Page 1

ThermoSaver

02/12/10

Hot Gas

TM

PRODUCT DATA,

APPLICATION &

INSTALLATION GUIDE

Bulletin K40-THERM-PDI-13

1069130

Supplement to Condensing Unit

Installation & Maintenance Manual

Defrost System

For use on select Air, Remote or

Water-cooled Condensing Units

matched with Low, Medium or High

Prole Evaporators

R22 - R404A 2-30 HP

-30°F to +34°F Room Temperatures

CONTENTS PAGE

Application Guideline..............................

ThermoSaver Operation Cycle...............

Wiring Diagrams.....................................

Installation..............................................

ThermoSaver Control Settings...............

Troubleshooting Guide...........................

Service Parts List...................................

Warranty.................................................

2

3,4

5-7

8

8,9

10

11

BACK

● Provides fast, efcient evaporator

defrosting.

● Complete factory pre-piping of all

controls and valves.

● Utilizes existing liquid line as hot gas

pipe.

● Reduces installation time and provides

maximum savings during operation.

● Ensures maximum compressor

protection using large capacity

suction accumulator and outlet

pressure regulating valve.

Page 2

APPLICATION GUIDELINE

K40-THERM-PDI-13

- 2 -

02/12/10

ThermoSaver Hot Gas Defrost systems provide for a

fast defrost alternative over comparable electric defrost

systems. They can be used on any freezer or cooler

application ranging in room temperatures from –30°F to

34°F, with capacity ranges of 2 – 30HP , available as an

Indoor Air Cooled, Outdoor Air Cooled, Remote or Water

Cooled Condensing unit.

The basic piping, layout and design concept are covered in pages 3 and 4 of this manual. These should be

reviewed rst to understand the refrigerant ow and to

identify the special defrost components used.

Important design points are:

1. Concept is similar to a “three-pipe” hot gas bypass

system yet only uses two pipes (shares the liquid line

and reduces eld piping and labour cost). The main

difference is the third shared pipe does not need to

be oversized. During the initial hot gas cycle Liquid is

fed rst, then a mixture, only at the latter part of the

cycle is it all hot gas. (so high pressure drops are not

realized)

2. The defrost is very fast - less than 10 minutes and

uses pressure controls (not temperature) for termination and fan delay functions. (results in faster

response time)

3. The evaporator used must be included together with

the Condensing Unit (i.e. sold/supplied as a complete system package) as it must be properly selected and piped with the correct defrosting components.

Line runs and sizes need to be reviewed. (keep

within 100 feet) Electric heat drain pans (using time

–delay relay function) are recommended in place of

hot gas loops.

4. This unique defrost system can be used with either

one or multiple evaporators (regardless of the application, freezer or cooler) and all can be defrosted

at once.

5. There does exist added suction pressure drop across

the outlet pressure regulator (CPR) and suction

accumulator so for load calculation purposes do not

undersize (keep adequate added safety margin).

6. Excessive system refrigerant charges (from long

runs, oversized evaps, oversized receivers) must be

avoided. During the latter portion of the defrost cycle

and post defrost refrigeration cycle, refrigerant will

ood back to the suction accumulator. Keeping the

overall system charge low will reduce the amount of

oodback.

To ensure maximum design benets:

1. Review the line runs and sizes (use short and

properly sized liquid lines -do not oversize).

2. Use minimal refrigerant charge. Use only enough to

satisfy the condenser ooding valve (low ambient

control), receiver seal, liquid line and evaporator

charge requirements.

3. Field adjust these ve critical defrost components to

proper initial settings:

(a) Outlet Press Regulator (CPR) Valve- Must be set

to the lowest possible setting (approx 10-15°F

above evap temp design) without compromising post defrost pull-down time. This valve is not

primarily set for motor compressor motor overload

protection, it’s main purpose is to keep a pressure

differential during the defrost .

(b) Defrost Termination Control- Must not be set too

high. Keep to lowest possible setting (as soon as

ice and frost has melted and pressure then starts

to rise). Higher settings result in longer defrosts

(over 10 minutes) and excessive oodback.

(c) Fan Delay Control- Must not be set too low (as

will promote ooding of the evap resulting in increased amount of refrigerant ood back after the

defrost)

(d) Timeclock - Fail safe Time should not be set

greater than 20 minutes. If the defrost is taking too

long then an issue exists with the control settings

or application. (This must be identied and resolved.)

(e) Time –Delay (Hot gas cycle) – Must be set at

least for two minutes (up to 5 min) in order to (i)

pump out all remaining refrigerant in the evaporator and (ii) Pre-heat the drain pan prior to the hot

gas entering the coil. This timer setting must be

longer than the compressor anti-short cycle setting (if equipped)

Important initial set points are covered on pages 8 and 9 in

this manual and must be followed. Further adjustments can

then be made to suit local eld conditions.

Page 3

THERMOSAVER OPERATION

K40-THERM-PDI-13

- 3 -

02/12/10

The ThermoSaver defrost cycle system provides a

quicker defrost period (up to three times faster) over the

conventional electric defrost system. This minimizes the

rise in box temperature during the defrost which reduces

product deterioration and increases the system efciency.

This results in lower running times and reduced energy

costs. When using more than one evaporator on the

same condensing unit, all the evaporators can be defrosted

simultaneously.

All ThermoSaver components are completely factory

installed, pre-piped and pre-wired. An extra third pipe

(hot gas line) is not required.

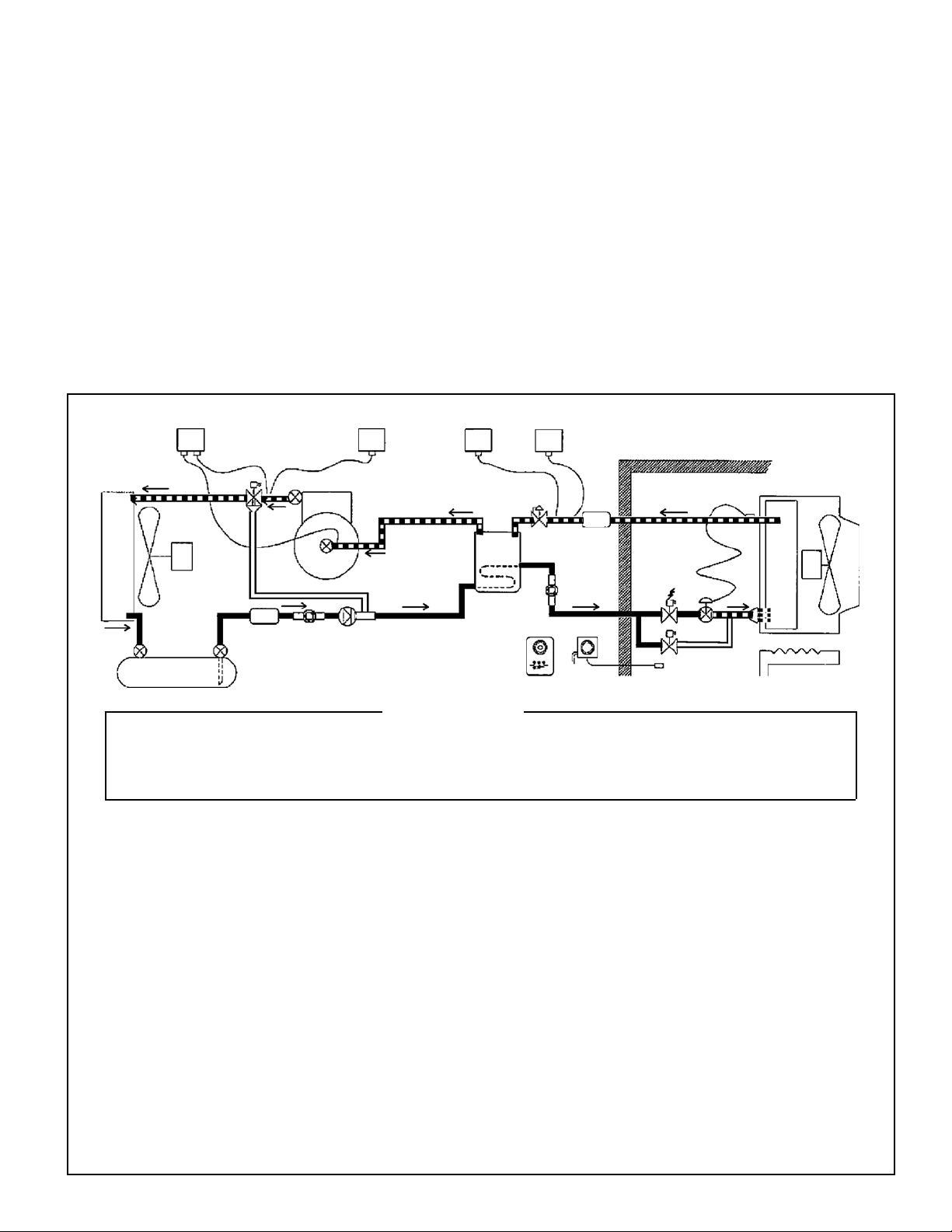

REFRIGERATION

L M

Suction

Accumulator

Condenser

C

D

Compressor

This signicantly reduces the overall installation time

and cost. Factory installed standard components include

the evaporator distributor nozzle, thermostatic expansion

valve (TXV), liquid line solenoid valve, hot gas solenoid

valve, liquid check valves, three way solenoid valve,

defrost regulating valve, suction accumulator, defrost

termination / fan delay pressure controls and drain pan

heater and timeclock. Room thermostat and suction

lter are optional to be eld installed.

The following diagrams explain the ThermoSaver operation

during both refrigeration and defrost cycles.

N

H

Filter

Evaporator

FB

Boil Out

Drier

Receiver

A - Room Thermostat

B - Liquid Line Solenoid Valve

C - Dual Hi / Lo Pressure Control

D - Three Way Hot Gas Solenoid Valve *

E - Liquid Line Check Valve

* On larger (15 HP & up) systems, a separate N/O and N/C solenoid valve is used in place of 3-way valve

As the box temperature rises, the room thermostat (A)

energizes the liquid line solenoid valve (B). This allows

refrigerant to enter the evaporator, build up pressure,

cause the low pressure control (C) to energize the

compressor contactor and start the compressor. The

compressor’s hot discharge gas is piped out to the

condenser through the de-energized 3-Way valve (D).

or seperate N/O and N/C solenoid valves. The hot

refrigerant gas is condensed by the condenser. The

liquid then ows to the receiver through the opened

check valve (E) and on through the coiled liquid line

within the suction accumulator (this performs the function

as a suction to liquid heat-exchanger). The subcooled

liquid then ows through the liquid line solenoid valve

(energized/open) and on to the TXV (F)

(Thermostatic expansion valve).

E

F - Thermostatic Expansion Valve

H - Defrost Regulating Valve

I - Timeclock

Heat Exchanger

I

LEGEND

The refrigerant is then directed through the distributor

at a lower pressure and ows into the evaporator. The

refrigerant liquid / vapour mixture is then boiled by the

warmer box air from the evaporator fan. The refrigerant

vapour then ows though a defrost regulating valve (H)

preventing a motor overload from high suction pressures

and enters the suction accumulator and on to the compressor.

The cycle continues until the room temperature is satised. This de-energizes the liquid line solenoid, initiating a

pumpdown cycle that reduces the suction pressure to the

cut-out setting on the low pressure control which de-energizes the compressor.

A

J - Drain Pan Heater

K - Hot Gas Solenoid Valve

L - Three Way Hi Pressure Control

M - Defrost Termination Pressure Control

N - Fan Delay Pressure Control

K

J

Page 4

THERMOSAVER OPERATION

K40-THERM-PDI-13

- 4 -

02/12/10

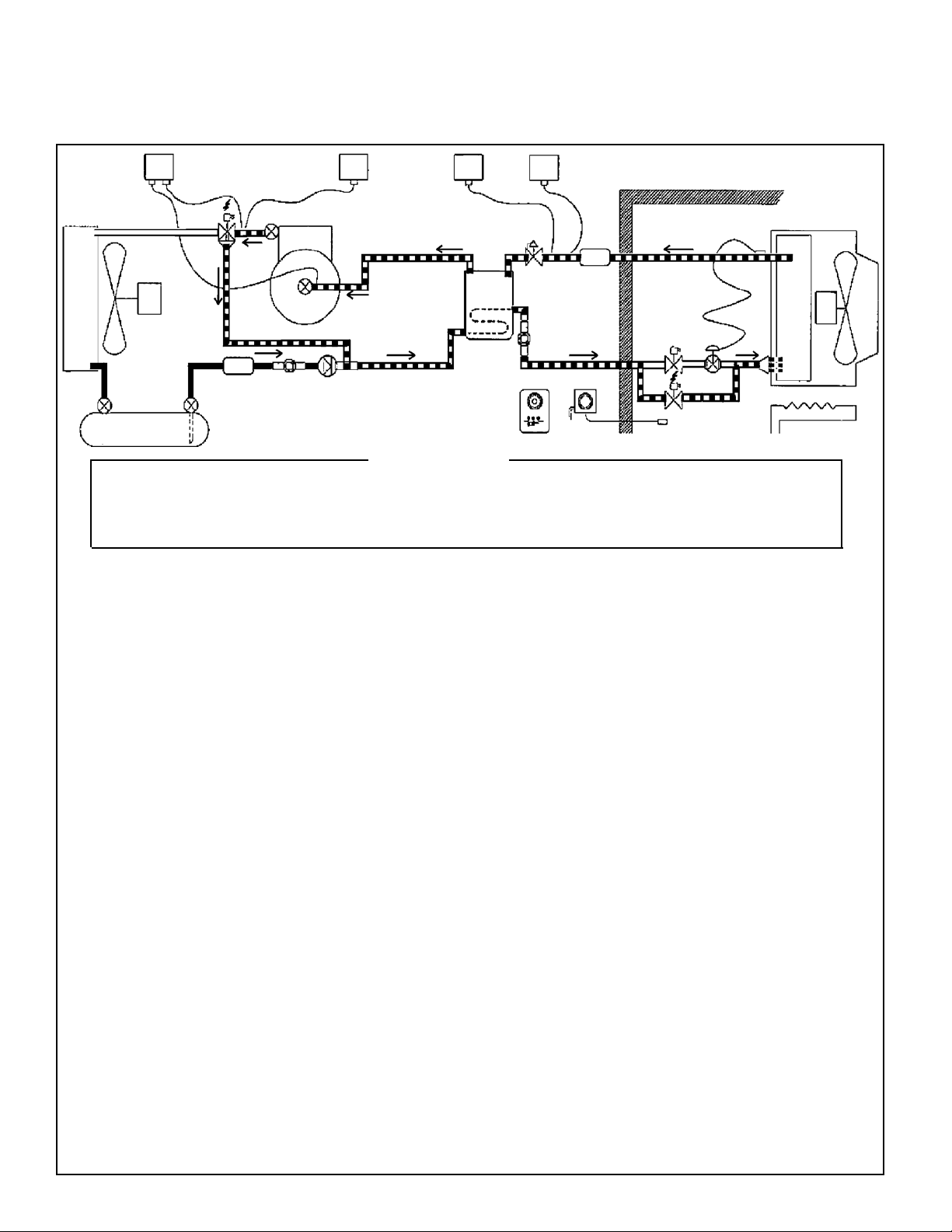

DEFROST

C

Condenser

D

Compressor

L M

Suction

Accumulator

H

N

Evaporator

Filter

FB

Boil Out

Drier

Receiver

A - Room Thermostat

B - Liquid Line Solenoid Valve

C - Dual Hi / Lo Pressure Control

D - Three Way Hot Gas Solenoid Valve*

E - Liquid Line Check Valve

* On larger (15 HP & up) systems, a separate N/O and N/C solenoid valve is used in place of 3-way valve

E

F - Thermostatic Expansion Valve

H - Outlet Pressure Regulator

I - Timeclock

Heat Exchanger

I

LEGEND

Third

K

A

J - Drain Pan Heater

K - Hot Gas Solenoid Valve

L - Three Way Hi Pressure Control

M - Defrost Termination Pressure Control

N - Fan Delay Pressure Control

Pipe

J

The refrigeration cycle results in frost formation on the

surface of the evaporator. This frost will eventually build

up to the point where it will restrict the air ow causing a

loss of refrigeration capacity. To prevent this, a timeclock

(I), usually set to repeat every 6 or 8 hours, initiates a

defrost cycle which melts the frost.

The clock de-energizes (closes) the liquid line solenoid

valve which causes the compressor to pumpdown and

shut off from the low pressure control. The clock also

energizes the drain pan heater (J) in the evaporator and

timer relay which after a two or more minute delay energizes (opens) the 3-way valve and hot gas solenoid valve

(K) which then builds up pressure in the evaporator causing

the low pressure control to close and start the compressor.

The hot discharge gas from the compressor ows through

the 3-way valve forcing all the liquid left in the liquid line

into the evaporator. If pressure builds up too high the

3-way valve safety pressure control (L) will de-energize

the solenoid valve and allow pressure to relieve through

the condenser.

Pressures within the evaporator will increase during the

defrost. The outlet pressure regulator (H) maintains a desired pressure differential in the system, as well as reducing the amount of liquid refrigerant back to the accumulator.

The regulator also minimizes any high suction pressure

avoiding compressor motor overloads.

Once all the frost has melted the pressure will continue to rise until the defrost termination pressure

control (M) energizes the timeclock’s internal solenoid terminating the defrost cycle. The 3-way valve,

hot gas valve solenoids are then de-energized. The

liquid line solenoid valve opens and the compressor

continues to run. The evaporator fans do not start

up until the pressure in the evaporator is low enough

to close the Fan delay control (N). By delaying the

fans this allows any moisture left on the coil to drain

away or freeze. As soon as the evaporator fans are

energized the system will then resume back to the

refrigeration cycle.

The cycle continues until the room temperature is

satised.

This de-energizes the liquid line solenoid, initiating a

pumpdown cycle that reduces the suction pressure to

the cut-out setting on the low pressure control which

de-energizes the compressor.

Page 5

WIRING DIAGRAMS

K40-THERM-PDI-13

- 5 -

02/12/10

TYPICAL SYSTEM WITH LOW PROFILE EVAPORATOR

Page 6

WIRING DIAGRAMS

K40-THERM-PDI-13

- 6 -

02/12/10

TYPICAL SYSTEM WITH MEDIUM PROFILE EVAPORATOR

Page 7

WIRING DIAGRAMS

K40-THERM-PDI-13

- 7 -

02/12/10

TYPICAL SYSTEM WITH HIGH PROFILE EVAPORATOR

Page 8

INSTALLATION

K40-THERM-PDI-13

- 8 -

02/12/10

For general installation procedures refer to the Condensing unit Installation and

Maintenance instructions included with the unit. (Bulletin K40-CU-IM, part # 1068155)

THERMOSAVER CONTROL SETTINGS

The following controls should be initially set as listed

below and then MUST be re-adjusted to suit local eld

conditions.

Dual (HI-Lo) Pressure Control

The High side setting is strictly a safety cut out (in the

event of a high pressure build up due to condenser fan

failure, blocked condenser air or restriction in the

discharge line etc.) The control is normally closed. The

low side setting should be adjusted for a pumpdown

mode. When the space thermostat is satised the

liquid line solenoid de-energizes (closes) causing the

pumpout. The low pressure control then opens up,

de-energizing the compressor contactor coil.

See Table 1 for initial settings

Three-way High Pressure Control

During the defrost cycle the three way solenoid valve

(or separate N/O and N/C hot gas solenoid valve) is

energized by the three way pressure switch which is

normally closed. This control only operates during the

defrost cycle. It is a safety control to prevent the

discharge pressure from reaching excessive pressures.

It is important this is set high enough to prevent

unnecessary short cycling. In the event of a trip it will

de-energize the Three way solenoid valve. This control

MUST be set to cut out at a lower cut-out setting than

that of the main high pressure control.

See Table 1 for initial settings.

Defrost Termination Pressure Control

After all the ice and frost has melted on the evaporator

coil, the suction pressure will rapidly rise and once a

pre-set pressure is reached (the cut-in pressure setting)

the control closes and energizes the Timeclock’s “X”

terminal which then terminates the hot gas defrost.

This control must be carefully set to suit the local eld

conditions. Too low of a cut in setting will terminate the

defrost too soon (which may still leave some ice/frost

on the evaporator). Too high of a cut-in setting may extend the defrost period and cause excessive oodback

to the compressor as well as adding unnecessary heat

to the evaporator. See Table 1 for initial settings.

An ideal setting for the control is after the evaporator

coil is completely clear of frost, there is an approx 2

minute time period before the defrost cycle terminates.

Fan Delay Pressure Control

Once the defrost cycle has terminated the refrigeration

cycle then starts back up (liquid line solenoid opens and

feeds the TXV). To prevent any moisture and water droplets

from blowing off the evaporator coil the fans must be

delayed. The fan delay pressure control is open (above the

cut-in set point) at the start of the cycle, which de-energizes

the fan contactor. Once the suction pressure starts to drop,

the evaporator becomes colder and re-freezes any water

left remaining on the coil. At this time the pressure drops

to the cut-in set point and energizes the fan contactor. The

fan delay pressure control should not be set at too low of a

cut-in setting since it will delay the fans too long. See Table

1 for initial settings.

Outlet Pressure Regulator

During refrigeration mode, this valve regulates the outlet

pressure and ensures that the suction pressure does not

rise above the set point (adjustable). This limits the pressure

to the compressor to an acceptable pressure that prevents

the compressor motor from overloading. During defrost this

regulator provides ideal pressure differential through the

evaporator during defrost. Further, the properly set regulator

can minimize the ood back. A correct setting of the regulator plays a crucial role in defrost operation. The maximum

setting should be no higher than the pressure equivalent to

the compressor maximum allowed saturated suction temperature (SST). The minimum setting should be no lower

than the pressure equivalent of 15°F above the compressor normal operating evaporating temperature. See Table

2 for initial settings.

Page 9

INITIAL PRESSURE SETTINGS (PSIG)

K40-THERM-PDI-13

- 9 -

02/12/10

SETTINGS MUST BE FINE TUNED TO SUIT FIELD CONDITIONS

Note: Various control manufacturer types result in different range scale and differential congurations. (Refer to the

control manufacturers instructions for these details) The table below covers the switch action as High or Low event and

the applicable switch position (open or closed). Most manufacturers use the Range scale as the high event value. The

differential setting value will be the difference between the high event less the low event pressure.

TABLE 1

PRESSURE CONTROL HIGH EVENT LOW EVENT HIGH EVENT LOW EVENT

Main Low Press

Main High Press (Air Cooled) 360 (open) 300 (close) 400 (open) 340 (close)

Main High Press (Water Cooled) 300 (open) 240 (close) 360 (open) 300 (close)

Three-way High Press (Air Cooled)

Three-way High Press (Water Cooled)

Defrost Termination Press 120 (close) 80 (open) 145 (close) 90 (open)

Fan Delay Press (Med Temp application) 70 (open) 40 (close) 85 (open) 50 (close)

Fan Delay Press (Low Temp application) 55 (open) 25 (close) 70 (open) 35 (close)

*

*

Set for Pumpdown mode and suited to Application and Ambient

340 (open) 280 (close) 380 (open) 320 (close)

280 (open) 220 (close) 340 (open) 280 (close)

R22 R404A

- see P.27 of Installation Manual

* Must be set at 20 PSIG lower than the main safety HP control.

Defrost Timeclock

This controls the refrigeration and defrost cycles. During

refrigeration it provides power to the space thermostat

and liquid line solenoid valve. During the defrost cycle it

de-energizes the power to the space thermostat and liquid

line solenoid valve and energizes the drain pan heater

and hot gas time delay relay (2 minutes or more). After

the delay it then energizes the hot gas solenoid valve and

three way hot gas valve. The clock has an internal solenoid relay that once energized by the defrost termination

pressure control, switches the clock contacts back to the

refrigeration cycle mode. The clock has a fail safe setting

that will terminate the defrost after a set time period.

Suggested initial settings: 4 defrosts per day / 20

minutes fail safe MAX.

Hot Gas Time Delay Relay

This timer allows the drain pan to be pre-heated prior

to the defrost cycle. This timer also allows the evaporator

to be pumped out prior to the defrost cycle. In some

applications (extra- low temp. freezers) the timer may

have to be set for a longer delay if the drain pan does

not clear properly, and must be set at a longer delay

than the compressor time delay (if equipped).

Suggested initial setting: 2 minutes.

Note:

1. Liquid line only needs to be sized based on

refrigeration mode. Long line run (over 100 ft) and

oversizing will result in excessive ood back during

defrost cycle.

2. During the start of the defrost cycle (timeclock

switches to defrost) ensure the time delay is

adjusted to (1) properly pre-warm the drain pan

heater and (2) ensure all of the refrigerant is removed

from the low side system and has performed a

pumpdown cycle. Increase the setting if necessary for

a longer delay.

TABLE 2

Note: To speed up pull down during start-up, the regulating valve may be opened temporarily.

INITIAL HOT GAS REGULATING VALVE SETTING

SETTINGS MUST BE FINE TUNED TO SUIT FIELD CONDITIONS

EVAP TEMP. (°F) R22 (PSIG) R404A (PSIG)

-40 to -30 15 20

-29 to -20 20 30

-19 to 0 40 50

1 to 10 50 65

11 to 25 60 80

Page 10

TROUBLESHOOTING GUIDE

K40-THERM-PDI-13

- 10 -

02/12/10

PROBLEM POSSIBLE CAUSES

Compressor is ooding back It is normal for refrigerant to ood back to the suction accumulator during the

latter part of the defrost cycle and after defrost. However if excessive refrigerant oods back past the accumulator then following areas need attention:

1. Is there an excessive overcharged system charge? Reduce charge.

2. Are the defrost controls set up properly? See P. 9 Table 1

3. Are liquid lines too big and long? Do not size the liquid by hot gas sizing

method. Liquid line should be sized for refrigeration liquid requirement only.

4. Defrost cycle is on too long.

Defrost cycle is longer than 15

minutes.

Evaporator coil not clear of

ice after defrost.

Ice building up at drain pan. 1. Pre-heat cycle too short (increase time delay)

1. Has drain pan had adequate pre-heat time? (Increase time delay)

2.Check that CPR is not set too high. (follow guidelines)

3. Check Defrost termination setting. (lower the setting)

1. Defrost time too short. Improper defrost (increase termination setting,

re-adjust CPR valve, follow guidelines)

2. Timeclock defrost time duration setting too short.

3. Inadequate hot gas supply. Malfunction of Three-way or HG solenoid valves.

4. Not enough defrosts per day.

5. Excessive inltration. Reduce humidity, install air curtains

2. Improper slope in drain pan.

3. Blocked drain line (unheated, not insulated)

4. Drain pan heater issue - low voltage, miswiring.

Compressor does not run

during defrost cycle.

5. Not enough defrosts per day

6. Lack of or improper P-trap in drain line.

1. It is normal for the compressor not to run during the drain pan pre-heat

period. (unless due to compressor pump-down)

2. Compressor anti-short cycle time delay is still timing out after drain pan

heater timer has timed out. Ensure compressor timer is not set for longer time

period than the Drain Pan Timer. (i.e. if compressor is set at 2 minutes ,then

pan timer should no shorter than 3 minutes. If compressor timer is set at 5

minutes then pan timer must be at least at 6 minutes, etc.) Note: Energizing

the hot gas solenoids without the compressor starting up can result in major

defrosting problems.

Page 11

SERVICE PARTS LIST

K40-THERM-PDI-13

- 11 -

02/12/10

DESCRIPTION PART NUMBER

Hot Gas Time Delay Relay 1049535

Defrost Termination Pressure Control 1049770 (1/4 SAE)

Fan Delay Pressure Control 1045264 (1/4 SAE)

Three Way Valve Pressure Control 1064271 (1/4 SAE)

PROJECT INFORMATION

System

Model Number Date of Start-Up

Serial Number Service Contractor

Refrigerant Phone

Electrical Supply Fax

Page 12

Finished Goods Warranty

02/12/10

The terms and conditions as described below in the General Warranty Policy cover all products

manufactured by National Refrigeration.

GENERAL WARRANTY POLICY

Subject to the terms and conditions hereof, the Company warrants all Products, including Service Parts,

manufactured by the Company to be free of defects in material or workmanship, under normal use and

application for a period of one (1) year from the original date of installation, or eighteen (18) months from

the date of shipment from the Company, whichever occurs rst. Any replacement part(s) so supplied will

be warranted for the balance of the product’s original warranty. The part(s) to be replaced must be made

available in exchange for the replacement part(s) and reasonable proof of the original installation date of

the product must be presented in order to establish the effective date of the warranty, failing which, the effective date will be based upon the date of manufacture plus thirty (30) days. Any labour, material, refrigerant, transportation, freight or other charges incurred in connection with the performance of this warranty

will be the responsibility of the owner at the current rates and prices then in effect. This warranty may be

transferred to a subsequent owner of the product.

THIS WARRANTY DOES NOT COVER

(a) Damages caused by accident, abuse, negligence, misuse, riot, re, ood, or Acts of God (b) damages

caused by operating the product in a corrosive atmosphere (c) damages caused by any unauthorized

alteration or repair of the system affecting the product’s reliability or performance (d) damages caused

by improper matching or application of the product or the product’s components (e) damages caused by

failing to provide routine and proper maintenance or service to the product (f) expenses incurred for the

erecting, disconnecting, or dismantling the product (g) parts used in connection with normal maintenance,

such as lters or belts (h) products no longer at the site of the original installation (i) products installed or

operated other than in accordance with the printed instructions, with the local installation or building codes

and with good trade practices (j) products lost or stolen.

No one is authorized to change this WARRANTY or to create for or on behalf of the Company any

other obligation or liability in connection with the Product(s). There is no other representation, warranty

or condition in any respect, expressed or implied, made by or binding upon the Company other than the

above or as provided by provincial or state law and which cannot be limited or excluded by such law, nor

will we be liable in any way for incidental, consequential, or special damages however caused.

The provisions of this additional written warranty are in addition to and not a modication of or subtraction

from the statutory warranties and other rights and remedies provided by Federal, Provincial or State laws.

NATIONAL REFRIGERATION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BLVD., BRANTFORD, ONTARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

USA

985 WHEELER WAY, LANGHORNE, PA. 19047 USA

PHONE:1-888-KEEPUS1 OR 1-888-533-7871

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

Loading...

Loading...