Page 1

www.keithley.com

Series 3700 System Switch/Multimeter

Quick Start Guide

3700S-903-01 Rev. A / August 2007

3700S-903-01.qxd 8/10/07 3:27 PM Page 1

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of

one (1) year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

software, rechargeable batteries, diskettes, and documentation.

During the warranty period, Keithley Instruments will, at its option, either repair or replace any product that proves

to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions.

Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original

warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments’ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software,

non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE

OF ITS INSTRUMENTS AND SOFTWARE, EVEN IF KEITHLEY INSTRUMENTS, INC. HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COST OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF

INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (1-888-534-8453) • www.keithley.com

Keithley Instruments, Inc.

3/07

Page 3

Page 4

System Switch/Multimeter

Series 3700

Quick Start Guide

Document Number: 3700S-903 -01 Rev. A / August 2007

©2007, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Page 5

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for

this manual. The Revision Level letter increases alphabetically as the manual undergoes

subsequent updates. Addenda, which are released between Revisions, contain important

change information that the user should incorporate immediately into the manual. Addenda are

numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the new Revision of the manual. Each

new Revision includes a revised copy of this print history page.

Document Number: 3700S-903-01 Rev. A ........................................ August 2007

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 6

Safety Precautions

The following safety precautions should be observed before using this product an d any associated instrumentation. Although some

instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may

be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer

to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the instrument.

They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or

replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained service

personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rate d Measurement Category I and Measurement

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient

over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak,

or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators are

prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact.

Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of

operating at or above 1000V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited sources. NEVER

connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit f

and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

ault current

06/07

Page 7

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power

!

disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test.

AL W AYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers,

installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information,

and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid

interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the user documentaion.

The symbol on an instrument shows that it can source or measure 1000V or more, including the combined effect of normal and

common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product , it indicates that mercur y is present in the display lamp. Please note that the lamp must be properly

disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read the

associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

T o maintain protection from electric shock and fire, replacement components in mains circuits - including the power transformer, test leads,

and input jacks - must be purchased from Keithley Instruments. Standard fuses with applicable national safety approvals may be used if

the rating and type are the same. Other components that are not safety-related may be purchased from other suppliers as long as they

are equivalent to the original component (note that selected parts should be purchased only through Keithley Instruments to maintain

accuracy and functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley Instruments

office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply cleaner

directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis

(e.g., a data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the

board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

Page 8

Table of Contents

Introduction 1-1

Overview ...................................................................................................................... 1-1

Measure and switching capabilities ................................................................ ................. 1-2

Introduction .................................................................................................................... 1-2

User manual content ...................................................................................................... 1-2

Reference manual content .............................................................................................. 1-3

Warranty information .................................................................................................... 1-3

Displaying the unit's serial number .................................................................................. 1-4

Safety symbols and terms ............................................................................................ 1-4

Using the Front Panel 2-1

Front panel introduction ................................................................................................ 2-1

Display ......................................................................................................................... 2-3

Front panel keys .......................................................................................................... 2-6

Special keys and power switch ....................................................................................... 2-6

Operation keys ............................................................................................................... 2-7

Range, multifunction keys, and wheel ............................................................................. 2-8

Function keys ................................................................................................................. 2-8

Rear Panel 3-1

Rear panel summary .................................................................................................... 3-1

Rear panel connections ................................................................................................ 3-2

Analog backplane AMPS fuse ......................................................................................... 3-2

Slots .............................................................................................................................. 3-2

TSP-Link connector ........................................................................................................ 3-2

Instrument fuse .............................................................................................................. 3-2

Power connector ............................................................................................................ 3-2

Digital I/O port ................................................................................................................ 3-3

GPIB connector .............................................................................................................. 3-4

Ethernet connector (RJ-45) ............................................................................................. 3-4

USB connectors ............................................................................................................. 3-4

Analog backplane connector ........................................................................................... 3-5

Switching module installation and connections ............................................................. 3-6

Module installation ....................................................................................................... 3-7

Connections ................................................................................................................... 3-9

Pseudocards ................................................................................................................ 3-10

Channel assignments ................................................................................................... 3-10

Bus operation ............................................................................................................. 3-11

Power-up ................................................................ ................................................... 3-12

Line power connection .................................................................................................. 3-12

Power-up sequence ...................................................................................................... 3-13

Page 9

Contents Series 3700 System Switch/Multimeter Quick Start Guide

Contents Document Number: 3700S-903 -01 Rev. A / August 2007

Frequently Asked Questions 4-1

General questions ................................ ................................................................ ........ 4-1

How do I power up the instrument? ................................................................................. 4-1

How do I control switches? ............................................................................................. 4-2

How do I make measurements? ...................................................................................... 4-7

How do I save data to a USB flash drive? ...................................................................... 4-10

How can I save/recall setups from the internal memory or USB drive? ........................... 4-10

Questions about web page operation ......................................................................... 4-12

How do I connect to the internal web page? .................................................................. 4-12

What am I able to do through the web page? ................................................................. 4-13

Questions about remote operation .............................................................................. 4-15

What remote interfaces can I use? ................................................................................ 4-15

How do I use Test Script Builder? ................................................................................. 4-17

TSB main sections ....................................................................................................... 4-19

How can I use TSB to make measurements? ................................................................ 4-20

How do I use other programs? ...................................................................................... 4-21

Questions about Test Script Processor interaction ...................................................... 4-24

What is a script? ........................................................................................................... 4-24

How do I run a script from the front panel? .................................................................... 4-24

How do I interact with scripts from Test Script Builder? .................................................. 4-25

Index Index - 1

Page 10

List of Figures

Figure 1-1: DMM measurement capabilities ................................................................ ......... 1-2

Figure 2-1: Model 3706 System Switch/Multimeter ................................ .............................. 2-1

Figure 2-2: Model 3706-S System Switch (no DMM)............................................................ 2-2

Figure 2-3: Model 3706-NFP System Switch/Multimeter ...................................................... 2-2

Figure 2-4: Model 3706-SNFP System Switch (no DMM) ..................................................... 2-3

Figure 2-5: Active channel display example ......................................................................... 2-3

Figure 2-6: MAIN MENU display .......................................................................................... 2-6

Figure 3-1: Rear panel features ................................................................ ........................... 3-1

Figure 3-2: Digital I/O port ................................................................................................... 3-3

Figure 3-3: USB connectors ................................................................................................ 3-5

Figure 3-4: Analog backplane connector ............................................................................. 3-5

Figure 3-5: Typical module installation................................................................................. 3-8

Figure 4-1: Multiplexer card display ..................................................................................... 4-5

Figure 4-2: Matrix card display ............................................................................................ 4-6

Figure 4-3: Two-wire resistance measurements .................................................................. 4-7

Figure 4-4: Two-wire switching module resistance connection ............................................. 4-8

Figure 4-5: Setup menu....................................................................................................... 4-12

Figure 4-6: Network address example ................................................................................. 4-12

Figure 4-7: Home page ....................................................................................................... 4-14

Figure 4-8: GPIB cable ........................................................................................................ 4-16

Page 11

Page 12

In this section:

Overview ........................................................................................................ 1-1

Warranty information ....................................................................................... 1-3

Safety symbols and terms ............................................................................... 1-4

Section 1

Introduction

Overview

If you have any questions after reviewing this information, please contact your local

Keithley Instruments representative or call one of our Applications Engineers at

1-888-KEITHLEY (1-888-534-8453). You can also contact us through our website at

www.keithley.com.

The Series 3700 instruments offer scalable, instrument grade switching and multi-channel

measurement solutions that are optimized for automated testing of electronic products and

components. The Series 3700 includes four versions of the Model 3706 system switch

mainframe along with a growing family of plug-in switch and control cards. When the Model

3706 mainframe is ordered with the high performance multimeter, you receive a tightly

integrated switch and measurement system that can meet the demanding application

requirements in a functional test system or provide the flexibility needed in stand-alone data

acquisition and measurement applications.

Page 13

Section 1: Introduction Series 3700 System Switch/Multimeter Quick Start Guide

1-2 Document Number: 3700S-903 -01 Rev. A / August 2007

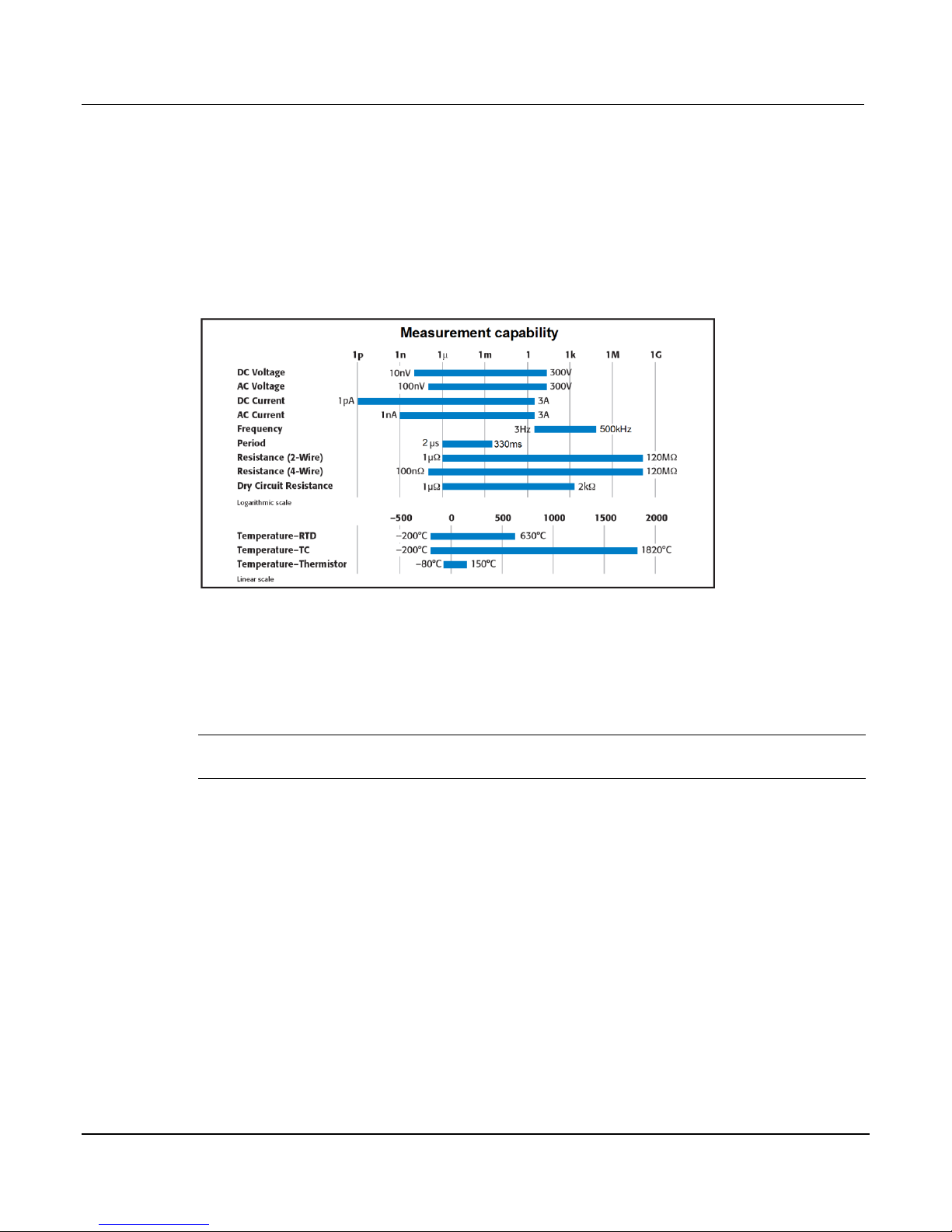

Measure and switching capabilities

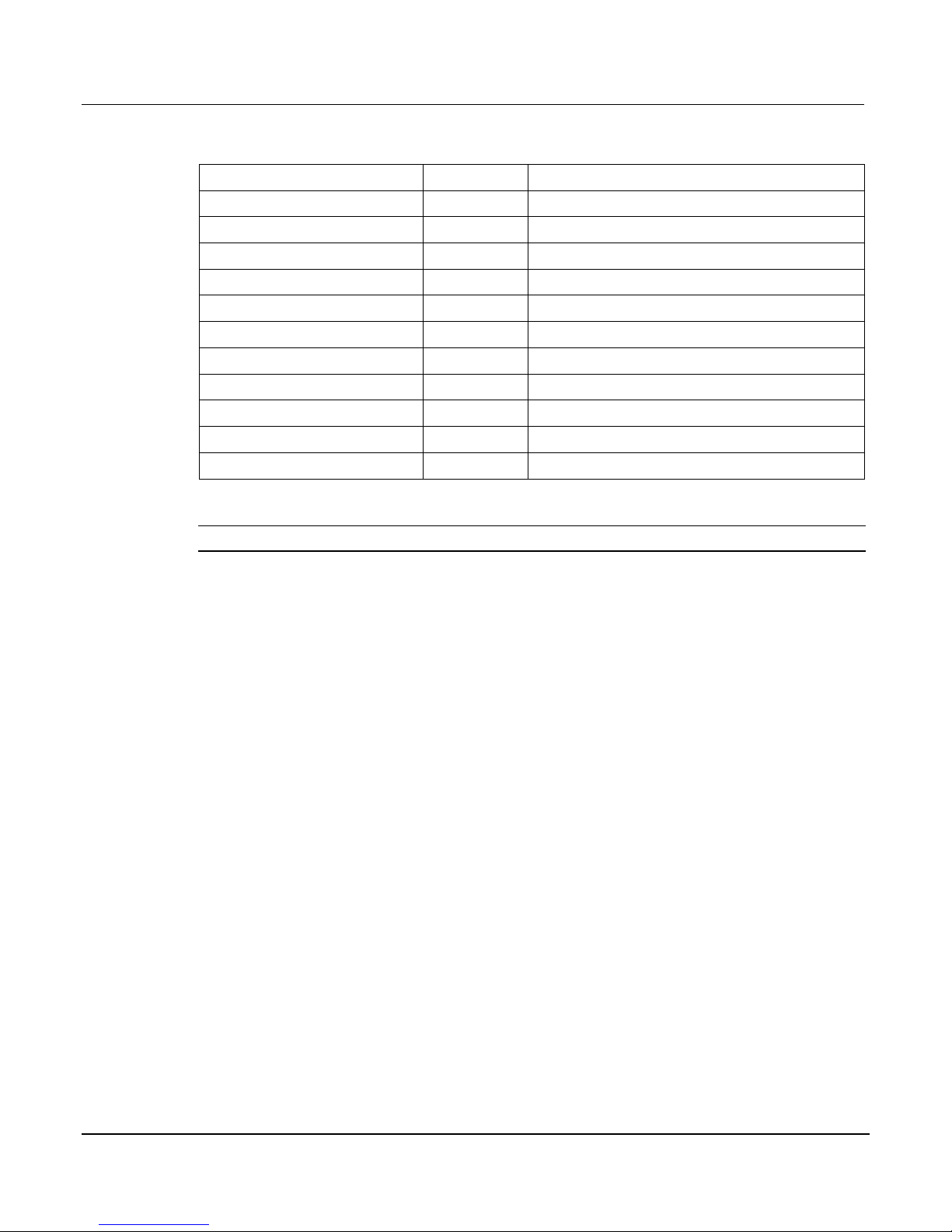

The basic measurement capabilities of Series 3700 systems are summarized in the following

figure.

Figure 1-1: DMM measurement capabilities

Introduction

This Quick Start Guide is intended to get a new user familiar with the operation of the

instrument. It summarizes operation for basic measurement functions and most features of the

Series 3700 instruments as well as provides answers to frequently asked questions.

NOTE In this guide, front panel controls are described. Your specific Series 3700 model may

or may not be equipped with all front panel controls and indicators shown.

User manual content

Refer to the Series 3700 User’s Manual for Series 3700 operations including a listing of

applicable Instrument Control Library (ICL) commands. The User's Manual includes important

additional information on topics covered in the Quick Start Guide, and full details on topics not

covered in this guide.

Details on the switching modules are covered in the Section 9 of the User’s Manual.

Page 14

Series 3700 System Switch/Multimeter Quick Start Guide Section 1: Introduction

Document Number: 3700S-903-01 Rev. A / August 2007 1-3

Reference manual content

Refer to the Series 3700 Reference Manual for specific listing of advanced operation including:

Range

Digits

Rate Bandwidth

Filter

Relative

Math

dB

Buffer

Scanning

Calibration

Also included in the reference manual is a detailed listing of the Instrument Control Library (ICL)

commands.

Warranty information

Detailed warranty information is located at the front of this manual. Should your Series 3700

require warranty service, contact the Keithley Instruments representative or authorized repair

facility in your area for further information. When returning the instrument for repair, be sure to

complete the service form at the back of this manual and give it to the repair facility with all

relevant information.

NOTE The service form requires the serial number of the Series 3700. The serial number

label is located inside the unit on the bottom panel. The serial number can be viewed

by removing the slot covers and/or switching modules from the mainframe.

WARNING Before removing (or installing) switching modules, make sure you turn off

the Series 3700 and disconnect the line cord. Also, remove any other

external power connected to the instrument or switching module(s).

Failure to remove power before removing (or installing) switching

modules may result in personal injury or death due to electric shock.

Page 15

Section 1: Introduction Series 3700 System Switch/Multimeter Quick Start Guide

1-4 Document Number: 3700S-903 -01 Rev. A / August 2007

Displaying the unit's serial number

To display the serial number on the front panel:

NOTE If the Series 3700 is in remote mode, press the EXIT key once to place the unit in local

mode.

1. When in local mode, press the MENU key.

2. Scroll to the SYSTEM-INFO menu and press the ENTER key.

3. On the SYSTEM INFORMATION menu, scroll to the SERIAL# and press the ENTER key.

The Series 3700 serial number will be displayed.

Safety symbols and terms

The following symbols and terms may be found on the System Switch/Multimeter or used in this

manual:

The symbol indicates that the user should refer to the operating instructions located in the

manual.

The symbol shows that high voltage may be present on the terminal(s). Use standard safety

precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to

prevent burns.

The WARNING heading used in this manual explains dangers that might result in personal

injury or death. Always read the associated information very carefully before performing the

indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage the unit. Such

damage may invalidate the warranty.

Page 16

In this section:

Front panel introduction ................................................................................... 2-1

Display ........................................................................................................... 2-3

Front panel keys ............................................................................................. 2-6

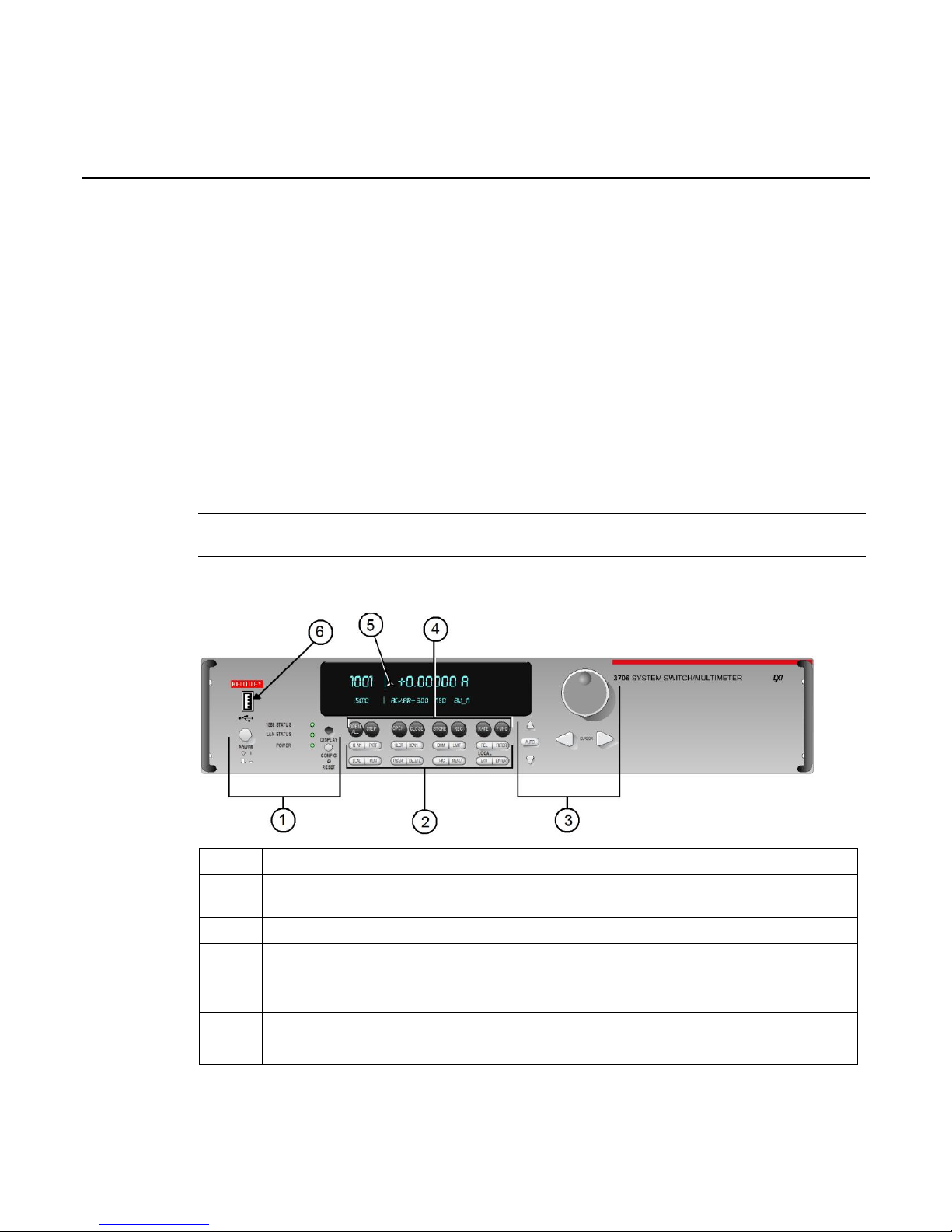

Item

Description

1

Special keys and power switch (quick start guide) (see "Special keys and power switch" on

page 2-6)

2

Operation keys (quick start guide) (see "Operation keys" on page 2-7)

3

Range, multifunction keys, and wheel (quick start guide) (see "Range, multifunction keys,

and wheel" on page 2-8)

4

Function keys (quick start guide) (see "Function keys" on page 2-8)

5

Display (on page 2-3)

6

USB connector (see "USB connectors" on page 3-4)

Section 2

Using the Front Panel

Front panel introduction

Typical Series 3700 front panels are shown below.

NOTE Not all models will have a DMM installed. All DMM related documentation is not

applicable to those models.

Figure 2-1: Model 3706 System Switch/Multimeter

Page 17

Section 2: Using the Front Panel Series 3700 System Switch/Multimeter Quick Start Guide

2-2 Document Number: 3700S-903 -01 Rev. A / August 2007

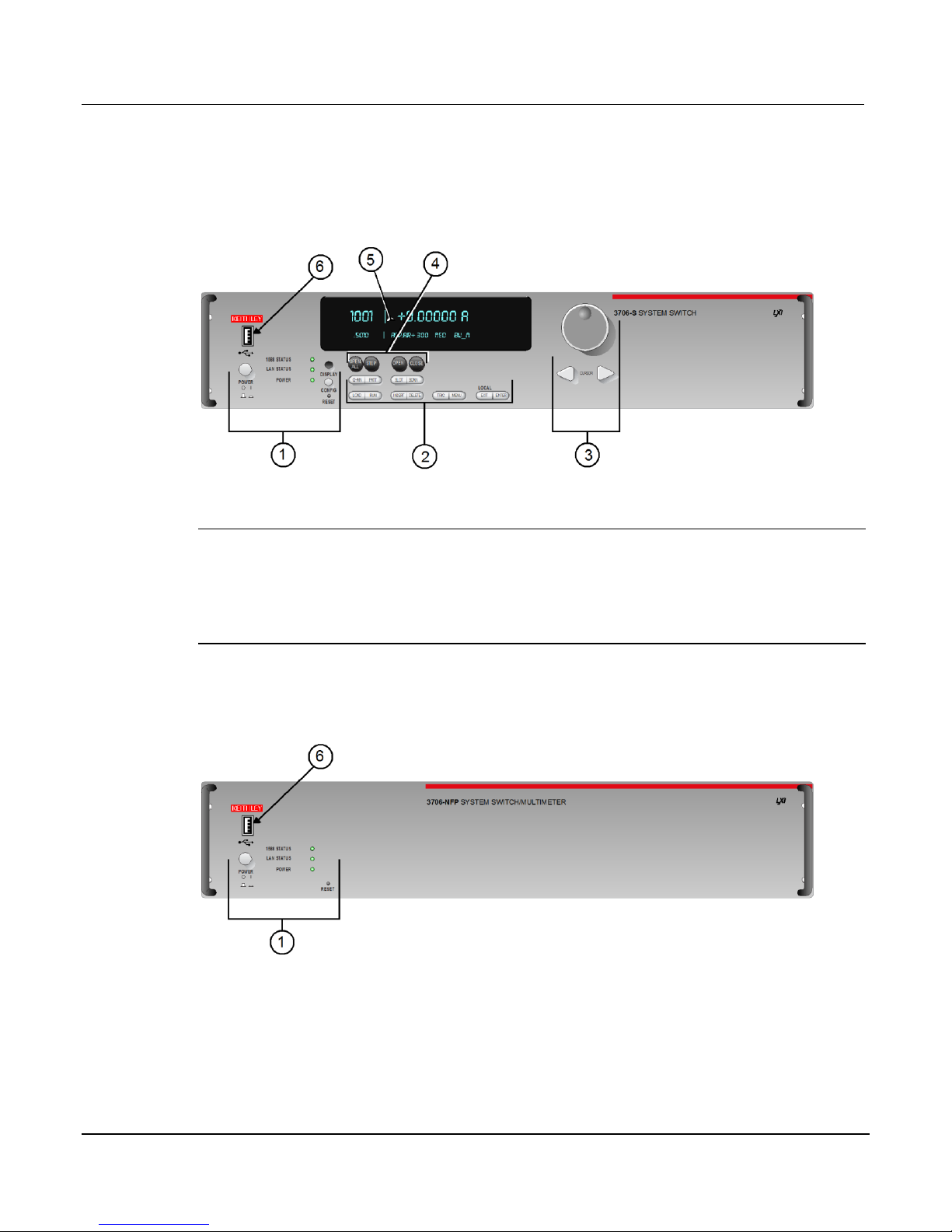

Figure 2-2: Model 3706-S System Switch (no DMM)

NOTE If your model does not have a front panel, please refer to the reference manual for

information on how to change:

1. GPIB address with gpib.address command.

2. LAN configuration using LAN functions. To see current settings for LAN, see the

applicable lan.status.* commands (for example, to see the present IP address of the

Series 3700, send the following command: lan.status.ipaddress.

Figure 2-3: Model 3706-NFP System Switch/Multimeter

Page 18

Series 3700 System Switch/Multimeter Quick Start Guide Section 2: Using the Front Panel

Document Number: 3700S-903-01 Rev. A / August 2007 2-3

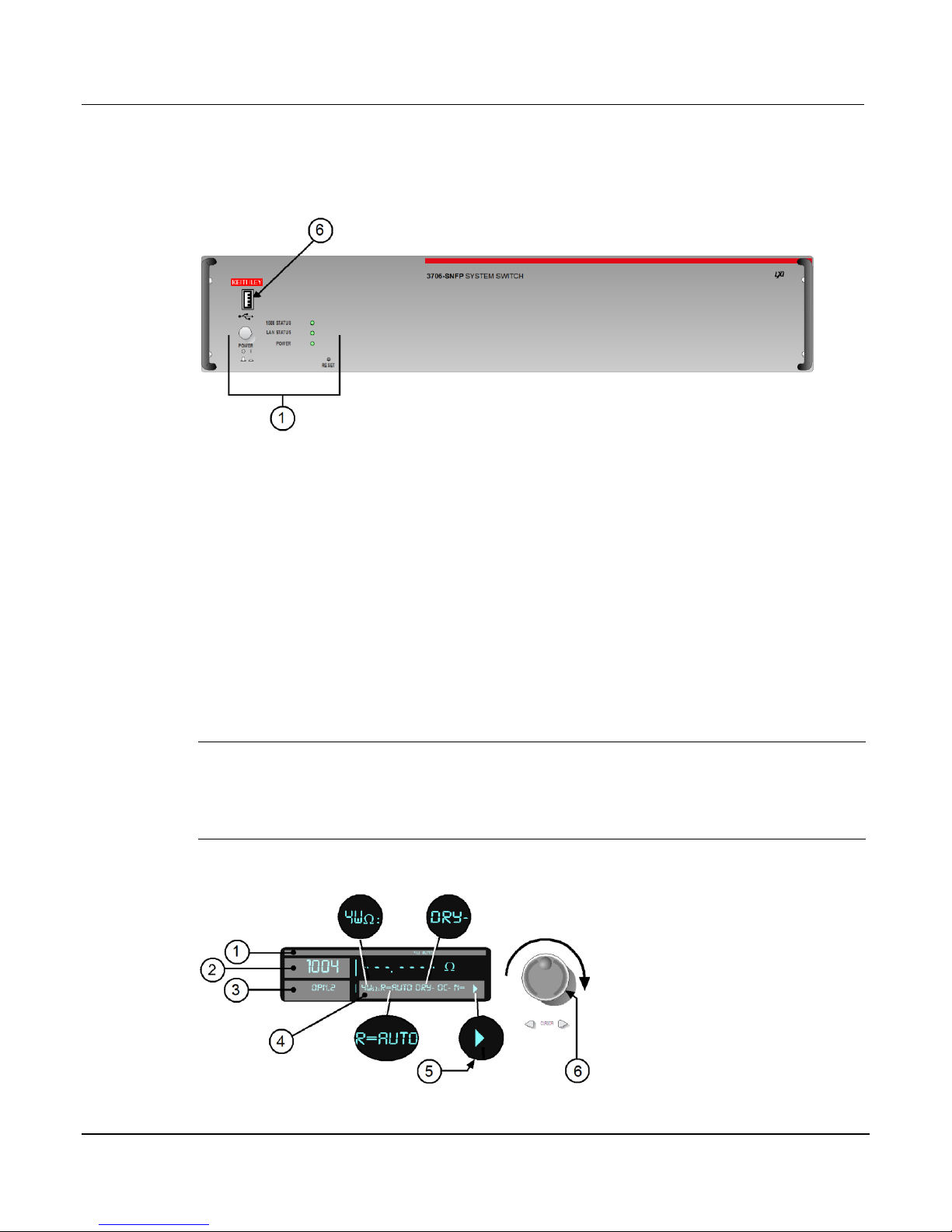

Figure 2-4: Model 3706-SNFP System Switch (no DMM)

Display

The Series 3700 display provides visual information on the present active channel. The display,

with the wheel, provides a means to change the active channel or channel ranges, as well as

access to view and edit the various menus and menu items.

See the following figure for an active channel example. The display has the 4W and AUTO

range annunciators lit (1). Also, the active channel is 1004 (Slot 1 Channel 004). The present

state of the channel is open, and it has two poles (3). The present state of the attributes for this

channel (4) are: 4W function set for AUTO range, dry-circuit ohms disabled (DRY-), offset

compensation off (OC-). Other attributes, such as NPLC, are available for this specific active

channel (1004) as indicated by arrow (5) being lit. These may be viewed by turning the wheel (6)

to scroll through the attribute list.

NOTE Attribute lists, as well as menu lists, that are larger than the display, can be accessed

by turning the wheel (6). Displayed arrows (5) indicate additional attributes (or menu

items, as applicable) are available for access by turning the wheel (6) in the direction

the arrow points. If an arrow (5) is not displayed, there are no additional menu choices

in that direction.

Figure 2-5: Active channel display example

Page 19

Section 2: Using the Front Panel Series 3700 System Switch/Multimeter Quick Start Guide

2-4 Document Number: 3700S-903 -01 Rev. A / August 2007

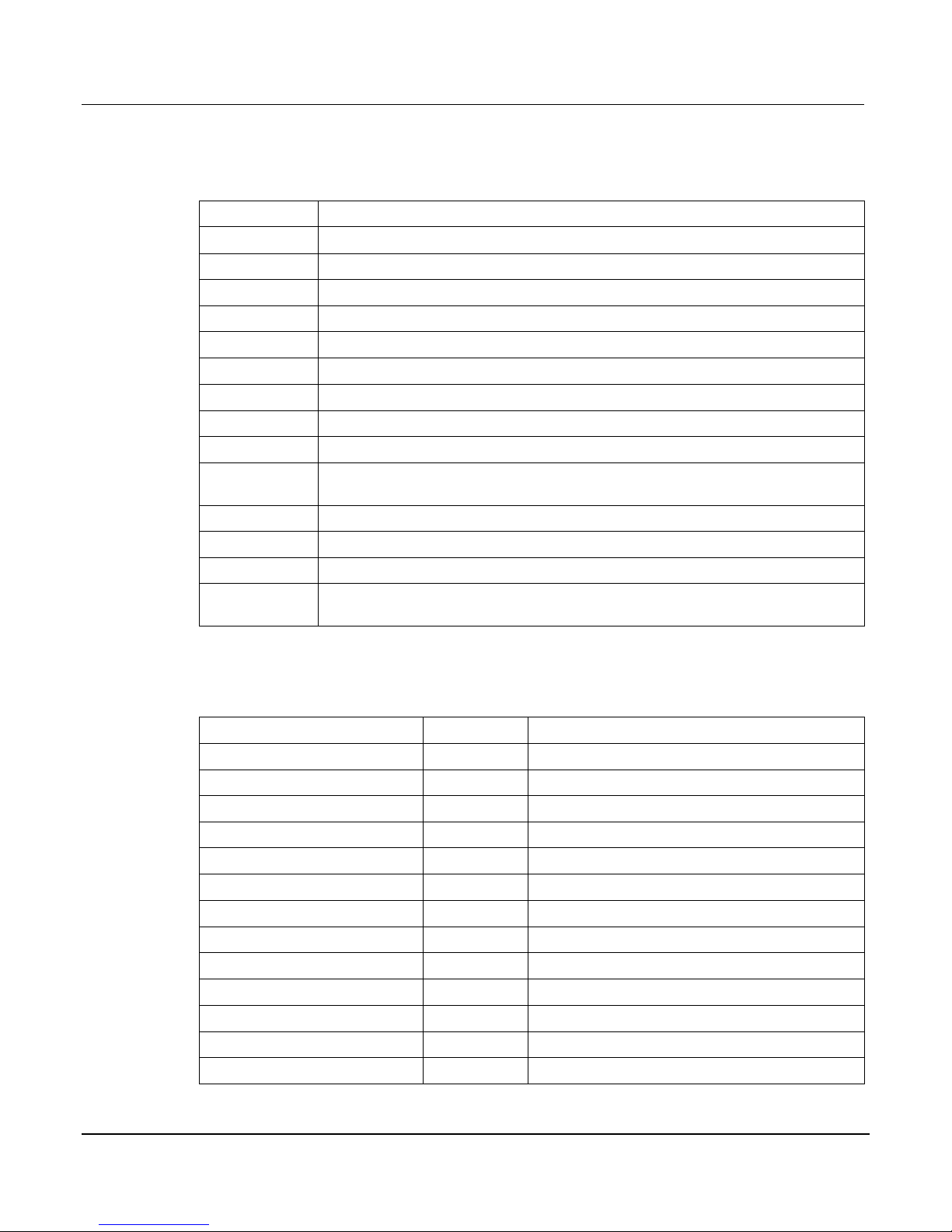

The top line of the display (1) contains the following annunciators:

Annunciator

Description

* (asterisk)

Front panel readings are being stored in the selected reading buffer.

4W

4-wire resistance or RTD temperature reading displayed.

ARM

Unit armed and ready to use.

AUTO

Auto range enabled for the selected DMM function.

EDIT

Unit in edit mode (for front panel).

FILT

Filter enabled for the selected DMM function.

LSTN

Instrument addressed to listen over GPIB.

MATH

mX+b, percent, or reciprocal (1/X) calculation enabled for the selected DMM function.

REL

Relative enabled for selected DMM function.

REM

Instrument in bus remote mode or web control mode (all interfaces, LAN, GPIB, or

USB).

SMPL

Flashes whenever the DMM has completed a reading.

SRQ

Service request over GPIB.

TALK

Instrument addressed to talk over GPIB bus.

TRIG

External triggering selected. The TRIG annunciator will blink if taking continuous

triggered readings on front panel.

Front pnel DMM atribute

Symbol

Values

range

R=

AUTO or n, here n equals the range

nplc

N=

n, where n equals the nplc

auto delay

AD

+ for ON, 1 for ONCE, or 0 for OFF

auto zero

AZ

+ for ON or – for OFF

line sync

LS

+ for ON or – for OFF

limit

LIM

+ for a limit enabled or – for limits disabled

detector bandwidth

DBW

3, 30, or 300

threshold

THR=

n, where n indicates the threshold

aperture

A=

n, where n indicates the aperture setting

dry circuit

DRY

+ for ON or – for OFF

offset compensation

OC

+ for ON or – for OFF

thermocouple sensor K

K_T/C

N/A

thermocouple sensor T

T_T/C

N/A

The bottom line of the display (4) contains the attribute symbols. The symbols that appear are

dependent on whether the attribute exists for the selected function. If the symbol has also

contains a value, the third column in the table indicates the value definition. The following table

indicates the DMM attribute symbols that may appear on the front panel.

Page 20

Series 3700 System Switch/Multimeter Quick Start Guide Section 2: Using the Front Panel

Document Number: 3700S-903-01 Rev. A / August 2007 2-5

Front pnel DMM atribute

Symbol

Values

thermocouple sensor E

E_T/C

N/A

thermocouple sensor R

R_T/C

N/A

thermocouple sensor S

S_T/C

N/A

thermocouple sensor B

B_T/C

N/A

thermocouple sensor N

N_T/C

N/A

thermistor

THRM

N/A

three-wire RTD

3RTD

N/A

four-wire RTD

4RTD

N/A

simulated reference junction

RJ_SIM

N/A

internal reference junction

RJ_INT

N/A

external reference junction

RJ_EXT

N/A

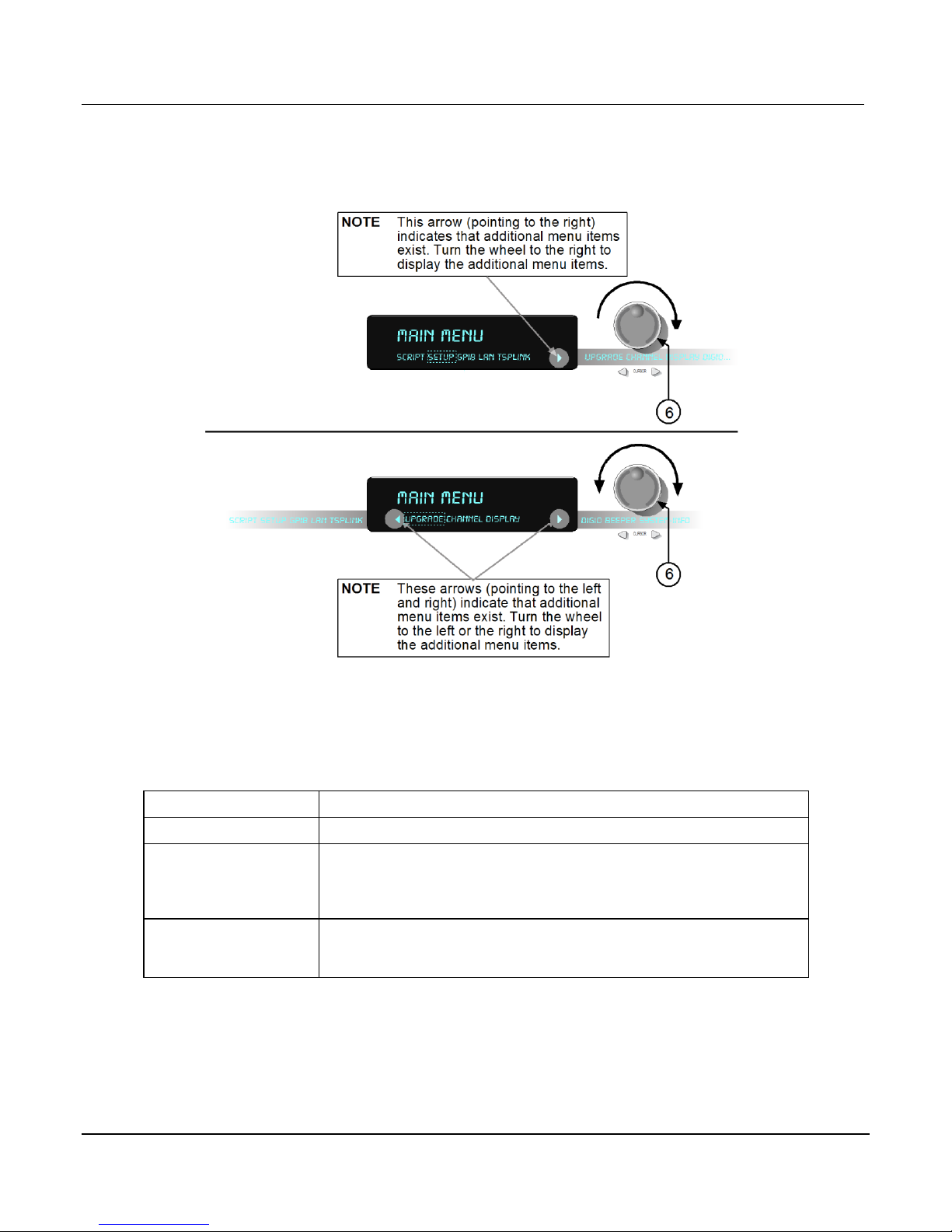

NOTE To access the main menu, press the MENU key.

See the following figure for a menu example. In the example, the MAIN MENU is displayed.

Turn the wheel (6) or press the cursor keys, to scroll through the available menu items. In the

following figure's first display, there is a right arrow indicator. This indicates there are additional

menu items to the right. In figure's second display, both right and left arrows are active indicating

there are additional items in both directions. To select the highlighted (flashing) menu item,

press the wheel (or press the ENTER key).

Page 21

Section 2: Using the Front Panel Series 3700 System Switch/Multimeter Quick Start Guide

2-6 Document Number: 3700S-903 -01 Rev. A / August 2007

Figure 2-6: MAIN MENU display

POWER switch:

Press this switch to turn the Series 3700 on (I); press it again to turn it off (O).

DISPLAY key:

Press this key to toggles between main and user display modes.

CONFIG key:

Use this key to access the an attribute menu that enables you to configure

channels, channel patterns, DMM functions, or settings, reading buffer,

scans, and other operations. Refer to the user's manual for additional

information the CONFIG key.

RESET switch:

Use this switch to restore the Series 3700 factory default LAN settings. Refer

to the reference manual LAN functions (lan.config.x, where x represents the

specific command) for factory default information.

Front panel keys

Special keys and power switch

Page 22

Series 3700 System Switch/Multimeter Quick Start Guide Section 2: Using the Front Panel

Document Number: 3700S-903-01 Rev. A / August 2007 2-7

Operation keys

CHAN key:

Pressing this key opens the CHANNEL ACTION MENU that contains the

following menu items: OPEN, CLOSE EXCLOSE, EXSLOTCLOSE, and

RESET.

PATT key:

Pressing this key opens the PATTERN ACTION MENU that contains the

following menu items: OPEN, CLOSE, EXCLOSE, EXSLOTCLOSE,

CREATE, VIEW, DELETE, and RESET.

SLOT key:

Press this key to display installed card(s) and instrument information, as well

as main system information. The information displayed includes firmware

revisions of both main and installed components. After pressing this key,

scroll through all available instruments, including the internal DMM.

SCAN key:

If a scan list is present, this key opens the SCAN ACTION MENU that

contains the following menu items: EXECUTE, CREATE, LIST, CLEAR, and

RESET.

DMM key:

Opens the DMM ACTION MENU that contains the following menu items:

MEASURE, COUNT, LOAD, SAVE, OPEN, CLOSE, RESETFUNC,

RESETALL, and CONNECT.

LIMIT key:

Pressing this key will cycle through the four combinations of limit state

settings (Limit1 and Limit2 off, Limit1 on and Limit2 off, Limit1 off and Limit2

on, Limit1 and Limit2 on).

REL key:

Pressing this key enables/disables relative for selected function. Causes REL

annunciator to light when enabled. Also see Relative in the reference manual.

FILTER key:

Pressing this key enables/disables filter for selected function. When the filter

is enabled, the FILT annunciator will light. Also see Filter in the reference

manual.

FUNC key:

Pressing this key selects the active DMM function for the channel. Related

ICL command: dmm.func

LOAD key:

Pressing this key loads user-defined scripts, along with Lua chunks added

with display.loadmenu.add for execution. This key opens the LOAD TEST

menu which contains the following menu items: USER and SCRIPTS.

RUN key:

Pressing this key runs last selected script or load menu item.

INSERT key:

Pressing this key appends the present channel to the scan list.

DELETE key:

Pressing this key deletes the present channel (including function) from the

scan list. If the present channel is not contained in the scan list, no error is

reported.

TRIG key:

Pressing this key triggers a measurement equivalent to the dmm.measure

command.

MENU key:

Pressing this key opens the MAIN MENU that contains the following menu

items: SCRIPT, SETUP, GPIB, LAN, TSPLINK, UPGRADE, CHANNEL,

DISPLAY, DIGIO, BEEPER, and SYSTEM-INFO.

EXIT key:

Cancels the selection and moves back to the measurement display.

ENTER key:

Pressing this key accepts selection, moves to next choice, or back to

measurement display.

Page 23

Section 2: Using the Front Panel Series 3700 System Switch/Multimeter Quick Start Guide

2-8 Document Number: 3700S-903 -01 Rev. A / August 2007

Range keys:

▲▼ Selects the next higher/lower measurement range for the selected

function when on measurement display.

To set the range, use the RANGE keys ▲ or ▼. If the Series 3700 displays

the overflow message on a particular range, select a higher range until an onrange reading is displayed. Use the lowest range possible without causing an

overflow to ensure best accuracy and resolution. For details see Auto ranging

over the front panel in the reference manual.

AUTO key:

Enables or disables autorange for the selected function, and causes the

AUTO annunciator to light when enabled.

CURSOR keys

◄ CURSOR ► Use the CURSOR arrows in a menu to control cursor position

for making selections or changing values.

Wheel

Turn the wheel to scroll to the desired menu option or to change the value of

the selected numeric parameter. Also, press the wheel to cause the same

function as pressing the ENTER key. Also see ENTER key. Turn the wheel to

scroll to the desired digit location to edit, press the wheel to enter edit mode,

and then turn the wheel to increase or decrease the value.

NOTE When changing a multiple character value, such as an IP address or

channel pattern name, press the wheel to enter edit mode, rotate the

wheel to change the characters value as desired, but do not leave

edit mode. Use the cursor keys to scroll to the other characters and

use the wheel to change their value as needed. Press the ENTER

key when finished changing all the characters.

OPEN ALL key:

Opens all closed channels.

STEP key:

Steps through channels associated with the defined scan list; sends a trigger

after each channel.

OPEN key:

Opens selected channels or channel pattern.

CLOSE key:

Closes specified channels or channel pattern.

STORE key:

Opens the RD BUFF ACTION MENU. This menu contains:

CREATE: Allows creation of a reading buffer, or allows you to select a

previously created reading buffer. When a new buffer is created, you can set

the number of readings to store and then select the buffer. Related

Instrument Control Library (ICL) command: dmm.makebuffer

SELECT: Allows you to select a previously created reading buffer. Related

Instrument Control Library (ICL) command: dmm.measure

CLEAR: Removes readings from a previously created buffer.

SAVE: Allows you to save a previously created reading buffer to a USB flash

drive (flash drive must be installed and have enough available space).

RECall key:

Displays stored readings and buffer statistics for selected reading buffer. Use

the ◄ CURSOR ► keys or turn the wheel to navigate through buffer.

Range, multifunction keys, and wheel

Function keys

Page 24

Series 3700 System Switch/Multimeter Quick Start Guide Section 2: Using the Front Panel

Document Number: 3700S-903-01 Rev. A / August 2007 2-9

RATE key:

Sets measurement speed (fast, medium, or slow) for the active or selected

function.

FUNCtion key:

This key select the active function by cycling through the following list as

listed. Each press of the FUNC key has the DMM and configured to the next

function in the list:

dcvolts: DC voltage

acvolts: AC voltage

dccurrent: DC current

accurrent: AC current

twowireohms: Two-wire ohm (resistance)

fourwireohms: Four-wire ohm (resistance)

commonsideohms: Common-side ohm (resistance)

frequency: Frequency

period: Period

continuity: Continuity

temperature: Temperature

Page 25

Page 26

In this section:

Rear panel summary ....................................................................................... 3-1

Rear panel connections ................................................................................... 3-2

Switching module installation and connections ................................................. 3-6

Module installation .......................................................................................... 3-7

Bus operation ................................................................................................ .. 3-11

Power-up ........................................................................................................ 3-12

Item

Description

1

Analog backplane fuse (see "Analog backplane AMPS fuse" on page 3-2)

2

Slots (6 places) (see "Slots" on page 3-2)

3

TSP-link® connectors (2 places) (see "TSP-Link connector" on page 3-2)

4

Instrument fuse (on page 3-2)

5

Power connector (on page 3-2)

6

Digital I/O port (on page 3-3)

7

GPIB connector (on page 3-4)

8

Ethernet connector (see "Ethernet connector (RJ-45)" on page 3-4)

9

USB connector (see "USB connectors" on page 3-4)

10

Analog backplane connector (on page 3-5)

Section 3

Rear Panel

Rear panel summary

Figure 3-1: Rear panel features

Page 27

Section 3: Rear Panel Series 3700 System Switch/Multimeter Quick Start Guide

3-2 Document Number: 3700S-903 -01 Rev. A / August 2007

Rear panel connections

Analog backplane AMPS fuse

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE FUSE WITH SAME

Slots

TSP-Link connector

TYPE AND RATING (3A / 250V). See Fuse replacement for details.

Use any of the six slots of the Keithley Instruments Series 3700 for the switching modules.

When a module is not installed, make sure to cover the slot with a slot cover. For additional

information on an installed module, press the SLOT key.

Instrument fuse

Use with TSP-link cable to expand system.

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE FUSE WITH SAME

TYPE AND RATING (1.25A / 250V). See Fuse replacement for details.

Power connector

Using the supplied line cord, connect to a grounded AC power outlet. See Line power

connection (on page 3-12) for connection details.

Page 28

Series 3700 System Switch/Multimeter Quick Start Guide Section 3: Rear Panel

Document Number: 3700S-903-01 Rev. A / August 2007 3-3

Digital I/O port

Pin

Description

1

...

9

Digital I/O #1

...

Digital I/O #9

10

...

14

Digital I/O #10 (High Current Pins see Note)

...

Digital I/O #14 (High Current Pins see Note)

15-21

Ground

22

V EXT

23

V EXT

24

NC (no connection)

25

V EXT

The Series 3700 has a digital input/output port that can be used to control external digital

circuitry. For example, a handler that is used to perform binning operations can be used with a

Digital I/O port. The Digital I/O port is a standard female DB-25 connector.

Figure 3-2: Digital I/O port

NOTE High Current Pins (10-14) can be used for binning applications or for external relays.

Page 29

Section 3: Rear Panel Series 3700 System Switch/Multimeter Quick Start Guide

3-4 Document Number: 3700S-903 -01 Rev. A / August 2007

Connecting cables

Use a cable equipped with a standard male DB-25 connector (Keithley Instruments part number

CA-126-1).

Digital I/O lines (pins 1 through 14)

The port provides 14 digital I/O lines. Each output is set high (+5V) or low (0V) and can read

high or low logic levels.

+5V output (pins 22, 23, and 25)

The Digital I/O Port provides a +5V output that is used to drive external logic circuitry. Maximum

current output for this line is 600mA. This line is protected by a self-resetting fuse (one hour

recovery time).

GPIB connector

For GPIB communication, connect to GPIB port of computer using an IEEE-488 cable (Keithley

Instruments Model 7007).

Ethernet connector (RJ-45)

For Ethernet communication, connect to Ethernet port of a computer, or to a hub or receptacle

of an Ethernet system.

To connect the Series 3700 directly to a computer, use an Ethernet cross-over cable (RJ-45,

male/male).

To connect the Series 3700 to an Ethernet system hub or receptacle, use a standard Ethernet

cable (RJ-45, male/male).

USB connectors

The downstream USB-2.0 receptacle (Type B) located on the rear panel connects to a host. The

front panel has an upstream USB-2.0 connector (Type A) that connects to a user supplied USB

flash drive.

Page 30

Series 3700 System Switch/Multimeter Quick Start Guide Section 3: Rear Panel

Document Number: 3700S-903-01 Rev. A / August 2007 3-5

Use the rear connector to communicate with the instrument over USB by sending the desired

commands. Use the front panel connector to insert a USB flash drive for saving or loading

reading buffers, user setups, or scripts. See the Reference Manual for more information on

reading buffers, user setups and scripts.

Figure 3-3: USB connectors

Analog backplane connector

Refer to the following figure for analog backplane connector information. See Connections (on

page 3-9) before making any connections.

Figure 3-4: Analog backplane connector

Page 31

Section 3: Rear Panel Series 3700 System Switch/Multimeter Quick Start Guide

3-6 Document Number: 3700S-903 -01 Rev. A / August 2007

The table below contains pin numbers and descriptions for the analog backplane connector.

Description

Pin Description

Pin

Analog backplane 3-HI

5 DMM-SLO

4

Analog backplane 3-LO

6 DMM-SHI

3

Analog backplane 4-HI

7 DMM-LO

2, 9

Analog backplane 4-LO

8 DMM-HI

1

Analog backplane 5-HI

12 AMP-LO

2, 9

Analog backplane 5-LO

13 AMP

10, 11

Analog backplane 6-HI

14

Analog backplane 6-LO

15

Switching module installation and connections

In order to exercise close/open operations explained in this section, a switching module (or

pseudocard) must be installed in the mainframe. A switching module can be installed by the

user, however external connections to the switching module are only to be performed by

qualified service personnel.

WARNING To prevent electric shock that could result in injury or death, NEVER

handle a switching module that has power applied to it:

• Before installing (or removing) a switching module, make sure the Series

3700 is turned off and disconnected from line power.

• If the switching module is already connected to a device under test

(DUT), make sure power is removed from all external circuitry.

NOTE For inexperienced users, it is recommended that DUT and external circuitry not be

connected to switching modules. This will allow you to exercise safe close/open

operations without the dangers associated with live test circuits.

Page 32

Series 3700 System Switch/Multimeter Quick Start Guide Section 3: Rear Panel

Document Number: 3700S-903-01 Rev. A / August 2007 3-7

Module installation

WARNING Slot covers must be installed on unused slots to prevent personal contact

Perform the following steps to install a switching module into the Series 3700 mainframe:

1. Turn the Series 3700 off and disconnect the power line cord and any other cables

connected to the rear panel.

2. Position the Series 3700 so that you are facing the rear panel.

3. Remove the slot cover plate from the desired mainframe slot. Retain the plate and screws

for future use.

4. With the top cover of the switching module facing up, align the module's card edge into the

slot's card guide and slide in the module. For the last ¼ inch or so, press in firmly to mate

the module connector to the mainframe connector.

5. On each side of the module, there is a mounting screw. Tighten these two screws to secure

the module to the mainframe. Do not overtighten.

6. Reconnect the power line cable and any other cables to the rear panel.

with high voltage circuits.

Page 33

Section 3: Rear Panel Series 3700 System Switch/Multimeter Quick Start Guide

3-8 Document Number: 3700S-903 -01 Rev. A / August 2007

7. Press the SLOT key to see the model numbers, description, and the firmware revision of the

Item

Description

1

Card guide (part of Series 3700)

2

Module

3

Card edge (part of module)

4

Mounting screw (part of module)

installed switching module(s), along with the mainframe firmware and DMM (if present).

Figure 3-5: Typical module installation

Page 34

Series 3700 System Switch/Multimeter Quick Start Guide Section 3: Rear Panel

Document Number: 3700S-903-01 Rev. A / August 2007 3-9

Connections

WARNING Connection information for switching modules is intended for qualified

To prevent electric shock that could result in serious injury or death,

Before making or breaking any connections to the switching module,

Do not connect signals that will exceed the maximum specifications of

If both the rear analog backplane connector of the Series 3700 and the

service personnel. Do not attempt to connect DUT or external circuitry to a

switching module unless qualified to do so.

comply with these safety precautions:

make sure the Series 3700 is turned off and power is removed from all

external circuitry.

any installed switching module.

switching module terminals are connected at the same time, the test lead

insulation must be rated to the highest voltage that is connected. For

example, if 300V is connected to the analog backplane connector, the test

lead insulation for the switching module must also be rated for 300V.

Dangerous arcs of an explosive nature in a high energy circuit can cause

severe personal injury or death. If the multimeter is connected to a high

energy circuit when set to a current range, low resistance range, or any

other low impedance range, the circuit is virtually shorted.

Dangerous arcing can result (even when the multimeter is set to a voltage

range) if the minimum voltage spacing is reduced in the external

connections. For details about how to safely make high energy

measurements, see High-energy circuit safety precautions.

As described in the International Electrotechnical Commission (IEC)

Standard IEC 664, the Series 3700 is Installation Category I and must not

be connected to mains.

Page 35

Section 3: Rear Panel Series 3700 System Switch/Multimeter Quick Start Guide

3-10 Document Number: 3700S-903 -01 Rev. A / August 2007

Pseudocards

You can perform open/close/scan operations and configure your system without having an

actual switching module installed in your Series 3700. Using remote programming, you can

assign a pseudocard to an empty switching module slot, allowing the Model 3700S to operate as

if a switching module were installed.

A pseudocard, which is essentially a "virtual switching module," cannot be installed from the

front panel. However, once the remote installation is complete, you can take the Series 3700 out

of remote mode and use the front panel. Pressing the LOCAL or EXIT key takes the Series

3700 out of remote mode.

When the instrument is turned off, the pseudocard will be lost (uninstalled). In order to recall a

pseudocard, make it part of a saved setup.

NOTE A saved setup retains the model number of the module installed in each slot. The

model number of a pseudocard is the same as the model number of an actual module.

This allows a saved setup to be recalled provided the installed card (or pseudocard)

matches the model number for the slot in the saved setup.

Pseudocards programming example

Use the following command line to set the pseudocard of Slot 6 for 3720 Dual 1 x 30 Multiplexer

card simulation:

Channel assignments

Each switching module has a certain number of channels. For example, the Model 3720

switching module has 60 channels (1 through 60). When you encounter a 1 to 3-digit channel

number in this manual, the switching module channel is the point of discussion. A four-digit

channel number includes the slot followed by the 3-digit channel number.

A switching module can be installed in any of the mainframe's six slots. Therefore, to close,

open, or scan a channel, it is necessary to specify the slot location and channel number of the

switching module. This is accomplished by using a four-digit channel number for the mainframe.

The first digit (1, 2, 3, 4, 5, or 6) indicates the slot number, and the next three digits indicate one

of the following:

The channel number of a switching module (see "Mux (multiplexer) channel notation" on

page 4-5)

The row and column of a matrix card (see "Matrix card notation" on page 4-5)

slot[6].pseudocard = slot.PSEUDO_3720

The modules' backplane relay (see "Backplane relay notation" on page 4-4)

Page 36

Series 3700 System Switch/Multimeter Quick Start Guide Section 3: Rear Panel

Document Number: 3700S-903-01 Rev. A / August 2007 3-11

Bus operation

The Series 3700 supports bus operation over USB, Ethernet and GPIB. The GPIB settings may

be set from the front panel, or once controlled by the bus, over the bus.

1. Viewing or configuration using the front panel:

2. Viewing or configuration over the bus:

USB is always connected and available to send bus commands. There are no unique USB

settings. To use USB, make sure have installed the Test Script Builder application. The

applicable USB driver is available after installing this software.

NOTE For your Series 3700 to be recognized by your computer over the USB interface, the

a) Press MENU key to bring up the main menu,

b) Turn the wheel to scroll to "GPIB" menu item and press the ENTER key.

c) Select setting to change ADDRESS or ENABLE

a) gpib.address to change the address

b) gpib.enable to change the enable setting.

ON: GPIB will respond to bus commands.

OFF: GPIB will not respond to bus commands.

proper driver must be installed. Installing the Test Script Builder application also

installs the applicable USB driver (it becomes available after installing this software).

To complete the USB driver installation, after installing the Test Script Builder

application, connect the Series 3700 USB connector (rear panel) to the computer.

Ethernet supports various settings. The LAN logical device has options that show the current

status under lan.status commands while it has pending configuration settings under lan.config.

The config settings will take effect when lan.applysettings is executed. Using the lan.reset

command is equivalent to doing a lan.restoredefaults followed by a lan.applysettings. To only

restore defaults without resetting to them, use the lan.restoredefaults command by itself. Please

refer to the LAN ICLs directly for individual settings that may be controlled with the LAN logical

device. From the front panel, the LAN (Ethernet) options may be enabled or disabled collectively

under MAIN MENU and LAN settings. From the bus, one may enable or disable certain aspects

of LAN with:

1. comm.lan.telnet.enable

2. comm.lan.web.enable

3. comm.lan.vxi11.enable

4. comm.lan.rawsockets.enable

Page 37

Section 3: Rear Panel Series 3700 System Switch/Multimeter Quick Start Guide

3-12 Document Number: 3700S-903 -01 Rev. A / August 2007

The following list contains the four LAN default port numbers (along with corresponding ICLs to

query for these values):

1. telnet is 23 (ICL: lan.status.port.telnet)

2. rawsocket is 5025 (ICL: lan.status.port.rawsocket)

3. vxi11 is 1024 (ICL: lan.status.port.vxi11)

4. dead socket termination is 5030 (ICL: lan.status.port.dst)

When changing between the various bus interfaces, send the abort command to have that

interface become the active one for receiving and processing bus commands. For example, if

changing from communicating with instrument over GPIB and to send ICLs with a telnet session

(assuming both interfaces are enabled):

1. Connect via telnet.

2. Send abort to leave the GPIB interface and switch over to telnet.

3. Send commands as desired.

Any of the enable settings will take effect the next time the unit powers up. Therefore, after

making changes to these settings, power cycle the unit.

Power-up

Line power connection

Follow the procedure below to connect the Series 3700 to line power and turn on the instrument.

The Series 3700 operates from a line voltage of 100V to 240V at a frequency of 50Hz or 60Hz.

Line voltage is automatically sensed. There are no switches to set. Make sure the operating

voltage in your area is compatible.

WARNING The power cord supplied with the Series 3700 contains a separate ground

wire for use with grounded outlets. When proper connections are made,

instrument chassis is connected to power line ground through the ground

wire in the power cord. Failure to use a grounded outlet may result in

personal injury or death due to electric shock.

CAUTION Operating the instrument on an incorrect line voltage may cause damage to the

instrument, possibly voiding the warranty.

Page 38

Series 3700 System Switch/Multimeter Quick Start Guide Section 3: Rear Panel

Document Number: 3700S-903-01 Rev. A / August 2007 3-13

1. Before plugging in the power cord, make sure that the front panel power switch is in the off

(O) position. See Rear panel summary (on page 3-1) for connector location.

2. Connect the female end of the supplied power cord to the (5) Power Connector (AC

receptacle) on the rear panel. Connect the other end of the power cord to a grounded AC

outlet.

3. Turn on the instrument by pressing the front panel power switch to the on (I) position. See

Front panel introduction for switch location.

Line frequency

NOTE Line frequency only applies to models with a DMM installed.

The Series 3700 will operate at line frequencies of either 50Hz or 60Hz. The line frequency is

auto-detected at startup.

Use the localnode.linefreq bus command to see the line frequency. For example:

Fuse replacement

print(localnode.linefreq)

Refer to the Fuse replacement topic contained in the user's manual for fuse replacement

information.

Power-up sequence

On power-up, the Series 3700 performs self-tests on its ROM, NVRAM, and RAM and

momentarily lights all segments and annunciators. If a failure is detected, the instrument

momentarily displays an error message and the ERR annunciator turns on. (Error messages are

listed in Error and status messages contained in the Reference manual.)

NOTE If a problem develops while the instrument is under warranty, return it to Keithley

Instruments, Inc., for repair.

Assuming no errors occur, the Series 3700 will power-up as follows:

1. "No Comm Link" is briefly displayed.

2. "Initializing" is displayed for several seconds.

3. Nearing the end of initialization, the 1588 and LAN status LEDs light.

4. All of the display pixels briefly light.

Page 39

Section 3: Rear Panel Series 3700 System Switch/Multimeter Quick Start Guide

3-14 Document Number: 3700S-903 -01 Rev. A / August 2007

5. The display shows:

KEITHLEY

Series 3700

System identification

6. Main display appears.

Serial number, firmware revision, and calibration dates can be displayed by selecting the

SYSTEM-INFO item of the main menu (press MENU > SYSTEM-INFO).

Select FIRMWARE, SERIAL#, or CAL as desired.

For remote programming, use the *IDN? query to read system information.

Beeper

With the beeper enabled, a beep will be issued to acknowledge the following actions:

A short beep, emulating a keyclick, is issued when a front panel key is pressed.

A short beep, emulating a keyclick is also issued when the wheel is turned or pressed.

To control the beeper from the front panel, select MENU > BEEPER > KEYCLICK, then

ENABLE or DISABLE the keyclick as desired.

For remote programming, use the beeper.enable command to control the beeper. For

example, the following enables the beeper:

beeper.enable = 1

Page 40

In this section:

General questions ................................................................ ........................... 4-1

Questions about web page operation ............................................................... 4-12

Questions about remote operation ................................................................... 4-15

Questions about Test Script Processor interaction ............................................ 4-24

Section 4

Frequently Asked Questions

General questions

How do I power up the instrument?

Step 1: Connect to line power

CAUTION Operating the instrument on an incorrect line voltage may cause damage to the

1. Before plugging in the power cord, make sure that the front panel power switch is in the off

(O) position.

2. Connect the female end of the supplied power cord to the AC receptacle on the rear panel.

Connect the other end of the power cord to a grounded AC outlet.

WARNING Failure to use a grounded outlet may result in personal injury or death due

instrument, possibly voiding the warranty.

to electric shock.

Step 2: Turn on power

Turn on the instrument by pressing the front panel power switch to the on (I) position. Assuming

no errors occur, the Series 3700 will power-up as follows:

The unit will initialize

KEITHLEY

SERIES 3700 will be displayed.

NOTE The line frequency is automatically sensed at power-up.

Page 41

Section 4: Frequently Asked Questions Series 3700 System Switch/Multimeter Quick Start Guide

4-2 Document Number: 3700S-903 -01 Rev. A / August 2007

How do I control switches?

NOTE This paragraph provides information for controlling switches using channel operation

(for channel pattern operation, refer to the Channel pattern operation paragraph

contained in the User's manual). It contains information on opening and closing all

switches from the front panel, as well as over the bus.

Close/open overview

NOTE This section provides basic close/open information for switching module channels.

Operating characteristics unique to a specific Series 3700 switching module are

provided in an instruction sheet provided with the specific switching module.

Terminology used throughout this manual is detailed in the applicable sections of the

user's and reference manuals.

The switching channels of a Series 3700 support a concept of "duality." This means that each

channel has specific settings for switching and specific settings for switching with DMM

operations. The location of the specific operation request determines the setting that activates.

An operation request residing in the channel logical device causes the switching settings to be

used (example commands are channel.close, channel.open, channel.exclusiveclose); an

operation request residing in the DMM logical device such as dmm.close or dmm.open, causes

the DMM settings to be used. Refer to the reference manual for more information on logical

devices (TSP section).

Open a Microsoft web-browser and type in the IP address (see How do I connect to the internal

web page? (on page 4-12) located in the Quick Start Guide). The Series 3700 home page will

appear. Use this home page to see a visual representation of the present channel status (select

the desired slot or model contained under "Cards").

NOTE Java application may need to be installed.

The Series 3700 supports opening and closing channels through either Channel operation or

through Channel pattern operation:

Channel operation (non-channel pattern operation): This mode of operation should be used

exclusively by most (if not all) users. When you close a channel for a measurement operation,

other channels on the switching module close automatically to internally connect it through the

backplane to the DMM of the Series 3700. When you close a channel for a switching operation,

the channel (and possibly the channel pair) will close but, no backplane relays are closed unless

associated with the channel.

Channel pattern operation: This mode of operation provides additional flexibility by providing

individual control of each switching module and backplane channel. Careless operation in this

mode could create a safety hazard and/or damage the switching module and other equipment.

Channel pattern operation should only be used by experienced test engineers.

Page 42

Series 3700 System Switch/Multimeter Quick Start Guide Section 4: Frequently Asked Questions

Document Number: 3700S-903-01 Rev. A / August 2007 4-3

WARNING Careless channel pattern operation could create an electric shock hazard

ICL

Description

Usage

channel.close

Function: Closes specified

items in ch_list without

opening any channels.

channel.close(ch_list)

ch_list: string listing the items to close.

Items can include channels, backplane

relays, and channel patterns.

channel.open

Function: Opens items

specified in ch_list.

channel.open(ch_list)

ch_list: string listing the items to open.

Items can include channels, backplane

relays, and channel patterns.

dmm.close

Function: Closes the

specified channel or channel

pattern in preparation for a

DMM measurement.

dmm.close(ch_list)

ch_list: string listing the channel or channel

pattern to close

dmm.open

Function: Opens the

specified channel and/or

channel pattern.

dmm.open(ch_list)

ch_list: string listing the channel or channel

pattern to open

that could result in severe injury or death. Improper operation can also

cause damage to the switching modules and external circuitry. Controlling

multiple channels using channel patterns should be restricted to

experienced test engineers who recognize the dangers associated with

multiple channel closures.

CAUTION To prevent damage to a switching module, do not exceed the maximum signal

level input for that module. Most switching modules are rated for 300V.

NOTE The Series 3700 is capable of scanning switching module channels. Each channel in

the scan can have its own unique DMM configuration.

Close/open bus operation

Use the following commands to control switches over the bus. For detailed information

specifying what happens with each of these commands, see the reference manual.

Page 43

Section 4: Frequently Asked Questions Series 3700 System Switch/Multimeter Quick Start Guide

4-4 Document Number: 3700S-903 -01 Rev. A / August 2007

Close/open key operation

Reference

Analog backplane relay

1921

analog backplane relay 1

1922

analog backplane relay 2

1923

analog backplane relay 3

1924

analog backplane relay 4

1925

analog backplane relay 5

1926

analog backplane relay 6

The front panel CLOSE and OPEN keys operate in the same manner as one of the following:

channel.close and channel.open commands

dmm.close and dmm.open commands

The operation of the keys depend on the selected channel or channel patterns function

association.

To have the keys work as channel.close and channel.open:

Make sure the DMM function of the DMM configuration associated with the selected

channel or channel pattern is "nofunction."

To have the keys work as dmm.close and dmm.open:

Make sure the DMM function of the DMM configuration associated with the selected

channel or channel pattern is not "nofunction" (for example, DC volts).

Channel and backplane notation

There are three different notations used to control relays: Backplane relay notation, Mux

(multiplexer) channel notation, and Matrix card notation.

Backplane relay notation

To control analog backplane relays for slots with analog backplane relay channels, use S9BX

where:

S: Slot number

9: Backplane notation designation (always 9 when referencing a backplane relay)

B: Bank number

X: Analog backplane relay number

Analog backplane relays (bank 2 of Slot 1) examples:

Page 44

Series 3700 System Switch/Multimeter Quick Start Guide Section 4: Frequently Asked Questions

Document Number: 3700S-903-01 Rev. A / August 2007 4-5

Mux (multiplexer) channel notation

Reference

Slot

Channel

1004

1

004

1020

1

020

2100

2

100

3003

3

003

Reference

Slot

Row

Column

1104

1 1 04

1203

1 2 03

2305

2 3 05

To control channels using mux channel notation, use SCCC where:

S: Slot number

CCC: Channel number (always use 3 digits)

Multiplexer examples:

Figure 4-1: Multiplexer card display

Matrix card notation

To control channels using matrix card notation, use SRCC where:

S: Slot number

R: Row number

CC: Column number (always use 2 digits)

Matrix channel examples:

Page 45

Section 4: Frequently Asked Questions Series 3700 System Switch/Multimeter Quick Start Guide

4-6 Document Number: 3700S-903 -01 Rev. A / August 2007

Reference

Slot

Row

Column

3112

3 1 12

6101

6 1 01

Figure 4-2: Matrix card display

Channel list parameter <ch_list>

The channel list parameter <ch_list>, used when controlling the Series 3700's relays over the

bus, is a string-type parameter. An example:

Channel 1 (of Slot 1) is associated with analog backplane relays 3 and 4, while Channel

3 (of the same slot) has analog backplane relays 5 and 6. The <ch_list> used in this

example is ("1001, 1003"). The response to a channel.getbackplane("1001, 1003") will

be "1913, 1914;1915,1916". To associate the backplane relays as indicated with

Channel 1, the corresponding command would be channel.setbackplane('1001', '1913,

1914').

Therefore, when sending this parameter:

Enclose the contents of the channel list in either single (') or double (") quotes, but the

quote style must match.

Use a comma or semicolon to separate the channel list or channel patterns.

The string may contain a single channel, channel pattern or analog backplane relay as

well as multiple ones that are indicated by a range or comma separated.

Use a colon to specify a range of channels. Example:

channel.getbackplane("1001:1003") responds with the range of Slot 1 channels from 1 to

3.

Although a parameter string may be valid, the command that calls it will determine the string's

ultimate validity. For example, only channels have a pole setting (channel patterns do not). If a

channel pattern is passed to the poles setting command, an error would be generated.

Channel patterns may be included as a <ch_list> parameter.

Page 46

Series 3700 System Switch/Multimeter Quick Start Guide Section 4: Frequently Asked Questions

Document Number: 3700S-903-01 Rev. A / August 2007 4-7

<ch_list> queries

For queries that return a channel list parameter, a channel configured for 4-pole operations will

indicate the paired channel in parenthesis. For example, Channel 3003 on a 60-channel card is

configured for 4-pole, then sending:

channel.close('3003')

print(channel.getclose('slot3') 3003(3033)

NOTE In the above examples output the paired channel associated with 3003 is 3033 and

is in included in parenthesis.

How do I make measurements?

Step 1: Connect the DUT

Connect a 10k resistor to the input terminals as shown.

Figure 4-3: Two-wire resistance measurements

Step 2: Select measurement function and range

Page 47

Section 4: Frequently Asked Questions Series 3700 System Switch/Multimeter Quick Start Guide

4-8 Document Number: 3700S-903 -01 Rev. A / August 2007

Select the 2-wire resistance measurement function by pressing the FUNC key until

twowireohms is displayed.

Select the measurement range with the RANGE keys. For the purposes of this example,

press AUTO RANGE, and note the AUTO annunciator turns on. The instrument will

automatically select the best range based on the measured value. You can also use

manual ranging by pressing the up or down RANGE key, but be sure to use the lowest

possible range for best accuracy.

Step 3: Make measurements

Observe the readings on the display. (Press the TRIG key if necessary to trigger the unit

to begin taking readings.)

Single channel through switch

Step 1: Connect the DUT

Connections for the switching module are shown below. As shown, each of the 20 channels can

be used to perform 2 measurements.

Figure 4-4: Two-wire switching module resistance connection

Step 2: Select measurement function and range

Select the 2-wire resistance measurement function by pressing the FUNC key until

twowireohms is displayed.

Select the measurement range with the RANGE keys. For the purposes of this example,

press the AUTO RANGE key, and note the AUTO annunciator turns on. The instrument

will automatically select the best range based on the measured value. You can also use

manual ranging by pressing the up or down RANGE key, but be sure to use the lowest

possible range for best accuracy.

Step 3: Make measurements

Observe the readings on the display. (Press TRIG if necessary to trigger the unit to begin