Page 1

Instruction Manual

Model 169

Digital Multimeter

01979, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A

Document Number 30161

Page 2

TABLE OF CONTENTS

SECTION

1.

GENERAL INFORMATION.

1.1.

INTROOUCTION

1.3.

FEATURES .......................... l-1

1-5.

WARRANTY INFDKMATION ....................

l-7.

CHANGE NOTICES

1-9.

SAFETY SYMBOLS

l-11. SPECIFICATIONS

2.

OPERATION.

2-l. INTRODUCTION

2-3.

2-5.

2-6.

2-7.

2-8.

2-10. Front Panel Switches

2-12. Input Connections.

2-14. Tilt Bail/Handle

2-16. INITIAL FUNCTIONAL CHECK

2-18. OPERATING INSTRUCTIONS

2-20. DC VOLTAGE MEASUREMENT

2-22. AC VOLTAGE MEASUKEMENT

2-24. AC OR DC CUKRENT MEASUREMENT

2-26. RESISTANCE (n) MEASUREMENT

3.

PERFORWINCE VERIFICATION

3-1.

3.3.

3-5. ENVIRONMENTAL CONDITIONS .................. 3-l

3-7.

3-9. Initial Conditions

3-11. DC Volts Checkout.

3-12. AC Volts Checkout.

3-13. Resistance Checkout.

3-14. DC Current Checkout.

3-15. ANALYSIS

4.

ACCESSORIES.

4-1.

4-3.

4-5.

4-7.

4-9.

4-11.

4-13. MODEL 1684 CARRYING CASE

4-15. MODEL 1635 CLAMP-ON AC CURRENT PROBE

4-17. MODEL

4-19.

4-21. MODELS

............................ 2-l

UNPACKING AND INSPECTION .................. 2-l

PREPARATION FOR USE. .................... 2-l

Installation of Batteries, if required ........... 2-1

CONTROLS, INDICATORS AND CONNECTORS. ............

Display ........................... 2-1

GENERAL ........................... 3-l

RECOMMENDED TEST EQUIPMENT ................. 3-1

PERFORMANCE VERIFICATION PROCEDURE ............. 3-1

...........................

GENERAL ........................... 4-l

MODEL

1600

MODEL

1651

MODEL 1681 CLIP-ON TEST LEAD SET .............. 4-l

MODEL 1682 RF PROBE. ....................

MODEL 1683 UNIVERSAL TEST LEAD KIT

1691

MODEL

1699

1010

.......................

........................

.......................

.......................

.......................

........................

.................... 2-2

.....................

......................

..................

...................

...................

...................

................

.................

.....................

.....................

..................... 3-2

.....................

.................... 3-3

....................

..........................

HIGH VOLTAGE PROBE. ............... 4-l

50-AMPERE SHUNT ................. 4-1

............. 4-2

..................

............ 4-2

GENERAL PURPOSE TEST LEAD SET

SPARE PARTS KIT

and 1017 RACK MOUNTING KITS.

................. 4-2

.......... 4-2

.......... 4-2

PAGE

l-l

1-l

1-2

1-2

l-2

1-2

2-l

2-l

2-2

2-4

2-4

2-4

2-5

2-5

2-5

2-6

3-l

3-2

3-2

3-3

3-3

4-l

4-1

4-2

5.

THEORY OF OPERATION.

5-l.

GENERAL.

5-3.

OVERALL OPERATION.

5-6.

SIGNAL CONDITIONING.

5-7.

AC/DC Voltage Measurements

5-10.

AC/DC Current Measurements

5-12.

Resistance Measurements.

5-14.

A/D CONVERTER.

ii

I

.......................

................

.............

...........

..........

.......

.......

........

........

........ 5-l

........ 5-l

........

........ 5-I

........ 5-2

........ 5-2

6-l

5-l

5-I

i i

Page 3

TABLE OF CONTENTS (Cont'd)

SECTION

5-16. DISPLAY CIRCUITS

5-18. REFERENCE SOURCE

5-20. LOW BATTERY DETECTOR

5-22. INPUT PROTECTION

5-24. Voltage Protection

5-27. Current Protection

5-29. Ohms Protection.

6. MAINTENANCE.

GENERAL ...........................

6-1.

CALIBRATION. ........................

6-3.

Recormended Calibration Equipment.

6-5.

Environmental Conditions

6-7.

Case Cover Removal

6-9.

6-11. Calibration Adjustment

6-14. TROURLESHOOTING.

6-16. Special tiandling of Static Sensitive Devices

6-18. Power supply

6-20. A/D Converter and Display Driver

6-22. AC Converter

6-24. Voltage Divider, Reference Source and Ohms Circuit

b-26. Current Circuitry.

6-31. LIQUID CRYSTAL DISPLAY REPLACEMENT

6-33. BATTERY REPLACEMENT.

6.35. CURRENT FUSE REPLACEMENT

7. REPLACEABLE PARTS.

GENERAL ...........................

7-I.

ORDERING INFORMATION

7-3.

FACTORY SERVICE.

J-5.

SCHEMATIC. .........................

7-J.

COMPONENTS LAYOUT.

7-9.

J-11.

MODEL

...........................

1699

......................

......................

....................

......................

.....................

.....................

......................

.....................

...................

......................

........................

........................

.....................

....................

........................

....................

......................

.....................

SPARE PARTS KIT

.............

..................

..............

.............

..................

.................

........

.....

PAGE

5-2

5-3

5-3

5-3

5-3

5-3

5-3

6-1

6-l

6-l

h-l

h-l

6-1

6-I

6-2

6-2

6-3

6-3

h-3

6-3

6-3

6-4

6-9

6-9

7-D

7-o

7-D

7-O

7-O

7-D

7-O

FIGURE

l-l

2-l

2-2

2-3

4-l

4-2

4-3

4-4

5-I

5-2

5-3

5-4

6-1

6-2

6-3

6-4

6-5

7-l

ILLUSTRATIONS

TITLE JhGJ

Model lG9.

Installation of Batteries.

Model 169 Front Panel Display.

Operating Controls

High Voltage Probe and RF Probe.

Current Probe and Current Shunt.

Convenience Cable and Connectors

Carrying Case and Hack Mounting Kits

Model 169 DMM Overall Signal Flow Block IDiagram.

Simplified AC/DC Voltage Measurement

Simplified AC/DC Current Measurement

Simplified Resistance Measurement.

Calibration Adjustment Location.

LCD Assembly

Integrator Waveform.

AC/DC Converter Waveform

Current Fuse Removal/Replacement

Covers and Panels.

.......................

...............

.............

...................

............

............

............

..........

..........

..........

...........

............

......................

..................

................

............

...................

.... 5-5

I-1

2-o

2-O

2-3

4.2

4.3

4.3

4.4

5-6

5-J

5-8

6-2

6-4

6-6

6-J

6-9

7-4

Page 4

Page 5

MOOEL 169

GENERAL INFORMATION

SECTION 1. GENERAL INFORMATION

l-l.

INTRODUCTION.

The Model 169 is a rugged, low cost, battery-

l-2.

operated digital multimeter that provides full

measurement capability for many general purpose

applications.

IOOuVldigit to 1OOOV on five dc and five ac voltage

ranges, lOOnA/digit to 2000mA (2 amperes) on five dc

and five ac current ranges, and lOIlmn/digit to 20

megohms on six resistance ranges. Ranges and

~ccurxy are listed in the Table of Specifications

on page 1-3.

FEATURES.

l-3.

The Model 169 incorporates features that help

l-4.

prevent instrument damage through customer abuse and

provide maximum instrument reliability, operator

safety and simplicity of operation.

features are:

A ZOOO-count (3-l/2 digit) liquid crystal dis-

e

play (LCD) with large 0.6" numerals, function

and range annunicators, and a low battery indi-

It provides dccurate readings from

Some of these

cator (BAT).

minus sign (-) are also displayed, positive

polarity is implied.

l

The Model 169 is built rugged. The full benchsire cdse is molded from impact-resistant dnd

flame-retardant plastic.

tection prevents damage on all

Voltage ranges dre protected up to 1400V peak,

resistance ranges to 300VRMS and current ranges

dre protected by dn externally accessible 2A

(25OV) fuse.

0 Pushbutton switches dre color coded to the

front panel for quick and edsy selection of

function and range. The decimal point is dutomatically positioned by the rdngc pushbutton.

Annunciators on the display

selected function and range.

and function combinations are indicated by

contradicting function and/or range d""u"cidtars appearing dt the sdme time.

Appropriate decimal point and

Effective input pro-

functions.

Indicate

Improper range

the

FIGURE l-l. Model

169.

l-l

Page 6

GENERAL INFORMATION

The latest LSI technology and stable precision

l

components have been used in the Model 169 to

provide long term accuracy and minimize main-

tenance.

required, once a year. If alkaline batteries

are used, battery life can be the same as the

calibration cycle.

an MTRF of up to 20,000 hours can be expected.

Only one calibration adjustment is

Barring destructive misuse,

MODEL

l-l.

CHANGE NOTICES.

l-8.

which occur after printing of the Instruction Manual

will be explained on a Change Notice sheet attached

to the inside back cover.

l-9.

Improvements or changes to the instrument

SAFETY SYMBOLS.

169

Automatic zeroinq, automatic polarity and only

l

two input terminals simplify operation by

eliminating potentiometer zeroing and lead

changing.

Optional accessories can be ordered to extend

l

the measurement capability of your Model

Some of these are:

High Voltage Probe allows your DMM to measure

from 1000V to 40kV dc.

High Frequency (RF) Probe allows your DMM to

measure from 0.25V to 30V rms ac over a frequency range of IOOkHZ to IOOMHZ.

Clamp-On AC Current Probe allows your DMM to

measure from zero to 200A rms ac.

50.Ampere Current Shunt allows your IXIM to

neasure from zero to 50A. ac and dc.

NOTE

Refer to Section 4 for more detailed

information on accessories.

l-5.

WARRANTY INFORMATION.

169.

l-10.

follows:

l-11.

1-12.

given in Table I-I.

Safety symbols used in this manual we as

IMPORTANT

The A symbol can be found in various

places in this manual. Carefully read the

associated CAUTION statements with regard

to proper use and handling of the instrument. Damage to the instrument may occur

if these precautions are ignored.

This

places in this manual. This svmbal indicates those areas on the instrument which

are potential shock hazards. Carefully

read the associated WARNING statements

with regard to proper use and handling of

the instrument. Serious personal injury

result if

w

ignored.

SPECIFICATIONS.

Detailed specifications for the Model 169 are

symbol can be found in various

these precautions are

l-6.

cover of this Instruction Manual.

need to exercise the warranty, contact the Keithley

Representative in your area to determine the proper

action to be taken.

facilities in the United Kingdom and West Germany,

as well as in the United States.

front cover of this manual for addresses.

1-2

The warranty is given on the inside front

If there is a

Keithley maintains service

Check the inside

Page 7

MODEL 169

GENERAL INFORMATION

TABLE 1-1.

Specifications

Mode

1169

MAXIM”M ALLOWABLE INPUT: 10”“” ims. ,400” prak.

,“*“.Hr. cO”ti”“o”S except 2”“m” range: 35”” m”,i”uuLkr. 15

sec. rndXirnUnl above 35”“.

1-3

Page 8

BATTERY

ADJUSTMENT

RlO,

l-

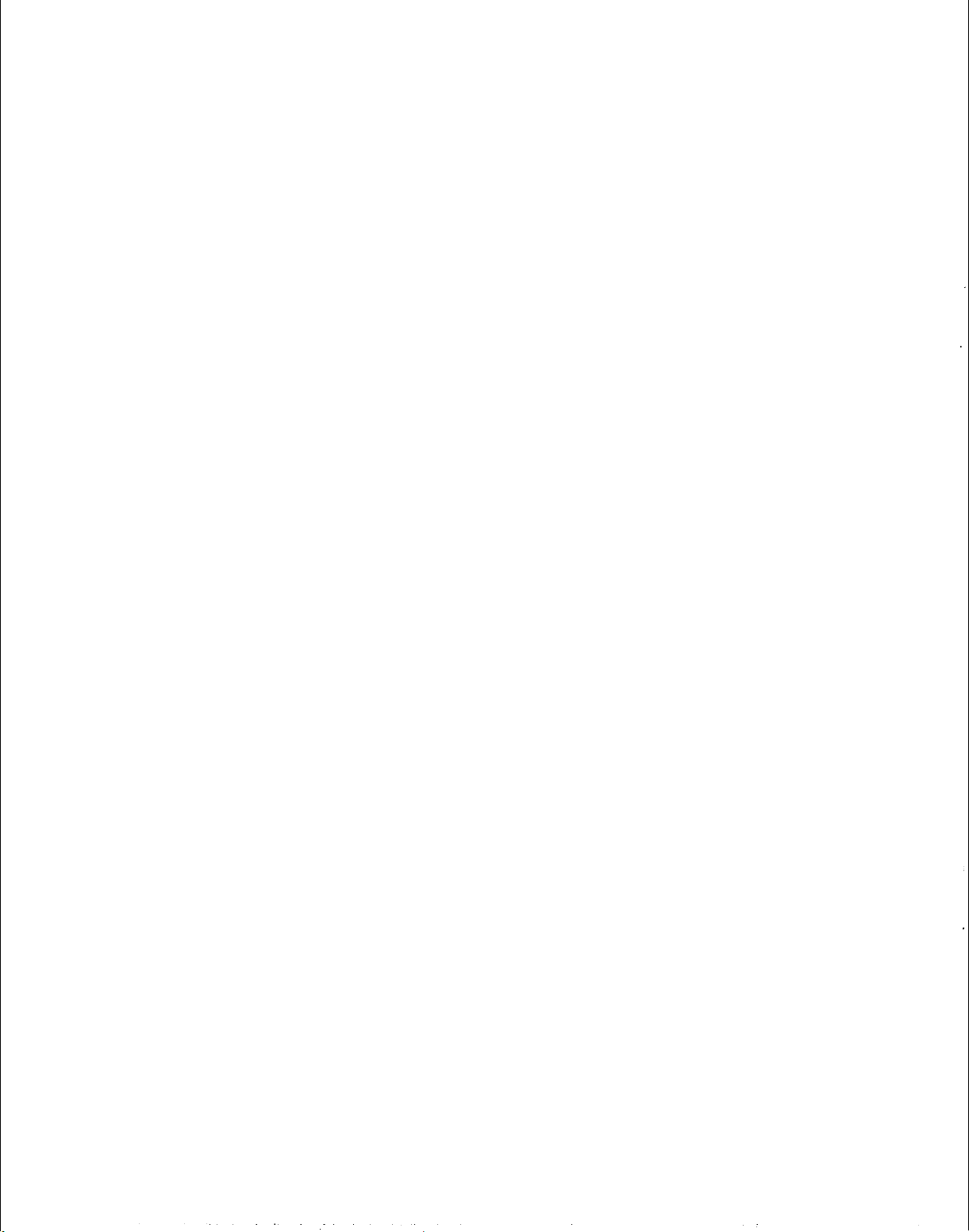

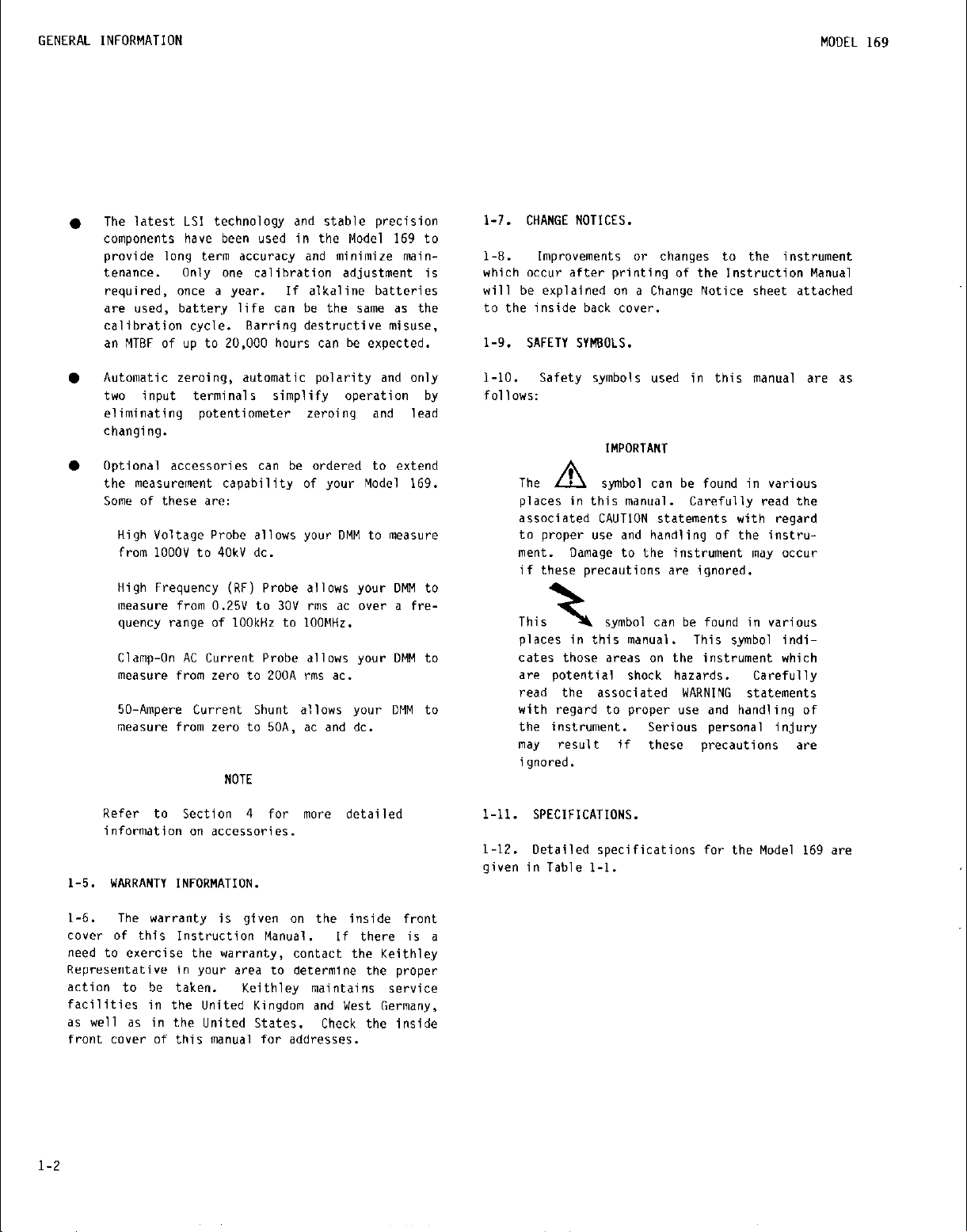

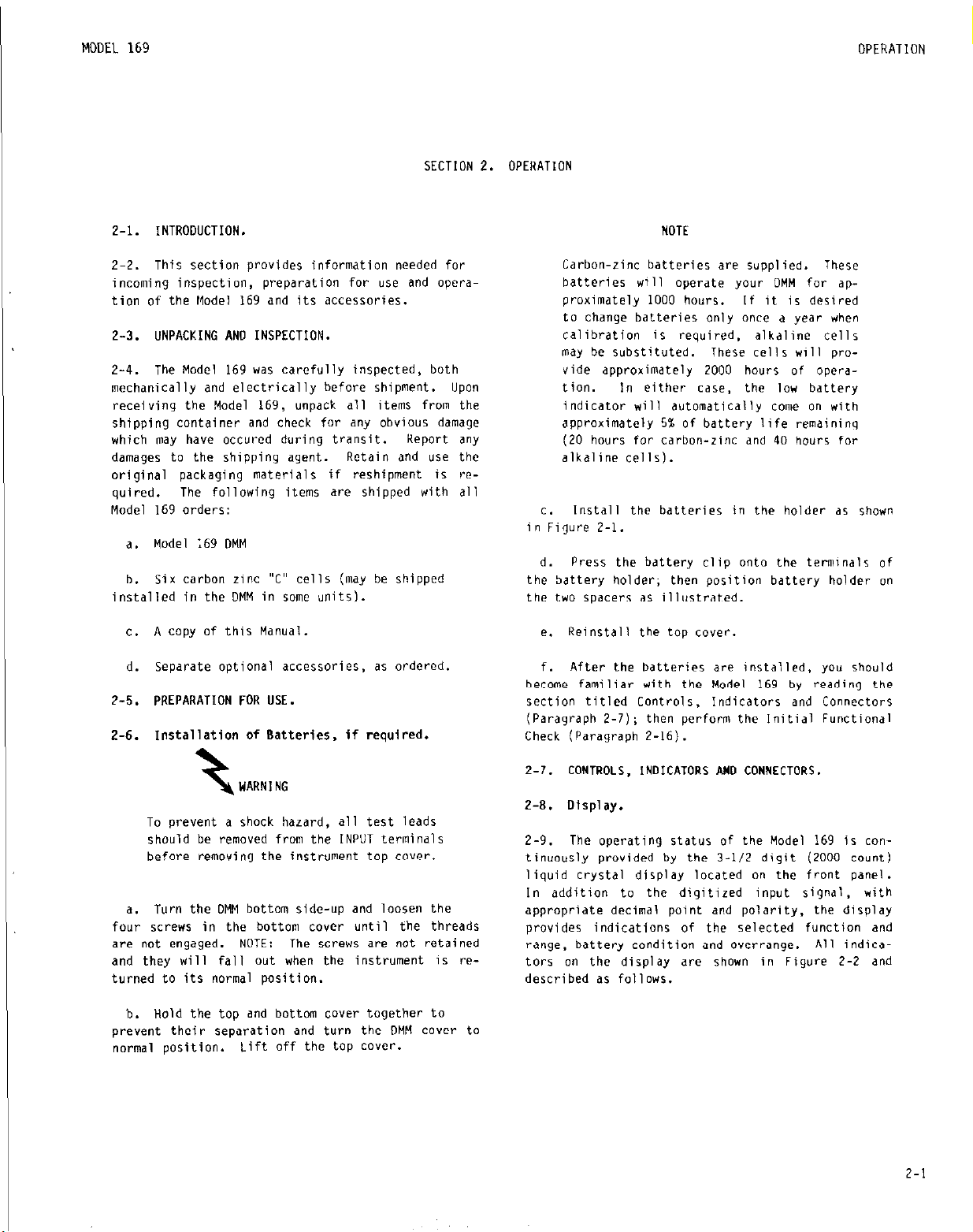

FIGURE 2-1.

NEGATIVE

DISPLAYED,

POSITIVE

IWLIED WHEN LW

MINUS l-1 CFF

AC DIPLAYEO,

DC IWLIE"

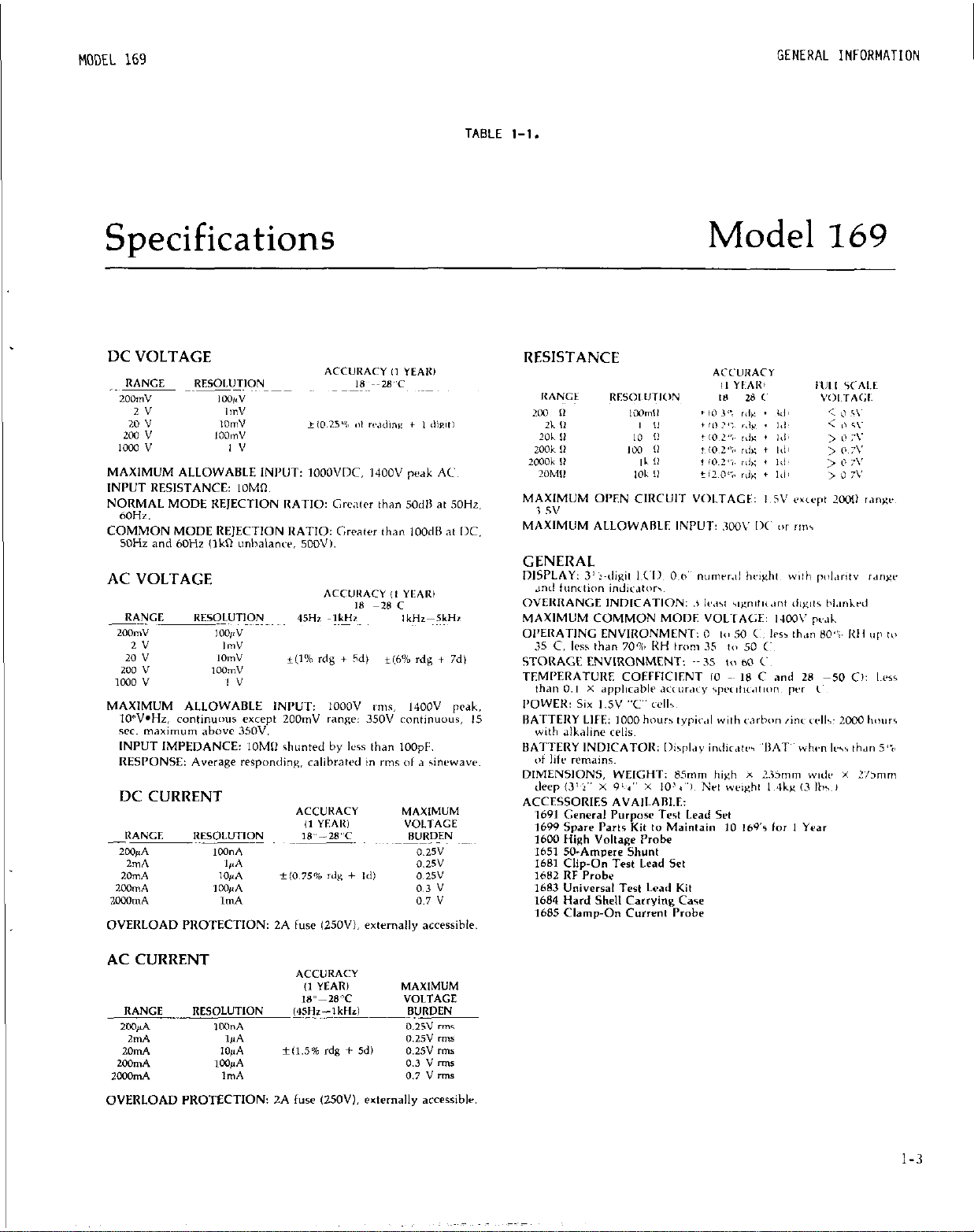

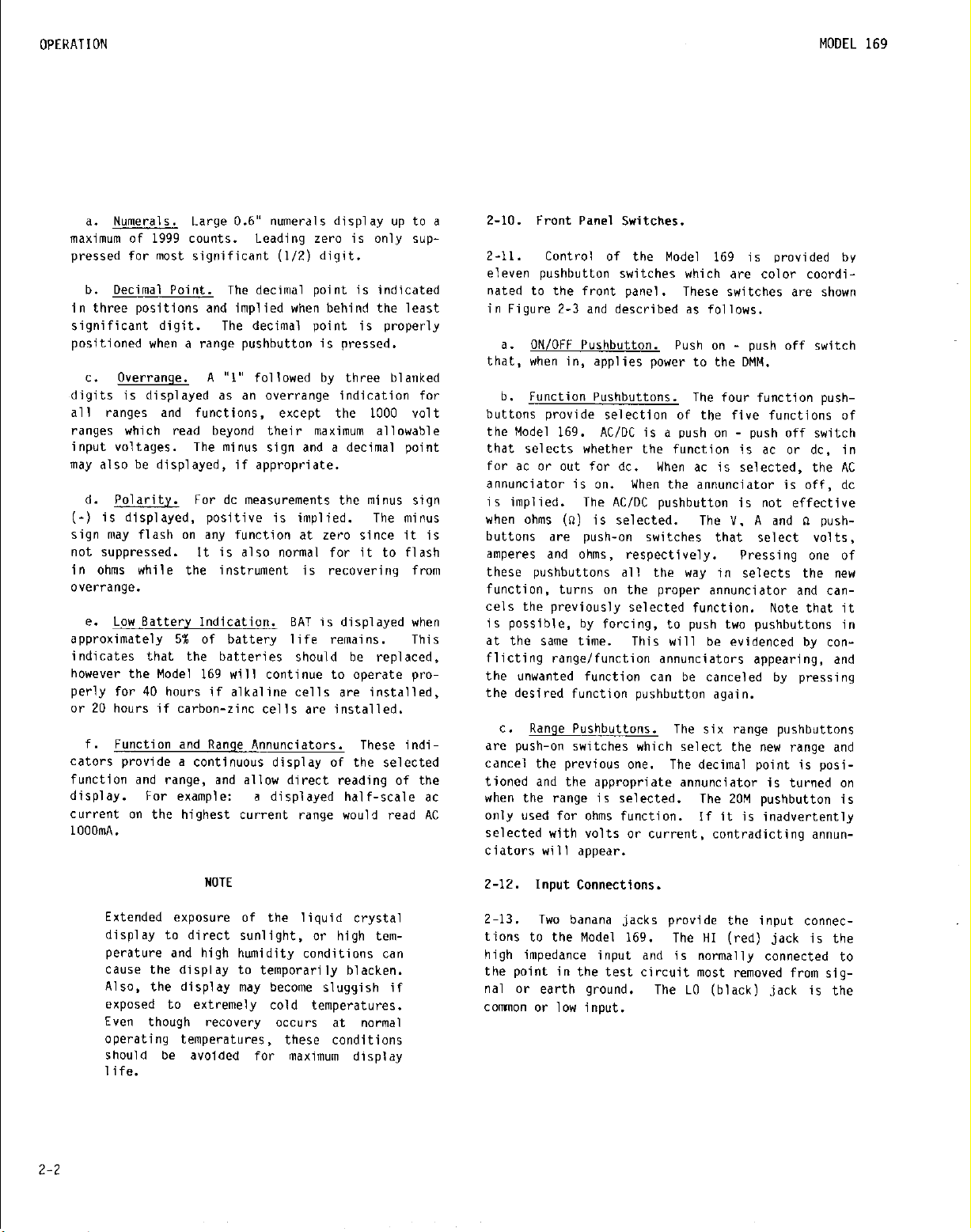

FIGURE 2-2.

BATTERY

I

3-l/2 DIGITS

WITH DECIMAL

-__

Installation of Batteries.

MILLI (10-3)

MICRO I 10-6)

I

POINT

Model 169 Front Panel Display.

2-O

Page 9

I

MODEL 169

SECTION 2. OPERATION

OPERATION

2-1. INTRODUCTION,

2-2. This section provides information needed for

incoming inspection, preparation for use and operation of the Model 169 and its accessories.

2-3. UNPACKING AN0 INSPECTION.

2-4. The Model 169 was carefully inspected, both

mechanically and electrically before shipment. Upon

receiving the Model 169, unpack all items from the

shipping container and check for any obvious damage

which (may have occured during transit.

damages to the shipping agent. Retain and use the

original packaging materials if reshipment is re-

quired.

Model 169 orders:

a. Model 169 DMM

b. six carbon zinc "C' cells (may be shipped

installed in the DMM in some units).

c.

d.

2-5.

2-6.

The following items are shipped with all

A copy of this Manual.

Separate optional accessories, as ordered.

PREPARATION FOK USE.

Installation of Batteries, if required.

neport any

NOTE

Carbon-zinc batteries are supplied. These

batteries will operate your DMM for approximately 1000 hours. If it is desired

to change batteries only once a year when

calibration is required, alkaline cells

may be substituted. These cells will pro-

vide approximately 2000 hours of opera-

tion.

indicator will automatically come on with

approximately 5% of battery life remaining

(20 hours for carbon-zinc and 40 hours for

alkaline cells).

t. Install the batteries in the holder ds shown

in Figure 2-1.

d. Press the battery clip onto the terminals of

the battery holder; then position battery holder on

the two spacers as illustrated.

e. Reinstall the top cover.

f. After the batteries are installed. you should

become familiar with the Model I69 by reading the

section titled Controls, Indicators and Connectors

(Paragraph Z-7); then perform the Initial Functional

Check (Paragraph Z-16).

In either case,

the low battery

WARNING

3

To prevent a shock hazard, all test leads

should be removed from the INPUT terminals

before removing the instrument top cover.

a. Turn the DMM bottom side-up and loosen the

four screws in the bottom cover until the threads

are not engaged.

and they will fall out when the instrument is returned to its normal position.

b. Hold the top and bottom ‘over together to

prevent their separation and turn the DMM cover to

normal position.

NOTE: The scrws are not retained

Lift off the top cover.

2-7.

CONTROLS, INDICATORS AND CONNECTORS.

2-B.

Display.

2-9. The operating status of the Model 169 is continuously provided by the 3-l/2 digit (2000 count)

liquid crystal display located on the front panel.

In addition to the digitized input signal, with

appropriate decimal point and polarity, the display

provides indications of the selected function and

range, battery condition and overrange. All indicators on the display are shown in Figure 2-2 and

described as follows.

2-1

Page 10

OPERATION

MODEL 169

a. Numerals.

maximum of 1999 counts.

pressed for most significant (l/Z) digit.

b. Decimal Point. The decimal point is indicated

in three positions and implied when behind the least

significant digit. The decimal point is properly

positioned when a range pushbutton is pressed.

C. Overrange. A "1" followed by three blanked

digits is displayed as an overrange indication for

all ranges and functions, except the 1000 volt

ranges which read beyond their maximum allowable

input voltages. The minus sign and a decimal point

may also be displayed, if appropriate.

d. Polarity. For dc measurements the minus sign

(-) is displayed, positive is implied. The minus

sign may flash on any function at zero since it is

not suppressed. It is also normal for it to flash

in ohms while the instrument is recovering from

overrange.

e. Low Battery Indication. BAT is displayed when

approximately 5% of battery life remains.

indicates that the batteries should be replaced,

however the Model 169 will continue to operate properly for 40 hours if alkaline cells are installed,

or 20 hours if carbon-zinc cells are installed.

f. Function and Range Annunciators.

cators provide a continuous display of the selected

funCtiOn and range, and allow direct reading of the

display. For example:

current on the highest current range would read AC

IOOOmA.

Large 0.6" numerals display up to a

Leading zero is only sup-

This

These indi-

a displayed half-scale ac

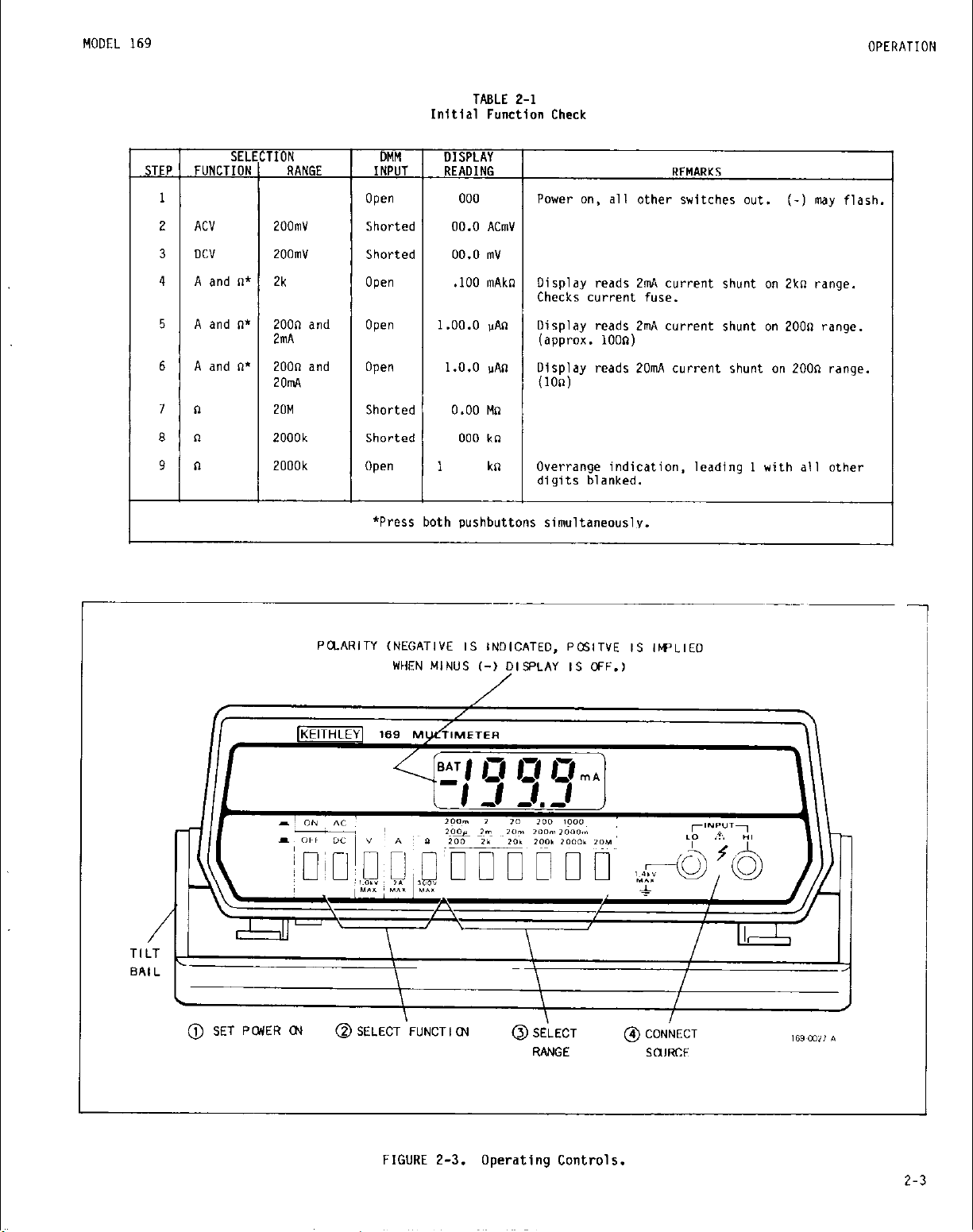

Z-10. Front Panel Switches.

Z-11.

eleven pushbutton switches which are color coordinated to the front panel. These switches are shown

in Figure 2-3 and described as follows.

that, when in, applies power to the DMM.

buttons provide selection of the five functions of

the Model 169.

that selects whether the function is ac or dc, in

for ac or out for dc.

annuncmtor is on.

is implied. The AC/DC pushbutton is not effective

when ohms (0) is selected.

buttons are push-on switches that select volts,

amperes and ohms, respectively.

these pushbuttons all the way in selects the new

function, turns on the proper annunciator and cancels the previously selected function. Note that it

is possible, by forcing, to push two pushbuttons in

at the same time. This will be evidenced by conflicting range/function annunciators appearing, and

the unwanted function can be canceled by pressing

the desired function pushbutton again.

are push-on switches which select the new range and

cancel the previous one. The decimal point is positioned and the appropriate annunciator is turned on

when the range is selected. The 20M pushbutton is

only used for ohms function. If it is inadvertently

selected with volts or current, contradicting annun-

ciators will appear.

Control of the Model 169 is provided by

a. ON/OFF Pushbutton. Push on - push off switch

b. Function Pushbuttons. The four function push-

AC/DC is a push on - push off switch

When ac is selected, the AC

When the annunciator is off, dc

The Y, A and " push-

Pressing one of

c.

Range Pushbuttons. The six range pushbuttons

2-2

NOTE

Extended exposure of the liquid crystal

display to direct sunlight, or high temperature and high humidity conditions can

cause the display to temporarily blacken.

Also, the display may become sluggish if

exposed to extremely cold temperatures.

Even though recovery occurs at normal

Operating temperatures. these conditions

should be avoided for maximum display

life.

2-12.

Z-13.

tions to the Model

high impedance input and is normally connected to

the point in the test circuit most removed from signal or earth ground.

common or low inout.

Input connections.

Two banana jacks provide the input connec-

169.

The HI (red) jack is the

The LO (black) jack is the

Page 11

I

MODEL 169

TABLE 2-1

Initial Function Check

OPERATION

STEP FUNCTION RANGE INPUT READING

1

2 ACV 200"V Shorted 00.0 ACmV

3 DC"

4

5

6

SELECTION DMM

200mV Shorted

A and n* 2k

A and n*

A and n* 2DOn and

200n

and Open 1.00.0 ,,An

2mA

open

open .I00 mAkn

Open 1.0.0 uAfl Display reads 20mA current shunt on 200n range.

DISPLAY

000

00.0 "V

2olTd (100)

7 ”

8 n

9 " 20DOk Open

2DM

2DOOk Shorted

Shorted

*Press both pushbuttons simultaneously.

0.00 M"

000 k"

1

kn Overrange indication, leading 1 with all other

REMARKS

Power on, all other switches out. (-1 mdy flash.

Display reads 2mA current shunt on 2kn range.

Checks current fuse.

Display reads 2mA current shunt on 200n range.

(approx. loon)

digits blanked.

SET PWER Q4

@SELECT F"NCTI(N

FIGURE 2-3. operating COntPOlS.

@SELECT

RANGE

@CONNECT

SOJRCE

IEZ302,A

z-3

Page 12

OPERATION

MODEL 169

Z-18. OPERATING INSTRUCTIONS.

WARNING

t

To avoid electrical shock and/or instrument damage, do not connect the LO input

to any source of more than 1400 volts

(peak) above earth ground.

2-14. Tilt Bail/Handle.

2-15. The 16 position tilt bail/handle allows you

to position the instrument for the best viewing

angle of the display.

2-16.

Z-17.

have become familiar with your OMM, the initial

checkout procedure given in Table 2-1 should be performed. This procedure provides d quick and easy

functional check of the DMM. Only test leads are

required.

ciators to appear, except for low battery (BAT).

All decimal point locations are checked. All digit

segments are checked, except for the horizontal center segment on the last three digits.

minus sign (-) is not suppressed on any function, it

should periodically flash on one or snore of the

funcrions at zero with the input shorted. By

selecting two functions and/or ranges in the test,

the current fuse is checked and d rough indication

of the condition of the respective current shunt and

range resistor is obtained.

not intended to check the DMM accuracy, and thus,

the indicated readings in the table are nominal with

*5 digits allowed. If it is desired to check the

DMM accuracy specifications, perform the Performance

Verification, Section 3.

Check is begun with power on and all other pushbuttons wt.

necessary to press unselected function and range

pushbuttons slightly to cancel previous selections.

After completing the functional check, operate the

Model 169 in accordance with the Operating Instructions beginning with Paragraph 2-18.

INITIAL FUNCTIONAL CHECK.

Now that the batteries are installed and you

The check is designed to cause all annun-

Since the

However, this test is

The Initial Functional

To obtain this condition it may be

2-19.

Model

there are individual instructions provided in this

section which describe how to nakt specific function

meas"rements.

DMM as follows.

button.

useable immediately to rated accuracy.

ambient temperature is within 18-28°C range, but the

DMM has been subjected to temperature extremes, up

to I hour may be required to obtain rated accuracy.

pushbuttons.

range pushbutton.

the medsupement.

should be used ds required.

The basic operating instructions for the

169

DMM are outlined below. In addition,

Refer to Figure 2-3 and operate the

CAUTION

A

Do not exceed the maximum input limits

given in Table 2-2.

a.

Turn on power by depressing the ON/OFF push-

If the instrument is within I&28“C, it is

If

the

b. Select the function with the AC/DC, V, A or n

c. Select the range by depressing the appropriate

d. Connect the source to the INPUT jacks and make

Accessories described in Section 4

TABLE 2-2

Sumnary of Maximum Inputs

-

MAXIMUM

INPUT

1OOOV DC, 1400V Peak AC

350V rms continuous, 15

sec. maximum above 350V

IOOOV rms, 1400 peak,

lO%.Hz

ZA, 250V DC or rms (fuse

protected)

2-4

Page 13

I

MODEL 169

OPERATION

Z-20.

Z-21.

digit to 1000 volts.

is 1999 with appropriate decimal point. Polarity is

automatically sensed and the minus sign (-) will be

displayed, if applicable.

a "1" and three blanked digits, except on the 1OOOV

range.

beyond the maximum allowable input voltage. Maximum

allowable input: 1OOOV dc, 1400 peak ac. Use the

Model 169 to measure dc voltage as follows:

select dc volts with the V and AC/DC pushbuttons.

The "V" annunciator should appear.

able.

pushbutton.

2QOmV range is selected.

INPUT HI and LO jacks; observe the voltage reading

on the display.

2-22.

2-23. The Model 169 reads ac voltages from lOOuV/

digit to 1000 volts.

responding, calibrated to read the root mean square

value of a sine wave within a frequency of 45Hz to

5kHz.

decimal point.

lowed by three blanked digits, except on the IOOOV

range.

beyond the maximum allowable input voltage. Maximum

allowable input voltage:

106V.Hz maximum.

ac voltage as follows.

OC VOLTAGE MEASUREMENT.

The Model

On the 1OOOV range, the display can read

00 not exceed the maximum allowable input

voltage. Instrument damage may occur.

Turn on power with the ON/OFF pushbutton;

a.

Select the range from the five ranges avail-

b.

The decimal point is positioned by the range

c. Connect the signal to be measured between the

AC VOLTAGE MEASUREMENT.

The maximum reading is 1999 with appropriate

On the 1OOOV range, the instrument can read

169 reads dc voltage from 1OOpV/

The maximum displayed reading

Overrange is indicated by

CAUTION

A

The 'm' annunciator will appear if

The instrument is average

Overrange is indicated by a "1" fol-

1ooov Pm,

Use the Model

1400V peak,

169 to measure

A

CAUTION

00 not exceed the maximum allowable input

voltage.

Turn on power With the ON/OFF pushbutton;

a.

select dc volts with the V and AC/DC pushbuttons.

Select the range from the five ranges avail-

b.

able.

pushbuttons.

200mV range selected.

INPUT Hi and LO jacks; observe the voltaqe readin

on the display.

2-24.

2-25.

lOOnA/digit to 2000 milliamperes (ZA). For ac measurements the instrument is average rsponding, calibrated to read the root mean square value of d sine

wave of d frequency within 4%~ to

mum reading is 1999. with appropriate decimal point.

Overrange is indicated by d

blanked digits.

vided by ZA, 250V dc or rms, quick-blow fuse.

the Model 169 to measure, ac or dc current as

follows.

The decimal point is positioned by the range

C. Connect the signal to be measured between the

AC OR DC CURRENT HEASUREIIENT.

The Model

00 not install .3 larger capacity current

fuse than the one originally supplied (ZA,

25OV).

Turn on power with the ON/OFF pushbutton.

a.

Select ac or dc with the AC/DC pushbutton; depress A

pushbutton.

with the "AC" annunicator if dc was selected.

instrument damage may occur.

The "rn' annunciator will appear if

169

reads ac and dc currents from

1kHz.

“1”

followed by three

Input overload protection is pro-

CAUTION

A

Instrument damage may occur'.

The "A" annunciator should appear along

The maxi-

Use

2-5

Page 14

I

OPERATION

Select the range from the five ranges avail-

b.

able.

pushbutton.

200uA range was selected; otherwise, the W annunciator will appear.

voltage drop across the current shunt in the instrument (called voltage burden) can affect the circuit

under test if it has a low source voltage.

voltage burden can be reduced by selecting the

highest current range that will resolve the desired

meas"rement.

HI and LO jacks; observe the current reading on the

display.

The decimal point is positioned by the range

The '11" annunciator will appear if

It should be noted that the

C. Connect the signal to be measured to the INPUT

2-26.

2-27.

digit to 20 megohms.

with appropriate decimal point.

cated by a

Maximum Allowable Input: 3OOV dc or rms. Use the

Model 169 to measure resistance as follows.

RESISTANCE (n) MEASURENENl

The Model 169 reads resistance from 1OOnW

The maximum reading is 1999

Overrange is indi-

"1" followed by three blanked digits.

CAUTION

A

Turn the test circuit off and discharge

all capacitors before attempting incircuit measurements.

present in the circuit if either the minus

sign is displayed, along with a steady

displayed number other than zero, OP the

reading changes more than two digits when

the leads are reversed.

A voltage may be

This

MODEL 169

c.

Read the resistance an the display.

ZOOn range is selected, disconnect the test leads at

the test circuit, short them together and subtract

the reading obtained from the reading obtained

above.

NOTE

As previously mentioned far in-circuit

meas"rements, the presence of a voltage

will cause a change in the reading when

the leads are reversed. The presence of a

forward biased semiconductor junction will

also cause a significant error, and there-

fore, it is a good practice to reverse the

leads and make comparative measurements of

in-circuit resistances.

should be noted that the bottom two resistance ranges will not turn on most

semiconductors, except in an overrange

condition.

d. Diode Tests. Any of the top four ohms ranges

will turn on semiconductor junctions, with an

on-scale reading. but the 20Kn range is recommended

for out-of-circuit tests of semiconductors because

its test current is higher. To test a junction,

first forward bias it and then reverse bias it while

observing the display reading for both conditions.

The HI jack is positive. Compare the results as

follows:

INDICATION

In addition, it

If the

JUNCTION

CONDITION

Turn on power and depress the 0 pushbutton.

a.

The "n" annunciator should appear.

b. Connect the circuit to be measured to INPUT HI

and LO and select the desired range from the six

ranges available.

by the range pushbutton and the applicable range

annunciator should appear.

2-6

The decimal point is positioned

1. Overrange. both Polarities

2. Low reading, both polarities

3. Overrange when reverse biased

and an on-range reading when

forward biased

OPEN

SHORTEO

PROBABLY

GOOD

Page 15

MODEL 169

PERFORMANCE VERIFICATION

SECTION 3.

3-l.

GENERAL.

3-2. Performance verification inay be performed upon

receipt of the instrument to ensure that no damage

or misadjustment has occured during transit.

fication may also be performed whenever there is

question of the instrument's accuracy, and following

calibration, if desired.

NOTE 3-5.

For instruments that are still under warranty (less than 12 months since date of

shipment), contact your Keithley representative or the factory immediately if

the instrument falls outside of specifications as determined by the Performance

Verification Procedure in paragraph 3-7.

PERFORMANCE VERIFICATION

Veri-

RECDHMENOEO TEST EQUIPMENT.

3-3.

3-4. Recommended test equipment for perfornance

verification (and calibration) is listed in Table

3-l. Alternate test equipment may be used.

ever, if the accuracy of the alternate test equip-

ment is not at least 10 times better than the

instrument specifications, additional allowance must

bc made in the readings obtained.

ENVIRONMENTAL CONDITIONS.

3-6. All measurements should be made at an ambient

temperature within the range of la0 to 28OC (65" to

BZ'F), and a relative humidity of less than 80%.

3-7.

PERFORWNCE VERIFICATION PROCEDURE.

3-B.

basic accuracy of the Model

resistance and current measurements.

Use the following procedures to verify the

169 for vo:tage,

HOW-

ITEM

-

A

B

C

0

E

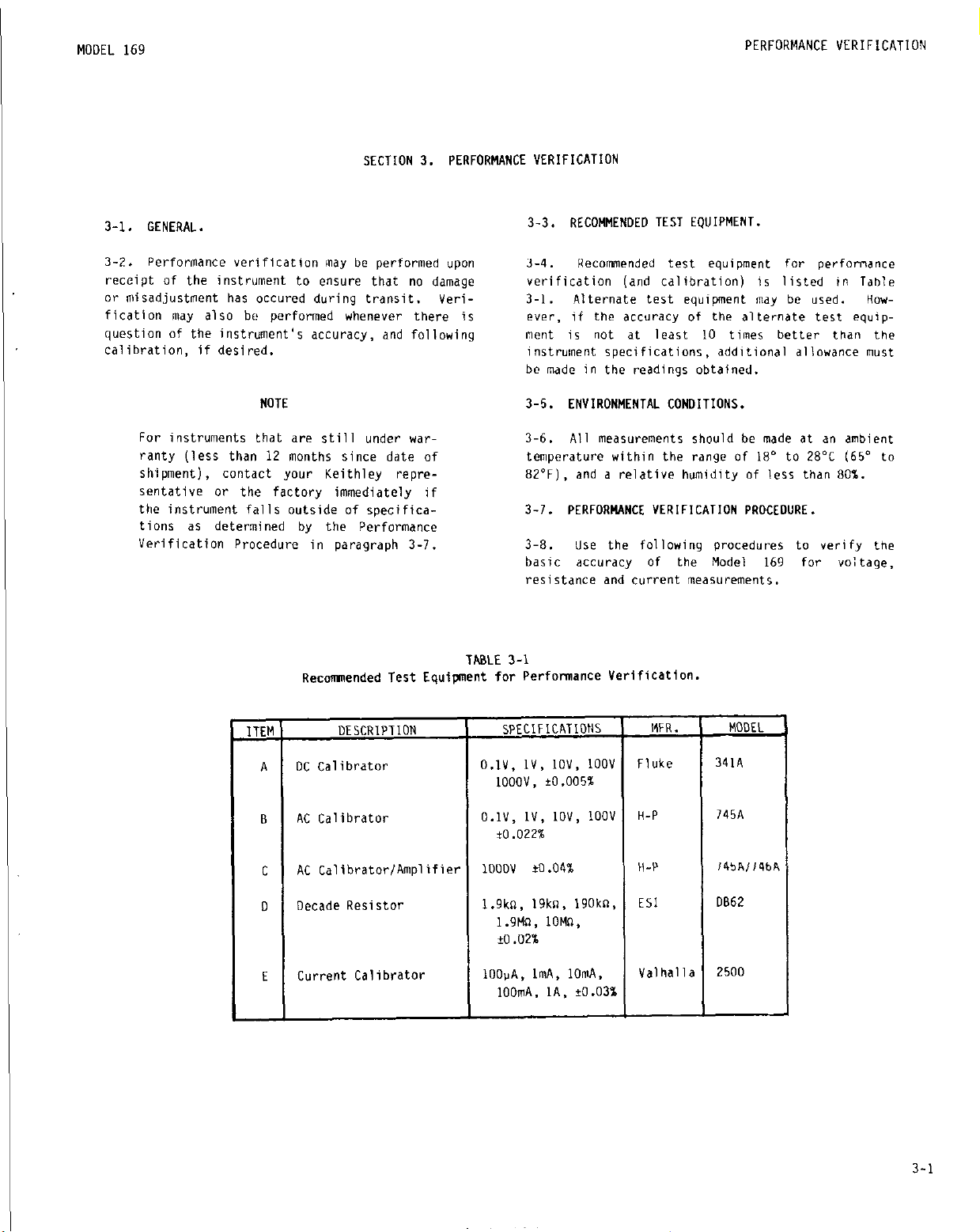

TABLE 3-l

Reformended Test Equipment for Performance Verification.

DESCRIPTION

DC Calibrator

SPECIFICATIONS

O.lV, lV, lOV, IOOV

Fluke

1ooov , to .005%

AC Calibrator

AC Calibrator/Amplifier

Decade Resistor

O.l”, 1”. lo”, 1oov

*0.0223

1000" 20.04%

1.9k", 19kn,

190kn,

H-P

H-P

ES1

1.9Hfl, lOMn,

?0.02%

Current Calibrator

lOOpA, lmA, lOmA.

IOOmA, 1A. to.034

Valhalla

IMFR .

MODEL

341A

745A

745R/746A

0862

2500

3-l

Page 16

PERFORMANCE VERIFICATION

I

MODEL 169

NOTE

Performance verification should be performed by qualified personnel using

accurate and reliable test equipment.

3-9. Initial Conditions.

3-10. Before beginning the verification procedure

the instrument must !meet the following conditions:

a. If the instrument has been subjected to

extremes of temperature, allow internal temperature

to stabilize for one (1) hour minimum at the

environmental conditions specified in paragraph 3-5.

b. Turn the instrument on and check for low

battery indication. If low battery indicator (BAT)

is on, remove and replace the batteries with fresh

O”L?S.

t

Some procedures require the use of high

voltage. Take care to prevent contact

with live circuits which could cause

electrical shock resulting in injury or

death.

3-11.

DC Volts Checkout.

WARNING

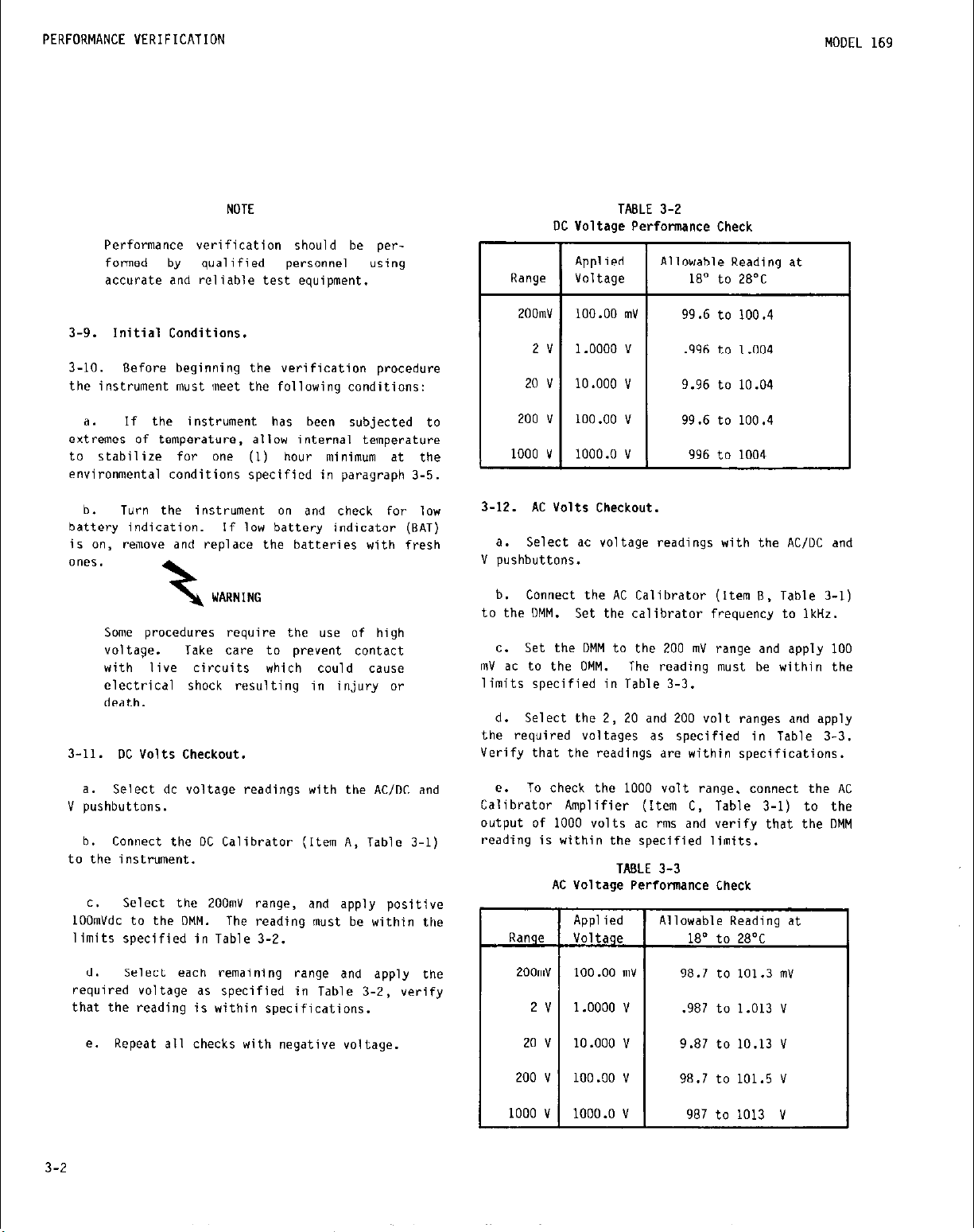

TABLE 3-2

DC voltage Perfornance Check

Applied

Range

ZOOmV

20 v

200 v

1000 v

3-12.

a. Select ac voltage readings with the AC/DC and

V pushbuttons.

b. Connect the AC Calibrator (Item B, Table 3-1)

to the OMM.

c. Set the DMM to the 200 mV range and apply

mV ac to the OMM. The reading must be within the

limits specified in Table 3-3.

d. Select the 2, 20 and 200 volt ranges and apply

the required voltages as specified in Table 3-3.

Verify that the readings are within specifications.

Voltage

100.00 mv

2v

1.0000 v

10.000 v

100.00 v

1000.0 v

AC Volts Checkout.

Set the calibrator frequency to

Allowable Reading at

180 to 2rc

99.6 to 100.4

.996 to 1.004

9.96 to 10.04

99.6 to 100.4

996 to 1004

1kHz.

100

a. Select dc voltage readings with the AC/DC and

V pushbuttons.

b. Connect the DC Calibrator (Item A, Table 3.1)

to the instrument.

c.

Select the 200mV range, and apply positive

1OOmVdc to the OMM. The reading must be within the

limits specified in Table 3-2.

d.

Select each remaining range and apply the

required voltage as specified in Table 3-2, verify

that the reading is within specifications.

e. Repeat all checks with negative voltage.

3-2

e.

To check the

Calibrator Amplifier (Item C, Table 3-l) to the

output of 1000 volts ac rms and verify that the OMM

reading is within the specified limits.

AC Voltage Performance Check

Applied

Range

200mV

20 v

200 v

1000 v

2v

Voltage

100.00 mv

1.0000 v

10.000 v

100.00 v

1000.0 v

1000

volt range, connect the AC

TABLE 3-3

Allowable Reading at

18’ to 28’C

98.7 to 101.3

.987 to 1.013 V

9.87 to 10.13 V

98.7 to 101.5

987 to 1013

mV

V

V

Page 17

I

MODEL 169

PERFORMANCE VERIFICATION

3-13. Resistance Checkout.

a. Select resistance readings by pressing the n

pushbutton.

b. Select the 2000 range.

C. Connect the decade resistor (Item 0, Table

3-1) to the OMM.

d. Set the decade resistor to zero and measure

the resistance of the test leads.

reading from the display in all of the following

steps.

Set the decade resistance to

e.

that the reading is within the limits specified in

Table 3-4.

f. Continue the resistance check by selecting the

next range and measuring the next resistance as

specified in Table 3-4.

within specifications.

Resistance Perfonance Check

Ran e

Resistance

Verify that the reading is

Test each item in the table.

TABLE 3-4

Allowable Reading at

Subtract this

190.0.

18’ to 28’C

Verify

3-14. DC Current Checkout.

a. Select dc current readings with the AC/DC and

A pushbuttons.

b. Connect the dc current source (Item E. Table

3-1) to the

C.

lOO.OOpA to the OHM. The reading must be within the

limits in Table 3-5.

d. Select each range and apply the required cuvrent as specified in Table 3-5.

reading is within specifications.

3-15. ANALYSIS.

3-16.

limits given in Tables 3-2 through 3-5. either

troubleshooting and repair or

described in Section 6, may be required.

recalibration will only be the indicated solution

when the instrument is out of speciflcbtlon on ~lofe

than one function (except for the higher ranges of

DC volts which are tht most critical).

instrument is still under warranty, refer to the

Note in Paragraph 3-2.

DMM.

Select the 200uA range and apply a current of

Verify that the

If the instiwwnt is out of the specified

calibration, a5

NO~Il~lly,

If the

kn

kn

kn

190.0 ”

1.9OOkn

19.0Okn

190

.Okn

200 n

r--t--

2

20

200

I

189.1

to

190.9 n

1.695 to 1.905 KZI

18.95 to 19.05

189.5 to 190.5

Kn

Kn

1895 to 1905 Kn

9.19 to 10.21

Mn

DC Current Performance Check

Applied

Range current

PA

nA

mA

mA

mA

100.00

1 .OOOO

10.000

100.00

1000.0

200

2

20

200

1000

TABLE 3-5

Allowable Reading at

18' to 28°C

"A

mA

mA

mA

mA

99.1 to 100.9

.991 to 1.009 mA

9.91 to 10.09 mA

99.1 to 100.9 mA

991 to 1009 mA

uA

3-3

Page 18

Page 19

MODEL 169

ACCESSORIES

SECTION 4.

4-l. GENERAL.

4-2.

This section describes the various accessories

and options available for use with the Model 169

OMM .

4-3.

MODEL 1600 HIGH VOLTAGE PROBE.

4-4. The Model 1600 High Voltage Probe (shown in

Figure 4-l) extends the measurable dc voltage range

up to 40 kilovolts. It has a 1OOO:l division ratio,

so that a reading of 1 volt on the DMM corresponds

to 1 kilovolt (1000 volts). To "se the probe,

select DCV and the required range, connect the high

voltage probe banana plug to the instrument, connect

the alligator clip to soui-ce low, and touch the

probe tip to source high.

WARNING

t

Be sure the alligator clip is connected to

source low before touching probe tip to

souw? high. A shock hazard or damage to

instrument may result.

Specifications

Voltage Range:

input Resistance:

Division Ratio: 1OOO:l.

Ratio Accuracy:

t1.5% at 25kV, decreasing to

Q.O% at 20k" and 30k",

e3.04 at 1OkV and 40kV, and

t4.0% at

Ratio Stability:

Heating Effects: Self-heating due to application

of high voltage for period in excess of 1 minute

will cause a maximum of 0.2% additional error at

40kV (error is less at lower voltage).

IkV.

0 to 40,000

1000 megohms.

?O.Ol%

per Y; *0.1x per year.

volts DC.

ACCESSORIES

4-5.

MODEL 1651 50-AMPERE SHUNT

4-6.

Figure 4-2) permits current measurements of up to 50

amperes ac or dc.

0.001 ohm ?l%, so that a 50-ampere current vill carrespond to a reading of 50 millivolts (0.0500 volt).

Set the "NM to ACV or DCV and select the required

rangc. TO use the shunt,

nished with the shunt from the shunt screw terminals

to the OMM input terminals. Use separate leads (not

furnished) to connect the source to the hex head

bolts. Be sure to use leads with a capacity of 50

amperes, or as needed.

4-7.

4-8.

leads with banana plugs at one end and spring-action

clip-on probes at the other end. TO use, insert the

banana plugs into the "NM and attach the prober to

the source.

4-9.

4-10.

permits measurement of dc voltages dt frequencies of

20 kilohertz to 100 megahertz. Connect the probe to

the input terminals and select 3CV and the appropriate range.

Specifications

The Model 1651 50-Ampere Shunt (shown in

The shunt has a resistance of

connect the leads fur-

MODEL

1681

CLIP-ON TEST LEAD SET

This set (shown in Figure 4-3) contains two

MODEL 1682 RF PROBE

The Model 1682 RF Probe (shown in Figure 4-1)

Voltage Range:

Transfer Accuracy: i0.5dS. 1OflkHr to 10OWr peak

responding calibrated in rms of d sinewave.

Input Impedance: 4 megohm shunted by 3pF.

Maximum Allowable input: 30V rms AC, ZOOV DC.

Accessories Supplied: straight-tip, hook tip,

ground clip, hi adapter, banan; plug adapter.

0.25 to 30 volts nns.

4-1

Page 20

ACCESSORIES

I

MODEL 169

4-11.

4-12.

test leads and 12 screw-in adapter tips. The tips

consist of two alligator tips with boots, two banana

plugs, two needle tips with chucks, two spade lugs

and four heavy duty tip plugs which permit con-

nection of the DMM to virtually any source within

its measurement range.

4-13. MODEL 1684 CARRYING CASE.

4-14. The Model 1684 Carrying Case (shown in Figure

4-4) is a hard vinyl case with a fitted foam insert

to help protect the Model 169 from damage. There is

also room in the case for the Instruction manual and

small accessories

4-15.

4-16.

(shown in Figure 4-2) permits measurement of ac

current by clamping around a single conductor,

eliminating the need to interrupt the current path.

Plug the ac current probe into the OMM and select

MODEL 1683 UNIVERSAL TEST LEA0 KIT.

This kit (shown in Figure 4-3) contains two

MODEL 1685 CLAMP-ON AC CURRENT PROBE.

The Model 1685 Clamp-On AC Current Probe

ACV and the appropriate range. The DMM will display

0.1

volt rms per ampere.

4-17. MODEL

4-18. The Model

(shown in Figure 4-3) consists of two .9lm (36

inches) test leads with probe tips terminated in

banana plugs.

4-19.

4-20.

parts that will mdintain up to

one year. The parts we listed in Table 7-l of

Section 7, Replaceable Parts.

4-21. MODELS

4-22.

permit mounting one or two Model

19-inch rack for convenient viewing.

1691

GENERAL PURPOSE TEST LEAD SET.

1691

General Purpose Test Lead Set

MODEL

1699

SPARE PARTS KIT.

The Model 1699 contains a complement of spare

10

Model

169

DMMs for

1010

and 1017 RACK HOUNTING KITS.

The rack mounting kits (shown in Figure 4-4)

169 DMMs

in

a

FIGURE 4-l. High Voltage Probe and RF Probe.

Page 21

MODEL 169

ACCESSORIES

MODEL 1651

50.AMPEKE SiiUIIT

CLAMP-ON AC CURRENT PROBE

MODEL 1685

FIGURE 4-2.

Current Probe and Current Shunt.

MODEL

CLIP-Ok TCST LEAD SET

MODEL 1691

GE,,ER,,L PURPOSE TEST

1681

LEAD SET

MODEL 1683

UNIVERSAL TEST LEAD KIT

FIGURE 4-3.

Convenience Cable and Connectors.

4-3

Page 22

ACCESSORIES MODEL 169

I

\- /’

MODEL 1684

CARRYING CASE

FIGURE 4-4. Carrying Case and Rack Mounting Kits.

“; :

;:I

:o i

SINGLE RACK I~lOIINTIllT; KIT

MODEL 1010

DUAL RACK ElOUNTIN(; KIT

I

4-4

Page 23

I

MOOEL 169

TtlEORY OF OPERATION

I

I

SECTION 5.

5-1.

GENERAL.

5-2. This section contains circuit descriptions for

the Model 169 OMM. An overall block diagram of sig-

nal flow is provided in Figur‘e 5-I.

schematic diagram, drawing 301800, is contained in

Section 7 of this m~nudl.

5-3.

OVERALL OPERATION.

5-4.

As shown in Figure 5-1, the heart of the Model

169 is d single chip A/D converter with built-in

liquid crystal display drivers.

reading is the ratio of two floating input voltages

to this converter.

one voltage (Reference) is IOOmV. The other voltage

(VINHI) is the unknown input cuwent 01‘ voltage

to the Model

the input signal conditioning circuitry to a dc

Voltage between zero and ?200m".

reading is then determined by the formula:

(YINHI +

also automatically determines the polarity of the

input signal and detects whether an overrange

condition exists

displayed, plus is implied, and an ove~~ange is

displayed by a I with the last three digits blanked.

The annunciators ape displayed by the combination Of

range dnd function switching, and the decimal point

is positioned by the range switching.

For the ohms function, d reference resistor is

5-5.

placed in series with the unknown resistor and a

voltage is applied.

through both resistors, the ratio of their voltages

is the sdme as the ratio Of their resistances.

Thus, the voltage w1‘oss each resistor is measured

by the A/O converter and their ratio is displayed

per the formula: IO00 (VR, i VRREFERENCE).

169

VREFERENCE).

On all functions except ohms,

which is converted and/or scaled by

The

(>1999

counts).

Since the Same current flows

The overall

The displayed

The displayed

1000

Conwrter

A/O

A minus sign is

THEORY OF OPERATION

5-6. SIGNAL CONDITIONING.

5-l. AC/DC Voltage Measure,wnts.

5.8. For voltage measurements, ds shown in Figure

5-2, the input is divided by

10,000 by the IO megohm resistive divider.

resulting output from the divider is d 0 to 200mV

voltage.

direct to the A/D co"vel‘teP along with the IOOmY

reference.

gain or attenuator stages are used. the dc dccurdcy

is determined primarily by the precision resistor

accuracies (actually their ratios) and the reference

adJ"stment.

5-9. For an x input, the output of the resistive

divider is first applied to the AC Converter.

AC conver‘ter is a half wave rectifier with IOOUV

resolution and sufficient gain to provide d positive

dc output voltage equivalent to the nns value of d

sinusoidal input.

lOOmVac, the output will be IOOmVdc. The important

gain determining elements of the converter dw

precision resistors so that d gain adjustment is not

required.

5-10.

5-11.

5-3, the appropriate shunt resistor is placed across

the OMM input in accordance with the selected range.

As with voltage medsurcments, the voltage drop

across the current shunt is designed to be 2OOmV for

a full scale input current on any range. Therefore,

after the input current is converted to d voltage,

the meaSUPement process for current is identical to

that for voltage measurements.

Current meaSurCments is primarily determined by the

ilccUrXies of the precision shunt resistors and the

reference adjustment.

ac accuracy along with any error contributed by the

AC Converter.

For a dc input, this voltage is applied

It should be noted that, since no active

Thus, for sinusoidal input of

AC/DC Current lkasuremnt.

FOT Current medsurements, its Shown in Figure

These two items also affect

1, 10, 100, 1000, or

Accuracy for dc

The

The

5-1

Page 24

THEORY OF OPERATION

MOOEL

169

5-12.

5-13.

the voltage drop across the unknown resistance to

the voltage drop of an internal reference resistor

as shown in Figure 5-4. For this ratio measurement

technique, d voltage is connected to the input

divider used for voltage measurements and the range

switching selects a l/2 of full scale value reference resistance to be placed in series with the

unknown resistor.

pared by the A/D converter and displayed on the LCD.

A 2 kilohm thermistor (RTlOl) provides overvoltage

input protection for the low resistance ranges and

it is in series with the reference resistor and the

unknown resistor on all but the 20 megohm range.

For this reason, the +V (t2.8V nominal) top of the

reference is selected on the 200 ohm range. On all

other ranges tl.ZV is used. Since a ratio technique

is used,

determine the

measurements, and no adjustments are necessary.

5-14. A/D CONVERTER.

5-15.

verter and display drivers ape contained on a single

integrated circuit (U102). This chip also contains

an oscillator and the regulators that are used to

establish the analog and digital grounds.

components are used to establish the timing and

reference levels required far A/O operation.

employs the dual slope principle of A/D conversion.

This method provides d ~asurement cycle consisting

of three consecutive time periods, autozero. signal

integrate and reference integrate (read).

for these periods, and thus the measurement period,

is a function of the oscillator frequency.

oscillator components are selected to provide 40 kHz

which results in a

period for best rejection of 50Hz and 60Hz. To

begin each measurement cycle. the autozero period is

set to a minimum of

period, the reference voltage input to the A/D is

Resistance

Resistance measurements are made by comparing

actual values of the reference resistors

As shown in Schematic

Measurements.

The voltage drops are then com-

primary accuracy for

301800,

100

millisecond signal integrate

100

milliseconds.

resistance

the A/O con-

External

During this

u102

Timing

The

stored on capacitor

referenced to analog cornnon.

is then stored on capacitor Cl02 for use during the

remainder of the measurfment cycle, if any amplifier

offset exists. The second phase of the measurement

cycle is the 100mS signal integration period as

previously mentioned.

differential voltage between IN HI and IN LO is

integrated.

of the integrated signal is also determined.

final phase is reference integrate, or read. During

this period,

reference capacitor will be connected with the

correct polarity to return the integrator output to

the autozero level.

output to return to this level is proportional to

the unknown input signal.

from zero to 200 milliseconds. corresponding to

displayed counts of zero to 2000 full scale as

determined by

input signals less than full

cmwrtw rewrts to wtozero far the remainder of

the reference integrate period.

measurement cycle is 400ms. which results in a

display update rate of 2-l/2 per second.

5-16.

5-17.

associated circuitry is shown in Schematic

As previously mentioned, the seven segment decoders

and drivers are provided by the A/D converter chip

u102.

on the output lines to the LCD.

driven by a square wave having the same amplitude

and frequency as the BACKPLANE line (nominally 0 to

t5V at 50Hz).

ments are driven out of phase with BACKPLANE the

segments are ON.

segments are OFF.

points are turned ON and OFF similarly, with the

phasing of their lines controlled by the range and

function switches through logic gates. A swnary of

annunciator switching is given in Table 5-1.

At the end of this period, the polarity

DISPLAY CIRCUITS.

The liquid crystal display (LCD) and its

The digitized measurement data is presented

Cl11

and the A/D converter is

A correction voltage

During this period, the

The

internal circuitry ensures that the

The time required for the

The read period can be

1000 (VI, + VREF).

scale,

Thus,

a complete

FW

the A/D

301800.

These lines are

When the lines to the display seg-

Conversely. when in-phase the

The annunciators and decimal

5-2

Page 25

MODEL 169

THEORY OF OPERATION

5-18.

5-19.

lated and calibrated) to the A/D converter for

voltage and current measurements.

approximately 2.8V to the 2008~ range and approximately 1.2V to all other n ranges during resistance

meas"rements. The heart of the reference source is

a band-gap reference (VRlOl) that regulates the

voltage to a value between

approximately SOOvA.

applied to the reference source depends on the

internal regulator in the A/O converter which

establishes analog ground nominally 2.8 volts below

vt. Thus, the value of RlOZG is selected to provide

a minimum current of 400uA to "8101 to ensure a good

temperature coefficient.

tion adjustment,

adjustment span and are stable precision resistors

to ensure the 1 year calibration cycle.

5-20.

5-21.

tor switch (QlO2) which compares the negative supply

to digital cornnon (ground). 9102 is set for a nominal supply voltage of 6.9 volts. (Actual battery

voltage will be about 7.2 volts due to the drop of

CRlO5.) In the Model 169, the primary limit to battery usefulness is the integrator swing on the high

ohms ranges with a full scale input. For this rea-

son, the low battery indicator (RAT) should turn on

with a battery voltage of 6.5 volts, or above, for

the proper functioning of the A/O Converter and the

low battery indicator.

5-22.

5-23. Effective input protection circuitry has been

designed into the Model 169 which provides protection against accidental input overloads on all

functions and ranges.

in the following paragraphs for each function.

REFERENCE SOURCE.

The reference source supplies lOOmV (regu-

It also provides

1.20 and 1.25 volts at

Recall that the voltage

RlOl

provides the calibra-

while R1020 and R102E limit the

LOW BATTERY DETECTOR.

The low battery detector is a simple transis-

INPUT PROTECTION.

This circuitry is described

5-24. Voltage Protectlo".

5-25.

during dc voltage measurements by limiting the current to *ImA.

5-26.

tected by using R107 for current limiting and CR103

and CR104 to clamp the voltage to digital cornnon and

vt.

through ClD7,

5-27. current Protection.

5-28.

opens for input current overloads with up to 250

Volts.

Clamp the input voltage to about 1 volt until F101

"PWS.

5-29. Ohms Protection.

5-30.

basic components used to provide protection during

resistance meas"reme"ts.

leakage zener to clamp any unintentially applied

voltage to ground. RTlOl is a positive temperature

Coefficient thermistor which bears the applied voltage by increasing its resistance. This timits cur-

rent to

of the A/O converter as in OC volts.

Voltage across 9101 can

tive

tects REF HI by limiting the current to +lOOuA.

Since

tected by RlOZG on the 200n range and by R102F plus

the divider resistance on the other ranges.

negative input overloads the circuit operates the

same, except

to ANALOG COMMON.

R107 and K103 protect the A/D converter

For ac voltage medsuremeotn, UlOI is pro-

Overload currents are returned to anal09 cornnon

Cl13

and the AID converter.

On the higher current ranges,

On the lower current ranges, CR106 and CR107

Transistor

4101

and thermfstor RTlOl are the

9101

protect

supply.

YRlOl has a current

QlOl.

R102C protects REF LO dnd RlOKE pro-

qlO1

RlO3 is used to protect IN Hi

be 10 volts above the posi-

limit of IOmA. it is pro-

is then forward biased and clamps

FlOl

(2A. 25OVl

is used as d low

Since the

For

5-3

Page 26

THEORY OF OPERATION

MOUEL 169

TABLE 5-1

Annunciator Truth Table

\NN!JNCIATOR

BAT

AC

DPl

DPZ

DP3

V

a

k

SWITCH

Q102

DC/AC

R

2K

20K or 20M

200

or ZOOK

V

a

200

and 20M

R

CONDITIOh

OFF

AC

OFF

ON

ON

ON

ON

ON

OFF

ON

20M

A

A and 200

A

1.

200

V and 200

2.

I

5-4

ON

ON

ON

ON

OFF

ON

Page 27

MODEL

169

THEORY OF OPERATION

INPUT

HI>

NOTES: 1.

n

TO CKTS

Output voltage from current shunts

and voltage attenuator are zen, to

200mVAC and zero to t200mVdc.

,-, +2.8V

AND ANNUNCIATOR

200n

DIGIT

SECML,,T

DATA

DISPLAY

t

2. Output of AC Converter is zero to

+2OOmVdc.

FIGURE 5-1.

Model 169 DMM Overall Signal Flow Block Diagram.

Page 28

’

THEORY OF OPERATION

MODEL 169

DECADE

RESISTIVE

DIVIDER

LO

9M

900K

90K

+

FIGURE 5-2.

0v to t200mV

Simplified AC/LX Voltage Measurement.

I

5-6

Page 29

HI

INPUI 0

MODEL 169

CURRENT

SHUllTS

zooun

900

2oA

90

2omA

LO>---

200mR

2oooaiA

0

RANGE

S~IITCHING

FIGURE 5-3.

9

.9

.l

Simplified AC/DC Current Meaurement.

Page 30

THEORY OF OPERATION

REFERENCE

SOURCE

MODEL 169

I

100.1

90K

900K

9M

9K

200

2K

20K

200K

2000K

20M

RANGE

SWITCHING

0

.

RTlOl

2K

,C c

I

5-8

RX

HI

-1n

A

REFERENCE

RESISTORS

FIGURE 5-4. Simplified Resistance Measurement.

Page 31

I

MODEL 169 MAINTENANCE

SECTION 6. MAINTENANCE

6-l. GENERAL.

6-2. This section contains information necessary to maintain

the Model 169 DMM. AdjustmenVcalibration, troubleshooting,

battery replacement, fuse replacement and LCD replacement

procedures are provided.

6-3. CALIBRATION.

6-4. Calibration should be performed yearly (every 12 months)

or whenever Performance Verification (see Section 3) indicates

that the Model 169 is out of specifications. If the Calibration Pro-

cedure cannot be periormed properly, r&r to Troubleshooting

information in this section or contact your Keithley representa-

tive or the factory.

NOTE

Calibration should be performed by qualified Peru

sonnel using accurate and reliable equipment.

6-5. Recommended Calibration Equipment.

6-6. The Fluke Model 341A DC Calibrator is recommended for

calibrating the Model 169. Alternate calibration equipment may

be used. However, the accuracy of the alternate 190 mVDC

source must be .025% or better.

a. Turn off power and disconnect ail leads from the 169 DMM

Input.

b. Loosen the four screwy in the bottom of lhe DMM until lhe

threads are disengaged. NOTE: These screws are not rep

tained and they will fall out when the DMM 1s returned to

the upright position.

c. Hold the top and bottom cover together to prevent ihew

separation and turn the DMM over lo !ls normal p&Ivan.

Remove the top cover.

d. Turn power on by depressing the ON/OFF pushbutlon.

and verify that the low battery indicator (BAT) does not apt

pear. (NOTE: It is recommended that fresh batteries be ins

stalled at this time to provide the longest possible use of

the Model 169 before additional maintenance is required.

Refer to Installation of Batteries, Paragraph 2-6).

6-11. Calibration Adjustment.

6-12. Only two adjustments are needed to calibrate the Model

169. Proceed as follows:

a. Place the Model 169 on the 200mVDC range.

6-7. Environmental Conditions.

6-8. Calibration should be performed under environmental con-

ditions having an ambient temperature of 23” i2”C and a relative humidity lessthan 70%. If the Model 169 has been exposed

to extremes of temperature or humidity, allow at least one hour

for the instrument to stabilize.

6-9. Case Cover Removal.

6-10. To gain access to the calibration pot and circuit components, remove the case cover as follows:

WARNING

Disconnect all te?,t circuits from the INPUT connections of the Model 169 before removing the case

CO”H.

b. Apply-190.0mVDCandadjusf RlOl (see Figure&l)far a

reading of -190.0.

c. Apply +19O,OmVDC and note reading.

d. Adjust I?1 01 for a reading halfway between the noted read-

ing and 190.0 (e.g., if noted reading is 190.2, adjust Al01

for a reading of 190.1).

e. Place the Model 169 on the ZVAC range.

f. Apply 1 .OVAC at 5kHz and adjust C1 17 for a reading be-

tween 1.025 and 1.035VAC. (The trimmer capacitor is located at the center of the PC board, between the ribbon cables.)

6-13. This completes calibration of the Model 169. Reinstall the

DMM top cover and verify performance as outlined in Section 3.

Page 32

MAINTENANCE

MODEL 169

SPACERS (21

CAL I

BRA; I ON

ADJUSTMENT

Rlcl

6-14.

6-15.

FIGURE 6-l.

TROUBLESHOOTING.

The following troubleshooting instructions

Calibration Adjustment Location.

are intended for qualified personnel having a basic

understanding of analog and digital

electronic

principles and components used in a precision

electronic test instrument.

Instructions have been

written to assist in isolating the defective circuit

or Subcircuit.

component has been left to the technician.

the case cover ds explained in Paragraph 6-9 to gain

access to

locations.

Isolation of the specific defective

circuit

components

and test

Remove

point

6-16. Special Handling of Static Sensitive Devices.

6.17.

CMOS devices a-e designed to function at very

high impedance levels for low power consumption.

For this reason, a normal static charge build up on

your person or clothing can be sufficient to destroy

these devices.

The following steps list the static

sensitive devices in your Model 169 and provide

instruction on how to avoid damaging them when they

must be removed/replaced.

6-Z

Page 33

I

MODEL 169

MAINTENANCE

a. Static sensitive devices:

Kfithley

Part Number

LSI-22

IC-102

IC-226

IC-228

OZ-62

b.

The above integrated circuits should be

handled and transported only in protective containers.

tubes or static protective foam. Keep the devices

in their original containers until ready for use.

c.

tainers only at d properly grounded work bench or

table, and only after grounding yourself by using a

wrist strap.

d. Handle the devices only by the body.

touch the pins.

e. Any printed circuit board into which a device

is to be inserted must a'150 be grounded to the bench

or table.

f. Use only anti-static type solder suckers.

g. Use only grounded tip soldering irons.

h. After soldering the device into the board, or

properly inserting it into the mating receptacle,

the device is adequately protected and normal

handling can be resumed.

Typically they will be rcceivcd in metal

Remove the devices from their protective con-

Reference

Designation

u102

u103

IJ104, u105

“106

VRlOl

DO not

6-21.

Display Driver circuit should be verified before

troubleshooting the signal conditioning circuits.

Check these circuits per Tables 6-2 and 6-3. If it

is determined that the Liquid Crystal Display is

defective,

6-31.

6-22.

6-23.

Converter circuitry.

Proper Operation of the A/D Converter and

replace per instructions in Paragraph

AC

Converter.

Problems with dc voltage may

Check this circuit per Table

involve

the AC

6-4.

6-24.

Circuit.

6-25.

may involve these Signal conditioning circuits.

Check out the Reference Source and Ohms Circuit per

Tables 6-S and 6-6.

checked by measuring the resistance of each resistor

individually with the instrument off and the pushbuttons in the out position.

Voltage Divider resistors are as follows:

Voltage Olvlder. Reference Source and Ohms

Problems with voltage or resistance ranges

The Voltage Divider can be

The tolerances of the

a. R108, 100.1n, 0.1%

b.

A109, 900n, 0.1%

c. RllO,

d.

e. H112, 900Kn,

f. R113, 9Mn, 0.08%

Rlll,

9Kn, 0.1%

90Kn, 0.1%

0.1%

6-18.

6-19. In general,

6-1,

and power supply are providing the correct voltages

to the electronic components.

that the battery needs replacing, refer to Paragraph

6-33, Battery Replacement.

6-20. A/O Converter and Oisplay Driver.

Power supply.

start troubleshooting with Table

Power Supply Checks, to verify that the battery

If it is determined

6-26. current Circuitry.

6-27.

check the current circuitry ds directed in the following pangraphs.

the current shunts are cornnon to both ac and dc cvrrent,

current ranges if there is d fault in the current

shunt circuitry.

If problems occur with current readings.

It should be noted that, since

problems should exist on the same ac dad dc

6-3

Page 34

MAINTENANCE

MODEL 169

6-28.

simultaneously depressing the A and n pushbuttons

while on the 2K range.

good fuse is nominally .lOOmAKn. A blown fuse Will

be indicated by an overranged display.

current fuse is blown, replace per instructions in

Paragraph 6-35.

6-29.

suring the resistance of each resistor Individually

with the instrument off and all the pushbuttons in

the out position.

as follows:

The cuwent fuse can be checked wt by

The display reading for a

If the

The Current Shunts can be checked by "ea-

The tolerances of the shunts are

a. R114A, 0.9Q, 0.5%

b. R1146, 0.10, 0.5%

c. R115, 9n, 0.5%

d. R116, 90n, 0.1%

e. R117, 9OOfl. 0.1%

6-30.

and CR108) as follows:

resistor to the input of the Model 169.

or less.

6-31. LIQUID CRYSTAL DISPLAY REPLACEMENT.

b-32.

Figure 6-4, to replace the display of the Model 169.

graph 6-9.

to the front panel.

careful of the LCII display (Keithley Part NO. DD-18)

as it will be loose and may fall out of the front

panel.

Check the current protection diodes (CR107

a. Select ZOO,,AOC range.

Apply 5VAC through a IKn current limiting

b.

Clamping across the diodes must occur at tlV

c.

Perform the following procedure, referring to

Remove the case cover as explained in Para-

a.

b. Remove the three 318" pal nuts holding PC-509

Separate PC-509 from the front panel being

c.

6-4

I

FIGURE 6-2.

CONNECTOR

(CS-376-1)

LCD Assembly.

Page 35

I

MODEL 169

TABLE 6-l

Power Supply Checks

STEP / ITEM/COMPONENT REQUIRED CONDITION' REMARKS

1

Battery Voltage 7.5V min.

2 CR105 0.5V drop max.

MAINTENANCE

3 UlO2, pin 40 and 15 7.OV min.

4 Cl07 2.4 to 3.2V output Of u102

0.8 to 2.6V output of u102

!

'Above checks with fresh batteries and power switch ON.

TABLE 6-2

A/O Converter

STEP ITEM/COMPONENT

1

2 Display Short input, 00.0 tld

3 Refewnce (UlO2, pin 5)

REWIRED CONDITIONS' REMARKS

power ON, ZOO","DC ,uan9e

Nominally 98mV using

voltmeter with 1OMn

Input Impedance

Supply to u102

(Analog Gnd)

(Oigital Gnd)

I

rero Check

IHigh ImpeddnCP

reference

4 Ratio Test Short "102 pin 5 to

5 Display

6 UlO6, Pin 3

7 External Voltage source

8 u102 Pin 14 to Input Lo

*Measurements made with respect to input lo

**Non-symmetrical in most cases

pin 10

100.0

*2d

40kHz f6kHz**

Approx. 5Vp-p

Apply +190.0mVAC Calibration

See waveform (Figure ,ntegrator

6-3) Check

connects reference to Input

If steps 3 and

5 are Correct

AID Converter

is functioning

properly

Clock check

poi nr

6-5

Page 36

MAINTENANCE

MODEL 169

190mVDC Input

FIGURE 6-3.

STEP

1

2 "102 pin 40 to pin 4 4.0 to 6.0 Volts

3 "102 pin 3 to Input Lo 4OkHz +6kHz Clack Check

4 U102 pin 20 to Input Lo

5 UlO2 - any display Approx. 50H.7 Square

6 U104, U105, UlO6,

ITEMICONPONENT

driver line wave, approx. svp-p backplane for

decimal point and wave, approx. svp-p

annunciator driver

lines

Integrator Waveform.

TABLE 6-3

Display Driver

REQUIRED CONDITIONS REMARKS

Power ON

Digital Supply

Apprax. S'ip-p

Approx. 50Hz Square

wave, approx. svp-p

In phase with

seqment Off,

out of phase

with backplane

for segment on

Approx. 50Hz square

6-6

Page 37

I

MODEL

169

MAINTENANCE

TABLE 6-4

AC Converter

STEP

c-

1

2

UlOl

External "oltagc Source Apply 1OOmVAC at 100Hz

Cl08

Ulol pin 6 to Input Lo

6

UlOl pin 6 to Input Lo

7

ITEM/COMPONENT REQUIRED CONDITIONS

Power 01,. 20h"AC Kangc

pin

7 to

pin 4

7V min.

98mVOC Nominal using

1OMfl input impedance

voltmeter

See Waveform (Figure

6-4)

Short Input

*SmVDC offset max.

Supply Voltage

Calibrated Input

IHigh Impedance

+440mV-

1OOnVAC Input

FIGURE 6-4.

AC/DC Converter Waveform.

6-l

Page 38

MAINTENANCE

TABLE 6-5

Reference source

MODEL

169

STEP ITEM/COMPONENT

1

2 U102 pin 40 to Input Lo

VRlOl

3

4

STEP

(<lOOpf probe)

R102

pin 8 to Input Lo

ITEM/COMPONENT

REQUIRE0 CONOITIONS

power ON

2.4 to 3.2 "DC

1.2 to 1.25v

Nominally 1OOmVDC using

voltmeter with ,lOMn

input impedance

TABLE 6-6

Ohms Circuit

REQUIRE0 CONDITIONS* REMARKS

REMARKS

Output Of u102

(Analog Supply)

Reference sourc

e

6-8

1

2 RTlOl l.OKn to 3.OKn (can

3 Reference Resistors R108 thru R113 can

4 Power ON, 200n

5

(1101

'Do not remove RTlOl unless absolutely necessary because the leads fall

off device easily while soldering.

Power OFF, DCV func-

tion, all range

buttons out

now be checked in

circuit)*

be checked in cir- R109 affects 2Kn range

wit for

XC"t-KY

range, Input open

0.1%

‘2 Volts across

errmitter collector junction

Resistance Check

R108 affects 2005, range

RI10 affects ZOK" range

Rlll

affects 200Kn range

It112

affects 2000Kn ran<

R113 affects 20Mn range

Voltage drop check

Page 39

MODEL 169

d. Make sure the rubber gasket is in place before

placing the new display in the slot of the front

panel.

e. The zebra strip should be installed after the

new display is placed in the front panel window.

Care must be taken to assure the zebra strip is kept

clean. The zebra strip should be aligned such that

the black stripes contact the conductors on the

display and the conductors on PC-509.

f. Reassemble PC-509 and the front panel using

the three 318" pal nuts.

are snug.

Turn the unit "ON" and check the display to

'3.

see that it is working properly. If the zebra strip

is not aligned properly or if it is dirty there will

be some segments on the display that will not light.

Tighten them until they

K-33. BATTERY REPLACEMENT.

6-34. The low battery indicator will automatically

come on with approximately 5% of battery life

remaining (20 hours for carbon-zinc and 40 hours for

alkaline cells). Replace per directions in Para-

graph 2-6.

6-35. CURRENT FUSE REPLACEMENT (Figure 6-5).

t

To prevent a shock hazard, disconnect all

circuits from the Model 169 INPUT termi-

nals before removing current fuse.

6-36. To remove the current fuse, turn the DMM over

and lay it carefully on its top. Insert d small

screwdriver blade into the slot on the fuse holder,

press gently and turn l/4-turn counter-clockwise.

Lift the holder and fuse out of the receptacle. The

fuse can now be removed for checking or replacement.

Replace with one of the following types:

WARNING

'FIGURE 6-5.

Installing a higher rated fuse than the

one specified could result in damage to

the instrument.

Current Fuse Removal/Replacement.

A

CAUTION

a. U.S.A. Use - 3AG, 25OV, 2A, Normal Blow

b. Europe Use - 5 x 20mm, 25OV, 2A, Normal Blow

6-9

Page 40

I

MODEL 169

SECTION 7. REPLACEABLE PARTS

REPLACEABLEPARTS

7-i. GENERAL.

7-2. This section contains information for ordering replacement

parts. Panel and covers are shown separately on Figure 7-l.