Page 1

DAS-800 Series

User’s Guide

A GREATER MEASURE OF CONFIDENCE

Page 2

Basic™ is a trademark of Dartmouth College.

IBM® is a registered trademark of International Business Machines Corporation.

PC, XT, and AT® are trademarks of International Business Machines Corporation.

Microsoft® is a registered trademark of Microsoft Corporation.

Turbo C® is a registered trademark of Borland International.

DriverLINX is a registered trademark of Scientific Software Tools, Inc.

All other brand and product names are trademarks or registered trademarks of their

respective companies.

Information furnished by Keithley Instruments is believed to be accurate and reliable.

However, Keithley Instruments assumes no responsibility for the use of such information nor

for any infringements of patents or other rights of third parties that may result from its

use. No license is granted by implication or otherwise under any patent rights of Keithley

Instruments.

WARNING

Keithley Instruments assumes no responsibility for damages consequent to

the use of this product. This product is not designed with components of a level of

reliability suitable for use in life support or critical applications.

Page 3

DAS-800 Series

User’s Guide

Revision D - June 2002

Part Number: 86870

Page 4

WARRANTY

Hardware

Keithley Instruments, Inc. warrants that, for a period of one (1) year from the date of shipment (3 years for Models 2000,

2001, 2002, 2010 and 2700), the Keithley Hardware product will be free from defects in materials or workmanship. This

warranty will be honored provided the defect has not been caused by use of the Keithley Hardware not in accordance with

the instructions for the product. This warranty shall be null and void upon: (1) any modification of Keithley Hardware that

is made by other than Keithley and not approved in writing by Keithley or (2) operation of the Keithley Hardware outside

of the environmental specifications therefore.

Upon receiving notification of a defect in the Keithley Hardware during the warranty period, Keithley will, at its option,

either repair or replace such Keithley Hardware. During the first ninety days of the warranty period, Keithley will, at its

option, supply the necessary on site labor to return the product to the condition prior to the notification of a defect. Failure

to notify Keithley of a defect during the warranty shall relieve Keithley of its obligations and liabilities under this

warranty.

Other Hardware

The portion of the product that is not manufactured by Keithley (Other Hardware) shall not be covered by this warranty,

and Keithley shall have no duty of obligation to enforce any manufacturers' warranties on behalf of the customer. On those

other manufacturers’ products that Keithley purchases for resale, Keithley shall have no duty of obligation to enforce any

manufacturers’ warranties on behalf of the customer.

Software

Keithley warrants that for a period of one (1) year from date of shipment, the Keithley produced portion of the software or

firmware (Keithley Software) will conform in all material respects with the published specifications provided such Keithley

Software is used on the product for which it is intended and otherwise in accordance with the instructions therefore.

Keithley does not warrant that operation of the Keithley Software will be uninterrupted or error-free and/or that the Keithley

Software will be adequate for the customer's intended application and/or use. This warranty shall be null and void upon any

modification of the Keithley Software that is made by other than Keithley and not approved in writing by Keithley.

If Keithley receives notification of a Keithley Software nonconformity that is covered by this warranty during the warranty

period, Keithley will review the conditions described in such notice. Such notice must state the published specification(s)

to which the Keithley Software fails to conform and the manner in which the Keithley Software fails to conform to such

published specification(s) with sufficient specificity to permit Keithley to correct such nonconformity. If Keithley determines that the Keithley Software does not conform with the published specifications, Keithley will, at its option, provide

either the programming services necessary to correct such nonconformity or develop a program change to bypass such

nonconformity in the Keithley Software. Failure to notify Keithley of a nonconformity during the warranty shall relieve

Keithley of its obligations and liabilities under this warranty.

Other Software

OEM software that is not produced by Keithley (Other Software) shall not be covered by this warranty, and Keithley shall

have no duty or obligation to enforce any OEM's warranties on behalf of the customer.

Other Items

Keithley warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes,

and documentation.

Items not Covered under Warranty

This warranty does not apply to fuses, non-rechargeable batteries, damage from battery leakage, or problems arising from

normal wear or failure to follow instructions.

Limitation of Warranty

This warranty does not apply to defects resulting from product modification made by Purchaser without Keithley's express

written consent, or by misuse of any product or part.

Page 5

Disclaimer of Warranties

EXCEPT FOR THE EXPRESS WARRANTIES ABOVE KEITHLEY DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KEITHLEY DISCLAIMS ALL WARRANTIES WITH

RESPECT TO THE OTHER HARDWARE AND OTHER SOFTWARE.

Limitation of Liability

KEITHLEY INSTRUMENTS SHALL IN NO EVENT, REGARDLESS OF CAUSE, ASSUME RESPONSIBILITY FOR

OR BE LIABLE FOR: (1) ECONOMICAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, PUNITIVE OR

EXEMPLARY DAMAGES, WHETHER CLAIMED UNDER CONTRACT, TORT OR ANY OTHER LEGAL THEORY,

(2) LOSS OF OR DAMAGE TO THE CUSTOMER'S DATA OR PROGRAMMING, OR (3) PENALTIES OR PENALTY

CLAUSES OF ANY DESCRIPTION OR INDEMNIFICATION OF THE CUSTOMER OR OTHERS FOR COSTS, DAMAGES, OR EXPENSES RELATED TO THE GOODS OR SERVICES PROVIDED UNDER THIS WARRANTY.

Keithley Instruments, Inc.

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

4/02

Page 6

S

The following safety precautions should be observed before using this product and any associated instrumentation.

Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations

where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read and follow all installation, operation, and maintenance information

carefully before using the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that

the equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately

trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use

of the instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting

the line voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only

properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Installation Category I and Installation

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected to mains voltage

or to voltage sources with high transient over-voltages. Installation Category II connections require protection for high

transient over-voltages often associated with local AC mains connections. Assume all measurement, control, and data

I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or

test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels

greater than 30V RMS, 42.4V peak, or 60VDC are present.

age is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that

operators are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to protect themselves from

the risk of electric shock. If the circuit is capable of operating at or above 1000 volts,

may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance

limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards,

install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect

the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

afety Precautions

A good safety practice is to expect that hazardous volt-

no conductive part of the circuit

5/02

Page 7

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main

input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the

operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting

or disconnecting cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the

safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid interlock.

If or is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined

effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact with these

voltages.

The

WARNING

associated information very carefully before performing the indicated procedure.

The

CAUTION

the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power

transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable

national safety approvals, may be used if the rating and type are the same. Other components that are not safety related

may be purchased from other suppliers as long as they are equivalent to the original component. (Note that selected parts

should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you

are unsure about the applicability of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do

not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist

of a circuit board with no case or chassis (e.g., data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

heading in a manual explains dangers that might result in personal injury or death. Always read the

heading in a manual explains hazards that could damage the instrument. Such damage may invalidate

Page 8

Table of Contents

Preface

1

Overview

Supporting Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Functional Description

2

Analog Input Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Gains and Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Channel Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Channel Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Conversion Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Hardware Gates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Digital I/O Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

8254 Counter/Timer Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Setup and Installation

3

Installing and Configuring DriverLINX for DAS-800

Series Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Installing the DAS-800 Series Standard

Software Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Installing DriverLINX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Configuration with DriverLINX . . . . . . . . . . . . . . . . . . . . . . .3-7

Unpacking the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Configuring the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Setting the Base Address . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Setting the Input Configuration . . . . . . . . . . . . . . . . . . . . . .3-13

Setting the Interrupt Level . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Installing the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

i

Page 9

Cabling and Wiring

4

Attaching Accessory and Expansion Boards . . . . . . . . . . . . . . .4-1

Attaching an STC-37 Screw Terminal Connector. . . . . . . . . 4-3

Attaching an STA-08 / STA-08PGA

Screw Terminal Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Attaching an EXP-16 or EXP-16/A Expansion Board . . . . . 4-5

Attaching an EXP-GP Expansion Board . . . . . . . . . . . . . . . .4-6

Attaching an MB Series Backplane . . . . . . . . . . . . . . . . . . . 4-7

Connecting Multiple Expansion Boards . . . . . . . . . . . . . . . . 4-7

Connecting Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Connecting an Analog Input Signal to a Single-Ended Input 4-9

Connecting an Analog Input Signal to a Differential Input .4-10

Connecting Digital Signals . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Connecting Counter/Timer I/O Signals . . . . . . . . . . . . . . . .4-12

Synchronizing Conversions on Multiple Boards . . . . . . . . . 4-13

5

DriverLINX Analog I/O Panel

Test Panel Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

6

Calibration

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Calibration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

7

Troubleshooting

Problem Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Specifications

A

Connector Pin Assignments

B

List of Figures

Figure 2-1 DAS-800 Series Functional Block Diagram . . . . .2-2

Figure 2-2 Channel Expansion . . . . . . . . . . . . . . . . . . . . . . . .2-7

Figure 2-3 Initiating Conversions . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-4 Initiating Conversions with a Hardware Trigger 2-13

Figure 2-5 Hardware Gate . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

ii

Page 10

Figure 2-6 Pulse on Terminal Count Mode . . . . . . . . . . . . .2-19

Figure 2-7 Programmable One-Shot Mode . . . . . . . . . . . . .2-20

Figure 2-8 Rate Generator Mode. . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-9 Square-Wave Generator Mode . . . . . . . . . . . . . . 2-22

Figure 2-10 Software-Triggered Strobe Mode . . . . . . . . . . . .2-23

Figure 2-11 Hardware-Triggered Strobe Mode. . . . . . . . . . . .2-24

Figure 3-1 DAS-800 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-2 DAS-801/802 Board . . . . . . . . . . . . . . . . . . . . . . .3-3

Figure 3-3 Setting the Base Address . . . . . . . . . . . . . . . . . . . 3-11

Figure 3-4 Setting the Input Configuration . . . . . . . . . . . . . . 3-14

Figure 3-5 Setting the Interrupt Level. . . . . . . . . . . . . . . . . . 3-15

Figure 4-1 Main I/O Connector on a DAS-800 Board . . . . . . 4-2

Figure 4-2 Main I/O Connector on a DAS-801

or DAS-802 Board. . . . . . . . . . . . . . . . . . . . . . . . .4-3

Figure 4-3 Attaching an STC-37 Screw Terminal Connector.4-4

Figure 4-4 Attaching an STA-08 / STA-08PGA

Screw Terminal Accessory . . . . . . . . . . . . . . . . . . 4-5

Figure 4-5 Attaching an EXP-16 or EXP-16/A

Expansion Board . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-6 Attaching an EXP-GP Expansion Board. . . . . . . .4-7

Figure 4-7 Connecting Multiple Expansion Boards . . . . . . . .4-8

Figure 4-8 Single-Ended Input . . . . . . . . . . . . . . . . . . . . . . .4-10

Figure 4-9 Differential Input . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Figure 4-10 Synchronizing Conversions on Multiple Boards.4-13

Figure 4-11 Dividing the Rate of the Master Clock . . . . . . . .4-14

Figure 6-1 Potentiometers (DAS-800) . . . . . . . . . . . . . . . . . .6-3

Figure 6-2 Potentiometers (DAS-801 / DAS-802) . . . . . . . . .6-3

Figure B-1 Main I/O Connector (DAS-800) . . . . . . . . . . . . . B-2

Figure B-2 Main I/O Connector (DAS-801 / DAS-802) . . . . B-5

iii

Page 11

List of Tables

Table 2-1 Supported Gains . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Table 2-2 Sources for 8254 Documentation . . . . . . . . . . . .2-25

Table 2-3 Expansion Board / Backplane Power

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Table 3-1 I/O Address Map (000H to 3FFH) . . . . . . . . . . .3-11

Table 3-2 Interrupt Levels . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Table 7-1 Troubleshooting Information . . . . . . . . . . . . . . . .7-4

Table A-1 DAS-800, DAS-801, and

DAS-802 Specifications . . . . . . . . . . . . . . . . . . . A-9

Table B-1 Main I/O Connector Pin Assignments

for the DAS-800 . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Table B-2 Main I/O Connector Pin Assignments

for the DAS-801 / DAS-802 . . . . . . . . . . . . . . . . B-6

iv

Page 12

Preface

The

DAS-800 Series User’s Guide

up, install, and use DAS-800 Series boards.

The manual is intended for data acquisition system designers, engineers,

technicians, scientists, and other users responsible for setting up, cabling,

and wiring signals to DAS-800 Series boards. It is assumed that users are

familiar with data acquisition principles and with their

particular application.

The

DAS-800 Series User’s Guide

●

Chapter 1 provides an overview of the features of DAS-800 Series

boards, including a description of supported software and accessories.

●

Chapter 2 provides a more detailed description of the analog input,

digital I/O, and counter/timer I/O features of DAS-800 Series boards.

Chapter 3 describes how to unpack, configure, and install DAS-800

●

Series boards.

provides the information needed to set

is organized as follows:

●

Chapter 4 describes how to attach accessory and expansion boards

and how to wire signals to DAS-800 Series boards.

Chapter 5 describes how to use DriverLINX Analog I/O Panel and

●

DriverLINX Test Panel options to test functions of DAS–800

Series boards.

●

Chapter 6 describes how to calibrate DAS-800 Series boards.

●

Chapter 7 provides troubleshooting information.

Appendix A lists the specifications for DAS-800 Series boards.

●

Page 13

Appendix B lists the connector pin assignments.

●

An index completes this manual.

Throughout the manual, keep the following in mind:

●

References to DAS-800 Series boards apply to the DAS-800,

DAS-801, and DAS-802 boards. When a feature applies to a

particular board, that board’s name is used.

●

References to Microsoft QuickBasic apply to both Microsoft

QuickBASIC (Version 4.0) and Microsoft QuickBasic (Version 4.5).

Page 14

1

Overview

The DAS–800 Series is a family of high–performance analog and digital

I/O boards with DriverLINX software requiring:

●

an IBM PC or compatible AT (386, or Pentium CPU) with 2 MB

of memory

at least one floppy disk drive, and one fixed disk drive

●

●

MS–DOS/PCDOS 3.1 or higher

Microsoft Windows 95/98 or Windows NT

●

a compiler supporting Microsoft Windows development

●

●

a mouse is highly recommended

The DAS–800 Series includes the DAS–800, DAS–801, and DAS–802

boards. The major features of DAS–800 Series boards are as follows:

Eight analog input channels (single-ended on the DAS-800;

●

single-ended or differential on the DAS-801 and DAS-802).

Fixed ±5 V analog input range for the DAS-800; nine unipolar and

●

bipolar, software-selectable analog input ranges for the DAS-801

and DAS-802.

On-board 8254 counter/timer circuitry, which you can use as a

●

hardware internal clock source and/or for general-purpose

counter/timer I/O operations.

●

Software-selectable conversion clock source.

●

Digital trigger.

1-1

Page 15

Hardware gate.

●

Four-word FIFO to store converted data; overrun detection logic to

●

detect lost data points.

Software-selectable interrupt source.

●

Three bits of digital input.

●

Four bits of digital output.

●

Note:

DAS-800 boards are enhancements of DAS-8 boards; DAS-801

boards are enhancements of DAS-8 PGA boards; DAS-802 boards are

enhancements of DAS-8 PGA/G2 boards. DriverLINX for DAS-800

Series does not support the older MetraByte DAS-8 Series. Both 16- and

32-bit support for the DAS-8 Series is available under Windows 95 only,

using a previous version of DriverLINX. Refer to the

Installation

and

Hardware—Configuring the DAS-800 Series

Supporting Software

The following software is available for operating DAS-800 Series boards:

DAS-800 Series standard software package -

●

DAS-800 Series boards. Includes DriverLINX for Microsoft

Windo ws and function libraries for writing application programs such

as Microsoft Visual C++; Microsoft Visual Basic; Borland Delphi

utility programs; and language-specific example programs.

●

DriverLINX -

device drivers for Windows application development includes:

DriverLINX

Configuration Guide and Using DriverLINX With Your

manuals.

Shipped with

®

the high-performance real-time data-acquisition

;

D

●

riverLINX API DLLs and drivers supporting the DAS-800

Series hardware

Analog I/O Panel - A DriverLINX program that verifies the

●

installation and configuration of DriverLINX to your

DAS-800 Series board and demonstrates several virtual

bench-top instruments

1-2 Overview

Page 16

Learn DriverLINX - an interactive learning and demonstration

●

program for DriverLINX that includes a Digital Storage

Oscilloscope

●

Source Code - for the sample programs

●

DriverLINX Application Programming Interface files - for the

DAS-800 Series compiler

●

DriverLINX On-line Help System - provides immediate help as

you operate DriverLINX

Supplemental Documentation - on DriverLINX installation and

●

configuration; analog and digital I/O programming;

counter/timer programming; technical reference; and

information specific to the DAS-800 Series hardware.

●

DAS-800 Series utilities -

The following utilities are provided as part

of both the DAS-800 Series standard software package:

●

DriverLINX Calibration Utility

DriverLINX Test P anel

●

DAS-800 Series register I/O map

●

- If you cannot satisfy your

application’s requirements with the available software packages and

you are an experienced programmer, you may be able to program

your DAS-800 Series board through direct register I/O instructions.

Contact the factory for more information.

Note:

Attempts to combine register-level programing of

counter/timer functions with DriverLINX programming can

produce unexpected results.

1-3

Page 17

Accessories

The following accessories are available for use with DAS-800

Series boards:

STC-37 screw terminal connector

●

- For all DAS-800 Series boards,

provides 37 screw terminals that allow you to access the functions of

the board; connects directly to the DAS-800 Series board without

a cable.

STA-08 screw terminal accessory

●

- For the DAS-800 board only,

provides screw terminals that allo w you to access the functions of the

board; provides a breadboard area with power and additional screw

terminals to access the user-designed circuitry.

STA-08PGA screw terminal accessory

●

- For the DAS-801 and

DAS-802 boards only, provides screw terminals that allow you to

access the functions of the board; provides a breadboard area with

power and additional screw terminals to access the

user-designed circuitry.

●

EXP-16 and EXP-16/A expansion board

s - Sixteen-channel

multiplexer and signal-conditioning expansion boards; provide cold

junction compensation (CJC) for thermocouples and

switch-selectable gains ranging from 0.5 to 2000.

●

EXP-GP expansion board

- An 8-channel signal-conditioning

expansion board; connects to RTDs, thermistors, strain gages, and

other variable resistance sensors; provides CJC for thermocouples

and switch-selectable gains of 1, 10, 100, and 1000 or 2.5, 25, 250,

and 2500.

●

MB Series modules and backplanes

- MB Series modules are

high-performance, signal-conditioning modules that measure

thermocouple, RTD, strain gage, voltage, and current inputs and are

installed in MB Series backplanes. MB Series backplanes provide

screw terminals for connecting the high-level analog I/O signals.

1-4 Overview

Page 18

STA-SCM8 screw terminal accessory

●

- Allows you to connect a

DAS-800 Series board to up to four MB-02 backplanes; provides

screw terminals that allow you to access the functions of the board;

provides a breadboard area with power for the user-designed circuitry.

C-1800 cable

●

- Unshielded, 18-inch cable with a 37-pin connector on

each end; allows you to connect a DAS-800 Series board to an

STA-08, STA-08PGA, EXP-16, EXP-16/A, or EXP-GP.

●

S-1800 cable

- Shielded, 18-inch cable with a 37-pin connector on

each end; allows you to connect a DAS-800 Series board to an

STA-08, STA-08PGA, EXP-16, EXP-16/A, or EXP-GP.

C8-MB1 cable

●

- Cable with a 37-pin connector on one end and a

26-pin-connector on the other end; allows you to connect a DAS-800

Series board to an MB-01 or MB-02 backplane.

C-2600 cable

●

- An 18-inch cable with a 26-pin connector at each end;

allows you to connect an STA-SCM8 screw terminal accessory to an

MB-02 backplane.

Refer to the Keithley

Data Acquisition Catalog & Reference Guide

or contact your local sales office for information on obtaining

these accessories.

1-5

Page 19

2

Functional Description

This chapter describes the following features of DAS-800 Series boards:

● Analog input features

● Digital I/O features

● Counter/timer I/O features

● Interrupts

● Power

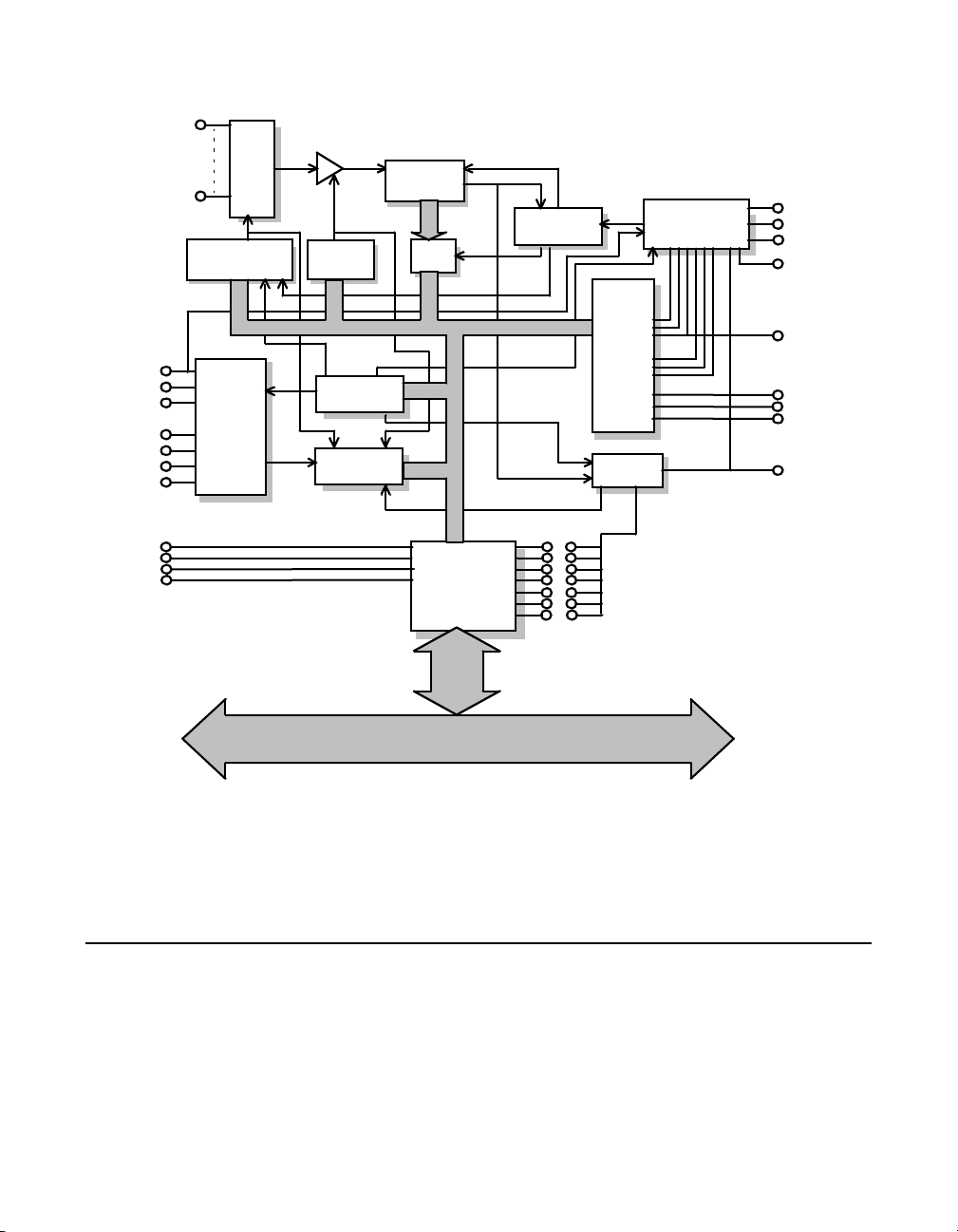

A functional block diagram of a DAS-800 Series board is shown in

Figure 2-1.

2-1

Page 20

Ch 0

Analog In

8 Channels

Ch 7

Digital I/O

IP1/TRIG

IP2

IP3

OP1

OP2

OP3

OP4

+5v

+12v

-12v

COM

Bus power for

Expansion & Interface

MUX

Channel Select

& Scan Logic

I/O

Buffers

Gain

Control

(DAS801/2)

Internal Data Bus

Control

Registers

Status

Registers

12 Bit A/D

with

Sample/Hold

FIFO

Bus Interface

Address

Decode &

Conversion

Control Logic

Interrupt Select

Levels 2-7

(Jumper)

Timer/

Counter

Clk 2

Gate 2

Out 2

Clk 1

Gate 1

Out 1

Clk 0

Gate 0

Out 0

Interrupt

Control

Clock Generate

& Control Logic

Clk 1

Gate 1

Gate 2

Out 1/CCLK

Out 2

Gate 0

Clk 0

Out 0

INT_IN/XCLK

IBM PC XT/AT Bus

Figure 2-1. DAS-800 Series Functional Block Diagram

Analog Input Features

DAS-800 Series boards use a 12-bit, successive approximation

analog-to-digital converter (ADC) with integral sample and hold. The

ADC provides 12-bit resolution ±1 least significant bit (LSB), providing

an effective accuracy of 11 bits. The ADC converts one sample every

25 µs, providing a maximum conversion frequency of 40 kHz.

2-2 Functional Description

Page 21

Channel Configuration

DAS-800 Series boards contain eight on-board analog input channels.

The following subsections describe the input configurations supported for

each channel, the gains and input ranges supported for each channel, and

the methods of specifying a channel or channels for an analog

input operation.

Input Configuration

On the DAS-801 and DAS-802, you can configure each channel as either

single-ended or differential. The differences between a single-ended and a

differential input configuration are described as follows:

● Single-ended - A single-ended input configuration is appropriate if

you are measuring relatively high-level signals (greater than 1 V), if

the source of the input signal is close to the board (less than two feet),

or if all input signals are referred to a common ground. This

configuration does not provide common-mode noise rejection.

● Differential - A differential input configuration is appropriate if you

are measuring low-level signals, if high source resistances (greater

than 100 Ω) exist, or if common-mode voltages exist between the

voltage source and the host’s chassis ground. In a differential

configuration, a separate positive and negative terminal is provided

for each channel. Any common-mode noise that is picked up equally

on both inputs is rejected because the difference is zero.

You specify the input configuration by setting switches on the board. The

switches connect or disconnect the inverting side of the input signal to

low-level ground. Refer to page 3-13 for information on setting

the switches.

Notes: On the DAS-800, the channels are always configured as

single-ended; all signals are referred to a single low-level ground.

If you are using EXP-16, EXP-16/A, or EXP-GP expansion boards or

MB-02 backplanes, you must configure the on-board analog input

channels associated with the expansion boards or backplanes as

single-ended.

2-3

Page 22

Gains and Ranges

A DAS-800 board measures analog input signals in the range of ±5 V.

Each DAS-801 or DAS-802 board contains a programmable gain

amplifier (PGA), which allows you to measure analog input signals in one

of several software-selectable unipolar and bipolar ranges. For each

channel on a DAS-801 or DAS-802 board, you can specify one of five

bipolar and four unipolar analog input ranges.

Table 2-1 lists the gains supported by DAS-800 Series boards and the

analog input voltage range for each gain.

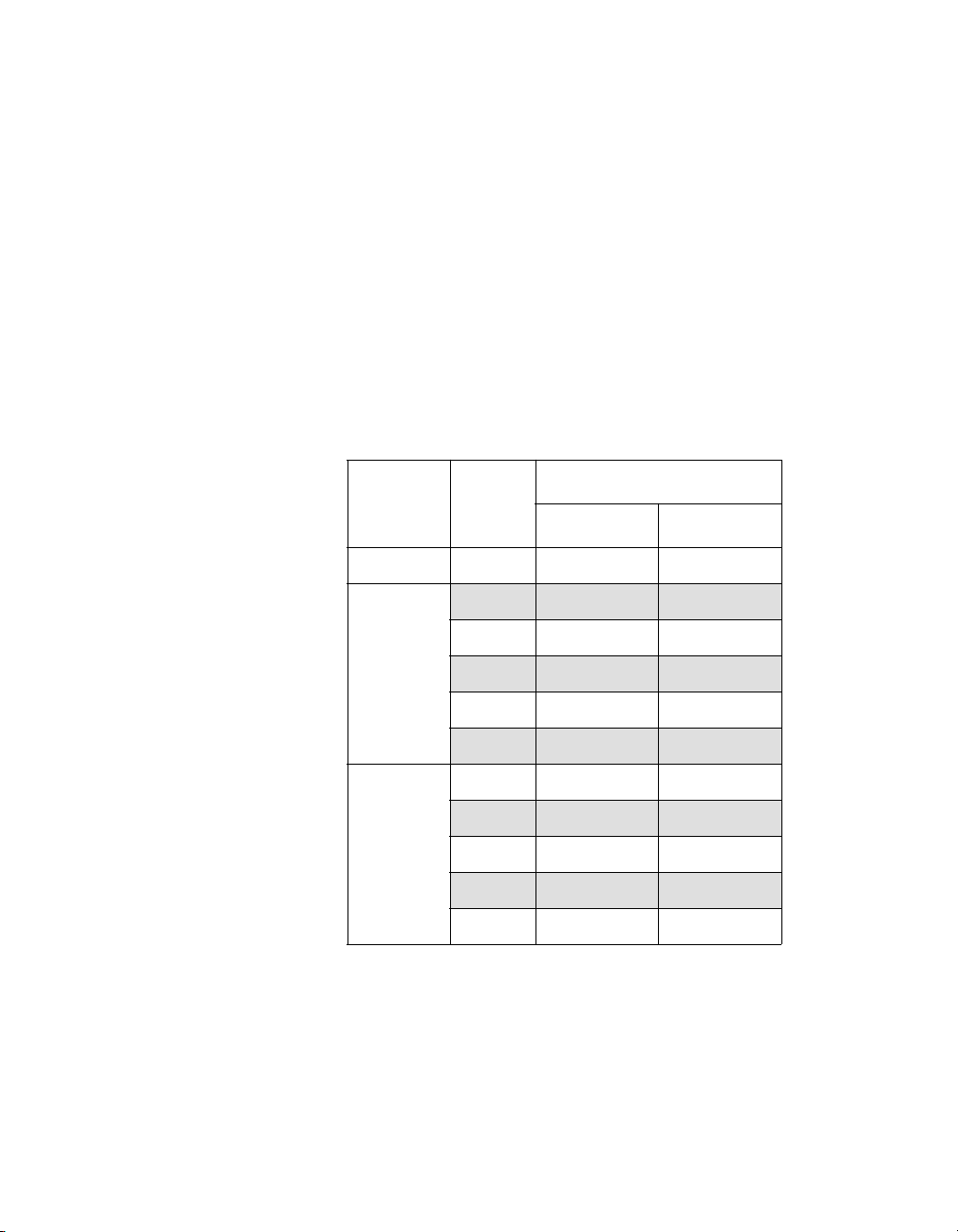

Table 2-1. Supported Gains

Range

Board Gain

DAS-800 1 ±5 V Not available

DAS-801 0.5 ±10 V Not available

1 ±5 V 0 to 10 V

10 ±500 mV 0 to 1 V

100 ±50 mV 0 to 100 mV

500 ±10 mV 0 to 20 mV

DAS-802 0.5 ±10 V Not available

1 ±5 V 0 to 10 V

2 ±2.5 V 0 to 5 V

4 ±1.25 V 0 to 2.5 V

8 ±625 mV 0 to 1.25 V

Bipolar Unipolar

2-4 Functional Description

Page 23

Note: Analog input channels on DAS-800 Series boards are provided

with protection against signals outside the specified analog input range.

All DAS-800 Series boards can tolerate voltages up to ±35 V and

transients of several hundred volts without damaging the board.

When measuring signals at differential inputs, DAS-801 and DAS-802

boards can tolerate common-mode voltages up to ±35 V and transients of

several hundred volts without damaging the board; however, for normal

operation of the board, make sure that the common-mode voltage is no

more than 12 V − ((G / 2) x VD), where G is the gain and VD is the

differential input voltage.

Channel Selection

You can use DAS-800 Series boards to acquire data from a single analog

input channel or from a range of contiguous, on-board analog input

channels using automatic channel scanning. These two methods of

channel selection are described as follows:

● Single channel - You use software to specify a single channel and

initiate a conversion.

● Automatic channel scanning - You use software to specify the first

and last channels in a range of contiguous, on-board channels (0 to 7).

The channels are sampled in order from first to last; the hardware

automatically increments the analog input multiplexer address shortly

after the start of each conversion. When the last address is reached,

the multiplexer returns to the start address and the channels are

sampled again. For example, assume that the start channel is 4, the

stop channel is 7, and you want to acquire five samples. Your program

reads data first from channel 4, then from channels 5, 6, and 7, and

finally from channel 4 again.

The start channel can be higher than the stop channel. For example,

assume that the start channel is 7, the stop channel is 2, and you want

to acquire five samples. Your program reads data first from channel 7,

then from channels 0, 1, and 2, and finally from channel 7 again.

When using automatic channel scanning, all contiguous, on-board

channels must have the same gain (analog input range).

2-5

Page 24

Note: DriverLINX allows you to acquire data from a range of

multiple channels that includes channels on expansion boards or MB

Series backplanes. The Expansion Board Configuration for Keithley

DAS-800 Series dialog in DriverLINX of the Special selection of the

Device Subsystem Page allows you to record the settings of your

analog input multiplexers and enable the expansion channels. Refer to

Keithley DAS-800 Series—Using DriverLINX with Your Hardware

manual that accompanies DriverLINX.

Automatic channel scanning is a hardware feature. In

multi-channel range mode, the DAS-800 Series acquires

all data from a consecutive range of analog channels.

● The Start channel’s gain only applies to the first channel

● DriverLINX uses the Stop Channel’s gain for all the other

analog channels in the range.

● If the Start Channel is greater than the Stop Channel, the

channel sequence is [Start Channel, ..., Last Channel, 0, ...,

Stop Channel], where Last Channel is the highest numbered

channel for the DAS-800 model the application is using.

In multi-channel list mode, the DAS-800 Series acquires all data from

a random list of analog channels.

● The channel-gain list may contain up to 256 channels in

any order with any allowed gain.

● The list may repeat the same channel with the same or

different gains.

Automatic channel scanning is a hardware feature. The

functions used to create a group of consecutive channels or a

channel-gain list emulate automatic channel scanning through

software. Therefore, the maximum attainable conversion

frequency is reduced when using a group of consecutive

channels or a channel-gain list.

2-6 Functional Description

Page 25

Channel Expansion

If you require additional analog input channels or signal conditioning for

transducer inputs, you can use any combination of up to eight 16-channel

EXP-16 expansion boards, eight 16-channel EXP-16/A expansion boards,

and/or eight 8-channel EXP-GP expansion boards to increase the number

of available channels to 128. You can also use up to four MB-02

backplanes to increase the number of available channels to 68.

For the EXP-16, EXP-16/A, and EXP-GP, you attach the expansion

boards in a daisy-chain configuration using the S-1800 or C-1800 cable.

The first expansion board in the daisy chain is associated with on-board

channel 0, the next expansion board is associated with on-board channel

1, and so on. You specify the associated on-board channel by setting a

jumper on each expansion board. You can access any unused on-board

channels by attaching an STA-08 or STA-08PGA screw terminal

accessory to the last expansion board in the daisy-chain configuration.

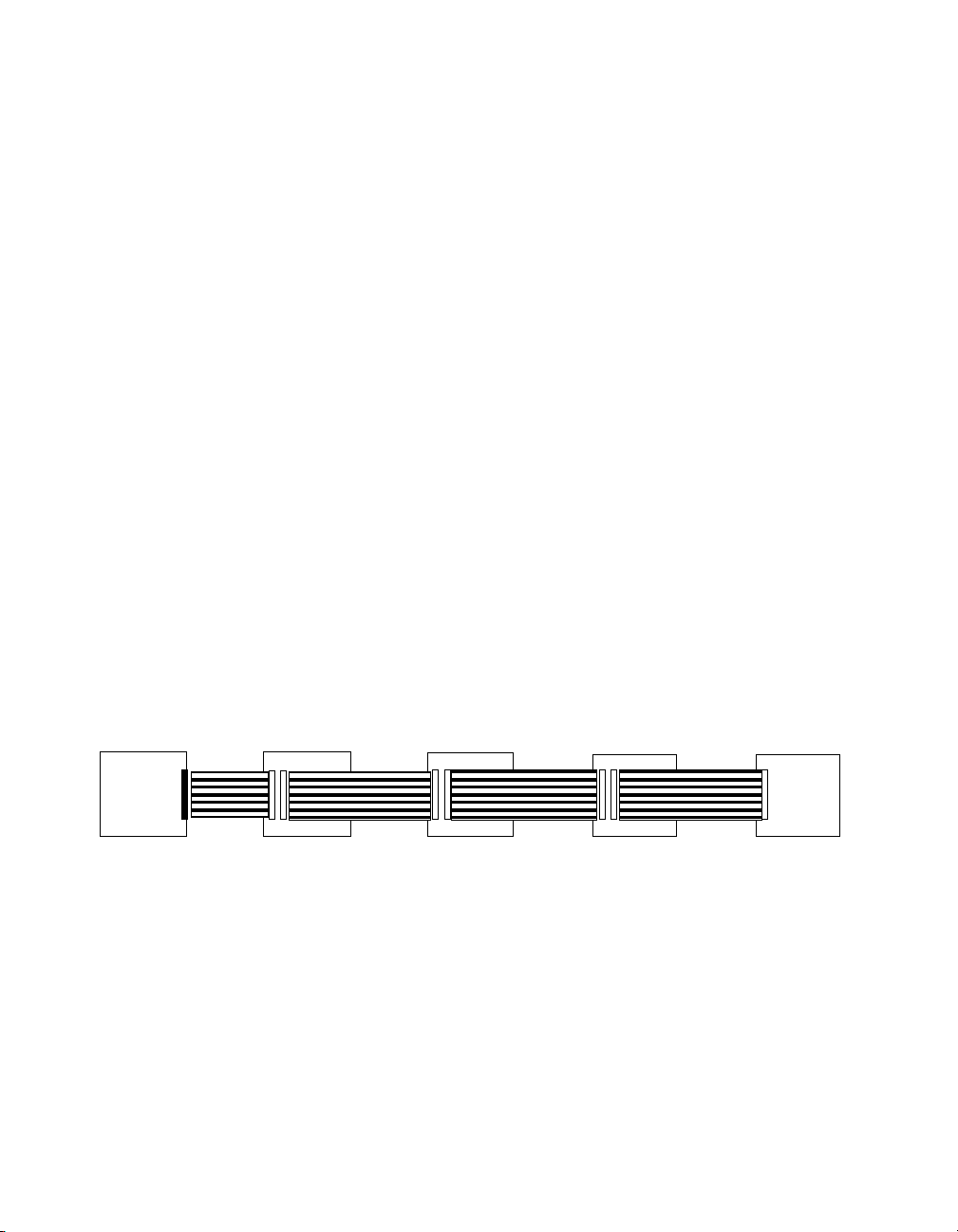

Figure 2-2 illustrates a daisy-chain configuration of two EXP-16

expansion boards, one EXP-GP expansion board, and an STA-08 screw

terminal accessory connected to a DAS-800 board.

DAS-800

Board

On-board

channel 0

EXP-16

On-board

channel 1

EXP-16

On-board

channel 2

EXP-GP

On-board

channels 3 to 7

STA-08

Figure 2-2. Channel Expansion

For information on attaching multiple MB-02 backplanes, refer to the

Series User’s Guide

.

MB

2-7

Page 26

Notes: You must specify a single-ended input configuration for all

on-board channels associated with channels on EXP-16, EXP-16/A, or

EXP-GP expansion boards or MB-02 backplanes.

If you are using EXP-16, EXP-16/A, or EXP-GP expansion boards or MB

Series backplanes, the digital output lines of the DAS-800 Series board

select the particular channel on the expansion board or backplane to read.

Refer to the appropriate expansion board documentation for more

information about the EXP-16, EXP-16/A, and EXP-GP expansion

boards. Refer to the MB Series User’s Guide for more information about

the MB-02 backplane.

Conversion Clock Sources

The conversion clock source determines when each analog-to-digital

(A/D) conversion is initiated. DAS-800 Series boards provide the

following software-selectable conversion clock sources:

● Software - When using a software conversion clock, the host

computer issues a command to initiate a conversion. The host polls

the board to determine if the conversion is complete. When the

conversion is complete, the host reads the data from the ADC and

returns the value. If the host reads data before the conversion is

complete, the data will be invalid.

Software-initiated conversions are suitable for measuring DC

voltages; however, in applications where you must accurately control

the sampling rate (as when measuring time-varying signals), it is

recommended that you use either an internal or an external hardware

conversion clock source.

At power-up or system reset, the board assumes that conversions will

be initiated through software.

● Hardware (internal clock source) - The internal clock source uses

the on-board 8254 counter/timer circuitry and a crystal-controlled

1 MHz time base. The 8254 counter/timer circuitry is normally in an

idle state. When you start an analog input operation, a conversion is

initiated immediately. The 8254 is loaded with its initial count value

2-8 Functional Description

Page 27

and begins counting down. When the 8254 counts down to 0, another

conversion is initiated and the process repeats.

Because the 8254 counter/timer uses a 1 MHz time base, each count

represents 1 µs. For example, if you load a count of 25, the time

interval between conversions is 25 µs; if you load a count of 65536,

the time interval between conversions is 65.536 ms.

The 8254 contains three counter/timers: C/T0, C/T1, and C/T2. If you

are using a hardware internal clock source, the time base logic uses

C/T1 and C/T2 in either normal or cascaded mode, as follows:

– Normal Mode - A software-selectable count is loaded into C/T2

of the 8254 counter/timer circuitry. Each time C/T2 reaches

terminal count, a conversion is initiated. The time interval

between conversions ranges from 25 µs to 65.536 ms.

– Cascaded Mode - A software-selectable count is divided between

C/T2 and C/T1 of the 8254 counter/timer circuitry. When C/T2

counts down to 0, C/T1 decrements by 1. C/T2 is reloaded with

its count value and begins counting down again. Each time C/T2

counts down to 0, C/T1 decrements by 1. Each time both C/T2

and C/T1 reach terminal count, a conversion is initiated. The time

interval between conversions ranges from 25 µs to 1.2 hours.

Note: For compatibility with the DAS-8 board, on power-up or

system reset, the DAS-800 board connects the clock input of C/T2 to

the CPU bus clock divided by two. If you specify a hardware internal

clock source through software, the DAS-800 board connects the clock

inputs of C/T1 and C/T2 to the 1 MHz time base. The DAS-801 and

DAS-802 boards always connect the clock input of C/T2 to the

1 MHz time base.

Refer to page 2-17 for more information about the 8254

counter/timer circuitry.

● Hardware (external clock source) - An external clock source is

useful if you want to sample at rates not available with the 8254

counter/timer circuitry, if you want to sample at uneven intervals, or if

you want to sample on the basis of an external event. An external

2-9

Page 28

clock also allows you to synchronize conversions on multiple boards

to a common timing source.

The external clock source is an externally applied TTL-compatible

signal, which you attach to the INT_IN / XCLK pin (pin 24) of the

main I/O connector. When you start an analog input operation,

conversions are armed. At the next falling edge of the external clock

source (and at every subsequent falling edge of the external clock

source), a conversion is initiated.

Note: If you are using a hardware external clock source, you cannot

use the INT_IN / XCLK pin (pin 24) to generate interrupts.

Figure 2-3 illustrates how conversions are initiated when using an internal

and an external clock source. (Note that Figure 2-3 assumes that you are

not using a hardware trigger; refer to Figure 2-4 for an illustration of

conversions when using a hardware trigger.)

Operation is started

External Clock

Source

Internal Clock

Source

Conversions begin

when using an

internal clock source

(idle state)

count

count

Conversions begin

when using an

external clock source

count

count

Figure 2-3. Initiating Conversions

2-10 Functional Description

Page 29

Notes: The ADC acquires data at a maximum of 40 kHz (one sample

every 25 µs). If you are using a hardware external clock, make sure that

the clock does not initiate conversions at a faster rate than the ADC

can handle.

To achieve full measurement accuracy when using a gain of 500, you

should limit the conversion frequency to a maximum of 25 kHz (one

sample every 40 µs).

If you are acquiring samples from multiple channels, the maximum

sampling rate for each channel is equal to 40 kHz divided by the number

of channels.

The rate at which the computer can reliably read data from the board

depends on a number of factors, including your computer, the operating

system/environment, whether you are using expansion boards, the gains

of the channels, and software issues.

You can synchronize conversions on multiple DAS-800 Series boards to a

common, externally applied conversion clock. In addition, you can use a

DAS-801 or DAS-802 board as a timing master; the output of the OUT1

pin (pin 5) on the main I/O connector of the master board acts as an

external hardware conversion clock to any additional boards. You can use

external circuitry, such as C/T0 on the 8254, to divide the rate of the

master clock; this allows you to synchronize conversions on the

additional boards to a rate different from that of the master board. Refer

to page 4-13 for more information on synchronizing conversions on

multiple boards.

2-11

Page 30

Triggers

A trigger is an event that must occur before a DAS-800 Series board starts

an analog input operation. You can use one of the following trigger

sources to trigger an analog input operation:

● Software - When you start the analog input operation, conversions

begin immediately.

● Hardware - You connect a digital trigger signal to the digital input

IP1 / TRIG pin (pin 25) of the main I/O connector. The trigger event

occurs when the board detects a rising edge on IP1 / TRIG.

The actual point at which conversions begin depends on whether you

are using an internal or external clock source. These considerations

are described as follows:

– Internal clock source - The 8254 counter/timer circuitry remains

idle until the trigger event occurs. When the trigger event occurs,

the board initiates the first conversion immediately.

– External clock source - Conversions are armed when the trigger

event occurs. At the next falling edge of the external clock source,

the board initiates the first conversion.

2-12 Functional Description

Page 31

Hardware Trigger

External Clock

Source

Internal Clock

Source

Figure 2-4 illustrates how conversions are started when using a

hardware trigger.

Trigger event occurs

Conversions begin

when using an

external clock source

(idle state)

count

count

count

count

Conversions begin

when using an

internal clock source

Figure 2-4. Initiating Conversions with a Hardware Trigger

2-13

Page 32

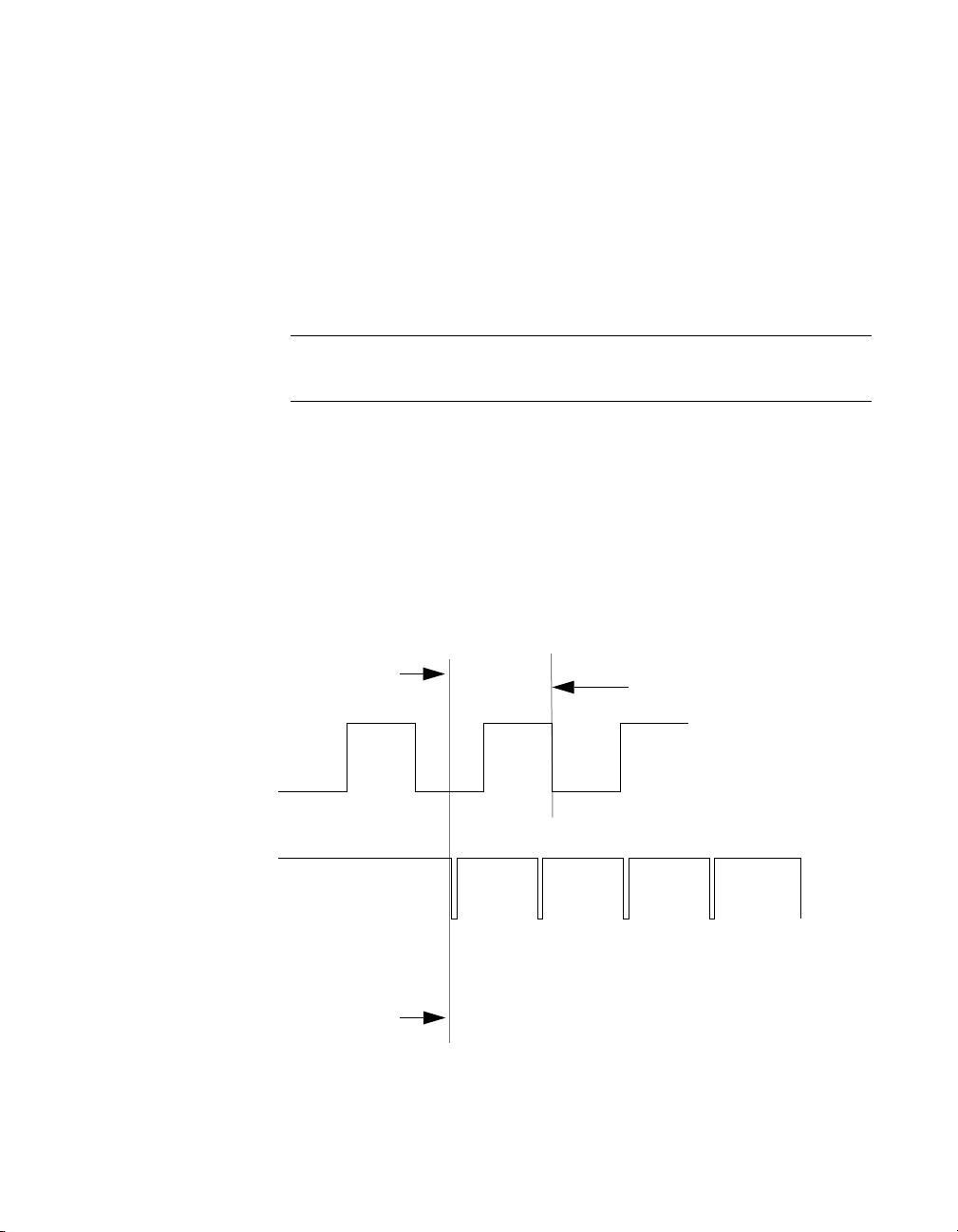

Hardware Gates

A hardware gate is an externally applied digital signal that determines

whether conversions occur. You connect the gate signal to the IP1 / TRIG

pin (pin 25) on the main I/O connector. DAS-800 Series boards support a

positive gate only. Therefore, if the hardware gate is enabled and the

signal to IP1 / TRIG is high, conversions occur; if the signal to IP1 /

TRIG is low, conversions are inhibited.

Note: You cannot use the hardware gate with a hardware trigger.

However, the gate signal itself can act as a trigger. If the gate signal is low

when the software starts the analog input operation, the board waits until

the gate signal goes high before conversions begin.

When using the hardware gate, the way conversions are synchronized

depends on whether you are using a hardware external clock or a

hardware internal clock, as follows:

● External clock - The signal from the external clock continues

uninterrupted while the gate signal is low; therefore, conversions are

synchronized to the external clock.

● Internal clock - The 8254 does not count while the gate signal is low.

Whenever the gate signal goes high, the 8254 is loaded with its initial

count value and starts counting; therefore, conversions are

synchronized to the gate signal.

Figure 2-5 illustrates how to use the hardware gate with both an external

clock and an internal clock.

2-14 Functional Description

Page 33

Gate Signal

Software starts

the operation

External Clock

Source

Gate is high;

conversions occur

1st conversion

(external clock)

Gate is low;

conversions inhibited

3rd conversion

(external clock)

2nd conversion

(external clock)

Internal Clock

Source

1st conversion

(internal clock)

. . . . . . . . . . . .

2nd conversion

(internal clock)

3rd conversion

(internal clock)

Figure 2-5. Hardware Gate

Note: Although DAS-800 Series boards do not provide a hardware-based

analog trigger, you can program an analog trigger through software, using

one of the analog input channels as the trigger channel. DriverLINX

provides functions for both an analog trigger and a digital trigger. Refer to

the Using DriverLINX With Your Hardware— Keithley DAS-800 manual

for more information.

4th conversion

(internal clock)

2-15

Page 34

Data Transfer

Because DAS-800 Series boards do not support DMA (Direct Memory

Access), data is always transferred from a DAS-800 Series board to the

host computer’s memory through an output port. Data can be transferred

as either a foreground process or a background process. If data is

transferred in the background, the end-of-conversion interrupt must be

enabled so that the board can notify the host computer when new data is

available; refer to page 2-25 for more information about interrupts. If data

is transferred in the foreground, interrupts are not required.

DAS-800 Series boards contain a four-word, first-in, first-out memory

location (FIFO). When you initiate conversions under hardware control,

using an internal or external clock source, the result of each conversion is

automatically stored in the FIFO.

Note: When you use software to initiate conversions, the FIFO control

logic is automatically disabled and the FIFO is emptied.

The FIFO increases the maximum attainable conversion frequency by

increasing the maximum software interrupt latency allowed by a factor of

four (up to the maximum conversion frequency of 40 kHz).

If the conversion frequency is too fast or if the time required to service the

interrupt is too long, the hardware may perform more than four

conversions before the converted data is read. The hardware can detect

this condition and generate an error to indicate that unread data in the

FIFO was overwritten and samples were lost.

Note: When using DriverLINX, the operation of the FIFO is transparent.

The DriverLINX software performs the data transfer.

2-16 Functional Description

Page 35

Digital I/O Features

DAS-800 Series boards contain three digital input lines and four digital

output lines. The digital input lines are associated with the IP1 / TRIG,

IP2, and IP3 pins on the main I/O connector; the digital output lines are

associated with the OP1, OP2, OP3, and OP4 pins on the main I/O

connector. Logic 1 at a pin indicates that the input/output is high (greater

than 2.0 V); logic 0 at a pin indicates that the input/output is low (less

than 0.8 V).

The digital input lines are compatible with TTL-level signals. If no signal

is connected to a digital input line, the input appears high (logic 1).

You can use the digital input and output lines for any general-purpose

task, with the following exceptions:

● If you are using an expansion board for an analog input operation, the

four digital output lines control the multiplexers on the expansion

boards to determine the expansion board channel that is acquiring

data; in this case, you cannot use the digital output lines for

general-purpose digital output operations.

● If you are using an external digital trigger or hardware gate, you must

use the IP1 / TRIG pin to attach the trigger/gate signal; in this case,

you cannot use IP1 / TRIG for general-purpose digital

input operations.

8254 Counter/Timer Circuitry

Each DAS-800 Series board contains 8254 counter/timer circuitry; the

8254 contains three counter/timers: C/T0, C/T1, and C/T2.

C/T0 is always available for general-purpose tasks. If you are using a

hardware internal clock source for an analog input operation, both C/T1

and C/T2 of the 8254 counter/timer circuitry are dedicated to internal

functions and cannot be used for general-purpose tasks. If you are using a

hardware external clock source, C/T0, C/T1, and C/T2 are always

available for general-purpose tasks.

2-17

Page 36

C/T0 and C/T1 have a clock input pin on the main I/O connector; all

counter/timers have a gate input pin and an output pin on the main I/O

connector. You can attach a clock source (0 to 10 MHz) to the clock input

pins (CLK0 and CLK1). Pull-up resistors of 3.3 kΩ are provided on the

three gate input pins (GATE0, GATE1, and GATE2); therefore, the gates

appear enabled if no signal is attached to the gate inputs. You can use the

output pins (OUT0, OUT1, and OUT2) for pulse or frequency outputs.

When C/T0, C/T1, and C/T2 are available for general-purpose tasks, you

can cascade counter C/T2 to counter C/T1 to provide an extended

counting range. To cascade these counters, externally wire the output of

counter C/T2 to the clock input of counter C/T1.

Notes: For compatibility with the DAS-8 board, on power-up or system

reset, the DAS-800 board connects the clock input of C/T2 to the CPU

bus clock divided by two. If you specify a hardware internal clock source

through software, the DAS-800 board connects the clock inputs of C/T1

and C/T2 to the 1 MHz time base. The DAS-801 and DAS-802 boards

always connect the clock input of C/T2 to the 1 MHz time base.

You can use the OUT1 pin of a DAS-801 or DAS-802 board to

synchronize conversions on multiple boards. Refer to page 4-13 for

more information.

The CLK1, GATE1, and GATE2 pins are provided for compatibility with

DAS-8, DAS-8 PGA, and DAS-8 PGA/G2 boards on power-up or system

reset. If you specify a hardware internal clock source through software,

you cannot use these pins.

2-18 Functional Description

Page 37

You can program the 8254 counter/timer circuitry to operate in one of the

following counter/timer modes:

● Pulse on terminal count (Mode 0) - This mode is useful for event

counting or for programming a time delay. The software forces the

output low. On the next clock pulse after the software writes the

initial count value, the counter is loaded. When the counter reaches

zero, the output goes high and remains high until the software writes

a new count value. Note that the output does not go high until n + 1

clock pulses after the initial count is written, where n indicates the

loaded count.

A high gate input enables counting; a low gate input disables

counting. The gate input has no effect on the output. Note that an

initial count value written while the gate input is low is still loaded on

the next clock pulse.

Figure 2-6 illustrates pulse on terminal count mode.

Clock pulse

Software forces

output low

Output

Software writes initial

count value of 3

3 2 1

Figure 2-6. Pulse on Terminal Count Mode

2-19

Page 38

Clock pulse

● Programmable one-shot (Mode 1) - This mode is useful for

providing a hardware-triggered delay or one-shot pulse. The output is

initially high. A trigger loads the initial count value into the counter.

At the next clock pulse after the trigger, the output goes low and

remains low until the counter reaches zero. (The one-shot pulse is n

clock cycles in duration, where n indicates the loaded count.) After

the counter reaches zero, the output goes high and remains high until

the clock pulse after the next trigger; this makes the one-shot

pulse retriggerable.

You do not have to reload the count into the counter. The gate input

has no effect on the output. Writing a new count to the counter during

a one-shot pulse does not affect the current one-shot pulse.

Figure 2-7 illustrates programmable one-shot mode.

Trigger loads initial

count value of 3

Output

3 2 1

Figure 2-7. Programmable One-Shot Mode

2-20 Functional Description

Page 39

Clock pulse

● Rate generator (Mode 2) - This mode is useful for generating a

real-time clock interrupt. The output is initially high. A trigger loads

the initial count value into the counter. At the next clock pulse after

the trigger, the counter starts counting down. When the counter

reaches one, the output goes low for one clock pulse and then goes

high again. The counter is then reloaded with the initial count value

and the process repeats.

A high gate input enables counting; a low gate input disables

counting. If the gate goes low during an output pulse, the output is set

high immediately; this allows you to use the gate input to synchronize

the counter.

Writing a new count to the counter while counting does not affect the

current counting sequence. In this mode, a count of 1 is illegal.

Figure 2-8 illustrates rate generator mode.

Output

Trigger loads initial

count value of 3

3 2

1 3 2 1 2

Figure 2-8. Rate Generator Mode

2-21

Page 40

Clock pulse

● Square-wave generator (Mode 3) - This mode is useful for

square-wave generation. The output is initially high. A trigger loads

the initial count value into the counter. At the next clock pulse after

the trigger, the counter starts counting down. When half the initial

count has elapsed, the output goes low for the remainder of the count.

When the total count elapses, the counter is reloaded with the initial

count value, the output goes high again, and the process repeats. If the

initial count is odd, the output is high for (n + 1) / 2 counts and low

for (n − 1) / 2 counts, where n indicates the loaded count.

A high gate input enables counting; a low gate input disables

counting. If the gate goes low while the output is low, the output is set

high immediately; this allows you to use the gate input to synchronize

the counter.

Figure 2-9 illustrates square-wave generator mode.

Trigger loads initial

count value of 4

Output

4 3 2 1 4 3 2 1

Figure 2-9. Square-Wave Generator Mode

2-22 Functional Description

Page 41

Clock pulse

● Software-triggered strobe (Mode 4) - The output is initially high.

Writing the initial count through software loads the initial count value

into the counter at the next clock pulse, but the counter does not start

counting. At the next clock pulse, the counter starts counting down.

When the counter reaches zero, the output goes low for one clock

pulse and then goes high again. Note that the output does not go low

until n + 1 clock pulses after the initial count is written, where n

indicates the loaded count.

A high gate input enables counting; a low gate input disables

counting. The gate input has no effect on the output.

Figure 2-10 illustrates software-triggered strobe mode.

Software writes initial

count value of 3

Output

Figure 2-10. Software-Triggered Strobe Mode

Software loads counter

with initial count

3 2

1

2-23

Page 42

Clock pulse

● Hardware-triggered strobe (Mode 5) - The output is initially high.

A rising edge of the gate input acts as a trigger. The counter is loaded

with the initial count value on the next clock pulse after the trigger,

but the counter does not start counting. At the next clock pulse, the

counter starts counting down. When the counter reaches zero, the

output goes low for one clock pulse and then goes high again. Note

that the output does not go low until n + 1 clock pulses after the

trigger event occurs, where n indicates the loaded count.

After the trigger event occurs, the gate input has no effect on the

output. Writing a new value during counting does not affect the

counting sequence.

Figure 2-11 illustrates hardware-triggered strobe mode.

Rising edge of gate

input acts as trigger

Output

Figure 2-11. Hardware-Triggered Strobe Mode

Refer to 8254 documentation for information on programming the 8254

counter/timer circuitry for general-purpose tasks. Table 2-2 lists several

companies that provide documentation for the 8254.

Counter is loaded with

initial count value of 3

3 2

1

2-24 Functional Description

Page 43

Table 2-2. Sources for 8254 Documentation

Company Address and Telephone Number

Intel Corporation Literature Sales

P.O. Box 7641

Mt. Prospect, IL 60056-7641

(800) 468-3548

Harris Semiconductor Literature Department

P.O. Box 883, MS CB1-28

Melbourne, FL 32901

(407) 724-3739

Interrupts

Newbridge

Microsystems

603 March Road

Kanata, Ontario

Canada K2K 1X3

(613) 592-0714

(800) 267-7231

DAS-800 Series boards can generate interrupts from one of the following

interrupt sources:

● External interrupt - An interrupt is generated when a rising edge

is applied to the INT_IN / XCLK pin (pin 24) on the main

I/O connector.

Note: If you are using an external interrupt, you cannot use the

INT_IN / XCLK pin (pin 24) to connect a hardware external

clock source.

● End-of-Conversion (EOC) interrupt - An interrupt is generated

when an A/D conversion is complete.

The interrupt source is software-selectable. At power-up or system reset,

the board assumes that the interrupt source is an external interrupt.

2-25

Page 44

Power

You can select only one interrupt at a time. If you are using an interrupt,

you must select the interrupt level (2, 3, 4, 5, 6, or 7) using a jumper on

the board. If you are not using an interrupt, you can disable interrupts

using a jumper on the board. Refer to page 3-14 for more information.

Note: If you are acquiring data in the background, interrupts must be

enabled and the interrupt source must be an EOC interrupt.

If an interrupt condition is satisfied, an on-board flip-flop is set. If

interrupts are enabled (through both hardware and software), the board

generates an interrupt to the host, driving the selected host interrupt line

to an active state.

The analog circuitry on the DAS-800 board is powered by the ±12 V of

the host computer. The DAS-801 and DAS-802 boards contain a DC/DC

converter to provide power to the analog circuitry.

Note: Many laptop computers and other types of battery-operated

computers do not have a −12 V power supply. If your computer does not

have a −12 V power supply, you cannot use a DAS-800 board.

The host computer can provide power for EXP-16, EXP-16/A, and

EXP-GP expansion boards and MB Series backplanes; however, certain

power limitations exist. Table 2-3 lists the maximum number of

expansion boards and backplanes that the host can power.

2-26 Functional Description

Page 45

Table 2-3. Expansion Board / Backplane Power Limitations

Expansion Board /

Backplane

EXP-16 4

EXP-16/A 4

EXP-GP 3

MB-01 Always use external power.

MB-02 Always use external power.

MB-03 4

MB-04 2

STA-1360 4

Maximum Number

Powered by Host

If you want to use more expansion boards or backplanes than indicated in

Table 2-3, you must connect an external power supply to the additional

expansion boards or backplanes. Refer to the appropriate expansion board

documentation for information on providing external power to EXP-16,

EXP-16/A, and EXP-GP expansion boards. Refer to the MB Series User’s

Guide for information on providing external power to MB

Series backplanes.

2-27

Page 46

3

Setup and Installation

This chapter describes how to install the software in your computer,

unpack and inspect the board, configure the board, and install the board in

your computer.

If you are familiar with switches and jumpers and with the items that are

configurable on DAS-800 Series boards, you can use Figure 3-1 as a

quick reference for configuring a DAS-800 board and Figure 3-2 as a

quick reference for configuring a DAS-801 or DAS-802 board. If you

need additional information, refer to Configuring the Board on page 3-9.

Read this chapter and all related DriverLINX documentation before you

attempt to install and use your DAS-800 Series board.

3-1

Page 47

BASE ADDRESS

O

1 2 3 4 5 6 7

N

IRQ

LEVEL

Switch

block S1

J1

2 3 4 5 6 7 X

J2

Main I/O

connector

Base Address

(On = 0, Off = 1)

0000000 = 000H

0000001 = 008H

0000010 = 010H

.

.

1100000 = 300H

.

1111111 = 3F8H

Interrupt level

Pin 1

(X = disabled)

Figure 3-1. DAS-800 Board

3-2 Setup and Installation

Page 48

Switch

block S1

O

1 2 3 4 5 6 7

N

8

BASE ADDRESS

O

1 2 3 4 5 6 7

N

Base Address

(On = 0, Off = 1)

0000000 = 000H

0000001 = 008H

0000010 = 010H

.

.

1100000 = 300H

.

1111111 = 3F8H

Switch

block S2

IRQ

LEVEL

Input Configuration

(On = single-ended,

Off = differential)

Switch 1 = Channel 0

Switch 2 = Channel 1

Switch 3 = Channel 2

Switch 4 = Channel 3

Switch 5 = Channel 4

Switch 6 = Channel 5

Switch 7 = Channel 6

Switch 8 = Channel 7

J1

2 3 4 5 6 7 X

Interrupt level

(X = disabled)

Figure 3-2. DAS-801/802 Board

J2

Main I/O

connector

Pin 1

3-3

Page 49

Installing and Configuring DriverLINX for DAS-800

Series Boards

Important:

install and test any new hardware, you should exit all other programs

and, if you use a disk cache, disable write caching. If the system does

crash and you’re using disk compression software or a disk cache

utility, as a precaution after any crash, run the utility that checks the

directory structures.

This section describes how to install the DAS-800 Series standard

software package. The contents of these software packages are described

as follows:

●

DAS-800 Series standard software package

DAS-800 Series boards. Includes DriverLINX®for Microsoft®

Windo ws and function libraries for writing application programs such

as Microsoft Visual C++; Microsoft Visual Basic; Borland Delphi®;

utility programs; and language-specific example programs.

●

DriverLINX-

device drivers for Windows application development includes:

–

DriverLINX API DLLs and drivers supporting the D AS-800

Series hardware

As a precaution against a system crash the first time you

- Shipped with

the high-performance real-time data-acquisition

– Analog I/O Panel - A DriverLINX program that verifies the

installation and configuration of DriverLINX to your

DAS-800 Series board and demonstrates several virtual

bench-top instruments

– Learn DriverLINX - an interactive learning and

demonstration program for DriverLINX that includes a

Digital Storage Oscilloscope

– Source Code - for the sample programs

3-4 Setup and Installation

Page 50

– DriverLINX Application Programming Interface files - for

the DAS-800 Series compiler

– DriverLINX On-line Help System - provides immediate help

as you operate DriverLINX

– Supplemental Documentation - on DriverLINX installation

and configuration; analog and digital I/O programming;

counter/timer programming; technical reference; and

information specific to the DAS-800 Series hardware

DAS-800 Series utilities

●

of both the DAS-800 Series standard software package:

DriverLINX Calibration Utility

–

- The following utilities are provided as part

– DriverLINX Test Panel Utility

Installing the DAS-800 Series Standard Software Package

Note:

software for the DAS-800, read the

Configuration Guide and the Using DriverLINX with your

Hardware—DAS-800 Series manuals that are packaged with the

DriverLINX software. They are accessed from the DriverLINX

CD-ROM after you have installed Adobe Acrobat®.

Before Installing DriverLINX

1. Inventory your DAS-800 board’s configuration settings.

Important—Before you begin installing any hardware or

DriverLINX Installation and

2. Determine the resources your DAS-800 Series board requires.

3. Inventory your computer’s resources already allocated to other

installed devices.

4. Determine whether your computer has sufficient resources for your

DAS-800 board

3-5

Page 51

5. Determine whether your DAS-800 board can use your computer’s

free resources.

6. Set any jumpers/switches to configure your DAS-800 board to use

your computer’s free resources.

7. Set any other jumpers/switches to configure your DAS-800 board the

way you want.

8. Install your DAS-800 board into an appropriate free slot in

your computer.

Selecting the DriverLINX components to Install

For your convenience in installing and uninstalling just the DriverLINX

components you need, the DriverLINX CD Browser will assist you in

selecting the components to install:

–

Install Drivers—

you need for configuring your hardware and running third-party

data-acquisition applications that require DriverLINX.

–

Install Interfaces—

and example programs that you will need to develop custom

applications for DriverLINX using C/C++, Visual Basic, Delphi,

and LabVIEW.

This required component installs only the files

This optional component installs the files

–

Install Documentation—

electronic documentation for DriverLINX that you can read,

search, and print using the Adobe Acrobat Reader.

Install Acrobat—

–

Acrobat Reader for the DriverLINX electronic documentation.

This optional component installs the Adobe

This optional component installs

Installing DriverLINX

1. Insert the DriverLINX CD-ROM into your computer’s

CD-ROM Drive.

2. Start the DriverLINX setup program. On most systems, wait a few