Page 1

Model 2461 1 kW Pulse Mode Interactive

SourceMeter® Instrument User’s Manual

2461-900-01 Rev. A / November 2015

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

*P246190001A*

2461-900-01A

A Greater Measure of Condence

A Tektr onix Company

Page 2

Interactive SourceMeter® Instrument

Model 2461

User's Manual

© 2015, Keithley Instruments

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments is strictly prohibited.

TSP®, TSP-Link®, and TSP-Net® are trademarks of Keithley Instruments. All Keithley Instruments

product names are trademarks or registered trademarks of Keithley Instruments. Other brand

names are trademarks or registered trademarks of their respective holders.

Document number: 2461-900-01 Rev. A / November 2015

Page 3

Safety precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are measurement, control, and data I/O

connections, with low transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high

transient overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 4

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of danger. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is marked on the instrument.

The symbol on an instrument means caution, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley Instruments. Standard fuses with applicable national

safety approvals may be used if the rating and type are the same. Other components that are not safety-related may be

purchased from other suppliers as long as they are equivalent to the original component (note that selected parts should be

purchased only through Keithley Instruments to maintain accuracy and functionality of the product). If you are unsure about the

applicability of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., a data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Safety precaution revision as of January 2013.

Page 5

Introduction ............................................................................................................... 1-1

Table of Contents

Welcome .............................................................................................................................. 1-1

Introduction to this manual ................................................................................................... 1-1

Extended warranty ............................................................................................................... 1-1

Contact information .............................................................................................................. 1-2

CD-ROM contents ................................................................................................................ 1-2

Organization of manual sections .......................................................................................... 1-2

Applications .......................................................................................................................... 1-3

Using the front-panel interface ................................................................................ 2-1

Front panel overview ............................................................................................................ 2-1

Power the instrument on or off ............................................................................................. 2-3

Turn the Model 2461 output on or off ................................................................................... 2-4

Touchscreen display ............................................................................................................ 2-5

Select items on the touchscreen ............................................................................................... 2-5

Scroll bars ................................................................................................................................. 2-6

Interactive swipe screens .......................................................................................................... 2-6

Menu overview .......................................................................................................................... 2-9

Store measurements on a USB flash drive ........................................................................ 2-10

Saving screen captures to a USB flash drive .................................................................... 2-10

Using a remote interface .......................................................................................... 3-1

Remote communications interfaces ..................................................................................... 3-1

Supported remote interfaces ................................................................................................ 3-1

GPIB communications .......................................................................................................... 3-2

Install the GPIB driver software ................................................................................................. 3-2

Install the GPIB cards in your computer .................................................................................... 3-2

Connect GPIB cables to your instrument .................................................................................. 3-2

Set the GPIB address ............................................................................................................... 3-3

LAN communications ........................................................................................................... 3-4

Set up LAN communications on the instrument ........................................................................ 3-4

Set up LAN communications on the computer .......................................................................... 3-5

USB communications ........................................................................................................... 3-6

Connect a computer to the Model 2461 using USB .................................................................. 3-6

Communicate with the instrument ............................................................................................. 3-7

Using the web interface...................................................................................................... 3-10

Connect to the instrument web interface ................................................................................. 3-10

LAN troubleshooting suggestions ............................................................................................ 3-10

Identify the instrument ............................................................................................................. 3-12

Review events in the event log ................................................................................................ 3-12

Determining the command set you will use ....................................................................... 3-12

Page 6

Table of Contents Model 2461 Interactive SourceMeter® Instrument User's Manual

Making basic front-panel measurements ................................................................ 4-1

Introduction .......................................................................................................................... 4-1

Equipment required for this application................................................................................ 4-2

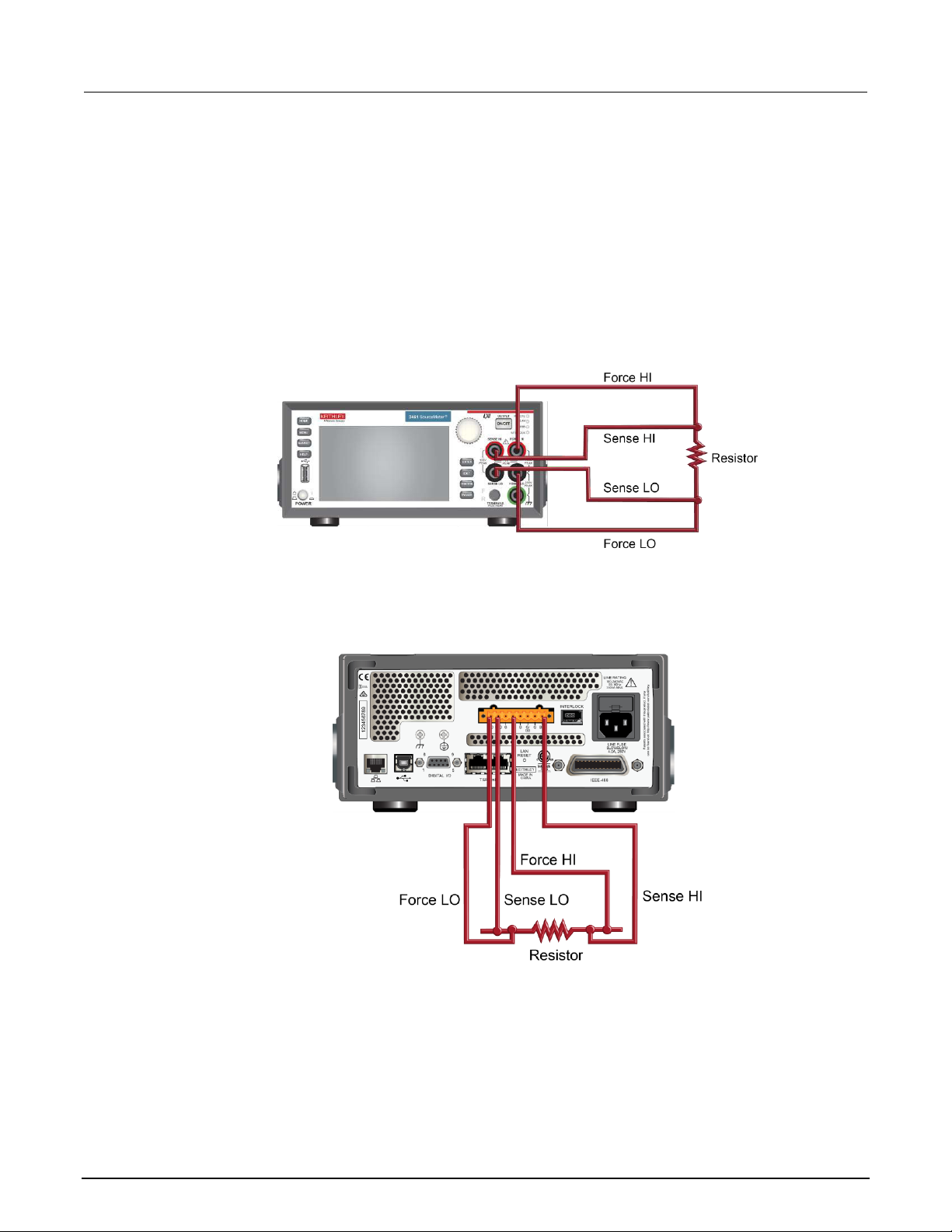

Device connections .............................................................................................................. 4-2

Make front-panel measurements ......................................................................................... 4-2

How to make front-panel measurements .................................................................................. 4-3

Measuring low-resistance devices .......................................................................... 5-1

Introduction .......................................................................................................................... 5-1

Equipment required .............................................................................................................. 5-1

Set up remote communications ........................................................................................... 5-1

Device connections .............................................................................................................. 5-2

Low-resistance measurements ............................................................................................ 5-5

Set up the measurement from the front panel ........................................................................... 5-5

View the measurements on the front-panel GRAPH swipe screen ........................................... 5-6

View the buffer statistics on the front panel ............................................................................... 5-6

Set up the low-resistance application using SCPI commands................................................... 5-6

Set up the low-resistance application using TSP commands .................................................... 5-7

Rechargeable battery measurements ...................................................................... 6-1

Introduction .......................................................................................................................... 6-1

Equipment required .............................................................................................................. 6-3

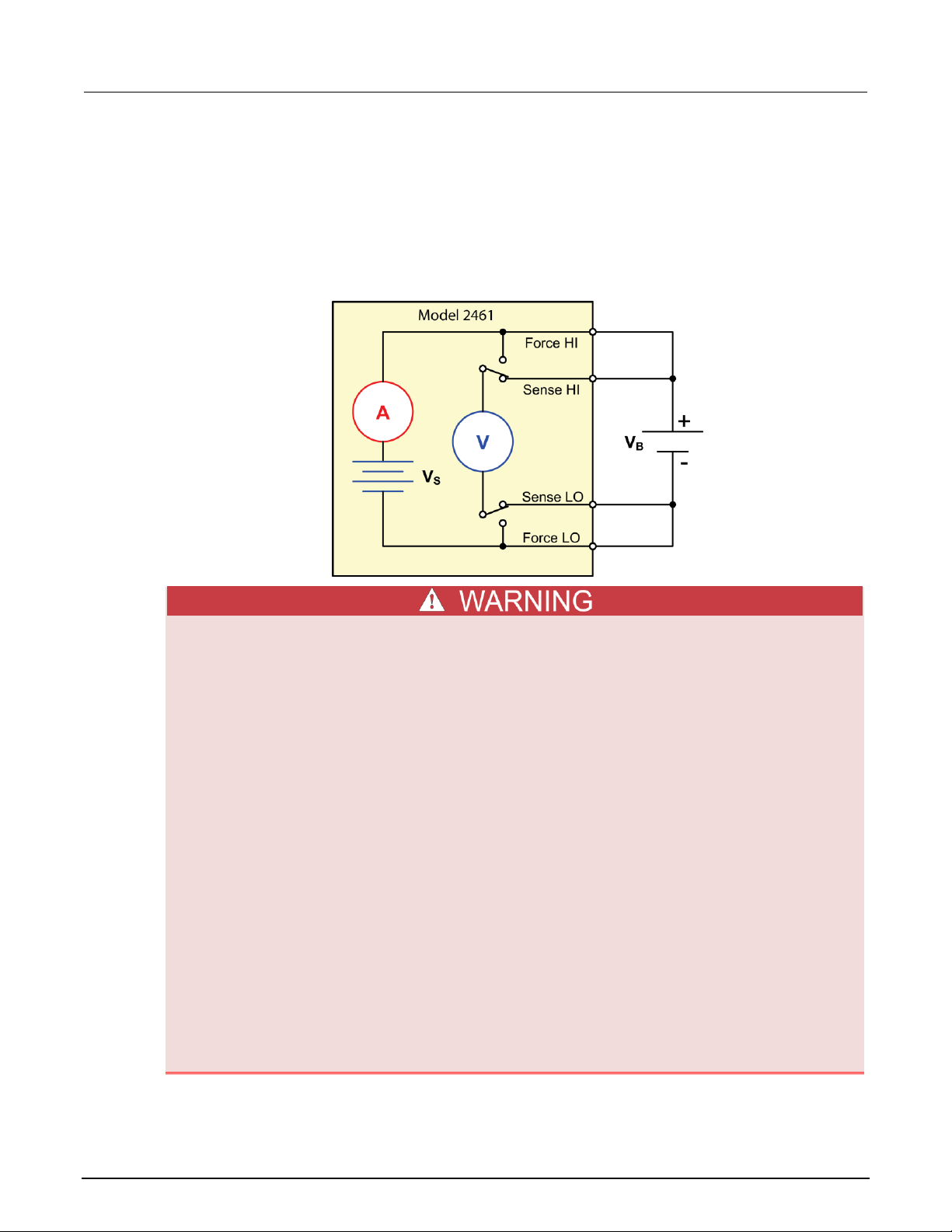

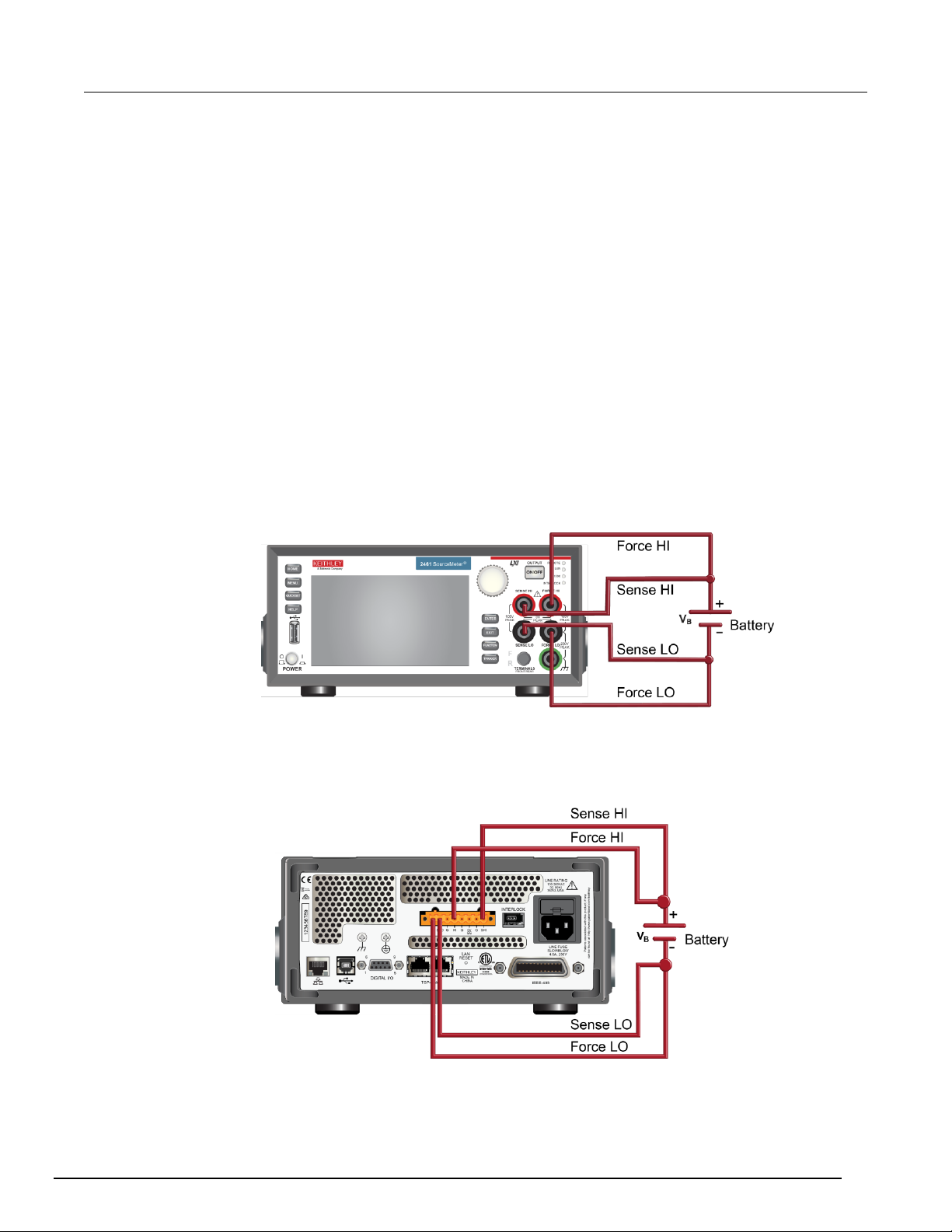

Device connections .............................................................................................................. 6-4

Automated battery charge and discharge cycle testing ....................................................... 6-6

Set up remote communications ................................................................................................. 6-7

Set up the battery application using SCPI commands .............................................................. 6-7

Set up the battery application using TSP commands ................................................................ 6-9

Generating an I-V sweep on an LED with KickStart ............................................... 7-1

Introduction .......................................................................................................................... 7-1

Equipment and software required ........................................................................................ 7-1

Set up remote communications ........................................................................................... 7-2

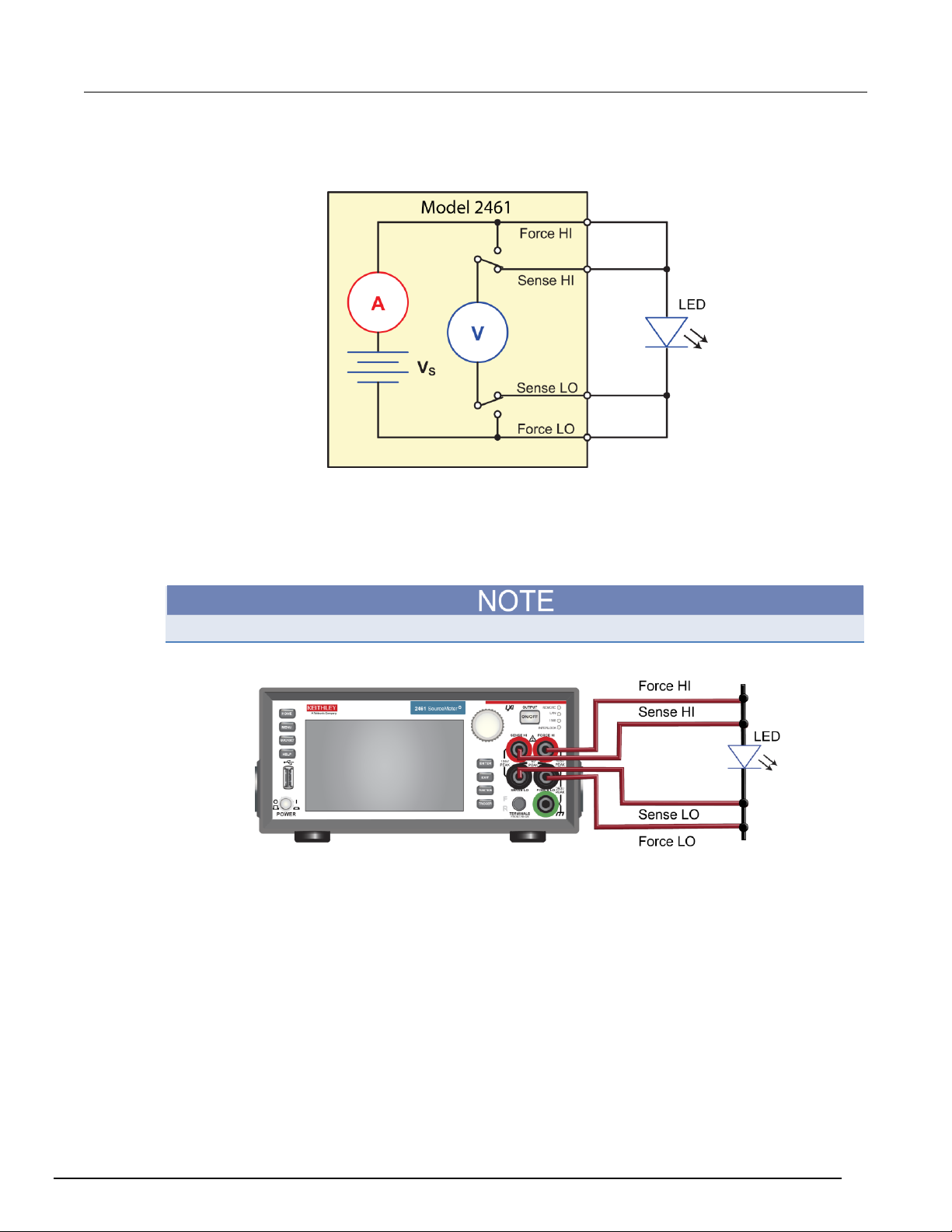

Device connections .............................................................................................................. 7-2

Generating an I-V sweep using KickStart ............................................................................ 7-4

Configure the Model 2461 to use the KickStart software .......................................................... 7-4

Launch KickStart and set up the test ......................................................................................... 7-5

Run the test and view the graph ................................................................................................ 7-7

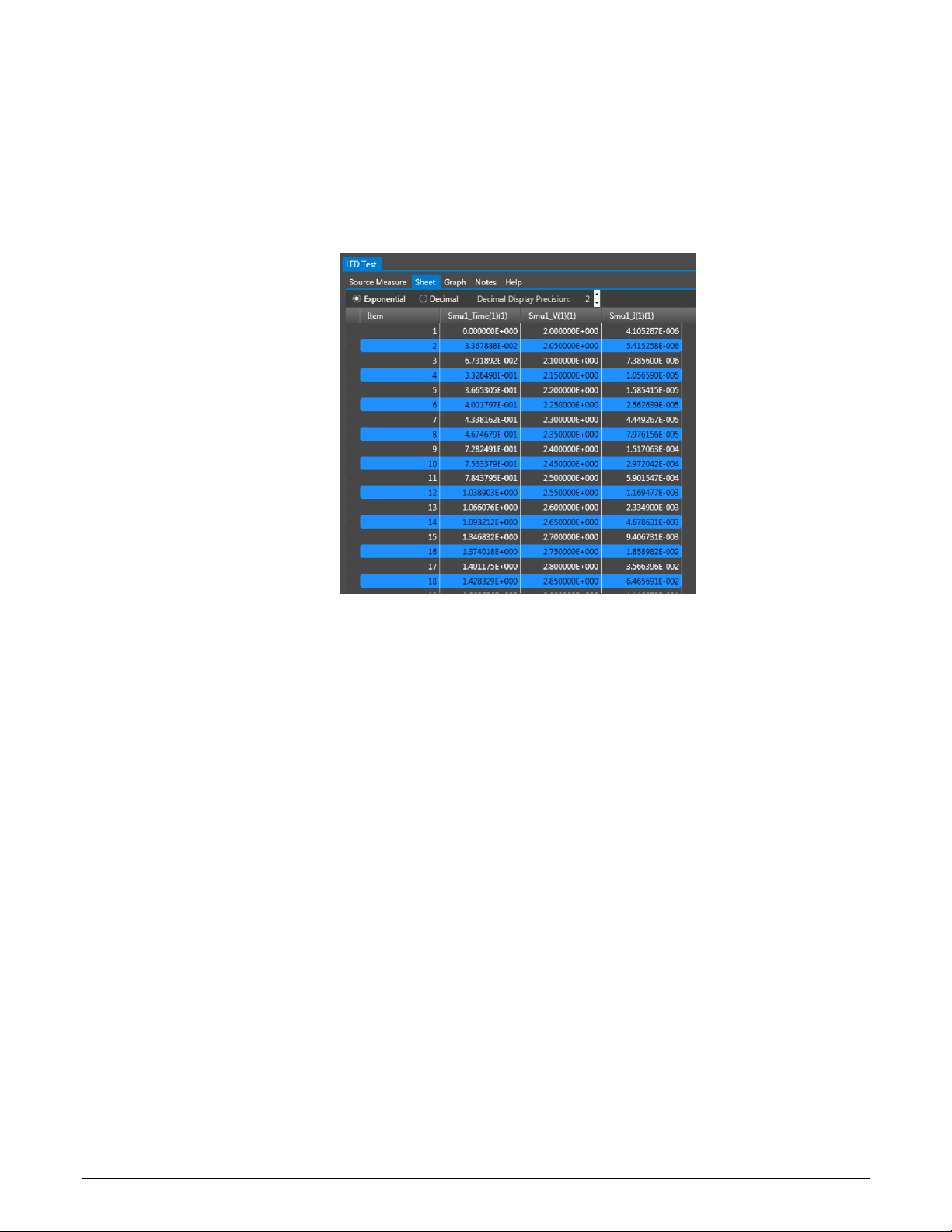

View and save the test data in tabular form .............................................................................. 7-8

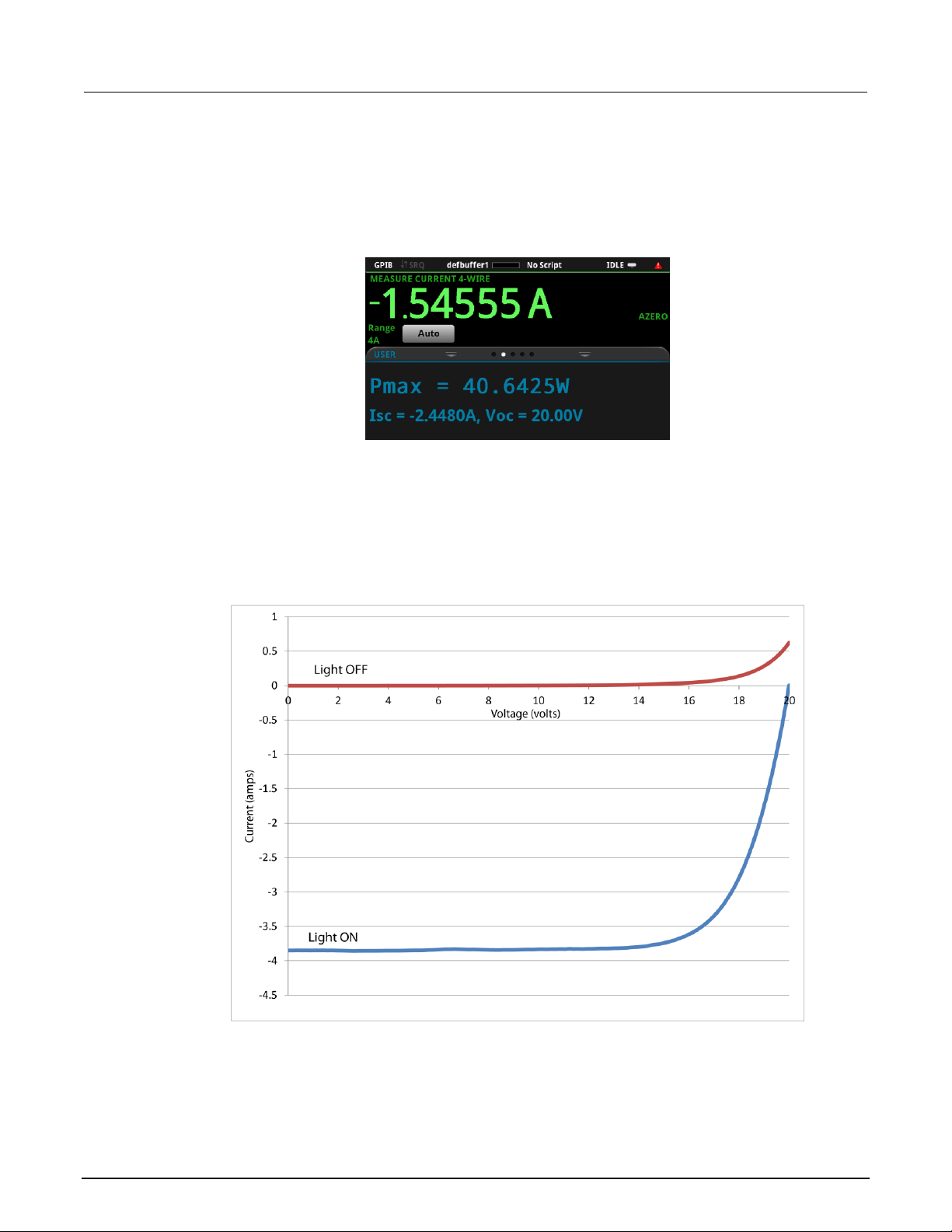

Measuring I-V characteristics of a solar panel ....................................................... 8-1

Introduction .......................................................................................................................... 8-1

Equipment required .............................................................................................................. 8-1

Page 7

Model 2461 Interactive SourceMeter® Instrument User's Manual Table of Contents

Set up remote communications ........................................................................................... 8-2

Device connections .............................................................................................................. 8-2

Solar panel characterization ................................................................................................ 8-4

Set up the solar panel I-V sweep from the front panel .............................................................. 8-4

Set up the solar panel I-V sweep using SCPI commands ......................................................... 8-6

Set up the solar panel I-V sweep using TSP commands .......................................................... 8-6

Pulse Testing High-Brightness LEDs ...................................................................... 9-1

Introduction .......................................................................................................................... 9-1

Equipment required .............................................................................................................. 9-1

Set up remote communications ........................................................................................... 9-2

Device connections .............................................................................................................. 9-2

High-speed, high-power pulses from a remote interface ..................................................... 9-4

Define the pulse sweep test parameters ................................................................................... 9-5

Set up the source and measure functions ................................................................................. 9-6

The pulse command's trigger model ......................................................................................... 9-6

Front-panel operations to output a high-current pulse sweep ................................................... 9-7

SCPI commands to output a high-current pulse sweep ............................................................ 9-7

TSP commands to output a high-current pulse train ................................................................. 9-8

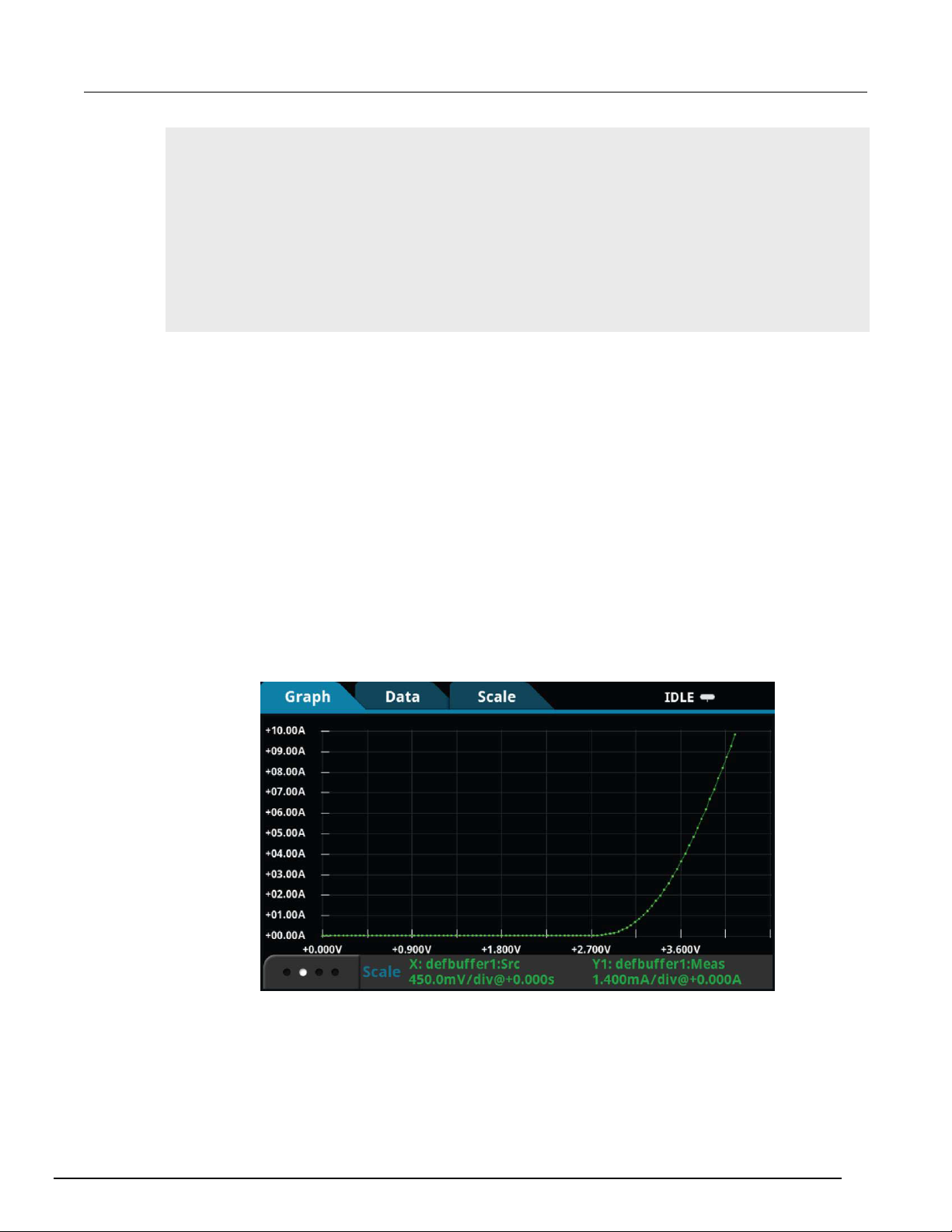

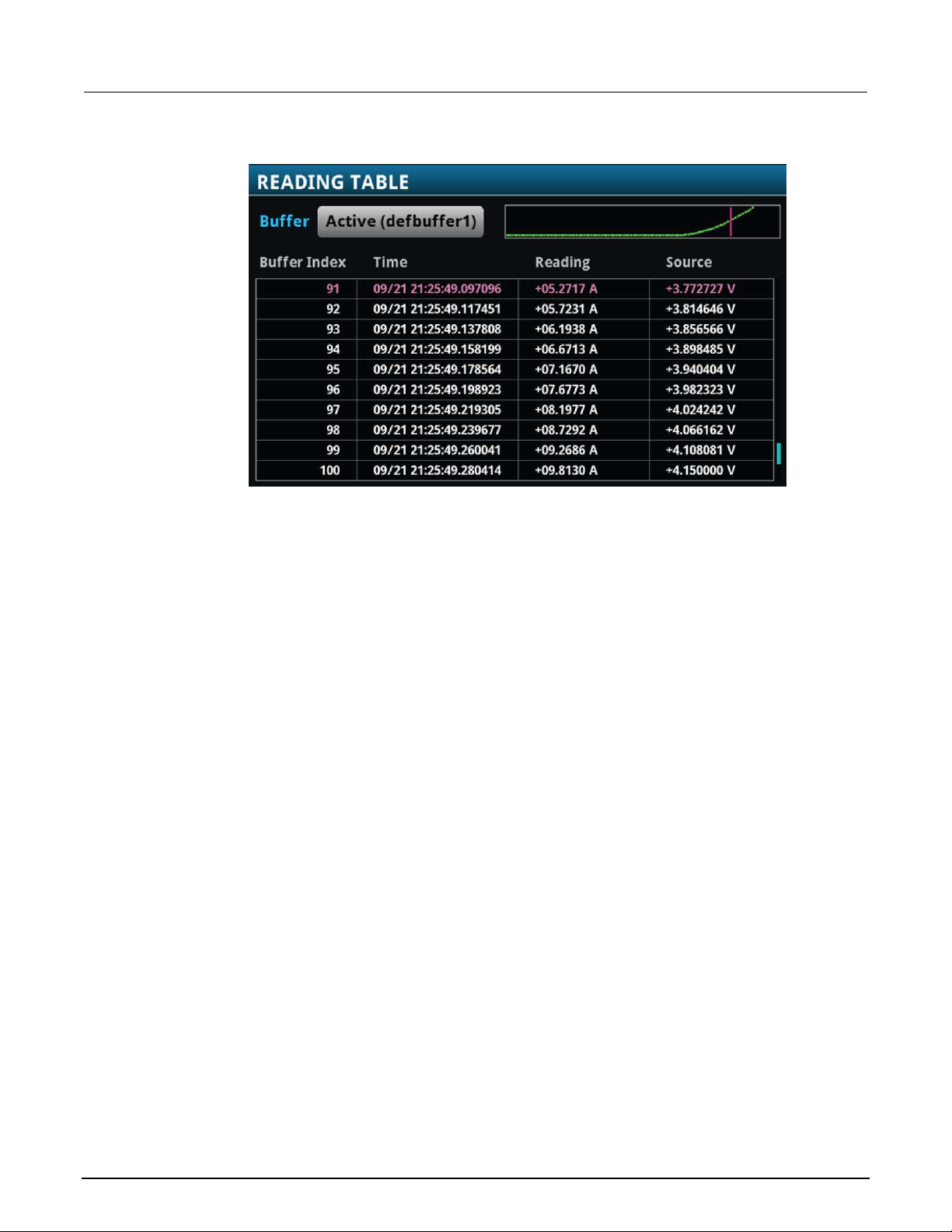

Viewing the results on the front panel ....................................................................................... 9-9

Capturing high-power pulse waveforms ............................................................... 10-1

Introduction ........................................................................................................................ 10-1

Equipment required ............................................................................................................ 10-1

Set up remote communications ......................................................................................... 10-2

Device connections ............................................................................................................ 10-2

High-speed, high-power pulses from a remote interface ................................................... 10-4

Define the pulse train test parameters .................................................................................... 10-5

The trigger model of the pulse command ................................................................................ 10-6

Front panel operations to output high-current pulses .............................................................. 10-7

SCPI commands to output high-current pulses ....................................................................... 10-7

TSP commands to output a high-power pulse waveforms ...................................................... 10-8

Viewing the measure waveform on the front panel ................................................................. 10-9

Viewing the source and digitize waveforms simultaneously on the front panel ..................... 10-10

Troubleshooting FAQs ........................................................................................... 11-1

About this section ............................................................................................................... 11-1

Where can I find updated drivers? ..................................................................................... 11-1

How do I upgrade the firmware? ........................................................................................ 11-2

Why can't the Model 2461 read my USB flash drive?........................................................ 11-2

How do I change the command set? ................................................................................. 11-2

Why am I getting a 5074 event code? ............................................................................... 11-3

How do I save the present state of the instrument? .......................................................... 11-4

Why did my settings change? ............................................................................................ 11-4

Page 8

Table of Contents Model 2461 Interactive SourceMeter® Instrument User's Manual

What are the Quick Setup options? ................................................................................... 11-5

Next steps ............................................................................................................... 12-1

Additional Model 2461 information ..................................................................................... 12-1

Page 9

In this section:

Welcome .................................................................................. 1-1

Introduction to this manual ....................................................... 1-1

Extended warranty ................................................................... 1-1

Contact information .................................................................. 1-2

CD-ROM contents .................................................................... 1-2

Organization of manual sections .............................................. 1-2

Applications .............................................................................. 1-3

Section 1

Introduction

Welcome

Thank you for choosing a Keithley Instruments product. The Model 2461 1 kW Pulse Mode Interactive

SourceMeter® Instrument is a precise, low-noise instrument that combines a stable DC power supply,

high-power, high-current source, electronic load, and high-impedance multimeter with pulse, contact

check, and digitize capabilities. This instrument features intuitive setup and control, enhanced signal

quality and range, and better resistivity and resistance capabilities than similar products on the

market.

The Model 2461 can source up to 7 A (10 A pulse), and features 1 A, 4 A, 5 A, 7 A, and 10 A ranges.

With 0.012 percent basic accuracy at 6½-digit resolution, the Model 2461 is a good solution for

testing a wide variety of materials and devices in applications such as power semiconductors, solar

energy, high brightness LEDs, power conversion, electrochemistry, batteries, and more.

Introduction to this manual

This manual provides detailed applications to help you achieve success with your Keithley

Instruments Model 2461. In addition, this manual provides information about the basics of the front

panel to familiarize you with the instrument.

This manual presents an overview of each application, followed by instructions to complete the

application using the front panel, SCPI code, TSP code, or Keithley KickStart Startup Software.

Extended warranty

More information about the commands that are used in these applications is available. Refer to the

SCPI and TSP command reference sections of the Model 2461 Reference Manual. This manual is on

the Product Information CD-ROM that came with your instrument.

Additional years of warranty coverage are available on many products. These valuable contracts

protect you from unbudgeted service expenses and provide additional years of protection at a fraction

of the price of a repair. Extended warranties are available on new and existing products. Contact your

local Keithley Instruments office, sales partner, or distributor for details.

Page 10

Section 1: Introduction Model 2461 Interactive SourceMeter® Instrument User's Manual

1-2 2461-900-01 Rev. A / November 2015

Contact information

If you have any questions after you review the information in this documentation, please contact your

local Keithley Instruments office, sales partner, or distributor.

CD-ROM contents

The Model 2461 instrument Interactive SourceMeter® SMU Instruments Product Information CD-ROM

(Keithley Instruments part number 24GDI-950-01) is shipped with each Model 2461 instrument.

The Model 2461 Interactive SourceMeter SMU Instrument Product Information CD-ROM

contains:

Quick Start Guide: Provides unpacking instructions, describes basic connections, reviews basic

operation information, and provides a quick test procedure to ensure the instrument is

operational.

User's Manual: Provides application examples that you can use as a starting point to create your

own applications.

Reference Manual: Includes advanced operation topics, maintenance information,

troubleshooting procedures, and in-depth descriptions of programming commands.

KickStart Startup Software Quick Start Guide: Provides instructions for the KickStart Startup

Software, which allows you to quickly make measurements and get results without having to

program test scripts.

Accessories information: Documentation for accessories that are available for the Model 2461.

Organization of manual sections

This manual is organized into the following sections:

Using the front-panel interface (on page 2-1): Describes the basics of using the front-panel

interface.

Using a remote interface (on page 3-1): Describes the basics of remote communications and

using the instrument web interface.

Application examples (see below): Provides detailed examples of how to use the Model 2461 in

some typical situations.

Page 11

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 1: Introduction

2461-900-01 Rev. A / November 2015 1-3

Troubleshooting FAQs (on page 11-1): Provides answers to frequently asked questions to help

you troubleshoot common problems encountered with the Model 2461.

Next steps (on page 12-1): Provides information about additional resources that can help you use

the Model 2461.

The PDF version of this manual contains bookmarks for each section. The manual sections are also

listed in the Table of Contents at the beginning of this manual.

For more information about bookmarks, see Adobe® Acrobat® or Reader® help.

Applications

This manual provides application examples that show you how to perform tests from the front panel

and over a remote interface. These applications are presented after the summary information about

the Model 2461. The applications include:

Making basic front-panel measurements (on page 4-1): Demonstrates the basic measurement

functionality using a single Model 2461 and a two-terminal device under test (DUT).

Measuring low-resistance devices (on page 5-1): Demonstrates how to use a Model 2461 to

make low-resistance measurements of a 20 m resistor.

Rechargeable battery measurements (on page 6-1): Demonstrates how to use a single Model

2461 to perform automated battery discharge and charge cycle testing.

Generating an I-V sweep on an LED with KickStart (on page 7-1): Demonstrates how use the

Model 2461 to test high-brightness light-emitting diodes (LEDs) using Keithley KickStart Startup

Software.

Measuring I-V characteristics of a solar panel (on page 8-1): Demonstrates using an I-V sweep to

characterize a solar panel using the Model 2461.

Making pulsed I-V measurements (on page 4-1): Demonstrates how to use the Model 2461

Interactive SourceMeter instrument to generate I-V curves of high-brightness LEDs (HBLEDs)

using the extended range pulsing capabilities of the instrument.

Capturing high-power pulse waveforms (on page 10-1): Demonstrates how to use the Model

2461 Interactive SourceMeter instrument to generate extended operating range, high-power

voltage pulses (up to 10 A at 100 V) and capture both the current and voltage waveforms of

high-power pulses.

Page 12

In this section:

Front panel overview ................................................................ 2-1

Power the instrument on or off ................................................. 2-3

Turn the Model 2461 output on or off ....................................... 2-4

Touchscreen display................................................................. 2-5

Store measurements on a USB flash drive ............................. 2-10

Saving screen captures to a USB flash drive ......................... 2-10

Section 2

Using the front-panel interface

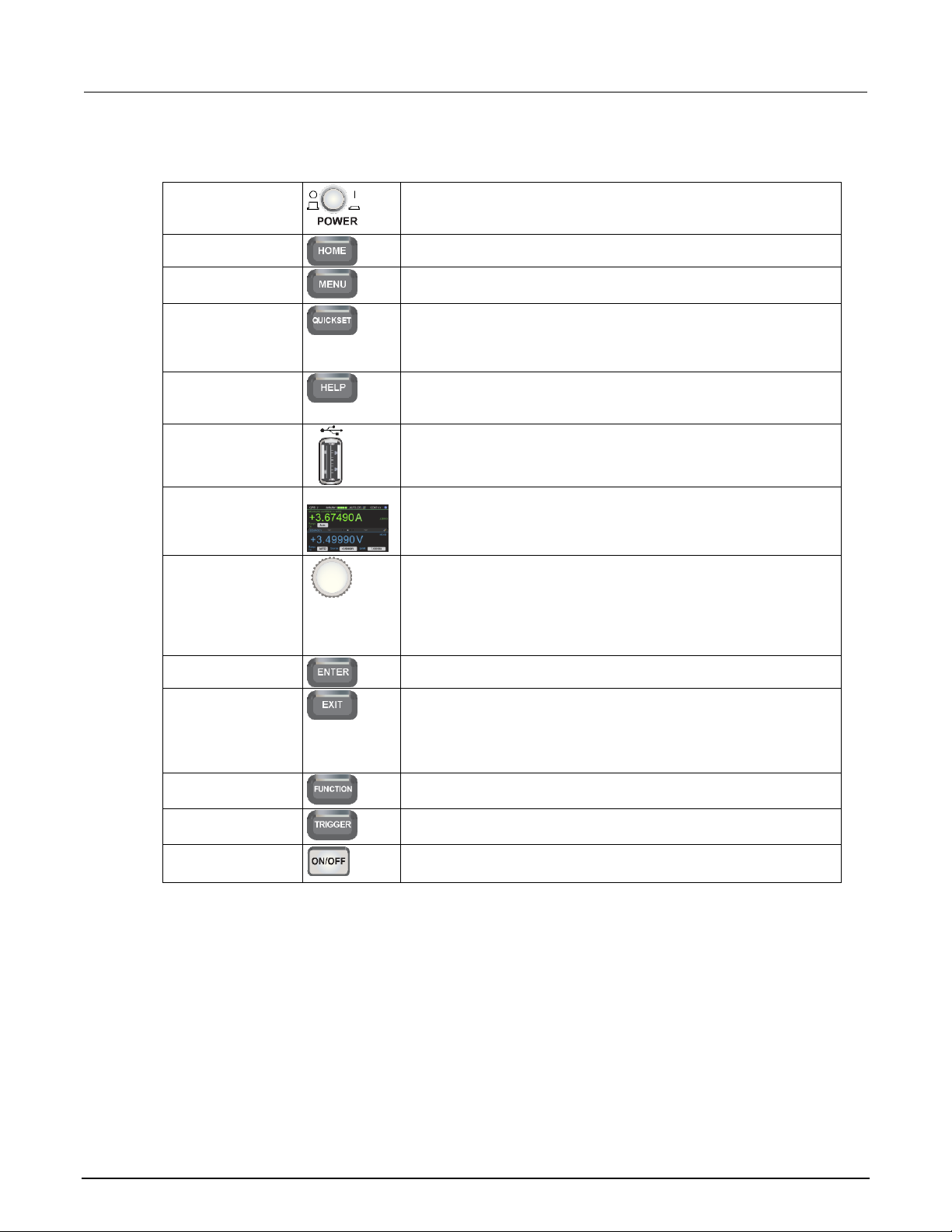

Front panel overview

The front panel of the Model 2461 is shown below. Descriptions of the controls on the front panel

follow the figure.

Figure 1: Model 2461 front panel

Page 13

Section 2: Using the front-panel interface Model 2461 Interactive SourceMeter® Instrument User's Manual

2-2 2461-900-01 Rev. A / November 2015

POWER switch

Turns the instrument on or off. To turn the instrument on, press the

power switch so that it is in the on position (|). To turn it off, press the

power switch so that it is in the off position (O).

HOME key

Returns the display to the Home screen.

MENU key

Opens the main menu. Press the icons on the main menu to open

source, measure, view, trigger, script, and system screens.

QUICKSET key

Opens a menu of preconfigured setups, including voltmeter,

ammeter, ohmmeter, and power supply. Also allows you to choose

source and measure functions and adjust performance for better

resolution or speed.

HELP key

Opens help for the area or item that is selected on the display. If

there is no selection when you press the HELP key, it displays

overview information for the screen you are viewing.

USB port

Saves reading buffer data and screen snapshots to a USB flash

drive. Also stores and retrieves scripts to and from a USB flash drive.

The flash drive must be formatted as a FAT drive.

Touchscreen

The Model 2461 has a high-resolution, five-inch color touchscreen

display. The touchscreen accesses swipe screens and menu options.

You can access additional interactive screens by pressing the

front-panel MENU, QUICKSET, and FUNCTION keys.

Navigation control

Turning the navigation control: Moves the cursor to highlight a list

value or menu item so that you can select it. Turning the control when

the cursor is in a value entry field increases or decreases the value in

the field.

Pressing the navigation control: Selects the highlighted choice or

allows you to edit the selected field.

ENTER key

Selects the highlighted choice or allows you to edit the selected field.

EXIT key

Returns to the previous screen or closes a dialog box. For example,

press the EXIT key when the main menu is displayed to return to the

Home screen. When you are viewing a subscreen (for example, the

Event Log screen), press the EXIT key to return to the main menu

screen.

FUNCTION key

Displays instrument functions. To select a function, touch the function

name on the screen.

TRIGGER key

Accesses trigger-related settings and operations. The action of the

TRIGGER key depends on the instrument state.

OUTPUT ON/OFF

switch

Turns the output source on or off. The key illuminates when the

source output is on.

Page 14

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 2: Using the front-panel interface

2461-900-01 Rev. A / November 2015 2-3

REMOTE LED

indicator

Illuminates when the instrument is controlled through a remote

interface.

LAN LED indicator

Illuminates when the instrument is connected to a local area network

(LAN).

1588 LED indicator

Illuminates when the instrument is connected to an IEEE-1588

INTERLOCK LED

indicator

Illuminates when the interlock is enabled.

SENSE terminals

Use the SENSE HI and SENSE LO terminal connections to measure

voltage at the device under test (DUT). When you use sense leads,

measurement of the voltage drop across the force leads is

eliminated. This produces more accurate voltage sourcing and

measurement at the DUT.

FORCE terminals

Use FORCE HI and FORCE LO terminal connections to source or

sink voltage or current to or from a device under test (DUT).

FRONT/REAR

TERMINALS switch

Activates the terminals on the front or rear panel. When the

front-panel terminals are active, a green "F" is visible to the left of the

FRONT/REAR switch. When the rear-panel terminals are active, a

yellow "R" is visible to the left of the switch.

Chassis connection

Banana jack connector that provides a chassis connection.

compliant device.

Note that 1588 functionality is not supported at this time. This

functionality will be made available with a firmware update.

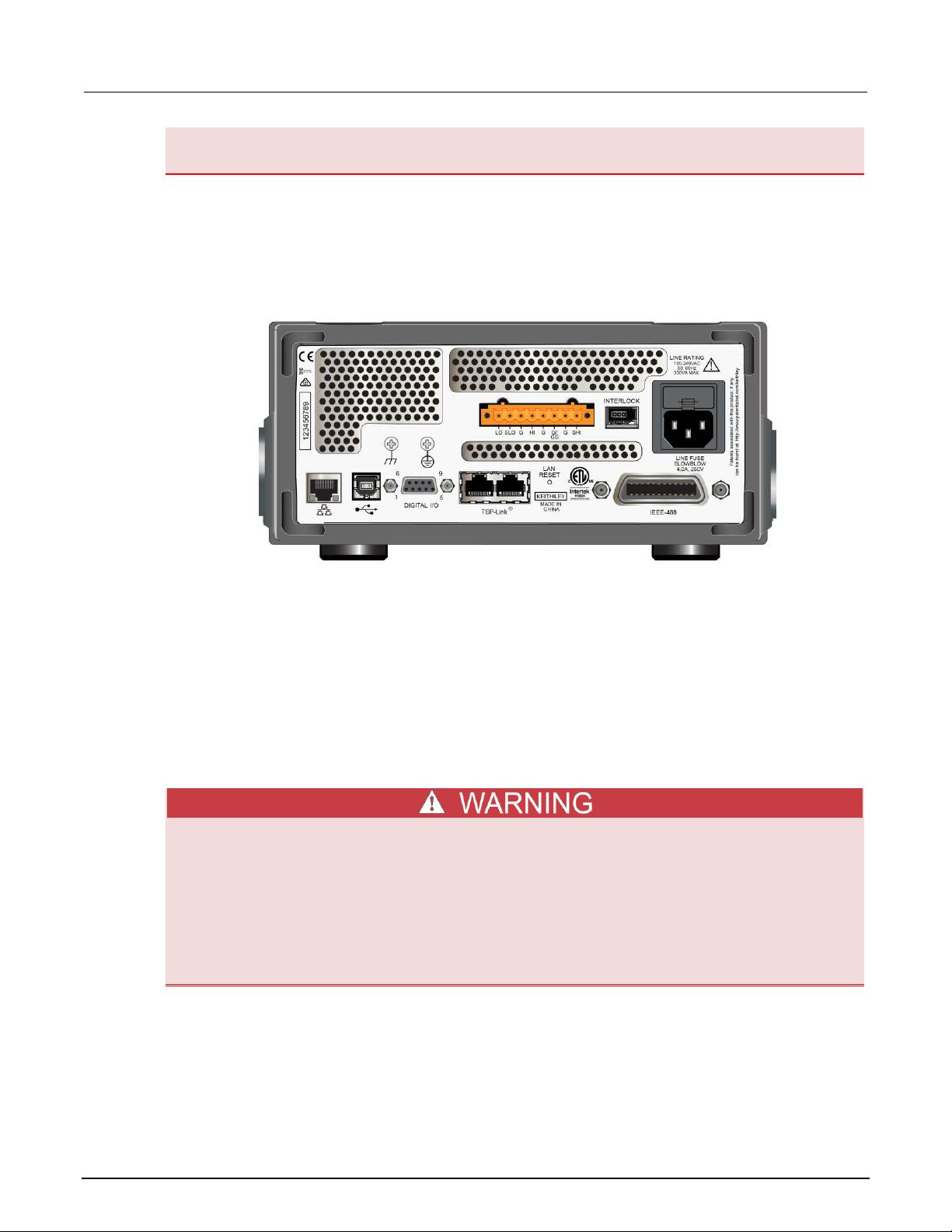

Power the instrument on or off

Follow the steps below to connect the Model 2461 to line power and turn on the instrument. The

Model 2461 operates from a line voltage of 100 V to 240 V at a frequency of 50 Hz or 60 Hz. It

automatically senses line voltage and frequency. Make sure the operating voltage in your area is

compatible.

You must turn on the Model 2461 and allow it to warm up for at least one hour to achieve rated

accuracies.

Operating the instrument on an incorrect line voltage may cause damage to the instrument, possibly

voiding the warranty.

The power cord supplied with the Model 2461 contains a separate protective earth (safety

ground) wire for use with grounded outlets. When proper connections are made, the

instrument chassis is connected to power-line ground through the ground wire in the power

cord. In addition, a redundant protective earth connection is provided through a screw on

the rear panel. This terminal should be connected to a known protective earth. In the event

of a failure, not using a properly grounded protective earth and grounded outlet may result

in personal injury or death due to electric shock.

Page 15

Section 2: Using the front-panel interface Model 2461 Interactive SourceMeter® Instrument User's Manual

2-4 2461-900-01 Rev. A / November 2015

Do not replace detachable mains supply cords with inadequately rated cords. Failure to use

properly rated cords may result in personal injury or death due to electric shock.

To connect the power cord:

1. Make sure that the front-panel POWER switch is in the off (O) position.

2. Connect the female end of the supplied power cord to the AC receptacle on the rear panel.

3. Connect the other end of the power cord to a grounded AC outlet.

Figure 2: Model 2461 rear panel

To turn a Model 2461 on or off:

1. Before turning the instrument on, disconnect any devices under test (DUTs) from the Model 2461.

2. To turn your instrument on, press the front-panel POWER switch to place it in the on (|) position.

The instrument displays a status bar as it powers on. The Home screen is displayed when power

on is complete.

3. To turn your instrument off, press the front-panel POWER switch to place it in the off (O) position.

Turn the Model 2461 output on or off

You can turn the Model 2461 output on from the front panel or by sending remote commands.

Turning the Model 2461 output off does not place the instrument in a safe state (an interlock

is provided for this function).

Hazardous voltages may be present on all output and guard terminals. To prevent electrical

shock that could cause injury or death, never make or break connections to the Model 2461

while the instrument is powered on. Turn off the equipment from the front panel or

disconnect the main power cord from the rear of the Model 2461 before handling cables.

Putting the equipment into an output-off state does not guarantee that the outputs are

powered off if a hardware or software fault occurs.

Page 16

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 2: Using the front-panel interface

2461-900-01 Rev. A / November 2015 2-5

When the source of the instrument is turned off, it may not completely isolate the instrument from the

external circuit. You can use the Output Off setting to place the Model 2461 in a known,

noninteractive state during idle periods, such as when you are changing the device under test. The

output-off states that can be selected for a Model 2461 are normal, high-impedance, zero, or guard.

See "Output-off state" in the Model 2461 Reference Manual for additional details.

Using the front panel:

Press the OUTPUT ON/OFF switch. The instrument is in the output-on state when the switch is

illuminated. The instrument is in the output-off state when the switch is not illuminated.

Using SCPI commands:

To turn the output on, send the command:

:OUTPut:STATe ON

To turn the output off, send the command:

:OUTPut:STATe OFF

Using TSP commands:

To turn the output on, send the command:

smu.source.output = smu.ON

To turn the output off, send the command:

smu.source.output = smu.OFF

Touchscreen display

The touchscreen display gives you quick front-panel access to source and measure settings, system

configuration, instrument and test status, reading buffer information, and other instrument

functionality. The display has multiple swipe screens that you can access by swiping the front panel.

You can access additional interactive screens by pressing the front-panel MENU, QUICKSET, and

FUNCTION keys.

Do not use sharp metal objects, such as tweezers or screwdrivers, or pointed objects, such as pens

or pencils, to touch the touchscreen. It is strongly recommended that you use only fingers to operate

the instrument. Use of clean-room gloves to operate the touchscreen is supported.

Select items on the touchscreen

To select an item on the displayed screen, do one of the following:

Touch it with your finger

Turn the navigation control to highlight the item, and then press the navigation control to select it

The following topics describe the Model 2461 touchscreen in more detail.

Page 17

Section 2: Using the front-panel interface Model 2461 Interactive SourceMeter® Instrument User's Manual

2-6 2461-900-01 Rev. A / November 2015

Scroll bars

Some of the interactive screens have additional options that are only visible when you scroll down the

screen. A scroll indicator on the right side of the touchscreen identifies these screens. Swipe the

screen up or down to view the additional options.

The figure below shows a screen with a scroll bar.

Figure 3: Touchscreen window with a scroll bar indicator

Interactive swipe screens

The Model 2461 touchscreen display has multiple screens that you can access by gently swiping left

or right on the lower half of the display. The options available in the swipe screens are described in

the following topics.

Swipe screen heading bar

The heading bar of the swipe screen contains the following options.

Figure 4: Swipe screens, maximized and minimized

Page 18

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 2: Using the front-panel interface

2461-900-01 Rev. A / November 2015 2-7

#

Screen element

Description

1

Minimize indicator

You can swipe down to minimize the swipe screens.

2

Swipe screen indicator

Each circle represents one swipe screen. As you swipe right or left, a different

circle changes color, indicating where you are in the screen sequence. Select a

circle to go to a swipe screen without swiping.

3

Calculations shortcut

Select to open the CALCULATIONS SETTINGS menu.

4

Settings shortcut

Select to open the MEASURE SETTINGS menu for the selected function.

5

Restore indicator

Indicates that you can swipe up to display the swipe screen.

6

Graph shortcut

Select to open the Graph screen.

SOURCE swipe screen

The SOURCE swipe screen shows the present value of the source and the set values for source,

source range, and source limit. You can change the set values from the front panel by selecting the

buttons on this screen.

Figure 5: SOURCE swipe screen

Source function indicators on the right side of the screen signify settings that affect the displayed

source value.

MEAS: Source readback is on and the value shown is the measured value of the source.

PROG: Source readback is off and the value shown is the programmed source value. If the

output is off, the displayed source value is replaced with Output Off.

The icon on the right side of the swipe screen heading bar is a shortcut to the full SOURCE

SETTINGS menu.

Page 19

Section 2: Using the front-panel interface Model 2461 Interactive SourceMeter® Instrument User's Manual

2-8 2461-900-01 Rev. A / November 2015

SETTINGS swipe screen

The SETTINGS swipe screen gives you front-panel access to some instrument settings. It shows you

the present settings and allows you to change, enable, or disable them quickly.

Figure 6: SETTINGS swipe screen

To disable or enable a setting, select the box next to the setting so that it shows an X (disabled) or a

check mark (enabled).

The icons on the right side of the swipe screen heading bar are shortcuts to the CALCULATIONS

SETTINGS and MEASURE SETTINGS menus.

For descriptions of the settings, use the navigation control to select the button, then press the HELP

key.

STATISTICS swipe screen

The STATISTICS swipe screen contains information about the readings in the active reading buffer.

When the reading buffer is configured to fill continuously and overwrite old data with new data, the

buffer statistics include the data that was overwritten. To get statistics that do not include data that

has been overwritten, define a large buffer size that will accommodate the number of readings you

will make. You can use the Clear Active Buffer button on this screen to clear the data from the

active reading buffer.

Figure 7: Model 2461 STATISTICS swipe screen

USER swipe screen

You can program custom text that appears on the USER swipe screen. For example, you can

program the Model 2461 to show that a test is in process. Refer to the Model 2461 Reference

Manual, "Customizing a message for the USER swipe screen"

Figure 8: USER swipe screen

Page 20

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 2: Using the front-panel interface

2461-900-01 Rev. A / November 2015 2-9

GRAPH swipe screen

The GRAPH swipe screen shows a graphical representation of the readings in the presently selected

reading buffer.

Figure 9: GRAPH swipe screen

To view the graph in the full screen and to access graph settings, select the graph icon on the right

side of the swipe screen header. You can also open the full-function Graph screen by pressing the

MENU key and selecting Graph under Views.

For more information about graphing measurements, see "Graphing" in the Model 2461 Reference

Manual.

Menu overview

To access the main menu, press the MENU key on the Model 2461 front panel. The figure below

shows the organization of the main menu.

Figure 10: Model 2461 main menu

The main menu includes submenus that are labeled in green across the top of the display. Touching

an icon in a submenu opens an interactive screen.

Page 21

Section 2: Using the front-panel interface Model 2461 Interactive SourceMeter® Instrument User's Manual

2-10 2461-900-01 Rev. A / November 2015

Store measurements on a USB flash drive

If there is measurement data in the buffer, you can copy it from the Model 2461 to a USB flash drive.

The information is saved in the .csv file format.

To store measurement data:

1. Insert a flash drive into the front-panel USB port.

2. Press the MENU key.

3. In the Measure column, select Reading Buffers.

4. Select the buffer that you want to save.

5. Select Save to USB.

6. Enter a name for the new file.

7. Select the OK button on the displayed keyboard.

8. Select Yes to confirm saving the file.

9. Select OK to close the dialog box.

Saving screen captures to a USB flash drive

You can save the content of the front-panel display to a graphic file. The instrument saves these

graphic files, also known as screen captures, to the USB flash drive in the .png file format.

To save the screen capture:

1. Insert a USB flash drive in the USB port on the front panel of the instrument.

2. Navigate to the screen you want to capture.

3. Press the HOME and ENTER keys. The instrument displays "Saving screen capture."

4. Release the keys.

Page 22

In this section:

Remote communications interfaces.......................................... 3-1

Supported remote interfaces .................................................... 3-1

GPIB communications .............................................................. 3-2

LAN communications................................................................ 3-4

USB communications ............................................................... 3-6

Using the web interface .......................................................... 3-10

Determining the command set you will use ............................ 3-12

Section 3

Using a remote interface

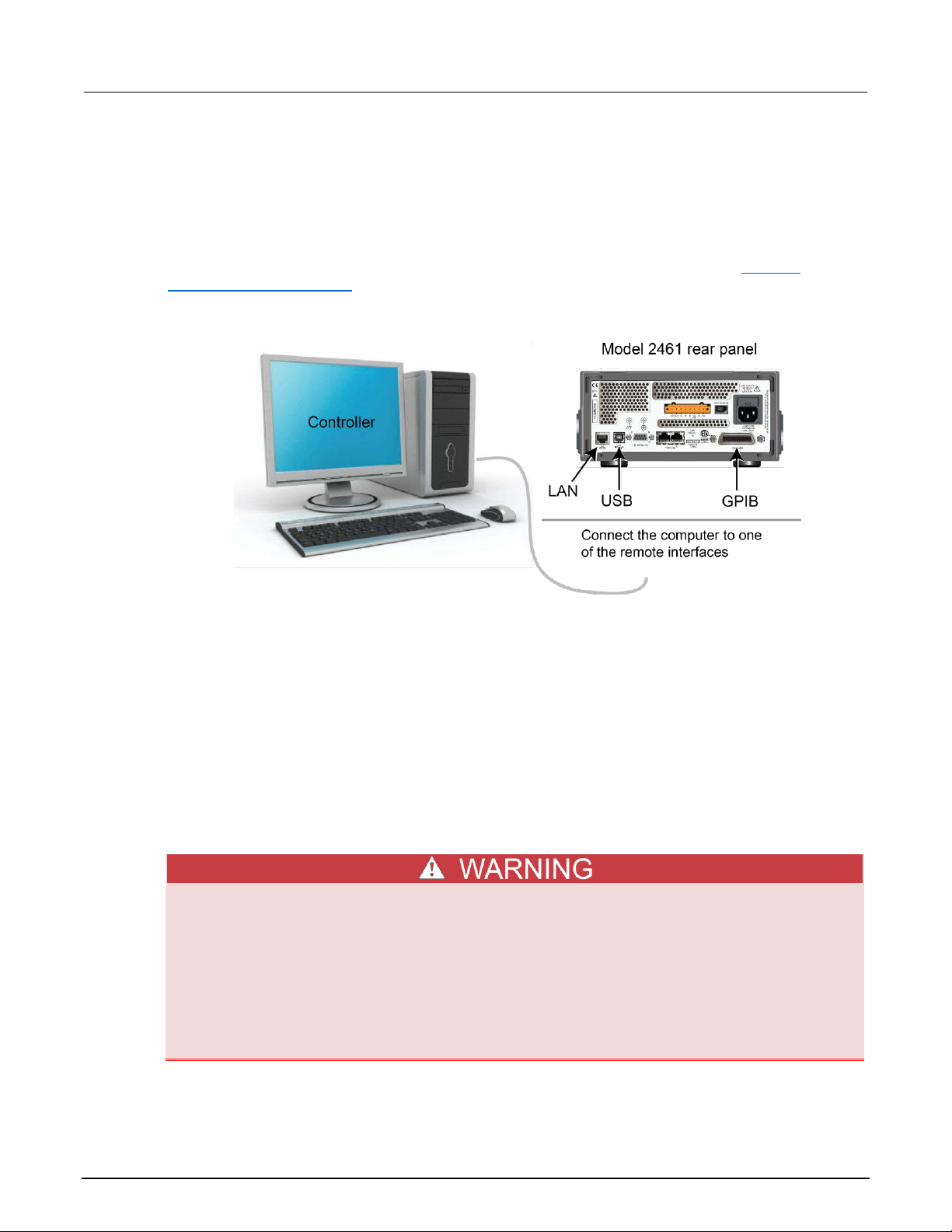

Remote communications interfaces

You can choose from one of several communication interfaces to send commands to and receive

responses from the Model 2461.

You can control the Model 2461 from only one communications interface at a time. The first interface

on which it receives a message takes control of the instrument. If another interface sends a message,

that interface can take control of the instrument. You may need to enter a password to change the

interface, depending on the access mode.

The Model 2461 automatically detects the type of communications interface (LAN, GPIB, or USB)

when you connect to the respective port on the rear panel of the instrument. In most cases, you do

not need to configure anything on the instrument. In addition, you do not need to reboot if you change

the type of interface that is connected.

Supported remote interfaces

The Model 2461 supports the following remote interfaces:

GPIB: IEEE-488 instrumentation general purpose interface bus

Ethernet: Local area network ethernet communications

USB: Type B USB port

TSP-Link: A high-speed trigger synchronization and communications bus that test system

builders can use to connect multiple instruments in a master-and-subordinate configuration

For details about TSP-Link, see "TSP-Link System Expansion Interface" in the Model 2461 Reference

Manual.

Page 23

Section 3: Using a remote interface Model 2461 Interactive SourceMeter® Instrument User's Manual

3-2 2461-900-01 Rev. A / November 2015

GPIB communications

The Model 2461 GPIB interface is IEEE Std 488.1 compliant and supports IEEE Std 488.2 common

commands and status model topology.

You can have up to 15 devices connected to a GPIB interface, including the controller. The maximum

cable length is the lesser of either:

The number of devices multiplied by 2 m (6.5 ft)

20 m (65.6 ft)

Install the GPIB driver software

You may see erratic bus operation if you ignore these limits.

Check the documentation for your GPIB controller for information about where to acquire drivers.

Keithley Instruments also recommends that you check the website of the GPIB controller for the latest

version of drivers or software.

It is important that you install the drivers before you connect the hardware. This prevents associating

the incorrect driver to the hardware.

Install the GPIB cards in your computer

Refer to the documentation from the GPIB controller vendor for information about installing the GPIB

controllers.

Connect GPIB cables to your instrument

To connect an instrument to the GPIB interface, use a cable equipped with standard GPIB

connectors, as shown below.

Figure 11: GPIB connector

Page 24

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 3: Using a remote interface

2461-900-01 Rev. A / November 2015 3-3

To allow many parallel connections to one instrument, stack the connectors. Each connector has two

screws to ensure that connections remain secure. The figure below shows a typical connection

diagram for a test system with multiple instruments.

To avoid possible mechanical damage, stack no more than three connectors on any one instrument.

To minimize interference caused by electromagnetic radiation, use only shielded GPIB cables.

Contact Keithley Instruments for shielded cables.

Figure 12: Model 2461 IEEE-488 connections

Set the GPIB address

The default GPIB address is 18. You can set the address to any address from 1 to 30 if it is unique in

the system. This address cannot conflict with an address that is assigned to another instrument or to

the GPIB controller.

GPIB controllers are usually set to 0 or 21. To be safe, do not configure any instrument to have an

address of 21. To change the controller address, see the documentation for the controller.

The instrument saves the address in nonvolatile memory. It does not change when you send a reset

command or when you turn the power off and then on again.

Page 25

Section 3: Using a remote interface Model 2461 Interactive SourceMeter® Instrument User's Manual

3-4 2461-900-01 Rev. A / November 2015

To set the GPIB address from the front panel:

1. Press the MENU key.

2. Under System, select Communication. The SYSTEM COMMUNICATIONS window opens.

3. Select the GPIB tab.

4. Next to Address, select the number. The GPIB Address dialog box is displayed.

5. Enter the address.

6. Select OK.

LAN communications

You can communicate with the instrument using a local area network (LAN).

When you connect using a LAN, you can use a web browser to access the internal web page of the

instrument and change some of the instrument settings. For more information, see Using the web

interface (on page 3-10).

The Model 2461 is an LXI version 1.4 Core 2011 compliant instrument that supports TCP/IP and

complies with IEEE Std 802.3 (ethernet LAN). There is one LAN port (located on the rear panel of the

instrument) that supports full connectivity on a 10 Mbps or 100 Mbps network. The Model 2461

automatically detects the speed.

The Model 2461 also supports Multicast DNS (mDNS) and DNS Service Discovery (DNS-SD), which

are useful on a LAN with no central administration.

Contact your network administrator to confirm your specific network requirements before setting up a

LAN connection.

If you have problems setting up the LAN, refer to LAN troubleshooting suggestions (on page 3-10).

Set up LAN communications on the instrument

This section describes how to set up manual or automatic LAN communications on the instrument.

Set up automatic LAN configuration

If you are connecting to a LAN that has a DHCP server or if you have a direct connection between the

instrument and a host computer, you can use automatic IP address selection.

If you select Auto, the instrument attempts to get an IP address from a DHCP server. If this fails, it

reverts to an IP address in the range of 169.254.1.0 through 169.254.254.255.

Both the host computer and the instrument should be set to use automatic LAN configuration.

Though it is possible to have one set to manual configuration, it is more complicated to set up.

Page 26

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 3: Using a remote interface

2461-900-01 Rev. A / November 2015 3-5

To set up automatic IP address selection using the front panel:

1. Press the MENU key.

2. Under System, select Communication.

3. Select the LAN tab.

4. For TCP/IP Mode, select Auto.

5. Select Apply Settings to save your settings.

Set up manual LAN configuration

If necessary, you can set the IP address on the instrument manually.

You can also enable or disable the DNS settings and assign a host name to the DNS server.

Contact your corporate information technology (IT) department to secure a valid IP address for the

instrument when placing the instrument on a corporate network.

The instrument IP address has leading zeros, but the computer IP address cannot.

To set up manual IP address selection on the instrument:

1. Press the MENU key.

2. Under System, select Communication.

3. Select the LAN tab.

4. For TCP/IP Mode, select Manual.

5. For IP Address, enter the LAN IP address. You can touch the number you want to change.

6. For Gateway, enter the gateway address.

7. For Subnet, enter the subnet mask.

8. Select Apply Settings to save your settings.

Set up LAN communications on the computer

This section describes how to set up the LAN communications on your computer.

Do not change your IP address without consulting your system administrator. If you enter an

incorrect IP address, it can prevent your computer from connecting to your corporate network or it

may cause interference with another networked computer.

Record all network configurations before modifying any existing network configuration information on

the network interface card. Once the network configuration settings are updated, the previous

information is lost. This may cause a problem reconnecting the host computer to a corporate

network, particularly if DHCP is disabled.

Be sure to return all settings to their original configuration before reconnecting the host computer to a

corporate network. Contact your system administrator for more information.

Wait for the LAN status indicator on the front panel to turn solid green

A solid green LAN status indicator confirms that the instrument was assigned an IP address. Note

that it may take several minutes for the computer and instrument to establish a connection.

Page 27

Section 3: Using a remote interface Model 2461 Interactive SourceMeter® Instrument User's Manual

3-6 2461-900-01 Rev. A / November 2015

Install LXI Discovery Browser software on your computer

You can use the LXI Discovery Browser to identify the IP addresses of LXI-certified instruments.

Once identified, you can double-click the IP address in the LXI Discovery Browser to open the web

interface for the instrument.

Run the LXI Discovery Browser

To run the LXI Discovery Browser software:

1. From the Microsoft Windows Start menu, select Keithley Instruments.

2. Select LXI Discovery Browser.

3. Click LXI Discovery Browser. The Keithley LXI Discovery Browser window is displayed.

The LXI Discovery Browser displays the instruments that it finds on the network and their

associated IP addresses.

4. Double-click an IP address in the LXI Discovery Browser dialog box. The instrument web page for

that instrument opens.

For information about using the web page, refer to Using the web interface (on page 3-10).

USB communications

To use the rear-panel USB port, you must have the Virtual Instrument Software Architecture (VISA)

layer on the host computer. See "How to install the Keithley I/O Layer" in the Model 2461 Reference

Manual for more information.

VISA contains a USB-class driver for the USB Test and Measurement Class (USBTMC) protocol that,

once installed, allows the Microsoft® Windows® operating system to recognize the instrument.

When you connect a USB device that implements the USBTMC or USBTMC-USB488 protocol to the

computer, the VISA driver automatically detects the device. Note that the VISA driver only

automatically recognizes USBTMC and USBTMC-USB488 devices. It does not recognize other USB

devices, such as printers, scanners, and storage devices.

In this section, "USB instruments" refers to devices that implement the USBTMC or

USBTMC-USB488 protocol.

Connect a computer to the Model 2461 using USB

To connect the Model 2461 to a computer using a USB connection, use Keithley Instruments

Model USB-B-1, which is shipped with the instrument.

Each Model 2461 needs its own USB cable to be connected to the computer.

To connect an instrument to a computer using USB:

1. Connect the Type A end of the cable to the computer.

2. Connect the Type B end of the cable to the instrument.

3. Turn on the instrument power. When the computer detects the new USB connection, the Found

New Hardware Wizard starts.

4. If the "Can Windows connect to Windows Update to search for software?" dialog box opens, click

No, and then click Next.

5. On the "USB Test and Measurement device" dialog box, click Next, and then click Finish.

Page 28

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 3: Using a remote interface

2461-900-01 Rev. A / November 2015 3-7

Communicate with the instrument

For the instrument to communicate with the USB device, you must use NI-VISATM. VISA requires a

resource string in the following format to connect to the correct USB instrument:

USB0::0x05e6::0x2461::[serial number]::INSTR

Where:

0x05e6: The Keithley vendor ID

0x2461: The instrument model number

[serial number]: The serial number of the instrument (the serial number is also on the rear

panel)

INSTR: Use the USBTMC protocol

To determine these parameters, you can run the Keithley Configuration Panel, which automatically

detects all instruments connected to the computer.

If you installed the Keithley I/O Layer, you can access the Keithley Configuration Panel through the

Microsoft® Windows® Start menu.

To use the Keithley Configuration Panel to determine the VISA resource string:

1. Click Start > All Programs > Keithley Instruments > Keithley Configuration Panel. The

Select Operation dialog box is displayed.

Figure 13: Select Operation dialog box

2. Select Add.

Page 29

Section 3: Using a remote interface Model 2461 Interactive SourceMeter® Instrument User's Manual

3-8 2461-900-01 Rev. A / November 2015

3. Click Next. The Select Communication Bus dialog box is displayed.

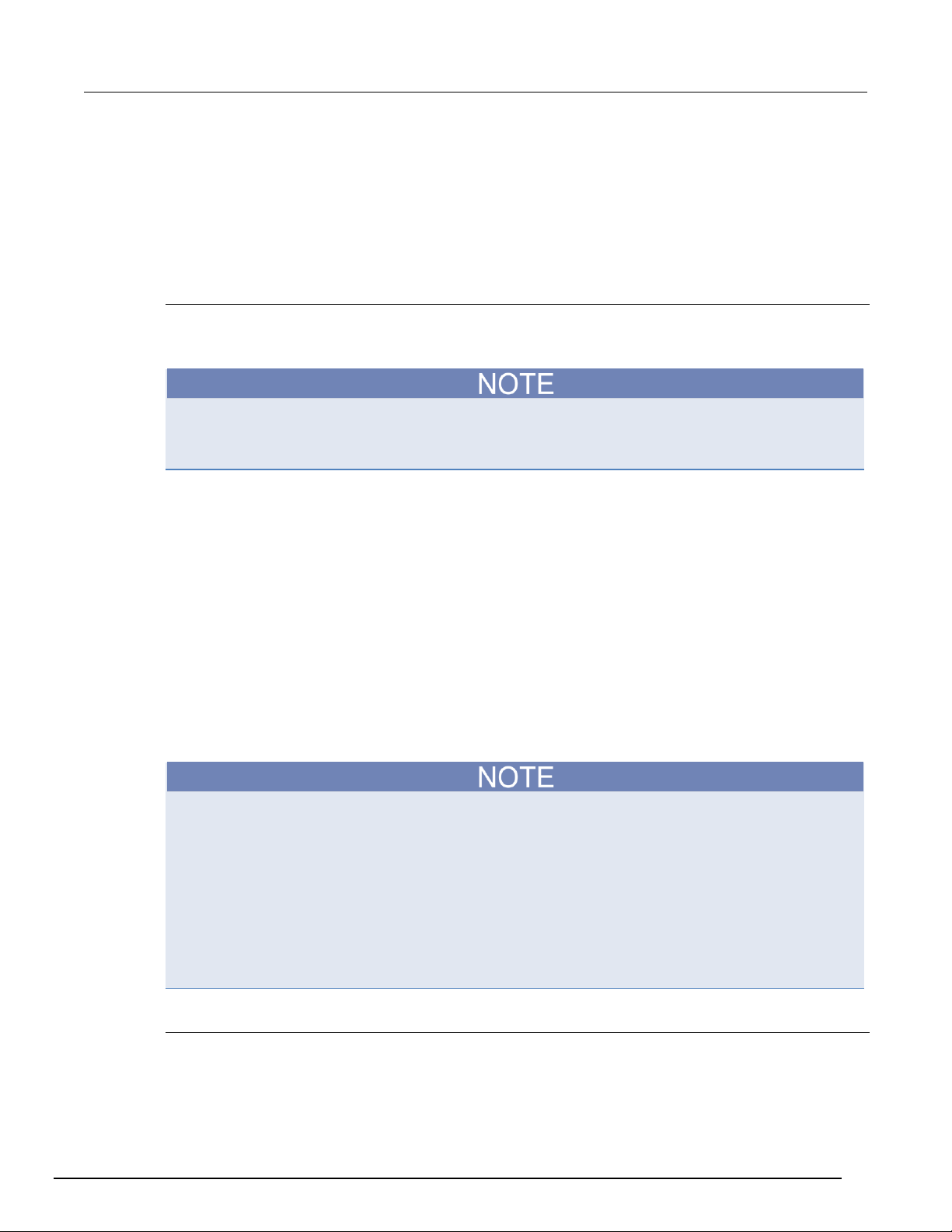

Figure 14: Select Communication Bus dialog box

4. Select USB.

5. Click Next. The Select Instrument Driver dialog box is displayed.

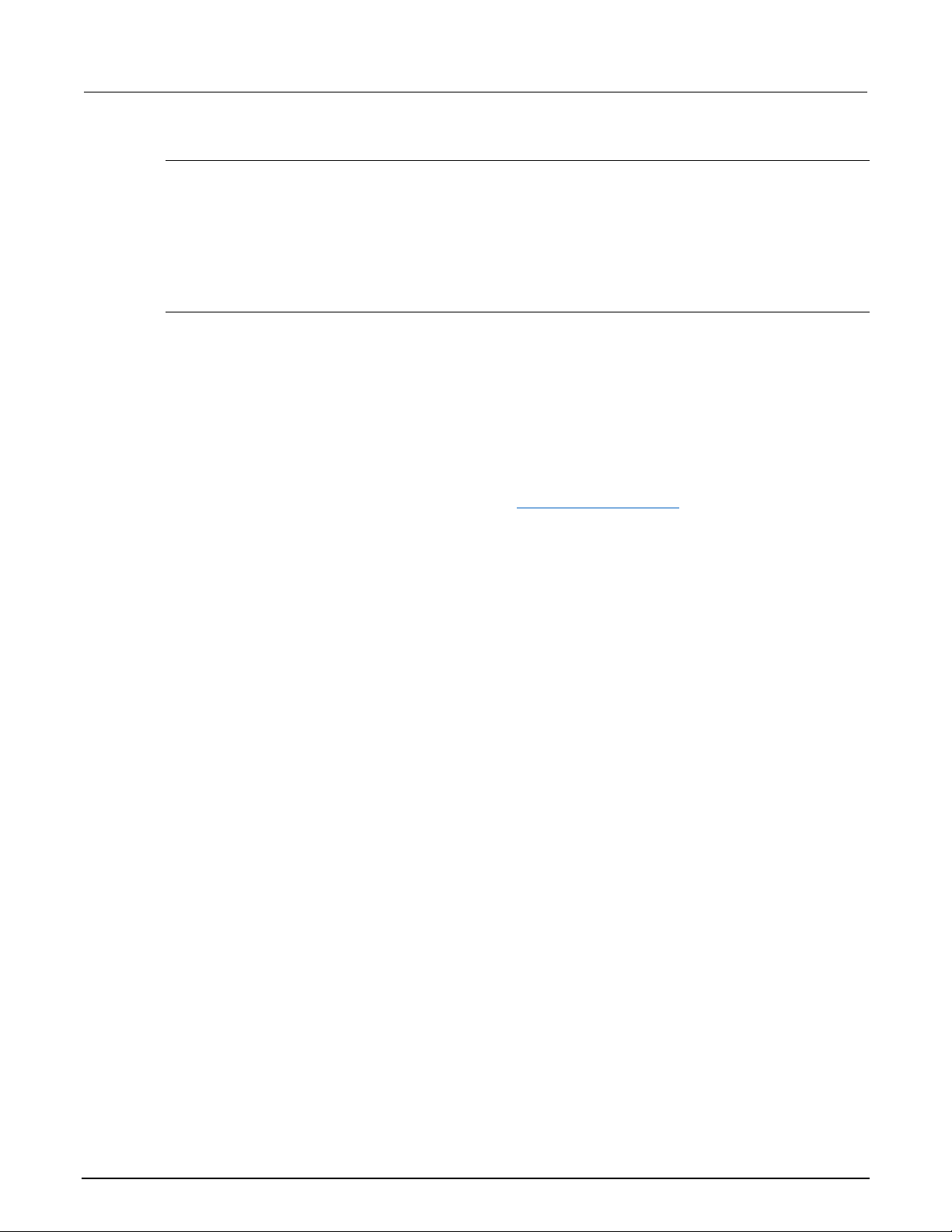

Figure 15: Select Instrument Driver dialog box

6. Select Auto-detect Instrument Driver - Model.

7. Click Next. The Configure USB Instrument dialog box is displayed with the detected instrument

VISA resource string visible.

8. Click Next. The Name Virtual Instrument dialog box is displayed.

Page 30

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 3: Using a remote interface

2461-900-01 Rev. A / November 2015 3-9

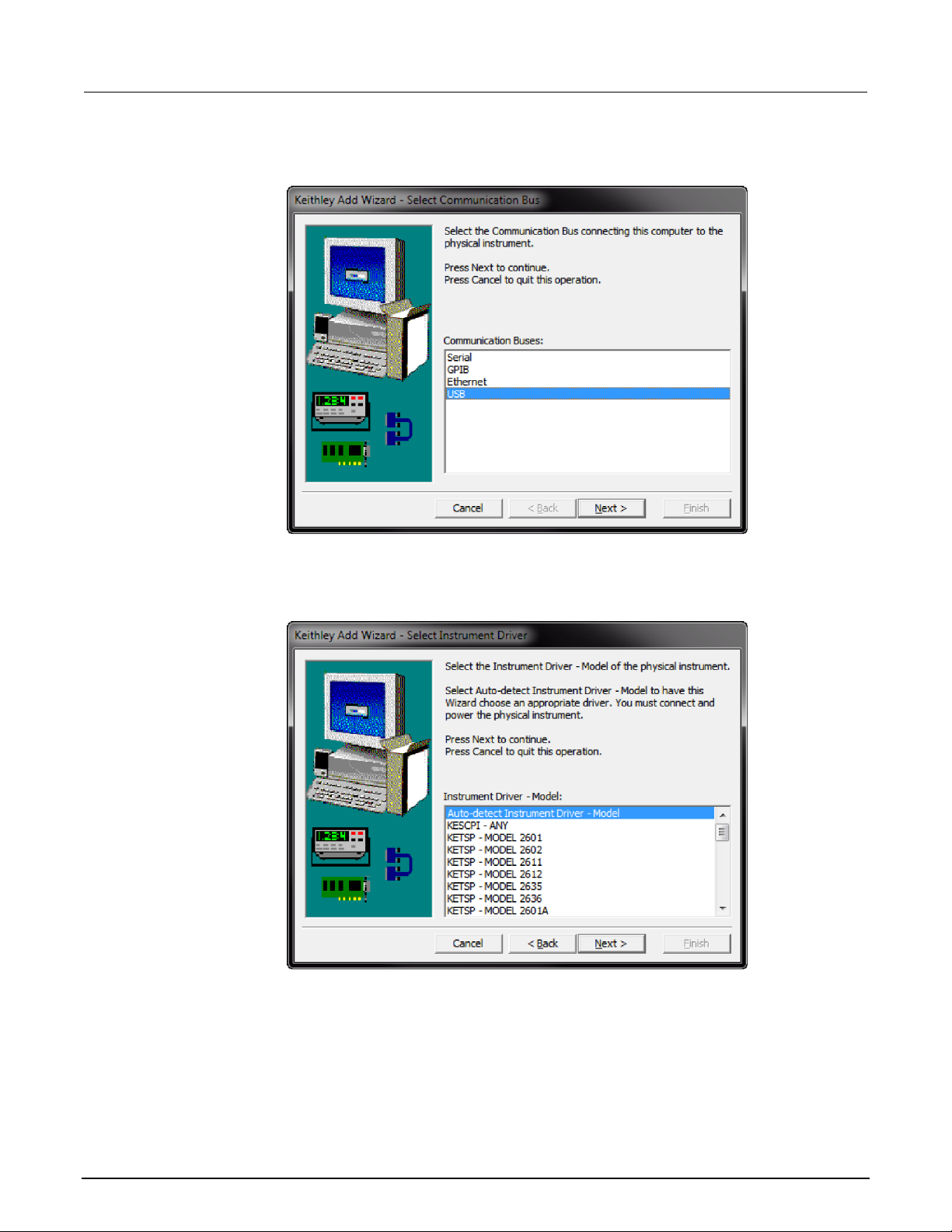

Figure 16: Name Virtual Instrument dialog box

9. In the Virtual Instrument Name box, enter a name that you want to use to refer to the instrument.

10. Click Finish.

11. Click Cancel to close the Wizard.

12. Save the configuration. From the Keithley Configuration Panel, select File > Save.

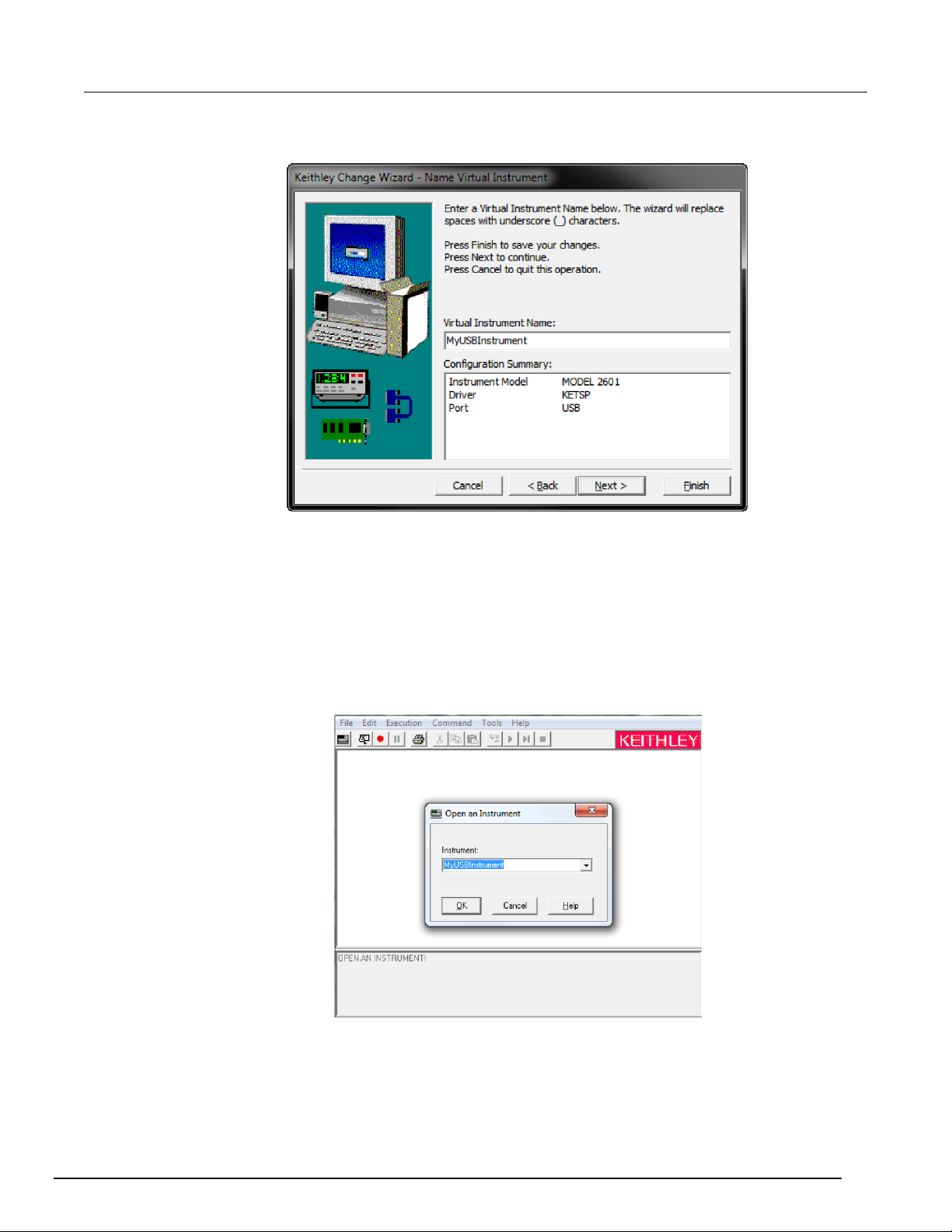

Verify the instrument through the Keithley Communicator:

1. Click Start > All Programs > Keithley Instruments > Keithley Communicator.

2. Select File > Open Instrument to open the instrument you just named.

Figure 17: Keithley Communicator Open an Instrument

3. Click OK.

4. Send a command to the instrument and see if it responds.

Page 31

Section 3: Using a remote interface Model 2461 Interactive SourceMeter® Instrument User's Manual

3-10 2461-900-01 Rev. A / November 2015

If you have a full version of NI-VISA on your system, you can run NI-MAX or the VISA Interactive

Control utility. See the National Instruments documentation for information.

If you have the Agilent IO Libraries on your system, you can run Agilent Connection Expert to check

your USB instruments. See the Agilent documentation for information.

Using the web interface

The Model 2461 web interface allows you to make settings and control your instrument through a web

page. The web page includes:

Instrument status.

The instrument model, serial number, firmware revision, and the last LXI message.

An ID button to help you locate the instrument.

A virtual front panel and command interface that you can use to control the instrument.

Download access to a .csv file that contains reading buffer data.

Administrative options and LXI information.

The instrument web page resides in the firmware of the instrument. Changes you make through the

web interface are immediately made in the instrument.

Connect to the instrument web interface

When the LAN and instrument establish a connection, you can open a web page for the instrument.

To access the web interface:

1. Open a web browser on the host computer.

2. Enter the IP address of the instrument in the address box of the web browser. For example, if the

instrument IP address is 192.168.1.101, enter 192.168.1.101 in the browser address box.

3. Press Enter on the computer keyboard to open the instrument web page.

4. If prompted, enter a user name and password. The default is admin for both.

LAN troubleshooting suggestions

If you are unable to connect to the web interface of the instrument, check the following items:

The network cable is in the LAN port on the rear panel of the instrument, not one of the

TSP-Link® ports.

The network cable is in the correct port on the computer. The LAN port of a laptop may be

disabled when the laptop is in a docking station.

The setup procedure used the configuration information for the correct ethernet card.

The network card of the computer is enabled.

The IP address of the instrument is compatible with the IP address on the computer.

The subnet mask address of the instrument is the same as the subnet mask address of the

computer.

Page 32

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 3: Using a remote interface

2461-900-01 Rev. A / November 2015 3-11

You can also try restarting the computer and the instrument. To restart the instrument:

1. Turn the instrument's power off, and then on.

2. Wait at least 60 seconds for the network configuration to be completed.

3. Press the MENU key.

4. Under System, select Communication.

5. Select the LAN tab.

6. Verify the settings.

Figure 18: Model 2461 web page

If the above actions do not correct the problem, contact your system administrator.

The Home page of the instrument provides information about the instrument. It includes:

The instrument model number, manufacturer, serial number, and firmware revision number.

The TCP Raw Socket number and Telnet Port number.

The last LXI message. The history link opens the LXI Home page.

The ID button, which allows you to identify the instrument. Refer to Identify the instrument (on

page 3-12).

Page 33

Section 3: Using a remote interface Model 2461 Interactive SourceMeter® Instrument User's Manual

3-12 2461-900-01 Rev. A / November 2015

Identify the instrument

If you have a bank of instruments, you can click the ID button to determine which one you are

communicating with.

To identify the instrument:

In the middle of the left side of the Home page, click the ID button.

The button turns green and the LAN status indicator on the instrument blinks.

Click the ID button again to return the button to its original color and return the LAN status indicator to

steady on.

Review events in the event log

The event log records all LXI events that the instrument generates and receives. The log includes the

following information:

The EventID column, which shows the event identifier that generated the event.

The System Timestamp column, which displays the seconds and nanoseconds when the event

occurred.

The Data column, which displays the text of the event message.

Determining the command set you will use

You can control the Model 2461 with command sets that are based on the SCPI or Test Script

Processor (TSP®) programming languages. You can change the command set that you use with the

Model 2461. The remote command sets that are available include:

SCPI: An instrument-specific language built on the SCPI standard.

TSP: A scripting programming language that contains instrument-specific control commands that

can be executed from a stand-alone instrument. You can use TSP to send individual commands

To clear the event log and update the information on the screen, click the Refresh button.

or use it to combine commands into scripts.

You cannot combine the command sets.

As delivered from Keithley Instruments, the Model 2461 is set to work with the Model 2461 SCPI

command set.

Using the front panel:

1. Press the MENU key.

2. Under System, select Settings.

3. Select the button next to Command Set and select the command set.

4. You are prompted to reboot.

Page 34

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 3: Using a remote interface

2461-900-01 Rev. A / November 2015 3-13

To change to the SCPI command set from a remote interface:

Send the command:

*LANG SCPI

Reboot the instrument.

To change to the TSP command set from a remote interface:

Send the command:

*LANG TSP

Reboot the instrument.

To verify which command set is selected:

Send the command:

*LANG?

Page 35

In this section:

Introduction .............................................................................. 4-1

Equipment required for this application .................................... 4-2

Device connections .................................................................. 4-2

Make front-panel measurements .............................................. 4-2

Section 4

Making basic front-panel measurements

Introduction

You can use the Model 2461 to source voltage or current and make measurements from the front

panel.

Make sure you select functions before you make changes to other instrument settings. The options

that you have for settings depend on the functions that are active when you make the changes. If

you make a change that is not compatible with the active functions, you may get unexpected results

or you may receive an event message. Also note that when you select a different function, the

instrument clears the buffer. The applications in this manual illustrate the order in which you should

perform operations for best results.

In this application, you make measurements on a 10 k resistor by sourcing voltage and measuring

current. You can make similar measurements on any two-terminal device under test (DUT) if

appropriate source values are used.

Some of the methods you can use to set up the Model 2461 to make measurements from the front

panel include:

Use Quicksets. Press the QUICKSET key to open a menu of preconfigured setups, including

voltmeter, ammeter, ohmmeter, and power supply setups. It also allows you to choose test

functions and adjust performance for better resolution or speed.

Select source and measure functions. Press the FUNCTION key to select from a list of source

and measure functions.

Use menu options. Press the MENU key to open a menu of options.

After selecting your source and measure functions, select buttons on the Model 2461 Home screen

and Settings swipe screens to change the settings.

You will use a combination of these methods to set up the measurement for this application.

Page 36

Section 4: Making basic front-panel measurements Model 2461 Interactive SourceMeter® Instrument User's Manual

4-2 2461-900-01 Rev. A / November 2015

Equipment required for this application

Equipment required for this application:

Model 2461 Interactive SourceMeter

Two insulated banana cables; you can use the set that is provided with the Model 2461, the

Keithley Instruments Model 8608 High-Performance Clip Lead Set

One 10 k resistor to test

Device connections

Turn the power to the instrument off before attaching connections to the Model 2461.

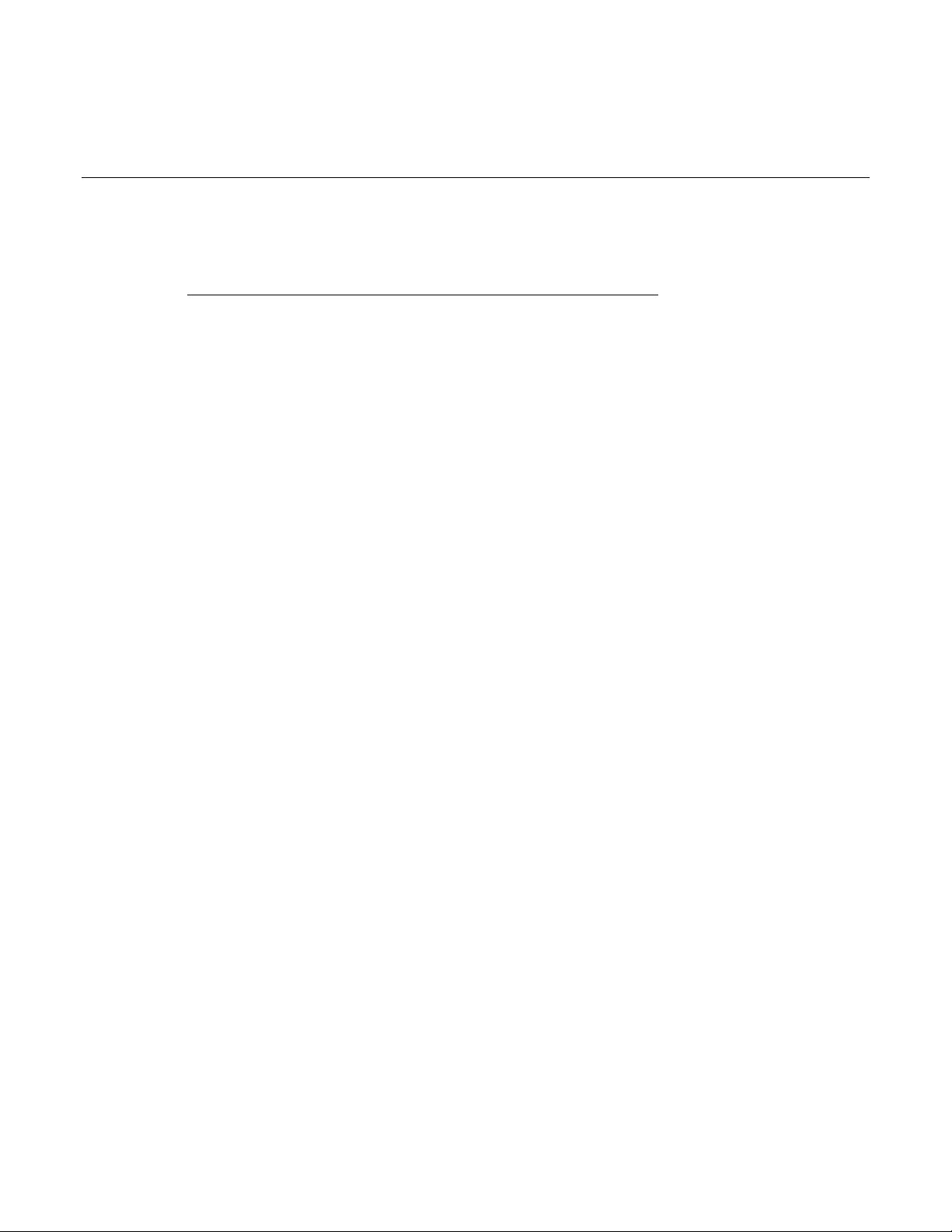

Connect the Model 2461 to the resistor in a 2-wire (local sense) configuration. In this configuration,

the device is connected between the FORCE HI and FORCE LO terminals.

The physical connections to the front panel are shown in the following figure.

®

Instrument

Figure 19: Model 2461 2-wire front-panel connections

Make front-panel measurements

For this application, you will:

Select the source and measure functions

Select the source range

Set the source value

Set the source limit

Select the measurement range

Turn on the source output

Observe the readings on the display

Turn off the source output

Page 37

Model 2461 Interactive SourceMeter® Instrument User's Manual Section 4: Making basic front-panel measurements

2461-900-01 Rev. A / November 2015 4-3

How to make front-panel measurements

To make a measurement from the front panel:

1. Press the POWER switch on the front panel to turn on the instrument or cycle power if the

instrument is already on.

2. Verify the source and measure function. On the front panel, press the FUNCTION key.

3. Under Source Voltage and Measure, select Current.

4. Select the source range. On the Home screen, under SOURCE V, select the button next to

Range.

5. Select 20 V.

6. Select the source voltage. Under SOURCE V, select the button next to Source.

7. Enter 10 V and select OK.

8. Set the limits for the source. Under SOURCE V, select the button next to Limit.

9. Enter 10 mA and select OK.

10. Select the measurement range. In the MEASURE area of the Home screen, select the button

next to Range.

11. Select Auto.

12. Turn on the output by pressing the OUTPUT ON/OFF switch. The OUTPUT indicator light turns

on.

13. Observe the readings on the display. For the 10 k resistor, typical display values are:

1.00000 mA

+9.99700 V

14. When measurements are complete, turn the output off by pressing the OUTPUT ON/OFF switch.

The OUTPUT indicator light turns off.

Page 38

In this section:

Introduction ............................................................................... 5-1

Equipment required .................................................................. 5-1

Set up remote communications ................................................ 5-1

Device connections .................................................................. 5-2

Low-resistance measurements ................................................. 5-5

Section 5

Measuring low-resistance devices

Introduction

This application example demonstrates how to use the Model 2461 to measure a low-resistance

device.

You may need to make low-resistance measurements (<10 ) in a number of applications. Typical

applications include continuity testing of cables and connectors, substrate vias, and resistors.

Typically, you make these resistance measurements by forcing a current and measuring the resulting

voltage drop. The Model 2461 automatically calculates the resistance. The measured voltage is

usually in the mV range or less. Built-in features of the Model 2461 optimize low-resistance

measurements, such as remote sensing and offset compensation.

Equipment required

Set up remote communications

One Model 2461 Interactive SourceMeter

®

Instrument

For front-panel connections, use four insulated banana cables, such as the Keithley Instruments

Model 8608 High-Performance Clip Lead Set (one set included with the Model 2461; you will

need another set)

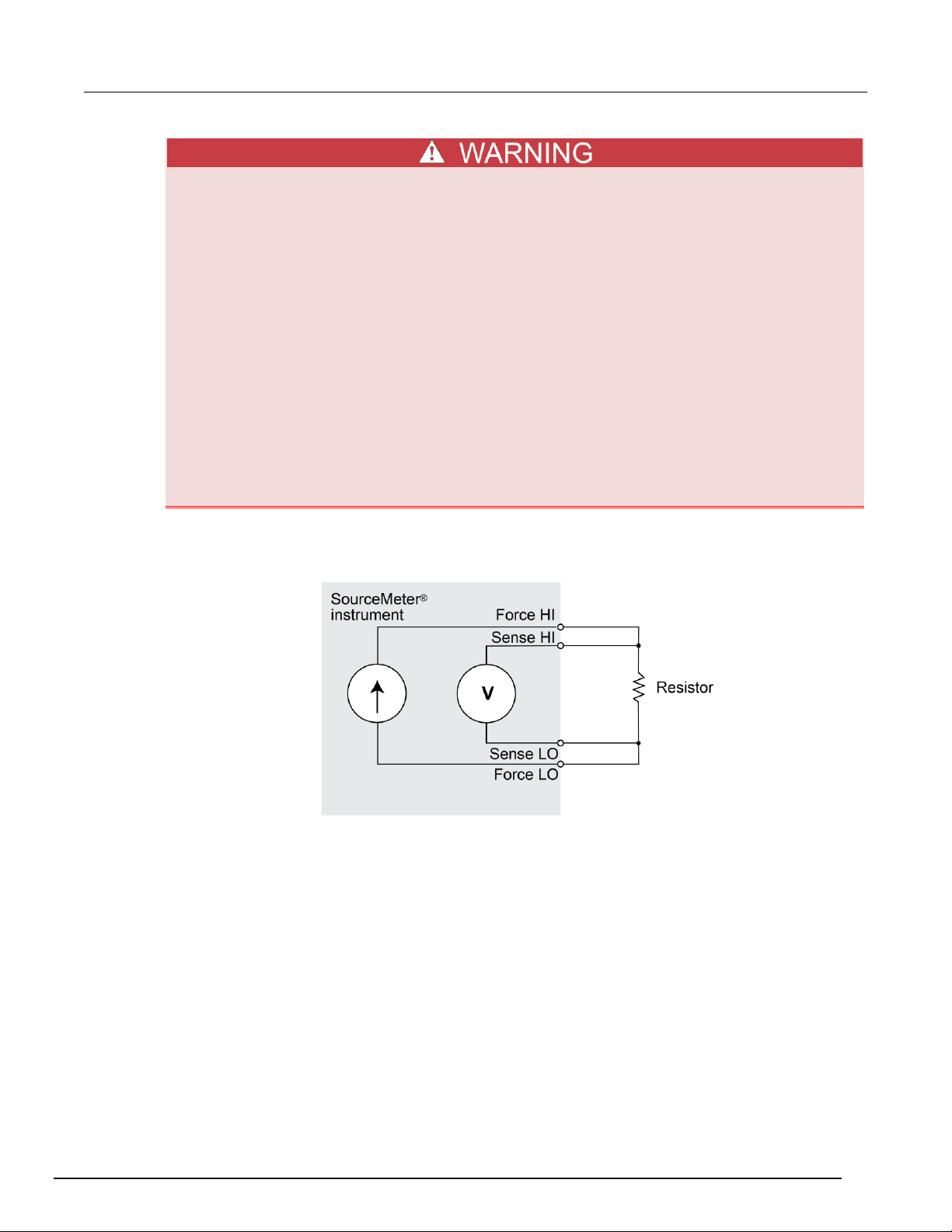

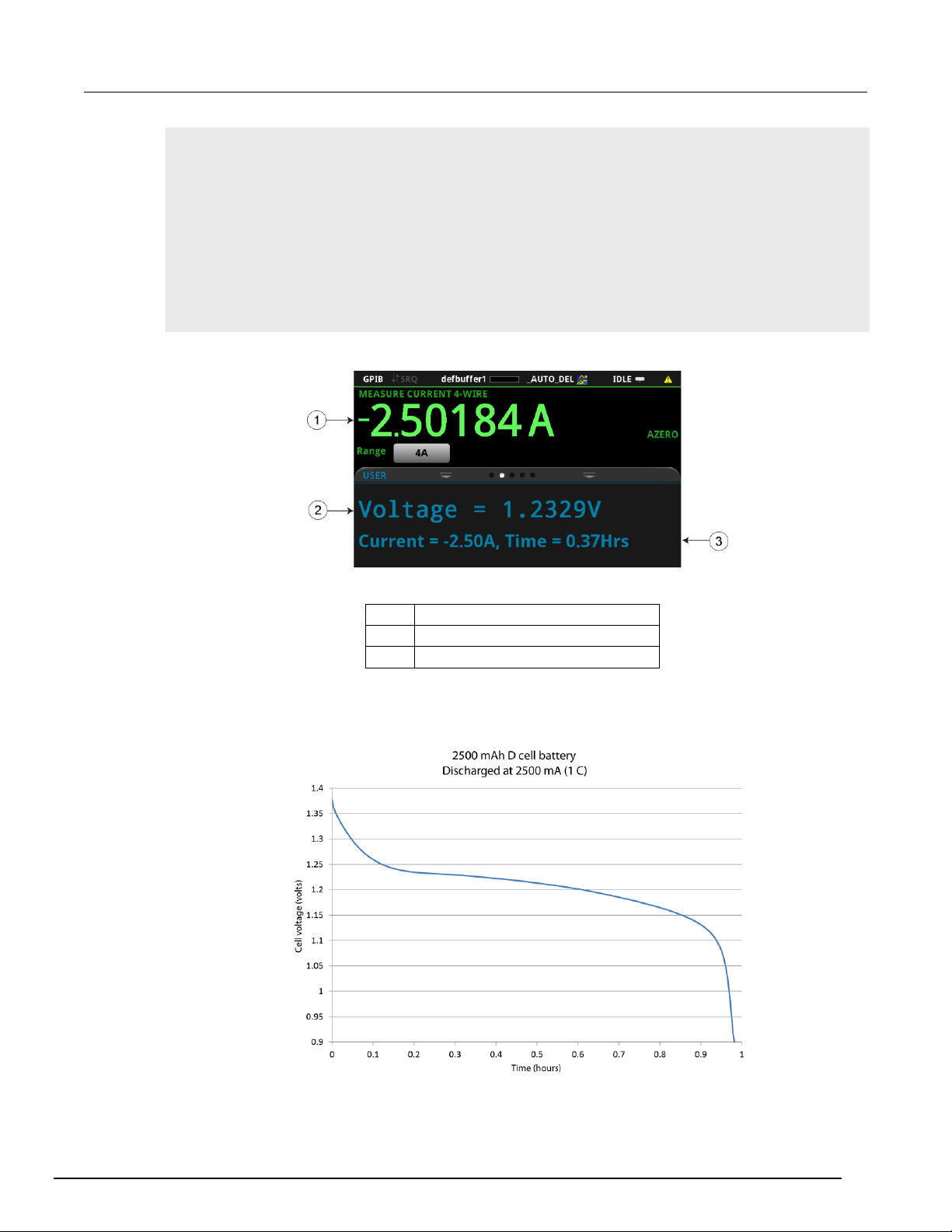

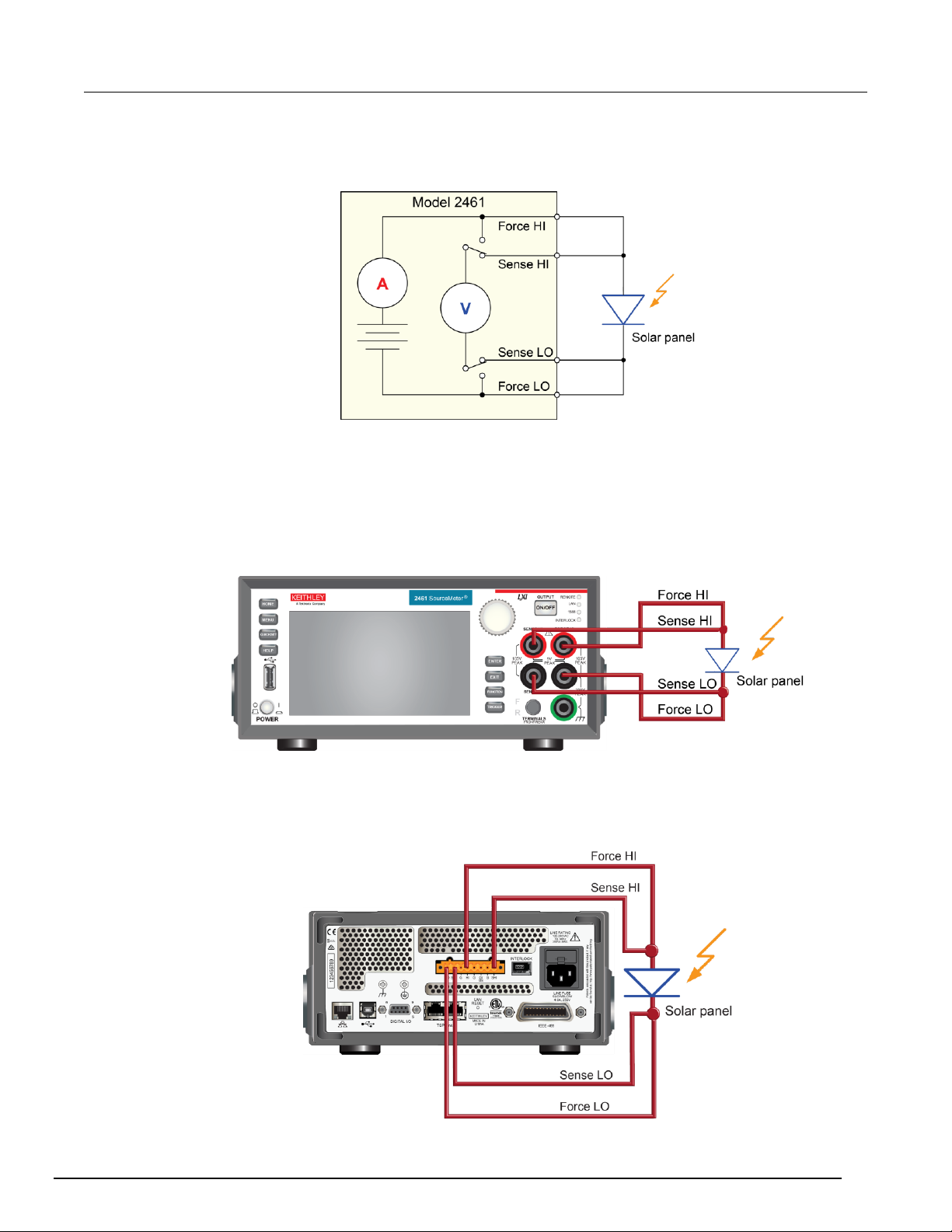

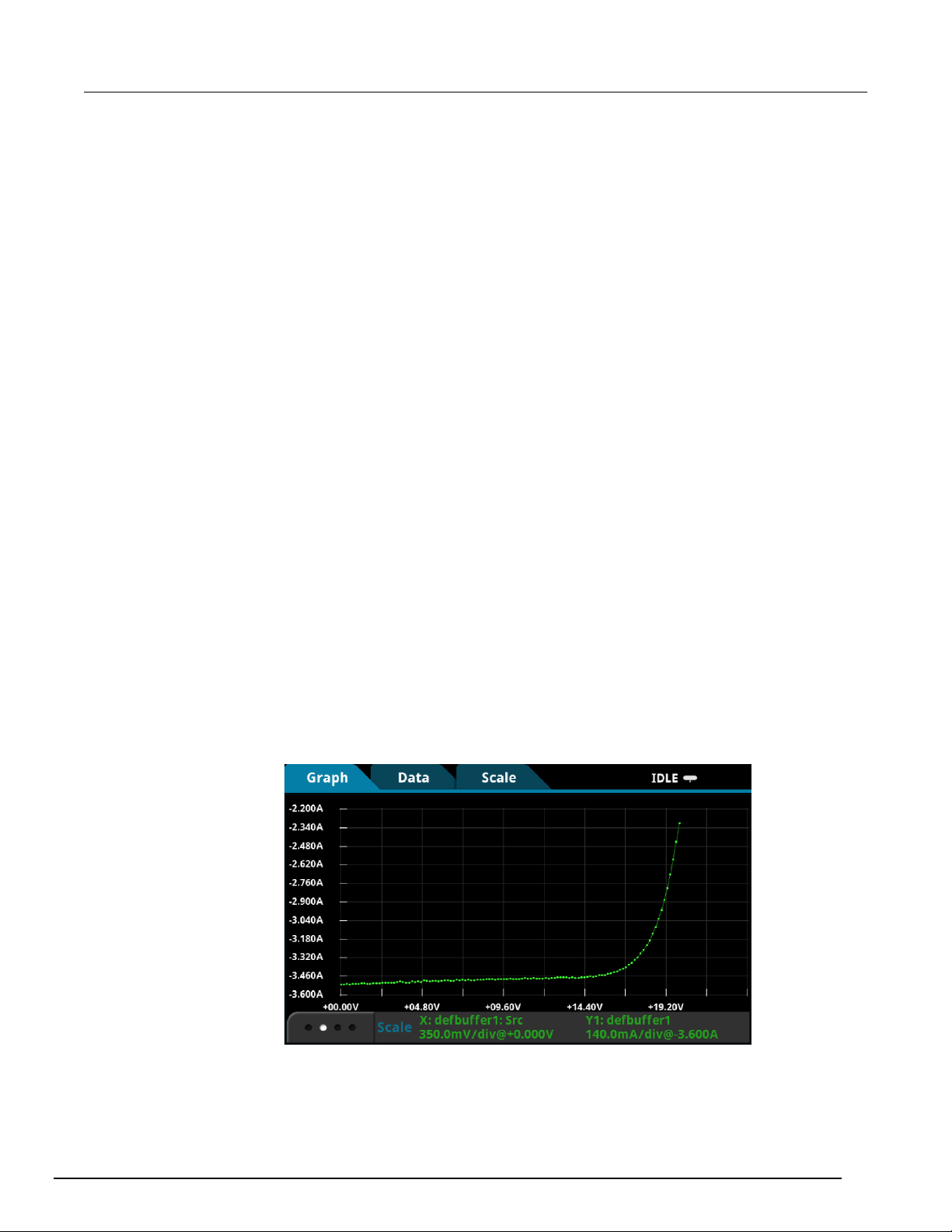

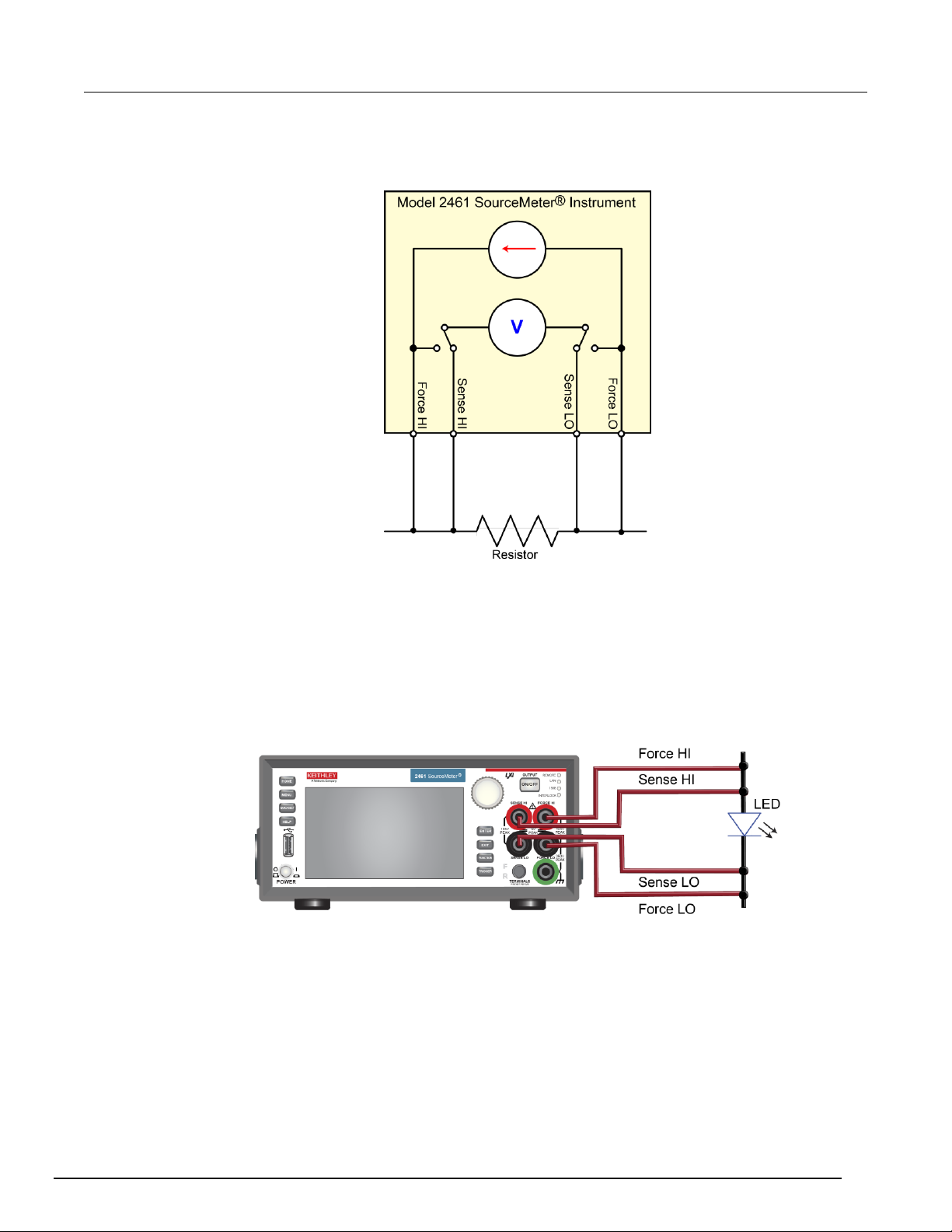

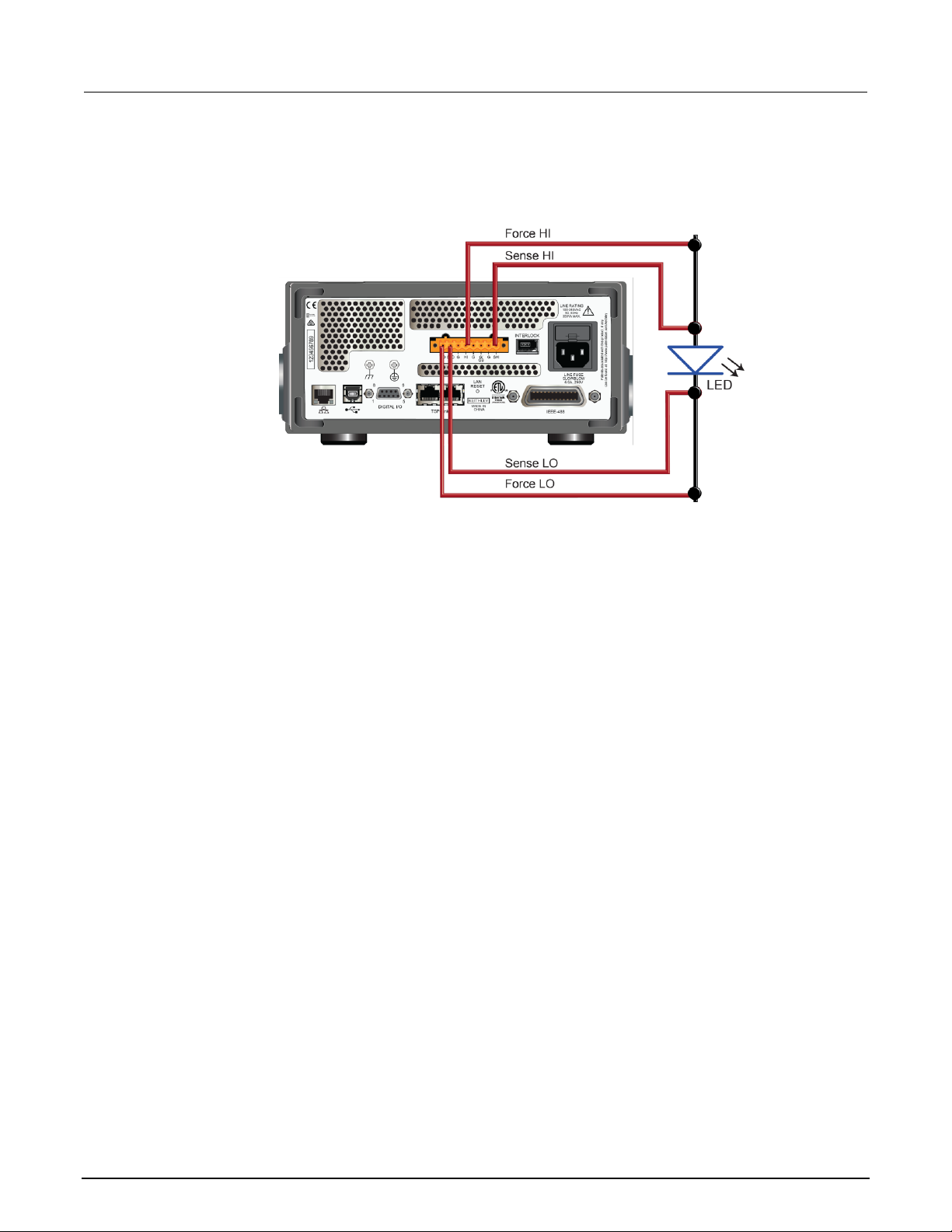

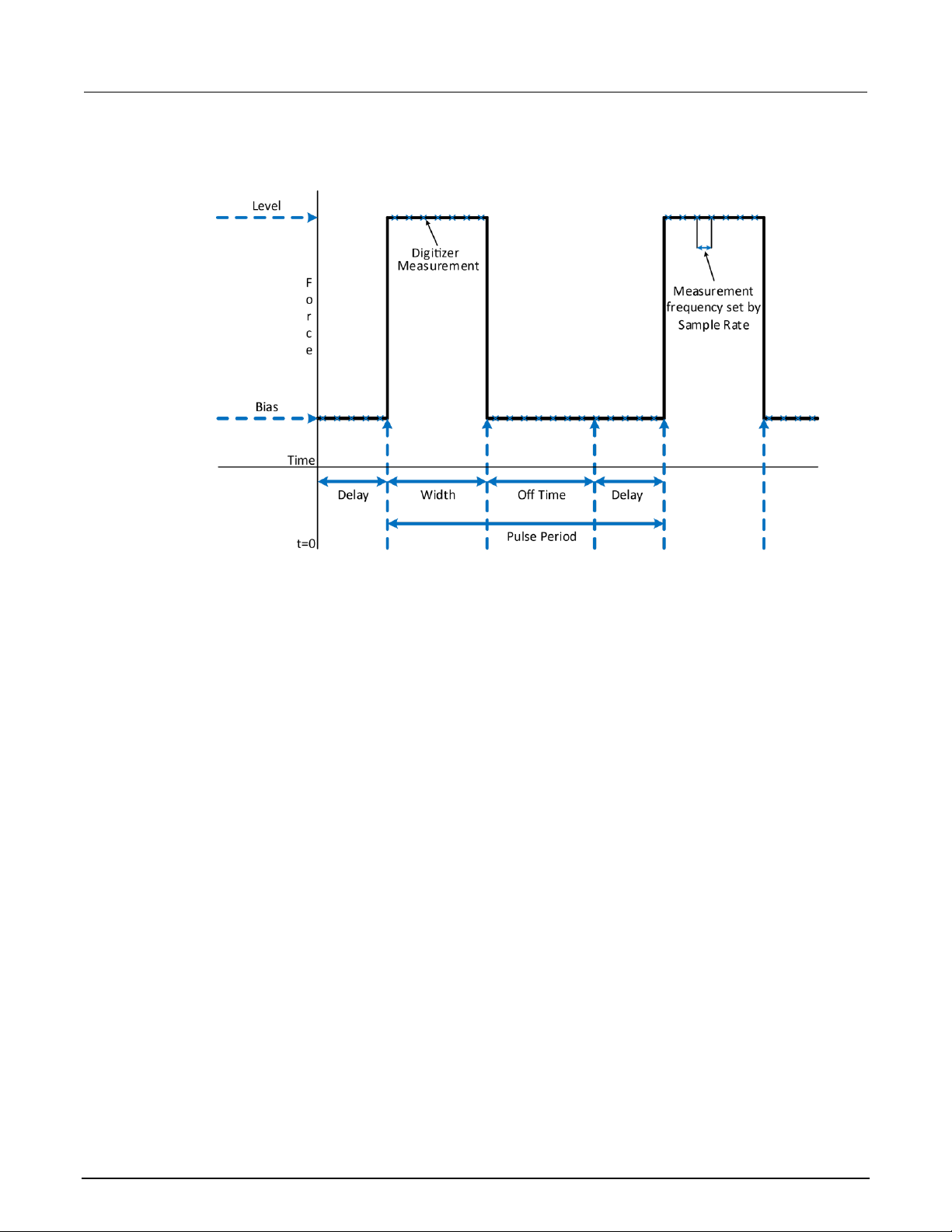

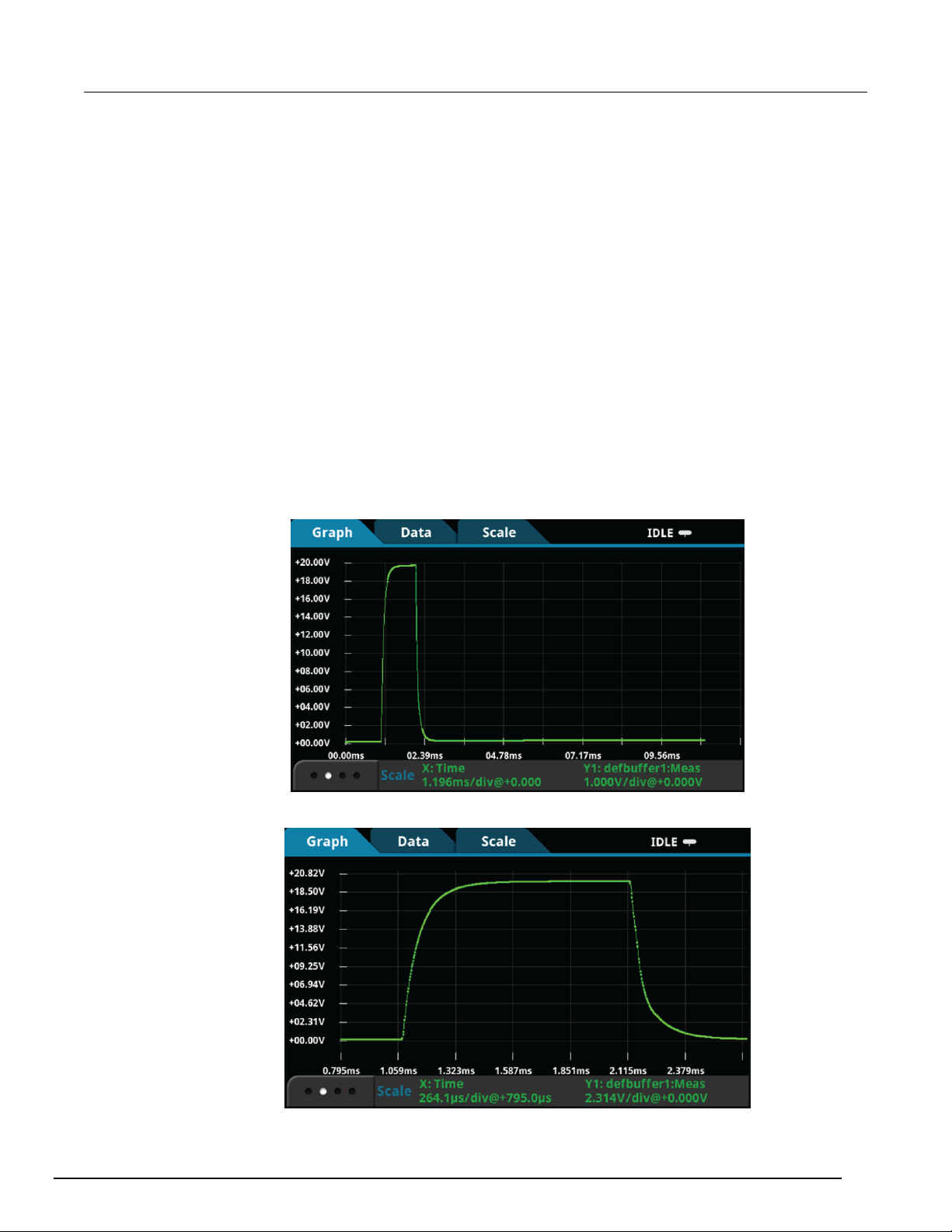

For rear-panel connections, use one Model 2460-KIT Screw-Terminal Connector Kit (provided