Keeprite KLC Installation Manual

PRODUCT DATA & INSTALLATION

Bulletin K40-KLC-PDI-3

1068825

We are on the Internet www.keepriterefrigeration.com

Lead Lag

Control Panel

Model KLC

Electrical Power: 115/1/60, 208-230/1/60, 200-220/1/50

NOMENCLATURE

KLC 1 - I S2 A

Model

KeepRite Lead Lag

Control Panel

Model Code

1 = Standard

2 = With Alarm/Auto Back-Up

Application

I = Indoor

Voltage

S1 = 115/1/60

S2 = 208-230/1/60

S6 = 200-220/1/50

Series / Generation

A = 1st Generation

•For use on TWO independent refrigeration systems using pumpdown control mode. (Thermostat wired into liquid line solenoid valve).

•Panel can be mounted at condensing unit on indoor installations or can be mounted remote inside on a wall when used with outdoor condensing units.

•Designed to alternate each system automatically at a preset 24 hour time period. (can be readjusted from a 6 to 300 hour time period).

Three position toggle switch provides:

1.Condensing Unit #1 runs only.

2.Lead Lag mode. (alternates unit #1 and unit #2 automatically).

3.Condensing unit #2 runs only.

•KLC1 model offers low cost simple operation by automatically (pre-set time) or manually alternating each unit.

•KLC2 model offers the same as KLC1 and includes supplemental refrigeration backup during abnormal load situations or in the event one refrigeration system fails. (Includes alarm dry contacts)

•Panel is suitable for use with Air, Electric and Hot Gas defrost systems.

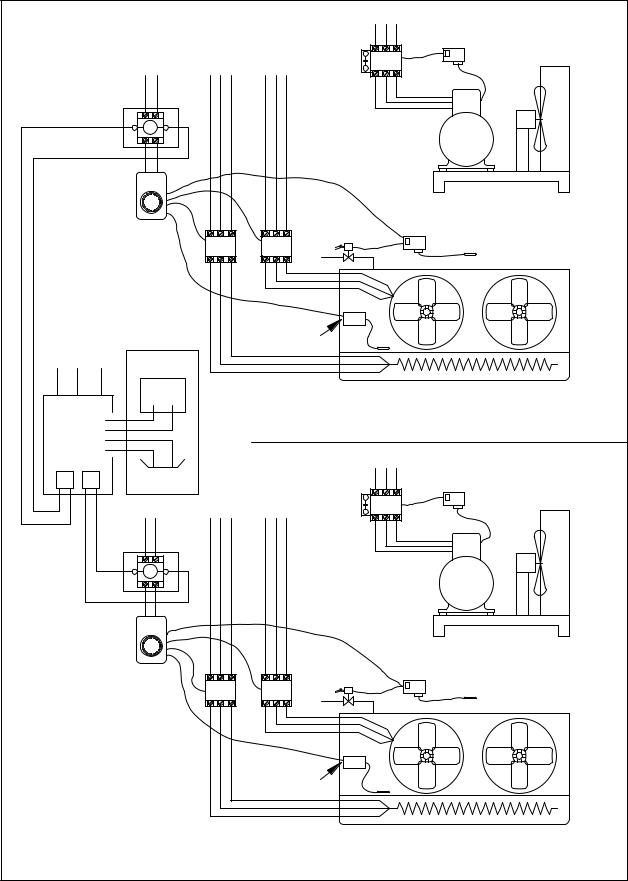

KLC |

TYPICAL SYSTEM LEAD-LAG WIRING |

||||

|

|

|

|

|

|

|

|

|

|

|

LOW PR. |

|

|

|

|

|

CONTROL |

|

|

|

|

|

COMPR |

|

|

|

|

|

CONT. |

|

LEAD |

|

|

|

|

|

|

C1 |

|

|

|

|

|

|

|

|

COMPR |

|

|

|

|

|

CONDENSING UNIT |

|

|

CLOCK |

|

LIQUID |

SPACE |

|

|

|

LINE |

THERMOSTAT |

|

|

|

|

|

||

|

|

DEFR. |

FAN |

SOLENOID |

|

|

|

|

|

||

|

|

CONT. |

CONT. |

|

EVAPORATOR |

|

|

|

|

|

|

|

REFER TO ACTUAL |

|

|

|

|

|

CONDENSING UNIT |

|

|

|

|

|

WIRING DIAGRAM ON |

|

|

|

|

|

UNIT CONTROL PANEL |

|

|

|

|

|

|

WITH KLC2 |

FAN DELAY/ |

|

|

|

|

DEFROST TERM. |

|

|

|

|

|

THERMOSTAT |

|

|

|

L1 |

L2 GND |

AUTO |

|

|

|

BACK-UP |

|

|

|

||

|

|

THERMOSTAT |

|

|

|

|

|

|

|

|

DEFROST HEATERS |

|

|

|

TYPICAL |

|

|

|

LEAD |

|

SYSTEM #1 |

(LEAD) |

|

|

LAG |

|

|||

CONTROL |

|

|

|

|

|

PANEL |

|

|

|

|

|

R1 |

R2 |

ALARM |

|

|

LOW PR. |

DRY CONTACT |

|

|

|||

|

|

CIRCUIT |

|

|

CONTROL |

|

|

|

|

|

COMPR |

|

|

|

|

|

CONT. |

|

LAG |

|

|

|

|

|

|

C2 |

|

|

|

|

|

|

|

|

COMPR |

|

|

|

|

|

CONDENSING UNIT |

|

|

CLOCK |

|

LIQUID |

SPACE |

|

|

|

LINE |

THERMOSTAT |

|

|

|

|

|

||

|

|

DEFR. |

FAN |

SOLENOID |

|

|

|

|

|

||

|

|

CONT. |

CONT. |

|

EVAPORATOR |

|

|

|

|

|

|

|

|

|

FAN DELAY/ |

|

|

|

|

|

DEFROST TERM. |

|

|

|

|

|

THERMOSTAT |

|

|

|

|

|

TYPICAL |

|

DEFROST HEATERS |

|

|

|

|

|

|

|

|

|

SYSTEM #2 |

(LAG) |

|

|

|

|

- 2 - |

|

|

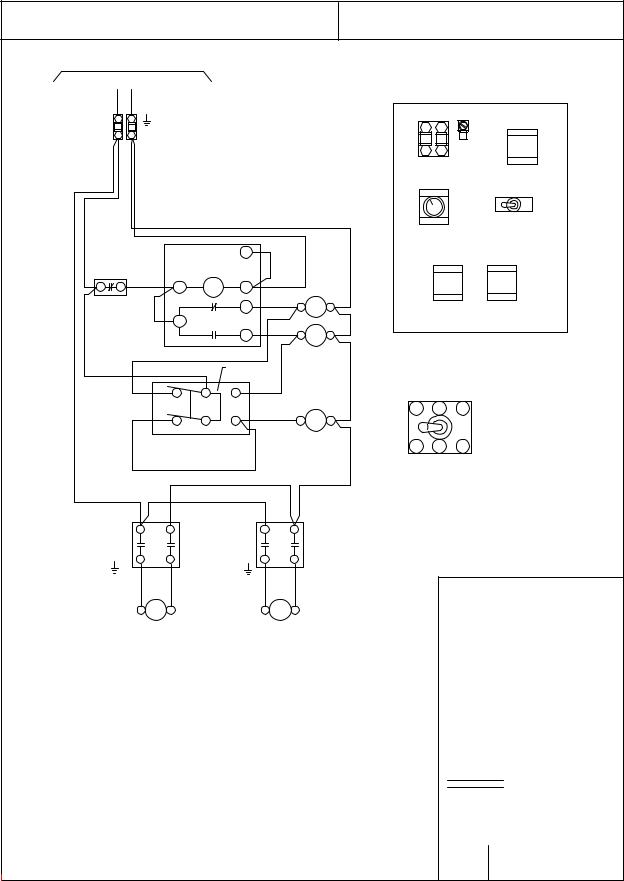

KLC

KLC1 PANEL WIRING

CONTROL PANEL WIRING DIAGRAM: 230-1-60 Hz

TO 208/230-1-60 OR 200/220-1-50 POWER SUPPLY

L1 L2

15A FUSE

CLASS CC

|

T1 TIMER |

SET: B MODE |

6 |

|

|

|

|

||

|

LEAD-LAG |

|

HRS UNIT |

|

#22 |

|

#21 |

|

|

|

R3 |

|

|

24 (0-30 RANGE) |

BL |

|

BL |

|

|

|

RD #5 |

|

|

|

|

|

|

|

|

1 |

4 |

10 |

T |

2 |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

#6 |

|

|

4 |

RD #7 |

2 |

R1 |

7 |

|

|

|

|

|

|||||

|

|

RD |

1 |

|

|

RD #8 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

RD #9 |

2 |

R2 |

7 |

RD #3 |

|

|

|

RD #4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

3 |

1 |

2 |

RD #10 |

|

|

|

|

|

|

|

|

|

|

|||

|

|

LEAD |

AUTO |

LAG |

|

|

|

|

|

|

|

|

6 |

4 |

5 |

RD #11 |

2 |

R3 |

7 |

|

|

|

|

||||||

|

|

|

DPDT TOGGLE |

|

|

|

|

||

|

|

|

|

SWITCH* |

#12 |

|

|

|

|

|

|

|

(BOTTOM VIEW) |

|

|

|

|||

|

|

|

RD |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BL 26 |

|

|

|

|

RD #1 |

|

|

|

|

RD 13 |

|

|

|

|

LEAD-LAG CONTROL PANELSTANDARD BASIC PANEL 230V CONTROL CIRCUIT

CONTROL PANEL

COMPONENT LAYOUT

FUSES |

TIMER OVERRIDE |

|

RELAY |

|

R3 |

T1 |

|

TIMER |

LEAD AUTO LAG |

|

|

|

MODE SWITCH |

LEAD |

LAG |

RELAY |

RELAY |

R1 |

R2 |

BL #23

*

LEAD AUTO LAG

MODE SWITCH

#24 |

(TOP VIEW) |

|||

BL |

||||

|

|

|

||

|

2 |

1 |

3 |

|

#25 |

5 |

4 |

6 |

|

BL |

||||

|

|

|

||

R1 R2

|

|

|

|

|

|

NOTES |

||

C1 |

C2 |

|

|

|

|

|

||

|

1. USE COPPER CONDUCTORS ONLY |

|||||||

LEAD TIMECLOCK |

LAG TIMECLOCK |

2. USE 90°C WIRE (OR HIGHER) |

||||||

3. OPTIONAL COMPONENT MAY BE FACTORY |

||||||||

CONTACTOR |

CONTACTOR |

|

INSTALLED OR SUPPLIED BY OTHERS |

|||||

COIL |

COIL |

4. HEATER LOADS ARE NOT CONCURRENT |

||||||

(AT COND UNIT #1) |

(AT COND UNIT #2) |

|

WITH REFRIGERATION LOADS. |

|||||

5. OVERCURRENT PROTECTION FOR EACH |

||||||||

|

|

|||||||

|

|

|

EVAPORATOR MUST NOT EXCEED MAXIMUM |

|||||

|

|

|

VALUE SHOWN ON EVAPORATOR NAMEPLATES. |

|||||

|

|

6. MAY BE FACTORY INSTALLED-MOUNTED |

||||||

|

|

|

AND WIRED ON EVAPORATOR |

|||||

|

|

|

(PRE-ASSEMBLED MODELS). |

|||||

|

|

|

ON MULTIPLE PRE-ASSEMBLED EVAPORATORS |

|||||

|

|

|

WIRE SECOND EVAPORATOR SOLENOID IN |

|||||

|

|

|

PARALLEL WITH FIRST. |

|||||

|

|

7. ALL FUSES TO BE CLASS CC OR J AND |

||||||

|

|

|

VOLTAGE RATED EQUAL (OR HIGHER) THAN |

|||||

|

|

|

OPERATING VOLTAGE. |

|||||

|

|

|

CONDUCTORS/WIRNG |

|

||||

|

|

|

|

|

|

FACTORY WIRING |

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

WIRING BY OTHERS |

||

|

|

|

|

|

|

OPTIONAL COMPONENT WIRING |

||

|

|

|

|

|

|

(SOME OPTIONAL COMPONENTS |

||

|

|

|

|

|

|

|

MAY BE FACTORY WIRED.) |

|

|

|

|

G=GREEN |

RD=RED BL=BLUE ALL OTHER BLACK |

||||

|

|

ALL FIELD WIRING MUST BE DONE IN |

||||||

|

|

COMPLIANCE WITH ALL APPLICABLE LOCAL |

||||||

|

|

AND NATIONAL CODES. |

||||||

|

|

|

DATE: |

|

|

|

DIAGRAM NUMBER |

|

|

|

|

|

|

|

CPB-S2-TLC1 |

||

|

|

|

|

|

||||

|

|

Feb7/07 |

|

|

|

|

||

- 3 -

Loading...

Loading...