Page 1

Model 2790 SourceMeter

®

Switch System

User’s Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

Model 2790 SourceMeter® Switch System

User’s Manual

©2002, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Third Printing, September 2003

Document Number: 2790-900-01 Rev. C

Page 3

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created

for this manual. The Revision Level letter increases alphabetically as the manual undergoes

subsequent updates. Addenda, which are released between Revisions, contain important change

information that the user should incorporate immediately into the manual. Addenda are

numbered sequentially. When a new Revision is created, all Addenda associated with the

previous Revision of the manual are incorporated into the new Revision of the manual. Each new

Revision includes a revised copy of this print history page.

Revision A (Document Number 2790-900-01)............................................................. March 2002

Revision B (Document Number 2790-900-01) ............................................................. March 2002

Revision C (Document Number 2790-900-01) ...................................................... September 2003

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 4

S

afety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body

ment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel

trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Measurement Category I and Measurement Category

II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with

high transient over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are for connection to

Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present.

circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts,

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting ca-

is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equip-

use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

perform routine procedures on the product to keep it operating properly, for example, setting the line

are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

A good safety practice is to expect that hazardous voltage is present in any unknown

no conductive part of the circuit may be exposed.

5/03

Page 5

bles or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment frame.

The

WARNING

information very carefully before performing the indicated procedure.

The

CAUTION

ranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased from

other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability

of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for

proper cleaning/servicing.

heading in a manual explains dangers that might result in personal injury or death. Always read the associated

heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the war-

Page 6

Table of Contents

1Test System Overview

Introduction ................................................................................ 1-2

Key features ........................................................................ 1-2

Technical terms ................................................................... 1-3

Model 2790 configurations ........................................................ 1-4

Test system ................................................................................. 1-5

Inflator tests ................................................................................ 1-6

Shunt bar test ....................................................................... 1-6

Bridgewire test .................................................................... 1-8

Insulation resistance (HIPOT) test (7751 and 7753 only) .. 1-9

2 Keithley 7751, 7752, and 7753 Switching Modules

Card configuration ...................................................................... 2-2

I-source – channels 21, 22, 24, and 27 ................................ 2-4

V-source and I/V amplifier (7751/7753 only) –

Cable discharge (7751/7753 only) – channel 20 ................. 2-4

Source readback – channels 13 and 25 ............................... 2-5

Interlock – J106 ................................................................... 2-5

General purpose terminal blocks – J105, J107, and J108 ... 2-5

Safety warnings ................................................................... 2-6

Setting source output levels ........................................................ 2-6

Remote programming ......................................................... 2-8

Math ........................................................................................... 2-9

Front panel operation ........................................................ 2-11

Remote programming ....................................................... 2-11

Opening and closing channels .................................................. 2-13

Front panel operation ........................................................ 2-13

Remote programming ....................................................... 2-14

Viewing closed channels .......................................................... 2-15

Open interlock errors ............................................................... 2-16

Cable discharge circuit (7751 and 7753) ................................. 2-17

Connection log ......................................................................... 2-19

Using memory patterns ............................................................ 2-20

Firmware revision level ..................................................... 2-20

Overview ........................................................................... 2-20

Front panel operation ........................................................ 2-20

Memory pattern commands .............................................. 2-21

Setting up and executing memory patterns ....................... 2-21

Memory pattern command options ................................... 2-22

Memory pattern scanning ................................................. 2-22

Memory pattern log ........................................................... 2-23

channels 21, 22, 23, 28 .................................................. 2-4

Page 7

3 Keithley 7702 Switching Module

Safety precautions ...................................................................... 3-2

Card configuration ...................................................................... 3-3

Typical connections .................................................................... 3-5

Connection log .................................................................... 3-7

Opening and closing 7702 channels ........................................... 3-9

Channel assignments ........................................................... 3-9

Front panel operation ........................................................ 3-10

Remote programming ........................................................ 3-11

Viewing closed channels .......................................................... 3-12

Using 7751/7753 V-source with 7702 module ......................... 3-13

4 Switching Module Wiring and Installation

Connections and wiring .............................................................. 4-2

Screw terminals ................................................................... 4-2

Cabling requirements .......................................................... 4-3

Wiring procedure ................................................................. 4-4

Zippertubing® shield .......................................................... 4-8

Guarding .............................................................................. 4-9

Switching module installation .................................................. 4-10

Module slot considerations ................................................ 4-10

Power supply restrictions with the 7753 module .............. 4-10

Installation procedure ........................................................ 4-10

5 Inflator Testing

Introduction ................................................................................ 5-2

Test procedures .................................................................... 5-2

Closed channels for test circuits .......................................... 5-3

Test system ................................................................................. 5-3

RS-232 interface (PLC or PC) ............................................. 5-4

GPIB (PC only) ................................................................... 5-4

Test signal connections ............................................................... 5-5

Interlock ...................................................................................... 5-9

Shunt bar test ............................................................................ 5-10

Test circuit ......................................................................... 5-11

Test procedure ................................................................... 5-12

I-source readback .............................................................. 5-12

Bridgewire tests ........................................................................ 5-14

Test circuit ......................................................................... 5-14

Test procedure ................................................................... 5-15

I-source readback .............................................................. 5-16

Page 8

Insulation resistance (HIPOT) tests (7751/7753 only) ............. 5-17

Contact checks .................................................................. 5-18

V-source readback ............................................................. 5-22

Cable discharge ................................................................. 5-23

HIPOT test ........................................................................ 5-24

Test procedure – HIPOT ................................................... 5-26

I-source readback ..................................................................... 5-28

Memory patterns test ................................................................ 5-30

Test circuit ......................................................................... 5-30

Test procedure ................................................................... 5-31

6 Model 2790 DMM Ohms Functions

Introduction ............................................................................... 6-2

Low ohms measurements .................................................... 6-2

Fuse resistance considerations ............................................ 6-2

High ohms measurements ................................................... 6-3

4-wire ohms ................................................................................ 6-3

Offset compensated ohms .......................................................... 6-5

Keithley 7702 module ................................................................ 6-6

Keithley 7751, 7752, and 7753 modules .................................... 6-8

A Specifications

(Models 2790, 7751, 7752, 7753, and 7702) ............................ A-1

Ohms specification calculations (7751/7752/7753) .................. A-8

7751/7752/7753 I-source ................................................... A-8

7751/7753 V-source ........................................................... A-9

Page 9

List of Illustrations

1Test System Overview

Figure 1-1 System connections ............................................................... 1-5

Figure 1-2 Shunt bar testing .................................................................... 1-7

Figure 1-3 Bridgewire testing .................................................................. 1-8

Figure 1-4 HIPOT testing (7751/7753) ................................................... 1-9

2 Keithley 7751, 7752, and 7753 Switching Modules

Figure 2-1 Simplified schematic of Keithley 7751, 7752, and 7753

switching modules ............................................................ 2-3

Figure 2-2 Setting I-source and V-source output levels ........................... 2-7

Figure 2-3 Enabling ohms math function .............................................. 2-11

Figure 2-4 Opening and closing channels ............................................. 2-14

Figure 2-5 Viewing closed channels ...................................................... 2-15

Figure 2-6 Cable discharge circuit ......................................................... 2-18

3 Keithley 7702 Switching Module

Figure 3-1 Simplified schematic of Keithley 7702 switching module .... 3-4

Figure 3-2

Figure 3-3

Figure 3-4 Current connections (DCI and ACI) ...................................... 3-6

Figure 3-5 Voltage connections (DCV or ACV) ...................................... 3-7

Figure 3-6 andkeys ................................................................................ 3-10

Figure 3-7 CLOSE key .......................................................................... 3-10

Figure 3-8 OPEN key ............................................................................ 3-11

Figure 3-9 Viewing closed channels ...................................................... 3-12

Figure 3-10 Using 7751/7753 V-source with 7702 module

Ω

2 and thermistor TEMP connections .................................. 3-5

Ω

4 and RTD TEMP connections ........................................... 3-6

(dual multiplexer) ........................................................... 3-14

4 Switching Module Wiring and Installation

Figure 4-1 Screw terminal access ............................................................ 4-3

Figure 4-2 Model 7751/7752/7753 screw terminal channel designations 4-5

Figure 4-3 Model 7702 screw terminal channel designations ................. 4-6

Figure 4-4 Wire dressing (7751/7752/7753) ........................................... 4-7

Figure 4-5 Zippertubing® shield (ZTZ-*-SH3 series) ............................ 4-8

Figure 4-6 Installed Zippertubing® shield .............................................. 4-9

Page 10

5 Inflator Testing

Figure 5-1 System connections ................................................................ 5-3

Figure 5-2 Test connections – shunt bar and bridgewire

testing – single stage inflator ............................................ 5-5

Figure 5-3 Test connections – shunt bar, HIPOT, and bridgewire

testing – single stage inflator ............................................ 5-6

Figure 5-4 Test connections – shunt bar and bridgewire bar

testing – dual stage inflator ............................................... 5-7

Figure 5-5 Test connections – shunt bar, HIPOT, and bridgewire

testing – dual stage inflator ............................................... 5-8

Figure 5-6 Interlock connections ............................................................. 5-9

Figure 5-7 Test circuit – shunt bar ......................................................... 5-11

Figure 5-8 Test circuit – bridgewire tests ............................................... 5-14

Figure 5-9 Test circuits – contact check – single stage inflator ............. 5-19

Figure 5-10 Test circuits – contact check – dual stage inflator ................ 5-19

Figure 5-11 V-source readback circuit ..................................................... 5-22

Figure 5-12 Test circuit – HIPOT ............................................................ 5-25

Figure 5-13 I-source readback circuit ...................................................... 5-29

Figure 5-14 Test circuits – memory patterns – dual stage

inflator contact test ......................................................... 5-30

6 Model 2790 DMM

Ohms Functions

Figure 6-1 Using W2 function to measure resistance .............................. 6-3

Figure 6-2 Using W4 function to measure resistance .............................. 6-4

Figure 6-3 Using Model 2790 4-wire ohms with 7702 module

(low ohms measurements) ................................................ 6-6

Figure 6-4 Using Model 2790 2-wire ohms with 7702 module

(high ohms measurements) ............................................... 6-7

Figure 6-5 Using Model 2790 4-wire ohms with 7751/7752/7753

module (low ohms measurements) ................................... 6-8

Figure 6-6 Using Model 2790 2-wire ohms with 7751/7752/7753

module (high ohms measurements) .................................. 6-9

Page 11

List of Tables

2 Keithley 7751, 7752, and 7753 Switching Modules

Table 2-1 Commands to set amplitude for V-source and I-source ......... 2-8

Table 2-2 Commands to select ohms calculations ............................... 2-12

Table 2-3 Commands to control 7751/7752/7753 module channels .... 2-14

Table 2-4 Connection log Model 7751/7752/7753 .............................. 2-19

Table 2-5 Basic memory pattern example ............................................ 2-22

Table 2-6 Memory pattern log ............................................................. 2-23

3 Keithley 7702 Switching Module

Table 3-1 Connection log Model 7702 .................................................. 3-8

Table 3-2 Commands to control 7702 module channels ...................... 3-11

5 Inflator Testing

Table 5-1 Test procedure – shunt bar ................................................... 5-13

Table 5-2 Test procedure – bridgewire ................................................. 5-15

Table 5-3 Test procedure – contact checks for single stage inflator .... 5-20

Table 5-4 Test procedure – contact checks for dual stage inflator ....... 5-21

Table 5-5 Test procedure – V-source readback .................................... 5-23

Table 5-6 Test procedure – HIPOT ...................................................... 5-26

Table 5-7 Command sequence for memory patterns test example

Table 5-8 Command sequence for memory patterns test example

using scanning ..................................................................... 5-31

using individual memory pattern recall ............................... 5-33

6 Model 2790 DMM

Ohms Functions

Table 6-1 Commands to set offset compensated ohms .......................... 6-5

Page 12

Test System Overview

•

Introduction

Model 2790 to test inflators. Covers some key features of the Model 2790 and

defines/explains technical terms associated with airbag inflators.

•

Model 2790 configurations

tions available from Keithley.

•

Test system

•

Inflator tests

and insulation resistance (HIPOT).

— Summarizes the switching modules that are used with the

— Explains the various mainframe/module combina-

— Shows a typical test system used to test inflators.

— Explains the three basic tests for inflators: shunt bar, bridgewire,

1

Page 13

1-2 Model 2790 SourceMeter® Switch System User’s Manual

Introduction

When used with one or two switching modules, the Model 2790 can be used to test inflators.

With a 7751/7752/7753 module, the Model 2790 can safely measure the resistance of

bridgewires and shunt bars. With a Model 7751 or 7753 module, the Model 2790 can use the

high voltage method to measure the insulation resistance of an inflator. The 7702 module can

be used for ohms testing that requires 20/40 channels of 4-wire/2-wire measurements.

Key features

•

Programmable I-source

programmable current source (0 to 50mA). This constant current source is used to

measure the resistance of bridgewires and shunt bars.

The Model 2790 has a low-ohms math function: SxIohms. It calculates (using the

programmed current and measured voltage) and displays the resistance (in ohms)

of the bridgewire or shunt bar. X is the slot number of the module being used.

•

Programmable V-source

mable voltage source (50 to 500V) and an I/V converter to measure the insulation

resistance of an inflator. Current through the insulator is applied to the I/V converter where it is converted to a voltage that is measured by the Model 2790.

The Model 2790 has a high-ohms math function: SxVohms. It calculates (using the

programmed V-source voltage and measured I/V converter output voltage) and displays the resistance (in ohms) of the insulation. X is the slot number of the module

being used.

•

Safety features

bility of inflator ignition and damage to the module due to excessive current.

•

Interlock

the sources (I-source and V-source) from the switching matrix. Details on the

interlock are provided in Section 5.

•

Fuses — Current limiting fuses for the current source of the Model 2790

DMM and the I-source of the 7751/7752/7753 module.

•

I-source current limiting

for the I-source of the 7751, 7752, and 7753 modules.

•

V-source current limiting

— The Model 2790 has built-in safety features to reduce the possi-

— The interlock feature of a 7751/7752/7753 module disconnects

— The 7751, 7752, and 7753 modules have a built-in

— The 7751 and 7753 modules have a built-in program-

— An active, high-speed current limiting circuitry

— An impedance circuit limits current to <1mA.

Page 14

Model 2790 SourceMeter® Switch System User’s Manual 1-3

Technical terms

The following defines and explains technical terms associated with airbag inflators:

•

Initiato

action. Sometimes referred to in classic military terms as a “squib”. The term

“squib” may be used to refer to the core element of an initiator (explosive coated

bridgewire) or to the entire initiator.

•

Airbag inflator

ing a stored chemical or pressurized inert gas (or both), and an electrical initiator.

•

Hybrid inflator

to generate the gas charge for bag inflation.

•

Airbag or Airbag module

textile bag and mounting frame (or enclosure).

•

E-check

modules. Consists of two basic resistance measurements:

•

HIPOT

using high voltage. The intent is not to break down the insulator, but to measure the

leakage current that flows through the insulator.

•

Body check (contact check)

housing must be verified. This is necessary because an open connection would

result in a reading that appears to be the resistance of the insulator, but would

instead be a high resistance reading that is the result of an open circuit.

•

Shorting clip (shunt bar)

(electro-static discharge) or other accidental discharge, every inflator module has a

spring loaded clip that shorts the initiator/squib pins together when a connector is

not installed. The connection cables also include shorting clips since many inflator

modules have cables attached when manufactured such that the open end of the

cables also have shorting clips. These clips are pneumatically pushed open during

E-check testing just after the clips resistance (as a short) is measured.

r — Pyro-technic device used to trigger the main gas charge generation

— The gas generating assembly, typically made of steel, contain-

— An inflator that uses both pressurized gas and a chemical reaction

— The fully functional device including initiator, inflator,

— Industry standard term for electrical testing of airbag inflators and

–Test continuity of the bridgewire (typically 2 to 3 ohms) using a constant current

method (typically 10 to 50mA).

– HIPOT test — Measure the insulation resistance (≥100MΩ) between the

bridgewire and the inflator housing using an applied voltage (typically 500V).

— Used in this manual to describe the high resistance measurements made

— Prior to HIPOT testing, connections to the inflator

— For handling and transport safety against ESD

Page 15

1-4 Model 2790 SourceMeter® Switch System User’s Manual

Model 2790 configurations

Model 2790 test configurations available from Keithley include the following:

2790-H configuration (one 7751 module)

This test system includes a single 7751 module. This module has a programmable 50 to

500V V-source and I/V amplifier for HIPOT testing. It also has a programmable 0 to

50mA constant current I-source to measure the resistance of shunt bars and bridgewires.

2790-HH configuration (two 7751 modules)

This test system includes two 7751 modules. When used with a “left and right” type

station, this two-module, high-voltage system allows higher throughput for increased

efficiency.

• When used with a “left and right” type station, this two-module, high-voltage system

allows two inflators to be tested. It provides higher throughput for increased efficiency. When soaking is required for HIPOT testing, one inflator can be tested while

the other inflator is soaking (high voltage applied).

•For a dual inflator, the two high-voltage module system allows parallel “soak and

test” of each half.

2790-HL configuration (one 7751 and one 7752 module)

This test system includes a 7751 module and a 7752 module. The high voltage module

(7751) can be used for HIPOT testing, while the I-source of the second module (7752) can

be used to test other non-inflator type circuitry (i.e., pushbutton switches and resistors) on

the steering wheel. The I-source allows accurate resistance measurements up to 100Ω.

2790-L configuration (one 7752 module)

This test system includes a single 7752 module. It is applicable for testing that does not

require high voltage HIPOT testing, but still needs the programmable I-source for low

ohms testing. Insulation resistance (up to 120MΩ) can be measured using the Ω2 function

of the Model 2790.

2790-H/L/A + 7702 configuration (one 7751/7752/7753, one 7702 module)

This test system includes a 7751, 7752, or 7753 module and a 7702 module. The 7702

module can be used for non-inflator related ohms testing that requires 20/40 channels of

4-wire/2-wire measurements. Typical tests using the 7702 module include burn-in/life/QA

testing of multi-pin connectors, wiring harnesses, power distribution/fuse centers,

switches and relays, and backplanes.

Page 16

Model 2790 SourceMeter® Switch System User’s Manual 1-5

2790-A configuration (one 7753 module)

This test system includes a single 7753 module. This module has a programmable 50 to

500V V-source and I/V amplifier for HIPOT testing. It also has a programmable 0 to

50mA constant current I-source to measure the resistance of shunt bars and bridgewires.

Supplementary system components

For added versatility or as spares, a Model 2790 mainframe, 7751, 7752, 7753, and 7702

modules can be purchased separately. However, this special order may require a longer

delivery time and additional handling charges.

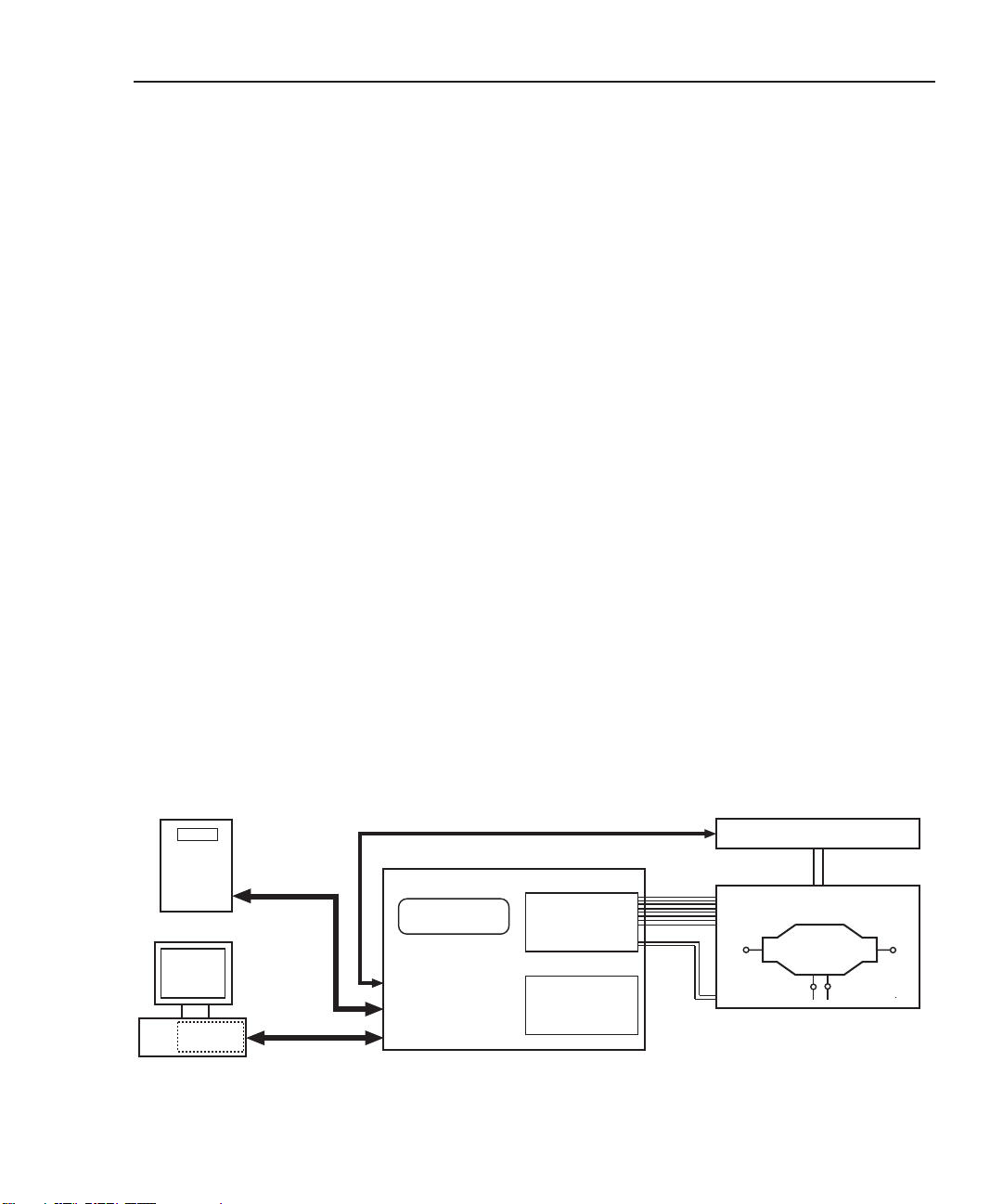

Test system

A typical test system for airbag inflators includes a Model 2790 that is controlled by a

PLC or PC, and a device handler/test station for the inflator. The Model 2790 has two slots

for switching modules. Modules for testing inflators include the Models 7751, 7752, and

7753. A Model 7702 module can also be used with the Model 2790.

NOTE Only one Model 7753 module can be installed in a Model 2790, and it should be

installed in slot 1. The 7753 can be installed in slot 2, but measurement accuracy

might be adversely affected because cards are always calibrated in slot 1.

Figure 1-1 shows a typical test system using a programmable logic controller (PLC) or a

PC. When using a PLC, communications with Model 2790 are done over the RS-232

interface. When using a PC, communications with the Model 2790 can be provided using

the GPIB or RS-232.

Figure 1-1

System connections

PLC

or PC

(RS-232)

OR

PC

(GPIB)

KPCI-488

Interface

RS-232

GPIB

Keithley 2790

MATH

2.790000

DIGITAL I/O

RS-232

IEEE-488

Device Handler Control

Slot 1

7751, 7752, or

Ω

7753 Module

Interlock

Slot 2

Test

System

Expansion

Test Signal

Cabling

Device Handler

Mechanical

Connection

Test Station

(with Interlock)

Inflator Under

Test

Interlock

Page 17

1-6 Model 2790 SourceMeter® Switch System User’s Manual

Inflator tests

There are three primary tests for an inflator:

• Shunt bar test

• Bridgewire test

• Insulation resistance (HIPOT) test

NOTE Interlock – The three primary tests can only be performed if the interlock of the

7751/7752/7753 module is enabled. With interlock open (disabled), the I-source

of the 7751/7752/7753 module and the V-source of the 7751/7753 module are

disconnected from the switching module matrix. Details on the interlock are provided in Section 5.

The following information provides an overview of the three tests that are used

to test an inflator. The actual detailed procedures for these tests are provided in

Section 5.

Shunt bar test

NOTE A shunt bar test is typically tested again after all other inflator tests are completed.

As a final test, it verifies that it is safe to install the inflator in a vehicle.

A shunt bar (shorting clip) is used to short the bridgewire(s) to prevent accidental ignition

when handling or installing the inflator. However, an oxide can form between the shunt

and the inflator terminals. It is this high-resistance oxide that diminishes the ability of the

shunt bar to act as an effective short across the bridgwire(s). Without a good contact short,

detonation could occur. The measured resistance of a shunt bar is typically between 10 to

100mΩ.

One method used for the shunt bar test is shown in Figure 1-2. In this case, the dry circuit

mode of the 7751/7752/7753 clamps voltage at 20mV (1mA maximum) for the constant

test current of the I-source. This low voltage will not pierce the oxide. With the low ohms

math function (SxIohms) selected, the R

play of the Model 2790.

reading can be read directly from the dis-

SHUNT

Page 18

Model 2790 SourceMeter® Switch System User’s Manual 1-7

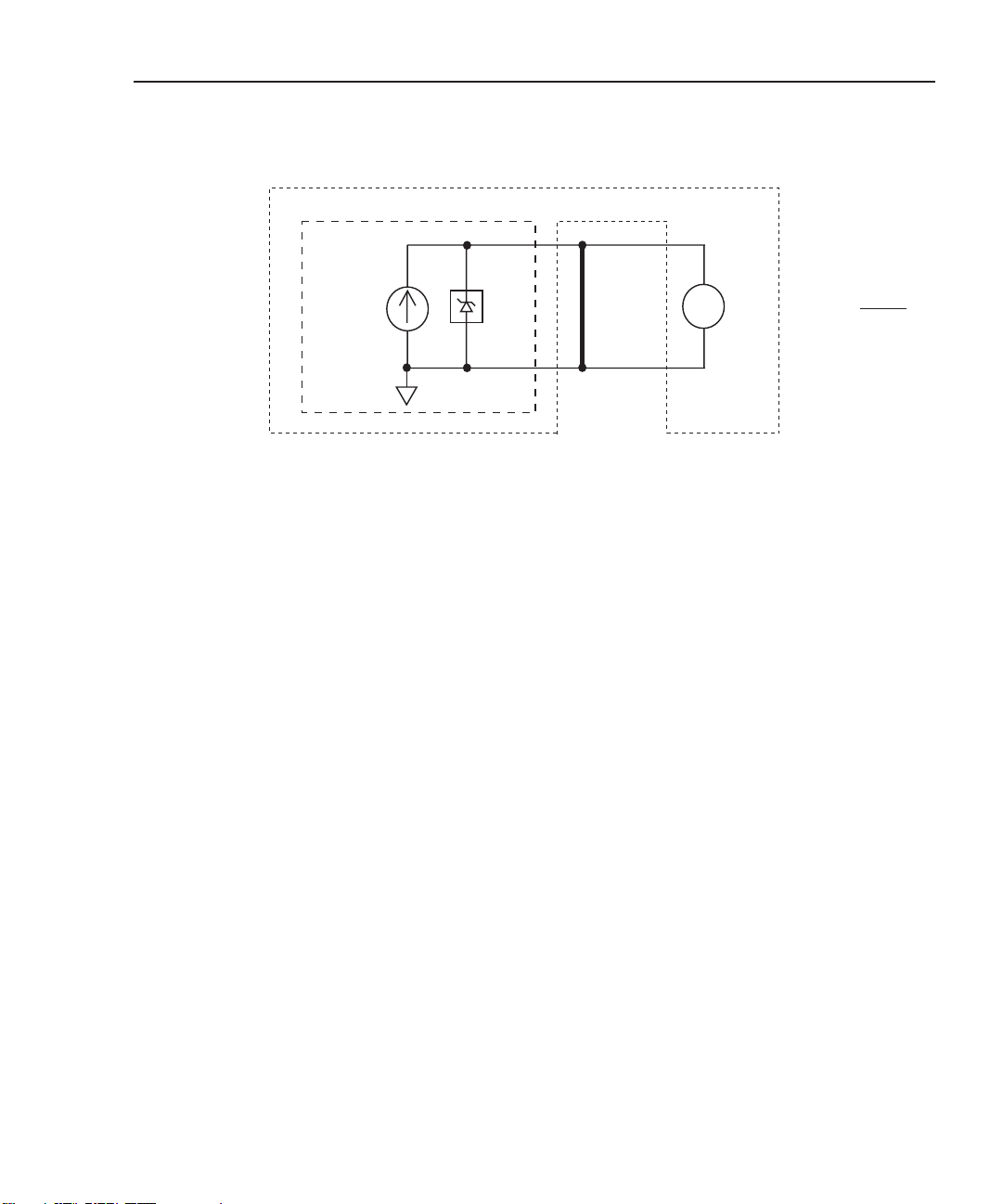

Figure 1-2

Shunt bar testing

Keithley 2790 SourceMeter Switch System

Keithley

7751,7752,

or 7753

Module

I

SOURCE

(1mA max)

20mV

Dry

Ckt

Shunt Bar

Under

Test

(R

SHUNT)

v

2790

DMM

RSHUNT =

MEAS

V

ISOUR

NOTE If required, a more accurate resistance measurement of the shunt bar can be

achieved by disabling the dry circuit and using a test current of 50mA. An even

more accurate resistance measurement can be achieved using the Ω4 function of

the Model 2790. Keep in mind that this is an additional test and does not replace

the test using the dry circuit.

NOTE Use this 2-step process to detect the presence of oxide build-up and more

accurately measure the resistance of the shunt bar:

1. Test the shunt bar using dry circuit ohms (channel 24 closed) and a test

current of 1mA. A resistance >100mΩ indicates the presence of oxide

build-up.

2. Accurately measure shunt bar resistance without dry circuit (channel 24

open) and a test current of 50mA or use the Ω4 function of the Model 2790.

Section 6 explains how to use the Ω4 function of the Model 2790 with the

7702 or 7751/7752/7753 module.

Page 19

1-8 Model 2790 SourceMeter® Switch System User’s Manual

Bridgewire test

The air bag inflator has two terminals connected to a bridgewire, which is coated with a

primer that ignites when sufficient current passes through the wire. The bridgewire’s resistance is typically from two to three ohms (2Ω being the most common). To avoid unintended

ignition, the level of test current applied is generally 50mA or less.

As shown in Figure 1-3, a fixed current is sourced through the bridgewire. The voltage

across the bridgewire is then measured by the DMM of the Model 2790.

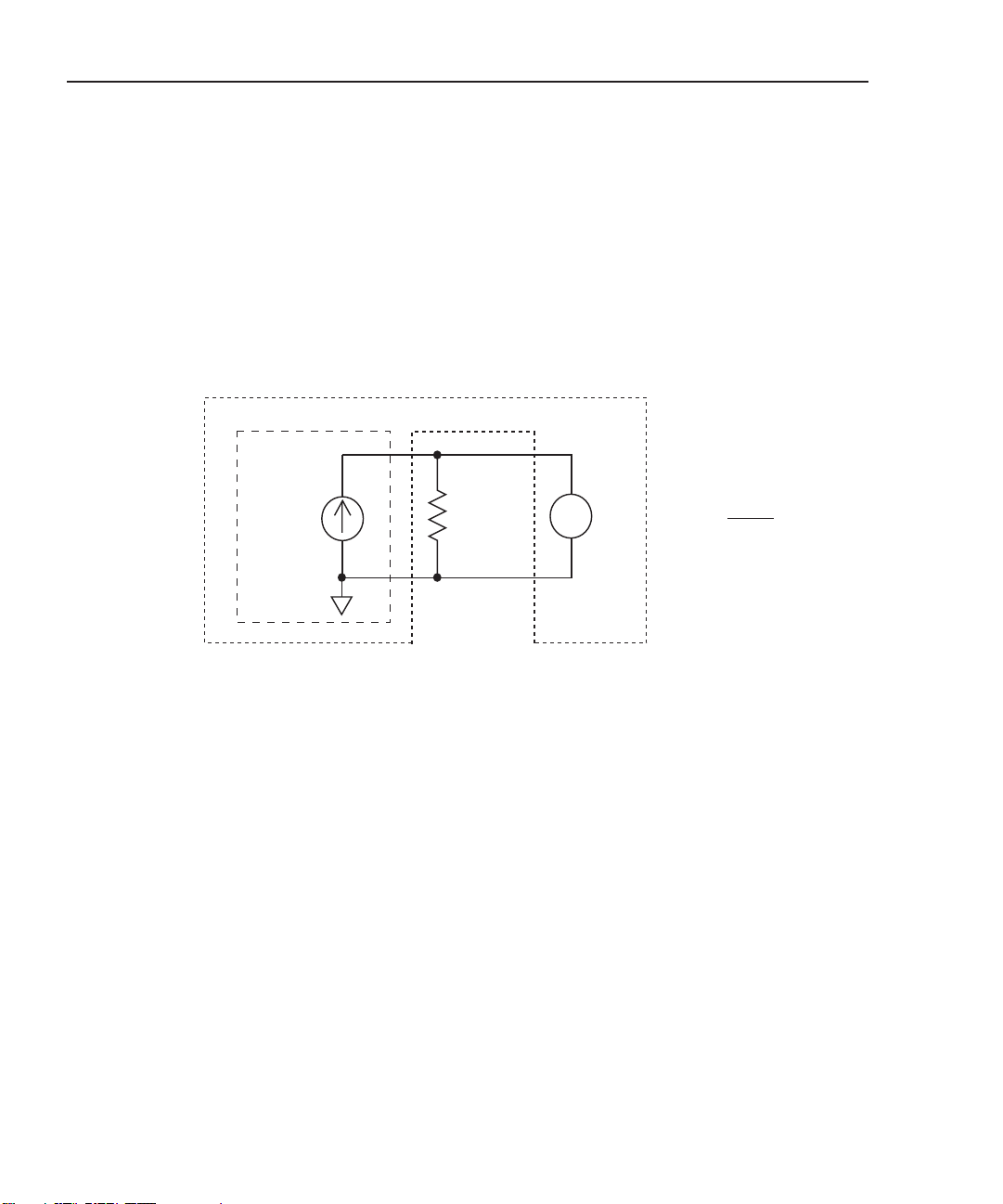

Figure 1-3

Bridgewire testing

Keithley 2790 SourceMeter Switch System

Keithley

7751,7752,

or 7753

Module

I

SOURCE

Bridgewire

Under

Test

(RBRID)

v

2790

DMM

RBRID =

MEAS

V

ISOUR

With the low ohms math function selected, the R

reading can be read directly from

BRID

the display of the Model 2790.

I-source readback — Before performing the bridgewire test, you can verify the actual

current flowing in the test circuit by using the I-source readback circuit.

NOTE A more accurate ohms reading can be achieved using the Ω4 function of the

Model 2790 (1mA fixed). See Section 6 for details.

Page 20

Model 2790 SourceMeter® Switch System User’s Manual 1-9

Insulation resistance (HIPOT) test (7751 and 7753 only)

WARNING The Models 7751 and 7753 are provided with outputs that are poten-

tially hazardous if not connected properly. It is the responsibility of the

customer to operate instruments in a safe manner. Be sure to read and

follow all installation and operating instructions before attempting to

use the 7751/7753 HIPOT function.

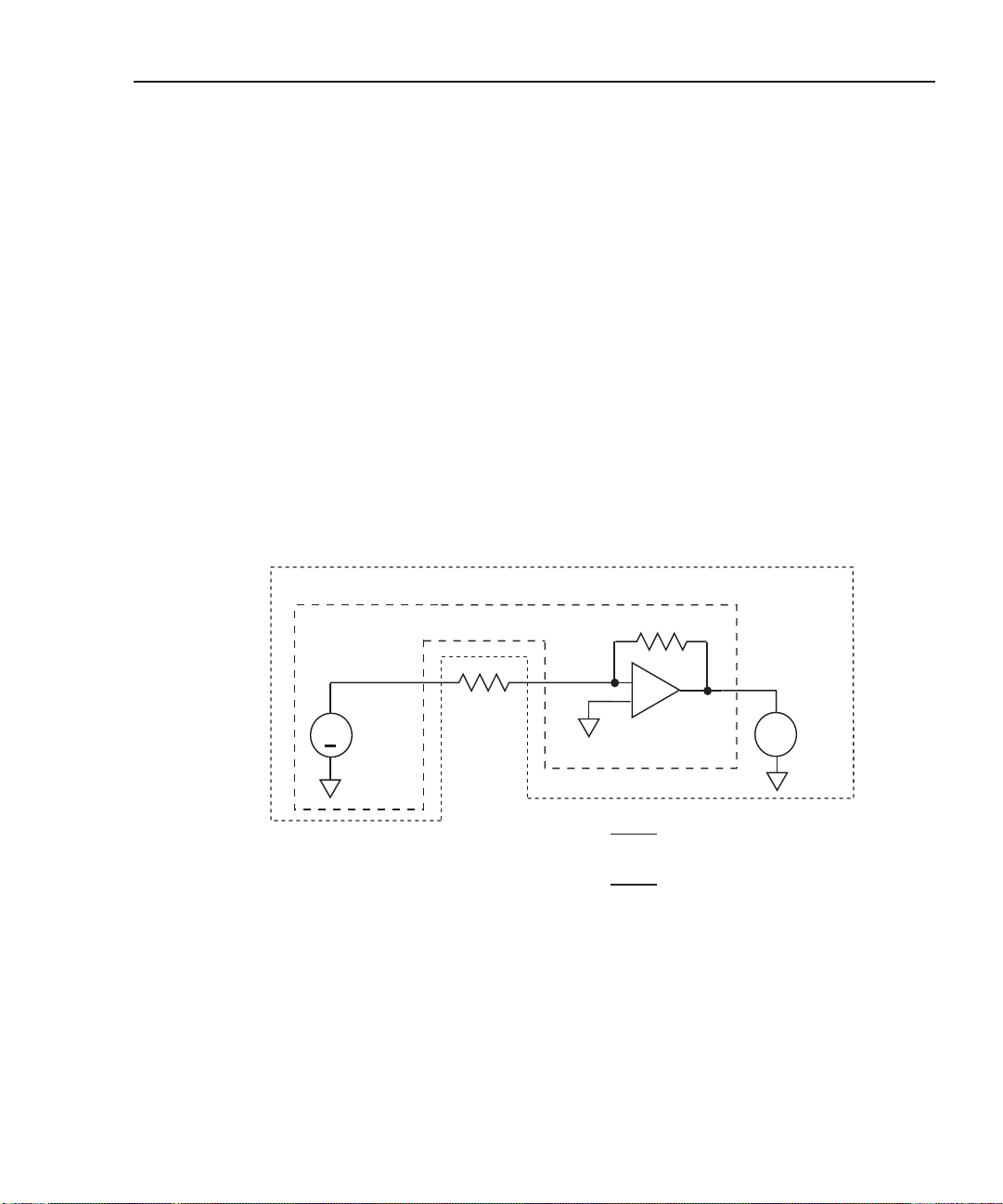

The leakage resistance (R

) between each of the initiators and the housing must be

HIPOT

verified. As shown in Figure 1-4, this is performed by applying a voltage, typically 500V,

between the bridgewire and the housing. The resultant test circuit current is applied to an

I/V amplifier, where it is converted to a voltage. This voltage is then measured by the

DMM of the Model 2790.

NOTE If not using a 7751/7753 module in your test system, resistance up to 120MΩ

can be measured using the Ω2 function of the Model 2790.

Figure 1-4

HIPOT testing (7751/7753)

Keithley 2790 SourceMeter Switch System

Keithley 7751/7753 Module

RF

–

+

I/V Amplifier

(7751/7753)

SOUR

V

x RF

VMEAS

500V

x R

MEAS

V

v

RF = 200kΩ (7751)

F = 20kΩ (7753)

R

F

2790

DMM

+

V

SOURCE

(500V)

RHIPOT

RHIPOT = –

= –

Page 21

1-10 Model 2790 SourceMeter® Switch System User’s Manual

With the high ohms math function (SxVohms) selected, the R

reading can be read

HIPOT

directly from the display of the Model 2790.

Before measuring R

, there are a couple of preliminary verification tests that should

HIPOT

be performed first:

• Contact checks — To properly perform the HIPOT test, contact must be made to

the air bag inflator housing. If good contact is not established, the measured high

resistance will not represent the isolation resistance. Contact is checked by performing continuity checks through the V-source test leads and the connection

points. The resistance reading for a contact should be less than 20 ohms (depending

on cabling).

• V-source readback — Before performing the HIPOT test, the output voltage of the

V-source should be verified. The V-source readback circuit allows you to directly

measure the output voltage using the DMM of the Model 2790.

Page 22

2

Keithley 7751, 7752, and 7753

Switching Modules

• Card configuration — Provides the simplified schematic of the Keithley 7751,

7752, and 7753 switching modules. Summarizes the individual components of the

modules.

• Setting source output levels — Explains how to set the output levels for the

I-source (7751/7752/7753) and V-source (7751/7753).

• Math — Covers the ohms math functions used to calculate low resistance when

using the I-source of the 7751/7752/7753, and high resistance when using the

V-source and I/V amplifier of the 7751/7753 module.

• Opening and closing channels — Explains how to open and close channels for the

7751, 7752, and 7753 modules.

• Viewing closed channels — Explains how to display closed channels on the

Model 2790.

• Open interlock errors — Explains the errors associated with an open interlock.

• Cable discharge circuit (7751 and 7753) — Explains the cable discharge circuit. It

dissipates voltage at the input channels. This unwanted voltage could ignite the

inflator.

• Connection log — Use to record connection information.

• Using memory patterns — Describes the memory patterns feature, which can be

used to simplify repetitive test procedures.

Page 23

2-2 Model 2790 SourceMeter® Switch System User’s Manual

NOTE Module wiring and installation into the mainframe of the Model 2790 is covered

in Section 4.

Details on using the Keithley 7751, 7752, 7753 modules to test inflators are

provided in Section 5.

The edit keys (left, right, up, and down arrow keys) are used to display menu

items and output levels. With the desired menu item or output level displayed, it

is selected by pressing ENTER.

For remote programming, the <clist> parameter is used as follows:

<clist> = (@SCH)

where: S = Mainframe slot number (1 or 2)

CH = Switching module channel number of source (2 digits)

Examples: (@101) = Slot 1, Channel 1

(@101, 114, 118) = Slot 1, Channels 1, 14, and 18

Card configuration

CAUTION External energy sources should never be applied directly to a 7751,

7752, or 7753 module for any reason. Damage to the module and any

connected devices under test can result due to the application of

improperly selected or performing external energy sources.

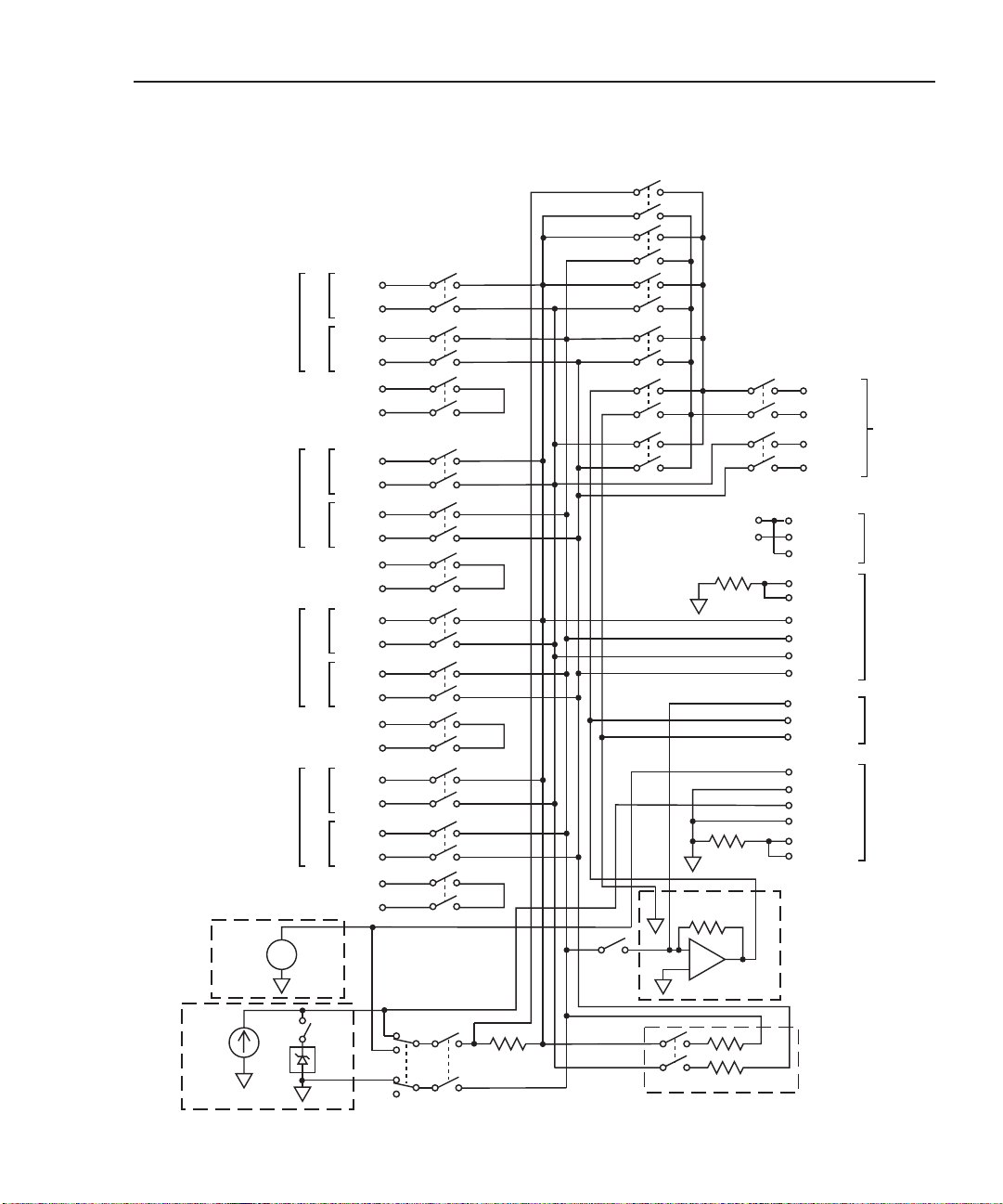

The simplified schematic for the 7751, 7752, and 7753 is provided in Figure 2-1.

• Channels 1-12 — Input channels for DUT (inflator).

• Channels 13-19 and 25 — Routes test signals to backplane of Model 2790.

• Channels 20-24, 27, and 28 — Control individual components of the 7751/7752/7753.

Page 24

Model 2790 SourceMeter® Switch System User’s Manual 2-3

Figure 2-1

Simplified schematic of Keithley 7751, 7752, and 7753 switching modules

Ch. 25

Ch. 13

Vsource

Ch. 28

(7751/7753

Only)

50-500V

Bank 1

J101

Bank 2

J102

Bank 3

J103

Bank 4

J104

Source

HI

Sense

Source

LO

Sense

Source

HI

Sense

Source

LO

Sense

Source

HI

Sense

Source

LO

Sense

Source

HI

Sense

Source

LO

Sense

+

–

Ch. 1

Ch. 2

A1

Ch. 3

B1

Ch. 4

Ch. 5

A2

Ch. 6

B2

Ch. 7

Ch. 8

A3

Ch. 9

B3

Ch. 10

Ch. 11

A4

Ch. 12

B4

Ch. 14

Ch. 15

Ch. 16 Ch. 18

Ch. 17

Ch. 23

Ch. 19

Source Enable

10kΩ

10kΩ

200kΩ (7751)

20kΩ (7753)

–

+

+5V

HI

Input

LO

HI

Sense

LO

Interlock

+5V

Interlock

Guard

Guard

Source HI

Source LO

Sense HI

Sense LO

I/V IN

I/V OUT

I/V LO

Vsrc HI

Vsrc LO

Isrc HI

Isrc LO

Guard

Guard

I/V

Current/Voltage

Amplifier

(7751/7753 Only)

To Model

2790

Backplane

J106

J105

J108

J107

Isource

Ch. 27

0-50mA

Ch. 24

20mV

Dry

Ch. 22

Ckt

Ch. 22 Open: I-source Select

Ch. 22 Close: V-source Select

Ch. 21

1Ω

Ch. 20

100kΩ

Cable Discharge

(7751/7753 Only)

Page 25

2-4 Model 2790 SourceMeter® Switch System User’s Manual

I-source – channels 21, 22, 24, and 27

The programmable I-source (0 to 50mA) is used as the test current to measure low resistance (inflator bridgewires and shunt bars).

• The I-source is designated as channel 27.

• Opening channel 22 selects the I-source.

• Closing channel 21 connects the I-source.

• Closing channel 24 connects the dry circuit clamp for the shunt bar test (20mV,

1mA limit).

NOTE “Ohms specification calculations” in Appendix A explains how to determine the

accuracy specification for source levels not specified in the “7751/7752/7753

Source/Switch Module Specifications” sheet.

V-source and I/V amplifier (7751/7753 only) – channels 21, 22, 23, 28

The programmable voltage source (50 to 500V) and I/V amplifier are used to measure

high resistance (insulation resistance of an inflator).

• The V-source is designated as channel 28.

• Closing channel 22 selects the V-source.

• Closing channel 21 connects the V-source.

• Closing channel 23 connects the I/V amplifier.

WARNING Do not connect V-source Hi to earth ground. The 7751/7752/7753 mod-

ule uses a floating ground. This floating ground is not connected to

safety earth ground. Not only will it create a shock hazard by floating

up to 500V, it will also effectively connect a 1nF capacitor across the

V-source, providing energy storage that could ignite an airbag under

fault conditions.

NOTE “Ohms specification calculations” in Appendix A explains how to determine the

accuracy specification for source levels not specified in the “7751/7752/7753

Source/Switch Module Specifications” sheet.

Cable discharge (7751/7753 only) – channel 20

A cable discharge circuit is used to dissipate charge build-up on the inputs to prevent accidental ignition of the inflator. For details, see “Cable discharge circuit”.

• Closing channel 20 discharges voltage on the input channels.

Page 26

Model 2790 SourceMeter® Switch System User’s Manual 2-5

Source readback – channels 13 and 25

The actual output of the selected source can be verified by using source readback, which

routes the selected source back to the DMM of the 2790 for measurement. I-source and

V-source readback are explained in Section 5.

• Opening channel 22 and closing channels 21, 25, and 18 connects the I-source

sense resistor to the DMM of the Model 2790.

• Closing channels 22, 21, 13, and 18 connects the V-source to the DMM of the

Model 2790.

Interlock – J106

A 7751/7752/7753 module has an interlock to disconnect its I-source and V-source from

the rest of the switch matrix. In order to use the module sources, interlock must be

enabled. The interlock switch of a test station is connected to the J106 terminals of the

module. When the interlock switch is open (i.e., safety shield open), the sources cannot be

connected to the switch matrix. Details on interlock are provided in Section 5.

NOTE The Interlock switch does not affect the output of J107. Voltage can still be present

at those terminals even if the interlock is disabled. See “General purpose terminal

blocks – J105, J107, and J108” for additional details.

General purpose terminal blocks – J105, J107, and J108

There are quick-disconnect terminal blocks available to the user to provide access to various

switching module components. These are provided for general purpose test applications that

are not necessarily related to airbags.

J105 (matrix backplane and guard)

The backplane terminals provide access to the relay matrix backplane. The matrix backplane

is the primary “artery” for signal routing though the module.

The guard terminals are typically used for shielding when using the V-source and I/V converter for high ohms measurements. Guard connections are explained in Section 4.

J107 (source outputs and guard)

The I-source and V-source (7751/7753) are always on and can be accessed by the user at

J107. The programmed output is routed to these terminals.

The guard terminals are typically used for shielding when using the V-source and I/V

converter for high ohms measurements. Guard connections are explained in Section 4.

Page 27

2-6 Model 2790 SourceMeter® Switch System User’s Manual

J108 (I/V converter)

The user also has access to the input, output, and ground of the I/V converter at J108.

Safety warnings

WARNING Integrated safety features protect the 7751/7752/7753 module from its

built-in I-source and V-source. However, if an external source (such as

the 12V car bus) is connected to the front panel inputs of the Model 2790

or through a 7702 module, these safety features are compromised, creating the very real possibility of igniting the airbag. Incorrect channel closures in the test system could inadvertently apply the external source to

the inflator and ignite it. Damage to the 7751/7752/7753 module may

also occur if an external source is connected to it.

WARNING Since the Model 2790 system is not an intrinsically safe device, it is the

responsibility of the user to ensure that external protection be provided, either by an inherently safe electrical barrier and/or a safety barrier around the DUT or airbag, to prevent injury in case of detonation.

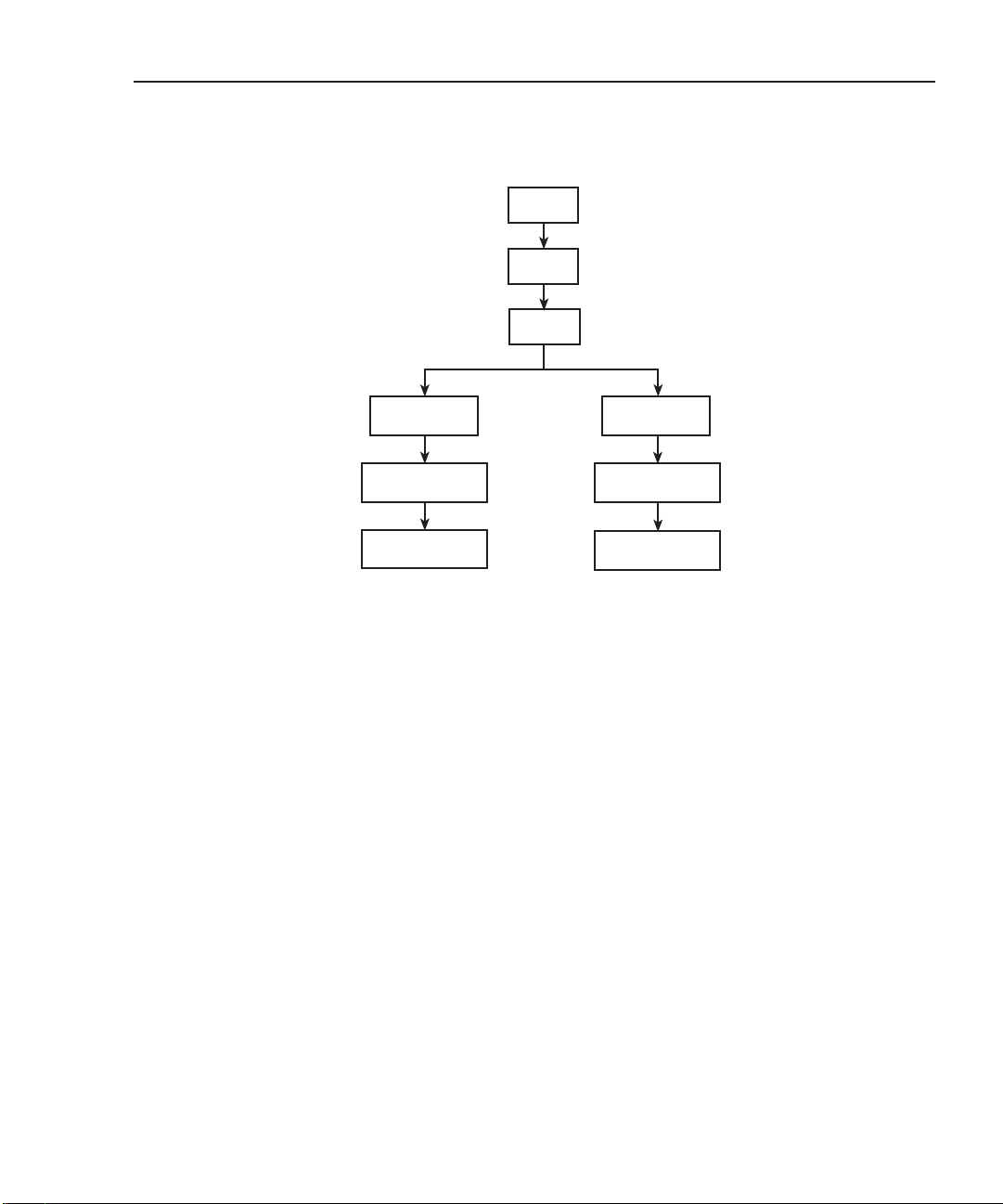

Setting source output levels

I-source and V-source (7751/7753) output levels are set from the CONFIG item of the

CARD menu. The menu structure, shown in Figure 2-2, is accessed by pressing and

releasing SHIFT and then pressing CARD.

• I-source — Set output from 0 to 50mA. In the menu structure, the I-source is designated as channel 27. The default setting is 1mA.

•V-source (7751/7753 only) — Set output from 50 to 500V. In the menu structure,

the V-source is designated as channel 28. The default setting is 50V.

NOTE When using the V-source as an independent source, limit 7751 output current to

50µA or 7753 output current to 500µA to achieve rated accuracy. Typical short

circuit current is <1mA.

Page 28

Model 2790 SourceMeter® Switch System User’s Manual 2-7

Figure 2-2

Setting I-source and V-source output levels

Press

Press

Select

SLOT1: 77xx

7751

7752

7753

7751

7753

I-C27:01.00 mA

V-C28:050.0 V

* 7753 should be installed in slot 1 for rated accuracy.

SHIFT

CARD

CONFIG

77xx =7751/7752/7753

Select module

Set I-source

output

Set V-source

output

SLOT2: 77xx

I-C27:01.00 mA

V-C28:050.0 V

7751

7752

7753*

7751

7753*

Page 29

2-8 Model 2790 SourceMeter® Switch System User’s Manual

Remote programming

As shown in Table 2-1, the amplitude command is used to set the outputs of the sources.

Notice that the channel number of the V-source (28) and I-source (27) must be included in

the command string.

Table 2-1

Commands to set amplitude for V-source and I-source

Commands Description Default

SOURce:VOLTage[:LEVel][:IMMediate]

[:AMPLitude] <NRf>, <clist> Set V-source output; 50 to 500 (V).

50V

<clist> = (@128) Slot 1

= (@228) Slot 2

[:AMPLitude]? <clist> Query V-source output level.

SOURce:CURRent[:LEVel][:IMMediate]

[:AMPLitude] <NRf>, <clist> Set I-source output; 0 to 50 (mA).

0.001A

<clist> = (@127) Slot 1

= (@227) Slot 2

[:AMPLitude]? <clist> Query I-source output level.

Note: Selecting an ohms calculation enables source tracking. Selecting any other math function disables

source tracking.

Page 30

Model 2790 SourceMeter® Switch System User’s Manual 2-9

Math

There is a shortcut math function to calculate low resistance when using the I-source of a

7751/7752/7753 module, and one to calculate high resistance when using the V-source and

I/V amplifier of a 7751/7753 module.

Low ohms calculation (SxIohms)

• SxIohms – Calculates and displays low resistance reading for 7751/7752/7753

module in slot x (where x =1 or 2).

This ohms function is a shortcut for the mX+b calculation. When selected, the following

“m” and “b” factors are used:

m = 1 / I

SOUR

b = 0

Calculation: R = mX + b

= (1/ I

= V

where: I

SOUR

MEAS

is the programmed current level of the I-source of the 7751, 7752, or

SOUR

/ I

) x V

SOUR

MEAS

+ 0

7753.

1 / I

V

MEAS

is the “m” factor for the calculation (mX+b).

SOUR

is the voltage measured by the DMM of the Model 2790. It is the “X”

variable for the calculation (mX+b).

When the SxIohms calculation is selected, the Model 2790 measures voltage (X) and

calculates mX+b using the above factors. The displayed reading will be in ohms (Ω). This

selection also sets DMM to DCV, 1V range.

NOTE SxIohms cannot be selected if the I-source is set to 0mA. Since “m” = 1 / I

SOUR

dividing 1 by 0 would result in an erroneous reading (positive infinity).

When using the low ohms calculation, the highest DCV measurement range that can be

selected is 1V. Attempting to select a higher range will cause error -222 (Parameter out of

range). Attempting to turn Autoranging on generates error -221 “Settings conflict” over

the GPIB or a “NO AUTORANGE” message on the display if done from the front panel

AUTO key.

Page 31

2-10 Model 2790 SourceMeter® Switch System User’s Manual

High ohms calculation (SxVohms)

• SxVohms – Calculates and displays the high resistance reading for the 7751/7753

module in slot x (where x =1 or 2).

This ohms function is a shortcut for the m/X+b calculation. When selected, the following

“m” and “b” factors are used:

m = -200,000 x V

m = -20,000 x V

SOUR

SOUR

(7751)

(7753)

b = 0

7751 calculation: R = m/X + b

= (-200,000 x V

= -V

SOUR

/ V

MEAS

SOUR

x 200,000

) / V

MEAS

+ 0

7753 calculation: R = m/X + b

where: V

= (-20,000 x V

= -V

is the programmed voltage level of the V-source of the 7751/7753.

SOUR

SOUR

/ V

For the 7751, (-200,000 x V

) / V

SOUR

x 20,000

MEAS

) is the “m” factor for the calculation (m/X+b).

SOUR

MEAS

+ 0

200,000 is the value of the feedback resistor (RF) for the I/V amplifier

(RF = 200kΩ).

For the 7753, (-20,000 x V

) is the “m” factor for the calculation (m/X+b).

SOUR

20,000 is the value of the feedback resistor (RF) for the I/V amplifier (RF = 20kΩ).

V

is the output voltage of the V/I amplifier measured by the DMM of the

MEAS

Model 2790. It is the “X” variable for the calculation (m/X+b).

When the SxVohms calculation is selected, the Model 2790 measures voltage (X) and

calculates m/X+b using the above factors. The displayed reading will be in ohms (Ω). This

selection also sets DMM to DCV, 10V range. Note that the V

reading will be negative

MEAS

(-). Because the output of the V/I amplifier is inverted, the negative value of “m” will cause

the ohms reading to be displayed as a positive value.

When using the high ohms calculation (SxVohms), the highest DCV measurement range

that can be selected is 10V. Attempting to select a higher range will cause error -222

(Parameter out of range).

If V> - 10mV, an overflow will occur. If V< -12V, an underflow will occur.

Attempting to turn Autoranging on generates error -221 “Settings conflict” over the GPIB

or a “NO AUTORANGE” message on the display if done from the front panel AUTO key.

NOTE Readings for both the 7751 and 7753 modules will overflow when the I/V output

is greater than -9mV and underflow when the I/V output is less than -12V.

Page 32

Model 2790 SourceMeter® Switch System User’s Manual 2-11

Front panel operation

An ohms math function is enabled from the MATH menu, which is accessed by pressing

and releasing SHIFT and then MATH (see Figure 2-3). Note that an ohms math function is

only available in the menu if the associated 7751, 7752, or 7753 module is installed.

Figure 2-3

Enabling ohms math function

Press

Press

Select math

function

SHIFT

MATH

S1IOHMS S1VOHMS S2IOHMS S2VOHMS

7751/7752/7753

in slot 1

* 7753 should be installed in slot 1 for rated accuracy.

Remote programming

As shown in Table 2-2, the :CALC:FORMat command is used to select an ohms math

function. Notice that the math setting can be global to all qualified channels or set on a

per-channel basis by using the <clist> parameter.

NOTE With an ohms math function selected, the Model 2790 is actually measuring

DCV. Therefore, if you send SENS1:FUNC? to query the selected function, it

will return “VOLT:DC”.

Source tracking

7751/7753

in slot 1

7751/7752/7753*

in slot 2

7751/7753*

in slot 2

The Model 2790 provides source tracking to ensure that the most recently set source

amplitude is used in the selected ohms calculation. If the source output level changes, the

“m” constant for the calculation will change accordingly.

Source tracking is enabled automatically when the desired ohms function is selected. No

other actions are required by the user.

However, if desired, source tracking can be disabled or the source that is being tracked can

be changed. The :TRACk and :SOURCe commands are listed in Table 2-2.

Page 33

2-12 Model 2790 SourceMeter® Switch System User’s Manual

Table 2-2

Commands to select ohms calculations

Commands Description Default

CALCulate[1]:FORMat <name> Select math function: NONE, MXB,

PERC

PERCent, RECiprocal, S1Iohms,

S1Vohms, S2Iohms, S2Vohms.

CALCulate[1]:FORMat? Query selected math format.

CALCulate[1]:STATe <b> Enable or disable math calculation.

CALCulate[1]:STATe? Query state of selected math calculation.

CALCulate[1]:DATA[:LATest]? Return last result of calculation.

CALCulate[1]:DATA:FRESh? Return last “fresh” result of calculation.

The following commands are set automatically when an ohms math function (SxIohms or SxVohms) is selected using the :FORMat command. No further actions are required by the user.

CALCulate[1]:KMATh:MMFactor:TRACk <b> Enable or disable source tracking1. OFF

CALCulate[1]:KMATh:MMFactor:TRACk? Query state of source tracking.

CALCulate[1]:KMATh:MMFactor:SOURce <name> Selects source to be tracked: NONE,

NONE

S1ISource, S1VSource, S2ISource,

S2VSource.

CALCulate[1]:KMATh:MMFactor:SOURce? Query source to be tracked.

1

Selecting an ohms calculation enables source tracking. Selecting any other math function disables source tracking.

Programming errors

-222 Parameter out of range — Attempted to select a source (:SOURCe command)

with a 7702 card installed.

-241 Hardware missing — Attempted to select a source (:SOURCe command) that is

not installed.

+870 Invalid current error — Attempted to track an I-source that is set to 0mA. For

the low ohms calculation, “m” = 1 / I

erroneous reading (positive infinity).

. Dividing 1 by 0 would result in an

SOUR

Page 34

Model 2790 SourceMeter® Switch System User’s Manual 2-13

Opening and closing channels

Multiple channel operations are used to control 7751, 7752, and 7753 channels:

• Only the specified channels are opened or closed. Unspecified channels are not

affected.

• Relays to connect signals to the backplane (DMM) of the Model 2790 do not close

automatically. You must explicitly close them to perform a measurement. For

example, with a DUT connected to channel 1 of a 7751, 7752, or 7753 module, you

would have to close channels 1, 14, and 18 to measure it with the Model 2790.

• Closed channels are not displayed by the Model 2790 while in the normal display

state. Closed channels can be viewed from the VIEW item of the CARD menu (see

“Viewing closed channels” for details).

To control the appropriate switching module, the slot number must be included with the

switching module channel number. The channel assignment is formatted as follows:

SCH where: S is the slot number (1 or 2)

CH is the channel number

Examples: 101 = Slot 1, Channel 1

218 = Slot 2, Channel 18

NOTE Interlock of the 7751/7752/7753 must be enabled in order to close channel 18,

19, or 21 and open channel 20. See “Open interlock errors” for errors associ-

ated with open interlock and see “Interlock” in Section 5 for details on using the

interlock.

Front panel operation

As shown in Figure 2-4, the OPEN and CLOSE keys are used to control 7751, 7752, and

7753 channels:

After closing or opening a single channel:

•A message indicating the action (i.e., “101 CLOSED”) will be displayed briefly.

•To close another channel, simply key in the channel number and press ENTER.

• Press EXIT to exit from the open/close menu structure.

NOTE The edit keys (left, right, up, and down arrow keys) are used to display a channel

number. Pressing ENTER opens or closes the channel.

Page 35

2-14 Model 2790 SourceMeter® Switch System User’s Manual

Figure 2-4

Opening and closing channels

A) Opening one or all channels

Display ALL option

and press OPEN again

B) Closing a channel

CLOSEOPEN

CLOSE:MULT

CLOSE MULT:XXX

Remote programming

The commands to control 7751, 7752, and 7753 channels are listed in Table 2-3.

Table 2-3

Commands to control 7751/7752/7753 module channels

OPEN: ALL

Press CLOSE key

Display MULT option

and press ENTER

Specify channel number

(XXX) and press ENTER

CLOSEOPEN

Press OPEN key

OPEN: MULT

OPEN MULT:XXX

Display MULT option

and press ENTER

Display channel number

(XXX) and press ENTER

Commands Description

ROUTe:MULTiple:CLOSe <clist> Specify one or more channels to close.

ROUTe:MULTiple:OPEN <clist> Open channels specified in list. Unlisted

channels not affected.

ROUTe:OPEN:ALL Open all channels*.

ROUTe:MULTiple:CLOSe? Returns a <clist> of all closed channels.

ROUTe:MULTiple:CLOSe:STATe? <clist> Query closed channels in specified list;

0 = open, 1 = closed.

* ROUT:OPEN:ALL will open all channels, except channel 20 if interlock is open.

Examples: ROUT:OPEN:ALL ‘ Open all channels.

ROUT:MULT:CLOS (@101,114,118) ‘ Close channels for slot 1.

ROUT:MULT:CLOS? ‘ Return list of closed channels.

Page 36

Model 2790 SourceMeter® Switch System User’s Manual 2-15

Viewing closed channels

Closed channels can be viewed from the VIEW item of the CARD menu. The menu structure is accessed by pressing and releasing SHIFT and then pressing CARD. As shown in

Figure 2-5, the closed channels will scroll across the display:

• The four dots (....) identify the end of the channel string.

• Use the ENTER key to pause and resume scrolling.

• Press EXIT to return to the normal display state.

NOTE For remote programming, closed channels can be identified using

ROUT:MULT:CLOS? and ROUT:MULT:CLOS:STAT? (see Table 2-3).

Figure 2-5

Viewing closed channels

Select module

Closed channels

scrolled*

Press

Press

Select

SHIFT

CARD

VIEW

SLOTx: 77xx

101, 114, 118 ....

SLOTx = Slot1 or Slot2

77xx = 7751/7752/7753**

*

Shows channels 101, 114,

and 118 closed.

** 7753 should be installed in

slot 1 for rated accuracy.

Page 37

2-16 Model 2790 SourceMeter® Switch System User’s Manual

Open interlock errors

The 7751, 7752, and 7753 modules have an interlock. When the interlock is open (disabled),

the I-source (7751, 7752, and 7753) and V-source (7751 and 7753) are disconnected from

the switching matrix. Details on enabling the interlock are explained in Section 5. The following errors are associated with an open interlock.

Front panel messages:

• INTRLCK OPEN is displayed briefly if you attempt to close channel 18, 19, or 21

with interlock open.

•With the INPUTS switch in the REAR position (in), readings will overflow

(OFLO) when the interlock is open.

• In the case of the OFLO readings for open interlock, the IL1 or IL2 message will

also be displayed. IL1 is displayed for a slot 1 violation and IL2 is displayed for a

slot 2 violation. In the case of errors for both slots, the IL1 message takes

precedence.

•Overflowed readings stored in the buffer do not provide interlock status. You cannot

tell if the overflow readings are true overflows or the result of open interlock (see

“Remote programming errors”, below).

Remote programming errors:

• When an open interlock is first detected, error +860 (slot 1 interlock violation)

or +861 (slot 2 interlock violation) occurs. The questionable event register in the

status byte can be read to determine which interlock tripped (see Section 11 of the

Model 2790 Reference Manual).

• The firmware polls for interlock violations every 50msec. To avoid filling up the

error queue, once an error is issued for a given interlock, it must be reset (interlock

enabled) before another error event will be issued to the status model for the same

interlock.

• Error -224 (parameter error) occurs if you attempt to close channel 18, 19, or 21

with interlock open.

•With interlock open, channel 20 will close and remain closed while interlock is

open. ROUT:OPEN:ALL will open all channels except channel 20.

ROUT:MULT:OPEN will generate error -224 (parameter error).

Page 38

Model 2790 SourceMeter® Switch System User’s Manual 2-17

Cable discharge circuit (7751 and 7753)

Leakage capacitance exists between signal paths on the switching module and in the test

cables. This capacitance can be high enough to store a high voltage charge from the

V-source of the 7751/7753 module.

As shown in Figure 2-6, capacitance exists between the source terminals (CSO) and the

sense terminals (CSE). These capacitors can be charged by the V-source of the 7751/7753

module during the HIPOT test. This unwanted voltage charge could ignite the inflator if it

is connected to a bridgewire.

To prevent a high voltage charge from appearing across the inflator, a discharge circuit is

used. As shown in Figure 2-6, channel 20 is closed to provide discharge paths through

100kΩ resistors.

In general, the discharge circuit is controlled as follows:

• When the interlock opens, channel 20 closes to discharge the capacitors. Channel 20

remains closed as long as interlock remains open (see “Interlock” in Section 5 for

details).

• Opening channel 22 closes channel 20 for approximately 5msec to discharge the

capacitors. Opening channel 22 selects the I-source (V-source disconnects from

rest of module and DUT).

In general, with the test cables connected to the module and the input channels (i.e., 1 and

2) closed, the following sequence should be used to properly perform cable discharge:

1. Open channel 21 to disconnect the V-source and I-source from the input.

2. Open channel 22 to perform cable discharge.

NOTE If channel 22 is already open, performing the MULT:OPEN operation will not

close channel 20 to perform cable discharge. However, the OPEN:ALL operation will perform cable discharge.

When the OPEN:ALL operation is performed, the following sequence of actions

occur:

1) Opens channel 21 to disconnect all sources.

2) Opens channel 22.

3) Closes channel 20 for 5msec to perform cable discharge.

4) Opens all channels.

NOTE In Section 5, the test procedure for HIPOT uses the OPEN:ALL operation to

perform cable discharge (see steps 7 and 11 in Table 5-6).

Page 39

2-18 Model 2790 SourceMeter® Switch System User’s Manual

Manual cable discharge

The discharge circuit can also be activated manually at any time by closing channel 20 of

the 7751/7753 module. Typically, manual discharge is used when a discharge time >5msec

is desired.

Figure 2-6

Cable discharge circuit

Keithley 7751/7753

Source

Inflator

Under

Test

LO

HI

Sense

Source

Sense

20

= Closed channel switches.

CSO

~1nF

100kΩ

100kΩ

C

SE

~1nF

Page 40

Model 2790 SourceMeter® Switch System User’s Manual 2-19

Connection log

Make a copy of Table 2-4 and affix it to the cover of the 7751/7752/7753 module. Use it to

record connection information and channel descriptions as needed.

Table 2-4

Connection log Model 7751/7752/7753

Bank Channel Color Description

CH1 (HI) Source

Sense

Bank 1CH2 (LO) Source

Sense

CH3 A1

B1

CH4 (HI) Source

Sense

Bank 2CH5 (LO) Source

Sense

CH6 A2

B2

CH7 (HI) Source

Sense

Bank 3CH8 (LO) Source

Sense

CH9 A3

B3

CH10 (HI) Source

Sense

Bank 4CH11 (LO) Source

Sense

CH12 A4

B4

Page 41

2-20 Model 2790 SourceMeter® Switch System User’s Manual

Using memory patterns

Firmware revision level

Memory patterns are supported in Model 2790 units with firmware A04 and higher. The

firmware revision level is displayed as part of the power-up cycle.

Overview

Most Model 7751/7752/7753 tests follow the same basic procedure: select a source and set

its level, configure the Model 2790 measurement, close the necessary relays, and take a reading. Memory Patterns simplify this process, allowing you to store combinations of multiple

closed channels, source settings, and DMM measurement configurations in nonvolatile

memory. Up to 40 such Memory Patterns, designated M1 through M40, can be stored. There

is also memory pattern M0, which is defined as an “all-open” pattern. Recalling M0 opens

all channels and resets all sources to their factory default values. Similar to closing one 7702

channel and taking a reading, you can recall an individual Memory Pattern to close multiple

channels and take a reading. More importantly, you can include Memory Patterns in a scan

list and cause the Model 2790 to automatically scan through the specified memory locations.

As each memory pattern is scanned, the sources and DMM are configured appropriately, the

specified group of channels is closed, and a reading is taken. Reading limits can also be

assigned to each memory pattern so that during a scan the readings will automatically be

inspected for PASS/FAIL conditions. Digital outputs corresponding to these conditions are

also available.

NOTE Memory patterns can be used only with the following functions: DC volts, 2-wire

ohms, and 4-wire ohms.

Front panel operation

Memory patterns cannot be defined from the front panel, but they can be recalled once

defined by remote commands (see below). To recall defined memory patterns from the

front panel:

1. Press CLOSE.

2. Use the RANGE and keys to select CLOSE: MEMORY, then press

ENTER.

3. Use , , , and to select the memory pattern number (1-40), then press

ENTER.

Page 42

Model 2790 SourceMeter® Switch System User’s Manual 2-21

Memory pattern commands

Memory patterns commands are summarized in Table 2-5. See Section 2 of the Model

2790 Reference Manual for details on these commands.

Command Description

:ROUTe:MEMory[:CHANnels] <n>, <clist> Create channel pattern for memory <n> (1-40).

Note: 7702 channels cannot be included in

<clist>.

:ROUTe:MEMory:SOURce:LEVel <n>, <NRf>, <clist> Assign source values to the channels in <clist>

that will be output when memory pattern <n>

is executed. (Source channels only: 127, 128,

227, or 228.)

:ROUTe:MEMory:DELay <n>, <NRf> Assign a variable delay to memory pattern

<n>. (Time in seconds after closing channels

and setting source values before making

measurements.)

:ROUTe:MEMory:RECall <n> Immediately execute memory pattern <n>.

:ROUTe:MEMory:READ[:STATe] <n>, <b> If set to ON, a reading will be collected after

the memory pattern has executed (applies to

scanning only). *

:ROUTe:MEMory:CLEar <n> Clear out memory pattern <n>, setting all

channels to open and removing all digital and

analog channels from this memory pattern.

:ROUTe:MEMory:CLEar:ALL Clear out all memory patterns.

* You must include at least one measurement channel or a memory pattern that takes a reading (ROUT:MEM:READ:STAT x, ON).

Failure to do so results in the scan list being rejected with Error +702, “No measurement channel in scanlist.”

Setting up and executing memory patterns

To set up memory patterns, use the following procedure:

1. Program the desired memory pattern locations using the ROUT:MEM commands.

Typically, you would set source value(s), define channels to close, and set up delay

for each memory location.

2. Define DCV, 2-wire ohms, or 4-wire ohms measurement function(s) for each memory

pattern location.

Page 43

2-22 Model 2790 SourceMeter® Switch System User’s Manual