Page 1

Model 776 Programmable Counter/Timer

Instruction Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

W ARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility . Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMIT A TION OF W ARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. • 28775 Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.keithle y.com

BELGIUM: Keithley Instruments B.V.

CHINA: Keithley Instruments China Y uan Chen Xin Building, Room 705 • 12 Yumin Road, Dew ai, Madian • Beijing 100029 • 8610-62022886 • Fax: 8610-62022892

FRANCE: Keithley Instruments Sarl 3, allée des Garays • 91127 Palaiseau Cedex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Keithley Instruments GmbH Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Keithley Instruments Ltd

INDIA: Keithley Instruments GmbH Flat 2B, WILOCRISSA • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Keithley Instruments s.r.l. Viale S. Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

NETHERLANDS: Keithley Instruments B.V. Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWITZERLAND: Keithley Instruments SA Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: Keithley Instruments Taiwan 1 Fl. 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3572-9077 • Fax: 886-3572-903

Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02/363 00 40 • Fax: 02/363 00 64

The Minster • 58 Portman Road • Reading, Berkshire RG30 1EA • 0118-9 57 56 66 • Fax: 0118-9 59 64 69

9/00

Page 3

Model 776 Programmable Counter/T imer

Instruction Manual

Serial Prefix T74

©1993, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Fifth Printing, April 2001

Document Number: 776-901-01 Rev. E

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The

Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are

released between Revisions, contain important change information that the user should incorporate immediately into

the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the new Revision of the manual. Each new Revision includes

a revised copy of this print history page.

Addendum D (Document Number 776-901-02) ............................................ January 1999

Revision E (Document Number 776-901-01)...................................................... April 2001

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over -voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. The user should assume all measurement, control, and

data I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present.

that hazardous voltage is present in any unknown circuit before

measuring.

Users of this product must be protected from electric shock at all

times. The responsible body must ensure that users are prevented

access and/or insulated from every connection point. In some cases,

connections must be exposed to potential human contact. Product

users in these circumstances must be trained to protect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts,

exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry , insulated

surface capable of withstanding the voltage being measured.

A good safety practice is to expect

no conductive part of the circuit may be

Page 6

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The

WARNING heading in a manual explains dangers that might

result in personal injury or death. Alw ays read the associated infor mation very carefully before performing the indicated procedure.

The

CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

2/01

Page 7

Table of Contents

1

l-l

l-2

l-3

1-4

l-5

l-6

1-7

l-8

2

2-1

2-2 Performance Checks..

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

General Information

Introduction .................................................................................................................................................

Instrument and Manual Identification ...................................................................................................... 1-I

Configuration.. .............................................................................................................................................

Warranty Information .................................................................................................................................

Manual Addenda .........................................................................................................................................

Safety Symbols and Terms ........................................................................................................................

Inspection .....................................................................................................................................................

Specifications ..............................................................................................................................................

installation

Introduction .................................................................................................................................................

Power Requirements..

Grounding Requirements.. .....................................................................................................................

Installation and Mounting ..........................................................................................................................

Bench Mounting ..........................................................................................................................................

Rack Mounting.. ..........................................................................................................................................

Portable Use.. ...............................................................................................................................................

Short Term Storage.. ...................................................................................................................................

Long Term Storage or Re-packaging For Shipment ..............................................................................

Safety ............................................................................................................................................................

I-1

l-2

l-2

I -2

I-2

l-2

1-Y

2-1

.............................................................................................................................. ...2-I

.............................................................................................................................. ...2-I

.,.,2-I

2-2

2-2

2-2

2-2

2-2

2-2

2-3

3

3-l

3-2

3-2-l

Operation

Introduction

Front Panel Famlllanzatlon ...........................................................................................................................

Controls ....................................................................................................................................................

..................................................................................................................................................

1-l

3-l

3-1

Page 8

3-2-2

...........................................................................................................................................................................................................................................................

3-2-3

3-3

3-3-l

3-4

3-5

3-6

3-6-l

3-6-2

3-7

3-8

3-9

3-10

3-11

3-12

3-13

3-14

3-14-1

3-14-2

3-14-2

3-15

3-16

3-17

3-18

3-19

3-20

3-20-l

3-20-2

3-2 1

3-22

Connectors ............................................................................................................................................... 3-2

Display And Indicators .......................................................................................................................... 3-2

Rear Panel Familiarization.. ......................................................................................................................

Connectors and Terminals .....................................................................................................................

Power-up Procedure ...................................................................................................................................

Software Reset ............................................................................................................................................ 3-4

Display Messages .......................................................................................................................................

IEEE-488 Error Messages..

Error Indtcatmn

Control Selection ........................................................................................................................................

Selecting a Function ................................................................................................................................... 3-6

Selecting Gate and Delay Time

Setting Trigger Levels.. .............................................................................................................................. 3-8

Setting Input

Selecting The Number Of Displayed Digits..

Selecting Measurement Rate ..................................................................................................................... 3-10

Arming .......................................................................................................................................................... 3-l 1

Continuous Arming With the Input Signal..

Front Panel Arming ................................................................................................................................ 3-l 1

External Arming.. .................................................................................................................................... 3-l 1

Using Auto Trigger Level .......................................................................................................................... 3-12

Using V Peak A.. ......................................................................................................................................... 3-12

Using User Gate.. ........................................................................................................................................ 3-12

Using Delay ................................................................................................................................................. 3-13

Using User Delay ........................................................................................................................................ 3-13

Using Front Panel Set-ups .........................................................................................................................

Store Set-ups.. .......................................................................................................................................... 3-14

Recall Set-ups.. ........................................................................................................................................ 3-14

Using The External Reference. ................................................................................................................. 3-14

Changing The GPIB Address

Condition Controls .............................................................................................................

................................................................................................................

.........................................................................................

........................................................................................

.................................................................................................................... 3-14

3-3

3-3

3-3

3-4

:;i

3-5

3-8

3-9

3-10

3-l 1

3-14

4

4-l Introduction .................................................................................................................................................

4-2 Bus Desdription ...........................................................................................................................................

4-3

4-3-l Bus Management Lines ..........................................................................................................................

4-3-z Handshake Lines .....................................................................................................................................

4-3-3 Data Lines ................................................................................................................................................

4-4

4-5

4-6 Hardware Considerations..

4-6-l

4-6-2 Connections ............................................................................................................................................. J-5

4-7

4-8 Bus Commands ............................................................................................................................................

4-8-l

4-S-2

4-8-3 Addressed Commands ............................................................................................................................

4-8-4

4-8-5

4-9 Device-Dependent Command Programming

4-9-l Function (F) .............................................................................................................................................

IEEE-488 Programming

4-l

4-I

IEEE-488 Bus Lines ...................................................................................................................................

Interface Function Codes ...........................................................................................................................

Software Considerations.

Typical Controlled System ....................................................................................................................

Changing GPIB Address ............................................................................................................................

Uniline Commands

Universal Multiline Commands

Unaddress Commands ............................................................................................................................

Device Dependent Commands

........................................................................................................................... 4-4

........................................................................................................................ .-I-4

.............................................................................................................................. ...4-G

........................................................................................................... .4-7

.............................................................................................................

_.

....

....................................................................................

4.2

4-2

4-2

4-3

4-4

4-5

4-5

4-6

4-7

4-9

.4-9

4-9

4-9

Page 9

4-9-2

4-9-3

4-9-4

4-9-5

4-9-6

4-9-l

4-9-8

4-9-9

4-9-10

4-9-l 1

4-9-12

4-9-13

4-9-14

4-9-15

4-9-16

4-9-17

4-9-18

4-9-19

4-10

4-10-l

4-10-2

4-10-3

4-11

4-11-1

4-11-2

Channels A. B Coupling (AC. BC)

Channels A_ B Attenuator (AA, BA)

Channels A. B Filter (AF. BF)

Channels A: B Slope (AS. BS).

Channels A. B Impedance (AI. BI)

Channels A; B Trigger Level

Channels A, B Auto Trigger Level (L)

Gate Time (G, GLJ) ..................................................................................................................................

Delay Time (W, WU) .........................................................

V Peak Measurement Rate (V)

Totalize Mode (M) ..................................................................................................................................

Ratio Mode (C) ........................................................................................................................................

Displayed Digits (N) ...............................................................................................................................

Set-ups (ST. RE). .....................................................................................................................................

Triggering (T) ..........................................................................................................................................

Rate (S). ....................................................................................................................................................

Display Modes (D). .................................................................................................................................

SRQ Mode (Q) and Serial Poll

Reading From Model 776 ..........................................................................................................................

Data Control Commands (R)

Terminator

Prefix (X) ..................................................................................................................................................

Front Panel Error Messages ......................................................................................................................

ILL INS (Illegal Instruction).

ILL PAR (Illegal Parameter)

................................................................................................................................................

......................................................................................................

....................................................................................................

..............................................................................................................

.............................................................................................................

......................................................................................................

(AL.

BL)

...............................................................................................

................................................................................................

. ....................................................................

.............................................................................................................. 4-13

Status Byte Format.. .........................................................................

.................................................................................................................

................................................................................................................ 4-18

.................................................................................................................

4-11

4-12

4-12

4-12

4-12

4-12

4-12

4-12

4-12

4-13

4-13

4-13

4-13

4-l 3

4-13

4-14

4-14

4-15

4-15

4-l 6

4-17

4-l 8

4-18

5

5-l

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-9-l

5-9-2

5-9-3

5-10

5-10-l

5-10-2

5-10-3

S-10-4

5- 10-5

5-10-6

5-10-7

5-10-S

5-10-9

5-10-10

5-10-l 1

S-10-12

Maintenance and Performance Checks

Introduction .................................................................................................................................................

Line Voltage Selection ...............................................................................................................................

Fuse Replacement .......................................................................................................................................

Selecting an External Reference

Disassembly Instructions ...........................................................................................................................

Special Handling Of Static Sensitive Devices

Cleaning .......................................................................................................................................................

Repair and Replacement ............................................................................................................................

Performance Checks ...................................................................................................................................

Environmental Conditions .....................................................................................................................

Warm-up Period. ......................................................................................................................................

Recommended Test Equipment..

Performance Checks Procedure

Channels A and B Sensitivity Check

Channel C sensitivity Check

Period A. Period A Averaged Operation Check

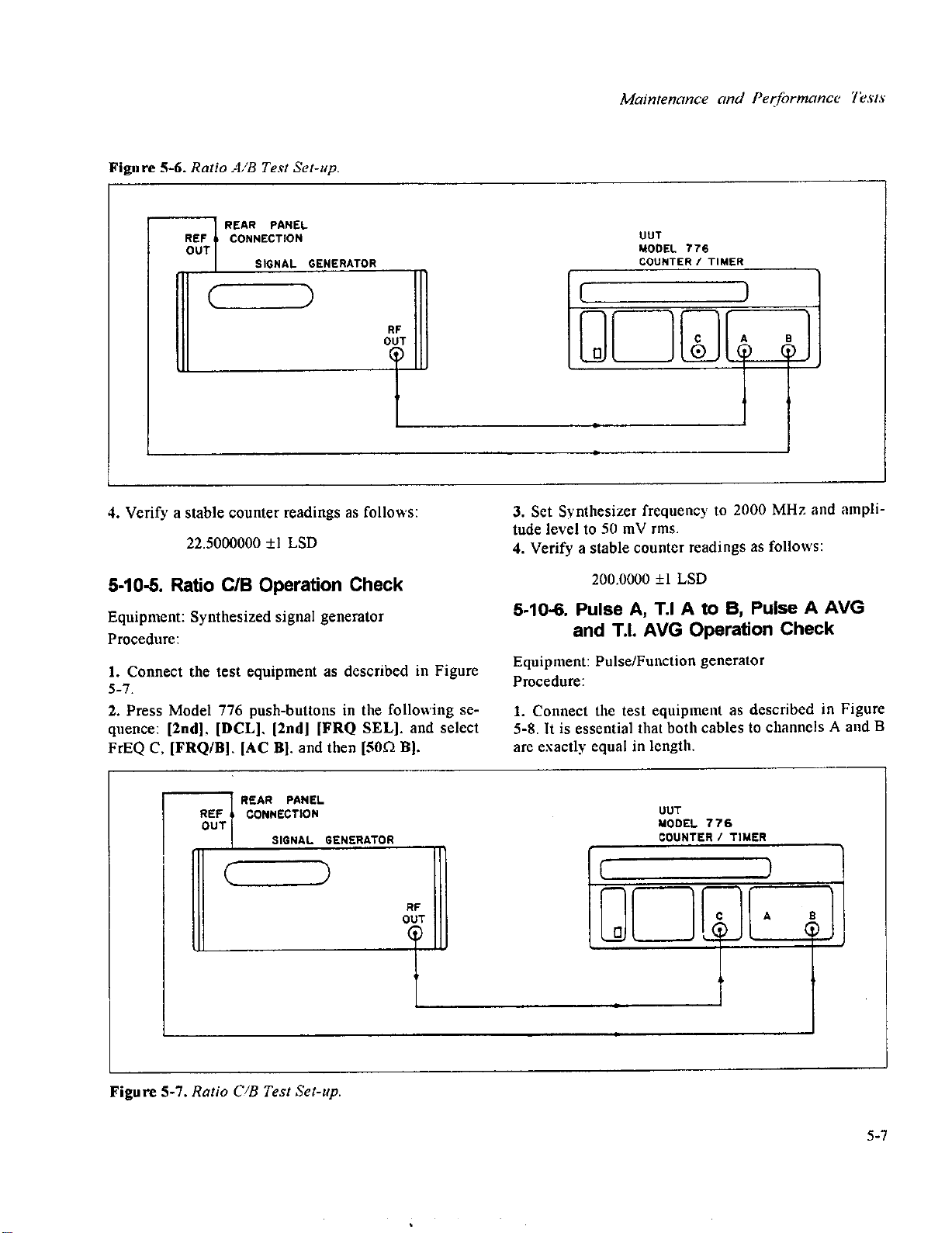

Ratio A/B Operation

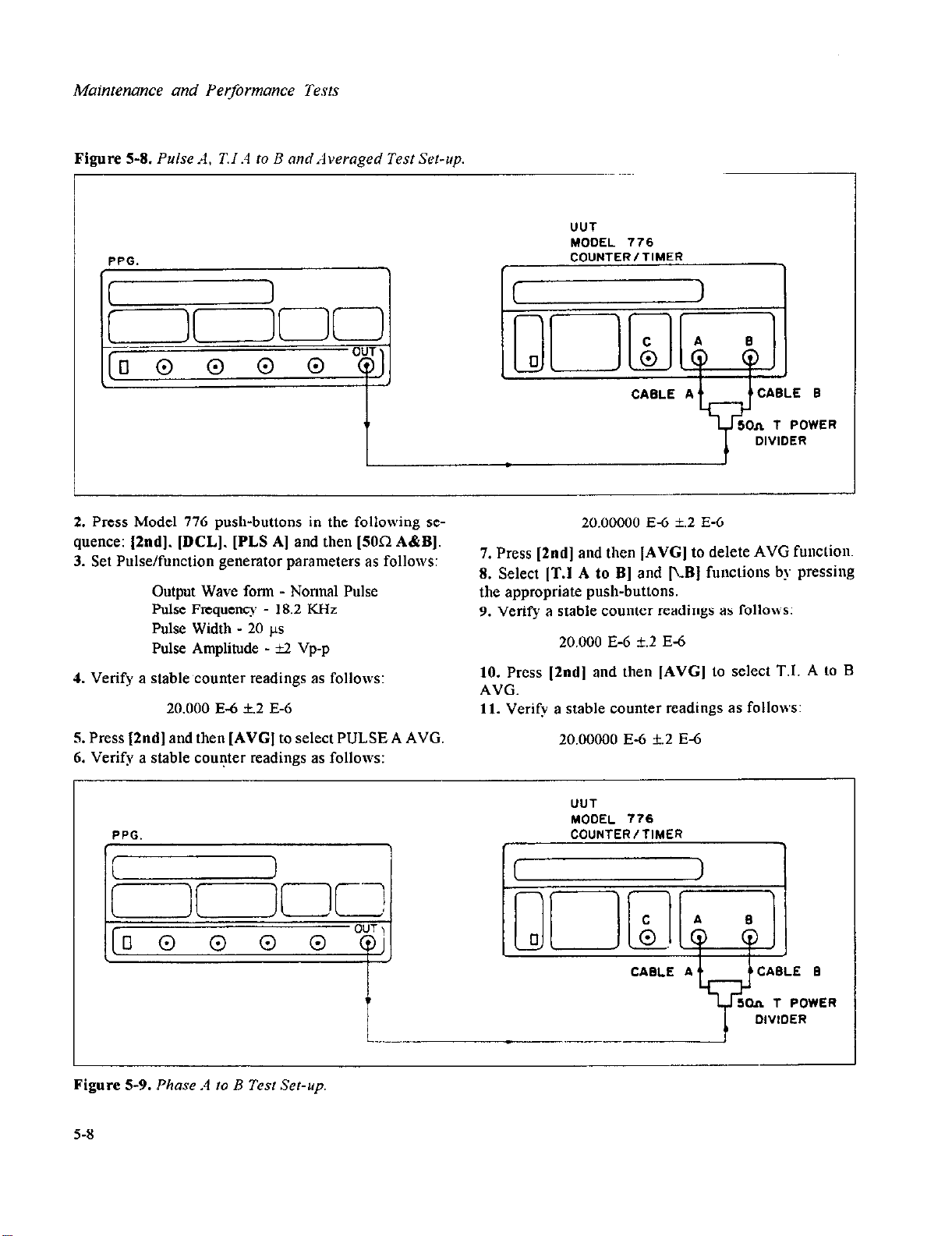

Ratio C/B Operation ...............................................................................................................................

Pulse A, T.1 A to B and Averaged Operation Check..

Phase A to B Operation Check ..............................................................................................................

Totalize B Operation Check

Auto Trigger Level A and B Operation Check

Delay Operation Check ..........................................................................................................................

User Gate Operation Check

Time Base Accuracy Check..

...............................................................................................................................

...............................................................................................................

........................................................................................

...........................................................................................................

.................................................................................................................

...................................................................................................

.................................................................................................................

.................................................................................

........................................................................

...................................................................................................................

...................................................................................

................................................................................................................... 5-l 1

.................................................................................................................

5-l

5-1

5-1

5-2

5-3

5-3

5-3

5-4

5-4

5-4

5-4

5-4

5-4

5-4

5-5

5-5

5-6

5-7

5-7

5-9

5-9

5-9

5-10

5-l 1

Page 10

6

6-l

6-2

6-3

6-3-l

6-3-2

6-3-3

6-3-4

6-3-5

6-367

6-4

6-4-l

6-4-2

6-4-3

6-4-4

6-4-S

Theory of Operation

Introduction .................................................................................................................................................

Overall Functional Description

Analog Circuitry

Input Circuits A and

Input Circuit C (option 2.4Ci).

10 MHz Standard Reference Oscillator

Reference Oscillator Circuit and TCXO (option 2.4G).

Measurement Logic Section

Power supply ...........................................................................................................................................

Digital Circuitry ..........................................................................................................................................

CPU Block Diagram

Memory Mapping ....................................................................................................................................

Address Decoding

KeyboardDisplay Interface

IEEE Interface .........................................................................................................................................

.........................................................................................................................................

B

...............................................................................................................................

...................................................................................................................................

................................................................................................................

.......................

..................................................................................................................

...................................................................................................................

. ...................................................................................................

...............................................................................................................

...............................................................................................

....................................................................

6-1

6-l

6-5

6-S

6-S

6-6

6-6

6-13

6-14

6-14

6-14

6-14

6-14

6-14

6-14

7

7-l

7-2

7-2-l

7-2-2

l-2-3

l-2-4

7-3

7-3-l

l-3-2

7-3-3

7-3-4

l-3-5

l-3-6

7-3-7

7-3-8

l-3-9

7-4

7-4-l

7-5

7-S-l

7-5-2

7-s-3

7-s-4

7-s-s

7-S-6

7-s-7

Adjustments and Troubleshooting

Introduction .................................................................................................................................................

Adjustments

Environmental Conditions.

Warm-up Period .......................................................................................................................................

Recommended Test Equipment

Adjustment Procedures

Adjustment Procedure ................................................................................................................................

Power Supply Adjustment

Trigger Level A Adjustment

Trigger Level B Adjustment

Trigger Level A Offset Adjustment

Trigger Level B Offset Adjustment

Input A xl0 High Frequency Adjustment

Input

Standard - S PPM Time Base Adjustment

TCXO.Time Base Adjustment (option 2.4G)

Troubleshooting

Recommended Test Equipment

Troubleshooting Procedure

Power Supply Checks

Digital Circuitry and Display Checks..

Standard S PPM Reference Oscillator Checks..

SO0 MHz Reference Oscillator and TCXO Checks

Trigger Level Checks

Signal Conditioning and Input Circuit Checks..

Measurement Logic

.................................................................................................................................................

....................................................................................................................

.............................................................................................................

..........................................................................................................................

.....................................................................................................................

..................................................................................................................

..................................................................................................................

......................................................................................................

......................................................................................................

...........................................................................................

B xl0 High Frequency Adjustment

..........................................................................................................................................

.............................................................................................................

.......................................................................................................................

.............................................................................................................................

.............................................................................................................................

Section Checks

............................................................................................

...........................................................................................

.....................................................................................

................................................................................................

.................................................................................

...........................................................................

.................................................................................

....................................................................................................

7-l

7-l

7-l

7-l

7-l

7-l

7-3

7-3

7-3

7-3

7-3

7-3

7-3

7-4

7-4

7-4

7-4

7-4

7-S

7-S

7-6

7-6

7-6

7-6

7-6

7-6

6

8-l

8-2 Ordering Information

8-3 Parts Description.. .......................................................................................................................................

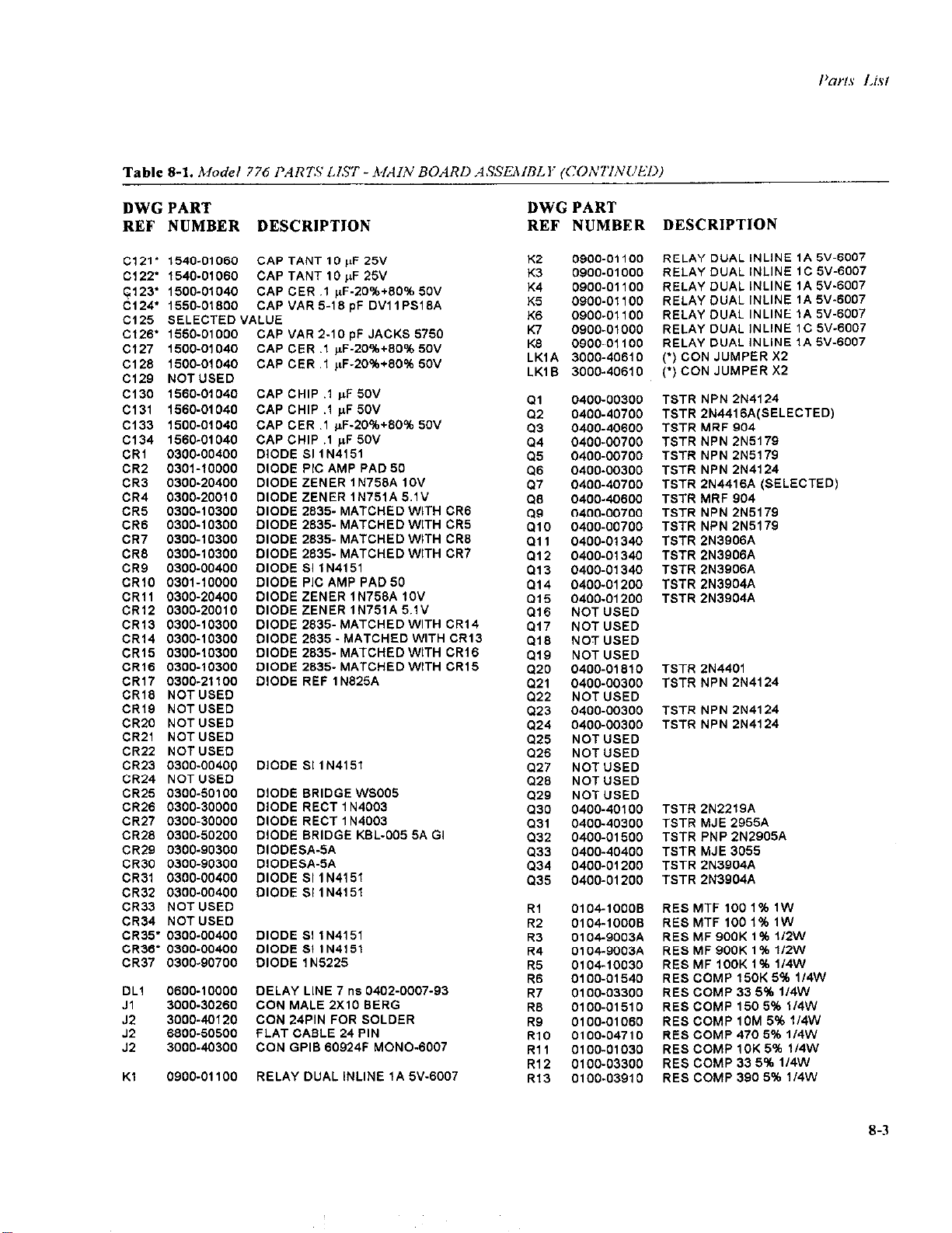

Parts List

General .........................................................................................................................................................

.................................................................................................................................

8-l

8-1

8-1

Page 11

General Information

l-l. Introduction

This manual provides operating and maintenance infor-

matron

Counter/Timer. Section 1 is a general description of the

instrument. Section 2 and 3 obtain installation and operating instructions. IEEE programming is explained in

Section 4. Maintenance and performance checks are

provided in Section 5. The theoF of operation is described in Section 6. Section 7 oullines calibration and

troubleshooting procedures. Section 8 contains tables of

replaceable parts. Section 9 contains schematic and

component location diagrams.

Model 776 is a Fen digit microprocessor based fullyprogrammable. three-channel Universal Counrcr I

Timer. The instrument mcasurcs with a vev high resolution and precision the following paramctcrs: Frcquency A. Frequency B. Frequency C. Period A. Pulsewidth. Time interval A to B. Total counts B. Ratio A/B.

Ratio C/B. Phase A to B and Amplitude peaks. An

averaging function is available for improved resolution

in time measurement: resohes intervals of pica seconds. Various repetitive tests. no matter how complex.

are greatly simplified b>~ utiliziog any of the IO pre-programmed front panel set-up. Set-ups are stored in a

non-volatile memory and can be recalled by a simple

ke.s stroke.

for

the

Model

716

Programmable

as low as 0.01 Hz to more than 225 MHz. The reciprocal

technique is being used in low frequency mcasurcmcnts.

up to exactly 120 MHz. where the measurement tcchnique is changed to conventional measurement tcchnique. Model 776 measures frcqucncies of input signals

with minimum resolution of nine digits in one second

of gate time. With the TCXO

776l2.46. the displayed result in largely enhanced. both

in terms of stability and accuracy.

In Model 776. the lraditionally featured decade

steps of gale times. are replaced by a more flerible

variable gate time. This feature permits a choice from

500 internally pre-selected gate interwls. or an! esternal gate intcnal which is applied to a rear panel BNC

conneclor. Internal gate times range from 100 ps to IO

s. External gate expands this range to 1000 s. Trigger

leveI my be selected maounll~~ or left to bc aulomalicall? adjusted. by the instrument. to the optimum level.

thus eliminating false lriggcring on unknown signals.

NOTE

This manual provides a complclc dcscription of all fcrturcs of the 776

Series. Therefore. several of the features that are described in the following paragraphs may not be installed

in your instrument.

time

base of the Model

Model 776 utilizes a combination of two measurement techniques in order to always achieve maximum

display resolution. Some functions. such as Frequent!

measurement function. can be displayed with up to ten

digits. Such resolution can be gained from frequencies

1-2. Instrument Identification

These KeithIcy’ instmmcnts are identified by a serial

number. which is located on lhe rear panel. The lvo

most significant digits (Txs) identify instrumcnl modi-

I-I

Page 12

•

•

•

General Information

fication. If this prefix differs from that listed on the title

page of this manual, there are differences between this

manual and your instrument.

1-3. Configuration

There are two configurations available for the Model 776:

Model 776 - Two-channel 225 MHz programmable

counter/timer.

Model 776/2.4G - Same as above with 2.4 GHz Channel C and TCXO time base.

Model 776/2.4G/R - Same as above with rear panel

inputs.

1-4. Warranty Information

Warranty information is located on the inside front cover

of this instructions manual. Should your Model 776

require warranty service, contact the Keithley representative or authorized repair facility in your area for further

information. When returning the instrument for repair, be

sure to fill out and include the service form at the back of

this manual to provide the repair facility with the necessary information.

1-5. Manual Addenda

Any improvements or changes concerning the instrument

or manual will be explained in an addendum included with

the manual. Be sure to note these changes and incorporate

them into this manual.

1-6. Safety Symbols And Terms

The following symbols and terms may be found on an

instrument or used in this manual.

!

The symbol on an instrument indicates that the user

should refer to the operating instructions located in the

manual.

The WARNING heading used in this manual explains

dangers that might result in personal injury or death.

Always read the associated information very carefully

before performing the indicated procedure.

The CAUTION heading used in this manual explains

hazards that could damage the instrument. Such damage

may invalidate the warranty.

1-7. Inspection

The Model 776 was carefully inspected, both electrically

and mechanically before shipment. After unpacking all

items from the shipping carton, check for any obvious

signs of physical damage that may have occurred during

transit. (Note: There may be a protective film over the

display lens, which can be removed.) Report any damage

to the shipping agent immediately. Save the original

packing carton for possible future re-shipment. The

following items are included with every Model 776 order:

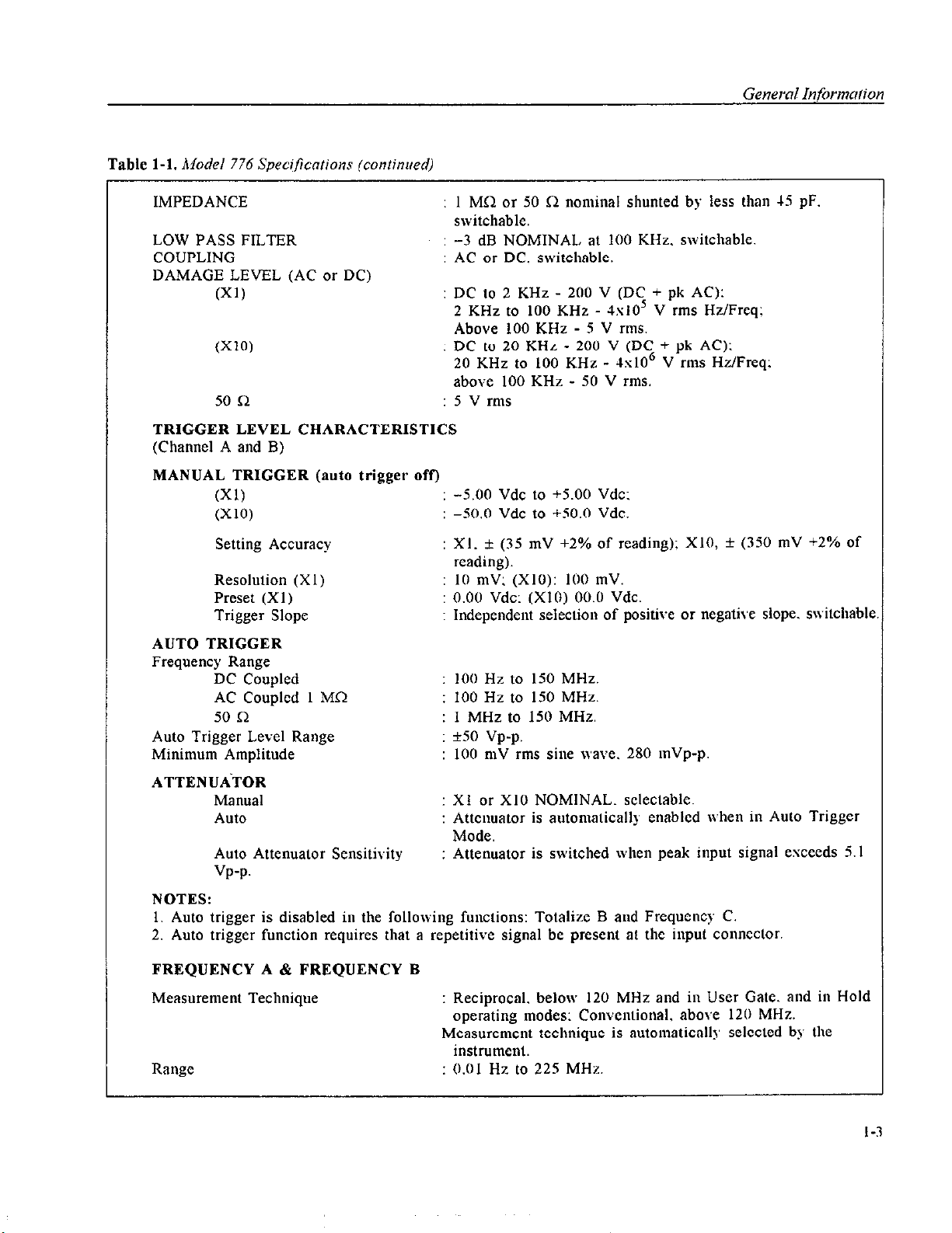

Table 1-1. Model 776 Specifications

INPUT CHARACTERISTICS

(Channel A & B)

RANGE

DC coupled

AC coupled 1 M Ω

50 Ω

SENSITIVITY (X1)

0 to 200 MHz

200 MHz to 225 MHz

5 ns Minimum Pulse Width

SIGNAL OPERATING RANGE

(X1)

(X10)

DYNAMIC RANGE (x1)

0 to 100 MHz

100 MHz to 225 MHz

Page 1-2

: 0 to 225 MHz.

: 30 Hz to 225 MHz.

: 1 MHz to 225 MHz.

: 50 mV rms sine wave.

: 75 mV rms sine wave.

: 75 mVp-p.

: -5.00 Vdc to +5.00 Vdc.

: -50.0 Vdc to +50.0 Vdc.

: 75 mV to 5 Vp-p.

: 150 mV to 2.5 Vp-p.

Page 13

Table l-l.

Model 776 Specificntions (continued)

IMPEDANCE

: 1 MQ or 50 .Q nominal shunted by less than 4.5 pF.

switchable.

LOW PASS FILTER : -3 dB NOMINAL at 100 KHz. switchable.

COUPLING

: AC or DC. switchable.

DAMAGE LEVEL (AC or DC)

(Xl)

: DC to 2 KHz - 200 V (DC + pk AC):

2 KHz to 100 KHz - lsi05 V rms Hz/Freq:

Above 100 KHz - S V rms.

(X10)

: DC to 20 KHz - 200 V (DC + pk AC):

20 KHz to 100 KHz - 4~10~ V rms Hz/Freq:

abo\:e 100 KHz - 50 V rms.

50 R

: 5 v rms

TRIGGER LEVEL CHARACTERISTICS

(Channel A and B)

MANUAL TRIGGER (auto trigger off)

(Xl)

(X10)

: -5.00 Vdc to +5.00 Vdc:

: -50.0 Vdc to i50.0 Vdc.

Setting Accuracy : Xl. * (35 mV +2% of reading): X10, + (350 mV +2% of

reading).

Resolution (X 1) : 10 mV: (X10): 100 tnV.

Preset (Xl) : 0.00 Vdc: (X10) 00.0 Vdc.

Trigger Slope

: Independent selection of positive or negative slope. switchable

AUTO TRIGGER

Frequency Range

DC Coupled : 100 Hz to 150 MHz.

AC Coupled 1 MO : 100 Hz to 150 MHz.

50 n

: 1 MHz to 150 MHz.

Auto Trigger Level Range : 150 vp-p.

Minimum Amplitude : I00 mV rms sine wave. 280 mVp-p.

ATTENUATOR

Manual

: X1 or Xl0 NOMINAL. selectable.

Auto : Attenuator is automalically enabled when in Auto Trigger

Mode.

Auto Attenuator Sensitivity : Attenuator is switched when peak input signal exceeds 5. I

VP-P.

NOTES:

1. Auto trigger is disabled in the following functions: Totalize B and Frequency C.

2. Auto trigger function requires that a repetitive signal be present at the input connector.

FREQUENCY A & FREQUENCY B

Measurement Technique : Reciprocal. below I20 MHz and in User Gate. and in Hold

operating modes: Conventional, above I20 MHz.

Measurement technique is automatically selected by the

instrument.

Range : 0.01 Hz to 225 MHz.

1-3

Page 14

General Information

Table l-l.

Model 776 Specifications (continued)

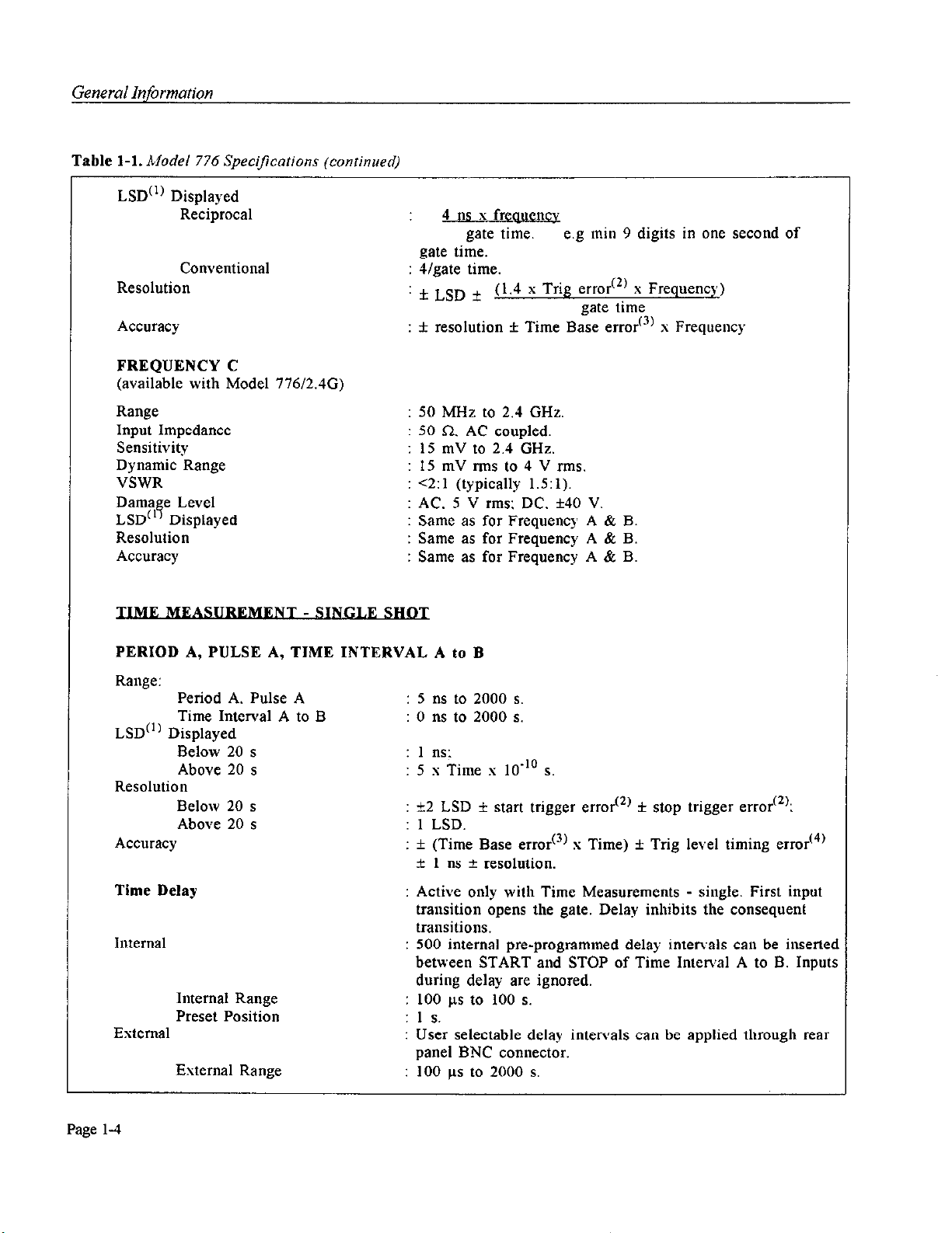

LSD(‘) Displayed

Reciprocal

Conventional

Resolution

Accuracy

FREQUENCY C

(available with Model 776/2.46)

Range

Input Impedance

Sensitivity

Dynamic Range

VSWR

Dama e Level

7

LSD(’ Displayed

Resolution

Accuracy

4

ns s freaw

gate time.

e.g min 9 digits in one second of

gate time.

l/gate time.

* LSD * (1.4 x Trig errorc2) s Frequency)

gate time

i resolution i Time Base error’3’ s Frequent)

50 MHz to 2.4 GHz.

SO .f2. AC coupled.

15 mV to 2.4 GHz.

15

mV rms to 4 V rms.

<2:1 (typically l.S:l).

AC. 5 V rms: DC. f40 V.

Same as for Frequency A & B.

Same as for Frequency A & B.

Same as for Frequency A & B.

PERIOD A, PULSE A, TIME INTERVAL A to B

Range:

LSD(‘)

Period A. Pulse A

Time Interval A to B

Displayed

Below 20 s

Above 20 s

5 ns to 2000 s.

0 ns

to

1 ns:

5 s Time s 10.” s.

Resolution

Below 20 s

Above 20 s

Accuracy

+2 LSD + start trigger error@) i stop trigger error?

; LSD.

f (Time Base errorc3)

f 1 ns * resolution.

Time Delay

Active only with Time Measurements - single. First input

transition opens the gate. Delay inhibits the consequent

transitions.

Internal

500 internal pre-programmed delay intervals can be inserted

between START and STOP of Time Interval A to B. Inputs

during delay are ignored.

Internal Range

Preset Position

External

100 ps to 100 s.

1 s.

User selectable delay intervals can be applied through rear

panel BNC connector.

External Range

100 ps

to

2000 s.

2000 s.

1 Time) i Trig level timing error

(4)

Page l-4

Page 15

General Information

Table l-l.

Model 776 Specijjcotions (continued)

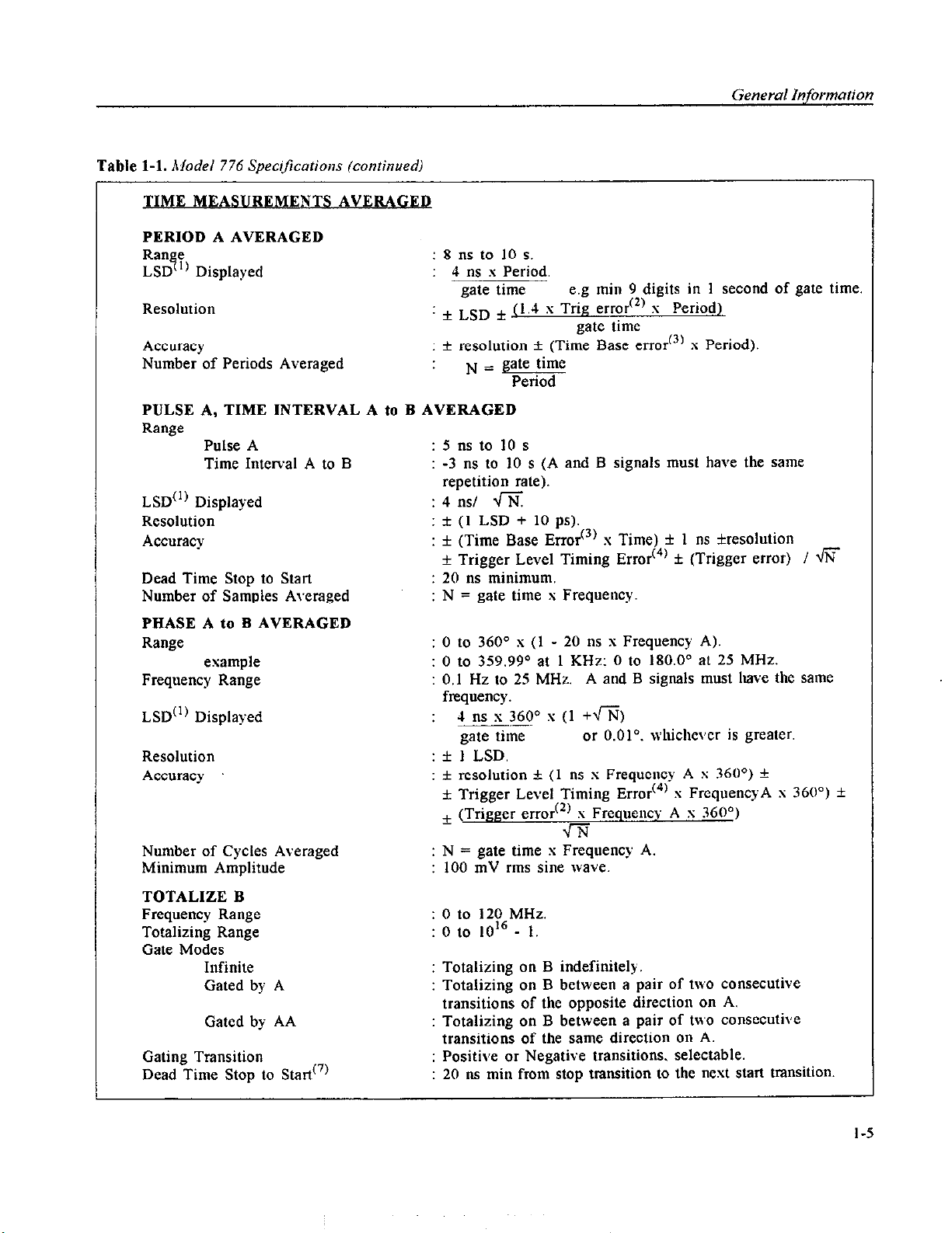

TIME MEASUREMENTS AVERAGED

PERIOD A AVERAGED

&!?‘) Displayed

Resolution

Accuracy

Number of Periods Averaged

PULSE A, TIME INTERVAL

Range

Pulse A

Time Interval A to B

LSD(‘) Displayed

Resolution

Accuracy

Dead Time Stop to Start

Number of Samples Averaged

: 8 ns to 10 s

: 4 ns s Period.

gate time

: f LSD * il.4 s Trig error(‘) s Period)

It resolution + (Time Base errorc3) s Period).

A to B AVERAGED

5 ns to 10 s

-3 ns to 10 s (A and B signals must have the same

repetition rate).

4 ns/ J

3~ (1 LSD + 10 ps).

+ (Time Base Error”) x Time) zt 1 ns i!resoiution

+ Trigger Level Timing Errorc4) f (Trigger error) / fi

20 ns minimum.

N = gate time s Frequency.

e.g miu 9 digits in 1 second of gate time.

eate time

PHASE A to B AVERAGED

Range

example

Frequency Range

LSD(‘) Displayed

Resolution

Accuracy

Number of Cycles Averaged

Minimum Amplitude

TOTALIZE B

Frequency Range

Totalizing Range

Gate Modes

Infinite

Gated by A

Gated by AA

Gating Transition

Dead Time Stop to Sta#)

0 to 360” s (1 - 20 ns s Frequency A).

0 to 359.99O at 1 KHz: 0 to 180.0’ at 25 MHz.

0.1 Hz to 25 MHz. A and B signals must have the same

frequency.

4 ns s 360’ s (1 +fi)

gate time

or 0.01”. whichever is greater.

+ 1 LSD.

k resolution f (1 ns s Frequency A s 360’) *

It Trigger Level Timing

+ (Trigger error

(2) s Frequency A s 36OO)

(4) s FrequencyA x 360”) ?

Error

\iN

N = gate time s Frequency A.

100 mV rms sine wave.

0 tn 120 MHz.

0 to lOI - 1.

Totalizing on B indefinitely.

Totalizing on B between a pair of two consecutive

transitions of the opposite direction on A.

Totalizing on B between a pair of two consecutive

transitions of the same direction on A.

Positive or Negative transitions. selectable.

20 ns min from stop transition to the nest start transition.

1-5

Page 16

General Information

Table l-l.

Model

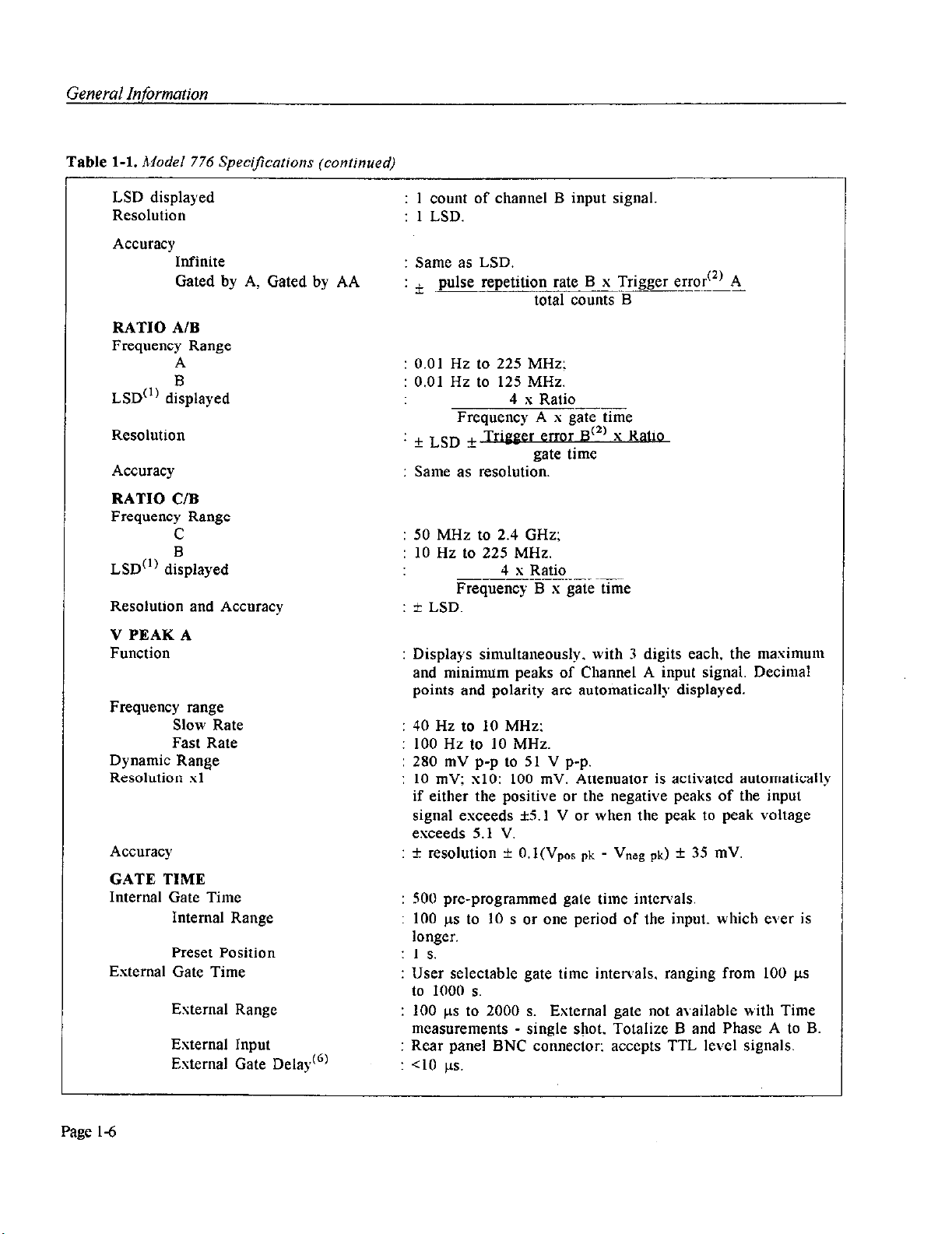

LSD displayed

Resolution

Accuracy

Infinite

Gated by A, Gated by AA

RATIO AIB

Frequency Range

A

B

LSD(‘) displayed

Resolution

Accuracy

RATIO C/B

Frequency Range

C

B

LSD(‘) displayed

Resolution and Accuracy

776

Specifications (continued)

: 1

count

of channel B input signal.

: 1 LSD.

: Same as LSD.

: * pulse repetition rate B x Trigger error(2) A

total counts B

: 0.01 Hz to 225 MHz:

: 0.01 Hz to 125 MHz.

4 x Ratio--__

Frequency A s gat;z:‘”

: + LSD ,Trieeer B x Ratio

gate time

: Same as resolution.

: SO MHz to 2.4 GHz;

: 10 Hz to 225 MHz.

4 s Ratio

Frequency B s gate time

: k LSD.

V PEAK A

Function

Frequency range

Slow Rate

Fast Rate

Dynamic Range

Resolution xl

Accuracy

GATE TIME

Internal Gate Time

Internal Range

Preset Position

External Gate Time

External Range

External Input

External Gate Delay(‘)

: Displays simultaneously. with 3 digits each, the maximum

and minimum peaks of Channel A input signal. Decimal

points and polarity are autotiaticallg displayed.

: 40 Hz to 10 MHz:

: 100 Hz to 10 MHz.

: 280 mV p-p to 51 V p-p.

: 10 mV: x10: 100 mV. Attenuator is activated automalically

if either the positive or the negative peaks of the input

signal exceeds fS.l V or when the peak to peak voltage

exceeds 5.1 V.

: + resolution i O.l(Vpas pli - Vneg & * 35 mV.

: 500 pm-programmed gate time intervals.

: 100 ps to 10 s or one period of the input. which ever is

longer.

: 1 s.

: User selectable gate time intemals. ranging from 100 ps

to 1000 5.

: 100 ps to 2000 s. External gate not available with Time

measurements - single slmt. Totalize B and Phase A to B.

Rear panel BNC connector: accepts TTL level signals.

j cl0 ps.

Page l-6

Page 17

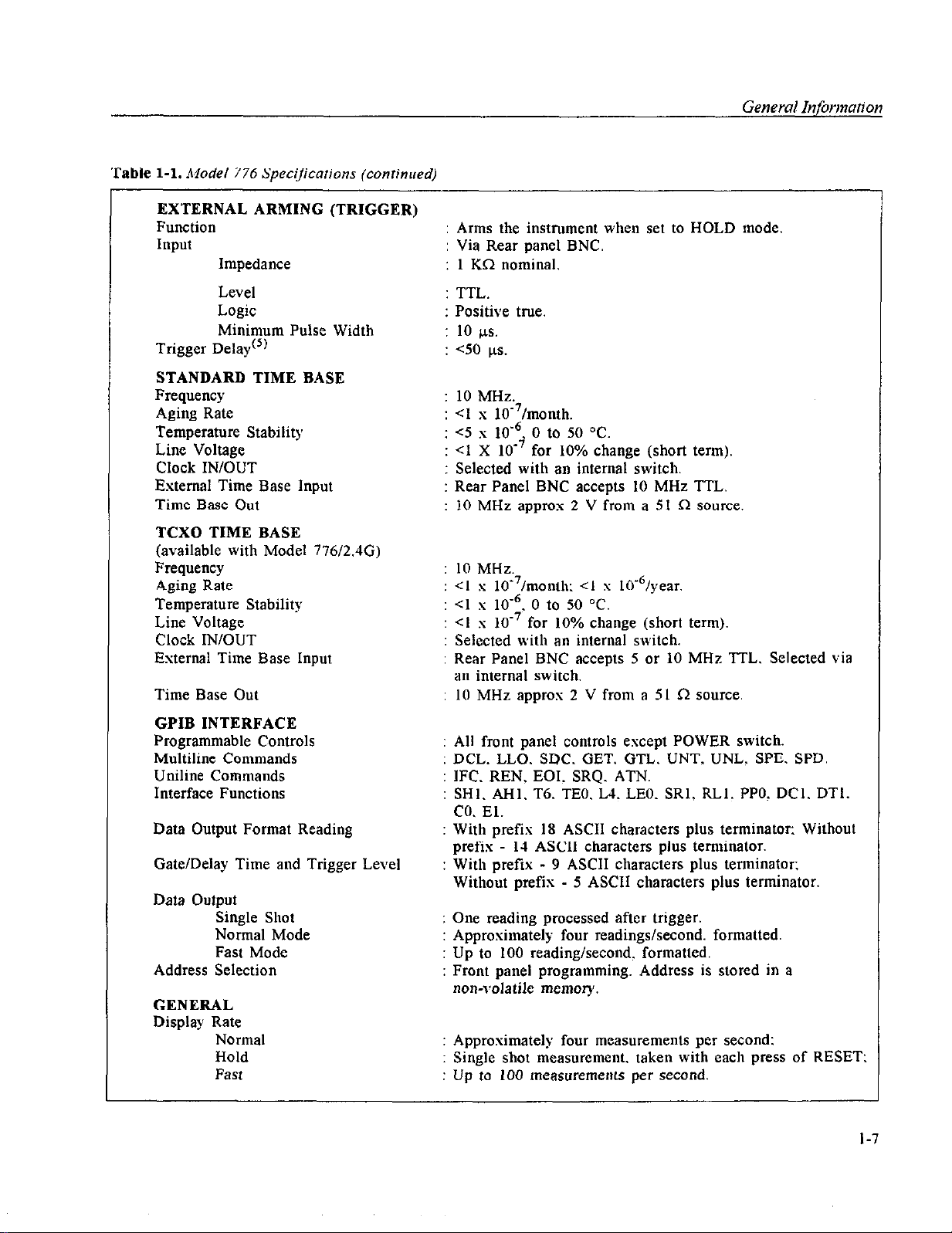

Table l-l. A,fodel 776

EXTERNAL ARMING (TRIGGER)

Function

I”PUl

Impedance

.Speci@?tions (continued)

Arms the instrument when set to HOLD mode

Via Rear panel BNC.

1 KC2 nominal.

Level

Logic

Minimum Pulse Width

Trigger Delay(‘)

STANDARD TIME BASE

Frequency

Aging Rate

Temperature Stabilit)

Line Voltage

Clock IN/OUT

External Time Base Input

Time Base Out

TCXO TIME BASE

(available with Model 776/2.46)

Frequency

Aging Rate

Temperature Stability

Line Voltage

Clock IN/OUT

External Time Base Input

Time Base Out

GPIB INTERFACE

Programmable Controls

Multiline Commands

Uniline Commands

Interface Functions

Data Output Format Reading

Gate/Delay Time and Trigger Level

Data Output

Single Shot

Normal Mode

Fast Mode

Address Selection

GENERAL

Display Rate

Normal

Hold

Fast

TTL.

Positive true

10 ps.

<SO ps.

10 MHz.

<I s IO-‘/month.

<5 s 10’6 0 to 50 “C.

<I X 10.’ for 10% change (short term).

Selected with an internal switch.

Rear Panel BNC accepts 10 MHz TTL.

10 MHz appros 2 V from a 51 0 source.

10 MHz.

<I s lO~‘/month: <I x 10e6/year.

Cl s 10‘6. 0 to 50 “C.

<I s 10“‘for 10% change (short term).

Selected with an internal switch.

Rear Panel BNC accepts 5 or 10 MHz ‘ITL. Selected via

an internal switch.

10 MHz appros 2 V from a 51 n source.

: All front panel controls except POWER switch.

: DCL. LLO. SDC. GET. GTL. UNT. UNL> SPE. SPD.

: IFC. REN. EOI. SRQ. ATN.

: SHl. AHl. T6. TEO. L4. LEO. SRI, RLI. PPO. DCI. DTI.

CO. El.

: With prefix 18 ASCII characters plus terminator: Without

prefix - 1-t ASCII characters plus terminator.

: With prefix - 9 ASCII characters plus terminator;

Without prefix - 5 ASCII characters plus terminator.

One reading processed after trigger.

Approximately four readings/second. formatted.

Up to 100 reading/second. formatted.

Front panel programming. Address is stored in a

non-volatile memory.

Approximately four measurements per second:

Single shot measurement. taken with each press of RESET:

Up to 100 measuremeals per second.

Page 18

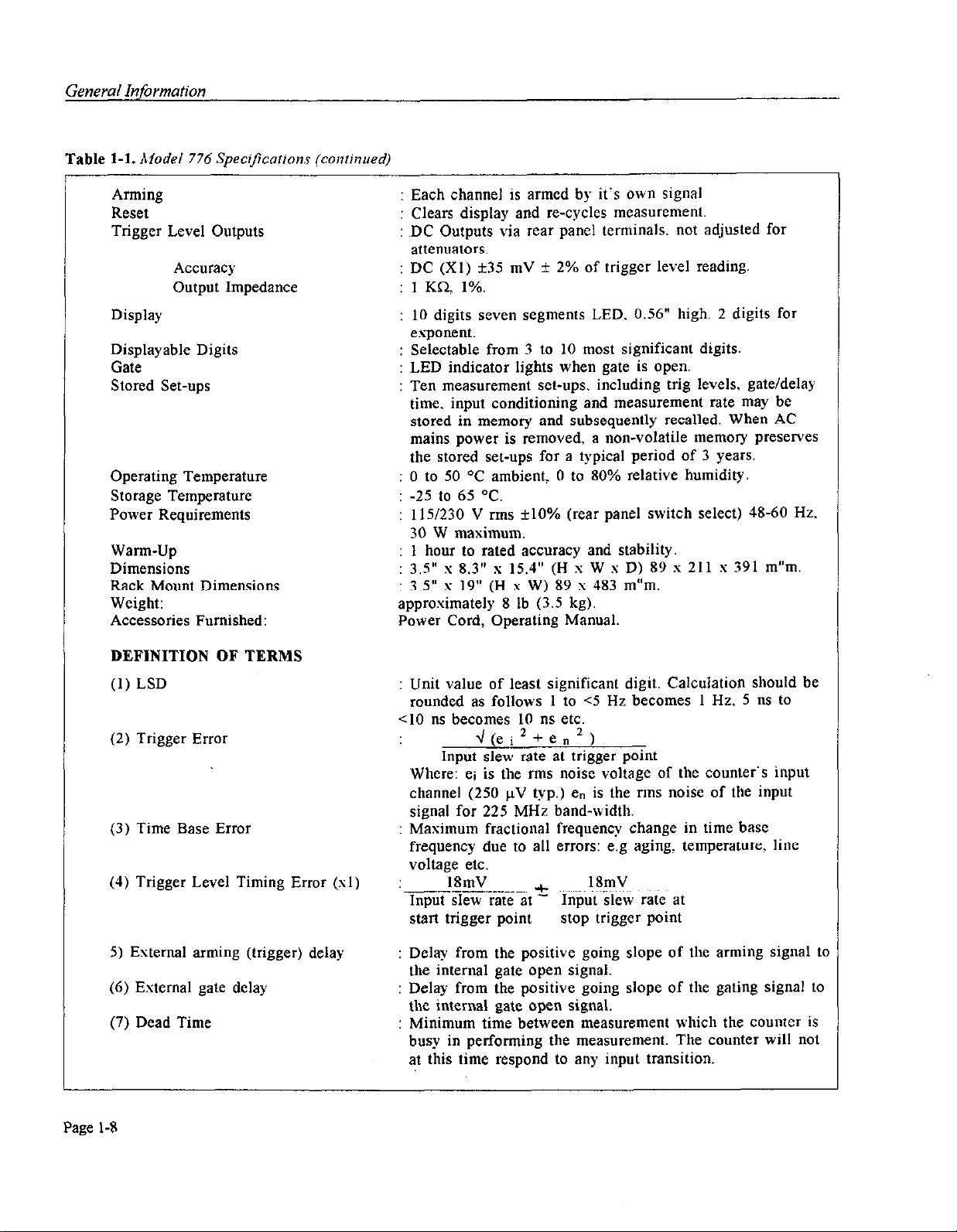

Table l-1.

Model 776 SpeciJiconons (continued)

Arming

Reset

Trigger Level Outputs

: Each channel is armed by it’s own signal

: Clears display and re-cycles measurement.

: DC Outputs via rear panel terminals. not adjusted for

attenuators.

Accuracy

: DC (Xl) *35 mV * 2% of trigger level reading.

Output Impedance : 1 KQ 1%.

Display

: 10 digits seven segtnents LED. 0.56” high. 2 digits for

exponent.

Displayable Digits : Selectable from 3 to 10 most significant digits.

Gate : LED indicator lights when gate is open.

Stored Set-ups : Ten measurement set-ups. including trig levels, gate/delay

time. input conditioning and measurement rate may be

stored in memory and subsequently recalled. When AC

mains power is removed. a non-volatile memory preserves

the stored set-ups for a typical period of 3 years.

Operating Temperature : 0 to 50 OC ambient. 0 to 80% relative humidity.

Storage Temperature

Power Requirements

: -25 to 65 “C.

: llY230 V rms &lo% (rear panel switch select) 48-60 Hz.

30 W maximum.

Warm-Up : I hour to rated accuracy and stability.

Dimensions

Rack Mount Dimensions

Weight:

Accessories Furnished:

: 3.5” s 8.3” s 15.4” (H s W s D) 89 s 211 s 391 m”m.

: 3.5” s 19” (H s W) 89 x 483 m”m.

approximately 8 lb (3.5 kg).

Power Cord, Operating Manual.

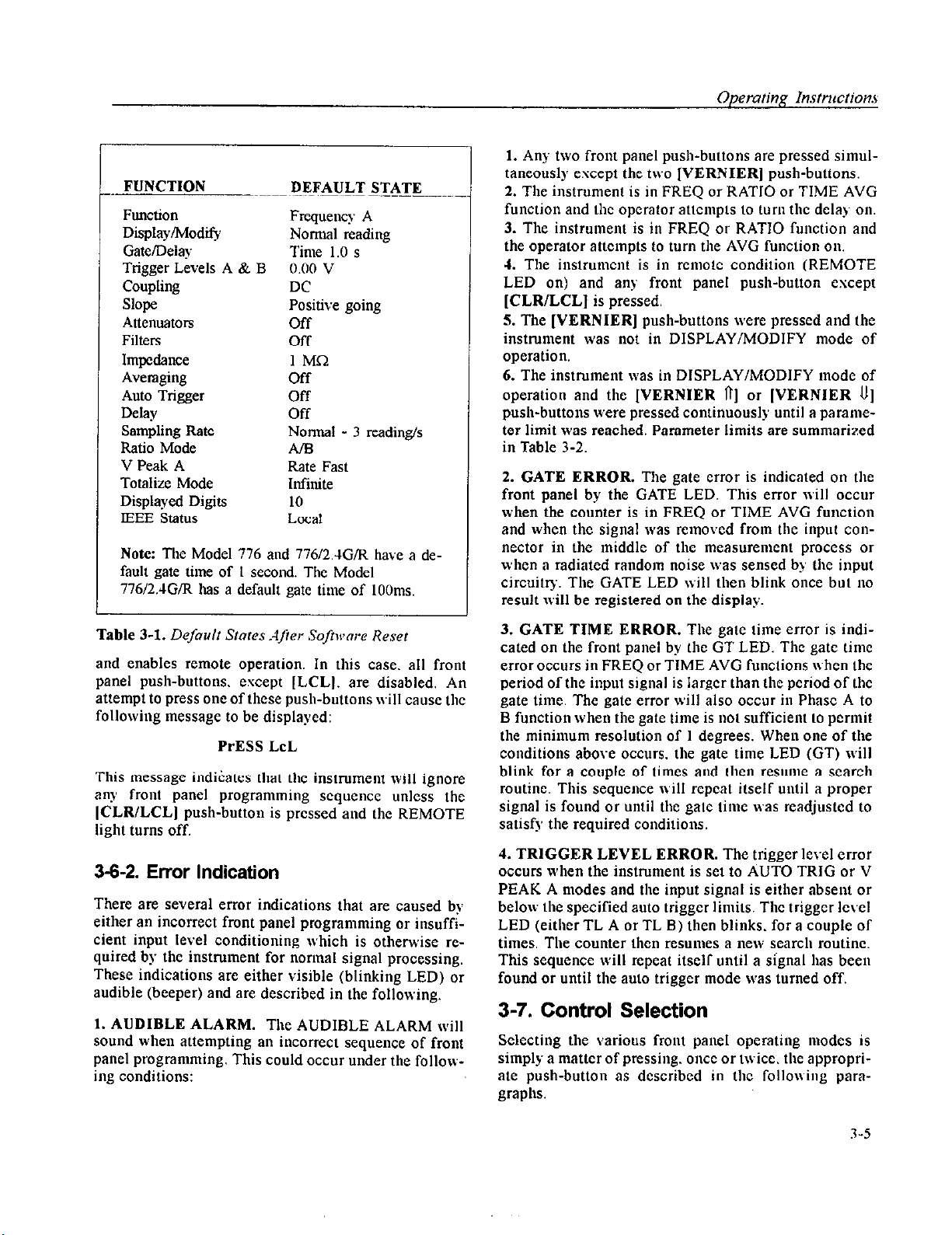

DEFINITION OF TERMS

(1) LSD : Unit value of least significant digit. Calculation should be

rounded as follows 1 to <5 Hz becomes I Hz. 5 ns to

cl0 ns becomes 10 ns etc.

(2) Trigger Error

d(ei*+On*)

Input slew rate at trigger point

Where: ei is the rms noise voltage of the counter‘s input

channel (250 pV typ.) en is the rms noise of the input

signal for 225 MHz band-width.

(3) Time Base Error

: Maximum fractional frequency change in time base

frequency due to all errors: e.g aging. temperature. line

voltage etc.

(4) Trigger Level Timing Error (xl)

:

18mV

_.~~ + ~?rnV

Input slew rate at - Input slew rate at

start trigger point stop trigger point

5) External arming (trigger) delay

: Delay from the positive going slope of the arming signal to

the internal gate open signal.

(6) External gate delay

: Delay from the positive going slope of the gating signal to

the internal gate open signal.

(7) Dead Time

: Minimum time between measurement which the counter is

busy in performing the measurement. The counter will not

at this time respond lo any input transition.

Page l-8

Page 19

l

Model 776 Programmable CounterfIimer with line

cord.

. Model 776 Instructions Manual.

If an additional manual is required, order:

. Keithley part number 776-901-00.

1-8. Specifications

Instrument specifications are listed in Table I-l. These

specifications are the performance standards or limits

against which the instrument is tested.

General Informnlion

NOTE

All specifications in the following

table apply after a warm-up period of

1 hour and at ambient temperature of

25Y f50C.

1-9

Page 20

Installation

2-1. Introduction

This section contain information and instructions necessary for the installation and shipping of the Model

776. Details are providedforpowerconnection. grounding safety requirements. installation information. and

x-packing instructions for storage or shipment.

2-2. Performance Checks

The instrument was carefully inspected for mechanical

and electrical performance before shipment from the

factory. It should be free of physical defects and in

perfect electrical order upon receipt. Check the instrument for damage in transit and perform the electrical

procedures outlined in Section 5. If there is indication

of damage or deficiency. see the warranty in this manual

and notify your local Keithley field engineering representative or the factory

CAUTION

It is recommended that the operator

be fully familiar with the specifica-

tions and all sections of this manual.

Failure to do so may compromise the

warranty and the accuracy which

Keithley has engineered into your instrument.

2-3. Power Requirements

The instrument may be operated from any one of the

following sources: a. 103.5 to 126.5 Volts (1 IS Volts

nominal) b. 207 to 253 Volts (230 Volts nominal).

The instrument operates over the power mains frcquency range of 18 to 63 Hr. Always verify that the

operating power mains voltage is the same as that specified on the rear panel voltage selector switch.

CAUTION

Failure to switch the instrument to

match the operating line voltage will

damage the instrument and may void

the warranty.

The instrument should be operated

from a power source with its neutral

at or near ground (earth potential).

The instrument is not intended for

operation from two phases of a

multi-phase ac sqstcm or across the

legs of a single-phase. three-wire ac

power system. Crest factor (ratio of

peak voltage to rms) should be typi-

cally within the range of 1.3 to I.6

at 10% of the nominal rms mains

voltage.

24. Grounding Requirements

To insure the safety of operating personnel. the U.S.

O.S.H.A. (Occupational Safety and Health) rcquirement and good engineering practice mandate that the

instrument panel and enclosure be “earth” grounded.

All Keithley instruments are provided with an Uuderwriters Laboratories (U.L. and V.D.E) listed lhrec-conductor power cable. which when plugged into an appropriate power rcceptaclc. grounds the instrument.

2-l

Page 21

The long offset pin on the male end of the power cable

carries the ground wire to the long pin of the receptacle

on the rear panel of the instrument.

CAUTION

To avoid operator shock hazard do

not exceed the power mains voltage

frequency rating which limits the

leakage current between case and

powr mains. Never expose the instrument to rain. excessive moisture,

or condensation.

2-5. Installation And Mounting

tective covering such as a plastic bag or strong krali

paper. Place power cable and other accessories with

the instrument. Store the cowred voltmeter in a clean

dry area that is not subject to extreme temperature varta&s or conditions which may cause moisture to condense on the instrument.

2-10. Long Term Storage Or

Re-Packing For Shipment

If the instrument is to be stored for a long period or

shipped. proceed as directed below. If you have any

questions ccmtact your local Keilhley field engineering

representative or the Keithlcy Scwice Department at

the factory.

The instrument is fully solid state and dissipates only

a small amonnt of power. No special cooling is required.

However. the instrument should not be operated where

the ambient temperature exceeds 50°C. when the relative humidity exceeds 80% or condensation appears

anywhere on the instrument. Avoid operating the in-

strument close to strong magnetic fields which may

be found near high power equipment such as motors.

pumps. solenoids. or high power cables. Use care when

rack mounting to locate the instrument away from

sources of excessive heat or magnetic fields. Always

leave 1 cm (1.5 inches) of ventilation space on all

sides of the instrument.

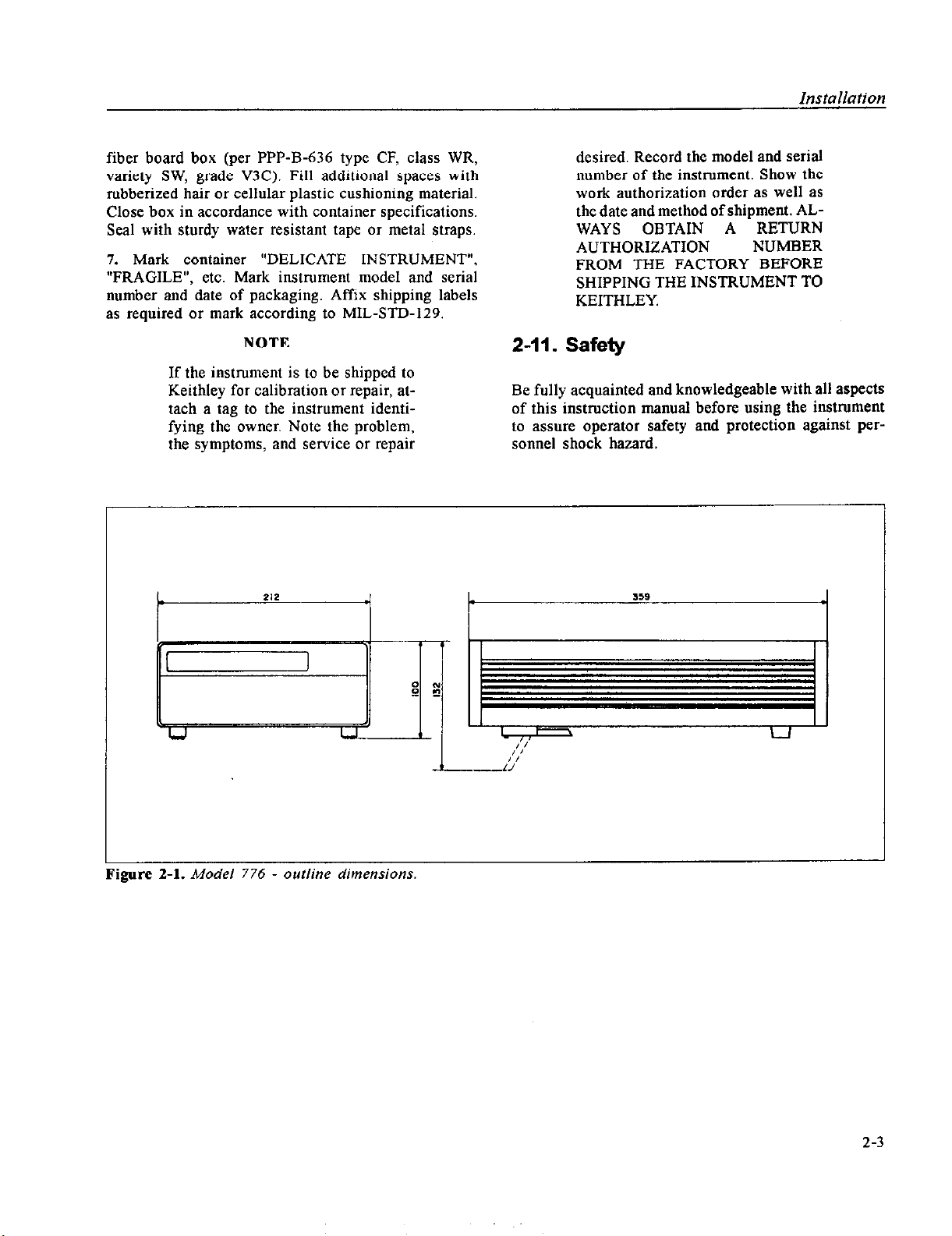

2-9. Bench Mounting

The instrument is shipped with plastic feet. tilt stand

in place and ready for use as a bench or portable in-

strument. See outline drawing Figure 2-l for dimen-

smns.

2-7. Rack Mounting

The instrument may be rack mounted in a standard 19

inch EIA rack. The instrument may be rack mounted

in Rack Mount Kit option Rack.

2-9. Portable Use

The instrument may be used in applications requiring

portability. A tilt stand consisting of two retractable

legs is provided with each unit.

2-9. Short Term Storage

If the instrument is to be stored for a short period of

time (less than three months). place cardboard over

the panel and cover the instrument with suitable pro-

If the original Keithley supplied packaging is to

be used proceed as follows:

1. If the original wrappings. packing material. and container have been saved. *e-pack the instrutnent and accessories originally shipped to you. If the original container is not wailablc. one may be purchased through

the Keithley Service Department at the factory.

2. Be sure the carton is well sealed with strong tape

or metal straps.

3. Mark the carton with the model number and serial

number with indelible marking. If it is to bc shipped.

show sending address and return address cm two sides

of the box: cover all previous shipping labels.

If the original container is not available. proceed

as follows:

1. Before packing the unit. place all accessories into

a plastic bag and seal the bag.

2. For extended storage or long distance shipping only.

use U.S. govermnent packing method II C and tape a

two-unit bag of desiccant (per MIL-D-3164) on the

rear cover.

3. Place a I3 cm (5 inch) by Xl cm (I2 inch) piece

of sturdy cardboard over the front panel for protection.

4. Place the counter into a plastic bag and seal the

bag.

5. Wrap the bagged instrument and accessories in one

inch thick flexible cellular plastic film cushioning material (per PPP-C-795) and place in a barrier bag (per

MIL-B-131). Extract the air from bag and heat seal.

6. Place bagged instrument and acccssorics into a 250

mm (10 inch) s 360 mm (I-I inch) s SO8 mm (20 inch)

2-2

Page 22

Installation

fiber board box (per PPP-B-636 type CF, class WR,

variety SW, grade V3C). Fill additional spaces with

rubberized hair or cellular plastic cushioning material.

Close box in accordance with container specifications.

Seal with sturdy water resistant tape or metal straps.

7. Mark container “DELICATE INSTRUMENT”,

“FRAGILE”, etc. Mark instrument model and serial

number and date of packaging. Affix shipping labels

as required or mark according to MIL-STD-129.

NOTE

If the instrument is to be shipped to

Keithley for calibration OT repair, attach a tag to the instrument identifying the owner. Note the problem,

the symptoms, and service or repair

desired. Record the mode1 and serial

number of the instrument. Show the

work authorization order as we11 as

the date and method of shipment. ALWAYS OBTAIN A RETURN

AUTHORIZATION

NUMBER

FROM THE FACTORY BEFORE

SHIPPING THE INSTRUMENT TO

KEITI-ILEY.

2-11. Safety

Be fully acquainted and knowledgeable with al1 aspects

of this instnxtion manual before using the instrument

to assure operator safety and protection against personnel shock hazard.

igure

2-l.

Model 776 - outline dimensions.

2-3

Page 23

lnstnllation

Notes

2-1

Page 24

3

Operating Instructions

3-I. introduction

Model 776 operation is divided into two general categories: basic bench operation. and IEEE-488 operation.

Basic bench operation. which is covered in this section.

consists of using the Model 776 to perform basic frequency. time. peak voltage. and phase measurements.

IEEE programming can also be used to greatly enhance

the capability of the instrument in applications such as

automatic test equipment. These aspects are covered in

details in Sections 3 and 1.

3-2. Front Panel Familiarization

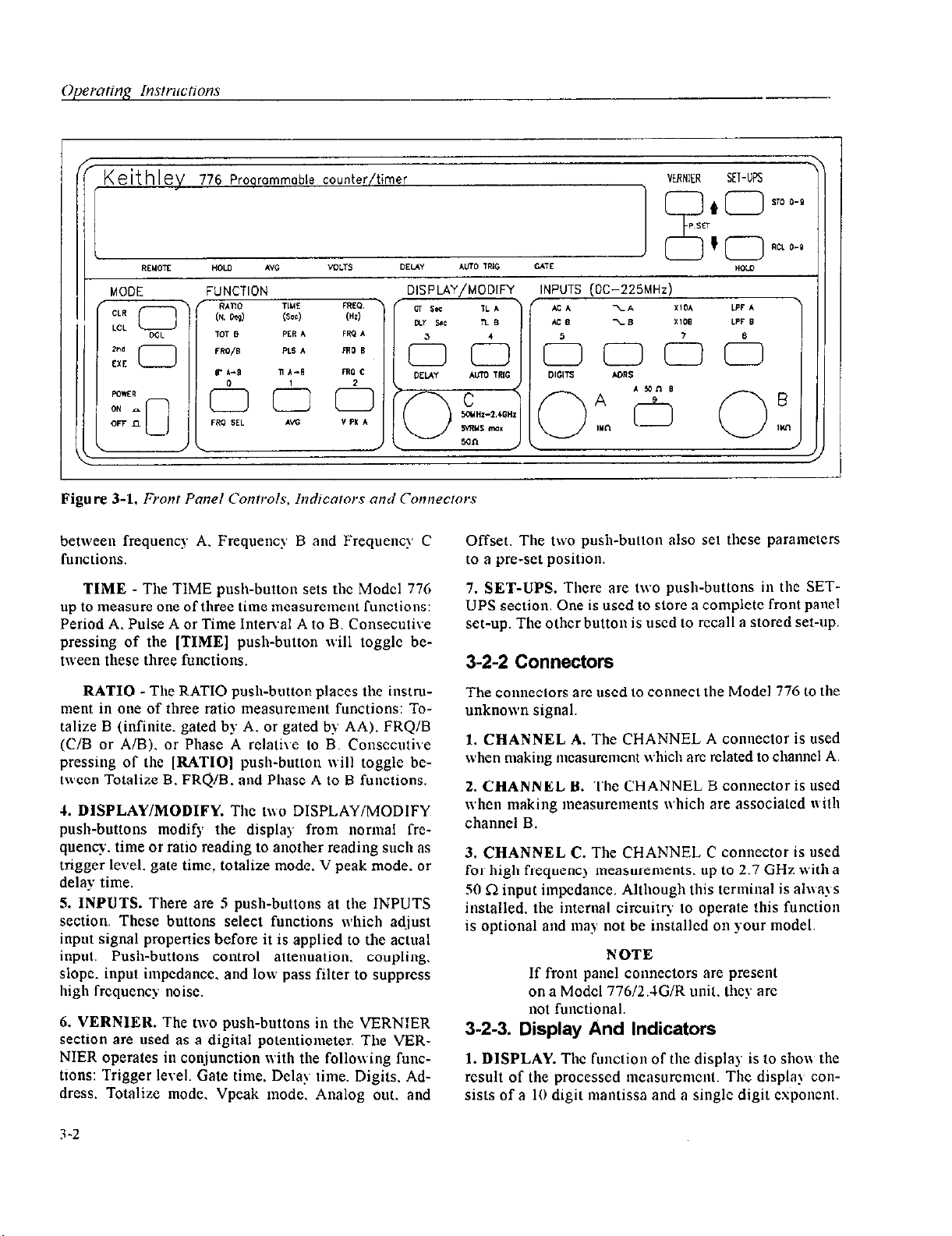

The front panel layou1 of the Model 776 is shown in

Figure 3-l. The fionl panel is generally divided into

three sections: controls. conneclors. display and indicators. The following paragraphs describe the purpose of

each of these items in details.

3-2-l.

All the front panel controls escepc [POWER] are mo-

mcntarv contact switches. Many controls include an

annu&ator light to indicate the selected mode. Controls which do not have an annunciator ligh1. when

pressed. will cause an immediate reaction on the dis-

play. The con1roIs arc dbided into func1ional groups for

easier operation. Front panel controls are divided to 1he

following functional groups: Power. Mode. Funclions.

Display Modifiers. and Inpu1 Setting.

1. POWER The [POWER] witch controls the AC

power to the instrument. Pressing and releasing the

Controls

switch once turns the power on. Pressing and rclcasing

the switch a second time turns 1hc power off.

2. MODE. There are two push-buttons in the MODE

section: [CLRLCL] (clear/local). and [ZndlEXEj

(second/execute). The [2nd] push-button is used to se-

lect secondary functions. Normally. the secondary functions are marked below the push-buttons. To help distinguish between normal and secondary functions. all

secondary funclions are prin1ed in yellow. Pressing the

[2nd/EXE] push-button will cause the instrunlcnl to

display the following reading:

2nd ?

The reading is blinking indicaling lhat the counlcr is

ready for a conscqucnt press of anolhcr push-bulton

which was assigned a second function. Pressing the

[2nd/EXEj push-button again will res1ore normal op

eration. The [CLR/LCL) push-bulton when pressed.

and the instrument nas in remote operation (bu1 not in

remote lockout condition LLO). restores local operation. When

this push-bulton clears the display and arms the counter

for the next n1casurcn1cn1 cycle.

3. FUNCTION. The 1hree FUNCTION push-buttons

control the 1ype of measurcmcnt. Each push-button is

used IO select one of three functions.

FREQ. - The FREQ push-butlon places the instrument in one of three frcqucocy ntcasurcn~cnt functions:

Frequency A. Frequency B or Frequency C. Consccutive pressing of the [FREQJ push-butlon uill toggle

the

instrumen1 is in local operation. pressing

3-1

Page 25

MODE

FUNCTION

between frequency A. Frequency l3 and Frequency C

functions.

TIME - The TIME push-button sets the Model 776

up to measure one of three time

measurement

functions:

Period A. Pulse A or Time Intenxl A to B. Consecutive

pressing of the [TIME] push-button will toggle be-

tween these three functions.

RATIO -The RATIO push-button places the inslm-

ment in one of three ratio measurement functions: To-

talize B (infinite. gated by A. or gated by AA). FRQlB

(C/B or A/B). or Phase A relative to B. Consecutive

pressing of the [RATIO] push-button will toggle betwcen Totalize B. FRC$B. and Phase A to B functions.

1. DISPLAY/MODIFY. The two DISPLAY/MODIFY

push-buttons modify the display from normal frequency. time or ratio reading to another reading such as

trigger level. gate time. totalize mode. V peak mode. or

delay time.

5. INPUTS. There are 5 push-buttons at the INPUTS

section. These buttons select functions which ad.iust

input signal properties before it is applied to the actual

input. Push-buttons control attenuation. coupling.

slope. input impedance. and low pass filter to suppress

high frequency noise.

6. VERNIER. The two push-buttons in the VERN!ER

section are used as a digital potentiometer. The VERNIER operates in conjunction with the following functions: Trigger leyel. Gate time. Dela! time. Digits. Address. Totalize mode. Vpeak mode. Analog out. and

Offset. The two push-button also set these parameters

to a pm-set position.

7. SET-UPS. There are tn’o push-buttons in the SETUPS section One is used to slorc a complete front panel

set-up. The other button is used to recall a stored set-up.

3-2-2 Connectors

The connectors arc used to connect the Model 776 to the

unknown signal.

1. CHANNEL A. The CHANNEL A connector is used

\\hen making mcasurcmcnt which arc related to channel A.

2. CHANNEL B. The CHANNEL B connector is used

when making measurements which are associated with

channel B.

3. CHANNEL C. The CHANNEL C connector is used

for high frequency measurements. up lo 2.7 GHz with a

50 fi input impedance. Although this terminal is alva!~s

installed. the internal circuitq to operate this function

is optional and ma: not be installed cm your model.

NOTE

If front panel connectors are present

on a Model 776/2.4G/R unit. they are

not functional.

3-2-3. Display And Indicators

1. DISPLAY. The function of the display is to shou the

result of the processed mcaswcmcnt. The display con-

sists of a 10 digit mantissa and a single digit csponcnt.

3-2

Page 26

The exponent uses a leading minus to indicate negative

values. The sign on the exponent changes to + for zero

or positive values. The display is also used to indicate

information other than the measurement such as the gate

time or the trigger level.

2. INDICATORS. There are 30 indicators located on

the front panel. The indicators are used to point at a

selected function or signal to the user that the instrument is set to a special function like auto trigger or

remote operation.

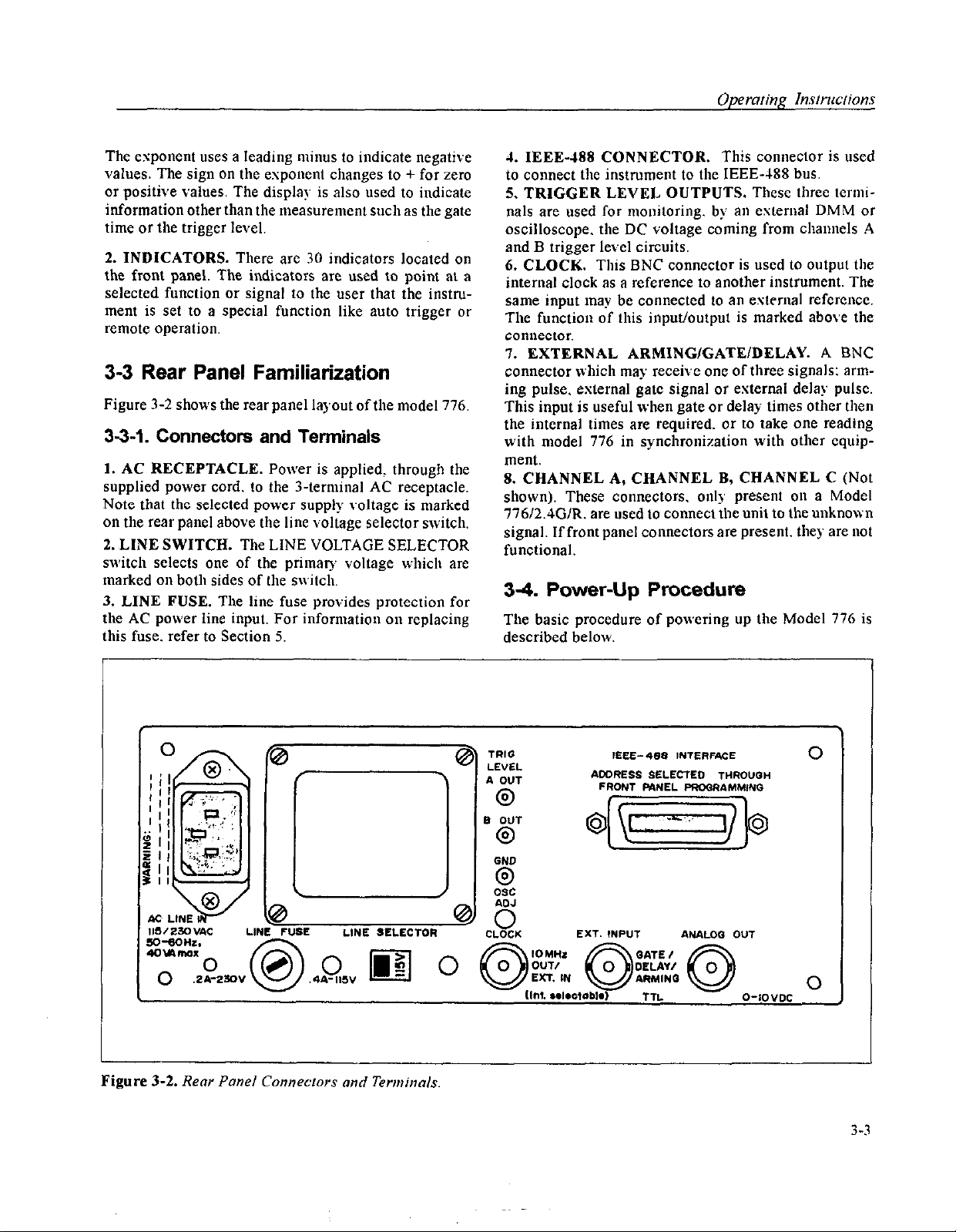

33 Rear Panel Familiarization

Figure 3-2 shows the rear panel layout of the model 776.

3-3-l. Connectors and Terminals

1. AC RECEPTACLE. Power is applied_ through the

supplied power cord. to the 3-terminal AC receptacle.

Note that the selected power supply voltage is marked

on the rear panel above the line voltage selector switch.

2. LINE SWITCH. The LINE VOLTAGE SELECTOR

switch selects one of the primary voltage which are

marked on both sides of the switch

3. LINE FUSE. The line fuse provides protection for

the AC power line input. For information on replacing

this fuse. refer to Section 5.

4. IEEE-188 CONNECTOR. This conneclor is used

to connect the instrument to the IEEE-488 bus.

5. TRIGGER LEVEL OUTPUTS. Tbesc three lerminals are used for monitoring. by an external DMM or

oscilloscope. the DC voltage coming from channels A

and B trigger level circuits.

6.

CLOCK. This BNC connector is used to output tbe

internal clock as a reference to another instrument. The