Page 1

I

nstruction Manua

l

Model 7174A

8×12 Low Current Matrix Card

Contains Operating and Servicing Information

7174A-901-01 Rev. A / 9-98

Page 2

W ARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty , write or call your local Keithley representative, or contact Keithle y headquarters in Cleveland, Ohio. Y ou will

be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMIT A TION OF W ARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT , SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. • 28775 Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.keithley.com

CHINA: Keithley Instruments China • Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-62022886 • Fax: 8610-62022892

FRANCE: Keithley Instruments SARL • BP 60 • 3 Allée des Garays • 91122 Palaiseau Cédex • 33-1-60-11-51-55 • Fax: 33-1-60-11-77-26

GERMANY: Keithley Instruments GmbH • Landsberger Strasse 65 • D-82110 Germering, Munich • 49-89-8493070 • Fax: 49-89-84930759

GREAT BRITAIN: Keithley Instruments, Ltd. • The Minster • 58 Portman Road • Reading, Berkshire, England RG3 1EA • 44-1189-596469 • Fax: 44-1189-575666

ITALY: Keithley Instruments SRL • Viale S. Gimignano 38 • 20146 Milano • 39-2-48303008 • Fax: 39-2-48302274

NETHERLANDS: Keithley Instruments BV • Avelingen West 49 • 4202 MS Gorinchem • 31-(0)183-635333 • Fax: 31-(0)183-630821

SWITZERLAND: Keithley Instruments SA • Kriesbachstrasse 4 • 8600 Dübendorf • 41-1-8219444 • Fax: 41-1-8203081

TAIWAN: Keithley Instruments Taiwan • 1FL., 85 Po Ai Street • Hsinchu, Taiwan • 886-3-572-9077 • Fax: 886-3-572-9031

Page 3

Model 7174A 8 × 12 Low Current Matrix Card

Instruction Manual

©1998, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

First Printing September 1998

Document Number: 7174A-901-01 Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision

Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 7174A-901-01)............................................................................ September 1998

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read the operating information

carefully before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, and for ensuring that operators are

adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating, for example, setting the line voltage or replacing consumable materials. Maintenance procedures are described in

the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service

personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present.

that hazardous voltage is present in any unknown circuit before

measuring.

A good safety practice is to expect

Users of this product must be protected from electric shock at all

times. The responsible body must ensure that users are prevented

access and/or insulated from every connection point. In some cases,

connections must be exposed to potential human contact. Product

users in these circumstances must be trained to protect themselves

from the risk of electric shock. If the circuit is capable of operating

at or above 1000 volts,

exposed.

As described in the International Electrotechnical Commission

(IEC) Standard IEC 664, digital multimeter measuring circuits

(e.g., Keithley Models 175A, 199, 2000, 2001, 2002, and 2010) are

Installation Category II. All other instruments’ signal terminals are

Installation Category I and must not be connected to mains.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

no conductive part of the circuit may be

Page 6

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The

WARNING heading in a manual explains dangers that might

result in personal injury or death. Alw ays read the associated infor mation very carefully before performing the indicated procedure.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean the instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument.

The

CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Page 7

7174A 8×12 Low Current Matrix Card Specifications

MATRIX CONFIGURATION: Single 8 rows×12 columns. Expanding

the columns can be done internally by connecting the rows of

multiple 7174A cards together with coax jumpers.

CROSSPOINT CONFIGURATION: 2-pole Form A (Signal Guard).

CONNECTOR TYPE: 3-lug triax (Signal, Guard, Chassis).

MAXIMUM SIGNAL LEVEL:

Pin to Pin or Pin to Chassis: 200V. 2A carry current.

CONTACT LIFE: Cold Switching: 10

8

closures.

OFFSET CURRENT: 100fA max., 10fA typical (with 0V applied to

inputs and outputs).

ISOLATION: Path (Signal to Signal): >2×10

14

Ω, 1pF.

Common (Signal to Chassis): >1014Ω, <10pF.

SETTLING TIME: <2.5s to 400fA (all pathways) after 10V applied

(typical).

CROSSTALK (1MHz,50Ω Load): <–70dB.

INSERTION LOSS (1MHz, 50ΩLoad): <–0.2dB typical.

3dB BANDWIDTH:

(50Ω Load, 50Ω Source): 30MHz typical.

(1MΩ Load, 50Ω Source): 40MHz typical.

RELAY DRIVE CURRENT (per crosspoint): 17mA.

RELAY SETTLING TIME: <1ms.

ENVIRONMENT:

Offset Current and Path Isolation Specifications: 23°C, <60%

R.H.

Operating: 0° to 50°C, up to 35°C at 70% R.H.

Storage: –25° to +65°C.

MAXIMUM LEAKAGE:

Pin to Ground: 0.01pA/V. Pin to Pin: 0.005pA/V.

INSULATION RESISTANCE: 6.7×10

13

Ω minimum.

CAPACITANCE: (Guard Driven): Path to Ground: <10pF. Path to

Path: 1pF typical.

ACCESSORY SUPPLIED: Instruction manual and eight MCX expan-

sion cables.

ACCESSORIES AVAILABLE:

7078-TRX-TBC 3-Lug Triax to BNC Adapter

7078-TRX-T 3-Lug Triax Tee Adapter

7078-TRX-3 3-Lug Triax Cable, 0.9m (3 ft.)

7078-TRX-10 3-Lug Triax Cable, 3m (10 ft.)

7078-TBC 3-Lug Female Triax Bulkhead Connector with Cap

7078-CSHP Cable Set to Connect 7174 to HP 4145, 4155, 4156

Specifications are subject to change without notice.

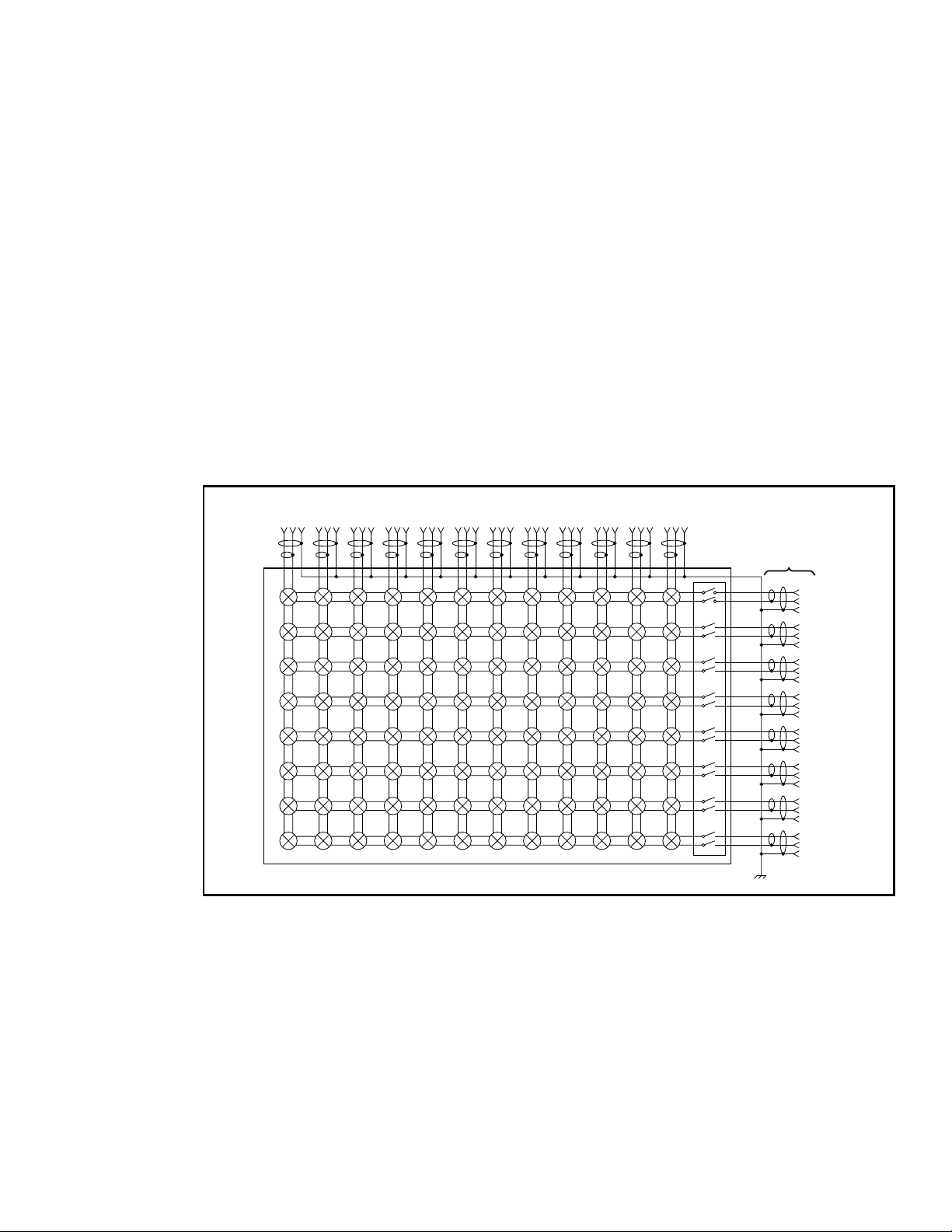

Columns

HGCHGCHGCHGCHGCHGCHGCHGCHGCHGCHGCHGC

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

222

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

222

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

User

connections

and expansion

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

H

G

C

H

G

C

H

G

C

H

G

C

H

G

C

H

G

C

H

G

C

H

G

C

Rows

Page 8

Table of Contents

1 General Information

1.1 Introduction ....................................................................................................................................................... 1-1

1.2 Features ............................................................................................................................................................. 1-1

1.3 Warranty information ........................................................................................................................................ 1-1

1.4 Manual addenda ................................................................................................................................................ 1-2

1.5 Safety symbols and terms ................................................................................................................................. 1-2

1.6 Specifications .................................................................................................................................................... 1-2

1.7 Unpacking and inspection ................................................................................................................................. 1-2

1.7.1 Inspection for damage ............................................................................................................................... 1-2

1.7.2 Shipment contents ..................................................................................................................................... 1-2

1.7.3 Instruction manual ..................................................................................................................................... 1-2

1.8 Packing for shipment ........................................................................................................................................ 1-2

1.9 Optional accessories .......................................................................................................................................... 1-2

2 Operation

2.1 Introduction ....................................................................................................................................................... 2-1

2.2 Handling precautions ........................................................................................................................................ 2-1

2.3 Environmental considerations ........................................................................................................................... 2-1

2.4 Card installation and removal ........................................................................................................................... 2-2

2.5 Connections ....................................................................................................................................................... 2-2

2.5.1 Card connectors .......................................................................................................................................... 2-2

2.5.2 Recommended cables and adapters ............................................................................................................ 2-3

2.5.3 Triax banana plug adapter .......................................................................................................................... 2-4

2.5.4 General instrument connections ................................................................................................................. 2-5

2.5.5 Keithley instrument connections .............................................................................................................. 2-11

2.5.6 Typical test fixture connections ............................................................................................................... 2-17

2.6 Matrix configuration ....................................................................................................................................... 2-18

2.6.1 Switching matrix ...................................................................................................................................... 2-18

2.6.2 Path isolators ............................................................................................................................................ 2-18

2.6.3 Internal matrix expansion ......................................................................................................................... 2-21

2.7 Measurement considerations ........................................................................................................................... 2-22

2.7.1 Magnetic fields ........................................................................................................................................ 2-22

2.7.2 Electromagnetic Interference (EMI) ....................................................................................................... 2-22

2.7.3 Ground loops ........................................................................................................................................... 2-22

2.7.4 Keeping connectors clean ....................................................................................................................... 2-23

2.7.5 Noise currents caused by cable flexing ................................................................................................... 2-23

2.7.6 Shielding ................................................................................................................................................. 2-23

2.7.7 Guarding .................................................................................................................................................. 2-24

2.7.8 Matrix expansion effects on card specifications ..................................................................................... 2-24

2.8 Coaxial jumper access ..................................................................................................................................... 2-25

i

Page 9

3 Applications

3.1 Introduction ........................................................................................................................................................ 3-1

3.2 CV measurements ............................................................................................................................................... 3-1

3.2.1 Stand alone system configuration ............................................................................................................... 3-1

3.2.2 Computerized system configuration ........................................................................................................... 3-1

3.2.3 Optimizing CV measurement accuracy ...................................................................................................... 3-3

3.2.4 Basic CV test procedure ............................................................................................................................. 3-3

3.2.5 Typical CV curves ...................................................................................................................................... 3-3

3.3 Semiconductor test matrix ................................................................................................................................. 3-5

3.3.1 System configuration .................................................................................................................................. 3-5

3.3.2 Testing common-source characteristic of FETs ......................................................................................... 3-6

3.4 Resistivity measurements ................................................................................................................................... 3-7

3.4.1 Test configuration ....................................................................................................................................... 3-7

3.4.2 Test procedure ............................................................................................................................................ 3-7

3.4.3 Resistivity calculations ............................................................................................................................... 3-9

3.5 Semiconductor IV characterization .................................................................................................................... 3-9

3.5.1 Test configuration ....................................................................................................................................... 3-9

3.5.2 Cable connections ..................................................................................................................................... 3-10

4 Service Information

4.1 Introduction ........................................................................................................................................................ 4-1

4.2 Handling and cleaning precautions .................................................................................................................... 4-1

4.3 Principles of operation ........................................................................................................................................ 4-2

4.3.1 Block diagram ............................................................................................................................................ 4-2

4.3.2 ID data circuits ........................................................................................................................................... 4-2

4.3.3 Relay control .............................................................................................................................................. 4-3

4.3.4 Power-on sequence ..................................................................................................................................... 4-3

4.3.5 Isolator relays ............................................................................................................................................. 4-4

4.4 Troubleshooting .................................................................................................................................................. 4-4

4.4.1 Recommended equipment .......................................................................................................................... 4-4

4.4.2 Gaining circuit access ................................................................................................................................. 4-4

4.4.3 Troubleshooting procedure ......................................................................................................................... 4-4

4.5 Special handling of static-sensitive devices ....................................................................................................... 4-5

4.6 Performance verification .................................................................................................................................... 4-5

4.6.1 Environment conditions .............................................................................................................................. 4-5

4.6.2 Recommended test equipment .................................................................................................................... 4-5

4.6.3 Offset current verification .......................................................................................................................... 4-6

4.6.4 Path isolation verification ........................................................................................................................... 4-7

4.6.5 Path resistance verification ......................................................................................................................... 4-9

4.7 Reed pack replacement...................................................................................................................................... 4-11

5 Replaceable Parts

5.1 Introduction ........................................................................................................................................................ 5-1

5.2 Parts list .............................................................................................................................................................. 5-1

5.3 Ordering information .......................................................................................................................................... 5-1

5.4 Factory service .................................................................................................................................................... 5-1

5.5 Component layout and schematic diagram ......................................................................................................... 5-1

ii

Page 10

List of Illustrations

2 Operation

Figure 2-1 Model 7174A installation .......................................................................................................................... 2-2

Figure 2-2 Card connectors ......................................................................................................................................... 2-3

Figure 2-3 Triax connector configuration ................................................................................................................... 2-3

Figure 2-4 Triax cable preparation ............................................................................................................................. 2-4

Figure 2-5 General instrument connections ................................................................................................................ 2-6

Figure 2-6 Model 617 electrometer connections ...................................................................................................... 2-11

Figure 2-7 Model 196 DMM connections ................................................................................................................ 2-12

Figure 2-8 Model 230 voltage source connections ................................................................................................... 2-13

Figure 2-9 Model 590 CV analyzer connections ...................................................................................................... 2-14

Figure 2-10 Model 220 current source connections ................................................................................................... 2-15

Figure 2-11 Model 236/237/238 source measure unit connections ............................................................................ 2-16

Figure 2-12 Typical test fixture connections .............................................................................................................. 2-17

Figure 2-13 Equivalent circuit of test fixture connections .......................................................................................... 2-18

Figure 2-14 Matrix configuration ............................................................................................................................... 2-19

Figure 2-15 Connecting three cards for an 8 × 36 matrix ........................................................................................... 2-21

Figure 2-16 Jumper connector locations ..................................................................................................................... 2-21

Figure 2-17 Two cards in daisy chain configuration .................................................................................................. 2-22

Figure 2-18 Power line ground loops ......................................................................................................................... 2-23

Figure 2-19 Eliminating ground loops ........................................................................................................................ 2-23

Figure 2-20 Shielded and guarded .............................................................................................................................. 2-24

Figure 2-21 Guarded circuit ........................................................................................................................................ 2-24

Figure 2-22 Coaxial jumper access ............................................................................................................................. 2-25

3 Applications

Figure 3-1 Stand alone CV system configuration ........................................................................................................ 3-2

Figure 3-2 Computerized CV system configuration .................................................................................................... 3-2

Figure 3-3 Typical quasistatic CV curve generated by Model 595 ............................................................................. 3-4

Figure 3-4 Typical high-frequency CV curve generated by Model 590 ...................................................................... 3-4

Figure 3-5 Semiconductor test matrix ......................................................................................................................... 3-5

Figure 3-6 System configuration for measuring common-emitter characteristics ....................................................... 3-6

Figure 3-7 Typical common-source FET IV characteristics ........................................................................................ 3-6

Figure 3-8 Resistivity test configuration ..................................................................................................................... 3-7

Figure 3-9 Resistivity measurement conventions ........................................................................................................ 3-8

Figure 3-10 Multi-unit test system using Models 236 and 237 source measure units ................................................. 3-10

iii

Page 11

4 Service Information

Figure 4-1 Model 7174A block diagram ...................................................................................................................... 4-2

Figure 4-2 ID data timing ............................................................................................................................................. 4-3

Figure 4-3 Offset verification test connections ............................................................................................................ 4-6

Figure 4-4 Connections for path isolation verification ................................................................................................ 4-7

Figure 4-5 Triaxial cable preparation ........................................................................................................................... 4-8

Figure 4-6 Connections for path resistance verification .............................................................................................. 4-9

Figure 4-7 Shorting measurement paths using triax tee adapter ................................................................................ 4-10

Figure 4-8 Cross point relays ..................................................................................................................................... 4-12

Figure 4-9 Isolator relays ........................................................................................................................................... 4-13

iv

Page 12

List of Tables

2 Operation

Table 2-1 Recommended cables and adapters ............................................................................................................ 2-3

Table 2-2 Parts for special triaxial cable .................................................................................................................... 2-4

Table 2-3 Column numbering by slot and unit ......................................................................................................... 2-20

3 Applications

Table 3-1 CV test crosspoint summary ...................................................................................................................... 3-3

Table 3-2 Crosspoint summary for resistivity measurements .................................................................................... 3-9

4 Service Information

Table 4-1 Recommended troubleshooting equipment ................................................................................................ 4-4

Table 4-2 Troubleshooting procedure ........................................................................................................................ 4-4

Table 4-3 Recommended verification equipment ...................................................................................................... 4-5

5 Replaceable Parts

Table 5-1 Model 7174A electrical parts list ................................................................................................................5-3

Table 5-2 Model 7174A mechanical parts list ........................................................................................................... 5-4

v

Page 13

1

General Information

1.1 Introduction

This section contains general information about the Model

7174A Low Current Matrix Card. The Model 7174A Low

Current Matrix Card is designed for semiconductor research,

development, and production applications that require high

quality and performance switching I-V (current versus voltage) and C-V (capacitance versus voltage) signals. The

model 7174A is ideal for use with Keithley Model 236

Source Measure Unit for semiconductor testing and other

low current switching applications. Model 237 and Model

238 Source Measure Units can also be used below the maximum signal level (200V, 2A carry) of the Model 7174A Low

Current Matrix Card (for full specifications, refer to paragraph 1.6). The Model 7174A also can be used with Models

590 and 595 C-V instruments.

Section 1 is arranged in the following manner:

1.2 Features

1.3 Warranty information

1.4 Manual addenda

1.5 Safety symbols and terms

1.6 Specifications

1.7 Unpacking and inspection

1.8 Packing for shipment

1.9 Optional accessories

1.2 Features

Key features of the Model 7174A Low Current Matrix Card

include:

• Eight row by twelve column (8 × 12) switching matrix

configuration, with signal and guard switched at each

crosspoint

• Paths have offset currents of less than 100fA with typical offset currents of 50fA

• Maximum Leakage Currents:

Pin to Ground -- 0.01 pA/V

Pin to Pin -- 0.005 pA/V

• 3-lug Triaxial Connectors (Signal, Guard, Chassis) for

all row and columns allow guarding of each signal pathway, minimizing effects of stray capacitance, leakage

current, and leakage resistance

• Model 7174A cards can be connected together internally using the supplied SMB to SMB cables (jumpers)

to expand the number of columns in the matrix.

1.3 W arranty information

Warranty information is located on the inside front cover of

this manual. Should your Model 7174A require warranty

service, contact your Keithley representative or authorized

repair facility in your area for further information.

1-1

Page 14

General Information

1.4 Manual addenda

Any improvements or changes concerning the matrix card or

manual will be explained in an addendum included with the

unit. Be sure to note these changes and incorporate them into

the manual before using or servicing the unit.

1.5 Safety symbols and terms

The following symbols and terms may be found on an instrument or used in this manual.

!

The symbol on an instrument indicates that the user

should refer to the operating instructions located in the instruction manual.

The symbol on an instrument shows that high voltage

may be present on the terminal(s). Use standard safety precautions to avoid personal contact with these voltages.

The WARNINGS heading used in this manual explains dangers that might result in personal injury or death. Always

read the associated information very carefully before performing the indicated procedure.

1.7.2 Shipment contents

The following items are included with every Model 7174A

order:

• Model 7174A Low Current Matrix Card.

• Model 7174A Instruction Manual.

• Coaxial jumper cables Model CA-121A (8) for matrix

expansion.

• Additional accessories as ordered.

1.7.3 Instruction manual

The Model 7174A Instruction Manual is three-hole drilled so

that it can be added to the system three-ring binder. After

removing the plastic wrapping, place the manual in the

binder after the mainframe instruction manual. Note that a

manual identification tab is included and should precede the

matrix card instruction manual.

If an additional manual is required, order the manual package (Keithley part number 7174A-901-00). The manual

package includes an instruction manual and any pertinent

addenda.

The CAUTION heading used in this manual explains hazards that could damage the matrix card. Such damage may

invalidate the warranty.

1.6 Specifications

Model 7174A specifications may be found at the front of this

manual. These specifications are exclusiv e of the matrix card

file specifications, which are located in the Model 707A

Switching Matrix manual.

1.7 Unpacking and inspection

1.7.1 Inspection for damage

If you ordered the Model 7174A separately from a system,

carefully unpack it from its shipping carton and inspect the

card for any obvious signs of physical damage. Report any

such damage to the shipping agent immediately. Save the

original packing carton for possible future reshipment.

1.8 Packing for shipment

Should it become necessary to return the Model 7174A for

repair, carefully pack the card in its original packing carton

or the equivalent, and include the following information:

• Advise as to the warranty status of the matrix card.

• Write ATTENTION REPAIR DEPARTMENT on the

shipping label.

• Fill out and include the service form located at the back

of this manual.

1.9 Optional accessories

Cables

Model 7078-TRX-3 — A 0.9 m (3 ft.) triaxial cable termi-

nated at both ends with 3-slot male triax connectors. This

type of cable is also available in 10 ft. (Model 7078-TRX-10)

and 20 ft. (Model 7078-TRX-20) lengths.

Model CA-93-1 — BNC to right angle SMB (coaxial) cable.

1-2

Page 15

General Information

Model 7078-CSHP — Is a cable set containing:

Eight 10 ft. (3m) cables — Cables to connect the Model

7174A to a HP-4145 Semiconductor Parameter Analyzer.

Four BNC to triax adapters — Used with eight cables

listed above

Four 3 slot triax cables— Cable set to connect the Model

7174A to Source Measurement Units

Four BNC to BNC coax cables — Adapt the measurement

and source modules in the HP-4145 to the connectors of

the Model 7174A.

Adapters

Model 7078-TRX-TBC — A 3-lug female triax bulkhead

connector (with cap). Use this connector for custom applications and interface connections such as test fixtures.

Model 7078-TRX-T — 3-slot male to dual 3-lug female

triax tee adapter.

Model 237-BAN-3 — 3-slot male triax to male banana plug.

Model 237-ALG-2 — 3-slot male triax to alligator clips.

Model 7078-TRX-BNC — 3-slot male triax to BNC

adapter, connections to center and inner shell. For nonguarded applications, use Model 7078-TRX-GND.

Model 6171 — 3-slot male triax to 2-lug female triaxial

adapter.

Tools

Model 9172-314 — A tool designed to remove and install

internal coaxial jumpers between adjacent Model 7174A

Low Current Matrix Cards.

1-3

Page 16

2

Operation

2.1 Introduction

WARNING

The installation and operation procedures in this section are intended for use

only by qualified service personnel. Do

not perform these procedures unless

qualified to do so. Failure to recognize

and observe normal safety precautions

could result in personal injury or death.

This section contains information on matrix card connections, installation and matrix programming, and is arranged

as follows:

2.2 Handling precautions — Discusses precautions that

should be taken when handling the card to avoid contamination that could degrade performance.

2.3 Environmental considerations — Outlines environ-

mental aspects of using the Model 7174A.

2.4 Card installation and removal — Details installation

in and removal from the Model 707A Switching

Matrix.

2.7 Measurement considerations — Reviews a number

of considerations when making low-level current and

capacitance measurements.

2.8 Coaxial jumper access — Provides information on

jumper removal.

2.2 Handling precautions

To maintain high impedance isolation, care should be taken

when handling the matrix card to avoid contamination from

such foreign materials as body oils. Such contamination can

substantially lower leakage resistance, degrading performance. The areas of the card that are most sensitive to contamination are those associated with Teflon® insulators. To

avoid any possible contamination, always grasp the card by

the handle or the card edges. Do not touch board surfaces,

components, or card edge connectors.

Dirt and other particle build-up over a period of time are

other possible sources of contamination. To avoid this problem, operate the mainframe and matrix card only in a clean

environment. If contamination is suspected, clean the card as

discussed in Section 4.

2.5 Connections — Discusses card connectors, cables

and adapters, and typical connections to other

instrumentation.

2.6 Matrix configuration — Discusses the switching

matrix, as well as matrix expansion by connecting two

or more cards together.

2.3 Environmental considerations

For rated performance, the card should be operated within

the temperature and humidity limits given in the specifications at the front of this manual.

2-1

Page 17

Operation

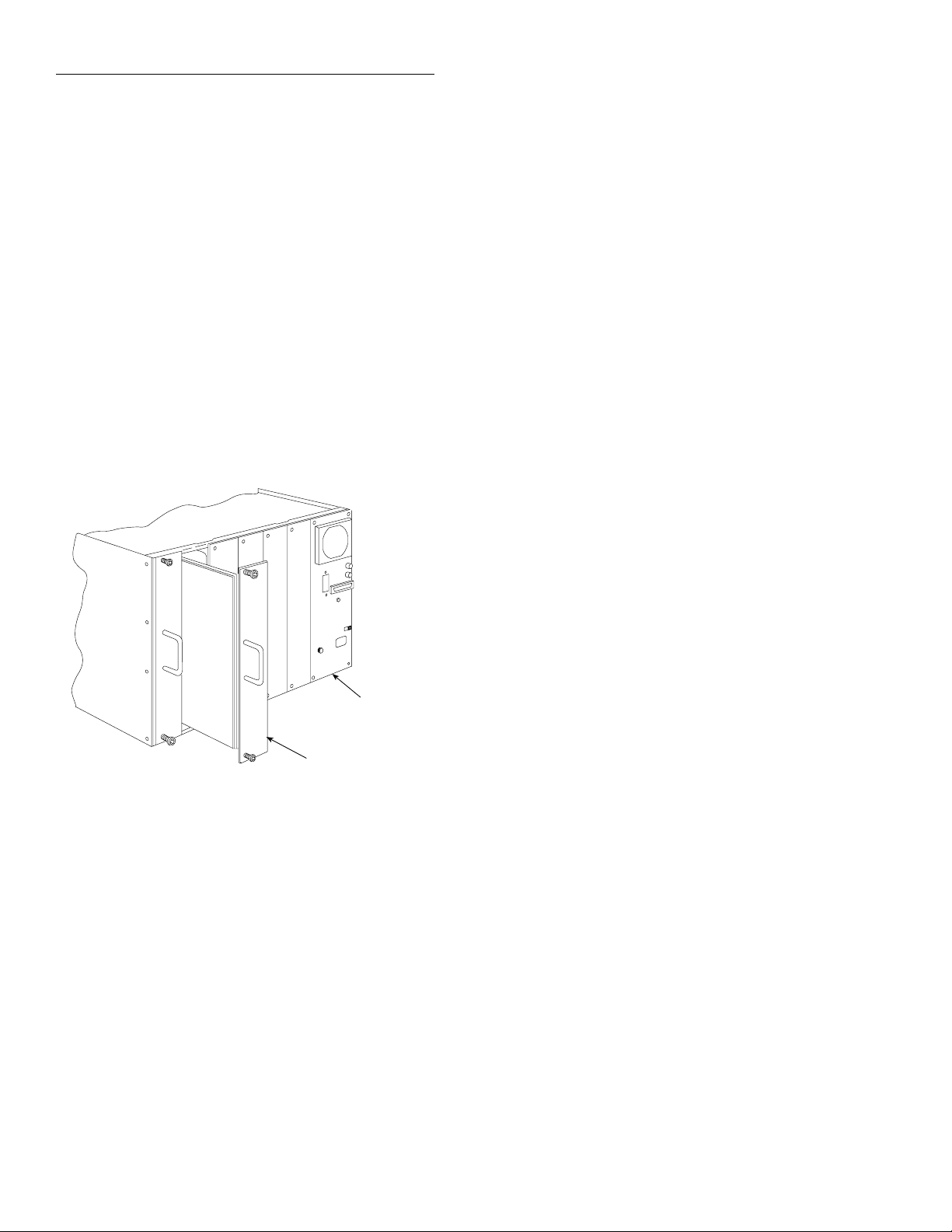

2.4 Card installation and removal

Before making connections, the Model 7174A should be

installed within the Model 707A Switching Matrix, as summarized below. Figure 2-1 shows the installation procedure.

WARNING

T urn off the system power before installing or removing matrix cards.

NOTE

The coaxial jumpers used to expand the

matrix with two or more Model 7174A

cards can not be installed before card

insertion; an access door on top of the

mainframe allows access to the connectors

after the card is installed.

2. With one hand grasping the handle, and the other holding the bottom of the card, line up the card with the

tracks in the desired slot. Make certain that the component side of the card is facing the fan on the mainframe.

3. Slide the card into the mainframe until it is properly

seated in the edge connectors at the back of the slot.

Once the card is properly seated, secure it to the mainframe by finger tightening the spring-loaded screws.

WARNING

The mounting screws must be secured to

ensure proper chassis ground connections between the card and the mainframe. Failure to properly secure this

ground connection may result in personal injury or death due to electric

shock.

4. To remove a card, first turn off the system power. Disconnect all external and internal jumper cables (internal

cables can be reached through the access door). Loosen

the mounting screws, then pull the card out of the mainframe by the handle. When the back edge of the card

clears the mainframe, support it by grasping the bottom

edge near the back or back edge.

Model 707A

Switching Matrix

Model 7174A Low

Current Matrix Card

Figure 2-1

Model 7174A installation

1. Before installing the card, make sure the access door on

top of the Model 707A Switching Matrix is fully closed

and secured. The access door contains tracks for the card

slots and must be in place to properly install the card.

CAUTION

Do not touch the card surfaces or any

components to avoid contamination

that could degrade card performance.

2.5 Connections

Card connectors, recommended cables and adapters, and

typical connections to test instruments are discussed in the

following paragraphs.

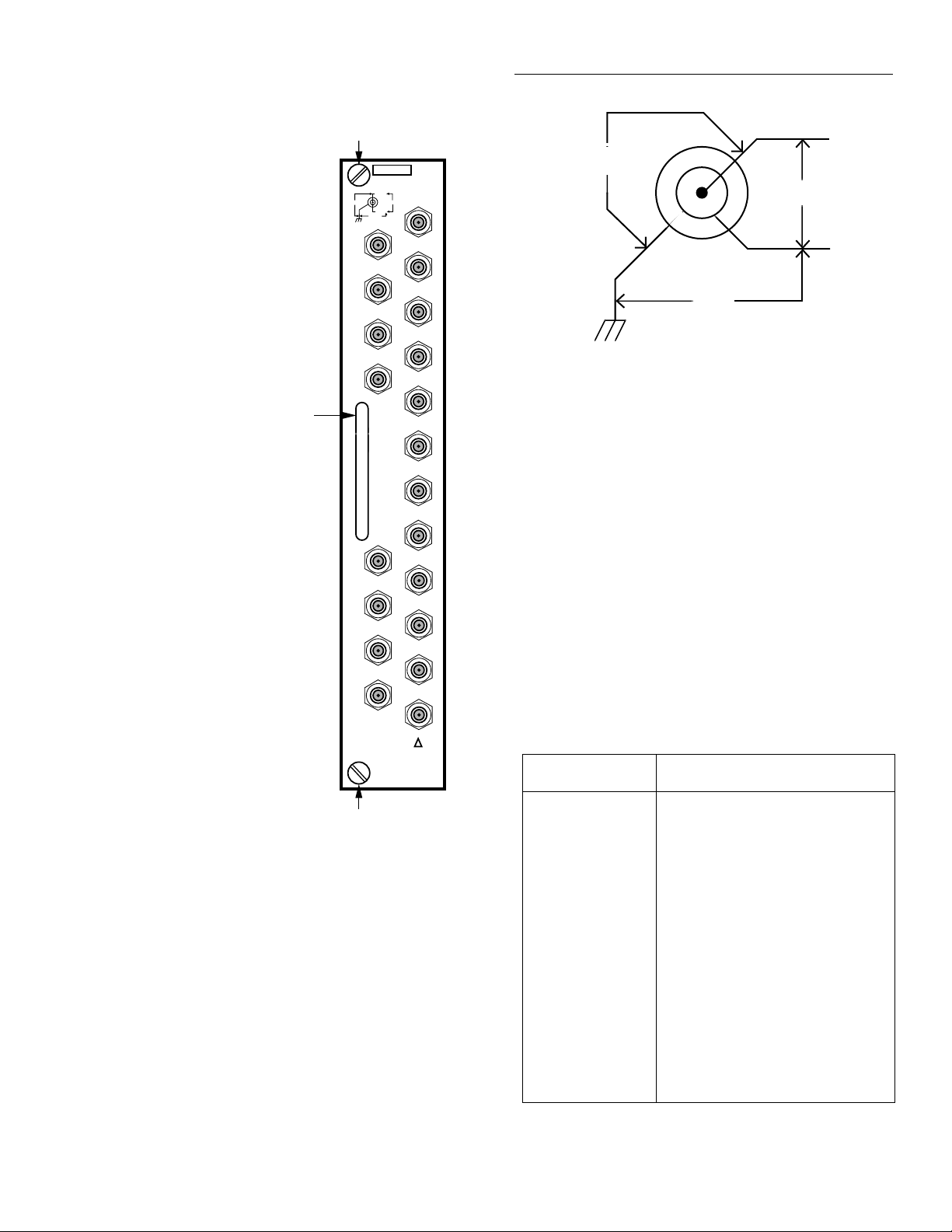

2.5.1 Card connectors

The card connectors are shown in Figure 2-2. Each pin is

equipped with a 3-lug triax connector. As shown in Figure

2-3, the center conductor is signal, the inner shield is guard,

and the outer shield is chassis ground.

CAUTION

Do not exceed 200V between any two

pins or between any pin and chassis.

The Model 7174A has 12 columns (labeled 1 through 12)

and 8 rows (labeled A through H).

2-2

Page 18

Chassis

Ground

200V

Peak

Guard

200V Peak

Signal

200V

Peak

Caution:

Do not exceed maximum

voltage levels shown.

Figure 2-3

Triax connector configuration

Operation

Mounting

Screw

KEITHLEY

7174A

8x12LOW

CURRENT MATRIX

SIGNAL

200VPK

200VPK

Carrying

Handle

B

C

D

A

200VPK

ROWS

COLUMNS

GUARD

1

2

3

4

5

6

Caution:

Remove internal row

jumpers before removing

card.

Figure 2-2

Card connectors

Mounting

Screw

E

F

10

G

11

H

12

!

WARNING:

TIGHTEN MOUNTING SCREWS

TO ENSURE PROPER

CHASSIS GROUND

MADE INU.S.A.

7

2.5.2 Recommended cables and adapters

8

Table 2-1 summarizes the cables recommended for use with

9

the Model 7174A. Equivalent user-supplied items may be

substituted as long as they are of sufficient quality (low of fset

current, high leakage resistance). Using substandard cables

and connectors may degrade the integrity of the measurements made. See paragraph 2.7 for a discussion of measurement considerations.

Table 2-1

Recommended cables and adapters

Model Description

7078-TRX-x

3-slot male triax connectors on

both ends (x=3, 10 or 20 ft.)

237-BAN-3

3-slot male triax to male banana

plug

237-ALG-2

7078-TRX-BNC

3-slot male triax to alligator clips

3-slot male triax to BNC adapter,

connections to center and inner

shell

7078-TRX-GND

3-slot male triax to BNC adapter,

connections to center and outer

shell

7078-TRX-T

3-slot male to dual 3-lug female

triax tee adapter

6171

3-slot male triax to 2-lug female

triax adapter

CA-93-1

BNC to right angle SMB cable

2-3

Page 19

Operation

2.5.3 T riax banana plug adapter

For instruments that use banana jacks, you need a triax cable

terminated with a 3-slot male triax and a single banana plug.

Use the Model 237-BAN-3 or prepare a special cable as outlined below (Special triax to banana plug cable prepara-

tion) using the parts listed in Table 2-2.

Table 2-2

Parts for special triaxial cable

Keithley part or

model number Description

7078-TRX-3 triax cable*

BG-10-2

*One connector must be cut off

Figure 2-4 shows the conductors and insulation layers of a

triaxial cable. These layers must be carefully stripped back,

cleaned thoroughly and insulated with high insulation resistance material such as Teflon to maintain the integrity of

the cable and measurement system. With the Model 237BAN-3, the center conductor of the triax is connected to the

banana plug. The inner and outer shields have no connection.

With the special cable shown in Figure 2-4, the inner shield

is shorted to the center conductor. Which cable to use

depends on your application. The length of unshielded conductor that is connected to the banana plug should be minimized to maintain signal integrity. The topic of signal

integrity is also discussed in paragraph 2.7 Measurement

considerations.

Triax cable terminated with

3-slot male triax connectors

Red banana plug

4. Strip the insulator back 1/2 inch, then twist the strands

of the conductor together as shown in Figure 2-4(C).

5. Unscrew the cover from a banana plug, then slide the

cover over the conductor.

6. Insert the stripped center conductor through the hole in

the body of the banana plug, then wrap the wire around

the plug body as shown in Figure 2-4(D).

7. Screw on the plastic cover as shown in Figure 2-4(E).

Make certain the wire is secure by gently pulling on the

plug.

Cut

1"

(A) Cut off insulation with knife.

Cut off outer shield.

Insulation Over

Inner Shields

3/4"

(B) Strip insulation off inner shield.

(C) Twist inner shield then strip inner conductor.

Twister inner shield and center conductor together,

slip on plastic cover.

Cut

Note that you can use either an unterminated triax cable, or

cut a dual-connector cable (7078-TRX-10) in half to construct two special cables.

Special triax to banana plug cable preparation

The following steps outline a procedure for installing a

banana plug on the end of a triaxial cable (with inner shield

shorted to center conductor).

1. Using a knife, cut and strip back the jacket about 1-1/2

inches.

2. Remove the outer insulation, then cut away the outer

shield as far as the insulation is stripped as shown in Figure 2-4(A).

3. Carefully strip away the insulation over the inner shield

one inch, then cut the inner shield and guard wire off

even with the stripped insulation as shown in Figure

2-4(B).

2-4

(D) Insert wires into hole and wrap around body.

(E) Screw on plastic cover.

Figure 2-4

Triax cable preparation

Page 20

Operation

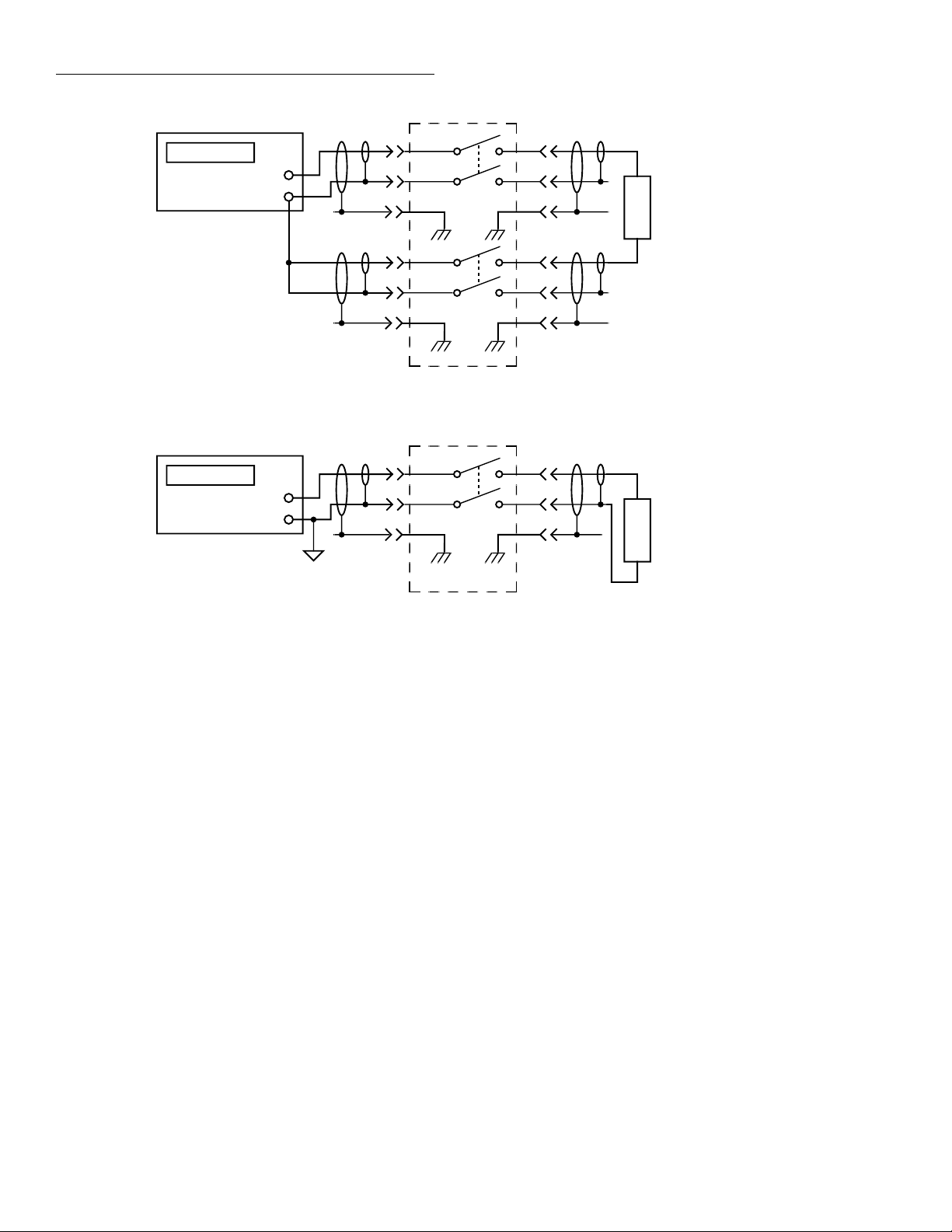

2.5.4 General instrument connections

The following paragraphs discuss connecting the Model

7174A to various general classes of instrumentation such as

DMMs, electrometers, sources, and source/measure units.

Because these configurations are generic in nature, some

modification of the connecting schemes may be necessary

for your particular instrumentation. Also, special cables or

adapters may be necessary. In all cases, 3-lug triax cables

must be used to make the connections.

WARNING

Do not use coaxial cables and adapters

because hazardous voltage from guard

sources may be present on the cable

shields.

Figure 2-5 shows the general instrument connections for the

discussions below. Note that DUT guarding or shielding are

not included here; see Figures 2-22 and 2-23 for shielding

and guarding information. As shown, all figure assume

instruments are connected to rows, and the DUT is connected to columns.

DMM connections

General DMM connections are shown in Figure 2-5 (A), (B),

and (C). Floating connections are shown in (A) with LO and

HI routed to two separate jacks on the Model 7174A. The

common LO connections in (Figure 2-5B) should be used

only for non-critical applications because the performance of

the GUARD pathway is not specified.

WARNING

Hazardous voltage from other guard

sources may be present on LO or the

DUT if other crosspoints are closed.

Electrometer connections

T ypical electrometer connections are shown in Figure 2-5(D)

through (G). The unguarded volts connections in (D) show

the HI signal path routed through one jack, and the LO path

goes through the other connector. Both GUARD pathways

are connected to electrometer LO. For guarded voltage (E),

Model 7174A GUARD is connected to electrometer

GUARD.

The connections for electrometer fast amps and resistance

measurements are shown in Figure 2-5(F) and (G). These

configurations are essentially the same as those discussed

above. For the case of fast amps, both GUARD paths are

connected to electrometer LO, while in the case of guarded

resistance, one GUARD path is connected to electrometer

GUARD, and the other GUARD path is connected to electrometer LO.

Source connections

Voltage and current source connections are shown in Figure

2-5(H) through (J). The HI and LO paths of the voltage

source (H) are routed through two jacks, with both card

GUARD pathways connected to voltage source LO. For the

unguarded current source connections (I), card GUARD is

again connected to source LO, with source HI and LO routed

through two pathways. In the case of the guarded current

source in (J), card GUARD of the HI signal path is connected

to source GUARD, and the other GUARD path is connected

to source LO.

Source/measure unit connections

Figure 2-5(K) shows typical connections for a source/measure unit (SMU). In this instance, a remote-sensing type of a

SMU is shown, requiring a total of four signal pathways to

the DUT. For critical measurements, both source and sense

HI pathways would be guarded as shown, with two of the

four card GUARD pathways connected to SMU GUARD

terminals. As with other instrument connections, the LO card

GUARD pathways are connected to SMU LO terminals.

4-wire DMM connections are shown in Figure 2-5(C). In this

case, a total of four jacks are required; HI, LO, SENSE HI,

and SENSE LO.

2-5

Page 21

Operation

Rows Columns

S

ignal

HI

LO

DMM

A.) DMM Floating

Rows Columns

HI

LO

DMM

Warning:Hazardous voltage from guard

sources may be present on LO.

Guard

Signal

Guard

Signa

Guard

7174A

l

7174A

DUT

DUT

Note: Use this configuration only for

non-critical measurements.

B.) DMM Common LO

Figure 2-5

General instrument connections

2-6

Page 22

Operation

Sense HI

Sense LO

DMM

HI

LO

Rows Columns

Signal

Guard

Signal

Guard

DUT

Signal

Guard

Signal

Guard

C.) DMM 4-Wire

LO

Electrometer

D.) Electrometer, Unguarded Volts

Figure 2-5

General instrument connections (cont.)

HI

7174A

Rows Columns

Signal

Guard

DUT

Signal

Guard

7174A

2-7

Page 23

Operation

Rows Columns

Signal

HI

Guard

LO

Electrometer

E.) Electrometer, Guarded Volts

HI

LO

Electrometer

Guard

DUT

Signal

Guard

7174A

Rows Columns

Signal

Guard

DUT

Signal

Guard

F.) Electrometer,Fast Current

HI

LO

Guard

Electrometer

G.) Electrometer, Resistance (Guarded)

Figure 2-5

General instrument connections (cont.)

7174A

Signal

Guard

DUT

Signal

Guard

7174A

2-8

Page 24

ignal

S

Operation

HI

LO

Voltage

Source

H.) Voltage Source

HI

LO

Electrometer

Guard

DUT

Signal

Guard

7174A

Signal

Guard

DUT

Signal

Guard

I.) Current Source, Unguarded

Guard

Current Source

J.) Current Source, Guarded

Figure 2-5

General instrument connections (cont.)

HI

LO

7174A

Rows Columns

Signal

Guard

DUT

Signal

Guard

7174A

2-9

Page 25

Operation

Force

IorV

Sense

VorI

Source/Measure

Guard

Guard

Unit

HI

LO

HI

LO

Rows Columns

Signal

ua

G

Signal

Guard

S

ignal

uard

G

Signal

Guard

d

r

DUT

K.) Source/Measure Unit

Note: DUT shielding/guarding not shown. See Figures 2-20 and 2-21.

Figure 2-5

General instrument connections (cont.)

7174A

2-10

Page 26

Operation

2.5.5 Keithley instrument connections

The following paragraphs outline connecting typical Keithley instruments to the Model 7174A 8 × 12 Low Current

Matrix Card. Other similar instruments can be connected

using the same cabling as long as their input/output configurations are the same. Instrument connections covered

include:

• Model 617 Electrometer/Source

• Model 196 DMM

• Model 230 Programmable Voltage Source

• Model 220 Programmable Current Source

• Model 590 CV Analyzer

• Model 236/237/238 Source Measure Unit

Model 617 electrometer connections

Connections for the Model 617 Electrometer are shown in

Figure 2-6. The electrometer INPUT and COM can be con-

6172 2-slot to 3-lug

Triax Adapter

Guard off

COM

INPUT

Model 617

nected to any row. Figure 2-6 shows connections to rows A

and B.

1. Connect one end of a Model 7078-TRX- (3, 10, or 20)

3-lug triaxial cable to row A of the Model 7174A.

2. Connect the other end of the triax cable to the Model

617 INPUT connector using a Model 6172 adapter.

3. Connect the triax end of a triax/banana cable to row B of

the Model 7174A.

4. Connect the banana plug end of the triax/banana cable

to the COM terminal of the Model 617. The shorting

link between COM and chassis ground should be removed for this application.

5. Place the GUARD switch in the OFF position.

6. T o connect the v oltage source to the Model 7174A, connect the V-SOURCE HI and LO connector of the Model

617 to the desired row connectors on the matrix card.

Figure 2-6 shows connections to rows C and D.

KEITHLEY

7174A

8x12LOW

CURRENT MATRIX

SIGNAL

200VP K

COLUMNS

200VPK

GUARD

200VP K

7078 - TRX Triax

237-BAN-3 o r Special Triax

237-BAN-3

ROWS

1

A

2

B

3

C

4

D

5

L

6

7

Voltage Source

Connections

Figure 2-6

Model 617 electrometer connections

237-BAN-3 o r Special Triax

Note: See paragraph 2.5.3 and Figure

2-4 f or special triax to banana

cable.

8

E

9

F

10

G

H

!

WARNING:

TIGHTENMOUNTINGSCREWS

TOENSUREPROPER

CHAS SIS GRO UND

11

12

7174A Matrix Card

2-11

Page 27

Operation

Model 196 DMM connections

Connect the Model 196 or other similar DMM to the matrix

card using the general configuration shown in Figure 2-7.

The V OLTS OHMS HI and LO terminals should be connected to the desired rows using triax/banana cables. For 4-wire

ohms measurements, the OHMS SENSE HI and LO termi-

237-BAN-3

237-BAN-3

or Special

Triax

HI

nals should be connected to two additional rows using the

same type of cables.

NOTE

For low-level voltage measurements, connect the inner shield of the HI cable to

VOLT OHMS LO to minimize noise.

KEITHLEY

7174A

8x12LOW

CURRENT MATRIX

SIGNAL

COLUMNS

200VP K

200VPK

GUARD

200VPK

ROWS

A

B

C

D

1

2

Note

3

4

5

L

6

: See paragraph 2.5.3

and Figur

special triax to banana

2-4 for

e

cable.

196 DMM

Connect inner shield to LO for

low-levelmeasurements.

(Modify the cable of Figure 2-4.)

Figure 2-7

Model 196 DMM connections

LO

7

8

E

F

G

H

TIGHTE N MOUNTING SCR EWS

WARNING:

TOENSUREPROPER

CHASSIS GROUND

9

10

11

12

!

7174A Matrix Card

2-12

Page 28

Operation

Model 230 voltage source connections

Connect the Model 230 OUTPUT and COMMON terminal

to the desired rows using triax/banana plug cables, as shown

Common

230 C urrent Source

Note: See paragraph 2.5.3 and Figure

2-4 for special triax to banana cable.

Output

in Figure 2-8. For remote sensing applications, the SENSE

OUTPUT and SENSE COMMON connectors can be routed

through two additional rows using similar cables.

KEITHLEY

7174A

8x12LOW

CURRENT MATRIX

SIGNAL

COLUMNS

200VP K

200VP K

GUARD

200VPK

237-BAN-3 or Special Triax

237-BAN-3

ROWS

A

B

C

D

E

F

G

H

WARNING:

TIGHTENMOUNTING SCRE WS

TOE NSURE P R OPER

CHASSIS GROUND

1

2

3

4

5

6

7

8

9

10

11

12

!

Figure 2-8

Model 230 voltage source connections

7174A Matrix Card

2-13

Page 29

Operation

Model 590 CV analyzer connections

The Model 590 CV analyzer can be connected to any row or

any column as shown in Figure 2-9. The BNC cables that are

. .

590 CV Analyzer

supplied with the Model 590 can be used; however, Model

7078-TRX-BNC adapters must be used at the Model 7174A

end.

7078-TRX-BNC

Triax-to-BNC

Adapters

7051 BNC Cables

KEITHLEY

8x12LOW

CURRENT MATRIX

SIGNAL

200VPK

200VPK

GUARD

200VP K

ROWS

A

B

C

D

E

F

G

H

WARNING :

TIGHTENMOUNTINGSCREWS

TOENSUREPROPER

CHASSISGROUND

7174A

COLUMNS

!

1

2

3

4

5

6

7

8

9

10

11

12

Figure 2-9

Model 590 CV analyzer connections

7174A Matrix Card

2-14

Page 30

Operation

Model 220 current source connections

The Model 220 current source can be connected to the matrix

card using the Model 6167 Guarded Adapter, as shown in

Figure 2-10. This configuration guards the output signal to

minimize the effects of distributed capacitance and leakage

current.

NOTE

The Model 6167 adapter must be modified

by internally disconnecting the inner

shield connection of the input jack from

the GUARDED/UNGUARDED selection

switch. Otherwise, instrument LO will be

Model 6167

Guarded Adapter

connected to chassis ground through the

adapter.

1. Connect the Model 6167 adapter to the Model 220

OUTPUT jack.

2. Connect a Model 7078-TRX-(3, 10 or 20) triax cable

between the guarded adapter and the desired row of the

Model 7174A.

3. Connect the Model 220 GUARD output to GUARD

INPUT terminal of the adapter.

4. Connect the triax end of a triax/banana cable to the

desired row on the Model 7174A.

5. Connect the banana plug end of the triax/banana cable

to the OUTPUT COMMON jack of the Model 220.

KEITHLEY

7174A

8x12LOW

CURRENT MATRIX

SIGNAL

COLUMNS

200VP K

200VP K

GUARD

200VPK

7078-TRX T riax

237-BAN-3 or Special Triax

ROWS

1

A

2

B

3

C

4

D

5

6

Connect GUARD OUT

to GUARD

Note: See paragraph 2.5.3 and Figure

2-4 for special triax to banana cable.

Figure 2-10

Model 220 current source connections

220 C urrent Source

7

8

E

F

G

H

TIGHTENMOUNTING SCRE WS

WARNING:

TOE NSURE P R OPER

CHASSIS GROUND

9

10

11

12

!

7174A Matrix Card

2-15

Page 31

Operation

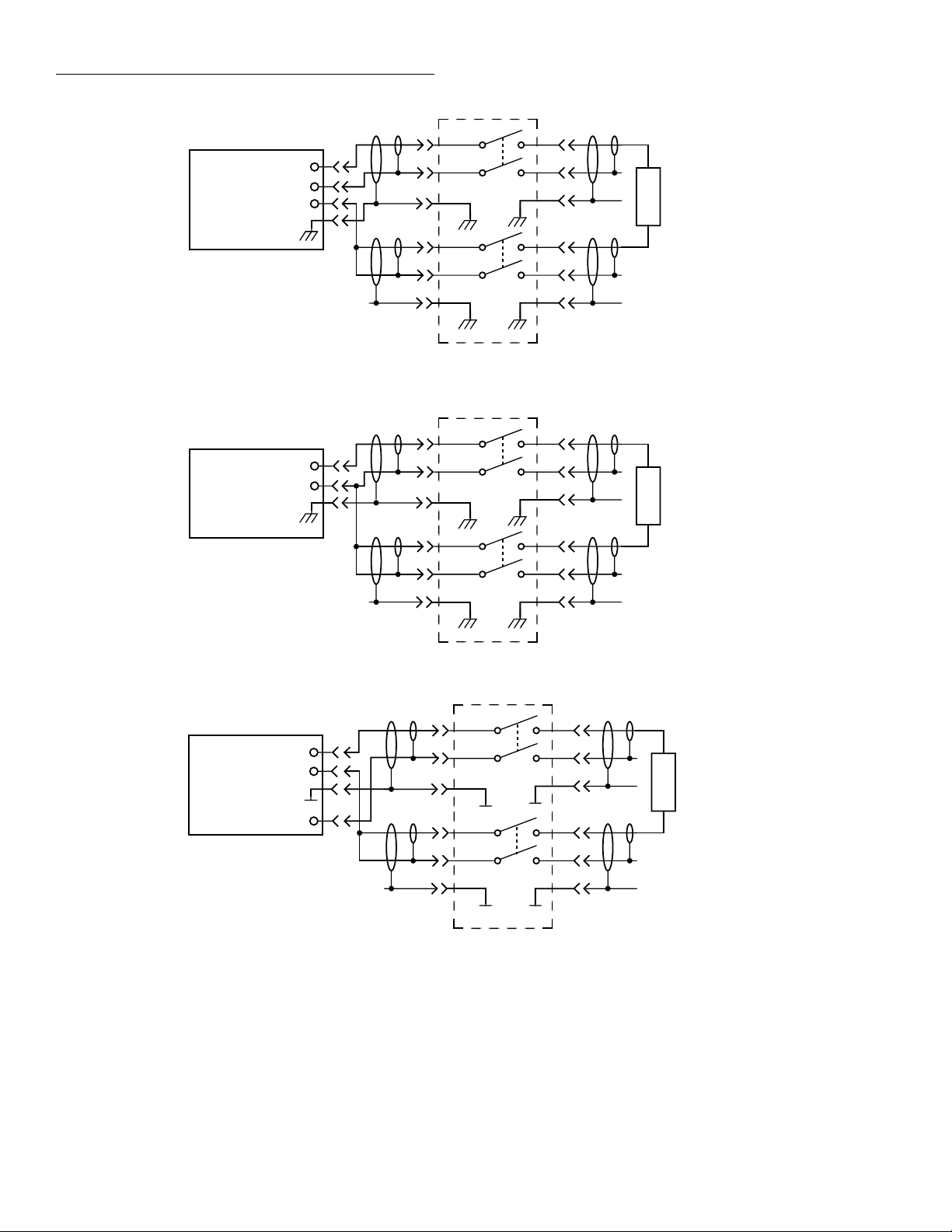

Model 236/237/238 source measure unit connections

Source measure units are connected to the matrix card using

Model 7078-TRX cables. A Model 237-B AN-3 triax/banana

cable can also be used to connect the output low binding post

on the source measure unit to the matrix. Figure 2-11 shows

connections for remote and local sensing applications.

LINERATING

TRIGGER

MAXOUTPUT

KEITHLEY

GUARD

!

110V

MADEIN

U.S.A.

LO

HI

HI

OUTPUT

OUTPUT

SENSE

GUARD

A. Remote Sensing

OUT IN

OUTPUT

SENSE

LO

LO

LINEVOLTAGE

200V

MAX

SELECTED

LINEF USE

SLOWBLOW

INTERLOCK

50-60Hz

1

ACONLY

100VAMAX

2

IEEE-488INTERFACE

ADDRESSENTERED VIA

FRONTPANEL PROGRAM

CAL

ENABLE

7078-TRX Triax

7078-TRX Triax

7078-TRX Triax

CAUTION

Models 237 and 238 source measure

units can only be used within the specified maximum signal levels of the Model

7174A (200V, 2A).

KEITHLEY

7174A

8x12LOW

CURRENTMATRIX

SIGNAL

200VPK

200VPK

COLUMNS

GUARD

200VPK

ROWS

1

A

2

B

3

C

4

D

5

6

7

8

E

9

F

10

G

11

H

12

WARNING:

!

TIGHTENMOUNTING SCREWS

TOENSUREPROPER

CHASSISGROUND

7174A Matrix Card

TRIGGER

OUT IN

MAXOUTPUT

KEITHLEY

GUARD

!

110V

MADEIN

U.S.A.

OUTPUT

OUTPUT

SENSE

LO

LO

LO

HI

HI

200V

MAX

OUTPUT

SENSE

GUARD

LINEVOLTAGE

SELECTED

LINEF USE

SLOWBLOW

INTERLOCK

ENABLE

B. Local Sensing

Figure 2-11

Model 236/237/238 source measure unit connections

7078-TRX Triax

237-BAN-3 or Special Triax

LINERATING

50-60Hz

1

ACONLY

100VAMAX

2

IEEE-488INTERFACE

ADDRESSENTERED VIA

FRONTPANELPROGRAM

CAL

Caution:

The models 237 and 238 Source Measure Units

can only be used within the specified maximum

signal levels of the Model 7174A (200V, 2A carry).

KEITHLEY

7174A

8x12LOW

CURRENTMATRIX

SIGNAL

COLUMNS

200VPK

200VPK

GUARD

200VPK

ROWS

1

A

2

B

3

C

4

D

5

6

7

8

E

9

F

10

G

11

H

12

!

WARNING:

TIGHTENMOUNTINGSCREWS

TOENSURE PROPER

CHASSISGROUND

7174A Matrix Card

2-16

Page 32

Operation

2.5.6 T ypical test fixture connections

Typically, one or more test fixtures will be connected to

desired columns of the Model 7174A. Typically, the test fix-

tures will be equipped with card-edge connectors with wires

soldered to them. In some cases, the test fixture will be

equipped with triax connectors; for those types, Keithley

Model 7078-TRX-(3, 10, or 20) cables can be used, as shown

in Figure 2-12.

WARNING

Do not use BNC cables and adapters in

cases where hazardous voltages from

guard sources could be present on the

BNC cable shields.

KEI THLE Y

7174A

8x12LOW

CURRENTMATRIX

SIGNAL

COLUMNS

200VP K

200VP K

GUARD

200VP

K

ROWS

A

B

C

D

1

2

3

4

5

Internally, the test fixture should be wired as shown in the

equivalent circuit of Figure 2-13. SIGNAL should be connected to the probe or other device contact points, while

GUARD should be carried through as close to the device as

possible. If coaxial probes are to be used, connect GUARD

to the probe shield if the probe shield is insulated from the

fixture shield.

Usually, the chassis ground terminal of the triax connector

will automatically make contact with the fixture shield by

virtue of the mounting method. However, ground integrity

should be checked to ensure continued protection against

hazardous guard voltages.

3 - Lug Female

Test Fixture

Triax Connectors

(or run cables through strain

reliefs and connect internally)

6

7

8

E

F

G

H

TIGHT EN MOUNTING S CR EWS

WARNING:

TOENSUREPROPER

CHAS SIS GR OUND

9

10

11

12

!

7174A Matrix Card

Figure 2-12

Typical test fixture connections

®

Note: Teflon

-insulated connectors

recommended for specified

performance.

Warning:Donot use BNC connectors

to avoid possible shock

hazard.

2-17

Page 33

Operation

Triax Cable

Signal

Probe

From

7174A

Card

Guard

Chassis

Ground

Figure 2-13

Equivalent circuit of test fixture connections

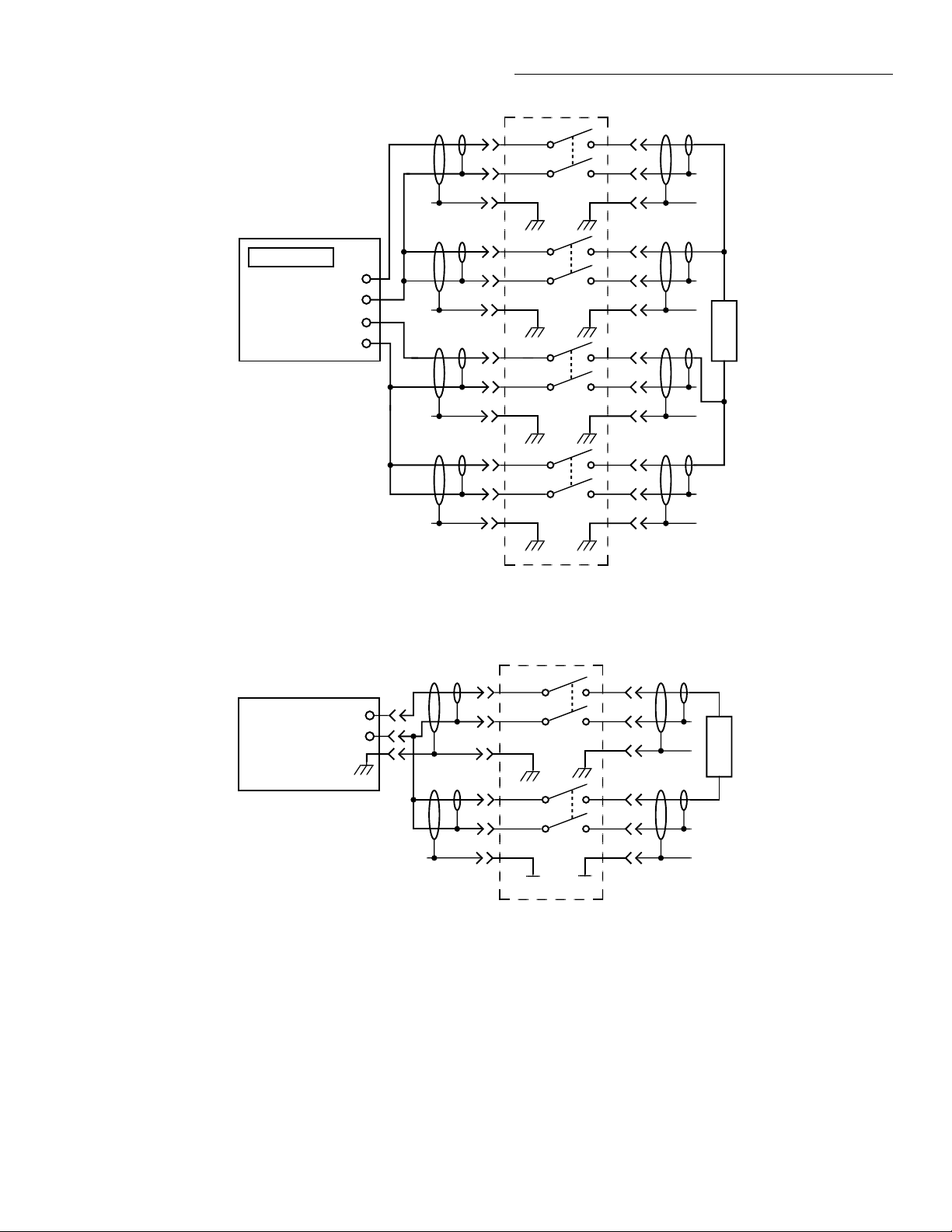

2.6 Matrix configuration

This section describes the matrix configuration of the Model

7174A. It also explains ways to expand the matrix by installing and connecting additional matrix cards in the Model

707A Switching Matrix.

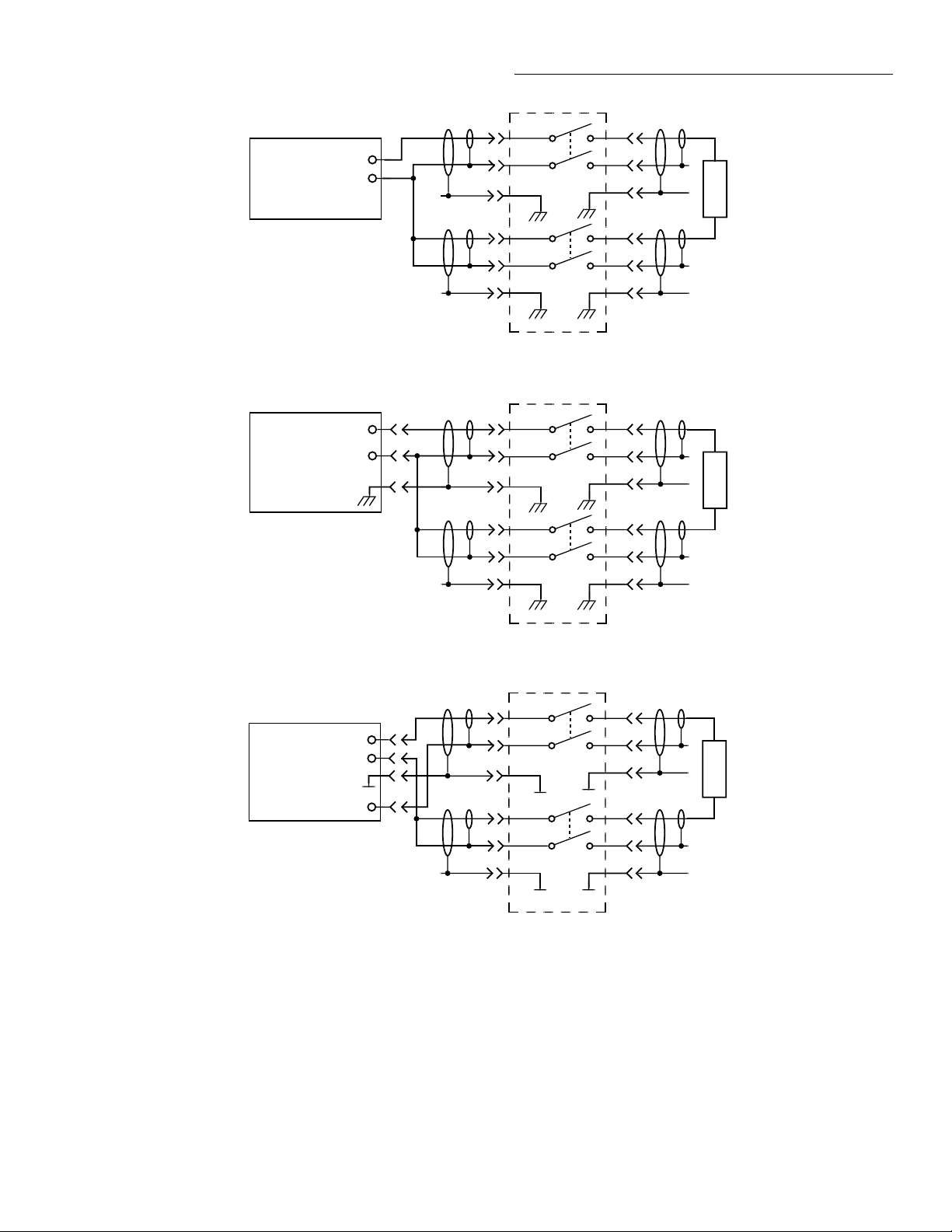

2.6.1 Switching matrix

As shown in Figure 2-14, the Model 7174A is organized as

an 8 × 12 (8 rows by 12 columns) matrix. The rows on the

card are labeled A through H while the columns are numbered 1 through 12. The actual column number to use when

programming depends on the slot and unit number (Table

2-3). For example, card column number 2 on a card in slot 5

of unit 1 is accessed as matrix column 50.

Wafer

Test Fixture Chassis

Each intersecting point in the matrix is called a crosspoint

that can be individually closed or opened by programming

the Model 707A mainframe. By closing the appropriate crosspoint, required pathways and pins may be connected. All

crosspoints are configured for 2-pole switching, as shown in

Figure 2-14. SIGNAL and GUARD are switched separately

to any of the 12 columns on the card.

2.6.2 Path isolators

The path isolator relay switches shown in Figure 2-14 serve

to isolate a given path from the rest of the matrix when no

crosspoint (relay) is closed in that pathway. This topology

minimizes leakage current and capacitance to pathways

which are active. These isolators close automatically when

any crosspoint on the path is closed and open automatically

when all crosspoints on the path are opened.

2-18

Page 34

Columns

HGC HG C HG C HGC HGC HGC HGC HG C HGC HGC HGC

Operation

HGC

User

connections

and expansion

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Path Isolator

Relay Switch

Signal Guard

Row

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Signal

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Guard

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Note: For schematic,

refer to Section 5.

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

H

G

C

H

G

C

H

G

C

H

G

C

H

G

C

H

G

C

H

G

C

H

G

C

Rows

Column

Figure 2-14

Matrix configuration

2-19

Page 35

Operation

Table 2-3

Column numbering by slot and unit

Unit Slot Columns (1 through 12)

1

1