Page 1

Model 7999-6GPIB RF Relay Unit

Instruction Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

W ARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be

defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation

prepaid, to the indicated service facility . Repairs will be made and the product returned, transportation prepaid.

Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMIT A TION OF W ARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written

consent, or misuse of any product or part. This warranty also does not apply to fuses, software, nonrechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT , INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF

THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION,

LOSSES SUSTAINED AS THE RESULT OF INJURY T O ANY PERSON, OR DAMAGE T O PROPER TY.

Keithley Instruments, Inc.

BELGIUM: Keithley Instruments B.V.

CHINA: Keithley Instruments China

FRANCE: Keithley Instruments Sarl

GERMANY: Keithley Instruments GmbH

GREAT BRITAIN: Keithley Instruments Ltd

INDIA: Keithley Instruments GmbH

ITALY: Keithley Instruments s.r.l.

NETHERLANDS: Keithley Instruments B.V.

SWITZERLAND: Keithley Instruments SA

TAIWAN: Keithley Instruments Taiwan

• 28775 Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.k eithley.com

Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02/363 00 40 • Fax: 02/363 00 64

Y uan Chen Xin Building, Room 705 • 12 Y umin Road, De wai, Madian • Beijing 100029 • 8610-62022886 • Fax: 8610-62022892

3, allée des Garays • 91127 Palaiseau Cedex • 01-64 53 20 20 • Fax: 01-60 11 77 26

Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

Unit 2 Commerce Park, Brunel Road • Theale • Reading • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

Flat 2B, WILOCRISSA • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

Viale S. Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

1 Fl. 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3572-9077 • Fax: 886-3572-903

4/01

Page 3

Model 7999-6 GPIB RF Relay Unit

Instruction Manual

©2001, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

First Printing, April 2001

Document Number: 7999-6-901-01 Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created

for this manual. The Revision Le vel letter increases alphabetically as the manual under goes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered

sequentially . When a new Re vision is created, all Addenda associated with the previous Re vision

of the manual are incorporated into the new Revision of the manual. Each ne w Revision includes

a revised copy of this print history page.

Revision A (Document Number 7999-6-901-01)............................................................ April 2001

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous

voltages, there are situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid possible injury. Read the operating information carefully

before using the product.

The types of product users are:

Responsible body

ensuring that the equipment is operated within its specifications and operating limits, and for ensuring

that operators are adequately trained.

Operators

and proper use of the instrument. They must be protected from electric shock and contact with hazardous

live circuits.

Maintenance personnel

setting the line voltage or replacing consumable materials. Maintenance procedures are described in the

manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be

performed only by service personnel.

Service personnel

ucts. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Installation Category I and

Installation Category II, as described in the International Electrotechnical Commission (IEC) Standard

IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not

be directly connected to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for high transient over-v oltages often associated with local AC mains connections. The user should assume all measurement, control, and data I/O connections

are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage lev els greater than 30V RMS, 42.4V peak, or 60VDC are present.

practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Users of this product must be protected from electric shock at all times. The responsible body must ensure that users are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product users in these circumstances must be

trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or

above 1000 volts,

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with

impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting

sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a

separate main input power disconnect device must be provided, in close proximity to the equipment and

within easy reach of the operator.

is the individual or group responsible for the use and maintenance of equipment, for

use the product for its intended function. They must be trained in electrical safety procedures

are trained to work on live circuits, and perform safe installations and repairs of prod-

no conductive part of the circuit may be exposed.

perform routine procedures on the product to keep it operating, for example,

A good safety

Page 6

For maximum safety , do not touch the product, test cables, or an y other instruments while po wer is applied to

the circuit under test. ALWAYS remove power from the entire test system and discharge an y capacitors before:

connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power

line (earth) ground. Alw ays make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions

or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications

and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth

ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation

requires the use of a lid interlock.

If a scre w is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in

the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal and common mode voltages. Use standard safety precautions to av oid personal contact

with these voltages.

The

WARNING

read the associated information very carefully before performing the indicated procedure.

CAUTION

The

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the

power transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses,

with applicable national safety approvals, may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as long as they are equivalent to the original

component. (Note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a replacement component,

call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument

only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

heading in a manual explains dangers that might result in personal injury or death. Always

heading in a manual explains hazards that could damage the instrument. Such damage may

Rev. 2/01

Page 7

7999-6 GPIB RF Relay Unit

Relay Specifications

CONNECTOR TYPE:

Input: Female SMA connector (on relay).

Output: N-type.

CONTACT LIFE: 5 ×10

ACTUATION TIME: 15ms.

FREQUENCY RANGE: DC to 4GHz. Relay paths are 50Ω terminated

when open.

INSERTION LOSS: 0.3dB + 0.115

ISOLATION: 100dB minimum; 130dB typical.

SWR: 1.2 maximum.

INTERFACE: GPIB (IEEE-488.2) and SCPI.

INDICATORS: Power, relay position status and error LED.

CONTACT CLOSURE COUNTERS: One counter per relay path, up to

10 million counts each, maintained in non-volatile memory.

MAXIMUM COMMON MODE: 42V peak, any terminal to earth.

MAXIMUM SWITCHING SIGNAL: 1W CW, CAT I.

POWER: User-supplied 24VDC (22VDC min., 30VDC max.), 1.8A max.

ENVIRONMENT: Operating: 0° to 40°C, up to 35°C <80% RH.

EMC: Conforms with European Union Directive 89/336/EEC.

SAFETY: Conforms with European Union Directive 73/23/EEC.

DIMENSIONS: 429mm long × 133mm wide × 161mm deep (19.00˝ ×

5.25˝ × 6.34˝).

ACCESSORIES SUPPLIED: Instruction manual.

Specifications are subject to change without notice.

6

cycles minimum; 10 × 10

×

frequency (in GHz).

GENERAL

Storage: –25° to 65°C.

6

typical.

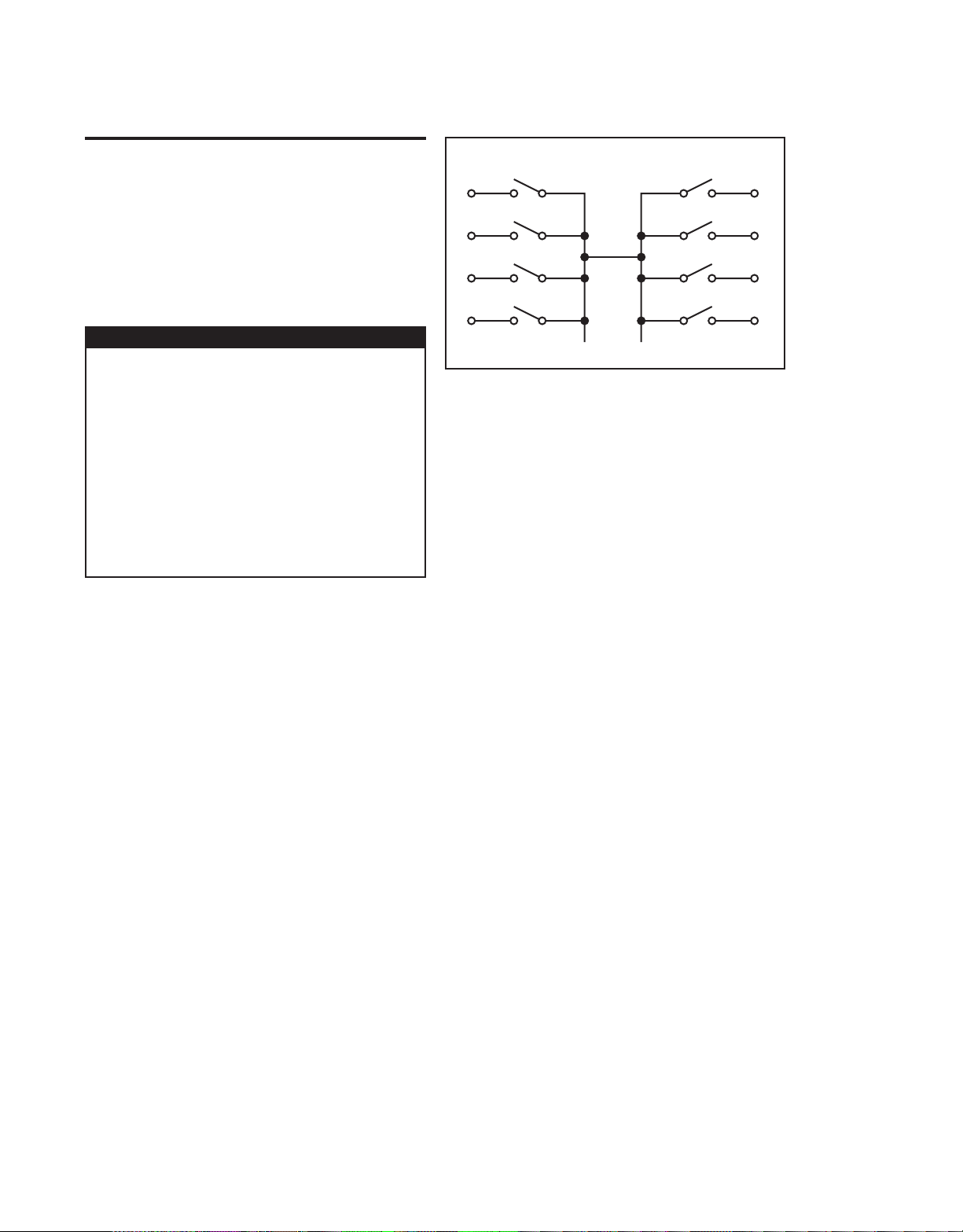

Simplified Schematic

SBG 4/9/01

Rev. A

Page 8

Page 9

T able of Contents

1 General Information

Introduction ................................................................................ 1-2

Feature overview ........................................................................ 1-2

Warranty information ................................................................. 1-2

Manual addenda ......................................................................... 1-2

Safety symbols and terms .......................................................... 1-3

Specifications ............................................................................. 1-3

Unpacking and inspection .......................................................... 1-3

Inspection for damage ......................................................... 1-3

Handling precautions .......................................................... 1-3

Shipment contents ............................................................... 1-4

Instruction manual .............................................................. 1-4

Repacking for shipment ...................................................... 1-4

Connections ................................................................................ 1-4

2 Connections

Introduction ................................................................................ 2-2

Handling precautions ................................................................. 2-2

Configuration ............................................................................. 2-2

Layout ................................................................................. 2-2

Simplified schematic ........................................................... 2-4

Connections ................................................................................ 2-5

GPIB control connection ..................................................... 2-5

Power connector .................................................................. 2-8

3 Operation

Introduction ................................................................................ 3-2

Maximum signal considerations ................................................ 3-2

Bus operation (GPIB) ................................................................. 3-3

Bus connections .................................................................. 3-3

Primary address ................................................................... 3-3

Programming syntax ........................................................... 3-3

Response messages ............................................................. 3-7

Status model ............................................................................... 3-8

Event register sets ............................................................. 3-10

Enable registers ................................................................. 3-11

Queues ............................................................................... 3-11

Status byte and SRQ ......................................................... 3-13

Service request enable register .......................................... 3-14

Serial polling and SRQ ..................................................... 3-15

Clearing registers and queues ................................................... 3-16

Page 10

Programming enable registers .................................................. 3-17

Reading registers ............................................................... 3-17

Common commands ................................................................. 3-18

GPIB commands ....................................................................... 3-26

ROUTe commands ............................................................ 3-26

:CLOSe............................................................................... 3-28

:CONFigure........................................................................ 3-29

STATus commands ............................................................ 3-30

:QUEue............................................................................... 3-30

SYSTem commands .......................................................... 3-32

Manual operation ...................................................................... 3-34

Switching considerations .......................................................... 3-35

Connector integrity ............................................................ 3-35

Voltage Standing Wave Ratio ............................................ 3-35

Path isolation ..................................................................... 3-36

Insertion loss ..................................................................... 3-36

RFI/EMI ............................................................................ 3-36

Errors ........................................................................................ 3-37

4 Service Information

Introduction ................................................................................ 4-2

Handling and cleaning precautions ............................................ 4-2

Handling precautions ........................................................... 4-2

Card and connector cleaning ............................................... 4-2

Performance verification ............................................................. 4-3

Environmental conditions .................................................... 4-3

Recommended equipment ................................................... 4-3

Channel resistance tests ....................................................... 4-3

Replacing components ................................................................ 4-4

Replacement parts ............................................................... 4-4

Replacement precautions ..................................................... 4-5

Soldering considerations ..................................................... 4-5

Relay replacement ............................................................... 4-5

Circuit board removal .......................................................... 4-8

GPIB address .............................................................................. 4-8

5 Replaceable Parts

Introduction ................................................................................ 5-2

Parts list ...................................................................................... 5-2

Ordering information .................................................................. 5-2

Factory service ............................................................................ 5-2

Component layout ...................................................................... 5-2

Page 11

List of Illustrations

2 Connections

Figure 2-1 General layout (front panel) ................................................... 2-3

Figure 2-2 General layout (rear panel) .................................................... 2-4

Figure 2-3 Simplified schematic .............................................................. 2-4

Figure 2-4 GPIB control connector ......................................................... 2-7

Figure 2-5 Power connector .................................................................... 2-8

3 Operation

Figure 3-1 Command diagram ................................................................. 3-5

Figure 3-2 Controlling relay connections ................................................ 3-6

Figure 3-3 Status model structure ........................................................... 3-9

Figure 3-4 Standard event status ............................................................ 3-10

Figure 3-5 Status byte and service request (SRQ) ................................. 3-13

Figure 3-6 16-bit status register ............................................................. 3-17

Figure 3-7 Standard event enable register ............................................. 3-20

Figure 3-8 Standard event status register ............................................... 3-21

Figure 3-9 Service request enable register ............................................ 3-23

Figure 3-10 Status byte register ............................................................... 3-25

Figure 3-11 Manual operation ................................................................. 3-34

4 Service Information

Figure 4-1 Channel resistance test connections ....................................... 4-4

Figure 4-2 Model 7999-6 exploded view ................................................ 4-6

Figure 4-3 GPIB address switch example ............................................... 4-9

Page 12

Page 13

List of T ables

2 Connections

Table 2-1 GPIB control connector terminals ......................................... 2-6

Table 2-2 Power connector pinouts ........................................................ 2-8

3 Operation

Table 3-1 Parameter types ...................................................................... 3-4

Table 3-2 SCPI commands — error queue .......................................... 3-12

Table 3-3 Common and SCPI commands — reset registers and

Table 3-4 IEEE-488.2 common commands and queries ...................... 3-18

Table 3-5 :ROUTe subsystem command set ........................................ 3-27

Table 3-6 :STATus subsystem command set ........................................ 3-30

Table 3-7 :SYSTem subsystem command set ...................................... 3-32

Table 3-8 Error and status message ...................................................... 3-37

4 Service Information

Table 4-1 Recommended verification equipment .................................. 4-3

5 Replaceable Parts

Table 5-1 Parts list—electronic components ......................................... 5-3

Table 5-2 Parts list—mechanical parts ................................................... 5-5

clear queues .................................................................... 3-16

Page 14

Page 15

1

General Information

Page 16

1-2 General Information

Introduction

This section contains general information about the Model 7999-6 GPIB RF Relay. The

information is organized as follows:

• Feature overview

• Warranty information

• Manual addenda

• Safety symbols and terms

• Specifications

• Unpacking and inspection

• Connections

If you have any questions after reviewing this information, please contact your local

Keithley representative or call one of our Applications Engineers at 1-800-KEITHLEY.

Worldwide phone numbers are listed at the front of this manual.

Feature overview

The Model 7999-6 is an IEEE-488 controlled, single or dual, 4 or 6 pole, 19-inch rack

mounted relay unit. Additional features of the Model 7999-6 are as follows:

• N-type bulkhead connectors (insulated)

• +24VDC power connections

• LED indicators for error, power, and relay status

• Operating range to 4GHz (relay dependent)

• Can be upgraded from 4-pole to 6-pole relays

W arranty information

Warranty information is located at the front of this instruction manual. Should your Model

7999-6 require warranty service, contact the Keithley representative or authorized repair facility in your area for further information. When returning the Model 7999-6 for repair, be sure to

fill out and include the service form at the back of this manual to provide the repair facility with

the necessary information.

Manual addenda

Any improvements or changes concerning the Model 7999-6 or manual will be explained in

an addendum included with the manual. Be sure to note these changes and incorporate them

into the manual.

Page 17

Safety symbols and terms

The following symbols and terms may be found on the Model 7999-6 or used in this manual.

The symbol indicates that the user should refer to the operating instructions

!

located in the manual.

The

symbol

dard safety precautions to avoid personal contact with these voltages.

The

WARNING

injury or death. Always read the associated information very carefully before performing the

indicated procedure.

The

CAUTION

Such damage may invalidate the warranty.

shows that high voltage may be present on the terminal(s). Use stan-

heading used in this manual explains dangers that might result in personal

heading used in this manual explains hazards that could damage the switch.

Specifications

Full Model 7999-6 specifications are included at the front of this manual.

General Information 1-3

Unpacking and inspection

Inspection for damage

The Model 7999-6 is packaged in a re-sealable, anti-static bag to protect it from damage due

to static discharge and from contamination that could degrade its performance. Before removing the Model 7999-6 from the bag, observe the precautions on handling discussed below.

Handling precautions

• Always grasp the Model 7999-6 by the covers. Do not touch board surfaces or

components.

• After removing the Model 7999-6 from its anti-static bag, inspect it for any obvious

signs of physical damage. Report any such damage to the shipping agent immediately.

• When the Model 7999-6 is not installed and connected, keep the unit in its anti-static

bag and store it in the original packing carton.

Page 18

1-4 General Information

Shipment contents

The following items are included with every Model 7999-6 order:

• Model 7999-6 GPIB Relay Unit (single or dual 4-pole/6-pole IEEE-488 controlled

relay switch)

• Model 7999-6 Instruction Manual (this manual)

• Additional accessories as ordered

Instruction manual

If an additional Model 7999-6 Instruction Manual is required, order the manual package,

Keithley part number 7999-6-901-00. The manual package includes an instruction manual and

any pertinent addenda.

Repacking for shipment

Should it become necessary to return the Model 7999-6 for repair, carefully pack the unit in

its original packing carton or the equivalent, and follow these instructions:

• Call the Repair Department at 1-800-552-1115 for a Return Material Authorization

(RMA) number.

• Advise as to the warranty status of the Model 7999-6.

• Write ATTENTION REPAIR DEPARTMENT and the RMA number on the shipping

label.

• Fill out and include the Service Form located at the back of this manual.

Connections

The following are available Model 7999-6 connections:

• Power receptacle: 9-pin D-sub connector

• IEEE-488 port (GPIB connector)

• N-type bulkhead connectors

NOTE

Refer to Section 2 for detailed connection information.

Page 19

2

Connections

Page 20

2-2 Connections

Introduction

This section contains information about overall switch configuration and connections and is

organized as follows:

• Handling precautions

• Configuration

• Connections

WARNING

The procedures in this section are intended only for qualified service personnel. Do not perform these procedures unless you are qualified to do so.

Failure to recognize and observe normal safety precautions could result in

personal injury or death.

Handling precautions

To maintain high-impedance isolation, care should be taken when handling the switch to

avoid contamination from foreign materials such as body oils. Such contamination can reduce

isolation resistance. To avoid possible contamination:

• Always grasp the switch by the handles or the relay housing.

• Do not touch bulkhead connector insulators.

• Operate the switch in a clean environment. If the switch becomes contaminated, it

should be thoroughly cleaned as explained in Section 4.

Configuration

Layout

Figure 2-1 and Figure 2-2 show the general layout of the Model 7999-6 featuring the

following:

Connectors:

• Power receptacle (9-pin male D-sub connector)

• GPIB Control: IEEE-488 interface connector

• N-type insulated bulkhead input connectors

Indicators:

• Power LED

• ERR LED (communication error or failed power on self-test)

• Relay state LEDs (one for each relay pole)

Switches:

• Manual toggle switch (one per relay)

Page 21

Figure 2-1

X225

X201

2

General layout (front panel)

7999-6 GPIB RF RELAY UNIT

OPEN

ALL

1

STEP POS.

RELAY 1

2

(1-6)

3

4

X225 X201 X202 X226 X203

Connections 2-3

5

6

PWRERR

MS CODE: 00309

1

3

4

5

6

OPEN

ALL

STEP POS.

(1-6)

OPEN

ALL

STEP POS.

X204

(1-6)

X225 X203

RELAY 1

1

2

3

4

5

6

PWRERR

X201

Relay 1 Manual

toggle switch

Relay 1 state LEDs

Power LED

ERR LED

RELAY 2

1

2

3

4

Relay 2 state LEDs

5

6

OPEN

ALL

STEP POS.

(1-6)

Relay 2 Manual

toggle switch

Output

connectors

Input connectors

(N-type, insulated

from chassis)

Page 22

2-4 Connections

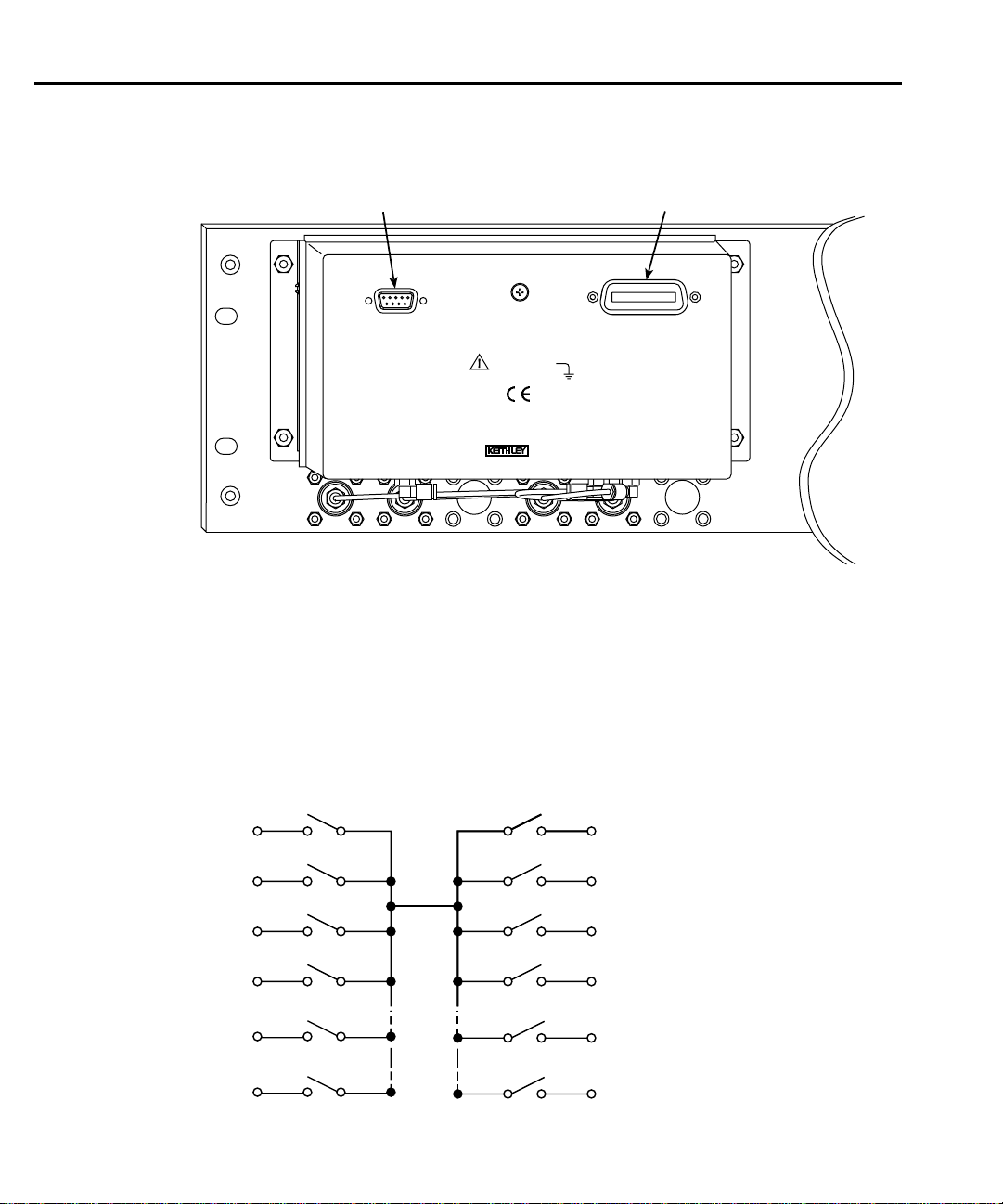

Figure 2-2

General layout (rear panel)

Power connector GPIB connector

Simplified schematic

Figure 2-3 shows a simplified schematic diagram of the Model 7999-6. The solid lines rep-

resent a 4-pole relay; the additional dashed lines represent a 6-pole relay.

Figure 2-3

Simplified schematic

Output

Connections

2

INPUT POWER

(24 VDC)

CATI

WARNING

NO INTERNAL OPERATOR

SERVICABLE PARTS, SERVICE

BY QUALIFIED PERSONNEL ONLY.

42V MAX.

ANY CONDUCTOR

MS CODE: 00313

MADE IN

(SET IEEE ADDRESS INTERNALLY)

U.S.A

RELAY #1RELAY #2

IEEE-488

X201

3

5

6

1

4

X202

X203

X204

X225

X226

Page 23

Connections

GPIB control connection

The GPIB control port is connected to the GPIB port of a computer (controller) using a

shielded IEEE-488 interface cable with metric mating screws.

Remember the following restrictions when attaching instruments to the GPIB:

If you cannot meet these requirements, the use of bus extenders is recommended.

Connections 2-5

– A maximum separation of 4 meters between any two instruments on the bus.

– A maximum total cable length of 20 meters.

– No more than 15 devices on the bus.

– No two instruments having the same address.

CAUTION

Connectors may be stacked to allow a number of parallel connections to one instrument.

Two screws located on a standard connector maintain secure connections between connectors.

NOTE

Connect devices to the GPIB as follows:

1. Line up the cable connector with the connector located on the Model 7999-6. The connector’s design allows installation to the port in only one position.

2. Secure connector by tightening screws firmly (do not overtighten).

3. Add any additional connectors to the port as required.

4. Connect the free end of the cable to the controller.

5. Check that the GPIB address and other GPIB protocol information is properly set. (See

Section 4 of this manual for GPIB address information.)

IEEE-488 common is connected to digital common. Maximum voltage

between digital common and earth ground is 0V.

To minimize interference caused by electromagnetic radiation, use shielded

IEEE-488 cables.

Page 24

2-6 Connections

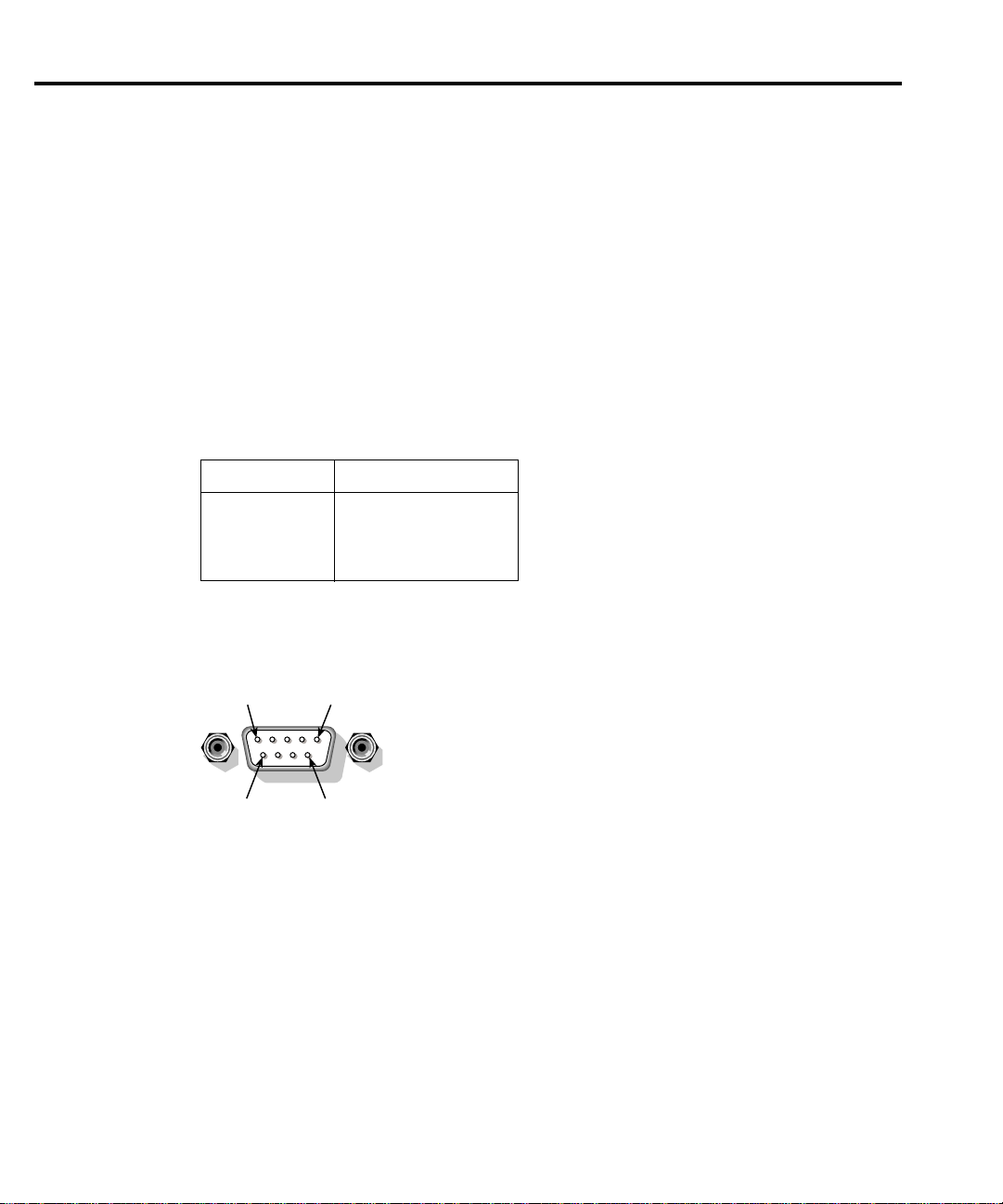

Table 2-1

GPIB control connector terminals

* Numbers in parentheses refer to signal ground return of referenced contact

Contact

Number IEEE-488 designation Type

01 DI01 Data

02 DI02 Data

03 DI03 Data

04 DI04 Data

05 EOI (24)* Management

06 DAV Handshake

07 NRFD Handshake

08 NDAC Handshake

09 IFC Management

10 SRQ Management

11 ATN Management

12 SHIELD Ground

13 DI05 Data

14 DI06 Data

15 DI07 Data

16 DI08 Data

17 REN (24)* Management

18 Gnd (6) * Ground

19 Gnd (7) * Ground

20 Gnd (8) * Ground

21 Gnd (9) * Ground

22 Gnd (10) * Ground

23 Gnd (11) * Ground

24 Gnd, LOGIC Ground

number. EOI and REN signal lines return on contact 24.

Page 25

Figure 2-4

GPIB control connector

Connections 2-7

12

24

1

13

GPIB address

On the main circuit board, there are five GPIB address DIP switches. When shipped from

the factory, the GPIB address is set to 3. To change the GPIB address of the relay, refer to

Section 4 of this manual.

Page 26

2-8 Connections

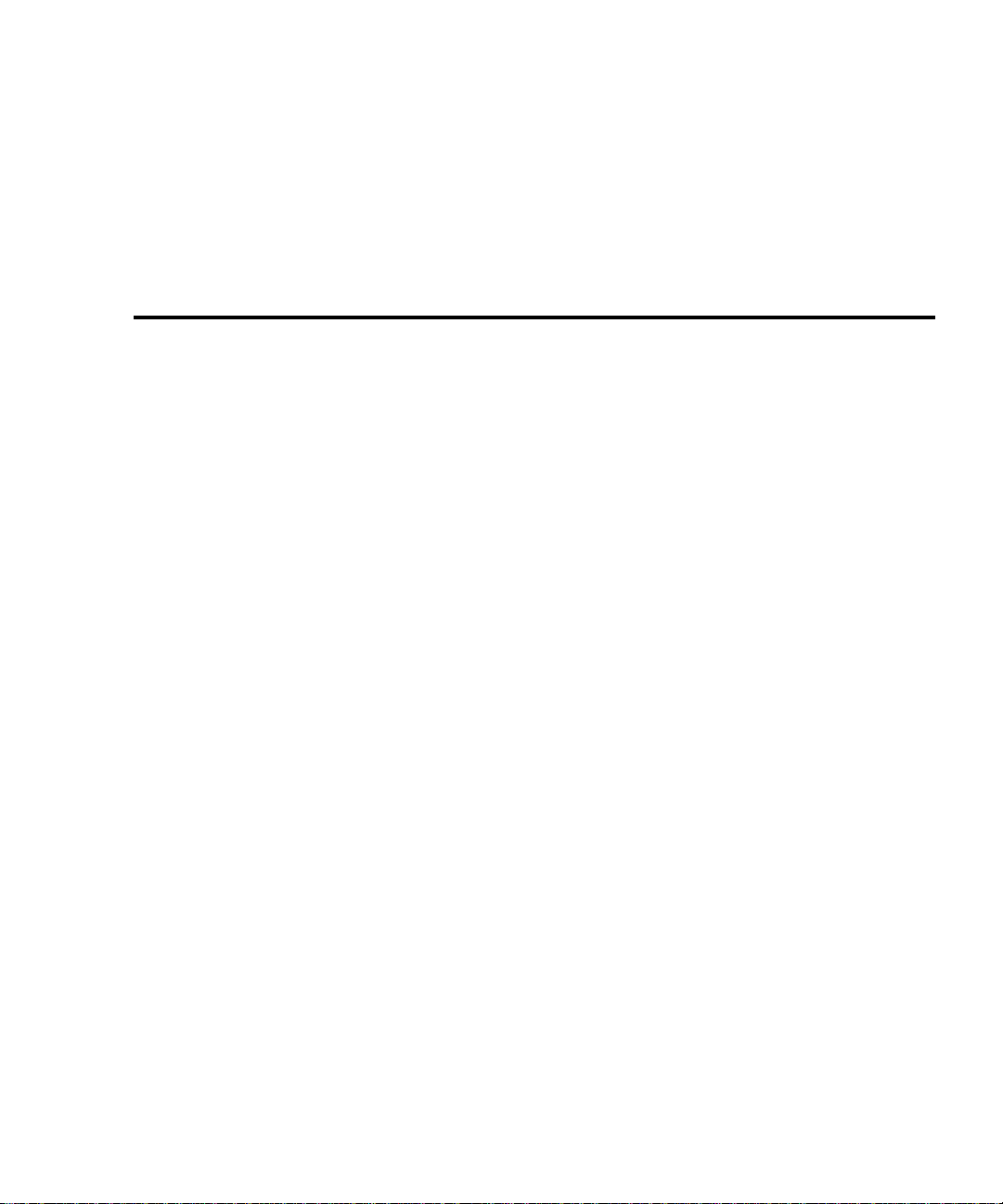

Power connector

properly wired (UL listed cable with a 9-PIN D-subminiature female connector—the Model

7999-6 power connector’s pinouts are shown in Figure 2-5 with the pin descriptions contained

in Table 2-2).

Connect the 24VDC power supply to the power connector. Make sure the power supply is

WARNING

Table 2-2

Power connector pinouts

Pin Number Description

1, 2 Positive (+)

4, 5 Negative (-)

6, 7, 8, 9 (Not used)

Figure 2-5

Power connector

Pin 1

Pin 6 Pin 9

To prevent damage to the Model 7999-6 and to prevent the risk of electric

shock, use only a properly rated power supply. The power supply must be

double insulated, have the required safety agency approvals for the low

voltage directives, EMC directives, and CE certification. It must also provide output current limiting and short-circuit protection.

3 (Not used)

Pin 5

Page 27

3

Operation

Page 28

3-2 Operation

Introduction

This section contains the following operating information for the Model 7999-6:

• “Maximum signal considerations” on page 3-2

• “Bus operation (GPIB)” on page 3-3

• “Status model” on page 3-8

• “Programming enable registers” on page 3-17

• “Common commands” on page 3-18

• “GPIB commands” on page 3-26

• “Manual operation” on page 3-34

• “Switching considerations” on page 3-35

• “Errors” on page 3-37

Maximum signal considerations

WARNING

CAUTION

• Maximum Voltage: 30VDC, 42V peak

• Maximum Switching Signal: 1W CW, CAT I

Maximum voltage between any conductor and ground is 42V.

T o prevent damage to the Model 7999-6, do not exceed the following maximum signal level specifications of the switch:

Page 29

Bus operation (GPIB)

Operation 3-3

NOTE

The term GPIB (General Purpose Bus Interface) is used in this manual. GPIB is

simply another term for the IEEE-488 bus.

Bus connections

Before using the switch, you must connect the IEEE-488 connector on the rear panel of the

switch to the IEEE-488 connector of the controller. Use a Keithley Model 7077 or similar

shielded IEEE-488 cable for this connection. Refer to Section 2 for more information on the

IEEE-488 connection.

Primary address

The primary address of the Model 7999-6 must agree with the primary address you intend to

specify in the controller’s programming language. On the main circuit board, there are five

GPIB address DIP switches. When shipped from the factory, the GPIB address is set to 3. To

change the GPIB address of the relay, refer to Section 4 of this manual.

Programming syntax

Syntax rules for programming the Model 7999-6 are covered in this paragraph.

Commands and parameters

The general form for SCPI commands is demonstrated in Tables 3-2 through 3-4. They are

hierarchical in nature and begin with a root command. For example, to open all channels for

relays 1 and 2, send the following command:

:OPEN:ALL

The root path command for the above example is ROUTe. This is an optional command

word (as indicated by the brackets ([ ]) in the table) and need not be used.

The general form for Common Commands is shown in Table 3-4.

NOTE

Each common command is preceded by a star (*).

Page 30

3-4 Operation

Parameters provide specific types of information. The following list (Table 3-1) contains the

definitions of the different parameter types.

Table 3-1

Parameter types

Parameter Description

<name> Name parameter: Select a parameter name from a listed group.

<clist> List of channels. The following examples demonstrate proper format:

(@1!1,1!5) Channels 1 and 5 of relay 1

<b> Boolean: Enable (1 or on) or disable (0 or off) a function.

<NRf> Numeric representation format: Number can be expressed as an integer ,

real number or an exponent (e.g. 2.3E6).

<n> Numeric value: An NRf number or one of the following name

parameters:

-DEFault: Uses the *RST default parameter value

-MINimum: Uses the lowest allowable parameter value

-MAXimum: Uses the largest allowable parameter value

Short-form commands

Most SCPI command words and name parameters have a short-form version. The short-

form versions are identified in the SCPI tables by the upper case characters. Example:

:ROUT:CLOS (@1!2,2!4) = :ROUTe:CLOSe (@1!2,2!4)

NOTE

Command words and parameter names are not case sensitive.

Query commands

Query commands request information (queries) and can be identified by the question mark

appearing after the command (?). Example:

:CLOSe?

Queries the channels that are closed.

Command messages

Program Message — A program message is made up of one or more command words sent

by the computer to the instrument. Some programming operations require several command

words.

Single Command Message — This program message uses the command words required to

perform a single programming operation. Example:

:SYST:ERR?

Reads the system error queue.

Page 31

Operation 3-5

Multiple Command Message — This program message contains two or more command

operations. Each command string is separated by a semicolon (;). The following example uses

the short-form format to reduce the size of the message:

:ROUT:CLOS (@1!2,2!4);:ROUT:CLOS?

The above program message closes 1!2 and 2!4, and then queries for closed relays.

Commands that are on the same command level can be executed without having to repeat

the entire command path. For example:

:ROUT:CONF:CPOL1 4;CPOL2 4

Since :CPOL1 and :CPOL2 are on the same command level (see ), the :ROUT:CONF command word does not have to be repeated for the second command string. Note also that the

leading colon (:) for :CPOL2? is not used. Common commands and SCPI commands can be

used in the same program message as long as they are separated by a semicolon (;). Example:

*RST;CLOSe (@1!1,l!3)

Example command

To connect the N-connector X201 to output 5 of relay 1, send:

:ROUT:CLOS (@2!2,1!5);

Refer to Figure 3-1 for a diagram of the parts of this command and to Figure 3-2 for an illustration of the physical connections.

Figure 3-1

Command diagram

Command

Root path

Relay number

:ROUT:CLOS (@2!2,1!4);

Channel number

Page 32

3-6 Operation

Figure 3-2

Controlling relay connections

OPEN

ALL

STEP POS.

RELAY 1

1

(1-6)

2

3

4

5

6

X225 X203

X201

PWRERR

RELAY 2

1

2

3

4

5

6

OPEN

ALL

STEP POS.

(1-6)

NOTE

4-pole relay shown.

Dashed lines designate

additional paths for

6-pole relay.

N-type bulkhead

connectors

Input

1!5

1!6

1!1

2!1 2!4

2!2 2!3 2!5 2!6

X225 X201 X202 X226 X203

5

4

3

6

1

1

2

X204

2

3

4

6

5

1!4

1!2

1!3

Relay 1

Output

Relay 2

Input

The Model 7999-6 contains two relays that are IEEE controlled and connected center-tocenter with blocking. The signal is brought in through one of four bulkhead connections and

switched to one of four output connections (switching is controlled over the IEEE bus). In our

example, relays 2!2 and 1!5 are closed which completes the path from N-type bulkhead connector X201 to relay #1 output connector 5 (see Figure 3-2).

Page 33

Program message terminator (PMT)

Each program message must be terminated with a LF (line feed), EOI (end or identify), or a

LF + EOI. The bus will hang if your computer does not pro vide this termination. The follo wing

example shows how a program message must be terminated:

utp on <PMT>

:o

Command execution rules

• Commands execute in the order presented in the program message.

• An invalid command generates an error and is not executed.

• Valid commands preceding an invalid command in a multiple command program

message are executed.

• Valid commands following an invalid command in a multiple command program

message are ignored.

Response messages

A response message is the message sent by the instrument to the computer in response to a

query command program message.

Operation 3-7

Sending a response message

After sending a query command, the response message is placed in the output queue. When

the relay unit is then addressed to talk, the response message is sent from the output queue to

the computer.

Multiple response messages

If you send more than one query command in the same program message the multiple

response messages for all the queries are sent to the computer when the relay unit is addressed

to talk. The responses are sent in the order the query commands were sent and are separated by

semicolons (;). Items within the same query are separated by commas (,). The following example shows the response message for a program message that contains four single item query

commands:

0;1;1;0

Response message terminator (RMT)

Each response is terminated with an LF (line feed) and EQI (end or identify). The follo wing

example shows how a multiple response message is terminated:

0;l;l;0 <RMT>

Page 34

3-8 Operation

Message exchange protocol

Two rules summarize the message exchange protocol:

Rule 1: You must always tell the relay unit what to send to the computer.

Rule 2: The computer must receive the complete response message before another pro-

Status model

The relay unit provides status registers and queues allowing the operator to monitor and

manipulate the various instrument ev ents. The status structure is sho wn in Figure 3-3. The heart

of the status structure is the status byte register. This register can be read by the user’s test program to determine if a service request (SRQ) has occurred, and what event caused it.

Perform the following two steps to send information from the relay switch to the

computer:

1. Send the appropriate query command(s) in a program message.

2. Address the relay switch to talk.

gram message can be sent to the relay unit.

Page 35

Figure 3-3

Status model structure

Operation 3-9

Error Queue

Output Queue

Operation Complete

Query Error

Device Specific Error

Execution Error

Command Error

Power On

(Always Zero)

Standard Event Registers

Event

Register

OPC

1

QYE

DDE

EXE

CME

6

PON

8

9

10

11

12

13

14

15

*ESR?

Event Enable

Register

&

OPC

&

1

&

QYE

&

DDE

&

EXE

&

CME

&

6

&

PON

&

8

&

9

&

10

&

11

&

12

&

13

&

14

&

15

*ESE <NRf>

*ESE?

Logical

OR

Status Byte

Register

0

1

EAV

3

MAV

ESB

RQS/MSS

7

*STB?

Service Request

Enable Register

&

&

&

&

&

&

&

0

1

EAV

3

MAV

ESB

6

7

*SRE

Logical

OR

*SRE?

Master Summary Status (MSS)

EAV = Error Available

MAV = Message Available

ESB = Event Summary Bit

RQS/MSS = Request for Service/Master

Summary Status

NOTE: RQS bit is in serial poll byte,

MSS bit is in *STB? response.

Page 36

3-10 Operation

Event register sets

event occurs, the appropriate e vent register bit sets to 1. The bit remains latched (to 1) until the

register is reset. When an event register bit is set and its corresponding enable bit is set (as programmed by the user), the output (summary) of the register will set to 1, which in turn sets the

summary bit of the status byte register.

Figure 3-4

Standard event status

An event register set is made up of an event register and an event enable register. When an

To ESB bit

of Status Byte

Register

*ESR?

OR

*ESE <NRf>

*ESE?

Decimal

Weights

(B15 - B8)

(B7)

(B15 - B8)

(B7)

PON = Power On

CME = Command Error

EXE = Execution Error

DDE = Device-Dependent Error

QYE = Query Error

OPC = Operation Complete

PON

(B7)

&

PON

(B7)

128

7

(2

)

CME

(B6)

(B5)

&

&

CME

(B6)

(B5)

32

(25)16(24)8(23)4(22)

EXE

DDE

(B4)

(B3)

&

&

EXE

DDE

(B4)

(B3)

& = Logical AND

OR = Logical OR

QYE

(B2)

&

QYE

(B2)

(B1)

(B1)

OPC

(B0)

&

OPC

(B0)

1

0

(2

)

Standard Event

Register

Standard Event

Enable Register

Page 37

Enable registers

The enable register is user programmed and serves as a mask for the corresponding event

register. An even bit is masked when the corresponding bit in the enable register is cleared (0).

When masked, a set bit in an event register cannot set a bit in the status byte register

(1 AND 0 = 0).

T o use the status byte re gister to detect events (i.e., serial poll), unmask the e v ents by setting

the appropriate bits of the enable registers.

Use *ESE and *ESE? (common commands) to program and read the standard ev ent register.

Queues

The relay unit uses an output queue and an error queue. The response messages to query

commands are placed in the output queue. As various programming errors and status messages

occur, they are placed in the error queue (this queue holds up to ten messages). When a queue

contains data, it sets the appropriate summary bit of the status byte register.

Output queue

When data is placed in the output queue, the message available bit (MAV) in the status byte

register sets. A data message is cleared from the output queue when it is read. The output queue

is considered cleared when it is empty. A cleared output queue clears the MAV bit in the status

byte register. A message is read from the output queue by addressing the unit to talk after the

appropriate query is sent.

Operation 3-11

The following command sequence enables the MAV bit (B4) of the status byte register set

and then causes an SRQ:

*SRE 16 'Enable MAV bit of the status byte to cause an SRQ.

Language specific

Language specific

Language specific 'Read the query response.

'Send a query command to the unit.

'Wait for an SRQ indicating ready to read.

Error queue

When a message is placed in the error queue, the error available bit (EAV) in the status byte

register sets. An error/status message is cleared from the error queue when it is read. The error

queue is considered cleared when it is empty. A cleared error queue clears the EAV bit in the

status byte register.

Read an error message from the error queue by sending either of the following SCPI query

commands and then addressing the Model 7999-6 to talk:

:SYSTem:ERRor?

:STATus:QUEue?

Page 38

3-12 Operation

Messages in the error queue are stored in a FIFO (First In-First Out) manner . The commands

to read the error queue are listed in Table 3-2. When you read a single message in the error

queue, the “oldest” message is read and then removed from the queue. If the queue becomes

full, the message “350, ‘queue overflow’” will occupy the last memory location. On power-up,

the error queue is empty. When empty, the message “0, No Error” is placed in the queue.

Messages in the error queue are preceded by a code number. Negative (-) numbers are used

for SCPI defined messages, and positive (+) numbers are used for Keithley defined messages.

The error messages are listed in Table 3-8 on page 3-37.

On power-up, all error messages are enabled and will go into the error queue as they occur.

Status messages are not enabled and will not go into the queue. As listed in Table 3-2, there are

commands to enable and/or disable messages. For these commands, the <list> parameter is

used to specify which messages to enable or disable. The messages are specified by their codes.

The following examples show various forms for using the <list> parameter.

<list> = (-110) Single message

= (-110,-222,-220) Comma separated entries

When you enable messages, messages not specified in the list are disabled. When you disable messages, each listed message is removed from the enabled list.

NOTE

To prevent all messages from entering the error queue, send the enable command

along with the null list parameter as follows: STATus:QUEue:ENABle ().

Table 3-2

SCPI commands — error queue

Command Description Default

STATus

:QUEue

[:NEXT]?

:ENABle<list>

:ENABle?

:DISable<list>

:DISable?

:CLEar

SYSTem

:ERRor?

:CLEar

Notes:

1.Power-up and *CLS empties the error queue. STATus:PRESet has no effect.

2.Power-up enables error messages and disables status messages. *CLS and STATus:PRESet have no effect.

STATus subsystem:

Read error queue:

Read and clear oldest error/status message.

Specify error and status messages for error queue.

Read the enabled messages.

Specify messages not to be placed in queue.

Read the disabled messages.

Clear messages from error queue.

SYSTem subsystem:

Read error queue:

Clear messages from error queue.

(Note 1)

(Note 2)

(Note 2)

(Note 1)

For more information on these commands, see the specific command listing in the SCPI

command section.

Page 39

Status byte and SRQ

Service request is controlled by two 8-bit registers: the Status Byte Re gister and the Service

Request Enable Registers. Figure 3-5 shows the structure for these registers.

Figure 3-5

Status byte and service request (SRQ)

Operation 3-13

Status Summary Messages

Service

Request

Generation

* STB?

Serial Poll

OR

* SRE

* SRE?

Decimal

Weights

RQS

ESB

(B5)

&

ESB

(B5)

32

(2

MAV

MAV

5

)16(24)

(B4)

(B3)

&

(B4) (B3)

(B6)

(B7)

MSS

(B7) (B6)

MSS = Master Summary Status

RQS = Request for Service

ESB = Event Summary Bit

MAV = Message Available

EAV = Error Available

EAV

(B2)

(B1)

&

EAV

(B2) (B1)

4

(22)

& = Logical AND

OR = Logical OR

Status Byte

Register

(B0)

Service Request

Enable Register

(B0)

Page 40

3-14 Operation

Status byte register

The summary messages from the status registers and queues are used to set or clear the

appropriate bits (B2, B4, B5, and B6) of the status byte register. These summary bits do not

latch, and their states (0 or 1) are solely dependent on the summary messages (0 or 1). For

example, if the standard event register is read, its register will clear. As a result, its summary

message will reset to 0, which in turn will reset the ESB bit in the status byte register.

Depending on how it is used, Bit B6 of the status byte register is either the request for service (RQS) bit or the master summary status (MSS) bit:

When using the serial poll sequence of the relay unit to obtain the status byte (a.k.a. serial

poll byte), B6 is the RQS bit. See “Serial Polling and SRQ” for details on using the serial poll

sequence.

When using the *STB? command (see Figure 3-4 on page 3-10) to read the status byte, B6 is

the MSS bit.

The status byte register receives the summary bits of the Standard Event Register set and

two queues. The register set and queues monitor the various instrument events. When an

enabled event occurs, it sets a summary bit in the status byte register. When a summary bit of

the status byte is set and its corresponding enable bit is set (as programmed by the user), the

RQS/MSS bit will set to indicate that an SRQ has occurred.

Service request enable register

The generation of a service request is controlled by the service request enable register. This

register is programmed by the user and is used to enable or disable the setting of bit B6 (RQS/

MSS) by the status summary message bits (B2, B4, B5, and B6) of the status byte register. As

shown in Figure 3-5, the summary bits are logically ANDed (&) with the corresponding enable

bits of the service request enable register. When a set (1) summary bit is ANDed with an

enabled (1) bit of the enable register , the logic “1” output is applied to the input of the OR gate

and, therefore, sets the MSS/RQS bit in the status byte register.

The individual bits of the service request enable register can be set or cleared by using the

*SRE common command. To read the service request enable register, use the *SRE? query

command. The service request enable register clears when po wer is cycled or a parameter v alue

of 0 is sent with the *SRE command (i.e. *SRE 0). The commands to program and read the

SRQ enable register are listed in Table 3-2.

Page 41

Serial polling and SRQ

Any enabled event summary bit that goes from 0 to 1 will set bit B6 and generate an SRQ

(service request). In your test program, you can periodically read the status byte to check if an

SRQ has occurred and what caused it. If an SRQ occurs, the program can, for example, branch

to an appropriate subroutine that will service the request.

Typically, SRQs are managed by the serial poll sequence of the relay unit. If an SRQ does

not occur, bit B6 (RQS) of the status byte register will remain cleared, and the program will

simply proceed normally after the serial poll is performed. If an SRQ does occur, bit B6 of the

status byte register will set, and the program can branch to a service subroutine when the SRQ

is detected by the serial poll.

The serial poll automatically resets RQS of the status byte register. This allows subsequent

serial polls to monitor bit B6 for an SRQ occurrence generated by other event types. After a

serial poll, the same event can cause another SRQ, e v en if the e vent re gister that caused the first

SRQ has not been cleared.

The serial poll does not clear MSS. The MSS bit stays set until all status byte summary bits

are reset.

Operation 3-15

Page 42

3-16 Operation

Clearing registers and queues

When the relay unit is powered up, the bits of all registers in the status structure are clear

(set to 0) and the two queues are empty. Commands to reset the event and event enable registers, and the error queue are listed in Table 3-3. In addition to these commands, any enable register can be reset by sending the 0 parameter value with the indi vidual command to program the

register.

NOTE

*RST has no effect on status structure registers and queues. See “Queues” for

details on the error queue.

Table 3-3

Common and SCPI commands — reset registers and clear queues

Commands Description Ref

To reset Standard

Reset all bits of the Standard Event Register to 0. Note 1

event register:

*ESE 0

or

*CLS

To clear error queue:

*CLS

STATus

:QUEue

{:NEXT}?

:CLEar

SYSTem

:ERRor?

:CLEar

Notes:

1. The standard event enable register is not reset by STATus:PRESet (see “Status byte and service request

commands”).

2. STATus:PRESet has no effect on the error queue.

3. Use either of the two :CLEar commands to clear the error queue.

Clear all messages from error queue Note 1

STATus subsystem:

Error queue:

Read and clear the oldest error/status message.

Clear all messages from error queue.

Note 2

SYSTem subsystem:

Read and clear the oldest error/status message.

Clear all messages from error queue.

Note 2

Page 43

Programming enable registers

The registers that can be programmed by the user are the enable registers. All other registers

in the status structure are read-only registers. The following explains how to ascertain the

parameter value for the various commands used to program enable registers. The actual commands are covered later in this section (see Table 3-4).

A command to program an event enable register is sent with a decimal parameter value that

determines the desired state (0 or 1) of each bit in the appropriate register. The bit positions of

the register (see Table 3-5) indicate the parameter value in binary format. For example, if you

wish to set bits B5, B4, and B2 (set the bit’s value to 1), the binary value would be 110100

(where B5=1, B4=1, B3=0, B2=1, B1=0, B0=0 and all other bits are 0). The decimal equi valent

of binary 110100 is 52. Therefore, the parameter value for the enable command is 52.

Another way to determine the decimal value is to add up the decimal weights for the bits that

you wish to set. Note that Figure 3-6 includes the decimal weight for each register bit. To set

bits B5, B3, and B2, the parameter value would be the sum of the decimal weights for those bits

(32+16+4 = 52).

Figure 3-6

16-bit status register

Operation 3-17

A) Bits 0 through 7

Bit Position B7 B6 B5 B4 B3 B2 B1 B0

Binary Value 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

Decimal

Weights

B) Bits 8 through 15

Bit Position B15 B14 B13 B12 B11 B10 B9 B8

Binary Value 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

Decimal

Weights

Reading registers

Any register in the status structure can be read by using the appropriate query (?) command. The specific query commands are covered later in this section (see Table 3-4).

The response message to the query command is a decimal value. To determine which bits in

the register are set, convert that decimal value to its binary equivalent. For example, the binary

equivalent of decimal 48 is 110000. This binary value indicates that bits B5 and B4 are set.

128

7

(2

)

32768

15

(2

)

64

6

(2

16384

14

(2

32

5

(2

)

8192

13

(2

)

16

4

(2

)

4096

12

(2

)

8

3

(2

)

2048

11

(2

)

4

2

(2

)

1024

10

(2

)

2

1

(2

)

512

9

(2

)

1

0

(2

)

)

256

8

(2

)

)

Page 44

3-18 Operation

Common commands

NOTE Each common command is preceded by a star (*).

Common commands are device commands that are common to all de vices on the b us. These

commands are designated and defined by the IEEE-488.2 standard. Common commands are

listed in Table 3-4.

Table 3-4

IEEE-488.2 common commands and queries

Mnemonic Name Description

*CLS Clear status Clear the standard event register and error queue.

*ESE <NRf> Event enable command Program the standard event enable register.

*ESE? Event enable query Read the standard event enable register.

*ESR? Event status register

query

*IDN? Identification query Returns the manufacturer, model number, serial

*OPC Operation complete

command

*OPC? Operation complete

query

*RST Reset command Returns the relay unit to the *RST default condi-

*SRE<NRf> Service request enable

command

*SRE? Service request enable

query

*STB? Status byte query Reads the status byte register.

*TST? Self-test query Performs a checksum test on ROM and returns

*WAI Wait-to-continue

command

Read the standard event enable register and clear

it.

number, and firmware revision levels of the unit.

Set the operation complete bit in the standard

event register after all pending commands have

been executed.

Places an ASCII “1” into the output queue when

all pending selected device operations have been

completed.

tion.

Programs the service request enable register.

Reads the service request enable register.

the result.

Wait until all previous commands are executed.

*CLS — Clear status Clear status registers and error queue

Use the *CLS command to clear (set to 0) the bits of the following registers:

• Standard event register

• Error queue

Page 45

Operation 3-19

*ESE <NRf> — Event Enable Program the standard event enable register

*ESE? —Event Enable Query Read the standard event register

Parameter <NRf> = 0 Clear register

1 Set OPC(B0)

4 Set QYE (B2)

8 Set DDE(B3)

16 Set EXE(B4)

32 Set CME(B5)

64 Set URQ(B6)

128 Set PON(B7)

255 Set all bits

Use the *ESE command to program the Standard Event Enable Register. This command is

sent with the decimal equivalent of the binary value that determines the desired state (0 or 1) of

the bits in the register. This register is cleared on power-up.

This register is used as a mask for the Standard Event Register. When a standard event is

masked, the occurrence of that event will not set the Event Summary Bit (ESB) in the Status

Byte Register . Con versely, when a standard event is unmasked (enabled), the occurrence of that

event sets the ESB bit. For information on the Standard Event Register and descriptions of the

standard event bits, see the *ESR? command.

A cleared bit (0) in the enabled register prev ents (masks) the ESB bit in the Status Byte Register from setting when the corresponding standard event occurs. A set bit (1) in the enable register allows (enables) the ESB bit to set when the corresponding standard event occurs.

The Standard Event Enable Register is sho wn in Figure 3-7 and includes the decimal weight

of each bit. The sum of the decimal weights of the bits that you wish to be set is the parameter

value that is sent with the *ESE command. For example, to set the CME and QYE bits of the

Standard Event Enable Register, send the following command:

*ESE 36

where: CME (bit B5) = 32

QYE (bit B2) = __4

<NRf> = 36

If a command error (CME) occurs, bit B5 of the Standard Event Status Register sets. If a

query error (QYE) occurs, bit B2 of the Standard Event Status Register sets. Since both of

these events are unmasked (enabled) the occurrence of any one of them causes the ESB bit in

the Status Byte Register to set. Read the Standard Event Status Re gister using the *ESE? query

command.

Page 46

3-20 Operation

Figure 3-7

Standard event enable register

Bit position

Event

Decial Weighting

Value

Value: 1 = Enable Standard Event

0 = Disable (Mask) Standard Event

(B15 - B8)

B7 B5 B4 B3 B2 B1 B0B6

PON CME EXE DDE QYE

128

(2

0/1

7

)

32

(25)16(24)8(23)4(22)

Events: PON = Power On

CME = Command Error

EXE = Execution Error

DDE = Device-Dependent Error

QYE = Query Error

OPC = Operation Complete

OPC

1

0

(2

0/10/1 0/1 0/1 0/1

)

*ESR? - Event Status Register Query Reads then clears the standard event status

register

Use this command to acquire the value (in decimal) of the Standard Event Register (see Figure 3-8). The binary equivalent of the returned decimal value determines which bits in the register are set. The register is cleared on power-up.

A set bit in this register indicates that a particular event has occurred. For example, for an

acquired decimal value of 48, the binary equivalent is 00110000. From this binary value, bits

B4 and B5 of the Standard Event Status Register are set. These bits indicate that a devicedependent error and command error have occurred.

The bits of the Standard Event Status Register are described as follows:

• Bit B0, Operation Complete — A set bit indicates that all pending selected device

operations are completed and the Model 7999-6 is ready to accept new commands. This

bit only sets in response to the *OPC command. It is not affected by the *OPC?

command.

• Bit B1 — Not used.

• Bit B2, Query Error (QYE) — A set bit indicates that you attempted to read data from

an empty Output Queue.

• Bit B3, Device-Dependent Error (DDE) — A set bit indicates that an instrument

operation did not execute properly due to some internal condition.

Page 47

• Bit B4, Execution Error (EXE) — A set bit indicates that the Model 7999-6 detected

an error while trying to execute a command.

• Bit B5, Command Error (CME) — A set bit indicates that a command error has

occurred. Command errors include:

– IEEE-488.2 syntax error — Model 7999-6 received a message that does not follo w

– Semantic error — Model 7999-6 received a command that was misspelled, or

• Bit B6 — Not used.

• Bit B7, Power ON (PON) —A set bit indicates that the Model 7999-6 has been turned

off and turned back on since the last time this register has been read.

Figure 3-8

Standard event status register

Operation 3-21

the defined syntax of the IEEE-488.2 standard.

received an optional IEEE-488.2 command that is not implemented.

Bit position

Event

Decial Weighting

Value 0/10/1 0/1

*IDN? — identification query Reads identification code

The identification code includes the manufacturer, model number, serial number, and firmware revision levels. Identification codes vary with the model number, output formats and output types. Power supplies set for the exponential output format and Keithley output types have

the following codes:

(B15 - B8)

Value: 1 = Event bit set

B7 B5 B4 B3 B2 B1 B0B6

PON CME EXE DDE QYE

128

7

(2

)

0/1

2 = Event bit cleared

32

(25)16(24)8(23)4(22)

0/1 0/1

Events: PON = Power On

CME = Command Error

EXE = Execution Error

DDE = Device-Dependent Error

QYE = Query Error

OPC = Operation Complete

OPC

1

0

(2

)

KEITHLEY INSTRUMENTS INC., MODEL 7999-6, xxxxxxx, yyyyy

Where: xxxxxxx is the serial number.

yyyyy is the firmware revision level of the digital board ROM.

Page 48

3-22 Operation

*OPC — operation complete Sets OPC bit

*OPC? — operation complete query Places a “1” in output queue

When *OPC is sent, the OPC bit in the standard event re gister will set after all pending command operations are complete. When *OPC? is sent, an ASCII “1” is placed in the output

queue after all pending command operations are complete.

The following syntax rules explain how to use *OPC and *OPC? with other commands:

NOTE Send *OPC or *OPC?, separated by a semicolon, on the same line as another query.

If sent on separate lines, an error occurs. The *OPC? can be sent on the same line

with a command that is not a query, or on a separate line as a command (not a

query).

*RST — reset Return relay unit to *RST defaults

When the *RST command is sent, the relay unit performs the following operations:

1. Returns the instrument to the RST default conditions (see “Default” column of SCPI

tables) and opens all relay paths.

2. Cancels all pending commands.

3. Cancels response to any previously received *OPC and *OPC? commands.

*SRE <NRf> — Service Request Enable Program register

*SRE? — Service Request Enable Query Read register

Parameter <NRf> = 0 Clears enable register

4 Set EAV bit (Bit 2)

16 Set MAV bit (Bit 4)

32 Set ESB (Bit 5)

255 Set all bits

Use the *SRE command to program the Service Request Enable Register. Send this command with the decimal equivalent of the binary value that determines the desired state (0 or 1)

of each bit in the register. This register is cleared on power-up.

This enable register is used along with the Status Byte Register to generate service requests

(SRQ). With a bit in the Service Request Enable Register set, an SRQ occurs when the corresponding bit in the Status Byte Register is set by an appropriate ev ent. F or more information on

register structure, see the information presented earlier in this section.

Page 49

Operation 3-23

The Service Request Enable Register is shown in Figure 3-9. Notice that the decimal weight

of each bit is included in the illustration. The sum of the decimal weights of the bits that you

wish to set is the value that is sent with the *SRE command. For example, to set the ESB and

MAV bits of the Service Request Enable Register, send the following command:

where: ESB (bit B5) = 32

MAV (bit B4) = __16

<NRf> = 48

The contents of the Service Request Enable Register can be read using the *SRE? query

command.

Figure 3-9

Service request enable register

Bit position

Event

Decimal Weighting

Value 0/1 0/1 0/1

B7 B5 B4 B3 B2 B1 B0B6

ESB MAV EAV

32

5

(2

)16(24)

Event: ESB = Event Summary Bit

Value: 1 = Enable Service Request Event

MAV = Message Available Bit

EAV = Error Available

MSB = Measurement Summary Bit

0 = Disable (Mask) Service Request Event

4

(22)

Page 50

3-24 Operation

*STB? - Status Byte Query Read Status Byte Register

Use the *STB? query command to acquire the value (in decimal) of the Status Byte Re gister .

The Status Byte Register is shown in Figure 3-10. The binary equivalent of the decimal value

determines which bits in the register are set.

All bits, except Bit B6, in this register are set by other event registers and queues. Bit 6 sets

when one or more enabled conditions occur.

The *STB? query command does not clear the status byte register. This register can only be

cleared by clearing the related registers and queues.

For example, for an acquired decimal value of 48, the binary equivalent is 00110000. This

binary value indicates that bits 4 and 5 of the Status Byte Register are set.

The bits of the Status Byte Register are described as follows:

• Bit 0 — Not used.

• Bit 1 — Not used.

• Bit 2, Error Available (EAV) — A set bit indicates that an error or status message is

present in the Error Queue. The message can be read using one of the following SCPI

commands:

– :SYSTem:ERRor?

– :STATus:QUEue?

• Bit 3 — Not used.

• Bit 4, Message Available (MAV) — A set bit indicates that a message is present in the

Output Queue. The message is sent to the computer when the Model 7999-6 is

addressed to talk.

• Bit 5, Event Summary Bit (ESB) — A set bit indicates that an enabled standard event

has occurred. The event can be identifi ed by reading the Standard Ev ent Status Re gister

using the *ESE? query command.

• Bit 6, Master Summary Status (MSS)/Request Service (RQS) — A set bit indicates

that one or more enabled Status Byte conditions have occurred. Read the MSS bit by

using the STB? query command, or perform a serial poll to detect the occurrence of a

service request (RQS bit set).

• Bit 7 — Not used.

Page 51

Figure 3-10

Status byte register

Operation 3-25

Bit position

Event

Decimal Weighting

Value 0/1 0/1 0/1 0/1

B7 B5 B4 B3 B2 B1 B0B6

MSS

ESB MAV EAV

RQS

32

64

(2

Events: MSS = Master Summary Status

Value: 1 = Event bit set

5

6

(2

)16(24)

)

RQS = Request Service

ESB = Event Summary Bit

MAV = Message Available

EAV = Error Available

MSB = Measurement Available Bit

0 = Event bit cleared

4

(22)

*TST? — self-test query Run relay self test and read result

NOTE This command activates all paths of both r elays. Make certain the system is in a state

that can permit all paths of both relays to be opened and closed.

Use this query command to perform a self-test for the relay actuation mechanism.

This command initiates the following sequence:

1. All paths of both relays are opened.

2. One path is closed (for both relays) and the indicator is read back. This occurs for each

path. This ensures the actuator is energized and that only the single path closed.

3. The command places the coded result (0 or 1) in the output queue.

When the unit is addressed to talk, the coded result is sent from the output queue to the

computer.

A returned value of one (1) indicates that the test passed, and a value of zero (0) indicates