Page 1

ADC-16

Analog

Input

Board

User

Guide

Page 2

User Guide

for

the

ADC-16

Analog

Input

Board

Rev'sion

B

-

December

!992

Copyright Keithley Data Acquisition

1992

Part Number:

24446

KEITHLEY DATA ACQUISITION - Keithley MetraByte/Asyst

440

Myles

Standish Blvd., Taunton,

MA

02780

TEL.

5081880-3000,

FAX

5081880-0179

...

-

111

-

Page 3

Warranty Information

All products manufactured by Keithley Data Acquisition are warranted

against defective materials and workmanship for a period of one year

from the date of delivery to the original purchaser. Any product that

is

found to

be

defective within the warranty period will, at the option of

the manufacturer,

be

repaired or replaced. This warranty does not apply

to products damaged by improper use.

Warning

Keithley Data Acquisition assumes

no

liability for damages

consequent

to

the use of

this

product. This product is not designed

with components of a level

of

reliability suitable for use in

life

support or critical applications.

Disclaimer

Information furnished by Keithley Data Acquisition is believed to be

accurate and reliable. However, Keithley Data Acquisition assumes no

responsibility for the use of such information nor for any infringements

of patents or other rights of third parties that may result from its use.

No

license is granted by implication or otherwise under any patent rights of

Keithley Data Acquisition.

Copyright

All rights reserved.

No

part of this publication may be reproduced,

stored in a retrieval system, or transmitted in any form by any means,

electronic, mechanical, photo-reproductive, recording, or otherwise

without the express prior written permission

of

the Keithley Data

Acquisition.

Note:

Keithley MetraBytem is a trademark of Keithley Instruments.

Basic* is a trademark of Dartmouth College.

IBM@

is

a registered trademark of International Business Machines

Corporation.

PC,

XT,

AT,

PW2,

and Micro Channel Architecture@ are trademarks

of

International Business Machines Corporation.

Microsoft@ is a registered trademark of Microsoft Corporation.

Turbo

C@

is a registered trademark

of

Borland International.

-

iv

-

Page 4

Contents

CHAPTER

1

.

INTRODUCTION

1.1 Functional Overview

..................................

1.1

1.2 Software Overview

...................................

1.2

1.3 Accessories

......................................

. 1-3

1.4

Specifications

......................................

1.4

CHAPTER

2

.

INSPECTION. CONFIGURATION. & INSTALLATION

2.1 Inspection

........................................

2.1

2.2 Configuration

......................................

2.1

2.3 The Main

I/O

Connector J1

...............................

2.3

2.4 Software Installation

..................................

2.3

2.5 The Configuration Program

...............................

2.4

2.6 Hardware Installation

..................................

2.5

CHAPTER

3 . OPERATING & PROGRAMMING OVERVIEW

3.1 General

.........................................

3.1

3.2 The Pop-up Control Panel

...............................

3.1

.

3.3 The Call Driver

.....................................

3.1

3.4

Low-Level-Register

I/O

Programming

.........................

3.1

CHAPTER

4

.

THE POP-UP CONTROL PANEL

4.1 Overview

........................................

4.1

4.2 Driver Descriptions

...................................

4.1

4.3 Driver-File Loading/Unloading Options

........................

4-1

4.4 Syntax Conventions

..................................

4.3

4.5 VLEXE: Loading

&

Unloading

.............................

4.4

4.6 PADCl6.EXE: Loading

&

Unloading

.........................

4.6

4.6

Loading ANSLSYS

...................................

4.8

CHAPTER

5

.

POP-UP CONTROL PANEL OPERATION

5.1 Preliminary Requirements

...............................

5.1

5.2 Getting Started

.....................................

5.1

5.3 Important Hot Key Combinations

............................

5.1

5.4 The Control Panel

....................................

5.2

5.5

The Data Logging Panel

................................

5.3

CHAPTER

6

.

THE CALL INTERFACE

6.1 General

.........................................

6.1

6.3 QuickBASIC 4.0+, Including Professional BASIC

7.0+

................

6-7

6.5 List Of Calls

......................................

6-20

6.6 Glossary Of Call Terms

................................

6-22

6.2 GW BASIC, BASICA.

&

BASIC

............................

6.1

6.4 QBASlC

......................................... 6-13

CHAPTER

7

.

INDIVIDUAL CALL DESCRIPTIONS

.

v-

Page 5

Contents

CHAPTER

8 . REGISTER-LEVEL

I/O

MAPS

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

Introductory Information

................................

8-1

I/O Register Address Map

...............................

8-1

AID

Registers (Base Address

+O

&

+1)

........................

8-1

MUX & Gain Register (Base Address

+2)

......................

8-2

Control Register (Base Address

+3)

.........................

8-3

Status Register (Base Address

+3)

..........................

8-4

Typical Programming Sequence

...........................

8-4

BASIC Example Program

...............................

8-5

CHAPTER

9

.

CALIBRATION

9.1

Calibration Interval

...................................

9-1

9.2

Calibration Program

..................................

9-1

9.3

Required Test Equipment

...............................

9-1

CHAPTER

10

.

FACTORY RETURNS

APPENDIX

Appendix A . Summary

Of

Error Codes

...

.

vi-

Page 6

CHAPTER

1

INTRODUCTION

1.1

FUNCTIONAL

OVERVIEW

General

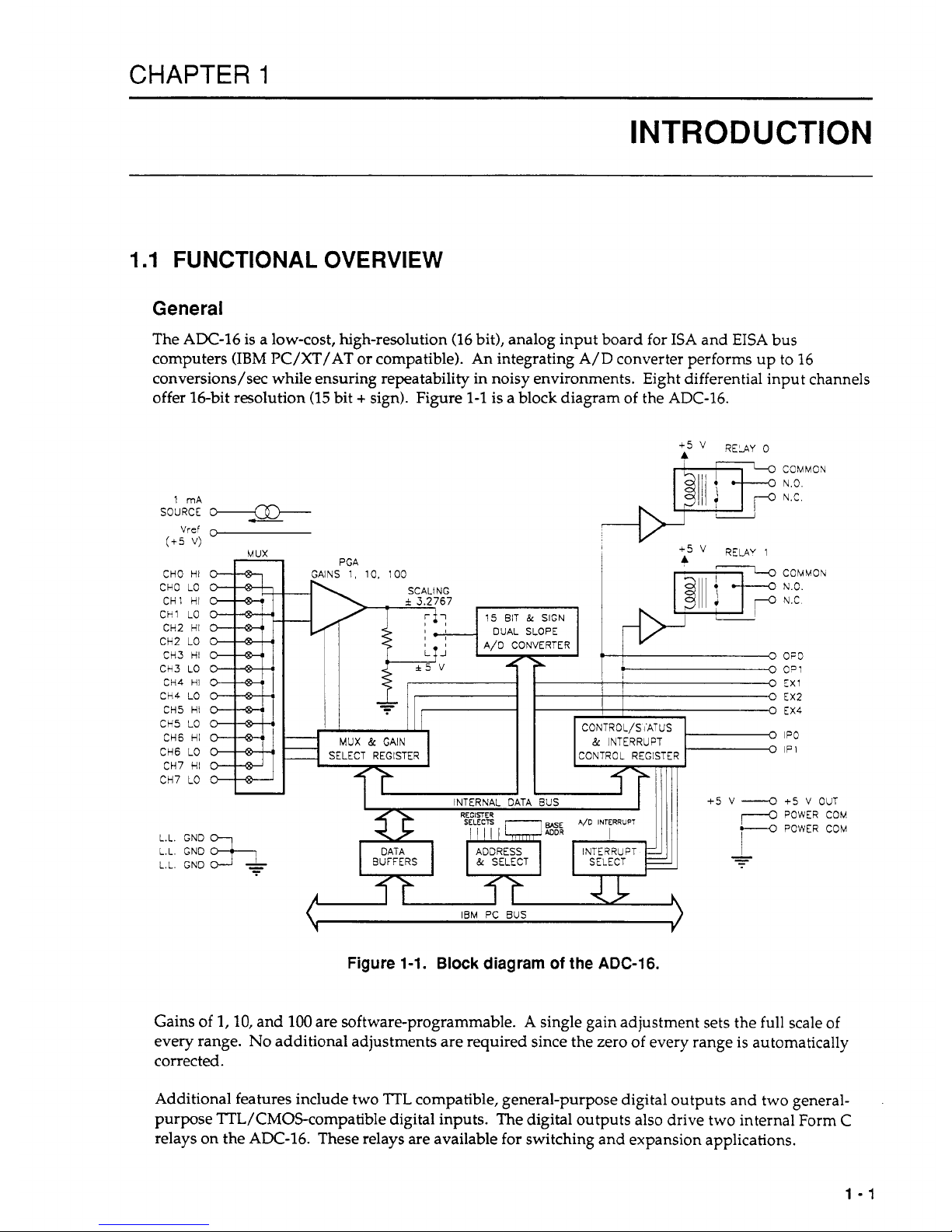

The AX-16 is a low-cost, high-resolution (16 bit), analog input board for ISA and EISA bus

computers (IBM PC/XT/AT or compatible). An integrating

A/D

converter performs up to 16

conversions/sec while ensuring repeatability in noisy environments. Eight differential input channels

offer 16-bit resolution

(15

bit + sign). Figure

1-1

is a block diagram of the ADC-16.

1 mA

SOURCE

O--

-

Vref

r,

(+5

V)

MUX

CHO HI

CHO

LO

CHI HI

CH1

LO

CH2 HI

CH2

LO

CH3 HI

CH3 LO

CH4

HI

CH4

LO

CH5 HI

CH5

LO

CH6 HI

CH6

LO

CH7 HI

CH7

LO

L.L.

GND

L.L. GND

L.L.

GND

GAINS

1,

10.

100

I

SCALING

fi

-

i

3.2767

I

.,

17

0

CONTROL/SiATUS

MUX

&

GAIN

&

INTERRUPT

SELECT REGISTER CONTROL REGISTER

I I

INTERNAL

DATA

aus

COMMON

N.3.

N.C.

COMMOlv

N.O.

N.C

OPD

C=:

EX1

EX2

EX4

IPO

IP

1

+5

V

OUT

POWER COU

POWER COM

IUI

IBM

PC

BUS

Figure

1-1.

Block

diagram

of

the

ADC-16.

Gains of

1,10,

and

100

are software-programmable. A single gain adjustment sets the full scale of

every range.

No

additional adjustments are required since the zero of every range is automatically

corrected.

Additional features include two

TTL

compatible, general-purpose digital outputs and two general-

purpose TTL/CMOScompatible digital inputs. The digital outputs

also

drive two internal Form C

relays on the ADC-16. These relays

are

available for switching and expansion applications.

1-1

Page 7

ADC-16

USER

GUIDE

Three more digital outputs become available when the optional STA-EX8 expansion multiplexer(s)

is

not used. A

1

mA,

high-precision current source with a compliance of -10 V to

+4

V

allows excitation

of resistance-based transducers such as RTDs.

All

connections to the ADC-16 pass through a standard

37-pin D connector using the manufacturer's C-1800 cable.

Optional equipment for the ADC-16 includes two screw-termination boxes: the STA-U and the STA-

EX8. The STA-U provides access to all ADC-16 interface signals via miniature screw-terminal

connectors. The STA-EX8 provides access to all ADC-16 interface signals via miniature screwterminal connectors, and it provides eight additional input channels. Up to eight STA-EX8s may be

added

to

an ADC-16, resulting in

64

fully differential channels.

Operating

Modes

A/D

Transfers

The ADC-16 conducts A/D conversions on a self-timing basis; the conversions progress as quickly as

the A/D circuitry can operate. When a previous conversion ends, the Driver starts another.

This

process continues until the scan is complete.

When a STart/Stop array is in use, the number of conversions is equal to the number of channels

specified in the array. This number can be up to

64

if eight STA-EX8s are in the system.

When a Channel/Gain array is in use, the number of conversions is equal to the number of entries in

the array.

This

number can

be

up to 256.

There are three modes of A/D operations:

SYNCHRONOUS MODE

-

where the transfers are occur in the foreground, forcing the user to

wait for the board to finish. This mode is invoked by the K-Syncstart call

(

see Chapters 6 and

7).

INTERRUPT MODE -

where the transfers occur in the background, allowing the user to execute

code until the board finishes. This mode is invoked by the K-IntStart call and tested for

completion by the K-IntStatus call (see Chapters 6 and

7).

These

two

modes require that channel and gain information

be

set into Frames using the K-SetBuf

and K-SetChanGary or K-SetStartStopG calls. For more information on Frames, refer to Section

6.6.

IMMEDIATE MODE

-

where when a single A/D operation takes place, all information is passed

via the Call parameters rather than by Frames, as in the two previous modes.

Digital Operations

Digital Input and Output operate

only

in the Immediate Mode, as described above for

Immediate

Mode

1.2

SOFTWARE OVERVIEW

This manual refers to the ADC-16 software as the

Distribution

Software.

The Distribution Software

contains a softwareinstallation program, driver files, utility files, calibration files, and programming

example files. For a list

of

these files, with descriptions, refer to the ASCII file

FILES.DOC.

1-2

Page 8

CHAPTER

1

:

INTRODUCTION

Because the Distribution Software arrives in compressed form,

it

is important that you follow the

installation instructions in Section

2.4.

You must use the installation program to uncompress these

files before you can access FILES.DOC.

The driver software supports the

Pop-up

Control Panel

and the

Cull Driver,

which are two of the three

interface options available for controlling the ADC-16. The third control interface is

Register-Level

I/O

programming. Chapter 3 describes of each of these interfaces.

Additional programming options are available in the

Advanced Software Option

(ASO)

,

which includes

the File I/O Command Driver, the Call Driver for C and Pascal, and the Dynamic Link Library for

Windows 3.X languages. Contact the manufacturer for information on this option.

NOTE:

The

README.DOC

file (in the Distribution Software), contains last-minute information

not included in this manual. READMEDOC

is

a readable ASCII file.

1.3

ACCESSORIES

STA-EX8

STA-U

C-1800

8-channel expansion multiplexer.

Standard Screw Terminal Board.

Cable to connect ADC-16 to STA-EX8 or STA-U.

ASO-ADC-16

Advanced Software Option for the ADC-16. This option includes Call

Driver for C and Pascal, the Dynamic Link Library for Windows

3.X,

and

the File

I/O

Driver. A user manual is also included.

1.4

SPECIFICATIONS

ADC-16

Board

A/D

Channels:

8

differential, expandable

to

64

with

STA-EX8 Boards.

Input Resolution:

16 bits

(15

plus a sign bit).

Coding:

Sign

plus

Magnitude (binary).

Input Ranges:

k5

V

or

k3.2768

V

Full Scale (jumper selectable).

Input Gains:

1,

10, or

100

(software-

or

jumper-selectable).

Sample Rate:

16 samples/second.

Input Settling Time:

50

p.

Input Offset:

Auto-zeroed; k10

pV

for Gain

=

100,

fl

LSB

for

Gain

=

1

or

10.

1-3

Page 9

ADC-16

USER

GUIDE

Absolute Accuracy

Gain = 1:

M.O1%

of

range typical

Gain

=

10:

f0.05%

of

range

typical

Gain

=

100:

M.05%

of

range typical

Relative Accuracy

Gain

=

l,lO,

and

100

maximum.

+_0.03%

maximum.

kO.lO% maximum.

k0.15% maximum.

Noise (Typical)

Gain = 1:

<

k1

bit

rms.

Gain

=

10:

c

+_1

bit

rms.

Gain

=

100:

<

+3

bits

rms.

Input Impedance:

Greater

than

100

MegOhms.

Input Bias Current:

50

nA max.

Common Mode Rejection:

Gain

=

1

-

100

dB

typ,

80

dB

min.

Gain

=

10

-

110

dB

typ,

86

dB

min.

Gain

=

100

-

120

dB

typ,

92

dE3

min.

Common Mode Range:

+_6

V.

Max Input Volts

w/o

Power On:

k35

VDC.

Damage:

Power

Off

k20 VDC.

DIGITAL

I/O

Digital Inputs

Number

of

Inputs:

2,

TTL/CMOS

compatible.

Logic Type:

High input returns

a

1.

Logic Levels:

Vil

=

.8

V, Vih

=

2.0

V.

Iil

=

-.2

mA, Iih

=

20

uA.

Digital Outputs

Number

of

Outputs:

5

TTL

compatible.

Logic Type:

Vol

=

.5

V rnax at 8.5 mA.

Voh

=

2.7 V min at

-0.4

mA.

Relay Outputs

Number

of

Channels:

2

Form

C.

Max Current:

2.0

A at

28

Vrms (resistive).

POWER REQUIREMENTS

+_0.005%

of

range typical

kO.012%

+5

V:

800

mA typ, 1 A max.

+12

V:

25 mA max.

-12

V:

15 mA max.

1-4

Page 10

CHAPTER

1

:

INTRODUCTION

ENViRONMENTAL

Operating Temperature: 0 to

70

OC.

Storage Temperature:

-25

to

85

OC.

Humidity: 0 to

95%

noncondensing.

PH YSiCAL

Dimensions:

9.0

x

4.2

in.

(22.9

x

10.7

cm)

Weight:

10

oz

(284

g).

STA-EX8

Board

Number

of

Inputs: 8 differential. Each

STA-EX8

board

uses

one

ADC-16

channel; up to

8

STA-EX

boards will work with a single

ADC-16.

Input Offset:

Auto-zeroed;

k10

pV

for Gain

= 100,

f1

LSB

for

Gain

= 1 or

10.

ACCURACY

Gain

=

1:

k.01%

of

Full

Scale.

Gain

=

10:

+.

1 % typ.

Gain

=

100:

2.1%

typ.

N

01s

E

(TYPICAL)

Gain

=

1:

<fl

bit

rms.

Gain

=

10:

<i2

bits

rms.

Gain

=

100:

<+15

bits

rms.

Input Impedance:

Greater than

100

Megohms.

Input Bias Current:

50

nA

max.

Common Mode Rejection:

Gain

=

1 - 100

dB typ,

80

dB min.

Gain

=

10 - 110

dB typ,

86

dT3

min.

Gain

=

100 - 120

dB

typ,

92

dB min.

Common Mode Range:

i6

V

Max

Input

Volts

w/o

Power

On:

i35 VDC.

Damage:

Power

Off

i20 VDC.

1-5

Page 11

ADC-16

USER

GUIDE

POWER REQUIREMENTS

+5

V:

10

mA

typ,

100

mA

max.

+12 V:

Not

used.

-12V:

Notused.

ENVIRONMENTAL

Operating Temperature:

0

to

70

"C.

Storage Temperature:

-25

to

85

"C.

Humidity:

0

to

95%

noncondensing.

PH YSlCAL

Dimensions:

6.7 x 5.4 x 2.3

in.

(17.0 x 13.7

x

5.8

cm)

Weight:

11

oz

(312

g).

STA-U

Board

This

board

is

simply a wiring feed-through for facilitating connections to the

ADC-16.

As

such, the

STA-U

has no meaningful specifications beyond the following.

ENVIRONMENTAL

Dimensions:

6.7 x 5.1

x

2.4

in.

(17.0 x 13.0

x

6.0

cm)

Operating Temperature:

0

to

70

"C.

Storage Temperature:

-25

to

85

"C.

Humidity:

0

to

95%

noncondensing.

1-6

Page 12

CHAPTER

2

INSPECTION, CONFIGURATION,

&

INSTALLATION

2.1

INSPECTION

After removing the wrapped Board

(ADC-16)

from its outer shipping carton, proceed as follows:

1.

Before unwrapping the Board, place one hand firmly

on

a metal portion of the computer chassis

to

discharge static electricity from yourself and the Board (the computer must be turned Off but

grounded).

2.

Carefully remove the Board from its anti-static wrapping material.

3.

Inspect the Board for signs of damage. If any damage is apparent, return the Board to the factory.

4.

Check

the

remaining contents of your package against the packing list

to

be sure your order

is

5.

When you are satisfied with preliminary inspection, you are ready to configure the Board. Refer

complete. Report any missing items to the factory immediately.

to the next section for configuration options.

2.2

CONFIGURATION

Switch

&

Jumper

Settings

Figure

2-1.

Location

of

Base Address switch and Input Range jumper.

2-1

Page 13

ADC-16

USER

GUIDE

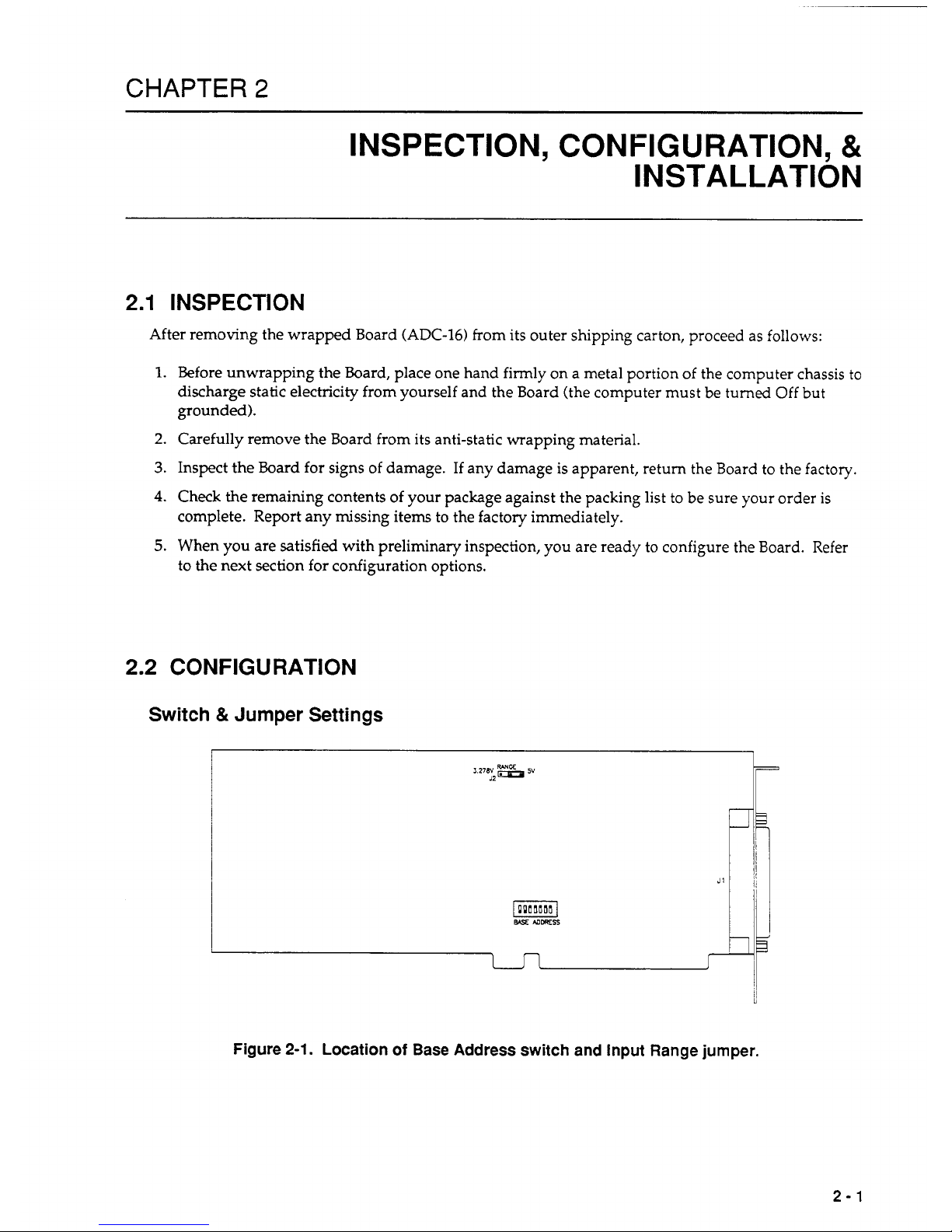

The Base Address

Switch

The factory-set Base Address is 300h (768 decimal).

If

this address

is

already in

use,

change the setting

of the Base Address Switch (refer to Figure 2-2 for

the address-setting arrangement of the Switch).

Any new Base Address setting must

be

within the

range of OOOh to 3FFh

(0

to 1023 Decimal) on an

8-

byte boundary. Use the Table 2-1 as an aid to

selecting a Base Address.

ADDRESS ADDRESS LINE VALUES

LINE

DECIMAL

*EX

512

2'X

256

>CC

64

10

16

IS

88

128

en

iiiiiii

Switch

settings

indicote

a

value

of

512

+

256

=

768

Decimol

200

+

1W

=

300

Her

or

1234567

Figure 2-2. Base Address Switch

Table

2-1.

PC/XT/AT

I/O

Address Space

HEX RANGE USAGE HEX RANGE USAGE

000-00F

020-02 1

040-043

060-063

060-064

070-07

1

080-O8F

OAO-OA

1

OAO-OAF

OCO-ODF

OFO-OFF

IFO-IFF

200-20F

210-21F

238-23B

23C-23F

278-2717

2BO-2BF

8237 DMA

#I

8259 PIC

#I

8253 Timer

8255 PPI

(XT)

8742 Controller (AT)

CMOS

RAM

&

NMI

Mask Reg.

(AT)

DMA

Page Registers

8259 PIC #2 (AT)

NMI

Mask Register

(XTj

8237 DMA #2 (AT)

Coprocessor

Hard

Disk (AT)

GameKontrol

Expansion Unit

(XT)

Bus Mouse

AIL

Bus Mouse

Parallel Printer

EGA

2CO-2CF

2DO-2DF

2EO-2E7

2E8

-

2EF

2F8-2FF

3

00-

3 OF

3 10-3 1F

320-32F

378-3717

380-38F

3AO-3AF

3BO-3BB

3BC-3BF

3CO-3CF

3DO-3DF

3E8-3EF

3FO-3F7

3F8-3FF

EGA

EGA

GPIB

(AT)

Serial Port

Serial Port

Prototype Card

Prototype Card

Hard Disk

(AT)

Parallel Printer

SDLC

SDLC

MDA

Parallel Printer

EGA

CGA

Serial Port

Floppy Disk

Serial Port

The

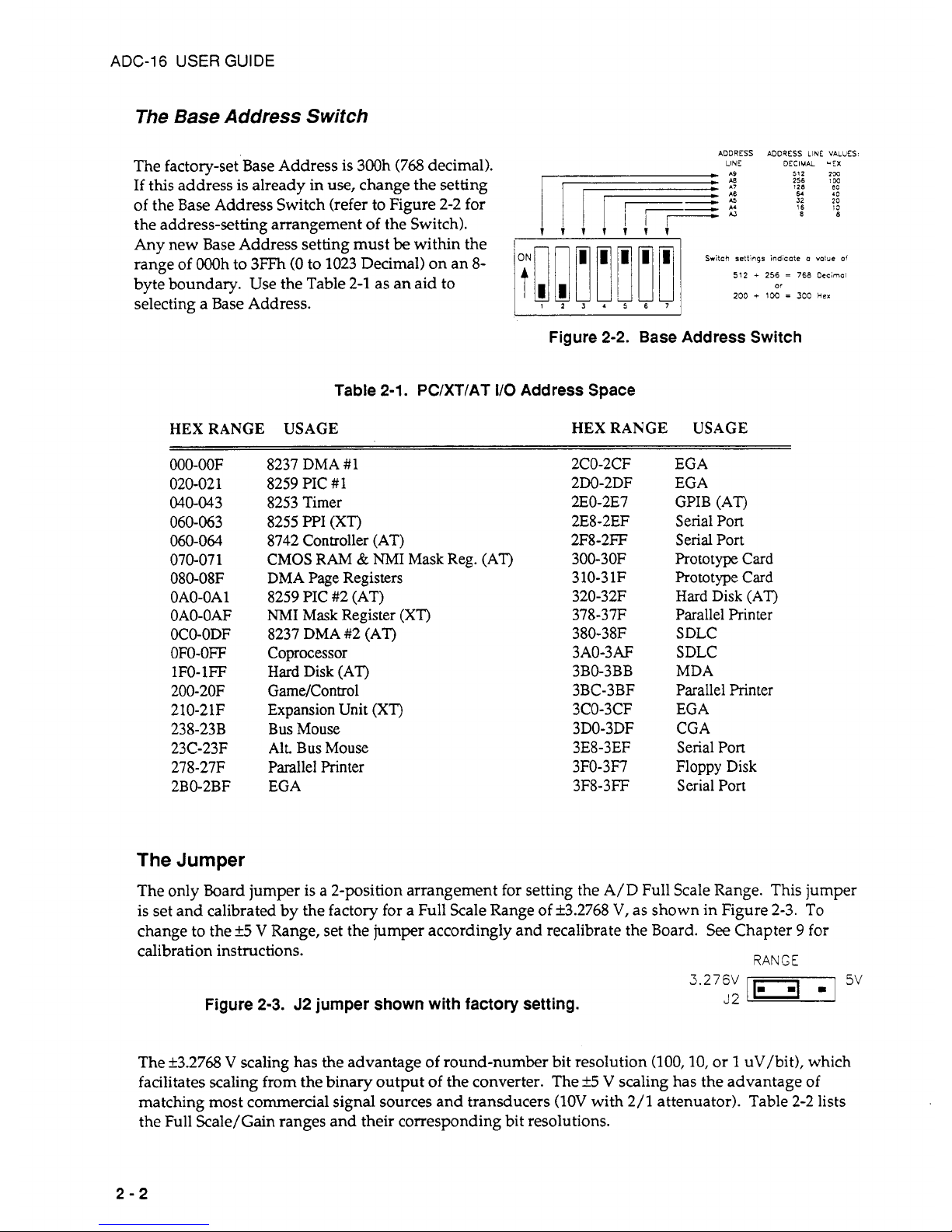

Jumper

The only bard jumper is a 2-position arrangement for setting the A/D Full Scale Range. This jumper

is set and calibrated by the factory for a Full Scale Range of i3.2768

V,

as shown in Figure 2-3. To

change to the

k5

V

Range, set the jumper accordingly and recalibrate the Board.

See

Chapter 9 for

calibration instructions.

RANGE

3.276v

J2

m

5v

Figure 2-3. J2 jumper shown with factory setting.

The k3.2768 V scaling has the advantage

of

round-number bit resolution

(100,10,

or 1 uV/bit), which

facilitates scaling from the binary output of the converter. The

k5

V

scaling has the advantage of

matching most commercial signal sources and transducers

(1OV

with

2/1

attenuator). Table 2-2 lists

the Full Scale/Gain ranges and their corresponding bit resolutions.

2-2

Page 14

CHAPTER

2:

INSPECTION, CONFIGURATION, & INSTALLATION

Table

2-2.

Input Range

vs.

Bit Resolutions

3.276

V

INPUT RANGE

5 V INPUT RANGE

GAIN RANGE RESOLUTION RANGE RESOLUTION

1

f3.2768

V

100

uv

i5

v

152.6

uV

10

f327.68

mV

10

uv

i500

mV

15.26

uV

100

k32.768

mV

1

uv

k50

mV

1.526

uV

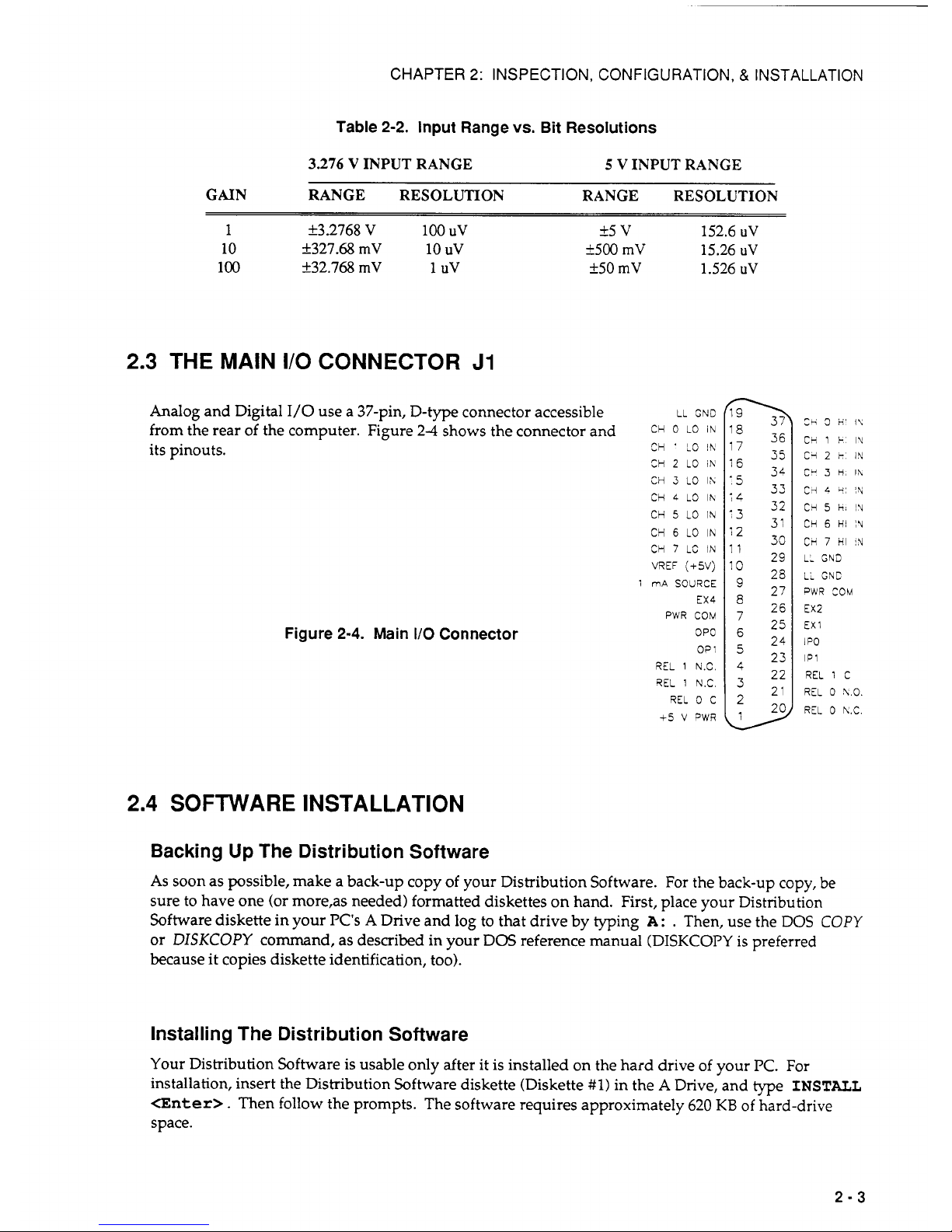

2.3

THE MAIN

I/O

CONNECTOR

J1

Analog

and Digital

I/O

use a 37-pin, D-type connector accessible

LL

GND

from the rear of the computer. Figure

2-4

shows the connector and

CH

0

LO

IN

its pinouts.

CH ' LO

IN

CH

2

LO

IN

CH

3

LO

IX

CH

4

LO

lh

CH

5

LO

IN

CY

6

LO

IN

CH

7

LC

IN

VREF

(+jV)

1

mA

SOURCE

EX4

PWR

CCM

OPO

CP

1

REL

1

N.C.

QEL

1

N.C

REL

0

C

+5

V

PWR

Figure

2-4.

Main

I/O

Connector

l8

36

I'

35

34

5

33

32

31

29

25

27

26

25

24

23

22

21

20

l2

33

I1

lo

4

>

Ch

3

H'

I\

CH

1

k

IU

C'i

2

r

IN

CY

3

H,

I\

c

4:

i\l

CH

5

it;

!A

CH

6

HI

IU

CH

7

HI

IN

LL

GND

LL

GNC

PWR

COM

EX2

EX

1

1

PO

lP1

REL

1

C

REL

0

X.0.

REL

0

K.C.

2.4

SOFTWARE INSTALLATION

Backing

Up

The Distribution Software

As

soon as possible, make a back-up copy of your Distribution Software. For the back-up copy, be

sure to have one (or more,as needed) formatted diskettes on hand. First, place your Distribution

Software diskette in your PC's

A

Drive and

log

to

that drive by typing

A

:

.

Then, use the DOS

COPY

or

DISKCOPY

command,

as

described in your DOS reference manual (DISKCOPY is preferred

because it copies diskette identification,

too).

Installing The Distribution Software

Your Distribution Software is usable only after it is installed on the hard drive of your

PC.

For

installation, insert the Distribution Software diskette (Diskette

#1)

in the A Drive, and type

INSTALL

<Enter>.

Then follow the prompts. The software requires approximately

620

KB

of hard-drive

space.

2-3

Page 15

ADC-16

USER

GUIDE

The README.DOC File

To learn of last-minute changes,

be

sure to read the ASCII file

READMEDOC.

This is an ASCII text

file that is readable with any text editor (word processor) or with the DOS

TYPE

command.

The FILES.DOC File

To learn the contents of your Distribution Software, refer to the ASCII file

FILESDOC . This file lists

and describes each of the files in the Distribution Software. This is an ASCII text file that is readable

with any text editor (word processor) or with the DOS

TYPE

command. FILES.DOC lists and briefly

describes the contents of the Distribution Software.

2.5

THE

CONFIGURATION

PROGRAM

Overview

NOTE:

Before you can run the Configuration Program, you must install the Distribution

Software (Section

2.4).

Your ADC-16 Distribution Software includes the Configuration Program

ADC16CFG.EXE , whose

purpose is to assist you in setting up Board parameters and saving them to a new or existing

configuration file. The default configuration file in your Distribution Software is

ADCI6.CFG

;

however, the Configuration Program allows you to save a set of parameters to any configuration file

you specify.

A

configuration file is a necessary reference for Call Driver programs (Chapters 6 and

7)

and for the

Pop Up Control Panel. The file contains information such as the number of ADC-16s in use, Base

Address, Range, Interrupt Level, and the number of STA-EX8s linked

to

each Board.

If

you bypass the

configuration program, the Call Driver refers to the ADC16.CFG default file.

Factory Defaults

Factory settings for the ADC16.CFG file are as follows:

BoardNumber

0

Board Name

ADC16

Base Address

&H300

Range

3.2768

Number Type

SignMagnitude

Interrupt Level

7

Installed STA-EX8s

0

Running the Configuration Program

To

start the configuration program, log to its directory, and type

ADCl6CFG

follow the on-screen instructions.

f

i

1

ename

.

Then

2-4

Page 16

CHAPTER

2:

INSPECTION, CONFIGURATION, & INSTALLATION

filename

is the name of the configuration file to be modified;

it

may be an existing filename, or

it

may

be a new filename that complies with DOS file-naming conventions. The default file is ADC16.CFG.

2.6

HARDWARE

INSTALLATION

Installation

Of

The

Board

To install the ADC-16 in a PC, proceed as follows:

1.

Turn Off power to the PC and all attached equipment.

WARNING!

ANY

ATTEMPT TO INSERT OR REMOVE

ANY

ADAPTER BOARD

WITH COMPUTER POWER

ON

COULD DAMAGE YOUR

COMPUTER!

2.

Remove the cover of the PC.

3.

Choose an available option slot. Loosen and remove the retainer screw at the top of the blank

4.

Before touching the Board, place one hand on any metallic part of the PC/AT chassis (but not

on

5.

Make sure the Board switches have been properly set (refer to the configuration sections).

6. Align the Board connector with the desired accessory slot and with the corresponding rear-panel

slot. Gently press the Board into the socket. Secure the Board in place with retainer screw for

the

rear-panel adapter-plate.

7.

Replace the computer's cover.

8.

Plug in all cords and cables. Turn the power to the computer back on. You are now ready to

adapter plate. Then slide the plate up and out to remove.

any components) to discharge any static electricity from your body.

make any necessary system connections.

Installation

Of

The Expander Boxes

All connections to the ADC-16 are made through the Main I/O connector. Two interface options are

the STA-U and STA-EX8 accessory boxes.

If

your application requires access to ADC-16 interface

signals via screw terminals and eight or fewer channels of analog input use the STA-U.

If

your

application requires additional channels (more than eight), use the STA-EX8. This section describes

the installation of each. Note that the ADC-16 must already be installed for these procedures.

STA-U

Installation

The STA-U allows access to ADC-16 interface signals via screw terminals. To connect the STA-U

to

the ADC-16, obtain a C-1800 cable. Then, proceed as follows:

1.

Turn your computer off.

2.

If

the STA-U is enclosed, loosen the four comer screws and remove the top cover.

3.

Plug one end

of

the C-1800 cable into the Main

1/0

Connector of the ADC-16.

2-5

Page 17

ADC-16

USER

GUIDE

4.

Plug the other end of the C-1800 cable into one of the

two

37-pin connectors on the STA-U.

5. Make any other connections the STA-U, as required by your application.

6. Replace the cover on the STA-U and tighten the screws,

if

desired.

STA-

EX8

Installation

OVERVIEW

The STA-EX8 is a multiplexed expander box with screw connections to the ADC-16 interface signals

and the eight input channels. Up to eight STA-EX8 Boards connect to a single ADC-16 to offer up to

64

fully differential channels. The STA-EX8 has two 12-screw terminal blocks (TBI and TB2) and two

24-screw terminal blocks (TB5 and

TB6)

allowing access to the ADC-16 interface signals.

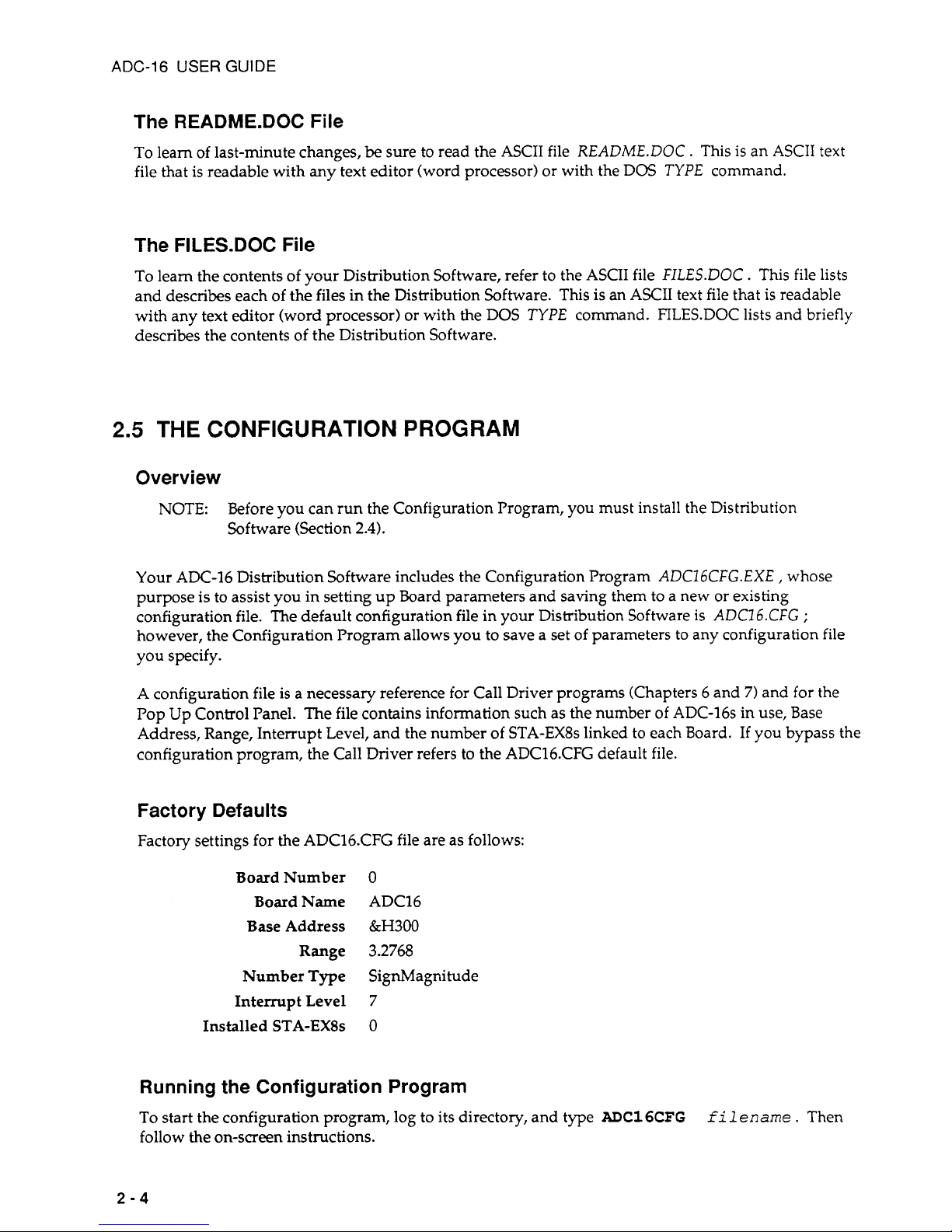

TB1 and TB2 provide access for digital input and power signals. TB2 provides two TTL-compatible

digital outputs,

two

TTL/CMOScompatible digital inputs, and access for power signals.

TBl

allows

direct connection to the

two

internal Form C relays on the ADC-16. Note that the signals through

TBl

and

TE32

run in parallel across the C-1800 cable; this

is

significant when accessing the power signals.

Figure 2-5 shows the signal assignments for

TBl

and

TB2.

TB2

TB

1

,

Figure

2-5. TB1

and

TB2

signals.

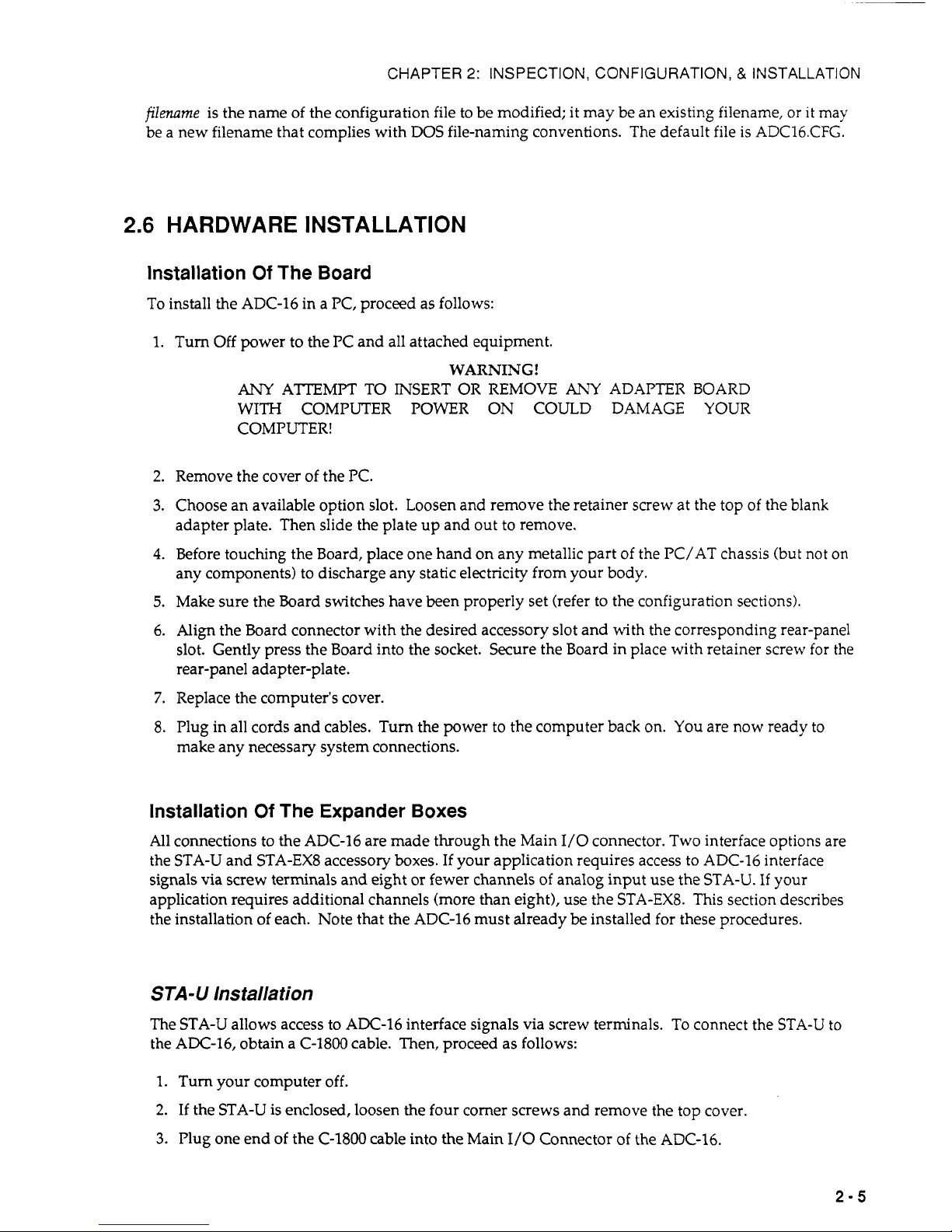

TB5 and TI36 accommodate connections to the input channels. In addition, these two terminal blocks

provide extra input channels (see section on input-channel assignments, ahead). Figure 2-6 shows the

signal assignments for TB5 and TB6.

I

I

Figure

2-6. TB5

and

TB6

signal assignments.

Two 37-pin connectors share pin assignments with the ADC-16 Main

1/0

Connector. These two

connectors may

be

used to

daisy-chain

multiple STA-EX8s. Refer to Figure 2-4 for pinouts of these

connectors.

CHO

CHI CH2 CH3 CH4 CH5 CH6

CH7

mlrl

TB4

TB

3

Figure

2-7.

Channel Select Jumper

2-6

Page 18

CHAPTER

2:

INSPECTION, CONFIGURATION, & INSTALLATION

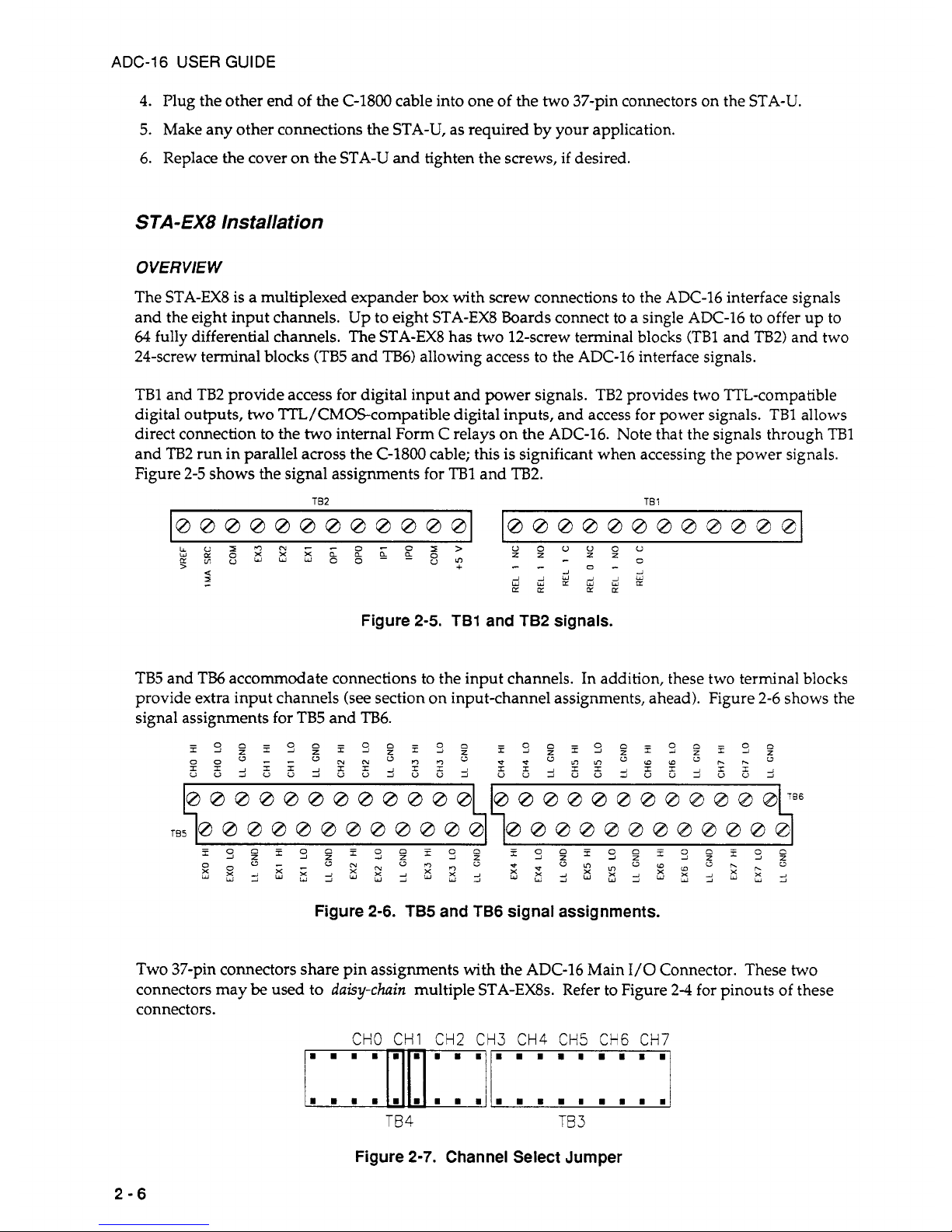

Finally, the Channel Select Jumper (TB3 and

TB4)

determines which ADC-16 input channel the STAEX8 will use for communication. You may have up to eight STA-EX8s connected to one ADC-16.

Each STA-EX8 must have its own ADC-16 input channel. For example,

if

your application requires

two STA-EX~S, one might be assigned to Channel

0,

the other to Channel

1.

Figure

2-7

shows the

Channel Select Jumper configured for Channel

1.

INSTALLATION PROCEDURE

Obtain the required C-1800 cables, and connect STA-EX8b) to an ADC-16 as follows:

1.

Be

sure your computer is off.

2.

Remove the top cover of the STA-EX8 (loosen the four corner screws and remove; then,

lift

the

cover).

3. Set the Channel Select Jumper for an available ADC-16 input channel.

4.

Plug one end of the C-1800 cable into the ADC-16's

I/O

Connector.

5.

Plug the other end of the C-1800 cable into the first 37-pin connector

(J1)

on STA-EX8

#1.

6.

If

you are connecting more than one STA-EX8, daisy-chain the first STA-EX8 to the second. Plug

one end of a second C-1800 cable into the second 37-pin connector

(J2)

of STA-EX8

#1.

Then,

connect the C-1800 to

J1

on STA-EX8

#2.

Repeat this step for successive STA-EX8s. (Remember,

you cannot install more than eight STA-EX8s.I

7. Make all other STA-EX8 connections, as required by your application.

8.

Replace the cover(s) on the STA-EX8(s).

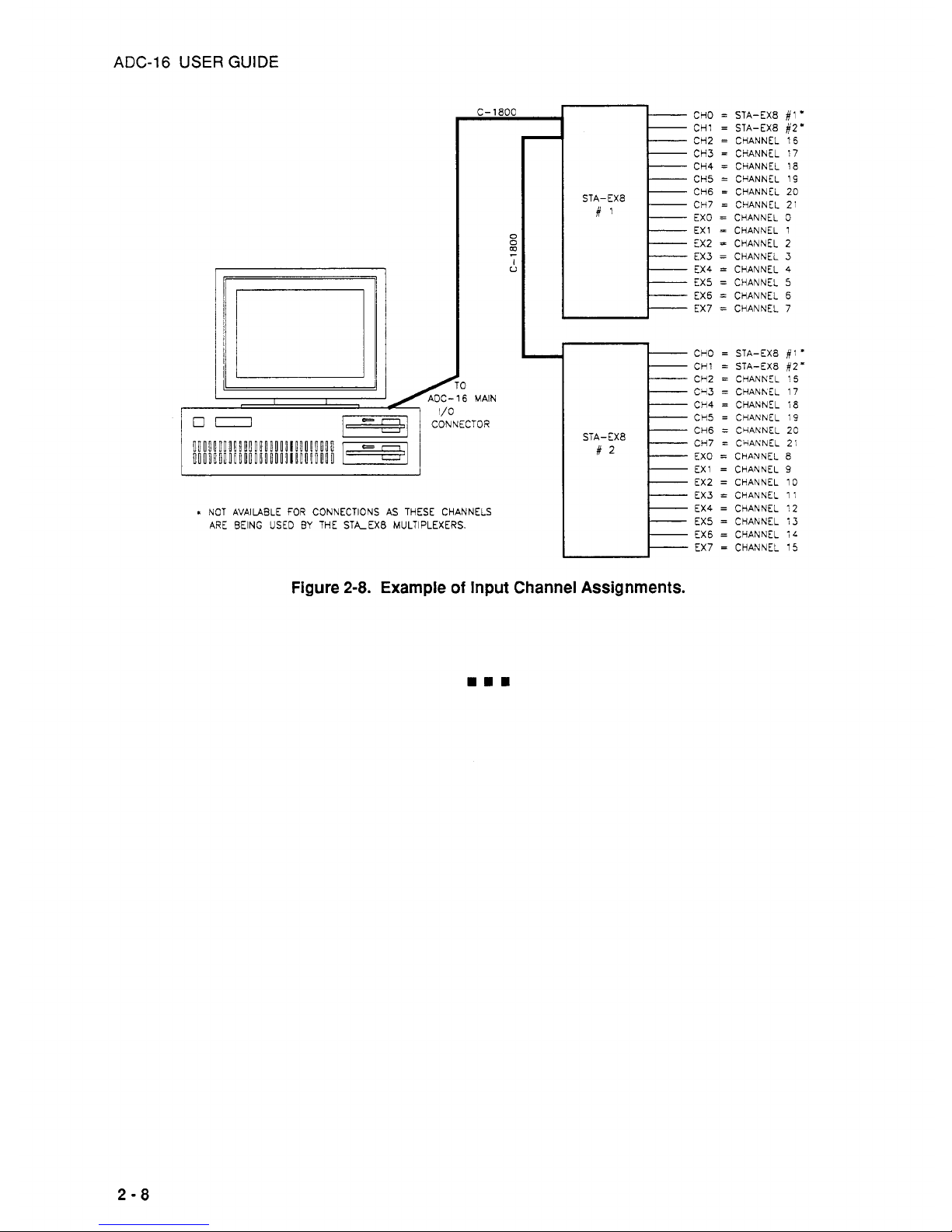

INPUT CHANNEL ASSIGNMENTS

When programming the ADC-16 to accept the data presented on the channels added by the STA-EX8

multiplexer,

you

must understand the assignment of the input channels. First, the Channel

Select

'jumper on each STA-EX8 determines which ADC-16 input channel

(CHO,

CHI, CH2, CH3, etc.) the

STA-EX8 will use for communication. The multiplexed channels

(EXO,

EX1,

etc.) are then allocated

consecutively from the assigned ADC-16 channel. For example, if your application has two STA-EX~S,

you

will assign the first STA-EX8 to ADC-16 Channel

CHO.

The multiplexed channels will then be

allocated as follows: EX0

=

Channel

0,

EX1 = Channel

1,

EX2 = Channel

2,

...

EX7 = Channel 7. Then,

you

will assign the second STA-EX8 to ADC-16 Channel CH1. The multiplexed channels

of

the

second STA-EX8 will then

be

EX0 = Channel

8,

EX1

=

Channel

9,

...

EX7 = Channel

15.

The remaining

ADC-16 input channels will then follow EX7

=

Channel

15;

that is, CH2 = Channel 16, CH3 = Channel

17,

...

CH7 = Channel

21.

Be aware that the ADC-16 input channels run in parallel across the cable.

For example, the CH2 output is associated with channel 16 on both STA-EX8s. Figure

2-8

illustrates

this arrangement.

Note that the STA-EX8 multiplexed inputs are not usable by the Pop Up Control Panel.

2-7

Page 19

ADC-16

USER

GUIDE

C-1800

AOC-16 MAIN

I/

-1

I

CONNECTOR

L

NOT AVAILABLE FOR CONNECTIONS AS THESE CHANNELS

ARE BEING

USED

BY

THE STA-EX8 MULTIPLEXERS.

0

0

I

U

z

CHO

=

STA-EX8

#I

*

CH1

=

STA-EX8

82'

CH2 = CHANNEL

15

CH3 = CHANNEL

17

CH4 = CHANNEL

18

CH5 = CHANNEL 19

CH6

=

CHANNEL 20

CH7

=

CHANNEL 21

EX0 = CHANNEL

3

EX1 = CHANNEL 1

EX2

=

CHANNEL

2

EX3 = CHANNEL

3

EX4 = CHANNEL

4

EX5 = CHANNEL

5

EX5 = CHANNEL

6

EX7 = CHANNEL 7

STA-EX8

CHO

=

STA-EX8

#l

*

CH1 = STA-EX8

#2'

CH2 = CHANNEL

:5

Cq3 = CHANhEL

17

CH4 = CHANNEL

18

CH5 = CHANNEL :9

CH5

=

CciANNEL

20

CH7 = CHANNEL

2:

EX0 = CHANNEL

8

EX1 = CHANNEL

9

EX2 = CHANNEL 10

EX3

=

CHANNEL 11

EX4 = CHANNEL

12

EX5 = CHANNEL 13

EX5

=

CHANNEL

iL

EX7 = CHANNEL 15

STA-EX8

Figure

2-8.

Example

of

Input Channel Assignments.

2-8

Page 20

CHAPTER

3

OPERATION

&

PROGRAMMING

OVERVIEW

3.1

GENERAL

The ADC-16 Distribution Software Package provides the following options:

The Pop Up Control Panel

The Call Driver for BASIC

Low-level-Register 1/0 Programming

Additional programming options, PASCAL and C support, and Windows

3.x

languages support

are

available in the Advanced Software Option.

3.2

THE POP UP CONTROL PANEL

The Pop Up Control Panel allows you direct control of ADC-16 operation without programming.

You

may configure the board to perform an analog or digital operation and to store the resultant data in a

disk file. The Pop-up uses two control panels that you may pop up with a keyboard sequence and

control using either the keyboard or mouse while under DOS or inside an applications package. This

Interface provides a quick way

to

test your board as well as to debug/monitor operation.

By

selecting

the data logging menu, you may

turn

the ADC-16 into an automatic data logging system.

Chapter

4

contains instructions for loading the Pop Up Control Panel drivers. Chapter 5 covers

operation.

3.3

THE CALL DRIVER

The Call Driver is a collection of functions (Calls) for use in programs written in Interpreted BASIC,

QuickBASIC, or QBASIC. The Calls allow you to write control programs without using register-level

programming, and they perform the most commonly used set-up and operating functions. The

Advanced Software Option provides Call Drivers for PASCAL and C and Windows

3.x

languages.

Chapter 6 lists and briefly describes each of the Call drivers and each of the Calls. Chapter

7

covers

the use of each Call and provides examples for Interpreted BASIC, QuickBASIC, and QBASIC.

3.4

LOW-LEVEL-REGISTER

I/O

PROGRAMMING

You

may also program the ADC-16 by writing directly to the on-board registers. Chapter 8 supplies

ADC-16 register maps and corresponding bit functions.

3-1

Page 21

CHAPTER

4

THE POP UP CONTROL PANEL

4.1

OVERVIEW

The Pop Up Control Panel is a software tool for setting up and monitoring the operation

of

your ADC16 board. In its monitoring capacity, the Pop-up is also useful for verifying settings and for isolating

incorrect settings or problems.

Supporting software for the Pop-up consists of the two drivers

VLEXE

and PADC16.EXE; both

drivers are in the Distribution Software. For descriptions, refer to Section

4.2.

To

use the Pop Up Control Panel, you must first load

VI.EXE

and PADC16.EXE into DOS memory.

Loading may

be

via the DOS command line or via batch file. For complete loading instructions, refer

to Sections

4.4

and

4.5.

4.2

DRIVER DESCRIPTIONS

VI.EXE

PADCl6.EXE

Virtual Instrument driver program that supports the graphics, functions,

and background operations

of

the Pop Up Control Panel for the ADC-16

and other products from the manufacturer. This driver occupies

approximately

55K

of DOS memory, and

it

must be loaded before

PADC16.EXE.

The driver program that supplies the graphics, functions, and

background operations for the ADC-16 Pop Up Control Panel. This

program loads from the

DOS

command line, and it must be loaded after

VLEXE.

After loading these drivers, you may display

or

hide the Pop Up Control Panel panels using

hot

keys,

either the default hot keys or those you assign during the PADCl6.EXE loading. Pop Up Control

Panel panels occupy the top eight character lines of the computer display; you operate their controls

by either mouse or keyboard. For complete Pop Up Control Panel opcrating instructions, refer to

Chapter

5.

4.3

DRIVER-FILE LOADING/UNLOADING OPTIONS

General

Your options for loading and unloading driver files are as follows:

Via the AUTOEXEC.BAT file (for loading only).

Via the command line.

4-1

Page 22

ADC-16 USER GUIDE

Via a batch file.

Via the SHOW.BAT utility.

With each of these options, the load/unload order must be as follows:

ProDer loadinp

-

order:

First,

load

VI.EXE

Then,

load

PADC16.EXE

Prowr unloading. order:

First,

unload

PADC16.EXE

Then,

unload

VI.EXE

Loading Via AUTOEXEC.BAT

When you load via the AUTOEXEC.BAT file, your driver files load automatically with each computer

boot-up. The files remain active until you unload them or shut down the computer.

Modify the AUTOEXEC.BAT file to include driver-loading instructions in either of two ways,

as

follows:

1.

Use a text editor. Edit AUTOEXEC.BAT to include

VI

PADC16

Note that using these instructions without switch options gives you default settings (see

Chapter

2

for default settings).

To

change the default settings, use the switch options

described in Section

4.5.

2.

Use the ATXSETUP.EXE setup utility (from the Distribution Software) to automatically

install the basic driver-loading instructions in AUTOEXEC.BAT. To use this utility,

log

to the

directory containing the Distribution Software and

type

ADCSETUY

c

Enter

>

.

Loading/Unloading From The Command Line

This method allows you to load and unload the driver files on an as-needed basis. You may

also

change your switch parameters with each loading. Unfortunately, this method can be tedious,

especially when your entry contains an error. Drivers loaded from the

DOS

command line may be

unloaded from the command line, or they may be unloaded by rebooting the

PC.

Loading/Unloading Via Batch Files

Batch files also allows you to load and unload your driver files on an as-needed basis. However, you

are confined to a single set

of

switch parameters unless you modify your start-up file or you have

additional batch files.

You

must also use separate batch files for loading and unloading. Use a text

editor to create your batch files, and be sure you insert your instructions in the correct order (refer to

LoadinglUnIoading

Order

1.

4-2

Page 23

CHAPTER

4:

THE POP UP CONTROL PANEL

Loading

Via

SHOW.BAT

The Distribution Software contains the file

SHOW.BAT

for the purpose of fast and easy batch-file

loading.

SHOW.BAT

loads

VI.EXE

and PADC16.EXE in the required order, leaving you with the

Pop

Up Control Panel on the screen.

Note that loading

PAX16

without switch options gives you the board's default settings. See Chapter

2

for a list of default settings.

4.4

SYNTAX

CONVENTIONS

Unless otherwise noted, the syntax for the driver load/unload sections Sections

4.5

and

4.6)

use

the

following character-formatting rules:

Bold

=

Indicates a mandatory entry, as follows:

BOLD

UPPER-CASE : enter exactly what is shown.

bold

lower-case

:

substitute a name, string, or value.

Italic

=

Indicates oDtional entw , as follows:

ITALIC UPPER-CASE

:

enter exactly what is shown.

ifalic lower-case

:

substitute a name, string, or value.

Plain

=

Indicates characters not reauired for execution of the command.

Plain

characters ap ear in the syntax only for clarity; whether used

or not, they have no e

P

fect.

4-3

Page 24

ADC-16

USER

GUIDE

4.5

VI.EXE:

LOADING & UNLOADING

Syntax for loading/unloading

VI.EXE

is as follows:

NOTE: Refer to Section

4.4

for syntax conventions.

path

Vf.exe

MONO

/HK

=

x

/MK

=

m

/SK

=

s

/U

where

path

DOS

path to VI.EXE. Example:

C:\ADC16\

MONO

Optional command for computers with monochromatic displays.

If

MONO

is

not specified,

COLOR

is assumed.

/HK

=

x

Help Key switch: to specify your choice of key(s) for bringing up the Help

Screen for the Pop Up Control Panel. The default Help Keys are

<

Alt

>

+

<

H

>.

x

is one, two, or three keys, as follows:

(1)

One key: any choice

of

c

A

>

through

< Z > , <

F1>

through

<

F10

>

,

<O>

through c9>,or

<Tab>,

<Esc>,or

<?>;

(2)

Two or three keys: it can be a combination of the

<

Ctrl>

and/or

<

Alt > key(s) plus any choice of

< A >

through

< Z > , <

F1>

through

<F10>,

<O>

through <9>,or

<Tab>,

<Esc>,or

<?>.

Note that your entry must

be

spelled out. For example, entering

/HK

=

F1

assigns the function key

<

F1>

to

be

the Help Key. Or entering

/HK

=

Ctrl

D

specifies that the

c

Ctrl>

and

< D >

keys must be pressed at the same time to

bring

up the Help screen.

IMK

=

m

Mode

Select Key switch: to specify whether the Pop-up Menu is to be

Keyboard or a Mouse operated. The default Mode Select keys are

<

Alt

>

+

< M > . Using the Mode Select key combination switches the Pop-up Menu

into Keyboard mode; from there, you press

c

Esc

>

to enter Mouse mode.

m

is one,

two,

or three keys, as follows:

(1)

One key: any choice of

< A >

through

< Z > , <

F1>

through

<

F10

>

,

<

0

>

through < 9

>

,

or

<

Tab

> , <

Esc

>

,

or

< ? >

;

(2)

Two or three keys: it can

be

a combination of the < Ctrl> and/or

<

Alt

>

key(s) plus any choice of

< A >

through

< Z >

,

<

F1>

through

cF10>,

<O>

through <9>,or

<Tab>,

<Esc>,or

<?>.

4-4

Page 25

CHAPTER

4:

THE

POP

UP

CONTROL PANEL

Note that your entry must be spelled out. For example, entering

/MK

=

F8

assigns the function key

<

F8

>

for Mode Select. Or entering

NK

=

Ctrl

T

specifies that the

<

Ctrl

>

and

< T >

keys must be pressed at the same time.

ISK

=

s

Instrument Select Key switch:

if

you have other ADC-16 boards installed in

your computer, this switch enables you to toggle between Pop-up Panels of

each instrument for the HELP function or for Mode selection of Keyboard

input. The default Instrument Select key is

<

Alt

>

+

<

Tab

>

.

s

is one, two, or three keys, as follows:

(1)

One key: any choice of < A > through

< Z >

, < F1>

through

<

F10

>

,

< 0 >

through

< 9 >

,

or

<

Tab

>

,

<

Esc

>

,

or

< ? >

;

(2)

Two

or three keys:

it

can be a combination of the

<

Ckl>

and/or

<

Alt

>

key(s) plus any choice of < A > through

< Z > , <

F1>

through

<

F10

>

,

<

0

>

through

< 9 >

,

or

<

Tab

>

,

<

Esc

>

,

or

< ? >

.

Note that your entry must be spelled out. For example, entering

/SK

=

F3

assigns the function key

<

F3

>

as the Mode Select key. Or entering

/SK

=

Ctrl

S

specifies that the

<

Ctrl>

and

< S >

keys must be pressed

at

the

same time.

IU

Unload switch: when

VI.EXE

is already loaded and you wish to unload

it

from

memory, you use only this switch in your instruction. For example, using the

example path given above your unload instruction will be

C:\ADC16\VI

/U

NOTE that before you can unload VI.EXE, you must first unload PADC16.EXE.

An example instruction for

VI.EXE

is

C:\VI.EXE

/HK

=

Alt

X

/MK

=

Alt

Y

/SK

=

Alt

2

You

would enter this instruction at the DOS command line or into the AUTOEXEC.BAT file. This

instruction specifies the following:

VI.EXE

is in the root directory of the C Drive

Color monitor

Helpkeysare <Alt>

+

<X>

Mode

Select

keys

are < Alt

> + < Y >

Instrument Select keys are < Alt

> + < Z >

.

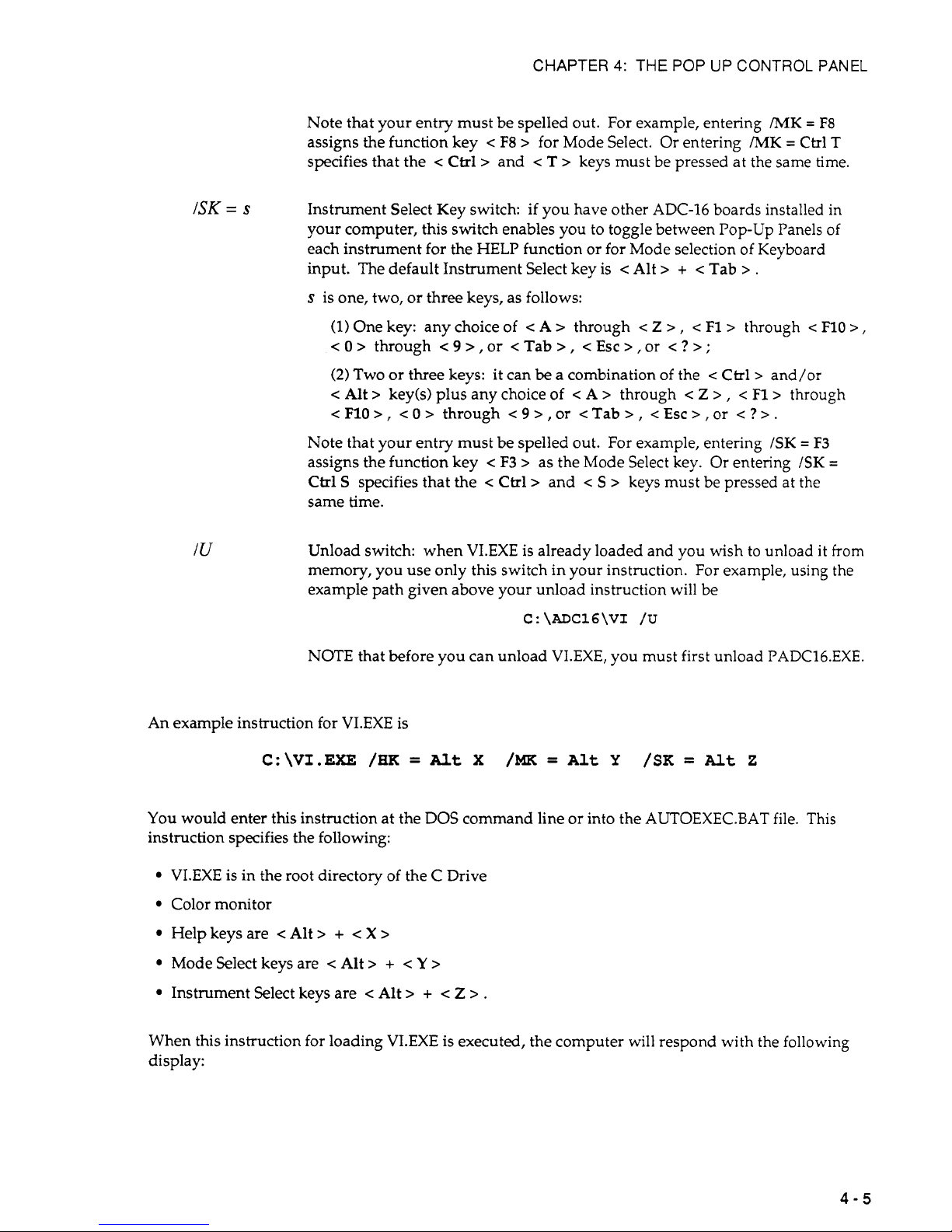

When this instruction for loading VI.EXE is executed, the computer will respond with the following

display:

4-5

Page 26

ADC-16 USER GUIDE

******

V1.m

Rev

3.04

o

HELP

KEY

is

ALT

X

o

INSTRUMENT

SELECT

KEY

is

ALT

2

o

MODE SELECT

KEY

is

ALT Y

4.6 PADCI 6.EXE: LOADING & UNLOADING

Before you load PADC16.EXE, you must load

VLEXE.

Syntax for loading/unloading PADC16.EXE is

as follows:

NOTE: Refer to Section

4.4

for syntax conventions.

path

PADC16.exe

/aA

=

b

/F

=

cfgfile

/PK

=

p

/NAME

=

devname /Help

/u

The elements of this model are explained as follows (note that if you do not use the switch options,

their default values remain in effect):

path

DOS path to PADC16.EXE. Example: C:\ADC16\

/BA

=

b

Base Address: The Base Address setting for the board being loaded (refer to

base-address selection, in Chapter

2).

The default Base Address is &H300

(768

decimal).

b

is

the Base Address value. Either hex (range = &H200-&H3FO) or decimal

values are acceptable; however, if they are given in hex they must be preceded

by

an

ampersand

(&)

and an H (for example,

&H300).

Make certain the Base

Address you enter has

not

been already assigned to another device.

/F

=

cfgfile

Default Override: allows you

to

change any or all of the default

parameters discussed in the configuration section (Section

2.2)

of Chapter

2.

cfgfile

the name of a configuration file created with the ADC16CFG.EXE

utility discussed in Chapter

2.

The example file used for discussion in Chapter

2

is

ADCZ6.CFG.

/PK

=

p

Pop Up Control Panel hot key switch: when the number of installed boards is

greater than one, each instrument should have its own Pop-up key assignment.

The default Pop Up Control Panel hot key is

<

Alt

>

c

F5

>

.

p

is one, two, or three keys, as follows:

(1)

One key: any choice of < A > through

< Z > , <

F1> through

<

F10

>

,

< 0 >

through

< 9 >

,

or

c

Tab > ,

<

Esc

>

,

or

<

?

> . Note that in working

with

a

single key, the key you choose will be unusable for any other

function while CALL.EXE

is

loaded; you might therefore want to confine

your single-key choice to one of the function keys

(

<

F1> through < F10

>

).

4-6

Page 27

CHAPTER

4:

THE

POP

UP CONTROL PANEL

/NAME

=

n

/Help

IU

(2)

Two or three keys:

it

can

be

a combination of the

<

Ctrl>

and/or

<

Alt > key(s) plus any choice of < A > through

<

Z

> , <

F1>

through

<

F10

>

,

< 0 >

through

< 9 >

,

or < Tab

> , <

Esc

>

,

or

<

?

>

.

Note that your entry must

be

spelled out. For example, entering

/PK

=

F3

assigns the function key

<

F3

>

for Mode Select. Or entering

/PK

=

Ctrl

P

specifies that the < Ctrl> and < P > keys must be pressed at the same time.

Use when the number of installed boards is greater than one and you wish to

display the Pop Up Control Panel for any two of the boards simultaneously.

You

must enter

an

PADC16,EXE instruction

for

both boards--to give each

board unique hot

keys,

Base Address, and name.

n

is the name you enter for one board;

it

must be

1-8

characters. Any of the

following characters are acceptable:

<

A

>

through

<

Z

>

,

< 0 >

through

<9>,

<$>,

<&>,

<#>,

<@>,

<!>,

<%>,

<(>,

<I>,

<->,

<{>,

c

1

>

,

c

- > .

Note that

/,

\,

and * are illegal.

For example,

NAME=ADC16

Use this switch to list all command-line options for the ADC16.EXE driver.

When you use this switch, you will need no other switches, because the driver

is not installed.

Unload switch: when

you

wish to unload PADCl6.EXE from memory, use

only this switch in your instruction. For example, using the path given above

your unload instruction will

be

NOTE that you must unload PADC16.EXE before VI.EXE.

An

example instruction for PADC16.EXE

is

as follows:

C:

\ADC16\PADC16

You

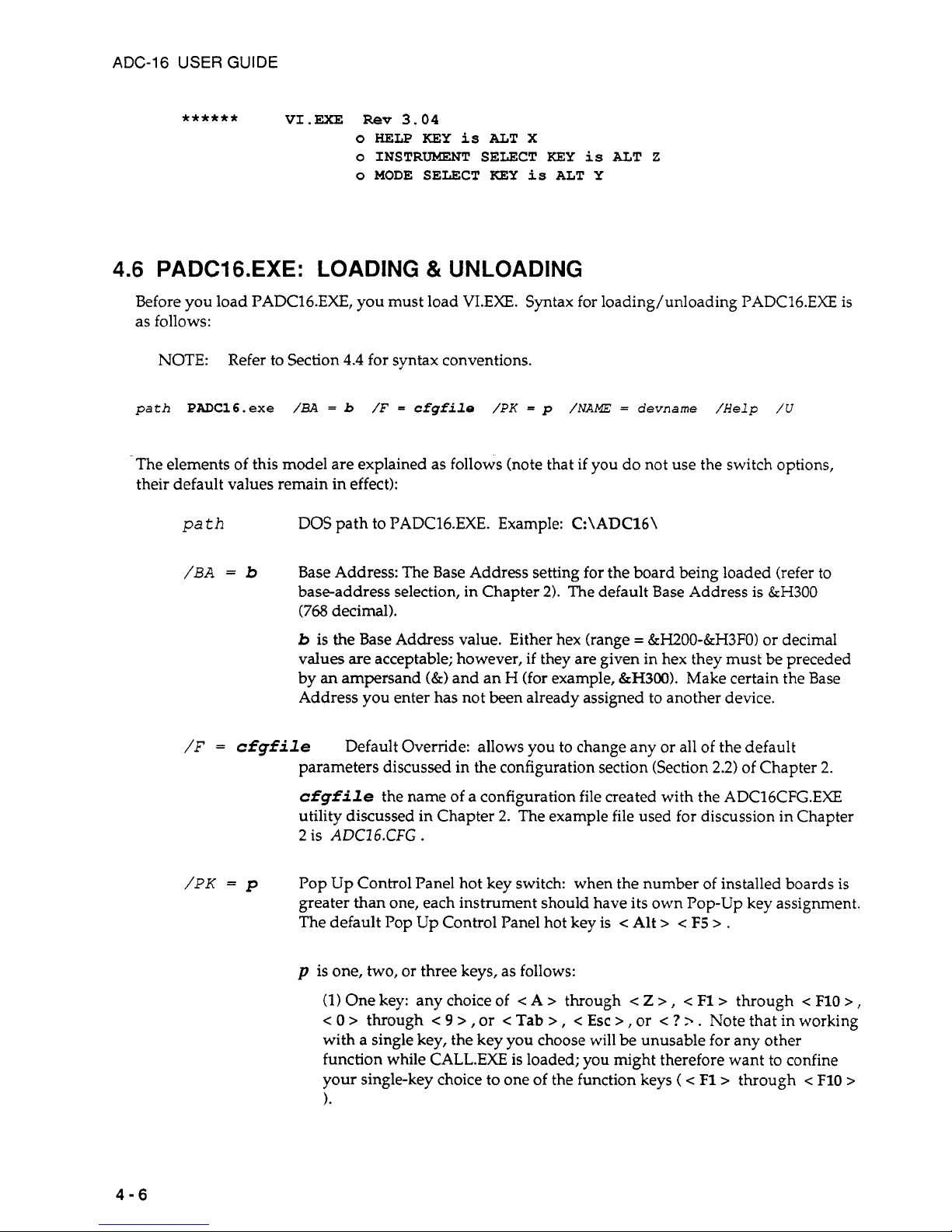

would enter this instruction at the DOS command line or into the AUTOEXEC.BAT file. This

instruction specifies the following:

PADC16.EXE is in the ADC16 directory of the C Drive

With no switches, the software uses the factory-preset parameters.

When this instruction for loading PADC16.EXE is executed, the compliter responds with the following

display.

4-7

Page 28

ADC-16

USER

GUIDE

******

PADC16.EXE

popup

Driver Rev

1.00

o

popup

Hot

Key

is

ALT

F6

o

Factory

Configuration

assumed

Number

Of

Bytes

Used

By Device

:

57968

At

Memory

Segment

[llB3]

4.7

LOADING

ANSLSYS

To

obtain optimum computer performance while working with the

VI.EXE

and

PADC16.EXE

files,

your system may require access to the

DOS

ANSI.SYS

file.

ANSI.SYS

is generally included with the

files in your computer's DOS software.

To

activate

ANSI.SYS,

you must modify your computer's

CONFIG.SYS

file to include an

ANSI.SYS

loading instruction.

Your

instruction must use the syntax of

the following model:

DEVICE

=

path

ANSI.SYS

For example, if

ANSI.SYS

is in a directory called

DOS

on the D Drive, your instruction would be

DEVICE=D:\DOS\ANSI.SYS

Remember that when you alter a

CONFIGSYS

file, you must re-boot before the new changes can take

effect.

4-8

Page 29

CHAPTER

5

POP UP CONTROL PANEL OPERATION

5.1

PRELIMINARY REQUIREMENTS

Before you can use the Pop Up Control Panel, your ADC-16 board must be properly installed and

your

VI.EXE

and PADC16.EXE drivers properly loaded. For board-installation instructions, refer to

Chapter

2.

For driver-loading instructions, refer to Chapter

4.

5.2

GETTING STARTED

To

Get

Up &

Running Quickly

NOTE:

This

procedure

is

valid only when ADC-16 factory configuration is in effect for both

hardware and software and when

you

are logged to the directory containing the

Distribution Software.

1.

With the board installed,

type

SHOW

2.

Click your mouse on

ADSTART,

located at the

top

of the Panel.

You

are now acquiring samples

from channels at

16

Hz.

The data from this first channel scan should be showing on the Panel.

3.

Connect known voltages to Analog Input channels and repeat Step

2.

to put the Analog Panel

Jt

the top

of

your display.

To

Get

Up

&

Running

Via

Hot

Keys

1.

With the board installed and drivers loaded, use the hot keys to access the Pop Up Control

Panel. The default hot keys are

c

Alt

>

c

F6

> ; press these keys simultaneously to put the

Analog Panel at the top of your display.

2.

Click your mouse on

ADSTART,

located at the top right of the Panel.

You

are now acquiring

samples from channels at 16

Hz.

The data from this first channel scan should be showing on the

Panel.

3.

Connect known voltages to Analog Input channels and repeat Step

2.

5.3

IMPORTANT HOT KEY COMBINATIONS

Familiarity with the hot-key combinations can speed up operation. The following hot keys are the

default combinations; you may change any or all of them to keys of your choice.

To

change any of

these keys, refer to the switch options in the driver-loading instructions of Sections

4.4

and

4.5.

5-1

Page 30

ADC-16

USER

GUIDE

c

Alt

>

c

F6

>Pop Upmown Keys. Use these keys to show and hide the Pop Up Control Panel panels.

c

Alt

>

c H >

Help Keys. Use these keys to show the Help Panel whenever a Pop Up Control

Panel Panel is showing.

c

Alt

>

c

Tab >Next Pop Up Keys. Use these keys to move

from

Pop Up to Pop

Up when panels for multiple boards are showing.

Keyboard Mode Entry Keys. Use these keys to change to the Keyboard Entry

Mode. Use the

c

Esc

>

key to exit this mode.

c

Alt

>

c M >

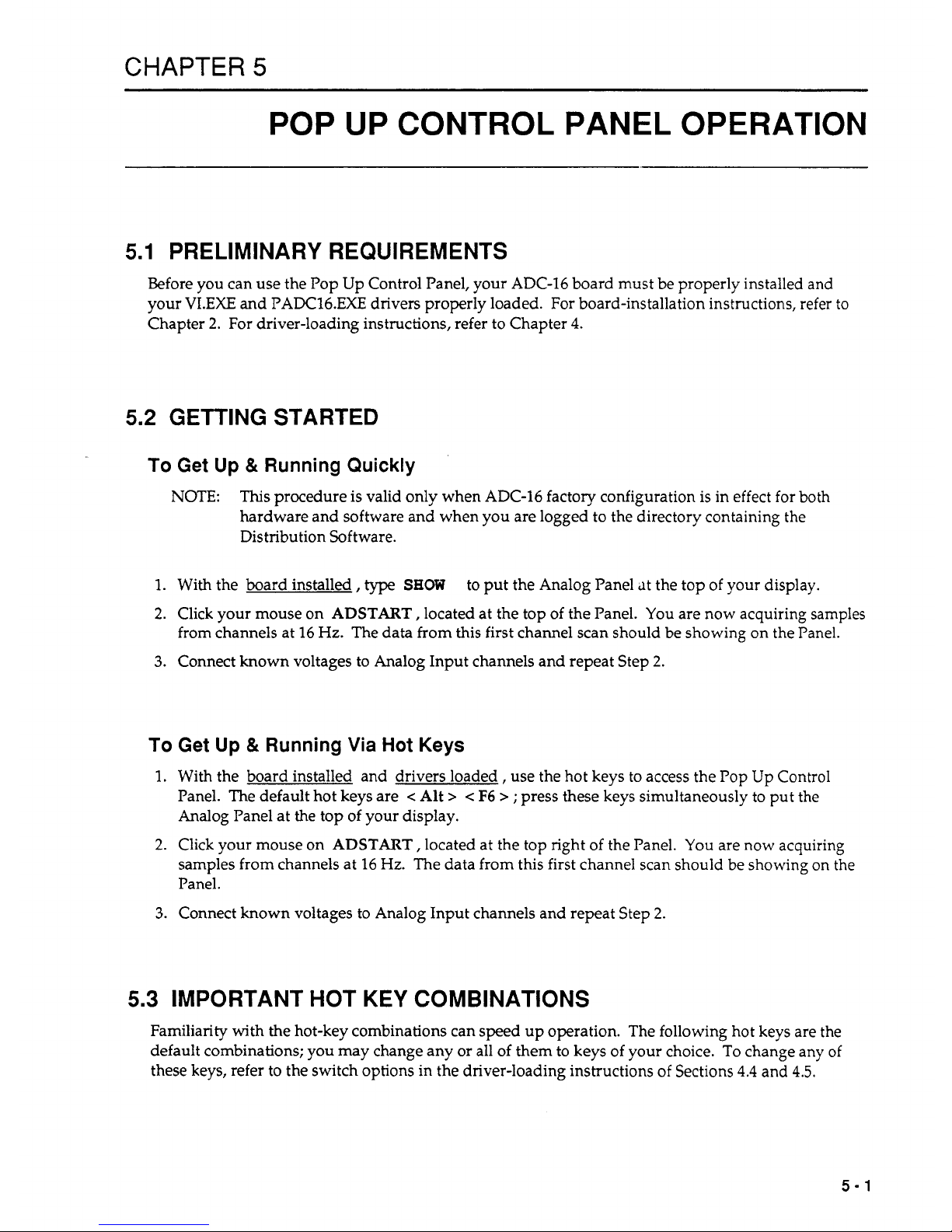

5.4

THE CONTROL PANEL

The Control Panel of the Pop Up Control Panel appears as follows:

Control Panel Menu

This menu appears along the top of the Panel and contains three options, as follows:

This

option toggles between the keyboard and mouse control of the Pop Up Control

Panel.

This

option starts an

A/D

conversion takes you to the Digital Panel. However,

before starting a conversion, make any necessary changes to the Setup controls.

This option stops an A/D conversion.

Keyboard

ADStart

ADStop

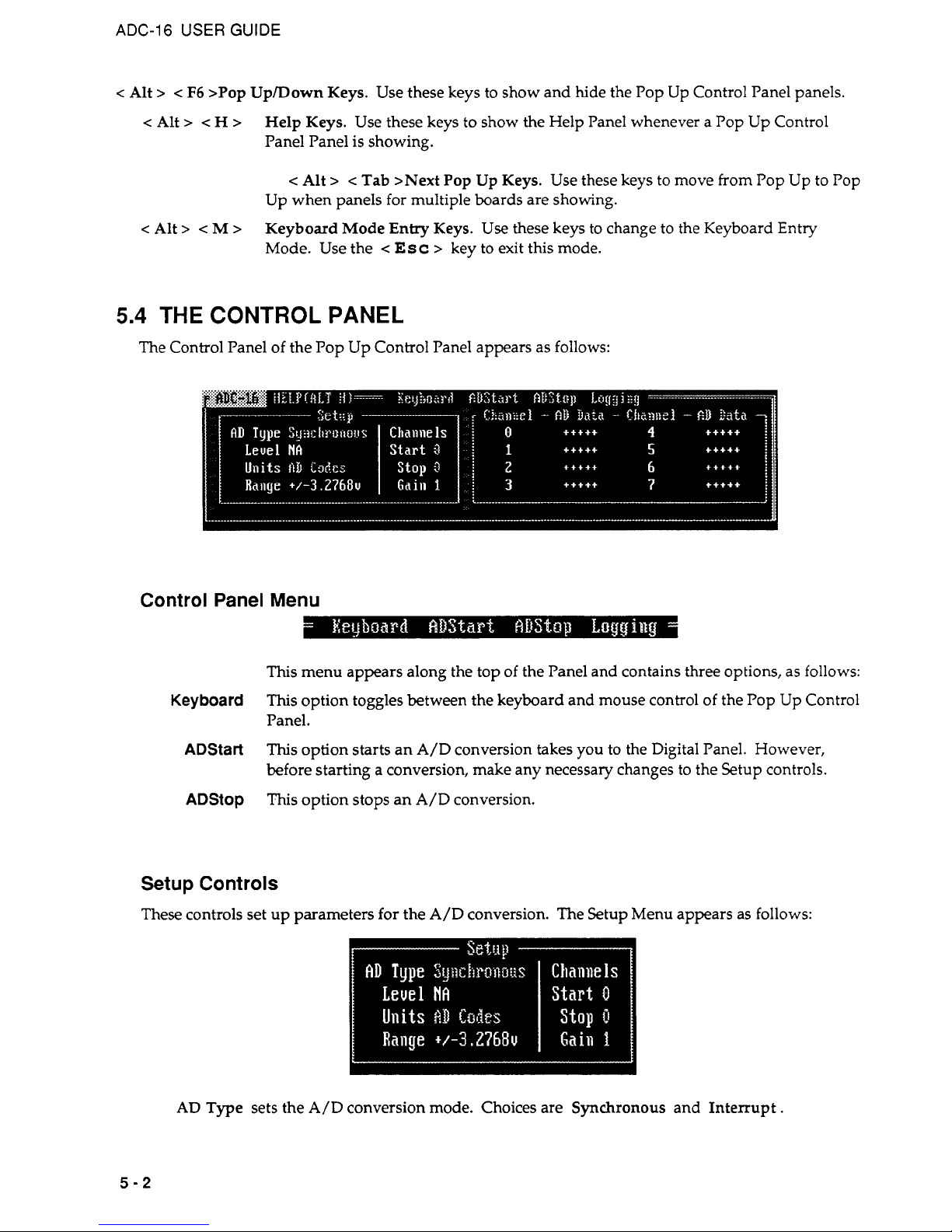

Setup Controls

These controls set up parameters for the A/D conversion. The Setup Menu appears as

follows:

AD

Type sets the

A/D

conversion mode. Choices are

Synchronous

and Interrupt.

5-2

Page 31

CHAPTER

5:

POP UP CONTROL PANEL OPERATION

Level

is active only when the

AD

Type is Interrupt. Choices are

2,

3,

4,5,7,10,11,

and

15.

Units

selects

AD

Codes

or

Volts.

Start

selects the Start Channel for the A/D conversion. The Start Channel may range from

0-7;

however, it can

be

no greater than the number specified for the Stop Channel.

Stop selects the Stop Channel for the

A/D

conversion.

Gain

Selects the gain for the

A/D

conversion. Choices are

1,

10,

and

100.

Channel - A/D Data

The monitor panel for the

A/D

conversion(s) appears as follows:

Only the channels specified by Start and Stop (under Setup)

will

show results. These results update

with each conversion cycle.

5.5

THE

DATA

LOGGING PANEL

The Data Logging Panel appears as follows:

Data Logging Menu

This menu appears along the top of the Logging Panel and contains 3 options as

follows:

This option toggles between the keyboard and mouse control

of

the Control Panel.

This

option starts the Logging function and StopLog is displayed.

If

StopLog is

selected then StartLog is displayed and logging

is

stopped.

Displays the Main Control Panel Screen.

Keyboard

StartLog

Main

...

5-3

Page 32

CHAPTER

6

THE

CALL

DRIVER

6.1

GENERAL

The Call Driver is a comprehensive set of functions you may incorporate into your own application

programs. These functions provide a high-level interface to the ADC-16 and perform all required

register-level reads and writes.

The

Call Driver is compatible with most BASIC programming languages. Specifically, the Driver

supports the following:

Interpreted BASIC (GWBASIC, BASICA, BASIC) - Section 6.2.

QuickBASIC Versions 4.0 and 4.5 - Section 6.3.

Quick/Professional BASIC Version

7.0

and above - Section 6.3.

QBASIC - Section6.4

Example programs for each of the supported languages are included in the Distribution Software.

You

may find it helpful to refer

to

one

or

more of these example programs while reading this chapter.

Since the syntax and application of the BASIC languages are different, this chapter describes

programming in each language separately.

Section 6.5 includes a listing of Calls available in the ADC-16 driver. This section is a quick-reference

only. Detailed descriptions of the Calls are in Chapter

7.

6.2

GWBASIC, BASICA, & BASIC

Program

Flow

A

typical programming sequence is as follows:

1.

Initialize the entry pointers to the driver.

*

2.

Load the driver.

*

3. Declare and dimension all variables to be used in the program.

*

NOTE:

Failure

to

declare all variables before opening the driver will cause program pointers

to

be shifted

and

the program

to

fail.

4.

Load the ADC-16 hardware configuration, and open the driver.

*

5.

Initialize the driver and board, and establish communications between the driver and the

program.

*

6-1

Page 33

ADC-16

USER

GUIDE

6.

EITHER

a. Execute a simple ADC-16 operation.

OR

b. Select the desired group of ADC-16 operations, referred to as the group's

Frame.

Execute

these operations, taking some data.

*

Indicates that this function is performed in the "Quick-Start'' programs. (see next section).

Choose Step

6a

for simple applications such as performing a single A/D conversion or reading a

digital input port. Choose 6b for more complex operations such as an interrupt-based scan of the

multiple channels.

The following sections describe the various parts of the program flow diagram. However, many

programmers may learn faster simply by referring to the example programs in the Distribution

Software.

Quick-Start Program

To

aide in the creation of programs, the Distribution Software includes a

Quick-Starf

program, which

includes all driver loading, pointer definition, and ADC-16 initialization. For interpreted BASIC, the

Quick-Start program is

ADC16.BAS

.

The program is in standard BASIC source code with an

Insert

Your

Code

Here

section.

When you begin a program, it will

be

easiest to begin with the Quick-Start program and add new

sections to the existing code. The alternative is to struggle through rewriting the driver, pointer, and

initialization code.

Initializing Pointers And Loading The Driver

The last part

of

Section 6.2 contains a listing of an Interpreted BASIC example program.

You

may

wish to refer to this example program during the discussions in this section.

In Interpreted BASIC, the driver and a number of pointers to the driver must

be

loaded within the

program itself. The entry-point variables must

be

loaded at this time (each command has a unique

entry point).

This

is performed by a subroutine in ADC16.BAS. Since there are several entry points,

it

is recommended that the ADC16.BAS Quick-Start program (or one of the example programs) be used

as the starting point for new programs.

This

will ensure the correct loading of pointers. The following

statement calls the subroutine that loads the driver entry points.

260

GOSUB

710

7

10

&Cl6DEVOPEN%=O

720 ADCl6GE!FDEVHANDLE%=3

xxx

RETURN

6-2

Page 34

CHAPTER 6 THE CALL DRIVER

The following statements then load the driver.

270

DEF SEG = &€I9000

2

8

0

BLOAD "ADC16. BIN",

0

This

code loads the driver at 9000h (at the 576K segment) and is usually a good choice. However,

computers with

512

KB

or less memory will require loading the driver at a lower address (for

example, 4000h or 5000h).

Initializing The Variables

You

must declare all your program variables before opening the driver. Using an undeclared variable

during the program will move the entry points and cause the program to fail. Examples of

declarations are as follows:

340 ADCl6

=

0

'declare

ADC16

as

real

370 DIM ADValue%(2)

'declare

an

integer

array

390 NumDfBrds%=O: ErrFlag%=O: BrdNum%=O

'declare

integers

400

GAIN%=O:

CHAN%=O

410

N$='"'

'declare

W$

string

402

VEL=O:DIRECT=O:TEMP=O

'declare

application

'dependent

variables

Opening The Driver

The next step opens the driver, and reads the current configuration file (see Section 2.6) for the ADC-

16 hardware (Base Address, Interrupt Level, input configuration). The ADCl6DevOpen command

performs this function, which is demonstrated (along with other required initialization functions) in

the example program in Section 6.3. The

syntax

for the ADC16DevOpen function

is

shown below:

500

N$ = "ADC16.CFG"

+

CHR$(O)

'Setup

filename

510

CALL

ADCl6DevOpen% (N$, NumOfBrds%, ErrFlag%) 'Read ADC-16

520

'configuration

file

Establish Communications Between The Driver & Program

To allow the use of multiple boards, the

Calls

require a board identifier for each board. The board

identifier is called a

Device Handle,

or simply

Handle

.

Without Handles, a

KADRead

command

would not know which board (in a multi-board system) to call.

The Handle for each board is returned by the

ADC16GetDevHandle

command after a successful call

to

ADC16DevOpen,

which is included in the Quick-Start programs. Additional information on the

ADCl6GetDevHandle

function (and concept) is as follows:

SINGLE

BOARD

SYSTEMS

In single-board systems, obtain the Handle via the ADCl6GetDevHandle function. The following

examples show use of the Handle.

6-3

Page 35

ADC-16

USER

GUIDE

First, get the Handle, as follows:

539 BrdNum%

=

0 '0

since only 1 board in

system

540

CALL

ADC16GetDevHandle%(BrdNum%,Dev€Iandle,ErrFlag%)

Subsequent calls use the variable

DevHandle

to select the installed

ADC-16.

You

may change the variable name

DeuHandle

to make the program easier to read. For example, the

following program lines reflect a variable change from

DeuHundIe

to

ADCZ

6

.

539

Bra=%

=

0

'0

since only 1 board in system

540

CALL

ADC16GetDevHandle%(BrdNum%,ADCl6,ErrFlag%)

MULTIPLE BOARD SYSTEMS

In systems with more than one

board,

you must use more than one Handle. The following example

shows how to obtain and use Handles in a system with two

ADC-16s.

530

BrdNum%

=

0

'First ADC-16 board

540

CALL

ADC16GetDevHandle%(BrdNuxi%,ADCl6A,ErrFlag%)

550 BrdNum% = 1 'Second ADC-16 board

560

CALL

ADCl6GetDevHandle% (BrdNum%, ADCl6B, ErrFlag%)

NOTE:

In this example, declaration of variables

ADC16A

and

ADC16B

should be in the variable-

declaration section.

Subsequent function calls will use either the

ADC16A

or

ADCl6B

Handle to determine the selected

board.

Immediate Execution Commands & Frames

Two

types

of Call commands may

be

used to control the

ADC-16

once the driver is installed and the

Board initialized. These are

Immediate

Operation

commands and

Setup

or

Frame

commands.

IMMEDIATE OPERATION COMMANDS

A

variety of single-function commands may

be

executed without any prior setup. The simplest of

these is

KADRead

,

which specifies an input channel, an input gain, and then performs a single

A/D

conversion. The syntax for

this

command is as follows:

620 Gain%=O:Chan%=O

630

CALL

=Read% (ADC16A, man%, Gain%, ADValue%

(0)

,

ErrFlag%)

640

PRINT

"Board 1 returned",ADValue%

(0)

Note that the

ADVulue%(O)

must

be

defined as an integer array. The

ADCl6A

Handle is a single-

precision, real variable and must

be

declared in the variable declaration section. The actual numeric

value of the Handle is simply a pointer within the driver and should

be

passed where required.

MULTIPLE BOARD SYSTEMS

Systems with more than one board must use more than one Handle. The following example opens the

Handles for

two

ADC-16s

and then takes an

A/D

reading from Channel 0 of the first Board and from

Channel

5

of the second.

6-4

Page 36

CHAPTER 6 THE CALL DRIVER

530 BrdNum%

=

0

'First ADC-16 board

540 CALL

ADC16GetDevHandle%(BrdNum%,ADCl6A,ErrFlag%)

550 BrdNum% = 1 Second ADC-16 board

560 CALL

ADC16GetDevHandle%(BrdNum%,ADCl6B,ErrFlag%)

570 man%

=

0:

Gain%

=

0

580 CALL KADRead(ADC16A, man%, Gain%, =Value%

(0)

,

ErrFlag%)

590

PRINT

"The

first

ADC-16 returned",ADValue%

(0)

600 man% = 5: Gain%

=

0

610

CALL

KADRead(ADC16B, man%, Gain%, ADValue%

(0)

,

ErrFlag%)

620

PRINT

"The second ADC-16 returned",ADValue%

(0)

Note that line

580