1

Matenance Manual

Model: Focus/Matrix

COPY RIGHT:

KEEWAY INTERNATIONAL DEVELOPMENT CO.,LTD.

FEB.2006

2

If you have any problems can not fnd the solution in this manual, please

fell free to contact with:

KEEWAY INTERNATIONAL DEVELOPMENT CO.,LTD

2000 SZENTENDRE U.8 KOZUZO. HUNGARY

TEL:0036-26-500005

FAX:0036-26-312034

EMAI: info@keewaymotor.com

Our engineer are very glad to give you the necessary assistance

and help.

3

Index

The service manual has been

specially prepared to provide all the

necessary information for the proper

maintenance and servicing of

FOCUS/MATRIX.

The FOCUS/MATRIX is a new type of

scooter that has many techinal features

such as:

V-belt drive automatic transmission

Forced air-cooling system

CDI ignition system

Electric starter system

The FOCUS/MATRIX fits the needs of

a wide variety of scooter user. Those who

will be servicing the scooter should

carefully review the manual before

performing any repair or services. Major

modifications and changes incorporated later

will be advised to QIANJIANG product

distributor in each market. Therefore, if

newest information is requested in the future,

please contact the local QIANJIANG

distributor.

The FOCUS/MATRIX scooters

distributed in your country mignt differ in

minor respects from the standard

specification and, if they do, it is because

some minor modifications had to be made to

comply with the statutory requirements of

your country.

前前前前

4

Index

Termly maintenance and repair 2

Engine 3

Fuell and lubricate system 4

Electrical system 5

Frame 6

Maintenance information 7

General principles 1

5

6

GENERAL PRINCIPLES

TYPE IDENTIFICATION 1-1

FUEL AND ENGINE OIL 1-1

BREAK-IN PROCEDURE 1-1

PRECAUTIONS AND GENERAL INSTRUCTIONS 1-2

MAINTENANCE TOOLS 1-3

SPECIFICATIONS 1-4

CONTENTS

7

1-1 GENERAL PRINCIPLES

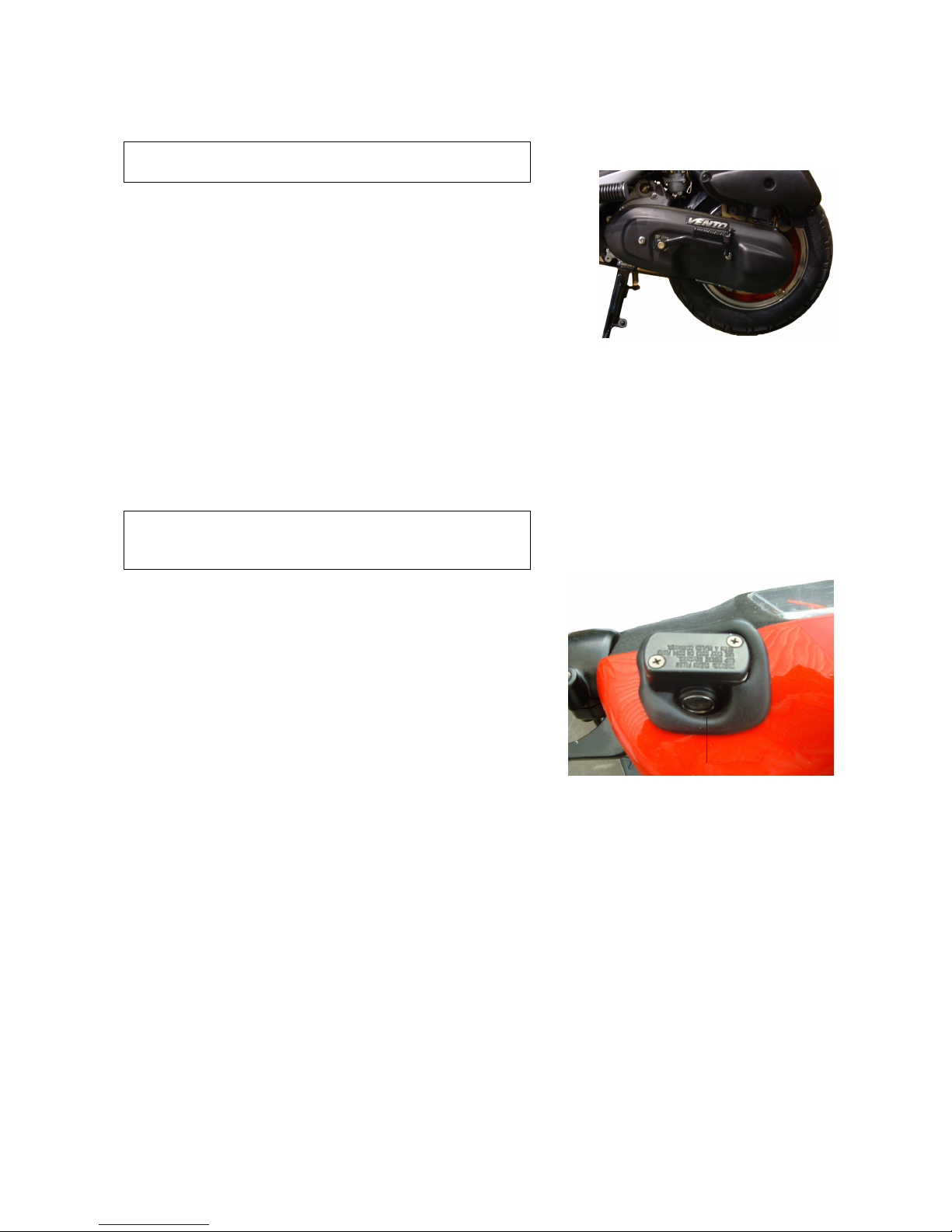

TYPE IDENTIFICATION

①①①①

ENGINE NUMBER

ENGINE NUMBER① is carved on rear crankcase as

Shown in figure.

Both FRAME NUBER AND ENGINE NUMBER are

Designed specially for registering your scooter

and ordering spare parts.

FUEL AND ENGINE OIL

Be sure to use specified fuel and engine oil.

Some specifications are as follows:

FUEL

Unleaded, the minimum octane number is 90 or more.

ENGINE OIL

For QIANJIANG CCI SYSTEM, we recommend special engine oil, you can choose high quality two-stroke

engine oil (without being diluted) if without special oil.

GEAR OIL

Use high quality, all-purpose SAE90 engine oil for scooter.

BREAK-IN TIME

General requirements are as follows:

Limit break-in speed:

At the first 1000KMS(600 miles)mileage,play throttle less than 4/5 throttle;

After mileage exceeds 1000KMS(600 miles),play full throttle;

Don’t run engine too long during break-in time, and try to change throttle position.

8

1-2 GENERAL PRINCIPLES

PRECAUTIONS AND GENERAL INSTRUCTIONS

Correctly abide by the following items when disassembling and assembling scooter:

□ Don’t run engine indoors with little or no ventilation;

□ Be sure to replace new bushings, circlips, O-rings and cotter pins with new ones;

CAUTION

It is forbidden to use the circlip removed from shaft, only use new one;

Be very carefull to install new circlip for fear that the end hatch of circlip exceeds required sliding surface for

shaft;

After installing circlip, inspect whether it has been completely clipped into the groove.

□ Fix bigger diameter bolt first when tightening cylinder head or cylinder, and tighten to specified torque

gradually from inside to outside at diagonal order.

□ Use special tools for some special requrements;

□ Use original components and recommended engine oil;

□ Keep each other’s safety when several persons do;

□ Inspect looseness and operating state of components after reassembling them.;

□ Take high care of gasoline, which is explosive, and never use gasoline as lotion.

The words like warning, notice, note may turn out incessantly in the manual, which means:

WARNING——The personal safety of the rider may be involved. Disregarding the information could

result in injury to the rider.

CAUTION—These instructions point out special service procedures or precautions that must be followed to

avoid damaging the machine.

NOTE——it provides some special information, which keeps maintanance easier and important instructions

clearer..

REPLACEMENT COMPONENTS

Be sure to use genuine QIANJIANG components or their equivalent.. Genuine QIANJIANG components are

high quality parts which are designed specially for QIANJIANG vehicle.

CAUTION

Damage to the scooter may result from use of replacement components which are not

Equivalent in quality to genuine QIANJIANG parts, and it can lead to performance problems.

9

1-3 GENERAL PRINCIPLES

SPECIFICATIONS

DIMENSION AND NET WEIGHT

OVERALL LENGTH……1830mm

OVERALL LENGTH………695mm

OVERALL HEIGHT………1160 mm

WHEELBASE………………1295mm

NET WEIGHT………………92kg

CHASSIS

Front shock absorber……spring, without damp

Rear shock absorber……spring, oil damp

Turning angle … … … … … 48 º (toward the

left\toward the right)

Front wheel…………120/70-12

Rear wheel…………130/70-12

Front brake…………Discφ190

Rear brake…………Drumφ110

ENGINE

Type………two-stroke, forcible wind cooling

Intake system…………piston-reed valve

Cylinder QTY.…………1

Bore………………40.0mm

Stroke………………39.6mm

Discharge ………………49.8mL

Compression ratio……………6.9:1

Carburetor……………flat inhale stopper style

Air cleaner……………dry

Starting system…electricity start and kicking start

Lubricating system………pressure lubricating

ELECTRIC

Ignition mode…………CDI

Ignition timing…………150 at 1500RPM

Spark plug……………BP8HS

Storage battery…………YTX5L-BS

Generator……………AC magneto

Fuse……………8A

Headlight ……………12V—35/35W

Turning light……………12V/10W

Taillight ………………12V—21/5W

Meter light……………12V/1.7W

Oil level signal indicator light…12V/3W

Turning signal indicator light…12V/3W

CAPACITY

FUEL TANK……………5.2L

ENGINE OIL TANK……………1L

GEAR OIL……………0.1L

Transmission system

Clutch system .......dry auto acentric

Gearshift mechanism.....CVT stepless

Operating mode of gears shift mechanism...Automatic acentric

Stepless shift range.....0.86~2.64

*the above data may be modified without

any notification.

10

TERMLY MAINTENANCE AND REPAIR

CONTENT

Periodic maintenance and service schedule……………………… 2-

1

Maintenance and service procedures…………………………… 2-2

Storage battery………………………………………………… 2-2

Spark plug………………………………………………………… 2-3

Cylinder head nut and exhaust pipe bolt……………………… 2-3

Cylinder head and cylinder…………………………………………2-4

Fuel level line………………………………………………………2-4

Air cleaner……………………………………………………………2-5

Throttle cable…………………………………………………………2-5

Engine idle speed……………………………………………………2-5

Oil pump………………………………………………………………2-6

Gear oil………………………………………………………………2-7

Braking…………………………………………………………2-7

Tire …………………………………………………………………2-10

Steering………………………………………………………………2-10

Front shock absorber…………………………………………………2-11

Rear shock absorber…………………………………………………2-11

Vehicle bolts and nuts…………………………………………………2-11

11

Periodic maintenance and service schedule

The following table lists all required intervals for maintenance and service,following which, you are assred to

have your scooter perform in the best way.

Note

Do more frequent maintenance when often riding on bad road

Periodic maintenance table

Mile 600 4000 7500 11000 15000

Kilometer

1000 6000 12000 18000 24000

Interval

Months. 2 12 24 36 48

Storage battery I

I I I I

Cylinder head nut and

exhaust pipe bolt

T

T T T T

Cylinder head and

cylinder

—

C C C C

Spark plug —

R R R R

Air cleaner Clean every 3000KM(2000 miles)

Idle speed rpm

I I I I I

Throttle cable play

I I I I I

Oil pump

I I I I I

Gear oil I — I — I

I I I I

I

Fuel line

Replace every 4 years

Brake

I I I I I

I I I I I

Brake hose

Replace every 4 years

I I I I I

Brake fluid

Replace every 2 years

Steering

I I I I I

Front fork

I I I I I

Rear shock absorber

I I I I I

Tire

I I I I I

Vehicle body bot

andnut

T

T T T T

Note

I=inspect,clean,adjust,lubricate,or replace if necessary;

A=adjust; C=clean; R=replace; T=tighten

12

Maintenance and adjustment procedures

The section describes the servicing procedures for each item of the Periodic Maintenance requirements.

Storage battery

Inspect at initially 1000KM(600 miles,2 months),

andevery 6000KM(4000 miles,12 months)thereafter

□ Uncover seat, and then remove the battery box cap in the

Middle of helmet barrel.

□ Disconnect negative pole line end, positive end, and then remove battery;

□ Measure the voltage between the two ends of battery with

voltage gauge,charge if the voltage is below 12V

13

Cylinder head nuts and exhaust pipe bolts

Tighten at initially 1000 km(600 miles,2 moths),and

every 6000 km(4000 miles,12 months)

If cylinder head nuts are not tightened to the

specified torque, may result in leakage of

compressed fuel-air mixture and reduce output,

tighten the cylinder head nuts in the following

procedures::

1. Remove the frame lower covers.

2. Remove the cylinder head cover bolt.

3. Remove spark plug cap.

4. Tighten the nuts evenly one by one to the

their specified torque. Tighten the nuts in the

order indicated.

Tithtening torque::::

Cylinder head nut::::15-18N.m

Exhaust pipe bolt::::15-18N.m

Cylinder and cylinder head

Remove carbon every 6000 km( 4000

miles,12 months)

Carbon deposits in the combustion chamber and the

cylinder head will raise the compression ratio and may cause

preignition and overheating. Carbon deposited at the exhaust

port of the cylinder will prevent the flow of exhaust gases,

reducing the output. Remove carbon deposits periodically.

14

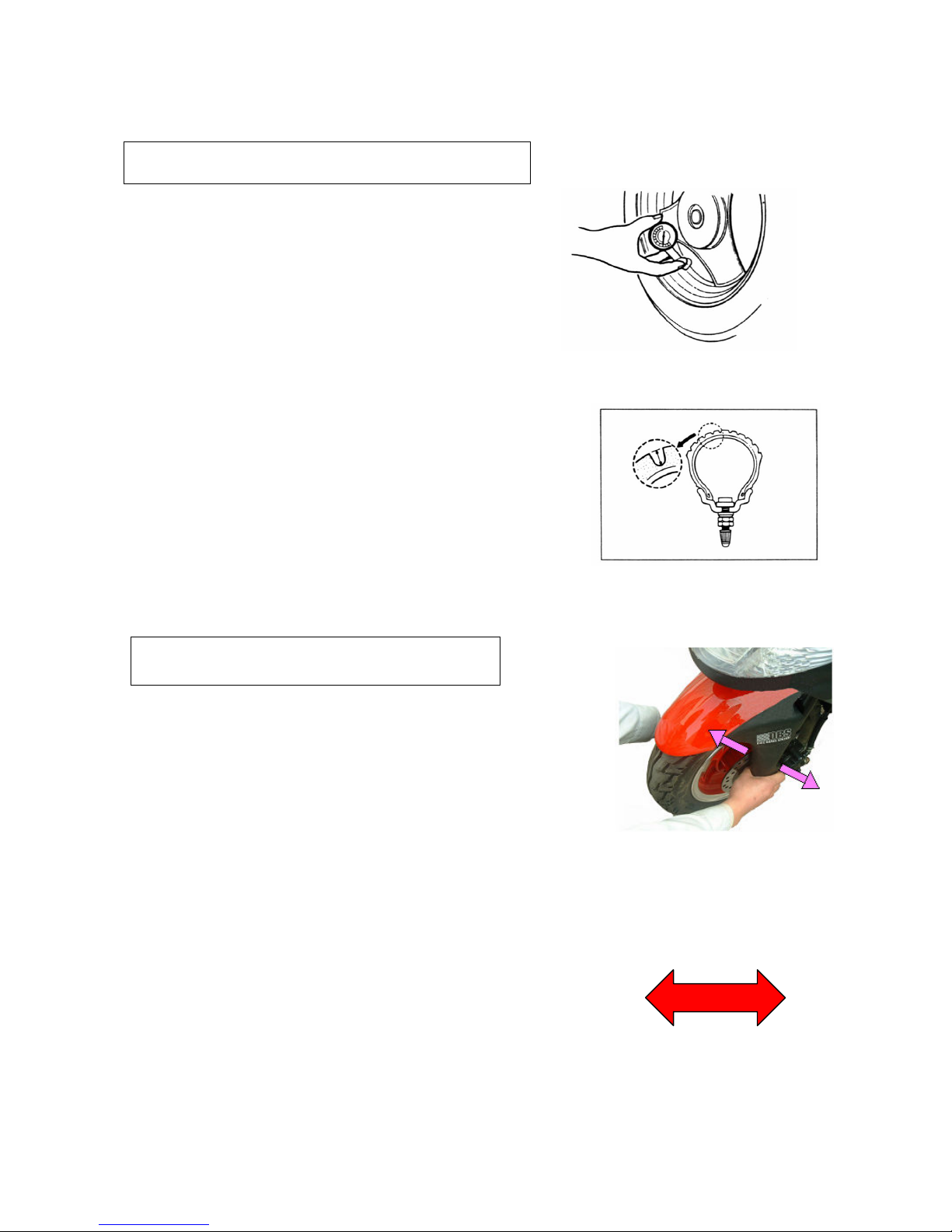

SPARK PLUG

Neglecting the spark plug maintenance eventually leads to

difficult starting and poor performance. If the spark plug is used for a

long time, the electrode gradually burns away and carbon builds up

along the inside part. In accordance with the periodic table, the plug

should be removed for inspection, cleaning and to reset the gap.

Carbon deposits on the spark plug will prevent good sparking

and cause misfiring. Clean the deposits off periodically.

If the center electrode is fairly worn down, the plug should be

replaced and the plug gap set to the specified gap using a

thickness gauge.

Thickness gauge

Spark plug gap:0.6-0.7 mm (0.024-0.028 inch)

Check the spark plug for burnt condition. If abnormal replace the spark

plug as indicated in the chart.

NGK TROCH REMARKS

BPR7HS E8RTC

If the standard plug is apt to get wet,

replace with the plug.

BPR8HS E7RTC Standard

BPR9HS E6RTC

If the standard plug is apt to

overheat, replace with the plug.

Tighten the spark plug to the specified torque.

Spark plug

Tightening torque:15-18N.m

NOTE:

To check the spark plug, first make sure that the fuel used is

unleaded gasoline, and if plug is either sooty with carbon or

burnt white, replace it.

Confirm the thread size and reach when replacing the plug.

FUEL LINE

Inspect at initially 1000 km (600 miles,2 months) and every

6000 km (4000 miles,12 months), replace every 4 years.

15

AIR CLEANER

Clean every 3000KM(2000 miles)

①①①①

If the air cleaner is clogged with dust, intake resistance will,

be increased with a resultant decrease in power output and an

increase in fuel consumption. Check and clean the element in the

following manner.

③③③③

Remove clamp ① and screw ②,take down air cleaner

Unscrew tapping screw③,remove air cleaner cap④。 ④ ②

Fill a washing pan of a proper size with

Non-flammable cleaning solvent. Immerse the air

Cleaner in the cleaning solvent and wash them clean.

Squeeze the cleaning solvent out of the washed element

By pressing it between the palms of both hands: do not twist

or wring the air cleaner filter core element or it will develop tears.,

Immerse cleaned filter core of air cleaner

in CCI or CCI SUPER oil, and squeeze the oil out of

the core,which may be slightly wet with oil.

Install air cleaner filter core in the reverse

order of removal.

CAUTION:

Before and during the cleaning operation, inspect the core for tears. A tore core must be

replaced

Be sure to position the filter core,so that no

incoming air will bypass it. remember, rapid wear

of piston rings and cylinder bore is ofter caused by

defective or poorly fitted filter core.

А Non-flammable cleaning solvent

БCCI or CCI SUPER oil

THROTTLE CABLE

Adjust at initially 1000KM(600 miles,2 months),

and every 6000 km(4000 miles,12 months)

Loosen locknut ①,and adjust throttle cable play by

turning adjuster ② in or out to obtain the

following cable play. After adjusting the calbe

play,tighten the locknut.

Cable play:0.5-1.0MM(0.02.-0.040 inch)

Engine idle speed

Adjust at initially 1000KM(600 miles,2 months)

and

every 6000 km(4000 miles,12 months)

thereafter.

② ①

Adjust the throttle cable play.

warm up the engine.

Note

NoteNote

Note::::

Warm up engine for 10 minutes.

Warm up engine for 10 minutes.Warm up engine for 10 minutes.

Warm up engine for 10 minutes.

16

Connect an electric tachometer to the connecting protiion of the magneto lead wire as shown I nthe

illustration. Use the selector key “C’ position.

Tachometer

Adjust the throttle stop screw to obtain the idle r/min as follows:

Idle speed:1400±100r/min

Finally adjust the throttle cable play.

OIL PUMP

Inspect at initially 1000KM( 600 miles, 2 months)

andevery 6000 km(4000 miles,12 months)thereafter.

The engine oil is fed by the oil pump to the engine. The amount of oil fed to

it is regulated by engine speed and oil pump control lever which is controlled

by amount of throttle opening.

Check the oil pump in the following manner to confirm correct operation for

Throttle valve full opening position.

Turn the throttle grip full open.

Check whether the red mark ① on the oil pump control lever

Is aligned with the index mark ② when the throttle valve is positioned as above.

If the marks are not aligned, loosen lock nuts ③ and turn the adjuster ④ in or out to align the marks.

After align the marks, tighten the locknuts.

Caution:

Oil pump calbe adjustment must be done after throttle cable adjustment.

17

GEAR OIL

Inspect at initially 1000 km((((600 miles,,,,2 months))))and every

6000 km((((4000 miles,,,,12 months))))thereafter.

Inspect gear oil periodically as follows:

Remove the cover and hose

Remove the kicking starter lever

Remove clutch cover

Remove oil level bolt and inspect oil level, if oil level is below oil hole,

Add oil until oil flows from the level hole.

Tighten oil level bolt to the specified torque.

Tightening toque::::9-15N.m

((((0.9-1.5 kg-m ,,,,6.5-11.0 lb-ft))))

BRAKES

Inspect at initially 1000 km((((600 miles,,,,2 months)))) and

every 6000 km((((4000 miles,,,,12 months))))thereafter, replace

brake fluid every 2 years, replace brake hose every 4 years.

Front brake fluid level

Keep the scooter upright and place the handlebar staight.

Check brake fluid level by observing the lower limit line

on the brake fluid reservoir.

When the level is below the lower limit line, replenish with

Brake fluid that meets the following specification.

Specification and classification::::DOT4

QIANJIANG BRAKE FLUID

WARNING::::

The brake system of the scooter is filled with a glycol-based brake the lowest line

Fluid. Do not use or mix different types of fluid such as silicone-based and petroleum-based. Do not use any

brake fluid taken from old, used or unsealed containers. Never reuse the brake fluid left over from the

last servicing and stored for long periods.

18

WARNING::::

Brake fluid, if it leaks, will interfere with safe running and immediately discolor painted surfaces.

Check the brake hoses for cracks and hose joints for leakage before riding.

Brake pads

Wearing condition of brake pads can be checked by observing the limit

Line ① marked on the pad. When the wear exceeds the limit mark, replace

The pads with new ones.

Bleeding air from the brake fluid circuit

Air trapped in the fluid circuit acts like a cushion to absorb a large

proportion of the pressure developed by the master cylinder and thus

interferes with the full braking performance of the brake caliper. The

presence of air is indicated by “sponginess” of the brake lever and

also by lack of braking force. Considering the danger to which such

trapped air exposes the machine and rider, it is essential that, after

remounting the brake and restoring the brake system to the normal

condition, the brake fluid circuit be purged of air in the following manner:

Fill up the master cyliner reservoir to the upper end of the inspection

window. Replace the reservoir cap to prevent entry of dirt.

Attach a pipe to the caliper bleeder valve, and insert the free end of

The pipe into a receptacle.

□ Bleed air from the bleeder valve.

Squeeze and release the brake level several times in rapid succession. And squeeze the lever fully without

releasing it. loosen the bleeder valve by turning it a quarter of a turn so that the brake fluid runs into the

receptacles: the will remove the tension of the brake lever causing it to touch the handlebar grip. Then, close the

valve, pump and squeeze the lever, and open the valve. Repeat the process until the fluid flowing into the

receptacle no longer contains air bubbles.

19

NOTE::::when bleeding the brakign system, replenish the brake fluid reservoir if necessary.

Make sure that there is always some fluid visible in the reservoir.

Close the bleeder vavle, disconnect the pipe. Fill the reservoir with brake fluid to the upper end of the

inspection window.

BLEEDER VALVE

TIGHTENING TORQUE: 6-9N.m(0.6-0.9kg-m,4.5-6.5lb-ft)

CAUTION:

Handle brake fluid with care: the fluid reacts

chemically with paint, plastics, rubber materials, etc.

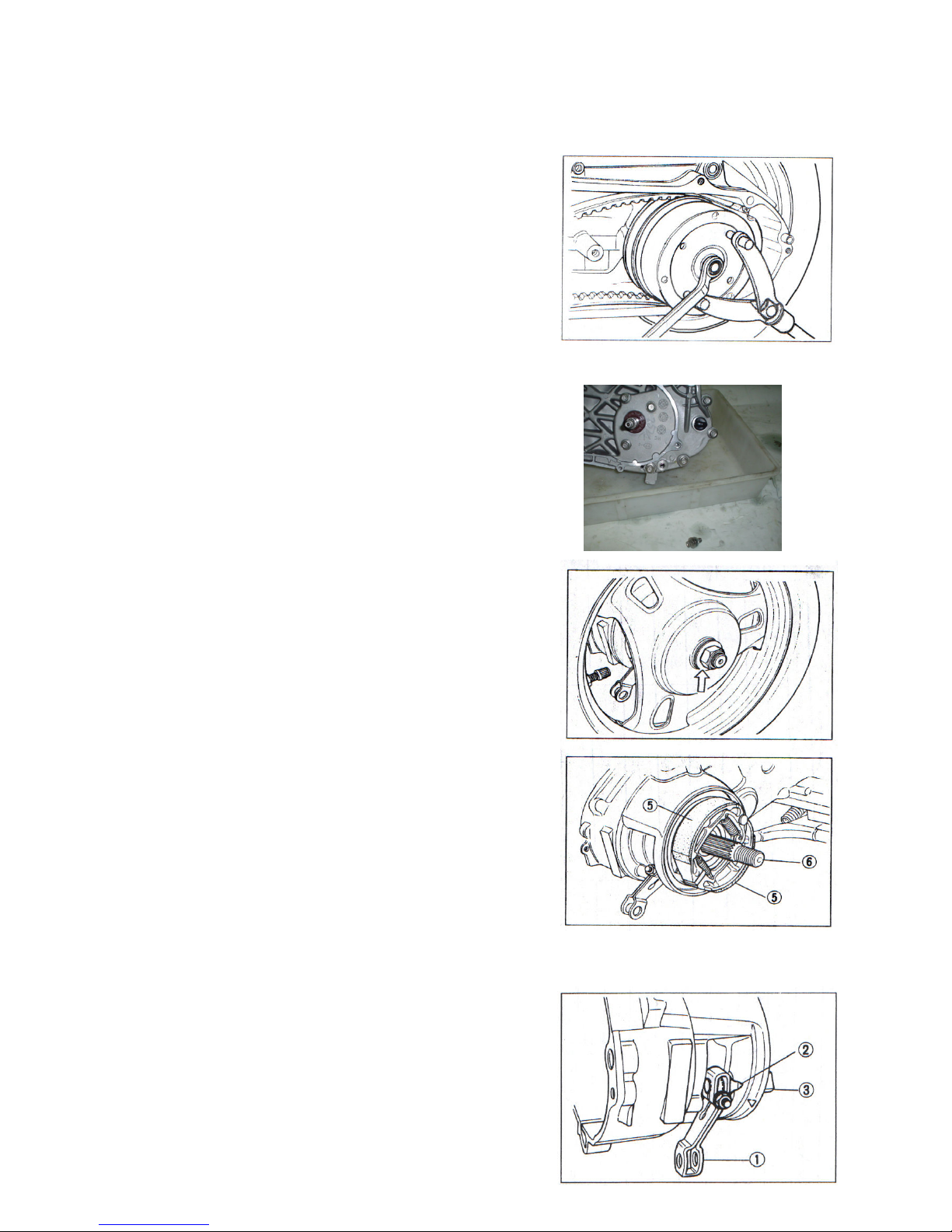

Rear brake

Turn adjusting nut ① so that the the play ② of

Brake lever is 15-25MM as shown in the illustration.

Brake shoe wear:

The vehicle is equipped with the brake lining limit

Indicator ③ on the rear brake.

Inspect brake lining limit as follows:

1. First check if the brake system is properly

Adjusted.

2. when operating the brake, check to see that

the tip of indicator ③ is within the range ④.

3. if the tip of indicator is beyond the range,

the brake shoe assembly should be raplaced with a ②

new set of shoe.

②

20

Tire

Inspect at initially 1000KM(600 miles,2 months) and every

6000KM(4000 miles,12 months)thereafter

Tire pressure:

If the pressure is too high, the scooter will tend to rede stiffly

and have poor traction. Conversely, if tire pressure is too low,

stability will be adversely affected. Thereafter, maintain the

correct tire pressure for good roadability and to prolong tire life.

CAUTION:

Caution:

The standard air pressure of tires is 175/196Kpa, The use of other

Than standard may cause handling instability. It is highly

recommended to use a QIANJIANG genuine tire.

Tire tread condition:

Operating the scooter with the excessively worn tires will decrease

riding stability and consequently invite dangerous situation. It is highly

recommended to replace the tire when the remaining depth of tire tread

reaches the following specification.

Front and rear:1.6MM(0.064IN)

Tire depth gauge

Steering

inspect at initially 1000KM(600 miles,2 months)

and every 6000KM thereafter.

Steering should be adjusted properly for smooth turning of handlebars

and safe running. Too stiff steering prevents smooth turning of handlebars

and too loose steering will cause poor stability.

Check that there is no play in the front fork assembly by supporting the

machine so that the front wheel is off the ground, with wheel staight ahead,

grasp lower shock absorber near the axle and pull forward. If play is

found, perform steering bearing adjustment.

21

Front shock absorber

Adjust at initially 1000KM(600 miles,2 months)

and

every 6000 km(4000 miles,12 months)thereafter.

Inspect the front shock absorber for oil leakage or other damage, and replace the defective parts, if necessary.

Rear shock absorber

Adjust at initially 1000KM(600 miles,2 months)and every

6000 km(4000 miles,12 months)thereafter.

Inspect front shock absorber for oil leakage and other damage, and replace the defective parts if necessary.

No. Item N•m Kg-m

1 Front axle nut 55-60 5.5-6

2 Handle tightenging nut 37-44 3.7-4.4

3 Steering sterm locknut 37-44 3.7-4.4

4 Disc brake caliper fixing bolt 22-29 2.2-2.9

5 Disc brake master cylinder hose fixing bolt 22-29 2.2-2.9

6 Disc brake fixing bolt 5-9 0.5-0.9

7 Front shock absorber fixing bolt 37-44 3.7-4.4

8 Engine pivot fixing nut 55-60 5.5-6

9 Engine bracket fixing nut 37-44 3.7-4.4

10 Rear wheel fixing nut 100-130 10-13

11 Rear brake rocker arm fixing bolt 5-9 0.5-0.9

12 Rear shock absorber under fixing bolt 22-29 2.2-2.9

13 Start pedal mounting screw 15-20 1.5-2

14 Rear shock absorber top fixing bolt 37-44 3.7-4.4

22

③③③③

①①①①

②②②②

④④④④

⑤⑤⑤⑤

⑥⑥⑥⑥

⑦⑦⑦⑦

⑧⑧⑧⑧

⑨⑨⑨⑨

⑩⑩⑩⑩

14

23

LUBRICATION

Proper lubrication is important for smooth operation and long life of each working part of the scooter. The

major lubrication points are indicated below:

NOTE:

1. Lubricate exposed parts which aare subject to ruse with engine oil.

2. Before lubricating each part, clean off any rusty spots and wipe off any grease, oil dirt of grime.

WARNING:Be careful not to apply too much grease to the rear brake camshaft, otherwise brake slippage will

result from the presence of grease in brake drum.

①steering stem bearing

②front wheel bearing

③engine bracket

④rear brake camshaft

⑤side stand

⑥rear brake shaft and rear brake calbe

⑦speedometer calbe and gear box

⑧main stand

Αlubrication

①A

②⑦A ④A

⑥A

⑤⑧A

③A

24

ENGINE

CONTENS

Engine components removal with the engine in place

Engine removal and remounting

Engine removal

Engine remounting

Engine disassembly

Engine components inspection and servicing

Bearings

Oil seals

crankshaft

automatic clutch inspection

cylinder head

cylinder

piston

reed valve

engine remounting

oil seals

bearings

bushings

crankshaft

crankcase

rear axle shaft

transmission

starter pinion and starter gear

Movable driven and clutch

Movable drive

Kicking starter

Piston

Oil pump and oil pump driven gear

Intake pipe

Magneto

25

Engine components removable with the engine in place

The parts listed below can be removed and reinstalled without removing the engine

from the frame.

Engine left side

Kicking starter lever

Clutch brake pad kit

Driver left face

V-belt

Driver belt right face

Electric starter gear

Super clutch

Driven face

Engine center

Carburetor

Intake pipe

Reed valve

Oil pump

Worm wheel

Cylinder head

Cylinder

Piston

engine right side

cooling fan

Magneto

Starter motor

26

ENGINE ASSY.

Remove the muffler

Remove cooling fan cover

Remove cylinder cover

Remove cooling fan

Remove magneto nut with special tools.

remove magneto rotor and half circle key

with special tools.

remove magneto stator and paper gasket

remove oil pump

27

Remove worm wheel and oil seal press board

remove cylinder head and

cylinder

Place a cloth stopper beneath the piston

and remove the circlip with a plier.

remove the piston pin and piston.

Remove the kick starter lever.

Remove side cover

Remove movable ratchet wheel and clip

28

Remove starting driven ratchet wheel by removing the nuts.

Rmove fan⑤ and V-belt⑥.

Disassemble the movable drive

face⑦.

Remove electric gear press board, electric

gear And super clutch

Remove starter motor

29

Remove the clutch housing with the

special tool.

drain gear oil

remove rear axle nut

remove rear wheel

remove brake shoe⑤ and rear axle⑥。

Remove the rear brake cam lever①,indicator

plate② and camshaft③.

30

remove spring④

remove cotter pin⑤ and shaft⑥

remove main stand⑦

remove gearcase cover

Remove paper gasket① and middle gear assy.②,

Remove output gear assy.③

remove carburetor

remove intake pipe

remove reed valve and paper gasket.

Loading...

Loading...