Page 1

I

l

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

nstruction Manua

Models 7015-S and 7015-C

40-Channel Solid-State Multiplexer Cards

Contains Operating and Servicing Information

7015-901-01 Rev. A / 6-93

Page 2

WARRANTY

Keithley Instruments, Inc. w

arrants this product to be free from defects in material and workmanship for a period of 1 year from

date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You

will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility.

Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance

of the original warranty period, or at least 90 days.

LIMITATION OF W

This warranty does not apply to defects resulting from product modification without Keithle

ARRANTY

y’s express written consent, or misuse

of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN

ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS

OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

CHINA: Keithley Instruments China • Y

FRANCE: Keithley Instruments SARL • BP 60 • 3 Allée des Garays • 91122 Palaiseau Cédex • 33-1-60-11-51-55 • Fax: 33-1-60-11-77-26

GERMANY: Keithley Instruments GmbH • Landsberger Strasse 65 • D-82110 Germering, Munich • 49-89-8493070 • Fax: 49-89-84930759

GREAT BRITAIN: Keithley Instruments, Ltd. • The Minster • 58 Portman Road • Reading, Berkshire, England RG3 1EA • 44-1189-596469 • Fax: 44-1189-575666

ITALY: Keithley Instruments SRL • Viale S. Gimignano 38 • 20146 Milano • 39-2-48303008 • Fax: 39-2-48302274

NETHERLANDS: Keithley Instruments BV • Avelingen West 49 • 4202 MS Gorinchem • 31-(0)183-635333 • Fax: 31-(0)183-630821

SWITZERLAND: Keithley Instruments SA • Kriesbachstrasse 4 • 8600 Dübendorf • 41-1-8219444 • Fax: 41-1-8203081

TAIWAN: Keithley Instruments Taiwan • 1FL., 85 Po Ai Street • Hsinchu, Taiwan • 886-3-572-9077 • Fax: 886-3-572-9031

uan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-62022886 • Fax: 8610-62022892

1/99

Page 3

Models 7015-S and 7015-C Instruction Manual

©1993, Keithley Instruments, Inc.

All Rights Reserved

Cleveland, Ohio, U. S. A.

First Printing June 1993

Document Number: 7015-901-01 Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately

into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated

with the previous Revision of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 7015-901-01) ...................................................................................June 1993

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Users of this product must be protected from electric shock at all

times. The responsible body must ensure that users are prevented

access and/or insulated from every connection point. In some cases,

connections must be exposed to potential human contact. Product

users in these circumstances must be trained to protect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts, no conductive part of the circuit may be

exposed.

As described in the International Electrotechnical Commission

(IEC) Standard IEC 664, digital multimeter measuring circuits

(e.g., Keithley Models 175A, 199, 2000, 2001, 2002, and 2010) are

Installation Category II. All other instruments’ signal terminals are

Installation Category I and must not be connected to mains.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures.The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

Page 6

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

Rev. 2/99

Page 7

Model 7015-C, 7015-S

40-Channel Solid State Multiplexer Cards

MULTIPLEX CONFIGURATION: Four independent 1×10 2-pole

multiplex banks or two independent 1×10 4-pole multiplex banks.

Adjacent banks can be connected together. Jumpers can be removed to

isolate any bank from the backplane.

CONTACT CONFIGURATION: 2-pole Form A (Hi, Lo).

CONNECTOR TYPE:

7015-C: 96-pin male DIN connector.

7015-S: Screw terminal, #16AWG maximum wire size, with .092 inch

O.D. 28 conductors per card maximum. #22AWG typical wire size

with .062 inch O.D. 88 conductors per card maximum.

MAXIMUM SIGNAL LEVEL: 175V peak between any two pins, 34mA

resistive load, 0.3VA max., 1 × 106V•Hz max.

COMMON MODE VOLTAGE: 175V peak, any pin to chassis.

CONTACT TYPE: Solid state switch.

CHANNEL RESISTANCE (per conductor): < 210Ω.

Bank A

H I

Channel 1

LO

Channels 2-9

H I

Channel 10

LO

CONTACT POTENTIAL:

7015-C:<5µV per channel contact pair.

7015-S: <4µV per channel contact pair.

OFFSET CURRENT: < 1nA.

ACTUATION TIME: <500µs.

ISOLATION:

Bank: >109Ω, <25 pF.

Channel to Channel: >109Ω, <50 pF.

Differential: Configured as 1×10: >109Ω, <100pF.

Common Mode: Configured as 1×10: >109Ω, <375pF.

INSERTION LOSS (50Ω Source, 1MΩ Load): <0.1dB below 250kHz,

<3dB below 500kHz.

ENVIRONMENT: Operating: 0° to 50°C, up to 35°C at 80% RH.

Configured as 1×40: >109Ω, <200pF.

Configured as 1×40: >109Ω, <1100pF.

Storage: –25°C to 65°C.

Specifications subject to change without notice.

H I

Output

LO

J

J

H I

Backplane

LO

Banks B-C

Bank D

H I

LO

Channels 2-9

H I

Channel 10

LO

Channel 1

J

J

JJ

H I

Output

LO

J

J

H I

Backplane

LO

Page 8

Table of Contents

1 General Information

1.1 Introduction.......................................................................................................................................................... 1-1

1.2 Features ................................................................................................................................................................ 1-1

1.3 Warranty information........................................................................................................................................... 1-1

1.4 Manual addenda ................................................................................................................................................... 1-2

1.5 Safety symbols and terms .................................................................................................................................... 1-2

1.6 Specifications ....................................................................................................................................................... 1-2

1.7 Unpacking and inspection .................................................................................................................................... 1-2

1.7.1 Inspection for damage.................................................................................................................................. 1-2

1.7.2 Shipment contents ........................................................................................................................................ 1-2

1.7.3 Instruction manual........................................................................................................................................ 1-2

1.7.4 Repacking for shipment ...............................................................................................................................1-3

1.8 Optional accessories............................................................................................................................................. 1-3

2 Mutliplexing Basics

2.1 Introduction......................................................................................................................................................... 2-1

2.2 Basic multiplexer configurations .........................................................................................................................2-1

2.2.1 Multiplexer bank-to-bank jumpers............................................................................................................... 2-2

2.2.2 Backplane jumpers....................................................................................................................................... 2-5

2.3 Typical multiplexer switching schemes ............................................................................................................... 2-6

2.3.1 Single-ended switching ................................................................................................................................ 2-6

2.3.2 Differential switching ..................................................................................................................................2-6

2.3.3 Sensing ......................................................................................................................................................... 2-6

2.4 Multiplexer expansion.......................................................................................................................................... 2-8

2.4.1 Multi-card switching systems ......................................................................................................................2-8

2.4.2 Mainframe multiplexer expansion ...............................................................................................................2-9

i

Page 9

3 Card Connections & Installation

3.1 Introduction ..........................................................................................................................................................3-1

3.2 Handling precautions............................................................................................................................................3-1

3.3 Connections ..........................................................................................................................................................3-1

3.3.1 Bank-to-bank jumpers ..................................................................................................................................3-2

3.3.2 Backplane jumpers .......................................................................................................................................3-3

3.3.3 Screw terminal connector card .....................................................................................................................3-4

3.3.4 Multi-pin (mass termination) connector card ...............................................................................................3-6

3.4 Typical connection schemes...............................................................................................................................3-10

3.4.1 Single card system......................................................................................................................................3-10

3.4.2 Two-card system ........................................................................................................................................3-13

3.4.3 Multiple-card systems ................................................................................................................................3-13

3.4.4 Two-mainframe system ..............................................................................................................................3-13

3.5 Model 7015 installation and removal .................................................................................................................3-18

4 Operation

4.1 Introduction ..........................................................................................................................................................4-1

4.2 Maximum signal levels.........................................................................................................................................4-1

4.3 Mainframe control of multiplexer card ................................................................................................................4-1

4.3.1 Channel assignments ....................................................................................................................................4-1

4.3.2 Front panel control .......................................................................................................................................4-3

4.3.3 IEEE-488 bus operation ...............................................................................................................................4-4

4.4 Multiplexer applications.......................................................................................................................................4-5

4.4.1 High-speed scanning ....................................................................................................................................4-5

4.4.2 Resistor testing .............................................................................................................................................4-7

4.4.4 Testing with matrix cards ...........................................................................................................................4-10

4.4.3 Transistor current gain testing ....................................................................................................................4-10

4.5 Measurement considerations ..............................................................................................................................4-12

4.5.1 Thermoelectric potentials ...........................................................................................................................4-12

4.5.2 Channel resistance ......................................................................................................................................4-13

4.5.3 Path isolation ..............................................................................................................................................4-14

4.5.4 Magnetic fields ...........................................................................................................................................4-15

4.5.5 Radio frequency interference .....................................................................................................................4-15

4.5.6 Ground loops ..............................................................................................................................................4-15

4.5.7 Keeping connectors clean...........................................................................................................................4-16

4.5.8 Scanning speed considerations ...................................................................................................................4-16

5 Service Information

5.1 Introduction ..........................................................................................................................................................5-1

5.2 Handling and cleaning precautions ......................................................................................................................5-1

5.3 Performance verification .....................................................................................................................................5-2

5.3.1 Environmental conditions.............................................................................................................................5-2

5.3.2 Recommended equipment ............................................................................................................................5-2

5.3.3 Multiplexer card connections .......................................................................................................................5-3

5.3.4 Channel resistance tests................................................................................................................................5-3

5.3.5 Offset current tests........................................................................................................................................5-4

5.3.6 Contact potential tests...................................................................................................................................5-6

5.3.7 Bank and channel-to-channel isolation tests ................................................................................................5-7

5.3.8 Differential and common-mode isolation tests...........................................................................................5-11

ii

Page 10

5.4 Special handling of static-sensitive devices....................................................................................................... 5-13

5.5 Principles of operation .......................................................................................................................................5-13

5.5.1 Block diagram ............................................................................................................................................ 5-13

5.5.2 ID data circuits ........................................................................................................................................... 5-14

5.5.3 Relay control .............................................................................................................................................. 5-15

5.5.4 Power-on safeguard.................................................................................................................................... 5-15

5.6 Troubleshooting ................................................................................................................................................. 5-16

5.6.1 Troubleshooting equipment .......................................................................................................................5-16

5.6.2 Troubleshooting access .............................................................................................................................. 5-16

5.6.3 Troubleshooting Procedure ........................................................................................................................ 5-16

6 Replaceable Parts

6.1 Introduction.......................................................................................................................................................... 6-1

6.2 Parts lists .............................................................................................................................................................. 6-1

6.3 Ordering information ........................................................................................................................................... 6-1

6.4 Factory service ..................................................................................................................................................... 6-1

6.5 Component layouts and schematic diagrams .......................................................................................................6-1

iii

Page 11

×

×

×

List of Illustrations

2 Multiplexing Basics

Figure 2-1 Model 7015 simplified schematic .............................................................................................................. 2-2

Figure 2-2 Four 1

Figure 2-3 Two 1

Figure 2-4 One 1

Figure 2-5 Model 7001/7002 analog backplane .......................................................................................................... 2-5

Figure 2-6 Bank connections to backplane .................................................................................................................. 2-6

Figure 2-8 Differential switching example .................................................................................................................. 2-7

Figure 2-9 Sensing example......................................................................................................................................... 2-7

Figure 2-7 Single-ended switching example................................................................................................................ 2-7

Figure 2-10 Two separate multiplexer systems ............................................................................................................. 2-8

Figure 2-11 Multiplexer input expansion example ........................................................................................................ 2-9

Figure 2-12 Mixed card type example ......................................................................................................................... 2-10

10 multiplexer configuration (jumpers not installed) .................................................................. 2-3

20 multiplexer configuration (jumpers installed) ........................................................................ 2-3

40 multiplexer configuration (jumpers installed) ......................................................................... 2-4

3 Card Connections & Installation

Figure 3-1 Bank-to-bank jumper locations .................................................................................................................. 3-2

Figure 3-2 Bank-to-bank jumper terminal identification............................................................................................. 3-2

Figure 3-3 Bank-to-bank jumper installation............................................................................................................... 3-3

Figure 3-4 Backplane jumpers ..................................................................................................................................... 3-4

Figure 3-5 Model 7015 screw terminal connector card ............................................................................................... 3-4

Figure 3-6 Typical screw terminal connections........................................................................................................... 3-5

Figure 3-7 Cable clamp for screw terminal connector card......................................................................................... 3-5

Figure 3-8 Typical round cable connection techniques ............................................................................................... 3-8

Figure 3-9 Model 7011-MTR connector pinout .......................................................................................................... 3-9

Figure 3-10 Model 7011-KIT-R (with/cable) assembly ................................................................................................ 3-9

Figure 3-11 Single-card system example (multi-pin connector card).......................................................................... 3-11

Figure 3-12 Single card system example (screw terminal connector card) ................................................................. 3-12

Figure 3-13 Two-card system example (multi-pin connector card) ............................................................................ 3-14

Figure 3-14 Two-card system example (screw terminal connector card).................................................................... 3-15

Figure 3-15 Two-mainframe system example (multi-pin connector card) .................................................................. 3-16

Figure 3-16 Two-mainframe system example (screw terminal connector card) ......................................................... 3-17

Figure 3-17 Model 7015 card installation in Model 7001 ........................................................................................... 3-19

Figure 3-18 Model 7015 card installation in Model 7002 ........................................................................................... 3-19

v

Page 12

4 Operation

Figure 4-1 Channel status display ................................................................................................................................ 4-2

Figure 4-2 Display organization for multiplexer channels........................................................................................... 4-2

Figure 4-3 Model 7015 programming channel assignments ........................................................................................ 4-3

Figure 4-4 High-speed scanning connections............................................................................................................... 4-6

Figure 4-5 Four-wire resistance testing........................................................................................................................ 4-8

Figure 4-6 Low-resistance testing ................................................................................................................................ 4-9

Figure 4-7 Configuration for current gain test ........................................................................................................... 4-11

Figure 4-8 Connecting multiplexer and matrix cards together................................................................................... 4-12

Figure 4-9 Thermoelectric generation ........................................................................................................................ 4-13

Figure 4-10 Channel resistance .................................................................................................................................... 4-13

Figure 4-11 Path isolation resistance............................................................................................................................ 4-14

Figure 4-12 Voltage attenuation by path isolation resistance ...................................................................................... 4-14

Figure 4-13 Power line ground loops ........................................................................................................................... 4-15

Figure 4-14 Eliminating ground loops ......................................................................................................................... 4-16

5 Service Information

Figure 5-1 Path resistance test connections.................................................................................................................. 5-4

Figure 5-2 Differential and common mode offset current test connections................................................................. 5-5

Figure 5-3 Contact potential test connections .............................................................................................................. 5-6

Figure 5-4 Bank isolation test connections .................................................................................................................. 5-7

Figure 5-5 Channel-to-channel isolation test connections ........................................................................................... 5-9

Figure 5-6 Differential isolation test connections ...................................................................................................... 5-11

Figure 5-7 Common-mode isolation test connections................................................................................................ 5-13

Figure 5-8 Model 7015 block diagram....................................................................................................................... 5-14

Figure 5-9 Start and stop sequences ........................................................................................................................... 5-15

Figure 5-10 Transmit and acknowledge sequence ....................................................................................................... 5-15

vi

Page 13

List of Tables

3 Card Connections & Installation

Table 3-2 Bank-to-bank jumpers (on connector card)................................................................................................. 3-2

Table 3-3 Backplane jumpers (on relay card).............................................................................................................. 3-3

Table 3-6 Multipin card terminal identification ..........................................................................................................3-6

Table 3-7 Mass termination accessories ...................................................................................................................... 3-7

4 Operation

Table 4-7 Paired Channels in 4-pole Operation ..........................................................................................................4-7

5 Service Information

Table 5-2 Verification equipment................................................................................................................................ 5-2

Table 5-8 Bank isolation test summary ....................................................................................................................... 5-8

Table 5-9 Channel-to-channel isolation test summary ................................................................................................ 5-9

Table 5-12 Differential and common-mode isolation testing...................................................................................... 5-12

Table 5-16 Recommended troubleshooting equipment............................................................................................... 5-16

Table 5-17 Troubleshooting procedure .......................................................................................................................5-17

vii

Page 14

×

1

General Information

1.1 Introduction

This section contains general information about the Model

7015 40-Channel Solid-State Multiplexer Card.

There are two basic versions of this multiplexer card; the

Model 7015-S and the Model 7015-C. The Model 7015-S assembly consists of a screw terminal connector card and a relay card. External test circuits are wired directly to the screw

terminals of the connector card. Also available from Keithley

is the Model 7015-ST, which is an extra screw terminal connector card. With an extra connector card, you can wire a

second test system without disturbing the wiring configura

tion of the first test system.

The Model 7015-C assembly consists of a multi-pin (mass

termination) connector card and the relay card. External test

circuit connections to the multiplexer are made via the 96pin male DIN connector on the connector card. Keithley offers a variety of optional accessories that can be used to make

connections to the connector card (see paragraph 1.8).

The rest of Section 1 is arranged in the following manner:

1.7 Unpacking and inspection

1.8 Repacking for shipment

1.9 Optional accessories

1.2 Features

The Model 7015 is a solid-state, two-pole, quad, 1

tiplexer card. Some of the key features include:

• Solid-state relays for fast switching, indefinite “contact” life, and quiet operation.

• Low contact potential and offset current for minimal effects on low-level signals.

• The connector board detaches from the relay board allowing easy access to the screw terminals (Model 7015S) and jumpers.

• Easy jumper configuration of one, two, three or four

multiplexer banks.

• Backplane jumpers. Cutting jumpers disconnects multiplexer bank outputs from the Model 7001 or Model

7002 analog backplane.

10 mul-

1.2 Features

1.3 Warranty information

1.4 Manual addenda

1.5 Safety symbols and terms

1.6 Specifications

1.3 Warranty information

Warranty information is located on the inside front cover of

this instruction manual. Should your Model 7015 require

warranty service, contact the Keithley representative or authorized repair facility in your area for further information.

1-1

Page 15

General Information

×

When returning the multiplexer card for repair, be sure to fil

out and include the service form at the back of this manual in

order to provide the repair facility with the necessary information.

1.4 Manual addenda

Any improvements or changes concerning the multiplexer

card or manual will be explained in an addendum included

with the card. Addenda are provided in a page replacement

format. Simply replace the obsolete pages with the new pages.

1.5 Safety symbols and terms

The following symbols and terms may be found on an instrument or used in this manual.

!

The symbol on an instrument indicates that the user

should refer to the operating instructions located in the instruction manual.

1.7 Unpacking and inspection

1.7.1 Inspection for damage

The Model 7015 is packaged in a re-sealable, anti-static bag

to protect it from damage due to static discharge and from

contamination that could degrade its performance. Before removing the card from the bag, observe the following precautions on handling.

Handling Precautions:

1. Always grasp the card by the side edges and shields. Do

not touch the board surfaces or components.

2. When not installed in a Model 7001/7002 mainframe,

keep the card in the anti-static bag and store it in the original packing carton.

After removing the card from its anti-static bag, inspect it for

any obvious signs of physical damage. Report any such damage to the shipping agent immediately.

1.7.2 Shipment contents

The WARNING heading used in this manual explains dangers that might result in personal injury or death. Always

read the associated information very carefully before performing the indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage the multiplexer card. Such damage

may invalidate the warranty.

1.6 Specifications

Model 7015 specifications are found at the front of this manual. These specifications are exclusive of the multiplexer

mainframe specifications

The following items are included with every Model 7015 order:

• Model 7015 Quad 1

• Model 7015 Instruction Manual

• Additional accessories as ordered

10 Multiplexer Card

1.7.3 Instruction manual

If an additional instruction manual is required, order the

manual package, Keithley part number 7015-901-00. The

manual package includes an instruction manual and any pertinent addenda.

1-2

Page 16

General Information

1.7.4 Repacking for shipment

Should it become necessary to return the Model 7015 for repair, carefully pack the unit in its original packing carton or

the equivalent, and include the following information:

• Advise as to the warranty status of the multiplexer card.

• Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

• Fill out and include the service form located at the back

of this manual.

1.8 Optional accessories

The following accessories are available for use with the

Model 7015:

Model 7015-ST This screw terminal connector card is

identical to the one provided with the Model 7015-S assembly. An extra screw terminal connector card allows you to

wire a second test system without disturbing the wiring configuration of the first connector card

Model 7011-KIT-R This connection kit includes a 96-pin

female DIN connector that will mate directly to the connector on the Model 7015-C or to a standard 96-pin male DIN

bulkhead connector (see Model 7011-MTR). This connector

uses solder cups for connections to external circuitry. It includes an adapter for a round cable and the housing.

Model 7011-MTC-2 This 2-meter round cable assembly

is terminated with a 96-pin female DIN connector on each

end. It will mate directly to the connector on the Model

7015-C and to a standard 96-pin male DIN bulkhead connector (see Model 7011-MTR).

Model 7011-MTR This 96-pin male DIN bulkhead con-

nector uses solder cups for connections to external circuitry.

It will mate to the Model 7011-KIT-R connector, and Model

7011-MTC-2 cable assembly.

1-3

Page 17

×

×

×

2

Multiplexing Basics

2.1 Introduction

This section covers the basics for multiplex switching and is

arranged as follows:

2.2 Basic multiplex configurations: Covers the basic

multiplex configurations: quad 1

20 configuration and single 1

nificance of the backplane jumpers is also c vered here.

2.3 Typical multiplex switching schemes: Explains

some of the basic ways a multiplexer can be used to switch

source or measure applications. Covers single-ended switching, differential (floating) switching and sensing.

10 configuration, dual 1

40 configuration. The sig-

2.4 System expansion: Discusses the various configura

tions that are possible by using multiple cards.

2.2 Basic multiplexer configurations

A simplified schematic of the Model 7015 multiplexer card

is shown in Figure 2-1. It is organized as four

plexer banks. Each bank has 10 inputs and one output. Twopole switching is provided for each multiplexer input, with

HI and LO switched. Two or more banks can be jumpered together to expand multiplexer inputs, and backplane jumpers

provide bank connections to a second card installed in a

Model 7001 or Model 7002 mainframe.

1 ×

10 multi-

2-1

Page 18

Multiplexing Basics

×

×

×

×

×

×

7015

110

Inputs

Bank A

Bank B

Outputs

Bank C

Bank D

110

110

110

HI

LO

(Solid State Switching)

Figure 2-1

Model 7015 simplified s hematic

Input (1 of 40)

HI

Bank

Switching Topology

for all Channels

LO

HI

LO

HI

LO

Bank to Bank

Note : Factory Configuration shown

C

Jumpers

D

Jumpers

HI

LO

Backplane Jumpers

(to 7001/7002 Analog

Backplane)

HI

LO

2.2.1 Multiplexer bank-to-bank jumpers

Jumpers are installed on the connector card to connect multiplexer banks together to form a 1

jumper set connects two adjacent banks together. These

jumper sets are included with the Model 7015.

The bank-to-bank jumpers allow you to configure the multiplexer card in a variety of ways. Typical multiplexer config

urations include:

40 multiplexer. Each

• Four 1

10 multiplexers; no jumpers installed (Figure

2-2).

•Two 1

20 multiplexers; Bank A jumpered to Bank B,

Bank C jumpered to Bank D (Figure 2-3).

• One 1

40 multiplexer; all bank-to-bank jumpers in-

stalled (Figure 2-4).

Other combinations are possible, including multiplexers of

various sizes (in multiples of 10 channels). For example, you

could install jumpers to configure the card as one 1

one 1

10 multiplexer.

30 and

Refer to Section 3 for information on installing bank-to-bank

jumpers.

2-2

Page 19

F

Multiplexing Basics

Inputs

1

Bank A

10

2

2

2

Output A

1

Bank B

10

1

Bank C

10

1

Bank D

10

2

2

2

2

2

2

Figure 2-2

Four 1 × 10 multiplexer configu ation (jumpers not installed)

Inputs

1

Bank A

10

1

Bank B

10

2

2

2

2

2

2

2

2

2

Output B

Output C

Output D

Output A

2

Jumpers

1

Bank C

10

1

Bank D

10

2

2

2

2

2

2

Output C

2

Jumpers

igure 2-3

Two 1 × 20 multiplexer configu ation (jumpers installed)

2-3

Page 20

Multiplexing Basics

F

Bank A

Bank B

Bank C

Bank D

Inputs

1

10

1

10

1

10

1

10

2

2

2

2

2

2

2

2

2

2

2

2

Output A

2

Jumpers

2

Jumpers

2

Jumpers

igure 2-4

One 1 × 40 multiplexer configu ation (jumpers installed)

2-4

Page 21

Multiplexing Basics

2.2.2 Backplane jumpers

There are four pairs of backplane jumpers located on the relay card. With the jumpers installed, the banks of the multiplexer card are connected to the analog backplane of the

Model 7001/7002 allowing expansion with a second card installed in the mainframe. With the jumpers removed (cut),

the multiplexer card is isolated from another card installed in

the same mainframe.

Model 7001/7002

Card 1 Card 2

H

L

G

H

Row 1 or Bank A

Row 2 or Bank B

The three-pole analog backplane of the Model 7001/7002

mainframe is shown in Figure 2-5. Through this analog backplane, the banks of a Model 7015 multiplexer card, installed

in one slot, can be connected to the banks (or rows) of a compatible card installed in another slot of the mainframe.

Note that the Model 7002 also has backplane jumpers, which

can be used to isolate cards into two groups of fi e.

Analog

Backplane

H

L

G

H

Figure 2-5

Model 7001/7002 analog backplane

H = High

L = Low

G = Guard

L

G

H

L

G

H

L

G

Row 3 or Bank C

Row 4 or Bank D

L

G

H

L

G

H

L

G

Row = Matrix Card (7012)

Bank = MUX Card (7015)

2-5

Page 22

Multiplexing Basics

Ω

Ω

Figure 2-6 shows how each bank of the Model 7015 is connected to the backplane. Notice that since the Model 7015 is

a two-pole card, there is no connection made to the Guard

terminal of the backplane. The Model 7015 is shipped from

the factory with the backplane jumpers installed.

7001/7002

Analog

Backplane

H

L

G

H

L

H = High

L = Low

G = Guard

7015

Bank

(1 of 4)

Backplane

Jumpers

Figure 2-6

Bank connections to backplane

Removing (cutting) the backplane jumpers isolates the card

from the backplane, and subsequently, any card installed in

an other slot. For information on removing the jumpers, refer

to Section 3.

NOTE

The Model 7001/7002 does not provide an

analog backplane for the non-701X series

cards. As a result, any of these cards installed in one slot in the mainframe is electrically isolated from any card(s) installed

in an other slot. The only way to connect a

Model 7015 to one of these cards is to wire

them together using the connector blocks

or terminals.

2.3 Typical multiplexer switching schemes

The following paragraphs describe some basic switching

schemes that are possible with a two-pole switching multiplexer. These switching schemes include some various

shielding configurations to help minimize noise pickup in

sensitive measurement applications. These shields are shown

connected to chassis ground. For some test configurations

shielding may prove to be more effective with shields connected to circuit common or LO. Chassis ground is accessible at the rear panel of the Model 7001/7002.

2.3.1 Single-ended switching

In the single-ended switching configuration, the source or

measure instrument is connected to the DUT through a single pathway, as shown in Figure 2-7. The instrument is connected to the output of one of the banks, and the DUT is

shown connected to one of the inputs for that bank.

2.3.2 Differential switching

The differential or floating switching configuration is shown

in Figure 2-8. The advantage of using this configuration is

that the terminals of the source or measure instrument are not

confined to the same pathway. Each terminal of the instrument can be switched to any available input in the test system.

2.3.3 Sensing

Figure 2-9 shows how the multiplexer card can be configure

to use instruments that have sensing capability. The main advantage of using sensing is to cancel the effects of switch

card path resistance (<210

tance of external cabling. Whenever path resistance is a consideration, sensing should be used.

, <130

typical) and the resis-

2-6

Page 23

Multiplexing Basics

HI

LO

Source or

Measure

Figure 2-7

Single-ended switching example

LO

Bank A-D Input 1-10

H

Out In

L

7015

Bank A, B Input 1-10

HI

Out In

Out In

H

L

H

L

Optional

Shield

DUT

DUT

Source or

Measure

Figure 2-8

Differential switching example

Source HI

Sense HI

Sense LO

Source LO

Source or

Measure

Figure 2-9

Sensing example

Bank C, D Input 1-10

Bank A, B

7015

H

Out In

L

H

Out In

L

Input 1-10

7015

Bank C, D Input 1-10

DUT

2-7

Page 24

Multiplexing Basics

×

×

×

2.4 Multiplexer expansion

With the use of additional switching cards and mainframes,

larger systems can be configured. Each Model 7001 Switch

System mainframe will accommodate up to two cards, and

the Model 7002 Switch System mainframe can accommodate up to 10 cards.

2.4.1 Multi-card switching systems

Separate switching systems

Multiple single-card systems can be configured by removing

the backplane jumpers from each additional card. All cards

will be controlled by the same mainframe, but they will be

electrically isolated from each other. Figure 2-10 shows an

example using two Model 7015 multiplexer cards.

Multiplexer input expansion

You can double the number of multiplexer inputs by simply

installing two “as shipped” Model 7015s in the Model 7001

mainframe. Similarly, the number of multiplexer inputs can

be increased by a factor of 10 by installing 10, “as shipped”

Model 7015s in a Model 7002. By leaving the backplane

jumpers installed, the banks of the multiplexer card installed

in slot 1 (CARD 1) are automatically connected to the banks

of the multiplexer card installed in slot 2 (CARD 2) through

the analog backplane (and with any remaining cards installed

in a Model 7002).

Figure 2-11 shows an example of input expansion. Each

Model 7015 card is configured as four 1

10 multiplexers.

By connecting the banks together (via Model 7001/7002 analog backplane), the resulting multiplexer system has 20 2pole inputs for each of the four banks. Note that, if all the

bank-to-bank jumpers on any card are installed (as shipped),

the result would be a single 1

80 multiplexer. A total of 10

Model 7015 cards installed in a Model 7002 would yield a

single 1

400 multiplexer with all bank-to-bank jumpers in-

stalled.

NOTE

Connecting any two banks on one card together also connects the corresponding

banks of the backplane together. Thus, the

corresponding banks of other card(s) will

be connected together even if the bank-tobank jumpers on those cards are not installed.

110

Bank A

110

Bank B

110

Bank C

110

Bank D

Four 1x10 Multiplexers

Figure 2-10

Two separate multiplexer systems

Card 1

7015

7001/7002

Backplane

Backplane

Jumpers

Removed

Analog

Card 2

7015

110

110

110

110

Four 1x10 Multiplexers

2-8

Page 25

Card 1

7001/7002

Analog

Backplane

Multiplexing Basics

Card 2

110

7015

Bank A

110

Bank B

110

Bank C

110

Bank D

Quad 1x10 Multiplexers

Quad 1x20 Multiplexer

Figure 2-11

Multiplexer input expansion example

Mixing card types

Different types of cards can be used together to create some

unique switching systems. For example, you could have a

Model 7015 multiplexer card installed in one slot and a Model 7012 matrix card installed in another slot.

110

7015

110

110

110

Quad 1x10 Multiplexers

Backplane

Jumpers

installed

multiplexer banks. On the multiplexer card, the bank-tobank jumpers must be removed to maintain isolation between matrix rows. See the instruction manual for the Model

7012 for complete information on the matrix card.

2.4.2 Mainframe multiplexer expansion

Figure 2-12 shows one possible switching system using a

matrix card and a multiplexer card. The backplane jumpers

for both the matrix and multiplexer cards must be installed.

This arrangement allows matrix rows to be connected to

Multiplexer systems using up to 12 or 60 multiplexer cards

are possible by using six Model 7001 or 7002 mainframes together. Each Model 7015 added to the system provides 40

additional inputs. Paragraph 3.4.3 explains how to connect a

test system using two mainframes.

2-9

Page 26

Multiplexing Basics

110

1

2

Rows

3

4

Notes : 1. Models 7015 and 7012 backplane jumpers

must be installed.

2. Model 7015 bank-to-bank jumpers must be

removed.

Figure 2-12

Mixed card type example

Card 1

7012

Columns

4 x 10 Matrix

7001/7002

Backplane

Card 2

7015

110

110

110

110

Inputs

Bank A

Bank B

Bank C

Bank D

Quad 1 x 10 Mux

2-10

Page 27

3

Card Connections & Installation

3.1 Introduction

WARNING

The procedures in this section are intended only for qualified service personnel. Do not perform these procedures

unless qualified to do so. Failure to recognize hazards and observe normal

safety precautions could result in personal injury or death.

The information in this section is arranged as follows:

3.2 Handling precautions: Explains precautions that

must be followed to prevent contamination to the multiplexer card assembly. Contamination could degrade

the performance of the multiplexer card.

3.3 Connections: Covers the basics for connecting exter-

nal circuitry to the two available connector cards for

the multiplexer; the screw terminal connector card and

the multi-pin connector card.

3.2 Handling precautions

To maintain high-impedance isolation, care should be taken

when handling the relay card to avoid contamination from

such foreign materials as body oils. Such contamination can

substantially lower leakage resistances, thus degrading performance.

To avoid possible contamination, always grasp the relay and

connector cards by the side edges or shields. Do not touch

the board surfaces, components, or areas adjacent to the electrical contacts. Dirt build-up over a period of time is another

possible source of contamination. To avoid this problem, operate the mainframe and multiplexer card in a clean environment.

If a card becomes contaminated, it should be thoroughly

cleaned as explained in paragraph 5.2.

3.3 Connections

3.4 Typical connection schemes: Provides some typical

connection schemes for single card, two-card and twomainframe system configurations.

3.5 Model 7015 installation: Provides a procedure to in-

stall the multiplexer card assembly in the Model 7001

or Model 7002 mainframe.

This paragraph provides the basic information needed to

connect your external test circuitry to the multiplexer. It includes the installation of the bank-to-bank jumpers on the

connector card, installation/removal of backplane jumpers

on the relay card, and detailed information on making external connections to the two available connector cards.

3-1

Page 28

Card Connections & Installation

WARNING

The following connection information is

intended to be used by qualified service

personnel. Failure to recognize hazards

and observe standard safety precautions

could result in personal injury or death.

3.3.1 Bank-to-bank jumpers

As explained in paragraph 2.2.1, the banks of the multiplexer

card can be connected together (using plug-in jumpers) to

form larger multiplexers. The locations of the bank-to-bank

jumper terminals for both connector cards are shown in Figure 3-1.

Terminal identification is provided by Figure 3-2. On the

drawing, the six terminal pairs are labeled W100 through

W105. The top three terminal pairs (W101, W103 and

W105) are used to connect the LO terminals of the banks together. The bottom terminal pairs (W100, W102 and W104)

are used to connect the HI terminals of the banks together.

Table 3-1 summarizes the purpose of each jumper.

Bank

A to B

LO

W101

HI

W100

Bank

B to C

W103

W102

Figure 3-2

Bank-to-bank jumper terminal identificatio

Table 3-1

Bank-to-bank jumpers (on connector card)

Installed

jumper* Connection

W101

W100

W103

W102

W105

W104

*See Figure 3-1 for location.

Bank A LO to Bank B LO

Bank A HI to Bank B HI

Bank B LO to Bank C LO

Bank B HI to Bank C HI

Bank C LO to Bank D LO

Bank C HI to Bank D HI

Bank

C to D

W105

W104

Jumper Terminals

A. Screw Terminal Connector

Card (Model 7015-S)

Figure 3-1

Bank-to-bank jumper locations

3-2

Bank-to-Bank

Bank-to-Bank

Jumper Terminals

B. Multi-pin Connector Card

(Model 7015-C)

Page 29

Card Connections & Installation

Referring to Figure 3-1 for jumper locations, perform the following steps to install bank-to-bank jumpers:

1. If mated together, separate the relay card from the connector card by removing the mounting screw and pulling

the two cards away from each other. Remember to handle the cards only by the edges and shields to avoid contamination.

2. Refer to Figure 3-2 and Table 3-1 to determine which

jumpers to install.

3. Using Figure 3-3 as a guide, install the jumpers on the

appropriate terminal pairs.

Jumper

Jumper Terminal

Pair

Figure 3-3

Bank-to-bank jumper installation

1. If mated together, separate the relay card from the connector card by removing the mounting screw and pulling

the two cards away from each other. Remember to handle the cards only by the edges and shields to avoid contamination.

2. Use Figure 3-4 and Table 3-2 to locate the jumpers that

are to be removed.

3. It is not necessary to unsolder the jumpers from the PC

board. Using a pair of wire cutters, cut both ends of each

jumper, then remove each cut jumper completely.

Table 3-2

Backplane jumpers (on relay card)

Jumper* Backplane connection

W100

W101

W102

W103

W104

W105

W106

W107

*See Figure 3-4 for location.

Bank A HI

Bank A LO

Bank B HI

Bank B LO

Bank C HI

Bank C LO

Bank D HI

Bank D LO

3.3.2 Backplane jumpers

The Model 7001 and Model 7002 mainframes have an analog backplanes that allow the banks of a Model 7015 multiplexer to be internally connected to a compatible switching

card installed in another slot (see paragraph 2.4.1 for details).

The backplane jumpers for the multiplexer card assembly are

located on the relay card as shown in Figure 3-4, and Table

3-2 summarizes jumper connections. The card is shipped

from the factory with the jumpers installed.

Jumper removal

Perform the following steps to remove backplane jumpers:

Jumper installation

Referring to Figure 3-4 for jumper locations, perform the following steps to install backplane row jumpers:

1. If mated together, separate the relay card from the connector card by removing the mounting screw and pulling

the two cards away from each other. Remember to handle the cards only by the edges and shields to avoid contamination.

2. Physically remove a cut jumper by unsoldering the two

cut ends from the PC board.

3. Install a new #22 AWG jumper wire (Keithley P/N J-

15), and solder it to the PC board.

4. Remove the solder flux from the PC board. The cleaning

procedure is explained in paragraph 5.2.

3-3

Page 30

Card Connections & Installation

Backplane Jumpers

7015 Relay Card

W100

W101

W102

W103

W104

W105

W106

W107

Figure 3-4

Backplane jumpers

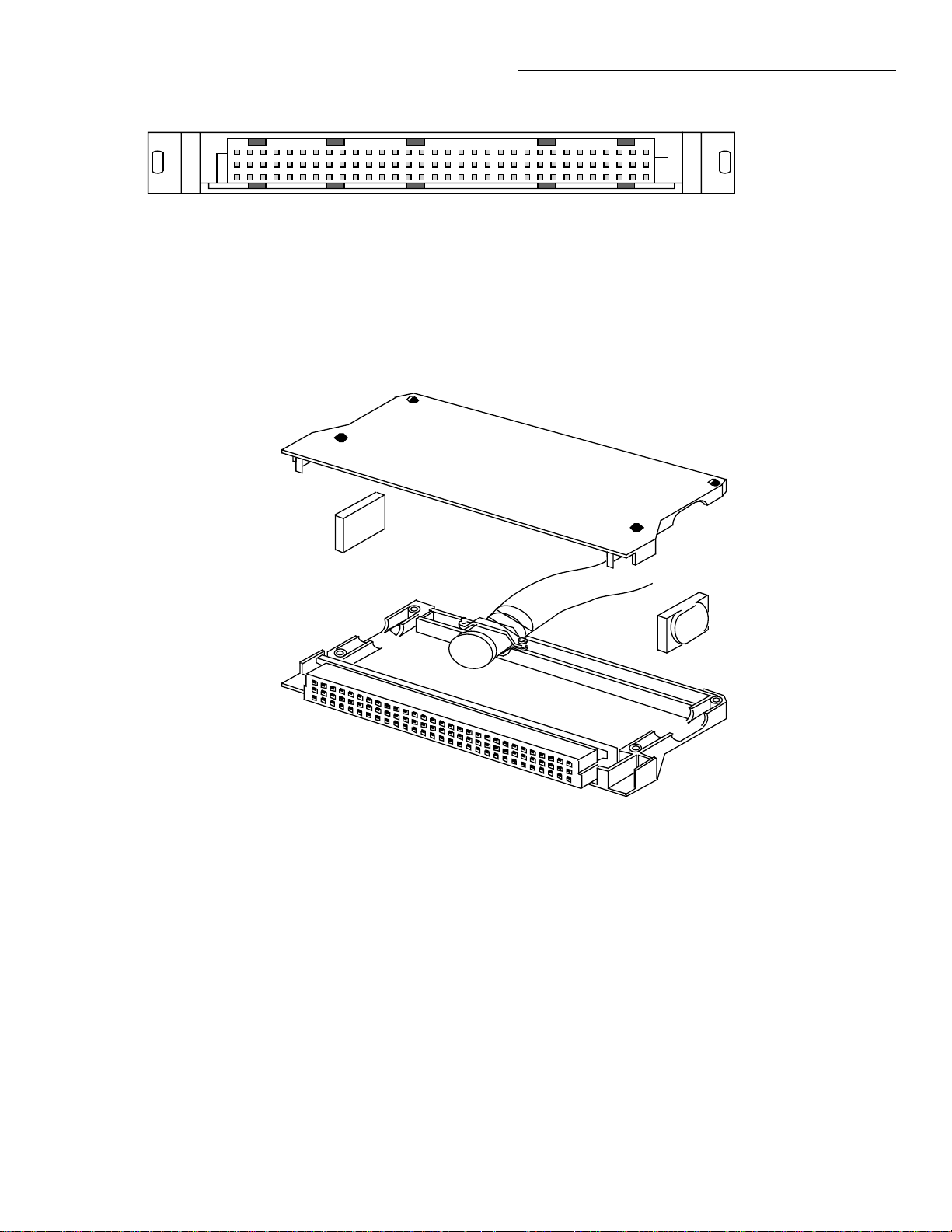

3.3.3 Screw terminal connector card

The screw terminal connector card is shown in Figure 3-5.

Connections are made directly to the screw terminals of the

twelve terminal blocks. Each screw terminal will accommodate #16-22 AWG wire.

3-4

Figure 3-5

Model 7015 screw terminal connector card

Page 31

Figure 3-7

Cable clamp for screw terminal connector card

Clips

Screw

Card Connections & Installation

Wiring procedure

Perform the following procedure to wire circuitry to the

screw terminal connector card:

WARNING

Make sure all power is off and that any

stored energy in external circuitry is discharged.

1. If mated together, separate the connector card from the

relay card by removing the mounting screw and pulling

the two cards away from each other. Remember to handle the cards only by the edges and shields to avoid contamination.

2. Using an insulated screwdriver, connect the circuitry to

the appropriate terminals. Figure 3-6 shows how the output of Bank A would be connected to a DMM.

3. Referring to Figure 3-7, remove the top half of the cable

clamp as follows:

A. Loosen the cable clamp screw enough to disengage

it from the bottom half of the cable clamp.

B. Using your thumb and forefinge , press the retaining

clips inward and, with your other hand, remove the

top half of the clamp.

4. Route wires under wire guide/connector shim.

5. Route the wires through the bottom half of the cable

clamp.

6. Replace the top half of the clamp. It simply snaps onto

the bottom half of the clamp. Tighten the cable clamp

screw. The clamp serves as a strain relief for terminal

block wires.

7. Mate the connector card to the relay card. The Model

7015 is now ready to be installed in the Model 7001 or

Model 7002 mainframe. See paragraph 3.5 for details.

#16 - 22 AWG Wires

Bank A

H

Output

L

H

CH 1

L

H

CH 2

L

H

CH 3

L

Figure 3-6

Typical screw terminal connections

HI

DMM

LO

3-5

Page 32

Card Connections & Installation

3.3.4 Multi-pin (mass termination) connector

card

Since connections to external circuitry are made at the 96-pin

male DIN bulkhead connector, there is no need to separate

the connector card from the relay card. If the connector card

is separated from the relay card, carefully mate them together and install the supplied 4-40 mounting screw. Be sure to

handle the cards by the edges and shields to avoid contamination.

Table 3-3

Multipin card terminal identificatio

Mux

Terminal

Bank A

Input 1 HI

LO

Input 2 HI

LO

Input 3 HI

LO

Input 4 HI

LO

Input 5 HI

LO

Input 6 HI

LO

Input 7 HI

LO

Input 8 HI

LO

Input 9 HI

LO

Input 10 HI

LO

Output HI

LO

Connector

Desig.

1a-32c

32c

32b

32a

31c

31b

31a

30c

30b

30a

29c

29b

29a

28c

28b

28a

27c

27b

27a

26c

26b

26a

25c

Schem.

Desig.

1-96

Terminal

Bank B

96

Input 1 HI

64

3295Input 2 HI

6331Input 3 HI

9462Input 4 HI

3093Input 5 HI

6129Input 6 HI

9260Input 7 HI

2891Input 8 HI

5927Input 9 HI

9058Input 10 HI

2689Output HI

Mux

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

Connector

Desig.

1a-32c

24c

24b

24a

23c

23b

23a

22c

22b

22a

21c

21b

21a

20c

20b

20a

19c

19b

19a

18c

18b

18a

17c

Schem.

Desig.

1-96

88

56

2487Input 2 HI

5523Input 3 HI

8654Input 4 HI

2285Input 5 HI

5321Input 6 HI

8452Input 7 HI

2083Input 8 HI

5119Input 9 HI

8250Input 10 HI

1881Output HI

Terminal identification for the DIN connector of the multipin connector card is provided by Table 3-3. This connector

will mate to a 96-pin female DIN connector.

Keithley has a variety of cable and connector accessories

available to accommodate connections from the connector

card to test instrumentation and DUT (devices under test). In

general, these accessories, which are summarized in Table 34, utilize a round cable assembly for connections.

Mux

Terminal

Bank C

Input 1 HI

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

Connector

Desig.

1a-32c

16c

16b

16a

15c

15b

15a

14c

14b

14a

13c

13b

13a

12c

12b

12a

11c

11b

11a

10c

10b

10a

9c

Schem.

Desig.

1-96

Terminal

Bank D

80

Input 1 HI

48

1679Input 2 HI

4715Input 3 HI

7846Input 4 HI

1477Input 5 HI

4513Input 6 HI

7644Input 7 HI

1275Input 8 HI

4311Input 9 HI

7442Input 10 HI

1073Output HI

Mux

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

LO

Connector

Desig.

1a-32c

8c

8b

8a

7c

7b

7a

6c

6b

6a

5c

5b

5a

4c

4b

4a

3c

3b

3a

2c

2b

2a

1c

Schem.

Desig.

1-96

72

40

8

71

39

7

70

38

6

69

37

5

68

36

4

67

35

3

66

34

2

65

Notes: 1. Pins 9a and 9b (pins 9 and 41 on schematic) are shield.

2. Short pin 1a to 1b on the mating connector (pins 1 and 33 on schematic) to allow the output relays on the connector card to close.

Pins of the Model 7015-C mass termination connector can be identified in one of three ays:

1. Mux terminal, consisting of banks A-D and inputs 1-10.

2. Connector description, consisting of rows a-c and columns 1-32.

3. Schematic and component layout designation (1-96).

3-6

Page 33

Table 3-4

Mass termination accessories

Model Description

7011-KIT-R 96-pin female DIN connector and

housing for round cable.

Card Connections & Installation

male DIN connector. The output relays will close only when

the Model 7011-MTC-2 cable assembly is connected to card.

If building your own cable assembly, you must make sure

that it shorts pin 1a to 1b of the card connector (Table 3-3)

when it is mated to the card. Shorting pin 1a to 1b allows the

output relays to close.

7011-MTC-2 Two-meter round cable assembly ter-

minated with a 96-pin female DIN

connector on each end.

7011-MTR 96-pin male DIN bulkhead connec-

tor.

Typical connection techniques

All external circuitry, such as instrumentation and DUTs,

that you wish to connect to the multiplexer card must be terminated with a single 96-pin female DIN connector. The following connection techniques provide some guidelines and

suggestions for wiring your circuitry.

WARNING

Before beginning any wiring procedures, make sure all power is off, and

any stored energy in external circuitry is

discharged.

Round cable assemblies

cable connection techniques using accessories available

from Keithley.

In Figure 3-8A, connections are accomplished using a Model

7011 MTC-2 cable and a Model 7011-MTR bulkhead connector. The two-meter round cable is terminated with a 96pin female DIN connector at each end. This cable mates directly to the multi-pin connector card and to the bulkhead

connector. The bulkhead connector has solder cups to allow

direct connection to instrumentation and DUT. Figure 3-9

provides the pinout for the bulkhead connector.

In Figure 3-8B, connections are accomplished using a Model

7011 MTC-2 cable assembly that is cut in half. The 96-pin

female DIN connector on one end of the cable mates directly

to the multi-pin connector card. The unterminated end of the

cable is wired directly to instrumentation and DUT. The other half of the cable assembly could be used for a second

switching card.

Figure 3-8 shows typical round

NOTE

External circuitry should be connected

(plugged in) only with the mainframe

power off, after the Model 7015 assembly

is installed in the Model 7001 or 7002

mainframe. Installation is covered in paragraph 3.5.

Output relays

for each of the four output banks. These output relays are

normally open to prevent any hazardous voltages (via the

mainframe backplane) from appearing on the pins of the

The multi-pin connector card uses a relay

In Figure 3-8C, connections are accomplished using a custom-built cable assembly that consists of a Model 7011-KITR connector and a suitable round cable. Hitachi cable part

number N2807-P/D-50TAB is a 50-conductor cable. Two of

these cables can be used to supply 100 conductors.The connector has solder cups to accommodate the individual wires

of the unterminated cable. Figure 3-10 provides an exploded

view of the connector assembly and shows how the cable is

connected. The connector end of the resultant cable assembly mates directly to the multi-pin connector card. The unterminated end of the cable assembly is wired directly to

instrumentation and DUT.

3-7

Page 34

Card Connections & Installation

A)

B)

C)

Multi-Pin

Connector

Card

Multi-Pin

Connector

Card

Multi-Pin

Connector

Card

7011-MTC-2

cable assembly

7011-MTC-2

(Cut in Half)

Wire instrumentation and

DUT to bulkhead connector

(See Figure 3-9 and Table 3-3

for terminal identification)

7011-MTR

bulkhead connector

Wire directly to

instrumentation

and DUT

Wire directly to

instrumentation

and DUT

Cable

Figure 3-8

Typical round cable connection techniques

7011-Kit-R

Connector Kit

Notes : Figure 3-10 provides an exploded view showing

how the connector (with cable) is assembled.

Cable Hitachi p/n N2807-P/D-50TAB is a

50-conductor round cable. Two of these cables

can be used to supply 100 conductors.

3-8

Page 35

Note : See Table 3-3 for terminal

identification.

Figure 3-9

Model 7011-MTR connector pinout

Card Connections & Installation

3231302928272625242322212019181716151413121110987654321

c

b

a

View from solder

cup side of

connector

Figure 3-10

Model 7011-KIT-R (with/cable) assembly

3-9

Page 36

Card Connections & Installation

×

3.4 Typical connection schemes

The following information provides some typical connection

schemes for single card, two-card and two-mainframe system configurations. Connection schemes for the multi-pin