Page 1

Model 3321 LCZ Meter

Operator’s Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. l 28775 Aurora Road l Cleveland, OH 44139 l 440-248-0400 l Fax: 440-248-6168 l http://www.keithley.com

BELGIUM:

CHlNA:

FRANCE:

GERMANY:

GREAT BRITAIN:

INDIA:

ITALY:

NETHERLANDS:

SWITZERLAND:

TAIWAN:

Keithley

Instruments

B.V. Bergenseateenweg 709 s B-1600 Sint-Pieters-Leeuw l 02/363 00 40 l Fax: 02/363 00 6d

Keithley Instruments China

Yoan Chen Xin Building, Roam 705 l 12Yumio Road, Dewai, Madian l Beijing loo029 l 8610-62022886 l Fax: 861@62022892

Keithley

Instrumeets

Sari B.P. 60 l 3, all&e des Gamys l 91122 Palaiseau Ckdex l 0164 53 20 20 l Fax: 01 60 I I 77 26

KeithIey

Instruments

GmbH Landsberger Strasse 65 l D-821 10 Germering .089/84 93 07-40 l Fax: 089184 93 07-34

Keithley

Instruments

LM The Minster l 58 Portman Road l Reading, Berkshire RG30 LEA l 01 IS-9 57 56 66 l Fax: 0118-9

59 64 69

Keithley Instruments GmbH

Flat 2B, WILOCRISSA l 14, Rest House Crescent l Bangalore 560 001 l 91-80-509+1320/21 l Fax: 91-80-509-1322

Keithley

Instruments

s.r.1. Viale S. Gimignano, 38 l 20146 Mitano * 02/48 30 30 08 * Fax: 02/48 30 22 74

Keithley Instruments B.V.

Postbus 559.4200 AN Gorinchem l 0183-635333 l Fax: 0183-630821

Keithky Instruments SA Kriesbachstrasse 4 l 8600 Diibendorf* 01-82194 44 l Fax: 01-820 30 81

Keithley Instruments

Taiwan I Fl. 89 PO Ai Street l Hsinchu, Taiwan, R.O.C. -886-3572-9077 . Fax: 886-3572-903

10/99

Page 3

Model 3321 LCZ Meter

Operator’s Manual

01991, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, April 2000

Document Number: 3321-900-01 Rev. B

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revi-

sion Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released

between Revisions, contain important change information that the user should incorporate immediately into the manual.

Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision

of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this

print history page.

Revision A (Document Number 3321-900-01)

................................................. March 199 1

Addendum A (Document Number 3321-900-02).

................................................ May 1993

Addendum A (Document Number 3321-900-03). .......................................

December 1995

Revision B (Document Number 3321-900-01)

................................................... April 2000

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

2/02

Page 6

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

Page 7

+

Safety Precautions

The following safety precautions should be observed before using the Model 3321 LCZ Meter and any associated instruments.

This instrument is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read over this manual carefully before using the instrument.

Exercise extreme caution when a shock hazard is present at the test circuit. The American National Standards Institute

(ANSI) states that a shock hazard exists when voltage levels greater than 30V rms or 42.4V peak are present. A good

safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Inspect the connecting cables and test leads for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the test cables or any instruments while power is applied to the circuit under test.

Turn off the power and discharge any capacitors before connecting or disconnecting cables from the instrument.

Do not touch any object which could provide a current path to the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

Instrumentation and accessories should not be connected to humans.

+

Page 8

2

Table of Contents

General Information

INTRODUCTION..

.............................................................................................................................................

I- 1

PRODUCT DESCRIPTION

...............................................................................................................................

I- 1

Condensed Specifications ...........................................................................................................................

l- 1

Features .......................................................................................................................................................

I - 1

WARRANTY

INFORMATION.. .......................................................................................................................

l-2

MANUAL

ADDENDA ......................................................................................................................................

l-2

SAFETY

SYMBOLS and TERMS..

...................................................................................................................

1-2

INSPECTION

.....................................................................................................................................................

l-2

OPTIONAL

ACCESSORIES .............................................................................................................................

l-2

SPECIFICATIONS

.............................................................................................................................................

l-2

Getting Started

INTRODUCTION..

.............................................................................................................................................

2- 1

POWER-UP

........................................................................................................................................................

2- 1

BASIC

MEASUREMENTS ...............................................................................................................................

2-2

Operation

INTRODUCTION..

.............................................................................................................................................

3- 1

FRONT AND

REAR PANEL FAMILIARIZATION..

......................................................................................

3- 1

Front Panel ..................................................................................................................................................

3-2

Rear Panel ...................................................................................................................................................

3-6

POWER-UP

PROCEDURE ...............................................................................................................................

3-7

Line Voltage Setting ...................................................................................................................................

3-7

Fuse Replacement .......................................................................................................................................

3-8

Power Cord .................................................................................................................................................

3-8

Power up Sequence

.....................................................................................................................................

3-8

Default Conditions

......................................................................................................................................

3-9

TEST CONNECTIONS

......................................................................................................................................

3-9

BASIC

MEASUREMENTS

.............................................................................................................................

3- 10

Measurement Function Selection..

............................................................................................................ 3- 10

Measurement Function Parameter Selection..

........................................................................................... 3- 11

Equivalent Circuit Selection

.....................................................................................................................

3- 1 1

Measurement Range Selection..

................................................................................................................

3- 12

FREQUENCY

SELECTION..

..........................................................................................................................

3- 1.5

SIGNAL

LEVEL SELECTION..

......................................................................................................................

3- 1.5

DC

BIAS..

.........................................................................................................................................................

3-15

Page 9

4

GPIB Interface

ZERO CORRECTION

......................................................................................................................................

3-16

Zero Correction Procedures

.......................................................................................................................

3-16

Equivalent Circuits of Measurement System

............................................................................................

3-17

Correctable Range

.....................................................................................................................................

3- 17

MEASUREMENT CABLES

............................................................................................................................

3- 17

Cable Requirements

...................................................................................................................................

3-17

Additional Error

.........................................................................................................................................

3-20

-

ERROR MESSAGES

3-20

.........................................................................................................................................

GPIB Address and Delimiter

.... .........................................................................................................................

3-21

INTRODUCTION ...............................................................................................................................................

4-l

Ma.jor GPIB Specifications.. ........................................................................................................................

4- 1

Bus Line Signals and Operations

................................................................................................................

4-2

GPIB Handshaking

......................................................................................................................................

4-2

Data Transfer Example ................................................................................................................................

4-3

Basic Talker Functions

................................................................................................................................

4-3

Basic Listener Functions

.............................................................................................................................

4-3

Major Specifications

of Controller Functions

.............................................................................................

4-4

Multi-line Interface

Message..

.....................................................................................................................

4-4

GPIB Programming Example..

............................................................................................................................

4-6

GFIB SPECIFICATIONS

...................................................................................................................................

4-6

Interface Functions ......................................................................................................................................

4-6

Bus Drivers..

................................................................................................................................................

4-6

Address

........................................................................................................................................................

4-6

Receive and Transmit Codes

.......................................................................................................................

4-7

Delimiters

....................................................................................................................................................

4-7

Program Codes

............................................................................................................................................

4-7

Response to Interface Messages..

..............................................................................................................

4-10

Remote/Local Operation

...........................................................................................................................

4-10

Service Request (SRQ)

..............................................................................................................................

4-11

Status Byte..

...............................................................................................................................................

4- 1 1

Process Time

.............................................................................................................................................

4-12

SETTING GPIB ADDRESS AND DELIMITER

.............................................................................................

4-12

GPIB PROGRAMMING

...................................................................................................................................

4-12

Setting Messages

.......................................................................................................................................

4- 13

Inquiry Messages

.......................................................................................................................................

4-13

Reading Measured Data

............................................................................................................................

4-17

MEASUREMENTS OVER GPIB

....................................................................................................................

4-18

Preparation

.................................................................................................................................................

4-18

Measurement and Reading

of Data

..........................................................................

.

................................

4-l 8

GPIB OPERATING CONSIDERATIONS..

................................................................

,

....................................

4- 19

GPIB ERRORS

.................................................................................................................................................

4-19

EXAMPLE PROGRAMS

........................................................................

.

........................................................

4-20

GPlB Initialization

.....................................................................................................................................

4-20

Display Setting

..........................................................................................................................................

4-20

Inquiry

.......................................................................................................................................................

4-20

SRQ and Serial Poll ......................

.

............................................................................................................

4-21

Measurements

............................................................................................................................................

4-21

ii

Page 10

2

Figure 2- 1

3

Figure 3- 1

Figure 3-2

Figure 3-3

Figure 3-4

Figure 3-5

Figure 3-6

Figure 3-7

Figure 3-8

Figure 3-9

Figure 3-10

4

GPIB Interface

Figure 4- 1

Interface Connector

.....................................................................................................................................

4-2

Figure 4-2

Handshake Timing Diagram

.......................................................................................................................

4-3

Figure 4-3

Data Transfer Example

...............................................................................................................................

4-4

Figure 4-4

Basic Syntax Program Code

.......................................................................................................................

4-7

list of Illustrations

Getting Started

Model 3321 Test Fixture Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..‘........................................................

2-3

Operation

Model 3321 Front Panel

..............................................................................................................................

3-2

Model 3321 Rear Panel..

.............................................................................................................................

3-6

Cleaning Air Filter..

....................................................................................................................................

3-7

Fuse Replacement

.......................................................................................................................................

3-8

_

Connection to the Device Under Test

.......................................................................................................

3- 10

Equivalent Circuits of Device Under Test

................................................................................................

3-11

OPEN Measurement

.................................................................................................................................

3-16

SHORT Measurement

...............................................................................................................................

3-17

Equivalent Circuits of Measurement System

............................................................................................

3-18

Test Cables..

..............................................................................................................................................

3-19

.

111

Page 11

3

Table 3-l

Power-up Defaults.. .....................................................................................................................................

3-9

Table 3-2

AUTO Function Selections

.......................................................................................................................

3-10

Table 3-3

AUTO Equivalent Circuit Selections..

......................................................................................................

3-l 2

Table 3-4

Impedance Ranges

....................................................................................................................................

3-14

Table 3-5

Additional Error of I Z I Caused by Test Cables (Reference Data)

...........................................................

3-20

Table 3-6

Error Message

...........................................................................................................................................

3-2 1

4

GPIB Interface

Table 4- 1

Multi-Line Interface Message..

...................................................................................................................

4-5

Table 4-2

Interface Functions..

....................................................................................................................................

4-6

Table 4-3

Bus Drivers .................................................................................................................................................

4-6

Table 4-4

List of Program Codes ................................................................................................................................

4-9

Table 4-5

Response to Interface Messages

................................................................................................................

4-10

Table 4-6

Status Bytes

...............................................................................................................................................

4-11

Table 4-7

Process Time of Program Codes

(Reference Data)

........................................

. .........................................

4-12

Table 4-8

Setting Messages..

.....................................................................................................................................

4- I4

Table 4-9

Inquiry Messages

......................

.

...............................................................................................................

4-15

Table 4- 10

GPIB Error Messages

................................................................................................................................

4- 19

list of Tables

Operation

Page 12

SECTION 1

General Information

1 .l INTRODUCTION

This section contains general information about the

Model 3321.

1.2 PRODUCT DESCRIPTION

The Model 3321 LCZ Meter is a high accuracy (0.1%

basic accuracy), full function LCZ meter. It includes an

IEEE-488 interface to control operation from a computer.

The Model 3321 drives a device under test (DUT) with a

known voltage sine wave signal. Impedance is derived

by precisely measuring the resultant current that flows

through the DUT.

1.2.1 Condensed Specifications

The following condensed specifications help summarize

the capabilities of the Model 3321. Complete, detailed

instrument specifications are located in Appendix A.

Measurement Functions: L, C, I Z I, Q, D, ESR, G, 8.

These functions can be automatically selected.

Basic Accuracy: 0.1% (at 1kHz)

Measurement Ranges (Display):

IZI

O.lmQ to 19.999Ma

C

O.OOlpF to 199.99mF

b, D

O.lnH to 19.999kH

0.0001 to 19999

8

-180.00” to +179.99”

Measurement Frequency:

120Hz, lkHz, 1OkHz or

1ookHz.

Measurement Signal Level: 1V rms, 50mV rms

Equivalent Circuit: Series, parallel and automatic

DC Bias:

DC Bias: Internal: 2V

External: 0 to *35V

Zero Correction: Automatic (OPEN, SHORT).

Measuring Time: FAST (64ms), MED (150ms), SLOW

(480ms).

1.2.2 Features

l High Accuracy - Basic accuracy of 0.1% with dis-

play resolution of 0.0001 at 4-l /2 digits.

l Wide Frequency Range

- Four frequency selections

in the range from 120Hz to 1OOkHz.

l Two Measurement Signal Levels - Selectable sine

wave signals of 50mV rms or 1V rms can be applied

l-l

Page 13

SECTION 1

General Infbvmation

to the DUT. Also, the signal can be biased by selecting the 2V internal DC bias or by externally applying

a DC bias up to i35V.

Variety of Measurement Functions - In addition to

the conventional functions including L, C, D and Q,

you can also display the equivalent series resistance

(ESR), parallel conductance (G), and polar coordinates expression ( I Z I - 0).

Automatic Function and Range Selection - In addition to the conventional autorange feature, function

and the equivalent circuits can also be automatically

selected.

Built-in DC Bias Power Supply - The built-in

2V DC bias power supply is used to measure the

capacitance of polarized devices such as electrolytic

capacitors and semiconductors.

IEEE-488 Interface - Allows the instrument to be

controlled by a computer.

1.3 WARRANTY INFORMATION

Warranty information is located on the

inside front

cover of this instruction manual. Should

your Model

3321 require warranty service, contact the Keithley representative or authorized repair facility in your area for

further information. When returning the instrument for

repair, be sure to fill out and include the service form at

the back of this manual in order to provide the repair

facility with the necessary information.

1.4 MANUAL ADDENDA

Any improvements or changes concerning the instrument or manual will be explained in an addendum

included with the manual. Be sure to note these changes

and incorporate them into the manual.

1.5

SAFETY SYMBOLS and TERMS

The following symbols and terms may be found on an

instrument or used in this manual.

The symbol !

n

on an instrument indicates that the

user should refer to the operating instructions located in

the instruction manual.

The WARNING heading used in this manual explains

dangers that might result in personal injury or death.

Always read the associated information very carefully

before performing the indicated procedure.

The CAUTION heading used in this manual explains

hazards that could damage the scanner card. Such damage may invalidate the warranty.

1.6 INSPECTION

The Model 3321 was carefully inspected, both electrically and mechanically, before shipment. After unpacking all items from the shipping carton, check for any

obvious signs of physical damage that may have

occurred during transit.

Report any damage to the shipping agent immediately.

Save the original packing carton for possible future

reshipment. The following items are included with

every Model 3321 order:

l Model 3321 LCZ Meter

l Model 3321 Instruction Manual

l Additional Accessories as ordered.

If an additional instruction manual is required, order

the manual package, Keithley part number 3321-901-00.

The manual package includes an instruction manual

and any pertinent addenda.

1.7 OPTIONAL ACCESSORIES

The following accessories are available from Keithley

for use with the Model 3321:

1.

2.

3.

4.

Model 3323 Direct Test Fixture. Allows leaded parts

to be directly inserted into this test fixture.

Model 3324 4-Terminal Alligator Clip Test Lead.

Designed for four-terminal components, in which

the current-supplying terminals and voltagemeasurement terminals are separated.

Model 3325 Kelvin Clip Test Lead. Uses two clips for

four-terminal connections. Used to measure large or

irregularly-shaped components which cannot be

inserted into the Model 3323 test fixture.

Model 3326 Chip Component Test Leads. This

tweezer-type test lead set permits easy connection to

surface mounted chip components.

The cables for all the above test leads are shielded to

minimize stray capacitance.

1.8 SPECIFICATIONS

Model 3321 specifications may be found in Appendix A

of this manual.

l-2

Page 14

SECTION 2

Getting Started

2.1 INTRODUCTION

This brief section will guide the user through front panel

operation. This section is intended to acquaint the user

with basic operation. Detailed operation is covered in

Section 3.

NOTE

Front and rear panel views of the instrument

(which may be helpful in locating controls, annunciators or connectors) are provided by

Figures 3-l and 3-2. These drawings are located in Section 3.

2.2 POWER-UP

The instrument is designed to operate from 90-132V or

198-250V line voltage ranges at 48 to 62Hz. Perform the

following steps to connect the instrument to line power:

1. Check the rear panel LINE SUPPLY selector switch

and make sure the setting agrees with the line voltage available in your area. If the switch setting needs

to be changed, perform the procedures in paragraph

3.3. Keep in mind that changing the line voltage setting requires a fuse change.

CAUTION

To prevent damage to the instrument that

may not be covered by the warranty, make

sure the rear panel LINE SUPPLY switch is

set to the correct line voltage setting.

2. The power cord is supplied with the instrument.

Connect the female end of the power cord to AC receptacle on the rear panel, and connect the other

end to a grounded AC outlet.

WARNING

The instrument is equipped with a 3-wire

power cord that contains a separate ground

wire and is designed to be used with

grounded outlets. When proper connections

are made, instrument chassis is connected to

the power line ground. If the AC outlet is not

grounded, the rear panel safety earth ground

terminal must be connected to a known

safety earth ground using #18 AWG (or

larger) wire.

3. Turn on the instrument by depressing the POWER

switch in to the ON position. The instrument will

perform its power up sequence (see paragraph

3.3.4). After successfully completing the power up

tests, the instrument will assume default conditions

+

2-1

Page 15

SECTION 2

Gettim Started

+

that configure the instrument for immediate measurements.

NOTE

The instrument is ready for immediate use.

However, to achieve rated accuracy, the instrument must be allowed to warm up for at

least l/2 hour.

2.3 BASIC MEASUREMENTS

A measurement is performed by applying a known rms

signal level at a specific frequency to the DUT and then

calculating and displaying the results.

NOTE

The following procedure assumes that the instrument is configured to its power-up default conditions. If you are not sure about the

setup configuration, simply turn the power

off and then on again.

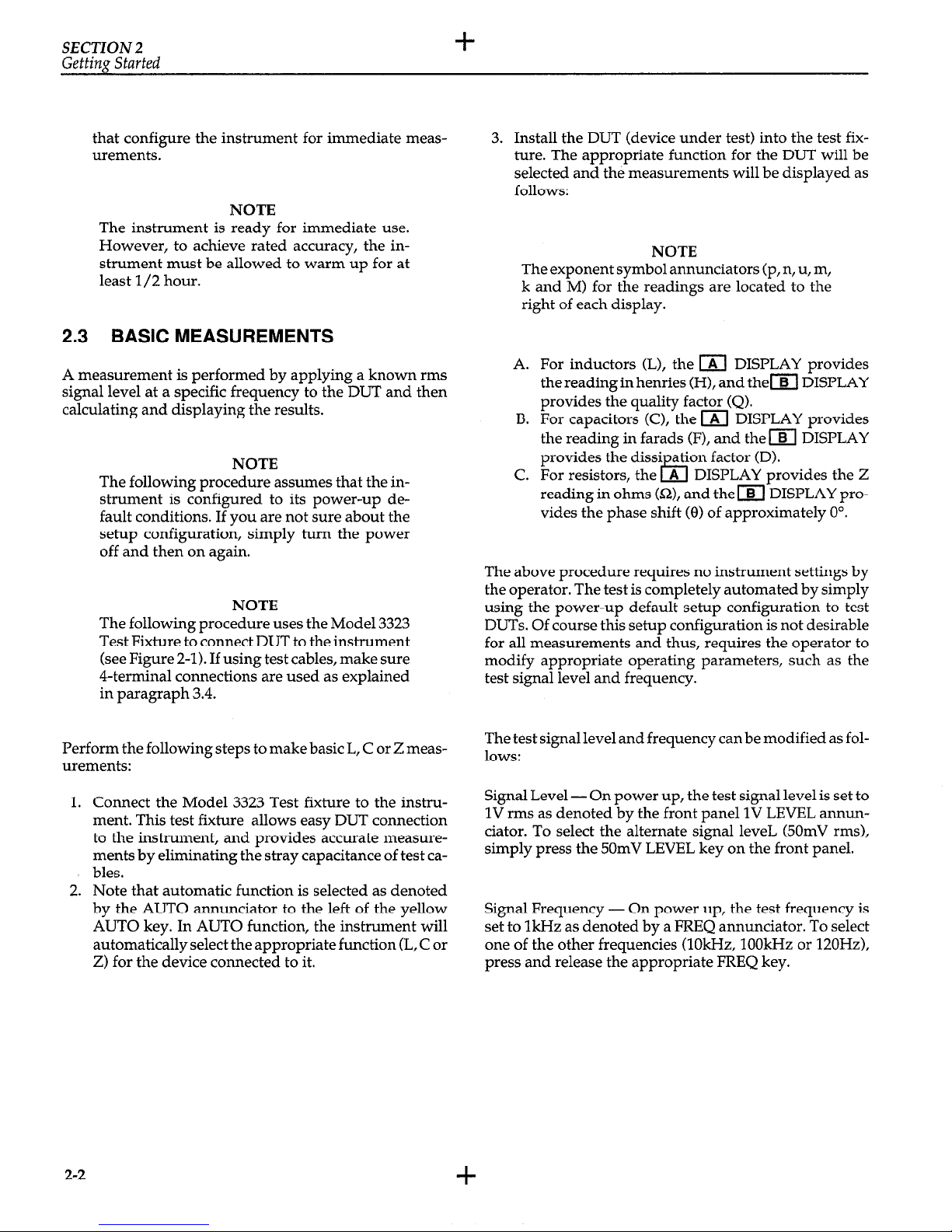

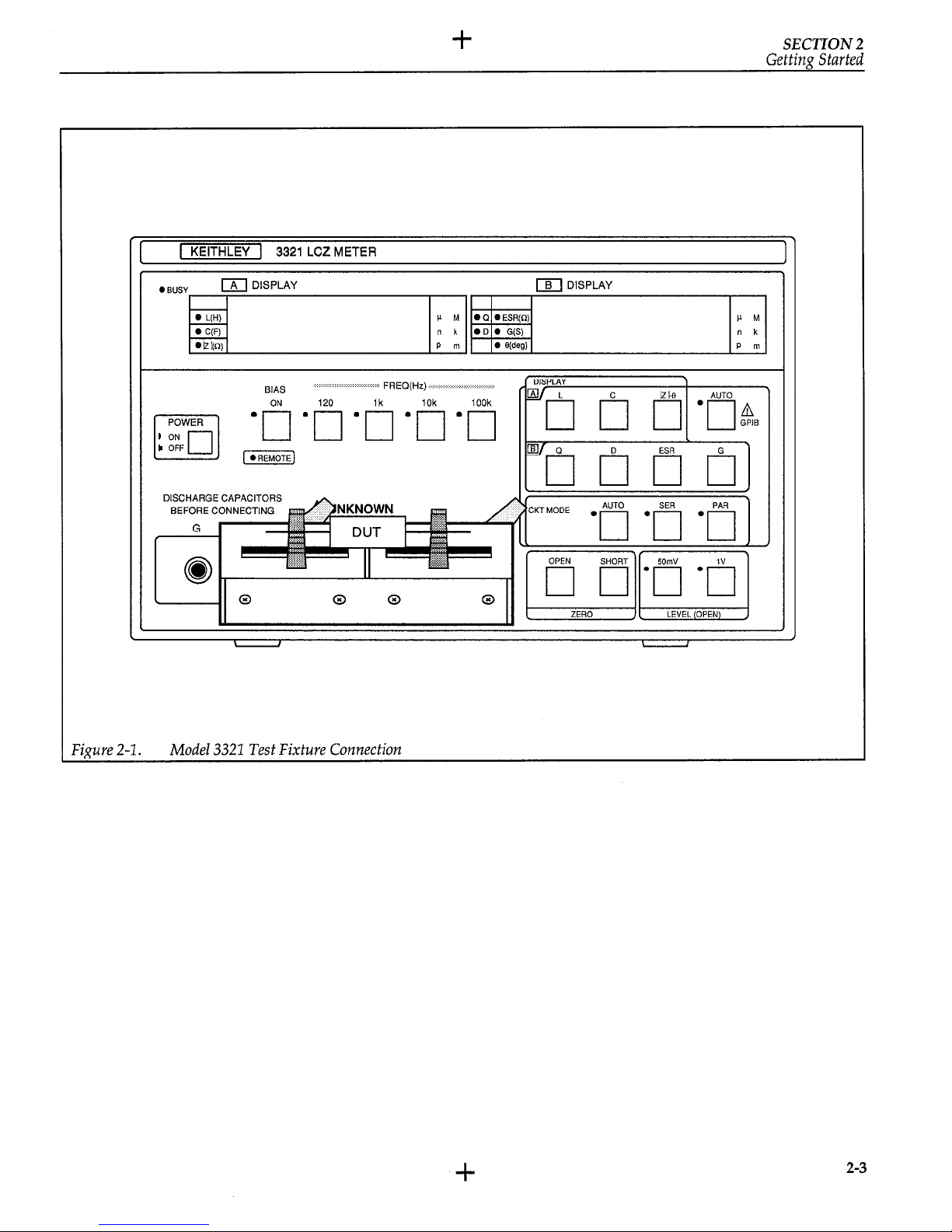

NOTE

The following procedure uses the Model 3323

Test Fixture to connect DUT to the instrument

(see Figure 2-l). If using test cables, make sure

4-terminal connections are used as explained

in paragraph 3.4.

Perform the following steps to make basic L, C or Z measurements:

1. Connect the Model 3323 Test fixture to the instrument. This test fixture allows easy DUT connection

to the instrument, and provides accurate measurements by eliminating the stray capacitance of test cables.

2. Note that automatic function is selected as denoted

by the AUTO annunciator to the left of the yellow

AUTO key. In AUTO function, the instrument will

automatically select the appropriate function (L, C or

Z) for the device connected to it.

3. Install the DUT (device under test) into the test fixture. The appropriate function for the DUT will be

selected and the measurements will be displayed as

follows:

NOTE

The exponent symbol annunciators (p, n, u, m,

k and M) for the readings are located to the

right of each display.

A.

B.

C.

For inductors (L), the m DISPLAY provides

the reading in henries (H), and them DISPLAY

provides the quality factor (Q).

For capacitors (C), the m DISPLAY provides

the reading in farads (F), and them DISPLAY

provides the dissi ation factor (D).

For resistors, the A

i!!b

DISPLAY provides the Z

reading in ohms (a), and them DISPLAY provides the phase shift (0) of approximately 0”.

The above procedure requires no instrument settings by

the operator. The test is completely automated by simply

using the power-up default setup configuration to test

DUTs. Of course this setup configuration is not desirable

for all measurements and thus, requires the operator to

modify appropriate operating parameters, such as the

test signal level and frequency.

The test signal level and frequency can be modified as follows:

Signal Level - On power up, the test signal level is set to

1V rms as denoted by the front panel 1V LEVEL annunciator. To select the alternate signal 1eveL (50mV rms),

simply press the 50mV LEVEL key on the front panel.

Signal Frequency - On power up, the test frequency is

set to 1kHz as denoted by a FREQ annunciator. To select

one of the other frequencies (lOkHz, 1OOkHz or 120Hz),

press and release the appropriate FREQ key.

2-2

+

Page 16

+

SECTION 2

Getting Started

1-1

3321 LCZ METER

I

1

ZERO

Jl LEVEL (OPEN) j

J

ciauve 2-l.

Model 3322 Test Fixture Connection

+

2-3

Page 17

+

SECTION 3

Operation

3.1 INTRODUCTION

ciators and connectors on the front and rear panels of the

instrument.

This section covers front panel operation. For operation

over the GPIB bus, see Section 4.

3.2 FRONT AND REAR PANEL

FAMILIARIZATION

The front and rear panels of the instrument are shown in

Figure 3-l and Figure 3-2.

The following information describes the controls, annun-

+

3-l

Page 18

SECTION 3

I

-1 3321 LCZMETER

I

l BUSY

m DISPLAY

m DISPLAY

l L(H)

C M

l a l ESR(O)

P M

. C(F)

n k 0 D 0 G(S)

n k

. h I,“\ D m l olden1 P m

BIAS

.:.-..:.:.:.:.<.:.:.:.:.:.:.:.:.:.,.:.:. FREQ(Hz) :.: ..:.:.:.:.:. :.:.:.:.:.:.: :.:.:.:.ix.:.:

DISCHARGE CAPACITORS

BEFORE CONNECTING

A UNKNOWN

I

\

II

ZERO

)I LE”EL,OPEN) j

I

I

\

I

\

I

Figure 3-1.

Model 3321 Front Panel

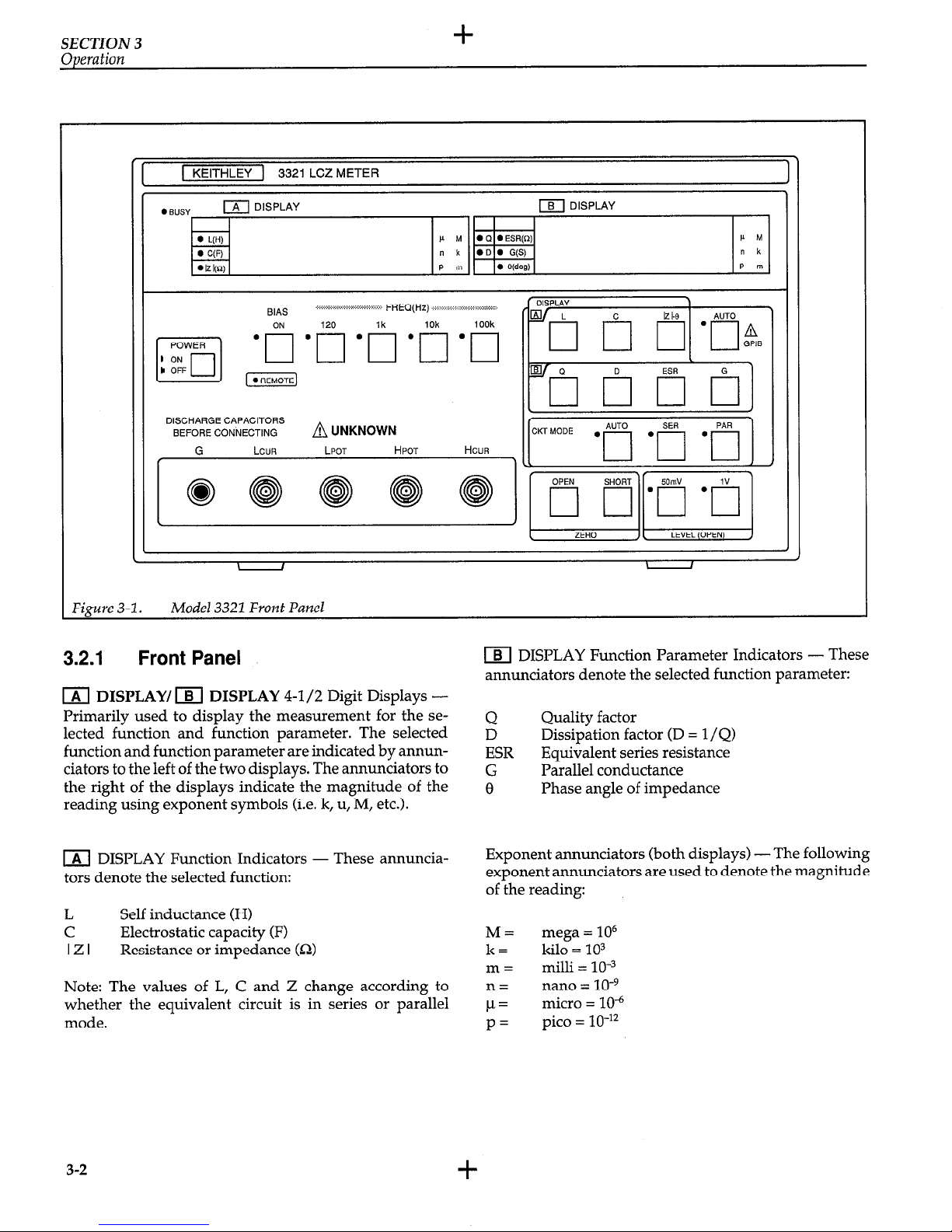

3.2.1 Front Panel

IAl DISPLAY/ m DISPLAY 4-l/2 Digit Displays -

Primarily used to display the measurement for the selected function and function parameter. The selected

function and function parameter are indicated by annunciators to the left of the two displays. The annunciators to

the right of the displays indicate the magnitude of the

reading using exponent symbols (i.e. k, u, M, etc.).

m DISPLAY Function Indicators - These annuncia-

tors denote the selected function:

L

Self inductance (H)

C Electrostatic capacity (F)

IZI Resistance or impedance (0)

Note: The values of L, C and Z change according to

whether the equivalent circuit is in series or parallel

mode.

m DISPLAY Function Parameter Indicators - These

annunciators denote the selected function parameter:

Q

Quality factor

D

Dissipation factor (D = 1 /Q)

ESR

Equivalent series resistance

G

Parallel conductance

8

Phase angle of impedance

Exponent annunciators (both displays) - The following

exponent annunciators are used to denote the magnitude

of the reading:

M= mega = lo6

k=

kilo = 103

m=

milli = 10”

n= nano = 10eg

P=

micro = lo4

P’

pica = 1O-‘2

3-2

Page 19

+

SECTION3

Operation

Front Panel Indicators:

BUSY-This indicator lights when a measurement is be-

ing made. This indicator is off while in OPEN or SHORT.

REMOTE -This indicator is on when the GPIB interface

is in the remote state. While in remote, the front panel

controls are disabled.

FREQ (Hz) -

Denotes the frequency (120H2, lkHz,

1OkHz or 1OOkHz) that was selected using the FREQ keys.

CKT MODE

- Denotes the equivalent circuit that was

selected using the CKT MODE keys.

AUTO Automatic selection mode; SER or PAR auto-

matically selected.

SER Series equivalent circuit.

PAR

Parallel equivalent circuit.

Note: CKT selections only affect readings on m DISPLAY.

LEVEL (OPEN)- Denotes the level of the measurement

signal that was selected using the LEVEL keys.

50m

50mV rms signal level. Basic accuracy is lowered

using this level.

1

Standard 1V rms signal level.

The indicated signal level is the voltage applied to the

output while under a “no load” condition. The output

impedance of the signal source is approximately 1OOfi.

When connecting the signal to a device that has an impedance of less than lkS& loading will cause the signal

level to drop below the indicated voltage level.

Front Panel Controls:

POWER ON-OFF

The “in” position turns power on and the “out” position

turns power off. After turning power off, wait at least

three seconds before turning it back on.

BIAS ON Key

Pressing this key enables the internal 2V bias power supply. Pressing the key a second time disables the bias supply. With the rear panel BIAS INT/EXT switch set to the

EXT position, the BIAS ON key will instead control the

externally applied bias supply.

NOTE

The bias supply can only be enabled with the

C (capacitance) function selected and AUTO

function disabled.

FREQ (Hz) Keys:

These keys are used to select the frequency of the measurement signal. The enabled annunciator denotes which

frequency is selected.

120 - Pressing this key sets the measurement frequency

to 120Hz.

lk - Pressing this key sets the measurement frequency

to 1kHz.

10k -Pressing this key sets the measurement frequency

to 10kHz.

100k -

Pressing this key sets the measurement fre-

quency to 1 OOkHz.

m DISPLAY Keys:

The following keys are used to select the measurement

function. The reading for the selected function is shown

on them DISPLAY. The default function parameter (Q,

D or 0) for the selected function is automatically selected

and shown on the m DISPLAY.

L - Pressing this key selects the inductance (L) function

and displays the reading in henries (H). The selected default function parameter is Q.

C-Pressing this key selects the capacitance (C) function

and displays the reading in farads (F). The selected default function parameter is D.

121-e-- Pressing this key selects the impedance (Z)

function and displays the reading in ohms (a). Note that

this function is used to measure resistance. The phase an-

le (0)

I5

for the impedance measurement is shown on the

B DISPLAY.

+

3-3

Page 20

SECTION 3

Operation

+

m DISPLAY Keys:

The following keys are used to select an alternate function parameter (Q, D, ESR or G) for the L or C function.

The reading for the function parameter is shown on the

m DISPLAY.

The function parameter keys are not operational with the

AUTO function feature enabled. Pressing one of these

keys with AUTO enabled results in “Err 13”.

Q - Pressing this key displays the quality factor (Q) for

the L or C measurement.

D - Pressing this key displays the dissipation factor (D)

for the L or C measurement.

ESR - Pressing this key displays the equivalent series

resistance (ESR) for the L or C measurement.

G - Pressing this key displays the conductance (G) for

the L or C measurement.

AUTO/GPIB Key:

This dual function key is used to select the AUTO func-

tion feature, or to check and/or change the GPIB address/delimiter.

AUTO

- Pressing and immediately releasing this key

enables the AUTO function feature. With AUTO function

enabled, the instrument determines the type of device

connected to its input and automatically selects the appropriate measurement function. AUTO function is disabled by pressing one of the function selection keys (L, C

or IZI-0).

GPIB - By pressing and holding in this key for approxi-

mately three seconds, the current GPIB address and de-

limiter will be displayed on them DISPLAY.

The address and delimiter values are separated by the

decimal point. Valid address values are 0 to 30. Delimiter

values can be 0 (for <CR><LF>) or 1 (for <CR> only). Use

the I Z I - 0 key and ESR key to change the address value,

and use the G key to toggle the delimiter.

The displayed address and delimiter values can be entered by again pressing the GPIB key. The instrument

will return to the normal measurement display state.

3-4

+

CKT MODE Keys:

The following keys are used to select the equivalent circuit:

AUTO -With AUTO CKT MODE enabled, the equiva-

lent circuit (SER or PAR) will automatically be selected

(enabled).

The AUTO CKT MODE is automatically enabled if the

AUTO function feature is enabled. With AUTO function

enabled, AUTO CKT MODE cannot be disabled. With

AUTO function disabled, ALIT.0 CKT MODE can be dis-

abled by pressing the SER or PAR key.

SER - This key is only operational if AUTO function is

disabled. When operational, pressing this key will disable AUTO CKT MODE (if enabled), and select (enable)

the series (SER) circuit mode.

PAR - This key is only operational if AUTO function is

disabled. When operational, pressing this key will disable AUTO CKT MODE (if enabled), and select (enable)

the parallel (PAR) circuit mode.

ZERO Keys:

Zero correction measures the residual impedance and

stray admittance, and then automatically corrects the displayed reading caused by these errors. The following

keys are used to perform zero correction:

OPEN -To perform zero correction, open the input and

press the OPEN key.

SHORT

- To perform zero correction, short the input

and press the SHORT key.

LEVEL (OPEN) Keys:

These keys are used to select the rms voltage level of the

measurement signal.

50mV

- Press this key to set the level of the measure-

ment signal to 50mV rms.

1V - Press this key to set the level of the measurement

signal to 1V rms.

Page 21

+

SECTION 3

Operation

Measurement Terminals:

UNKNOWN-The following front panel connectors are

used to connect the DUT to the instrument:

L CUR - Current detection terminal

L POT - Voltage detection terminal (Low)

H POT - Voltaie detection terminal (High)

H CUR - Drive signal output terminal.

G -Ground terminal that is connected to the chassis

of the instrument. Used for shielding.

The bias voltage and the drive signal can be monitored on

these terminals.

+

3-5

Page 22

SECTION 3

Operation

WARNING

-/%

NO INTERNAL OPERATOR

Figure 3-2. Model 3321 Rear Panel

CAUTION

FOR FIRE PROTECTION,

SERVICEABLE PARTS. SERVICE

3.2.2 Rear Panel

CAUTION

0 to *35V is the maximum voltage that can be

GLIB - This connector is used to connect the GPIB

applied to the BIAS IN connector. Voltages out-

interface of the instrument to GPIB interface of a com-

side this range may blow the fuse and cause

puter. See Section 4 for details.

damage to the instrument.

BIAS -The following switch, fuse and input connector

pertain to using an external bias supply:

INT/EXT Switch - This toggle switch is used to

switch between the built-in (INT) bias power supply (2V) and the externally (EXT) applied bias supply (up to 35V).

Fuse - Maintenance fuse for the external power

supply (O.lA quick acting type).

IN Connector - BNC connector used to connect the

external bias supply to the instrument power input connector. Use a 0 to +35V supply with low ripple and

noise.

Ventilation Fan - The fan is used to keep the inside of

the instrument free from damaging heat build-up. The

fan pulls cool air into the instrument and expels warm

air out of the vents in the top cover. For proper

ventilation:

1. Maintain at least 10cm between the rear panel and a

wall.

2. Do not block the air vents in the top cover.

3. Clean the air filter periodically to prevent clogging.

Figure 3-3 shows how to remove the filter for

cleaning.

WARNING

Be sure to turn off the power and remove the

power cord before removing or installing the

filter.

3-6

Page 23

+

SECTION 3

Operation

Rear Panel

(2) Remove and Clean

Air Filter

Figure 3-3.

Cleaning Air Filter

(1) Remove the inner holder

LINE SUPPLY-Set this switch to the available line voltage. Changing the line voltage setting will require a fuse

change. See paragraph 3.3.1 for details.

LINE 4%62Hz - Power Receptacle and Fuse. Use the

supplied line cord to connect the instrument to the line

power. Fuse replacement is covered in paragraph 3.3.2.

CAUTION

To prevent damage to the instrument that

may not be covered by the warranty, be sure

to turn off power and disconnect the line

cord before changing the line voltage setting. Do not use a fuse other than the one

specified for the line voltage setting.

3.3 POWER-UP PROCEDURE

3.3.1

Line Voltage Setting

The instrument is designed to operate from 90-l32V or

19%250V line power ranges at 48 to 62Hz. Perform the

following procedure to set the line voltage:

WARNING

Make sure the instrument is disconnected

from the power line and all other equipment

before proceeding.

Safety Ground Terminal - If the instrument is not con-

netted to a safety earth ground through the supplied

3-prong line cord, connect this terminal to a known safety

earth ground using #18 AWG (or larger) wire.

1. Check the line voltage setting of the LINE SUPPLY

switch on the rear panel. To change the setting, use a

flat-blade screw driver to set the rotary switch to the

setting that best matches the available line power.

+

3-7

Page 24

SECTION 3

Operation

2. If the switch setting was changed, install a fuse consistent with the operating voltage as described in the

next paragraph.

3.3.2 Fuse Replacement

A rear panel fuse located inside the AC LINE receptacle

is used to protect the power line input of the instrument.

If the fuse needs to be replaced (line voltage switch setting changed or blown fuse), perform the following

steps:

WARNING

Make sure the instrument is disconnected from

the power line and other equipment before

replacing the fuse.

1. Using a flat-blade screw driver, pry open the fuse

drawer as shown in Figure 3-4.

‘igure 3-4. Fuse Replacement

2. Remove the fuse from the fuse clip. Notice that there

is a spare fuse in front of it.

3. Replace the fuse with the following type:

Line

I----

Voltage

1oov/12ov

22OV/24OV

Fuse Rating

0.4A

0.5A

0.2A

0.25A

CAUTION

Do not use a fuse with a higher current rating

than specified, or instrument damage may occur.

4. Push the fuse drawer back into the receptacle.

3.3.3 Power Cord

Connect the female end of the power cord to the AC

receptacle on the rear panel of the instrument. Connect

the male end of the cord to a grounded AC outlet.

WARNING

The instrument is equipped with a 3-wire

power cord that contains a separate ground wire

and is designed to be used with grounded outlets. When proper connections are made, instrument chassis is connected to the power line

ground. If the AC outlet is not grounded, the

rear panel safety earth ground terminal must be

connected to a known safety earth ground using

#18 AWG (or larger) wire.

CAUTION

Be sure that the power line voltage agrees with

the indicated voltage of the LINE SUPPLY

switch. Failure to observe this precaution may

result in instrument damage not covered by the

warranty.

3.3.4 Power Up Sequence

To turn on the instrument, depress the POWER button.

During the power up cycle, the unit will perform the

following:

1. All annunciators and display segments will turn on

for a few seconds. This allows you to check for defec-

tive indicators or display digits.

2. The revision level of the firmware is displayed

briefly on the IAl DISPLAY. For example:

-l.lO-

3. The self-check on memory elements and self-

calibration of internal circuits are performed. During

this eriod, the “CAL” message will be displayed on

the b A DISPLAY and a countdown from 7 to 0 will

take place on the m DISPLAY. Any errors that

occur are denoted by error messages on the display.

Table 3-6 explains the error messages.

4. The unit will begin normal operation in accordance

with the power-up configuration discussed in the

next paragraph.

3-8

Page 25

+

SECTION 3

Operation

3.3.5

Default Conditions

3.4 TEST CONNECTIONS

Default conditions are the setup conditions that the in-

In general, 4-wire measurements are made on the device

strument will return to when the instrument is powered under test using the front panel BNC type terminals. A

up (or when a DCL or SDC command is sent over the

test fixture, such as the Model 3323 which connects diGPIB bus). The default conditions for the instrument are

rectly to the front panel, or test cables can be used to make

summarized by Table 3-1.

connections to the DUT.

Table 3-1. Power-up Defaults

The UNKNOWN terminals are described as follows:

Parameter

m DISPLAY

m DISPLAY

CKT MODE

FREQ

DELAY

LEVEL

Zero correction

BIAS

Header output

SRQ output

Address

Delimiter

Setting

AUTO

(AUTO)

AUTO

1kHz

Zero

1Vrms

No correction

Off

Inhibit (GPIB “HD 0”)

Inhibit (GPIB “RQ 0” )

2

<CR> <LF>

Remark

1

1

1

1

1,2,3

1,2

Remarks:

1. The setting for this parameter cannot be saved in one of the ten

battery back-up memories. The setting for all other parameters

can be returned to the power-down condition by recalling

Memory 0.

2. The setting for this parameter is stored in battery backed-up

memory and automatically returns to the last programmed value

on power-up.

3. Address 2 is factory default, but can be changed by the user.

G-Ground terminal for guard that can be used to shield

the DUT.

L CUR - Current detection terminal

L POT - Voltage detection terminal (Low)

H POT - Voltage detection terminal (High)

H CUR - Drive signal output terminal. Delivers the DC

bias and the sine wave signal.

When using individual cables, refer to Figure 3-5 and use

the following rules to connect them:

1. Connect the voltage detection terminals (H POT and

L POT) to the inner position on the DUT leads as

shown in the illustration.

2. Keep cables as short as possible.

3. If using long cables, twist the two voltage cables together, then twist the two current cables together. Finally, twist the two separate cable pairs together to

form one twisted cable assembly.

4. At the DUT, connect the shields of the BNC cables together.

+

3-9

Page 26

SECTION 3

Operation

1

Figure 3-5.

Connection to the Device Under Test

Arrangement of

cables for twisting

(See Figure 3-l OA)

3.5 BASIC MEASUREMENTS

To achieve rated accuracy, zero correction must first be

performed as explained in paragraph 3.9. In general, zero

correction is performed by first opening the measurement terminals and pressing the OPEN key. After completion of the OPEN correction, the terminals are then

shorted and the SHORT key is pressed.

I Z I - 0 (Q) - Resistance or impedance

To manually select the desired function, simply press

and release the appropriate m DISPLAY key.

Automatic Function Selection - When AUTO is enabled, the instrument selects the function, function parameter and equivalent circuit automatically. It does this

by measuring the phase angle (f3) of the DUT connected at

the input. Table 3-2 defines the selected function and

function parameter that is based on the internally measured phase angle (e):

3.5.1

Measurement Function Selection

The basic measurement functions are selected using the

@l DISPLAY keys or the yellow AUTO key. The se-

lected function is denoted by the annunciators located to

the left of them DISPLAY. The measurement of the selected function is provided on them DISPLAY. The exponent annunciators for the measured reading are located to the right of the m DISPLAY. Available functions include:

AUTO - Automatic function selection. With AUTO

function selected, the instrument will determine the type

of device connected to the input and automatically select

the appropriate measurement function.

L (H) - Self-inductance (self-induction factor)

C (F) - Electrostatic capacity

Table 3-2.

AUTO Function Selections

Internally Measured Function

Phase Angle (0) Function Parameter

3-10

+

Page 27

+

SECTION 3

Operation

While in AUTO function:

1. Function parameters are automatically selected.

Pressing any m DISPLAY key will result in “Err

13”.

2. The equivalent circuit (CKT) is automatically

(AUTO) selected (SER or PAR).

3.5.2 Measurement Function Parameter

Selection

The measurement arameter for the selected function is

selected using the B

b

DISPLAY keys. Note however,

that if AUTO function is enabled, these keys are inoperative (Err 13). In AUTO function, the measurement pa-

rameter is automatically selected.

The selected function parameter is denoted by the annunciator located to the left of the m DISPLAY. The

m DISPLAY provides the reading of the selected parameter, while the exponent part of the reading is located

to the right of the display. The available function parameters include:

Q - Quality factor

D - Dissipation factor (D = 1 /Q)

ESR (a) - Equivalent series resistance

G (S) - Parallel conductance

8 (deg) - Phase angle of impedance

Note that there is not a separate key to select 9 (Deg). 8

(Deg) is automatically selected when I Z I-8 function is

selected.

To select the desired function parameter (AUTO off),

simply press and release the appropriate m DISPLAY

key.

When ESR or G is selected, the equivalent series resistance, or parallel conductance is displayed, respectively.

The readings for Q, D and 8 are not related to the equivalent circuit.

3.5.3

Equivalent Circuit Selection

The equivalent circuit (see Figure 3-6) is selected using

the CKT MODE keys. Note that if AUTO function is enabled, the CKT MODE keys are inoperative (Err 15) and

the equivalent circuit is placed in the AUTO mode.

SER (series) PAR (parallel)

I Figure 3-6. Equivalent Circuits of Device Under Test

The CKT annunciators on the front panel denote the selected equivalent circuit. The equivalent circuit selections

include:

AUTO - Automatic equivalent circuit selection

SER - Series Circuit

PAR - Parallel Circuit

To manually select the equivalent circuit (assuming

ATJTO function is disabled), simply press and release the

appropriate CKT MODE key.

With AUTO CKT MODE enabled, the instrument selects

an equivalent circuit automatically. The selected circuit is

determined according to the combination of selected

function, function parameter, and phase angle. Table 3-3

summarizes the combinations that determine the equivalent circuit while AUTO CKT is enabled.

3-11

Page 28

SECTION 3

Table 3-3. AUTO Equivalent Circuit Selections

3.5.4

Measurement Range Selection

Measurement Capabilities

Conditions for selection of

Conditions for selection of

series mode (SER)

parallel mode (PAR)

Function Function

Function

Parameter Function Parameter

ESR

?: (IZI 11wZ) Q,D

L, c

G

lil’

L,C,(lZl >lw1) Q,D

0

Measurement range selection for the selected function is

performed automatically. Reading range for the function

parameter (m DISPLAY) is also selected automatically.

The measurement capability of each function and func-

tion parameter is summarized as follows:

IZI, ESR

The instrument will go to the optimum (most accurate)

range to make the measurement.

4 l/2 digits (19999 digits max>.

Table 3-4 lists the impedance ranges for the instrument.

Notice that the valid measurement range is frequency

and level dependent. The reading limits for each range

are defined by the Lower Limit Extension and the Upper

Limit Extension. The instrument will not measure levels

that fall outside of these limits.

The optimum measurement is performed and displayed

120Hz

: O.OOOnF to 199.99mF

on the range that is bounded by the Lower Limit and Up-

1kHz : O.OpF to 19.999mF

per Limit (see Table 3-4). For example, for a 1Om meas-

1OkHz

: O.OOpF to 1.999mF

urement, the displayed reading will occur on Range 3.

1ookHz

: O.OOOpF to 199.99yF

Hysteresis - A hysteresis of approximately 10% is used

to keep the instrument from changing ranges for a reading that varies along the borderline of two ranges. When

a reading is increasing, the instrument will up range immediately after 19,999 counts. For example, on Range 2,

assume a reading of 1.9999w2. If the reading increases by

one count, the instrument up ranges and reads 2.000 Wz

on Range 3. When the reading is decreasing, the instrument will down range after 1800 counts. Continuing with

the same example, a decreasing reading will read 1.800

162 on Range 3. When the reading decreases one more

count, the instrument will down range to Range 2 and

read 1.7999 kfi. Thus, a window of 200 counts is provided

for reading variances.

C

Type: Exponent representation

Resolution:

4 l/2 digits (19999 max)

Range: O.OOOpF, +(O.OOlpF to 199.99mF)

The range of I C I changes according to

frequency:

L

Type: Exponent representation

Resolution: 4 l/2 digits (19999 max)

Range: O.OnH, rt(O.lnH to 19.999kH)

The range of I L I changes according to

frequency:

120Hz

: O.OpH to 19.999kH

1kHz

: O.OOpH to 1.9999kH

1OkHz

: 0.OOOu.H to 199.99H

1ookH

: O.OnH to 19.999H

3-12

+

Page 29

+

SECTION 3

Operation

Q,D

Type: Floating-point representation

Resolution:

4 l/2 digits (19999 max)

Range: .oooo, +(.oool to 19999)

8

Type:

Resolution:

Range:

Fixed-point representation

0.01”

-180.00° to +179.99O

Deviation

Range information for deviation is covered in

paragraph 3.6.3.

Calculating Admittance and Susceptance

Admittance Y ( I Y I and Qy) and susceptance B are not

displayed by the instrument, but can be calculated as fol-

lows:

IYI =l/lZl

0y=-0

B= IYI l Siney=-X/&2+X2)

where; Rs is the value of R (=ESR) for the series equivalent circuit (SER).

3-13

Page 30

SECTION3

Operation

+

Table 3-4.

Impedance Ranges

Applied Impedance Range 622)

Reference

Lower Limit Lower Limit Upper Limit Upper Limit

Level Frequency

Range Resistance 62) Extension

**

***

Extension

1v 120Hz *1 100

- 0 5

11

1kHz 2 100

0.9 5 2k

11 k

10kHz 3 lk

980 2k 20 k

110 k

4 10 k

9.8 k 20 k 200 k

l.lM

5 50 k

49 k 200 k 2M

5.5M

"6

50 k 450 k 2M 20M

co

1ookHz *1 100

- 0 5

11

2 100

0.9 5 2k

11 k

3 lk

980 2k 20 k

110 k

4 10 k

9.8 k 20 k 200 k

1.1 M

"5 10 k

90 k

200 k 2M

00

*6 10 k

90 k 200 k 2M

Co

50mV 120Hz “1 100

- 0 5

11

1kHz 2 100

0.9 5 2k

11 k

1 OkHz 3 lk

900 2k 20 k

110 k

4 10 k

9k 20 k 200 k

l.lM

5 50 k

45 k 200 k 2M

5.5M

*6

50 k

450 k

2M 20M

w

1OOkHz *1 100

- 0 5

11

2 100

0.9 5 2k

11 k

3 lk

900 2k 20 k

110 k

4 10 k

9k 20 k 200 k

l.lM

"5 10 k

90 k

200 k 2M

c-a

*6 10 k

90 k

200 k 2M

00

*Extension range

**Lower limit values are inclusive.

***Upper limit values are not inclusive.

3-14

+

Page 31

SECTION 3

Operation

3.6 FREQUENCY SELECTION

The impedance of a device under test changes with frequency. Therefore, it is advisable to measure the device

at its operating frequency.

Use the following guidelines to select a measurement

frequency:

120Hz: Use to measure large values of C

1kHz: Use to measure intermediate values of R, L

and C

1OkHz and 1OOkHz: Use to measure small values of

LandC

To select one of the four measurement frequencies

labeled on the front panel (120Hz, lkHz, lOk.Hz,

lOOkHz), press and release the appropriate FREQ key.

The selected frequency is denoted by the enabled

annunciator.

3.7 SIGNAL LEVEL SELECTION

The instrument measures devices by applying an rms

signal (at the selected frequency) and then measuring

the subsequent current. The signal levels that can be

selected are 50mV rms and 1V rms.

The IV signal level can be used for most measurements.

For semiconductors that have non-linear characteristics

that are affected by signal magnitude, use the 50mV

level.

The front panel LEVEL annunciator denotes the current

signal level. To select the alternate level, simple press

the 50mV or 1V key.

The specified signal levels are maintained for devices

that have an impedance of lm or more. At lower

impedances, loading lowers the level of selected signal.

Note: After a signal level is selected, the displays will

blank until the next measurement is completed.

3.8 DC BIAS

When measuring capacitance (C), a DC bias can be

applied. This b ias allows capacitance changes in

semiconductor junctions due to applied voltage to be

measured.

The instrument has a built in 2V bias that can be used,

or an external bias voltage from 0 to *35V can be

applied via a BNC connector on the rear panel. The bias

voltage (and drive signal) can be monitored on the H

CUR terminal.

DC bias cannot be used to measure L, R or Z. Pressing

the BIAS key while in one of these functions will result

in “Err 14”.

Bias Stabilization Time - When bias is abruptly

changed by turning BIAS on to its peak value, some

time is required to allow the bias voltage to stabilize

before an accurate capacitance measurement can be

made. Use the following equation to determine the time

required to achieve stability:

Stabilization time (in seconds) = 4 + 0.015C

where; C is the capacitance in PF

Perform the following steps use DC bias:

1.

2.

3.

4.

If using an external supply, connect it to the BIAS

EXT IN BNC connector on the rear panel. Make sure

the supply is in standby and is set for OV.

CAUTION

To prevent damage to the instrument, do not

apply voltage that is not within the OV to f35V

range. Also, adhere to the precautions and considerations explained affer this procedure.

Set the rear panel BIAS switch. If using the internal

supply, set the toggle switch to the INT 2V position.

If using an external bias supply, set the toggle switch