Page 1

PCC Horizontal

Product Coolers

PRODUCT DATA &

INSTALLATION

Bulletin K30-PCC-PDI-10

1064048

We are on the Internet

www.keepriterefrigeration.com

Air Defrost for Applications 35 °F

(1.6 °C) (Electric and Hot Gas Defrost

Models are Optional)

Up to 30 Tons Nominal Capacity

• Large face area centrifugal fan

• New “bolt-on” coil for maximum capacity in a minimum

space.

• Electronically balanced high efficiency fans with forward

curved blades provide quiet operation.

• Heavy gauge galvanized steel cabinet.

• Self-aligning ball bearings and heavy channel stiffeners

eliminate vibration and ensure quiet operation.

NOMENCLATURE

PCC 870 ED 4 5 A - -

PRODUCT

COOLER

CENTRIFUGAL FAN

MODEL NUMBER

DEFROST TYPE

HT = HIGH TEMP AIR

ED = ELECTRIC DEFROST

HG = HOT GAS

FIN SP ACING

ROWS DEEP

FIN THICKNESS

ALUM COPPER

A = .0055 D = . 005 5

B = .0075 E = .009

C = .009

FAN MOTOR AND DRIVE

AND MFG. OPTIONS

• Full size access doors for easy maintenance.

CONTENTS PAGE

Nomenclature......................................

Capacity Data.......................................

Correction Factor................................

Blower Data.........................................

General Data........................................

Dimensional Data................................

Installation Instructions......................

Service Log.........................................

Project Information.............................

Cover

7, Back

2

2

3

4

5, 6

Back

Back

FAN INSULA TION

- = NO INSULA TION

I = INSULA TION

Page 2

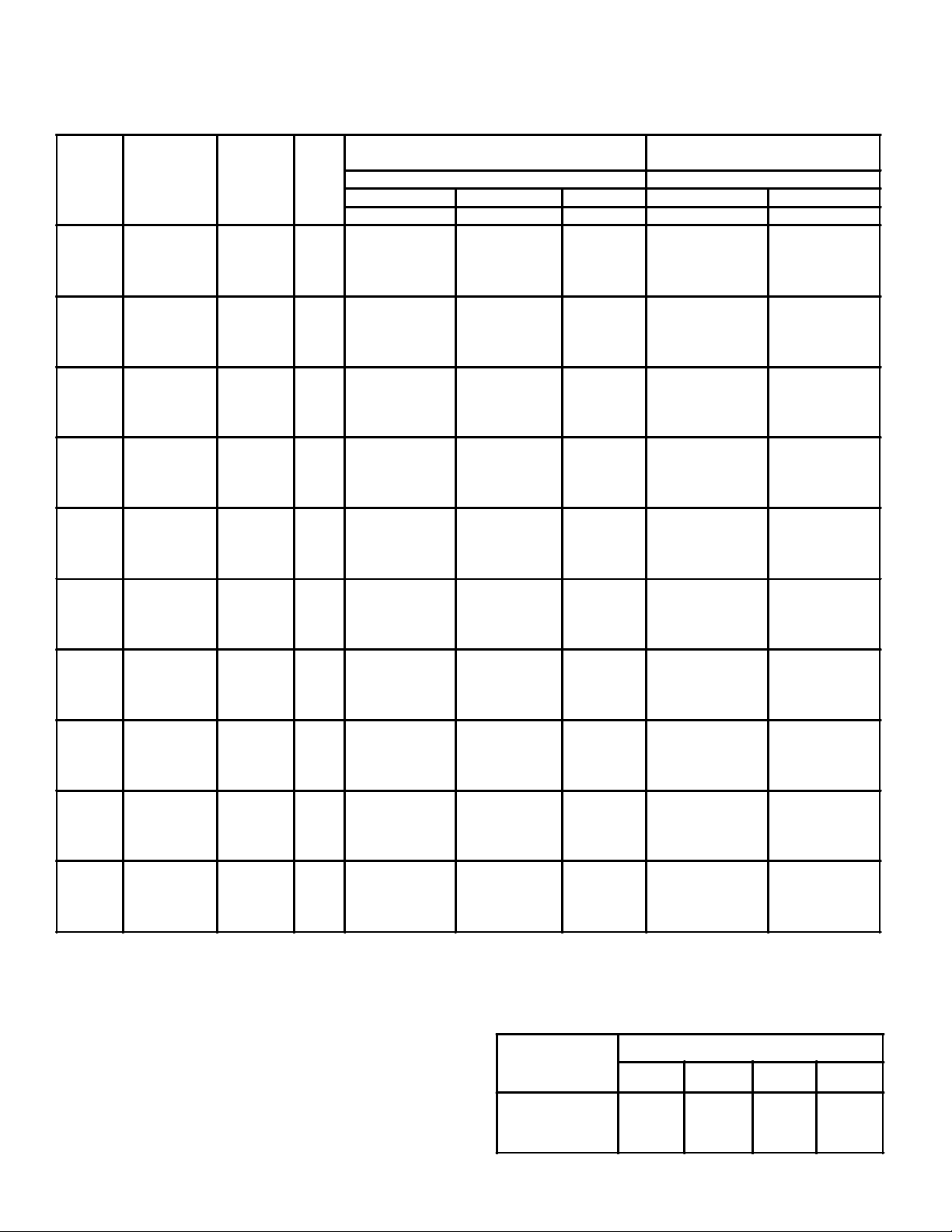

CAPACITY DATA

COOLING CAPACITIES - BTU / H °F T.D.

BASED ON 600 FPM (183m/min) FACE VELOCITY)

COIL ENT. AIR FROM 32°F (0°C) to 35°F

(1.6°C)

FIN SPACING FIN SPACING

8/INCH 6/INCH 4/INCH 6/INCH 4/INCH

DX DX DX DX DX

3460

4420

5040

5610

4630

5920

6750

7500

5810

7410

8450

9400

6980

8940

10160

11300

8560

10920

12490

13870

10480

13630

15560

17260

14270

18280

20780

23060

16250

20760

23660

26270

19000

24320

27740

30780

23700

30450

34680

38480

3210

4120

4670

5200

4310

5520

6290

6980

5400

6940

7880

8740

6510

8310

9450

10500

7960

10180

11560

12890

9950

12730

14440

16120

13240

17000

19290

21470

15110

19360

21900

24420

17650

22610

25750

28600

22040

28260

32210

35720

2630

3360

3830

4270

3520

4510

5130

5730

4410

5650

6450

7170

5310

6800

7750

8620

6530

8330

9500

10580

8120

10400

11820

13180

10850

13920

15750

17580

12310

15770

17950

20050

14460

18430

21090

23420

18050

23040

26320

29360

FACE VELOCITY CAPACITY CORRECTION FACTORS

TABLE 1

Face Velocity

F.P.M.

(m/min.)

600 (183)

500 (152)

400 (122)

MODEL

No.

PCC

870

PCC

1170

PCC

1470

PCC

1770

PCC

2270

PCC

2870

PCC

3770

PCC

4170

PCC

5070

PCC

6470

CFM *

(Litre/sec.) @

600 FPM

(183m/min.)

6,340

(2,992)

8,500

(4,012)

10,650

(5,026)

12,800

(6,041)

15,700

(7,410)

19,600

(9,250)

26,150

(12,341)

29,800

(14,064)

34,900

(16,471)

43,600

(20,577)

FACE

AREA

SQ. FT.

(m2)

10.5

(.975)

14.1

(1.30)

17.7

(1.64)

21.3

(1.97)

26.2

(2.43)

32.6

(3.02)

43.6

(4.05)

49.6

(4.60)

58.1

(5.39)

72.6

(6.74)

ROWS

DEEP

4

6

8

10

4

6

8

10

4

6

8

10

4

6

8

10

4

6

8

10

4

6

8

10

4

6

8

10

4

6

8

10

4

6

8

10

4

6

8

10

* For Applications in room temperatures above 35 °F (1.6 °C) maximum face velocity should not exceed 500 FPM

(152m/min) and capacities corrected accordingly (see table 1 for correction factors).

** These ratings are based on moderate coil frosting. For heavy frosting use factor of 0.95.

(1) “T.D.” - Represents the difference between temperature

of air entering cooling coil and coil refrigerant temperature.

Ratings for units using electric defrost may be determined by

multiplying ratings in above table by 0.95

(1)

**COIL ENT. AIR BELOW 32°F

(0°C)

2870

3800

4480

5020

3840

5120

6010

6740

4820

6400

7530

8440

5790

7690

9070

10150

7120

9420

11100

12450

8860

11820

13870

15450

11880

15750

18480

20660

13460

17830

21040

23480

15790

20980

24610

27600

19780

26170

30880

34580

Rows Deep In Direction Of Airflow

4 6 8 10

1.0

.91

.80

1.0

.90

.78

1.0

.89

.76

2350

3130

3680

4120

3150

4200

4930

5510

3940

5250

6170

6920

4750

6330

7410

8290

5830

7750

9080

10180

7270

9660

11360

12720

9710

12890

15170

16880

10990

14630

17150

19240

12920

17220

20200

22610

16090

21520

25220

28240

1.0

.89

.73

- 2 -

Page 3

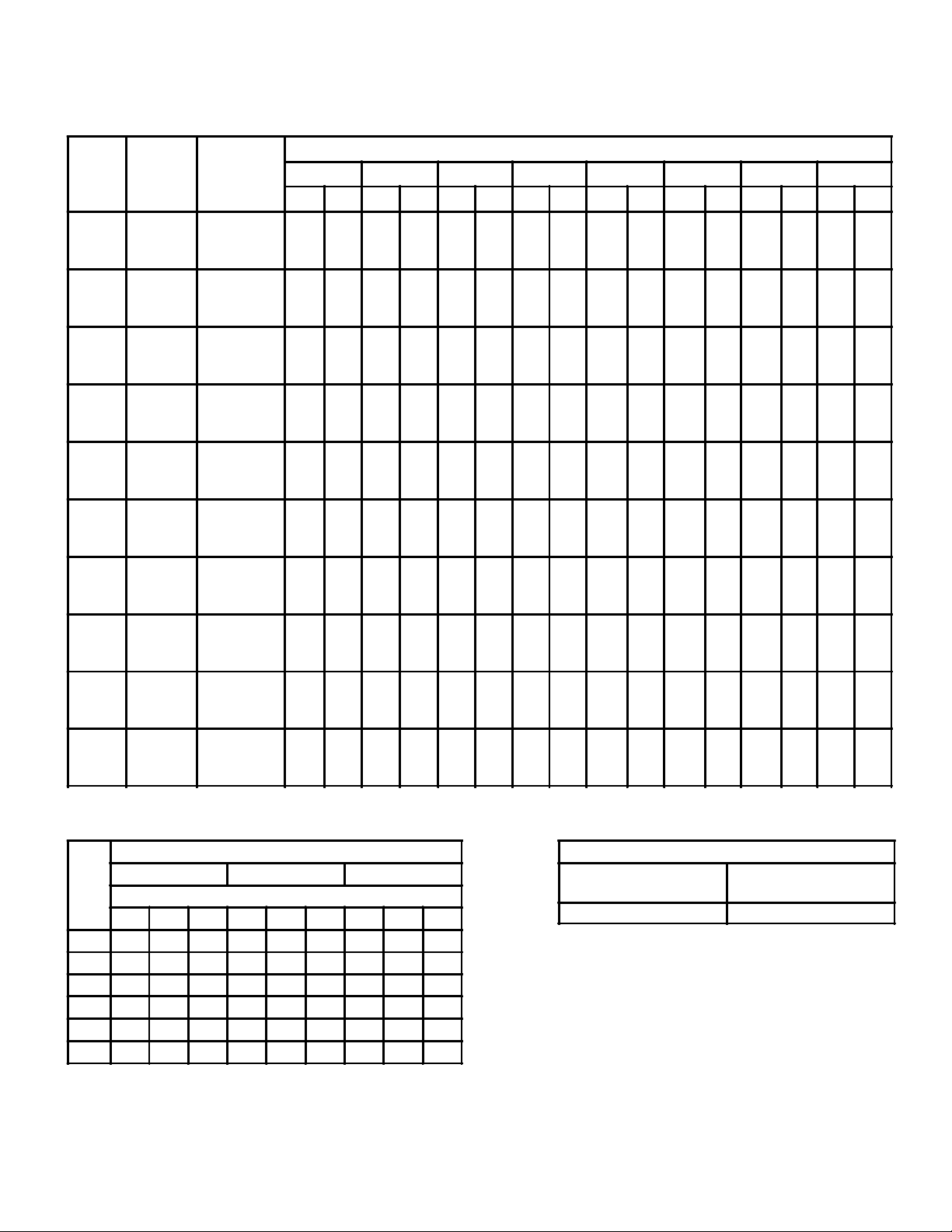

BLOWER DATA

FAN RPM AND MOTOR HP REQUIREMENTS

PCC

MODEL

870

1170

1470

1770

2270

2870

3770

4170

5070

6470

FACE

VELOCITY

FPM

(m/min.)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

400 (122)

500 (152)

600 (183)

CFM

(litre/sec.)

4,220 (1,992)

5,290 (2,497)

6,340 (2,992)

5,670 (2,676)

7,090 (3,346)

8,500 (4,012)

7,100 (3,351)

8,800 (4,153)

10,650 (5,026)

8,540 (4,030)

10,680 (5,040)

12,800 (6,041)

10,480 (4,946)

13,100 (6,183)

15,700 (7,410)

13,060 (6,164)

16,330 (7,707)

19,600 (9,250)

17,440 (8,231)

21,800 (10,289)

26,150 (12,341)

19,860 (9,373)

24,820 (11,714)

29,800 (14,064)

23,250 (10,973)

29,060 (13,715)

34,900 (16,471)

29,060 (13,715)

36,330 (17,146)

43,600 (20,577)

TOTAL STATIC PRESSURE (INCHES - WATER GAUGE)

TSP=.125" TSP=.25" TSP=.50" TSP=.75" TSP=1.00" TSP=1.25" TSP=1.50" TSP=1.75"

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

440

0.56

475

0.66

542

0.84

608

1.04

676

1.28

744

1.52

810

1.77

870

2.03

530

1.09

560

1.19

613

1.39

667

1.63

722

1.90

778

2.16

833

2.44

887

2.73

630

1.72

650

1.94

697

2.18

740

2.44

785

2.72

830

3.01

878

3.32

925

3.65

438

0.98

465

1.08

522

1.29

580

1.55

635

1.87

692

2.20

751

2.53

807

2.88

533

1.87

560

1.98

600

2.20

640

2.47

682

2.78

738

3.14

780

3.54

828

3.94

621

3.18

640

3.31

679

3.57

716

3.85

754

4.17

792

4.52

830

4.92

872

5.35

515

1.11

555

1.26

637

1.57

716

1.89

801

2.24

865

2.61

934

3.00

1000

3.42

612

2.00

648

2.20

718

2.59

784

2.97

848

3.36

912

3.76

973

4.19

1033

4.65

730

3.43

758

3.68

815

4.17

867

4.63

928

5.09

980

5.55

1035

6.02

1086

6.51

470

1.29

490

1.46

565

1.81

637

2.21

707

2.64

775

3.09

839

3.57

900

4.01

562

2.38

580

2.60

640

3.04

700

3.49

757

3.96

813

4.47

869

5.01

924

5.57

653

3.96

669

4.23

723

4.77

773

5.30

822

5.84

870

6.39

918

6.97

966

7.58

423

1.60

447

1.82

513

2.25

579

2.74

642

3.26

704

3.82

762

4.40

817

5.01

508

2.98

530

3.24

584

3.77

637

4.33

688

4.91

741

5.54

791

6.20

840

6.89

591

5.03

614

5.34

663

5.97

709

6.62

751

7.27

796

7.97

840

8.67

881

9.44

308

1.65

339

1.95

400

2.56

457

3.23

513

3.96

565

4.72

614

5.49

661

6.28

365

3.02

395

3.40

447

4.17

495

4.94

542

5.75

587

6.62

632

7.52

686

8.46

442

4.98

454

5.45

500

6.39

542

7.30

581

8.22

620

9.17

661

10.17

697

11.21

302

2.47

322

2.87

373

3.66

422

4.52

468

5.41

513

6.35

556

7.32

596

8.31

370

4.58

392

5.05

420

5.99

456

7.00

496

8.05

535

9.14

573

10.27

610

11.42

411

7.69

432

8.24

471

9.35

507

10.49

541

11.69

574

12.92

607

14.21

639

15.53

204

2.84

220

3.33

259

4.31

293

5.26

324

6.21

353

7.22

382

8.27

408

9.36

238

5.15

255

5.79

290

7.08

321

8.29

351

9.48

375

10.65

400

11.86

423

13.09

278

8.59

293

9.38

323

10.97

352

12.49

378

14.28

401

15.39

424

16.81

446

18.20

173

3.00

190

3.54

227

4.67

260

5.72

290

6.88

317

8.10

342

9.36

367

10.67

205

5.49

221

6.15

251

7.48

280

8.83

308

10.20

333

11.61

356

13.06

380

14.55

243

8.15

254

9.94

280

11.53

300

13.14

330

14.76

352

16.40

374

18.05

396

19.74

165

3.96

178

4.68

210

6.13

238

7.54

264

8.96

288

10.42

312

11.94

335

13.53

191

7.20

205

8.10

234

9.90

260

11.71

283

13.48

305

15.24

325

17.01

345

18.80

223

11.90

235

13.08

260

15.19

284

17.38

306

19.61

326

21.70

344

23.81

362

25.92

INTERNAL AIRSIDE RESISTANCE - INCHES, W. G. WET COIL CORRECTION FACTOR*

Coil

Rows

Deep

400 (122) 500 (152) 600** (183)

Fins Per Inch

4 6 8 4 6 8 4 6 8

4 .09 .12 .14 .13 .17 .20 .18 .23 .27

5 .12 .14 .16 .17 .21 .25 .23 .28 .34

6 .13 .16 .20 .20 .25 .30 .27 .34 .41

8 .18 .23 .27 .27 .34 .41 .35 .44 .53

10 .23 .28 .34 .34 .42 .51 .45 .56 .68

12 .27 .34 .41 .39 .49 .59 .53 .67 .81

** Coil face velocity should not exceed 500 FPM (152 m/min.)

for applications where room temperature is above 35 °F

(1.6 °C).

COIL FACE VELOCITY FPM (m/min)

* For medium frosted coil, use factor of 1.3

Example:

600 FPM (183 m/min.), 8 row coil 4 fins/in.

Evap. Temp. 40 °F (4.4 °C)

Ent. Air Dew Pont 45 °F (7.2 °C)

Internal Airside Resistance - .35

Wet Coil Correction factor = 1.12

Total Internal Airside

Resistance = 1.12 x .35 = .392

Ent. Air Dew Point Minus Refr. Temp.

10ºF (5.5ºC)

or Less

11ºF (6.1ºc) to

18ºF (10ºC)

1.12 1.24

- 3 -

Page 4

LARGE FACE AREA

COIL CIRCUITED FOR

EFFICIENT PERFORMANCE

GENERAL DATA

HEAVY CONTINUOUS

GALVANIZED STEEL CASINGS

BOLT ON COIL

ENSURES UNITIZED

CONSTRUCTION

GALVANIZED

FULL WIDTH DRAIN PAN

WITH ADEQUATE SLOPE

PHYSICAL DATA

MODEL NUMBER

FAN DATA

- No.

ins. 15 16 1/2 13 1/2 15 16 1/2 20 22 1/4 33 36 1/2 40 1/4

- Dia.

mm 381 419.1 342.9 381 419.1 508 565.1 838.2 927.1 1022.3

sq. ft. 2.82 3.45 4.65 5.63 6.90 10.26 12.42 13.79 16.77 20.48

Outlet Area

m

COIL DATA:

ins.

Face Size

mm

sq. ft. 10.5 14.1 17.7 21.3 26.2 32.6 43.6 49.6 58.1 72.6

Face Area

m

ELECTRIC DEFROST *

KW. REQUIREMENTS

4 6.1 7.1 8.6 12.1 13.8 17.3 17.3 19.6 21.9 26.3

LARGE

MAN SIZE

ACCESS DOORS

STURDY HEAVY GAUGE

STEEL CHANNEL SUPPORTS

PCC 870 PCC 1170 PCC 1470 PCC 1770 PCC 2270 PCC 2870 PCC 3770 PCC 4170 PCC 5070 PCC 6470

1 1 2 2 2 2 2 1 1 1

2

.261 .320 .431 .523 .731 .953 1.15 1.28 1.55 1.90

34 1/2 x4434 1/2 x5934 1/2 x7434 1/2 x8940 1/2 x9340 1/2 x

116 1/4

876 x

1118

2

.975 1.30 1.64 1.97 2.43 3.02 4.05 4.60 5.39 6.74

876 x

1499

876 x

1880

876 x

2261

1029 x

2362

1029 x

2953

52 1/2 x

116 1/4

1334 x

2953

61 1/2 x

116 1/4

1562 x

2953

72 x

116 1/4

1829 x

2953

90 x

116 1/4

2286 x

2953

Rows Deep

HOT GAS DEFROST

DRAIN PAN CONNS.

6 6.1 7.1 8.6 12.1 13.8 17.3 17.3 19.6 21.9 26.3

8 7.1 9.1 11.1 13.6 15.6 21.8 21.8 24.1 28.6 35.3

10 9.1 11.1 13.6 16.6 19.1 26.3 26.3 30.8 35.3 44.3

ALL SIZES 1-5/8" (41 mm) O.D. COPPER

* Defrost heaters rated for 230 volt or 575 volt operation.

SHIPPING WEIGHTS

MODEL NUMBER PCC 870 PCC 1170 PCC 1470 PCC 1770 PCC 2270 PCC 2870 PCC 3770 PCC 4170 PCC 5070 PCC 6470

*Fan Section

Drive and Motor

550 lbs.

249.4 kg

600 lbs.

272.1 kg

750 lbs.

340.1 kg

850 lbs.

385.5 kg

1,000 lbs.

453.5 kg

1,270 lbs.

576 kg

1,640 lbs.

743.8 kg

1,950 lbs.

884.5 kg

2,700 lbs.

1224.6 kg

3,610 lbs.

1637.4 kg

* This weights are for fan section, drive and motor only. Coil weights must be added to the weights shown above.

COIL

WEIGHTS

The weight of the copper / aluminium coils may be calculated on the basis of 6 lbs. (2.7 kg)

per square ft. face area / row deep.

Note: Metric figures are approximate to eliminate excessive decimals.

- 4 -

Page 5

DIMENSIONAL DATA

MODELS PCC 870 THRU PCC 2870

MODELS PCC 3770 THRU PCC 6470

Note: Metric figures are approximate to eliminate excessive decimals.

- 5 -

Page 6

DIMENSIONAL DATA

Model

No.

PCC

870

PCC

1170

PCC

1470

PCC

1770

PCC

2270

PCC

2870

PCC

3770

PCC

4170

PCC

5070

PCC

6470

A B D E F G H K L M N P R S T U V Y

ins 48 37 3/4 36 3/4 1 1/2 42 1/2 21 1/8 19 3/4 13 7/16 56 1/4 31 1/8 20 3/8 42 1/2 37 3/4 - 18 33 1/8 44 1/8 38 1/2

mm 1219.2 958.9 933.4 38.1 1079.5 536.5 492.1 341.3 1428.7 790.5 517.5 1079.5 958.8 - 457.2 841.3 1120.7 977.9

ins 63 37 3/4 36 3/4 1 1/2 57 1/2 23 1/4 21 1/2 19 7/8 56 1/4 31 1/8 20 3/8 57 1/2 37 3/4 - 18 33 1/8 59 1/8 53 1/2

mm 1600.2 958.9 933.4 38.1 1460.5 590.5 546.1 504.8 1428.7 790.5 517.5 1460.5 958.8 - 457.2 841.3 1501.7 1358.9

ins 78 37 3/4 36 3/4 1 1/2 72 1/2 19 17 7/8 10 56 1/4 31 1/8 20 3/8 72 1/2 37 3/4 20 21 33 1/8 74 1/8 68 1/2

mm 1981.2 958.9 933.4 38.1 1841.5 482.6 454 254 1428.7 790.5 517.5 1841.5 958.8 508 533.4 841.3 1882.7 1739.9

ins 93 37 3/4 36 3/4 1 1/2 87 1/2 21 1/8 19 3/8 12 11/16 56 1/4 31 1/8 20 3/8 87 1/2 37 3/4 25 3/4 21 33 1/8 89 1/8 83 1/2

mm 2362.2 958.9 933.4 38.1 2222.5 536.5 492.1 322.1 1428.7 790.5 517.5 2222.5 958.8 644.5 533.4 841.3 2263.7 2120.9

ins 97 44 3/4 43 3/4 2 1/2 91 1/2 23 1/4 21 5/8 12 5/8 63 1/4 - - - 44 3/4 25 1/4 21 39 1/8 93 1/8 -

mm 2463.8 1136.7 1111.2 63.5 2324.1 590.5 549.2 320.6 1606.5 - - - 1136.6 641.3 533.4 993.7 2365.3 -

ins 120 44 3/4 43 3/4 2 1/2 114 1/2 28 3/16 26 1/2 15 29/32 63 1/4 - - - 44 3/4 3113/16 23 39 1/8 116 1/4 -

mm 3048.0 1136.7 1111.2 63.5 2908.3 715.9 673.1 404.0 1606.5 - - - 1136.6 808.0 584.2 993.7 2952.7 -

ins 122 1/8 57 1/2 45 5/8 2 1/2 117 7/8 31 7/16 28 3/4 15 5/32 65 1/8 - - - 39 1/2 29 1/16 25 51 7/8 116 1/4 -

mm 3101.9 1460.5 1158.8 63.5 2994 798.5 730.2 384.9 1654.1 - - - 1003.2 738.1 635 1317.6 2952.7 -

ins 122 1/8 65 3/4 59 1/8 2 1/2 117 7/8 46 3/8 43 1/4 37 7/8 78 5/8 - - - 53 - 25 60 1/8 116 1/4 -

mm 3101.9 1670 1501.7 63.5 2994 1177.9 1098.5 902 1997.1 - - - 1346.2 - 635 1527.1 2952.7 -

ins 122 1/8 75 1/2 66 5/8 1 3/4 117 7/8 51 1/2 47 1/4 35 5/16 86 1/8 - - - 60 1/2 - 25 70 5/8 116 1/4 -

mm 3101.9 1917.7 1692.2 44.4 2994 1308.1 1200.1 896.9 2187.5 - - - 1536.7 - 635 1793.8 2952.7 -

ins 122 1/8 93 1/2 72 5/8 1 3/4 117 7/8 56 3/4 52 3/8 32 11/16 92 1/8 - - - 66 1/2 - 25 88 5/8 116 1/4 -

mm 3101.9 2374.9 1844.6 44.4 2994 1441.4 1330.3 830.1 2339.9 - - - 1689.1 - 635 2251.1 2952.7 -

DIMENSIONAL DATA

MODELS PCC 870 THRU PCC 2870

MODELS PCC 3770 THRU PCC 6470

DIMENSIONAL DATA

STANDARD ON ALL MODELS

- 6 -

Page 7

INSTALLATION INSTRUCTIONS

GENERAL

The Product cooler should be carefully inspected for

damage when received. Visible or concealed damage

should be reported immediately to the carrier and a

claim filed for damage.

Product coolers are constructed from heavy gauge

galvanized steel and are thoroughly inspected before

leaving the plant. Care should be taken during

installation to prevent damage to the units.

Care should be taken to ensure that sufficient access is

available for servicing of the unit. Space should be

available for lubrication, belt adjustment and coil removal.

Fans and fan shafts should be inspected before start-up.

Fans are inspected before leaving the pant; however,

rough handling may cause misalignement.

LOCATING AND INSTALLATION HINTS

IMPORTANT: Product Coolers PCC3770, PCC4170,

PCC5070 and PCC6470 MUST be platform or floor

mounted.

Product Coolers may be placed in any suitable manner

in the room. However, low temperature units should not

be located over entrance doors, because of the heavy

frosting that will occur on the coils.

All Product Coolers must be installed level to ensure

proper drainage of water from the pre-engineered drain

pan.

Drain lines for all Product Cooler Models should be

pitched 45° and should be as short as possible. To

prevent drain line freezing problems the following recommendations should be carried out:

(a) Use a drain line heater (supplied by others) with a

density of 20 watts per foot. Six to eight feet of cable

per foot of drain line is recommended.

(b) Drain line heater should make at least a full turn

round the outlet of the drain pan.

distributor on the evaporator coil is equipped with a side

port connection to facilitate a hot gas connection.

Distributor tubes are oversized for hot gas operation.

A liquid line solenoid valve (supplied by others) should be

used so that evaporator coil may be pumped out before

each defrost cycle.

The following defrost control (supplied by others) methods

may be used with Product Coolers.

(1) TIME INITIATED- TEMPERATURE TERMINATED

When using a time initiated - temperatureterminated

method of defrosting a Paragon Timer 8145-20 or equal is

recommended for this application. Timer is used in

conjuction with a defrost termination thermostat. For 3

phase applications, the timer must be used with a contactor. As well as the defrost termination thermostat, the

timer will also have a fail safe feature built into unit.

The drfrost termination thermostat should be set at

approx. 35 °F (1.6 °C) and should be adjustable.

Differential should be 5 °F (2.8 °C) or less. Bulb should be

attached to a tube of the evaporator. As a part of this

system, a fan delay thermostat should be used to provide

a delay period between the end of the defrost and the

start-up of the fan. The fan delay thermostat should be

adjustable and set at 10-25 °F (5.6-13.9 °C) (depending on

application) and bulb should be attached to evaporator

tube. When installing thermostats, care should be taken

to ensure that bulbs are not attached to evaporator heater

tubes.

(2) TIME CONTROLLED OPERATION

Defrosting may also be carried out by a time contolled

sequense. This system utilizes a timer and fan delay

thermostat. Timer should have an adjustable length of

defrost from 2-110 minutes and should be Paragon 804520 or equal. Fan delay thermostat should be as indicated

in (1) above.

(c) The heated drain line should be insulated.

(d) The drain line should be provided with a trap outside

the freezer room. Traps should be filled with water

before initial start-up.

DEFROSTING

Product Coolers are obtainable with electric or hot gas

defrost systems. On hot gas defrost units, the

Initially, 4-30 minute defrost per day are reccomended.

However, it is important that the coil be completely

cleared of defrost at the end of the cycle. Should coil not

be cleared of all frost at the end of 30 minutes, more

frequent defrost of shorter duration should be used.

WIRING

For suggested wiring of defrost heaters see Drg. No.

41594D furnished with Product Cooler.

- 7 -

Page 8

INSTALLATION INSTRUCTIONS

03/15/2007

ST ART - UP

(a) Before start-up equipment, the amperage of all electric

defrost heaters, including drain pan heaters, motor,

etc. should be checked to ensure satisfactory

operation.

(b) Leak test entire system and make sure all joints are

tight.

(c) Check fan and motor for correct rotation.

(d) Check alignment of fan and motor sheave and belt

tension. Belts should have approx. 1” deflection.

PERIODIC SERVICE AND MAINTENANCE

1. Check all moving parts every six months for wear .

2. Check bearing collar set screws for tightness every six

months.

3. Fan bearings are pre-lubricated and do not require

lubrication at time of installation. Extended lube lines

SERVICE LOG

will have grease fittings located on unit panel.

Specific greasing instructions should be carried out in

accordance with tags and l;abels attached to unit.

Careshould be taken not to over lubricate. Grease

should be applied when unit is running, adding slowly

until there is a slight bleeding of the grease at the

seals.

For continuous operation in clean areas, in an

operating temperature range from -40 °F (-4 °C) to

140 °F (60 °C), normal lubrication interval is six

months.

ARMV AC 781, available from both Standard Oil Company and Imperial Oil Company is the recommended

lubricant for all product cooler shaft bearings.

REPLACEMENT P ARTS

When replacement parts are required on units

manufactured by KeepRite Refrigeration, furnish factory

with unit model number and serial number as shown on

serial plate on drive end blower section.

ETADSTNEMMOC

PROJECT INFORMATION

metsyS

rebmuNledoM pU-tratSfoetaD

rebmuNlaireS rotcartnoCecivreS

tnaregirfeRenohP

ylppuSlacirtcelExaF

NA TIONAL REFRIGERA TION &

AIR CONDITIONING CANADA CORP.

CANADA

159 ROY BL VD., BRANTFORD, ONT ARIO, CANADA N3R 7K1

PHONE: 1-800-463-9517 (519)751-0444 FAX (519)753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

USA

985 WHEELER WA Y, LANGHORNE, PA. 19047 USA

PHONE:1-888-KEEPUS1 OR 1-888-533-7871

Loading...

Loading...