Page 1

PRODUCT DATA &

INSTALLATION

Bulletin K70-KWS-PDI-11

1064614

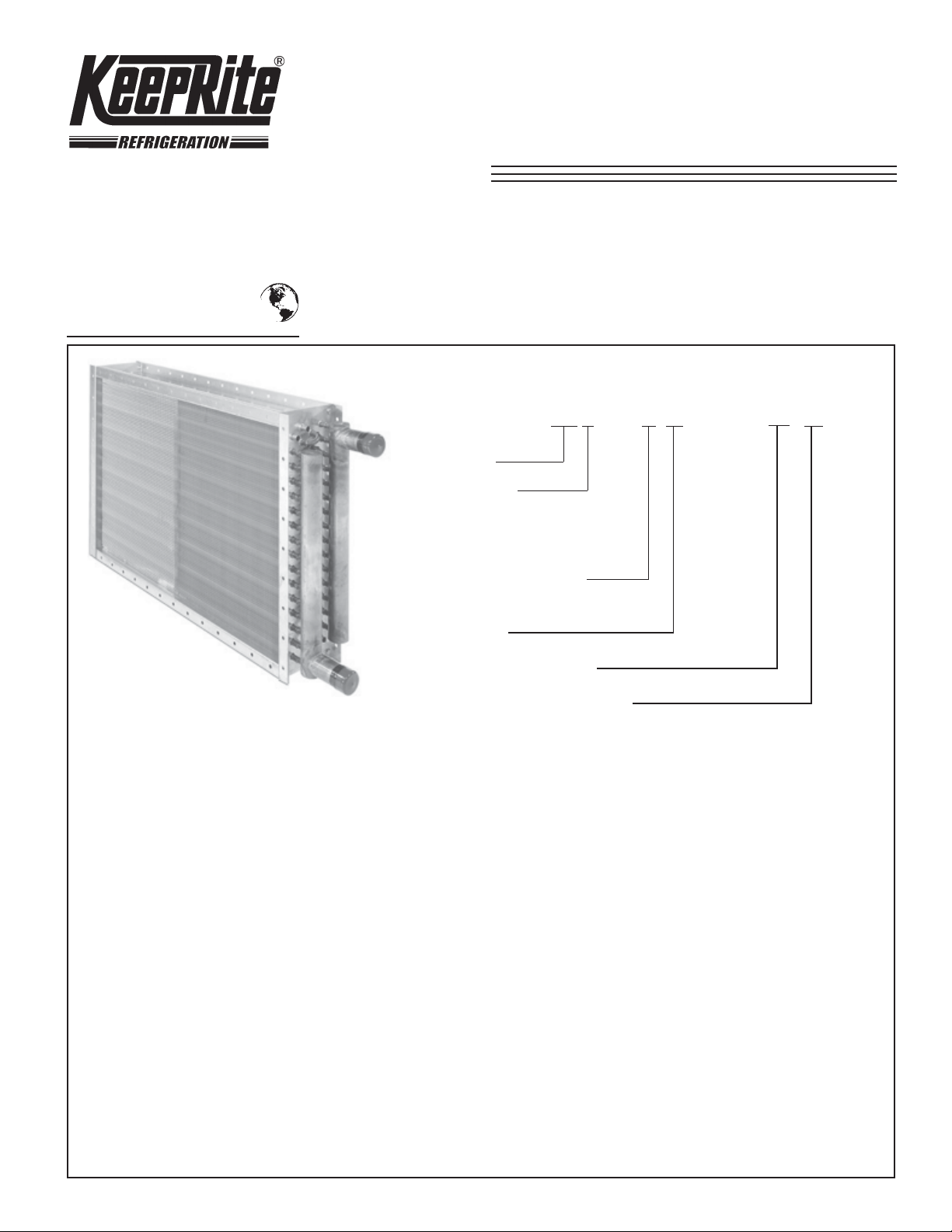

Water Cooling

Coils

Type KWS Single Serpentine

Type KWH Half serpentine

We are on the Internet

www.keepriterefrigeration.com

Water Cooling Coils ........................................2

General Specifications ....................................3

Type KWS Coil................................................4

Nomenclature..................................................4

Type KWH and KWD Water Coils...................5

General Formulas ...........................................6

Wet Bulb Depression Ratio.............................6

System Design ................................................7

Coil Selection - Sizes - Table 1 .......................7

Coil Selection - Fin Series Capacity

Correction Factors - Table 2....................8

Coil Selection - General Considerations .........8

Conversion of Air Volume to St andard Air .......9

Total Heat - Table 3........................................10

Explanation for Using Direct

Selection Tables..............................11, 12

Direct Selection - Table 4 .....................13 to 21

Example Coil Selection No. 1 ........................22

Example Coil Selection No. 2 ...................23,24

Mean Effective Temperature

Difference -Table 5 ................................25

Type KWD Double Serpentine

NOMENCLATURE

TYPE MODEL FACE DIMENSIONS

KW

Coil Type

CIRCUITING:

S = Single Serpentine

D = Double Serpentine

H = Half Serpentine

Fin Series (70, 80, 100

or 120) (100 shown)

Rows Deep

“W” Dimensions (inches)

Nominal Tube Length (inches)

CONTENTS

Standard Coil Circuiting - Table 6 ..................26

Wetted Surface Factor - Figure 3..................26

Heat Transfer Coef ficient - Figure 4 .............. 27

Fin Correction - Table 7 .................................27

Wet Bulb Depression Factors.......................28

Air Pressure Drop - Figure 6 ......................... 29

Air Friction Fin Series Correction

Factors -Table 8 ....................................29

Air Friction Sample Calculation

Example No.3........................................ 29

Water Pressure Drop Curve - Figure 7 .........30

Water Pressure Drop Correction Factors

and Example Problems......................... 31

Water Pressure Drop Coil Type - Table 9...... 31

Dimensional Drawings ..................................32

Application Recommendations ..................... 33

Pipe Size Selection Chart - Figure 1 1 ..........33

Psychrometric Functions ..............................34

Psychrometric Chart - Figure 16...................35

Engineering Specifications............................36

S

D

H

- 1 0 5 - 18 x 45

Page 2

Water Cooling Coils

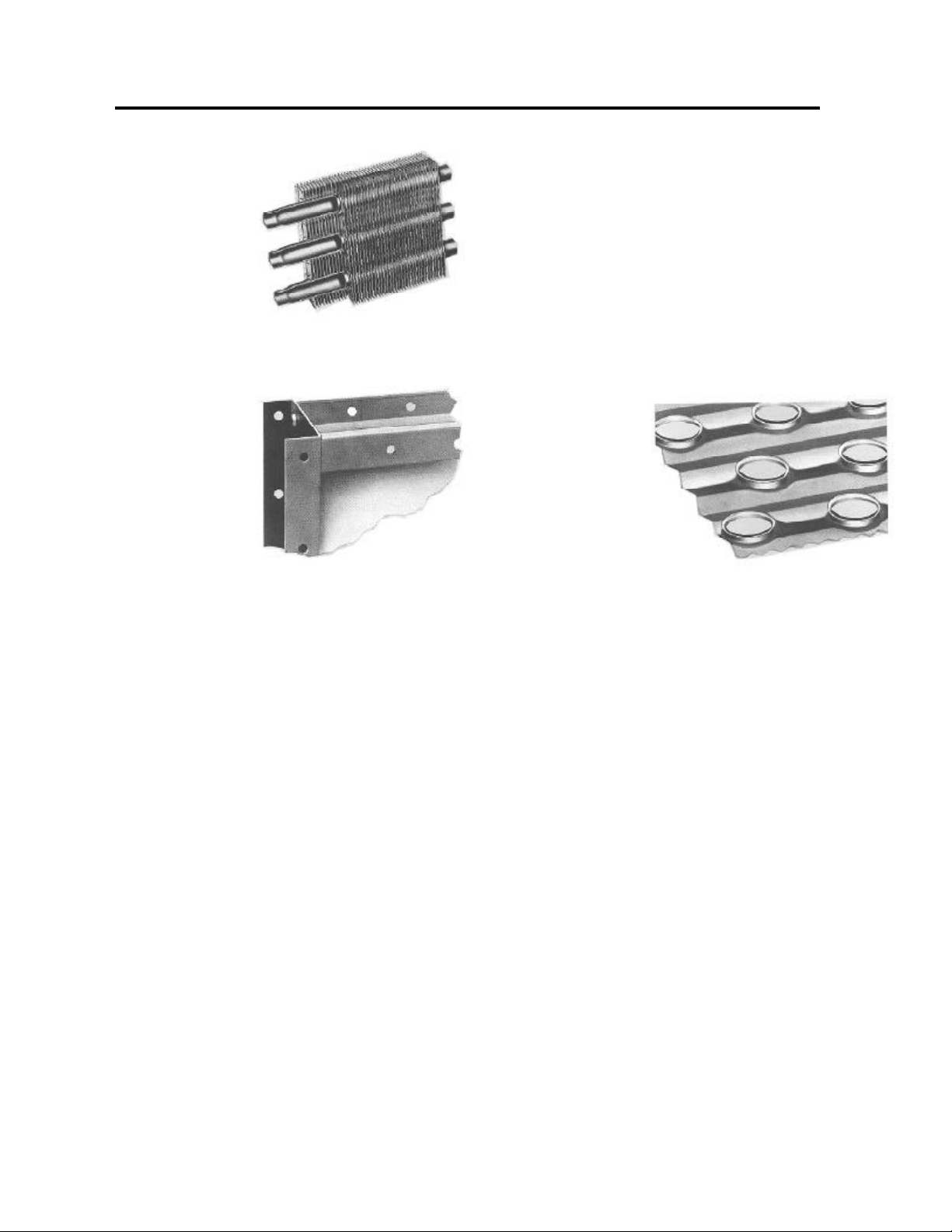

MECHANICAL

PRESSURE BOND

KeepRite Mechanical

Pressure Bond guarantees

that each tube and fin collar

make positive permanent

metal to metal contact.

No need for using low

conductivity metals or alloys,

FLANGED CASINGS

Double flanged galvanized

steel casings on all

KeepRite Water Heating

Coils provide greater

strength - better support

for easier coil stacking.

Simplifies moving and handling operations.

Top and bottom casing flanges are turned back to

form two channel sections in a “box shape”.

Provides maximum strength and durability.

COPPER TUBE HEADERS

Made from heavy gauge seamless drawn copper

tube, KeepRite designed headers lengthen coil life

- provide necessary header flexibility to

compansate for expansion and contraction during

operation.

Header flexibility also reduces coil core “strains”

during start up. Further proof that KeepRite

design means long life and top performance.

FULL FIN

COLLARS

Efficient KeepRite

fin presses perform

multi - stage operations

to draw full fin collars

with wide, smooth surfaces

that completely cover coil

tubes - actually form a tube within a tube for

greater strength and maximum heat transfer.

Lack of sharp collar edges make KeepRite

Coils easier to clean - smoother KeepRite

Collars retard lint and dirt accumulation.

- 2 -

Page 3

AVAILABLE IN FOUR STANDARD

FIN SPACING

GENERAL

SPECIFICATIONS

70 FIN SERIES is designed and used for applications re-

quiring high latent loads and for installations requiring low

air pressure drop. With the 70 Fin Series Coil, it is possible to more accurately match sensible and total loads,

particularly when the water temperature is low and the

entering wet bulb air temperature is high.

80 FIN SERIES has been more or less a standard in the

industry for 15 to 20 years. This fin series and the 100 Fin

Series surface are widely used for regular

commercial applications because the S/T ratios achieved

with these surfaces meet the normal S/T ratio

requirements.

When only the 80 Fin Series Coil surface was available,

frequently more rows of coil were required to meet either a

total or sensible load than is now required with 100 and

120 Fin Series Coils. When extra rows are furnished to

meet either a sensible or total requirement, the

excessive capacity furnished can result in something less

than ideal conditions in the conditioned space.

100 FIN SERIES introduced approximately ten years ago

by KeepRite has been furnished for special industrial

applications that require higher than normal sensible

cooling loads. Experience has shown this is an excellent

heat transfer surface, not only for high sensible load

requirements, but also for average S/T ratio jobs, when

space will not permit larger face areas and/or more rows

to be installed and capacity requirements exceed the

capabilities of 80 Fin Series Coils.

The increase in air friction that results by changing from

an 80 Fin Series to a 100 Fin Series with shallow depth

coils is usually less than the increase in air friction if one

additional row of 80 Fin Series Coil is utilized.

PRIMARY SURFACE - 5/8" O.D. round copper

tubes on 11/2" equilateral centers.

SECONDARY SURFACE-Rippled aluminum or copper, die

formed plate type fins. Fin collars are full drawn to provide

accurate control of fin spacing and to completely cover the

tube for maximum heat transfer.

HEADERS-Extra heavy seamless copper tubing. Tube

holes provide flexibility for uneven stresses and the

maximum brazing surface possible.

CONNECTIONS-Male pipe supply and return

connections.

BRAZING-All core joints are brazed with copper

brazing alloys.

CASING-Die formed heavy gauge continuous galvanized

steel with reinforced mounting flanges. Fin angles

completely brace the core assembly in the casing of all

large coils to prevent air by-pass and damage in shipment.

VENTS AND DRAINS-Furnished on all coils.

TESTS - Complete coil tested leak free at 300 PSIG

air pressure under water.

120 FIN SERIES was designed as a maximum capacity

surface with reasonable air pressure drop and is

particularly suitable for use in commercial and industrial

installations requiring higher than average sensible total

ratios.

The 120 Fin Series heat transfer surface offers the

maximum BTU capacity per dollar invested for

applications where this surface is suitable. The 120 Fin

Series provides the maximum amount of total external

surface per sq. ft. of face area per row deep that is

practical without encountering excessive air pressure

drops.

OPERATING CONDITIONS-Standard coils are suitable for

use up to 200 PSIG.

- 3 -

Page 4

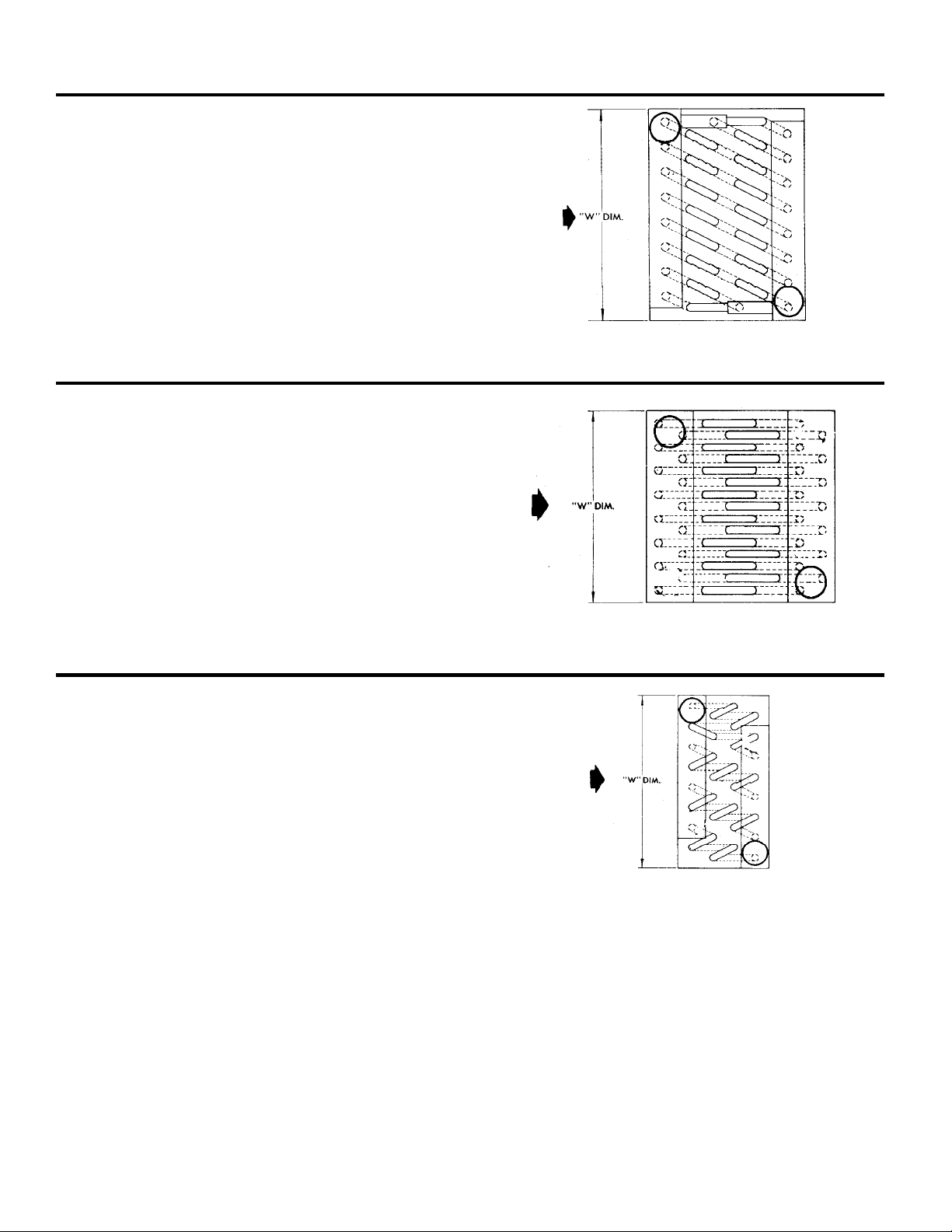

WATER COOLING COILS

TYPE “KWS” COILS

Type “KWS” Coils are specifically designed and

engineered to meet most applications requiring normal

water quantities and normal water pressure drop.

Type “KWS” Coils are counterflow, single serpentine

circuited to deliver absolute maximum performance.

With single serpentine coils every tube in the first row is

fed as indicated in the circuiting drawing on the right.

Type “KWS” Coils of two, four, six, eight and ten rows

deep are furnished with the supply and return connections on the same and of the coil.

TYPE “KWD” COILS

Type “KWD” Coils are designed for use in applications

that require high water quantities and low water pressure

drop.

“KWD” Coils are counterflow, double serpentine circuited

to maintain normal water velocities and low water

pressure drops. With double serpentine coils every tube in

the first and second rows are fed as shown in the

circuiting drawing on the eright.

AIR FLOW

6 ROW KWS CIRCUITING

HORIZONTAL OR VERTICAL AIR FLOW

AIR FLOW

Fourn and eight row coils have the supply and return

connections on the same end of the coil.

TYPE “KWH” COILS

Type “KWH” Coils are designed to produce high

capacity with limited water quantity. High capacity is

obtained from the counterflow half serpentine water

circuiting which gives higher water velocities.

With half serpentine coils every other tube in the first

row is fed as shown in the circuiting drawing on the

right.

All Type “KWH” Coils, regardless of row depth, have

both the supply and return connections on the same end

of the coil. When ordering KWH Coils, state vertical or

horizontal air flow as required.

8 ROW KWD CIRCUITING

HORIZONTAL OR VERTICAL AIR FLOW

AIR FLOW

4 ROW KWH CIRCUITING

HORIZONTAL AIR FLOW

- 4 -

Page 5

GENERAL INFORMATION

1. TOTAL BTU/HR

Total BTU/HR = 4.5 x CFM X (Total Heat Ent. Air - Total

Heat Lv. Air)

Where 4.5 = Density Std. Air x 60

Density Std. Air = .075 lbs./Cu. Ft.

Minutes/hr. = 60

5. WATER VELOCITY

1.144* x GPM

Water Velocity FPS =

*Use 1.326 for high pressure coils

Use 1.35 for .049 tube wall.

Number tubes fed

2. TOTAL BTU/HR

Total BTU/HR = 500 X GPM X (Lv. Water Temp. - Ent.

Water Temp.)

Where 500 = Lbs./Gal. X Min./Hr. X Specific Heat Water

Lbs./Gal. = 8.33

Min./Hr. = 60

Sp. Heat Water = 1

3. SENSIBLE BTU/HR

Sensible BTU/HR = 1.09 X CFM X (Ent. Air D.B. - Lv.

Air D.B.)

Where 1.09 = (sp. Ht. of air at 70°F.) X (Minutes/Hr.)

X Density Std. Air

Sp. Ht. of Air = .24 at 70°F.

Min./Hr. = 60

Density Std. Air = .075 Lbs./Cu. Ft.

4. LEAVING AIR DRY BULB TEMPERATURE

(a) Lv. Air D.B. = Ent. Air D.B. =

(b) Ly. Air D.B. = Lv. W.B. + (W.B. Depression Factor

X Initial W.B. Depression)

(c) Lv. Air D.B. = Lv. W.B. + Final W.B. Depression

Sens. BTU/HR

1.09 X CFM

Total BTU/HR

6. ROWS DEEP =

Where WSF = Wetted Surface Factor (From Figure 3 , Page 26)

MED = Log Mean Temperature Difference (From Table 5,

Page 24)

F

= Fin Series Correction Factor (From Table 7, Page 27

FR

Face Area. ( Sq. Ft.) x WSF x Med. x U x F

7. FACE AREA

F.A. =

CFM

Face Velocity (FPM)

8. FACE VELOCITY

F.V. =

CFM

Face Area (Sq. Ft.)

9. SENSIBLE TOTAL RATIO

S/T Ratio =

Sensible BTU/HR

Total BTU/-HR

10. TONS PER SQUARE FOOT OF FACE AREA

Tons/Sq. Ft. =

Total BTU/HR

Face Area (Sq. Ft.) X 12000

11. INITIAL W.B. DEPRESSION

Initial W.B. Depression = Entering D. B.- Entering W.B.

12. FINAL W.B. DEPRESSION

Final W.B. Depression = leaving D.B. - leaving W.B.

FR

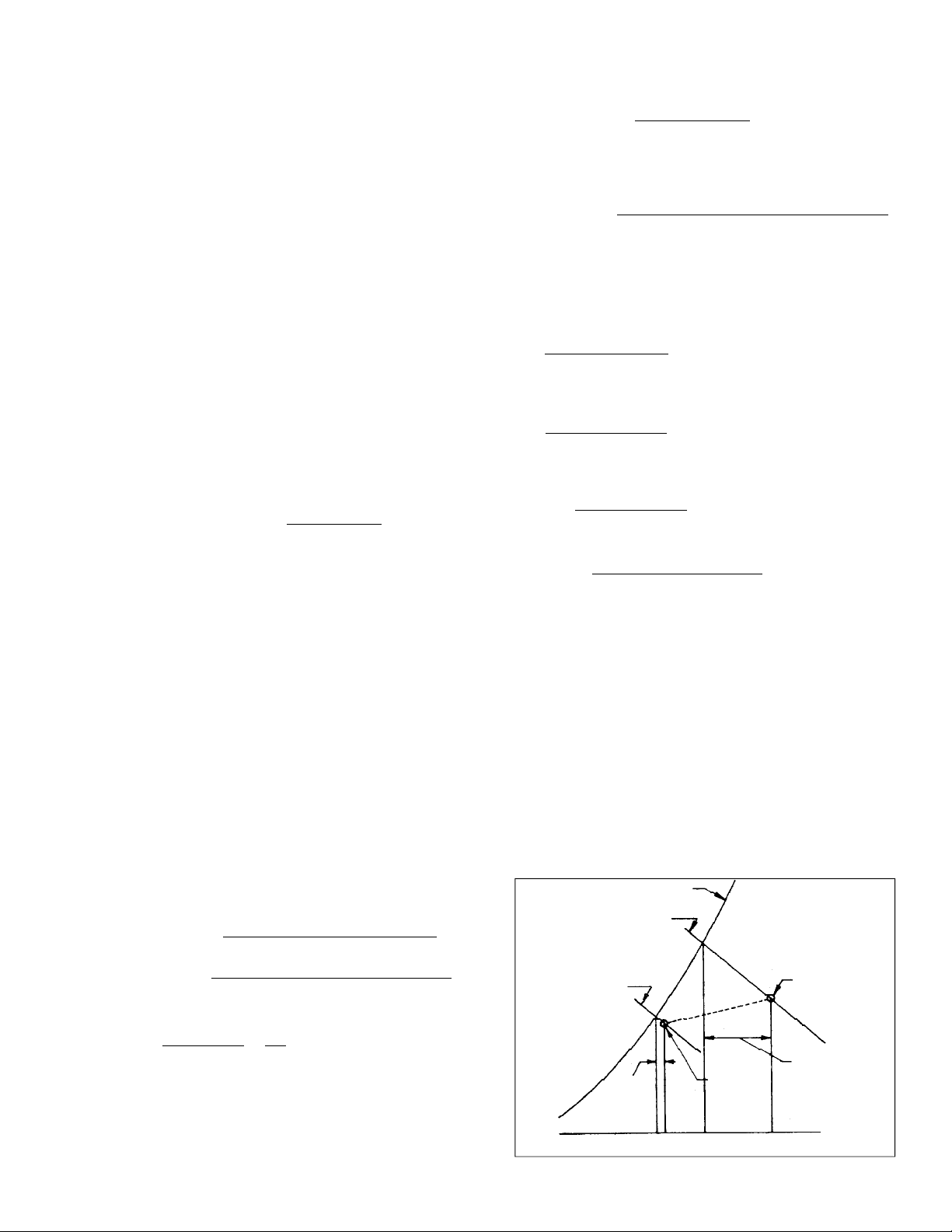

WET BULB DEPRESSION RATIO

Since both sensible and latent heat transfer are occurring

simultaneously between the surface of a chilled water

dehumidifying coil and the air passing over it, some coil

performance factor which establishes the relationship

between these two modes of heat transfer is required. For

this purpose KeepRite employs the wet bulb depression

factor which has the general acceptance of the finned tube

coil industry.

The wet bulb depression factor is the ratio of the leaving air

to entering air wet bulb depressions and is expressed as

follows:

Wet Bulb Depression

Factor (WBDF) =

Temp.

Temp.

For the example illustrated below, the Wet Bulb

Depression Factor Is:

WBDF =

80°F - 67°F = 13

61°F - 58°F 3

Since the wet bulb depression factor describes a heat

transfer relationship on the fin side of a coil only, it varies

with the air side heat transfer performance, the amount of

heat transfer surface and with the air velocity.The WB

depression factor is determined by laboratory tests of each

particular coil surface design. It should be noted that it is

Leaving Wet Bulb Depression

Entering Wet Bulb Depression

Lvg. Air D.B. - Lvg. Air W.B.

=

Ent. Air D.B. - Ent. Air W.B.

= .231

- 5 -

not influenced by the water flow rate. The wet bulb

depression factor does not apply to dry surface cooling

coils and is recommended for application only where the

sensible to total heat ratio is 0.9 or less. When the

sensible to total ratio is greater than 0.9, the fin surface

is essentially dry and the coil selection can be based on

dry surface to handle the total load.

Curves giving the wet bulb depression factors for

KeepRite Water Cooling Coils are shown on page 27.

SATURATION CURVE

ENTERING

67°F WET BULB

TEMP.

LEAVING

58°F WET BULB

TEMP.

LEAVING

DEPRESSION

W.B.

58 61 67 80

TEMPERATURE °F

AIR CONDITION

LEAVING COIL

AIR CONDITION

ENTERING COIL

ENTERING W.B.

DEPRESSION

Page 6

SYSTEM DESIGN AIR QUANITY DETERMINATION

In determining the CFM to circulate, the consulting

engineer normally considers: the volume of the conditioned

space, type of occupance or usage of the space, total load,

3. CFM for total load

CFM =

(4.5) (Enthalpy Ent. - Enthalpy Lvg.)

Total load

sensible load, ventilation requirements, air velocity in the

space (perceptability of air movement) and the sizes of

4. Air changes per hour (from A.S.H.R.A.E. Guide)

ducts required. Usually several of these factors affect the

determination of the CFM to be circulated; however, any

one factor may be controlling.

After determining the controlling factor or factors, the CFM

can be determined by any of the following methods or by

5. Ventilation requirements (from A.S.H.R.A.E.

Guide)

6. Fixed diffusion temperature (Ent. D.B - Lvg. D.B.)

(Usually 15° to 25°F.)

taking a compromise value between results obtained by

several of these methods.

1. CFM per ton (usually 400)

2. CFM for sensible load

CFM =

Sensible load (internal)

1.09 x (Ent. D.B. - lv. D.B.)

Although both total and sensible loads must be

considered in the final analysis, general practice is to

consider only the internal sensible load. Unless a

process is involved, usually the leaving dry bulb

temperature must be assumed and this is normally done

by actually assuming a diffusion temperature.

COIL SELECTION

SIZES

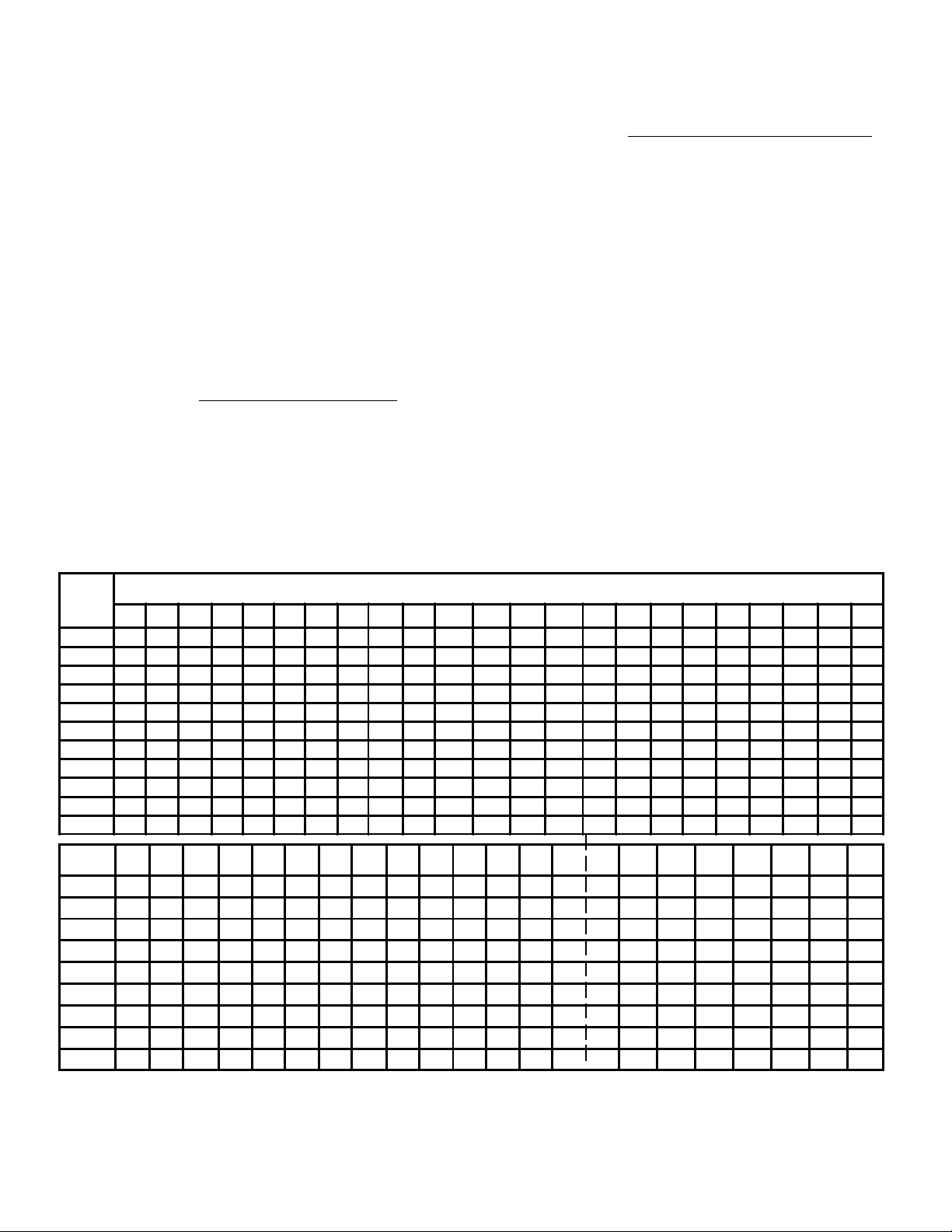

TABLE 1 - COIL SIZES - NOMINAL FACE AREA IN SQ. FT.

"W"

INCHES

12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75 78

6 .50 .62 .75 .87 1.00 1.13 1.25 1.38 1.50 1.63 1.75 1.88 2.0 2.1 2.2 2.4 2.5 2.6 2.7 2.9 3.0

9 .75 .94 1.12 1.31 1.50 1.69 1.87 2.06 2.25 2.44 2.62 2.81 3.0 3.2 3.4 3.6 3.7 3.9 4.1 4.3 4.5

12 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.0 4.3 4.5 4.8 5.0 5.3 5.5 5.8 6.0 6.3 6.5

15 1.56 1.87 2.19 2.50 2.81 3.12 3.44 3.75 4.06 4.37 4.68 5.0 5.3 5.6 5.9 6.2 6.6 6.9 7.2 7.5 7.8 8.1

18

2.25 2.62 3.00 3.37 3.75 4.12 4.50 4.87 5.25 5.62 6.0 6.4 6.7 7.1 7.5 7.9 8.2 8.6 9.0 9.4 9.7

21 3.06 3.50 3.94 4.37 4.82 5.25 5.69 6.12 6.56 7.0 7.4 7.9 8.3 8.7 9.2 9.6 10.1 10.5 10.9 11.4

24

4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5 13.0

27 5.06 5.62 6.19 6.75 7.32 7.87 8.44 9.0 9.6 10.1 10.7 11.2 11.8 12.4 12.9 13.5 14.1 14.6

30 6.25 6.88 7.50 8.12 8.75 9.37 10.0 10.6 11.2 11.9 12.5 13.1 13.7 14.4 15.0 15.6 16.2

33 7.56 8.25 8.94 9.62 10.30 11.0 11.7 12.4 13.1 13.7 14.4 15.1 15.8 16.5 17.2 17.9

36 9.00 9.75 10.50 11.20 12.0 12.7 13.5 14.2 15.0 15.7 16.5 17.2 18.0 18.7 19.5

NOMINAL TUBE LENGTH - NTL - (INCHES)

"W"

INCHES

In addition to the Finned Lengths listed above, KeepRite Refrigeration can furnish coils having any Finned Length

required up to 144 inches.

81 84 87 90 93 96 99 102 105 108 111 114 117 120 123 126 129 132 135 138 141 144

12 6.8 7.0 7.3 7.5 7.8 8.0 8.3 8.5 8.8 9.0 9.3 9.5 9.8 10.0

15 8.4 8.7 9.1 9.4 9.7 10.0 10.3 10.6 10.9 11.2 11.6 11.9 12.2 12.5

18 10.1 10.5 10.9 11.2 11.6 12.0 12.4 12.7 13.1 13.5 13.9 14.2 14.6 15.0 15.4 15.8

21 11.8 12.2 12.7 13.1 13.6 14.0 14.4 14.9 15.3 15.7 16.2 16.6 17.1 17.5 17.9 18.4 18.8 19.3

24 13.5 14.0 14.5 15.0 15.5 16.0 16.5 17.0 17.5 18.0 18.5 19.0 19.5 20.0 20.5 21.0 21.5 22.0 22.5 23.0 23.5 24.0

27 15.2 15.7 16.3 16.9 17.4 18.0 18.6 19.1 19.7 20.2 20.8 21.4 21.9 22.5 23.1 23.6 24.2 24.8 25.3 25.9 26.4 27.0

30 16.9 17.5 18.1 18.7 19.3 20.0 20.6 21.2 21.9 22.5 23.1 23.7 24.4 25.0 25.6 26.2 26.9 27.5 28.1 28.8 29.4 30.0

33 18.6 19.2 19.7 20.6 21.3 22.0 22.7 23.4 24.0 24.7 25.4 26.1 26.8 27.5 28.2 28.9 29.6 30.2 30.9 31.6 32.3 33.0

36 20.2 21.0 21.8 22.5 23.2 24.0 24.7 25.5 26.2 27.0 27.7 28.5 29.2 30.0 30.7 31.5 32.2 33.0 33.7 34.5 35.2 36.0

- 6 -

Page 7

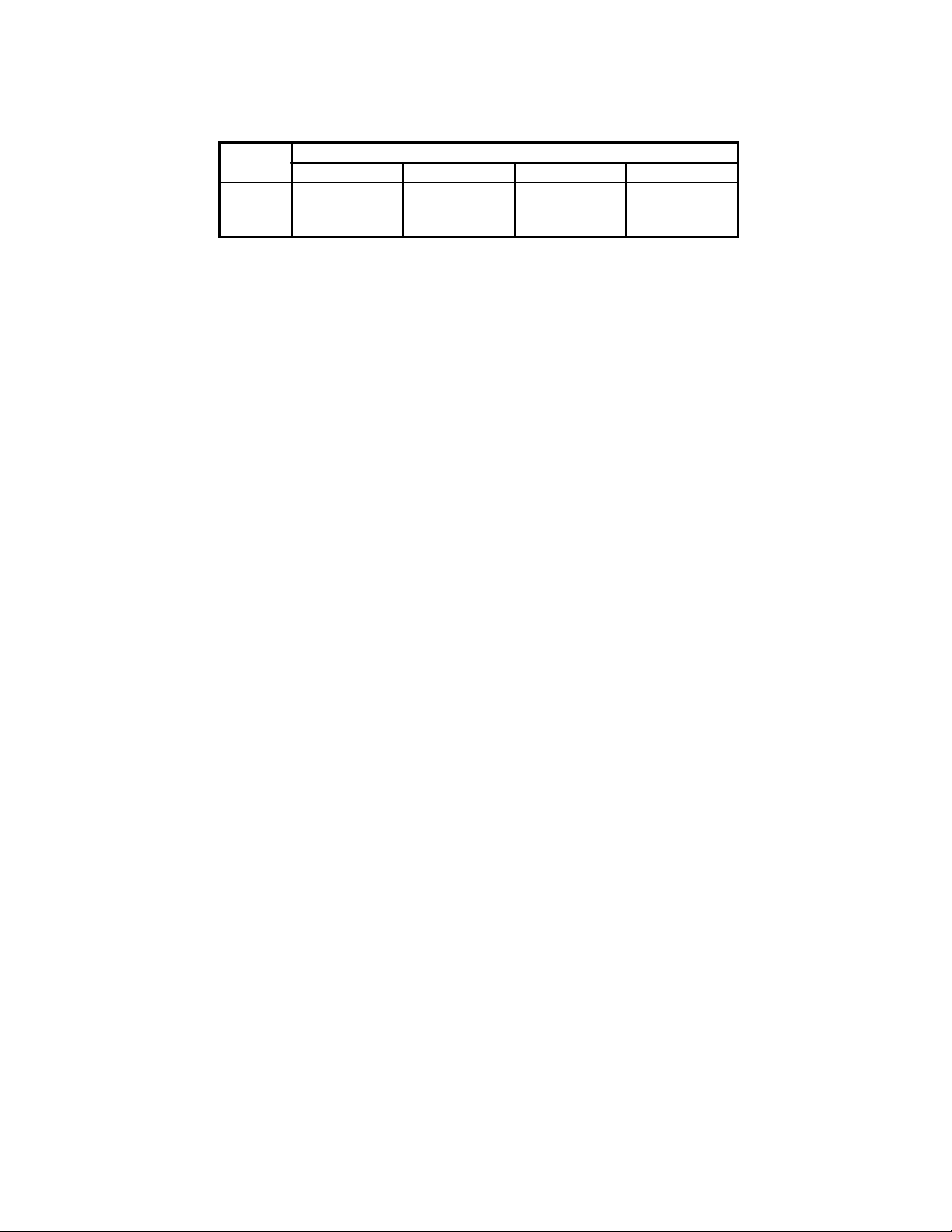

COIL SELECTION

FIN SERIES CAPACITY CORRECTION FACTORS

TABLE No. 2 F

FD

ROWS

DEEP

4

6

8

For use with tons per sq. ft. from Direct Selection Table No. 4

70 80 100 120

.89

.91

.92

1.00

1.00

1.00

GENERAL CONSIDERATIONS

The cooling process should always be plotted on a

Psychrometric Chart (Page 34) to be sure that the desired

psychromatic changes are feasible.

When selecting a coil it should be remembered that if the

required leaving wet bulb temperature is met, the total load

is satisfied and vice versa. Also, when the required

leaving dry bulb temperature is met, the sensible load

requirement is satisfied.

A coil must meet both the total and sensible load

requirement in order to achieve the conditions desired in the

space to be cooled. Normally the total load capacity is

checked first, however, the leaving dry bulb should always

be checked. When the sensible total ratio is low, the coil

selection is normally controlled by the total load even though

the sensible cooling capacity may exceed the requirement.

In some cases if the leaving dry bulb temperature is too low,

re-heat may be required.

When the S/T ratio is high the coil selection is normally

controlled by the sensible cooling even though the total capacity may exceed that required by an appreciable amount.

If the total capacity far exceeds the requirement, a re-check

on the system should be made to be sure

sufficient system capacity is available.

MATCHING SENSIBLE-LATENT REQUIREMENTS

To more accurately meet sensible and total loads, 70 and

80 Fin Series Coils are recommended for lower S,/T ratios,

and 100 and 120 Fin Series for higher S/T ratios. For

normal S/T ratios, Fin Series 80 and 100 are recommended.

Normal cooling coil face velocities are from 400 to 600 FPM.

500 FPM is recommended for most applications. Moisture

carry-over tends to become a problem when face

velocities in excess of 600 FPM are used unless dry

FIN SERIES

1.12

1.09

1.07

1.22

1.17

1.13

cooling occurs or special consideration is given in

advance to moisture elimination. KeepRite Rippled Fin

Coils of any standard fin series when properly installed

and operated in the normal range, will not require

eliminator plates.

Water cooling coils are normally selected to have a tube

length of three to four times the header height for economy

in coil and duct costs. Coils of several different face

dimensions are usually available from Table 1 page 6 to

meet the required face area. Select the most desirable.

Water velocity in the tubes of approximately 3 to 4 FPS is

desirable to attain high heat transfer rates with a

reasonable water pressure drop.

Cooling coils should not normally exceed 36 inches high

(“W” dimension) as the condensate draining from the top

portion of the coil tends to load up on the lower portion of

the coil. On high latent loads a significant reduction in air

flow and performance may result. Where “W” dimension

exceeds 36" we recommend two or more coils banked

one above the other and installed in accordance with the

recommendations shown on page 32.

In general, the capacity of a Type KWH (half serpentine)

Coil is higher than a Type KWS (single serpentine) for the

same entering air and water conditions because of higher

water velocity. However, the water pressure drop is higher.

The capacity of a Type KWD (double serpentine) Coil is

lower than a Type KWS for the same entering air and water conditions because of lower water velocity.

However, the water pressure drop is lower.

When a coil has a high S /T Ratio, .9 or above, the coil

should be considered dry and selected as a dry coil.

- 7 -

Page 8

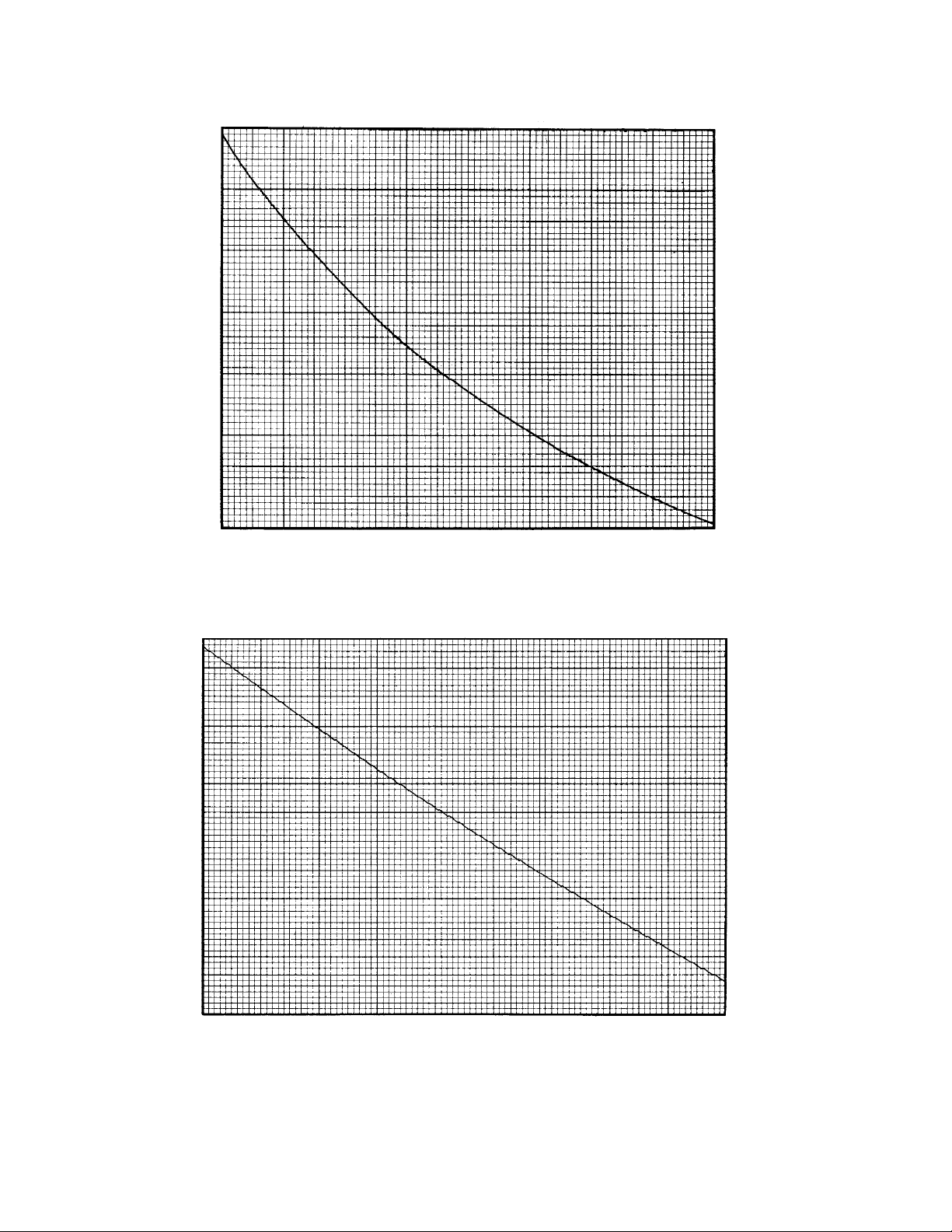

CONVERSION OF AIR VOLUME TO STANDARD AIR

FIGURE 1 - TEMPERATURE CONVERSION FACTOR

1.30

1.25

)

1

TEMPERATURE CONVERSION FACTOR (F

1.20

1.15

1.10

1.05

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0.65

-50 -25 0 25 50 75 100 125 150 175 200 225 250 275 300 325 350

1.30

1.25

1.20

1.15

1.10

1.05

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0.65

TEMPERATURE °F

When the specified air volume (CFM) is given at any temperature other than 70 °F or at any altitude other than sea level, these charts should be

used for correction before using the following capacity and friction tables (which are based on CFM @ standard air conditions).

FIGURE 2 - ALTITUDE CONVERSION FACTOR

1.025

1.000

)

0.975

2

0.950

0.925

0.900

0.875

0.850

0.825

0.800

0.775

TEMPERATURE CONVERSION FACTOR (F

0.750

0.725

0.700

-500 0 500 1500 2500 3500 4500 5500 6500 7500 8500

ALTITUDE (FEET ABOVE SEA LEVEL)

1.025

1.000

0.975

0.950

0.925

0.900

0.875

0.850

0.825

0.800

0.775

0.750

0.725

0.700

Example: To convert 15,900 CFM of air at 94 °F and at 3,000

ft. altitude to standard conditions:

CFM of Std. Air

= CFM of specified Air x F1 x F

2

= 15,900 X 955 X .896 = 13,600

Where: F1 = Temperature conversion factor from Fig. 1.

F2 = Altitude conversion factor from Fig. 2.

- 8 -

Page 9

TOTAL HEAT

(Enthalpy)

TABLE No. 3 - BTU CONTENT OF 1 LB. OF DRY AIR WITH WATER VAPOR TO SATURATE IT†

(Standard Atmospheric Pressure 29.921” HG.)

WET

BULB

°F. *

35

36

37

38

39

.0 .1 .2 .3 .4 .5 .6 .7 .8 .9

13.01

13.44

13.87

14.32

14.77

13.05

13.48

13.92

14.36

14.82

13.09

13.52

13.96

14.41

14.86

13.14

13.57

14.01

14.45

14.91

TENTHS OF DEGREES

13.18

13.61

14.05

14.50

14.95

13.22

13.66

14.10

14.54

15.00

13.27

13.70

14.14

14.59

15.05

13.31

13.74

14.19

14.63

15.09

13.35

13.79

14.23

14.68

15.14

13.39

13.83

14.27

14.73

15.18

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

15.23

15.70

16.17

16.66

17.15

17.65

18.16

18.68

19.21

19.75

20.30

20.86

21.44

22.02

22.61

23.22

23.84

24.48

25.12

25.78

26.46

27.15

27.85

28.57

29.31

30.06

30.83

31.62

32.42

33.25

15.28

15.74

16.22

16.71

17.20

17.70

18.21

18.73

19.26

19.81

20.36

20.92

21.49

22.08

22.68

23.28

23.90

24.54

25.19

25.85

26.53

27.22

27.92

28.64

29.38

30.14

30.91

31.70

32.50

33.33

15.32

15.79

16.27

16.75

17.25

17.75

18.26

18.79

19.32

19.86

20.41

20.98

21.55

22.14

22.74

23.34

23.97

24.61

25.25

25.92

26.60

27.29

27.99

28.72

29.46

30.21

30.99

31.78

32.59

33.42

15.37

15.84

16.32

16.80

17.30

17.80

18.32

18.84

19.37

19.92

20.47

21.03

21.61

22.20

22.80

23.41

24.03

24.67

25.32

25.98

26.67

27.36

28.07

28.79

29.53

30.29

31.07

31.86

32.67

33.50

15.42

15.89

16.37

16.85

17.35

17.85

18.37

18.89

19.43

19.97

20.52

21.09

21.67

22.26

22.86

23.47

24.10

24.74

25.38

26.05

26.74

27.43

28.14

28.87

29.61

30.37

31.15

31.94

32.75

33.59

15.46

15.93

16.41

16.90

17.40

17.91

18.42

18.95

19.48

20.03

20.58

21.15

21.73

22.32

22.92

23.53

24.16

24.80

25.45

26.12

26.80

27.50

28.21

28.94

29.68

30.44

31.22

32.02

32.83

33.67

15.51

15.98

16.46

16.95

17.45

17.96

18.47

19.00

19.53

20.08

20.64

21.21

21.79

22.38

22.98

23.59

24.22

24.86

25.52

26.19

26.87

27.57

28.28

29.01

29.76

30.52

31.30

32.10

32.92

33.75

15.56

16.03

16.51

17.00

17.50

18.01

18.52

19.05

19.59

20.14

20.69

21.26

21.84

22.44

23.04

23.65

24.29

24.93

25.58

26.26

26.94

27.64

28.35

29.09

29.83

30.60

31.38

32.18

33.00

33.84

15.60

16.08

16.56

17.05

17.55

18.06

18.58

19.10

19.64

20.19

20.75

21.32

21.90

22.50

23.10

23.72

24.35

24.99

25.65

26.32

27.01

27.71

28.43

29.16

29.91

30.68

31.46

32.26

33.08

33.92

15.65

16.12

16.61

17.10

17.60

18.11

18.63

19.16

19.70

20.25

20.81

21.38

21.96

22.56

23.16

23.78

24.42

25.06

25.71

26.39

27.08

27.78

28.50

29.24

29.98

30.75

31.54

32.34

33.17

34.00

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

34.09

34.95

35.83

36.74

37.66

38.61

39.57

40.57

41.58

42.62

43.69

44.78

45.90

47.04

48.22

49.43

34.18

35.04

35.92

36.83

37.75

38.71

39.67

40.67

41.68

42.73

43.80

44.89

46.01

47.16

48.34

49.55

34.26

35.13

36.01

36.92

37.85

38.80

39.77

40.77

41.79

42.83

43.91

45.00

46.13

47.28

48.46

49.68

34.35

35.21

36.10

37.02

37.94

38.90

39.87

40.87

41.89

42.94

44.02

45.12

46.24

47.39

48.58

49.80

34.43

35.30

36.19

37.11

38.04

39.00

39.98

40.97

42.00

43.05

44.13

45.23

46.36

47.51

48.70

49.92

34.52

35.39

36.28

37.20

38.13

39.09

40.07

41.07

42.10

43.15

44.23

45.34

46.47

47.63

48.82

50.04

34.61

35.48

36.38

37.29

38.23

39.19

40.17

41.18

42.20

43.26

44.34

45.45

46.58

47.75

48.95

50.17

34.69

35.57

36.47

37.38

38.32

39.28

40.27

41.28

42.31

43.37

44.45

45.56

46.70

47.87

49.07

50.29

34.79

35.65

36.56

37.48

38.42

39.38

40.37

41.38

42.41

43.48

44.56

45.68

46.81

47.98

49.19

50.41

34.86

35.74

36.65

37.57

38.51

39.47

40.47

41.48

42.52

43.58

44.67

45.79

46.93

48.10

49.31

50.54

* Use wet bulb temperature only in determining total heat. † Compiled from data in ASHRAE GUIDE for 1967

- 9 -

Page 10

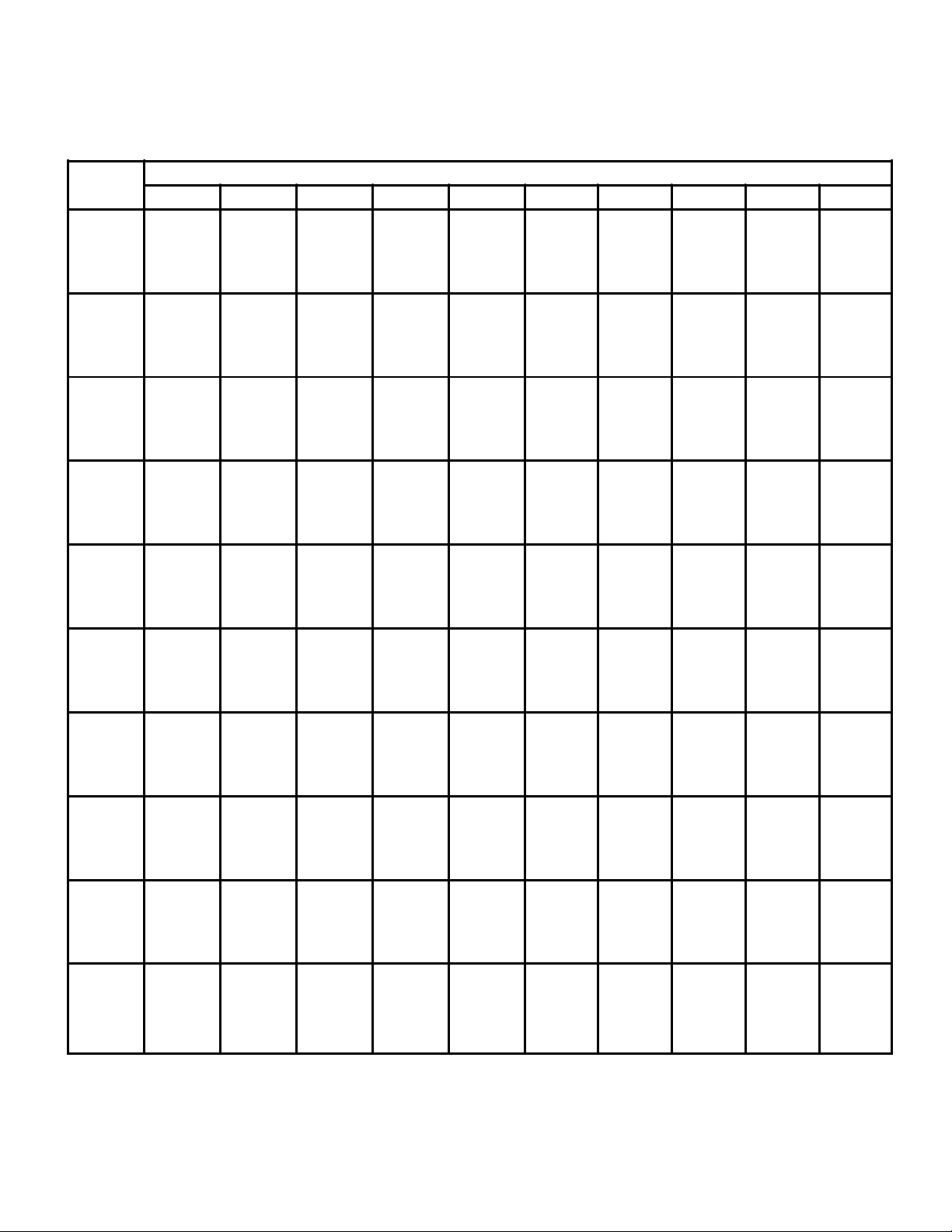

EXPLANATION FOR USING DIRECT SELECTION TABLES

I. PREFACE TO DIRECT SELECTION TABLE NO. 4

Direct Selection Table No. 4 contains a complete and

accurate compilation of data arranged for quick, easy

selection of water cooling coils to prepare or-meet a

specification.

The table covers the conditions normally encountered

in the air conditioning range for 80 Fin Series Coils.

Correction factors for Fin Series 70 100 and 120 are

shown in Table No. 2, page 7.

In many cases a slight adjustment in the CFM, face

area, water temperature rise, or percentage of fresh

air introduced can materially reduce the time required

to select a coil or group of coils.

Since Type KWS (single serpentine) Coils meet most

requirements, the majority of values shown in the

tables are for this coil type.

The color coil circuiting key for the Direct Selection

Tables is as follows: blue-half serpentine; white-single

serpentine; grey double serpentine.

See Dimensional Drawings, page 31 for complete coil

details.

Ill. LIMITATIONS OF CATALOG

1. All information contained in this catalog is based

on water as the cooling fluid. For fluids other

than water consult KeepRite Refrigeration.

2. Direct Selection Table No. 4 is based on 80 Fin

Series Coils. Applicable correction factors for 70,

100, and 120 Fin Series Coils are shown on

Table No. 2, page 7.

3. Interpolation between tables.

a. Interpolation between leaving wet bulb

temperatures should not be attempted as the

result will not be accurate.

b. Interpolation for performance values of Type

KWS, KWH and KWD is not possible, since

water velocities are vastly different. The

different type coils are indicated in the tables

by blue, grey and white.

c. Interpolation for 5 and 7 rows is permissible.

In preparing Direct Selection Tables, the use of

average correction factors has been avoided to

prevent multiplying of errors which could result in poor

coil selection. These tables could be within normally

accepted test laboratory accuracy.

II. VARIABLES COVERED IN DIRECT SELECTION

TABLE NO. 4

1. Values shown in Table No. 4 are for 80 Fin Series

Coils.

2. Entering wet bulb temperatures from 64°F through

70°F in 3°F increments.

3. Face velocities from 400 ft. per min. through 600

ft. per min. in 25 ft. per min. increments.

4. Entering water temperatures of 40, 45 and 50°F.

5. Water temperature rises of 8 and 10°F.

6. Finned lengths from 24" through 120" in 12"

increments.

d. Interpolation for entering water temperatures is

permissible.

e. Interpolation between water temperature rises

of 8 and 10 degrees is permissible.

f. Interpolation between entering wet bulb

temperature is permissible.

g. Interpolation between face velocities is

permissible.

h. Interpolation between finned length is

permissible.

i. Leaving wet bulb temperatures for other than 80

Fin Series Coils must be calculated.

4. Where use of Direct Selection Table No. 4 is not

possible the coil size may be calculated as shown

in Example Problems No. 1 and 2 on pages, 21,

22 and 23.

7. Row detpths of 4, 6, and 8.

8. Capacity in terms of tons per sq. ft. and leaving wet

bulb temperature.

5. Direct Selection Table No. 4 may not be used

when S/ T ratio is .90 or greater.

- 10 -

Page 11

EXPLANATION FOR USING DIRECT SELECTION TABLES

IV. USE OF DIRECT SELECTION TABLE NO.4

To determine row depth and finned length for a given

total load.

1. Before entering Direct Selection Table No. 4 it will be

necessary to know the following:

a. Coil face velocity. Calculate using Formula 8, or

assume 500 if unable to calculate or if not

specified.

b. Total tons per sq. ft.-Calculate using Formula 10

or leaving wet bulb temperature. If interpolation

of tables required, tons per sq. ft. must be

determined.

c. Leaving water temperature. Calculate using

Formula 2 when necessary.

2. Using the entering wet bulb temperature, entering

water temperature and leaving water temperature

find the proper page of Table No. 4.

3. Enter table at proper face velocity, read down to find

the value of tons per sq. ft. or leaving wet bulb

temperature most nearly meeting the requirement. It

is suggested that 4 row coils be checked first and if

insufficient the 6 and 8 rows be checked in turn.

Usually more than one selection is possible. Select

the coil having the fewest rows and the shortest

“NTL”. Since the coil height (“W” dimension) is

subsequently determined from the face area and

finned length keep the length height ratio in mind

when selecting the finned length from Table 4. Do

not overlook the possibility of using a higher or lower

fin series to more accurately match the capacity. In

many cases the higher fin series coil will reduce the

rows deep required. See Table 2, page 7 for fin

series correction factors to apply to the values of

tons per sq. ft. in Table No. 4.

5. Calculate leaving wet bulb temperature if not directly

readable from table.

6. Calculate the leaving dry bulb temperature using

Formula 3.

7. Determine water pressure drop as shown, page 29.

8. Determine air pressure drop as shown, page 29.

To determine capacity for a given coil.

1. Before entering table it will be necessary to know:

a. Coil face velocity. Calculate using Formula 8.

b. Coil “NTL”. Determine from Table 1, page 6.

c. Rows deep and fin series. (Would be

specified.)

d. Leaving water temperature-calculate using

Formula 2.

2. Using the entering wet bulb temperature entering water

temperature and leaving water temperature, find proper

page in Table No. 4.

3. Enter table in proper coil face velocity column, “NTL”

and row depth. Read capacity in terms of tons per sq.

ft. or leaving wet bulb temperature. If the given coil

is single serpentine and tables values are given for

KWH or KWD Type Coils, follow trial and error

procedure outlined in problems 1 and 2. For other than

80 Fin Series Coils multiply the value in tons per sq. ft.

from Table No. 4 by the fin series correction factor

(Table 2, page 7).

4. Calculate leaving wet bulb if not directly readable from

table.

5. Calculate leaving dry bulb temperature using

Formula 3.

4. Using the minimum required “NTL” and the minimum

coil face area find the minimum coil height

(“W” dimension) from Table 1, page 6.

6. Calculate water pressure drop as shown, page 30.

7. Calculate air pressure drop as shown, page 29.

- 11 -

Page 12

64°F, ENTERING AIR WET BULB, 40°F, ENTERING WATER, 48°F, LEAVING WATER

TABLE 4

Face Velocity

FPM

NTL Rows

Deep

24"

36"

48"

60"

72"

84"

96"

108"

120"

DIRECT SELECTION

400 425 450 475 500 525 550 575 600

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

2

ft.

°F.

4

1.10

1.41

1.65

1.16

1.50

1.71

1.21

1.54

1.75

1.25

1.57

1.77

1.28

1.59

1.79

1.30

1.61

1.80

1.31

1.62

1.81

1.22*

1.56*

1.75*

1.23*

1.57*

1.77*

52.9

49.3

46.3

52.2

48.2

45.5

51.6

47.6

44.9

51.2

47.3

44.7

50.8

47.0

44.4

50.6

46.8

44.3

50.5

46.7

44.1

51.5*

47.4*

44.9*

51.4*

47.3*

44.7*

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

ft.

1.13

1.48

1.73

1.20

1.56

1.79

1.26

1.61

1.83

1.30

1.64

1.86

1.34

1.67

1.88

1.36

1.69

1.90

1.37

1.70

1.83*

1.29*

1.63*

1.85*

1.30*

1.64*

1.87*

2

°F.

53.3

49.5

46.5

52.6

48.7

45.8

51.9

48.0

45.3

51.5

47.6

45.0

51.1

47.3

44.7

50.8

47.0

44.5

50.7

46.9

45.3*

51.6*

47.8*

45.1*

51.5*

47.6*

44.9*

ft.

1.16

1.54

1.82

1.25

1.63

1.88

1.31

1.68

1.92

1.35

1.72

1.95

1.39

1.74

1.98

1.42

1.77

2.00

1.43

1.78

1.92*

1.34*

1.71*

1.94*

1.35*

1.72*

1.96*

2

°F.

53.7

51.6

46.7

52.8

48.8

46.0

52.2

48.3

45.5

51.8

47.8

45.2

51.4

47.6

44.8

51.1

47.2

44.6

50.9

47.1

45.5*

51.9*

47.9*

45.3*

51.8*

47.8*

45.1*

ft.

1.19

1.61

1.89

1.29

1.70

1.97

1.36

1.75

2.01

1.41

1.79

2.05

1.45

1.82

2.07

1.48

1.84

2.00*

1.49

1.76*

2.02*

1.40*

1.78*

2.04*

1.41*

1.80*

2.05*

2

°F.

54.0

49.9

47.0

53.1

49.0

46.1

52.4

48.5

45.7

51.9

48.1

45.3

51.5

47.8

45.1

51.2

47.5

45.8*

51.1

48.4*

45.6*

52.0*

48.2*

45.4*

51.9*

48.0*

45.3*

ft.

1.22

1.68

1.98

1.34

1.77

2.06

1.41

1.83

2.11

1.47

1.87

2.14

1.51

1.90

2.16

1.53

1.92

2.09*

1.55

1.83*

2.11*

1.46*

1.86*

2.13*

1.48*

1.88*

2.15*

2

°F.

54.3

50.1

47.1

53.2

49.2

46.3

52.6

48.6

45.8

52.0

48.2

45.5

51.7

47.9

45.3

51.5

47.7

46.0*

51.3

48.6*

45.8*

52.1*

48.3*

45.6*

52.0*

48.1*

45.4*

ft.

1.25

1.75

2.06

1.38

1.84

2.14

1.47

1.90

2.19

1.52

1.95

2.22

1.56

1.98

2.15*

1.59

1.90*

2.18*

1.47*

1.91*

2.20*

1.50*

1.93*

2.22*

1.52*

1.95*

2.24*

2

°F.

54.6

50.2

47.3

53.5

49.4

46.5

52.7

48.8

46.1

52.3

48.4

45.7

51.9

48.1

46.4*

51.6

48.8*

46.1*

52.7*

48.7*

45.9*

52.4*

48.5*

45.7*

52.3*

48.4*

45.5*

ft.

1.28

1.81

2.14

1.42

1.90

2.22

1.51

1.97

2.27

1.57

2.02

2.30

1.62

2.06

2.23*

1.65

1.95*

2.26*

1.52*

1.98*

2.28*

1.55*

2.01*

2.31*

1.57*

2.03*

2.33*

2

°F.

54.8

50.4

47.5

53.7

49.6

46.7

53.0

49.0

46.3

25.5

48.6

46.0

52.0

48.2

46.7*

51.8

49.2*

46.4*

52.9*

48.9*

46.2*

52.6*

48.7*

45.9*

52.5*

48.5*

45.7*

ft.

1.31

1.88

2.22

1.47

1.97

2.30

1.56

2.05

2.36

1.62

2.10

2.39

1.67

2.13

2.32*

1.70

2.01*

2.35*

1.57*

2.05*

2.37*

1.59*

2.08*

2.40*

1.62*

2.11*

2.42*

W.B.

2

°F.

55.0

50.5

47.6

53.8

49.8

46.9

53.1

49.1

46.4

52.6

48.7

46.1

52.2

48.4

46.7*

52.0

49.4*

46.5*

53.0*

49.1*

46.3*

52.9*

48.8*

46.0*

52.6*

48.6*

45.9*

per

ft.

1.34

1.94

2.29

1.51

2.04

2.39

1.60

2.12

2.45

1.67

2.17

2.48

1.72

2.03*

2.40*

1.76

2.08*

2.43*

1.61*

2.12*

2.46*

1.64*

2.15*

2.49*

1.67*

2.18*

2.50*

Lvg.

W.B.

2

°F.

55.2

50.7

47.8

54.0

49.9

47.0

53.3

49.2

46.5

52.8

48.8

46.2

52.4

49.9*

46.9*

52.1

49.6*

46.7*

53.2*

49.2*

46.4*

53.0*

49.0*

46.1*

52.8*

48.7*

46.0*

67°F, ENTERING AIR WET BULB, 40°F, ENTERING WATER, 48°F, LEAVING WATER

Face Velocity

FPM

NTL Rows

Deep

24"

36"

48"

60"

72"

84"

96"

108"

120"

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

( ) = KWS, (†) = KWH, (*) = KWD

Above capacities are based on Series 80 fin spacing. For other fin spacings see Capacity Correction Factors Table No. 2, page 7.

Note: Table may NOT be used when S T ratio is 90 or greater.

400 425 450 475 500 525 550 575 600

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

per

ft.

1.25

1.70

1.98

1.36

1.79

2.04

1.43

1.84

2.08

1.49

1.88

2.10

1.52

1.90

2.11

1.55

1.91

2.06*

1.56

1.84*

2.07*

1.49*

1.85*

2.08*

1.50*

1.86*

2.09*

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

2

°F.

55.1

50.0

46.5

53.9

48.9

45.7

53.1

48.2

45.2

52.4

47.7

44.9

52.1

47.5

44.8

51.7

47.4

45.5*

51.6

48.2*

45.3*

52.4*

48.1*

45.2*

52.3*

48.0*

45.0*

2

t.

1.32

1.77

2.07

1.42

1.87

2.14

1.49

1.93

2.18

1.55

1.97

2.20

1.59

1.99

2.22

1.62

2.00

2.17*

1.63

1.92*

2.18*

1.55*

1.93*

2.19*

1.57*

1.94*

2.20*

°F.

55.2

50.4

46.9

54.1

49.3

46.1

53.4

48.5

45.5

52.8

48.1

45.3

52.4

47.8

45.1

52.0

47.7

45.7*

51.9

48.7*

45.5*

52.8*

48.5*

45.4*

52.6*

48.4*

45.3*

ft.

1.38

1.85

2.17

1.49

1.95

2.24

1.55

2.01

2.28

1.62

2.05

2.31

1.66

2.07

2.33

1.68

2.08

2.27*

1.69

2.00*

2.28*

1.61*

2.02*

2.30*

1.63*

2.03*

2.31*

2

°F.

55.4

50.6

47.9

54.3

49.5

46.3

53.7

48.9

45.9

53.0

48.4

45.5

52.6

48.2

45.3

52.4

48.2

46.0*

52.3

49.0*

45.9*

53.1*

48.8*

45.6*

52.9*

48.7*

45.5*

ft.

1.44

1.93

2.26

1.55

2.03

2.34

1.61

2.10

2.38

1.68

2.14

2.41

1.71

2.16

2.36*

1.74

2.17

2.37*

1.76

2.09*

2.39*

1.67*

2.11*

2.41*

1.69*

2.12*

2.42*

2

°F.

55.5

50.8

47.5

54.5

49.8

46.6

53.9

49.1

46.2

53.3

48.7

45.8

53.0

48.5

46.3*

52.7

48.4

46.3*

52.5

49.2*

46.1*

53.4*

49.0*

45.8*

53.2*

48.9*

45.7*

ft.

1.50

2.01

2.35

1.61

2.12

2.44

1.69

2.18

2.49

1.75

2.22

2.53

1.79

2.25

2.46*

1.81

2.16*

2.48*

1.72*

2.18*

2.50*

1.74*

2.20*

2.52*

1.75*

2.22*

2.53*

2

°F.

55.6

51.1

47.8

54.7

50.0

46.9

54.0

49.5

46.3

53.4

49.0

45.9

53.1

48.8

46.7*

52.9

49.7*

46.4*

53.7*

49.4*

46.3*

53.5*

49.3*

46.0*

53.4*

49.1*

45.9*

ft.

1.56

2.08

2.44

1.68

2.20

2.54

1.76

2.27

2.59

1.81

2.31

2.62

1.85

2.34

2.55*

1.87

2.25*

2.58*

1.79*

2.27*

2.60*

1.80*

2.29*

2.62*

1.82*

2.31*

2.63*

2

°F.

55.8

51.3

48.0

54.8

50.3

46.1

54.1

49.6

46.6

53.7

49.2

46.3

53.3

48.9

47.0*

53.2

49.8*

46.7*

53.8*

49.6*

46.5*

53.8*

49.4*

46.3*

53.6*

49.2*

46.2*

per

ft.

1.62

2.16

2.53

1.74

2.28

2.64

1.82

2.35

2.70

1.88

2.40

2.74

1.92

2.43

2.65*

1.94

2.33*

2.68*

1.85*

2.35*

2.70*

1.87*

2.38*

2.72*

1.89*

2.40*

2.73*

2

W.B.

°F.

55.9

51.5

48.2

54.9

50.5

47.3

54.3

49.9

46.7

53.8

49.4

46.3

53.5

49.1

47.2*

53.3

50.0*

46.9*

54.1*

49.9*

46.7*

53.9*

49.6*

46.5*

53.7*

49.4*

46.4*

Tons

per

ft.

1.68

2.24

2.62

1.80

2.36

2.73

1.88

2.44

2.80

1.94

2.49

2.84

1.98

2.52

2.75*

2.01

2.41*

2.78*

1.91*

2.43*

2.80*

1.93*

2.46*

2.83*

1.95*

2.48*

2.84*

W.B.

2

47.3*

50.3*

47.1*

54.3*

50.1*

46.9*

54.1*

49.8*

45.6*

53.9*

49.7*

46.5*

- 12 -

Lvg.

°F.

56.0

51.6

48.5

55.1

50.7

47.5

54.5

50.0

46.9

54.0

49.6

46.5

53.7

49.3

53.5

Tons

per

ft.

1.73

2.31

2.71

1.85

2.44

2.83

1.94

2.52

2.90

2.00

2.57

2.94

2.04

2.61

2.84*

2.07

2.50*

2.88*

1.96*

2.52*

2.91*

1.98*

2.55*

2.94*

2.00*

2.57*

2.95*

Lvg.

W.B.

2

°F.

56.1

51.8

48.7

55.3

50.8

47.6

54.6

50.2

47.1

54.2

49.8

46.7

53.9

49.5

47.5*

53.6

50.3*

47.2*

54.5*

50.2*

46.9*

54.3*

49.9*

46.7*

54.2*

49.8*

46.6*

Page 13

70°F, ENTERING AIR WET BULB, 40°F, ENTERING WATER, 48°F, LEAVING WATER

TABLE 4 - cont.

Face Velocity

FPM

NTL Rows

Deep

24"

36"

48"

60"

72"

84"

96"

108"

120"

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

400 425 450 475 500 525 550 575 600

Tons

per

ft.

1.51

2.00

2.31

1.61

2.10

2.37

1.68

2.16

2.41

1.73

2.19

2.44

1.77

2.20

2.38*

1.80

2.13*

2.39*

1.82

2.16*

2.41*

1.77*

2.18*

2.42*

1.78*

2.19*

2.43*

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

W.B.

per

W.B.

per

W.B.

per

W.B.

2

°F.

56.3

50.8

47.0

55.2

49.6

46.3

54.4

48.9

45.7

53.9

48.5

45.3

53.4

48.4

46.1*

53.1

49.2*

46.0*

52.9

48.9*

45.7*

53.4*

48.6*

45.6*

53.3*

48.5*

45.4*

ft.

1.58

2.10

2.44

1.68

2.20

2.51

1.76

2.26

2.55

1.81

2.30

2.58

1.86

2.31

2.51*

1.89

2.24*

2.53*

1.91

2.26*

2.54*

1.84*

2.28*

2.55*

1.85*

2.29*

2.57*

2

°F.

56.5

51.1

47.1

55.5

50.0

46.3

54.7

49.3

45.9

54.2

48.8

45.5

53.7

48.7

46.3*

53.3

49.5*

46.1*

53.1

49.3*

46.0*

53.9*

49.1*

45.9*

53.8*

48.9*

45.6*

ft.

1.65

2.19

2.57

1.76

2.30

2.64

1.84

2.37

2.68

1.90

2.41

2.71

1.94

2.42

2.63*

1.98

2.35*

2.65*

2.00

2.37*

2.67*

1.91*

2.39*

2.69*

1.92*

2.40*

2.70*

2

°F.

56.7

51.4

47.3

55.7

50.3

46.5

54.9

49.5

46.1

54.3

49.1

45.7

54.0

49.0

46.6*

53.6

49.7*

46.4*

53.4

49.5*

46.2*

54.3*

49.3*

46.0*

54.1*

49.2*

45.8*

ft.

1.72

2.29

2.68

1.83

2.40

2.76

1.92

2.47

2.81

1.98

2.52

2.84

2.03

2.54

2.76*

2.06

2.45*

2.78*

2.08

2.48*

2.80*

1.98*

2.50*

2.82*

1.99*

2.51*

2.83*

2

°F.

56.9

51.6

47.6

55.9

50.5

46.8

55.1

49.8

46.2

54.6

49.3

45.9

54.1

49.1

46.8*

53.8

50.0*

46.6*

53.6

49.7*

46.4*

54.6*

49.5*

46.2*

54.5*

49.4*

46.1*

per

ft.

1.78

2.38

2.79

1.91

2.50

2.88

2.00

2.57

2.93

2.06

2.63

2.96

2.11

2.66

2.88*

2.14

2.54*

2.91*

2.04*

2.57*

2.93*

2.05*

2.60*

2.95*

2.06*

2.61*

2.96*

2

W.B.

°F.

57.2

51.9

48.0

56.1

50.8

47.1

55.3

50.1

46.6

54.8

49.6

46.3

54.3

49.3

47.1*

54.1

50.4*

46.8*

55.0*

50.1*

46.6*

54.9*

49.8*

46.4*

54.8*

49.8*

46.3*

Tons

per

ft.

1.84

2.47

2.90

1.98

2.59

3.00

2.07

2.67

3.06

2.14

2.73

2.97*

2.19

2.60*

3.00*

2.21

2.64*

3.03*

2.11*

2.67*

3.06*

2.12*

2.70*

3.08*

2.13*

2.72*

3.09*

2

Lvg.

W.B.

°F.

57.4

52.2

48.3

56.3

51.1

47.3

55.6

50.4

46.8

55.0

49.8

47.6*

54.6

51.0*

47.3*

54.4

50.7*

47.0*

55.3*

50.4*

46.7*

55.2*

50.1*

46.6*

55.1*

49.9*

46.4*

To

ns

per

ft.

1.91

2.56

3.01

2.05

2.69

3.11

2.14

2.77

3.18

2.20

2.83

3.08*

2.25

2.69*

3.11*

2.27

2.74*

3.14*

2.17*

2.77*

3.17*

2.19*

2.80*

3.19*

2.20*

2.82*

3.21*

Lvg.

Tons

per

ft.

1.97

2.65

3.12

2.13

2.79

3.23

2.23

2.87

3.30

2.30

2.92

3.19*

2.34

2.79*

3.23*

2.20*

2.84*

3.26*

2.24*

2.87*

3.29*

2.26*

2.90*

3.32*

2.28*

2.92*

3.33*

Lvg.

W.B.

2

°F.

57.7

52.6

48.8

56.6

51.5

47.8

55.9

50.9

47.2

55.3

50.5

48.2*

55.0

51.5*

47.8*

56.1*

51.1*

47.6*

55.8*

50.9*

47.3*

55.6*

50.6*

47.0

55.5*

50.5*

46.9*

W.B.

2

°F.

57.6

52.4

48.5

56.5

51.3

47.6

55.8

50.6

47.0

55.3

50.1

47.9*

54.9

51.3*

47.6*

54.8

50.9*

47.4*

55.6*

50.6*

47.0*

55.4*

50.4*

46.9*

55.2*

50.2*

46.7*

Tons

per

ft.

2.03

2.74

3.23

2.20

2.88

3.34

2.30

2.96

3.41

2.37

3.00

3.30*

2.42

2.88*

3.34*

2.26*

2.93*

3.37*

2.30*

2.97*

3.40*

2.33*

3.00*

3.43*

2.35*

3.02*

2.44*

Lvg.

W.B.

2

°F.

57.9

52.8

48.9

56.7

51.7

48.0

56.0

51.1

47.4

55.5

50.8

48.4*

55.2

51.7*

48.0*

56.3*

51.4*

47.8*

56.0*

51.0*

47.5*

55.8*

50.8*

47.3*

55.7*

50.6*

47.2*

64°F, ENTERING AIR WET BULB, 45°F, ENTERING WATER, 53°F, LEAVING WATER

Face Velocity

FPM

NTL Rows

Deep

24"

36"

48"

60"

72"

84"

96"

108"

120"

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

400 425 450 475 500 525 550 575 600

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

per

ft.

.91†

1.04

1.25

.83

1.12

1.32

.89

1.17

1.36

.93

1.20

1.38

.96

1.23

1.40

.98

1.25

1.42

1.00

1.26

1.43

1.02

1.27

1.44

1.03

1.28

1.38*

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

2

55.0†

53.6

51.2

55.9

52.7

50.4

55.3

52.1

49.9

54.8

51.8

49.6

54.5

51.4

43.9

54.3

51.2

43.9

54.0

51.1

49.0

53.8

50.9

48.9

53.7

50.8

49.6*

°F.

2

.

.95†

1.09

1.31

.86

1.17

1.38

.92

1.22

1.42

.97

1.25

1.45

1.00

1.28

1.47

1.02

1.30

1.49

1.04

1.32

1.50

1.06

1.33

1.44*

1.07

1.34

1.45*

°F.

55.2†

53.7

51.4

56.1

52.9

50.6

55.5

52.4

50.2

55.0

52.0

49.8

54.7

51.7

43.9

54.5

51.5

49.4

54.3

51.3

49.3

54.1

51.2

49.9*

54.0

51.1

49.8*

2

ft.

.98†

1.13

1.37

.89

1.22

1.44

.96

1.28

1.49

1.01

1.31

1.51

1.04

1.34

1.54

1.06

1.36

1.56

1.08

1.38

1.57

1.10

1.39

1.50*

1.11

1.32*

1.51*

°F.

55.5†

54.0

51.6

56.3

53.1

50.8

55.6

52.5

50.3

55.2

52.2

50.1

54.9

51.9

49.8

54.7

51.7

49.6

54.5

51.5

49.5

54.3

51.4

50.2*

54.2

52.0*

50.1*

ft.

1.01†

1.18

1.43

.92

1.27

1.51

1.00

1.33

1.55

1.05

1.37

1.58

1.08

1.39

1.61

1.10

1.41

1.63

1.13

1.43

1.65

1.15

1.44

1.57*

1.16

1.37*

1.58*

2

°F.

55.7†

54.1

51.7

56.5

53.3

50.9

55.8

52.7

50.5

55.3

52.3

50.2

55.0

52.1

49.9

54.9

51.9

49.7

54.3

51.7

49.5

54.4

51.6

50.3*

54.3

52.3*

50.2*

ft.

1.04†

1.22

1.48

.96

1.32

1.57

1.03

1.39

1.62

1.09

1.42

1.65

1.12

1.45

1.68

1.15

1.47

1.70

1.17

1.49

1.63*

1.19

1.42*

1.65*

1.20

1.43*

1.66*

2

°F.

55.9†

54.3

52.0

56.6

53.4

51.1

56.0

52.8

50.7

55.5

52.5

50.4

55.2

52.2

50.1

54.9

52.1

49.9

54.7

51.9

50.6*

54.6

52.5*

50.4*

54.5

52.4*

50.3*

ft.

1.07†

1.27

1.54

.99

1.38

1.63

1.07

1.44

1.68

1.12

1.47

1.72

1.16

1.50

1.75

1.19

1.53

1.78

1.22

1.55

1.69*

1.24

1.47*

1.71*

1.25

1.48*

1.72*

2

°F.

56.1†

54.4

52.1

56.7

53.5

51.3

56.1

53.0

50.8

55.7

52.7

50.5

55.3

52.4

50.2

55.1

52.2

49.9

54.8

52.0

50.8*

54.7

52.7*

50.6*

54.6

52.6*

50.5*

per

ft.

1.11†

1.31

1.60

1.02

1.43

1.69

1.10

1.50

1.75

1.16

1.53

1.79

1.20

1.56

1.82

1.23

1.59

1.85

1.26

1.61

1.76*

1.28

1.53*

1.78*

1.29

1.54*

1.79*

2

W.B.

°F.

56.1†

54.6

52.2

56.8

53.6

51.4

56.2

53.0

50.9

55.7

52.8

50.8

55.4

52.5

50.3

55.2

52.3

50.1

55.0

52.1

50.8*

54.8

52.8*

50.7*

54.7

52.7*

50.6*

Tons

per

ft.

.93

1.35

1.66

1.05

1.48

1.75

1.14

1.56

1.81

1.20

1.59

1.85

1.24

1.62

1.89

1.27

1.64

1.80*

1.30

1.66

1.82*

1.32

1.58*

1.84*

1.33

1.59*

1.85*

Lvg.

Tons

per

ft.

.96

1.39

1.72

1.08

1.53

1.81

1.17

1.60

1.88

1.24

1.64

1.92

1.28

1.67

1.96

1.31

1.70

1.86*

1.34

1.61*

1.88*

1.23*

1.63*

1.90*

1.25*

1.65*

1.91*

Lvg.

W.B.

2

°F.

57.9

54.8

52.4

57.0

53.8

51.7

56.4

53.3

51.2

55.9

53.0

50.8

55.6

52.8

50.5

55.4

52.5

51.3*

55.2

53.2*

51.2*

56.0*

53.1*

51.0*

55.9*

52.9*

50.9*

W.B.

2

°F.

57.8

54.7

52.3

56.9

53.7

51.6

56.3

53.1

51.1

55.8

52.9

50.8

55.6

52.6

50.4

55.3

52.5

51.2*

55.1

52.3

51.0*

55.0

52.9*

50.8*

54.9

52.9*

54.8*

( ) = KWS, (†) = KWH, (*) = KWD

Above capacities are based on Series 80 fin spacing. For other fin spacings see Capacity Correction Factors Table No. 2, page 7.

Note: Table may NOT be used when S T ratio is 90 or greater.

- 13 -

Page 14

67°F, ENTERING AIR WET BULB, 45°F, ENTERING WATER, 53°F, LEAVING WATER

TABLE 4 - cont.

Face Velocity

FPM

Deep

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

8

8

Tons

per

ft.

1.14

1.32

1.57

1.05

1.41

1.64

1.12

1.46

1.68

1.16

1.49

1.71

1.19

1.52

1.73

1.21

1.54

1.74

1.23

1.55

1.68*

1.24

1.49*

1.70*

1.25

1.50*

1.71*

2

NTL Rows

24"

36"

48"

60"

72"

84"

96"

108"46

120"46

400 425 450 475 500 525 550 575 600

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

W.B.

°F.

56.3

54.3

51.5

57.2

53.3

50.7

56.5

52.8

50.2

56.1

52.4

49.8

55.7

52.1

49.6

55.5

51.8

49.5

55.3

51.7

50.2*

55.2

52.4*

50.1*

55.1

52.3*

49.8*

per

ft.

.98

1.38

1.65

1.10

1.47

1.72

1.16

1.53

1.76

1.20

1.56

1.79

1.23

1.59

1.81

1.26

1.61

1.82

1.28

1.62

1.76*

1.29

1.54*

1.78*

1.30

1.56*

1.79*

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

2

°F.

58.3

54.6

51.7

57.4

53.6

50.9

56.8

53.0

50.5

56.4

52.7

50.2

56.1

52.3

49.9

55.8

52.1

49.8

55.6

52.0

50.5*

55.5

52.9*

50.3*

55.4

52.7*

50.2*

ft.

1.02

1.43

1.72

1.14

1.53

1.80

1.21

1.59

1.84

1.25

1.63

1.88

1.28

1.66

1.90

1.31

1.68

1.83*

1.33

1.60*

1.85*

1.34

1.61*

1.86*

1.27*

1.63*

1.87*

2

°F.

58.7

54.9

52.0

57.6

53.9

51.1

56.9

53.3

50.7

56.6

52.9

50.3

56.3

52.6

50.1

56.0

52.4

50.8*

55.8

53.2*

50.6*

55.8

53.1*

50.5*

56.4*

52.9*

50.4*

ft.

1.06

1.49

1.79

1.18

1.59

1.88

1.26

1.65

1.93

1.30

1.69

1.97

1.33

1.72

1.99

1.36

1.74

1.91*

1.39

1.66*

1.93*

1.40

1.68*

1.94*

1.32*

1.69*

1.95*

2

°F.

58.8

55.0

52.2

57.8

54.1

51.3

57.1

53.6

50.8

56.7

53.2

50.4

56.5

52.9

50.2

56.2

52.7

51.1*

56.0

53.5*

50.8*

55.9

53.3*

50.7*

56.6*

53.2*

50.6*

2

ft.

1.10

1.55

1.87

1.22

1.66

1.96

1.30

1.72

2.01

1.34

1.76

2.05

1.38

1.79

2.07

1.41

1.81

1.99*

1.44

1.73*

2.01*

1.45

1.75*

2.03*

1.37*

1.76*

2.04*

°F.

59.0

55.2

52.4

58.0

54.2

51.5

57.3

53.7

51.1

57.0

53.4

50.7

56.7

53.1

50.1

56.4

52.9

51.2*

56.2

53.6*

51.1*

56.1

53.4*

50.9*

56.7*

53.4*

50.8*

ft.

1.14

1.60

1.94

1.27

1.72

2.04

1.35

1.78

2.10

1.39

1.83

2.13

1.43

1.86

2.16

1.46

1.88

2.07*

1.49

1.79*

2.09*

1.40*

1.81*

2.11*

1.42*

1.82*

2.12*

2

°F.

59.1

55.4

52.6

58.1

54.4

51.7

57.4

53.9

51.2

57.1

53.5

50.9

56.8

53.3

50.6

56.6

53.1

51.4*

56.3

53.8*

51.3*

57.1*

53.7*

51.1*

56.9*

53.6*

51.0*

ft.

1.18

1.66

2.02

1.31

1.78

2.13

1.39

1.85

2.18

1.44

1.89

2.22

1.49

1.92

2.12*

1.52

1.84*

2.15*

1.54

1.86*

2.17*

1.45*

1.88*

2.19*

1.47*

1.89*

2.20*

2

°F.

59.2

55.6

52.7

58.2

54.6

51.8

57.6

54.1

51.3

57.3

53.7

51.0

56.9

53.5

51.8*

56.6

54.1*

51.6*

56.5

54.0*

51.4*

57.2*

53.8*

51.3*

51.0*

53.7*

51.1*

per

ft.

1.22

1.71

2.09

1.35

1.84

2.21

1.44

1.91

2.27

1.49

1.96

2.30

1.54

1.99

2.21*

1.57

1.90*

2.23*

1.59

1.92*

2.25*

1.50*

1.94*

2.27*

1.52*

1.95*

2.29*

2

W.B.

°F.

59.3

55.7

52.8

58.4

54.8

51.9

57.7

54.2

51.4

57.4

53.9

51.1

57.0

53.6

51.9*

56.8

54.3*

51.7*

56.6

54.2*

51.6*

57.3*

54.0*

51.4*

57.1*

53.9*

51.2*

Tons

per

2

ft.

1.26

1.77

2.16

1.40

1.90

2.29

1.49

1.98

2.35

1.54

2.03

2.38

1.59

2.06

2.29*

1.62

1.97*

2.31*

1.62

1.99*

2.33*

1.55*

2.01*

2.35*

1.57*

2.02*

2.37*

Lvg.

W.B.

°F.

59.3

55.9

53.0

58.4

55.0

52.0

57.8

54.3

51.5

57.5

53.9

51.3

57.1

53.7

52.0*

56.9

54.4*

51.8*

56.7

54.3*

51.7*

57.4*

54.1*

51.5*

57.2*

54.0*

51.4*

70°F, ENTERING AIR WET BULB, 45°F, ENTERING WATER, 53°F, LEAVING WATER

Face Velocity

FPM

NTL Rows

Deep

24"

36"

48"

60"

72"

84"

96"

108"

120"

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

4

6

8

( ) = KWS, (†) = KWH, (*) = KWD

Above capacities are based on Series 80 fin spacing. For other fin spacings see Capacity Correction Factors Table No. 2, page 7.

Note: Table may NOT be used when S T ratio is 90 or greater.

400 425 450 475 500 525 550 575 600

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

Lvg.

Tons

per

ft.

1.20

1.62

1.90

1.33

1.71

1.98

1.39

1.76

2.02

1.42

1.79

2.04

1.45

1.81

2.06

1.47

1.83

1.99*

1.49

1.76*

2.01*

1.41*

1.77*

2.02*

1.43*

1.78*

2.03*

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

W.B.

per

2

°F.

59.4

55.1

51.9

58.1

54.1

51.0

57.5

53.5

50.5

57.2

53.2

50.3

56.9

53.0

50.1

56.7

52.8

50.9*

56.5

53.5*

50.7*

57.3*

53.4*

50.5*

57.1*

53.3*

50.4*

ft.

1.25

1.70

2.00

1.38

1.81

2.10

1.44

1.86

2.13

1.48

1.89

2.15

1.51

1.90

2.16

1.53

1.83*

2.11*

1.55

1.84*

2.12*

1.47*

1.86*

2.13*

1.50*

1.88*

2.14*

2

°F.

59.7

55.3

52.2

58.5

54.2

51.1

57.9

53.6

50.7

57.5

53.3

50.5

57.2

53.2

50.4

57.0

54.0*

51.0*

56.8

53.9*

50.9*

57.6*

53.6*

50.7*

57.3*

53.4*

50.6*

ft.

1.30

1.77

2.09

1.43

1.89

2.20

1.50

1.94

2.24

1.54

1.97

2.26

1.57

1.99

2.18*

1.60

1.91*

2.21*

1.61

1.93*

2.22*

1.54*

1.95*

2.24*

1.57*

1.98*

2.25*

2

°F.

59.9

55.6

52.4

58.7

54.4

51.3

58.1

53.9

50.9

57.8

53.6

50.7

57.5

53.5

51.5*

57.2

54.2*

51.2*

57.1

54.0*

51.1*

57.8*

53.9*

50.9*

57.5*

53.6*

50.9*

ft.

1.35

1.84

2.19

1.49

1.97

2.30

1.56

2.02

2.34

1.60

2.06

2.36

1.63

2.08

2.28*

1.66

1.99*

2.31*

1.67

2.01*

2.33*

1.60*

2.04*

2.35*

1.63*

2.07*

2.36*

2

°F.

60.1

55.9

52.6

58.9

54.7

51.5

58.3

54.2

51.1

57.9

53.8

50.9

57.7

53.6

51.7*

57.4

54.5*

51.4*

57.3

54.3*

51.2*

57.9*

54.0*

51.0*

57.7*

53.8*

50.9*

ft.

1.39

1.91

2.28

1.54

2.05

2.39

1.61

2.11

2.44

1.66

2.15

2.47

1.70

2.17

2.38*

1.73

2.07*

2.41*

1.63*

2.09*

2.43*

1.66*

2.13*

2.45*

1.69*

2.16*

2.47*

2

°F.

60.3

56.1

52.8