Page 1

Model 6220 DC Current Source

A GREATER MEASURE OF CONFIDENCE

Model 6221 AC and DC Current Source

User’s Manual

622x-900-01 Rev. B / June 2005

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation

prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation prepaid.

Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written

consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable

batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE

FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING

OUT OF THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS,

INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH

EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR

DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

12/04

Page 3

Model 6220 DC Current Source

Model 6221 AC and DC Current Source

User’s Manual

©2004, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, June 2005

Document Number: 622x-900-01 Rev. B

Page 4

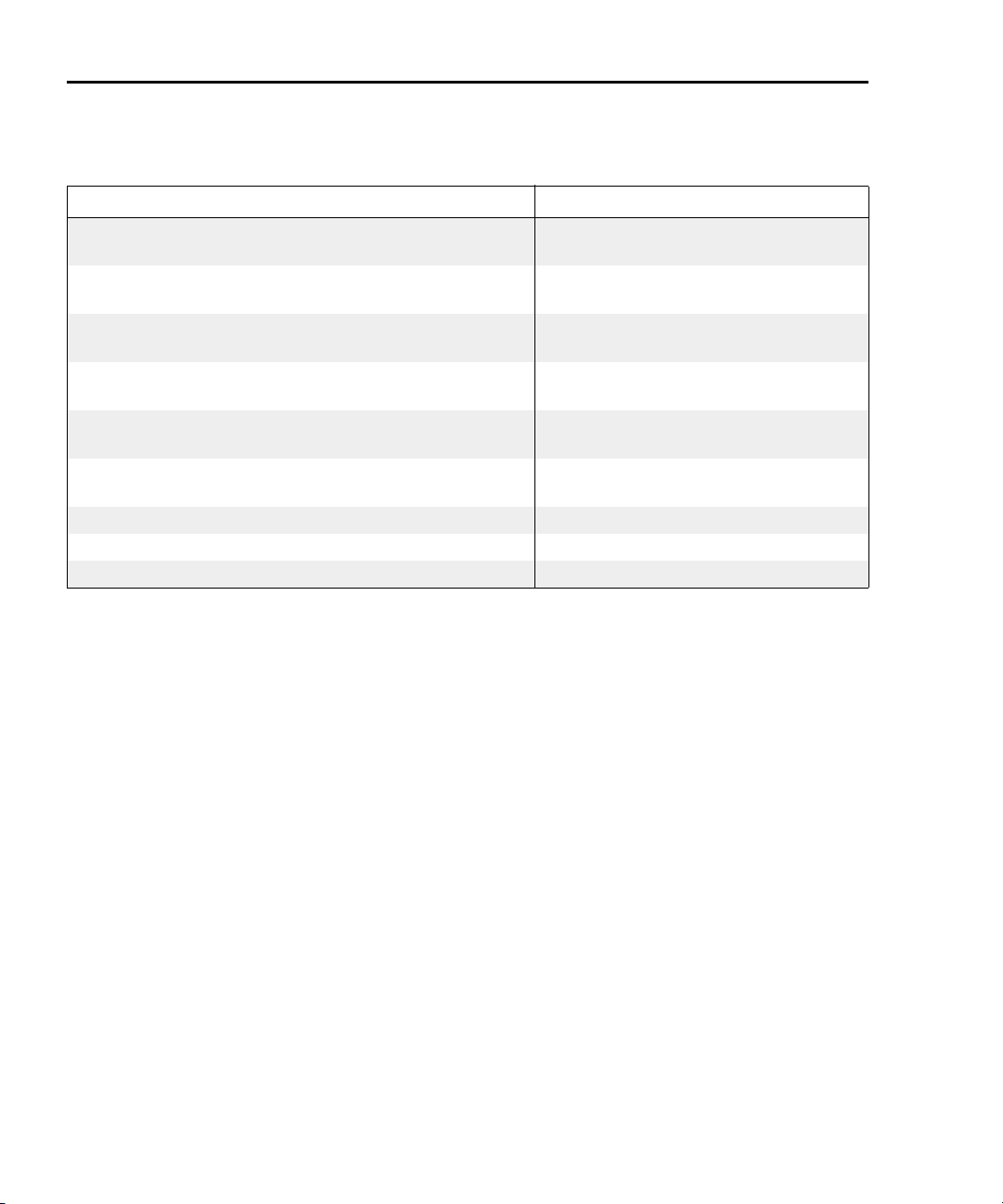

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain

important change information that the user should incorporate immediately into the manual.

Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision of the manual are incorporated into the new Revision of the

manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 622x-900-01) .................................................................... June 2004

Revision B (Document Number 622x-900-01) .................................................................... June 2005

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Measurement Category I and Measurement Category

II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with

high transient over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are for connection to

Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown

circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards dire

vices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting ca-

ctly to AC mains. When connecting sources to switching cards, install protective de-

5/03

Page 6

bles or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment frame.

The WARNING heading in a manual explains dangers that might result in personal injury or death. Always read the associated

information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased from

other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability

of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled accord-

structions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for

ing to in

proper cleaning/servicing.

Page 7

Table of Contents

1 Getting Started

Introduction ............................................................................................................. 1-2

User’s Manual content and structure ............................................................... 1-2

Capabilities and features .................................................................................. 1-2

General information ................................................................................................ 1-3

Warranty information ....................................................................................... 1-3

Contact information ......................................................................................... 1-3

Safety symbols and terms ................................................................................ 1-3

Unpacking and inspection ................................................................................ 1-3

Options and accessories ................................................................................... 1-4

Front and rear panel familiarization ........................................................................ 1-4

Front panel summaries ..................................................................................... 1-4

Rear panel summaries ...................................................................................... 1-8

Heat sink and cooling vents .................................................................................... 1-9

Power-up ............................................................................................................... 1-11

Line power connection ................................................................................... 1-11

Source preset .................................................................................................. 1-12

Disabling the front panel ................................................................................ 1-12

Menus .................................................................................................................... 1-13

CONFIG menus ............................................................................................. 1-13

Direct access menus ....................................................................................... 1-13

Editing controls ..................................................................................................... 1-14

Source and compliance editing ...................................................................... 1-14

Menu navigation ............................................................................................ 1-14

Password ............................................................................................................... 1-16

Remote interface ................................................................................................... 1-17

Error and status messages ..................................................................................... 1-17

Default settings ..................................................................................................... 1-18

Save and restore setups .................................................................................. 1-18

Select power-on setup .................................................................................... 1-19

SCPI programming ............................................................................................... 1-19

Optional command words .............................................................................. 1-19

Query commands ........................................................................................... 1-19

Page 8

2 Output Connections

Output connectors ................................................................................................... 2-2

Triax connector ................................................................................................ 2-2

Ground points .................................................................................................. 2-3

LO and GUARD banana jacks ........................................................................ 2-3

INTERLOCK .................................................................................................. 2-4

Output configurations ............................................................................................. 2-5

Triax inner shield ............................................................................................. 2-6

Triax output low .............................................................................................. 2-7

Guards ..................................................................................................................... 2-8

Triax Cable Guard .......................................................................................... 2-8

Floating the current source ..................................................................................... 2-9

Connections to DUT ............................................................................................... 2-9

Supplied triax cable ......................................................................................... 2-9

Basic connections .......................................................................................... 2-10

Shields and guarding ..................................................................................... 2-10

Using a test fixture ................................................................................................ 2-12

3 DC Current Source Operation

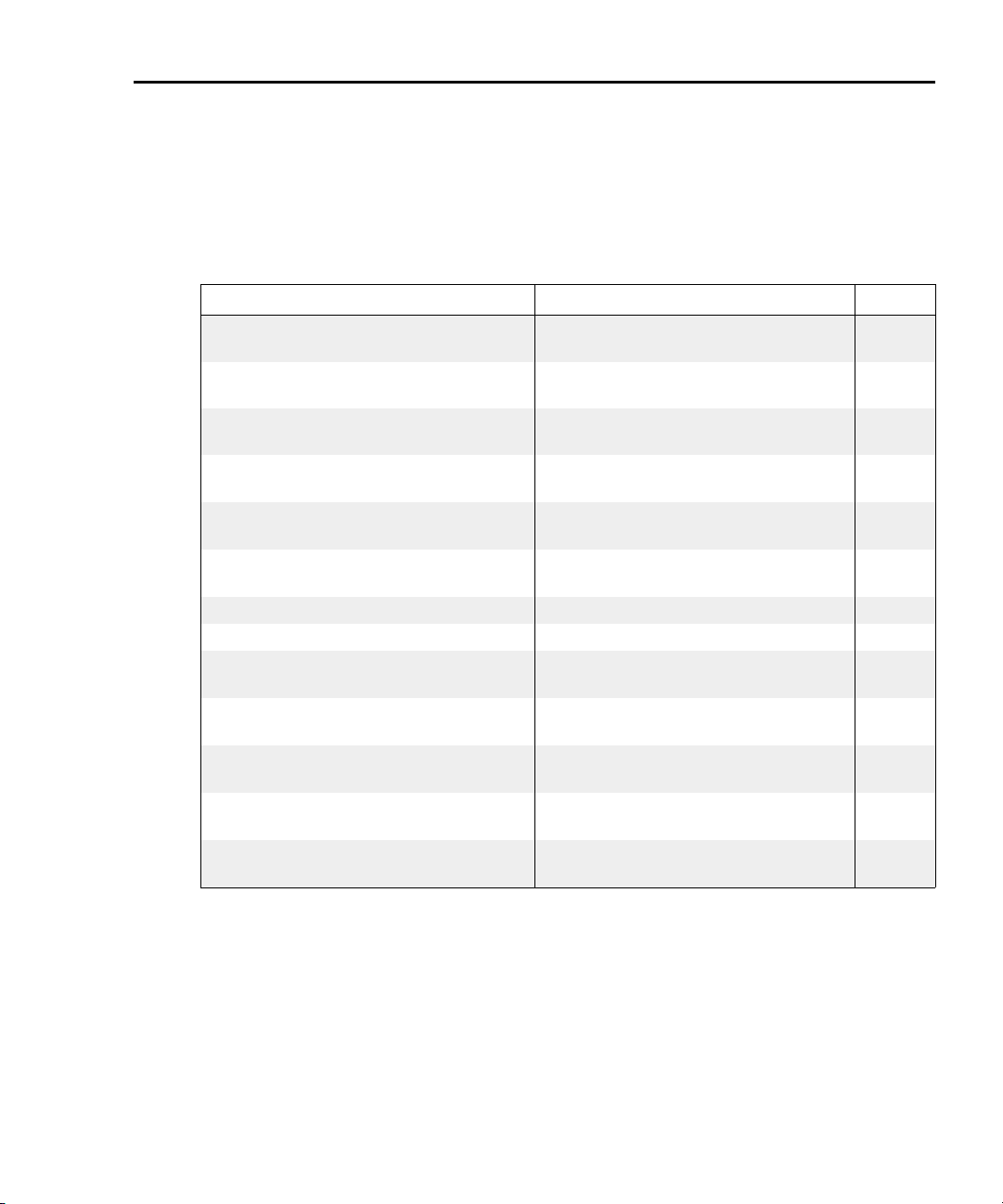

Current source output capabilities .......................................................................... 3-2

Source ranges .................................................................................................. 3-2

Compliance ...................................................................................................... 3-3

Output power (source or sink) ......................................................................... 3-3

Output response .............................................................................................. 3-5

Setting source and compliance ............................................................................... 3-8

Source and compliance editing ....................................................................... 3-8

Autorange ...................................................................................................... 3-11

Source preset ................................................................................................. 3-12

Sourcing current ................................................................................................... 3-12

Remote programming – source output commands ........................................ 3-15

Applications .......................................................................................................... 3-16

4 Sweeps

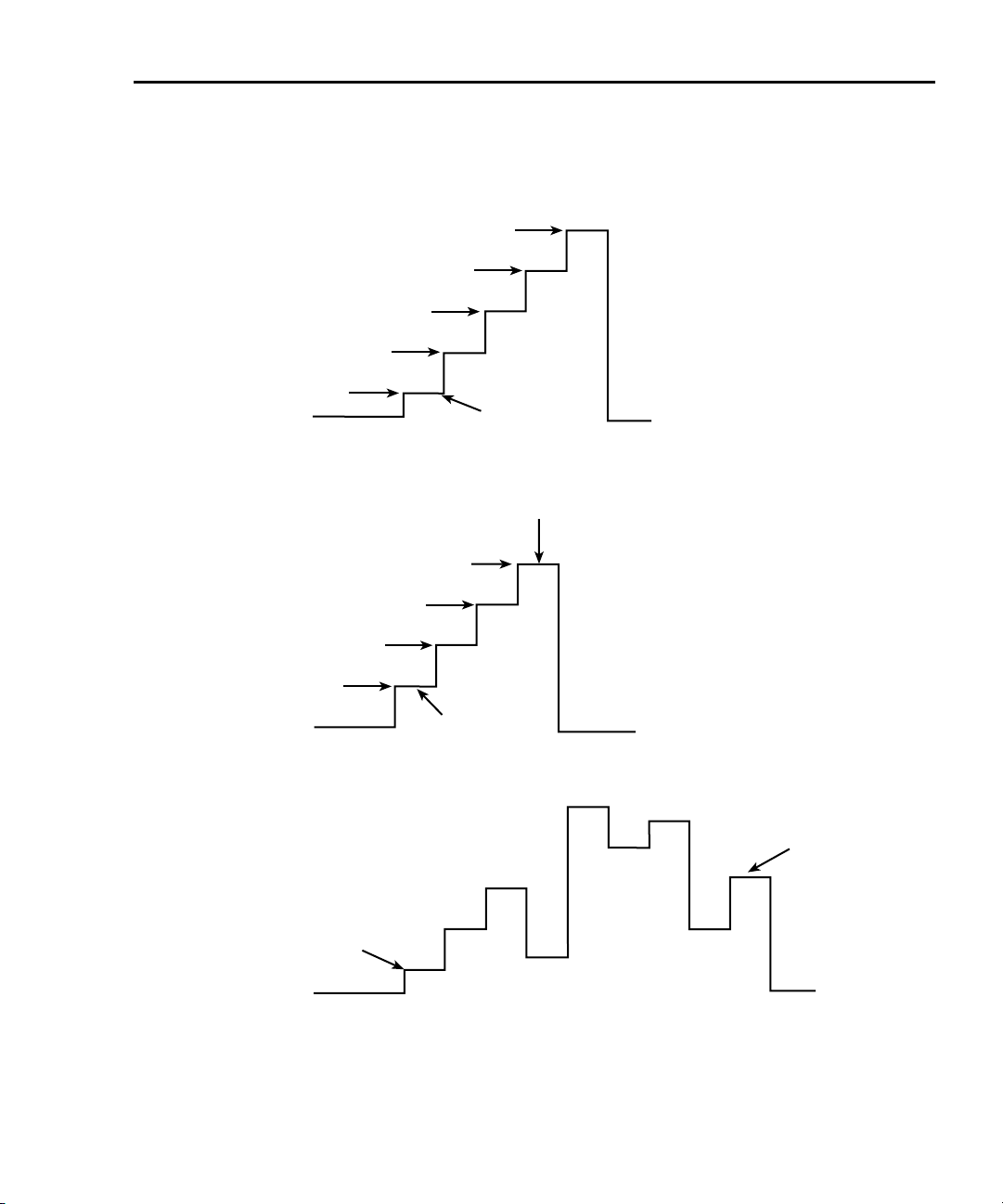

Sweep overview ...................................................................................................... 4-2

Linear staircase sweep ..................................................................................... 4-2

Logarithmic staircase sweep ........................................................................... 4-2

Custom sweep ................................................................................................. 4-2

Sweep characteristics .............................................................................................. 4-4

Custom sweep editing ..................................................................................... 4-4

Using auto-copy with custom sweeps ............................................................. 4-4

Source ranging ................................................................................................. 4-4

Sweep delay ..................................................................................................... 4-5

Page 9

Front panel sweep operation ................................................................................... 4-5

Using the sweep configuration menu ............................................................... 4-5

Performing a staircase sweep ........................................................................... 4-6

Performing a custom sweep ............................................................................. 4-7

Remote sweep operation ......................................................................................... 4-8

Running a staircase sweep ............................................................................... 4-9

Running a custom sweep ............................................................................... 4-10

SCPI commands — sweeps ........................................................................... 4-11

5 Delta, Pulse Delta, and Differential Conductance

Operation overview ................................................................................................. 5-2

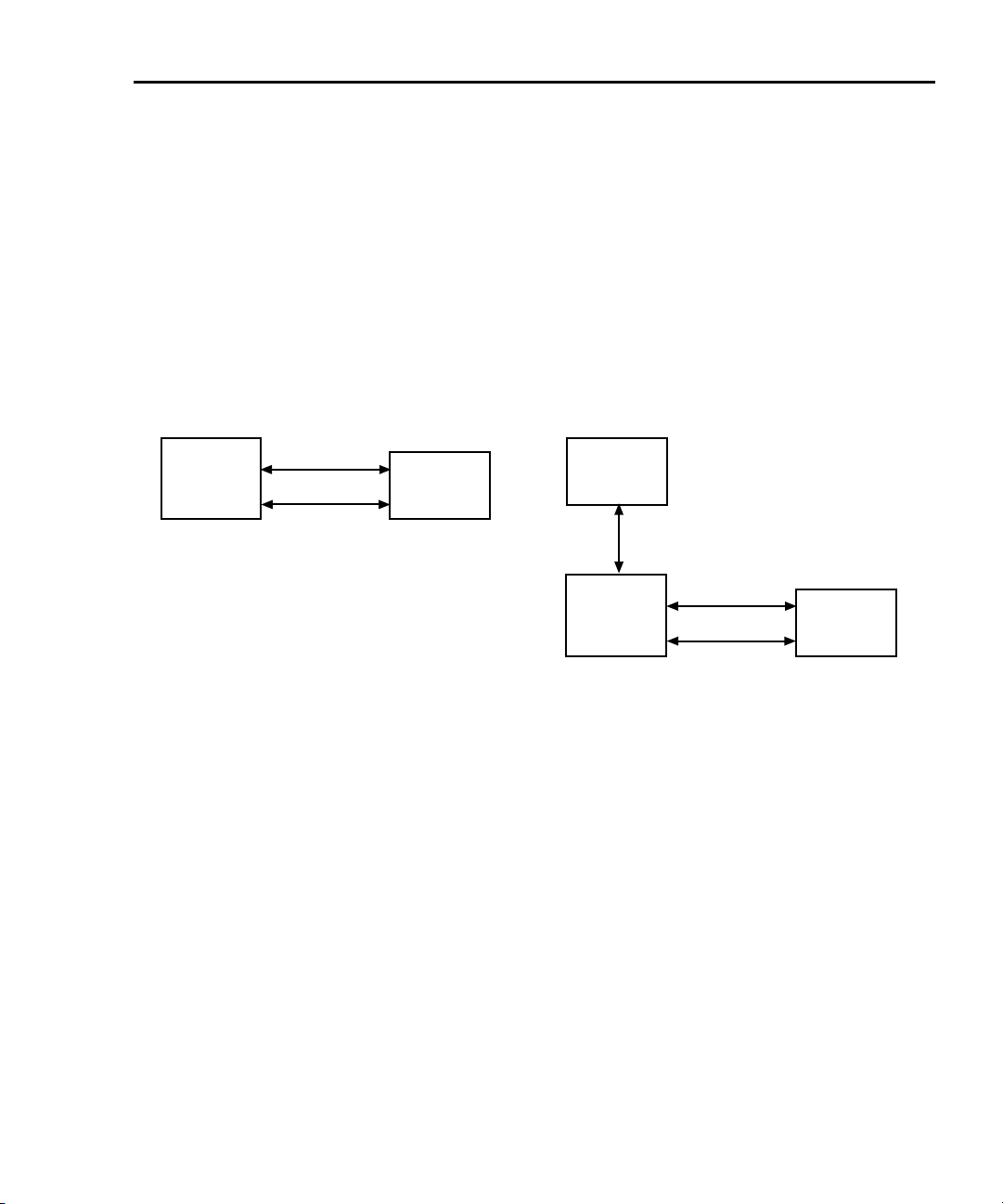

Test systems ............................................................................................................ 5-4

Keithley instrumentation requirements ............................................................ 5-4

System configurations ...................................................................................... 5-4

System connections .......................................................................................... 5-5

DUT test connections ....................................................................................... 5-8

Configuring communications ........................................................................... 5-9

Triggering sequence ....................................................................................... 5-10

Readings ................................................................................................................ 5-11

Display readings ............................................................................................ 5-11

Measurement units ......................................................................................... 5-11

Read commands ............................................................................................. 5-13

Delta ...................................................................................................................... 5-13

Model 622x measurement process ................................................................. 5-13

Configuration settings .................................................................................... 5-15

Operation ....................................................................................................... 5-16

Setup and arm commands .............................................................................. 5-19

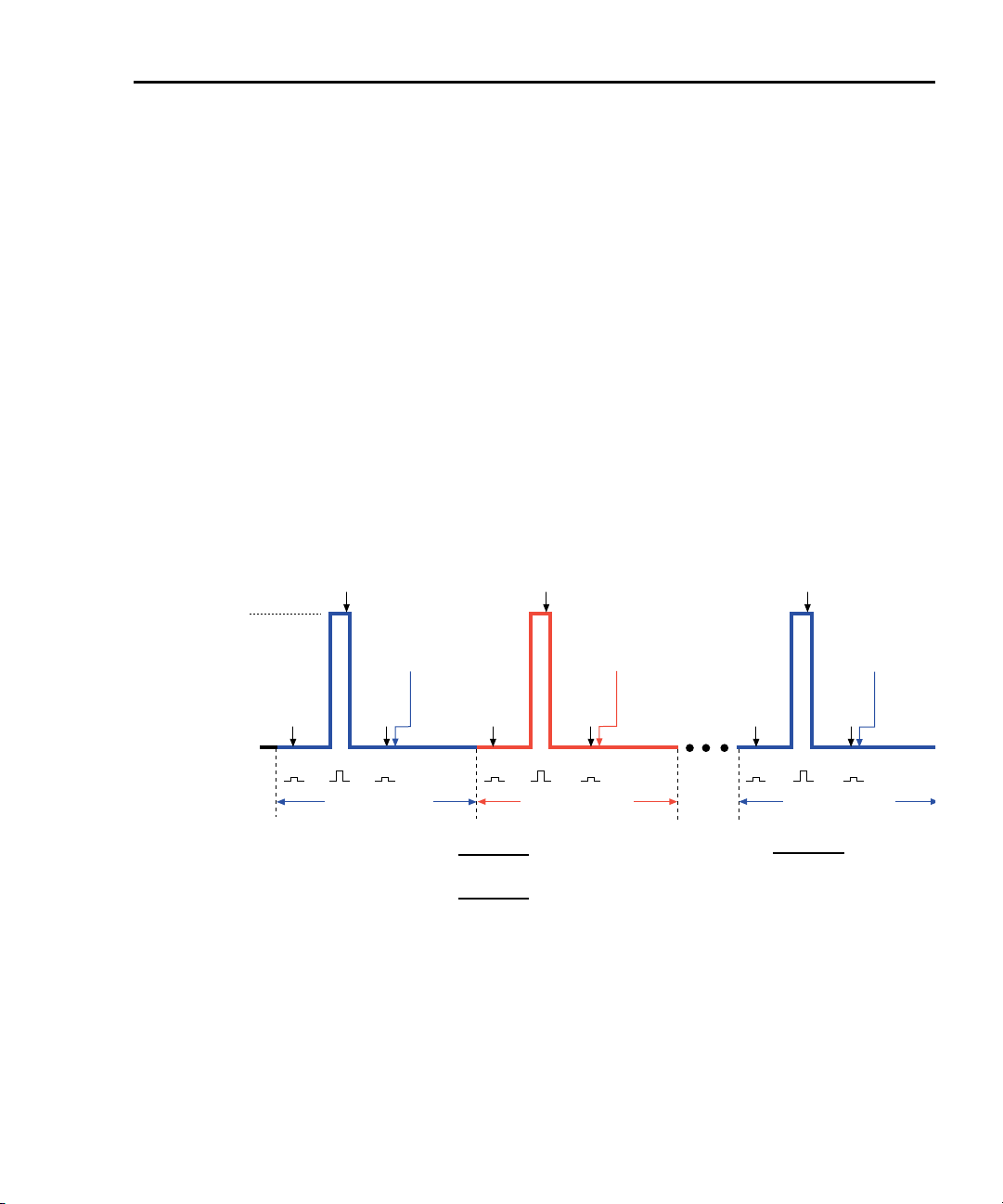

Pulse Delta ............................................................................................................ 5-21

Model 6221 measurement process ................................................................. 5-21

Pulse Delta outputs ........................................................................................ 5-22

Configuration settings .................................................................................... 5-26

Operation ....................................................................................................... 5-29

Setup commands ............................................................................................ 5-32

Differential Conductance ...................................................................................... 5-34

Model 622x measurement process ................................................................. 5-34

Configuration settings .................................................................................... 5-37

Operation ....................................................................................................... 5-38

Setup and arm commands .............................................................................. 5-41

Page 10

6 Averaging Filter, Math, and Buffer

Averaging filter ....................................................................................................... 6-2

Averaging filter characteristics ........................................................................ 6-2

Filter setup and control .................................................................................... 6-4

Remote programming – Averaging filter ........................................................ 6-4

Math ........................................................................................................................ 6-5

mX+b and m/X+b (reciprocal) ........................................................................ 6-5

Configuring mX+b and m/X+b ....................................................................... 6-6

Remote programming – Math ......................................................................... 6-6

Buffer ...................................................................................................................... 6-7

Buffer characteristics ....................................................................................... 6-7

Storing readings ............................................................................................... 6-8

Recall ............................................................................................................... 6-8

7 Wave Functions (6221 Only)

Wave function overview ......................................................................................... 7-2

Setting waveform parameters .......................................................................... 7-3

Ranging ........................................................................................................... 7-3

Frequency ........................................................................................................ 7-4

Offset ............................................................................................................... 7-4

Duty cycle ....................................................................................................... 7-5

Phase marker ................................................................................................... 7-6

Duration ........................................................................................................... 7-7

Externally triggered waveforms ...................................................................... 7-7

Front panel wave function operation ...................................................................... 7-8

Using the wave function menu ........................................................................ 7-8

Generating a sine wave .................................................................................. 7-10

Generating an arbitrary waveform ................................................................. 7-11

Remote wave function operation .......................................................................... 7-12

Programming sine waves ............................................................................... 7-13

Programming arbitrary waveforms ................................................................ 7-14

SCPI commands — wave functions .............................................................. 7-15

A Specifications

B SCPI Tables (Abridged)

Page 11

List of Illustrations

1 Getting Started

Figure 1-1 Models 6220 and 6621 front panels .................................................................... 1-5

Figure 1-2 Model 622x rear panel ........................................................................................ 1-8

Figure 1-3 Menu editing keys ............................................................................................. 1-14

2 Output Connections

Figure 2-1 Triax connector and grounds points .................................................................... 2-2

Figure 2-2 LO and GUARD banana jacks ............................................................................ 2-3

Figure 2-3 INTERLOCK ...................................................................................................... 2-4

Figure 2-4 Output configurations – triax inner shield connected to Output Low ................ 2-5

Figure 2-5 Output configurations – triax inner shield connected to Cable Guard ............... 2-6

Figure 2-6 Basic connections to DUT ................................................................................ 2-10

Figure 2-7 Noise shield ...................................................................................................... 2-10

Figure 2-8 Safety shield ...................................................................................................... 2-11

Figure 2-9 Cable Guard connections – triax inner shield connected to Cable Guard ........ 2-11

Figure 2-10 Connections for noise shield, safety shield, and guarding ................................ 2-12

3 DC Current Source Operation

Figure 3-1 Output boundaries (source and sink) .................................................................. 3-5

Figure 3-2 Source and compliance editing – Model 6220 ................................................... 3-8

Figure 3-3 Source and compliance editing – Model 6221 ................................................. 3-10

4 Sweeps

Figure 4-1 Comparison of sweep types ................................................................................ 4-3

5 Delta, Pulse Delta, and Differential Conductance

Figure 5-1 Delta, Pulse Delta, and Differential Conductance measurements ...................... 5-3

Figure 5-2 System configurations for Delta, Pulse Delta, and Differential Conductance .... 5-5

Figure 5-3 System connections – stand-alone operation ...................................................... 5-6

Figure 5-4 System connections – PC control of Model 622x .............................................. 5-7

Figure 5-5 Guarded test connections .................................................................................... 5-8

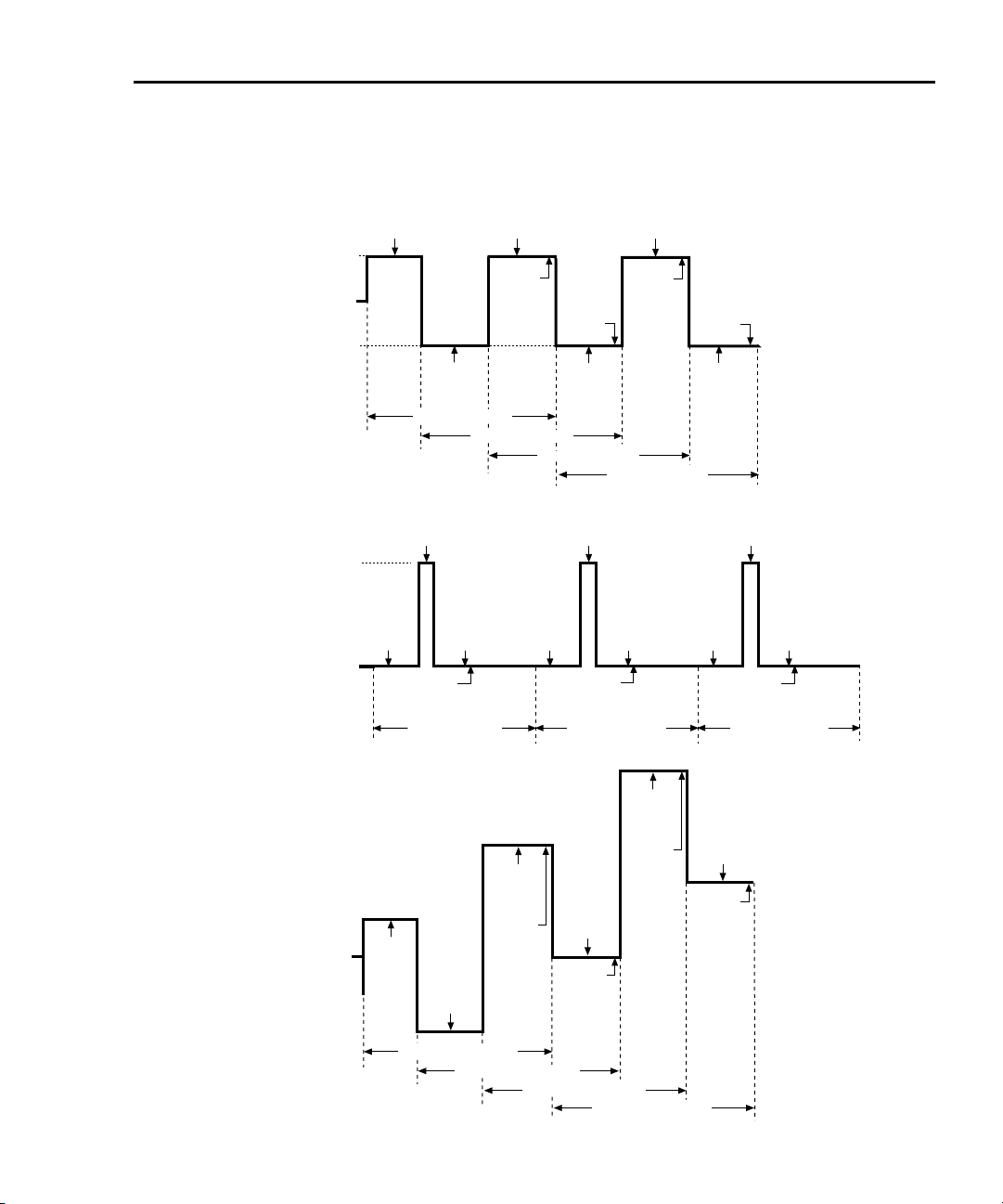

Figure 5-6 Delta measurement technique ........................................................................... 5-14

Figure 5-7 Pulse Delta 3-point measurement technique ..................................................... 5-21

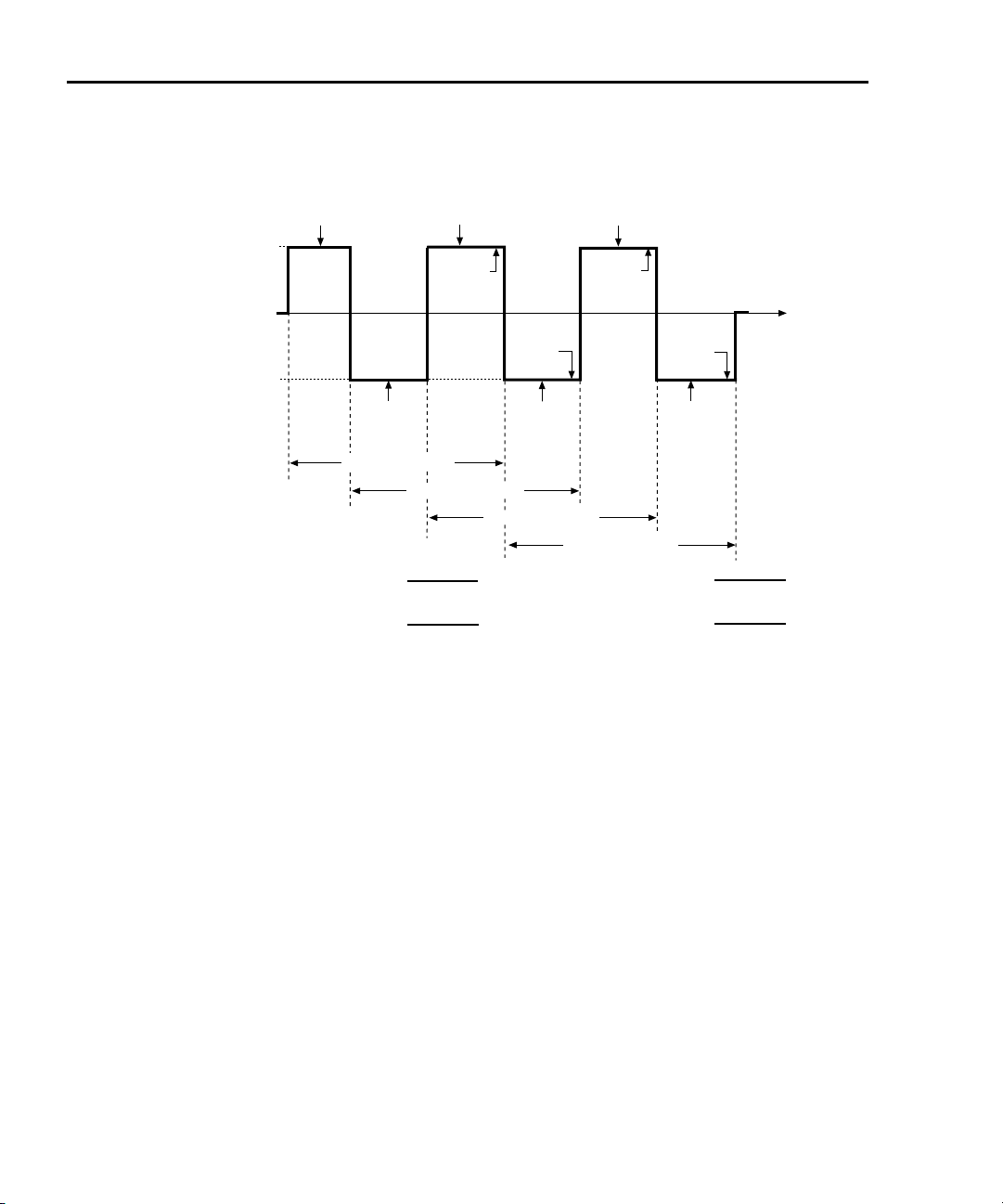

Figure 5-8 Pulse timing ...................................................................................................... 5-24

Figure 5-9 Pulse sweep output examples ........................................................................... 5-25

Figure 5-10 Differential Conductance measurement process ............................................... 5-35

6 Averaging Filter, Math, and Buffer

Figure 6-1 Buffer recall ........................................................................................................ 6-9

Page 12

7 Wave Functions (6221 Only)

Figure 7-1 Offset example ................................................................................................... 7-4

Figure 7-2 Duty cycle .......................................................................................................... 7-5

Figure 7-3 Phase marker ...................................................................................................... 7-6

Page 13

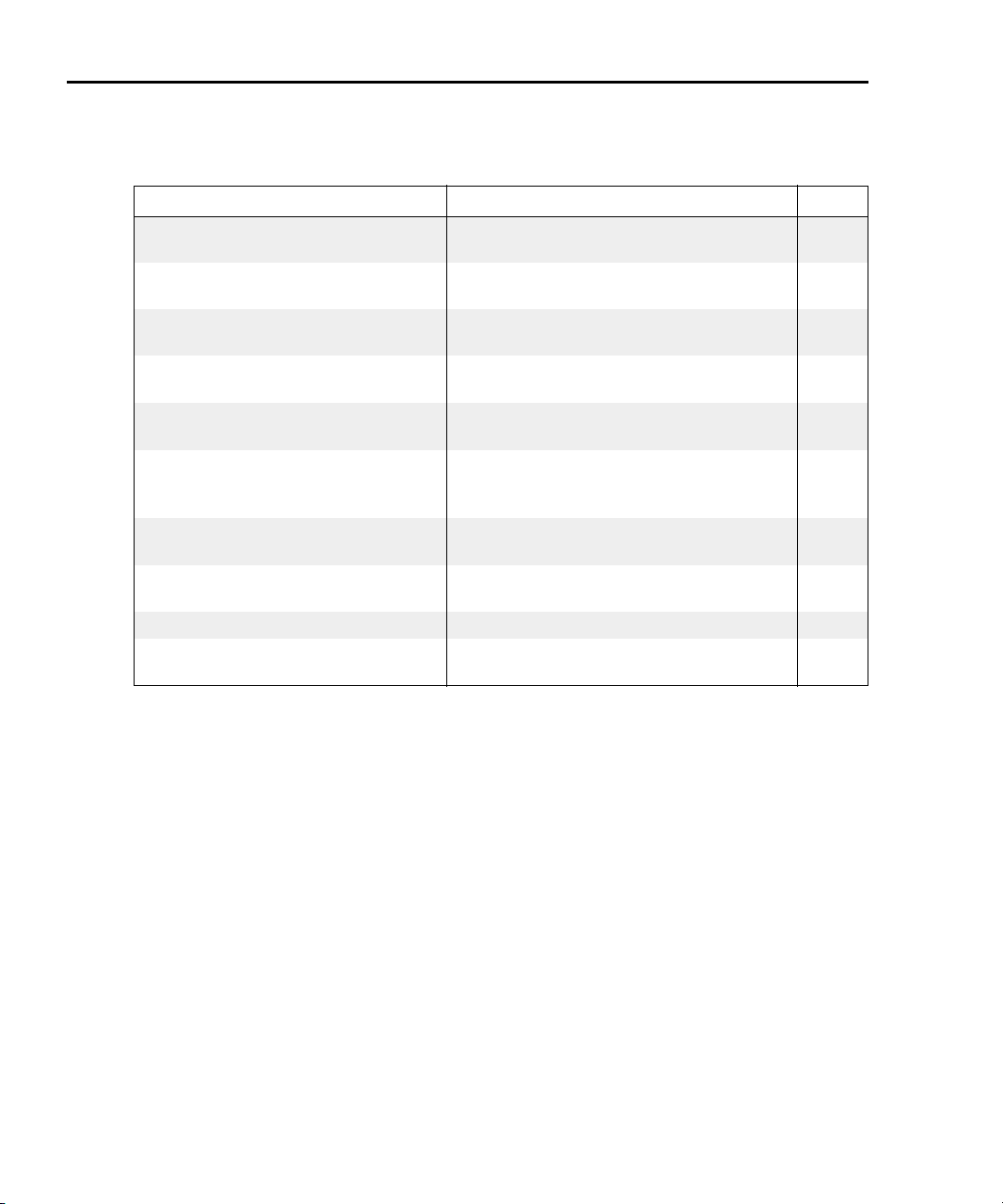

List of Tables

3 DC Current Source Operation

Table 3-1 Source ranges and maximum outputs ................................................................. 3-2

Table 3-2 DC output commands ....................................................................................... 3-15

4 Sweeps

Table 4-1 Sweep configuration menu ................................................................................. 4-5

Table 4-2 Sweep example parameters ................................................................................. 4-8

Table 4-3 Staircase sweep commands (linear and logarithmic) ........................................ 4-11

Table 4-4 Custom (list) sweep commands ........................................................................ 4-12

5 Delta, Pulse Delta, and Differential Conductance

Table 5-1 Measurement unit commands ........................................................................... 5-12

Table 5-2 Delta commands ............................................................................................... 5-20

Table 5-3 Pulse Delta commands ...................................................................................... 5-33

Table 5-4 Differential Conductance commands ................................................................ 5-42

6 Averaging Filter, Math, and Buffer

Table 6-1 Average filter types ............................................................................................. 6-2

Table 6-2 Averaging filter commands ................................................................................. 6-5

Table 6-3 Math commands .................................................................................................. 6-6

Table 6-4 Buffer commands ................................................................................................ 6-9

7 Wave Functions (6221 Only)

Table 7-1 Wave function characteristics ............................................................................. 7-2

Table 7-2 Wave function configuration menu ..................................................................... 7-8

Table 7-3 Waveform example parameters ......................................................................... 7-12

Table 7-4 Waveform function commands ......................................................................... 7-15

B SCPI Tables (Abridged)

Table B-1 Calculate command summary ............................................................................ B-2

Table B-2 Display command summary .............................................................................. B-2

Table B-3 Format command summary ............................................................................... B-3

Table B-4 Output command summary ................................................................................ B-3

Table B-5 Sense command summary ................................................................................. B-3

Table B-6 Source command summary ................................................................................ B-4

Table B-7 Status command summary ................................................................................. B-7

Table B-8 System command summary ............................................................................... B-8

Table B-9 Trace command summary .................................................................................. B-9

Table B-10 Trigger command summary ............................................................................. B-10

Table B-11 Units command summary ................................................................................ B-10

Page 14

Page 15

Getting Started

Section 1 topics

Introduction, page 1-2 Menus, page 1-13

User’s Manual content and structure, page 1-2 CONFIG menus, page 1-13

Capabilities and features, page 1-2 Direct access menus, page 1-13

General information, page 1-3 Editing controls, page 1-14

Warranty information, page 1-3 Source and compliance editing, page 1-14

Contact information, page 1-3 Menu navigation, page 1-14

Safety symbols and terms, page 1-3

Unpacking and inspection, page 1-3 Password, page 1-16

Options and accessories, page 1-4

Remote interface, page 1-17

Front and rear panel familiarization, page 1-4

Front panel summaries, page 1-4 Error and status messages, page 1-17

Rear panel summaries, page 1-8

Default settings, page 1-17

Heat sink and cooling vents, page 1-9 Save and restore setups, page 1-18

Select power-on setup, page 1-18

Power-up, page 1-11

Line power connection, page 1-11 SCPI programming, page 1-17

Source preset, page 1-12 Optional command words, page 1-19

Disabling the front panel, page 1-12 Query commands, page 1-19

1

NOTE The information in this section is an abbreviated version of

the information in Section 1 of the Reference Manual. Refer to

Section 1 of the Reference Manual for complete details and

additional information that is not provided in this manual.

Page 16

1-2 Getting Started Model 6220/6221 User’s Manual

Introduction

User’s Manual content and structure

This User’s Manual is provided as a hardcopy and is also provided on the supplied

Product Information CD in PDF format. The User’s Manual is an abbreviated version of the operation sections of the Reference Manual. The seven sections of the

User’s Manual correspond (in abbreviated form) to the first seven sections of the

Reference Manual.

The Reference Manual is on the Product Information CD in PDF format. Refer to

the Reference Manual for complete information.

Capabilities and features

• Source ±DC current from 0.1pA to 105mA.

• Voltage compliance limit from 0.1V to 105V in 10mV steps.

• 11W, four-quadrant sink or source operation (duty cycle limitation for high

power sink).

• Analog filter to slow down output response.

• Triax cable guarding to optimize output response speed and reduce leakage currents in high impedance test circuits.

• Banana jack guard output for voltage measurements.

• Sweep functions: linear staircase, logarithmic staircase, and custom.

• Waveform functions (6221 only): Sine, square, ramp, and arbitrary function

generator.

• Five user-saved setups.

• Delta testing when used with the Keithley Model 2182 or 2182A:

• Delta – Uses a square wave output and a 3-point measurement algorithm to cancel the effects of thermal EMFs.

• Pulse Delta (6221 and 2182A only) – Provides a pulse output and a

3-point (or 2-point) measurement algorithm for testing of temperature

sensitive Device Under Test (DUT).

• Differential Conductance – Uses a differential current output and a

3-point moving average algorithm to perform differential measurements.

• Buffer storage and recall for up to 65,536 delta readings

• Averaging filtering for delta readings

• Supported remote interfaces: Model 6220: GPIB and RS-232.

Model 6221: GPIB, RS-232, and Ethernet.

• KI-220 language – DDC commands to emulate Model 220 operation.

Return to Section 1 topics

Page 17

Model 6220/6221 User’s Manual Getting Started 1-3

General information

Warranty information

Warranty information is located at the front of this manual. Should your Model

622x require warranty service, contact the Keithley representative or authorized

repair facility in your area for further information. When returning the instrument

for repair, be sure to fill out and include the service form at the back of this manual

to provide the repair facility with the necessary information.

Contact information

Worldwide phone numbers are listed at the front of this manual.

Safety symbols and terms

The following symbols and terms may be found on the instrument or used in this

manual:

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts

or more, including the combined effect of normal and common mode voltages.

Use standard safety precautions to avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment frame.

The WARNING heading used in this manual explains dangers that might result in

personal injury or death. Always read the associated information very carefully

before performing the indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage

the instrument. Such damage may invalidate the warranty.

Unpacking and inspection

Inspection for damage

The Model 622x was carefully inspected electrically and mechanically before shipment. After unpacking all items from the shipping carton, check for any obvious

signs of physical damage that may have occurred during transit. (There may be a

protective film over the display lens, which can be removed.) Report any damage

Return to Section 1 topics

Page 18

1-4 Getting Started Model 6220/6221 User’s Manual

to the shipping agent immediately. Save the original packing carton for possible

future shipment. Before removing the Model 622x from the bag, observe the following handling precautions.

Handling precautions

• Always grasp the Model 622x by the covers.

• After removing the Model 622x from its anti-static bag, inspect it for any

obvious signs of physical damage. Report any such damage to the shipping

agent immediately.

• When the Model 622x is not installed and connected, keep the unit in its

anti-static bag and store it in the original packing carton.

Package content

The following items are included with every Model 622x order:

• Model 622x current source with line cord.

• Protective triax Shield/Cap (CAP-28-1).

• 237-ALG-2 Triax cable terminated with alligator clips on one end.

• Model 8501 Trigger Link cable.

• CA-351 null-modem serial cable.

• CA-180-3A Ethernet cross-over cable (Model 6221 only).

• Accessories as ordered.

• Certificate of calibration.

• Model 622x User’s Manual (P/N 622x-900-00).

• Product Information CD-ROM that contains PDFs of the User’s and Refer-

ence Manuals.

Options and accessories

The various options and accessories that are available from Keithley for the Model

622x are listed and explained in Section 1of the Reference Manual.

Front and rear panel familiarization

Front panel summaries

The front panels of the Models 6220 and 6221 are shown in Figure 1-1. The

descriptions of the front panel controls follow Figure 1-1.

Many of the keys that are used to select a function or operation are also used for

configuration by first pressing the CONFIG key. For example, to configure a

sweep, press CONFIG and then SWP.

Return to Section 1 topics

Page 19

Model 6220/6221 User’s Manual Getting Started 1-5

Figure 1-1

Models 6220 and 6621 front panels

Model 6220:

6220 PRECISION CURRENT SOURCE

EDIT/

LOCAL

CONFIG

POWER

FILT DCPRES

1

0

COMM

ADDR

67

SAVE SETUP TRIAX AVG

DISP

MODE

SWP

3

2

TRIG

89

DELTA

COND

4

RECALLUNITS

0000

+ / -

MATH MENU

5

EXIT ENTER

RANGE

AUTO

RANGE

OUTPUT

ON/OFF

1 2 3

Model 6221:

6221 DC AND AC CURRENT SOURCE

EDIT/

LOCAL

CONFIG

POWER

FILT DCPRES

1

0

COMM

ADDR

67

SAVE SETUP TRIAX AVG

2

DISP

89

1 2 3

SWP

3

TRIG

MODE

COND

4

RECALLUNITS

+ / -

MATH MENU

DELTA

5

0000

PULSE

EXIT ENTER

ARB

WAVE

FREQAMPL

RANGE

AUT O

RANGE

R

E

T

N

E

/

T

I

D

E

O

T

H

S

U

P

OUTPUT

ON/OFF

4

CURSOR

4

P

U

S

H

T

O

E

D

I

T

/

E

N

T

E

R

5

Return to Section 1 topics

Page 20

1-6 Getting Started Model 6220/6221 User’s Manual

1 Special keys and power switch:

EDIT/LOCAL Dual function – While in local, EDIT selects the source editing mode.

While in remote, LOCAL cancel the remote mode.

CONFIG Use to configure a function or operation.

POWER Power switch – In position turns 622x on (I), out position turns it off (O).

2 Function and operation keys:

Top Row

FILT Enables/disables analog filter.

PRES Enables/disables the pre-set source value. Press CONFIG > PRES to set

the source value for PRES.

DC Selects DC current source function.

SWP Arms the sweep function. Press CONFIG > SWP to configure the sweep.

COND Arms Differential Conductance. Press CONFIG > COND to configure Dif-

ferential Conductance.

DELTA Arms Delta. Press CONFIG > DELTA to configure Delta.

6220:

Increments value.

Decrements value.

6221:

PULSE Arms Pulse Delta. Press CONFIG > PULSE to configure Pulse Delta.

WAVE Arms Wave mode. Press CONFIG > WAVE to configure Wave.

Middle Row

COMM Configures communications: GPIB, RS-232, or Ethernet (6221). Can also

press CONFIG > COMM to configure communications.

ADDR Sets GPIB address.

DISP Turns off display. Press LOCAL or DISP to turn display back on.

TRIG Starts a sweep, delta, or wave (6221) test, or causes a manual trigger

event. Press CONFIG > TRIG to configure triggers.

UNITS Use to select measurement units for a delta function. Can also press

CONFIG > UNITS to select measurement units.

RECALL Displays buffer readings and statistics. Press CONFIG > RECALL to

access menu to clear the buffer.

6220:

Moves cursor (blinking digit or menu item) to the left.

Moves cursor (blinking digit or menu item) to the right.

6221:

AMPL Sets the amplitude for the Wave function. Can also press

CONFIG > AMPL to set the amplitude. When in a menu, use this key to

move the cursor to the left.

FREQ Sets the frequency for the Wave function. Can also press

CONFIG > FREQ to set the frequency. When in a menu, use this key to

move the cursor to the right.

Return to Section 1 topics

Page 21

Model 6220/6221 User’s Manual Getting Started 1-7

Bottom Row

SAVE Saves up to five instrument setups for future recall, and selects power-on

setup.

SETUP Restores a default setup (preset or *RST) or a user saved setup.

TRIAX Configures triax connector: Inner shield and Output Low. Can also press

CONFIG > TRIAX to configure triax connector.

AVG Enables/disables averaging filter. Press CONFIG > AVG to configure

averaging filter.

MATH Enables/disable math. Press CONFIG > MATH to configure math.

MENU Accesses the main menu for calibration, self-tests, serial number, and

beeper control.

EXIT Cancels selection, backs out of menu structure.

ENTER Accepts selection, moves to next choice or exits menu.

3 Range keys:

and Dual function – Selects the next higher or lower source range. When in a

menu, these keys increment or decrement values.

AUTO Enables or disables source autorange.

4 Output control and LED status indicator:

OUTPUT ON/OFF Turns source output on or off. For the 6221, press

CONFIG > OUTPUT to set the output response for the Model 6221.

LED indicator Turns on when output is on. Blinks if source goes into compliance.

5 Rotary knob and CURSOR keys (Model 6221):

When in source edit, use CURSOR keys for cursor control and rotate the knob to change

a source or compliance value. The rotary knob can also be used to enable or disable the

source EDIT mode.

When in a menu, use the CURSOR keys or rotary knob for menu item cursor control.

When displaying a menu value, use the CURSOR keys for cursor control and rotate the

knob to change the value. Pressing the knob opens a menu item or selects a menu option

or value.

6 Display annunciators (not shown):

EDIT Unit is in the source editing mode.

ERR Questionable reading or invalid cal step.

REM Unit in remote mode.

TALK Unit addressed to talk.

LSTN Unit addressed to listen.

SRQ Service request.

FILT Analog filter or Averaging filter is enabled.

MATH Math is enabled.

AUTO Auto source range selected.

ARM Sweep or delta function armed and ready to run.

TRIG External triggering selected.

* (asterisk) Readings being stored in buffer.

SMPL Blinks for every other reading acquired from the Model 2182/2182A.

Return to Section 1 topics

Page 22

1-8 Getting Started Model 6220/6221 User’s Manual

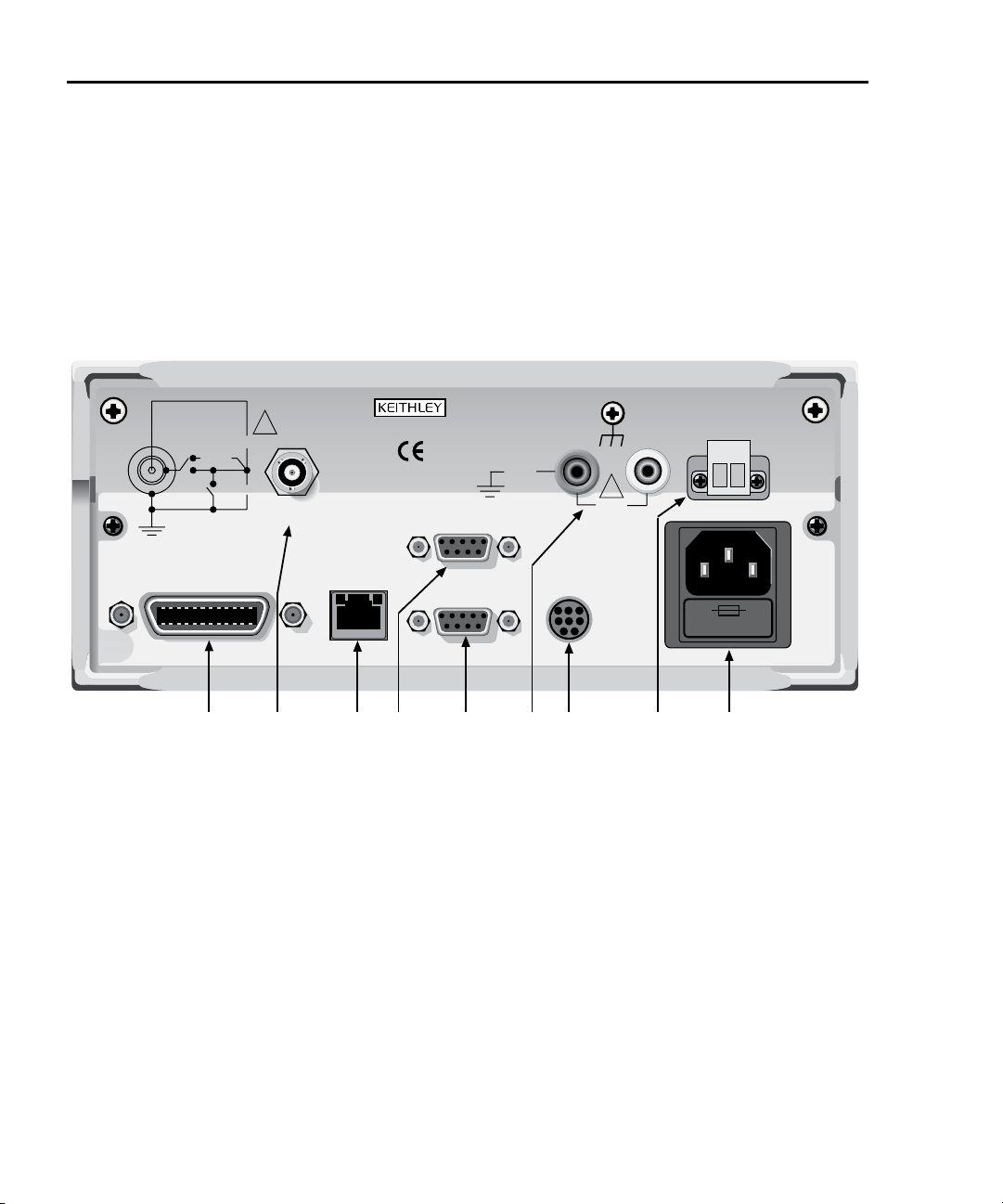

Rear panel summaries

The rear panel of the Models 622x is shown in Figure 1-2. The Model 6221 rear

panel is shown, but the Model 6220 is identical except it does not have the Ethernet connector. The descriptions of the rear panel components follow Figure 1-2.

Figure 1-2

Model 622x rear panel

NOTE

The rear panels of the Model 6220 and 6221 are the same, except the

Model 6220 does not have an Ethernet connector (3).

105Vpk

105Vpk

250Vpk

HI

!

OUTPUT

CAT I

10bT 100bT

ETHERNET

10/100 BaseT

MADE IN

U.S.A.

DIGITAL I/O

RS-232

250Vpk

LO

TRIGGER

LINK

GUARD

!

105Vpk

LINE FUSE

SLOWBLOW

1.6A, 250V

LINE RATING

100-240VAC

50, 60Hz

120VA MAX.

INTERNALLY

SWITCHED

1 AMP MAX.

CABLE

GUARD

LO

IEEE-488

(CHANGE IEEE ADDRESS

WITH FRONT PANEL MENU)

1 234567 89

6221 only

1 IEEE-488

Connector for IEEE-488 (GPIB) operation. Use a shielded cable, such as the Model

7007-1 or 7007-2.

2 OUTPUT

3-lug female triax connector for current source output. Mates to the supplied triax cable

(237-ALG-2). Will also mate to any triax cable terminated with a 3-slot male triax connector.

INTERLOCK

3 ETHERNET

RJ45 female connector for Ethernet operation. Use an RJ45 male/male cable for connection. Two status LEDs are located at the top of the connector. These LEDs indicate status

of the Ethernet (see Section 10 of the Reference Manual for details).

Return to Section 1 topics

Page 23

Model 6220/6221 User’s Manual Getting Started 1-9

4 DIGITAL I/O

Male DB-9 connector. Four pins for digital output, one pin for Start of Test (SOT) trigger,

and one for external voltage (VEXT) input.

5 RS-232

Female DB-9 connector:

• For RS-232 operation, use a straight-through (not null modem) DB-9 shielded cable

for connection to the PC.

• For Delta, Pulse Delta, and Differential Conductance, use the supplied serial cable

(CA-351) for connections between the Model 622x and the Model 2182/2182A

.

6 LO and GUARD

Banana safety jacks for output low and banana jack Guard.

7 TRIGGER LINK

Eight-pin micro-DIN connector for sending and receiving trigger pulses among connected

instruments. Use a trigger link cable (Model 8501) for connections.

8 INTERLOCK

Interlock connector – Provides two screw terminals for connection to an interlock switch.

When the interlock switch is closed, the OUTPUT of the 622x is enabled, allowing it to be

turned on. When the interlock switch is opened, the OUTPUT is disabled (OUTPUT cannot be turned on and will turn off if it was on).

9 Power module

Contains the AC line receptacle and power line fuse. The instrument can operate on line

voltages of 100V to 240VAC at line frequencies of 50 or 60Hz.

Heat sink and cooling vents

The Model 622x uses a heat sink and three cooling vents to dissipate heat. The

right side of the case is cut out to expose the black, finned heat sink. Cooling

vents are provided on both sides of the case and on the top cover.

The heat sink could get hot enough to cause burns. Even if the instrument is

turned off, you should assume that the heat sink is still hot as it takes considerable

time for it to cool off.

Return to Section 1 topics

Page 24

1-10 Getting Started Model 6220/6221 User’s Manual

WARNING When handling the Model 622x, NEVER touch the heat sink

located on the right side of the case. This heat sink could be

hot enough to cause burns.

CAUTION NEVER place a container of liquid (e.g., water, coffee, etc.) on

the top cover. If it spills, the liquid will enter the case through

the vents and cause severe damage.

Excessive heat could damage the Model 622x and at the very least, degrade its

performance. The Model 622x must be operating in an environment where the

ambient temperature does not exceed 50°C.

CAUTION To prevent damaging heat build-up and thus ensure specified

performance, adhere to the following precautions:

• The heat sink must be kept free of dust, dirt, and contaminates, since its ability to dissipate heat could become

impaired.

• The cooling vents must be kept free of any obstructions.

DO NOT place any objects on the top cover. Even partial

blockage could impair proper cooling.

• DO NOT position any devices adjacent to the Model 622x

that force air (heated or unheated) into or onto its cooling

vents or surfaces. This additional airflow could compromise accuracy performance.

• For bench top use, the Model 622x can be placed on a hard

surface that is at ambient temperature. The feet of the

Model 622x will raise the chassis off the surface to allow

adequate ventilation under the unit. DO NOT use the Model

622x on a soft, compliant surface, like a carpet.

• The Model 622x can be set on top of another instrument

that is dissipating heat, but additional spacing is required.

In order to maintain full power capability, 1.75” of spacing

is required. The feet of the Model 622x only provide 0.625”

(5/8”) of spacing.

• Rack mounting requires 1U of vertical spacing at the top

and bottom of the Model 622x. 1U is a standard vertical

spacing unit and is equal to 1.75”. The typical distance

between the mounting screw holes on the rack rails is

0.125” (1/8”).

• When rack mounting the Model 622x, make sure there is

adequate airflow around the sides and top to ensure proper

cooling. Adequate airflow enables air temperatures within

approximately one inch of the Model 622x surfaces to

remain within specified limits under all operating conditions.

Return to Section 1 topics

Page 25

Model 6220/6221 User’s Manual Getting Started 1-11

• Rack mounting high power dissipation equipment adjacent

to the Model 622x could cause excessive heating to occur.

The specified ambient temperature must be maintained

around the surfaces of the Model 622x to specified accuracies.

• A good measure to ensure proper cooling in rack situations with convection cooling only is to place the hottest

equipment (e.g., power supply) at the top of the rack. Precision equipment, such as the Model 622x, should be placed

as low as possible in the rack where temperatures are

coolest. Adding space panels below the Model 622x will

help ensure adequate air flow.

Power-up

WARNING When handling the Model 622x, NEVER touch the heat sink

located on the right side of the case. This heat sink could be

hot enough to cause burns.

Line power connection

Follow the procedure below to connect the Model 622x to line power and turn on

the instrument. The current source operates from a line voltage of 100 to 240V at

a frequency of 50 or 60Hz. Line voltage and line frequency are automatically

sensed. There are no switches to set. Make sure the operating voltage in your

area is compatible.

CAUTION Operating the instrument on an incorrect line voltage may

cause damage to the instrument, possibly voiding the warranty.

1. Before plugging in the power cord, make sure that the front panel power

switch is in the off (O) position.

2. Connect the female end of the supplied power cord to the AC receptacle on

the rear panel. Connect the other end of the power cord to a grounded AC

outlet.

Return to Section 1 topics

Page 26

1-12 Getting Started Model 6220/6221 User’s Manual

WARNING The power cord supplied with the Model 622x contains a sepa-

rate ground wire for use with grounded outlets. When proper

connections are made, instrument chassis is connected to

power line ground through the ground wire in the power cord.

Failure to use a grounded outlet may result in personal injury

or death due to electric shock.

3. Turn on the instrument by pressing the front panel power switch to the on (I)

position.

Source preset

The PRES key can be used to set the source to a preset value. When the PRES

key is pressed, the source will set to the preset value (“PRES” message displayed). When the PRES key is pressed again, the unit will return to the original

source value. See “Source preset” on page 3-12 for details on setting the preset

value.

Disabling the front panel

The front panel (display and most controls) can be disabled to allow testing on

light sensitive devices; eliminate step-to-step timing jitter for Sweeps, Delta, and

Differential Conductance; and increase system speed.

The front panel can be disabled by pressing the DISP key. The following message

will be briefly displayed before the display shuts off:

FRONT PANEL DISABLED

Press LOCAL or DISP to resume.

As indicated in the displayed message, press LOCAL or DISP to enable the front

panel.

Remote programming – Use the following command to control the front panel:

DISPlay:ENABle <b> ‘

Enable or disable the front panel.

<b> = ON or OFF.

‘

Default setting is front panel ON.

‘

Step-to-step timing jitter

For Sweeps, Delta, and Differential Conductance, step-to-step timing may jitter as

much as 1ms. This jitter can be eliminated by disabling the front panel.

If the display is disabled while a Sweep, Delta, or Differential Conductance is running, a 2-second pause in continuous operation will occur. To avoid this pause,

disable the front panel before arming the Sweep, Delta or Differential Conductance test. Keep in mind that remote programming must then be used to arm and

start the test.

Return to Section 1 topics

Page 27

Model 6220/6221 User’s Manual Getting Started 1-13

Menus

Many aspects of operation are configured through menus. A direct access menu

can be opened by pressing a single key, and other menus require that the

CONGIF key be pressed before pressing another key.

CONFIG menus

NOTE “Press CONFIG > Press SWP” is an example of a key-

press sequence. To open the menu, press the CONFIG

key and then the SWP key.

Models 6220 and 6221:

CONFIG > SWP opens CONFIGURE SWEEPS menu (Section 4).

CONFIG > COND opens DIFF CONDUCTANCE menu (Section 5).

CONFIG > DELTA opens CONFIGURE DELTA menu (Section 5).

CONFIG > TRIG opens CONFIGURE TRIGGER menu (Section 8 of the

622x Reference Manual).

CONFIG > RECALL opens CLEAR BUFFER? menu (Section 6).

CONFIG > MATH opens CONFIGURE MATH menu (Section 6).

Model 6221 only:

CONFIG > PULSE opens CONFIG PULSE DELTA menu (Section 5).

CONFIG > WAVE opens CONFIGURE WAVEFORM menu (Section 7).

CONFIG > OUTPUT opens OUTPUT RESPONSE menu (Section 3).

Direct access menus

NOTE All of the following keys to open direct access menus (ex-

cept RECALL) can also be opened by first pressing the

CONFIG key.

Models 6220 and 6221:

COMM opens COMMUNICATIONS SETUP menu (page 1-17).

ADDR opens ADDRESS = (value) menu for GPIB.

UNITS opens READING UNITS menu (Section 3).

RECALL opens menu for stored readings and statistics (Section 6).

SAVE opens SAVED SETUP MENU (page 1-18).

SETUP opens RESTORE SETUP menu (page 1-18).

TRIAX opens CONFIGURE TRIAX menu (Section 2).

MENU opens MAIN MENU (see “MAIN menu” below).

Return to Section 1 topics

Page 28

1-14 Getting Started Model 6220/6221 User’s Manual

Model 6221:

AMPL opens menu to set AMPL: (value) (Section 7).

FREQ opens menu to set FREQ (frequency) (Section 7).

MAIN menu

The MAIN MENU is a direct access menu that is opened by pressing the MENU

key. Menu items include CAL, TEST, SERIAL#, and BEEPER. See Section 1 of

the Reference Manual for more information on these MAIN MENU items.

Editing controls

Source and compliance editing

When the Model 622x is in the edit mode (EDIT annunciator on), the editing controls are used to set source and compliance values. The typical way to enter the

edit mode is to press the EDIT key. Details on “Source and compliance editing”

are provided on page 3-8.

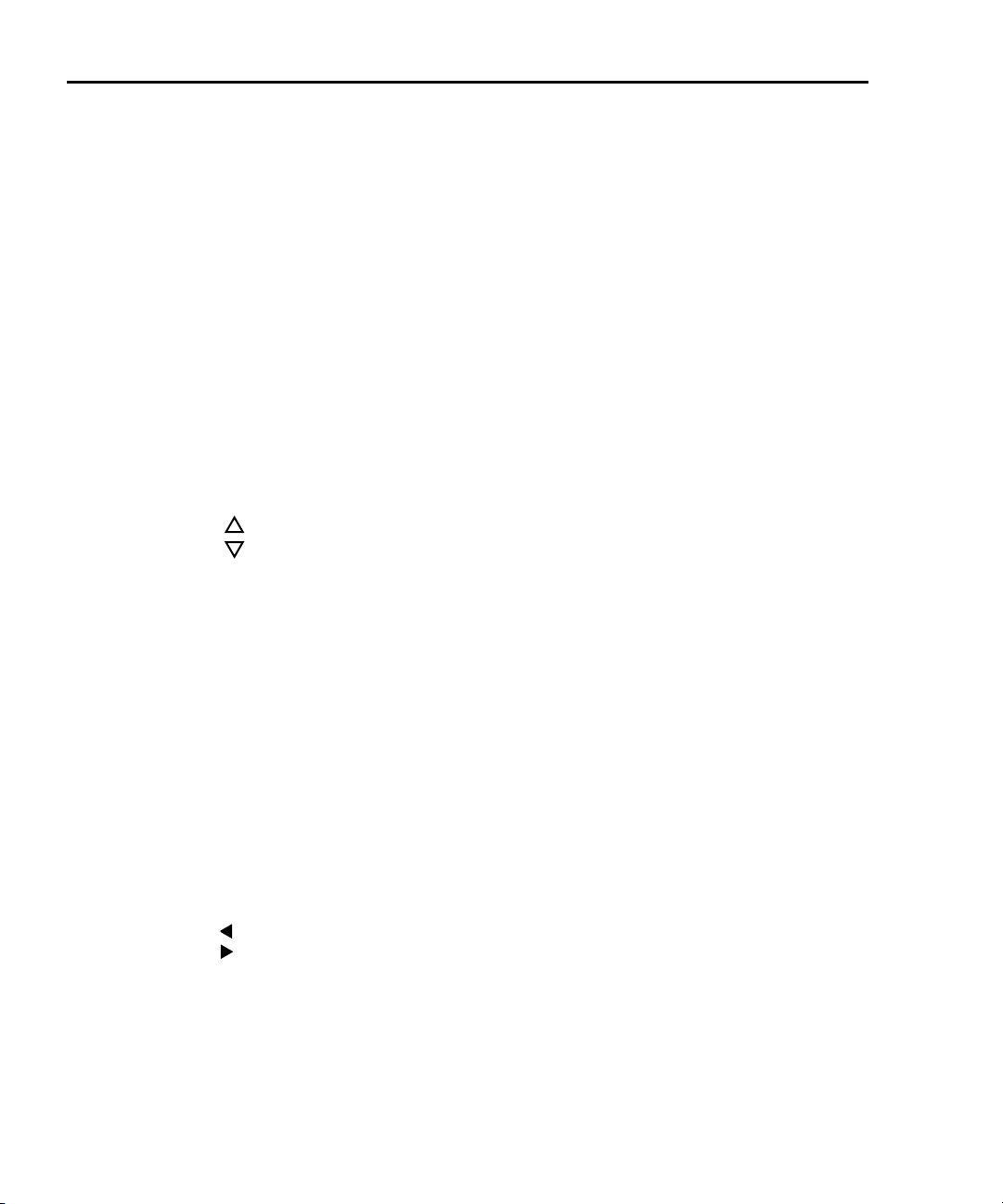

Menu navigation

When the Model 622x is not in the edit mode (EDIT annunciator off), the editing

controls (see Figure 1-3) are used to navigate menus to make selections and/or

set values.

Figure 1-3

Menu editing keys

6220 Editing Keys: 6221 Editing Keys:

Cursor Keys

Value Adjust Keys

RANGE

RANGE

Numeric Entry Keys

0 1 2 3 4 5 6 7 8 9 +/ 0000

ENTER / EXIT Keys

EXIT ENTER

Rotary Knob & Cursor Keys

PUSH TO ENTER

CURSOR

Cursor Keys

AMPL

FREQ

(right)(left)

Return to Section 1 topics

Value Adjust Keys

RANGE

RANGE

Numeric Entry Keys

0 1 2 3 4 5 6 7 8 9 +/ 0000

ENTER / EXIT Keys

EXIT ENTER

Page 29

Model 6220/6221 User’s Manual Getting Started 1-15

Model 6220 menu navigation

After entering a menu structure, use the editing keys as follows:

Selecting menu items

1. Use the Cursor Keys to place the blinking cursor on a menu item to be

opened or selected.

2. Press the ENTER key to select an item or open a sub menu.

3. Use the EXIT key to cancel a change or back out of the menu structure.

Setting a value

There are two ways to adjust a value: value adjust or numeric entry. Both methods

use the following editing techniques:

• To set a value to zero, press the 0000 numeric entry key.

• To toggle the polarity of a value, press the +/– numeric entry key.

Value adjust method:

1. Use the Cursor Keys to place the blinking cursor on the digit to be edited.

2. Use the Value Adjust Keys to increment or decrement the value of the digit.

Digit(s) to the left may also change as the edited value is changed beyond

“9” or under “0”.

3. Repeat steps 1 and 2 as needed to set the desired value.

4. Press ENTER to select the value. Pressing EXIT will cancel the change.

Numeric entry method:

1. Use the Cursor Keys to place the blinking cursor on the most significant

digit to be edited.

2. Key in a digit by pressing a Numeric Entry Key (0 to 9), The cursor moves

to the next digit on the right.

3. Repeat step 2 as needed to set the desired value.

4. Press ENTER to select the value. Pressing EXIT will cancel the change.

Return to Section 1 topics

Page 30

1-16 Getting Started Model 6220/6221 User’s Manual

Model 6221 menu navigation

Editing for the Model 6221 is basically the same as editing for the Model 6220,

except for the following differences:

• Cursor control is provided by the Cursor Keys located under the rotary

knob.

• When at a menu level that requires an item to be selected, the Rotary

Knob can also be used for cursor control. Turn the knob clockwise to move

the cursor to the right, and turn it counter-clockwise to move the cursor to

the left.

• With a value displayed, value adjust can be performed using the Rotary

Knob. Turn it clockwise to increment a digit, and turn it counter-clockwise to

decrement a digit.

• Pressing the ROTARY KNOB performs the same function as the ENTER

key. Press the knob to select or open a menu item, or to select a displayed

value.

Password

For remote programming, a user-defined password can be used to disable protected commands. Most Model 622x commands are protected. From the front

panel, the password can be cleared using the following key-press sequence:

Press COMM > Select PASSWORD > Select YES to clear the password

See Section 10 of the Reference Manual for details on password.

Return to Section 1 topics

Page 31

Model 6220/6221 User’s Manual Getting Started 1-17

Remote interface

For remote operation, one of the following interfaces can be used: GPIB, RS-232,

and (for the Model 6221) Ethernet. When using the GPIB, the SCPI or KI-220 lanuage can be used.

NOTE Interface selection and configuration can be performed

from the COMMUNICATIONS SETUP menu, which is accessed by pressing the COMM key. All details on interface selection and configuration are provided in Section

10 of the Reference Manual.

GPIB

At the factory, the GPIB (SCPI language) is the selected interface and the GPIB

address is set to 12. Use the following key-press sequence to change the

address:

Press ADDR > Set the address (0 to 30) > Press ENTER

RS-232

When the RS-232 interface is selected, the following defaults are intially set (but

can be changed):

Baud rate: 19.2k

Terminator: LF (line feed)

Flow control: None

Eight data bits, one stop bit, and no parity are used for the RS-232. These settings

are fixed and cannot be changed.

Ethernet (Model 6221 only)

The information for setting up the Ethernet is provided in Section 10 of the Reference Manual (see “Ethernet interface reference”).

Error and status messages

Error and status messages are displayed momentarily. During operation and programming, you will encounter a number of front panel messages. Typical messages are either status or error type, as listed in Appendix B of the Reference

Manual.

Return to Section 1 topics

Page 32

1-18 Getting Started Model 6220/6221 User’s Manual

Default settings

The Model 622x can be restored to one of seven setup configurations: five usersaved setups, PRESET (bench defaults), and *RST (bus defaults). As shipped

from the factory, the Model 622x powers up to the PRESET settings. PRESET settings provide a general purpose setup for front panel operation, while the *RST

settings do the same for remote operation.

NOTE User setups cannot be saved or recalled while Wave,

Sweep, Delta, Pulse Delta, or Differential Conductance is

armed or running. Attempting to do so will generate error

+413 Not allowed with mode armed.

A custom sweep cannot be saved as a user setup. Attempting to do so will generate error +528 Cannot save

CUSTOM sweep setup.

Source preset values are not saved as part of a user setup.

See Section 1 of the Reference Manual for more information on “Default settings”

including a table that lists all the default settings.

Save and restore setups

Save setup:

Press SAVE > Select SAVE > Set memory location (0 to 4) > Press ENTER

Restore user setup:

Press SETUP > Select USER > Set memory location (0 to 4) > Press ENTER

Restore PRESET defaults:

Press SETUP > Select PRESET

Restore *RST defaults:

Press SETUP > Select *RST

Remote programming

*SAV <NRf> ‘ Save present setup in memory.

*RCL <NRf> ‘‘Recall saved user setup from memory.

SYSTem:PRESet ‘ Restore PRESET default setup.

*RST ‘ Restore *RST default setup.

Return to Section 1 topics

<NRf> = 0, 1, 2, 3, or 4

Page 33

Model 6220/6221 User’s Manual Getting Started 1-19

Select power-on setup

Power-on to PRESET defaults:

Press SETUP > Select POWER ON > Select PRESET

Power-on to *RST defaults:

Press SETUP > Select POWER ON > Select *RST

Power-on to user setup:

Press SETUP > Select POWER ON > Select USER SETUP NUMBER >

Set memory location (0 to 4) > Press ENTER

Remote programming

SYSTem:POSetup <name> ‘

SCPI programming

SCPI programming information is integrated with front panel operation throughout

this manual. SCPI commands are listed in tables and additional information that

pertains exclusively to remote operation is provided after each table.

NOTE Except for Section 14 in the Reference Manual, most

SCPI tables in this manual are abridged to some degree.

That is, they may NOT include optional command words

and most query commands. Optional command words

and query commands are summarized as follows.

Optional command words

In order to be in conformance with the IEEE-488.2 and SCPI standards, the

Model 622x accepts optional command words. Any command word that is enclosed

in brackets ([]) is optional and need not be included in the program message.

Select power-on setup.

‘

<name> = RST, PRESet, SAV0, SAV1, SAV2, SAV3, or

‘

SAV4.

Query commands

Most command words have a query form. A query command is identified by the

question mark (?) that follows the command word. A query command requests

(queries) the programmed status of that command. When a query command is

sent and the Model 622x is addressed to talk, the response message is sent to

the computer.

Return to Section 1 topics

Page 34

1-20 Getting Started Model 6220/6221 User’s Manual

Return to Section 1 topics

Page 35

Section 2 topics

2

Output Connections

Output connectors, page 2-2

Triax connector, page 2-2

Ground points, page 2-3

LO and GUARD banana jacks, page 2-3

INTERLOCK, page 2-4

Output configurations, page 2-5

Triax inner shield, page 2-6

Triax output low, page 2-7

Guards, page 2-8

Triax Cable Guard, page 2-8

Floating the current source, page 2-9

Connections to DUT, page 2-9

Supplied triax cable, page 2-9

Basic connections, page 2-10

Shields and guarding, page 2-10

Using a test fixture, page 2-12

NOTE The information in this section is an abbreviated version of

the information in Section 2 of the Reference Manual. Refer to

Section 2 of the Reference Manual for complete details and

additional information that is not provided in this manual.

Page 36

2-2 Output Connections Model 6220/6221 User’s Manual

Output connectors

Triax connector

Current source output is accessed at the 3-lug female triax connector on the rear

panel. Use a 3-slot male triax cable to make connections to this connector. A triax

cable terminated with alligator clips (Model 237-ALG-2) is a supplied item for the

Model 622x (see “Supplied triax cable” on page 2-9). The triax connector is shown

in Figure 2-1.

Figure 2-1

Triax connector and grounds points

622x

Earth

Ground

Earth

Ground

Chassis

OUTPUT

1

FVR

Chassis

EARTH GROUND is a local signal ground and is defined as

the outer shield (shell) of the triax connector.

CHASSIS is defined as the metal chassis of the Model 622x.

Chassis screw terminal is connected to the metal chassis of the

Model 622x.

Chassis

Screw

Center conductor Output High

Inner shield Output Low or Cable Guard

Outer shield

(Earth Ground)

1) Frequency Variable Resistor (FVR) Isolates

the current source from high frequencies on

2

the chassis. For DC to 60Hz, the FVR is a

virtual short (zero ohms).

2) DO NOT use the Chassis Screw terminal to

make signal connections to external circuitry.

High frequency (>1MHz) on the chassis may

result in higher noise at the output.

Output Low for guarded configuration.

Triax connector terminals

The triax connector terminals are summarized as follows. For details on these terminals, see “Output configurations” on page 2-5.

Center conductor – The center conductor of the triax connector is always connected to Output High of the current source.

Inner shield – The inner shield of the triax connector can be connected to Output

Low or Cable Guard. See “Triax inner shield” on page 2-6 for details on the inner

Return to Section 2 topics

Page 37

Model 6220/6221 User’s Manual Output Connections 2-3

shield connection setting. See “Triax Cable Guard” on page 2-8 for details on

using the Cable Guard.

Outer shield – The outer shield of the triax connector is always connected to

Earth Ground of the Model 622x (see “Ground points” for details).

Frequency variable resistor (FVR)

The outer shield (Earth Ground) of the triax connector is isolated from the chassis

of the Model 622x by a Frequency Variable Resistor (FVR). The FVR (shown in

Figure 2-1) is used to isolate the current source circuitry from high frequencies

that may be present on the chassis of the Model 622x. As frequencies on the

chassis increase, the resistance of the FVR increases to dampen its effects.

Ground points

The various ground points used by the Model 622x are shown and explained in

Figure 2-1. The ground point for signal connections to external circuitry is Earth

Ground. Earth Ground is the outer shield of the triax connector and is isolated

from the Chassis by the FVR.

Keep in mind that the Chassis should never be used as a ground point for signal

connections. High frequencies present on the chassis of the Model 622x may

result in higher noise on the output.

The Chassis should only be used as a safety shield. Use the Chassis Screw for

connections to the chassis of the Model 622x.

LO and GUARD banana jacks

The LO and GUARD banana jacks are located on the rear panel and are shown in

Figure 2-2.

Figure 2-2

LO and GUARD banana jacks

GUARDLO

105Vpk

LO banana jack

The LO banana jack is electrically identical to the Output Low accessed at the

triax connector. However, when using the CABLE GUARD and FLOATING triax

settings, Output Low is not available at the triax connector. The LO banana jack

must be used as Output Low (see “Output configurations” on page 2-5 for details

on the triax connector settings).

Return to Section 2 topics

Page 38

2-4 Output Connections Model 6220/6221 User’s Manual

GUARD banana jack

The GUARD available at the banana jack is different from CABLE GUARD that

can be accessed at the triax cable. See “Guards” on page 2-8 for more information.

INTERLOCK

The Model 622x is equipped with an INTERLOCK that is to be connected to an

interlock switch (see Figure 2-3). When the interlock switch is open, the OUTPUT

of the Model 622x is disabled and cannot be turned on. If the OUTPUT is already

on, opening the interlock switch will turn the OUTPUT off. When the interlock

switch is closed, the OUTPUT is enabled and can be turned on.

Figure 2-3 shows the connector for INTERLOCK. It is a quick-disconnect

screw-terminal block. Pull the terminal block off the rear panel to connect the interlock switch.

The interlock switch is mounted on a test fixture such that the switch will open

(disable the OUTPUT) when the test fixture lid is opened. The switch will close

(enable the OUTPUT) when the test fixture lid is closed. See “Using a test fixture”

page 2-12 for details on using INTERLOCK with a test fixture.

Figure 2-3

INTERLOCK

INTERLOCK

Test Fixture

Normally

Open

Switch

NOTE The maximum allowable interlock

circuit impedance is 10W.

OUTPUT disabled

with switch open

WARNING An open INTERLOCK only disables the output from the Model

622x. If an external source is being used in the test circuit, its

voltage will be present in the test circuit. A hazardous voltage

from an external source could be connected directly to the

OUTPUT connector of the Model 622x.

As a general rule of safety, always turn off all external sources

before making or breaking connections to the test circuit.

Return to Section 2 topics

Page 39

Model 6220/6221 User’s Manual Output Connections 2-5

Output configurations

There are four configurations that can be used for current source output:

• Triax inner shield is connected to Output Low, which is connected to Earth

Ground (see Figure 2-4A).

• Triax inner shield is connected to Cable Guard and Output Low is connected to Earth Ground (see Figure 2-5A).

• Triax inner shield is connected to Output Low, which is disconnected from