtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present.

that hazardous voltage is present in any unknown circuit before

measuring.

A good safety practice is to expect

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts,

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specif cations and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as def ned in the specif cations and operating information, and as shown on the instrument or test f xture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against f re hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test f xture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

no conductive part of

Page 7

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The

WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The

CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and f re, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments off ce for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

11/01

Page 8

MODEL 7072-HV

High Voltage

Semiconductor Matrix Card

ROWS:

CROSSPOINT

CONFIGURATION:

OFFSET CURRENT:

PATH ISOLATION:

Resistance:

Capacitance bvxninal):

CROSSTALK: 1 MHz, 5oO load @picaI):

3dB BANDWIDTH @picaI), 500 load:

RELAY DRWE CURRENT

(per cmsspoint):

MAXIMUM SIGNAL LEVEL

Maximum between any 2 pins or chassis:

Maximum between Signal and Guard:

1A carry/0SA switched,

1OVA peak (resistive load)

CONTACT POTENTIAL (Signal to Guard):

MATRIX CONFIGURATION: 8 rows by I2

columns.

CONNECTOR TYPE: Three-lug triaxial

(Signal, Guard, Chassis).

CONTACT LIFE:

Cold Switching: IO’closures.

At Maximum Signal Level: 105 closures.

PATH RESISTANCE (per conductor): <IO

initial, <3.5Q at end of contact life.

RELAY SE’ITLING TIME <15ms.

Law Current General Purpose

(A-B) (C-F) (G-H)

2-p& Form A

4 pA

>1013 0

0.4 pF

<A0 dB

4MHZ

40m.4

1300”

2oov

<5o!lv

INSERTION LOSS UMHz, 50O source, 5OQ

load): O.ldB typical.

ENVIRONMENT:

OFFSETCURRENTandPATHISOLATION

Specificaticmc 23°C ~60% R.H.

Operating: 0’ to 5O”C, up to 35°C at 70% RH.

Storage: -25’ to +65*C.

ACCESSORY SUPPLIED: Instrnction manual.

Specifications subject to change without notice.

2-p& Form A I-pole Form A,

~20 pA

>lP R

1 PF

<A0 dB <-50 dB

8MHz 5MHZ

6Om.4

200”

2oov

<2opv

c-v

Common Guard

<20 pA

>10’2 n

0.6 pF

80 mA

2oov

2oov

<2ojlv

Page 9

Contains information on Model 707%HV features, specifi-

cations, and accessories.

Details installation of the Model 70724-N Semiconductor

Matrix Card within the Model 707 Switching Matrix, covers card connections, and also discusses measurement

considerations.

Gives four typical applications for the Model 707.2~HV, in-

cluding combined quasistatic and high-frequency CV

measurements, semiconductor switching matrix, van der

Pauw resistivity measurements, and semiconductor parameter analysis.

SECTION 1

General Information

SECTION 2

Operation

SECTION 3

Applications

Contains performance verification procedures, troubleshooting information and principles of operation for the

matrix card.

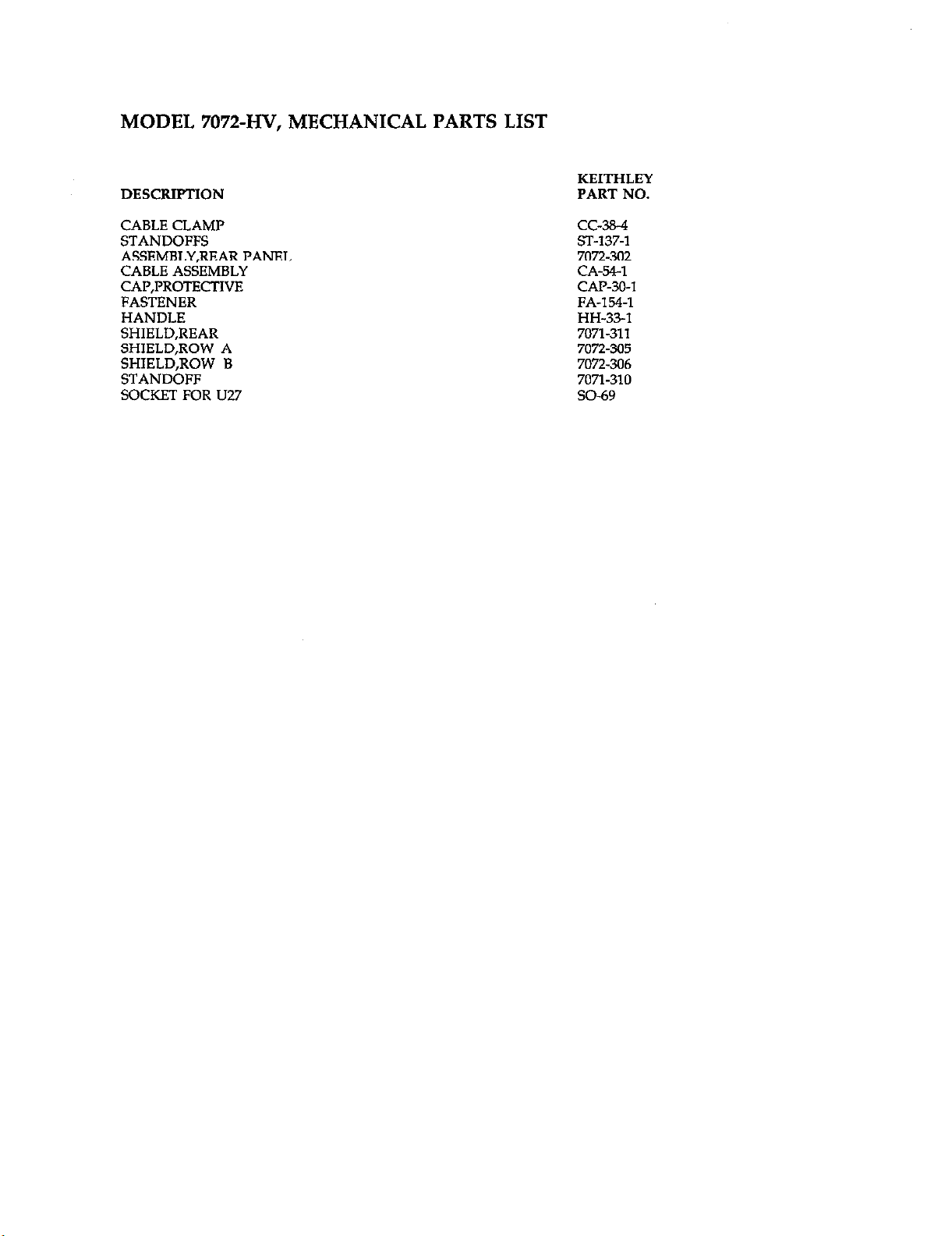

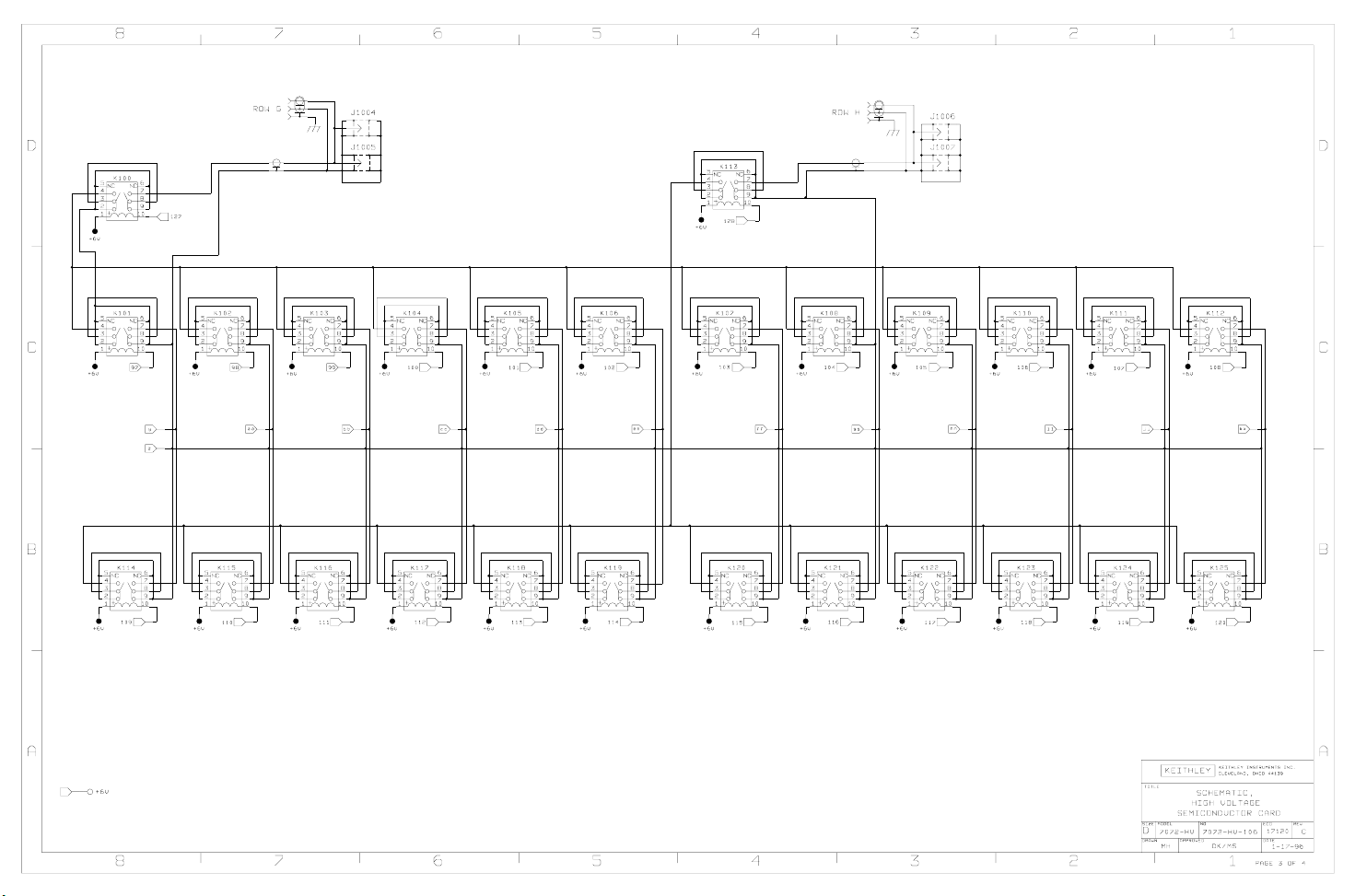

Lists replacement parts, and also includes component layout and schematic drawings for the Model 707%HV.

SECTION 4

Service Information

SECTION 5

Replaceable Parts

Page 10

Table of Contents

SECTION 1 — General Information

1.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 FEATURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 WARRANTY INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 MANUAL ADDENDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.5 SAFETY SYMBOLS AND TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.6 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7 UNPACKING AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.1 Inspect for Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.2 Shipment Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.7.3 Instruction Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.8 REPACKING FOR SHIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.9 OPTIONAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.10 COAXIAL JUMPER ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

SECTION 2 — Operation

2.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 HANDLING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 ENVIRONMENTAL CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.4 CARD INSTALLATION AND REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.5 CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.1 Card Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.2 Recommended Cables and Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5.3 Triaxial to Banana Plug Adapter Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5.4 General Instrument Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5.5 Keithley Instrument Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.6 Typical Test Fixture Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.6 MATRIX CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6.1 Switching Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6.2 Row and Column Isolators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.6.3 Pathway Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.6.4 Internal Matrix Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.6.5 External Matrix Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.7 MEASUREMENT CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.1 Magnetic Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.2 Electromagnetic Interference (EMI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7.3 Ground Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.4 Keeping Connectors Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.5 Noise Currents Caused by Cable Flexing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.6 Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.7 Guarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.8 Matrix Expansion Effects on Card SpeciÞcations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Page 11

SECTION 3

- Applications

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.3

3.3.1

3.3.2

3.4

3.4.1

3.4.2

3.4.3

3.5

3.5.1

3.5.2

3.6

3.6.1

3.6.2

3.6.3

3.6.4

INTRODUCTION .........................

CV MEASUREMENTS .....................

Stand Alone System Configuration ..........

Computerized System Configuration

Optimizing CV Measurement Accuracy

Basic CV Test Procedure ..................

Typical CV Curves ......................

SJ?MICONDUCTOR TEST MATRIX ...........

system Conf&uration ....................

Testing Common-Source Characteristic of FETs

REs1sTMTY MEASUREMENTS .............

Test Configuration

Test Procedure .........................

Resistivity CaIculations ...................

Semiconductor IV Characterization ............

TestConfiguration ......................

CableConnections ......................

SEMICONDUCTOR PARAMETER ANALYSIS

system Configuration ....................

CableConnections ......................

SPA Measurement Considerations ..........

Typical Test Procedure ...................

......................

........

......

...

...................

...................

...................

...................

...................

...................

...................

...................

...................

...................

...................

...................

...................

...................

...................

...................

...................

....................

...................

...................

...................

3-l

3-1

3-l

3-1

3-4

3-4

3-4

3-6

3-6

3-7

3-8

3-9

3-10

3-12

3-12

3-12

3-12

3-12

3-14

3-15

3-15

3-15

SECTION 4

4.1

4.2

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.4

4.5

4.5.1

4.5.2

4.5.3

4.6

4.6.1

4.6.2

4.6.3

4.6.4

4.6.5

INTRODUCTTON ...............................

HANDLING AND CLEANING PRECAUTIONS

PERFORMANCE VERIFICATION ..................

EnvironmentalConditions ......................

Recommended Test Equipment ...................

RelayTesting ................................

Offset Current Verification ......................

PathIsolationVt?rification .......................

Path Resistance Verification .....................

SPECIAL HANDLING OF STATIC- SENSITIVE DEVICES

TROUBLESHOOTING ...........................

Recommended Equipment ......................

Using the Extender Card ........................

Troubleshooting Procedure ......................

PRINCIPLES OF OPERATION .....................

Block Diagram ...............................

IDDataCircuits ..............................

RelayControl ................................

Power-on Safeguard ...........................

Isolator Relays ...............................

- Service Information

.......

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

4-l

4-1

4-1

4-l

4-l

4-1

4-3

4-5

4-7

4-9

4-9

4-9

4-Y

4-9

4-11

4-11

4-l 1

4-12

4-12

4-12

Page 12

SECTION

5 - Replaceable Parts

5.1

5.2

5.3

5.4

5.5 COMPONENT LAYOUT AND SCHEMATIC DIAGRAM

INTnODUCTION.............................................................. 5-l

PARTSLIST . . . . . . . . . . ..___..__......__...........__..........................

ORDERING INFORMATION .

FACTORYSERVICE................................................,........... 5-l

5-l

5-1

5-l

Page 13

List of Illustrations

SECTION

Figure 2-l

Figure 2-2

Figure 2-3

Figure 2-4

Figure 2-5

Figure 2-6

Figure 2-7

Figure 2-8

Figure 2-9

Figure 2-10

Figure 2-11

Figure 2-12

Figure 2-13

Figure 2-14

Figure 2-15

Figure 2-16

Figure 2-17

Figure 2-18

Figure 2-19

Figure 2-20

Figure 2-21

Figure 2-22

Figure 2-23

Figure 2-24

2 - Operation

Model7072-HVInstalIation

CardConnectors

Triax Connector Configuration

Triaxial Cable Preparation

General Inshument Connections

Model 617 Electrometer Connections

Model196DMMConnections

Model 230 Voltage Source Connections

Model 590 CV Analyzer Connections

Model 220 Current Source Connections

Typical Test Fixture Connections

Equivalent Circuit of Test Fixture Connections .

Model 7072.HV Matrix Organization

CoMectingThreeCardsforSx36Mahix

Jumper Connector Locations

Three Cards in Daisy Chain Configuration

l6x36MatrixConstmctedbyExtemalJumpering

Using Triax Tee Adapters to Daisy Chain Cards

Power Line Ground Loops

Eliminating Ground Loops

Shielding Example ................

Dual Shield Test Fixture

Guarded Circuit ..................

Typical Guarded Signal Connections

..................................................

.........................................

.......................................

...........................................

......................................

...................................

........................................

.................................

..................................

.................................

.....................................

..................................

...............................

.........................................

..............................

..........................

..........

..........

............

...

.........................

.

...........

...........

2-2

2-3

2-4

2-5

26

2-11

2-12

2-13

2-14

2-15

2-16

2-16

2-17

Z-19

2-19

2-20

2-21

2-22

2-24

2-24

2-25

2-26

2-26

2-27

SECTION

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-9

Figure 3-10

Figure 3-11

Figure 3-12

Figure 3-13

Figure 3-14

3 - Applications

Stand Alone CV System Configuration

Computerized CV System Configuration

Typical Quasistatic CV Curve Generated by Model 595

Typical High-frequency CV Curve Generated by Model 590

SemiconductorTestMatrix..

System Configuration for Measuring Common-Emitter Characteristics

Typical Common-Source FET IV Characteristics

Resistivity Test Configuration

Resistivity Measurement Conventions

Multi Unit Test System Using Models 236 and 237 Source Measure Units

Semiconductor Parameter Analysis Switching System

SPAConnections ................................................

System Configuration for JFET Test

TypicalJFETPlot ................................................

.......................................

.......................................

................................

..............................

....................

................

.........................

................................

.....................

...................................

........

.......

3-2

3-3

3-5

3-6

3-7

.

3-8

3-a

3-9

3-11

3-13

3-14

3-16

3-17

3-18

Page 14

SECTION 4

- Service Information

Figure 4-1

Figure 4-2

Figure 4-3

Figure 4-4

Figure 4-5

Figure 46

Figure 4-7

Figure 4-8

Figure 4-Y

Test Cable Preparation

Connecting the Test Cable to the Model 7072.HV

Offset Verification Test Connections

Connections for Path Isolation Verification

Triaxial Cable Preparation

Connections for path Res@tance Verification

Shorting Measurement Paths Using Triax Tee Adapter

IDDataTig

Model 7072~HV Block Diagram

....................................

..........

............................

., ...................

..........

....................

...............

..............

........................

......

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-10

4-11

Page 15

List of Tables

SECTION 2

Table 2-l

Table 2-2

Table 2-3

SECTION 3

Table 3-l CV Test Crosspoint Summary .

Table 3-2

Table 3-3

SECTION

Table 4-1

Table 42

Table 4-3

- Operation

Recommended Cables and Adapters ...........

Parts for Special Triaxial Cable ...............

Column Numbering by Slot and Unit ..........

- Applications

Crosspoint Summary for Resistivity Measurements

Crosspoint Summary for JFET Test

4 - Service Information

Recommended Verification Equipment

Recommended Troubleshooting Equipment

Troubleshooting Procedure L

................... 2-4

................... 24

. ................... 2-18

...................

...................

...................

................... 4-2

.................... 4-9

................... 4-10

34

3-10

3-15

Page 16

SECTION 1

General Information

1 .l INTRODUCTION

This section contains general information about the

Model 7072~HV Semiconductor Matrix Card. The Model

7072-HV is designed for flexibility in switching semiconductor test setups. Two low-current, high voltage pathways, and two C-V pathways in addition to four generalpurpose pathways allow complete system versatility.

Section 1 is arranged in the following manner:

1.2 Ff?&lI~S

1.3 warranty Information

1.4 Manual Addenda

Safety Symbols and Terms

1.5

1.6 Specifications

Unpacking and Inspection

1.7

1.8 Repacking for Shipment

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this instruction manual. Should your Model 7072~HV

require warranty service, contact the Keithley representative or authorized repair facility in your area for further

information. When returning the matrix card for repair,

be sure to fill out and include the service form at the back

of this manual in order to provide the repair facility with

the necessary information.

1.4 MANUAL ADDENDA

Any improvements or changes concerning the mati

card or manual will be explained in an addendum included with the the unit. Be sure to note these changes

and incorporate them into the manual before using or

servicing the unit.

1.5 SAFETY SYMBOLS AND TERMS

The following symbols and terms may be found on an in-

strument or used in this manual.

1.9 Optional Accessories

1.10 Coaxial Jumper Access

1.2 FEATURES

Key features of the Model 7072~HV High Voltage Semiconductor Matrix Card include:

. 8 x 12 (eight row by 12 column) switching matrix.

. Two rows (A and B) with low offset current for low-

current, high voltage measurements.

. Two dedicated rows (G and H) for CV measurements.

l

Three-lug hiax connectors for all row and columns allow guarding of each signal pathway to minimize the

effects of stray capacitance, leakage current, and leakage resista&. -

l

Model 7072~HV cards can be connected together to ex-

pand the number of columns in the matrix.

The A

user should refer to the operating instructions located in

the instruction manual.

The t symbol

may be present on the terminal(s). Use standard safety

precautions to avoid personal contact with these volt-

ages.

The WARNING heading used in this manual explains

dangers that might result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading used in this manual explains

hazards that could damage the matrix card. Such damage

may invalidate the warranty.

symbol on an instrument indicates that the

on an instrument shows that high voltage

l-1

Page 17

SECTION 1

General Information

1.6 SPECIFICATIONS

Model 7072~HV specifications may be found at the front

of this manual. These specifications are exclusive of the

matriv mainframe specifi~tiom,

Model 707 Instruction Manual.

which are located in the

1.7 UNPACKING AND INSPECTION

1.7.1

Upon receiving the Model 7072~HV, carefully unpack it

from its shipping cation and inspect the card for any obvious signs of physical damage. Report any such damage

to the shipping agent immediately. Save the original

packing carton for possible future reshipment.

1.7.2

The following items are included with every Model

7072~HV order:

l Model 7072-HV Semiconductor Ma&ix Card.

. Model 7072~HV Instruction Manual.

l Coaxial jumper cables (4) for matrix expansion.

. Additional Accessories as ordered.

Inspection for Damage

Shipment Contents

1.7.3 Instruction Manual

1.6 REPACKING FOR SHIPMENT

Should it become necessary to return the Model 7072~HV

for repair, carefully pack the card in its original packing

carton or the equivalent, and include the following information:

. Advise as to the warranty status of the mati card.

. Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

l Fii out and include the service form located at the back

of this manual.

1.9 OPTIONAL ACCESSORIES

Model 707%TBC 3-Lug Female Triax Bulkhead Connector with Cap-The Model 707%TBC can be used for applications such as test fixtures.

Model 7078-CSHP Cable Set-The Model 707%CSHP

Cable Set includes the necessary cables and adapters to

connect the Model 7072~HV to the Hewlett-Packard

Model 4145 Semiconductor Parameter Analyzer. The

Model 7078~CSHI’ includes four Model 707%TRX-10

loft. 3-lug triaxial cables, four Model 7051-10 loft. BNC

cables, and four Model 7078-TRX-BNC 3-lug triax to BNC

adapters.

The Model 7072~Hv Instruction Manual is three-hole

drilled so that it can be added to the three-ring binder of

the Model 707 Switching Matrix Instruction Manual. After removing the plastic wrapping, place the manual in

the binder after the mainframe instruction manual. Note

that a manual identification tab is included and should

precede the matrix card instruction manual.

If an additional instruction manual is required, order the

manual package, Keithley part number 7072~HV-901-00.

The manual package indudes an inshuction manual and

any perhnent addenda.

l-2

Recommended cables and adapters are summarized in

Table 2-1.

1.10 COAXIAL JUMPER ACCESS

Coaxial jumpers can be installed to expand rows A, B, G

and H of the matrix using two or more Model 7072~HV

Cards. An access door on the mainframe allows access to

these jumpers. To allow access when the Model 707 is

mounted in a rack, it is recommended that the Model

7079 Slide Rack Mount Kit be used.

Page 18

SECTION 2

Operation

2.1 INTRODUCTION

This section contains information on matrix card connec-

tions, installation and matrix programming, and is arranged as follows:

2.2 Handling Precautions: Discusses precautions that

should be taken when handling the card to avoid contamination that could degrade performance.

2.3 Environmental Considerations: Outlines environmental aspects of using the Model 7072~HV.

2.4 Card Installation and Removal: Details installation

in and removal from the Model 707 Switching Matrix

mainframe.

2.5 Connections: Discusses card connectors, cables and

adapters, and typical connections to other instnunenta-

tion.

2.6 Matrix Configuration: Discusses the switching matrix, as well as matrix expansion by connecting two or

more cards together.

2.7 Measurement Considerations: Reviews a number

of considerations when making low-level current and capacitance measurements.

ment. If contamination is suspected, clean the card as dis-

cussed in Section 4. Also, the performance verification

procedures in Section 4 can be used to test the card for

low leakage resistances that could signal contamination.

2.3 ENVIRONMENTAL CONSIDERATIONS

For rated performance, the card should be operated

within the temperature and humidity limits given in the

specifications at the front of this manual. Note that current offset and path isolation values are specified within a

lower range of limits than the general operating environment.

2.4 CARD INSTALLATION AND REMOVAL

Before making connections, the Model 7072.HV should

be installed within the Model 707 Switching Matrix, as

summarized below. Figure 2-1 shows the installation

procedure.

WARNING

Turn off the mainframe power and disconnect the line cord before installing or removing matrix cards.

2.2 HANDLING PRECAUTIONS

To maintain high impedance isolation, care should be

taken when handling the matrix card to avoid contami-

nation from such foreign materials as body oils. Such

contamination can substantially lower leakage resistances, degrading performance. The areas of the card that

are most sensitive to contamination are those associated

with the Teflon@ insulators. To avoid any possible contamination, always grasp the card by the handle or the

card edges. Do not touch board surfaces, components, or

card edge connectors.

Dirt build-up over a period of time is another possible

source of contamination. To avoid this problem, operate

the mainframe and matrix card only in a clean environ-

NOTE

The coaxial jumpers used to expand the matrix with two or more Model 7072~HV cards

are not installed before card insertion; an access door on top of the mainframe allows ac-

cess to the connectors after the card is in-

stalled.

1. Before installing the card, make sure the access door

on top of the Model 707 is fully closed and secured.

The access door contains tracks for the card slots and

must be in place to properly install the card.

2. With one hand grasping the handle, and the other

holding the bottom of the card, line up the card with

the tracks in the desired slot. Make certain that the

component side of the card is facing the fan on the

mainframe.

2-l

Page 19

SECTION 2

Operation

Figure 2-1. Model 7072.HV Installation

CAUTION

hveen the card and the mainframe. Failure to

Donot touchthecard sufacesoranycompo- properly secure this ground connection may

nerds to avoid contamination that could de- result in personal injury or death due to elecgrade card performance. tric shock.

3. Slide the card into the mainframe until it is properly

seated in the edge connectors at the back of the slot.

Once the card is properly seated, secure it to the

mainframe by finger tightening the spring-loaded

screws.

4. To remove a card, first turn off the power and disconnect the line cord from the mainframe. Disconnect all external and internal cables (internal cables

can be reached through the access door). Loosen the

mounting screws, then pull the card out of the main-

WARNING frame by the handle. When the back edge of the card

The mounting screws must be secured to en- clears the mainframe, support it by grasping the botsure a proper chassis ground connection be- tom edge near the back edge.

2-2

Page 20

SECTlON 2

Operation

2.5 CONNECTIONS

Card connectors, recommended cables and adapters, and

typical connections to test inshunents are discussed in

the following paragraphs.

2.5.1

The card connectors are shown in Figure 2-2. Each row

and column is equipped with a 3-lug female triax connector. As shown in Figure 2-3, the center conductor is SIGNAL, the inner shield is GUARD, and the outer shield, or

shell is chassis ground. Note that 3-lug connectors are

used to avoid possible damage from inadvertently attempting to connect BNC cables.

Card Connectors

CAUTION

Do not exceed 200V between any two pins on

rows C-H or SIGNAL and GUARD on rows

A and B, or 1300V between SIGNAL and

chassis ground, or GUARD and chassis

ground on rows A and 8.

ROWS

A-H

Carrying

Handle

Mounting

SCrW

-Columns

i-12

w

The Model 7072~HV has 12 columns that are labeled 1

through 12, as well as eight rows, A through H. Rows A

andBarelabeledLOWIandareintendedforlow-current

or high voltage measurements. Rows G and Hare labeled

CV and are designed for capacitance-voltage measurements. Rows C through F are general purpose rows that

can be used for ordinary voltage, current, or resistance

measurements. If a crosspoint in row A or B is closed, the

crosspoints in rows C through H of that column will nOt

be connected to rows A and B. This is to prevent high

voltage from being accidentally applied to rows C

through H.

2.5.2

Recommended Cables and

Adapters

Table 2-l summarizes the cables and adapters recom-

mended for use with the Model 7072~HV. Equivalent

user-supplied items may be substituted as long as they

are of sufficient quality (low offset current, high leakage

resistance). Using substandard cables and adapters may

degrade the integrity of the measurements made using

the matrix card. See paragraph 2.7 for a discussion of

measurement considerations.

Mounting

SCMV

Figure 2-2. Card Connectors

23

Page 21

SECTION 2

Operation

Chassis

Ground

* 2OOV Max on Caution : Do not Exceed Maximum

rows C-H Voltage Levels Shown

?aure 23.

Table 2-l. Recommended Cables and Adapters

1 Model

7078-TRX-x

237-BRE-1

237-BAN-3

237-ALG-1

6011*

237-BAN

7078~TRX-BNC

7078-TRX-GND

7078-TRX-T

237-SBT-NG

6171”

Triax Connector Confimuation

plug

3-slot male triax to alligator clips

Z-slot male triax to alligator clips

3-slot male triax to female banana

jack adapter

3slot male triax to BNC adapter,

connections to center and inner

shell

3-slot male triax to BNC adapter,

connections to center and outer

shell

3-slot male to dual 3-lug female

triax tee adapter

3-slot male to Slug female adapter, guard disconnected

3slot male triax to 2-lug female

triax adapter

2.5.3 Triaxial to Banana Plug Adapter

Preparation

For instruments that use banana jacks, a special 3-slot

triax-to-single banana plug must be prepared, as discussed below. This special cable can be prepared as outlined below using the parts listed in Table 2-2 or may be

purchased as a Model 237-BAN-3. Note that you can use

either an unterminated triax cable, or cut a dual-connec-

tor cable (7078-TRX-10) in half to construct two cables.

The steps for the procedure below are shown in Figure

2-4.

Table 2-2. Parts for Special Triaxial Cable

Keithley Part or

Model Number 1 Description

7078-TRX-3 triax cable” Unterminated 3slot triax

cable

Part #

BG-10-Z

‘One ConneCtor must be cut off

1. Using a knife, cut and strip back the outer insolation

about l-1/2 inches.

2. Remove the outer insulation, then cut away the outer

shield back as far as the insulation is stripped.

3. Carefully strip away the insulation over the inner

shield one inch, then cut the inner shield off even

with the shipped insulation.

4. Strip the inner conductor l/2 inch, then twist the

strands together.

5. Unscrew the cover from a banana plug, then slide

the cover over the center conductor of the triax cable.

6. Insert the stripped center conductor through the

hole in the body of the banana plug, then wrap the

wire around the plug body.

7. Screw on the plastic cover, and make certain the wire

is secure by gently pulling on the plug.

Red banana plug

2-4

Page 22

SECTION 2

Operation

Cut

/

u’

cut

/

/

I_ 1” ----+I

(A) Cut off insulation with knife

Cut off cuter shield.

Insulation ever

inner shield

f

(6) Strip insulation off inner shield

(C) Twist inner shield then strip inner conductor.

Twist inner shield and center conductor together,

slip on plastic ccvar.

WARNING

Do not use coaxial cables and adapters because hazardous voltage from guard sources

may be present on the cable shields.

Figure 2-5 shows the general instrument connections for

the discussions below. Note that DUT guarding or

shielding are not indicated here; see Figures 2-21 and 2-24

for shielding and guarding information. Also, 2-p&

switching for rows A-F is shown in the figures; GUARD

is not switched cm rows G and H. As shown, all figures

assume instruments are connected to rows, and the DUT

is connected to columns.

DMM Connections

General

(B), and (C). Floating connections are shown in (A), with

LO and HI routed to two separate jacks on the Model

7072~HV. The common LO connections in (B) should be

used only for non-critical applications because the performance of the GUARD pathway is not specified.

DMM connections are shown in Figure 2-5(A),

(D) Insert wire into hole and wrap around body.

(E) Screw on plastic cover.

Figure 2-4.

2.5.4

The following paragraphs discuss connecting the Model

7072~I-IV to various general dasses of instrumentation

such as DMMs, electrometers, sources, and source/

measure units. Because these configurations are generic

in nature, some modification of the connecting schemes

may be necessary for your particular instrumentation.

Also, special cables or adapters may be necessary. In all

cases, 3-lug triax cables must be used to make the ccmnec-

tions.

Triaxid Cable Preparation

General Instrument Connections

WARNING

Hazardous voltage from other guard sources

may be present on LO or the DUT if other

crosspoints are closed.

4-wire DMM connections are shown in Figure 2-50 In

this case, a total of four jacks are required; HI, LO, SENSE

HI, and SENSE LO.

Electrometer Connections

Typical electrometer connections are shown in Figure

2-5(D) through (G). The unguarded volts connections in

(D) show the HI signal path routed through one jack, and

the LO path goes through the other connector. Both

GUARD pathways are connected to electrometer LO. For

guarded voltage (E), Model 7072~HV GUARD is con-

nected to electrometer GUARD.

The connections for electrometer fast amps and resis-

tance measurements are shown in Figures 2-5(F) and (G).

These configurations are essentially the same as those

discussed above. For the case of fast amps, both GUARD

paths are connected to electrometer LO, while in the case

of guarded resistance, one GUARD path is connected to

electmmeter GUARD, and

nected to electrometer LO.

the other

GUARD path is con-

2-5

Page 23

SECTION 2

Overation

Source Connections

Voltage and current source connections are shown in Fig-

ures 2-5(H) through (J). The HI and LO paths of the vcltage source (H) are routed through two jacks, with both

card GUARD pathways connected to voltage source LO.

For the unguarded current source connections (I), card

GUARD is again connected to source LO, with source HI

and LO routed through two pathways. In the case of the

guarded current source in 0, card GUARD of the Hl signal path is connected to souxe GUARD, and the other

GUARD path is connected to sauce LO.

ROWS

Source/Measure Unit Connections

Figure 2-50) shows typical connections for a source/

measure unit (SMW. In this instance, a remote-sensing

type of a SMU is shown, requiring a total of four signal

pathways to the DUT. For critical measurements, both

source and sense HI pathways would be guarded as

shown, with two of the four card GUARD pathways connected to SMU GUARD terminals. As with other instmment connections, the LO card GUARD pathways are

connected to SMU LO terminals.

COLUMNS

Fipre 2-5.

A.) DMM Floating

ROW COLUMN

Warning : Hazardous voltage from guard

sources may be present on LO.

S.) DMM Common LO

General Instrument Connections (A-B)

L-----l

707.2.HV

707%HV

DUT

Note : Use this configuration only for

noncritical measurements.

2-6

Page 24

SECTION 2

Operation

C.) DMM 4.Wire

ROWS

COLUMNS

L-----l

7072.HV

General

Instrument

Electrometer

D.) Electrometer, Unguarded Volts

Connections (C-D)

ROWS

COLUMNS

L----A

7072.HV

2-7

Page 25

SECTION 2

Otleration

ROWS

Electrometer

E.) Electrometer, Guarded Volts

ROWS

_---__

r----i

COLUMNS

DUT

707%HV

COLUMNS

I

Electrometer

F.) Electrometer. Fast Current

i

G.) Electrometer. Resistance (Guarded)

GlWd

Electrometer

I

HI

LO

ROWS

7072.HV

r---_~

7072.HV

COLUMNS

DUl

General Instrument Connections (E-G)

243

Page 26

SECTION 2

Operation

H.) Voltage Source

ROWS

ROWS COLUMNS

r-----7

L----A

7072.HV

COLUMNS

I.) Current Source, Unguarded

ROWS

J.) Current Source. Guarded

L-----l

7072.HV

_ - - - - -

L----A

707BHV

COLUMNS

DUT

2-9

Page 27

SECl7ON 2

Operation

H

Force C”*n

IorV

r-

sense -..-.-

Vorl

Source/Measure

ROWS COLUMNS

K.) Source/Measure Unit

Notes : 1.) DUT shielding/guarding not shown. See figures Z-21 and2.24

~enerai Instrument Connections (K)

-7-J. AZ-+-

L-----l

7072-H”

2.) Z-Pole switching for rows A-F shown. GUARD is not witched

on rows G and H.

2-10

Page 28

SECTION 2

Operation

2.5.5

Keithley Instrument Connections

The following paragraphs outline connecting typical

Keithley instruments to the Model 7072~HV Semiconductor Matrix Card. Other similar instruments can be

connected using the same cabling as long as their input/

output configurations are the same. Instrument connections covered include:

. Model 617 Electrometer/Source

. Model 196 DMM

. Model 230 I’rogrammable Voltage Source

. Model 220 Programmable Current Source

. Model 590 CV Analyzer

. Model 236/237/238 Source Measure Unit

Model 617 Electrometer Connections

ConnectionsfortheModel617Electrometerareshownin

Figure 2-6. The electrometer INPUT should be connected

only to rows A and B for currents less than 2nA; otherwise, current offset will affect measurement accuracy.

1. Connect one end of a Model 7078-TIW-3 or -10 3-lug

triaxial cable to rcw A of the Model 7072-HV.

2. Connect the other end of the triax cable to the Model

617 INPUT connector using a Model 6172 adapter.

3. Connect the trlax end of a prepared triax/banana cable to row B of the Model 7072XV.

4.

Connect the banana plug end of the triax/banana cable to the COM terminal of the Model 617. The shorting link between COM and chassis ground should be

removed for this application.

5.

Place the GUARD switch in the OFF position.

6. To connect the voltage source to the Model 7072~HV,

connect the V-SOURCE HI and LO connectors of the

Model 617 to the desired row connectors on the matrix card. Figure 2-6 shows connections to rows C

and D.

I

Guard off --._I

Voltage Source 1

Connection

Model 617

t

Triax/Sanana Cables

(See Figure 2 - 4)

Figure 2-6. Model 617 Electrometer Connections

7078 - TRX Triax

@I

A

7072.HV Matrix Card

Page 29

SECllON 2

Operation

Model 196 DMM Connections

Cquwct the Model 196 or other similar DMM to the matrix card using the general configuration shown in Figure

2-7. The VOLTS OHMS HI and LO terminals should be

connected to the desired rows using the prepared triax/

banana cables discussed above. For 4-wire ohms measurements, the OHMS SENSE HI and LO terminals

should be connected to two additional rows using the

same type of cables.

NOTE

For low-level voltage measurements, connect

the inner shield of the HI cable to VOLT

OHMS LO to minimize noise.

Model 230 Voltage Source Connections

Connect the Model 230 OUTPUT and COMMON tenni-

nals to the desired rows using the prepared triax/banana

plug cables, as shown in Figure 2-8. For remote sensing

applications, the SENSE OUTPUT and SENSE COMMON connectors can be routed through two additional

rows using similar cables.

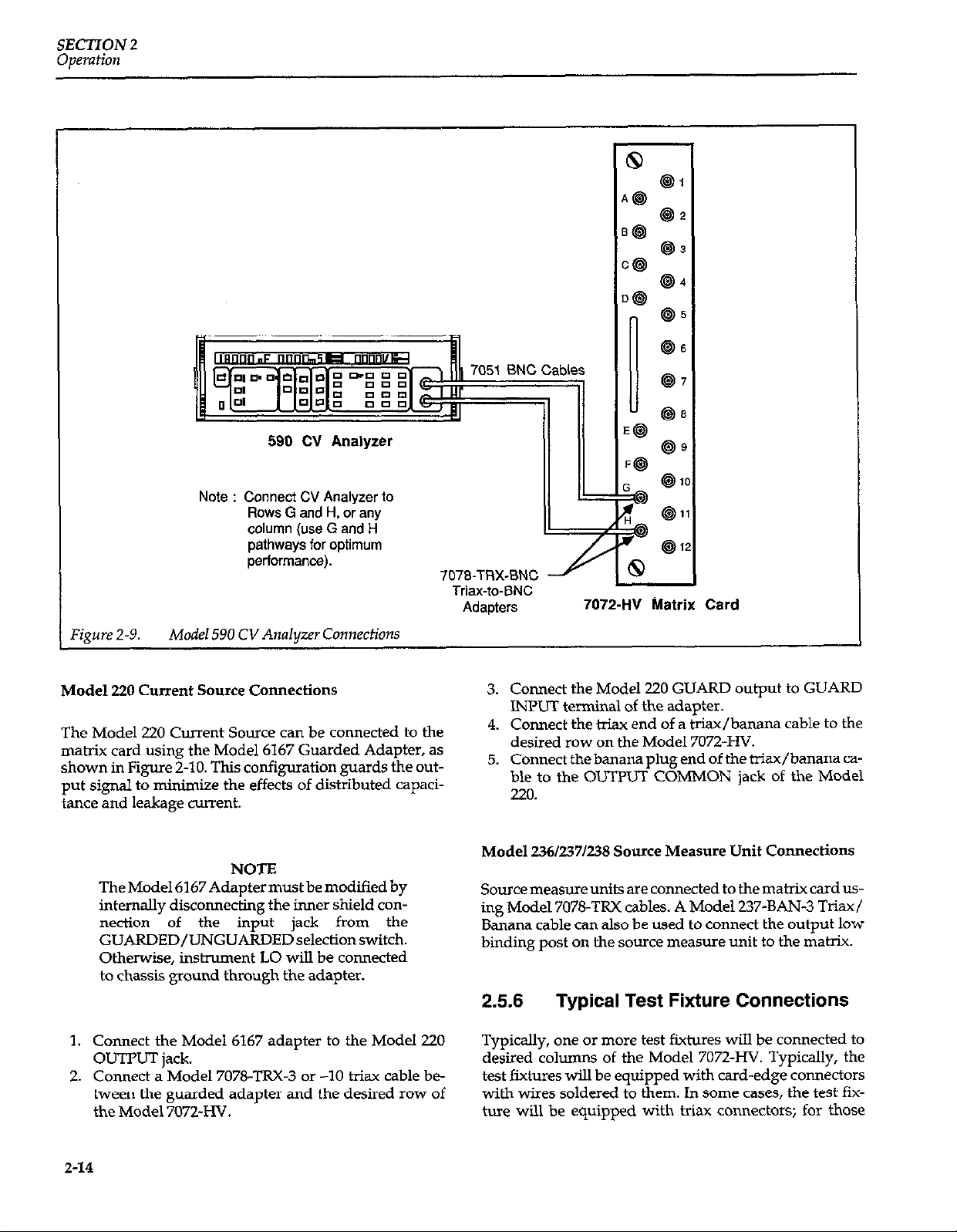

Model 590 CV Analyzer Connections

The Model 590 CV Analyzer should be connected to rows

G and H (CV rows), or any column as shown in Figure

2-9. The BNC cables that are supplied with the Model 590

can be used; however, Model 7078-TRX-BNC triax-toBNC adapters must be used at the Model 707%HV end.

‘igure 2-7.

2-12

(See Figure 2 - 1)

196 DMM

Inner Shield (Connect to LO -

for Low-Level Measurements)

7072WJ Matrix Card

Model 196 Dh4M Connections

Page 30

Common

SECTION 2

Operation

Figure 2-8.

230 Voltage Source

7072-HV Matrix Card

Model 230 Voltage Source Connections

Z-13

Page 31

SECTION 2

Operation

Note : Connect CV Analyzer to

Rows G and H, or any

column (use G and H

pathways for optimum

performance).

Figure 2-9. Model 590 CVAnalyzer Connections

Model 220 Current Source Connections

The Model 220 Current Source can be connected to the

matrix card using the Model 6167 Guarded Adapter, as

shown in Figure 2-10. This configuration guards the output signal to

minimize the effects of distributed capaci-

tance and leakage current.

NOTE

TheModel6167Adaptermust bemodified by

internally disconnecting the inner shield connection of the input jack from the

GUARDED/LJNGUARDEDselectionswitch.

Otherwise, instrument LO will be connected

to chassis ground through the adapter.

Triax-to-BNC

Adapters

7072-HV

Matrix Card

3. Connect the Model 220 GUARD output to GUARD

INPUT terminal of the adapter.

4. Connect the triax end of a triax/banana cable to the

desired row on the Model 7072~HV.

5. Connect the banana plug end of the triax/banana ca-

ble to the OUTPUT COMMON jack of the Model

220.

Model 236/237/238 Source Measure Unit Connections

Sourcemeasureunits are connected to the matrix card using Model 7078.TRX cables. A Model 237;BAN-3 Triaxl

Banana cable can also be used to connect the output low

binding post on the source measure unit to the matrix.

2.5.6

Typical Test Fixture Connections

1. Connect the Model 6167 adapter to the Model 220

OUTPUT jack.

2. Connect a Model 7078-TRX-3 or -10 triax cable between the guarded adapter and the desired row of

the Model 7072~HV.

2-14

Typically, one or more test fixtures will be connected to

desired columns of the Model 7072~HV. Typically, the

test fixtures will be equipped with card-edge connectors

with wires soldered to them. In some cases, the test fixture will be equipped with trlax connectors; for those

Page 32

Use Rows A and B when

Sourcing < 2nA

SECTION 2

OptTL?ti0Fl

II

Guarded Adapter -

Connect GUARD OU?

to GUARD

Figure 2-10. Model 220 Current Source Connections

7078.TRX Triax

IF-l

7072-HV Matrix Card

types, Keithley Model 7078-TRX-3 or -10 cables can be

used, as shown in Figure Z-11.

WARNING

Do not use BNC cables and adapters in cases

where hazardous voltages from guard

s.ource~ could be present on the BNC cable

shields.

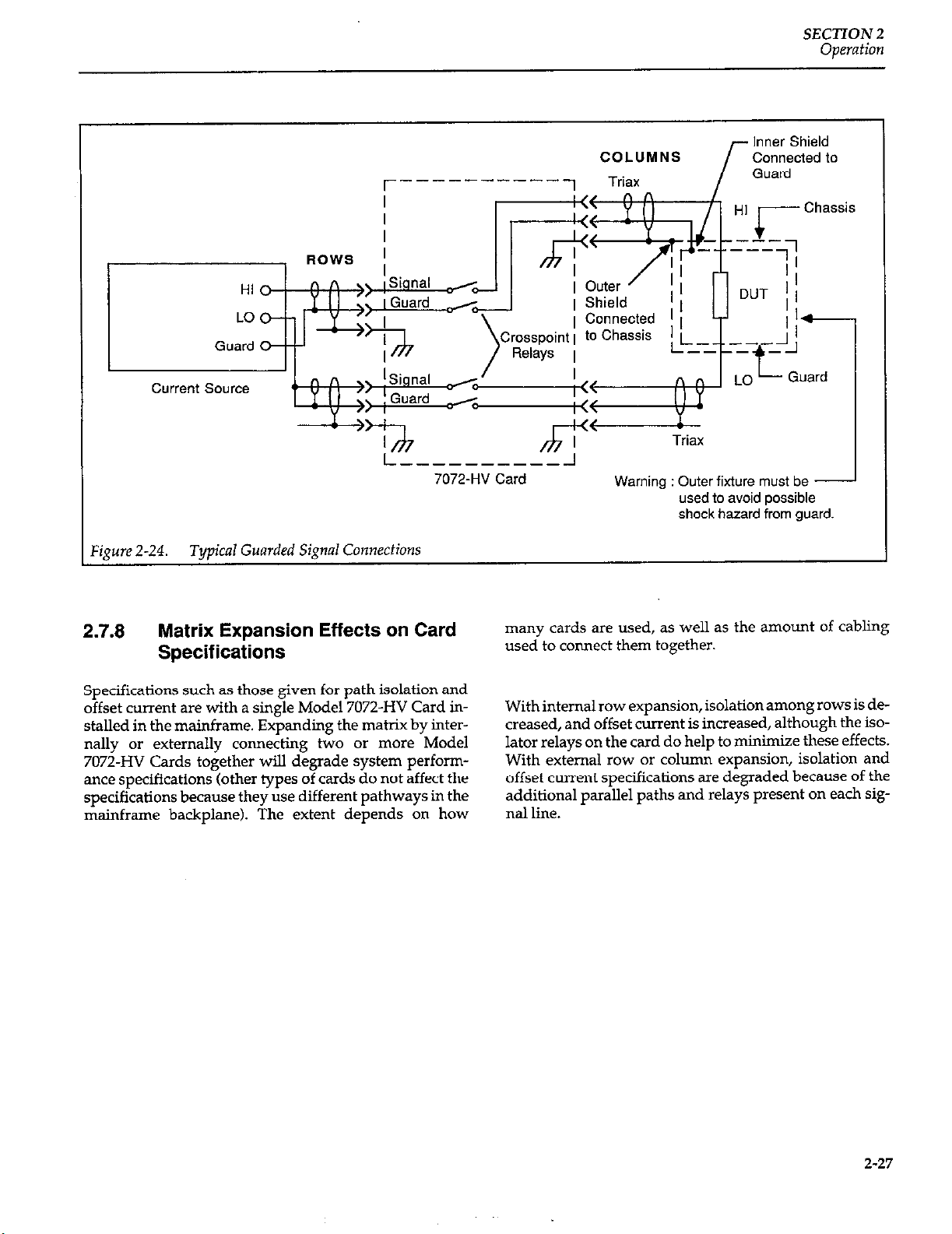

Internally, the test fixture should be wired as shown in

the equivalent circuit of Figure Z-12. SIGNAL should be

connected to the probe or other device contact points,

while GUARD should be carried through as close to the

device as possible. If coaxial probes are to be used, connect GUARD to the probe shield if the probe shield is insulated from the fixture shield.

Usually, the chassis ground terminal of the triax connector will automatically make contact with the fixture

shield by virtue of the mounting method. However,

ground integrity should be checked to ensure continued

protection against hazardous guard voltages.

2-15

Page 33

SECTION 2

Operation

3 - Lug Female

Triax Connectors

(or run cables through strain

reliefs and connect internally)

Note : Teflon@ - insulated connectors

recommended for specified

performance.

Warning : Do not use BNC cO”“ectorS

to avoid possible shock

hazard.

3gure 2-11.

Figure Z-12.

7072-HV Matrix Card

Typical Test Fixture Connections

From

7072-HV

CWd

Equivalent Circuit of Test Fixture

Triw Cable

Co?tne~tiofts

Chassis 1

Ground L

-----

1

Wafer

--_--_--- _I

Test Fixture Chassis

2-16

Page 34

SECTION2

Operation

2.6 MATRIX CONFIGURATION

The following paragraphs discuss the switching matrix

of the Model 707’2~HV as well as how to expand the matrix by connecting two or more cards together.

2.6.1

As showninFigureZ-13, theMode170724Visorganized

as an 8 x 12 (eight row by 12 column) matrix. The rows are

labeled A through H, while the columns on the card are

numbered 1 through 12. The actual column number to

use when programming depends on the slot and unit

number, as summarized in Table 2-3. For example, card

Switching Matrix

column number 2 on a card in slot 5 of unit 1 is accessed as

matrix column 62.

Each intersecting point in the matrixis called a crosspoint

that can be individually closed or opened by programming the Model 707 mainframe. The crosspoints for rows

A through F are configured for 2-pole switching, as

shown in Figure 2-13. For these rows, SIGNAL and

GUARD are switched separately to any of the 12 columns

on the card.

The crosspoints for rows G and H use l-pole switching,

with only SIGNAL being switched. The equivalent circuit for this arrangement is also shown in Figure 2-13.

1

Figure 2-13.

Model 7072-HVMatrix Organization

Crosspoint Switching

for Rows G and H.

Columns

1 - 12

2-17

Page 35

SECTION 2

Operation

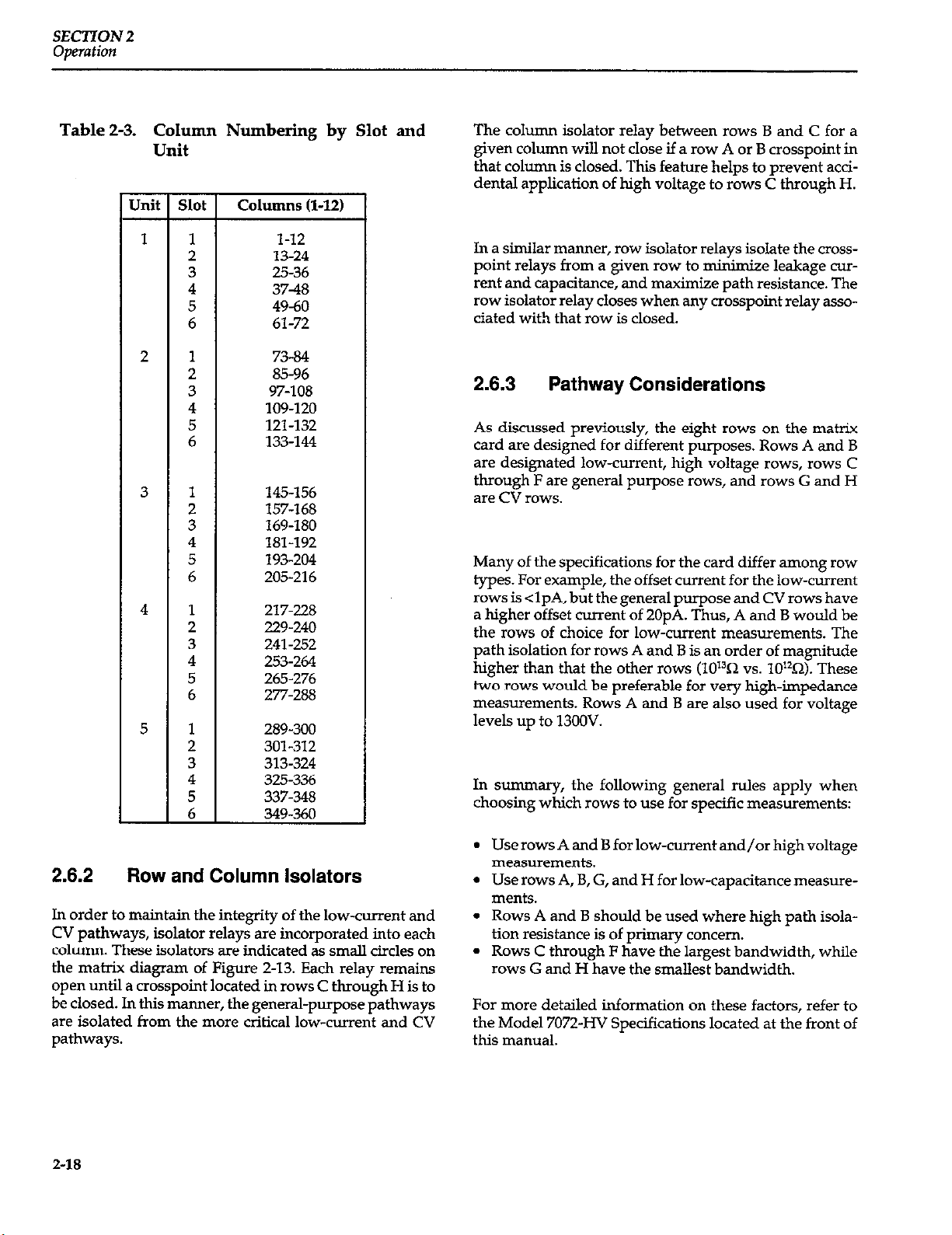

Table 2-3. Column Numbering by Slot and

Unit

Slot

1

2

3

4

5

6

1 73-84

2 85-96

3 97-108

4

5

6

1 145-156

2

3

4 181-192

5 193-204

6

1

2 229-240

3 241-252

4 253-264

5 265276

6 277288

1

2

3

4

5

6

-

2.6.2

In order to maintain the integrity of the low-current and

CV pathways, isolator relays are incorporated into each

column. These isolators are indicated as small circles on

the matrix diagram of Figure 2-13. Each relay remains

open until a crosspoint located in rows C through H is to

be closed. In this manner, the general-purpose pathways

are isolated from the more critical low-current and CV

pathways.

Row and Column Isolators

columns (l-12)

l-12

13-24

25-36

37-48

49-60

61-72

109-120

121-132

133-144

157-168

169-180

205-216

217.228

289-300

301312

313-324

325-336

337-348

349-360

The column isolator relay between rows B and C for a

given column will not close if a row A or B crosspoint in

that column is closed. This feature helps to prevent accidental application of high voltage to rows C through H.

In a similar manner, row isolator relays isolate the crosspoint relays from a given row to minimize leakage current and capacitance, and maximize path resistance. The

row isolator relay closes when any crosspoint relay associated with that row is closed.

2.6.3

As discussed previously, the eight rows on the matrix

card are designed for different purposes. Rows A and B

are designated low-current, high voltage rows, rows C

through F are general purpose rows, and rows G and H

are cv rows.

Many of the specifications for the card differ among row

types. For example, the offset current for the low-current

rows is <IpA, but the general purpose and CV rows have

a higher offset current of 20pA. Thus, A and B would be

the rows of choice for low-current measurements. The

path isolation for rows A and B is an order of magnitude

higher than that the other rows (10% vs. 10’2fL). These

two rows would be preferable for very high-impedance

measurements. Rows A and B are also used for voltage

levels up to 1300v.

In summary, the following general rules apply when

choosing which rows to use for specific measurements:

l Use rows A and B for low-current and/or high voltage

measurements.

l Use rows A, B, G, and H for low-capacitance measure-

ments.

l Rows A and B should be used where high path isola-

tion resistance is of primary concern.

l Rows C through F have the largest bandwidth, while

rows G and H have the smallest bandwidth.

For more detailed information on these factors, refer to

the Model 7072~HV Specifications located at the front of

this manual.

Pathway Considerations

2-18

Page 36

Note : Rows C - F jumpered through backplane.

ROWS A, B, G, and H require installation of coaxial jumpers (shown heavily shaded).

I

Figure 2-14. Connecting Three Cards

for

8 x 36 Matrix

SECTION 2

Operation

2.6.4

Two to six Model 7072-HV cards can be connected to-

gether within the mainframe to yield an 8 x N matrix,

where N depends on the number of cards. Figure 2-14

shows an internally expanded matrix with three cards,

resulting in an 8 x 36 (eight row by 36 column) matrix. As

s-arizedinTable2-3,the actualcolumnnumberused

when programming the unit is determined by the slot.

Rows C through F are automatically connected together

through the backplane of the mainframe. The mainframe

can be configured for two sets of three cards each by removing jumpers from the backplane of the mainframe;

see Section 3 of the Model 707 Instruction Manual for details on removing the jumpers. With the row jumpers removed, rows C through F of Model 7072~HV cards in

slots 1 through 3 are connected, and rows C through F of

Model 7072~HV cards in slots 4 through 6 are connected

together.

Because of more critical signal paths, rows A, B, G, and H

are not jumpered through the backplane. Instead, you

must install the supplied coaxial jumpers between appropriate connectors on Model 7072~HV cards (for critical

signal paths, rows can be isolated from other cards by not

installing these cables). Each card has two coaxial connectors for each row, allowing daisy chaining of card rows.

These connectors can be reached by lifting the access

door on the top of the mainframe; it is not necessary tore-

Internal Matrix Expansion

move cards to install the jumpers. Figure 2-15 shows an

edge-on view of the jumper connectors with row nunbers marked for convenience. Figure 2-16 demonstrates

how three cards can be daisy chained together using the

coaxial jumpers.

WARNING

The shells of the row jumpers are at guard

potential. To avoid a possible shock hazard,

always disconnect all cables from the row

andcolumn jacksbeforeremovingorinstalling jumpers.

2-19

Page 37

SECTION 2

Operation

Figure 2-16.

2.6.5

External jumper cables must be used to expand the num-

her of rows in the matrix, or to connect between columns

of cards installed in different mainframes. An example of

such an expanded matrix is shown in Figure Z-17. Here,

six cards are configured as a 16 x 36 matrix. Since the rows

are internally jumpered, only columns must be jumpered

externally in this config~~ration. Note that the backplane

7’hree Cards in Daisy Chain Configuration

External Matrix Expansion

jumpers must be removed to separate the cards into two

*CUPS.

Trim tee adapters (Model 7078-TIU-T) can be used to

provide daisy chain capability between the triax input

connectors. Figure Z-18 shows a typical arrangement be-

tween two Model 70724-W cards. Ideally, custom-length

biax cables should be used to avoid the cable “jungle”

that would occur with longer, standard-length cables.

Z-20

Page 38

SECTION 2

Operation

Figure 2-17.

16 x 36 Matrix Constructed by External Jumpering

2-21

Page 39

SECTION 2

Operation

Triax Tee

AdaDters

Matrix

Input/Output

Figure 2-18.

Using Trim Tee Adapters to Daisy Chain Cards

2-22

Page 40

SECTION 2

Operation

2.7 MEASUREMENT CONSIDERATIONS

Many measurements made with the Model 7072-HV concern low-level signals. Such measurements are subject to

various types of noise that can seriously affect low-level

measurement accuracy. The following paragraphs discuss possible noise sources that might affect these measurements.

2.7.1 Magnetic Fields

When a conductor cuts through magnetic lines of force, a

very small current is generated. This phenomenon will frequently cause unwanted signals to occur in the test leads of

a switching matrix system. If the conductor has sufÞcient

length, even weak magnetic Þelds like those of the earth

can create sufÞcient signals to affect low-level measurements.

Two ways to reduce these effects are: (1) reduce the

lengths of the test leads, and (2) minimize the exposed

circuit area. In extreme cases, magnetic shielding may be

required. Special metal with high permeability at low

ßux densities (such as mu metal) are effective at reducing

these effects.

Even when the conductor is stationary, magnetically

induced signals may still be a problem. Fields can be produced by various signals such as the AC power line voltage. Large inductors such as power transformers can

generate substantial mangetic Þelds, so care must be

taken to keep the switching and measuring circuits a

good distance away from these potential noise sources.

2.7.2 ELECTROMAGNETIC INTERFERENCE

(EMI)

• impulse sources as in the case of arcing in high-voltage environments

The effect on instrument performance can be considerable

if enough of the unwanted signal is present. A common

problem is the rectiÞcation by semiconductor junctions of

RF picked up by the leads.

The equipment and signal leads should be kept as far

away as possible from any EMI sources. Additional

shielding of the measuring instrument, signal leads, and

sources will often reduce EMI to an acceptable level. In extreme cases, a specially constructed screen room may be

required to sufÞciently attenuate the troublesome signal.

Many instruments incorporate internal Þltering that may

help to reduce RFI effects in some situations. In some cases,

external Þltering may also be required. Such Þltering, however, may have detrimental effects on the desired signal.

2.7.3 Ground Loops

When two or more instruments are connected together,

care must be taken to avoid unwanted signals caused by

ground loops. Ground loops usually occure when sensitive instrumentation is connected to other instrumentation with more than one signal return path such as power

line ground. As shown in Figure 2-19, the resulting

ground loop causes current to ßow through the instrument LO signal leads and then back through power line

ground. This circulating current develops a small but undesirable voltage between the LO terminals of the two instruments. This voltage will be added to the source

voltage, affecting the accuracy of the measurement.

The electromagnetic interference characteristics of the

Model 7072-HV Semiconductor Matrix Card comply with

the electromagnetic compatibility (EMC) requirements of

the European Union as denoted by the CE mark. However, it is still possible for sensitive measurements to be affected by external sources. In these instances, special

precautions may be required in the measurement setup.

Sources of EMI include:

• radio and television broadcast transmitters

• communications transmitters, including cellular

phones and handheld radios

• devices incorporating microprocessors and high

speed digital circuits

SIGNAL LEADS

INSTRUMENT 1

GROUND

CURRENT

INSTRUMENT 2

LOOP

POWER LINE GROUND

INSTRUMENT 3

Figure 2-19. Power Line Ground Loops

Figure 2-20 shows how to connect several instruments together to eliminate this type of ground loop problem.

2-23

Page 41

SECTION 2

Operation

Here, only one instrument is connected to power line

ground.

INSTRUMENT 1

‘igure Z-20.

INSTRUMENT 2

0

0 0

1 1

POWER LlNE GROUNrJ

T

Eliminating Ground Loops

INSTRUMENT

lo

1

3

Ground loops are not normally a problem with instmmats having isolated LO terminals. However, all instmmats in the test setup may not be designed in this manner. When in doubt, consult the manual for each instrument in the test setup.

2.7.5

Noise Currents Caused by Cable

Flexing

Noise currents can be generated by bending or flexing coaxialortriaxialcables. Suchcurrents, whichareknownas

triboelectxic currents, are generated by charges created

between a conductor and insulator caused by friction.

Low-noise cable can be used to minimize these effects.

Such cable has a special graphite coating under the shield

to provide lubrication and to provide a conduction path

to equalize charges.

Even low-noise cable generates some noise currents

when flexed or subjected to vibration. To miniie these

effects, keep the cables as short as possible, and do not