Page 1

www.keithley.com

Series 2600A System SourceMeter

®

User’s Manual

2600AS-900-01 Rev. B / September 2008

A GREATER MEASURE OF CONFIDENCE

Page 2

Page 3

WARRANTY

Keithley Instruments, Inc. warrant s this product to be free from defect s in materia l and workmanship fo r a per iod of

one (1) year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

software, rechargeable batteries, diskettes, and documentation.

During the warranty period, Keithley Instruments will, at its option, either repair or replace any product that proves

to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions.

Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted for the balan ce of the original

warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments’ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software,

non-rechargeable batteries, damage from batter y leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE

OF ITS INSTRUMENTS AND SOFTWARE, EVEN IF KEITHLEY INSTRUMENTS, INC. HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COST OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF

INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (1-888-534-8453) • www.keithley.com

3/07

Page 4

Page 5

Series 2600A

System SourceMeter® Instruments

User’s Manual

©2008, Keithley Instruments, Inc.

All rights reserved.

Any unauthorized reproduction, photocopy, or use the information herein, in whole or in part without the prior written

approval of Keithley Instruments, Inc. is strictly prohibited.

TSP, TSP-Link, and TSP-Net are trademarks of Keithley Instruments, Inc.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders

Cleveland, Ohio, U.S.A.

Document Number:

2600AS-900-01 Rev. B / September 2008

Page 6

Page 7

The following safety precautions should be observed before using this product an d any associated instrumentation. Although some

instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions may

be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the product. Refer

to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the instrument.

They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or

replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed only by service personnel.

Safety Precautions

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained service

personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rate d Measurement Category I and Measurement

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and

data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient

over-voltages. Measurement Category II connections require protection for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak,

or 60V DC are present. A good safety practice is to expect that hazardous voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators are

prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact.

Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If the circuit is capable of

operating at or above 1000V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited sources. NEVER

connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current

and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

11/07

Page 8

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input power

!

disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test.

AL W AYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting cables or jumpers,

installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions, or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information,

and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid

interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the user documentation.

The symbol on an instrument shows that it can source or measure 1000V or more, including the combined effect of normal and

common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be properly

disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death. Always read the

associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

T o maintain protection from electric shock and fire, replacement components in mains circuits - including the power transformer, test leads,

and input jacks - must be purchased from Keithley Instruments. Standard fuses with applicable national safety approvals may be used if

the rating and type are the same. Other components that are not safety-related may be purchased from other suppliers as long as they

are equivalent to the original component (note that selected parts should be purchased only through Keithley Instruments to maintain

accuracy and functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley Instruments

office for information.

To clean an instrument, use a damp cloth or mild, water-based cleaner. Clean the exterior of the instrument only. Do not apply cleaner

directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis

(for example, a data acquisition board for installation into a computer) should never require cleaning if handled according to instructions.

If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

Page 9

Table of Contents

Section T opic Page

1 Front and Rear Panel Operation........................................................ 1-1

Front and rear panel familiarization............................................................ 1-2

Front panel summaries......................................................................... 1-2

Rear panel summaries......................................................................... 1-2

Model 2601A/2602A and Model 2611A/2612A rear panels ................. 1-5

Model 2635A/2636A rear panels .......................................................... 1-7

What are the source-measure capabilities? ............................................... 1-9

Model 2601A and Model 2602A........................................................... 1-9

Model 2611A and Model 2612A........................................................... 1-9

Model 2635A and Model 2636A........................................................... 1-9

How do I power-up the instrument?.......................................................... 1-10

How do I make measurements?............................................................... 1-11

How do I use the reading buffer?.............................................................. 1-15

2 Remote Operation ................................................................................. 2-1

How do I use the remote interface?............................................................ 2-2

Connect to the interface....................................................................... 2-2

Configure the interface......................................................................... 2-2

Working with the web interface................................................................... 2-8

How to use the Virtual Front Panel....................................................... 2-9

TSP Express............................................................................................... 2-9

TSB embedded........................................................................................... 2-9

Issuing ICL commands....................................................................... 2-10

How do I use Test Script Builder?............................................................. 2-11

How do I use TSB to make measurements?............................................ 2-14

How do I use other programs?................................................................. 2-17

Using LabVIEW.................................................................................. 2-17

Using Visual Basic.............................................................................. 2-19

3 Test Script Processor Interaction...................................................... 3-1

What is a script?......................................................................................... 3-2

Factory scripts...................................................................................... 3-2

User scripts.......................................................................................... 3-2

How do I run a script from the front panel?................................................. 3-2

How do I save scripts to the USB flash drive?............................................ 3-3

How do I interact with scripts using Test Script Builder? ............................ 3-4

Running a factory script ....................................................................... 3-4

Modifying a factory script ..................................................................... 3-6

Running the user script...................................................................... 3-11

Deleting a user script and user tests.................................................. 3-12

How do I use other programs?................................................................. 3-12

Using LabVIEW.................................................................................. 3-12

Using Visual Basic.............................................................................. 3-14

4 Controlling Multiple Series 2600As (TSP-Link).............................. 4-1

How do I set up the TSP-Link system?....................................................... 4-2

How do I use the expanded system?.......................................................... 4-3

Accessing resources of TSP-Link nodes ............................................. 4-3

Running scripts in a TSP-Link system.................................................. 4-4

Page 10

Table of Contents Series 2600A System SourceMeter® Instruments User’s Manual

Appendix T opic Page

A Frequently Asked Questions.............................................................. A-1

How do I optimize performance? ............................................................... A-2

Setting speed....................................................................................... A-2

Disabling auto zero to increase speed ................................................ A-2

How do I upgrade the firmware?................................................................ A-2

How do I use the Digital I/O port?.............................................................. A-3

Digital I/O port terminals...................................................................... A-3

Controlling the digital I/O port.............................................................. A-3

How do I trigger other instruments?........................................................... A-3

Triggering a scanner............................................................................ A-3

Programming triggering....................................................................... A-4

How do I generate a service request?....................................................... A-4

Setting up a service request................................................................ A-4

Service request programming example............................................... A-4

Polling for SRQs.................................................................................. A-5

How do I store measurements in nonvolatile memory?............................. A-5

Front panel operation........................................................................... A-5

Remote programming.......................................................................... A-5

How do I stack channels to output higher voltage?.................................... A-6

How do I parallel channels to output higher current?................................. A-7

How do I make contact check measurements? ......................................... A-8

Contact check connections.................................................................. A-8

How do I make low-current measurements?.............................................. A-9

Low-current connections ..................................................................... A-9

Low-current measurement programming example ............................ A-10

Index....................................................................................................Index-1

ii 2600AS-900-01 Rev. B / September 2008

Page 11

List of Figures

Section Figure Title Page

1 Figure 1-1 Models 2601A, 2611A, 2602A, 2612A, 2635A,

and 2636A front panels.................................................................. 1-2

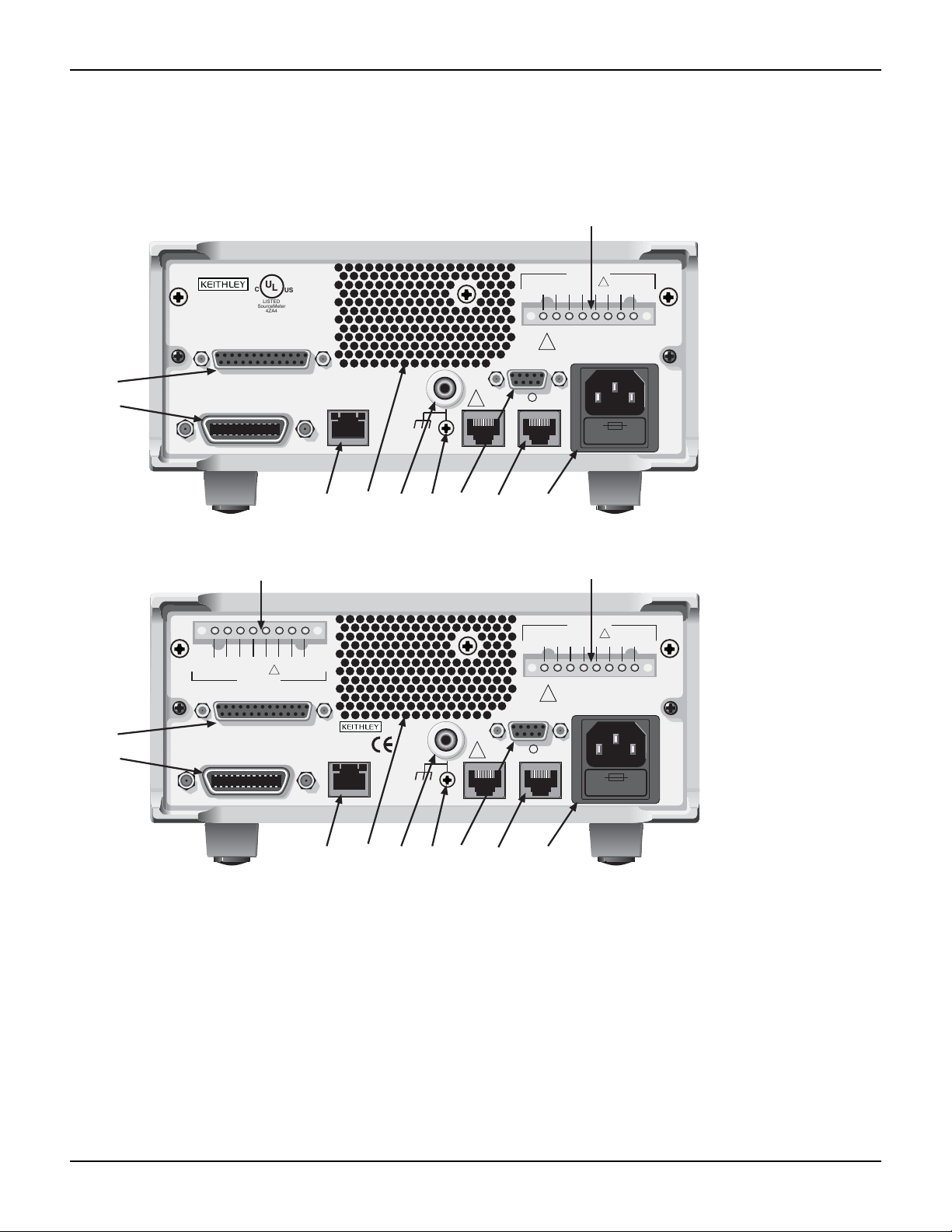

1 Figure 1-2 Model 2601A/2602A/2611A/2612A rear panels............................. 1-5

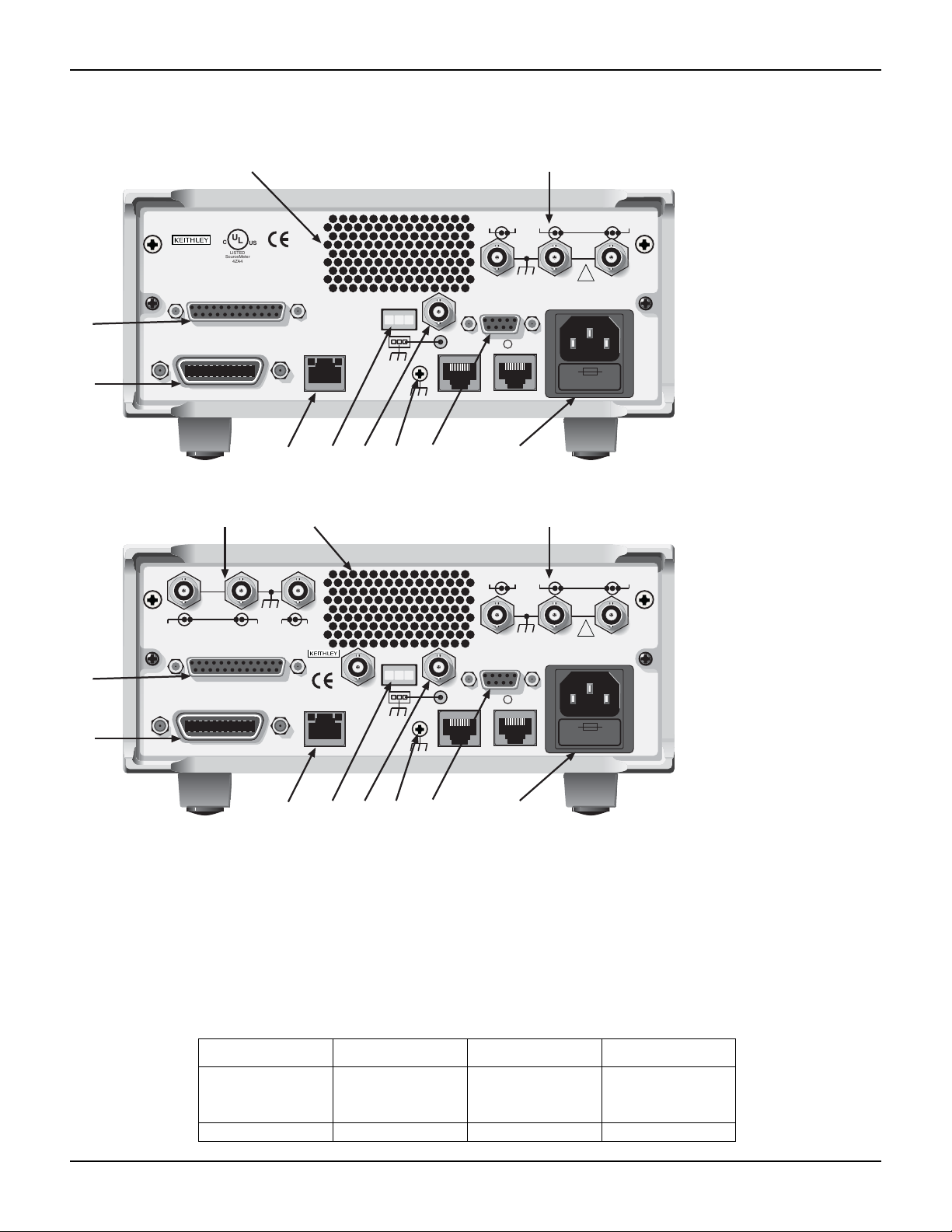

1 Figure 1-3 Model 2635A and 2636A rear panels............................................ 1-7

1 Figure 1-4 Model 2602A/2612A low-noise chassis ground ba nana jack

and chassis screw ....................................................................... 1-13

1 Figure 1-4 Model 2636A................................................................................ 1-13

1 Figure 1-5 Interlock circuit............................................................................. 1-14

1 Figure 1-6 Display modes............................................................................. 1-14

1 Figure 1-7 Buffer display format.................................................................... 1-17

2 Figure 2-1 GPIB cable..................................................................................... 2-2

2 Figure 2-2 RS-232 cable................................................................................. 2-2

2 Figure 2-3 Computer configuration using the command prompt..................... 2-4

2 Figure 2-4 Internet protocol (TCP/IP) properties dialog box........................... 2-6

2 Figure 2-5 LAN connection ............................................................................. 2-8

2 Figure 2-6 Web interface................................................................................. 2-9

2 Figure 2-7 Test Script Builder initial startup screen....................................... 2-12

2 Figure 2-8 Instrument console control icons................................................. 2-13

2 Figure 2-9 Select Instrument Resource dialog box....................................... 2-14

2 Figure 2-10 Source-measure command sequence in console window

(2601A/2602A version shown)..................................................... 2-15

2 Figure 2-11 LabVIEW source-measure example block diagram..................... 2-18

2 Figure 2-12 Visual Basic example user interface............................................ 2-19

2 Figure 2-13 Example program test results...................................................... 2-21

3 Figure 3-1 Pulse-measure cycle for the PulseVMeasureI function............... 3-4

3 Figure 3-2 Importing a factory script project from the Series 2600A............... 3-7

3 Figure 3-3 KIGeneral project imported into the Test Script Builder................. 3-8

3 Figure 3-4 Run configuration example - Main tab shown.............................. 3-10

3 Figure 3-5 Run configuration example - Script Attributes tab shown............ 3-11

3 Figure 3-6 LabVIEW source step example ................................................... 3-13

3 Figure 3-7 GUI after loading the non-function script (GPIB)......................... 3-16

3 Figure 3-8 GUI after running the non-function script (GPIB)......................... 3-17

3 Figure 3-9 GUI after loading and running the function script (GPIB)............ 3-18

3 Figure 3-10 GUI after calling the function (GPIB) ........................................... 3-19

4 Figure 4-1 TSP-Link connections.................................................................... 4-2

Appendix Figure Title Page

A Figure A-1 Digital I/O port terminals................................................................ A-3

A Figure A-2 Triggering a scanner...................................................................... A-4

A Figure A-3 Stacking channels for higher voltage............................................. A-7

A Figure A-4 Connecting channels in parallel for higher current ........................ A-8

A Figure A-5 Model 2601A/2602A/2611A/2612A contact check connections ... A-8

A Figure A-6 Model 2635A/2636A contact check connections........................... A-9

A Figure A-7 Model 2635A/2636A low-current connections............................. A-10

Page 12

List of Figures Series 2600A System SourceMeter® Instruments User’s Manual

This page left blank intentionally.

ii 2600AS-900-01 Rev. B / September 2008

Page 13

List of Tables

Section Table Title Page

1 Table 1-1 Connectors and triax cable conductors ......................................... 1-7

1 Table 1-2 Triax connector on ground module................................................ 1-8

1 Table 1-3 Model 2601A and 2602A source-measure capabilities ................. 1-9

1 Table 1-4 Model 2611A and 2612A source-measure capabilities.................. 1-9

1 Table 1-5 Model 2635A and 2636A source-measure capabilities ................. 1-9

Appendix T able Title Page

A Table A-1 Commands for basic I/O port......................................................... A-3

Page 14

List of Tables Series 2600A System SourceMeter® Instruments User’s Manual

This page left blank intentionally.

ii 2600AS-900-01 Rev. B / September 2008

Page 15

In this section:

Topic Page

Front and rear panel familiarization................................................. 1-2

Front panel summaries.................................................................. 1-2

Rear panel summaries .................................................................. 1-2

Model 2601A/2602A and Model 2611A/2612A rear panels........... 1-5

Model 2635A/2636A rear panels................................................... 1-7

What are the source-measure capabilities? .................................... 1-9

What are the source-measure capabilities?.................................... 1-9

Model 2601A and Model 2602A.................................................... 1-9

Model 2611A and Model 2612A.................................................... 1-9

Model 2635A and Model 2636A.................................................... 1-9

How do I power-up the instrument?................................................. 1-10

Connect to line power.................................................................... 1-10

Turn on power............................................................................... 1-10

Set line frequency.......................................................................... 1-10

Section 1

Front and Rear Panel Operation

How do I make measurements?....................................................... 1-11

Connect the DUT........................................................................... 1-11

Select source and set source level................................................ 1-11

Set compliance limit ...................................................................... 1-11

Select measurement function and range....................................... 1-12

Turn output on............................................................................... 1-12

Make measurements..................................................................... 1-12

Turn output off............................................................................... 1-12

How do I use the reading buffer?..................................................... 1-15

Connecting the device under test (DUT)....................................... 1-15

Set up source and measure functions........................................... 1-15

Configuring the reading buffer....................................................... 1-15

Turn on the outpu t......................................................................... 1-16

Storing re ad ing buffers.................................................................. 1-16

Turn off the output......................................................................... 1-16

Recalling readings......................................................................... 1-16

Page 16

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

P

U

S

H

T

O

E

D

I

T

/

E

N

T

E

R

P

U

S

H

T

O

E

D

I

T

/

E

N

T

E

R

P

U

S

H

T

O

E

D

I

T

/

E

N

T

E

R

P

U

S

H

T

O

E

D

I

T

/

E

N

T

E

R

2601A SYSTEM SourceMeter

®

POWER

AUTO

CURSOR

2602A SYSTEM SourceMeter

®

POWER

AUT O

CURSOR

EXIT ENTER

TRIG MENU

SPEED

DIGITS

REL

FILTER

SRC LIMITMEAS

MODE

0

1

0000

+ / -

LOAD RUN STORE RECALL

6

7

2

3

4

5

89

OUTPUT

ON/OFF

LOCAL

DISPLAY

CONFIG

RANGE

RANGE

1

Model 2601A and Model 2611A

2

3

4

5

EXIT ENTER

TRIG MENU

SPEED

DIGITS

REL

FILTER

SRC LIMITMEAS

MODE

0

1

0000

+ / -

LOAD RUN STORE RECALL

6

7

2

3

4

5

89

LOCAL

DISPLAY

CONFIG

RANGE

RANGE

SPEED

DIGITS

REL

FILTER

SRC LIMITMEAS

MODE

CHANNEL A CHANNEL B

CHAN

A

CHAN

B

OUTPUT

ON/OFF

Model 2602A and Model 2612A

KEITHLEY SourceMeter

KEITHLEY SourceMeter

5

4

3

2

1

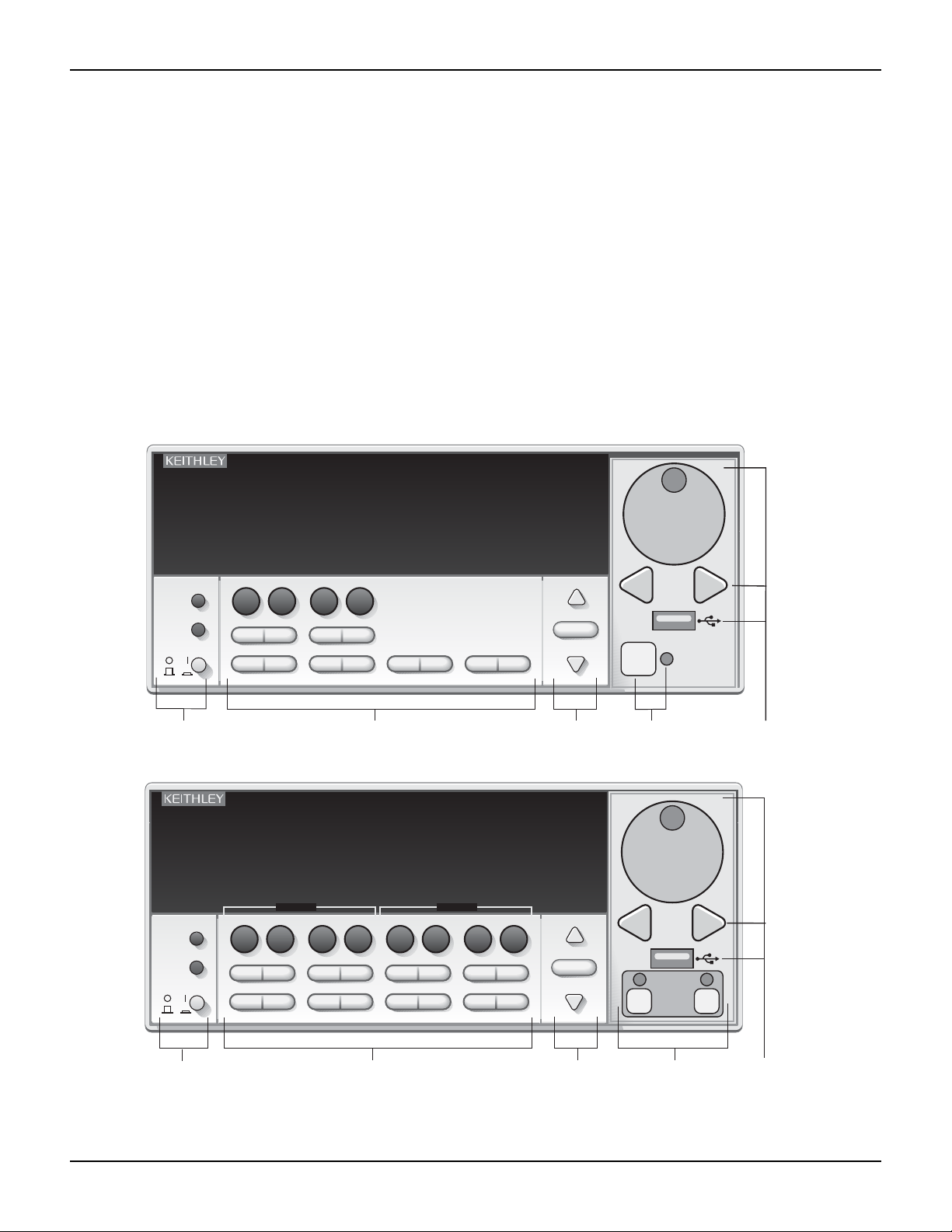

Front and rear panel familiarization

Front panel summaries

The front panels of the Keithley Instruments Series 2600A System SourceMeter® instrument are

shown in

Rear panel summaries

The rear panels of the Models 2601A/2602A and 2611A/2612A are shown in Figure 1-2. The rear

panels of the Models 2635A and 2636A are shown in Figure 1-3. The descriptions of the rear

panel components follow Figure 1-2 and Figure 1-3.

Figure 1-1

Models 2601A, 2611A, 2602A, 2612A, 2635A, and 2636A front panels

Figure 1-1. The descriptions of the front panel controls follow Figure 1-1.

1-2 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 17

Series 2600A System SourceMeter® Instruments User’s Manual Section 1: Front and Rear Panel Operation

NOTE The Models 2601A, 2611A, and 2635A have one SourceMeter

channel (Channel A) and the Models 260 2A, 2612A, and 2636A have

two SourceMeter channels (Channel A and Channel B).

1. Special keys and power switch:

DISPLAY Toggles between the various source-measure is displayed and the user message

mode.

Selects Models 2602A/2612A/2636A single or dual-channel display.

CONFIG Used to configure a function or operation.

POWER Power switch: “In” position (I) turns SourceMeter on, “out” position (O) turns

SourceMeter off (O).

Number keys The number keys (0-9, +/-, 0000) allow direct numeric entry in the EDIT mode.

2. Source-measure setup, performance control, and special operation:

Top Row: Source-measure setup

Model 2601A/2611A/2635A and Model 2602A/2612A/2636A:

SRC Channel A: Selects the source function (V or A) and places cursor in the source field

for editing.

MEAS Channel A: Cycles through measure fun c tions (V, A, Ω or W).

LIMIT Channel A: Places the cursor in the compliance limit field for editing.

MODE Channel A: Directly chooses the measurement function (V, A, Ω or W).

Model 2602A/2612A/2636A only:

SRC Channel B: Selects the source function (V or A) and places cursor in the source field.

MEAS Channel B: Cycles through measure fun c tions (V, A, Ω or W).

LIMIT Channel B: Places the cursor in the compliance limit field for editing.

MODE Channel B: Directly chooses the measurement function (V, A, Ω or W).

Middle Row: Source-measure setup

Model 2601A/2611A/2635A and Model 2602A/2612A/2636A:

DIGITS Channel A: Changes display resolution to 4-1/2, 5-1/2, or 6-1/2 digits.

SPEED Channel A: Sets the measurement speed by controlling the A/D converter measurement

aperture.

REL Channel A: Controls relative, which allows a baseline value to be subtracted from a

reading.

FILTER Channel A: Controls the digital filter, which can be used to reduce reading noise.

Model 2602A/2612A/2636A only:

DIGITS Channel B: Changes display resolution to 4-1/2, 5-1/2, or 6-1/2 digits.

SPEED Channel B: Sets the measurement speed by controlling the A/D converter measurement

aperture.

REL Channel B: Controls relative, which allows a baseline value to be subtracted from a

reading.

FILTER Channel B: Controls the digital filter, which can be used to reduce reading noise.

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 1-3

Page 18

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

Bottom Row: Source-measure setup

LOAD Loads factory or user-defined scripts for execution.

RUN Runs last selected factory or user-defined scripts.

STORE Stores readings, source values, and timestamp values in one of two internal buffers per

channel for later recall.

RECALL Recalls stored readings, source values, and timestamp values from either of the two buffers.

TRIG Triggers readings.

MENU Accesses the Main Menu for saving and recalling setups, selecting remote interface, line

frequency, self-tests, serial number and beeper control.

EXIT Cancels selection, and backs out of menu structure. Used as a LOCAL key to take the unit

out of remote.

ENTER Accepts selection, moves to next choice or exits menu.

3. Range keys:

and Selects the next higher or lower source or measure range.

AUTO Enables or disables source or measure auto range.

4. Output control and LED status indicator:

OUTPUT ON/OFF Turns source output on or off.

LED indicator Illuminated when output is on.

5. Navigation wheel, USB port, and CURSOR keys:

When in source edit, use the CURSOR keys for cursor control and then turn the navigation wheel to

change a source or compliance value. The can also be used to enable or disable the source edit mode.

When in a menu, use the CURSOR keys or navigation wheel for menu item cursor control. When

displaying a menu value, use the CURSOR keys for cursor control and turn the navigation wheel to

change the value. Pressing the navigation wheel opens a menu item or selects a menu option or value.

Use the USB port to connect a USB flash drive. The USB flash drive stores reading buffer data, scripts,

and user setup options.

6. Display indicators (not shown):

EDIT Unit is in the source editing mode.

ERR Questionable reading or invalid calibration step.

REM Unit in remote mode.

TALK Unit addressed to talk.

LSTN Unit addressed to listen.

SRQ Service request.

REL Relative mode enabled.

FILT Digital filter is enabled.

AUTO Auto source or measure range selected.

ARM Unit armed and ready to run.

* (asterisk)Readings are being stored in buffer.

1-4 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 19

Series 2600A System SourceMeter® Instruments User’s Manual Section 1: Front and Rear Panel Operation

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

MADE IN

U.S.A.

IEEE-488

LINE RATING

100-240VAC

50, 60Hz

240VA MAX.

DIGITAL I/O

RS-232

LINE FUSE

SLOWBLOW

3.15A, 250V

TSP-Link

R

CAT I

SS

LO LO HIHI GGGG

CHANNEL A

!

LAN

NO AUTO-MDIX

!

!

CAT I

SSLO

LOHI

HIGGG G

CHANNEL B

!

U

L

C

US

LISTED

SourceMeter

4ZA4

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

MADE IN

U.S. A.

IEEE-488

LINE RATING

100-240VAC

50, 60Hz

240VA MAX.

DIGITAL I/O

RS-232

LINE FUSE

SLOWBLOW

3.15A, 250V

LAN

TSP-Link

R

CAT I

SS

LO LO HIHI GGGG

CHANNEL A

!

!

!

Model 2601A/2611A

Model 2602A/2612A

1

2

3

4578

9

1

610

1

2

3

4578

9

6

10

Figure 1-2

Model 2601A/2602A/2611A/2612A rear panels

Model 2601A/2602A and Model 261 1A/2612A rear panels

1. CHANNEL A and CHANNEL B (Channel B on Model 2602A/2612A only)

Input/output connections for source, sense, and guard.

2. DIGITAL I/O

Female DB-25 connector. Fourteen pins for digital input or output, one pin for output enable (2601A/

2602A) or safety interlock (2611A/2612A); +5V and GND pins are also provided.

Use a cable equipped with a male DB-25 connector (Keithley Instruments part number CA-126-1CA).

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 1-5

Page 20

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

3. IEEE-488

Connector for IEEE-488 (GPIB) operation. Use a shielded cable, such as the Keithley Instruments

Model 7007-1 or Model 7007-2.

4. Cooling exhaust vent

Exhaust vent for internal cooling fan. Keep vent free of obstructions to prevent overheating.

5. Chassis ground

Ground screw for connections to chassis ground.

6. Low noise chassis ground

Ground jack for connecting Output HI or LO to chassis.

7. RS-232

Female DB-9 connector. For RS-232 operation, use a straight-through (not null modem) DB-9 shielded

cable (Keithley Instruments Model 7009-5) for connection to a PC.

8. TSP-Link

Expansion interface that allows a Series 2600A and other TSP-enabled instruments to trigger and

communicate with each other. Use a category 5e or higher LAN crossover cable (Keithley Instruments

part number CA-180-3A).

9. Power module

Contains the AC line receptacle and power line fuse. The instrument can operate on line voltages of

100V to 240V AC at line frequencies of 50 Hz or 60 Hz. See the Series 2600 A Reference Manual for

line fuse replacement instructions.

10. LAN

Use this RJ-45 connector to connect the instrument to the local area network. The RJ-45 connector

connects a network card, a network switch, a router or a hub. When connecting directly to a PC, a

crossover cable (included) must be used. When connecting to a network switch, router, or hub, a normal

CAT-5 cable (not provided) should be used unless your equipment has Auto-MDIX capabilities. If it does

have Auto-MDIX, the crossover cables may be used.

1-6 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 21

Series 2600A System SourceMeter® Instruments User’s Manual Section 1: Front and Rear Panel Operation

U

L

C

US

LISTED

SourceMeter

4ZA4

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

MADE IN

U.S.A.

IEEE-488

LINE RATING

100-240VAC

50, 60Hz

240VA MAX.

DIGITAL I/O

RS-232

LINE FUSE

SLOWBLOW

3.15A, 250V

LAN

TSP-Link

R

SENSE

LO LO HI

CHANNEL A

SENSE

HI

GUARD

A LO

!

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

MADE IN

U.S.A.

IEEE-488

LINE RATING

100-240VAC

50, 60Hz

240VA MAX.

DIGITAL I/O

RS-232

LINE FUSE

SLOWBLOW

3.15A, 250V

TSP-Link

R

SENSE

LO LO HI

CHANNEL A

SENSE

HI

GUARD

A LO

LAN

NO AUTO-MDIX

SENSE

LO

LOHI

CHANNEL B

SENSE

HI

GUARD

!

Model 2635A

Model 2636A

1

2

3

4

5611

8

910

1

2

3

4

5611

8

910

1

Figure 1-3

Model 2635A and 2636A rear panels

Model 2635A/2636A rear panels

1. CHANNEL A and CHANNEL B (Channel B on Model 2636A only)

Triax connectors for Input/output, guard, and sense connections. Use only low-noise triax cables such

as the Keithley Model 7078-TRX (available in several lengths). Connector terminals and associated

triax cable conductors are as follows:

Table 1-1

Connectors and triax cable conductors

Connector Center conductor Inner ring Outer ring

LO Sense LO Input/Output LO Chassis ground

HI Input/Output HI Guard Chassis ground

SENSE HI Sense HI Guard Chassis ground

Triax cable Center conductor Inner shield Outer shield

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 1-7

Page 22

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

2. DIGITAL I/O

Female DB-25 connector. Fourteen pins for digital input or output, one pin for safety inte rlock. Use a

cable equipped with a male DB-25 connector (Keithley Instruments part number CA-126-1CA).

3. IEEE-488

Connector for IEEE-488 (GPIB) operation. Use a shielded cable, such as the Model 7007-1 or Model

7007-2.

4. Cooling exhaust vent

Exhaust vent for internal cooling fan. Keep vent free of obstructions to prevent overheating.

5. Chassis ground

Ground screw for connections to chassis ground.

6. RS-232

Female DB-9 connector. For RS-232 operation, use a straight-through (not null modem) DB-9 shielded

cable (Keithley Instruments Model 7009-5) for connection to the PC.

7. TSP-Link

Expansion interface that allows a Series 2600A and other TSP-enabled instruments to trigger and

communicate with each other. Use a category 5e or higher LAN crossover cable (Keithley Instruments

part number CA-180-3A).

8. Power module

Contains the AC line receptacle and power line fuse. The instrument can operate on line voltages of

100V to 240VAC at line frequencies of 50Hz or 60Hz. See the Series 2600A Reference Manual for line

fuse replacement instructions.

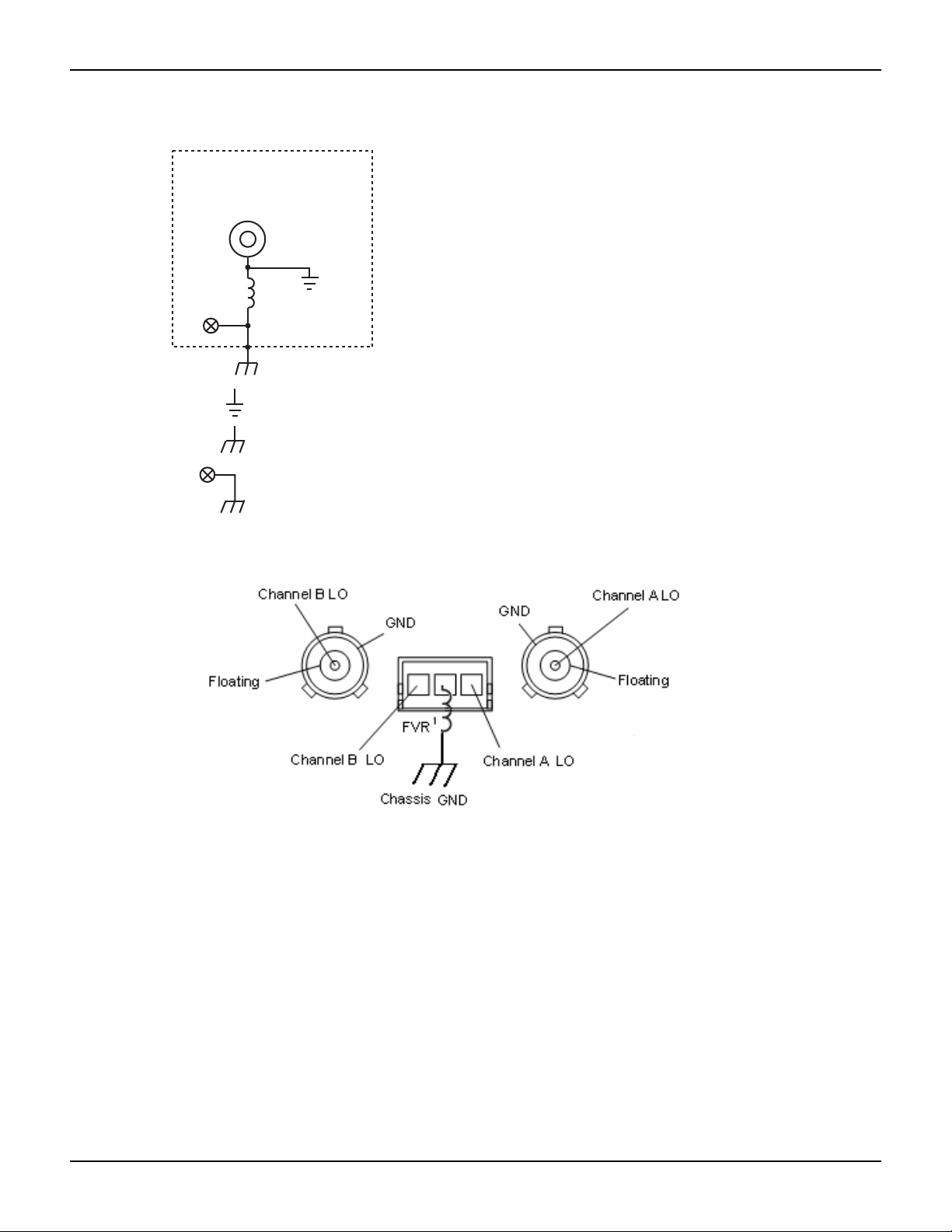

9. Ground / LO (Triax connector)

Channel A and Channel B low noise chassis ground triax connectors. Use only low-noise triax cables

such as the Keithley Model 7078-TRX. Connector terminals and associated triax cable connectors are

as follows:

Table 1-2

Triax connect or on ground module

Connector Center conductor Inner ring Outer ring

LO Output Lo Floating Chassis ground

Triax cable Center conductor Inner shield Outer shie ld

10. Ground / LO (Phoenix connector)

Channel A and Channel B low-noise chassis ground Phoenix connector.

11. LAN

Use this RJ-45 connector to connect the instrument to the local area network. The RJ-45 connector

connects a network card, a network switch, a router or a hub. When connecting directly to a PC, a

crossover cable (included) must be used. When connecting to a network switch, router, or hub, a normal

CAT-5 cable (not provided) should be used unless your equipment has Auto-MDIX capabilities. If it does

have Auto-MDIX, the crossover cables may be used.

1-8 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 23

Series 2600A System SourceMeter® Instruments User’s Manual Section 1: Front and Rear Panel Operation

What are the source-measure capabilities?

Model 2601A and Model 2602A

Basic DC source-measure capabilities for the Models 2601A and 2602A are listed in Table 1-3.

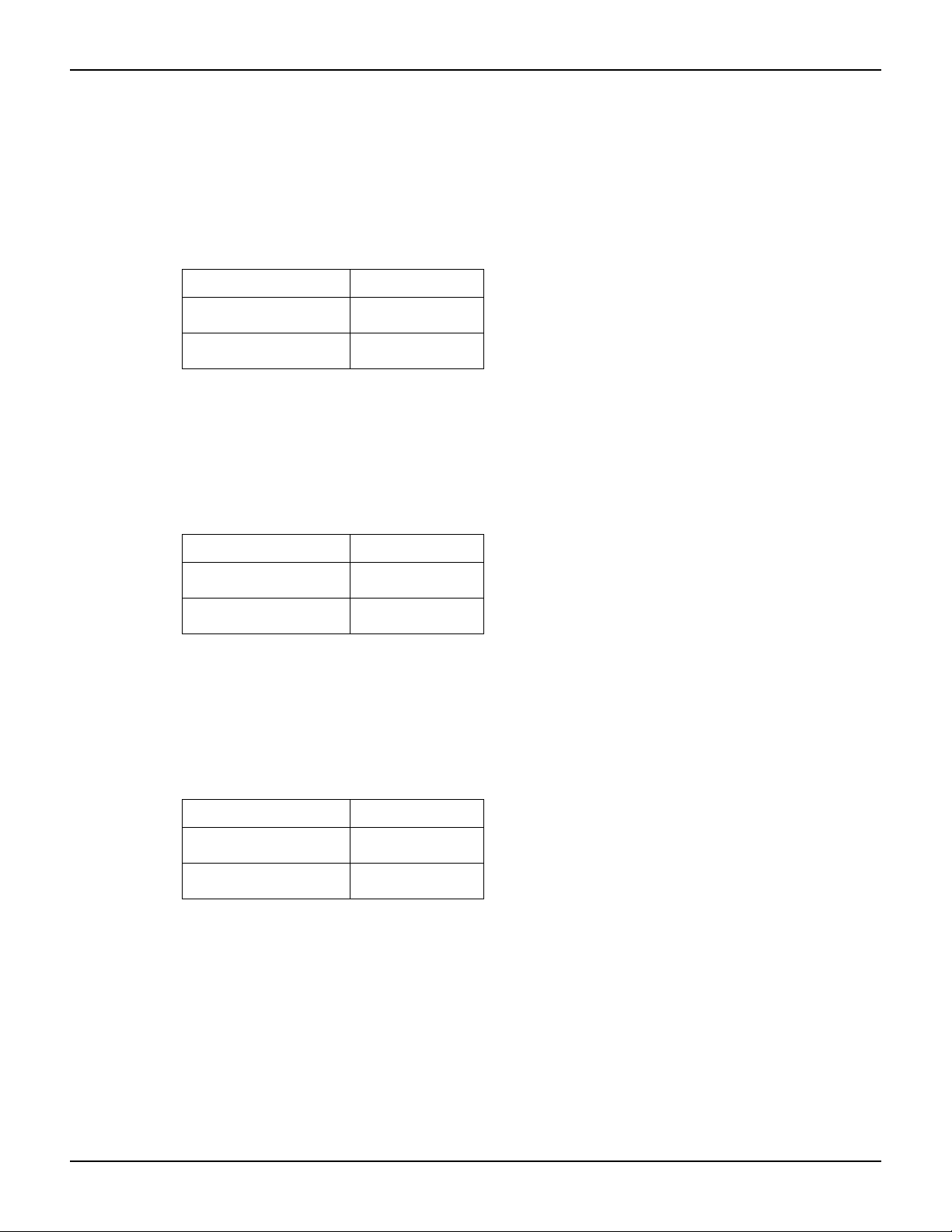

Table 1-3

Model 2601A and 2602A source-measure capabilities

Function Capabilities

Source ±DC voltage

Source ±DC current

Measure ±DC voltage

Measure ±DC current

1. 10A maximum available in pulse mode only.

Model 261 1A and Model 2612A

Basic DC source-measure capabilities for the Models 2611A and 2612A are listed in Table 1-4.

Table 1-4

Model 2611A and 2612A source-measure capabilities

1μV to 40.4V

1pA to 3.03A

1μV to 40.8V

1pA to 3.06A

1

1

Function Capabilities

Source ±DC voltage

Source ±DC current

Measure ±DC voltage

Measure ±DC current

1. 10A maximum available in pulse mode only.

1μV to 202V

1pA to 1.515A

1μV to 204V

1pA to 1.53A

Model 2635A and Model 2636A

Basic DC source-measure capabilities for the Models 2635A and 2636A are listed in Table 1-5.

Table 1-5

Model 2635A and 2636A source-measure capabilities

Function Capabilities

Source ±DC voltage

Source ±DC current

Measure ±DC voltage

Measure ±DC current

1μV to 202V

20fA to 1.515A

1μV to 204V

1fA to 1.53A

1

1

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 1-9

Page 24

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

How do I power-up the instrument?

Step 1: Connect to line power

CAUTION Operating the instrument on an incorrect line voltage may cause damage

to the instrument, possibly voiding the warranty.

1. Before you plug the power cord into the Series 2600A, make sure that the front panel powe r

switch is in the off (O) position.

2. Connect the female end of the supplied power cord to the AC receptacle on the rear panel.

Connect the other end of the power cord to a grounded AC outlet.

WARNING Failure to use a grounded outlet may result in personal injury or

death due to electric shock.

Step 2: T urn on power

Turn on the instrum ent by pressing the front panel power switch to the on (I) position. Assuming no

errors occur, the Series 2600A will power-up as follows:

1. The OUTPUT indicators and display pixels flash briefly.

2. The following items are shown in sequen ce :

• The firmware revision number.

• The line frequency.

• The TSP-Link node.

• The enabled command interface(s) and address (GPIB/LAN/RS-232).

Step 3: Set line frequency

The Series 2600A will operate at line frequencies of either 50Hz or 60Hz. For best measurement

noise performance, the unit should be con fig ur ed to match the actual line frequency used by

selecting MENU > LINE-FREQ > 50Hz, 60Hz, or AUTO (when set to AUTO, the SourceMeter will

automatically detect the power line frequency at power-up).

1-10 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 25

Series 2600A System SourceMeter® Instruments User’s Manual Section 1: Front and Rear Panel Operation

How do I make measurements?

See the Series 2600A Reference Manual for more information on the following:

• Basic source-measure procedure.

• Ohms measurements.

• Power measurements.

The measurement procedure below demonstrates how to set up the Series 2600A to source 10V

and measure current through a 10kΩ resistor.

WARNING Hazardous voltages may be present on the output and guard

terminals. To prevent electrical shock that could cause injury or

death, NEVER make or break connections to the Series 2600A

while the output is on. Power off the equipment from the front

panel or disconnect the main power cord from the rear of the

SourceMeter before handling cables connected to the outputs.

Putting the equipment into standby does not guarantee the outputs

are not powered if a hardware or software fault occurs.

Step 1: Connect the DUT

Connect a 10kΩ resistor to the SourceMeter Channel A HI and LO terminals as shown in

Figure 1-4. See the Series 2600A Reference Manual for complete connection information.

Step 2: Select source and set source level

Perform the following steps to select the voltage source and set the source value to 10V:

1. Press Channel A SRC to select the V-Source as indicated by the “V” units in the source

field on the display. The flashing cursor indicates which value is presently selected for

editing.

2. Press the up RANGE key, and select the 20V source range (Model 2611A/2612A/2635A/

2636A) or 40V source range (Model 2601A/2602A). Use the lowest possible source range

for best accuracy.

3. Use the CURSOR keys to move the cursor to the 10s digit, then press the navigation

wheel to enter the EDIT mode (EDIT indicator is displayed).

4. Using the navigation wheel, set the source value to 10.0000V, then press the ENTER key

or the navigation wheel.

Step 3: Set compliance limit

Perform the following steps to set the current compliance limit value to 10mA:

1. Put the Model 2602A/2612A/2636A in the single-channel display mode with the DISPLAY

key.

2. Press the LIMIT key, then press the ENTER key or the navigation wheel.

3. Move the cursor to the 10s digit, then press the navigation wheel to enter the EDIT mo de.

4. Using the navigation wheel, set the limit value to 10.000mA, then press the ENTER key or

the navigation wheel.

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 1-11

Page 26

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

Step 4: Select measurement function and range

1. Put the Model 2602A/2612A/2636A in the single-channel display mode with the DISPLAY

key, then select the current measurement function by pressing MEAS or MODE.

2. Select the measurement range with the RANGE keys. For the purposes of this example,

press AUTO RANGE, and note that the AUTO indicator is displayed. The instrument will

automatically select the best range based on the measured value. You can also use manual

ranging by pressing the up or down RANGE key, but be sure to use the lowest possible

range for best accuracy.

Step 5: T urn output on

Turn the output on by pressing the appropriate OUTPUT ON/OFF key. The

ON/OFF indicator LED will turn on when the channel output is on.

NOTE The Models 2611A, 2612A, 2635A, and 26 36A are equipped with a

safety interlock circuit that prevents operation on the 200V range if

the circuit is not energized. This circuit is illustrated in

to the Series 2600A Reference Manual for more information.

Figure 1-5. See

Step 6: Make measurements

1. Observe the readings on the display (press TRIG if necessary to trigger the unit to begin

taking readings). For the single-channel display mode, the readings will appear on the top

line, while source and limit values are on the bottom line. For the 10kΩ resistor under test,

typical display values are:

1.00000mA

SrcA: +10.0000 V LimA:010.0000mA

2. Use the DISPLAY key to cycle through the various display modes shown in Figure 1-6 (the

User State display messages are defined with specific display commands; see the Series

2600A Reference Manual for more information).

3. Press the MEAS key several times to display measured voltage, resistance, and power.

Typical values for the 10kΩ resistor are: 10.0000V, 10.0000kΩ, and 10.0000mW.

Step 7: T urn output off

When finished making measurements, turn the output off by pressing the OUTPUT ON/OFF key.

The OUTPUT indicator light will turn off.

1-12 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 27

Series 2600A System SourceMeter® Instruments User’s Manual Section 1: Front and Rear Panel Operation

FVR

Chassis

Series 2600A

Signal

Ground

Chassis

Signal Ground is a local signal ground and defined as

the Low-Noise Chassis Ground Banana Jack.

Chassis is defined as the metal chassis of the Series 2600.

1) Frequency Variable Resistor (FVR) Isolates

the SMUs from high frequencies on the chassis.

For DC to 60Hz, the FVR is a virtual short (zero

ohms).

2) DO NOT use the Chassis Screw terminal to

make signal connections to external circuitry.

High frequency (>1MHz) on the chassis may

result in higher noise at the output.

Chassis Screw terminal is connected to the metal chassis of the

Series 2600.

1

Chassis

Screw

2

Low-Noise

Chassis Ground

Banana Jack

Signal

Ground

Model 2636A

Figure 1-4

Model 2602A/2612A low-noise chassis ground banana jack and chassis screw

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 1-13

Page 28

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

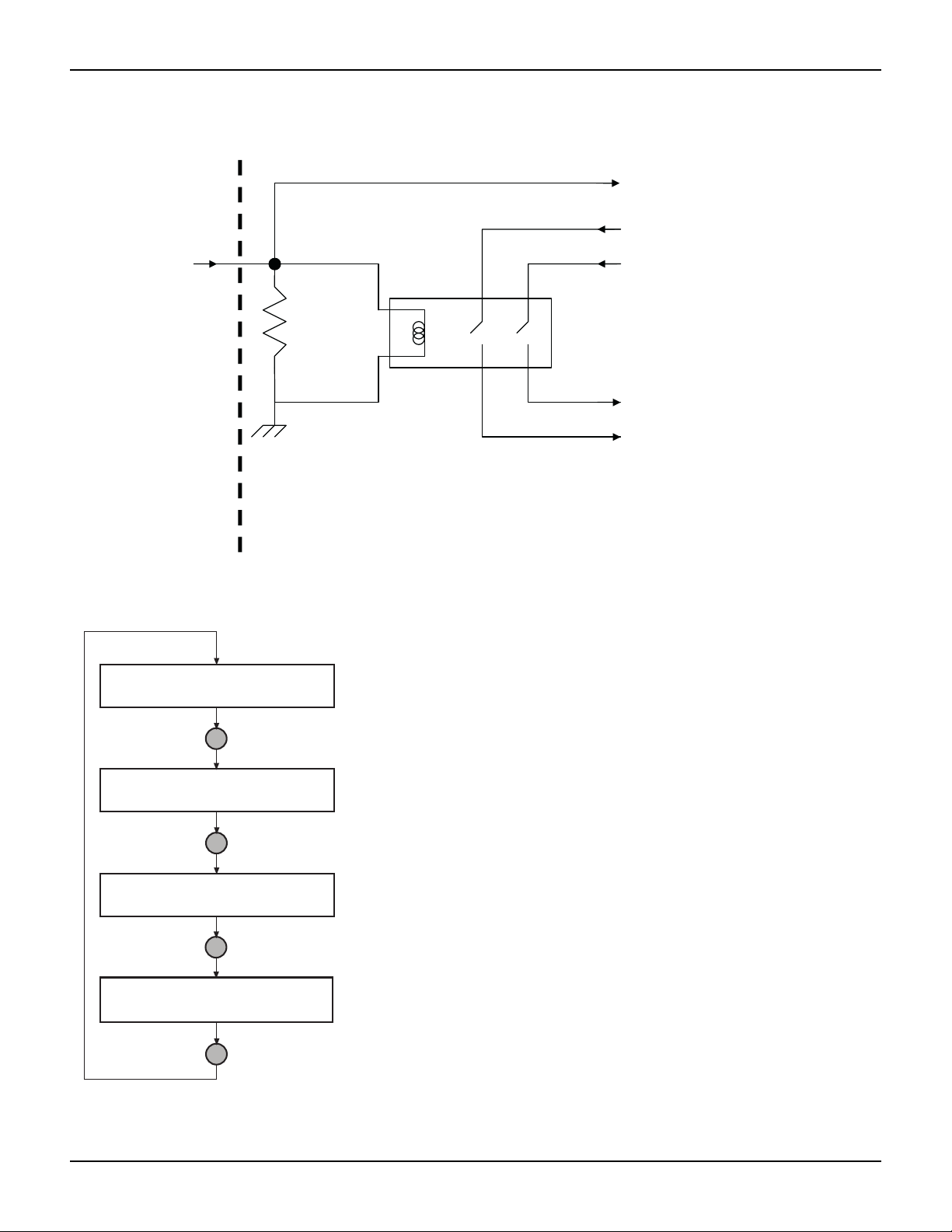

To output stage

10kW

Rear panel

Chassis ground

Coil resistance

145W +/- 10%

-220V supply

+220V supply

INTERLOCK pin

(on DIGITAL I/O connector)

Read by firmware

W

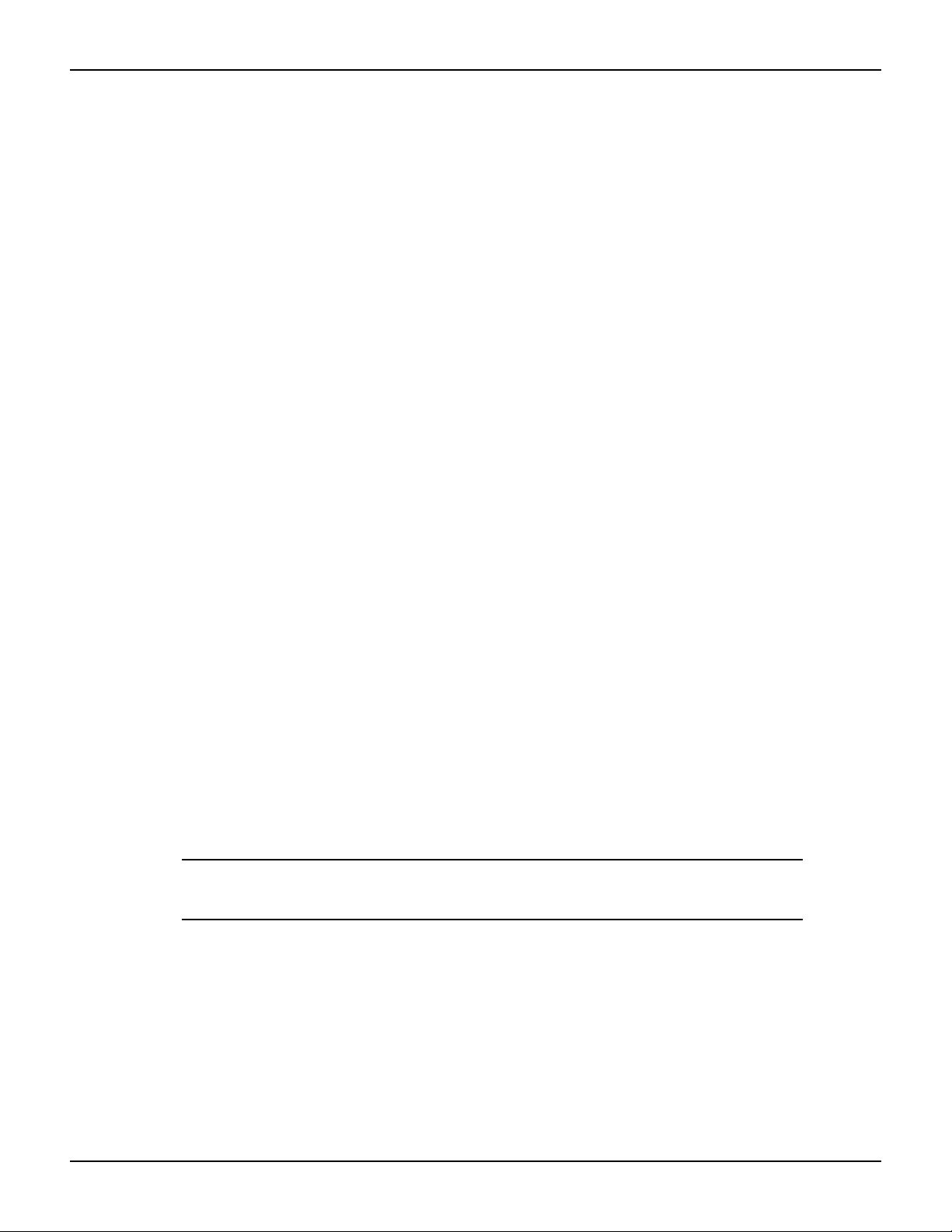

User State

1.00000mA . V

SrcA:+10.0000V SrcB:+000.000mV

1.00000mA

SrcA:+10.0000V LimA:10.0000mA

. V

SrcB:+000.000mV LimB:100.000mA

Press DISPLAY key

Press DISPLAY key

Press DISPLAY key

Press DISPLAY key

Source-Measure display for SMU A and SMU B:

Top line displays the measure function (V, A, W or W).

Bottom line displays the source function (V or A)

and level.

Source-Measure and Compliance Limit display for SMU A:

Top line displays the measure function (V, A, W or W)

Bottom line displays the source function (V or A) and level,

and the compliance limit (A or V).

Source-Measure and Compliance Limit display for SMU B:

Top line displays the measure function (V, A, W or W)

Bottom line displays the source function (V or A) and level,

and the compliance limit (A or V).

Display for user-defined messages and prompts.

Indicates that a measured reading has not been

triggered.

Figure 1-5

Interlock circuit

Figure 1-6

Display modes

1-14 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 29

Series 2600A System SourceMeter® Instruments User’s Manual Section 1: Front and Rear Panel Operation

How do I use the reading buffer?

The instrument has two dedicated reading buf fers per channe l that can store over 60,00 0 readings

with the time stamps and source values options enabled. Disable the time st amps and source

values options to store over 140,000 readings.

The following example shows how to store 100 readings, source values, and timestamps in

Channel A, Buffer 1 and recall them from the front panel.

Step 1: Connecting the device under test (DUT)

Connect a 10kΩ resistor to the Channel A HI and LO terminals (see Figure 1-4).

Step 2: Set up source and measure functions

Using the procedure described in How do I make measurements?, set up source and measure

functions:

• Source function: Volts.

• Source range: 20 V (2611A/2612A/2635A/2636A) or 40V (2601A/2602A).

• Source value: 10 V.

• Measure function: Current.

• Measure range: Auto.

Step 3: Configuring the reading buffer

Complete the following steps to configure reading buffers from the front panel:

1. Press CONFIG > STORE and then choose one of the following:

• CHANA-BUFF

• CHANB-BUFF

2. Select the DEST option and then choose one of the following :

• CHANX-BUFF1

• CHANX-BUFF2

• NONE

3. Select BUFFER1 or BUFFER2.

4. (Optional) To clear the buffer, turn the navigation wheel to select CLEAR > YES.

5. Turn the navigation wheel to select ELEMENTS.

NOTE You must clear the reading buffer before you enable or disable the

source value or the time stamp options.

6. (Optional) Push the navigation wheel to select TSTAMP, then select OFF or ON.

7. (Optional) Turn the navigation wheel to select SRC-VAL, then select OFF or ON.

8. Press the EXIT key to return to the main menu.

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 1-15

Page 30

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

NOTE Model 2601A/2611A/263 5A buffer configuration menu items are the

same as covered above except for channel selection.

Step 4: T urn on the output

Press the CHAN A (Model 2602A/2612A/2636A) OUTPUT ON/OFF key to turn on the source

output.

Step 5: Storing reading buffers

1. From the front panel, press STORE and then choose SAVE.

2. Select INTERNAL to save to internal nonvolatile memory.

3. Select one of the following:

• SMUA_BUFFER1

• SMUA_BUFFER2

• SMUB_BUFFER1

• SMUB_BUFFER2

4. The front panel displays Saving... This may take awhile.

5. Press the EXIT key to return to the main menu.

Step 6: T urn off the output

• Press the OUTPUT ON/OFF key to turn off the output after storage is completed.

Step 7: Recalling readings

1. Press the RECALL key to access buffer readings (repeatedly pressing RECALL will cycle

through Buffer 1 then Buffer 2 for Channel A and then Channel B). A message will be

displayed if a buffer is empty.

2. Note the buffer display data (see Figure 1-7):

•The buffer location number is on the right. For example, location #000001 indicates that

the displayed reading is stored at the first memory location.

•The source value is positioned at the lower left side of the display.

•The timestamp is positioned at the lower right side. The first source-measure reading

stored in the buffer (#000001) is time stamped at 00000.000000 seconds. Subsequent

readings are time stamped relative to when the time storage was started. The interval

between readings will depend on the reading rate.

3. To display the other readings stored in the buffer, choose the desired memory location

number:

•Use the navigation wheel to increment and decrement the selected digit of the location

number.

•Set the cursor position with the navigation wheel or CURSOR keys.

4. To exit from the data store recall mode, press EXIT.

1-16 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 31

Series 2600A System SourceMeter® Instruments User’s Manual Section 1: Front and Rear Panel Operation

1.00000 mA #0000001

SrcA1:+10.0000 V @00000.000000s

Use Knob

Use Knob

Use Knob

Buffer Location Number

Timestamp (seconds)

Reading

Source Value

1.00000 mA #0000002

SrcA1:+10.0000 V @00000.001000s

1.00000 mA #0000003

SrcA1:+10.0000 V @00000.002000s

1.00000 mA #0000004

SrcA1:+10.0000 V @00000.003000s

Note: Source values and timestamps

will be displayed only if enabled when

buffer is configured.

(SrcA1=

Chan. A,

Buffer 1)

Figure 1-7

Buffer display format

Saving the reading buffer to the USB flash drive

Complete the following steps to save the reading buffer data to a USB flash drive:

1. Insert the USB flash drive into the USB port.

2. Press STORE and use the navigation wheel to select SAVE > USB1.

3. Select one of the following file formats:

•CSV

•XML

4. Use the navigation wheel to select the desired reading buffer.

5. Use the navigation wheel to change the file name.

6. Push the navigation wheel or the ENTER key to save the file.

7. Push EXIT to return to the main menu.

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 1-17

Page 32

Section 1: Front and Rear Panel Operation Series 2600A System SourceMeter® Instruments User’s Manual

This page left blank intentionally.

1-18 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 33

Remote Operation

In this section:

Topic Page

How do I use the remote interface?................................................. 2-2

Connect to the interface ............................................................... 2-2

Configure the interface ................................................................. 2-2

Working with the web interface........................................................ 2-8

How to use the Virtual Front Panel............................................... 2-9

TSB embedded ............................................... ................................... 2-9

Issuing ICL commands ................................................................. 2-10

How do I use Test Script Builder?..................................................... 2-11

Run Test Script Builder ................................................................. 2-11

Open and close an instrument resource....................................... 2-13

Save and clear console window ................................................... 2-14

Select command and language reference views.......................... 2-14

How do I use TSB to make measurements?................................... 2-14

Reset instrument........................................................................... 2-15

Select source function and set output value................................. 2-15

Set compliance value and measure range ................................... 2-16

Turn on output............................................................................... 2-16

Make a measurement................................................................... 2-16

Print the result............................................................................... 2-16

Turn off output............................................................................... 2-16

Section 2

How do I use other programs? 2-17

Using LabVIEW ............................................................................ 2-17

Using Visual Basic........................................................................ 2-19

Page 34

Section 2: Remote Operation Series 2600A System SourceMeter® Instruments User’s Manual

GPIB Cable

Side View Side View

Connect one end of the cable to the host

PC and the other end to the SourceMeter.

Both cable connectors are identical.

Male DB-9 Connector

(connect to SourceMeter)

Pin View

Female DB-9 Connector

(connect to PC)

Pin View

Straight-through RS-232 Cable

How do I use the remote interface?

Connect to the interface

See Figure 1-2 for the locations of the GPIB (IEEE-488), RS-232, and LAN connectors, and make

connections as follows:

• GPIB: Use a shielded IEEE-488 cable such as the Keithley Instruments Model 7007 to

connect the Series 2600A IEEE-488 connector to the GPIB connector on the host PC (see

Figure 2-1).

• RS-232: Use a shielded 9-pin RS-232 cable like the Keithley Instruments Mod el 7009-5 to

connect the Series 2600A RS-232 connector to the serial port of the host PC

(see Figure 2-2).

• LAN: Use the crossover cable supplied with the Series 2600A to connect directly to the h ost

PC’s network card.

Figure 2-1

GPIB cable

Figure 2-2

RS-232 cable

Configure the interface

GPIB interface configuration

Set the primary address using the following procedure. The Series 2600A primary address must

be the same as that specified in your program, or the two devices will not be able to communicate.

1. Press MENU > GPIB and then press the ENTER key.

2. Select ADDRESS and then press the ENTER key. The Address screen is displayed.

2-2 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

3. Turn the navigation wheel to the right or to the left to select the desired number.

Page 35

Series 2600A System SourceMeter® Instruments User’s Manual Section 2: Remote Operation

4. Push the navigation wheel and then turn the navigation wheel to choose an address.

NOTE The GPIB address can range from 1-30.

5. Press the navigation wheel to set each digit.

6. Press the navigation wheel or the ENTER key to set the address.

7. Press EXIT to back out of the menu structure.

RS-232 interface configuration

Set RS-232 parameters as covered below. Before you can use the RS-232 interface to

communicate with the instrument, the serial port p ara meters for the host PC m ust match the seria l

parameters set on the instrument.

1. Press MENU to view the main menu.

2. Choose RS232, then press the ENTER key.

3. Choose the following options:

•Select BAUD and then choose the desired option.

• Choose BITS and then select the appropriate option.

•Select PARITY and then choose the desired option.

• Choose FLOW-CTRL and then select the appropriate option.

a. Use the navigation wheel to select ENABLE.

b. Select one of the following:

–ON

–OFF

6. Press EXIT to back out of the menu structure.

LAN interface configuration

Use the instructions below to configure the instrument's IP address based on the present IP

address of the host PC. Whenever there is an existing IP address configured for the network

interface card’s network settings, the IP address for the instruments on the Ethernet should also

be configured.

Step 1: Identify and record the PC's existing IP configuration Information

1. Open the command prompt to see the existing IP configuration information:

• In Windows 2000/XP:

a. Click the Start button and select Run.

b. Type cmd in the Open field and click OK.

• In Windows Vista:

a. Click the Start button.

b. Select All Programs.

c. Select Accessories.

d. Select Command Prompt.

2. At the command prompt, type ipconfig/all and click Enter (see Figure 2-3).

a. If the information for the Ethernet adapter displays Media Disconnected, then close

the command prompt and skip to Step 2:

IP address.

b. When the information is displayed, record the DHCP mode, IP address, subnet mask,

default gateway, and DNS servers.

Disable DHCP to use the computer's existing

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 2-3

Page 36

Section 2: Remote Operation Series 2600A System SourceMeter® Instruments User’s Manual

CAUTION The ipconfig/all command displays the configuration of all network

connections. Be sure to record the information for the proper network card.

Figure 2-3

Computer configuration using the command prompt

3. Verify DHCP or Static IP status.

• To determine the next step, check the DHCP Enabled setting in the IP configuration

screen or in the settings recorded earlier.

a. If DHCP Enabled = Yes, proceed to Step 2: Disable DHCP to use the computer's

existing IP address.

b. If DHCP Enabled = No, proceed to Step 3: Configure the Instrument's LAN settings.

NOTE When DHCP Enabled = Yes, the settings are assigned automatically

upon power up. However, if DHCP Enabled = No, the network will not

recognize the PC if the original settings are changed. If at any time

you are unsure how to proceed, contact your system administrator.

4. To exit the IP configuration screen, type exit at the command prompt and press ENTER.

2-4 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 37

Series 2600A System SourceMeter® Instruments User’s Manual Section 2: Remote Operation

Step 2: Disable DHCP to use the computer's existing IP address

NOTE Do not change the IP address at any time without talking to your

system administrator first. Entering an incorrect IP address can

prevent your PC from connecting to your corporate network.

1. Open the Internet Protocol Properties dialog box

• In Windows 2000:

a. Click the Start button, select Settings, and then open the Control Panel.

b. Open Network and Dial-up Connections.

c. Right-click Local Area Connection and select Properties. The Local Area

Connection Properties dialog box is displayed.

d. Double-click Internet Protocol (TCP/IP) in the items list. The Internet Protocol

(TCP/IP) Properties dialog box is displayed (see Figure 2-4).

• In Windows XP:

a. Click the Start button and open the Control Panel.

b. Open Network Connections.

c. Right-click Local Area Connection and select Properties. The Local Area

Connection Properties dialog box is displayed.

d. Double-click Internet Protocol (TCP/IP) in the items list. The Internet Protocol

(TCP/IP) Properties dialog box is displayed (see Figure 2-4).

• In Windows Vista:

a. Click the Start button and open the Control Panel.

b. Open Network & Sharing Center.

c. In the list, click View Status next to Connection. The Wireless Network Connection

Status dialog box is displayed.

d. Click Properties. Windows displays a permissions message.

e. If you are logged in as administrator, click Continue. If you are not logged in as

administrator, enter the administrator's password to continue.

f. The Network Connection Properties dialog box is displayed.

g. Double-click Internet Protocol Version 6 (TCP/IPv6) in the items list. The Internet

Protocol Version 6 ( TCP/IPv6) Properties dialog box is displayed (see

Figure 2-4).

2. Select Use the following IP address. The option for Use the following DNS server

addresses is automatically selected.

3. Set the IP Address

a. Are the IP address and subnet mask fields populated?

• Yes: If populated, record the address, subnet mask, default gateway, and DNS

servers to use in Step 3:

Configure the Instrument's LAN settings.

• No: If blank, enter the IP address 192.168.0.3 in the IP address field and

255.255.255.0 in the subnet mask field. These will be used to configure the

instrument’s LAN settings.

b. After recording or entering the IP address, click OK to close the Internet Protocol

(TCP/IP) Properties dialog box.

4. Close the Network Connections window.

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 2-5

Page 38

Section 2: Remote Operation Series 2600A System SourceMeter® Instruments User’s Manual

Figure 2-4

Internet protocol (TCP/IP) properties dialog box

Step 3: Configure the Instrument's LAN settings

To configure the Series 2600A using the front panel:

1. Press the MENU key to display the MAIN MENU. Use the navigation wheel to select LAN

to display the LAN MENU.

2. Change the IP address assignment method:

a. Select CONFIG > METHOD > MANUAL, then press the ENTER key.

b. Press the EXIT key once to return to the LAN MENU.

c. Select APPLY_SETTINGS > YES, then press the ENTER key.

3. Enter the IP address using the LAN MENU:

a. Select CONFIG > IP-ADDRESS.

b. Refer to the recorded computer's IP address. A portion of the computer's IP address will

be used as a base for the instrument's unique ID. Only the last three numbers (after the

last decimal point) will be different between the PC and instrument. The last three digit s

may be anything from 1-255 for a subnet mask of 255.255.255.0.

For example, the Internet Protocol (TCP/IP) Properties dialog box in Figure 2-3 shows

that the computer's IP address is 192.168.1.1. A unique address for the instrument is

192.168.001.101.

2-6 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 39

Series 2600A System SourceMeter® Instruments User’s Manual Section 2: Remote Operation

NOTE The instrument’s IP address can have leading zeros, but the

computer ’s cannot.

c. Use the navigation wheel to select and enter an appropriate IP address for th e

instrument. Be sure to record the instrument’s IP address to use in Step 5:

Access the

instrument's internal web page.

d. Push the ENTER key or navigation wheel to confirm the changes.

e. Press the EXIT key to return to the LAN MENU.

f. From the LAN MENU, select APPLY_SETTINGS > YES, then press the ENTER key.

4. Change the subnet mask from within the LAN MENU:

a. Select CONFIG > SUBNETMASK, then press the ENTER key. The SUBNETMASK

menu item is to the right of GATEWAY. Use the navigation wheel to scroll through the

options.

b. Modify the SUBNETMASK to match the PC settings recorded earlier or

255.255.255.000 if DHCP Enabled = YES.

c. Push the ENTER key or the navigation wheel when finished changing all the

characters.

d. Press the EXIT key to return to the LAN MENU.

e. From the LAN MENU, select APPLY_SETTINGS > YES, then press the ENTER key.

NOTE APPLY_SETTINGS must be used before changes to the IP address

or subnet mask are applied.

Step 4: Connect the crossover cable from the instrument to the PC network interface card

Connect the supplied crossover cable between the computer's NIC card and the Ethernet

connector on the instrument’s rear pane l. Ther e are multiple connectors on the Series 2600A rear

panel. Be sure to connect to the LAN connection port (see

Figure 2-5).

NOTE Connect the crossover cable into the same PC Ethernet port that was

used during the configuration of the instrument. This will ensure that

the system is using the correct network card.

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 2-7

Page 40

Section 2: Remote Operation Series 2600A System SourceMeter® Instruments User’s Manual

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

MADE IN

U.S.A.

IEEE-488

LINE RATING

100-240VAC

50, 60Hz

240VA MAX.

DIGITAL I/O

RS-232

LINE FUSE

SLOWBLOW

3.15A, 250V

TSP-Link

R

SENSE

LO LO HI

CHANNEL A

SENSE

HI

GUARD

A LO

LAN

NO AUTO-MDIX

SENSE

LO

LOHI

CHANNEL B

SENSE

HI

GUARD

!

Model 2636A

LAN connection port

Figure 2-5

LAN connection

Step 5: Access the instrument's internal web page

1. Open a web browser on the host PC.

2. Enter the instrument’s IP address in the browser's address box. For example, if the

instrument's IP address is 192.168.0.3, enter 192.168.0.3 in the browser's address box.

3. Press ENTER on the PC keyboard to open the instrument’s web page.

Working with the web interface

The Series 2600A has a web interface (see Figure 2-6) that you can use to remotely access the following:

• Connection string

• LXI class

• Firmware version number

• MAC address

• Instrument model

• Connection string

• Virtual front panel

• TSB embedded

• TSP Express

2-8 Return to Section Topics 2600AS-900-01 Rev. B / September 2008

Page 41

Series 2600A System SourceMeter® Instruments User’s Manual Section 2: Remote Operation

Figure 2-6

Web in terface

How to use the Virtual Front Panel

You can use the virtual front panel to access the features available from the front panel of the

Series 2600A. The same front panel features and functions are available from the Virtual Front

Panel with the exception of the POWER button.

TSP Express

TSP Express is a built-in utility that easily creates scripts for Series 2600A instruments (SMU). It

provides a menu of choices for building new test scripts as well as options for opening existing

projects and scripts. It also allows the user to view or change instrument configur ations. TSP

Express may be launched using a web link from any Series 2600A instrument or by using a

shortcut on the host PC.

TSB embedded

TSB embedded is an alternative to a full version of T est Script Builder (TSB) Suite. The cap abilities

of TSB embedded are very similar to TSB. TSB embedd ed includes a co mmand line interface that

you can use to issue ICL commands, create, modify, and save test scripts to the instrument.

2600AS-900-01 Rev. B / September 2008 Return to Section Topics 2-9

Page 42

Section 2: Remote Operation Series 2600A System SourceMeter® Instruments User’s Manual